Valve body inner hole burr removing apparatus

A deburring and inner hole technology, which is used in grinding machines, metal processing equipment, grinding/polishing equipment, etc., to facilitate the operation of workers, ensure the processing quality, and shorten the processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

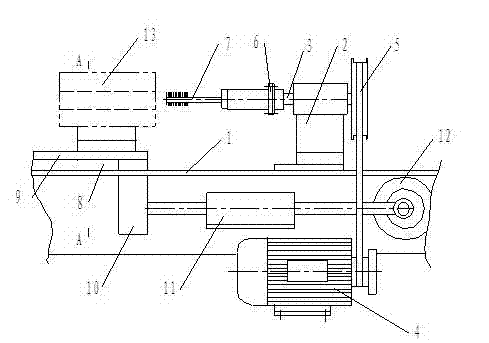

[0011] A valve inner hole deburring device, refer to figure 1 , 2 ,in:

[0012] One end of the workbench 1 is fixed with a bearing seat 2, and a rotating shaft 3 is arranged in the hole of the bearing seat 2, and the power of the motor 4 is transmitted to the rotating shaft 3 through the pulley 5, and the rotating shaft 3 transmits the power to the rotating shaft 3 through the coupling 6. The brush 7 in the shaft hole of the shaft coupling 6 drives the brush 7 to rotate;

[0013] The other end of the workbench 1 is provided with a guide rail 8, and the slide plate 9 is placed on the guide rail 8 through the protrusion 91 provided at the bottom thereof. A slide seat 10 is also fixedly connected to the bottom of the slide plate 9, and the slide seat 10 is connected with the hydraulic cylinder 11. Connected, under the control of the motor or hydraulic motor 12, the hydraulic cylinder 11 drives the slide seat 10, the slide plate 9 and the workpiece 13 placed on the slide plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com