Soil-crushing and soil-spraying fire extinguishing vehicle

A fire-fighting truck and soil blasting technology, which is applied in fire rescue, grain processing and other directions, can solve the problems of small fire-extinguishing range and cumbersome operation, and achieve the effect of large fire-extinguishing distance, strong safety, and improving continuous work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

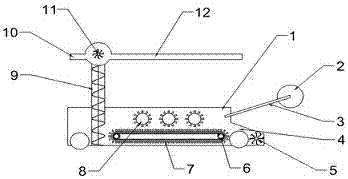

[0018] First, control the cutting depth adjustment hydraulic rod 3 to adjust the cutting depth of the rotary cutter 2, and take the soil directly from the surface through the rotation of the rotary cutter 2. After a crushing, a filter is installed through the opening of the bucket 4, and the qualified soil particles will pass through. Mesh, and turned over by the turning roller 5 to the transmission crawler 7, the transmission crawler 7 is driven by the transmission gear 6 to convey the crushed soil, and the crushed soil is further refined by the mechanical crushing wheel 8, and then the screw conveyor pipe 9 screw shaft The broken soil is lifted up by rotation, and the broken soil is further crushed by the further extrusion of the screw shaft during the lifting process, and transported to the soil spraying device. Spray the fine crushed soil to the fire source to complete the fire extinguishing operation by spraying soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com