Broiler breeding equipment

A technology for broilers and equipment, applied in the poultry industry, applications, poultry cages or houses, etc., can solve the problems of limited construction land and high land prices, and achieve the effects of reducing labor intensity, cost-effective, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

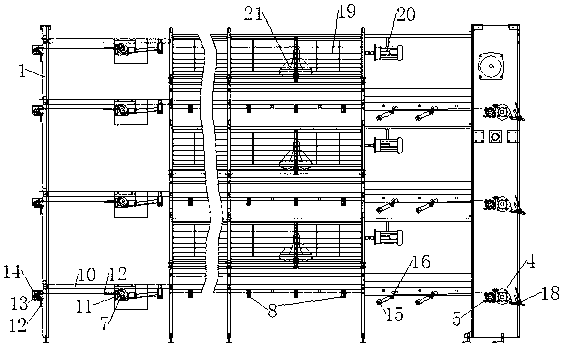

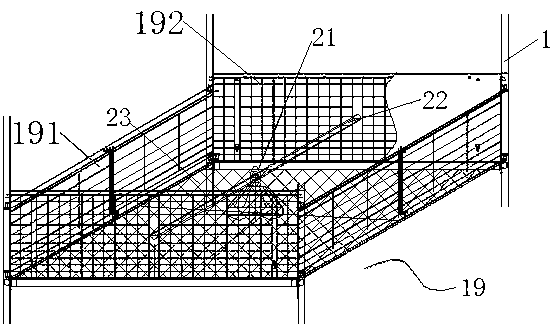

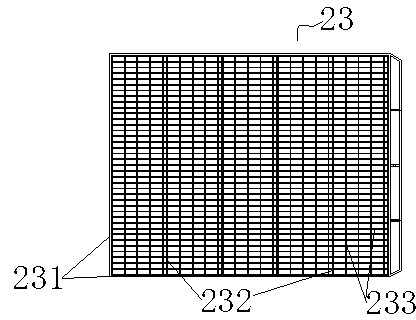

[0032] Such as Figure 1-5 As shown, a kind of broiler raising equipment of the present invention comprises chicken cage frame 1, is provided with one or more chicken cage layers on chicken cage frame 1, and each chicken cage layer is arranged side by side with one or more chicken cages 19 , feeding conveying pipeline 22, feeding drive motor 20, feeding hopper 21 and drinking water system are all installed on each chicken cage layer, and feeding feeding pan 21 is all installed in each chicken coop 19, and feeding feeding pan 21 It is located on the feeding conveying pipeline, and the chicken feed is provided by the feeding conveying pipeline to the feeding tray 21. A belt-type manure cleaning system is installed under each chicken cage layer, and each chicken cage 19 is equipped with a chicken cage. The bottom net 23, the chicken cag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com