Method for automatically detecting missed accessory during automatic assembly of injector by using machine visual system

A machine vision system and automatic detection technology, used in optical device exploration, sorting and other directions, can solve the problems of high labor intensity, low monitoring speed, and workers are prone to visual fatigue, etc., to prolong production time, improve utilization, reduce Detecting the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

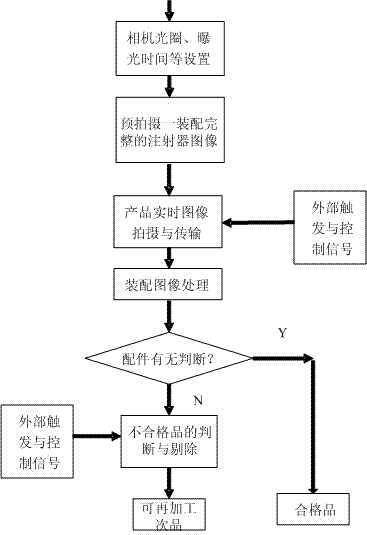

Method used

Image

Examples

Embodiment 1

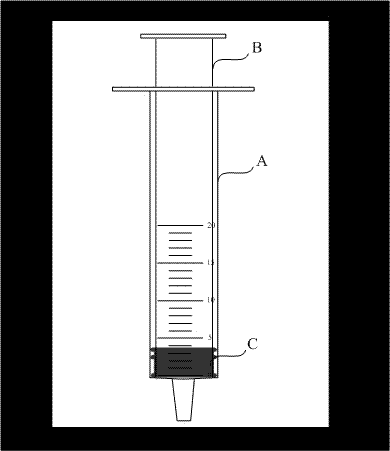

[0032] Embodiment 1, to the detection of qualified syringe product:

[0033] Such as figure 1 The image shown for the automated assembly of the syringe is a visual representation of the absence of fittings.

[0034] Fix the Basler ACA640-100GM industrial camera on the side of the syringe. The distance between the camera and the side of the syringe is about 100mm. Using a Schneider zoom lens, the focal length is adjusted to 8mm, the aperture is adjusted to the maximum value, and the exposure time is adjusted to 0.41ms. A special white LED bowl light source is used to irradiate the same side of the syringe from the camera (positive light), and a semi-closed metal frame is used to shield the influence of external stray light, so as to obtain a relatively stable visual image and reflect the obvious characteristics of the syringe . The LED bowl light source of this project uses the special machine vision light source of CCS Company (the LED bowl light source of other companies ca...

Embodiment 2

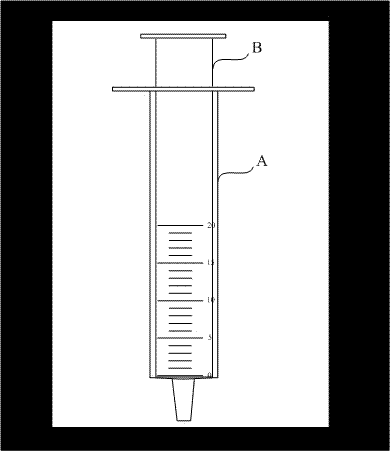

[0040] Example 2, detection of syringe products with missing accessories:

[0041] Such as figure 2 The image shown for the automated assembly of the syringe is a visual representation of the absence of fittings.

[0042]Fix the Basler ACA640-100GM industrial camera on the side of the syringe. The distance between the camera and the side of the syringe is about 100mm. Using a Schneider zoom lens, the focal length is adjusted to 8mm, the aperture is adjusted to the maximum value, and the exposure time is adjusted to 0.41ms. A special white LED bowl light source is used to irradiate the same side of the syringe from the camera (positive light), and a semi-closed metal frame is used to shield the influence of external stray light, so as to obtain a relatively stable visual image and reflect the obvious characteristics of the syringe . The LED bowl light source of this project uses the special machine vision light source of CCS Company (the LED bowl light source of other compan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com