Sectional ham sausage binding device

A ham sausage vertical erection technology, which is applied in the field of mechanical design and manufacturing, can solve the time-consuming and labor-consuming problems of ham sausage, and achieve the effects of reducing labor intensity, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

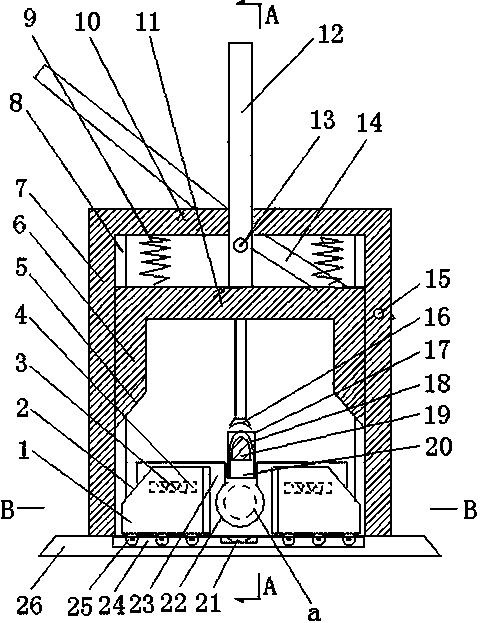

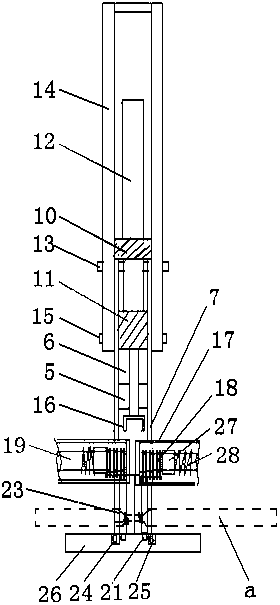

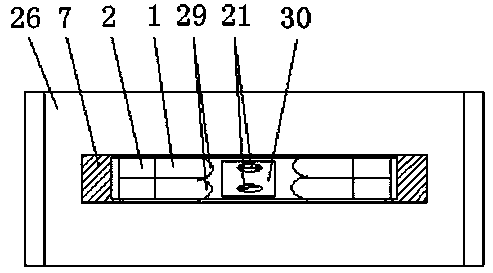

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , the ham sausage segmental binding device provided by the present invention includes a base 26 and a bracket on the base 26, the bracket is surrounded by left and right vertical poles 7 and top beams 10 to form a door-shaped frame, and the bracket is provided with a pressing binding mechanism , the base 26 is located below the pressing and binding mechanism to be provided with an extruding mechanism, and the two sides of the extruding mechanism are respectively provided with a binding nail conveying mechanism;

[0022] Described pressing binding mechanism comprises the left and right vertical chute 8 that is arranged on the inner side of left and right vertical pole 7, and the bottom of vertical chute 8 is provided with lubricating oil groove, and correspondingly is arranged on left and right vertical chute 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com