Surface roughness detecting device and operating method thereof

A technology of surface roughness and detection device, applied in the direction of measurement device, instrument, etc., can solve the problems of difficulty in detection work and large volume, and achieve the effect of convenient detection process, simple operation process and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0048] The invention provides an existing surface roughness detection device and an operation method thereof.

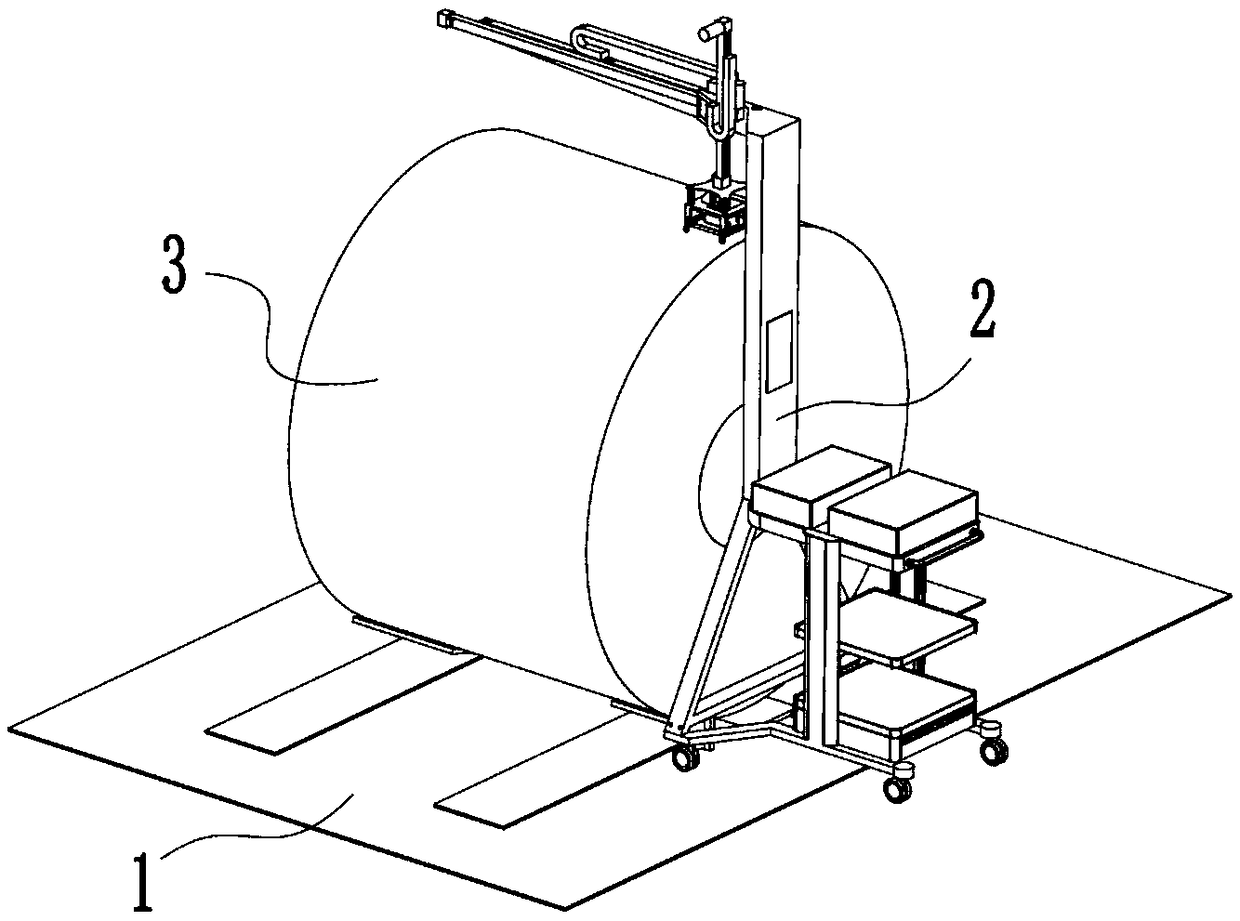

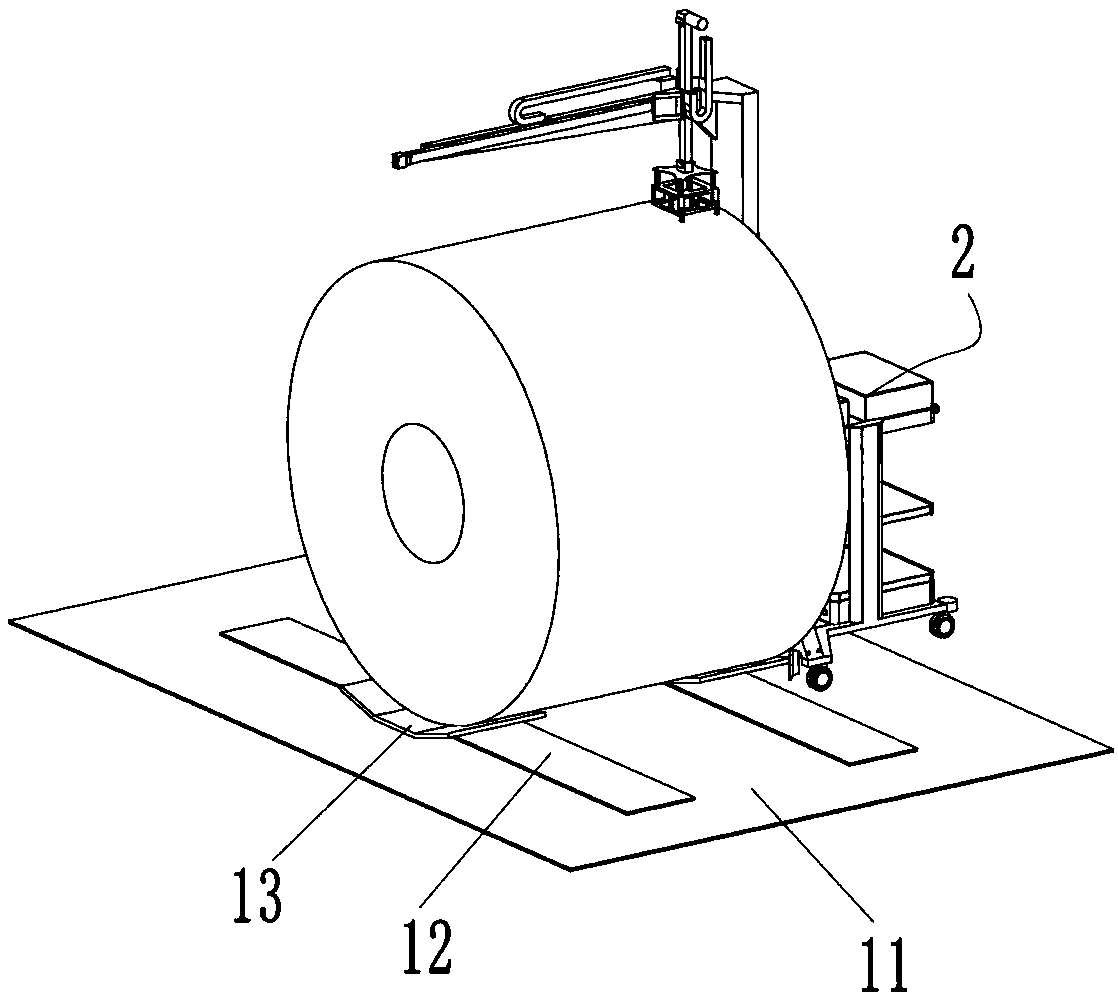

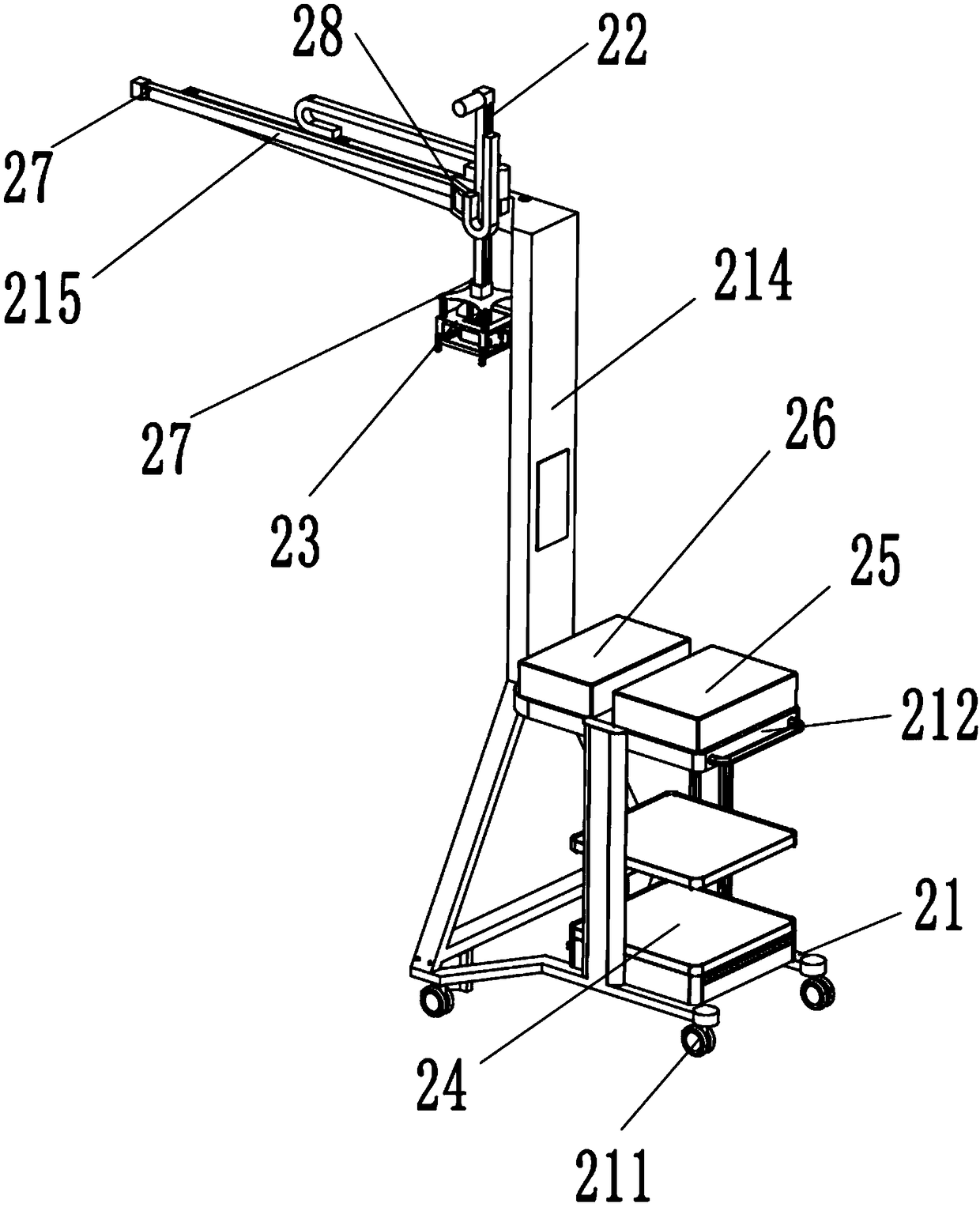

[0049] Such as figure 1 , figure 2 As shown, the device: includes a V-shaped tray 1 and a surface topography detection device 2, wherein the V-shaped tray 1 is used to place a steel coil 3 to be detected, such as image 3 and Figure 4 As shown, the surface topography detection device 2 includes a moving frame 21, a Z-direction slide rail 22, a surface measurement assembly 23, a main chassis 24, a motion operation panel 25, a measurement operation panel 26 and a travel switch 27,

[0050]The V-shaped tray 1 includes a bottom plate 11, a support bar 12 and a V-shaped plate 13. The support bar 12 is arranged on the bottom plate 11. The middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com