Patents

Literature

322results about How to "Realize mechanized operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for circularly using agricultural wastes and producing organic fertilizers

InactiveCN103288504AFast fermentationShort cycleBio-organic fraction processingGas production bioreactorsNutrientLeavening agent

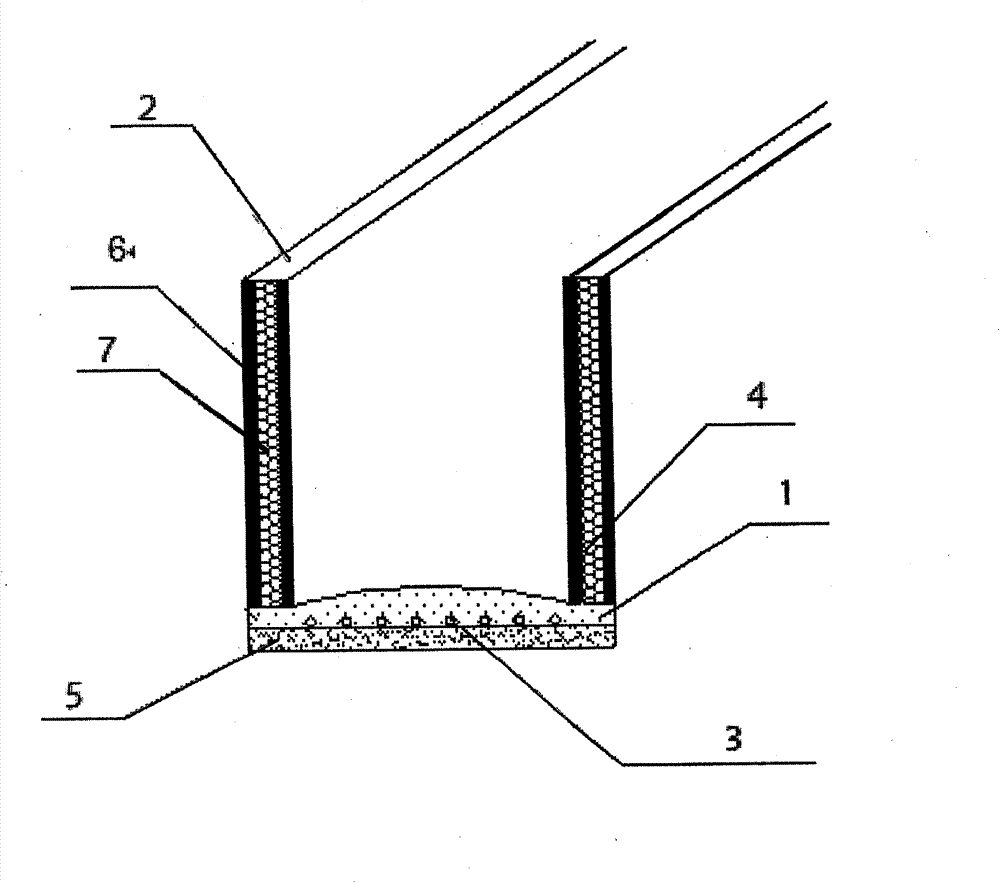

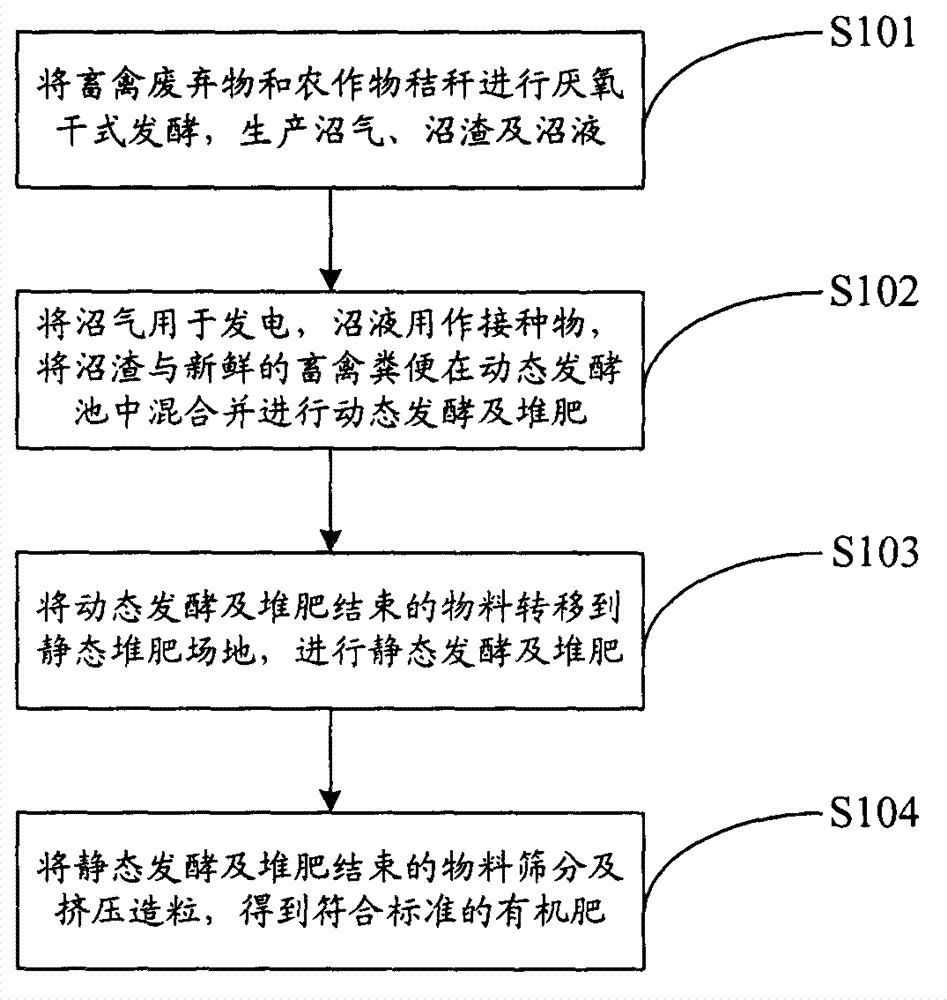

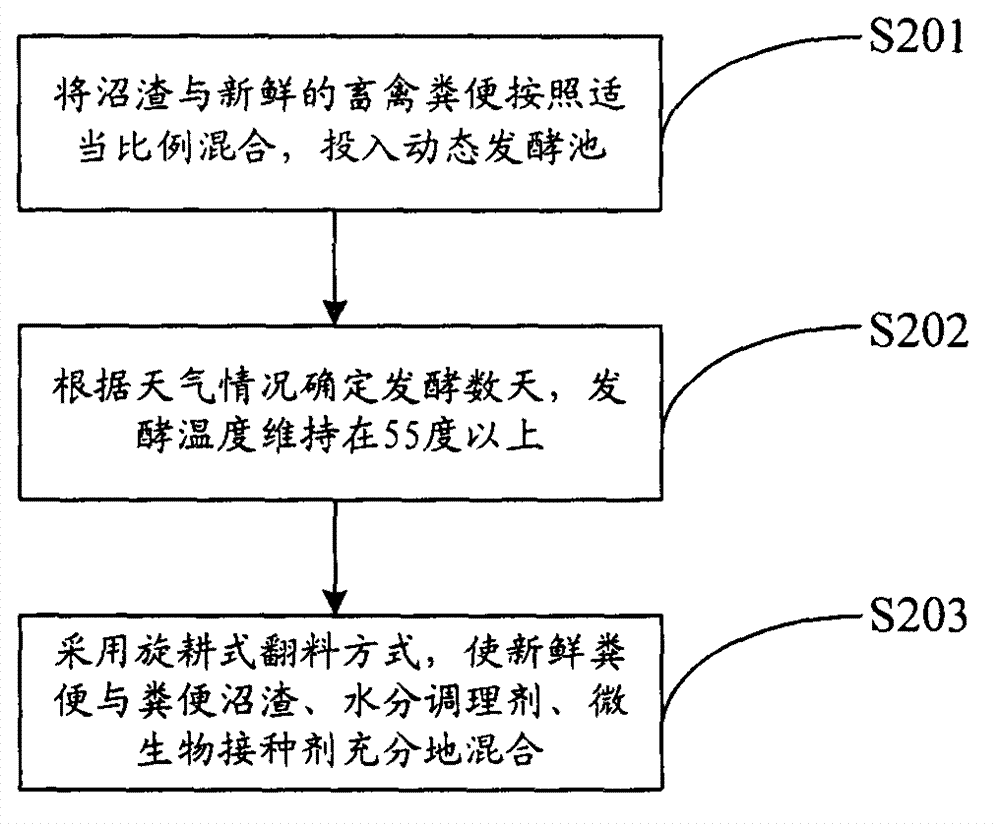

The invention belongs to the technical field of cyclic utilization of agricultural wastes, and provides a method for circularly using agricultural wastes and producing organic fertilizers. The method comprises the following steps: with the adoption of a dry type anaerobic fermentation technology, generating biogas by livestock wastes and crop straws through anaerobic fermentation; deodorizing and decomposing materials by means of natural microorganisms and inoculated microorganisms, wherein fermentation is fast in speed, short in period and easy to operate mechanically; meanwhile, recovering the biogas slurry for next anaerobic fermentation inoculum; generating electricity by biogas to provide energy sources to heat an anaerobic fermentation tank in low temperature seasons and meanwhile, providing an electric energy to production of organic fertilizers; adjusting nutrients and moisture of biogas residue and adding a leavening agent and converting the biogas residue into the organic fertilizers through a secondary static composting process. In the whole production process, substances and energies are recycled without secondary pollution, so that wastes are recycled, harmless and ecological, and substances and energies are recycled. Huge social, ecological and economical benefits can be generated, so that the method has stronger popularization and application values.

Owner:吴江市农业科技发展有限公司

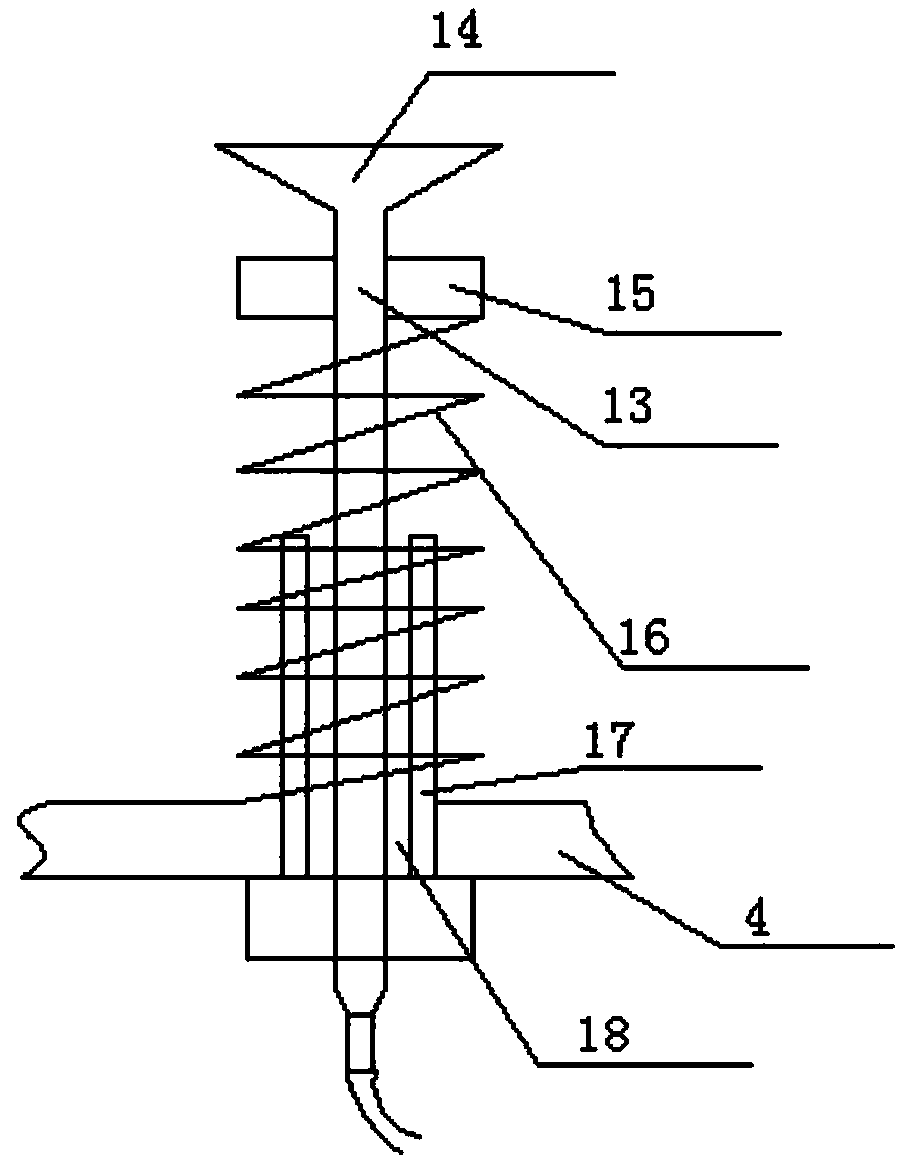

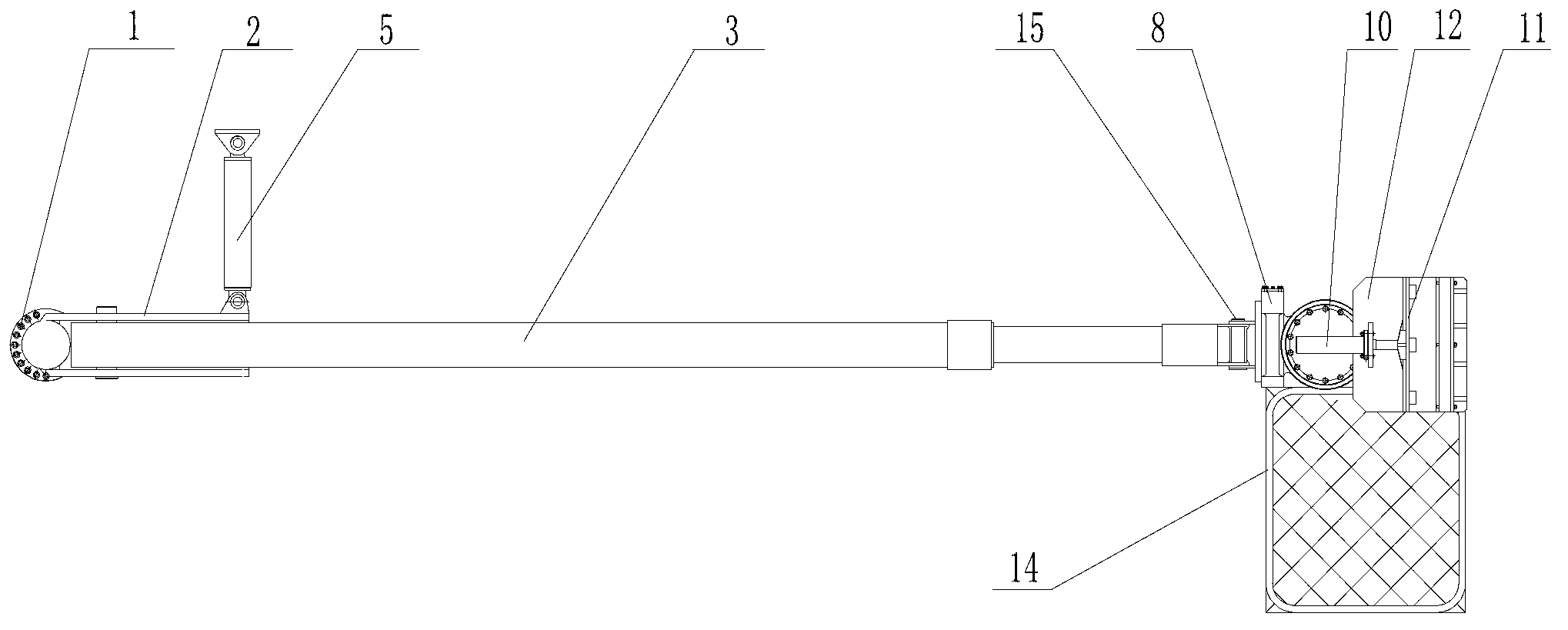

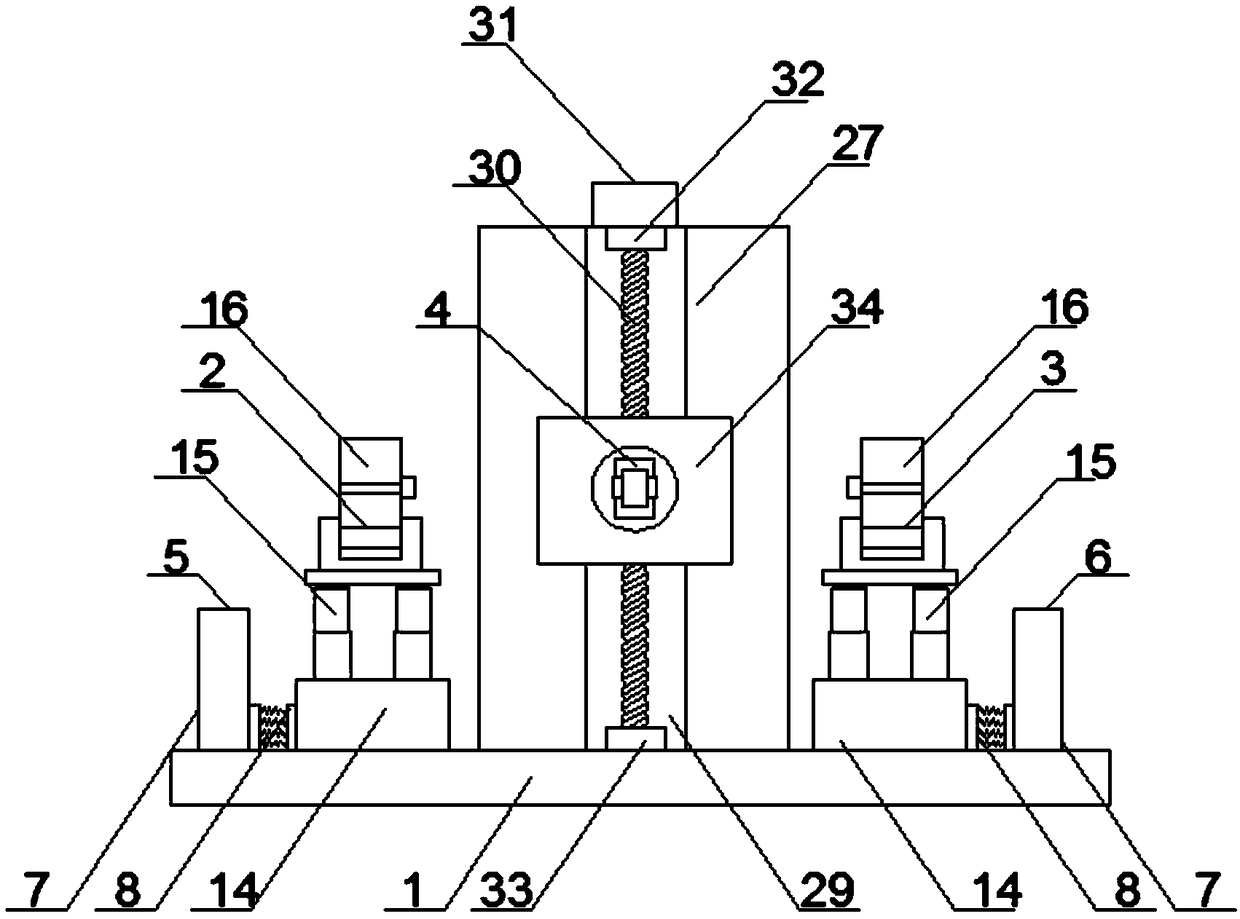

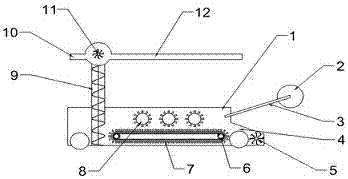

Ton bag feeding device and feeding method

ActiveCN103407797AAchieve accurate meteringRealize deliveryConveyorsBottle emptyingVacuum pumpingEngineering

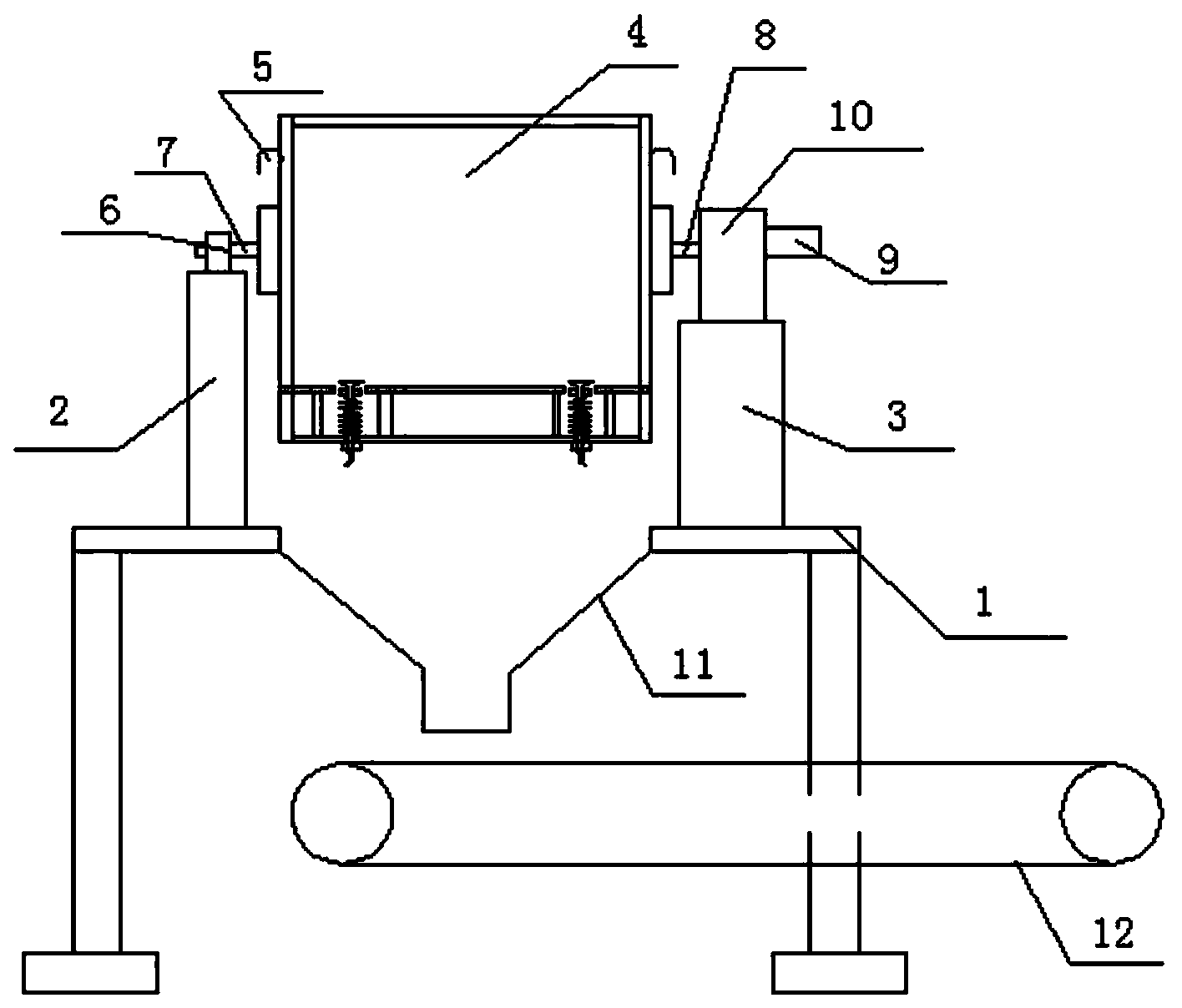

The invention discloses a ton bag feeding device and a feeding method. The device comprises a support device, a ton bag clamping turnover mechanism, a turnover motive power mechanism, a material collection hopper, a belt weigher and a vacuum absorption device. The method comprises the following steps: putting ton bag packed material into a turnover cage, hanging lifting lugs of the ton bag on ton bag hooks, compressing a vacuum sucker to be clung to the bottom of the ton bag, starting a vacuum pumping device, and absorbing the ton bag by the vacuum sucker; starting a motor, overturning the turnover cage, flowing the material in the ton bag into the material collection hopper, enabling the ton bag to be absorbed due to the absorbing force of the vacuum sucker, and dropping the material gradually until all material in the ton bag is poured out; rotating the turnover cage in an opposite direction, closing the vacuum pumping device, and taking the ton bag down. The device and the method can realize mechanized operation to clean up once; no manual assistance is needed; accurate measuring and delivering of the material are realized; the vacuum sucker adopts an elastic structure; the service life is long; the equipment is simple, and 360 degrees overturning of the ton bag can be realized; the method is suitable for the discharging and the delivering of various ton bag packed material, especially particles and powdery material.

Owner:度测(上海)科技服务中心

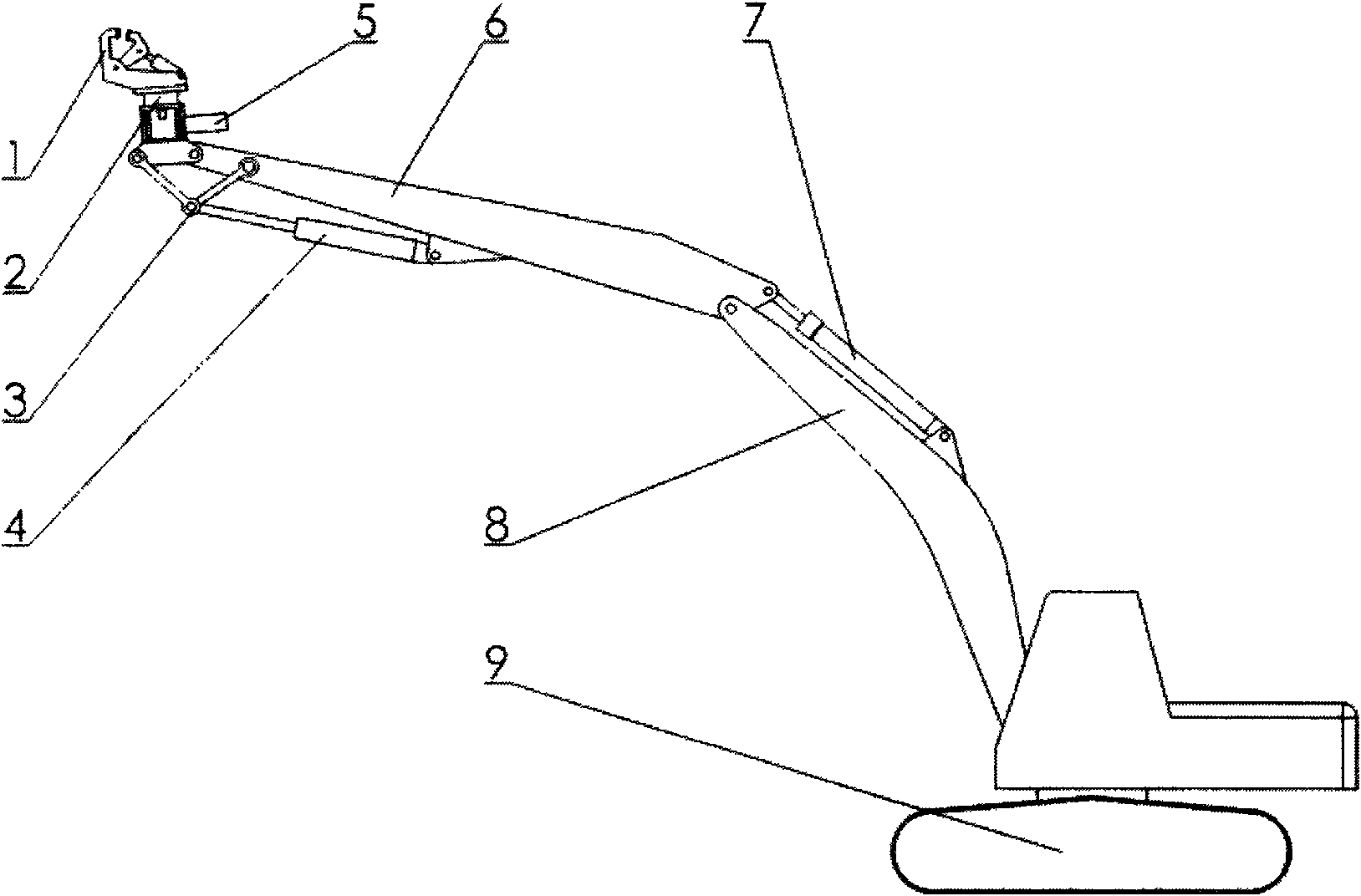

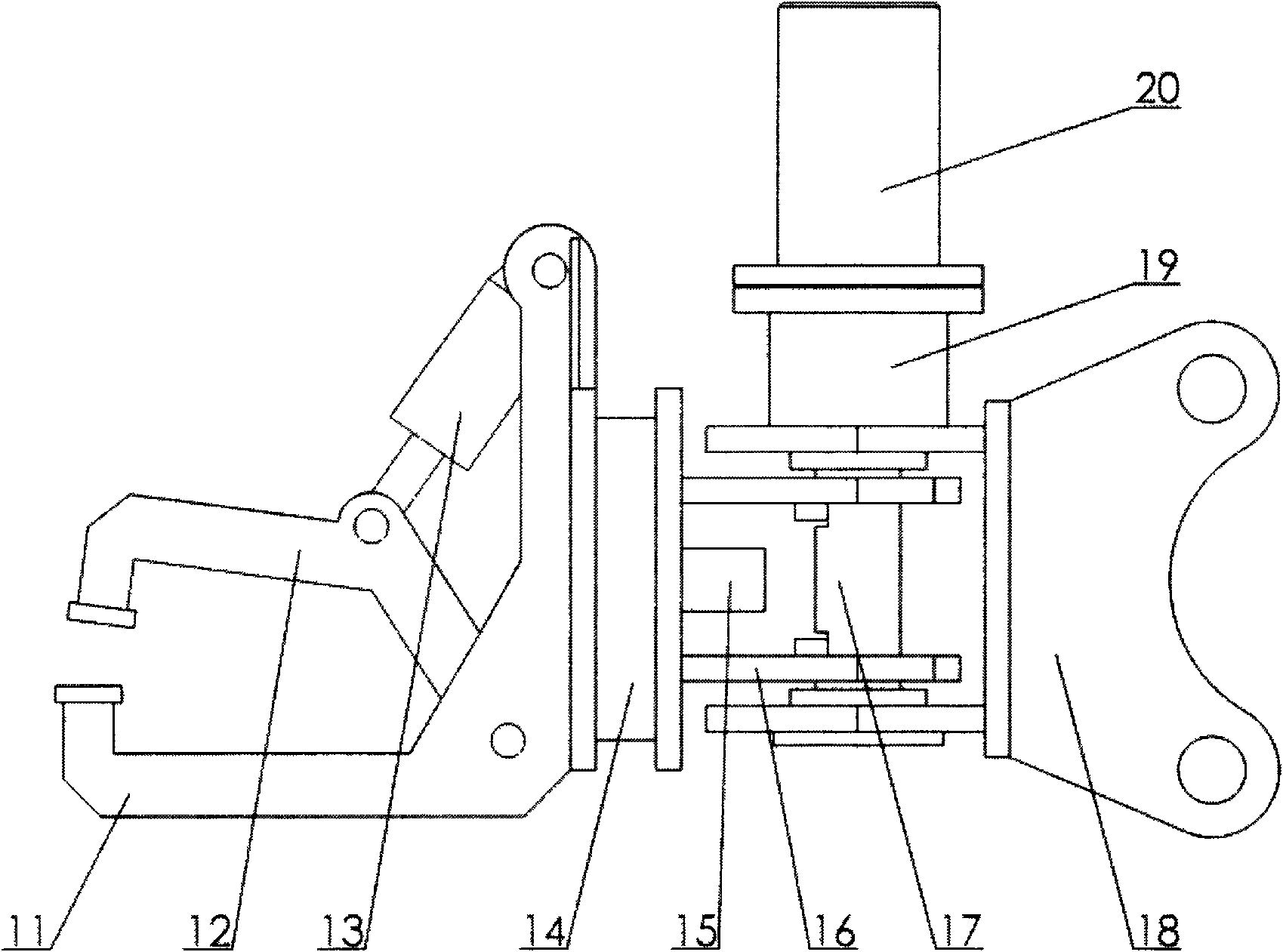

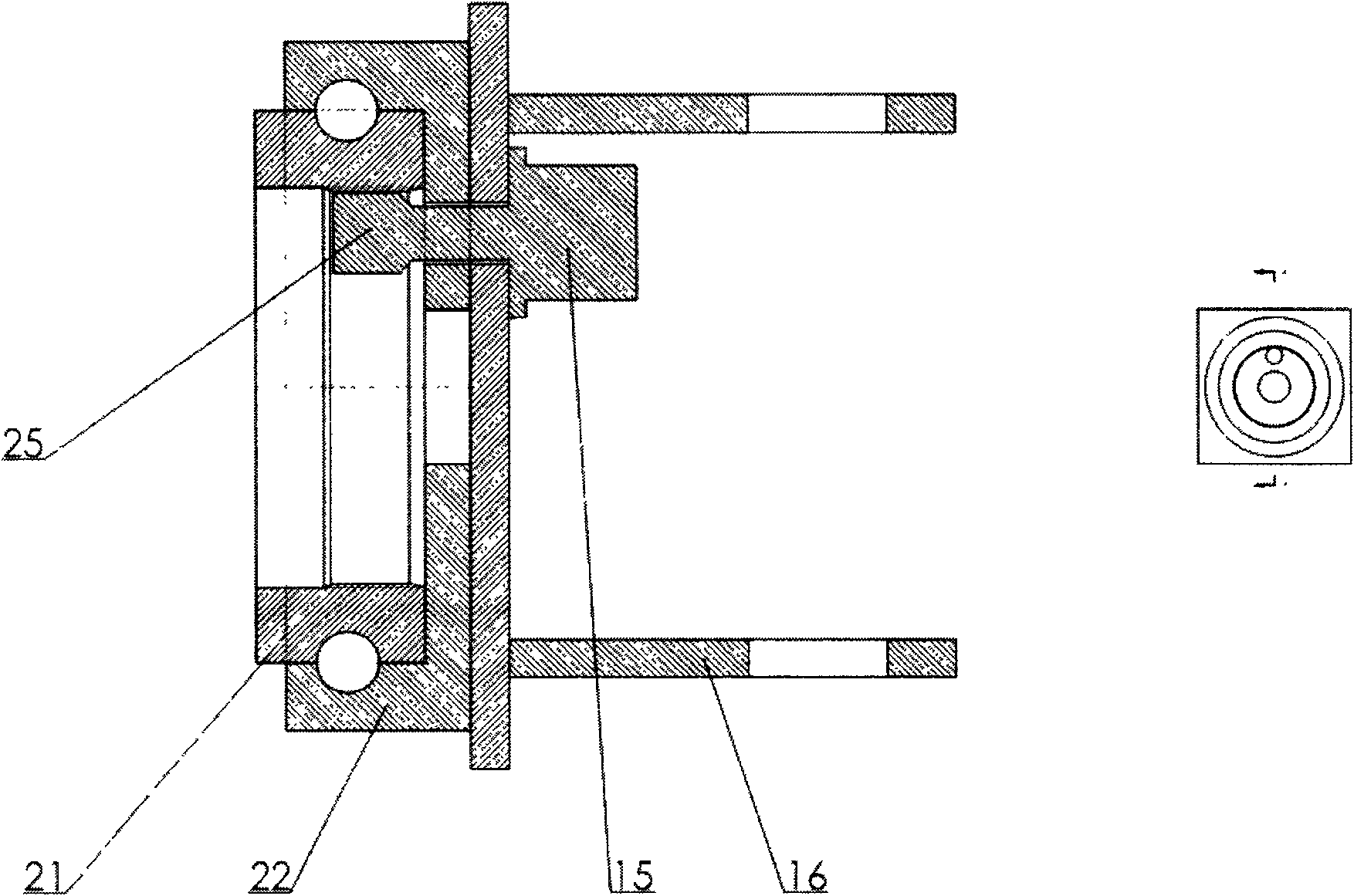

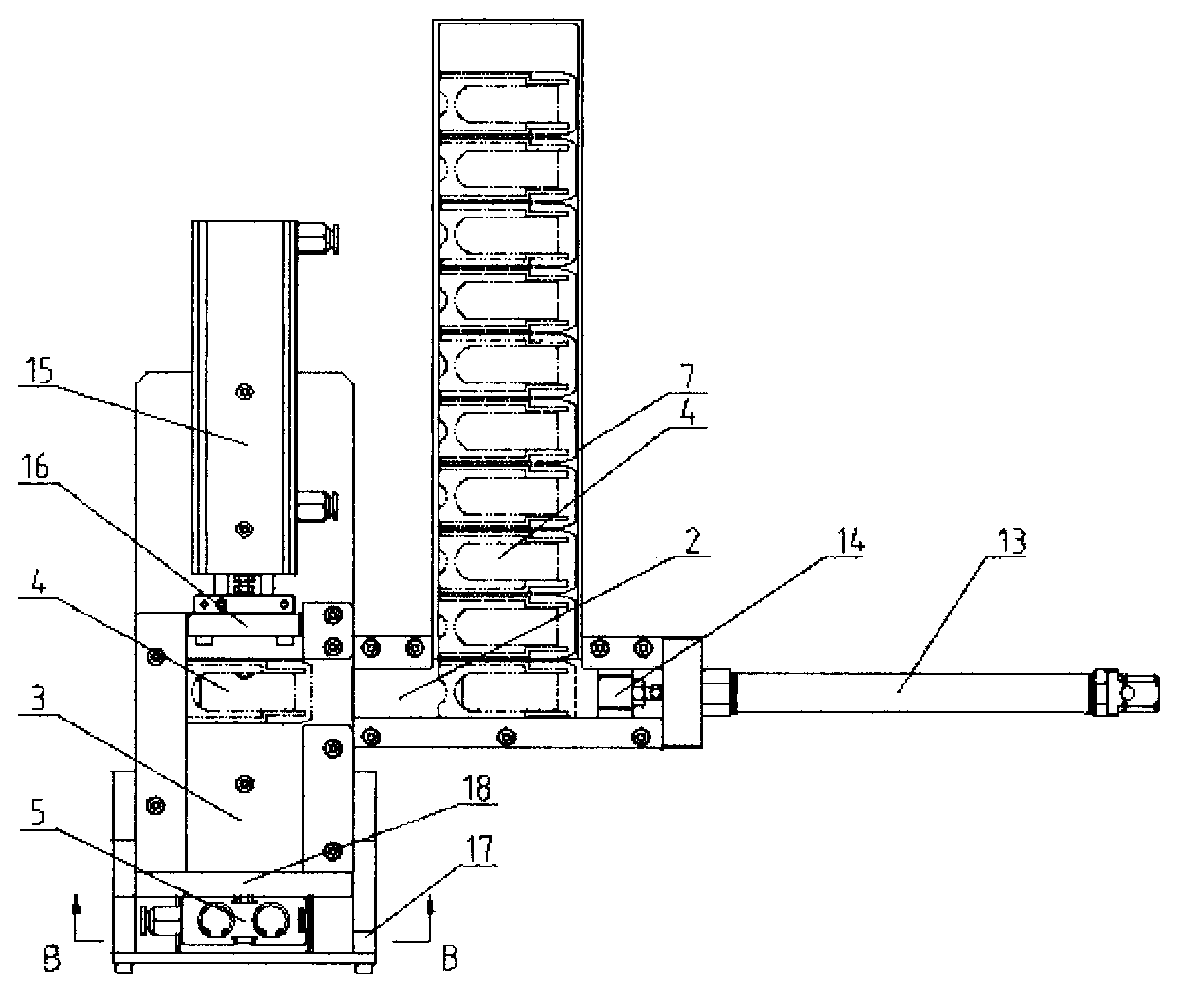

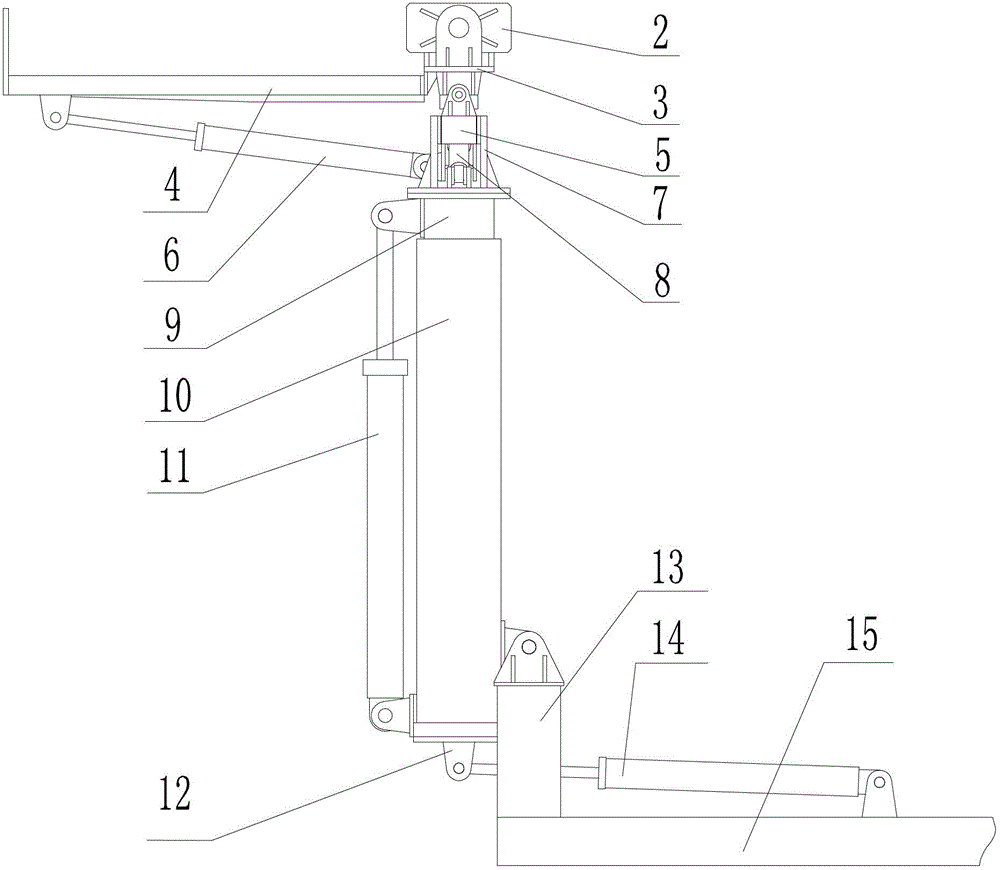

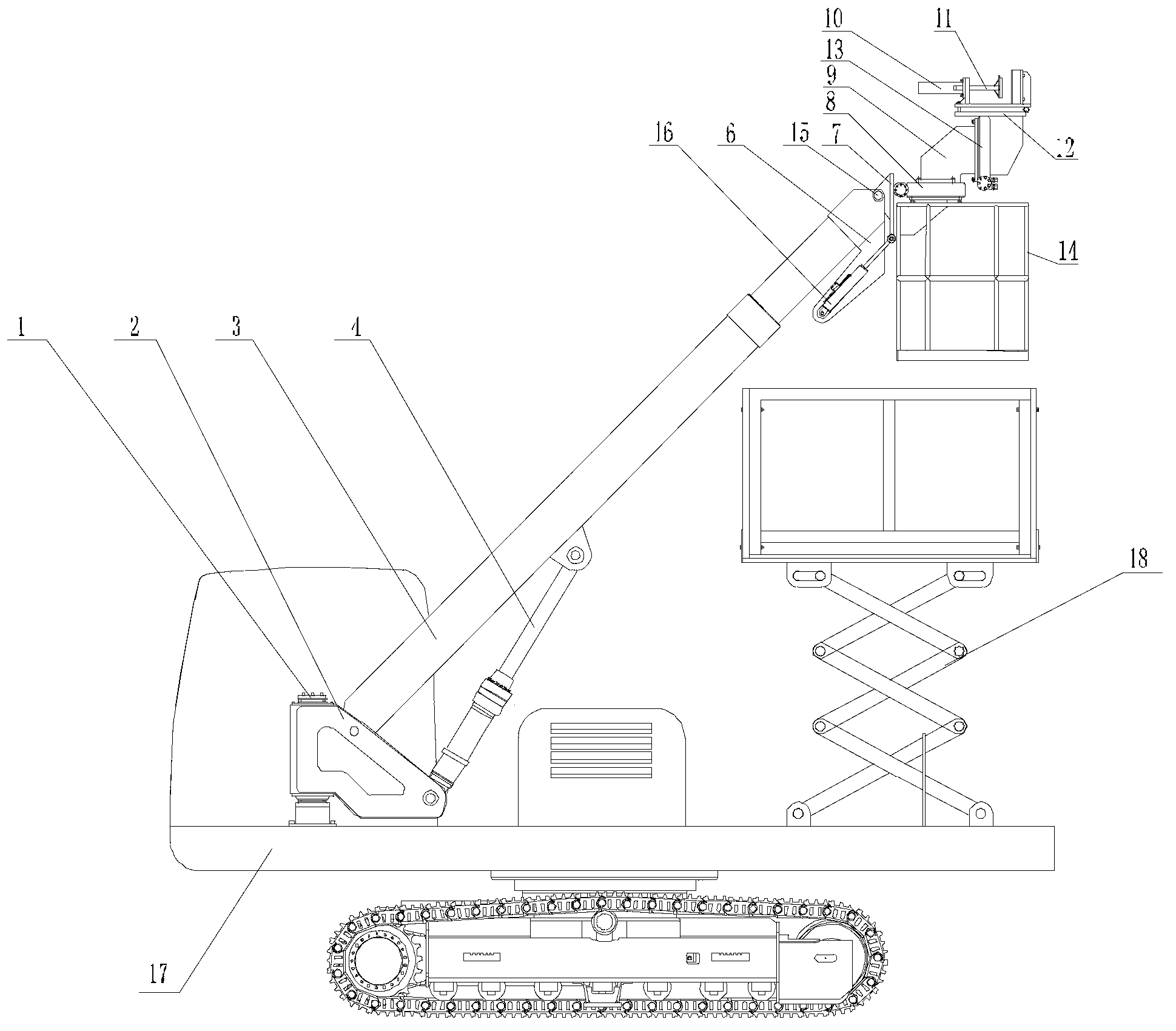

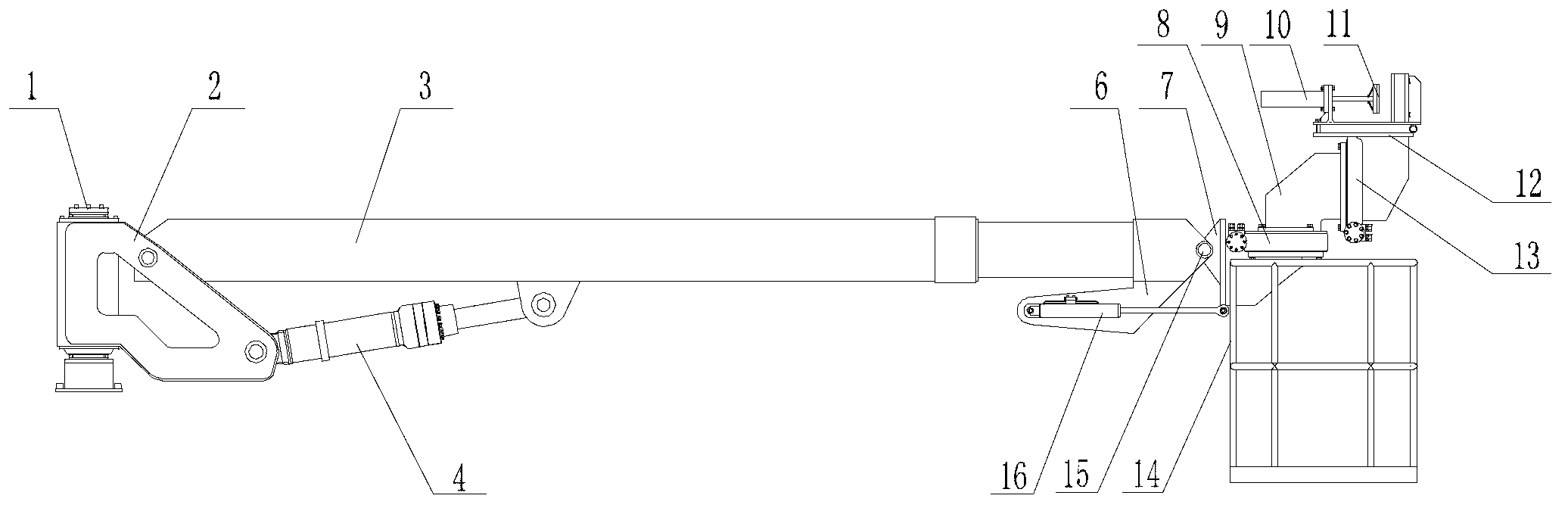

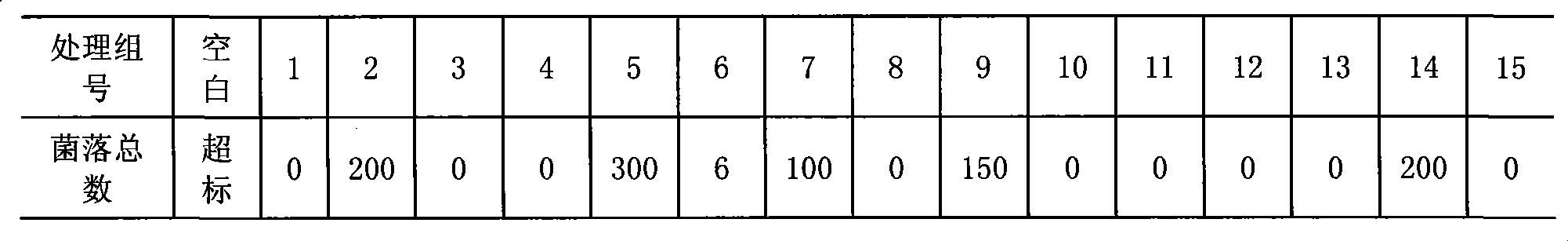

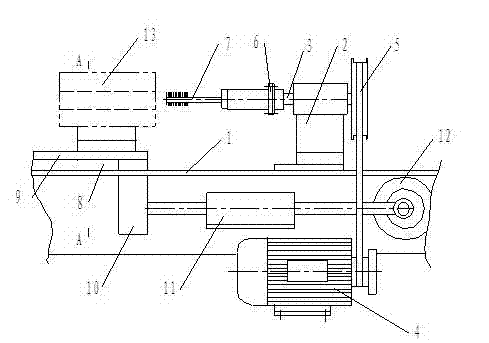

Arch center mounting device for construction of tunnel

The invention belongs to the technical field of mounting of arch centers of tunnels and provides an arch center mounting device for construction of the tunnel, which mainly comprises a chassis (9), a large arm (7), a small arm (6) and a workpiece clamping device, wherein the large arm (7) is arranged on the chassis (9), the small arm (6) is hinged at the end part of the large arm, a cylinder bodyof a small arm oil cylinder (8) is positioned on the large arm (7) and hinged with the large arm (7), and a piston of the small arm oil cylinder (8) is hinged with the end part of the small arm (6); the arch center mounting device is provided with a four-bar linkage and an overturning oil cylinder (4) for adjusting the pitching angle of a clamped workpiece; and the workpiece clamping device mainly comprises a body, a workpiece clamp (1), a clamp rotating mechanism, a clamp swinging mechanism and a clamp opening and closing driving mechanism. By adopting the device, the artificial labor intensity can be reduced, the fast mounting can be realized and the working efficiency can be improved.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

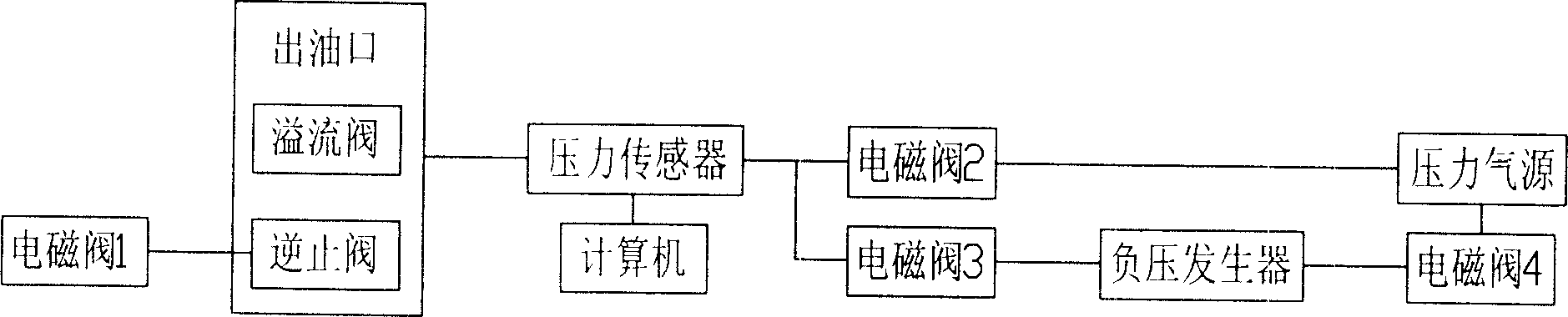

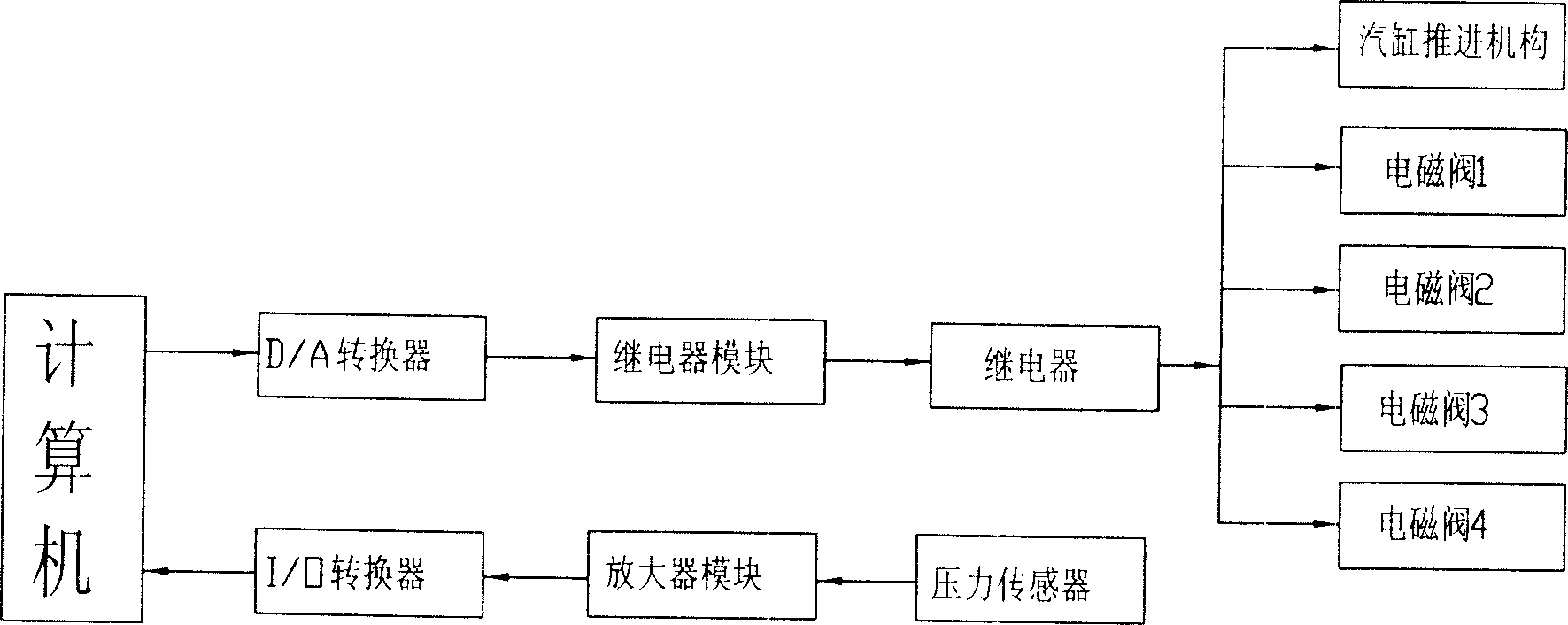

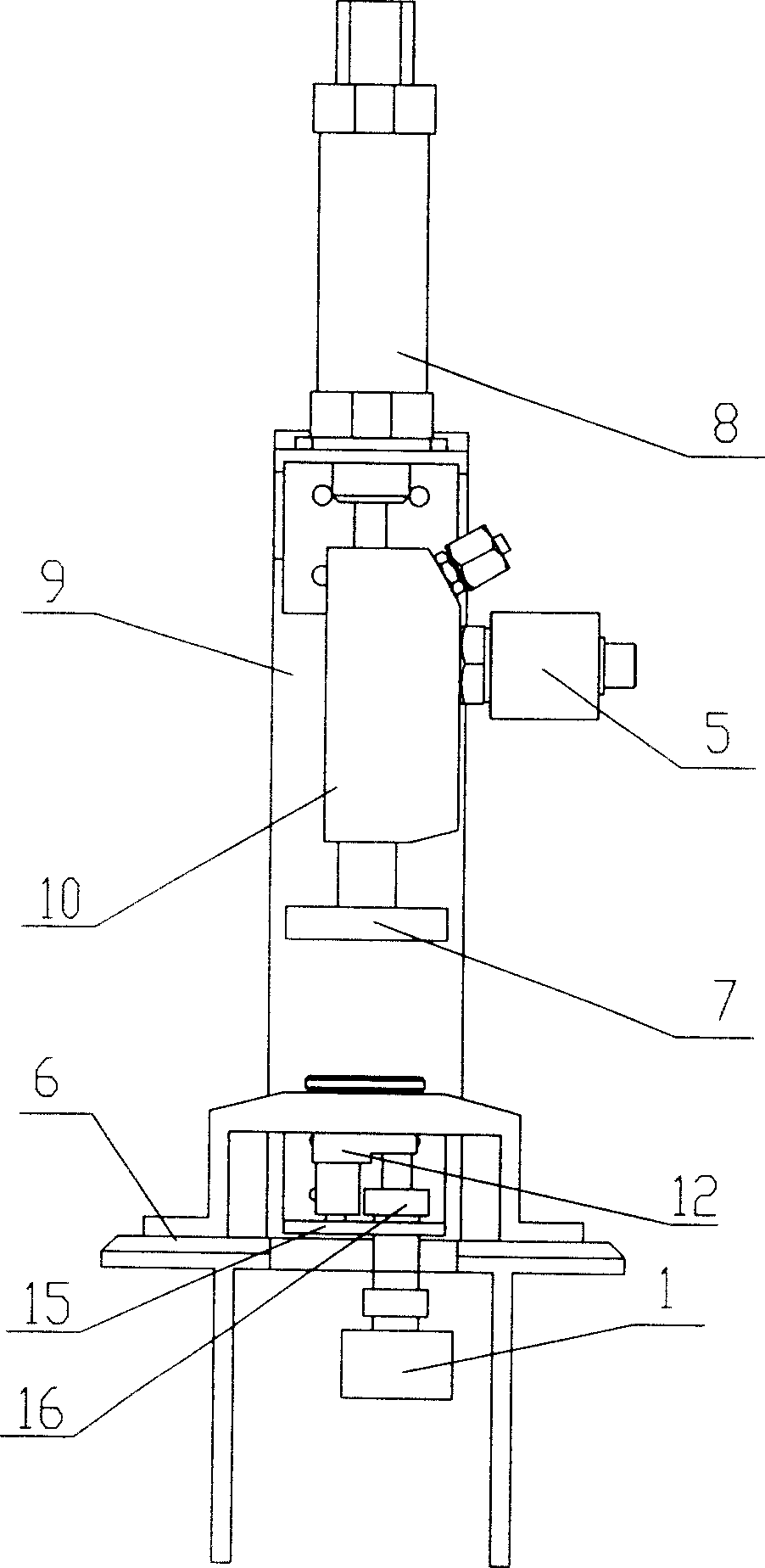

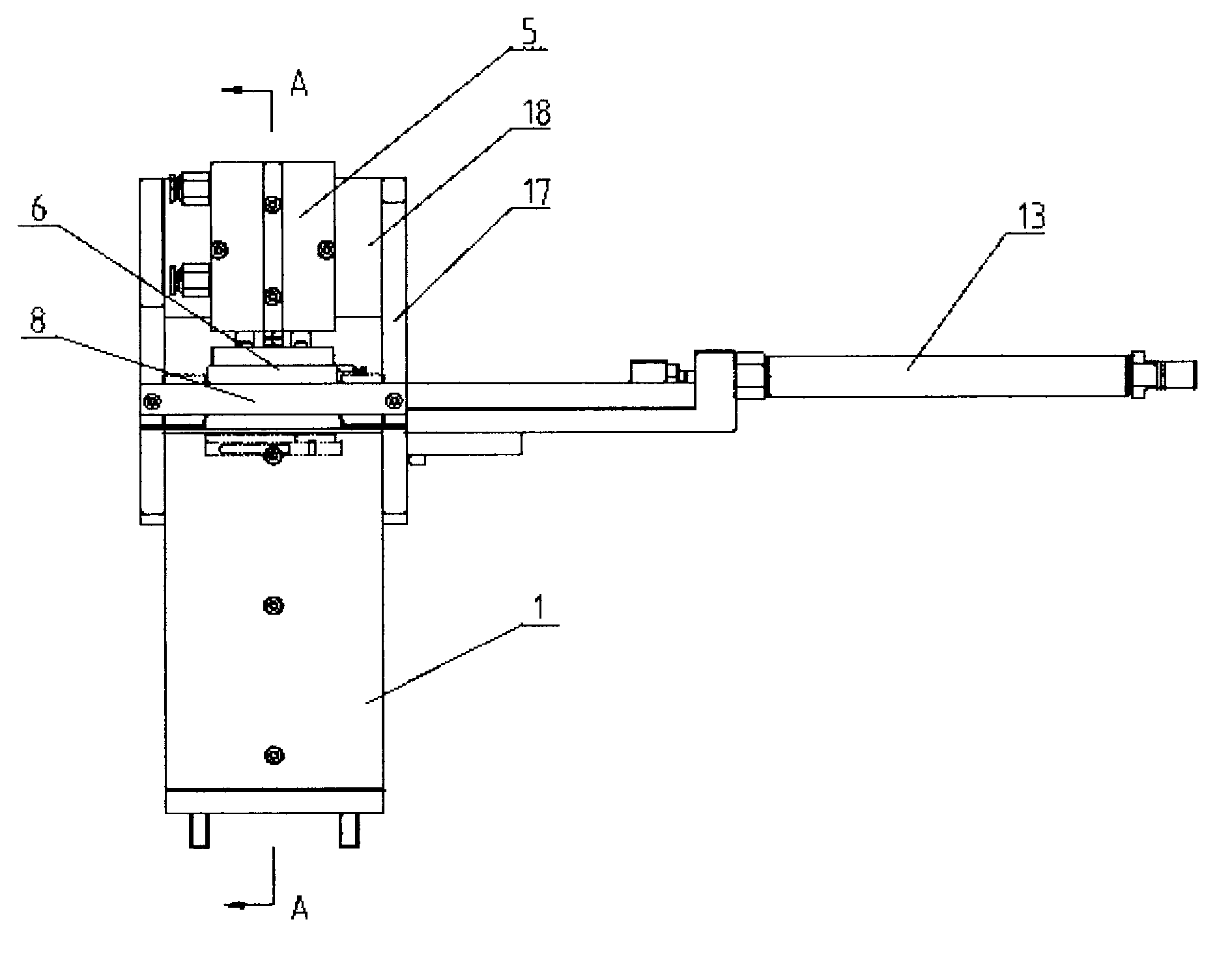

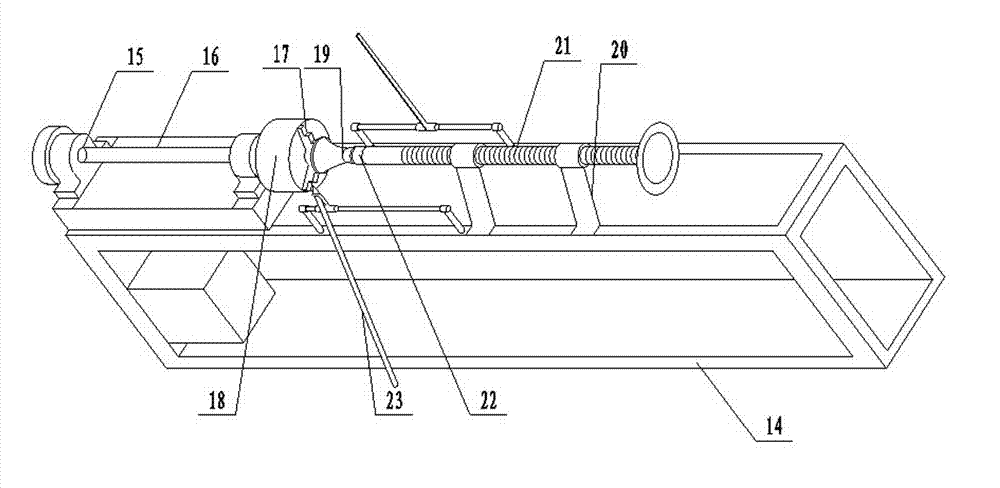

Equipment for testing valve performance of oil fuel pump

InactiveCN1687731AHigh precisionReduce mistakesMachine part testingMeasurement of fluid loss/gain rateSolenoid valvePositive pressure

The invention relates to the fuel pump valve performance testing equipment, which comprises the pipeline part, the pressure sensor testing the oil outtake pressure of the fuel pump, the electromagnetic valve on the outtake pipe of the reversing valve. The pipeline part comprises the pressure air source connecting the oil intake end of the output nozzle of the pump, the negative pressure producer connecting the intake end of the output nozzle of the fuel pump; the electromagnetic valves are between the intake end of the output nozzle of the pump and the pressure air source, and between the intake end of the output nozzle of the pump and the negative pressure producer; the output end of the pressure sensor connects the computer. The invention provides the positive pressure gas to the output nozzle through the pressure air source, vacuums through the negative pressure producer and makes the output nozzle produce the negative pressure, tests the starting pressure, the sealing performance of the overflow valve through the pressure sensor.

Owner:WUHAN UNIV OF TECH

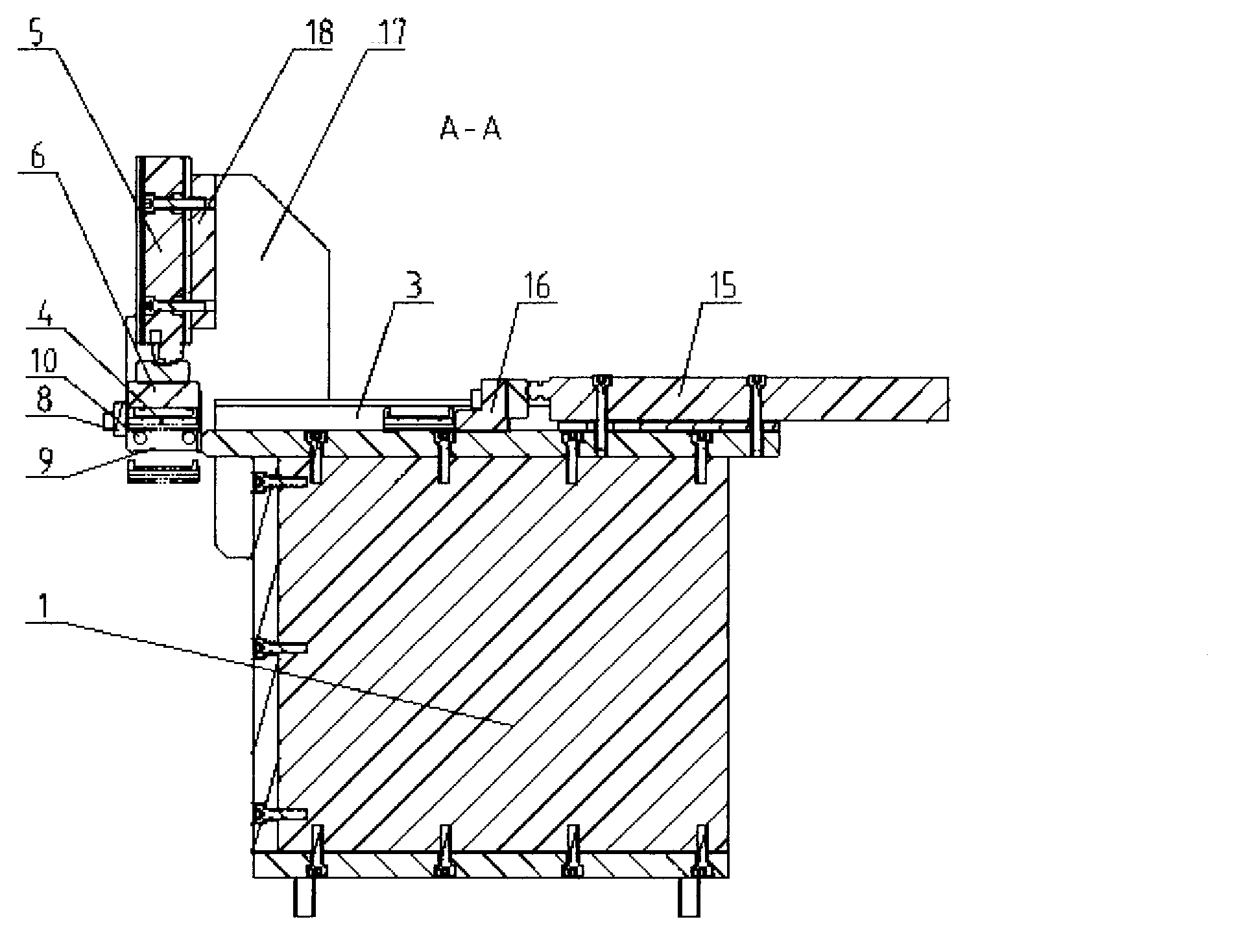

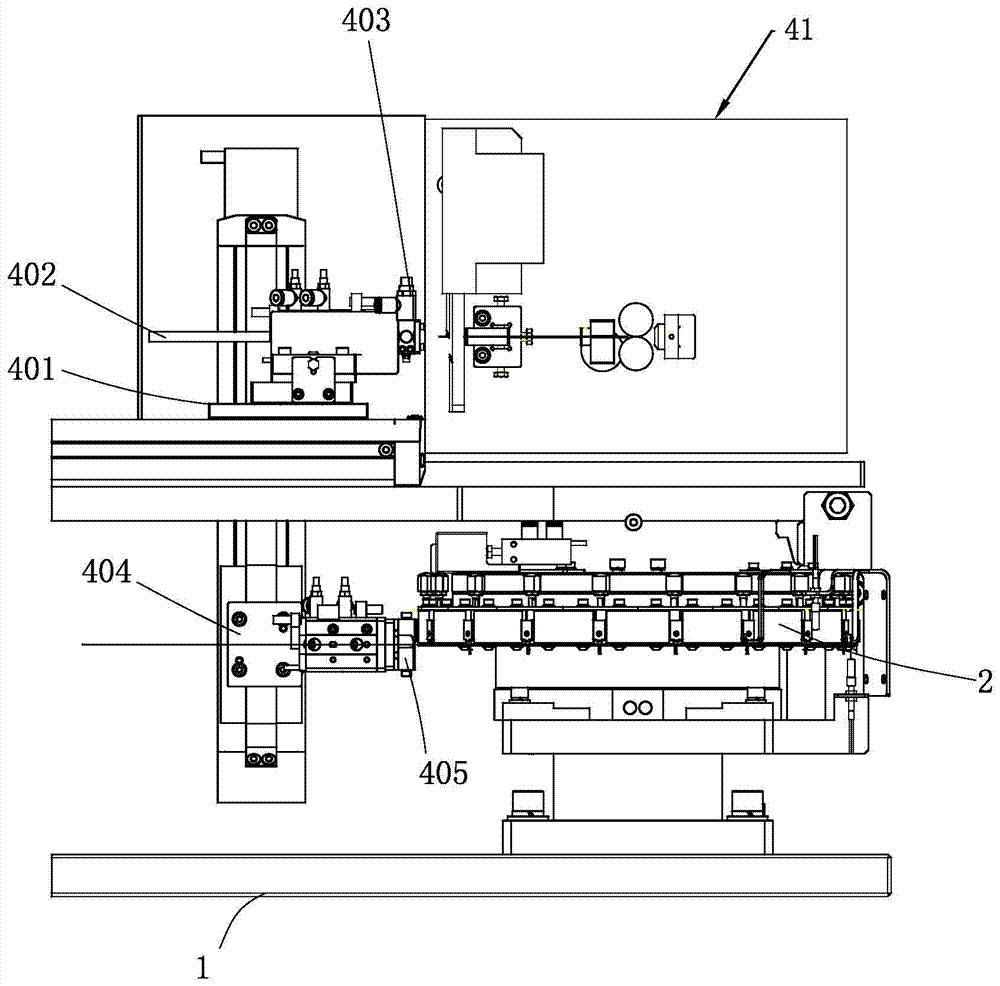

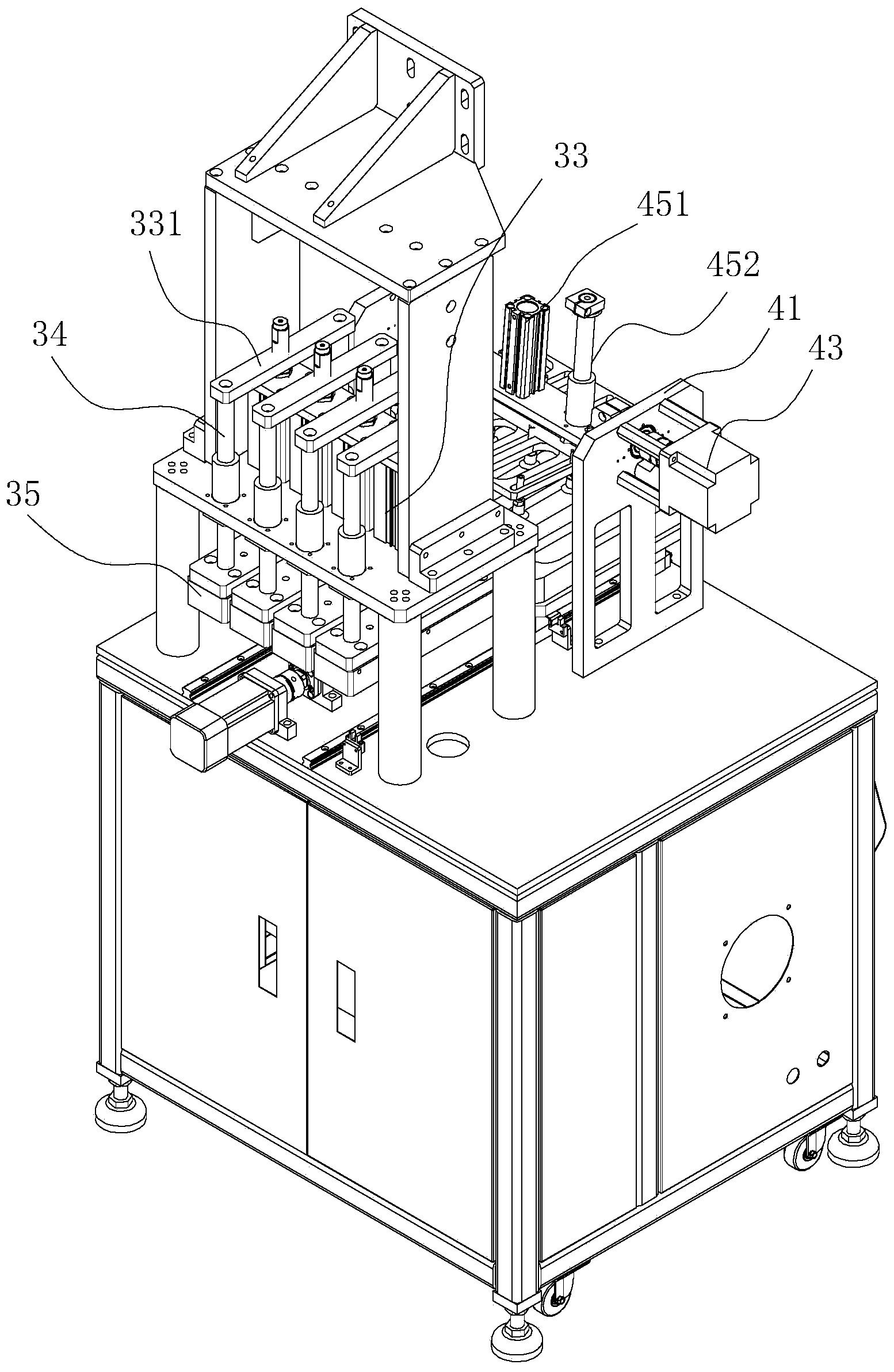

Shell feeding device of lockset spring assembly assembling machine

ActiveCN102794630ARealize mechanized operationImprove assembly qualityAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a shell feeding device of a lockset spring assembly assembling machine. The shell feeding device comprises a rack and a material pressing mechanism, wherein the rack is provided with a feeding rail and a material pushing rail; the tail end of the feeding rail is communicated with the front end of the material pushing rail; the front end of the material pushing rail is located below the material pressing mechanism, and the tail end of the feeding rail is provided with a feeding mechanism capable of conveying a shell into the material pushing rail; the tail end of the material pushing rail is provided with a material pushing mechanism capable of conveying the shell to be below the material pressing mechanism; the material pressing mechanism comprises a material pressing cylinder fixed on the rack and a material pressing plate fixed on the material pressing cylinder; and the rack is further provided with a fixing mechanism capable of fixing the shell which is conveyed to be below the material pressing plate. The shell feeding device disclosed by the invention has a high mechanical degree, can replace artificial assembling and has a high feeding speed, and can improve the assembling quality and stability of a lockset spring assembly.

Owner:CHANGZHOU INST OF NUMERICAL CONTROL TECH +1

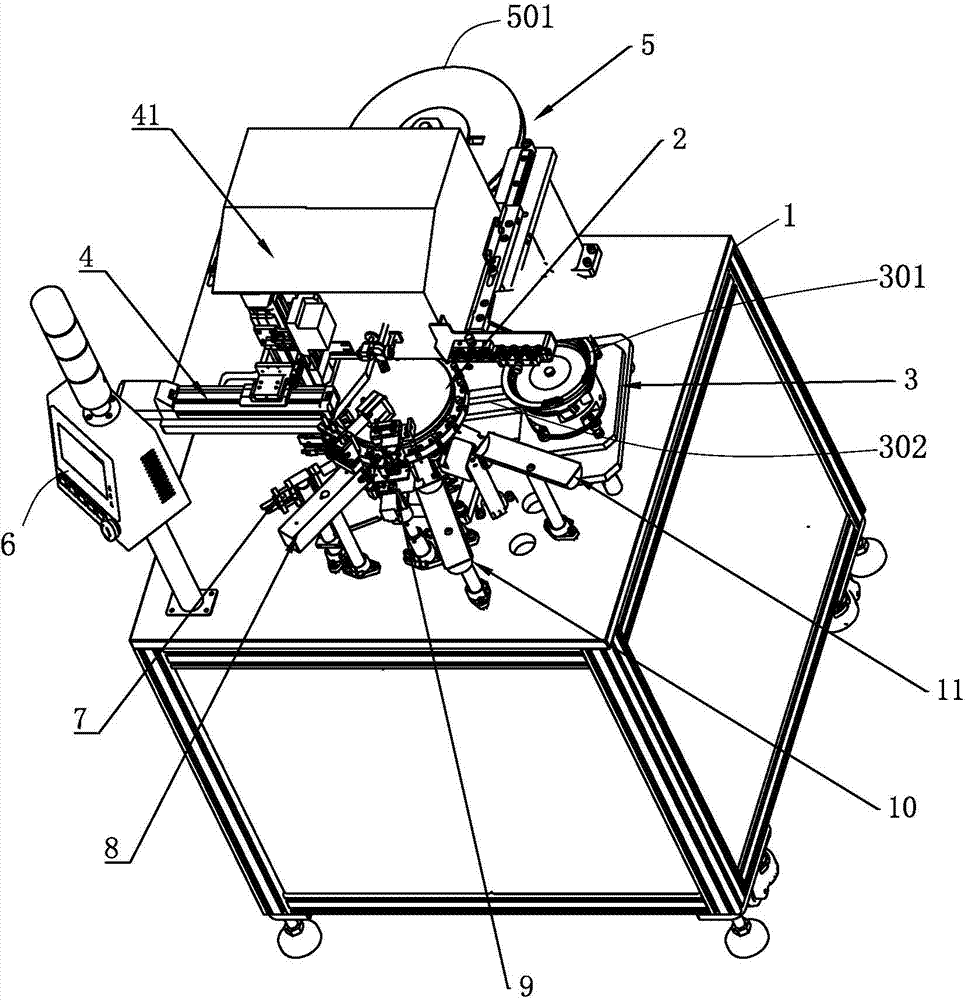

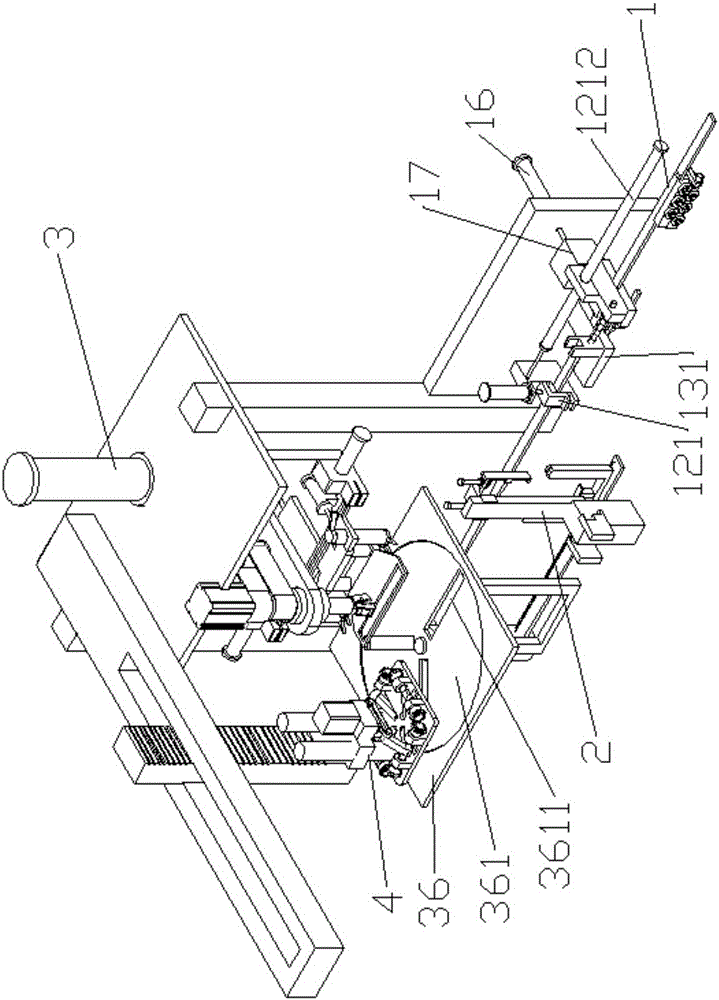

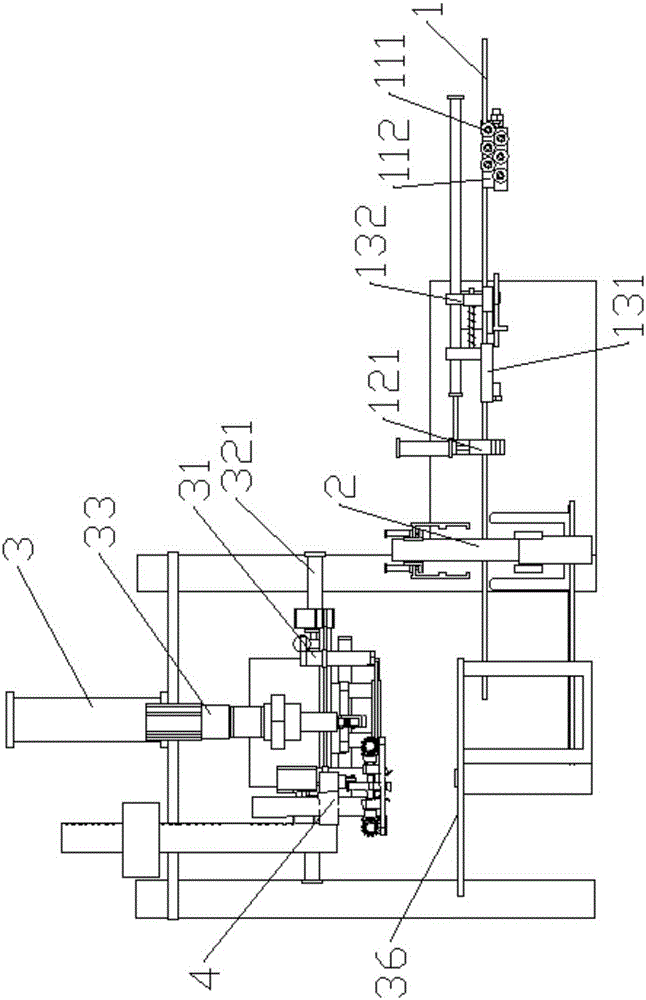

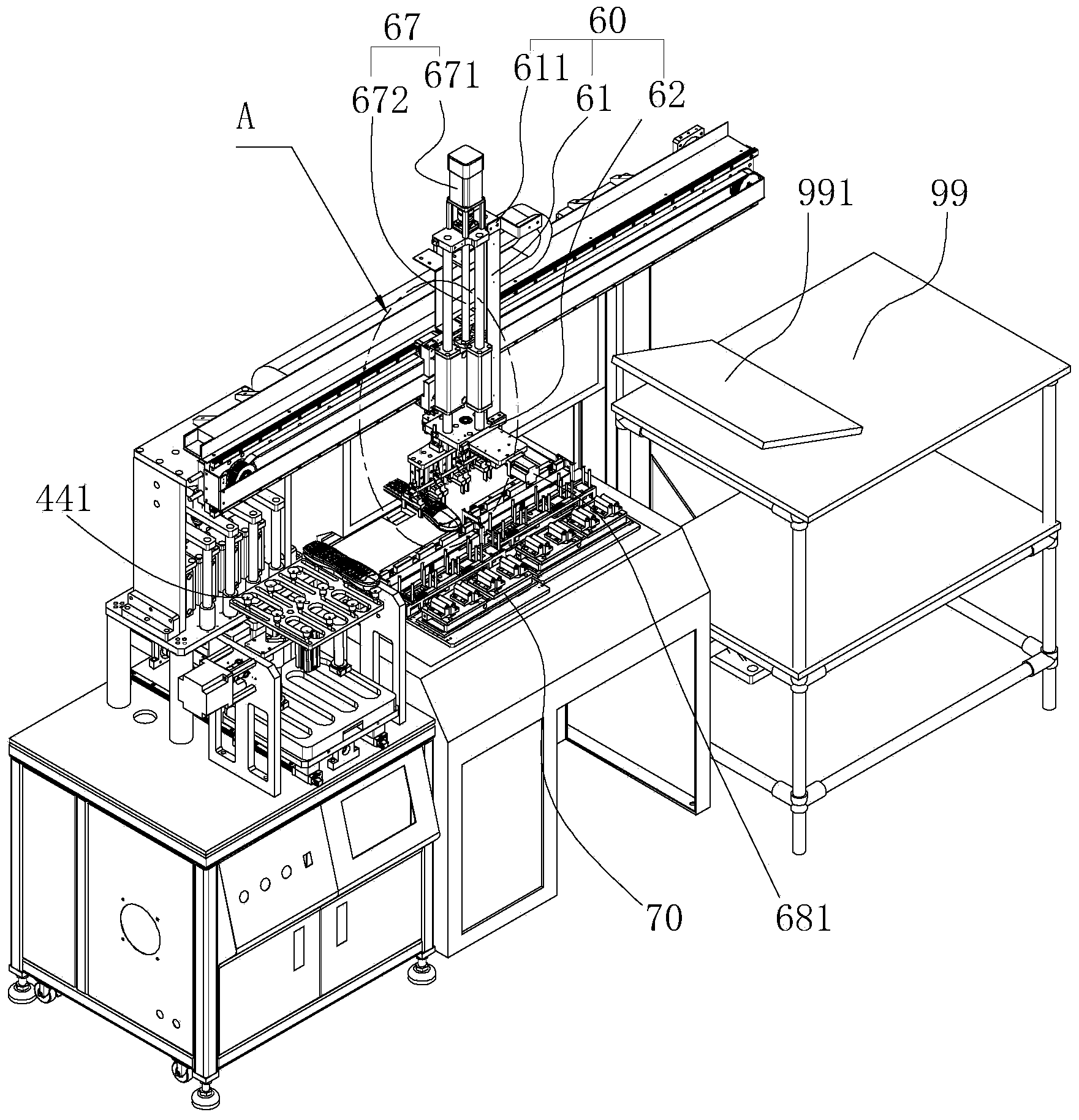

Full-automatic assembling device of puncture connector

ActiveCN103887683AImprove pass rateIncrease productivityContact member assembly/disassemblyElectrical controlEngineering

The invention discloses a full-automatic assembling device of a puncture connector and belongs to the technical field of electronic component assembling devices. The full-automatic assembling device of the puncture connector mainly comprises a machine frame, wherein a disc-shaped assembly working table is rotatably installed on the machine frame, and a plastic housing feeding device, a wire feeding device, a terminal feeding device, a breakover detection device, a marking device and a discharging device which are controlled by an electrical control device are sequentially arranged around the assembly working table. Steps of plastic housing feeding, wire feeding, terminal feeding, slitter edge folding, breakover detection, mark coating and discharging are sequentially finished, traditional manual operation is replaced, the assembly production efficiency of the puncture connector is improved, and the pass percent of an assembled connector is improved. The full-automatic assembling device is widely applied to the assembly working process of the puncture connector.

Owner:GOERTEK INC

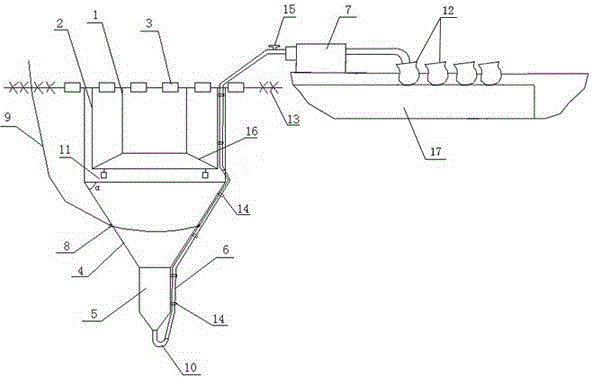

Low-carbon and environment-friendly fish-farming method

ActiveCN103548737AReduce pollutionReduce usageClimate change adaptationPisciculture and aquariaWater qualityAnimal feces

The invention discloses a low-carbon and environment-friendly fish-farming method. The method comprises the following steps: (1) performing cage culture in a pond and assembling a fish feces recovery system and a translation bottom sewage self-leaking system under a cage to recover fish feces, so that sewage and deposits at the bottom of the pond are discharged effectively, and pollution of fish feces and residual feeds on a water body is lowered; (2) arranging aeration equipment outside a cage culture zone to promote flow of the upper, lower and surface layers of the water body and increase dissolved oxygen of the water body; (3) planting aquatic plants in a floating bed and combining pond culture and wet land planting and culture outside the cage so as to realize coexistence of fishes and vegetables and biologically purify water; (4) performing scientific fish culture by adopting a scientific culture mode represented by seven words, namely, water, planting, feed, prevention, separation, mixing and labor. According to the low-carbon and environment-friendly fish-farming method, the current-stage pond fish culture facility is changed, engineering of innovative culture equipment is realized, scientific design and scientific layout are achieved, scientific combination of comprehensive technologies such as physical and biological purification and the like is performed, combination with an ecological and environment-friendly culture technology is realized, and integrated innovation is implemented.

Owner:天津通威饲料有限公司

Strapping machine

InactiveCN105173171ARealize mechanized operationRealize bundlingBundling machine detailsStrap deviceEngineering

The invention discloses a strapping machine. The strapping machine comprises a containing table used for containing objects to be strapped, a line feeding device used for feeding a stripping line to the position below the objects to be strapped and a strapping device used for strapping the objects to be strapped through the stripping line. The strapping machine is characterized in that the strapping device is located above the containing table and comprises two strapping line clamping devices, a strapping transverse movement mechanism for controlling the two strapping line clamping devices to transversely move, a rotary line clamping device and a rotary mechanism for controlling the rotary line clamping device to rotate; and the two strapping line clamping devices are located on the two sides of the rotary line clamping device respectively. The strapping machine has the beneficial effects that the structure is simple, and the objects to be strapped, in particular to an annular object, can be strapped through a metal wire.

Owner:屈统撑

Manufacturing method of relief silverware

ActiveCN102922936AImprove appearance qualityGuarantee the appearance qualitySpecial ornamental structuresSilver plateAdhesive

The invention relates to the field of processing of silverware and specifically relates to a manufacturing method of relief silverware, which can solve the problems of low work efficiency, low degree of mechanization, poor appearance quality and the like of conventional manual manufacturing of the silverware. The manufacturing method comprises the following steps: melting silver water; casting a silver blank; forging and pressing the silver blank into a thin silver plate with the thickness being 0.3-1mm on a forging and pressing machine; stamping the thin silver plate to form the basic contour of all parts of the silverware on a rotary stretch forming machine; welding all the parts by adopting welding materials according to the shape requirements of the silverware, and forming a matrix of the silverware; casting a filling adhesive into the matrix of the silverware, cooling and then forming a plastic support; carving flowers or patterns; removing the plastic support; washing; and grinding and polishing. The manufacturing method disclosed by the invention can not only inherit a quantity of traditional processes of old folk silversmiths, but also integrate with modernized devices and processes; and during the manufacturing process, the forging and pressing machine and a stretch forming machine are utilized, the structure is simple, the design is reasonable, the operation is simple and convenient, the mechanized operation of forging, pressing and forming of a silver plate can be realized, the operation is time-saving and labor-saving, the efficiency is high, and high-efficiency and fine manufacturing requirements in manufacturing of the silverware can be met.

Owner:繁峙县星河银业有限公司

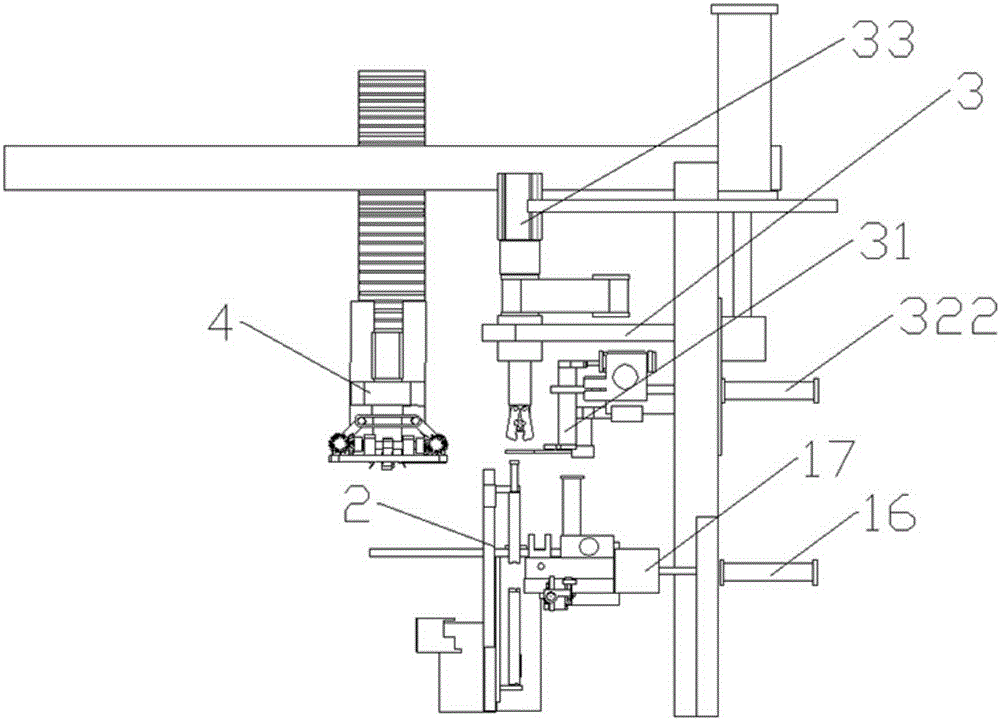

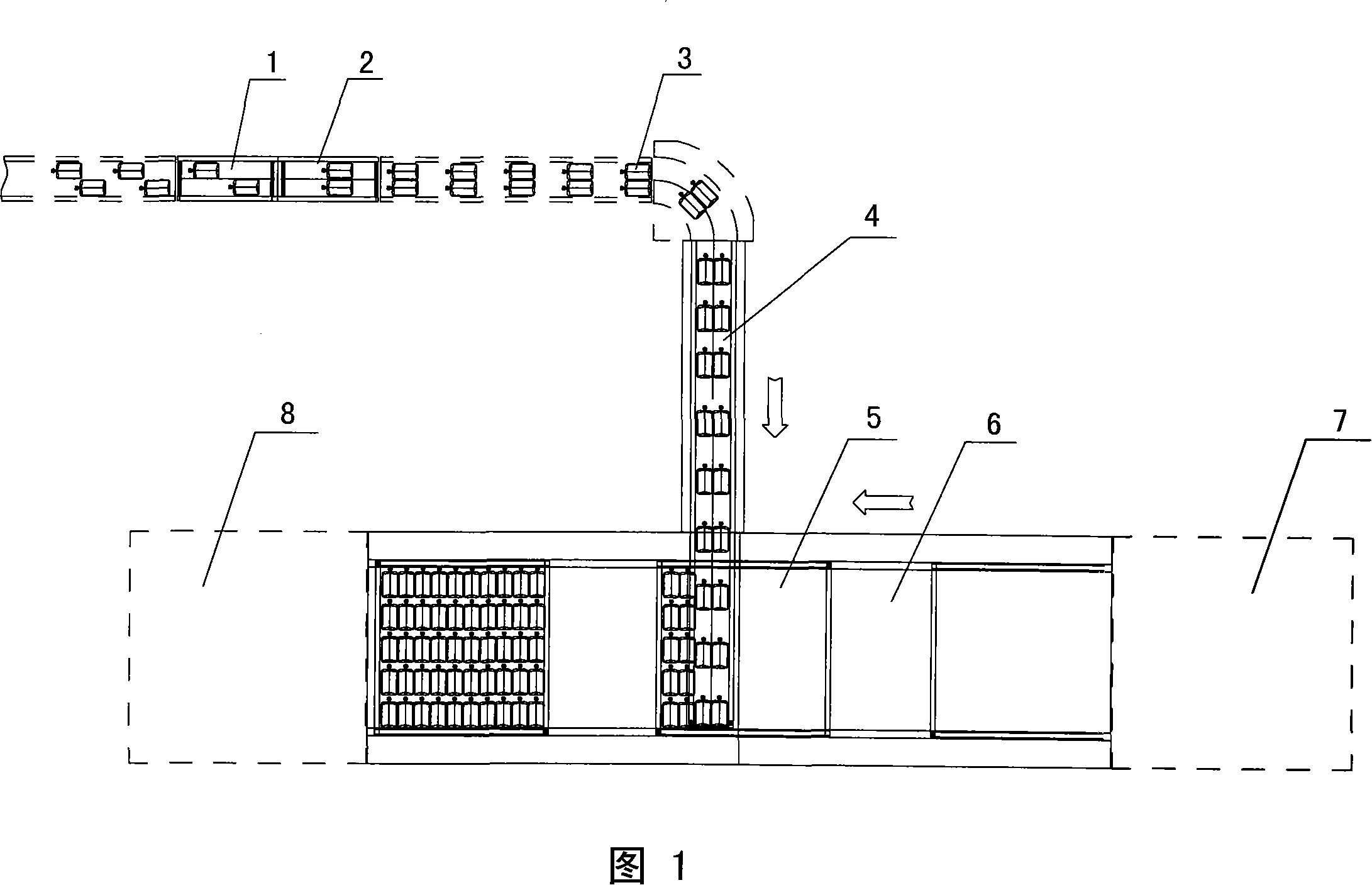

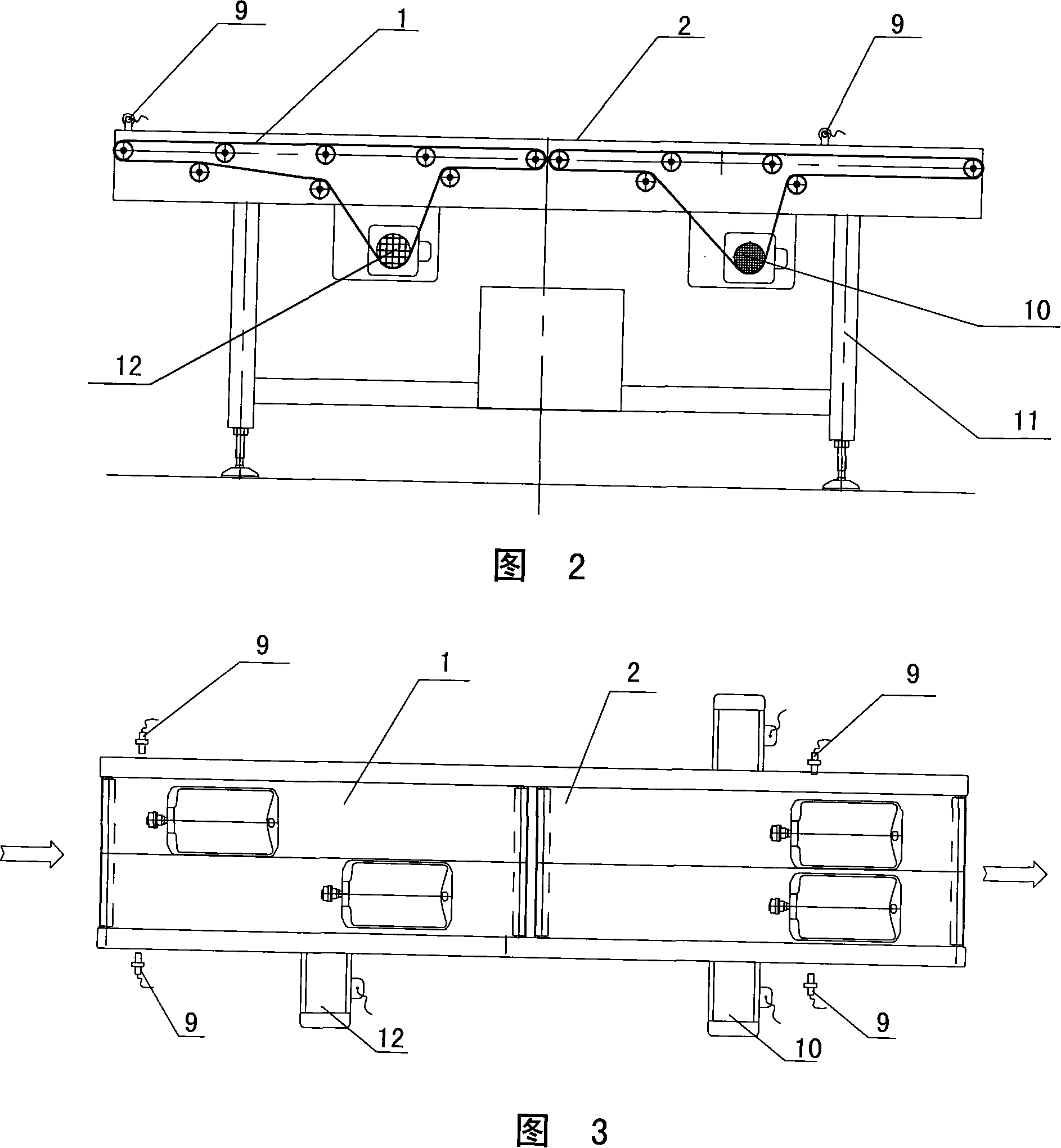

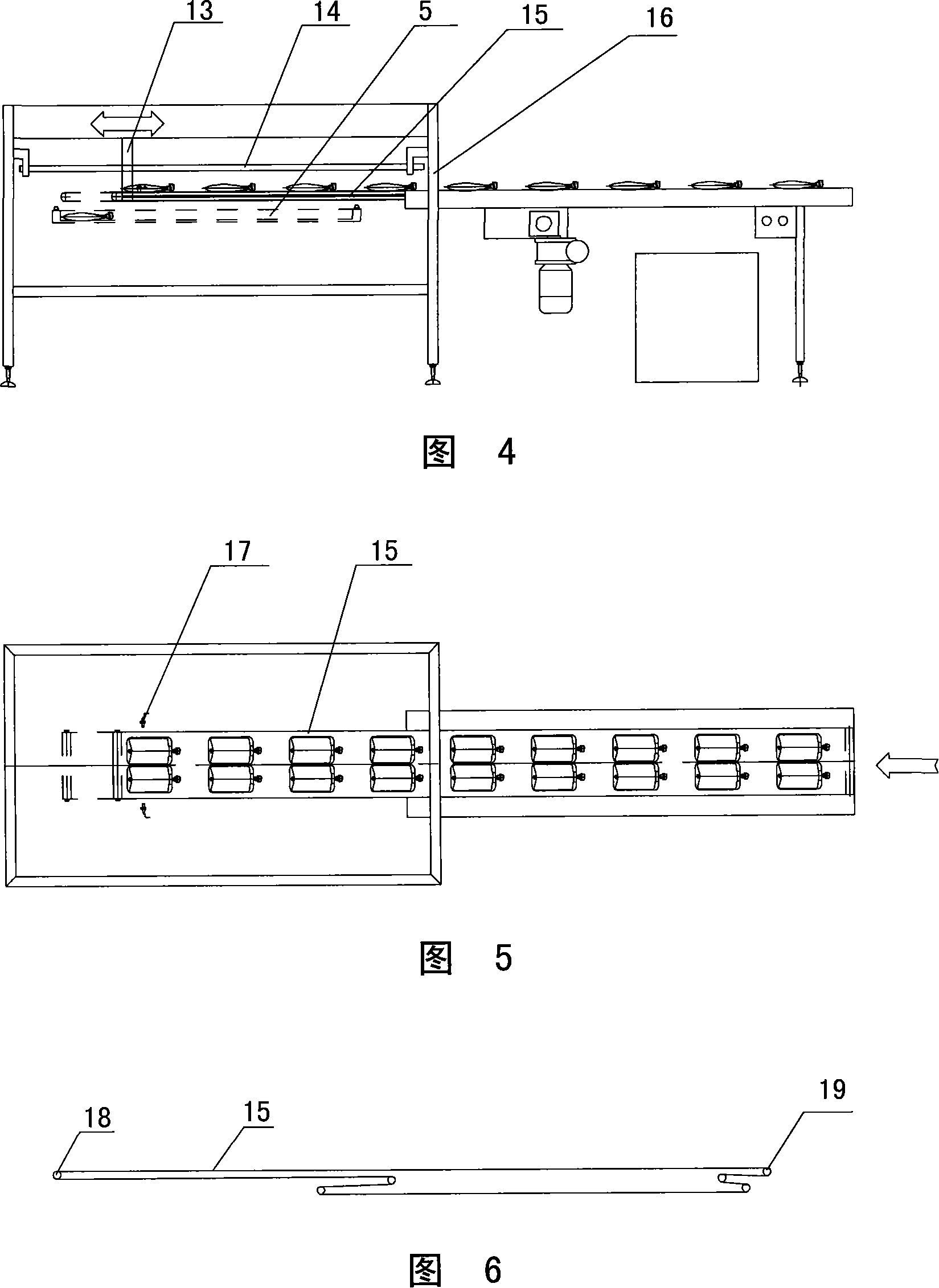

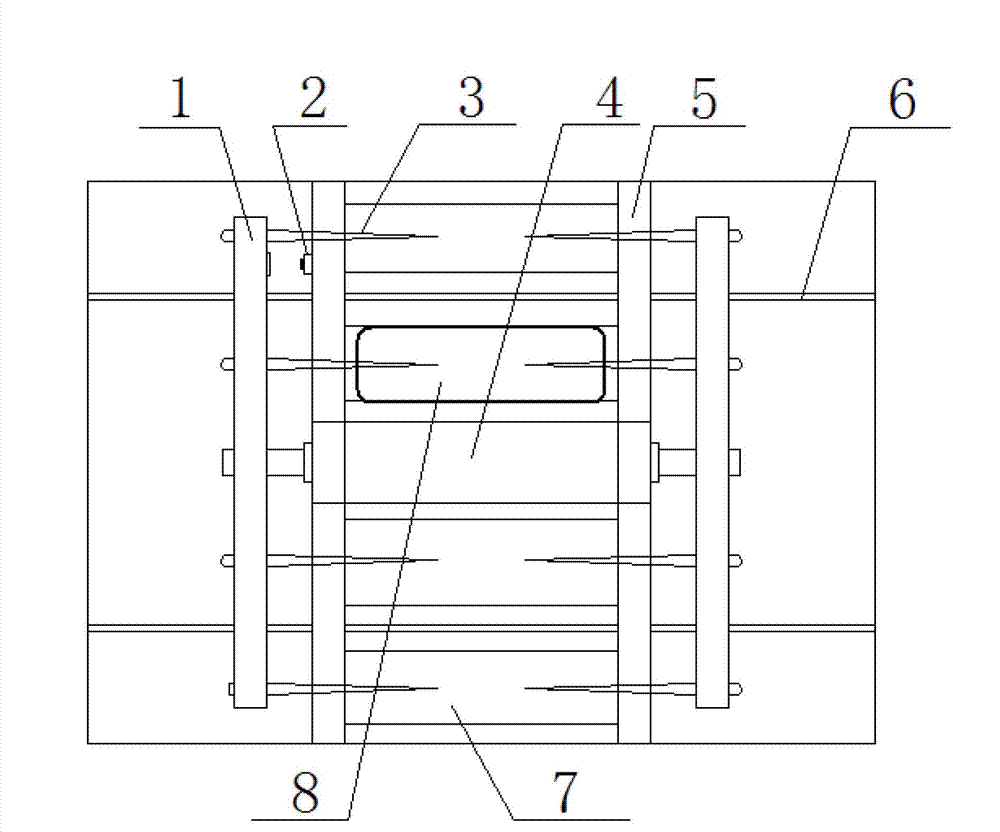

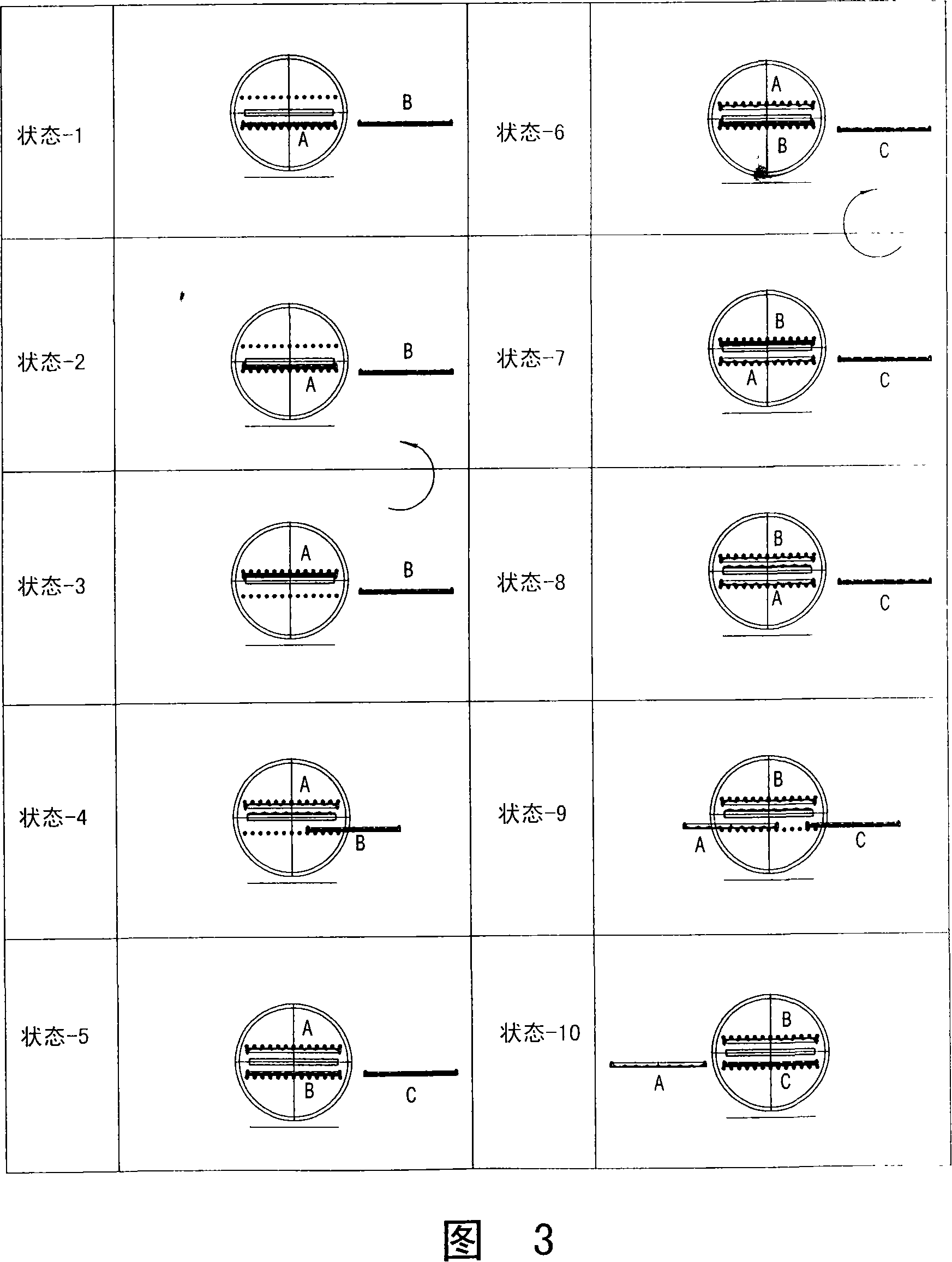

Automatic disk loading system of soft bag

ActiveCN101130388AReasonable structureRealize mechanized operationPackage sterilisationIndividual articlesDisk loadingEngineering

The invention relates to an automatic loading system for soft bag used for automatic loading for infusion soft bag in pharmaceutical production, comprising machine frame, soft-bag feeding device, soft-bag arranging and queuing device, bag swing device, feeding device for sterilization disk and power device. The soft-bag arranging and queuing device is docked with the bag swing device and the feeding belt of bag swing device is vertical to the feeding orbit of sterilization disk. Thereinto, the soft-bag arranging and queuing device comprises coordinated front and back feeding belts. The front feeding belt is docked with the back feeding belt. Power pulleys are set on the front feeding belt and the back feeding belt respectively. The bag swing device comprises expanding belt feeding machine and reciprocating moving mechanism. The expanding belt feeding machine comprises feeding belt, moving pulley and fixed pulley. The ring feeding belt is around the moving pulley and the fixed pulley in order. The invention is provided with reasonable structure and can take the place of manual work. The invention realizes mechanical operation and saves labor force. The invention improves producing efficiency and avoids contact of too many people. The invention also guarantees drug quality.

Owner:SHINVA MEDICAL INSTR CO LTD

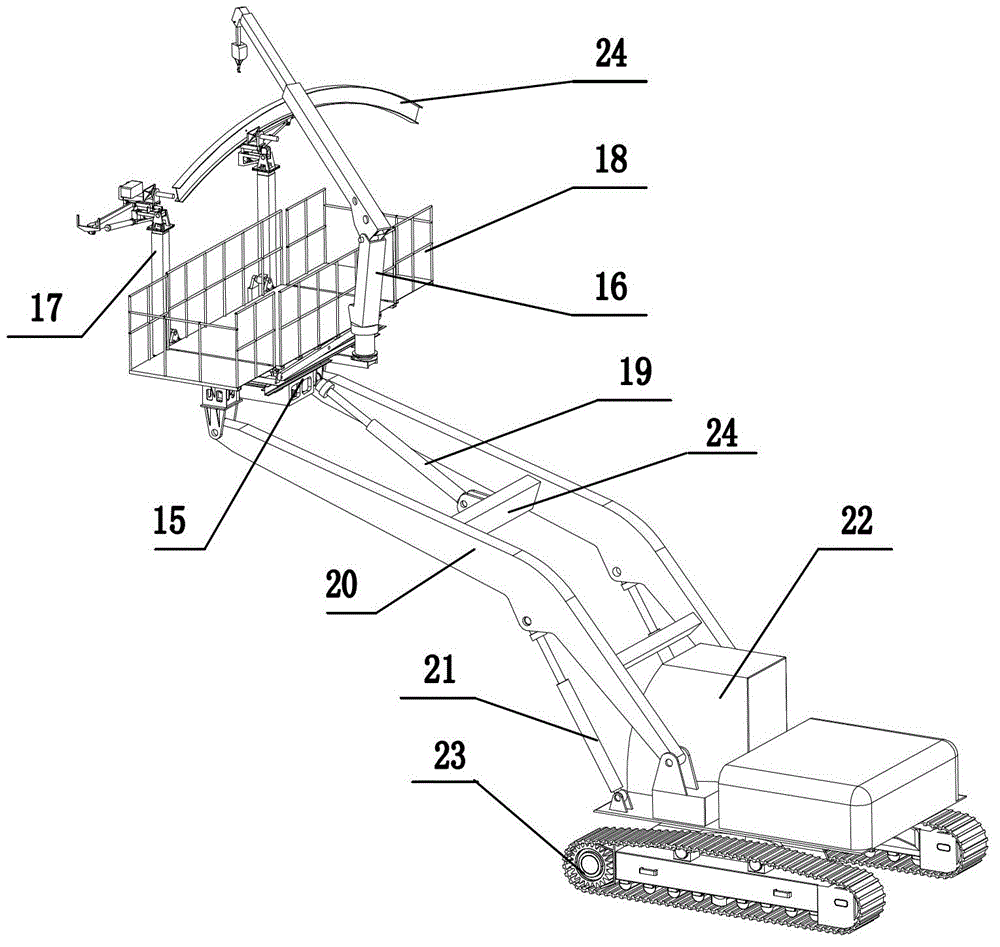

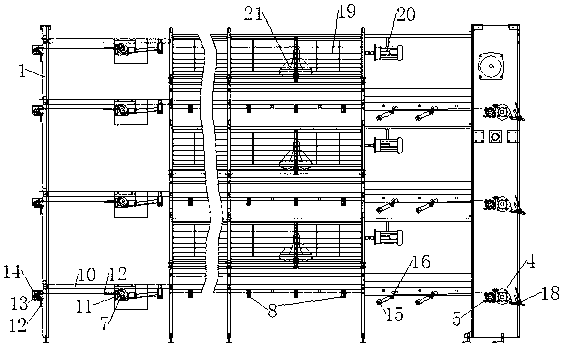

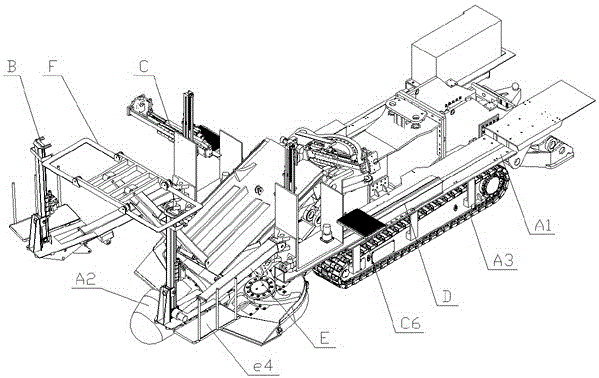

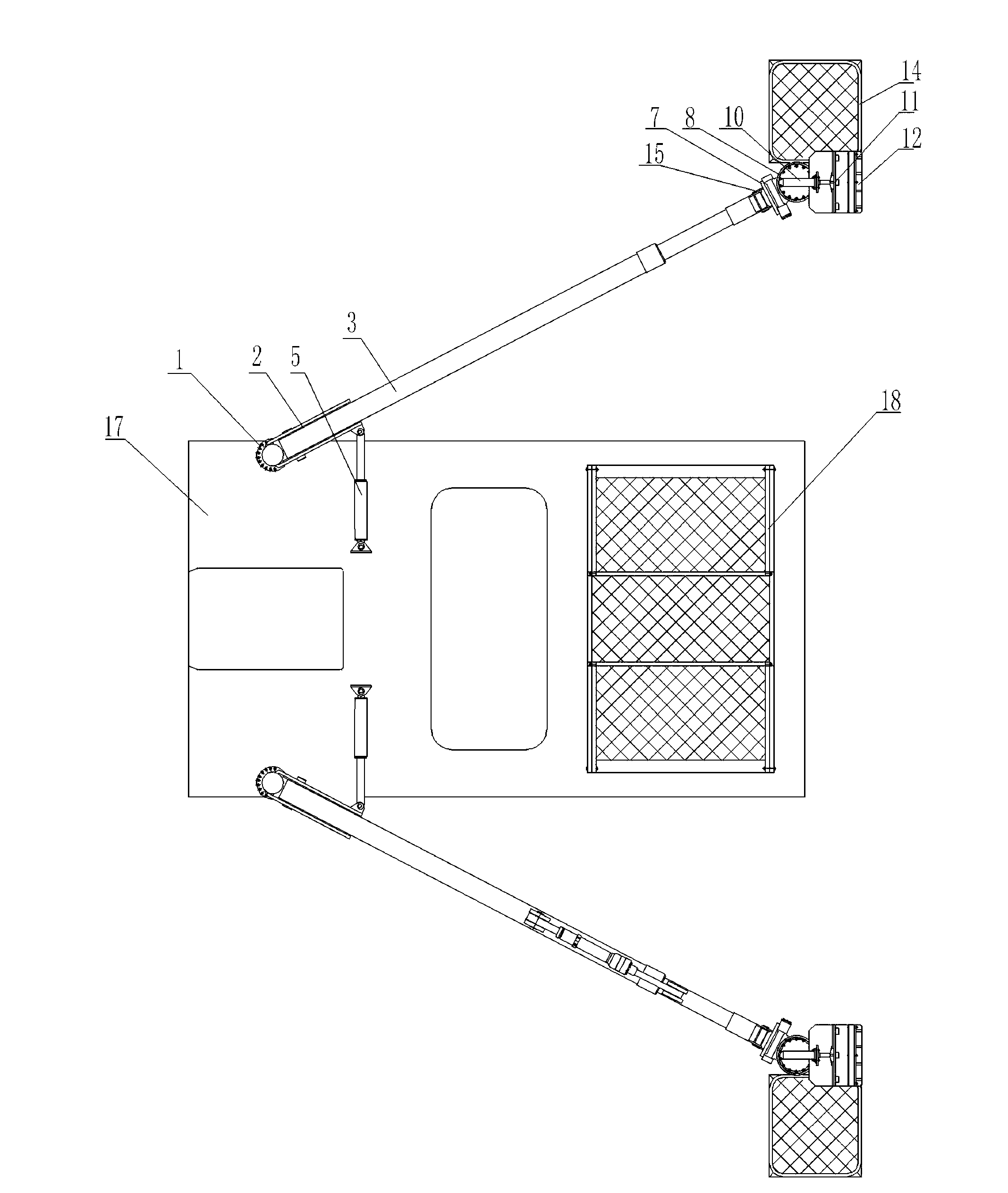

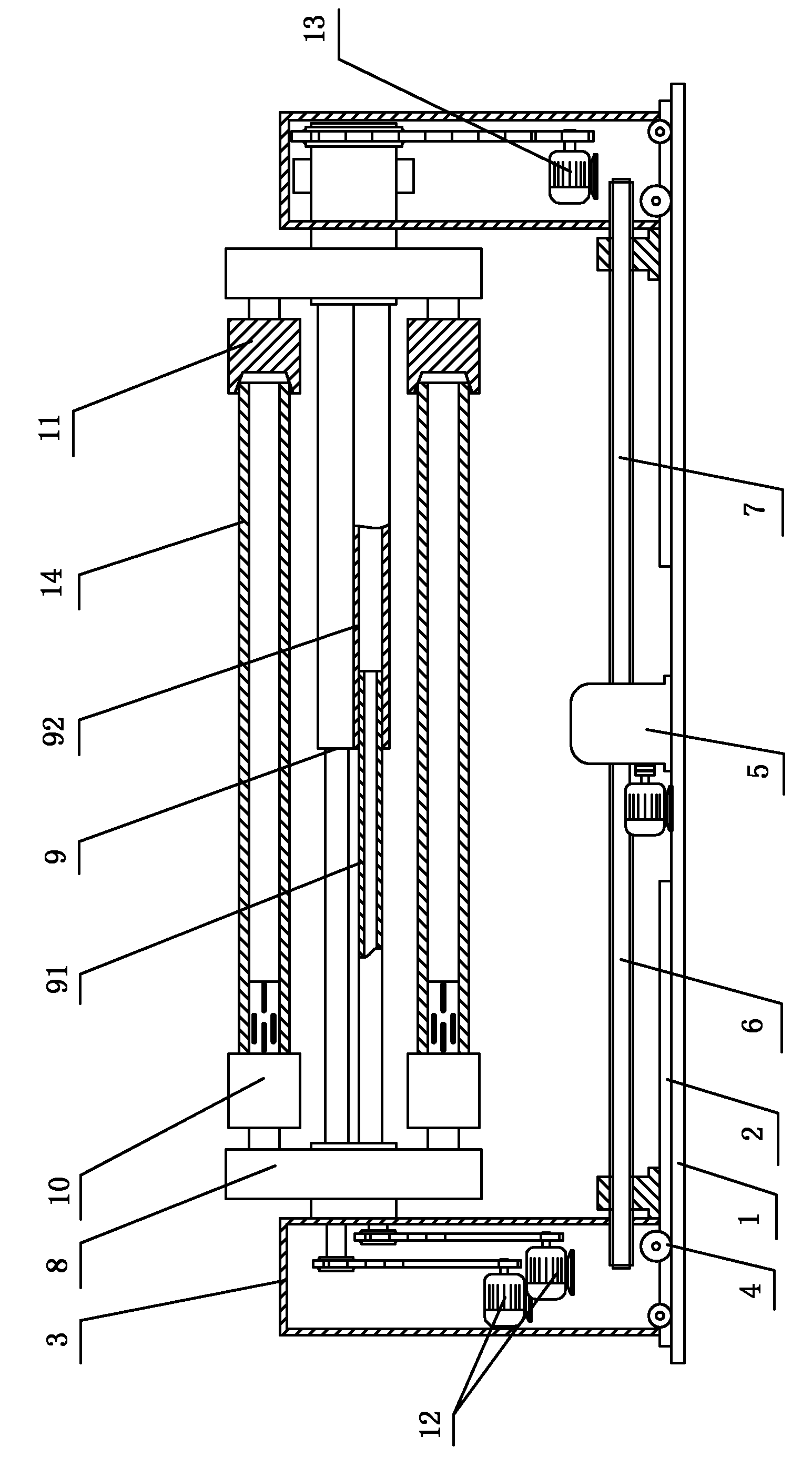

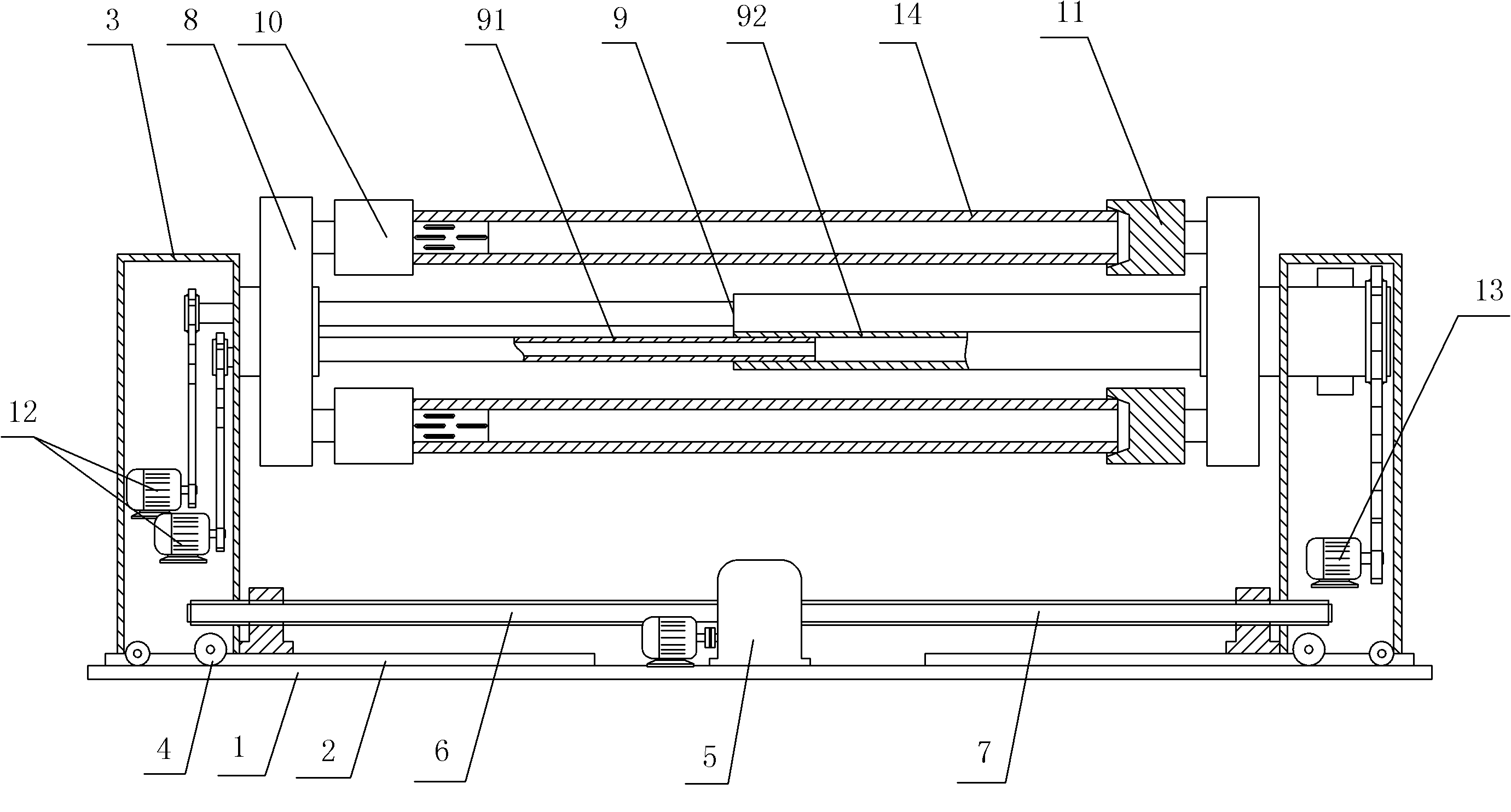

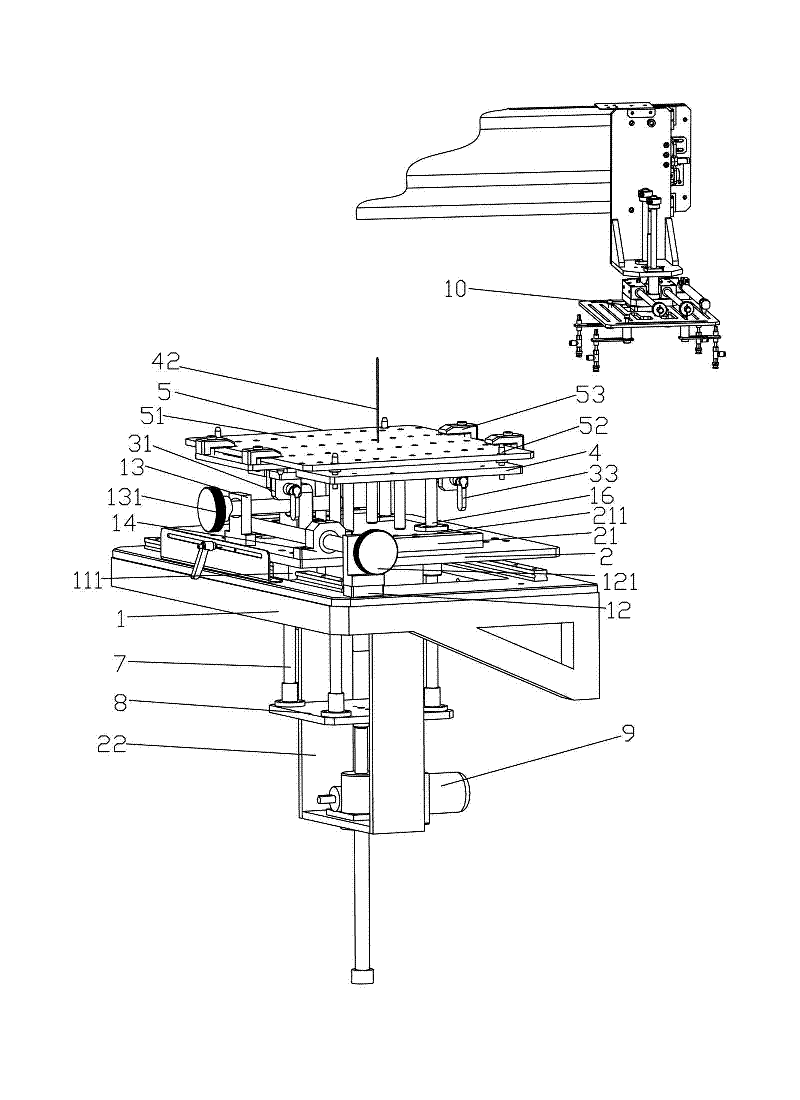

Multi-functional tunnel operation trolley

InactiveCN102748039ARealize mechanized operationAchieve fine-tuningUnderground chambersManipulatorHydraulic ramTruck

The invention discloses a multi-functional tunnel operation trolley, which comprises a chassis, a host platform and double movable arms, wherein the host platform is arranged on the chassis and is connected with the double movable arms through hinges; the double movable arms are rigidly connected through two connecting bridges; two movable arm hydraulic oil cylinders which synchronously act are arranged between the host platform and the double movable arms; the two ends of the movable arm oil cylinders are hinged with the host platform and the double movable arms respectively; the end parts of the double movable arms are hinged with a mounting platform; a leveling hydraulic oil cylinder is arranged between the mounting platform and the connecting bridges of the double movable arms; and the mounting platform is provided with a lifting platform, a truck mounted crane and a multidirectional adjusting manipulator. The multi-functional tunnel operation trolley has the technical effects that mounting work of an arching can be finished by only two or three operation staffs, mechanical operation of mounting of the arching can be realized, an I steel arching and a grid arching can be clamped and then lifted to any position in a tunnel, quick mounting is realized, the construction time is saved, the working efficiency is increased and other construction operations are facilitated.

Owner:湖南江麓实业发展有限公司

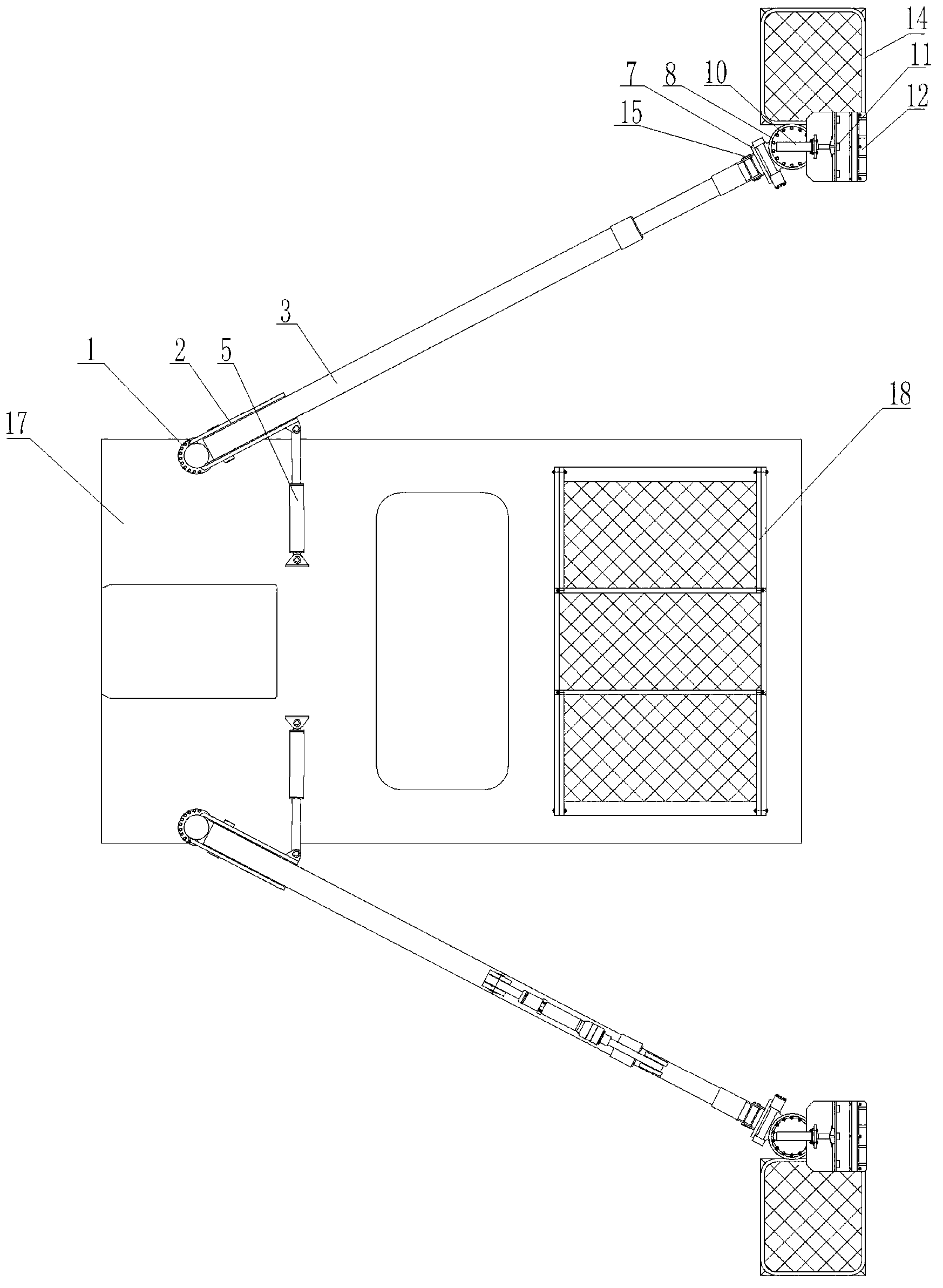

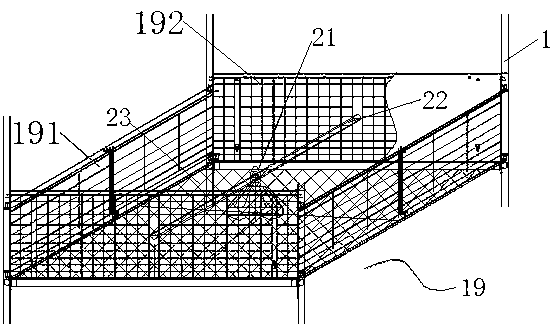

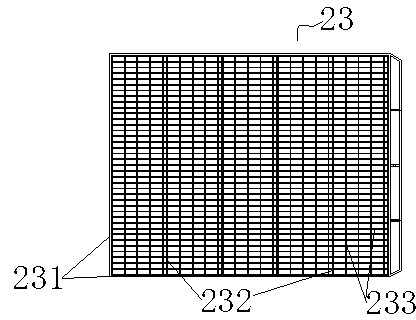

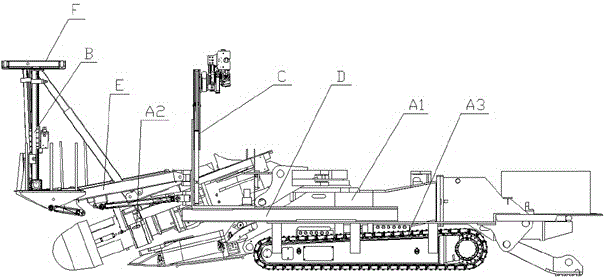

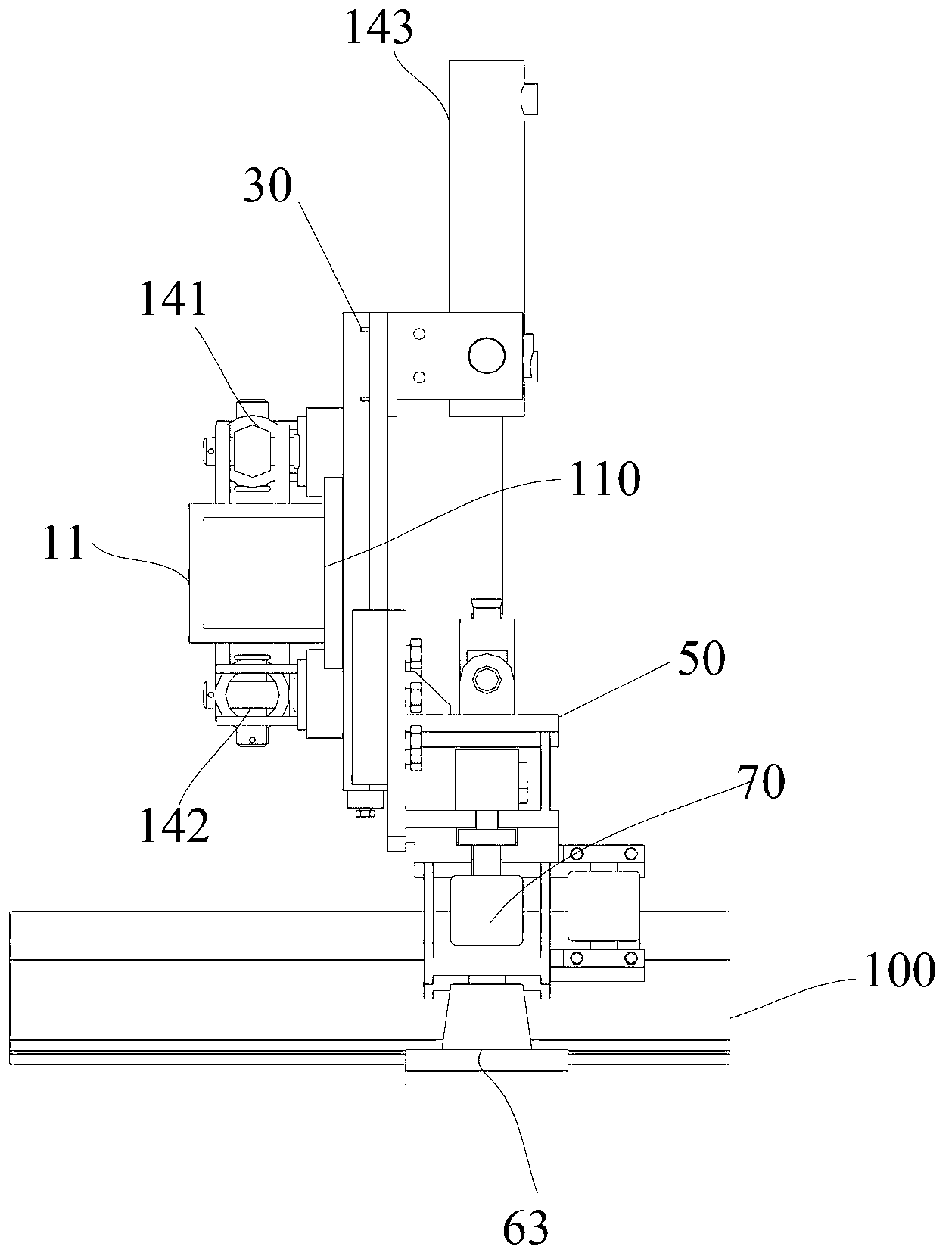

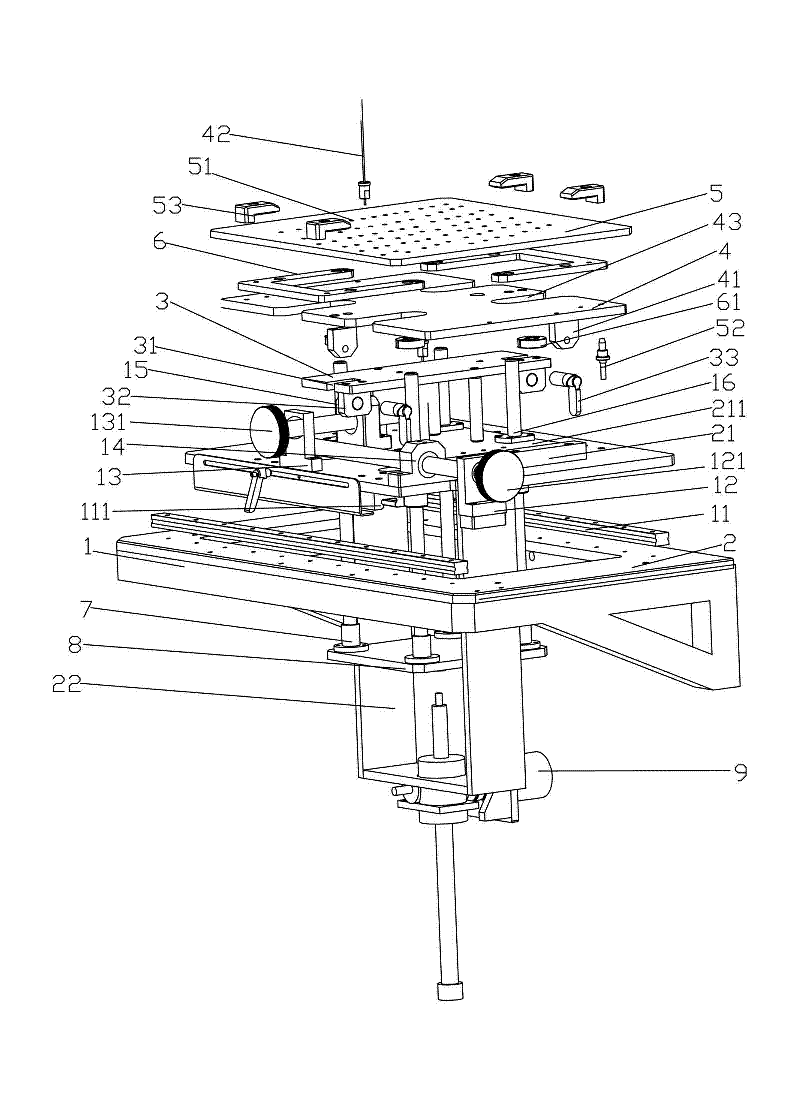

Multifunctional support trolley for tunnel arches

InactiveCN103244151ALabor savingImprove securityUnderground chambersTunnel liningManipulatorEngineering

The invention discloses a multifunctional support trolley for tunnel arches. A scissor lifting table is installed on a trolley platform, general purpose manipulators special for tunnels are installed on two sides of the trolley platform, each general purpose manipulator special for tunnels comprises a telescopic boom, one ends of the telescopic booms are mounted on telescopic boom rotating stands, and the telescopic boom rotating stands are provided with rotating seats and telescopic boom rotating hydraulic cylinders; and one ends of derricking cylinders are installed on the telescopic boom rotating stands, the other ends of the derricking cylinders are installed on the telescopic booms, and manipulators are installed at front ends of the telescopic booms. The multifunctional support trolley has the advantages that installation work of the arches can be finished only by three or four operators, and labor force is saved; the mechanized operation during installation of the arches can be achieved; I-beam arches and grid arches can be lifted to any position in tunnels after being clamped, and arches can be fine adjusted rapidly in all directions; general purpose manipulators special for left and right tunnels work simultaneously, so that rapid installation is facilitated, construction time is greatly saved, and the working efficiency is improved; and the scissor lifting table is installed on the trolley platform, so that other construction operations and tunnel defect treatment besides arch installation are facilitated.

Owner:湖南江麓实业发展有限公司

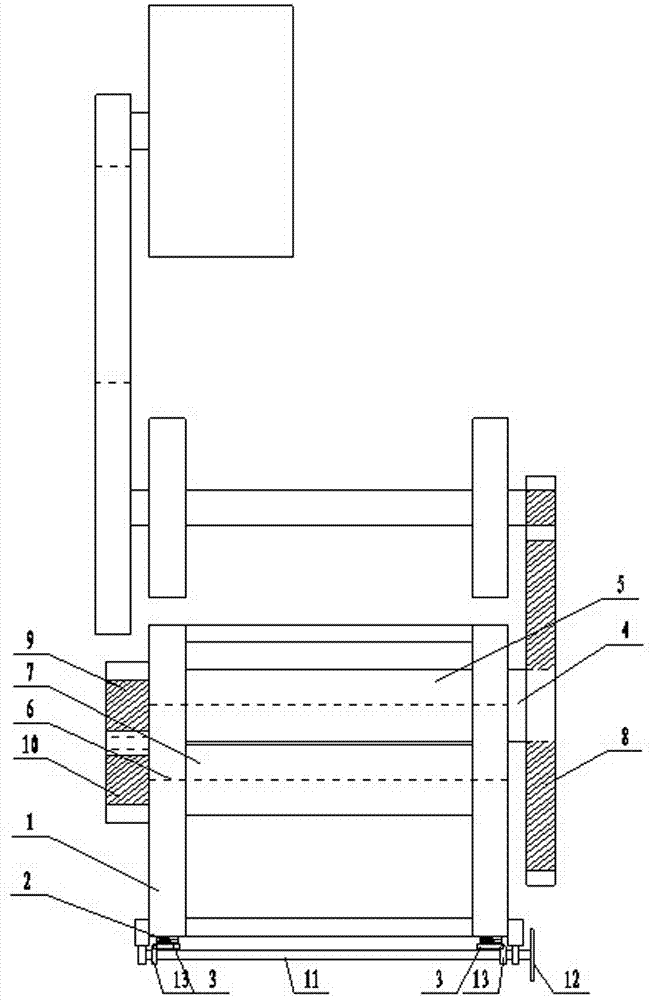

Broiler breeding equipment

ActiveCN103053438AIncrease stocking densityReduce the labor intensity of feedingBird housingsEngineeringWater drinking

The invention discloses broiler breeding equipment. The broiler breeding equipment is characterized by comprising a coop frame, wherein one or more coop layers are arranged on the coop frame, and one or more coops are juxtaposed on each of the coop layers; each of the coop layers is provided with a feeding conveying pipeline, a feeding driving motor, a feeding hopper and a water drinking system; a feeding disc is arranged in each of the coops; a belt-type manure cleaning system is arranged below each of the coop layers; a coop bottom net is arranged on each of the coops, and the coop bottom nets are plastic bottom nets; a sliding structure is arranged between each of the coop bottom nets and the coop frame; a broiler feeding belt is arranged at one end of the coop frame; and the boiler feeding belt is connected with a broiler packing box. The broiler breeding equipment disclosed by the invention is convenient in production, low in cost, mechanical to unload the broilers, and capable of improving working efficiency and reducing feeding labor intensity.

Owner:广州市华南畜牧设备有限公司

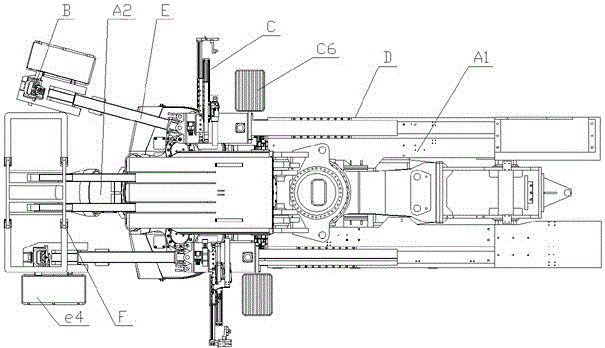

Tunneling, anchoring and supporting all-in-one machine

The invention provides a tunneling, anchoring and supporting all-in-one machine and belongs to the technical field of coal mining equipment. On account of the defects that existing tunneling, anchoring and supporting all-in-one machines are low in working efficiency, high in labor intensity and high in danger level, structural improvement is conducted. The tunneling, anchoring and supporting all-in-one machine structurally comprises a cantilever tunneling machine, drilling and anchoring systems and a temporary supporting mechanism. The cantilever tunneling machine comprises a body part, a cutting part located at the front end of the body part, and a caterpillar band traveling part located under the body part. The number of the drilling and anchoring systems is two, and the two drilling and anchoring systems are symmetrically arranged on the left side and the right side of the body part of the cantilever tunneling machine. Each drilling and anchoring system comprises a top anchor mechanism and a side anchor mechanism arranged front and back, and the top anchor mechanism and the side anchor mechanism of each drilling and anchoring system are fixedly installed on the body part of the cantilever tunneling machine through a longitudinal moving mechanism. Furthermore, each top anchor mechanism is installed on the corresponding longitudinal moving mechanism through a cantilever overturn mechanism. Structural improvement is conducted on the top anchor mechanisms, the side anchor mechanisms and the temporary supporting mechanism, and the application range of the tunneling, anchoring and supporting all-in-one machine is widened.

Owner:ZOUCHENG TIANHE SCI & TECH

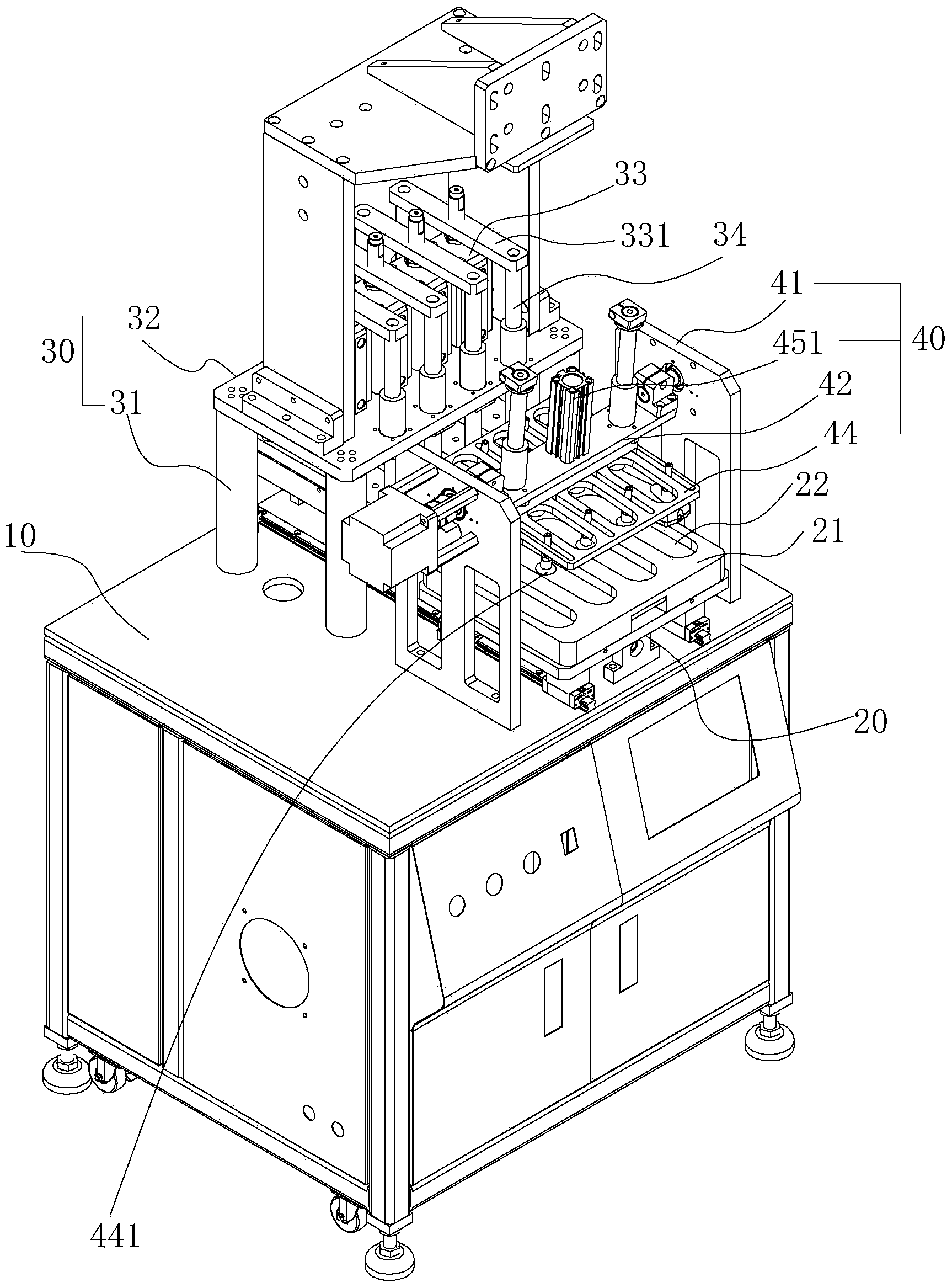

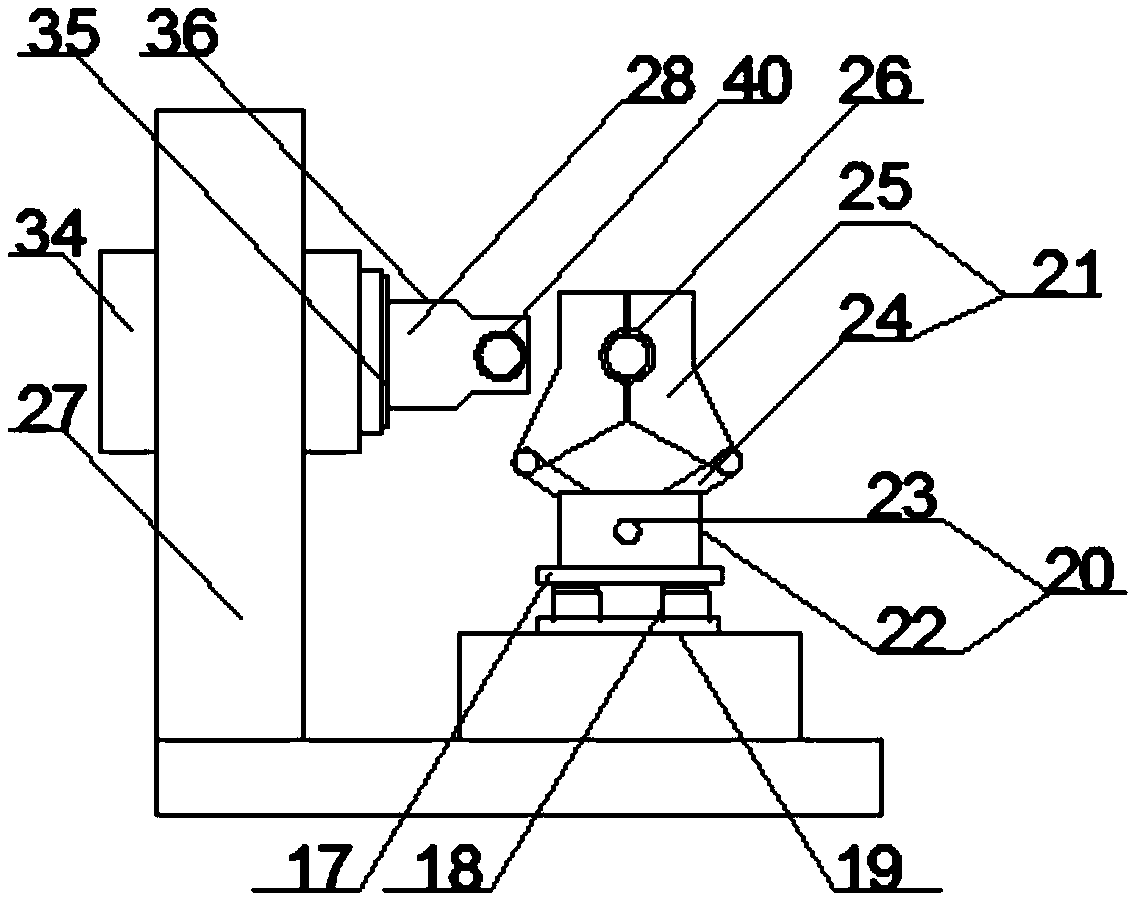

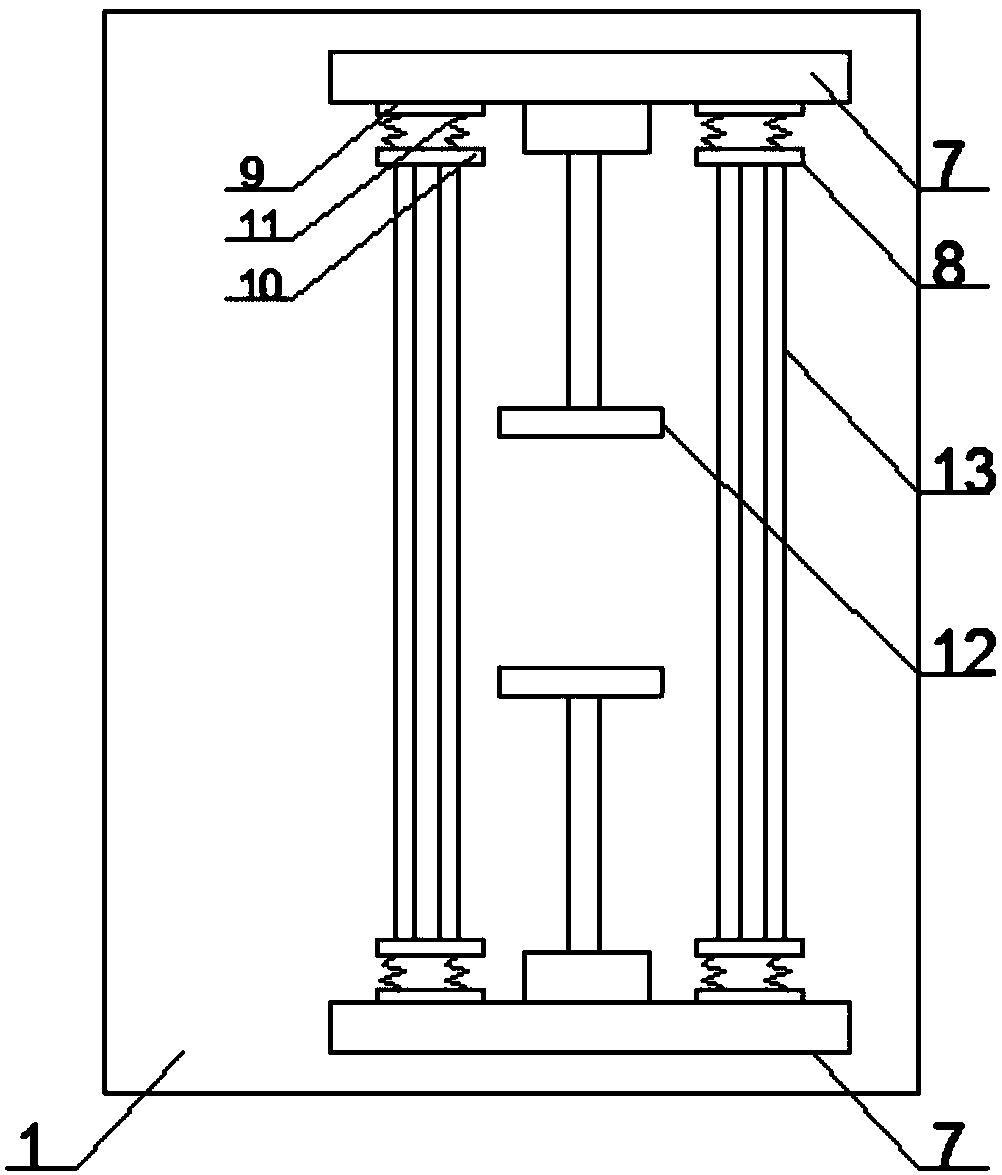

Press-fit device

InactiveCN103722375AAutomate operationRealize integrated layoutAssembly machinesTest efficiencyEngineering

The invention discloses a press-fit device which comprises a machine base. A longitudinal sliding table mechanism and a frame-shaped support are arranged on the machine base. The frame-shaped support comprises uprights located at the two sides of the longitudinal sliding table mechanism and an upper fixing board connected with the upper ends of the uprights at the two sides. The longitudinal sliding table mechanism is provided with a jig and a workpiece lower cavity is formed in the jig. A press-fit power piece and a press-fit guide mechanism for guiding the press-fit power piece are fixed to the portion above the upper fixing board. The movable end of the press-fit power piece is connected with an upper press-fit board. The press-fit power piece moves downwards, so that a workpiece in the jig is assembled in a press-fit mode. According to the press-fit device, the workpiece which needs to be pressed in the fit mode is fixed through the jig, press-fit assembly is completed through the press-fit power piece driven by an air cylinder or a motor, mechanical operation is achieved, the press-fit efficiency is improved, the labor cost is saved, the workpiece is automatically pressed in the fit mode, obtained and tested, the labor cost is saved, the assembly and test efficiency is improved, integrated arrangement of a production device is achieved, and the space of a production field is saved.

Owner:SHENZHEN RAPOO TECH

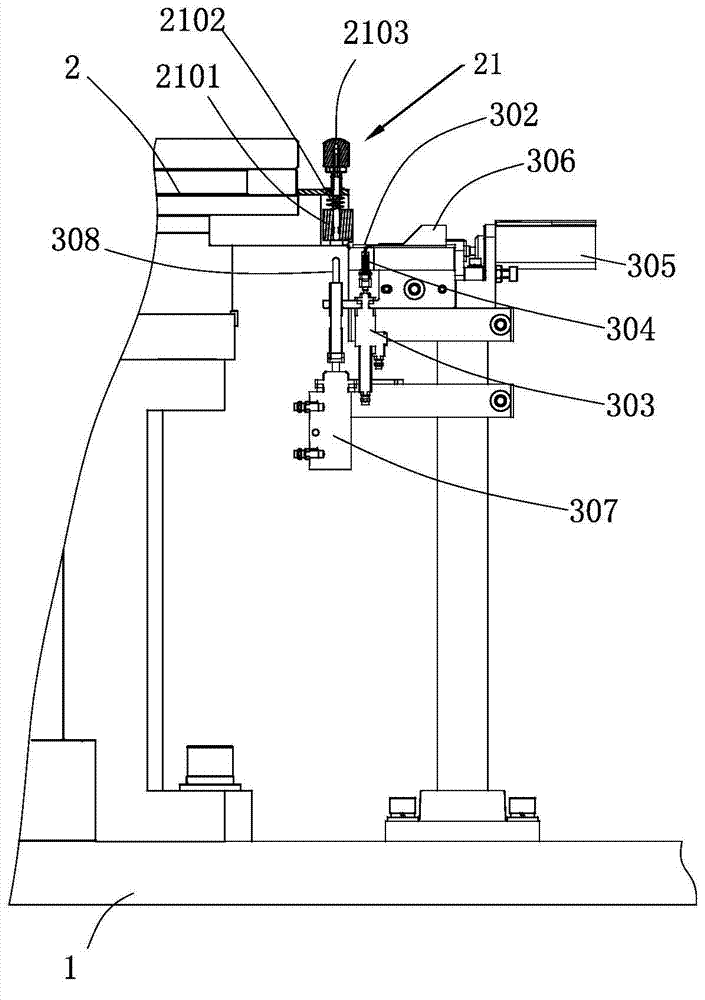

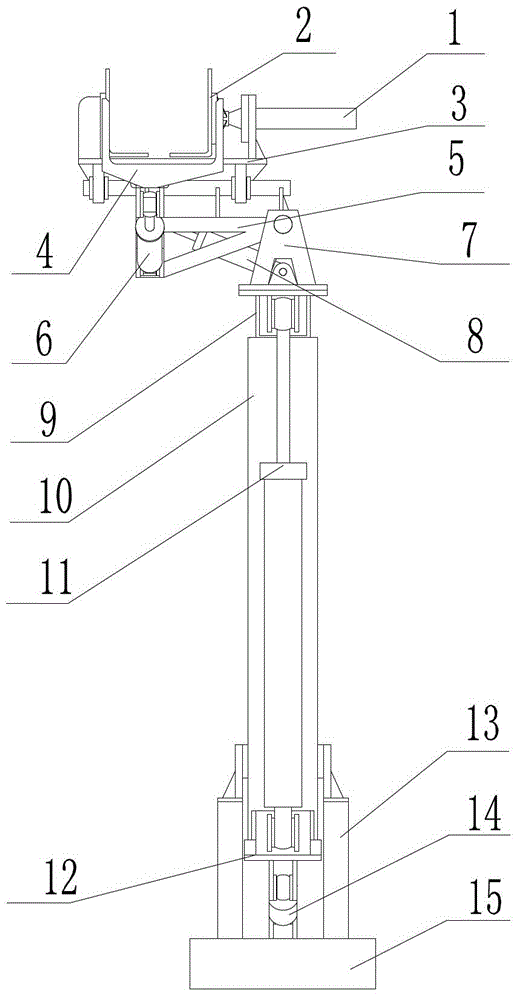

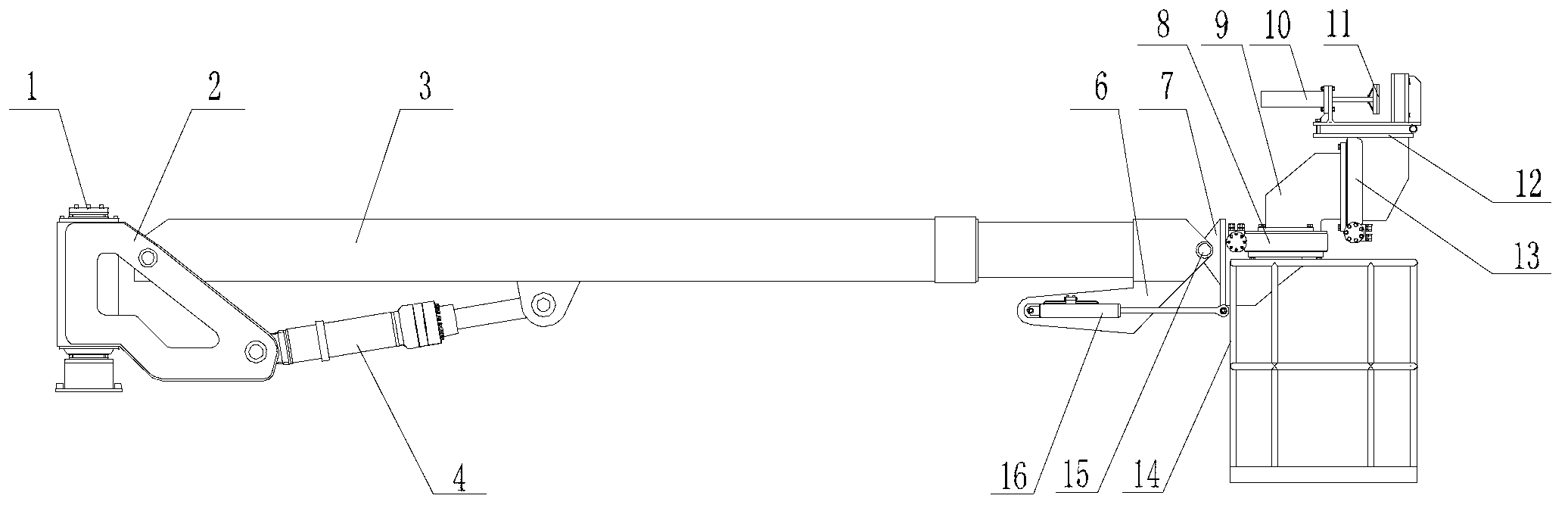

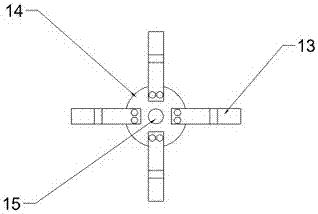

All-round manipulator special for tunnels

InactiveCN103291330ARealize mechanized operationAchieve fine-tuningUnderground chambersTunnel liningEngineeringStructural engineering

The invention discloses an all-round manipulator special for tunnels. The all-round manipulator special for tunnels comprise a telescopic arm. One end of the telescopic arm is mounted on a telescopic arm rotary support which is provided with a rotating base. The telescopic arm rotary support is provided with a telescopic arm rotary cylinder. One end of a luffing cylinder is mounted on the telescopic arm rotary support, and the other end of the luffing cylinder is mounted on the telescopic arm. A manipulator is mounted at the front end of the telescopic arm. The all-round manipulator special for tunnels has the advantages that the all-round manipulator special for tunnels is mounted on a tunnel arch support trolley, an arch can be mounted by only three or four operators, and labor is saved; mechanical arch erection can be realized, and safety is greatly improved for workers; after I-beam arches and grid arches are clamped, the arches are lifted to any position in a tunnel, the arches can be quickly finely adjusted in front-back, left-right and up-down directions; the left and right all-round manipulators special for tunnels are operated simultaneously, fast mounting can be achieved, construction time is saved greatly, and work efficiency is improved.

Owner:湖南江麓实业发展有限公司

Free-open-close turnover shaft-less film winding device

InactiveCN102139816AEasy loading and unloadingAdjustable axial distanceWebs handlingEngineeringAxial distance

The invention provides a free-open-close turnover shaft-less film winding device, relates to a film winding device, and is mainly used for solving the problem that a winding shaft needs to be extracted during the film winding process. The film winding device comprises a winding support, a turnover device and a transmission device, wherein, the winding support comprises a base, guide rails, sliding supports and a sliding connection device, the guide rails are respectively fixed on two ends of the base, the sliding supports are arranged above the guide rails, the bottom parts of the sliding supports are equipped with pulleys matched with the guide rails, and the sliding connection device is fixed between the two sliding supports through nuts; and the turnover device comprises turnover frames, clamping heads and a connecting shaft, the connecting shaft is fixed between the two turnover frames, the upper side and the lower side of the connecting shaft are equipped with the clamping heads fixed on the turnover frames, and the other sides of the turnover frames are fixed at the upper parts of the sliding supports. The free-open-close turnover shaft-less film winding device has the beneficial effects that a paper tube is directly sheathed on the clamping heads without the winding shaft during the winding process, thus being convenient for feeding and discharging; and the connecting shaft is telescoping so as to adjust axial distance, thus being applicable to the paper tubes with different length, realizing mechanized operation, improving production efficiency and lowering labor intensity.

Owner:聊城华塑工业有限公司

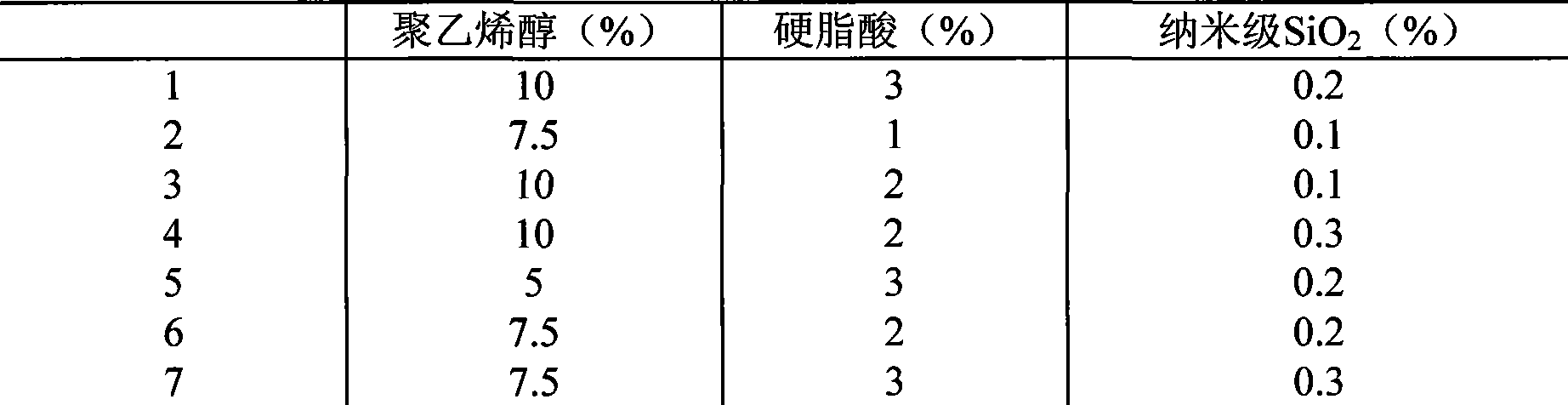

Traditional poultry eggs compound nano material coating-film fresh-keeping method

InactiveCN101390531ASimple film forming processUniform film thicknessEggs preservation by coatingComposite filmPolyvinyl alcohol

The invention relates to a traditional poultry egg product composite nano-material coating preservation method, belonging to the poultry egg fresh-keep packaging technical field. The method comprises the following steps: 5%-10% polyvinyl alcohol and 0.1%-0.5% nano-SiO2 are dissolved in water and heated; 1% -5% stearic acid is dissolved in (w / v is equal to 1:15-20) ethanol and heated; when the temperature of the polyvinyl alcohol solution and that of the stearic acid solution reach 80-85 DEG C at the same time, the two solutions are mixed, heated and stirred evenly to prepare the composite film coating agent; and the composite coating agent is hot-coated on the surface of the poultry egg and then dried with hot air and filmed. Compared with the cooked egg vacuum-packaging, the poultry egg coating preservation method can significantly reduce the using amount of packaging materials and simplify the packaging sterilization technique of the cooked eggs; besides, the poultry egg coating preservation method can achieve mechanized operation, effectively reduce the damage rate of eggs and significantly improve the economic benefits; moreover, the composite coating material is safe and degradable, which improves the marketability of products after being filmed on the egg surface and can also extend the shelf-life of the cooked egg products.

Owner:CHANGSHU YIHAO FOOD PACKAGING MATERIAL TECH +2

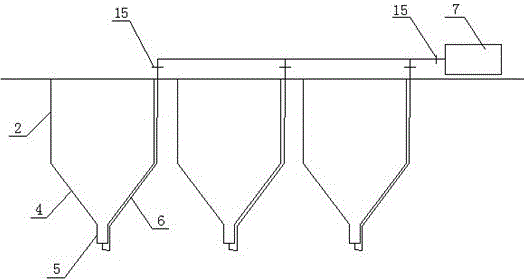

Full-automatic mushroom bacteria stick water injection machine

ActiveCN103238462ARealize mechanized operationIncrease productivityHorticultureWater resourcesEnvironmental engineering

The invention provides a full-automatic mushroom bacteria stick water injection machine, belongs to the technical field of mushroom production and mainly solves problems that manual operation wastes time and energy and is low in efficiency and water resource waste is serious in the prior art. The full-automatic mushroom bacteria stick water injection machine comprises a water injection mechanism, a pneumatic system and a waterway system and is characterized in that the pneumatic system drives a cylinder piston to drive a water injection needle frame, simultaneously water is injected into a plurality of mushroom bacteria sticks, and a circulating water tank of the waterway system recovers and recycles water overflowed after water injection. The full-automatic mushroom bacteria stick water injection machine has high production efficiency and saves mass water resources due to the fact that water overflowed in the water injection process is totally recovered and used.

Owner:张敏鹏

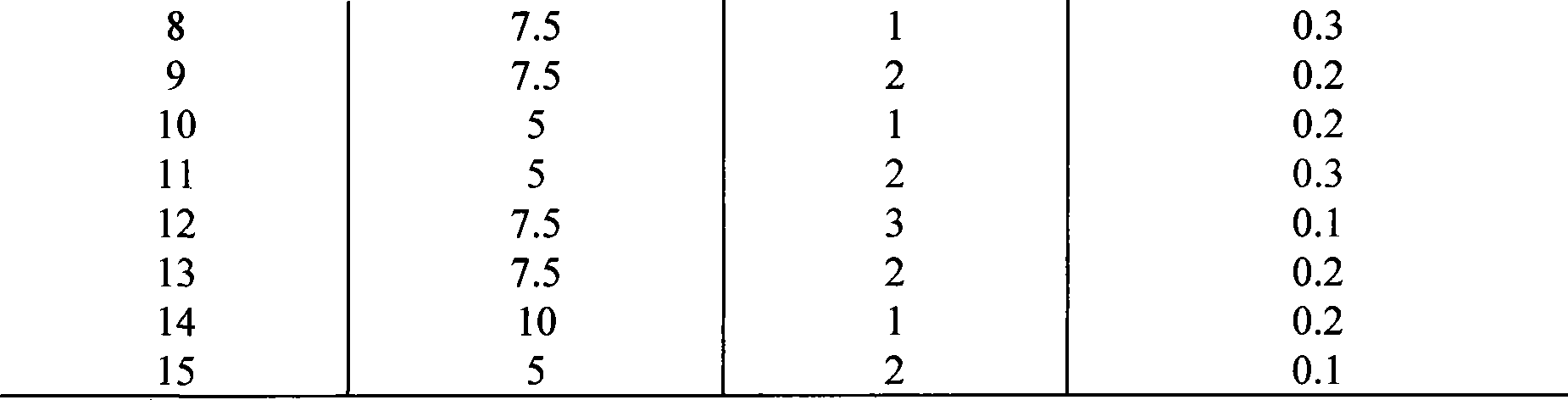

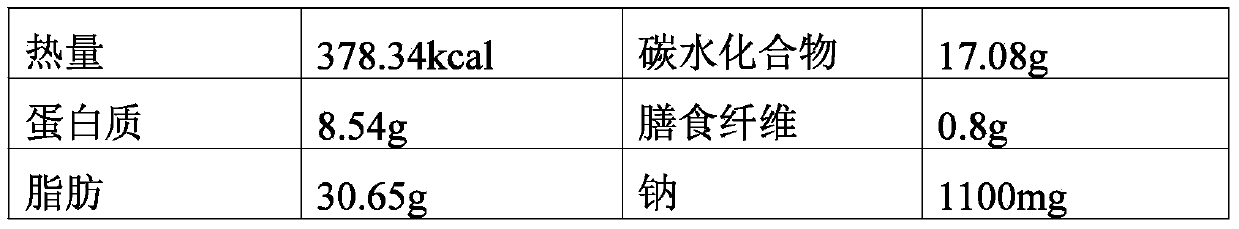

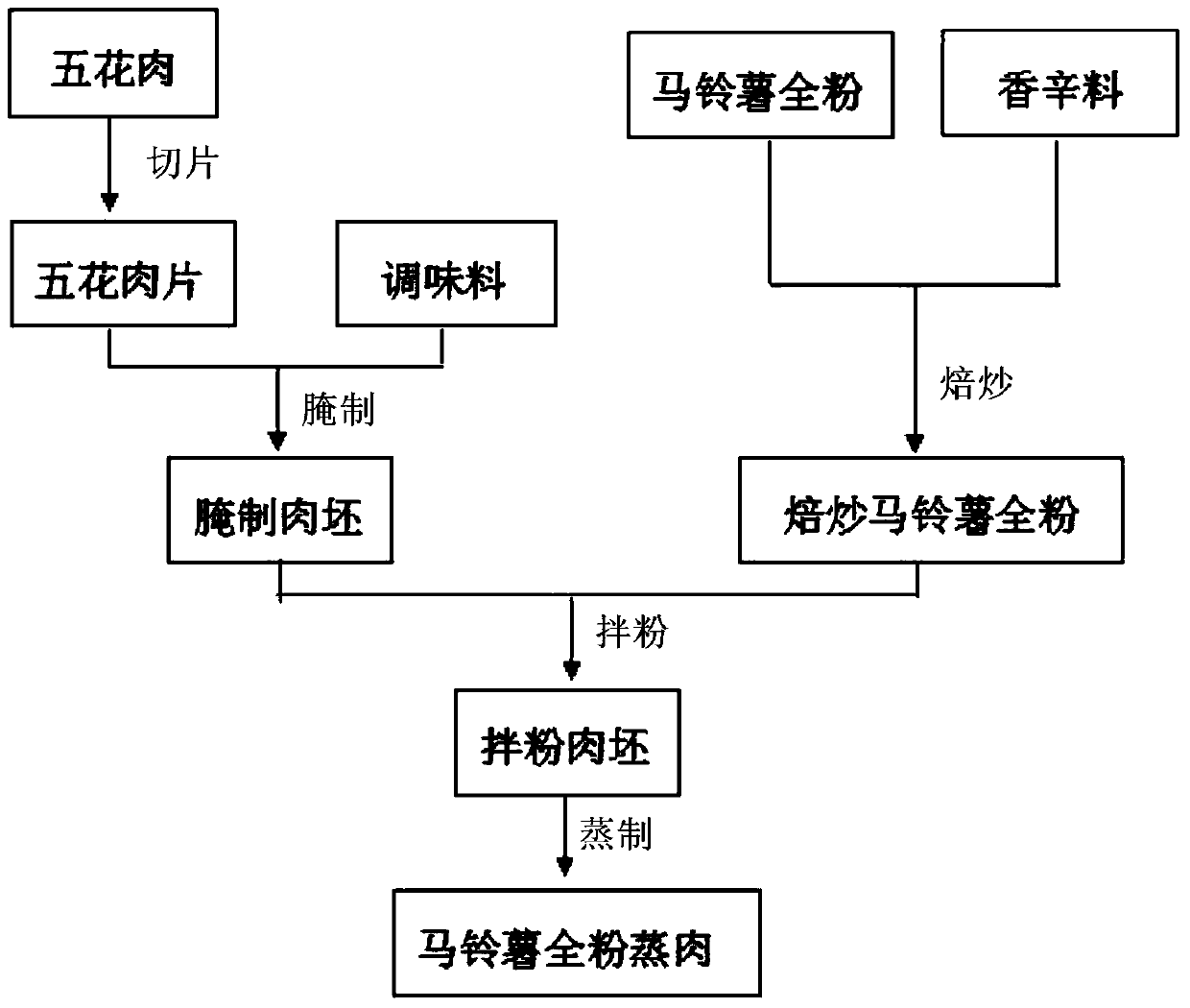

Pork steamed with total potato flour and processing method of pork steamed with total potato flour

InactiveCN104055130AFit for consumptionIncrease dietary fiber contentFood ingredient functionsFood preparationMonosodium glutamateAmomum tsaoko

The invention discloses pork steamed with total potato flour and a processing method of the pork steamed with total potato flour. The pork steamed with the total potato flour is prepared from the following main materials and condiments in parts by weight: 80-120 parts of streaky pork, 10-45 parts of the total potato flour, 0.5-1 part of edible salt, 2-3 parts of white sugar, 0.1-0.4 part of aginomoto, 3-4 parts of light soy sauce, 1-2 parts of bean paste, 1-2 parts of cooking wine, 1-2 parts of fermented bean curd juice, 1-3 parts of bruised shallot, 1-3 parts of bruised ginger, 0.1-0.2 part of cinnamon powder, 0.1-0.2 part of star aniseed powder, 0.1-0.2 part of pepper powder, 0.01-0.02 part of ground cloves powder, 0.05-0.1 part of fennel powder, 0.05-0.1 part of amomum tsaoko powder and 0.01-0.02 part of dried tangerine or orange peel powder, wherein the total potato flour is formed by roasting and frying potato flour with spices.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Valve body inner hole burr removing apparatus

InactiveCN102848280AGuarantee processing qualityEasy to operateEdge grinding machinesReciprocating motionElectric machinery

Owner:HUAIAN SHENGJIE HYDRAULIC MACHINERY

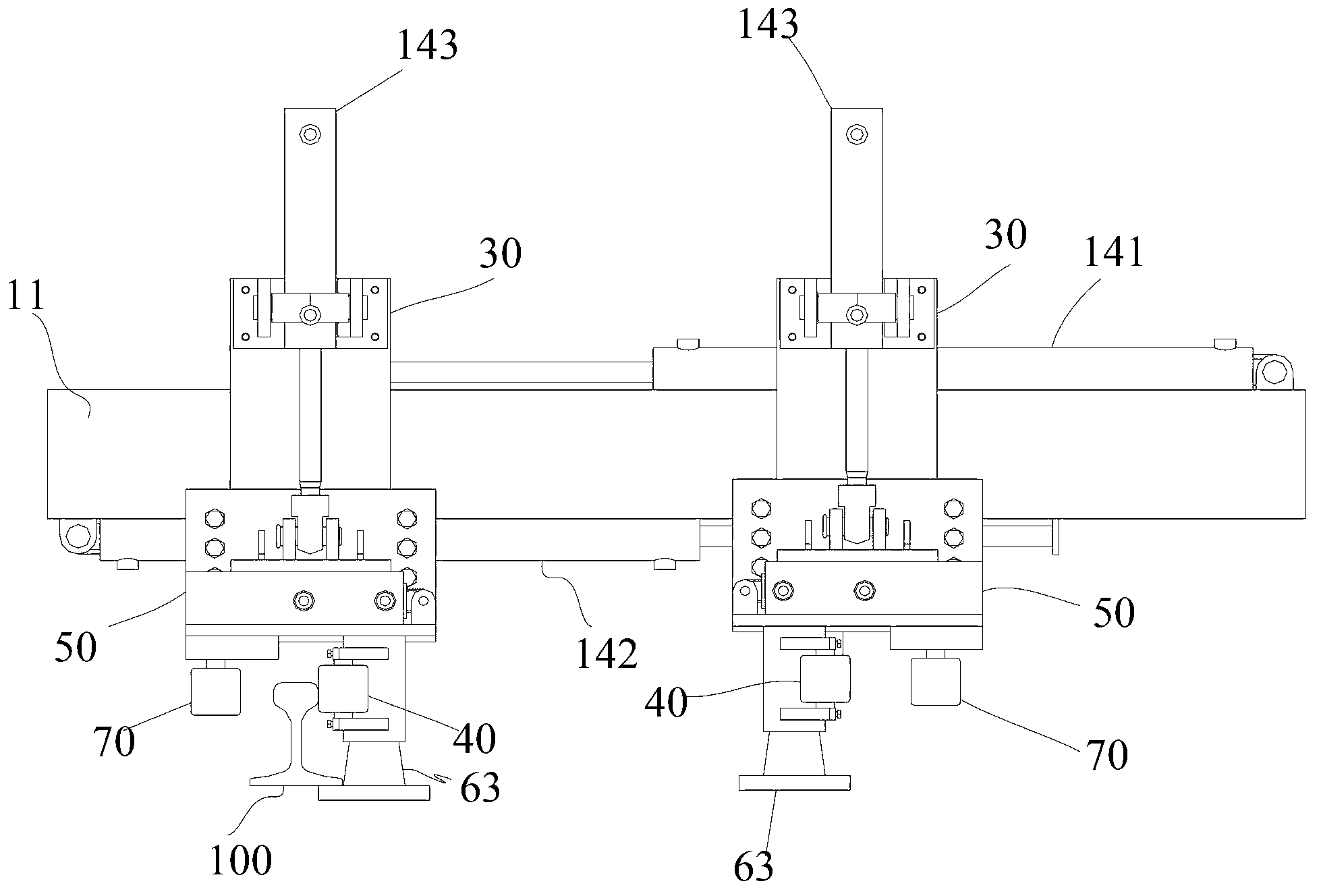

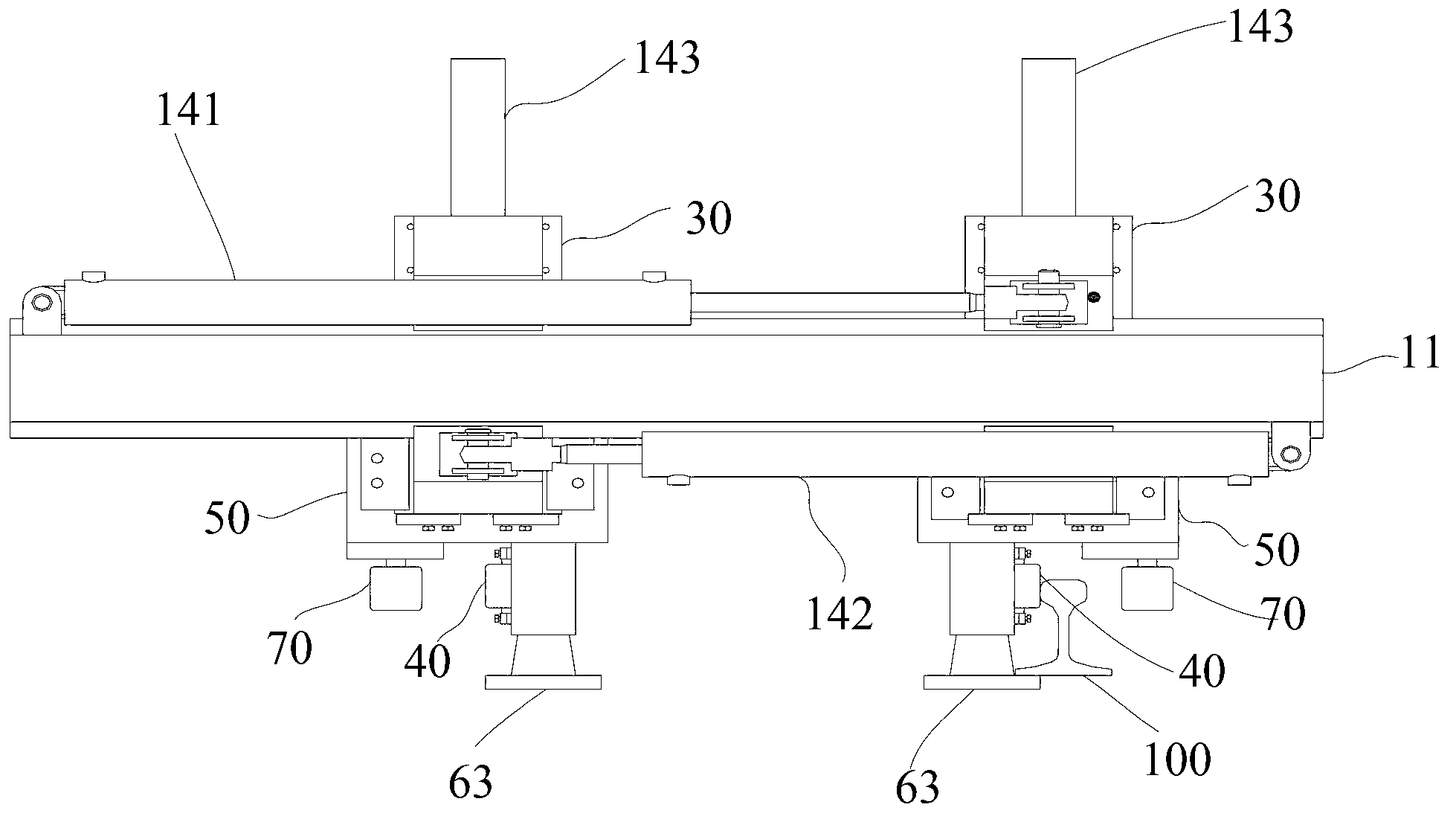

Rail shifter and long rail carrier vehicle

ActiveCN103015278ARealize mechanized operationReduce labor intensityRailway track constructionWagons/vansEngineeringUltimate tensile strength

The invention provides a rail shifter and a long rail carrier vehicle. The rail shifter comprises a transverse moving mechanism, at least one vertical moving mechanism and at least one jaw mechanism; the transverse moving mechanism comprises a transverse supporting beam and at least one transverse retractable arm fixed on the transverse supporting beam; the vertical moving mechanism comprises a slide rest capable of moving on the transverse supporting beam and a vertical retractable arm fixed on the slide rest; the jaw mechanism comprises a mounting base, a carrier roller assembly, a fixed jaw and a movable jaw, the mounting base is fixed on the bottom of the vertical retractable arm, the carrier roller assembly is used for supporting the bottom of a rail, the movable jaw can transversely move relative to the fixed jaw, both the carrier roller assembly and the fixed jaw are fixed on the mounting base, and the fixed jaw and the movable jaw are oppositely arranged and located over the carrier roller assembly; and the numbers of the vertical moving mechanism, the jaw mechanism and the transverse retractable arms are equal. By means of the invention, rails can be horizontally placed in order, a great deal of manual labor is not needed, labor intensity is decreased, the working efficiency is increased, and personal safety is protected.

Owner:CRRC SHENYANG CO LTD

Factory-like culture method for needle mushrooms

InactiveCN104823706ARealize mechanized operationAchieve mechanical propertiesHorticultureBiotechnologyEngineering

The invention discloses a factory-like culture method for needle mushrooms. The culture method comprises following steps of preparation of compost, bottling, sterilization, inoculation and cultivation, scratching and water injection, management of producing mushrooms, harvest and digging bottles. The factory-like culture method for needle mushrooms has following beneficial effects: the culture method helps to save time for mechanized operation and reduce cost and labor intensity; the needle mushrooms have short production periods and are produced yearly for many times; and the high-yield and highly-efficient cultivation mode is obtained.

Owner:吴中区胥口精益生物医药研究所

PPR pipe hot melting machine

The invention discloses a PPR pipe hot melting machine, and relates to the field of pipe connecting equipment. The PPR pipe hot melting machine comprises a platform, a first clamping mechanism, a second clamping mechanism and a hot melting mechanism; the first clamping mechanism and the second clamping mechanism are arranged on the platform, are positioned between a first limiting mechanism and asecond limiting mechanism, and are oppositely arranged, wherein the first clamping mechanism is near the first limiting mechanism, and the second clamping mechanism is near the second limiting mechanism; and the hot melting mechanism is arranged on the platform, and is positioned between the first clamping mechanism and the second clamping mechanism. The PPR pipe hot melting machine realizes mechanical operation of PPR pipe hot melting, can realize precise butt joint of PPR pipes, guarantees the pipe melting quality, and improves the melting efficiency.

Owner:王佳颖

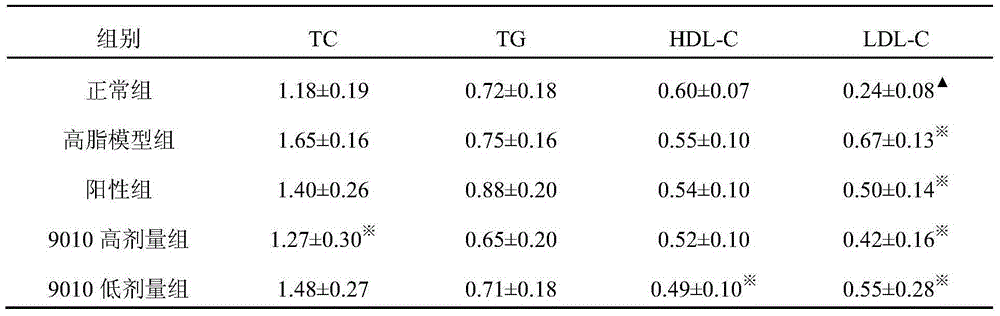

Pickle containing mixed lactic acid bacteria and making method thereof

InactiveCN105077113AConducive to anti-corrosion and quality assuranceAdd flavorFood ingredientsFood preparationLactobacillus casei subsp rhamnosusGenus Lactobacillus

The invention discloses pickle containing mixed lactic acid bacteria and a making method thereof. The mixed lactic acid bacteria contain Lactobacillus sp. DMDL 9010 and Lactobacillus casei subsp. Rhamnosus, the lactic acid bacteria are preserved in the Chinese common microbe bacterial preservation administration center on August 19, 2011, and the preservation serial number is CGMCC No.5172. The making method includes the steps that fresh vegetables are added into the mixed lactic acid bacteria to be subjected to anaerobic fermentation at the temperature of 20 DEG C to 40 DEG C 60 hours to 72 hours later, the mixed anaerobic fermentation is placed at the normal temperature for six months, the viable count of the lactic acid bacteria can reach 105 cfu / g to 106 cfu / g, and the salt content is lower than 3.0%. The made pickle is nearly free of nitrite, short in production cycle and stable in product quality, contains active probiotics and is instant food.

Owner:SOUTH CHINA UNIV OF TECH

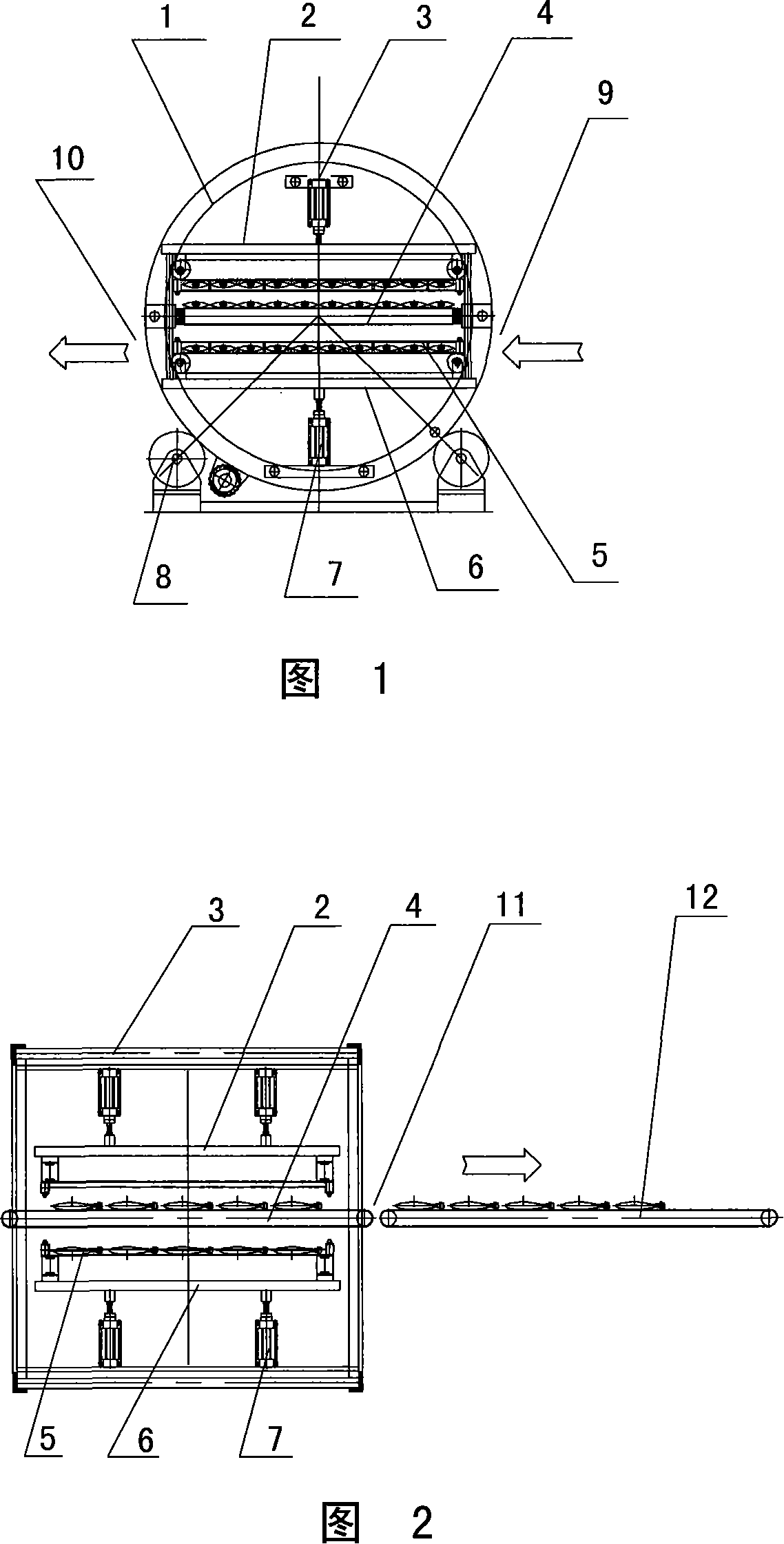

Automatic disk discharging machine of soft bag

InactiveCN101130393AAvoid long distance throwingCompact and reasonable structureArticle unpackingConveyor partsMechanical engineeringEngineering

The invention relates to an automatic unloading machine for soft bag used for automatic unloading for infusion soft bag in pharmaceutical production, comprising feeding belt. A rotary cage is set and in the cage independent soft-bag transverse feeding belt is set. Sterilization-disk feeding chains are set on upper and lower sides of transverse feeding belt respectively and correspondingly. Sterilization-disk chains are set on lifting support and hook of sterilization disk is set on the lifting support. The hook is faced to the transverse feeding belt and sterilization-disk feeding chains. Inlet and outlet of sterilization disk and outlet of soft bag are set on the rotary cage. The invention is provided with reasonable and compact structure and can take the place of manual work. Mechanical operation is realized and labor force is saved. Producing efficiency can be improved and dropping soft bag in long distance is avoided in unloading by manual work. Product quality is guaranteed.

Owner:SHINVA MEDICAL INSTR CO LTD

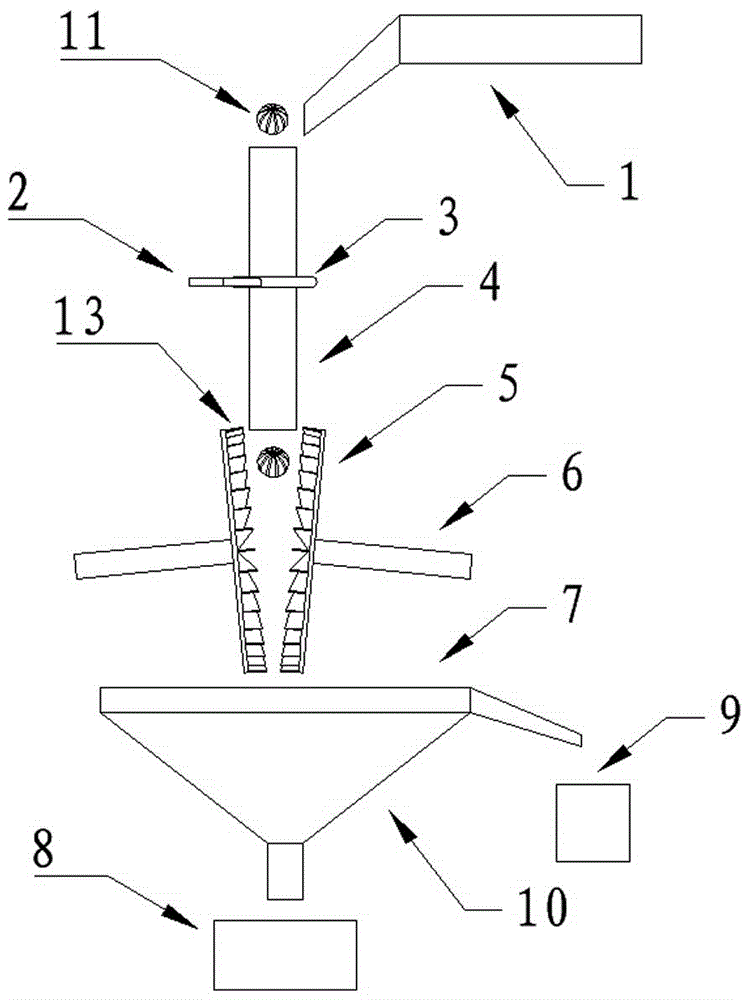

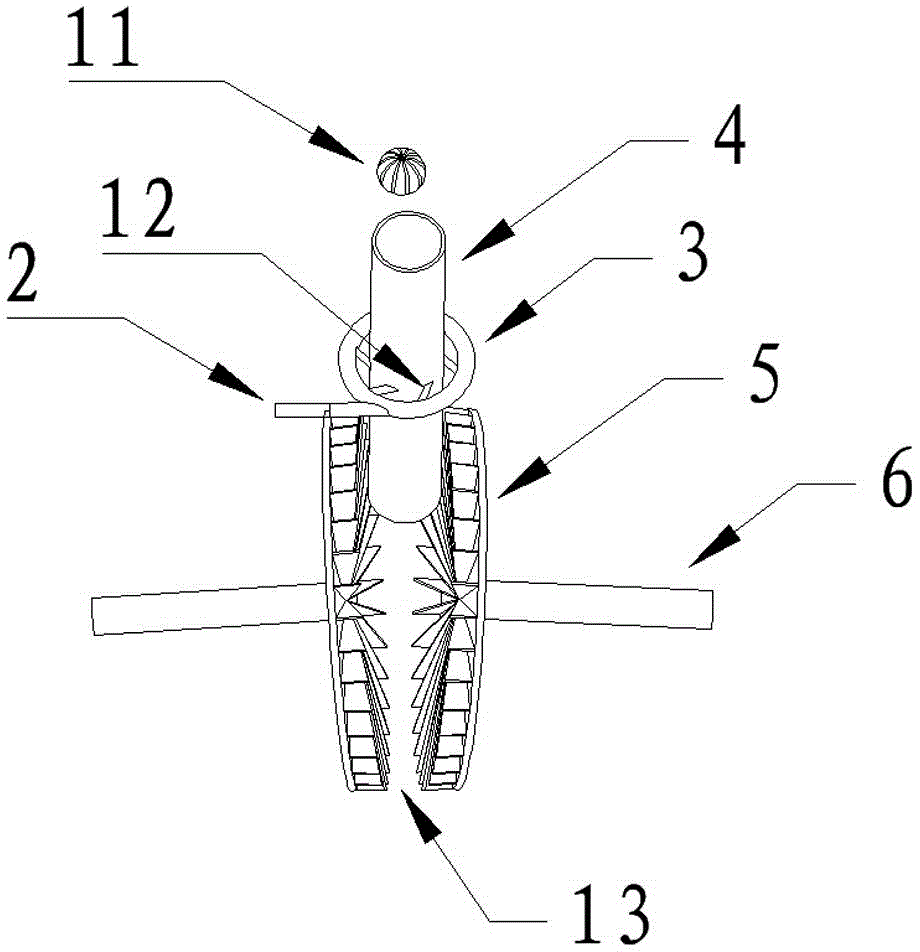

Rotary soft-blade lily bulb sectioning device

ActiveCN104351931AUniform and efficient feedingExact splitFood treatmentCycloneMechanical engineering

The invention discloses a rotary soft-blade lily bulb sectioning device. The rotary soft-blade lily bulb sectioning device comprises two soft turntables, wherein the two turntables are opposite to each other and rotate in opposite directions, each turntable is provided with soft blades for enhancing the attached drive to the lily bulb, and the distance between the two turntables is adjustable in the range of 1cm to 10cm; a cyclone pipe which is vertically arranged is arranged above each soft turntable, and an air spraying pipe which enters in the tangential direction is arranged no the cyclone pipe; a vibrating feeding machine is arranged above each soft turntable or the cyclone pipe; a vibrating sorting machine is arranged below each soft turntable. The soft turntables and the soft blades are ingeniously used for kneading the lily bulb, the centrifugal sectioning is promoted by the rotation acceleration, flexible extrusion and kneading also can be realized, not only can the sectioning be promoted, but also the lily bulb is not damaged, by combining the cyclone acceleration optimized application, high-efficient, reliable and nondestructive mechanical sectioning of the lily bulb can be realized, the labor intensity is alleviated, the working efficiency is greatly improved, a good foundation is set for the subsequent production of the lily bulb, and the prospect is wide.

Owner:OLSON FOOD JIANGMEN

Soil-crushing and soil-spraying fire extinguishing vehicle

InactiveCN107998552AImprove fire extinguishing effectImprove continuous work efficiencyFire rescueGrain treatmentsEngineeringEarth surface

The invention relates to a soil-crushing and soil-spraying fire extinguishing vehicle and belongs to the technical field of fire extinguishing devices. According to the fire extinguishing vehicle, a rotary cutting machine is used for directly and rotationally taking soil from the earth surface; after being crushed once, the soil is conveyed to a transmission crawler belt through a soil turning roller; then the crushed soil is conveyed by the transmission crawler belt to undergo secondary crushing through mechanical soil crushing wheels; and the soil is further crushed and then conveyed by a spiral conveying pipe into a soil spraying device, the fire extinguishing soil is crushed uniformly through repeated crushing and then is sprayed out through high-pressure airflow, and therefore soil spraying fire extinguishing effect can be effectively improved. The vehicle has the characteristics that the range is long, the continuous working efficiency is high, the safety is high, the fire extinguishing distance is long, and the fire extinguishing area is large; the cutting depth of the rotary cutting machine can be adjusted through a depth-cutting adjusting hydraulic rod, the soil taking mode is effectively improved, the soil taking effect is improved, manual operation is not needed, the mechanical operation is realized, the labor intensity is low, the operation is convenient, the safetyis high, and the continuous working efficiency can be greatly improved.

Owner:闫博文

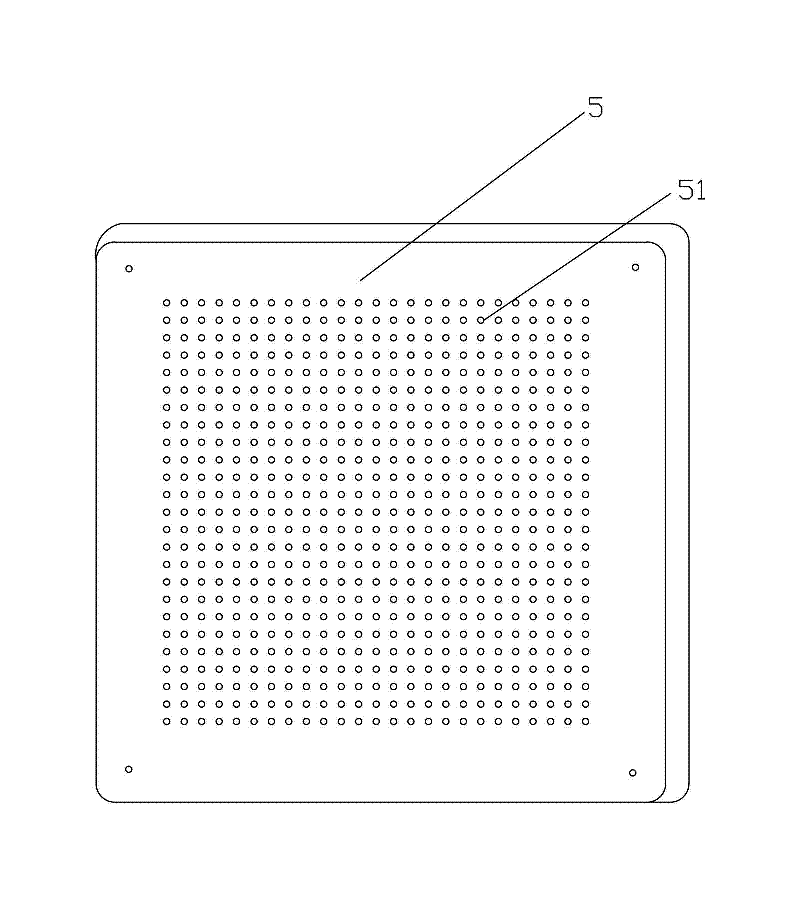

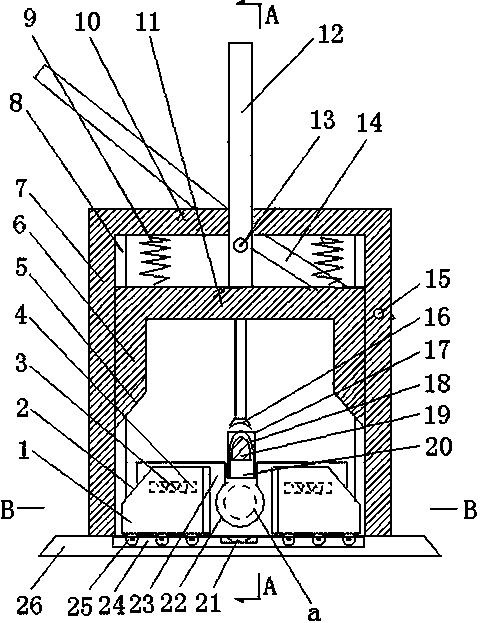

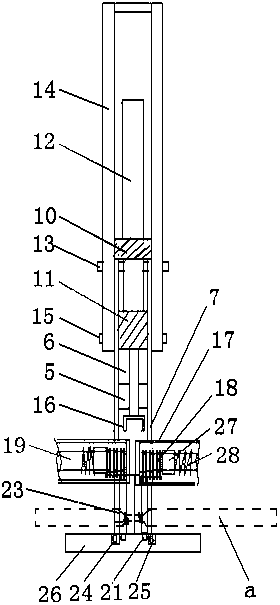

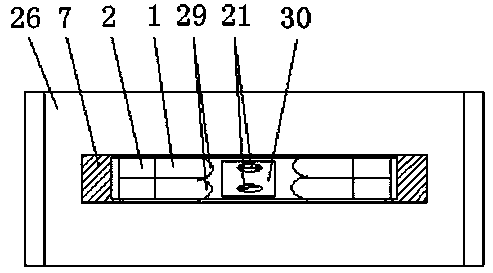

Positioning structure of circuit board

ActiveCN102407537AEasy to determine heightEasy to liftMetal working apparatusPunchingFlexible circuits

The invention discloses a positioning structure of a circuit board. The positioning structure comprises a base plate and a sliding plate which is fixedly arranged on the base plate, wherein a guide rail with a groove is arranged on the base plate; a bracket is fixedly arranged on the sliding plate; a sliding block which is occluded with the guide rail is fixedly arranged at the bottom of the sliding plate; a threaded connector matched with a fine-tuning screw is arranged on a movable plate; a support rod is arranged in the middle of the movable plate and a lining plate is connected onto the supporting rod; a fixing plate is arranged on the lining plate and is connected with a tray; and positioning holes which are arrayed according to a matrix are arranged at the top of the tray. Accordingto the positioning structure disclosed by the invention, the punching positions of a flexible circuit board can be positioned and punched in advance through a matrix positioning structure and an automatic-lifting system, and thus the processing with high precision and high efficiency is realized.

Owner:NETRON SOFT-TECH ZHUHAI CO LTD

Sectional ham sausage binding device

ActiveCN104186629AFast and efficient production processEasy to useSausage skin tying apparatusBiochemical engineeringPortal frame

The invention provides a sectional ham sausage binding device which comprises a base and a bracket on the base, wherein the bracket forms a portal frame by encircling a left vertical upright rod, a right vertical upright rod and a top transverse beam. The sectional ham sausage binding device is characterized in that a pressing and binding mechanism is arranged on the bracket; an extrusion mechanism is arranged at a position, which is positioned below the pressing and binding mechanism, on the base; and one side or each of two sides of the extrusion mechanism is provided with a binding nail conveying mechanism. According to the sectional ham sausage binding device provided by the invention, ham sausages can be conveniently arranged in through holes or straight slots in the middles of front and rear fixing plates of the extrusion mechanism and are extruded in a sectional mode through the extrusion mechanism, binding nails are conveyed to the sectional extrusion positions through the binding nail conveying mechanisms, and binding of the ham sausages at the sectional extrusion positions is synchronously finished by the pressing and binding mechanism, so that the whole ham sausage manufacturing process is rapid and high-efficiency. In addition, the sectional ham sausage binding device is simple in structure and convenient to use, can realize mechanical operation without excessive investment and is convenient for later repair and maintenance.

Owner:日照鑫博机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com