Patents

Literature

68results about How to "Reduce testing labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

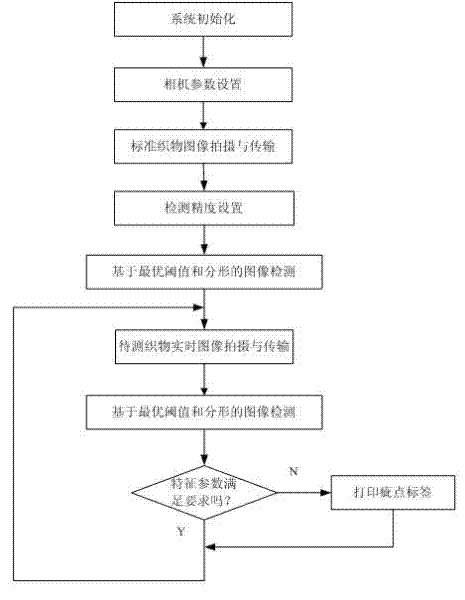

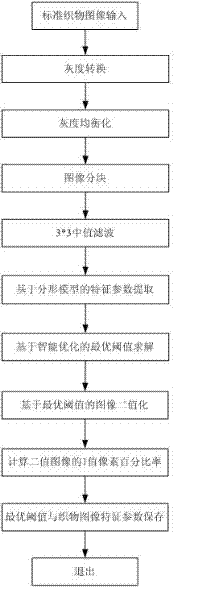

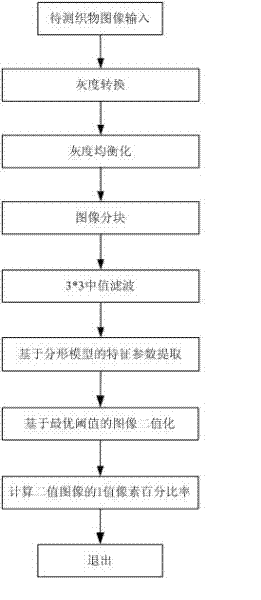

Online automatic detection method of fabric defects based on machine vision and device thereof

InactiveCN102221559AOvercome labor intensityOvercome visualInspecting textilesMaterial analysis by optical meansMachine visionFeature parameter

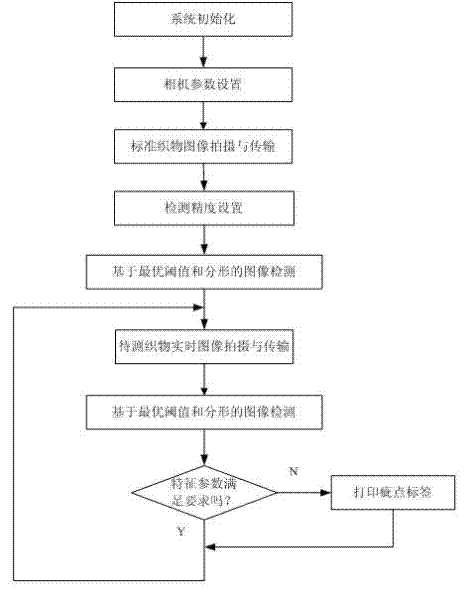

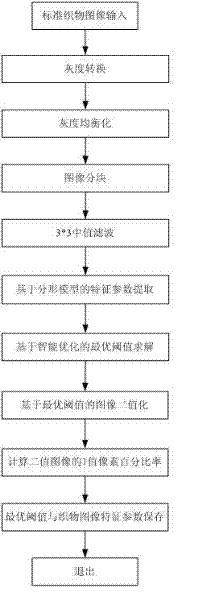

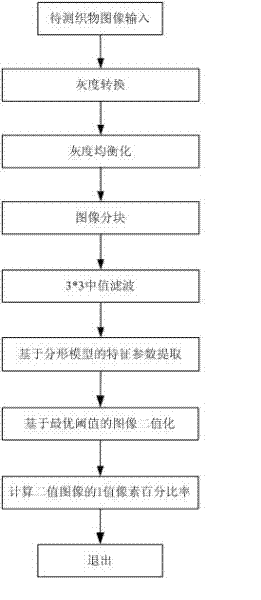

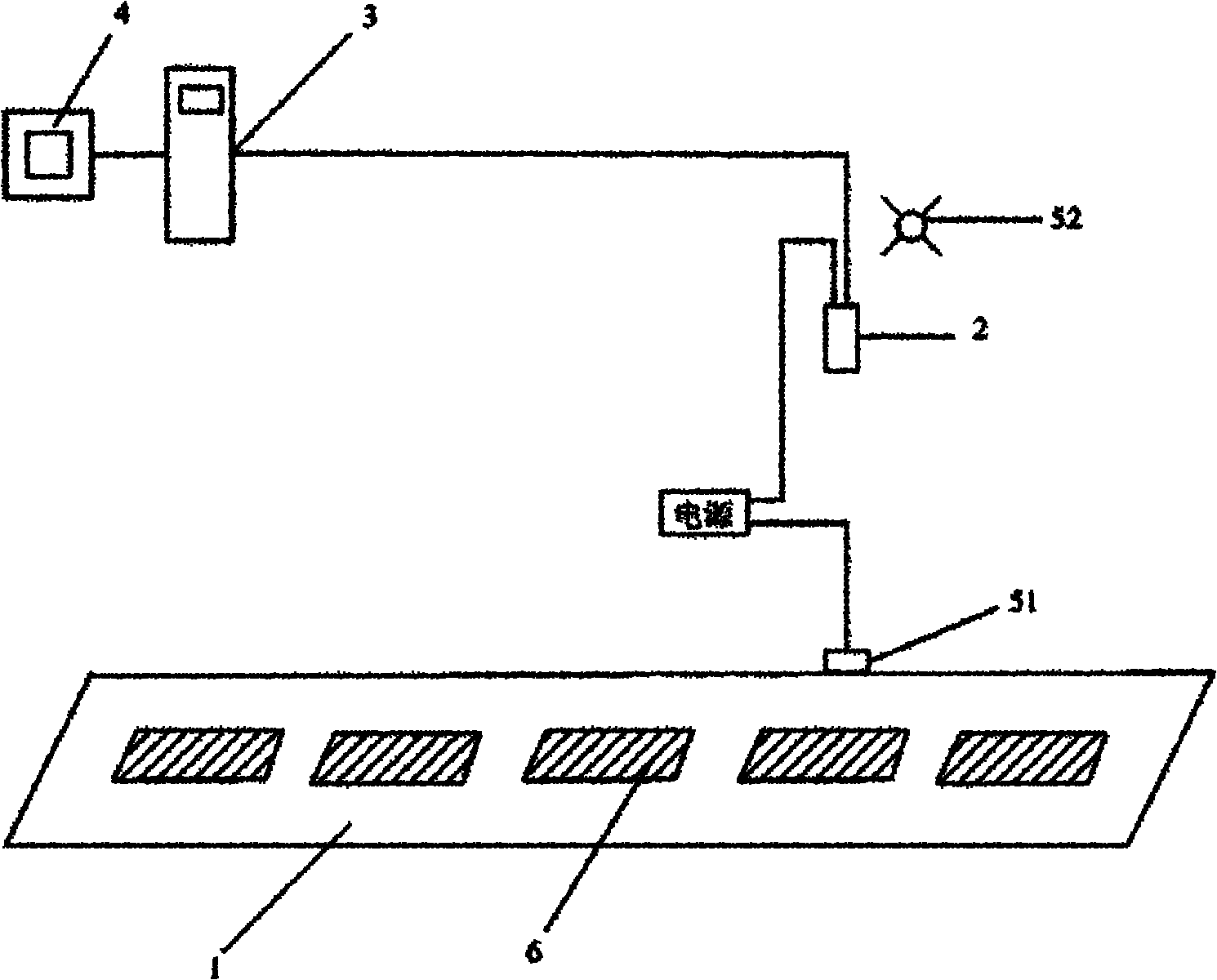

The invention relates to an online automatic detection method of fabric defects based on machine vision and a device thereof, wherein the clear and integral standard fabric images without the defects of the fabric are shot on a batching and burling machine as a standard image template by utilizing an industrial camera in order to solve the problems of great labor intensity and poor detection quality of the traditional manual detection method; the corresponding characteristic parameters are extracted and stored into a computer; the range of the fabric defect detection characteristic parameters is set according to the requirements of users; the fabric images which are shot in real time are transmitted to the computer to be compared with the standard image template by utilizing the industrial camera and compared with the standard characteristic parameters; if the fabric characteristic parameters are not in conformity with the set requirements, the alarm is started by detection software; the defects are analyzed; and the printing of defects labels is executed. The invention has the advantages of high detection accuracy and high speed; and the labor intensity is greatly reduced.

Owner:HOHAI UNIV CHANGZHOU

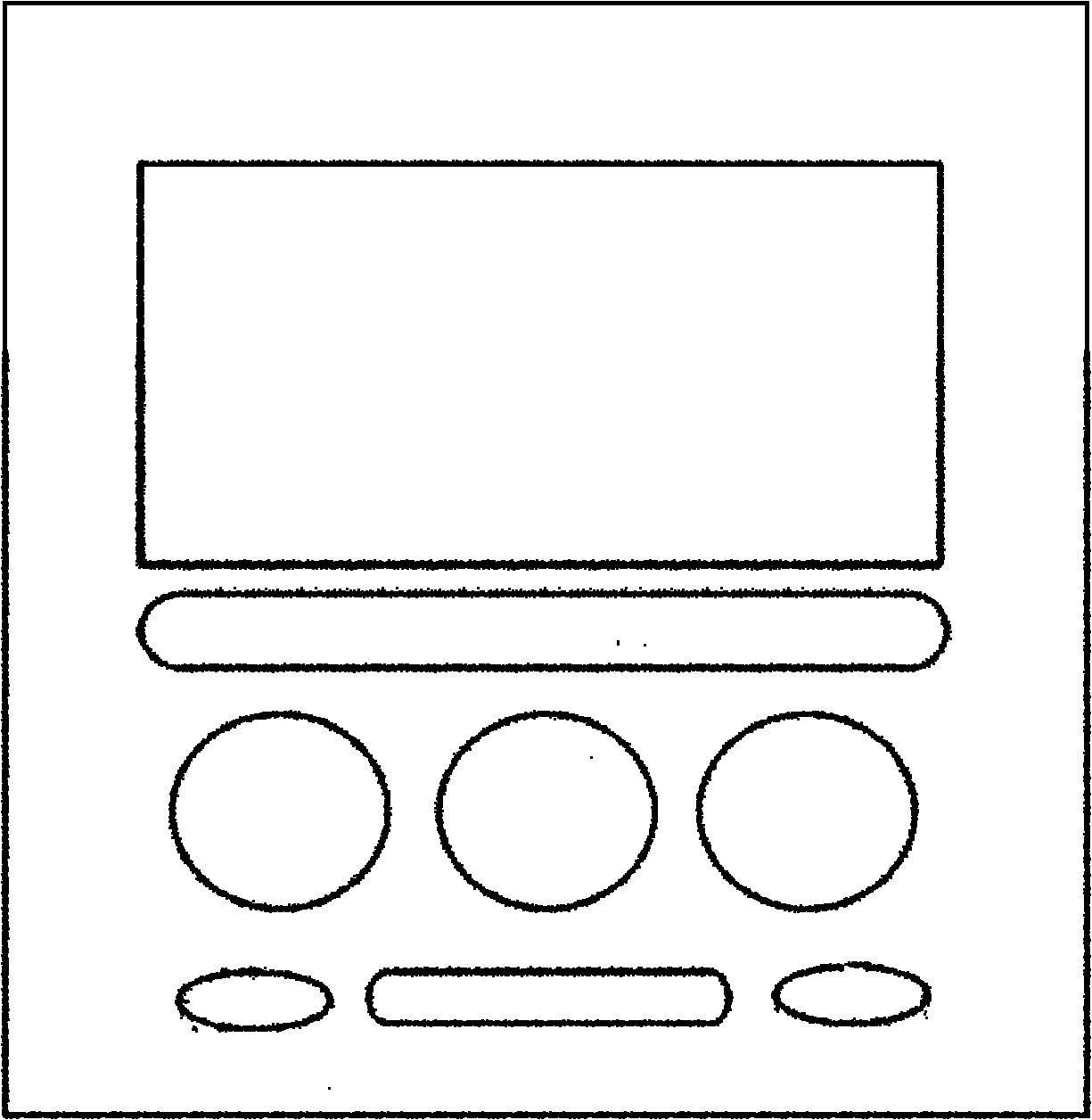

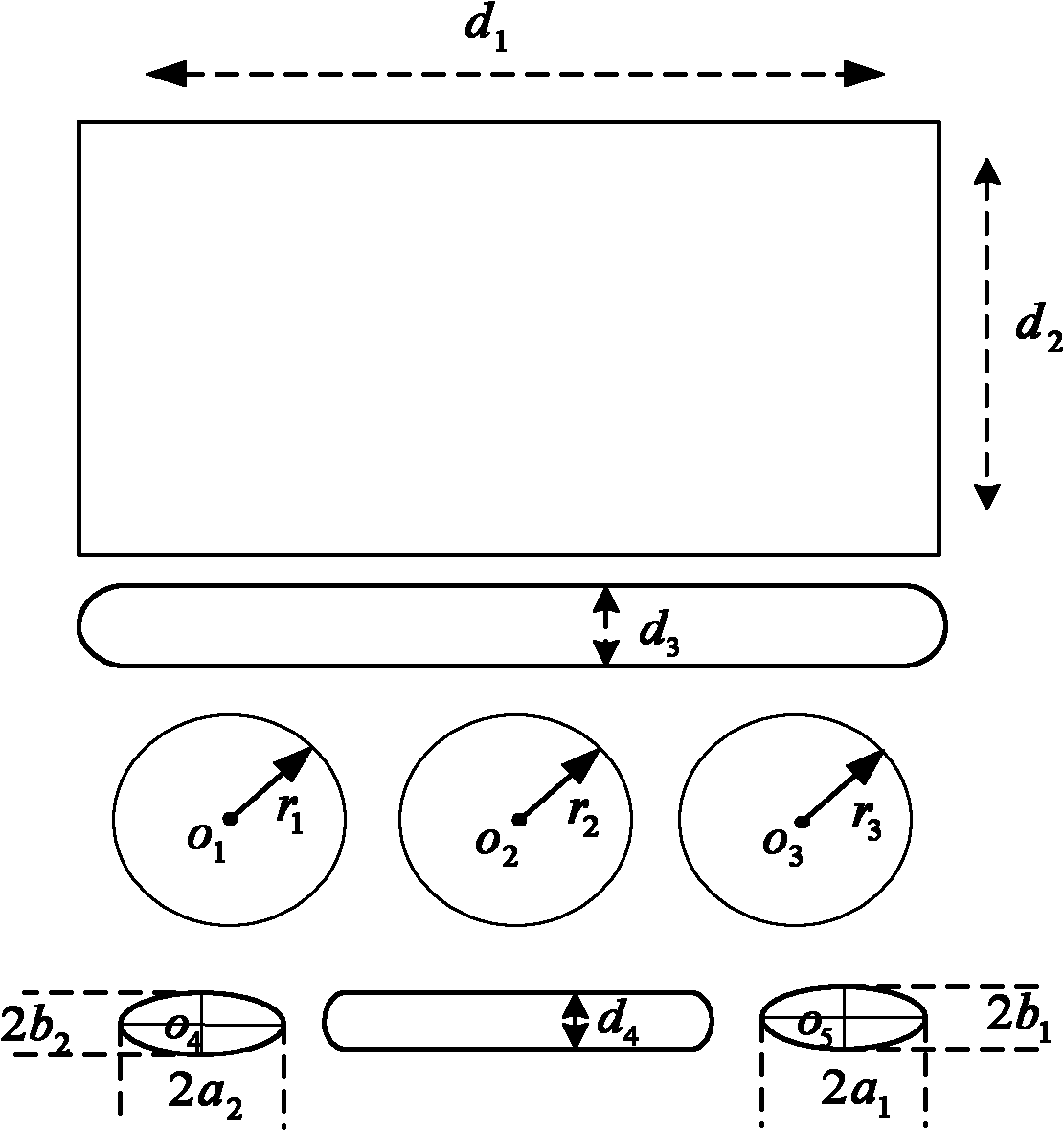

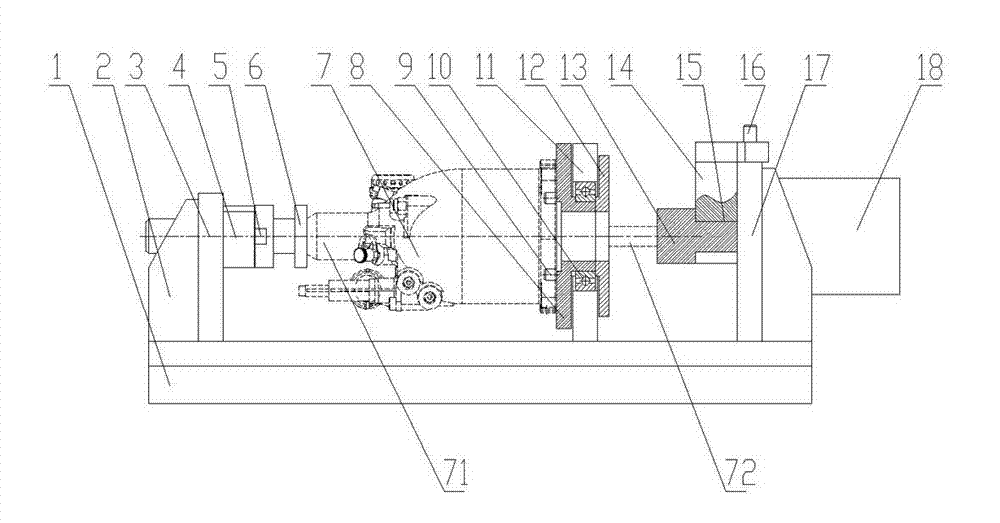

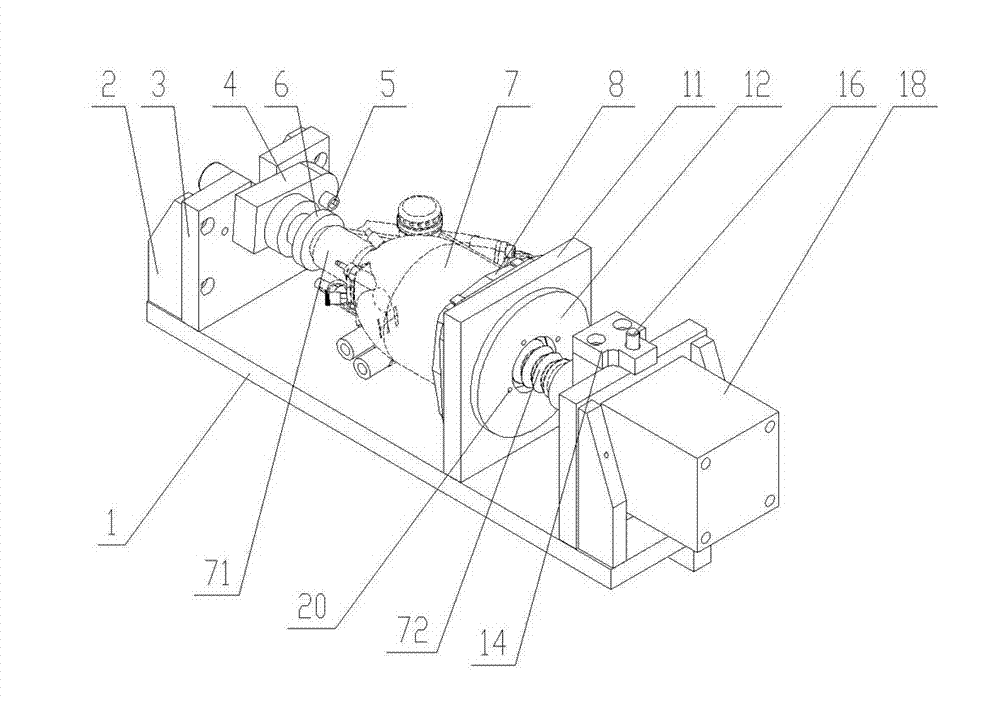

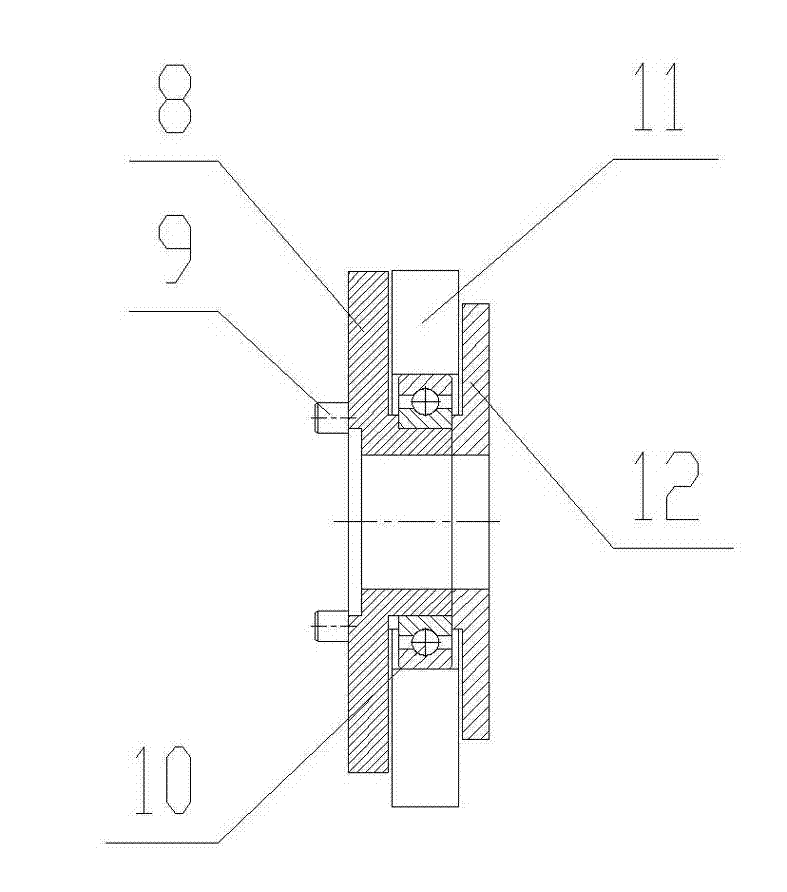

Automatic on-line detection method and device for size of automobile parts based on machine vision

InactiveCN102116610AReduce testing labor intensityHigh precisionBiological modelsUsing optical meansProduction lineImaging processing

The invention relates to the on-line detection technical field by utilizing machine vision and an image processing technology, in particular to an automatic on-line detection method and a device for size of automobile parts based on machine vision, aiming at solving the problems that the labor intensity is high and the detection quality is poor by adopting an artificial on-line detection method for size of automobile parts. An industrial camera is utilized for shooting a clear, complete and flaw-free standard image for the automobile part running in an automatic production line, the image is utilized as a standard image template and is stored in a computer, the precision range of detection parameters for the automobile part is set according to user requirements, the image of the on-line running automobile part, which is shot in real time by the industrial camera, is transmitted to the computer and is compared with the standard image template and is processed, the size of the automobile part can be computed, and if the precision of the part is lower than the setting requirements, the computer starts and gives an alarm, so as to prompt operational staff to treat inferior-quality products. The method and the device have high detection precision to the automobile parts and have rapid speed, so as to greatly reduce the labor intensity for artificial detection.

Owner:CHANGZHOU SITEEN AUTOMOTIVE TRIM SYST +1

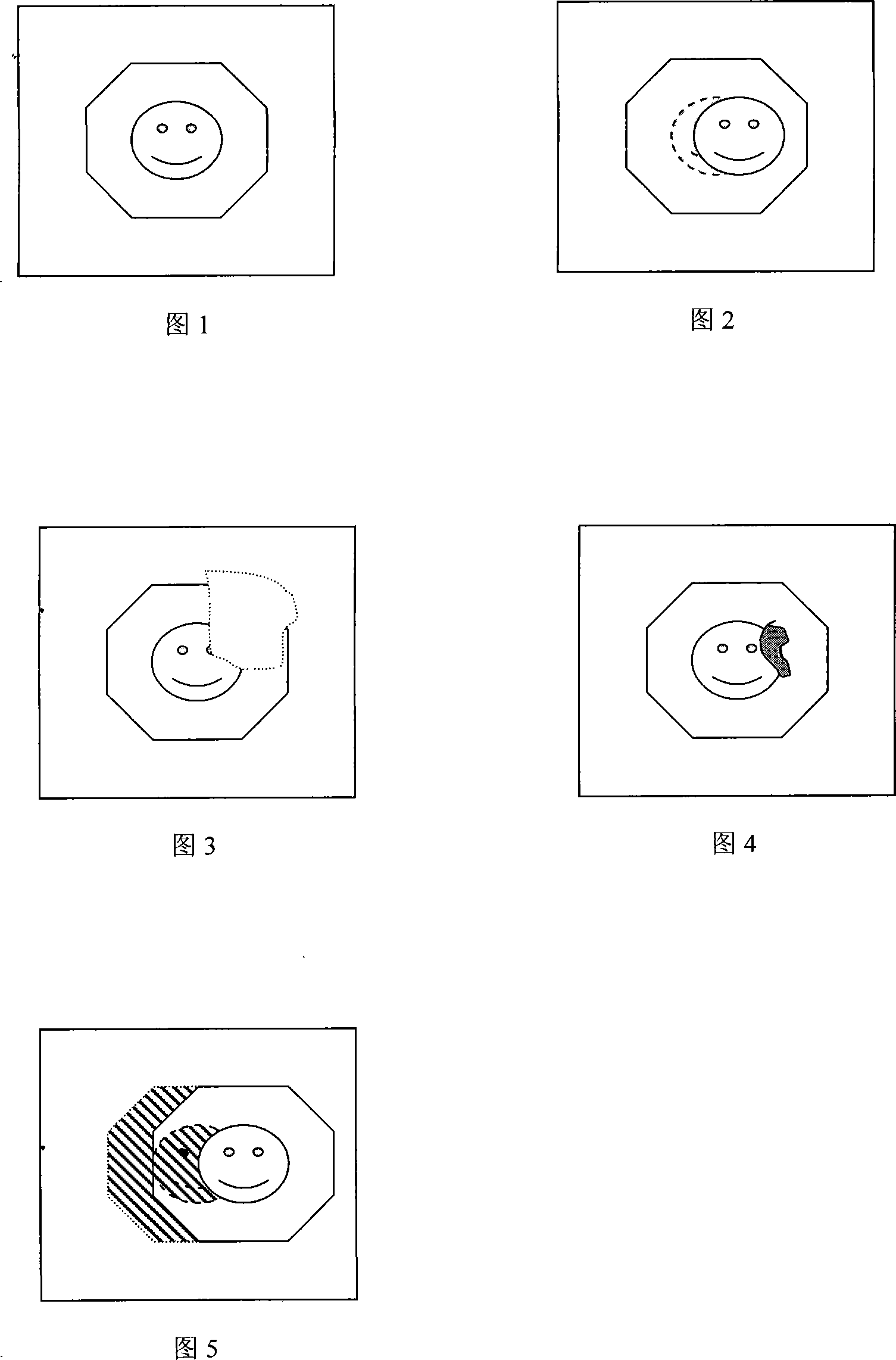

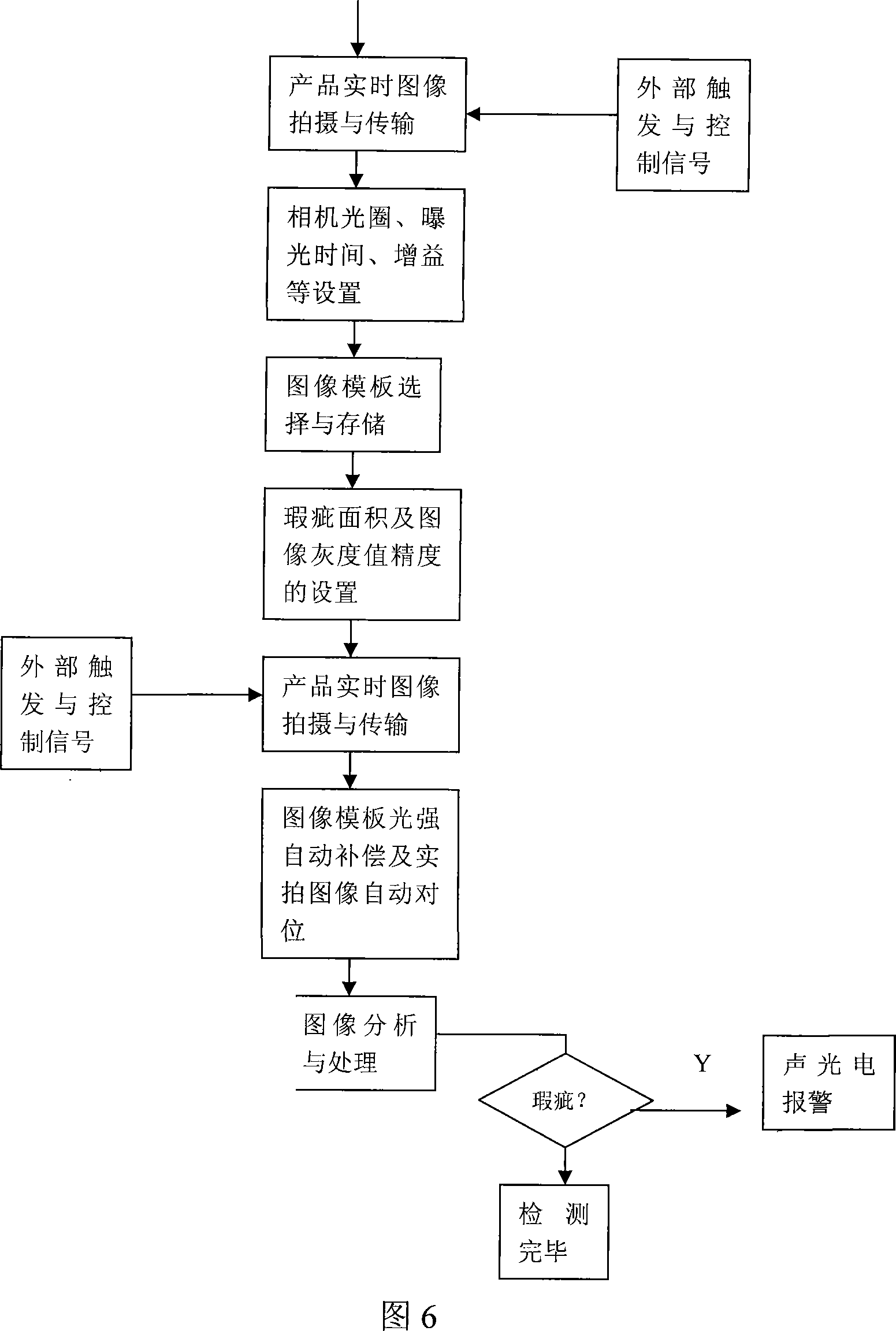

On-line detecting method of machine vision system for printed calico flaw

InactiveCN101158650AReduce testing labor intensityGuaranteed accuracyInspecting textilesMaterial analysis by optical meansVisual perceptionComputer science

The invention relates to an online detecting method of a machine vision system for detecting blemishes of a printed cloth. The invention aims at solving the problem that the labor intensity of manual online detecting blemishes of the printed cloth is high, and the detecting quality is bad. Clear and thorough, and spotless graphs are shot on the running printed cloth through industrial camera. The clear and thorough, and spotless graphs are stored in the calculating machine as a standard graph molding board. The blemish area and graphic gray value are taken as the detecting parameter of the blemish. The precision scope of the detecting parameter is arranged according to the requirement of the consumer. The graphs of the running printed cloth are shot in real-time, and are conveyed to the calculating machine. The real-timely shot graphs are compared with the standard graph molding board and are dealt with. If a blemish appears, the operating personnel are indicated to deal with the blemish of the printed cloth through an alarm. The alarm is started through the calculating machine. The invention can carry out light intensity self-compensating of the standard graph molding board, and dynamically correcting the shift of the pixel of the real-timely shot printed cloth graphs. The invention has the advantages of high precision and fast speed of detecting blemishes of the printed cloth, and greatly reduced labor intensity of manual detecting.

Owner:WUXI DONGWANG TECH

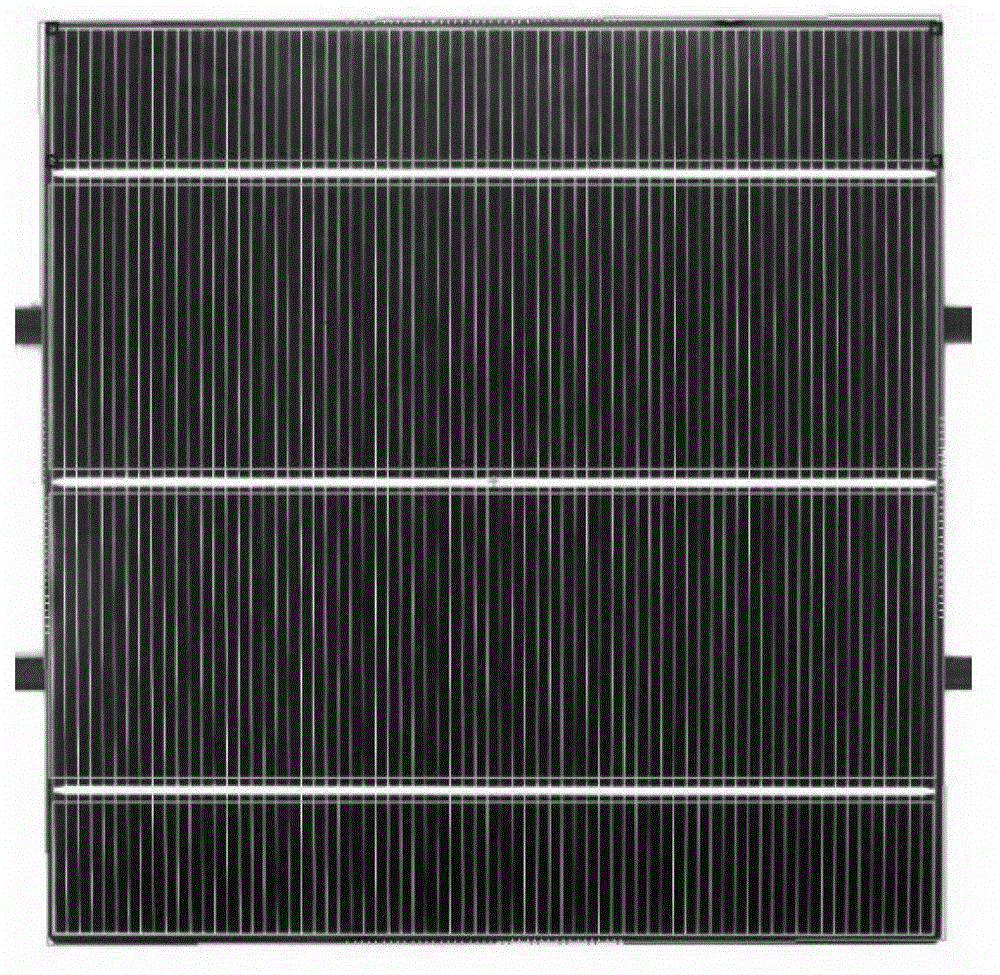

Machine vision-based method for detecting and sorting polycrystalline silicon solar energy

InactiveCN102974551AReduce testing labor intensityAvoid the build processSortingSilicon solar cellVisual perception

The invention discloses a machine vision-based method for detecting and sorting polycrystalline silicon solar energy. The method comprises the following steps of: 1) allowing a polycrystalline silicon solar cell to pass through an image acquisition area, and acquiring a corresponding image through a charge coupled device (CCD) camera; 2) performing image preprocessing on the acquired image, wherein the image preprocessing comprises image extraction, gray processing, image noise filtering, image enhancement, edge detection and solar cell positioning; and 3) performing image recognition, comparing the parameters of the polycrystalline silicon solar cell acquired in the step 2) with a template, performing image similarity measurement, performing color classification to sort the colors. The grey level histogram of the polycrystalline silicon solar cell is analyzed and is compared with a standard sample image for calculation to obtain the standard deviation of the histogram distribution, and a classification decision is made through the obtained standard deviation. Through the proving of the experiment proves, the method has the advantages that the detection speed is high and the accuracy is high and the detection requirements can be met.

Owner:SOUTH CHINA UNIV OF TECH

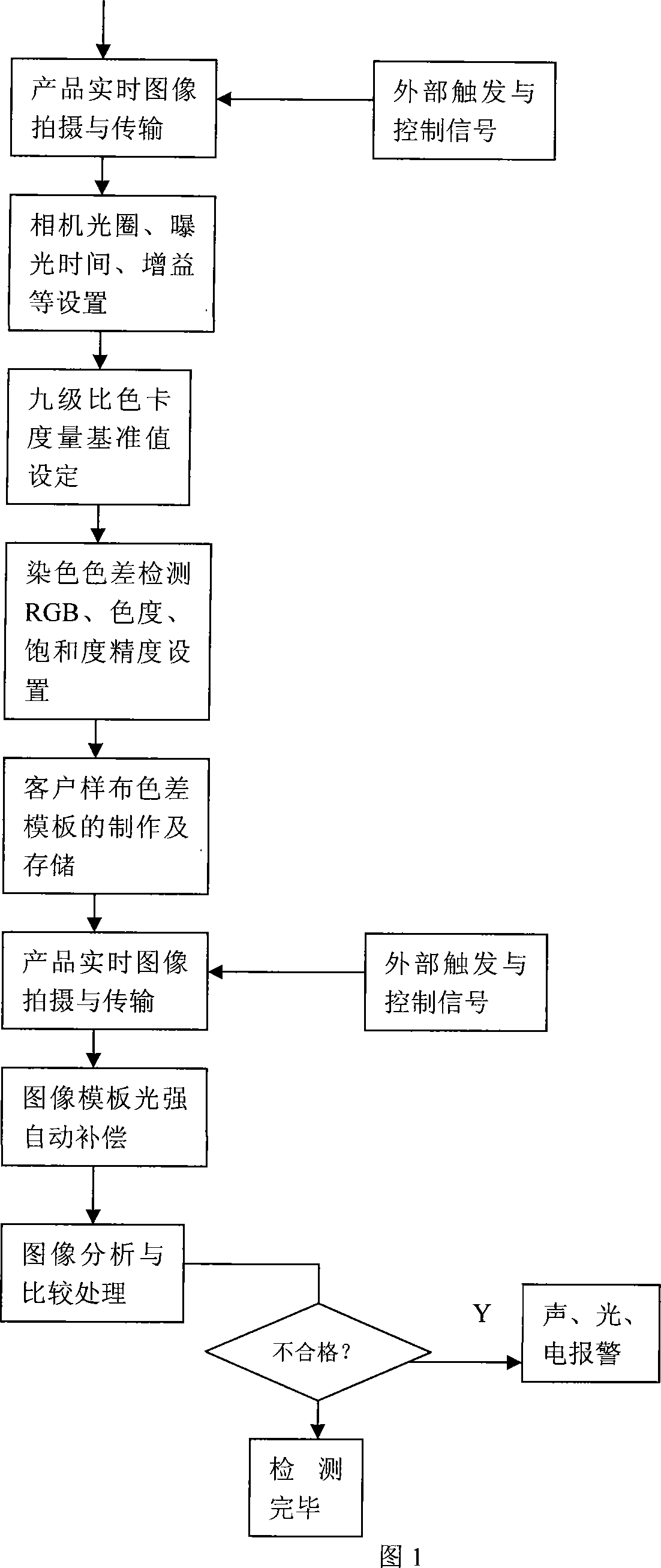

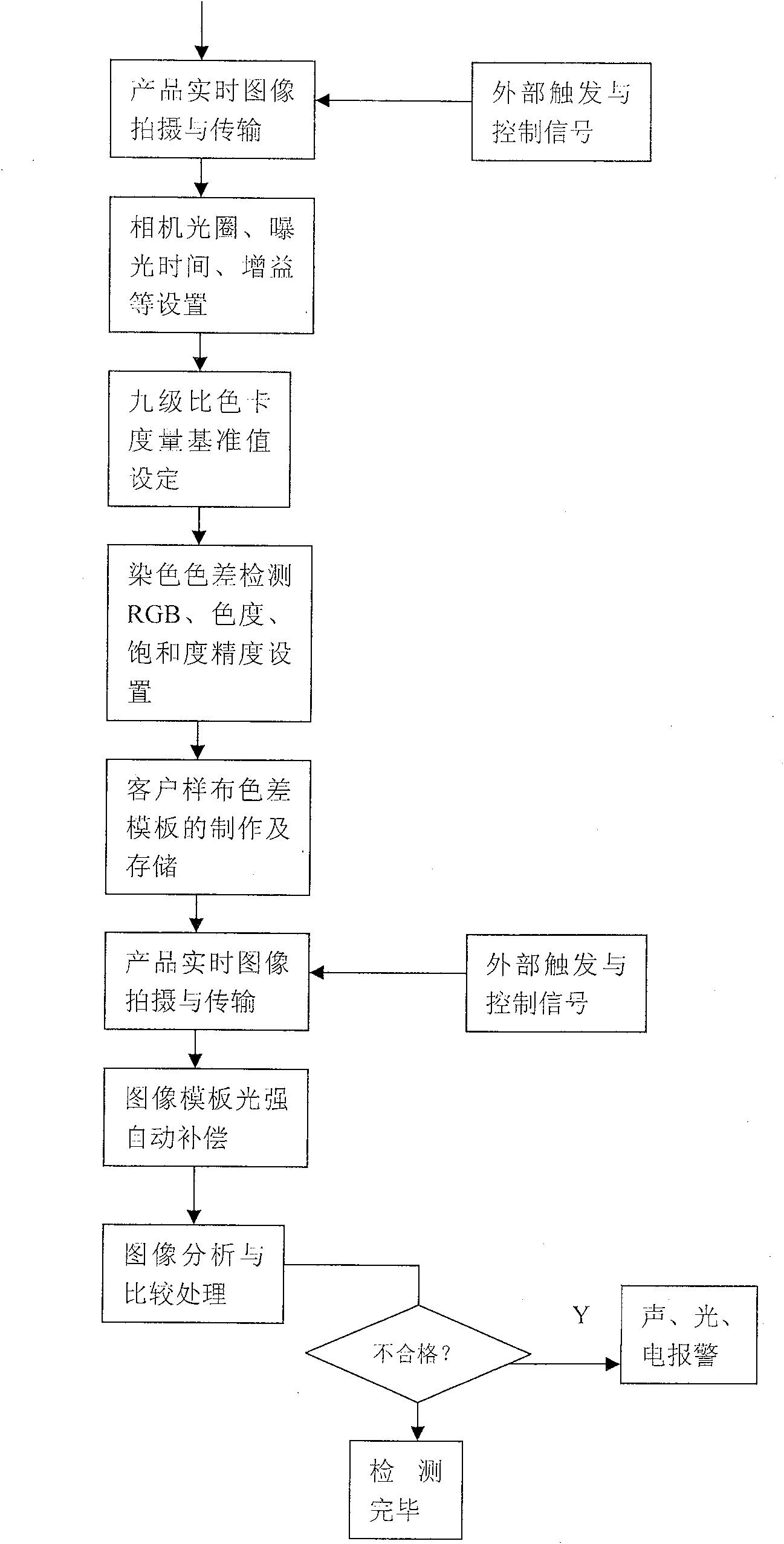

Printing dye aberration on-line detection method of machine vision system

InactiveCN101149291AReduce testing labor intensityImprove accuracyCharacter and pattern recognitionColor measuring using colour chartsColor differenceUser needs

The invention is the online detection method of the machine vision system to the printing and dyeing color difference. It can solve the big working strength and the bad detection quality of detecting the color difference by human. The invention makes the standard image module of the detecting print-dyeing color difference according to the client sampling cloth, which the RGB value, saturation value and color value are as the standard value of detecting dyeing color difference; it uses the national nine-degree colorimetric card as the standard of dyeing color difference; the RGB value, saturation value and color value are set as the detection parameters and it sets the parameter precision range according to the user need. While the environment light changing, the invention can compensate the light strength of shoot image automatically to determine the production dyeing color difference precisely. The invention meets the practical condition of the user dyeing color difference detection and improves the precision and detection speed of the color difference detection.

Owner:WUXI ZHONGWANG 4D TECH

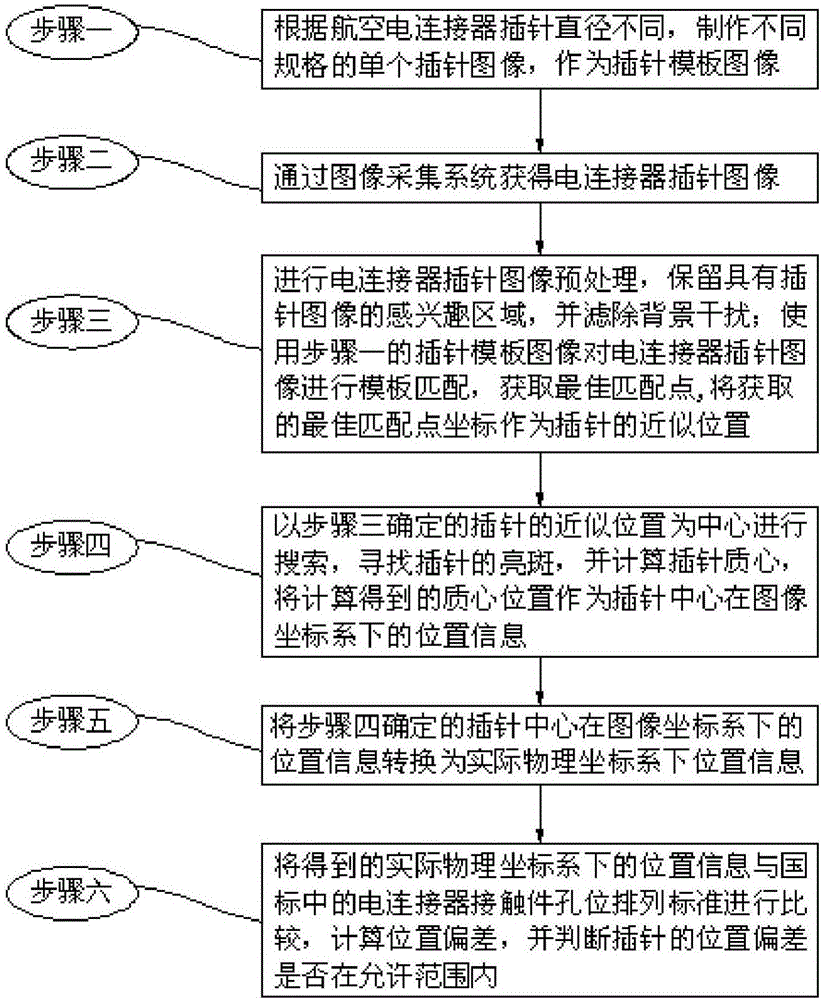

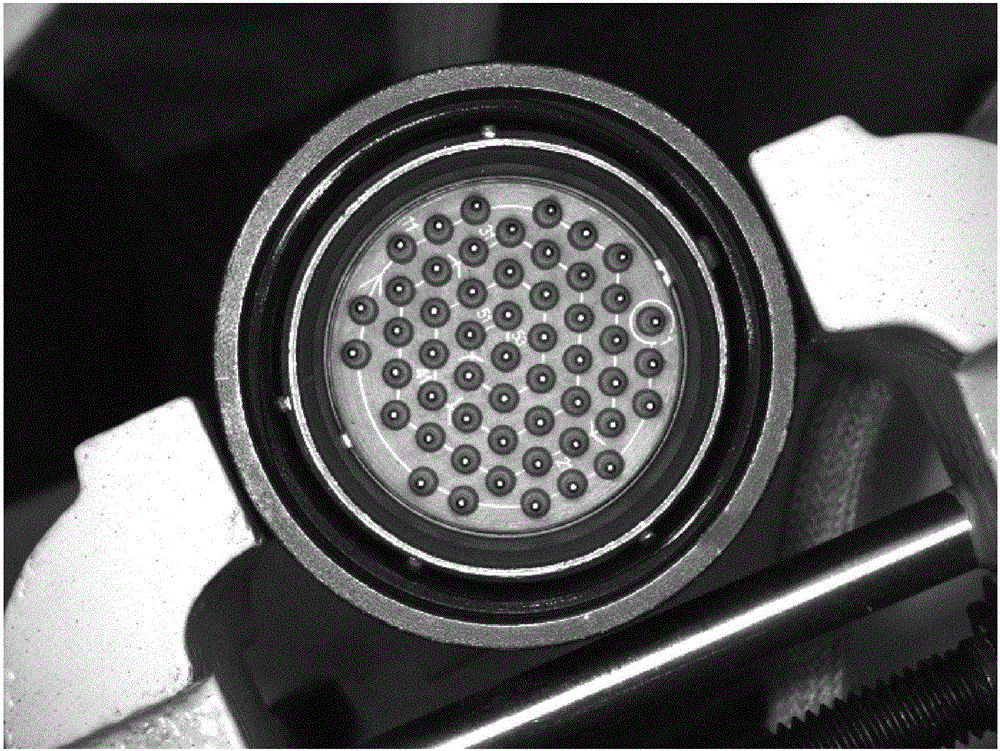

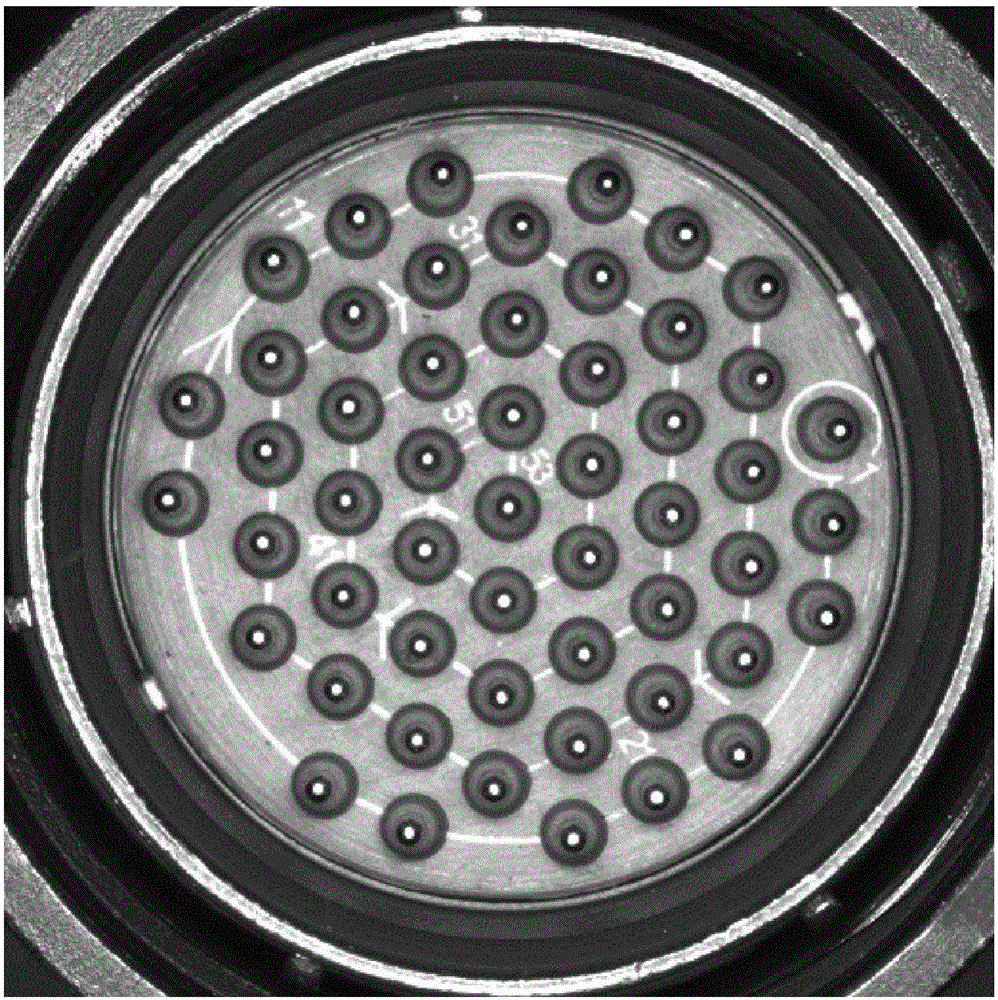

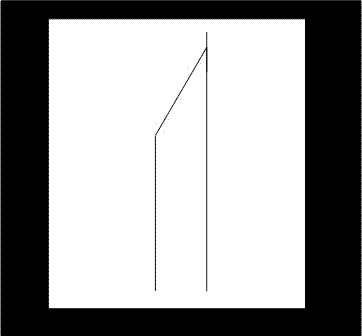

Aviation electric connector pin position deviation detection method

The invention discloses an aviation electric connector pin position deviation detection method and belongs to the field of machine vision high-precision detection, for solving the problems of low efficiency and proneness to missed detection existing in manual detection of an electric connector. According to the aviation electric connector pin position deviation detection method, pin template images with different specifications are made; electric connector pin images are obtained; an area of interest with the pin images is reserved, and background interference is filtered; coordinates of optimal matching points are obtained as approximate positions of pins by performing template matching on the electric connector pin images by use of the pin template images; search is carried out by taking the approximate positions of the pins as centers, pin bright spots are sought, calculated mass center positions are taken as position information of the pin centers under an image coordinate system, then after the position information is converted into position information under an actual physical coordinate system, the position information under the actual physical coordinate system is compared to an electric connector contact hole position arrangement standard in a national standard, and whether pin position deviations are within an allowed scope is determined. The method has the advantages of high precision, high automation efficiency and low miss rate.

Owner:HARBIN INST OF TECH

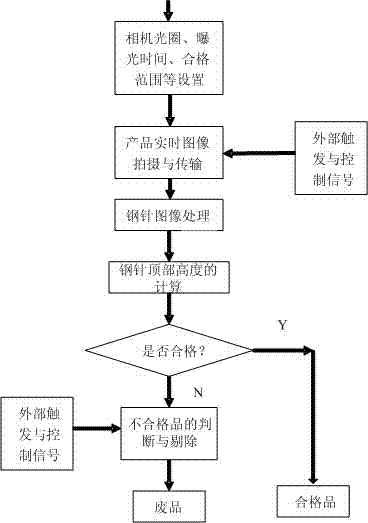

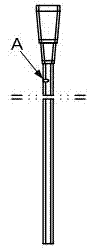

Method for automatically detecting bending of injector steel needles by using machine vision system

ActiveCN102303017AReduce testing labor intensityIncrease productivityOptically investigating flaws/contaminationSortingComputer visionInjector

The invention provides a method for automatically detecting the bending of injector steel needles by using a machine vision system. The method comprises the following steps of: setting transverse bending values of needle points of the steel needles to be detection parameters; setting detection accuracy and qualified ranges of different detection parameters according to requirements of users; starting a camera by using external trigger and control signals to shoot pictures of the steel needles operated on line in real time, and transmitting the shot pictures to a computer for detection; processing the pictures by using the computer by a picture algorithm; extracting the pictures in which the steel needles are bent, and computing the transverse bending values of two bending needles; and judging whether a product is a qualified product or a waste product through the computed transverse bending values, and eliminating the waste product from a specified material outlet through the externaltrigger and control signals. By the method, the injector steel needles can be detected at high accuracy and high speed, and the yield of the product can be effectively ensured.

Owner:WUXI ZHONGWANG 4D TECH

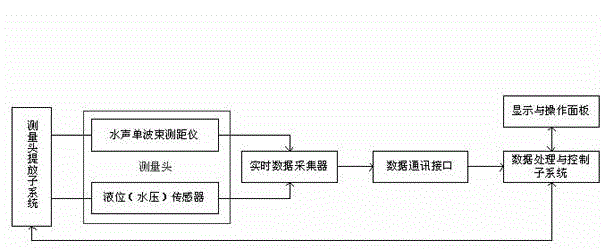

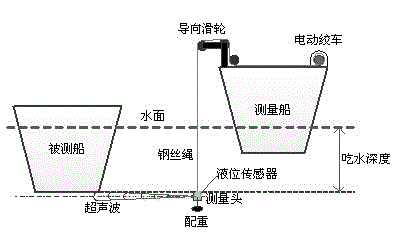

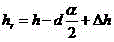

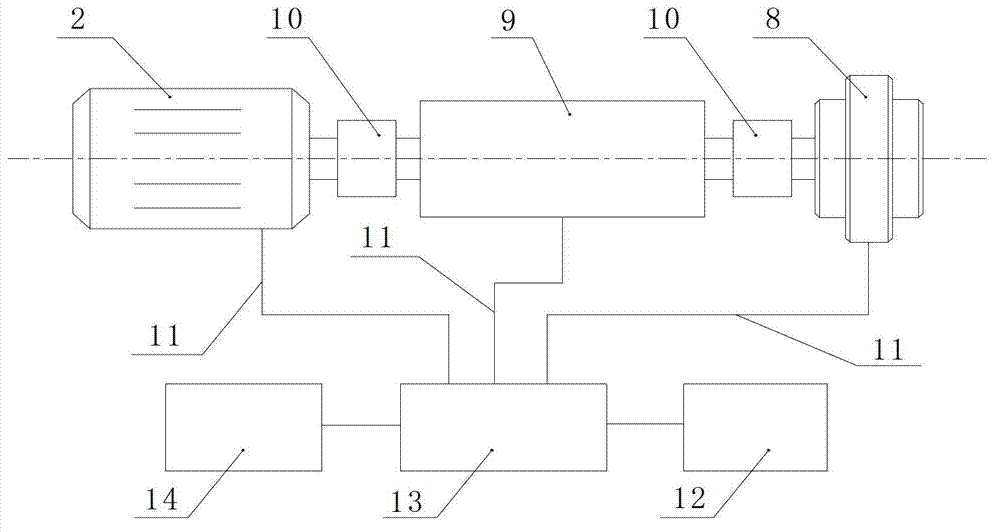

Automatic detection system for super draught of navigation vessel

InactiveCN102616346AImprove detection efficiencyImprove detection accuracyUsing optical meansVessel stability improvementCommunication interfaceEngineering

The invention discloses an automatic detection system for super draught of a navigation vessel. The automatic detection system comprises a measuring head, a measuring head lifting subsystem, a real-time data acquisition device, a data communication interface, a data processing and controlling subsystem and a display and operation panel, wherein the measuring head is connected to a steel wire rope of the measuring head lifting subsystem; the input end of the real-time data acquisition device is connected with the measuring head; the output end of the real-time data acquisition device is connected with the data processing and controlling subsystem through the data communication interface; and the data processing and controlling subsystem is connected with the display and operation panel. According to the automatic detection system, non-contact type automatic detection of (super) draught of the vessel during navigation is realized, the detection efficiency and the detection precision are increased and the detection cost is reduced.

Owner:江苏舾普泰克自动化科技有限公司

On-line detection method of PVC round tube surface flaw based on machine vision system

InactiveCN101832951AFully automatedReduce testing labor intensityMaterial analysis by optical meansPre treatmentVisual perception

The invention discloses an on-line detection method of a PVC round tube surface flaw based on a machine vision system, comprising the following steps: arranging four industrial cameras on a tuber surface, acquiring video signals and transferring the video signals into a PC computer; carrying out pre-processing; solving an actual area corresponding to each pixel; performing cosine correction on an image to enable the image area approximate to the real curved surface area of a tube; setting time for cameras to shoot regularly, storing shot images in an engineering work space and covering the images shot before, and correcting the images; calculating the amount and areas of heterogeneous pixels in the images; and sending a signal to control a flaw mark executing mechanism to mark near the flaws by the PC computer when the set minimum threshold valve is reached, accumulating the areas and amount of the connected regions of the heterogeneous pixels in the images, clearing and weighting the areas and amount of the connected regions of the heterogeneous pixels in the images in regular time, detecting the surface flaw of the tube so as to obtain the rating of the surface flaw. The invention can automatically detect the tube surface flaw.

Owner:CHINA JILIANG UNIV

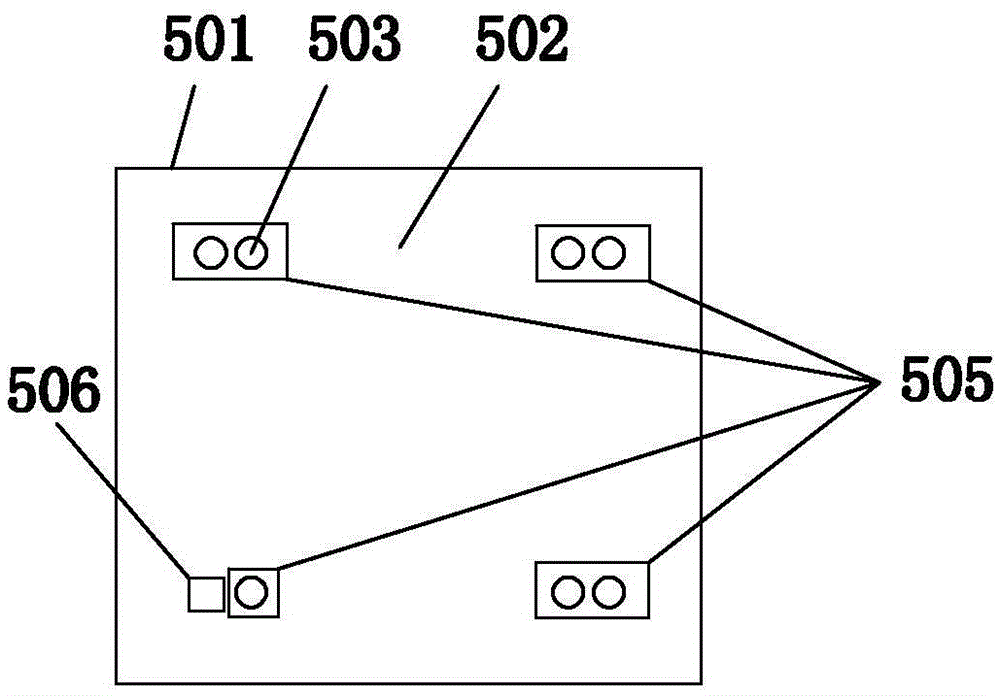

Seal testing device for automobile clutch booster

ActiveCN102829921AReduce testing labor intensityImprove work efficiencyFluid-tightness measurement using fluid/vacuumClutchEngineering

The invention relates to the field of automobile parts processing. The invention discloses a seal testing device for an automobile clutch booster. The seal testing device comprises a motherboard and an air cylinder, wherein a connector limiting plate and an air cylinder mounting plate are arranged on the motherboard, an air cylinder is arranged at one side of the air cylinder mounting plate, an output shaft of the air cylinder is connected with a tappet passing through the air cylinder mounting plate, a bearing pedestal provided with a bearing is arranged on the motherboard between the connector limiting plate and the air cylinder mounting plate, a rotary locating plate provided with a through hole is arranged on the bearing pedestal and can rotate on the bearing pedestal, and the rotary locating plate is provided with a positioning pin; an U-shaped hole is opened in the connector limiting plate, and the U-shaped hole in the connector limiting plate corresponds to the through hole of the rotary locating plate and the tappet. When the seal testing device for the automobile clutch booster, disclosed by the invention, is used for seal testing of the clutch booster, a workpiece can rotate easily, so that testers can carry out brushing testing conveniently, therefore labor intensity in testing is reduced, high work efficiency is achieved and testing quality is enhanced.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

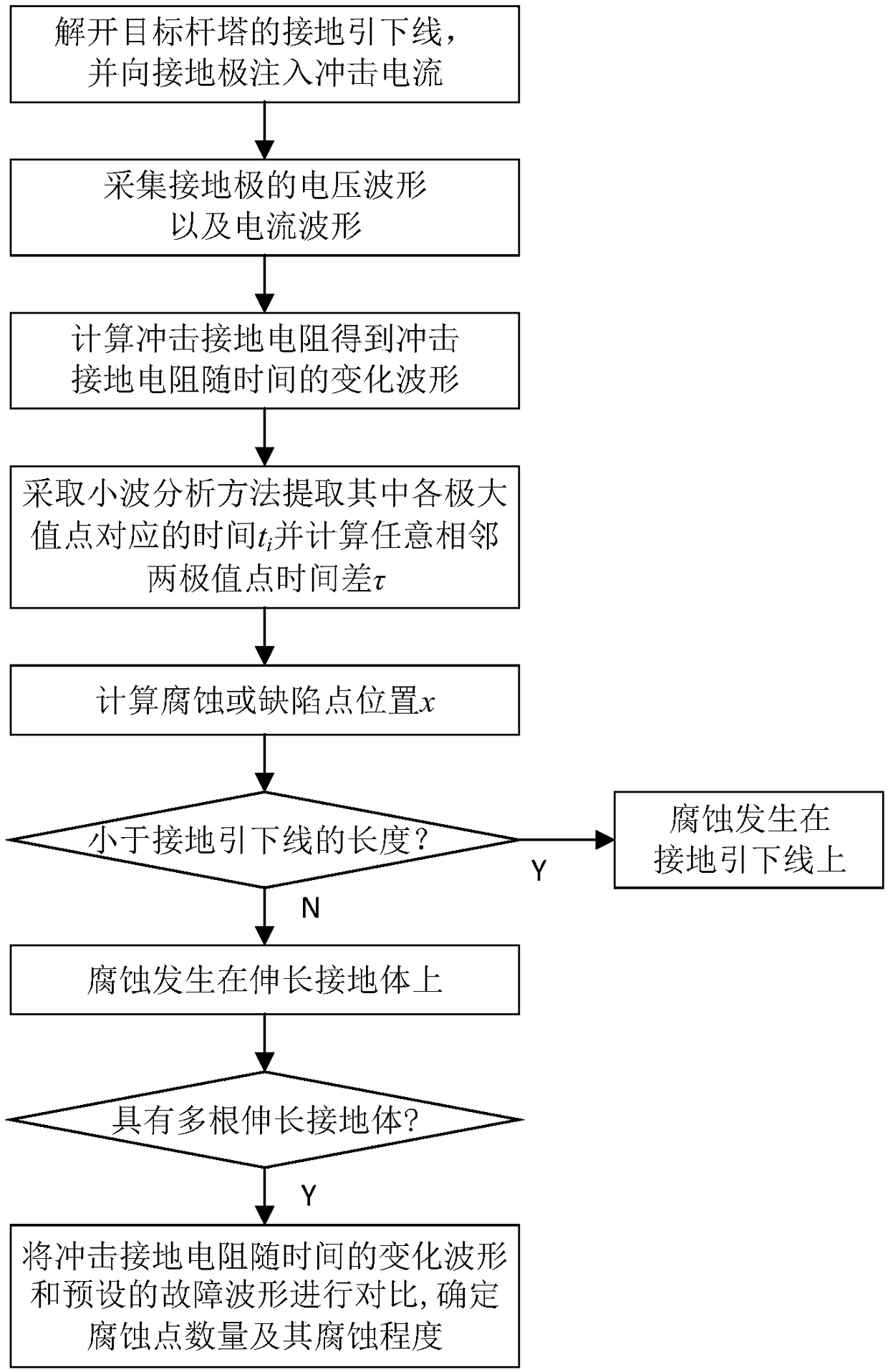

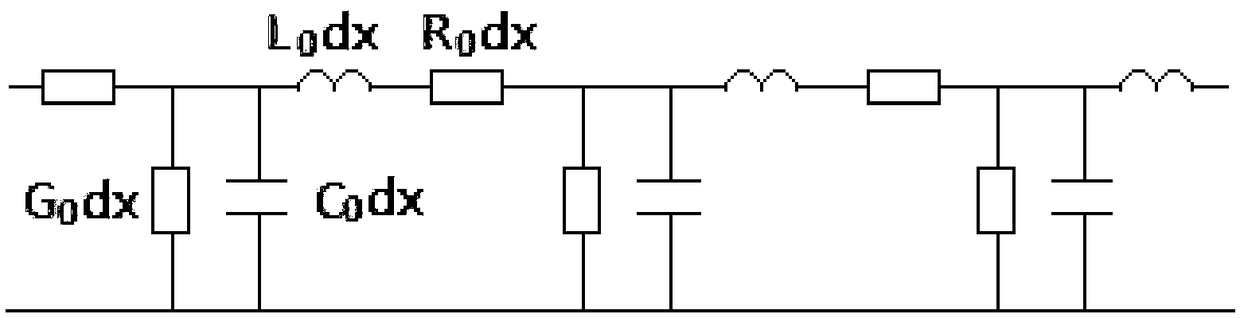

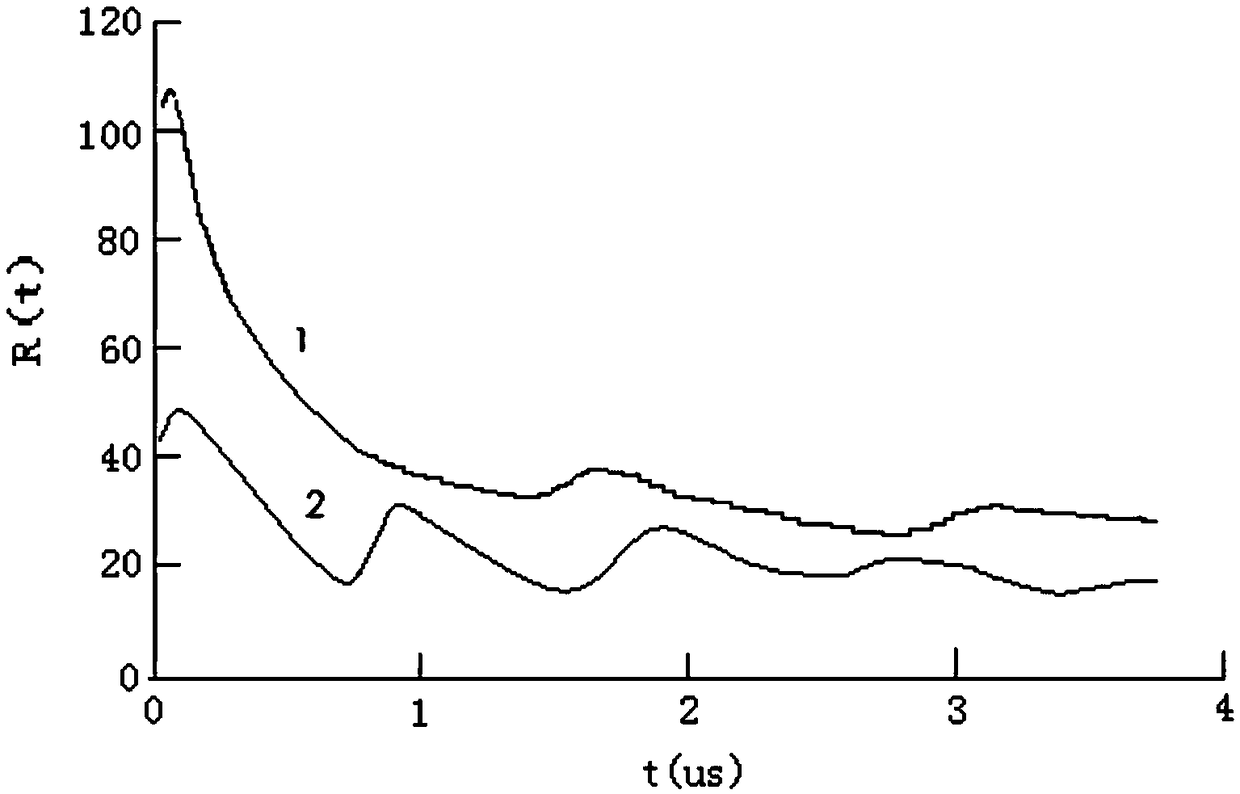

Grounding corrosion detection method for overhead line structure

ActiveCN108896472AImprove detection accuracyEasy to detectWeather/light/corrosion resistanceEngineeringGrounding resistance

The invention discloses a grounding corrosion detection method for an overhead line structure. The method comprises the following steps: unfastening a down conductor of a target tower; injecting an impact current into a ground electrode; collecting voltage and current waveforms of the ground electrode and calculating the change waveform of an impact ground resistor along with time change; analyzing and extracting the maximum value points from the change waveforms of the impact ground resistor along with time change to calculate corrosion or defect point positions x; judging that corrosion happens to the down conductor of the target tower when the corrosion or defect point positions x are smaller than the length of the down conductor of the target tower; otherwise, judging that corrosion happens to a prolonged grounding body of the target tower, and further determining the quantity and corrosion degrees of the corrosion points of the target tower when the target tower has a plurality ofprolonged grounding bodies. The method achieves corrosion detection on the grounding bodies of the tower based on a damaged line traveling wave refraction and reflection principle without excavation,and has the advantages of being high in detection accuracy, convenient and rapid to detect and low in detection labor intensity.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

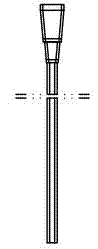

Method for automatically detecting back-stitching of steel needle of injector by using mechanical vision system

InactiveCN102305592AReduce testing labor intensityIncrease productivityUsing optical meansSortingImaging algorithmControl signal

The invention provides a method for automatically detecting back-stitching of a steel needle of an injector by using a mechanical vision system. The method comprises the following steps of: setting the top height of the steel needle as a detection parameter; setting the detection accuracy and qualified range of different detection parameters according to a user requirement; starting a camera by using an external trigger and control signal to shoot an image of an on-line operating steel needle in real time, and transmitting the shot image to a computer for detection; processing the image by using the computer with an image algorithm, and extracting the image of the top of the steel needle; calculating the top height of the steel needle, and judging whether a product is a qualified product or a rejected product by using the calculated top height of the steel needle; and eliminating the rejected product from an appointed discharge hole by using the external trigger and control signal. The method has the advantages that: the detection accuracy and speed of the back-stitching of the steel needle of the injector are high; and the yield of products can be effectively guaranteed.

Owner:WUXI ZHONGWANG 4D TECH

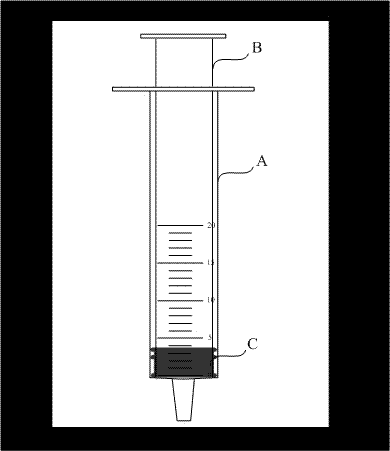

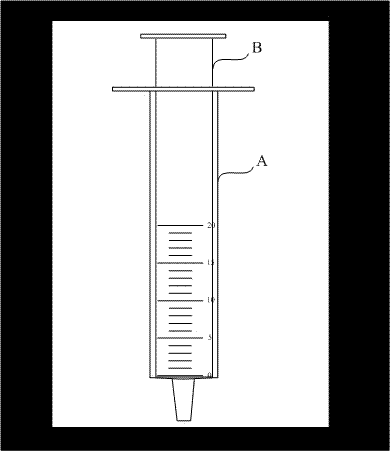

Automatic detection method for flaw of transfusion catheter through machine vision system

InactiveCN102495072AReduce testing labor intensityIncrease productivityOptically investigating flaws/contaminationInfusion catheterImaging algorithm

The invention provides an automatic detection method for a flaw of a transfusion catheter through a machine vision system. The method comprises the following steps of: pre-shooting an image of a standard transfusion catheter as a standard image of the transfusion catheter and storing the image in a computer, determining whether the pre-shot image and the standard image of the transfusion catheter have a difference and setting the difference as a detection parameter, starting a camera to shoot an image of an on-line working transfusion catheter in a real-time manner through an external trigger and a control signal, transmitting the shot image to a computer for detecting, performing an image algorithm treatment through the computer, extracting the image of the transfusion catheter, comparing the image of the transfusion catheter with the standard image of the transfusion catheter, judging whether a product is a qualified product or a defective product, and rejecting the defective product from an appointed discharge hole through the external trigger and the control signal. The automatic detection method, provided by the invention, has the advantages of high detection precision and quick speed on the flaw of the transfusion catheter, so that the qualified rate of the products can be effectively ensured.

Owner:WUXI ZHONGWANG 4D TECH

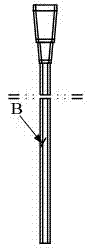

Method for automatically detecting burrs of injector steel needles by using machine vision system

ActiveCN102303018AReduce testing labor intensityIncrease productivityOptically investigating flaws/contaminationSortingControl signalWaste product

The invention provides a method for automatically detecting burrs of injector steel needles by using a machine vision system. The method comprises the following steps of: setting transverse lengths of protruded burrs and sunk burrs of needle point parts of the steel needles to be detection parameters; setting detection accuracy and qualified ranges of different parameters according to requirements of users; starting a camera by using external trigger and control signals to shoot pictures of the steel needles operated on line in real time, and transmitting the shot pictures to a computer for detection; processing the pictures by using the computer by a picture algorithm; extracting the pictures in which the burrs are generated, and computing the dimensions of two burrs; and judging whethera product is a qualified product or a waste product through the computed dimensions of the burrs, and eliminating the waste product from a specified material outlet through the external trigger and control signals. By the method, the burrs of the injector steel needles can be detected at high accuracy and high speed, and the yield of the product can be effectively ensured.

Owner:WUXI ZHONGWANG 4D TECH

Detection device for mechanical cam controller

ActiveCN102789228AEnter exactlyPermanent preservationElectric testing/monitoringAngular velocityEngineering

The invention discloses a detection device for a mechanical cam controller; a driving mechanism is used for driving the mechanical cam controller and an encoder to rotate by a coupler; the encoder is used for sending the acquired crankshaft angular velocity information into a control system; a movement monitoring signal generator is used for acquiring crankshaft status signals and sending the signals into the control system; a photoelectric position sensor is used for acquiring the switch position of a cam group and sending the switch position into the control system by a photoelectric signal receiver; and a switch contact is used for sending a switch power-on opening and closing signal into the control system. The control system can be used for processing the signals by an internal computing system, so that the test aim can be achieved. The detection device is suitable for testing the performances and the service life of the mechanical cam controller, can realize multi-parameter measurement, especially the measurement for repeatability precision, and has the characteristics of being accurate in test results, visual, quantitative, small in size and high in efficiency.

Owner:JIANGSU LANCHAUNG INFORMATION TECH SERVICESCO LTD

Method for automatically detecting abnormal shape of injector part by using mechanical vision system

InactiveCN102305597AReduce testing labor intensityIncrease productivityUsing optical meansControl signalImaging algorithm

The invention provides a method for automatically detecting an abnormal shape of an injector part by using a mechanical vision system. The method comprises the following steps of: pre-shooting an image of a standard part as an abnormal shape standard image, and storing the image into a computer; setting a difference proportion of the abnormal shape standard image as a detection parameter; setting the detection accuracy and qualified range of different detection parameters according to a user requirement; starting a camera by using an external trigger and control signal to shoot the image of the abnormal shape of an on-line operating injector part in real time, and transmitting the shot image to the computer for detection; processing the image by using the computer with an image algorithm, and extracting the image of the abnormal shape of the injector part; calculating an abnormal shape difference value, and judging whether a product is a qualified product or a rejected product by using the calculated abnormal shape difference value; and eliminating the rejected product from an appointed discharge hole by using the external trigger and control signal. The method has the advantages that: the detection accuracy and speed of the abnormal shape of the injector part are high; and the yield of products can be effectively guaranteed.

Owner:WUXI ZHONGWANG 4D TECH

Printing dye aberration on-line detection method of machine vision system

InactiveCN100561146CImprove accuracyReduce testing labor intensityCharacter and pattern recognitionColor measuring using colour chartsInternational standardColor printing

Owner:WUXI ZHONGWANG 4D TECH

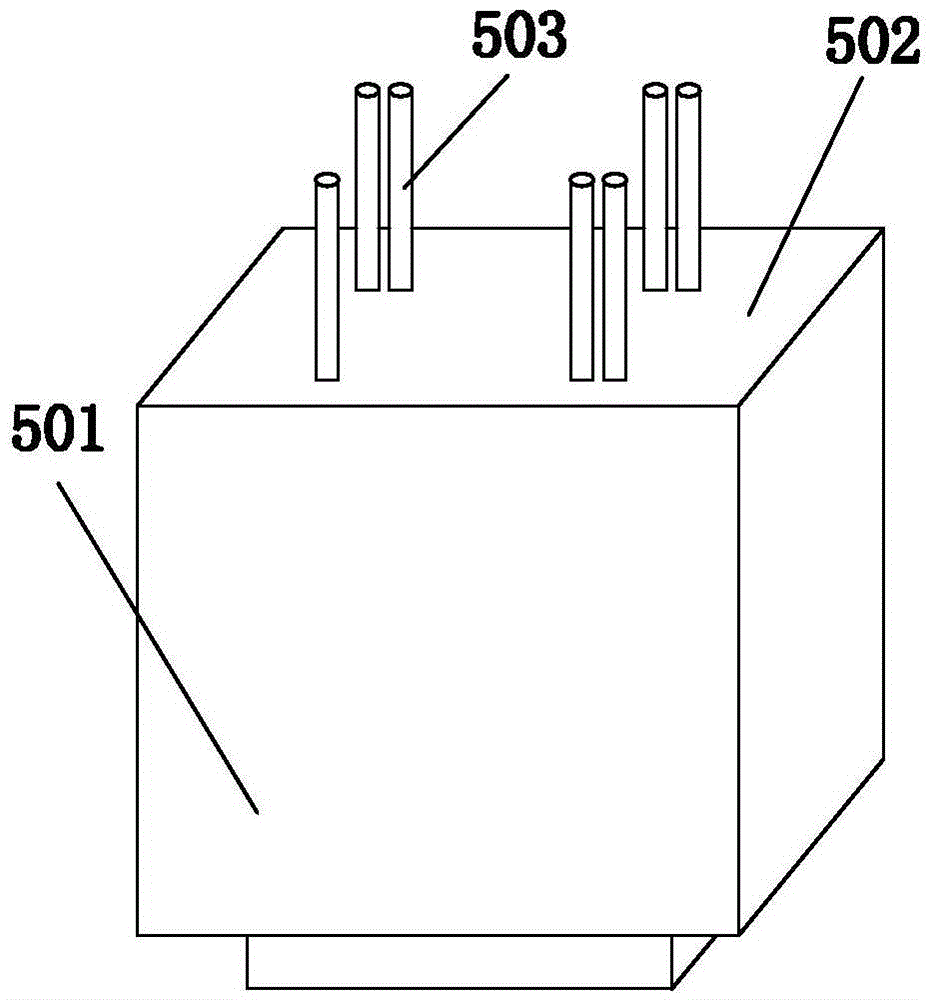

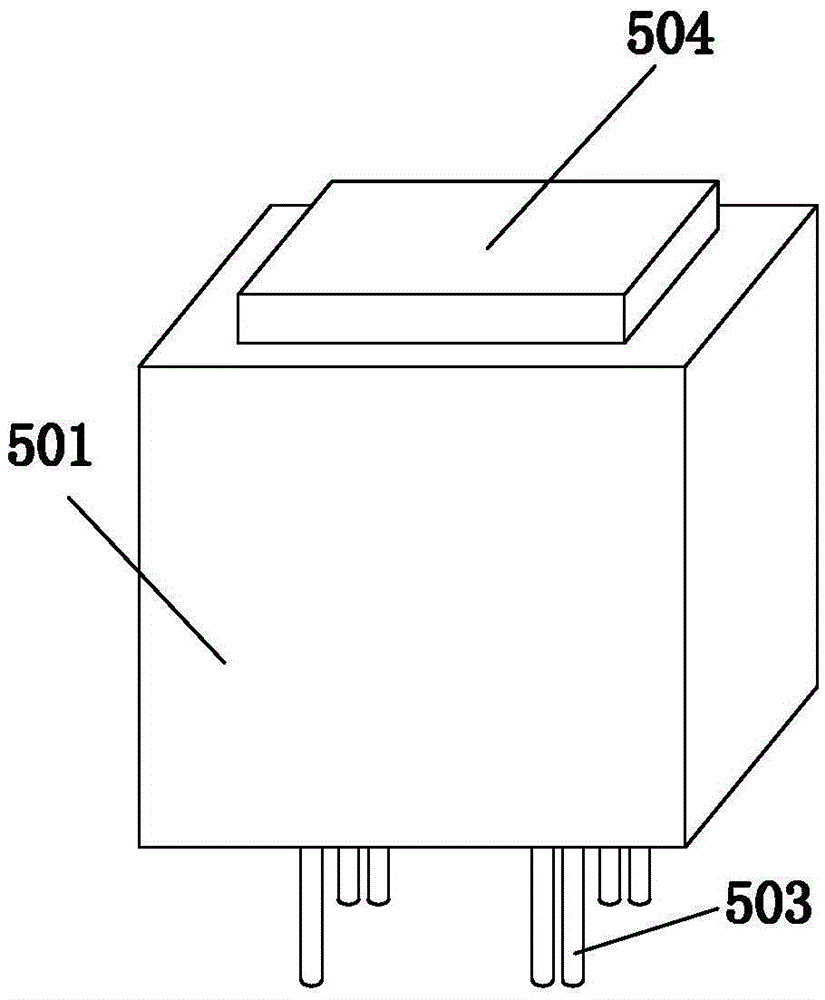

Automatic detection device for industrial frequency transformer and detection control method of automatic detection device

ActiveCN105478378AWill not cause electric shock accidentsReduce testing labor intensityOverturning articlesTypewritersElectricityTransformer

The invention discloses an automatic detection device for an industrial frequency transformer and a detection control method of the automatic detection device, and relates to the technical field of industrial frequency transformer detection. According to the automatic detection device for the industrial frequency transformer and the detection control method of the automatic detection device, the detection efficiency is high, the industrial frequency transformer is immediately fed into a code printing conveying unit for code printing after being detected, and the intelligent automation degree is high. The automatic detection device comprises a controller, a turning-over conveying unit, the code printing conveying unit, a qualified product container and four detection conveying units. Each of the four detection conveying units comprises a detection connecting mechanism and a detector, wherein the detection connecting mechanism comprises a detection support and a detection anvil which is arranged on the detection support in an up-down moving manner, and the detection anvil can move up and down over a detection area. The four detection conveying units are provided with the four detectors and the four detection anvils in all, and the four detectors are in one-to-one electric connection with the four detection anvils.

Owner:HANGZHOU XILI INTELLIGENT TECH CO LTD

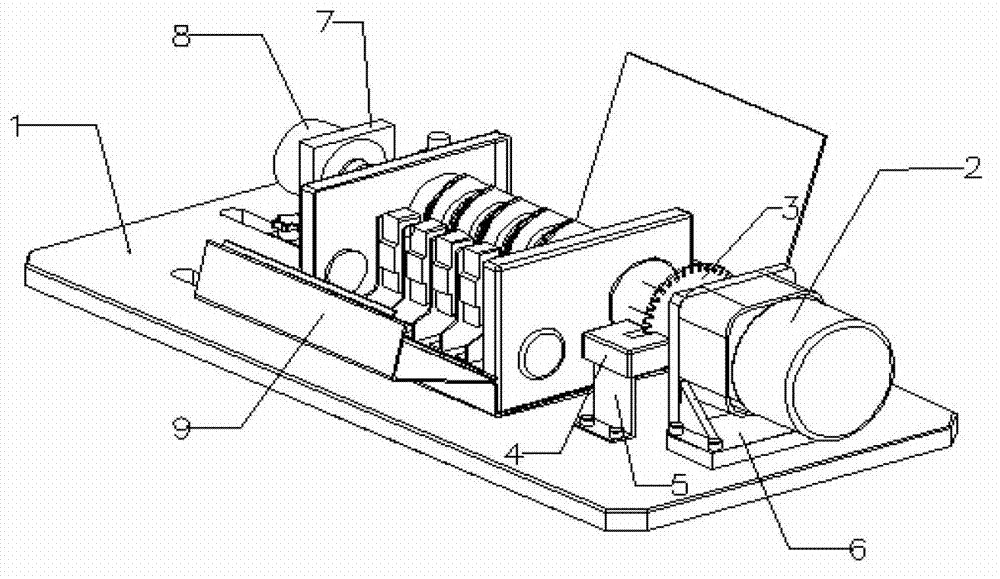

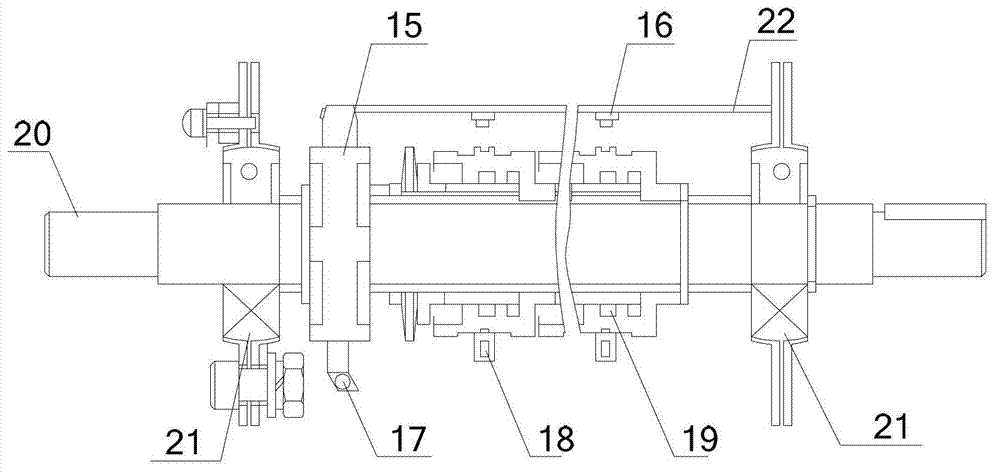

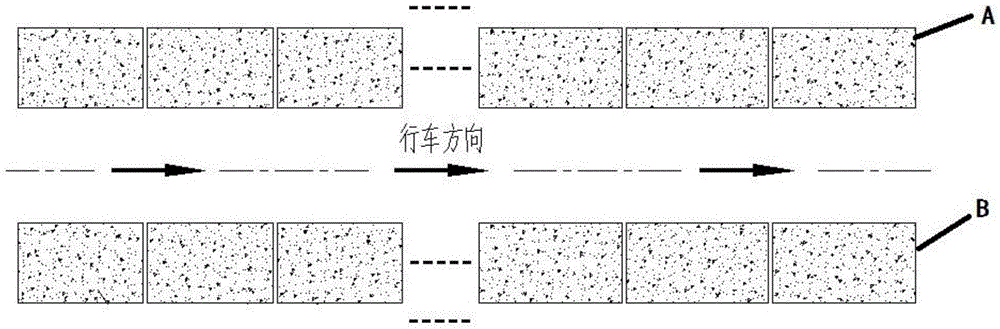

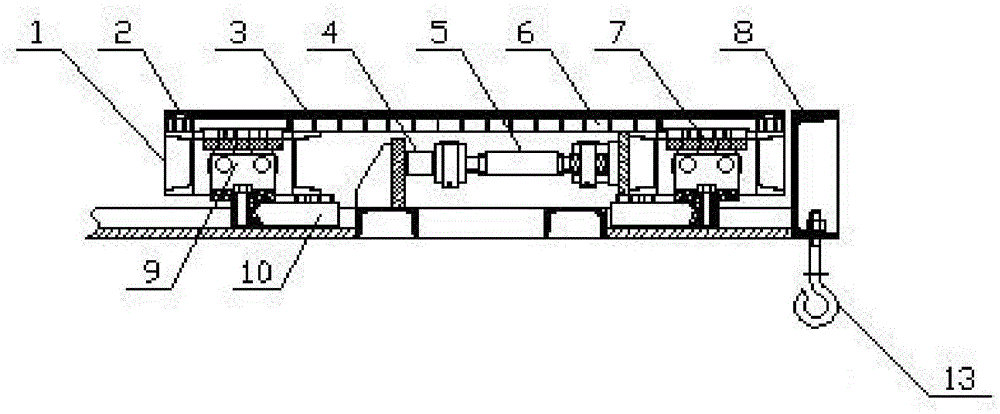

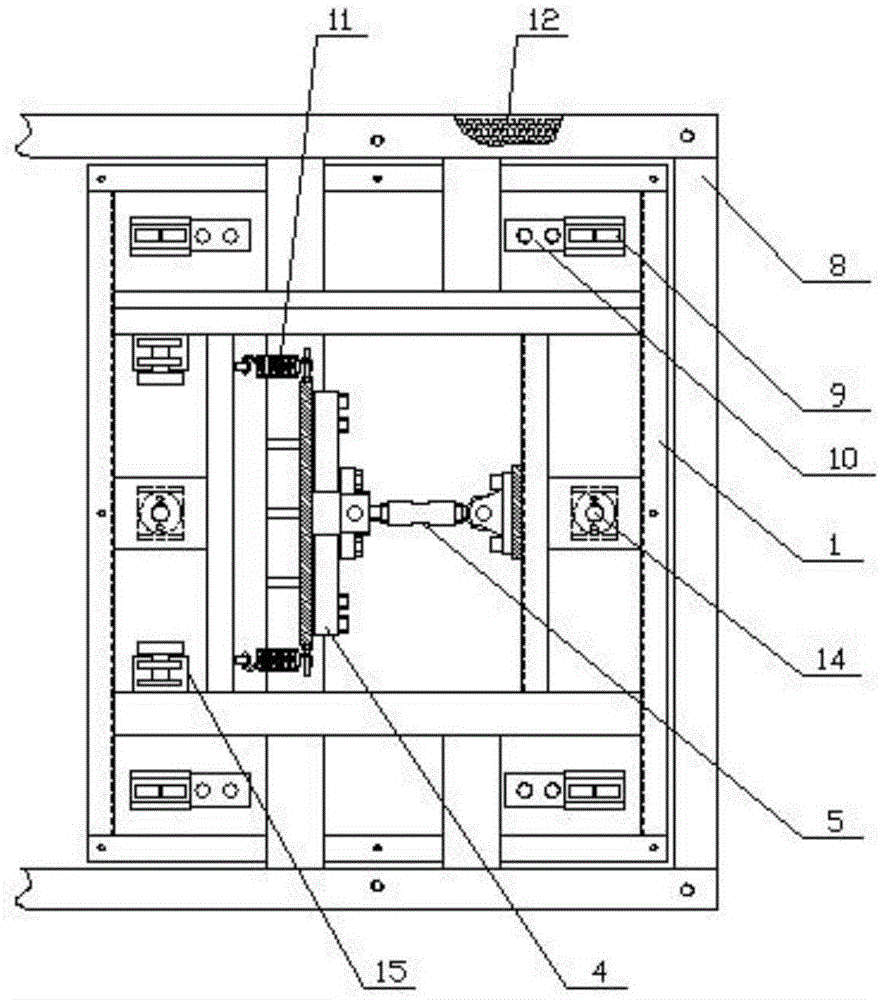

Test bed for braking performance of automobile/train

ActiveCN105606378AReduce testing labor intensityImprove detection efficiencyVehicle testingData processing systemElectricity

The invention discloses a test bed for the braking performance of an automobile / a train. The test bed is characterized in that a signal acquisition part of a sensor is composed of a left detection unit group and a right detection unit group which are formed by linearly arranging a plurality of detection units, and the left detection unit group and the right detection unit group are in symmetric distribution. A braking detection unit comprises a braking sand-adhering plate; the braking sand-adhering plates on the left detection unit group and the right detection unit group are independent, with a distance of 8 mm; each braking detection unit and each weighing detection unit work independently to respectively realize acquisition of braking data and weight data and are independently connected with a signal acquisition processing device; and the signal acquisition processing device is electrically connected with a data processing system. The automobile / train is subjected to multi-axial overall online detection, so that the braking time sequence of the vehicle, the dynamic braking power of the entire vehicle, the poor braking process, the coordinate time and the like of the entire vehicle can be detected in one braking process, therefore, the labor intensity of detection is alleviated, the detection efficiency is improved, and the braking performance of the vehicle can be reflected more truly.

Owner:SHENZHEN ANCHE TECH

Method for automatically detecting rupture of infusion bottle mouth by using machine vision system

InactiveCN102507602AReduce testing labor intensityIncrease productivityOptically investigating flaws/contaminationControl signalImaging algorithm

The invention provides a method for automatically detecting rupture of an infusion bottle mouth by using a machine vision system. The method comprises the steps of: pre-taking an image of a bottle mouth of a standard product as a bottle mouth standard image and storing the image in a computer; setting a differential proportion of the pre-taken image to the bottle mouth standard image as a detection parameter; setting detection precisions and qualification ranges of different detection parameters according to user requirements; starting up a camera according to an outer triggering and controlling signal to take images of the bottle mouth of the infusion bottle which is under on-line operation in real time; transmitting the taken images to the computer for detection; processing by the computer through an image algorithm; extracting images of the bottle mouth of the infusion bottle and calculating the difference; judging whether the product is a qualified product or a waste product through the calculated difference; and removing the waste product from an appointed discharge port through the outer triggering and controlling signal. The method for automatically detecting rupture of the infusion bottle mouth by using the machine vision system, disclosed by the invention, has high precision and high speed for detecting rupture of the bottle mouth of the infusion bottle and can be used for efficiently guaranteeing the qualified rate of products.

Owner:WUXI ZHONGWANG 4D TECH

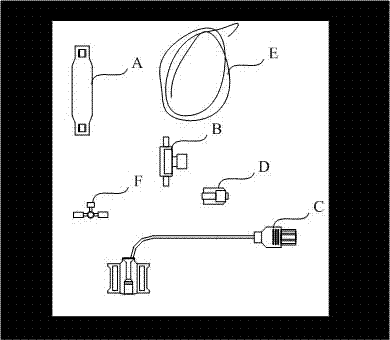

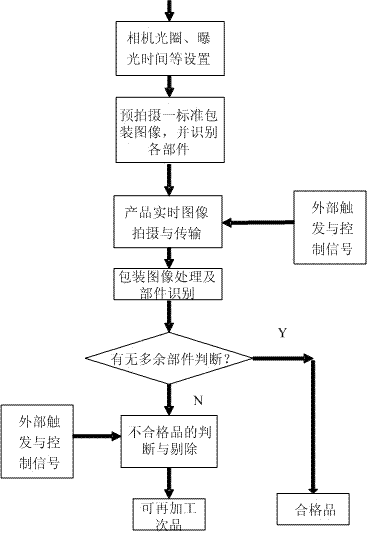

Method for automatically detecting foreign matter of medical product package by using machine vision system

InactiveCN102305797AReduce testing labor intensityExtended production timeOptically investigating flaws/contaminationMedical productForeign matter

The invention provides a method for automatically detecting a foreign matter of a medical product package by using a machine vision system, which comprises the following steps of: pre-shooting an image of a medical product packaging bag without the foreign matter, identifying various parts in the packaging bag, and numbering the various parts to form a standard library; setting whether a part which does not exist in the standard library exists in the image of the medical product packaging bag as a detection parameter; starting a camera through an external trigger and control signal to shoot the image of the on-line operated packaging bag in real time, transmitting the shot image to a computer for detection, and processing to identify the various parts in the packaging bag by using the computer through an image algorithm and a pattern recognition algorithm; and detecting whether any one part in the packaging bag has a corresponding number in the standard library or not, judging whether the product belongs to a qualified product or a defective product which can be reprocessed, and removing the defective product which can be reprocessed from a specified discharge hole through the external trigger and control signal. By the method, the detection accuracy and speed of the foreign matter of the medical product package are high, and the product yield can be effectively ensured.

Owner:WUXI ZHONGWANG 4D TECH

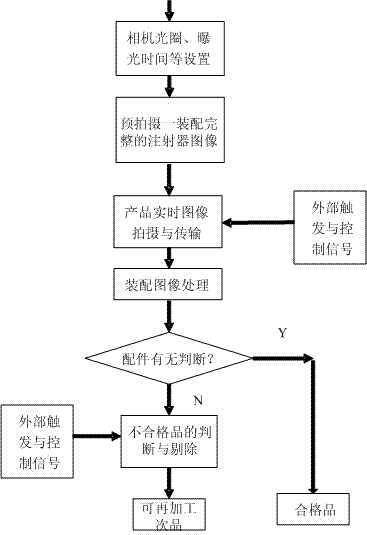

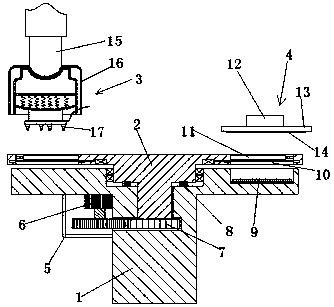

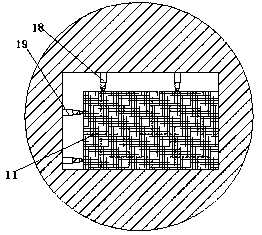

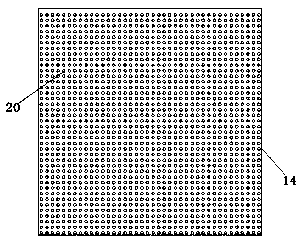

Method for automatically detecting missed accessory during automatic assembly of injector by using machine visual system

InactiveCN102305950AReduce testing labor intensityExtended production timeOptical detectionSortingControl signalImaging algorithm

The invention provides a method for automatically detecting a missed accessory during automatic assembly of an injector by using a machine visual system. The method comprises the following steps of: pre-shooting an assembly image of a qualified injector product to be used as a standard assembly image and stored in a computer; setting the existence of each accessory in the assembly image of the injector as a detection parameter; starting a camera by using an external trigger and control signal to shoot an image of the missed accessory during automatic assembly of the injector operating on line in real time; transmitting the shot image to the computer for detection; processing the transmitted image by using the computer by an image algorithm, and extracting the image of the missed accessory during automatic assembly of the injector; detecting whether any accessory in the standard assembly image has a corresponding image in the assembly image of the injector; judging whether the product is a qualified product or a degraded product which can be processed again; and removing the degraded product which can be processed again from an appointed discharge outlet by using the external trigger and control signal. By the method, the detection precision and the detection speed of the missed accessory during automatic assembly of the injector are high, and the qualification rate of the product can be effectively ensured.

Owner:WUXI ZHONGWANG 4D TECH

Electronic component testing device

ActiveCN108692662ARealize automated detectionRealize fully automated detectionElectrical testingUsing optical meansElectricityLight beam

The invention discloses an electronic component testing device, and the device can detect the size of an electronic component, and also can quickly detect the electrical performances of the electroniccomponent. The device is high in detection automation degree, and is reliable in detection. The device employs a multi-position mode for detection, and effectively reduces the labor intensity of detection. A multi-position rotating disc assembly can be cooperatively provided with feeding and discharging mechanical arms, thereby achieving the full-automatic detection. During detection, a jacking assembly jacks the electronic component to be fixed on a reference plane of a positioning groove at first when the feeding mechanical arm carries out the feeding operation, and then a vacuum absorptionassembly absorbs and fixes the electronic component. When the electronic component rotates to a size detection position, the device carries out the electronic component through a light beam, and a light beam receiver can judge the contour of the electronic component according to the received light, wherein the size can be calculated so as to judge whether the electronic component is qualified ornot: an electrical performance detection assembly is used for testing the electrical performances of the electronic component if the electronic component is qualified, or else, the mechanical arm takes out the unqualified product.

Owner:YULIN UNIV

Method for automatically detecting inclination of steel needle of injector by machine vision system

InactiveCN102305603AReduce testing labor intensityIncrease productivityUsing optical meansSortingControl signalImaging algorithm

The invention provides a method for automatically detecting the inclination of a steel needle of an injector by a machine vision system. The method comprises the following steps of: setting an inclination angle of the steel needle as a detection parameter; setting detection precision and qualified ranges of different detection parameters according to requirements of users; starting a camera to shoot an image of the online running steel needle in real time by an external trigger and control signal and transmitting the shot image to a computer for detection; extracting an image of the inclined steel needle by the computer through an image algorithm, and calculating two inclination modes; judging whether the steel needle is qualified or unqualified according to the calculated inclination angle; and rejecting the unqualified steel needle from an appointed material outlet by the external trigger and control signal. By the method, the precision and the speed of detection for the inclinationof the steel needle of the injector are high, and the yield rate of the steel needle can be guaranteed effectively.

Owner:WUXI ZHONGWANG 4D TECH

On-line detecting method of machine vision system for printed calico flaw

InactiveCN100593716CReduce testing labor intensityGuaranteed accuracyInspecting textilesMaterial analysis by optical meansComputer scienceVisual perception

Owner:WUXI DONGWANG TECH

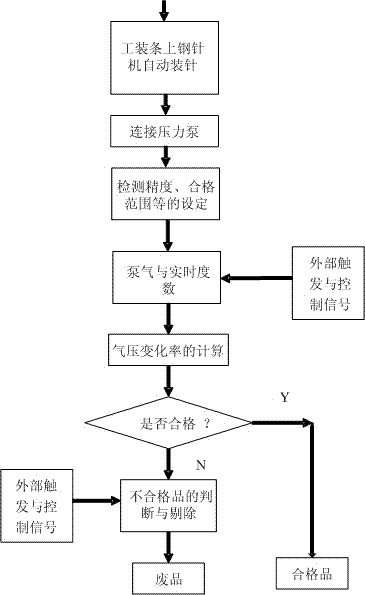

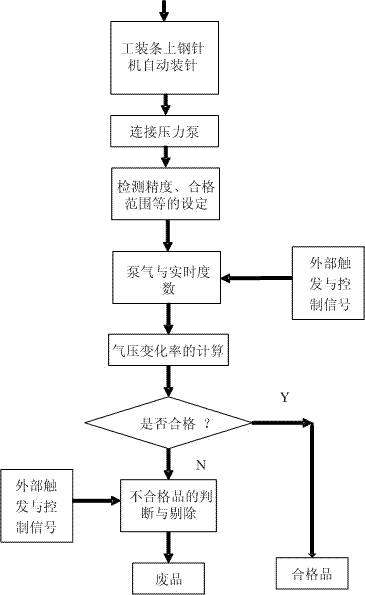

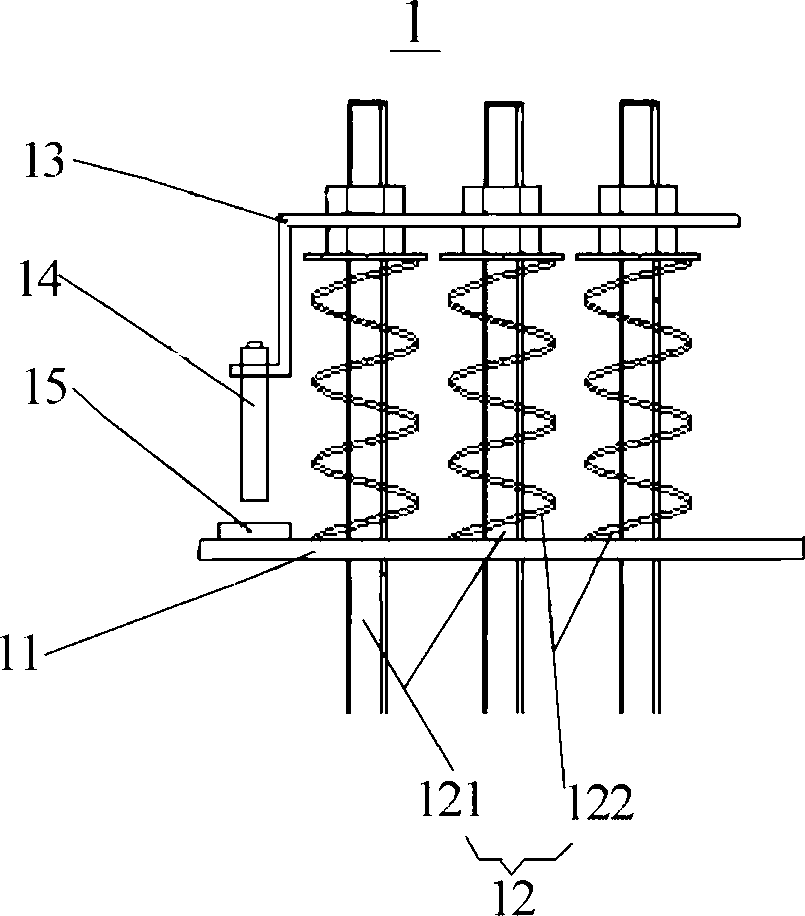

Method for automatically detecting plugging of injector steel needles based on air pressure

InactiveCN102303016AReduce testing labor intensityExtended production timeMeasurement of fluid loss/gain rateSortingSyringeInjector

The invention provides a method for automatically detecting the plugging of injector steel needles based on air pressure. The method comprises the following steps of: connecting a tool strip from the bottom of a needle seat to a pressure pump, and arranging an air pressure valve on a pump air path of the pressure pump; acquiring trigger and control signals, which are synchronous with a productionprocess, of the pressure pump by using a computer, starting the pressure pump by using external trigger and control signals to pump air from the bottom of the needle seat to the steel needles, opening the air pressure valve simultaneously, and transmitting air pressure values of all the steel needles which are detected by a pressure gauge when the air is started to be pumped and after the air is pumped for 0.5 seconds to the computer for detection; and judging whether a steel product is a qualified product or a waste product through the computed change rate of the air pressure generated when the air is pumped within 0.5 seconds, and eliminating the waste product from a specified material outlet through the external trigger and control signals. By the method, the plugging of the steel needles can be detected at high accuracy and high speed, and the yield of the product can be effectively ensured.

Owner:WUXI ZHONGWANG 4D TECH

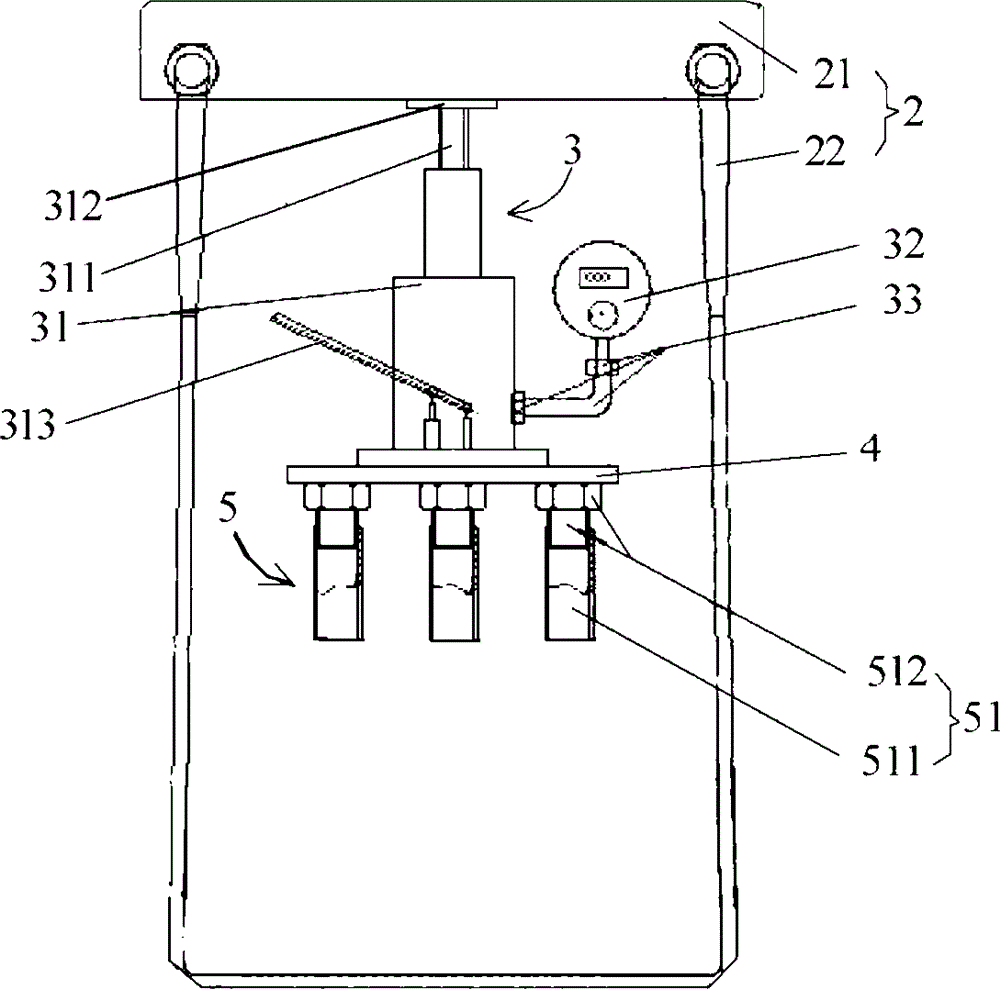

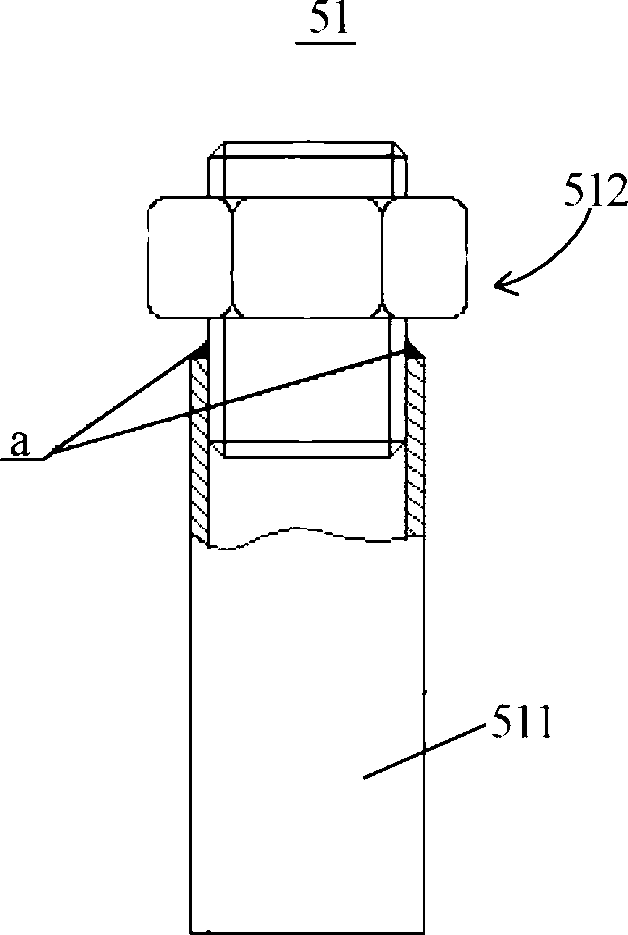

Detector and detection method of elevator overload protection device

InactiveCN105173937AGreat pressureSize creates pressureStructural/machines measurementElevatorsEngineeringHydraulic brake

The invention provides a detector and a detection method of an elevator overload protection device. The detector comprises a suspension mechanism, a hydraulic mechanism, a baseplate and an adjustable casing group, wherein the suspension mechanism comprises a suspension frame and a lifting belt used to limit the farthest distance of the suspension frame relative to a rope hitch plate; the hydraulic mechanism comprises a hydraulic jack and a pressure detector, the top end of an adjustment screw rod of the hydraulic jack is equipped with a top plate used to press against the suspension frame and make the hydraulic jack apply loads with the suspension frame as supporting during work, and the pressure detector is used to detect the value of loads applied by the hydraulic jack; the baseplate is located under the hydraulic jack and used to transmit the loads applied by the hydraulic jack; and the adjustable casing group is located under the baseplate and comprises a plurality of adjustable casings, one end of each adjustable casing is equipped with a casing used for cup-jointing of a rope hitch rod, and the other end is equipped with an adjustment mechanism which is used to adjust height of the adjustable casing. By applying the detector and the detection method of the elevator overload protection device provided by the invention, efficient and high-precision detection can be realized to the overload protection device through the rational structure and simple and convenient operations.

Owner:嘉兴市特种设备检验检测院

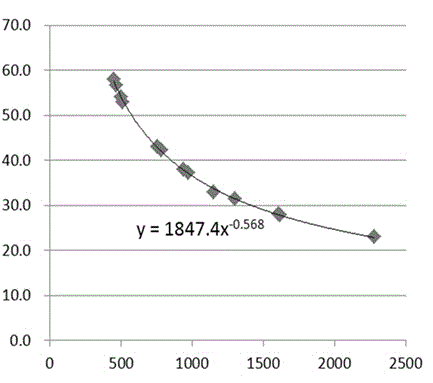

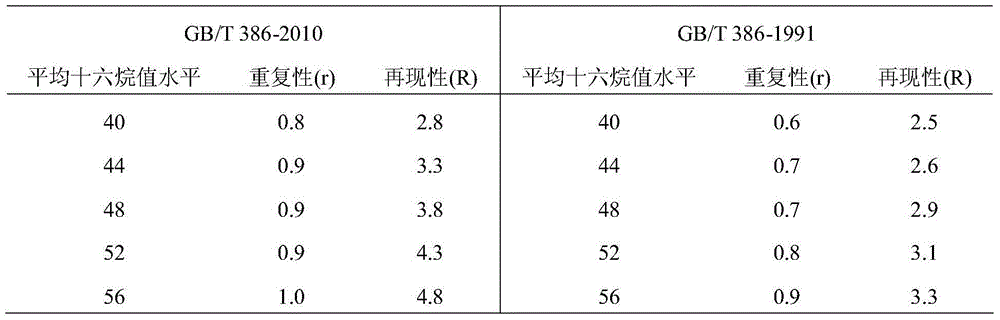

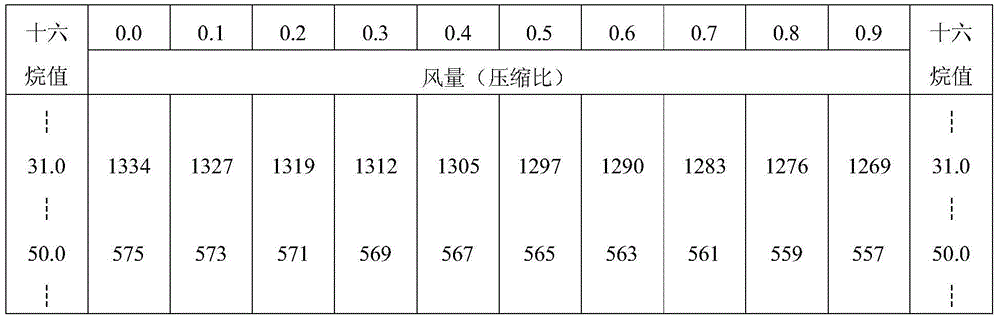

Method for determining diesel oil cetane number

ActiveCN106324211AGood repeatabilitySmall standard deviationFuel testingAir volumeRelative standard deviation

The invention provides a method for determining diesel oil cetane number. A method is used for determining cetane number of diesel oil by establishing a relation between air quantity of fuel and cetane number; the method comprises the following steps: establishing a cetane number determining machine air quantity-cetane number power curve formula, and determining cetane number of diesel oil fuel. The air quantity is air input when the fuel reaches a prescribed ignition delay period during a combustion process in a standard operation condition. The air quantity-cetane number power curve method has the advantages of good repeatability and high precision, and small relative standard deviation; and the method satisfies the requirements of method reproducibility in a GB / T386-2010 standard.

Owner:CHINA PETROLEUM & CHEM CORP

Online automatic detection method of fabric defects based on machine vision and device thereof

InactiveCN102221559BReduce testing labor intensityIncrease productivityInspecting textilesMaterial analysis by optical meansMachine visionUltimate tensile strength

The invention relates to an online automatic detection method of fabric defects based on machine vision and a device thereof, wherein the clear and integral standard fabric images without the defects of the fabric are shot on a batching and burling machine as a standard image template by utilizing an industrial camera in order to solve the problems of great labor intensity and poor detection quality of the traditional manual detection method; the corresponding characteristic parameters are extracted and stored into a computer; the range of the fabric defect detection characteristic parametersis set according to the requirements of users; the fabric images which are shot in real time are transmitted to the computer to be compared with the standard image template by utilizing the industrial camera and compared with the standard characteristic parameters; if the fabric characteristic parameters are not in conformity with the set requirements, the alarm is started by detection software; the defects are analyzed; and the printing of defects labels is executed. The invention has the advantages of high detection accuracy and high speed; and the labor intensity is greatly reduced.

Owner:HOHAI UNIV CHANGZHOU

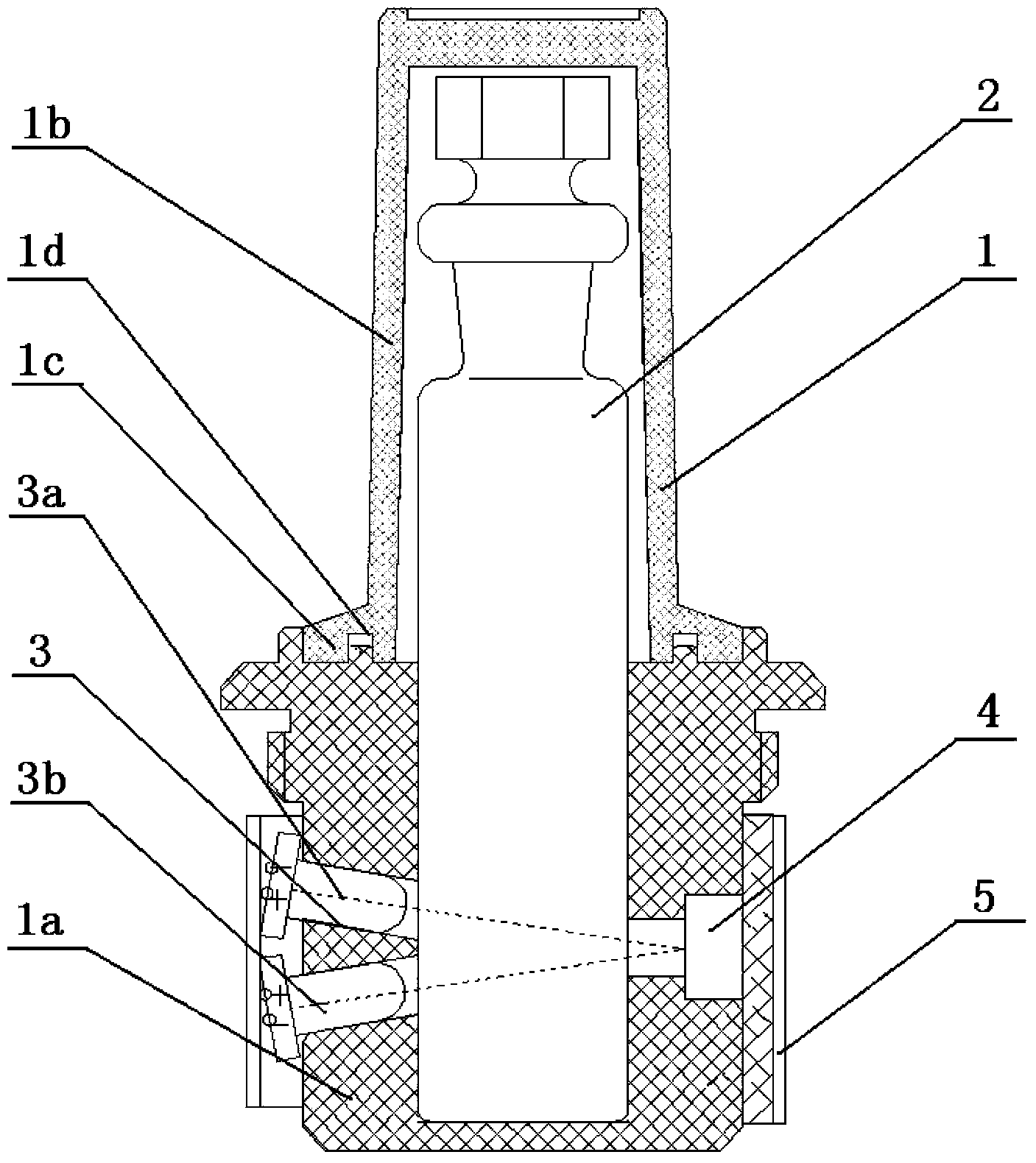

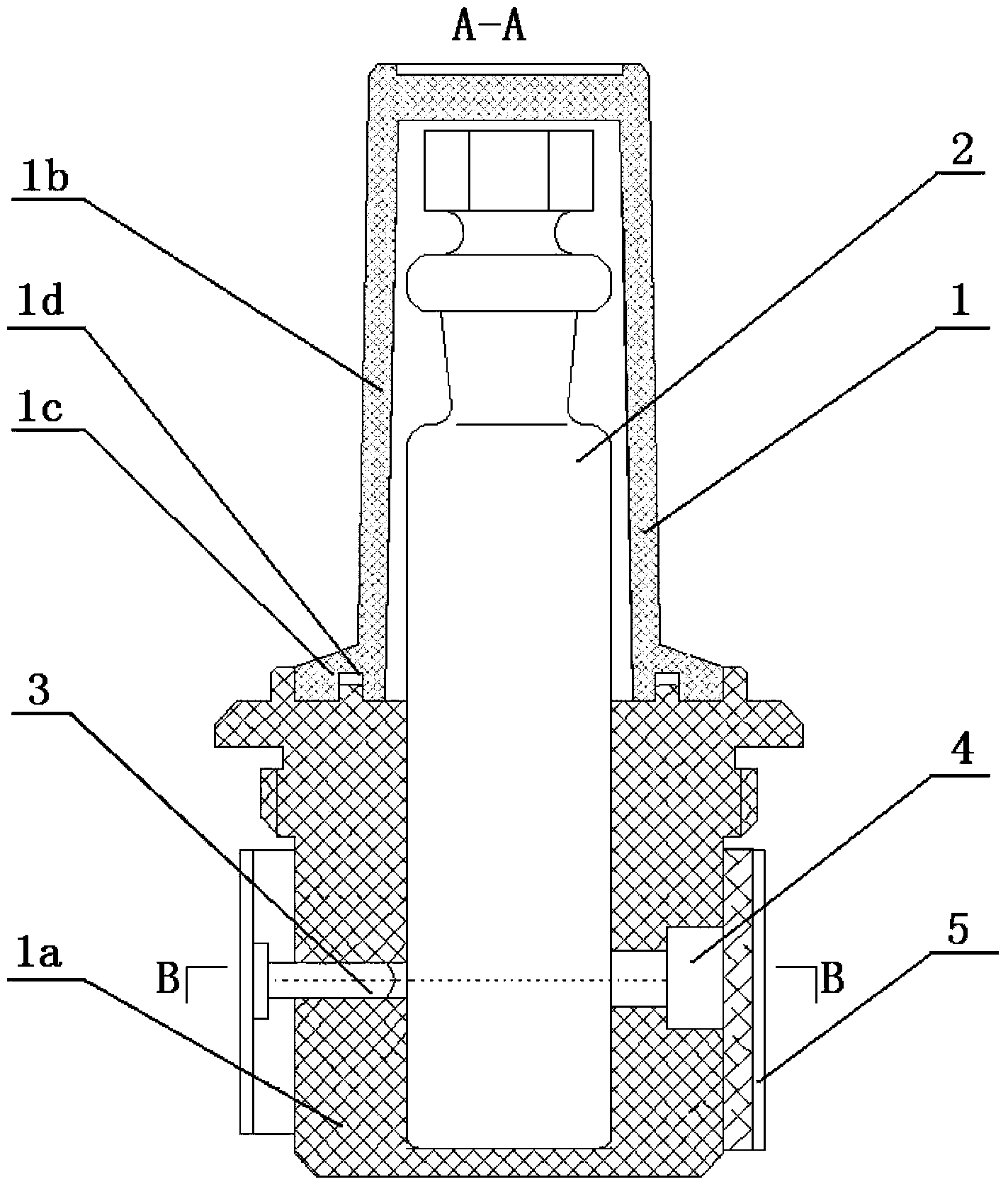

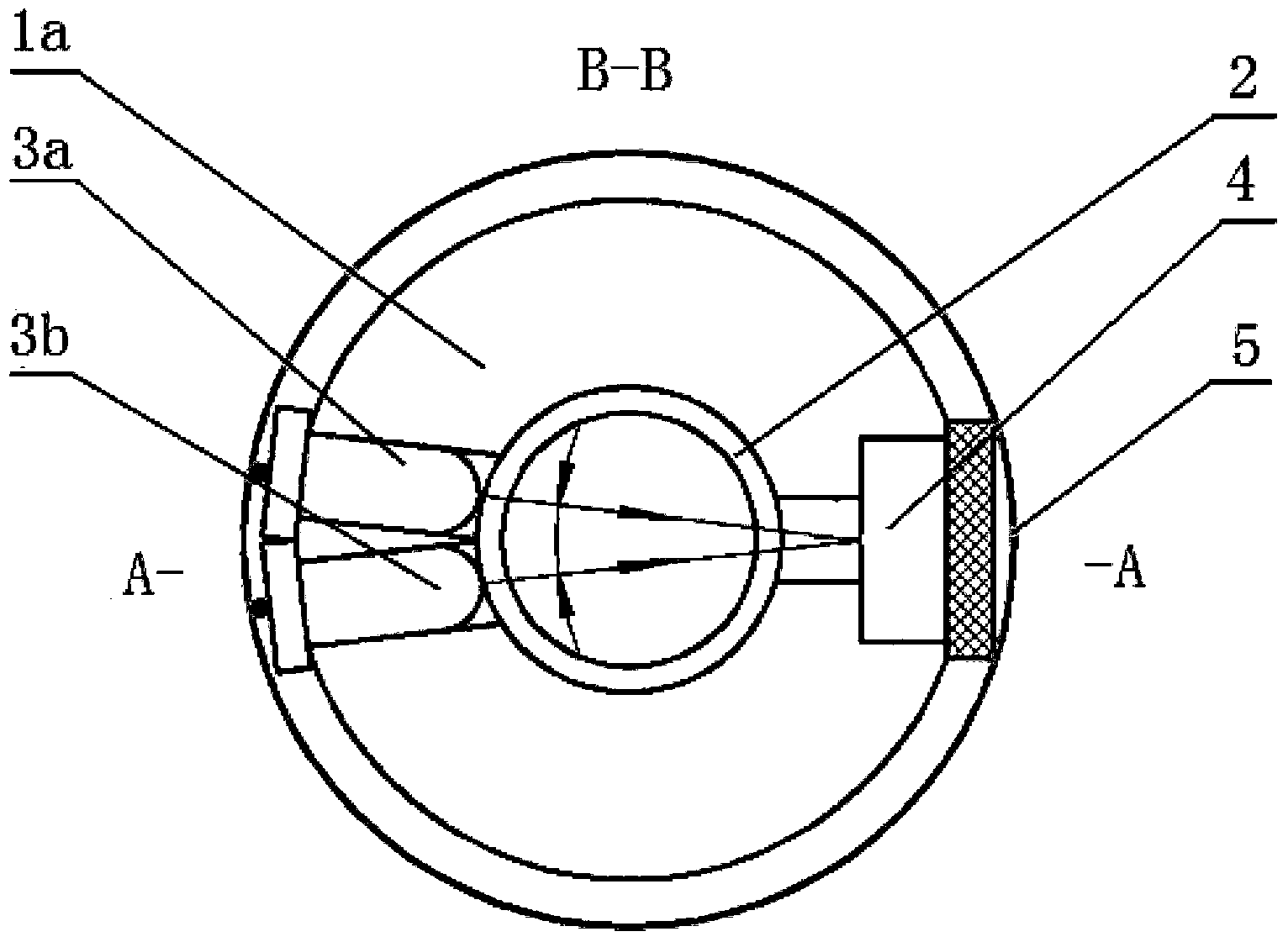

Spectrophotometric detector for detecting methanal and ammonia in air

InactiveCN103472016AImprove detection efficiencyShorten detection timeColor/spectral properties measurementsPHENOL LIQUIDNH3 compound

The invention discloses a spectrophotometric detector for detecting methanal and ammonia in air. The spectrophotometric detector comprises a bottle sleeve, a cylindrical spectrophotometric detecting bottle, a photosensitive sensor and a light emitting diode, wherein the bottle sleeve is composed of a base and a shading cap, and the cylindrical spectrophotometric detecting bottle is arranged in the bottle sleeve; the photosensitive sensor is arranged on the side wall of the base and positioned at one side of the spectrophotometric detecting bottle; the light emitting diode is used for emitting detecting light and gathering the detecting light onto the photosensitive sensor; shading rubberized fabrics are arranged on the light emitting diode and the photosensitive sensor; the light emitting diode is composed of a 412nm light emitting diode and a 630nm light emitting diode. The spectrophotometric detector integrates a phenol reagent method and a diacetone method for detecting methanal and a Nessler reagent method for detecting ammonia and can freely switch the methods as required in use, so that the detection efficiency is greatly improved, and the labor intensity of detection is reduced.

Owner:武汉分析仪器厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com