Printing dye aberration on-line detection method of machine vision system

A technology of machine vision system and detection method, which is applied in the direction of color measurement using color charts, color measurement devices, instruments, etc., can solve the problems of unguaranteed detection quality, low detection accuracy, and high labor intensity, so as to reduce the detection labor intensity , Improve the detection speed, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

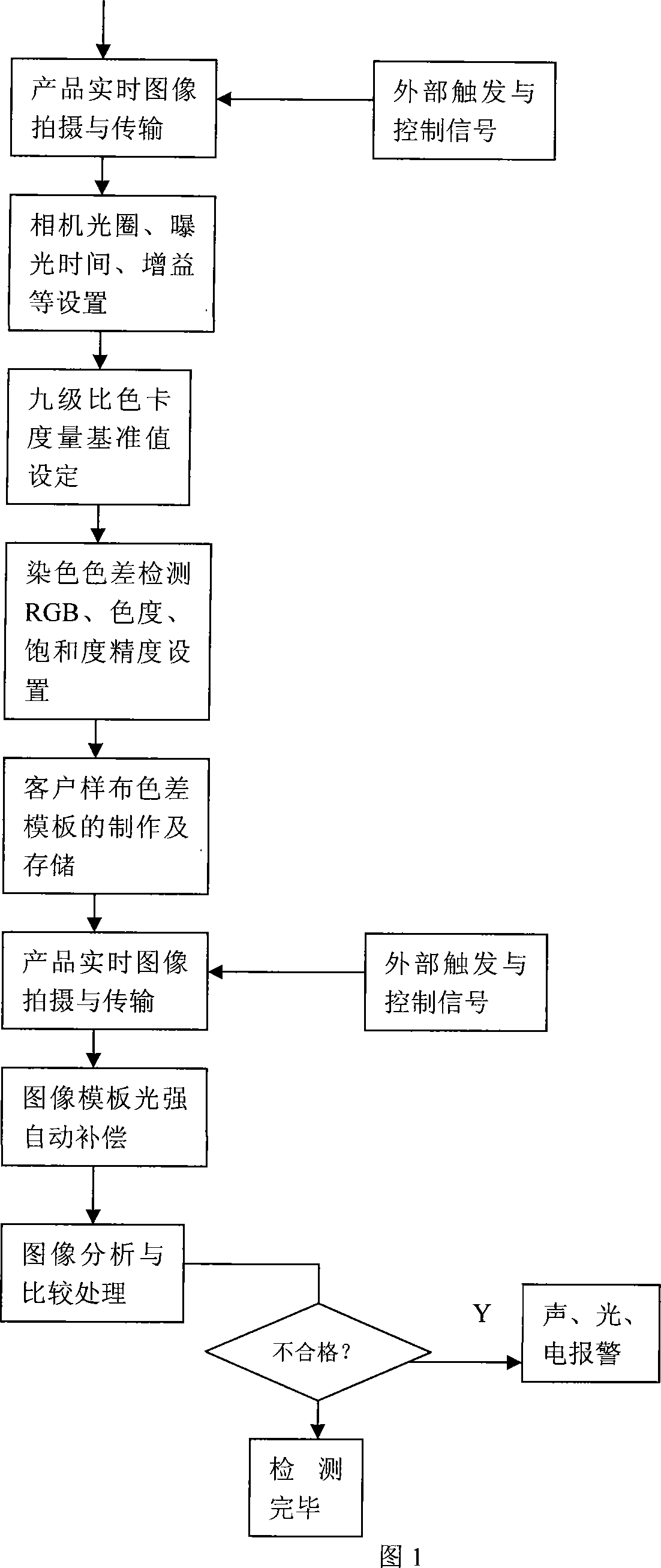

Method used

Image

Examples

Embodiment 1

[0019] Example 1, the detection of left, middle and right dyeing color difference (also known as left, middle and right difference or edge center difference) of printed and dyed cloth:

[0020] A. Detection cloth: The red pure cotton printing and dyeing cloth produced for a certain customer is adopted as the embodiment detection cloth.

[0021] B. Image shooting camera: fix the Beijing New Era MVC2000DA-GE16CCD industrial color camera at 50cm directly above the printing and dyeing cloth, the camera uses an 8mm COMPUTAR lens, the aperture is adjusted to the maximum value, the exposure time is adjusted to 0.58ms, and the gain value (which determines the image) The contrast effect) is adjusted to 0; the Boshi BS2007LED white light (2001ux) light source is fixed at 50cm above the back of the printing and dyeing cloth (45°incident angle), so as to be sensitive to the dyeing color difference of the cloth; the three above-mentioned cameras and light source devices are respectively Fi...

Embodiment 2

[0029] Embodiment 2, the detection of dyeing color difference (also known as front and back difference) before and after printing and dyeing cloth:

[0030]The detection equipment and method steps are the same as in Example 1, except that the RGB value (174, 27, 53) and saturation value ( 89) and chromaticity value (67) are stored in computer. The RGB value (183, 31, 68), saturation value (96) and chromaticity value (99) of the color of the dyed back end of the printed and dyed cloth (referring to the dyed cloth at the end of the dyed cloth) are compared and analyzed for judgment. The difference between RGB value, saturation value and chromaticity value exceeds the standard range for judging the qualified color difference of printing and dyeing cloth dyeing set in step D above (such as R difference value is 183-174=912, saturation difference is 96-89=718; among them, B value, chroma value greater than the allowable accuracy range of half-level color difference), it belongs to...

Embodiment 3

[0031] Example 3, detection of dyeing color difference (also known as batch difference or piece difference) between pieces of printed and dyed cloth:

[0032] The detection equipment and method steps are the same as in Example 1. According to the methods described in Example 1 and Example 2, the left, middle and right dyeing color difference and the front and back dyeing color difference detection of the whole piece of printing and dyeing cloth that is qualified and is a standard value are tested. The RGB value, saturation value, and chromaticity value of the middle and right (or front and back) positions are stored in the computer as the left, middle and right (or front and back) dyeing color difference of different batches of the same kind or different pieces of printing and dyeing cloth in the same batch The standard image template, real-time shooting images of different batches of the same kind or different pieces of printing and dyeing cloth in the same batch running onlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com