Automatic detection device for industrial frequency transformer and detection control method of automatic detection device

A power frequency transformer, automatic detection technology, applied in the manufacture of inductors/transformers/magnets, instruments, measuring devices, etc., can solve the problems that the inspectors are prone to electric shock injuries, incomplete data matching, and high inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

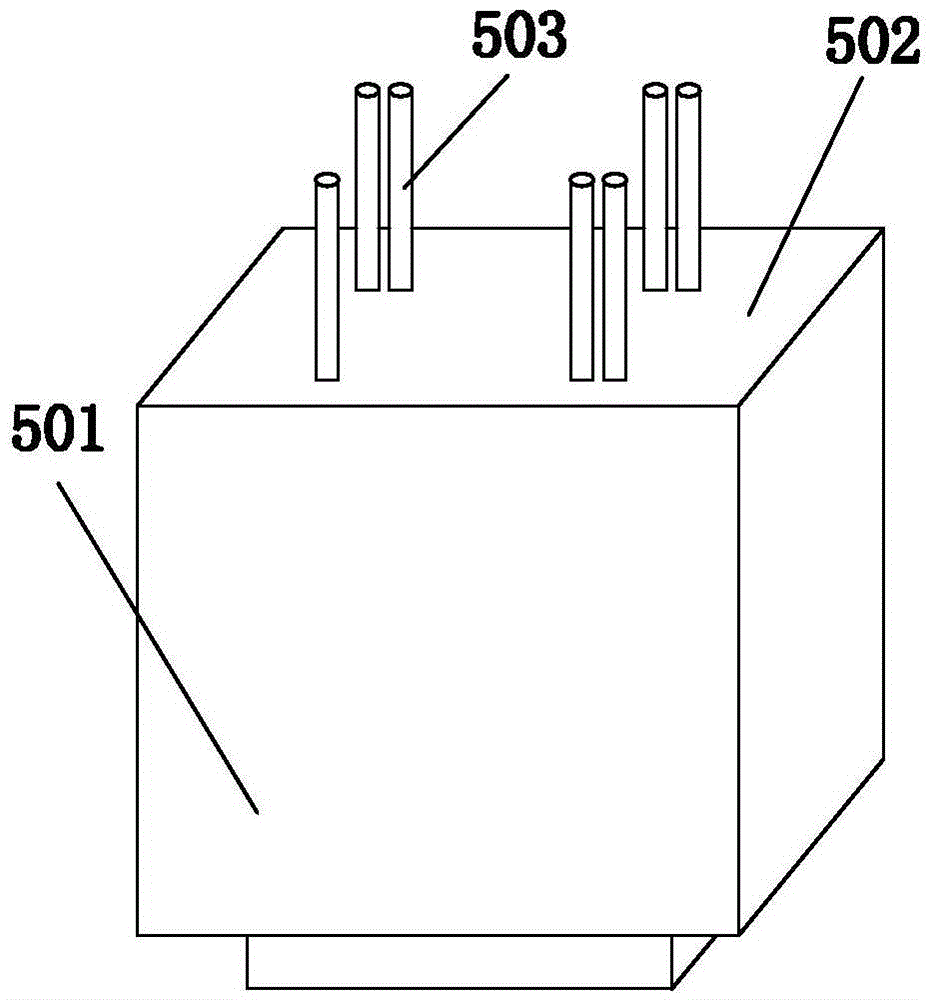

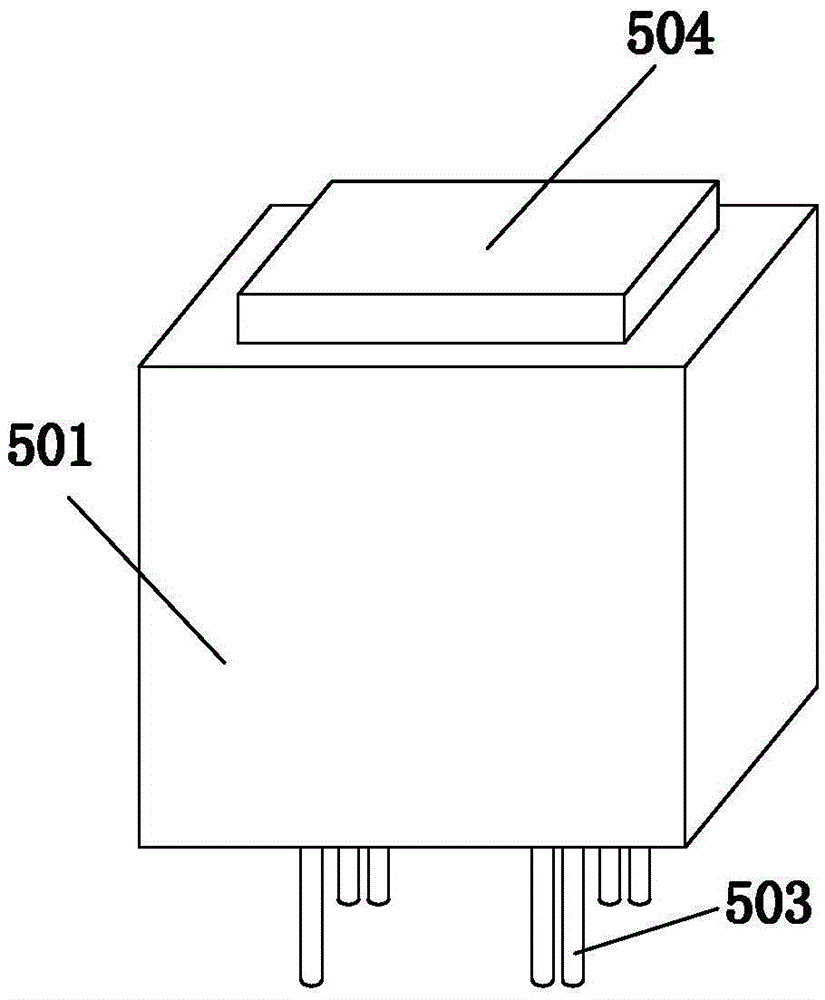

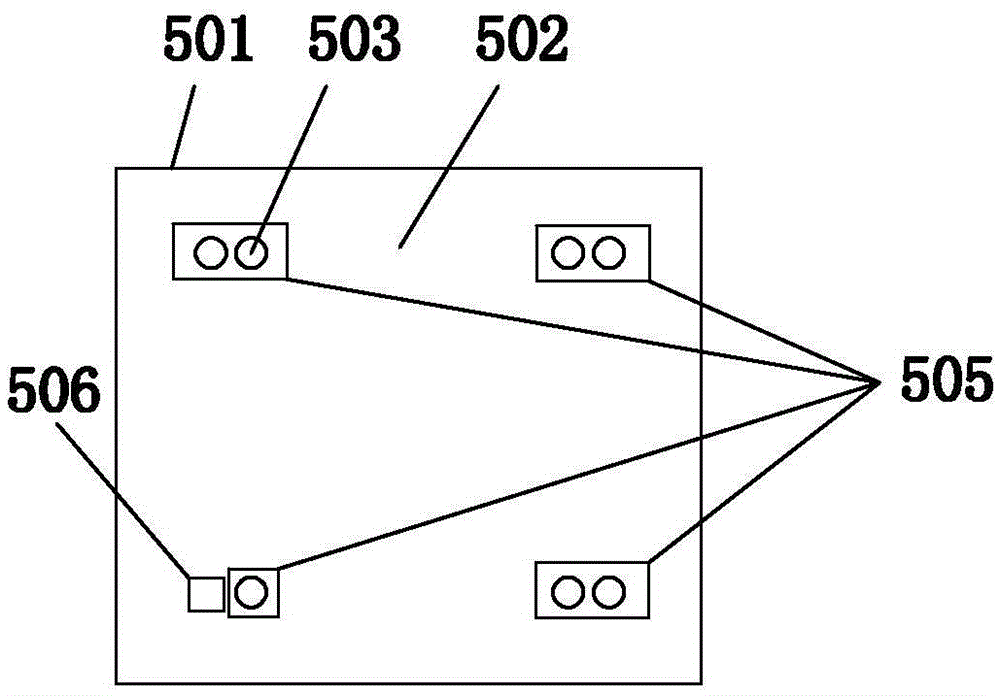

[0035] Embodiment, power frequency transformer automatic detection equipment, see figure 1 , figure 2 , image 3 , Figure 4 As shown, the power frequency transformer 501 includes a pin surface 502 and a label surface 504 facing the pin surface, and the pins 503 are arranged on the pin surface. When testing power frequency transformers, the pins face up and the label faces down, while when coding power frequency transformers, both the pins and the label face down vertically. Therefore, if the power frequency transformer just after the detection operation is to be sent to the coding conveying unit for coding operation, then the power frequency transformer must be turned 90 degrees.

[0036] see Figure 5shown. Automatic detection equipment for power frequency transformers, including a controller, an overturning conveying unit F, a coding conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com