Grounding corrosion detection method for overhead line structure

A corrosion detection and overhead line technology, which is applied in the field of electric power engineering, can solve problems such as heavy workload, corrosion of tower grounding body, endangering towers, etc., and achieve the effect of convenient and fast detection, high detection accuracy and low detection labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

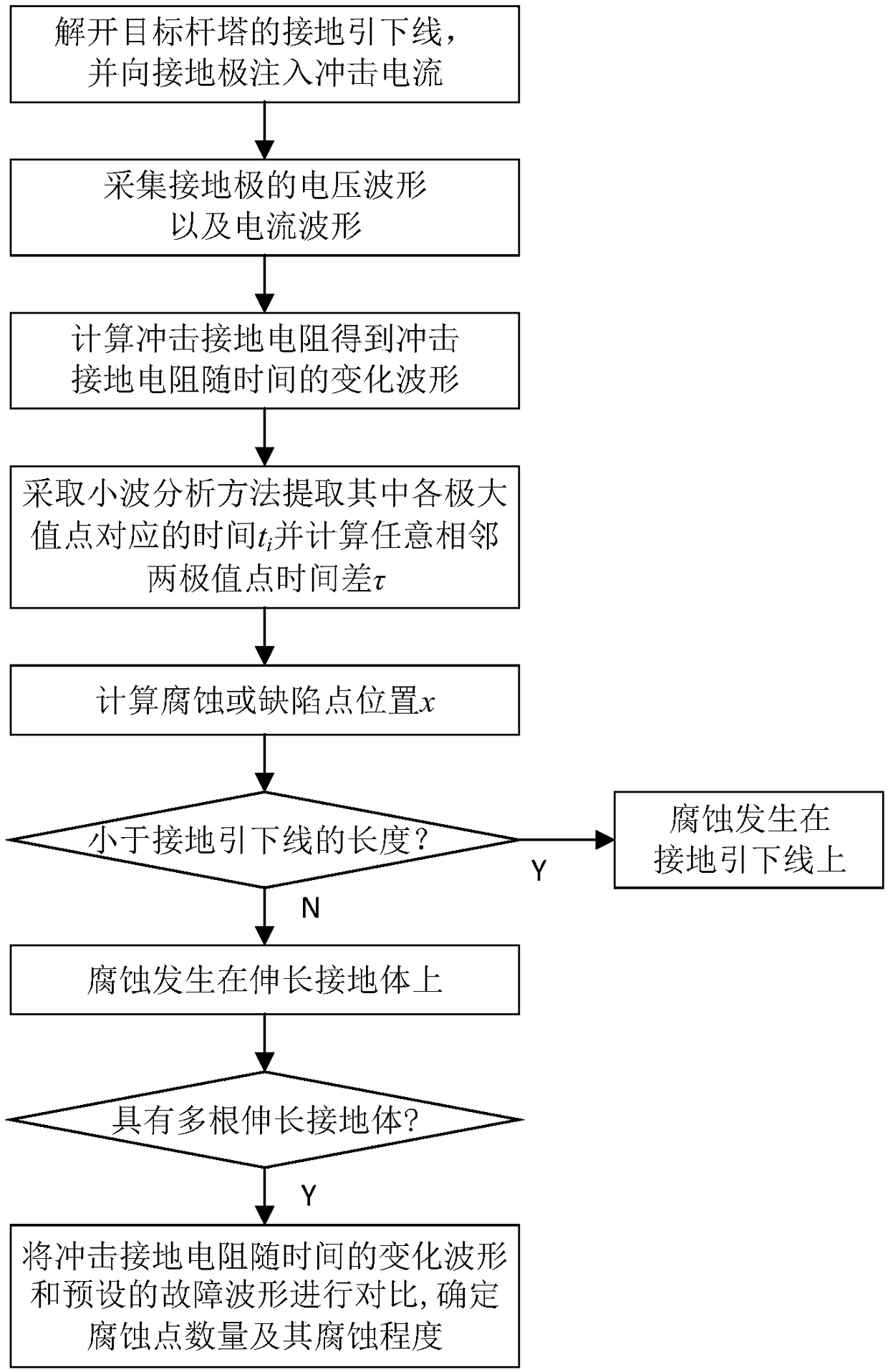

[0022] Such as figure 1 As shown, the implementation steps of the grounding corrosion detection method for overhead line towers in this embodiment include:

[0023] 1) Untie the grounding down conductor of the target tower, and inject an impulse current into the grounding electrode;

[0024] 2) Collect the voltage waveform and current waveform of the ground electrode;

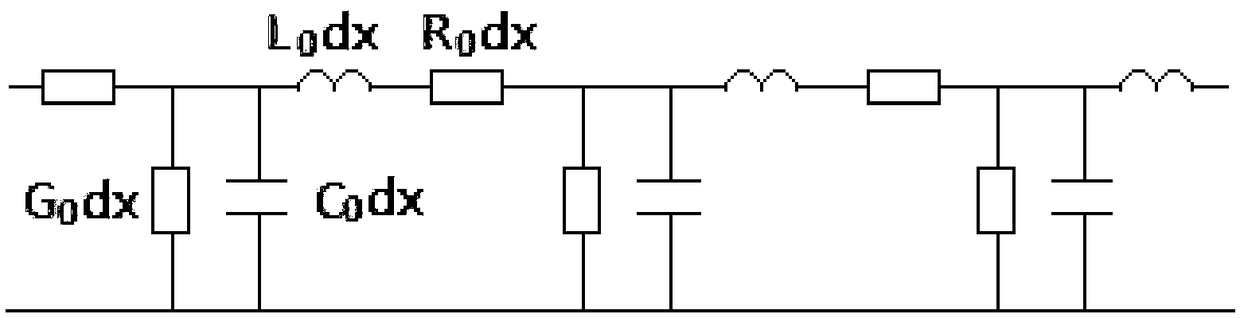

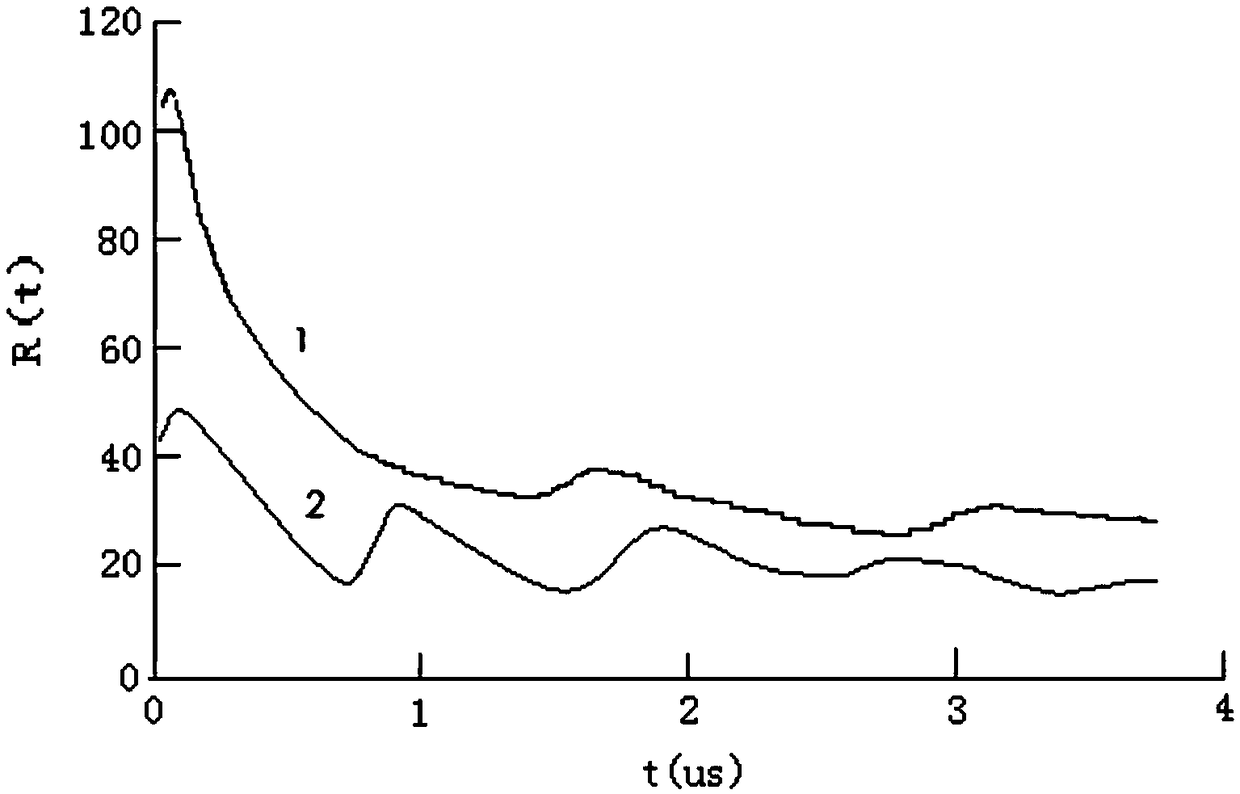

[0025] 3) Calculate the impact grounding resistance according to the voltage waveform and current waveform to obtain the time-varying waveform of the impact grounding resistance, and use the wavelet analysis method to extract the time t corresponding to each maximum point and calculate the time difference τ between any adjacent two extreme points;

[0026] 4) Calculate the position x of the corrosion or defect point according to the time difference τ between two adjacent extreme points, and judge whether the position x of the corrosion or defect point is less than the length of the grounding downconductor of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com