Method and device for measuring magnetic declination of tile-shaped magnet element

A tile-shaped, magnetic declination technology, applied in the field of magnetic declination measurement, can solve the problems of inability to guarantee the magnetic declination angle pass rate of tile-shaped magnetic components, complex equipment, high cost, etc., and achieve low cost, simple operation, The effect of avoiding misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

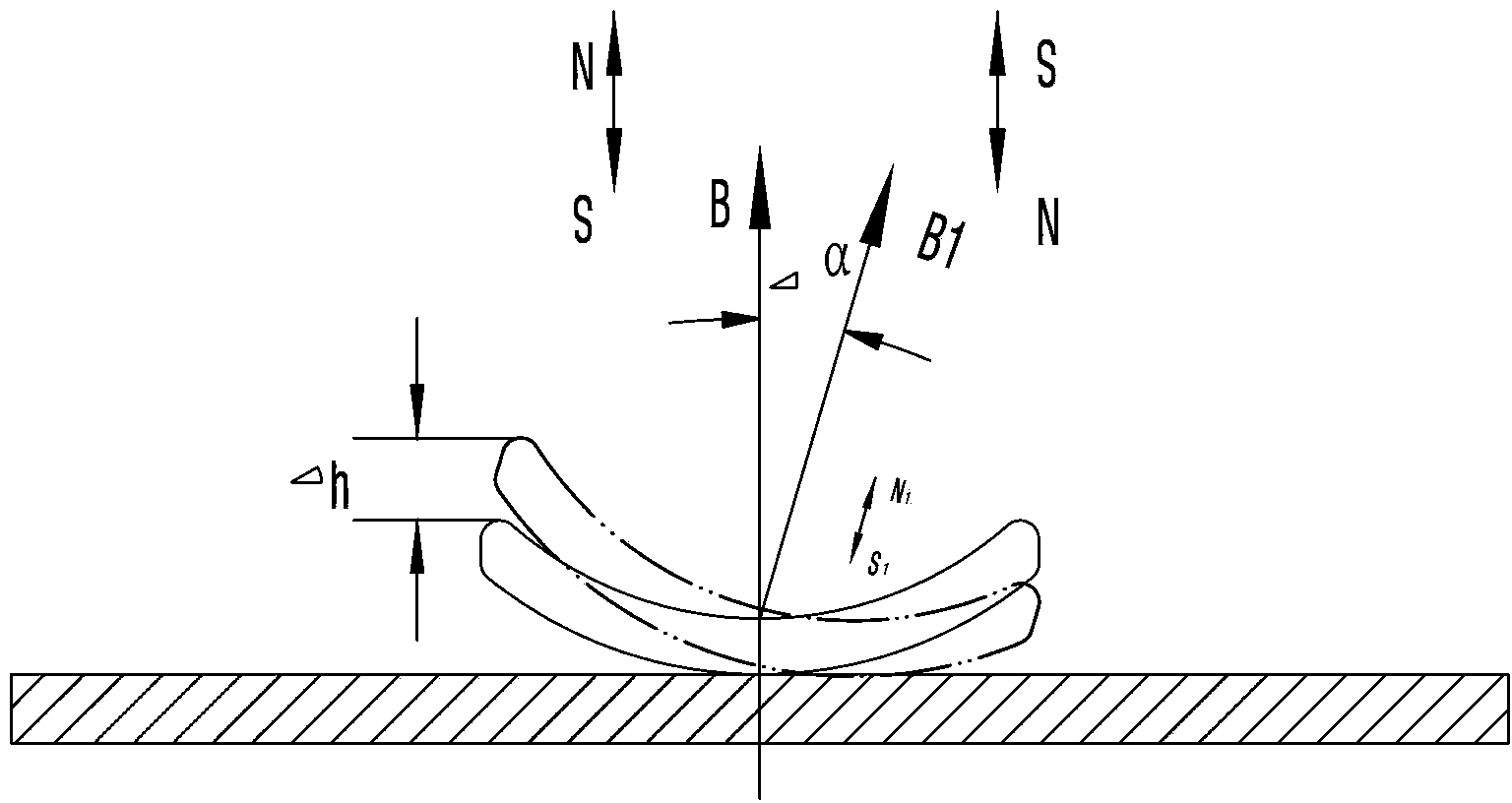

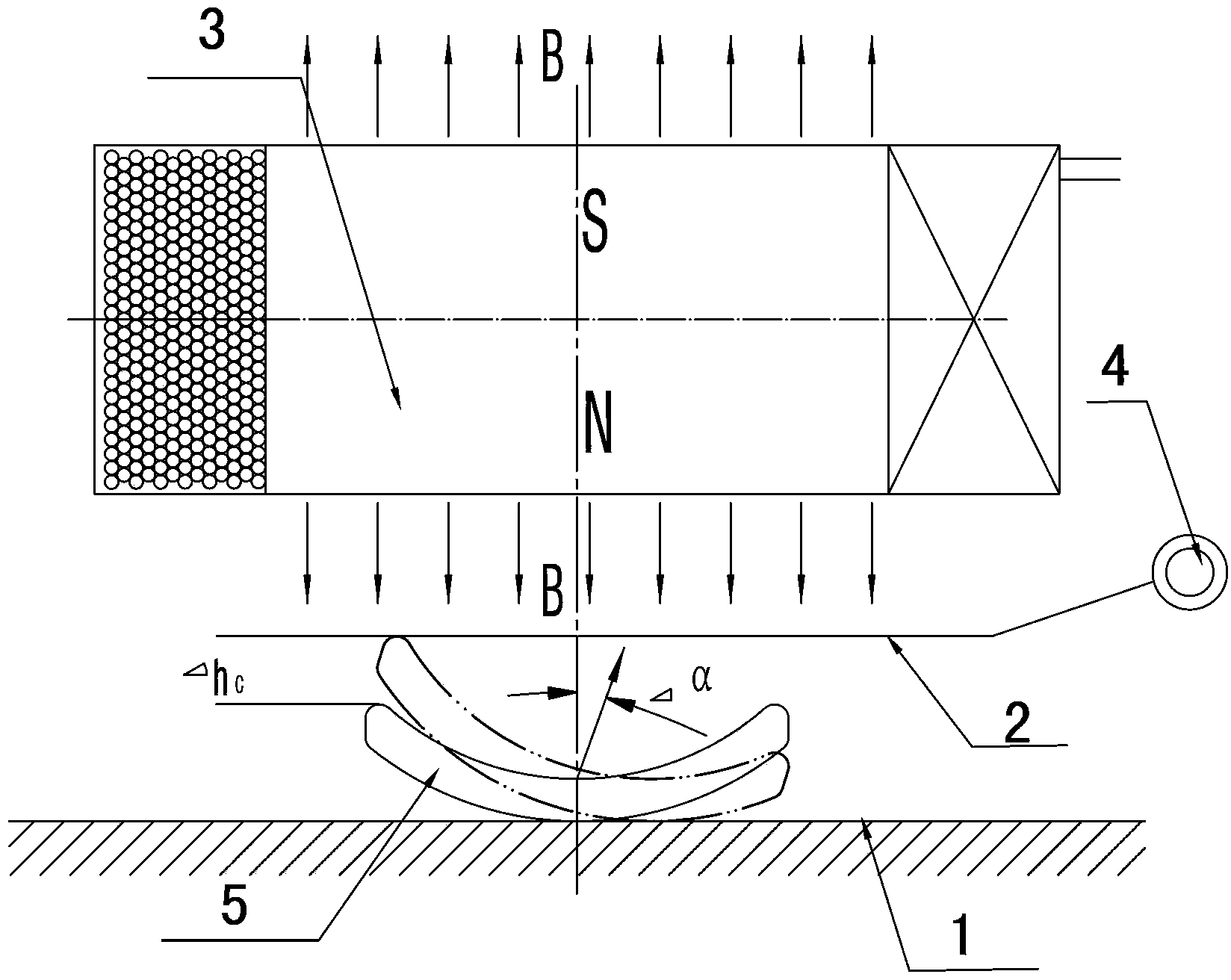

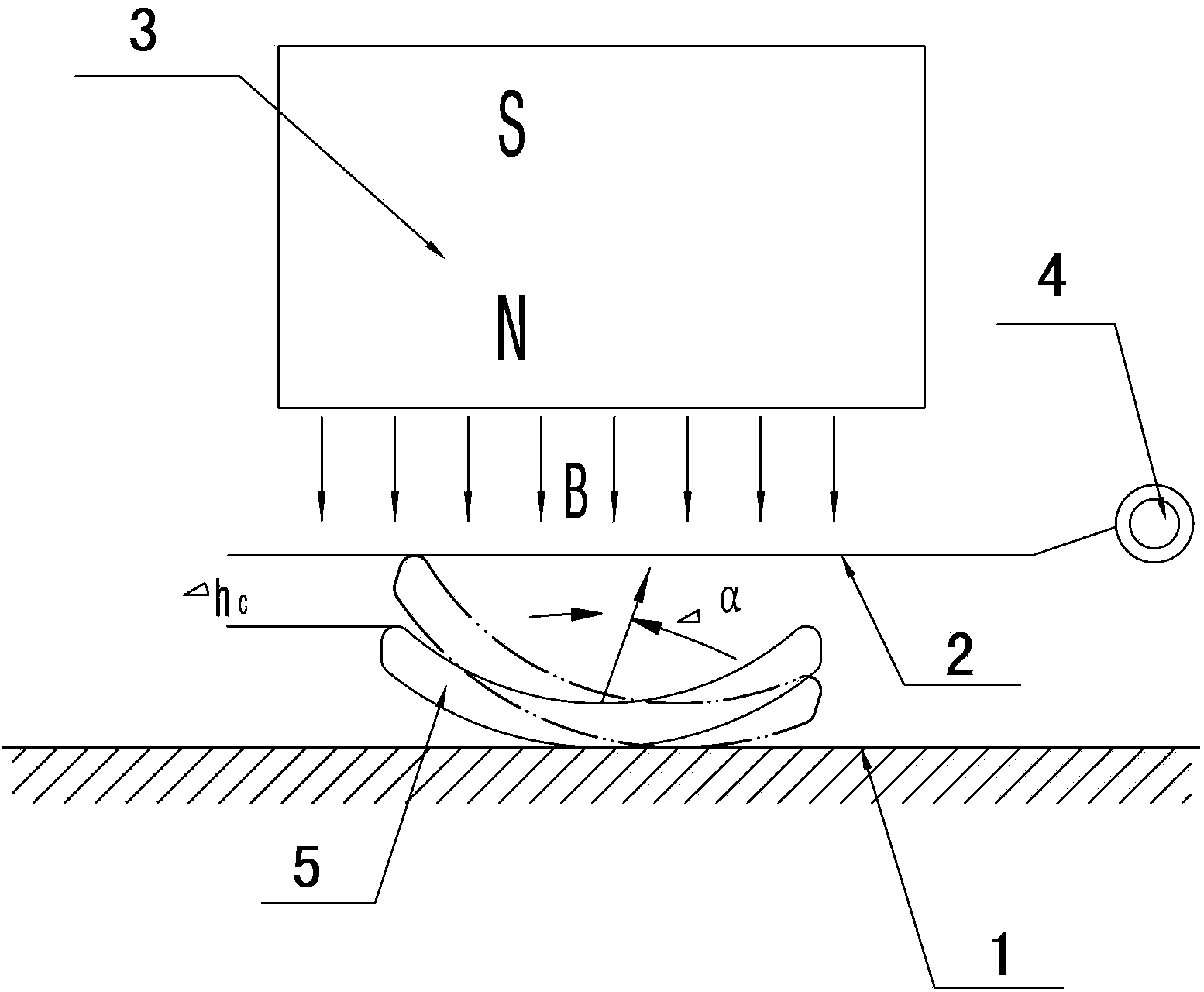

[0025] Such as figure 1 As shown, the present invention discloses a method for measuring the magnetic declination of a tile-shaped magnet element, comprising the following steps:

[0026] ① Select an unmagnetized tile-shaped magnet element whose declination angle is the upper limit of the qualified range as the reference piece;

[0027] ② Place the reference piece on a horizontal plate made of non-magnetic material, the concave surface of the reference piece faces upwards and the left and right ends are kept horizontal, and the connecting line between the vertices of the left and right ends at this time is set as the reference line;

[0028] ③A vertically downward or upward magnetic field is applied directly above the reference piece, and the left or right end of the reference piece is deflected upward;

[0029] ④ Detect the deflection heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com