On-line detection method of PVC round tube surface flaw based on machine vision system

A machine vision system, PVC pipe technology, applied in instruments, measuring devices, scientific instruments, etc., to achieve the effect of improving detection precision and accuracy, and improving the level of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

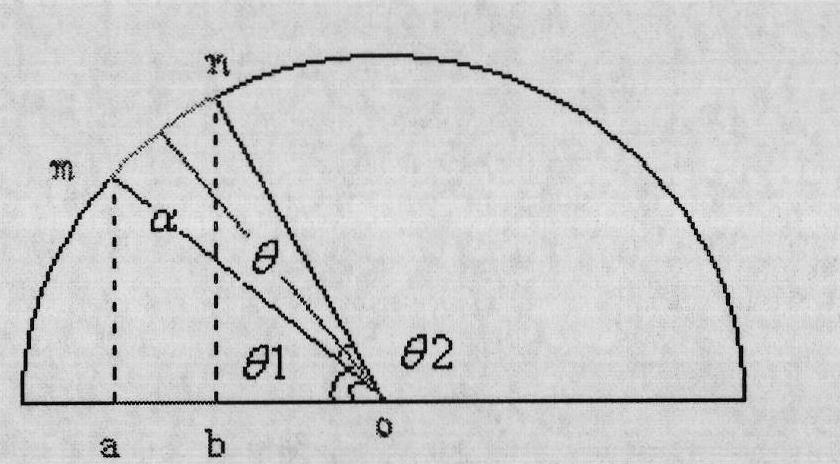

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

[0026] The present invention comprises the following steps:

[0027] 1) Four industrial cameras are installed on the surface of the circular PVC pipe in equal parts on the same circumference, and the collected four-way video signals are transmitted to the PC through the image acquisition card;

[0028] Adjust the object distance according to the focal length and depth of field of the industrial camera so that the industrial camera can obtain a clear image of the pipe surface, install the industrial camera with the optimal object distance, and use a black box device that allows the pipe to pass through to cover the industrial camera and the PVC pipe to be inspected. Implement coaxial illumination with an external light source, and then coordinately adjust the lens aperture, industrial camera exposure time, gain amount, and light source illumination brightness according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com