Method and device for automatically detecting powder material accumulation density

A powdery material and bulk density technology, which is applied in the field of automatic detection of the bulk density of semi-finished expanded ammonium nitrate of expanded ammonium nitrate explosives, can solve the problems of long detection time of manual sampling detection method, harsh operating environment for workers, and high risk of quality control. , to achieve the effect of reducing fixed inspection personnel, high accuracy and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

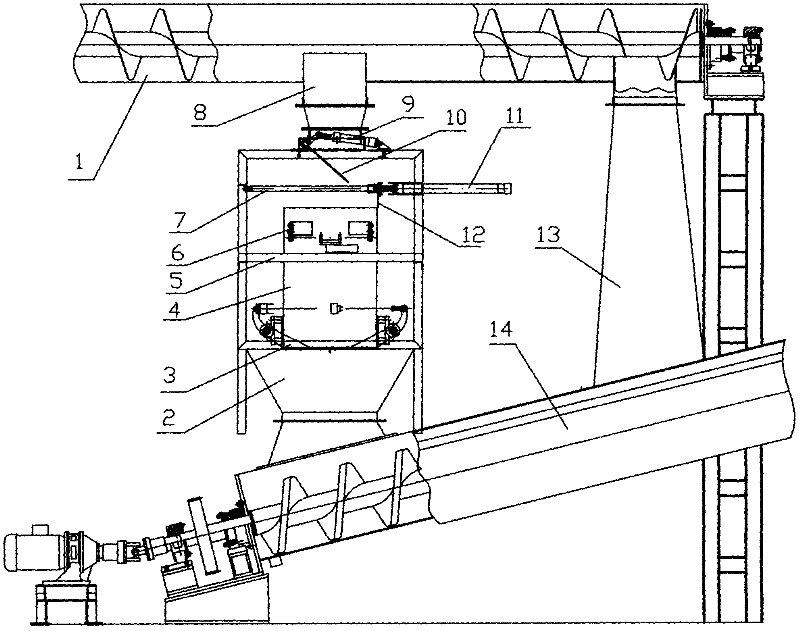

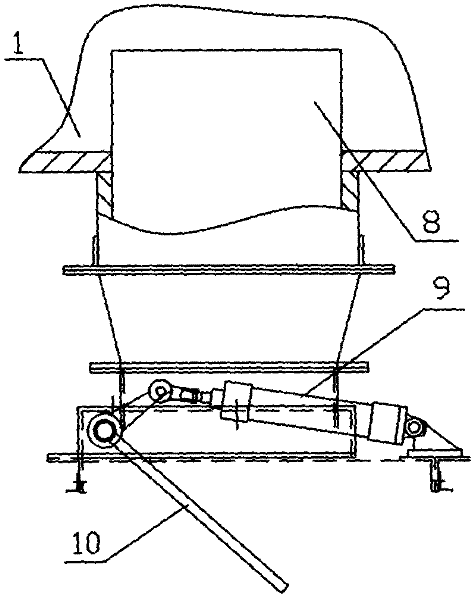

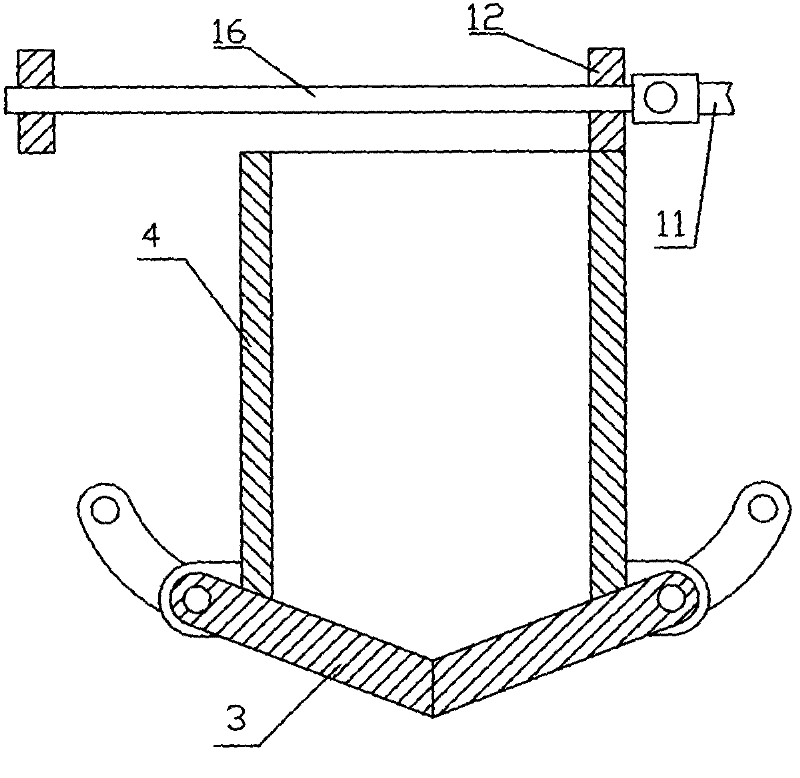

[0022] The structure of the present invention includes the original screw conveyor 1 and the feeding pipe 13. It is characterized in that: the bypass pipe at the bottom of the original screw conveyor 1 is fixedly connected with a distribution hopper 8, and the lower port of the distribution hopper 8 is sealed with a material distribution single door plate valve. 10. The rotating shaft of the single-door plate valve 10 is fitted in the bearing seat hole on the top of the bracket. One end of the rotating shaft is fixed with a connecting rod. The connecting rod and the piston rod head of the distribution cylinder 9 fixed on the top of the bracket are hinged. Connected; a pusher scraper device is installed below the sub-hopper 8 on the bracket, and the right part of the device is a circular shaft-shaped pusher rod 7 that fits and is fixed in the center hole of the middle part of the flat-shaped translation plate 12, and the pusher rod 7 The left end is movable and fitted in the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com