Pressfit method and equipment capable of measuring interference force

A technology of profit and equipment, applied in the field of presses, can solve the problems of inability to judge whether the release force can meet the product requirements, product scrapping, and inability to control the force of pressing down, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

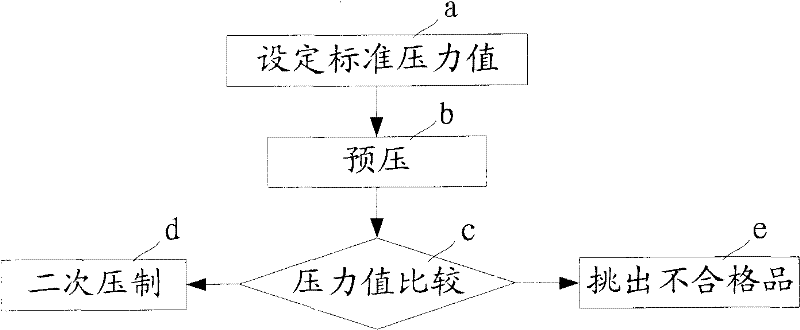

[0023] Such as figure 1 As shown, the first embodiment of the present invention is a press-fitting method with measurable interference force, which includes the following steps:

[0024] a. Set the standard pressure value required for the press-fitting of the finished product; set the pressure value collection point;

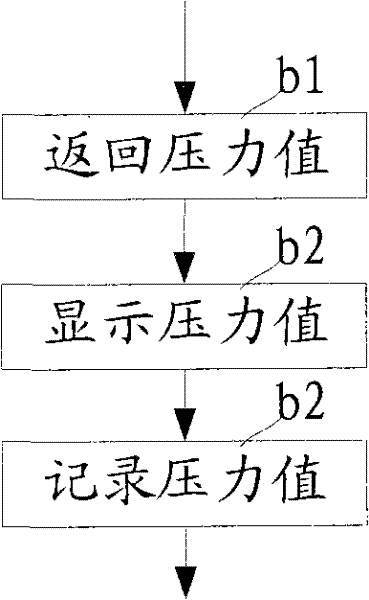

[0025] b. Perform a preload on the components, and measure the current pressure value during preload;

[0026] c. Compare the current pressure value with the standard pressure value;

[0027] d. When the current pressure value reaches the standard pressure value, perform secondary pressing to complete product processing;

[0028] e. When the current pressure value does not reach the standard pressure value, the processing is ended and it is picked out as a defective product.

[0029] Wherein, in step 1, the standard pressure value is set in advance according to different press-fit products, and the standard pressure value is slightly greater than the disengag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com