Method for determining diesel oil cetane number

A technology of cetane number and determination method, applied in the field of analytical chemistry, can solve problems such as failure to improve analysis efficiency, and achieve the effects of saving standard fuel, small relative standard deviation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Embodiment 1 fuel air flow measurement

[0099] Equipment condition:

[0100] Measuring machine: FCD-II type cetane number machine, the specific structure and working process can be found in the Chinese utility model patent (publication number CN 204060947U, authorized announcement date December 31, 2014).

[0101] The fuel air volume is determined by the following method:

[0102] (1) Setting parameters

[0103] Check the operating system to make it meet the requirements for the operation of the engine test typical diesel;

[0104] (2) Filling with fuel

[0105] Add the fuel to be tested into the fuel tank, rinse the measuring tube carefully, remove the air in the pipeline from the fuel tank to the pump, set the fuel switching valve to the position where the fuel is used to operate the engine, and start the motor;

[0106] (3) Adjust the injector flow

[0107] Under the following standard conditions, adjust the injector flow rate to 6.7±0.1mL / min or 180s±3s for 20mL...

Embodiment 2

[0122] Example 2 Air Volume-Cetane Number Curve and Air Volume-Cetane Number Power Curve Formula Establishment

[0123] Based on the FCD-Ⅱ cetane number machine, the air volume-cetane number curve and the air volume-cetane number power curve formula are established by the following methods:

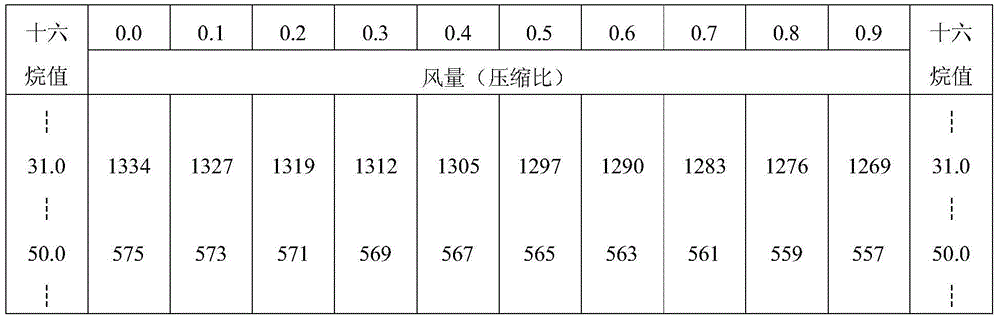

[0124] Secondary standard fuel T-26 (75.2CN) and U-19 (19.4CN) are prepared into a series of standard fuels with different cetane numbers according to the ratio shown in table 3, and each standard is tested according to the method described in Example 1 The air volume of the fuel is shown in Table 3 for the measurement results.

[0125] Table 3 Relationship between standard fuel air volume and cetane number

[0126]

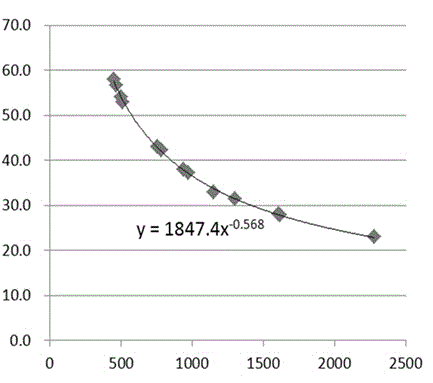

[0127] Taking the air volume as the abscissa and the cetane number as the ordinate, draw the air volume-cetane number curve of the measuring machine, see figure 1 . Depend on figure 1 For the air volume-cetane number curve shown, the power curve formula is established...

Embodiment 3

[0131] The investigation of embodiment 3 precision

[0132] Get different diesel oil samples, under the operating conditions of embodiment 1, on the described FCD-II type cetane number machine, measure the air volume of different diesel oil samples, each sample repeats measurement 5 times, the same diesel oil test The test was repeated at an interval of 0.5 minutes, and the results are shown in Table 4. Substitute the air volume measured each time into the power curve formula obtained in Example 2, calculate the cetane number of the sample, and calculate the range, repeatability, standard deviation and relative standard deviation. The results are shown in Table 5.

[0133] Table 4 Air volume measurement results of precision experiment

[0134]

[0135]

[0136] Table 5 Precision inspection results (unit: CN)

[0137]

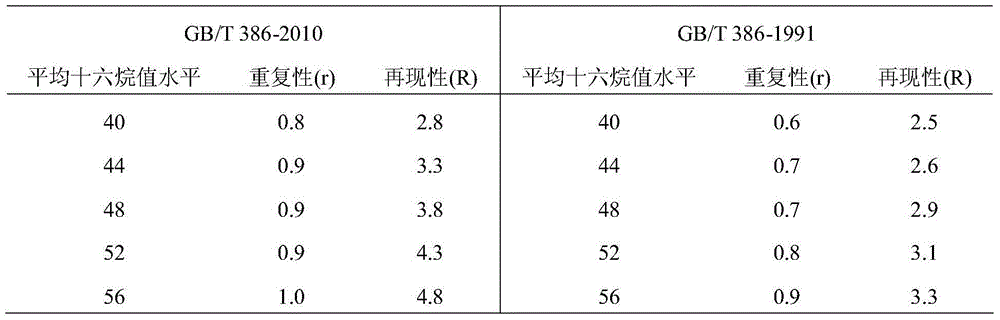

[0138] Table 5 shows that the method of the present invention measures the cetane number of different diesel oil samples, the maximum difference of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com