Method for automatically detecting plugging of injector steel needles based on air pressure

An automatic detection and syringe technology, which is applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum for liquid tightness measurement, sorting, etc. It can reduce the labor intensity of inspection, prolong the production time, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

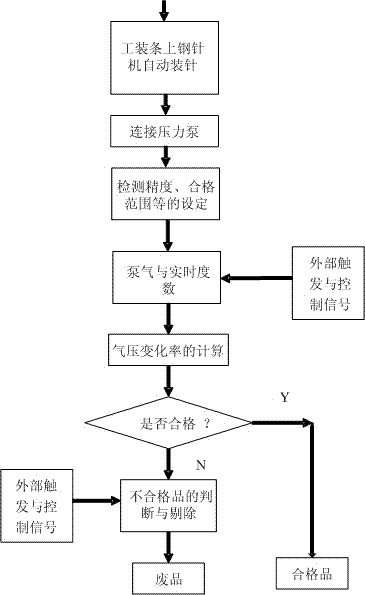

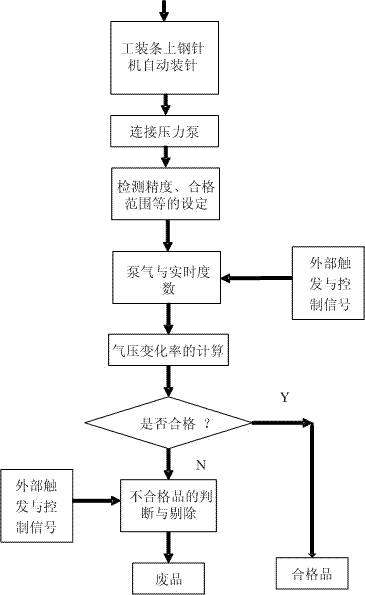

Image

Examples

Embodiment 1

[0025] Embodiment 1, the detection of all-through steel needle product:

[0026] Place the tooling strip containing multiple needle seats on the needle loading machine, and the needle loading machine will automatically and accurately send the steel needles to each needle seat on the tooling strip after detecting the tooling. The tooling strip that has fixed multiple steel needles is connected to the COIDO 6218 pressure pump from the bottom of the needle seat, and the pressure pump has a built-in precision pressure gauge. An air pressure valve is arranged on the pump air path where the pressure pump communicates with the needle seat of the steel needle, and the air pressure valve is in a closed state at this time. The pump air pressure of the pressure pump is set to 10Pa, and the detection accuracy of the air pressure is 0.1Pa.

[0027] The computer obtains the trigger and control signal that the pressure pump is synchronized with the production process, and the external trigg...

Embodiment 2

[0029] Embodiment 2, detection of fully blocked steel needle products:

[0030] Place the tooling strip containing multiple needle seats on the needle loading machine, and the needle loading machine will automatically and accurately send the steel needles to each needle seat on the tooling strip after detecting the tooling. The tooling strip that has fixed multiple steel needles is connected to the COIDO 6218 pressure pump from the bottom of the needle seat, and the pressure pump has a built-in precision pressure gauge. An air pressure valve is arranged on the pump air path where the pressure pump communicates with the needle seat of the steel needle, and the air pressure valve is in a closed state at this time. The pump air pressure of the pressure pump is set to 10Pa, and the detection accuracy of the air pressure is 0.1Pa.

[0031] The computer obtains the trigger and control signal that the pressure pump is synchronized with the production process, and the external trigge...

Embodiment 3

[0033] Embodiment 3, the detection of half blocked steel needle product:

[0034] Place the tooling strip containing multiple needle seats on the needle loading machine, and the needle loading machine will automatically and accurately send the steel needles to each needle seat on the tooling strip after detecting the tooling. The tooling strip that has fixed multiple steel needles is connected to the COIDO 6218 pressure pump from the bottom of the needle seat, and the pressure pump has a built-in precision pressure gauge. An air pressure valve is arranged on the pump air path where the pressure pump communicates with the needle seat of the steel needle, and the air pressure valve is in a closed state at this time. The pump air pressure of the pressure pump is set to 10Pa, and the detection accuracy of the air pressure is 0.1Pa.

[0035] The computer obtains the trigger and control signal that the pressure pump is synchronized with the production process, and the external trig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com