Check tool for pneumatic detection of taper angle and detection method

A pneumatic detection and detection method technology, applied in the direction of measuring devices, instruments, and fluid devices, can solve the problems of lack of accuracy, poor reproducibility, and unsuitable batch detection, etc., and achieve the effect of realizing full product inspection and speeding up the detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

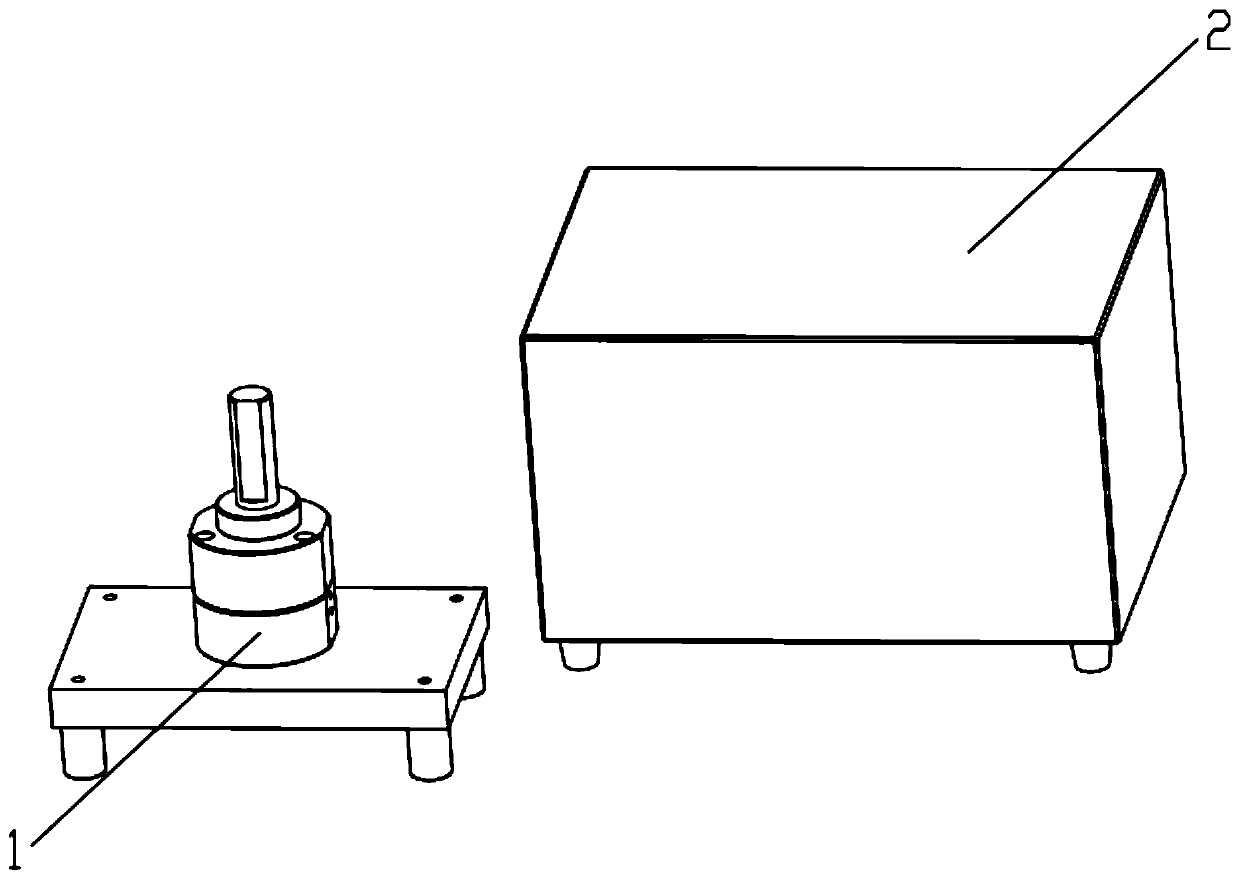

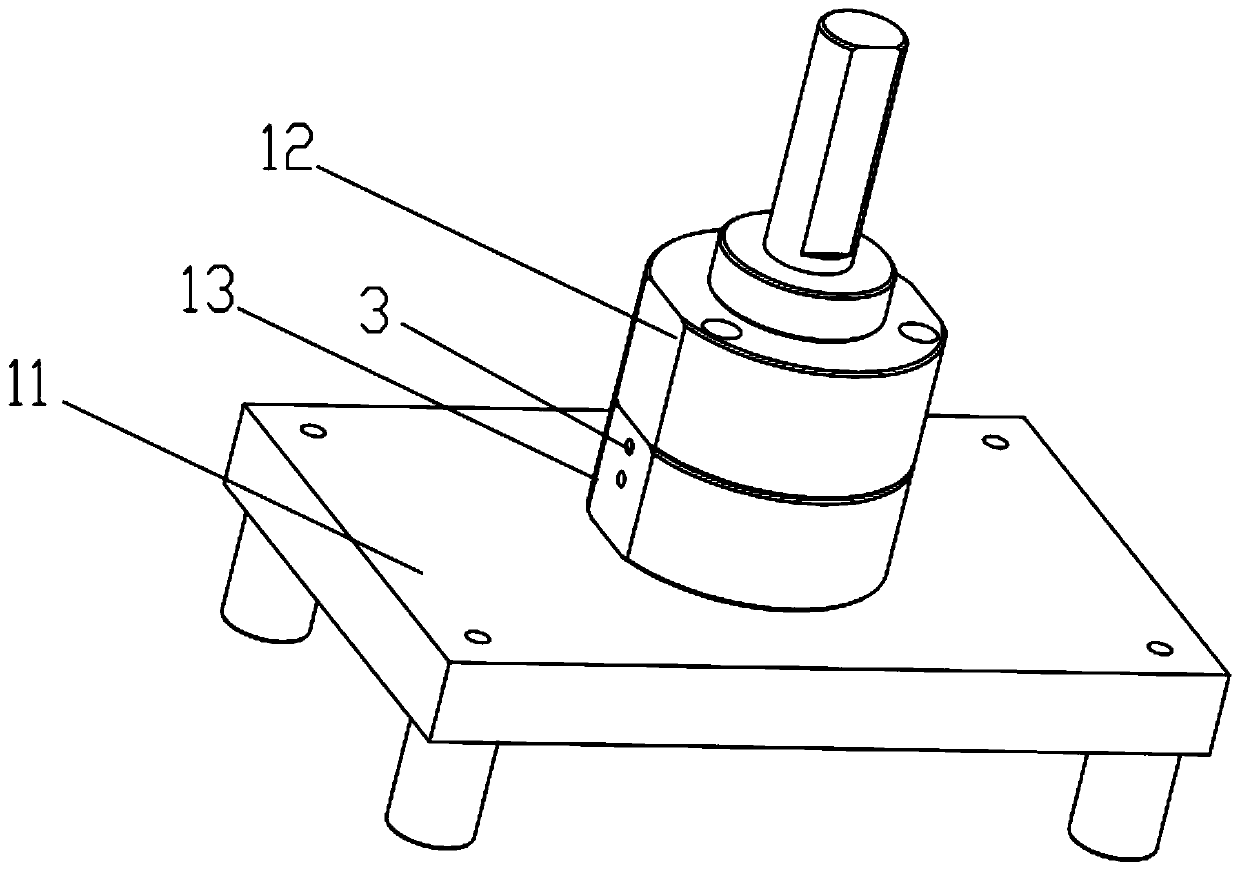

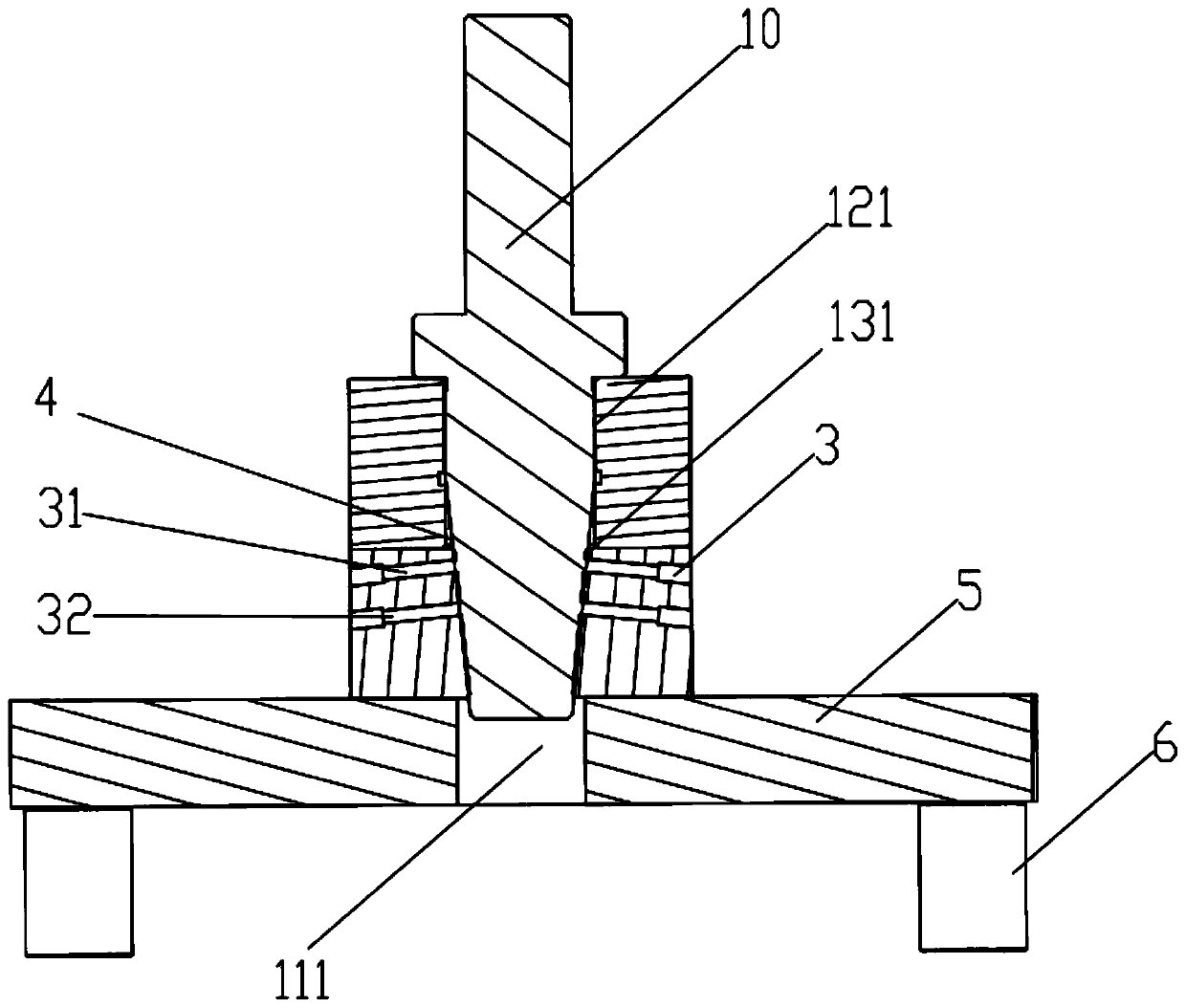

[0030] Such as Figure 1 to Figure 5 As shown, a pneumatic inspection tool for detecting taper angle in this embodiment includes a detection device 1 and a measuring instrument 2 , and the detection device 1 is connected to the measuring instrument 2 . The detection device 1 comprises a base 11, a pad cover 12 and a taper sleeve 13, the taper sleeve 13 is arranged on the base 11, the taper sleeve 13 has a tapered hole 131, and the side of the tapered hole 131 is provided with air holes 3, and the air holes 3 are respectively arranged on The upper and lower parts of the tapered hole 131, the axis of the air hole 3 are perpendicular to the generatrix of the measured cone surface 4. The pad cover 12 is arranged above the taper sleeve 13 , and the pad cover 12 and the taper sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com