Device for detecting dynamic balance of hub of assembly line

A detection device and assembly line technology, applied in static/dynamic balance test, measuring device, machine/structural component test, etc., can solve the problem that the dynamic balance detection equipment cannot meet the full inspection of the assembly line, so as to save the attitude switching device, The effect of simple structure and convenient assembly line operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

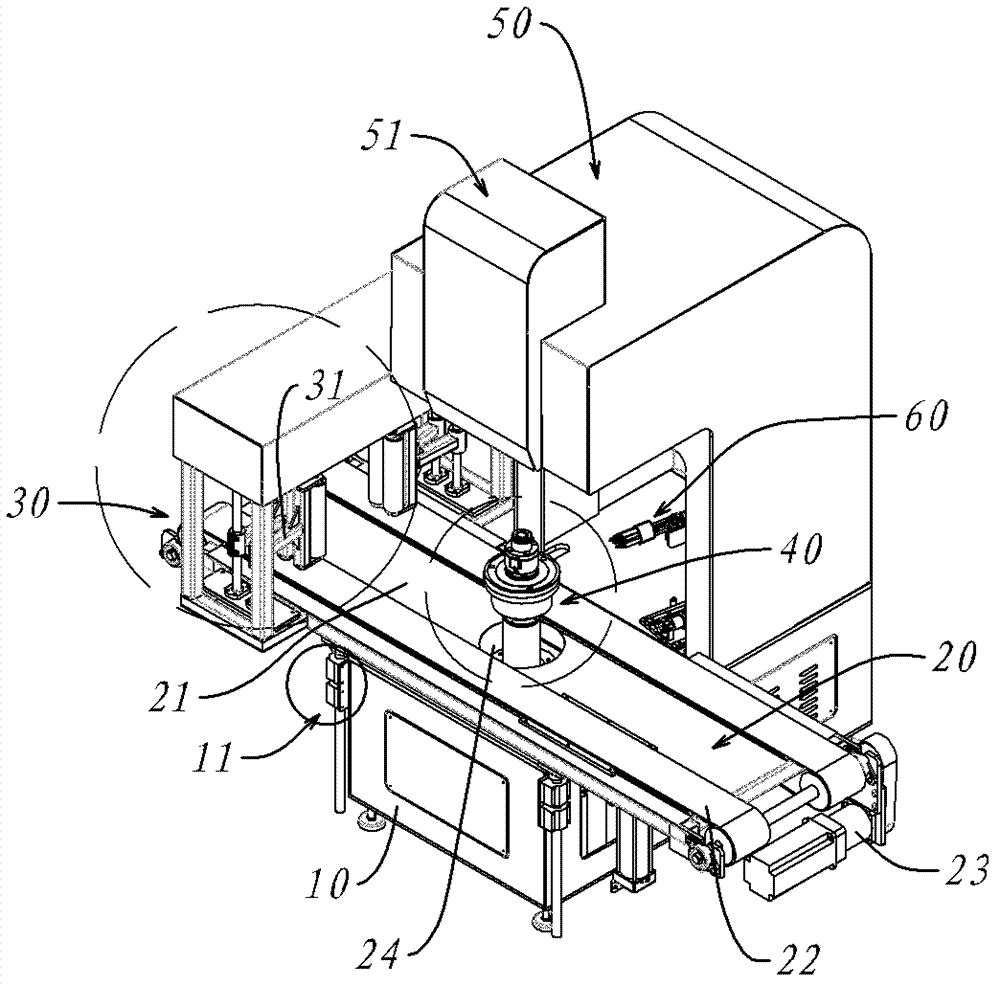

[0031] Such as figure 1 , a three-dimensional schematic diagram of an embodiment of the present invention:

[0032] The hub dynamic balance detection device has a base 10 placed on the level ground, and the base 10 controls the vertical lifting of the horizontal transmission mechanism 20 on the base 10 through a lifting device 11. Driven by the lifting device 11, the horizontal transmission mechanism 20 can be Move up and down vertically and position at a height.

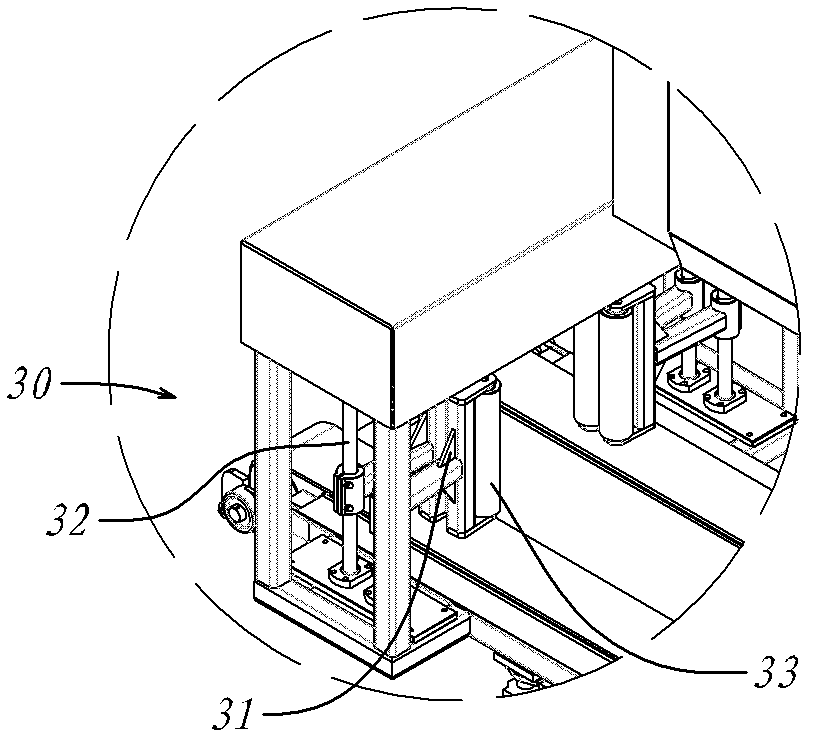

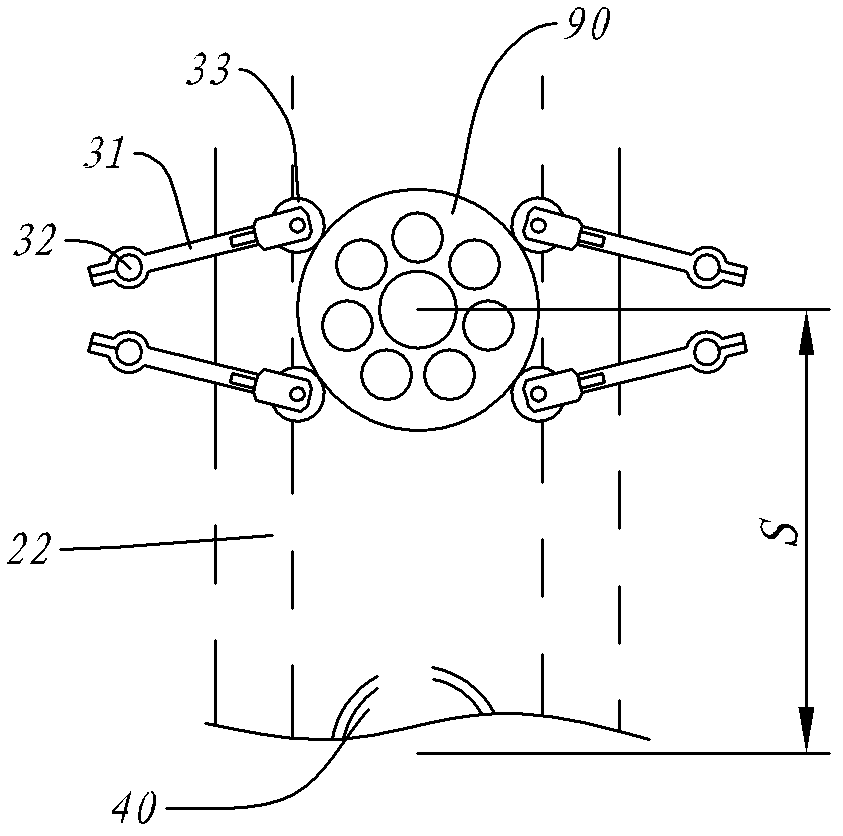

[0033] The horizontal transmission mechanism 20 has a transmission table 21, and this transmission table 21 is the shape of a long flat plate, and its one end is fixed with a positioning mechanism 30, and a conveyor belt 22 is arranged on it, and its other end is a driving device 23 for driving the transmission belt 22 to advance. Under the control of the driving device 23 , the conveyor belt 22 can drive the hub to move horizontally while maintaining a posture, starting from the positioning mechanism 30 and output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com