Aviation electric connector pin position deviation detection method

An electrical connector and deviation detection technology, which is applied in the field of position deviation detection of aviation electrical connector pins, can solve the problems of low pin insertion efficiency and easy missed detection, achieve low missed detection rate, reduce missed detection rate, and facilitate reference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

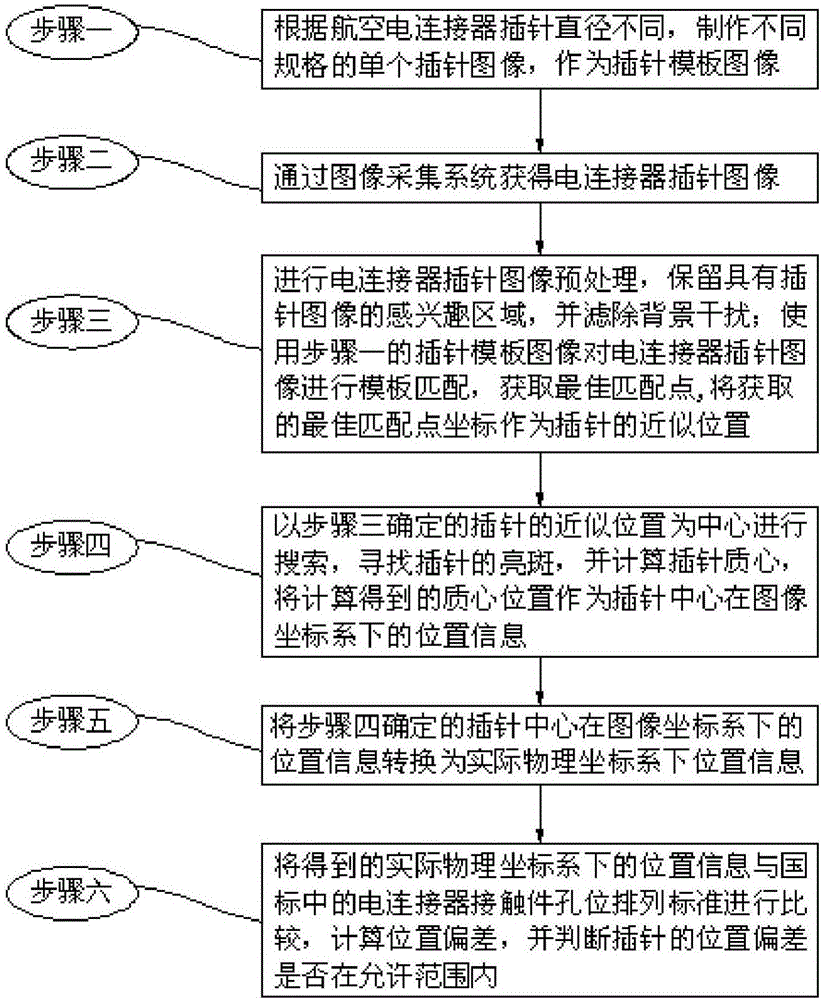

[0034] The method for detecting the position deviation of the pin position of the aviation electrical connector in this embodiment is realized by the following steps:

[0035] Step 1. According to the different diameters of the aviation electrical connector pins, make a single pin image of different specifications as a pin template image;

[0036] Step 2, obtaining the image of the pins of the electrical connector through the image acquisition system;

[0037] Step 3. Perform image preprocessing of electrical connector pins, retain the region of interest with pin images, and filter out background interference at the same time to prevent the background image from interfering with the extraction of pins; use the custom pin template image in step 1 Perform template matching on the pin image of the electrical connector to obtain the best matching point, and use the coordinates of the obtained best matching point as the approximate position of the pin;

[0038] Step 4. Search arou...

specific Embodiment approach 2

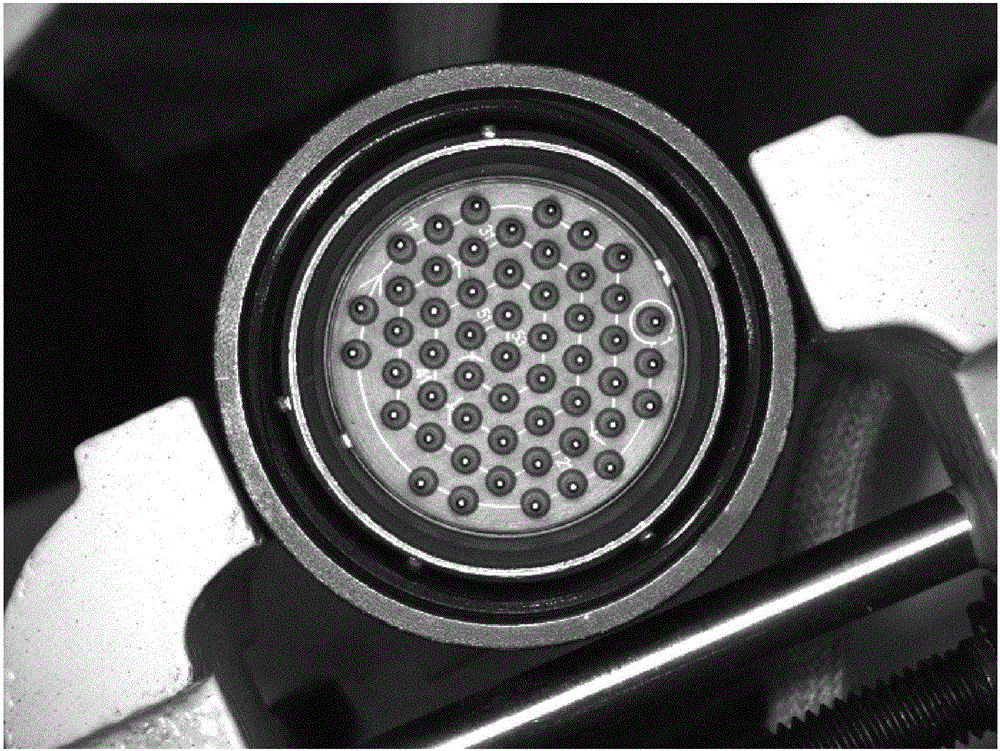

[0042] The difference from Embodiment 1 is that in the method for detecting the position deviation of the pin position of the aviation electrical connector in this embodiment, the process of obtaining the image of the pins of the electrical connector through the image acquisition system in step 2 is that the image acquisition system adopts a ring The light source performs high-angle forward lighting. The light emitted by the ring light source and irradiated on the pin to be tested is at an angle of 60° to the horizontal plane. The 500w pixel industrial camera lens is set directly above the connector to be tested to collect its image , and then calculate the resolution of the industrial camera in the horizontal and vertical directions to meet the minimum resolution requirements for the image acquisition system to obtain the image of the electrical connector pin:

[0043] Horizontal Resolution = Horizontal Field of View Size ÷ Minimum Accuracy (3-1)

[0044] Vertical resolution ...

specific Embodiment approach 3

[0060] The difference from the specific embodiment 1 or 2 is that in the method for detecting the position deviation of the pins of the aeronautical electrical connector in this embodiment, the image preprocessing of the electrical connector pins described in step 3 is carried out, and the region of interest with the pin image is retained , and the process of filtering background interference is to extract the pin position coordinates in the image through the image processing technology of image segmentation and image feature extraction, and obtain the pin coordinates in the image coordinate system:

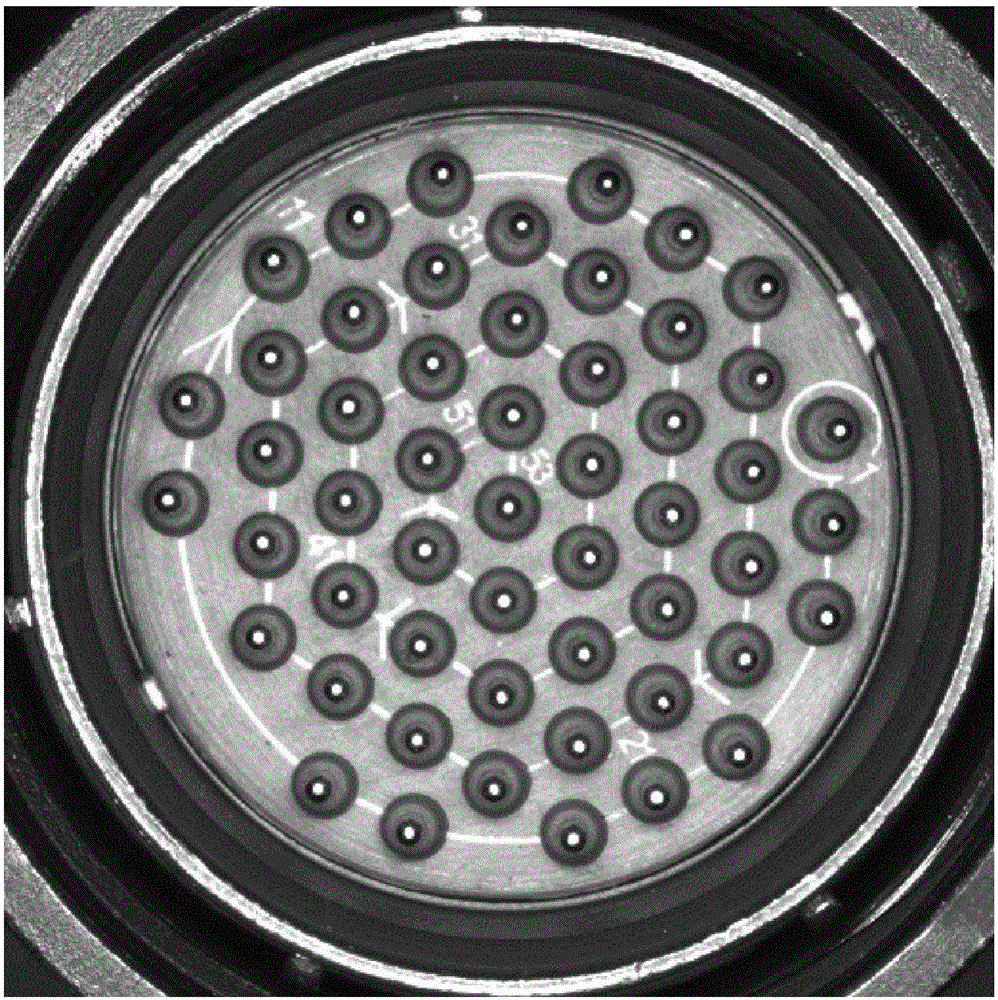

[0061] First, the image of the electrical connector is preprocessed to remove images of structures other than the electrical connector. The processing results are as follows image 3 shown;

[0062] Then, but the edge of the electrical connector is very bright, it is easy to cause mis-matching of the pins, continue to filter out the image outside the circular edge of the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com