Patents

Literature

500results about How to "Easy to mechanize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

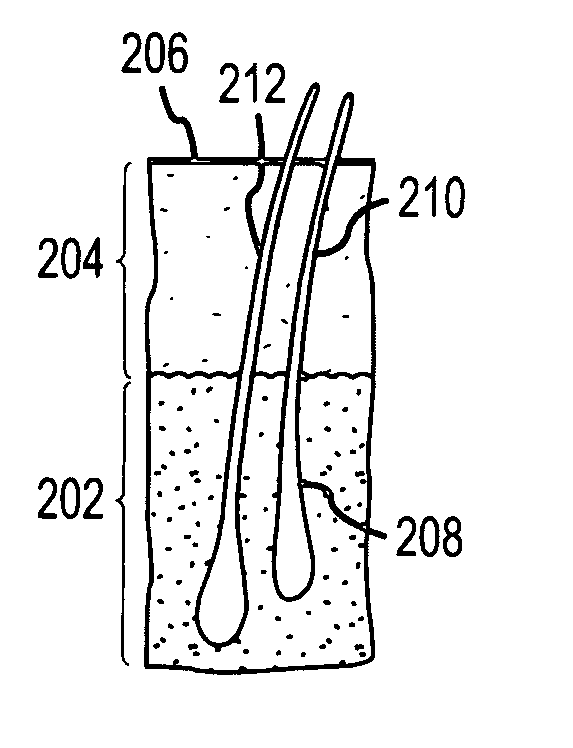

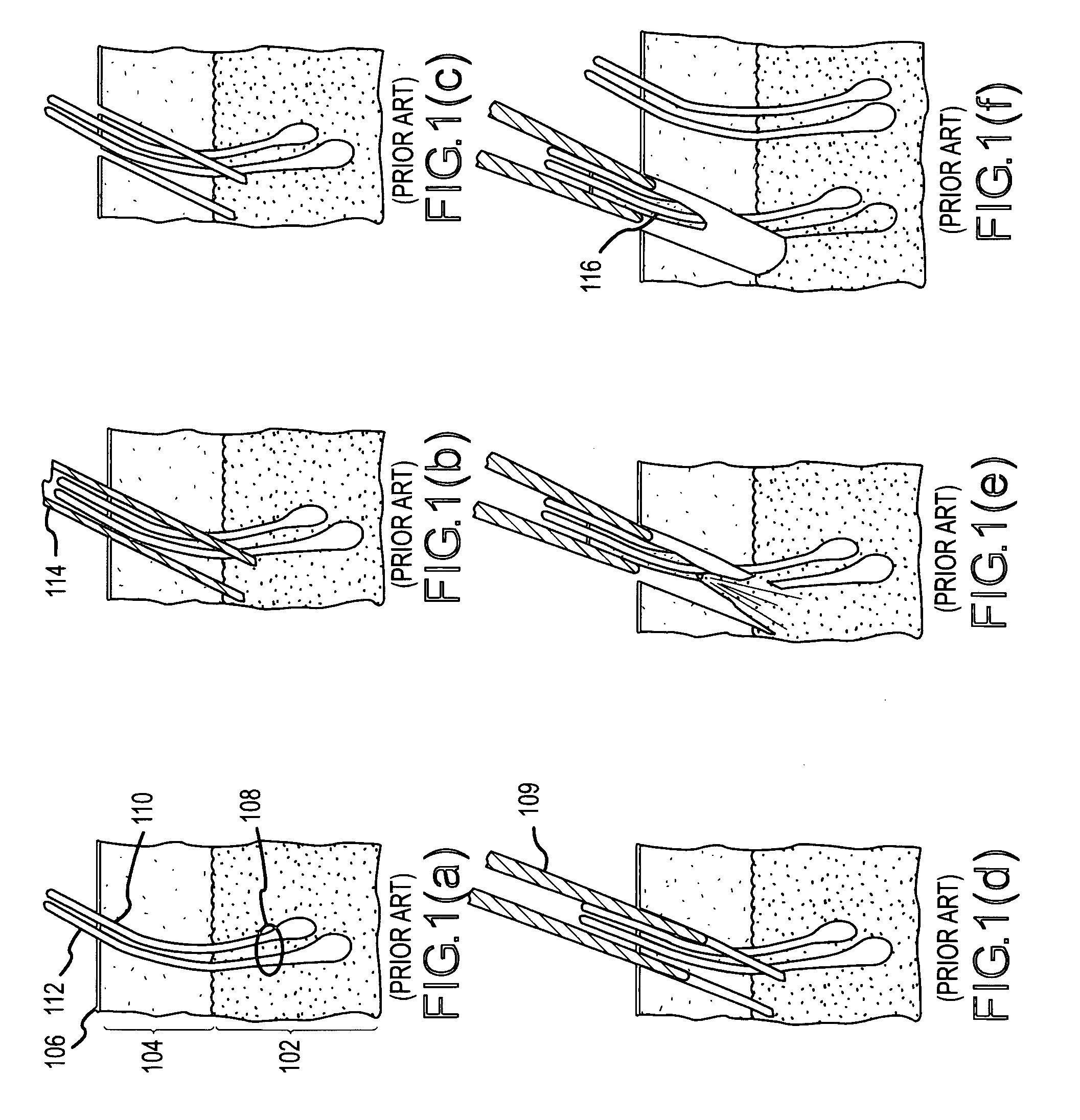

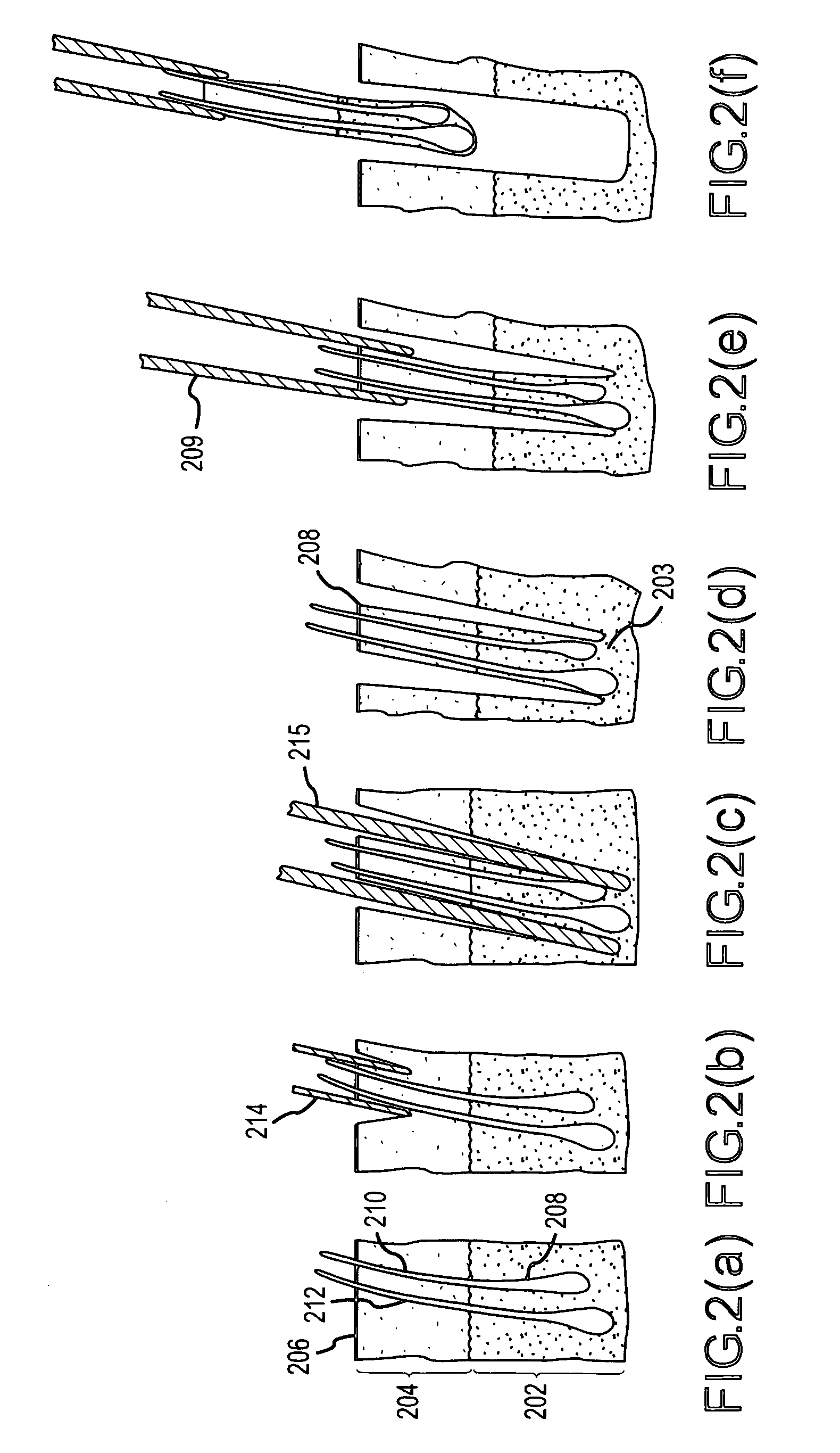

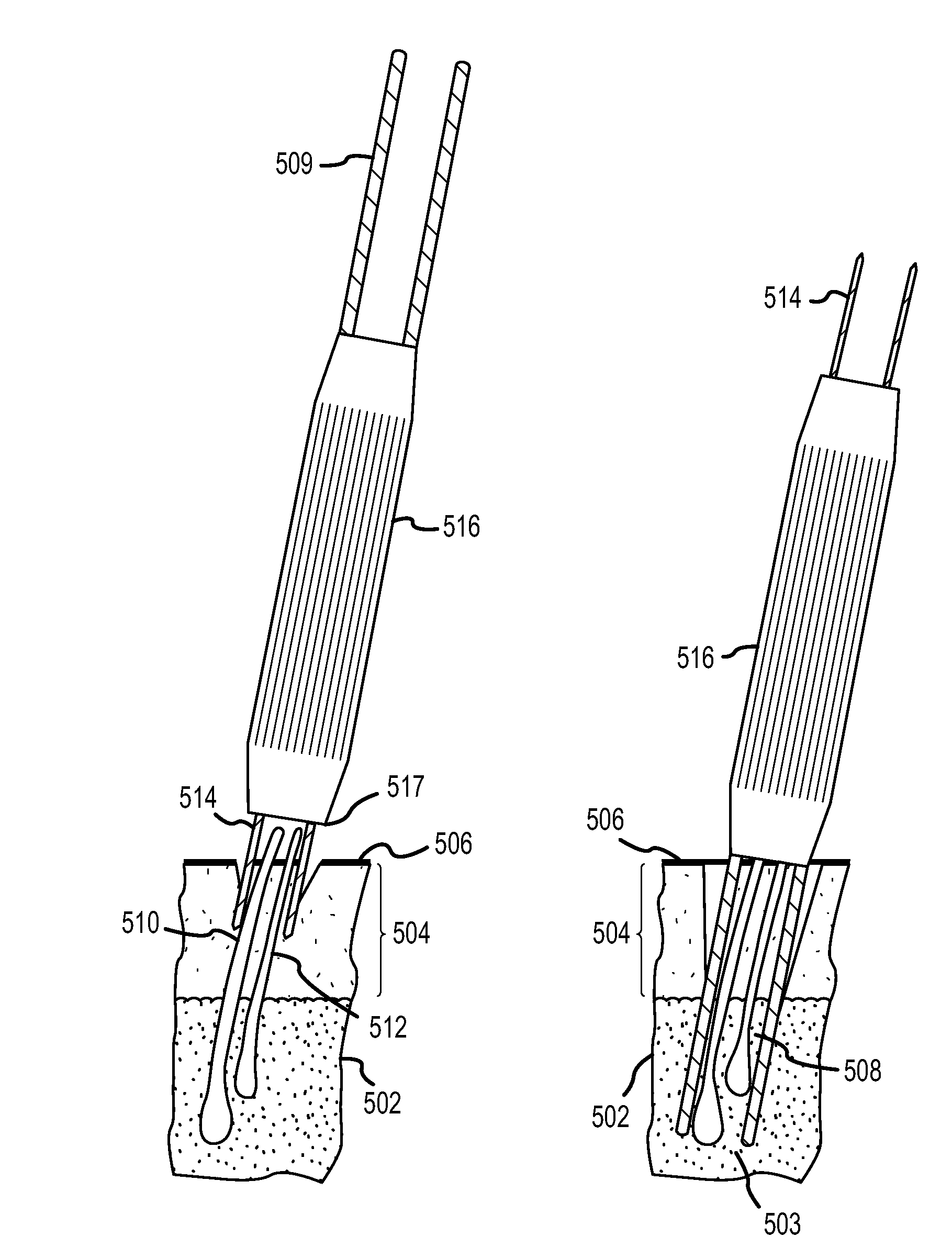

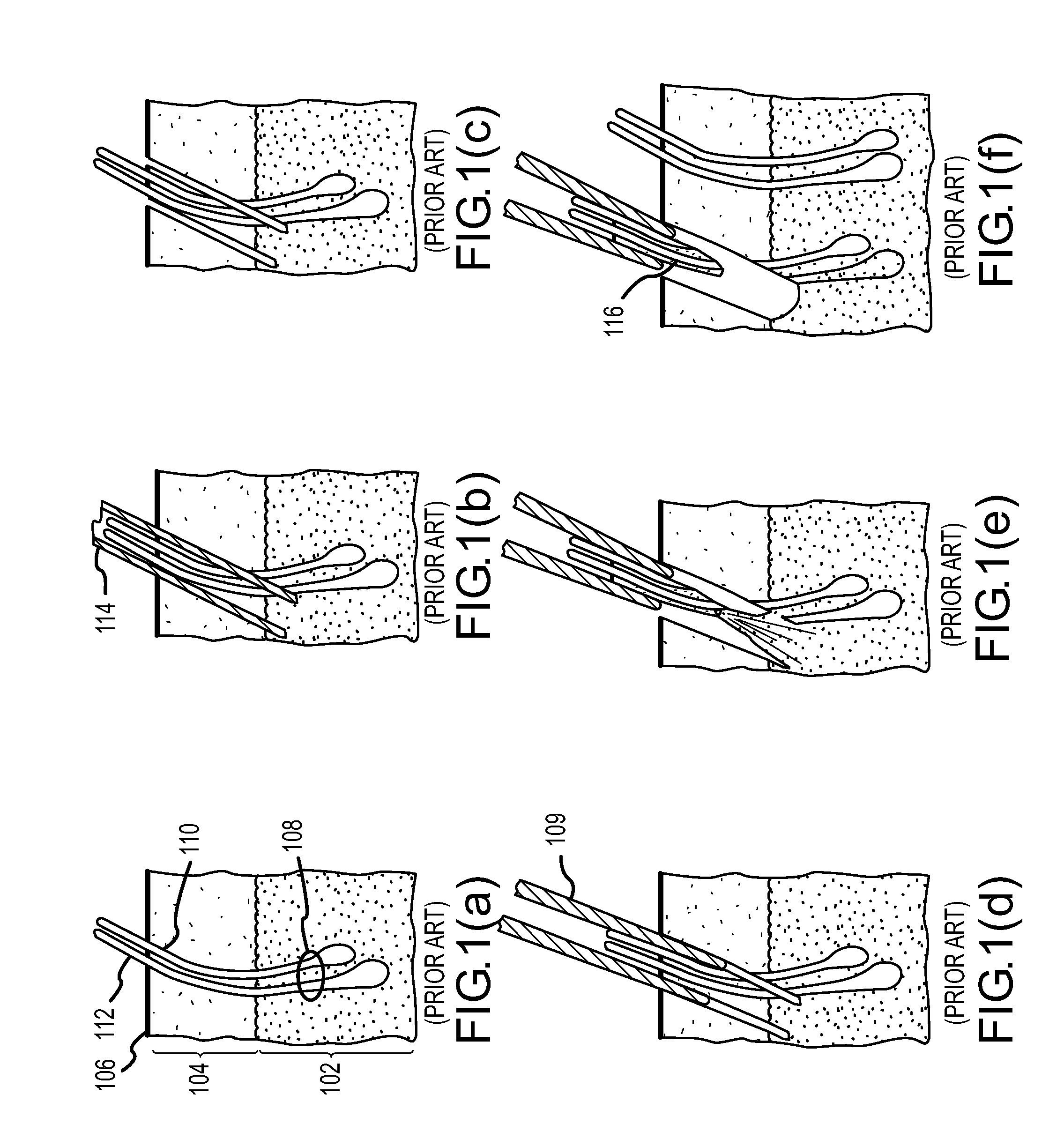

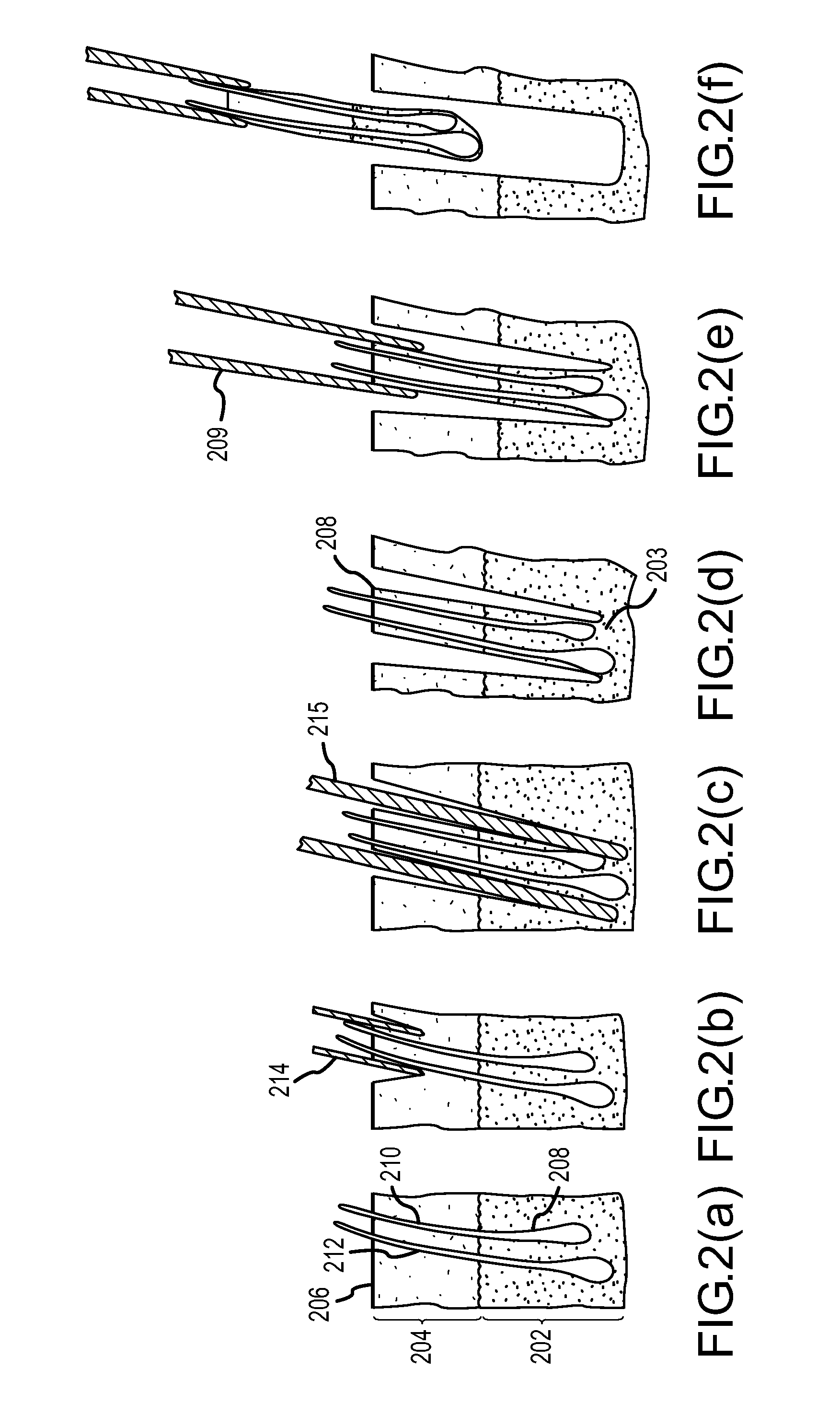

Follicular extraction method and device

ActiveUS20050267506A1Diminish and even eliminate shortcomingUnable to easily cut and inciseSkin implantsSurgical needlesTissue skinOvarian follicle

A method and device for the extraction of follicular units from a donor area on a patient. The method includes scoring the outer skin layers with a sharp punch, and then inserting a blunt punch into the incision to separate the hair follicle from the surrounding tissue and fatty layer. The method and device will significantly decrease the amount of follicular transection and increase the rate at which follicular units can be extracted.

Owner:HSC DEV

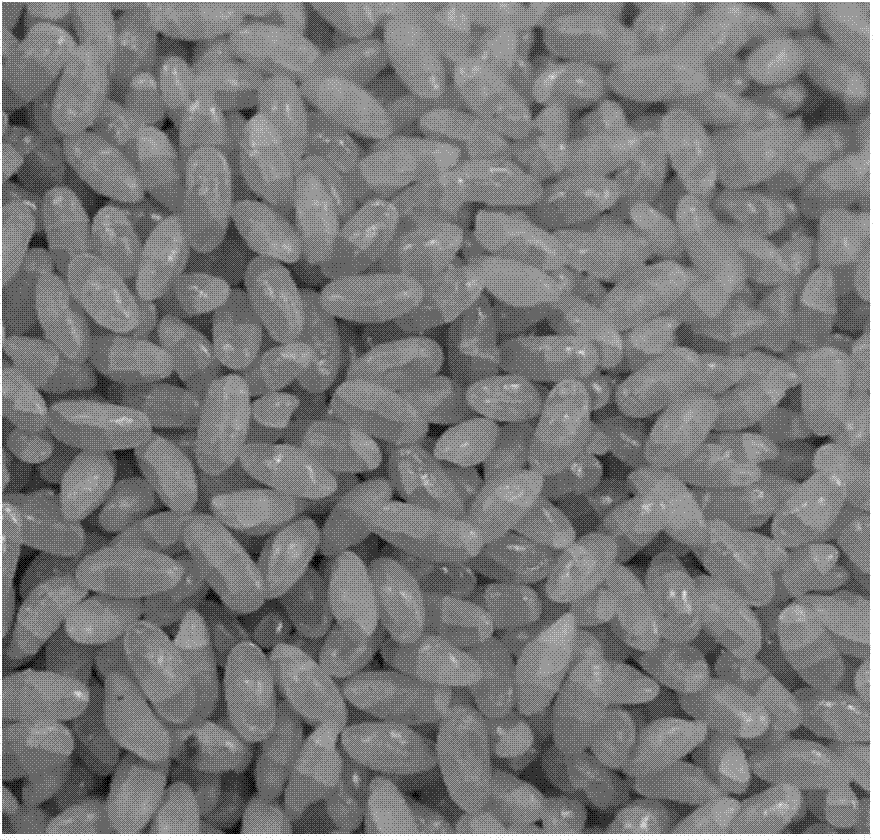

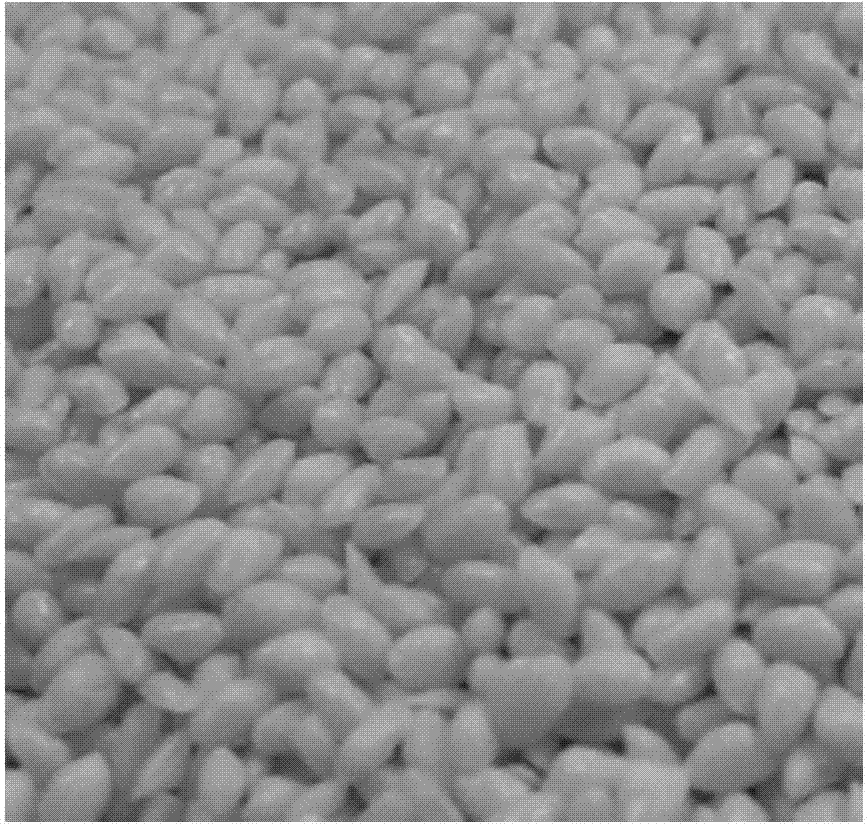

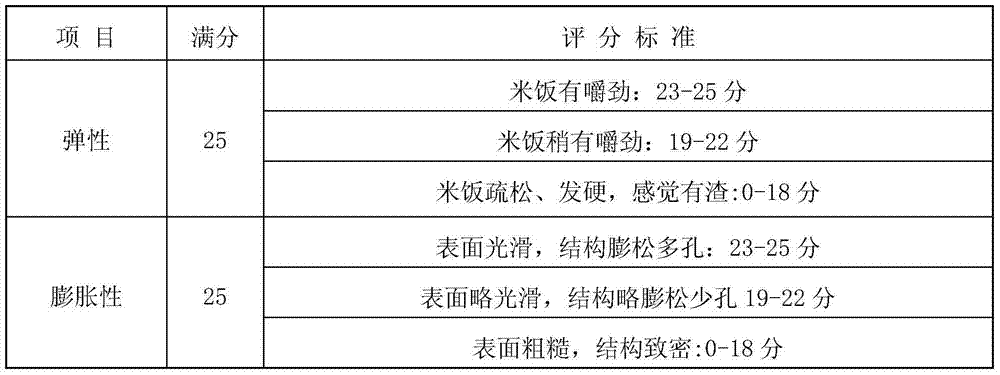

Coarse cereal instant rice and preparation method thereof

ActiveCN103564344ABlocking stickingPrevent too softFood ingredient functionsFood preparationPearl barleyGram

The invention discloses a coarse cereal instant rice and a preparation method of the coarse cereal instant rice. The coarse cereal instant rice is mainly prepared by conducting extrusion curing, cutting, pelletizing, drying, then baking and puffing on coarse cereal powder, starch and solid vegetable oil, wherein the coarse cereal is selected from one or combination of corn flour, rice flour, sorghum flour, buckwheat, pearl barley flour, black rice four, sweet potato flour, millet flour, coarse rice powder, glutinous rice flour, red rice flour, soybean flour, red bean flour, green gram starch, black bean flour, oat powder and wheat flour. The coarse cereal instant rice provided by the invention adopts a loose porous structure inside, so that the coarse cereal instant rice is good for digesting and absorbing and is excellent in rehydration property, the rehydration time is relatively short, the rehydrated rice is in full grain, and the coarse cereal instant rice is chewy and not hard or sticky when being eaten.

Owner:王金玺

Camellia oleifera container seedling raising technique

The invention relates to a plant seedling raising technique, in particular to a camellia oleifera container seedling raising technique which aims to solve the problems of low seedling survival rate and low seedling raising efficiency of a camellia oleifera seedling raising technique in the prior art. The camellia oleifera container seedling raising technique includes the steps of (1) collecting seeds, and placing the collected seeds in a refrigeratory for cold storage and reserve at the temperature of 0-5 DEG C; (2) pre-treating the seeds, and soaking the seeds prior to sand storage for accelerating germination; (3) sowing, sowing the camellia oleifera seeds subjected to germination accelerating in a container containing seedling raising substrates in a spot manner, and then placing the container on a seedbed; (4) grating rootstocks of seedlings; (5) performing grafted seedling management including water management, rootstock removal and weeding management, light and temperature management, nutrient management and the like; (6) performing biennial seedling production management; and (7) performing outplanting management. The technique has the advantages of high seedling survival rate, high breeding efficiency and good reliability; and seedling survival rate of the seedling raising technique is 10-20% higher than that of inarching seedling raising and leaf cutting seedling raising techniques.

Owner:YUNHE AGRI COMPREHENSIVE DEV

Fermentation pepper sauce and preparation thereof

The invention discloses a fermented pepper sauce and preparation method thereof, comprising cleaning and cutting the greenly red pepper; blanching; pulping; adding ginger, garlic, tomato, carrot, carbon source, salt as additive materials; sterilizing; and then inoculating the mold or yeast or compound bacteria of mold and yeast to perform alcohol fermentation; and then sterilizing; inoculating the acetic acid bacteria to perform acetic acid fermentation; finally adding sweeting agent and thickener to be canned. After blanching, the pulping is not necessary and the calcium salt is added to produce the products during process of preparing. The fermented pepper sauce has gentle pungent taste, delicious taste, fermentation flavor. The preparation method thereof can quickly produce the fermented pepper sauce with good and stable quality, fine flavor, safety without antiseptic, suitable for industrialized mass production with excellent market application foreground.

Owner:GUIZHOU UNIV

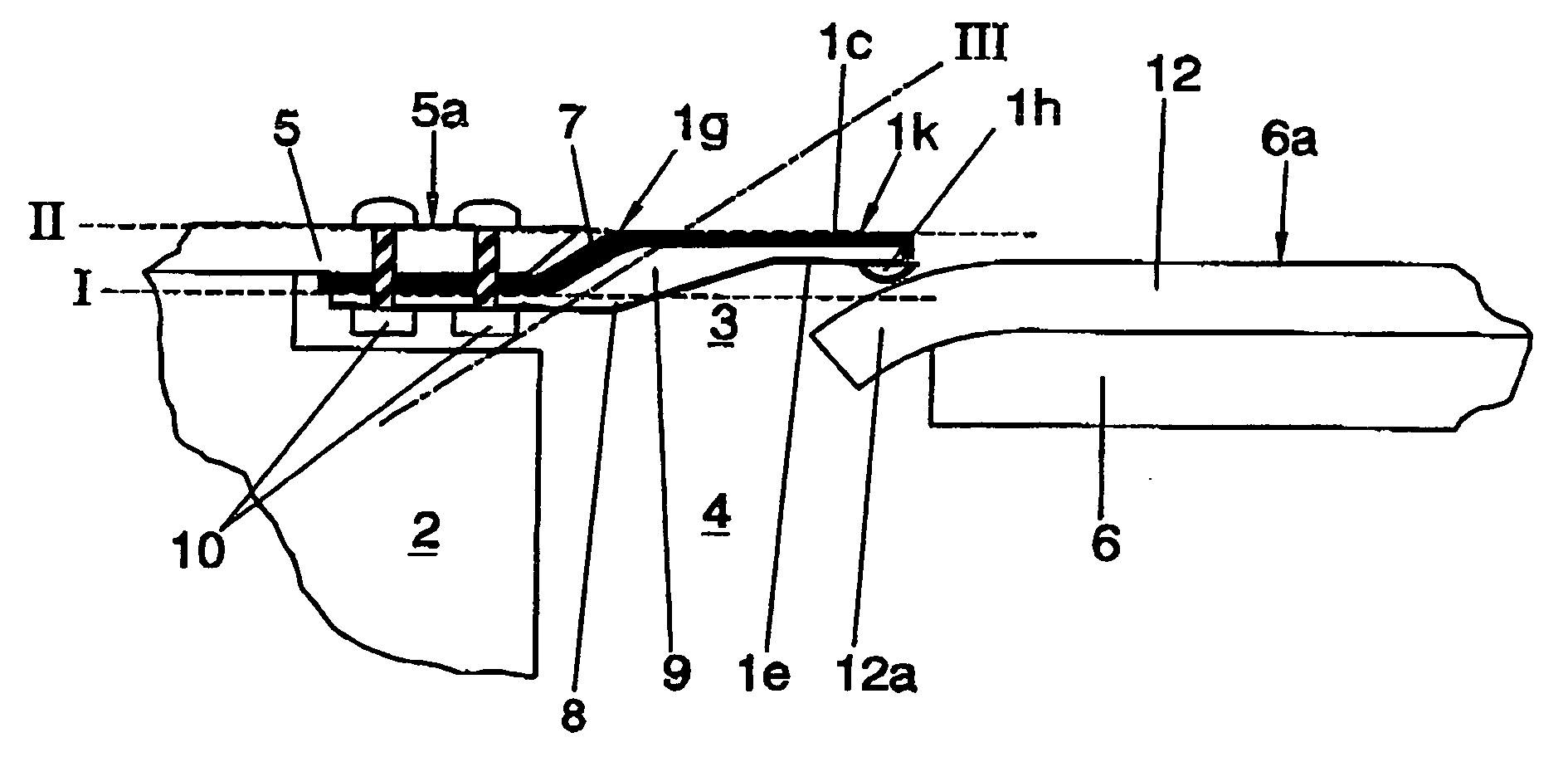

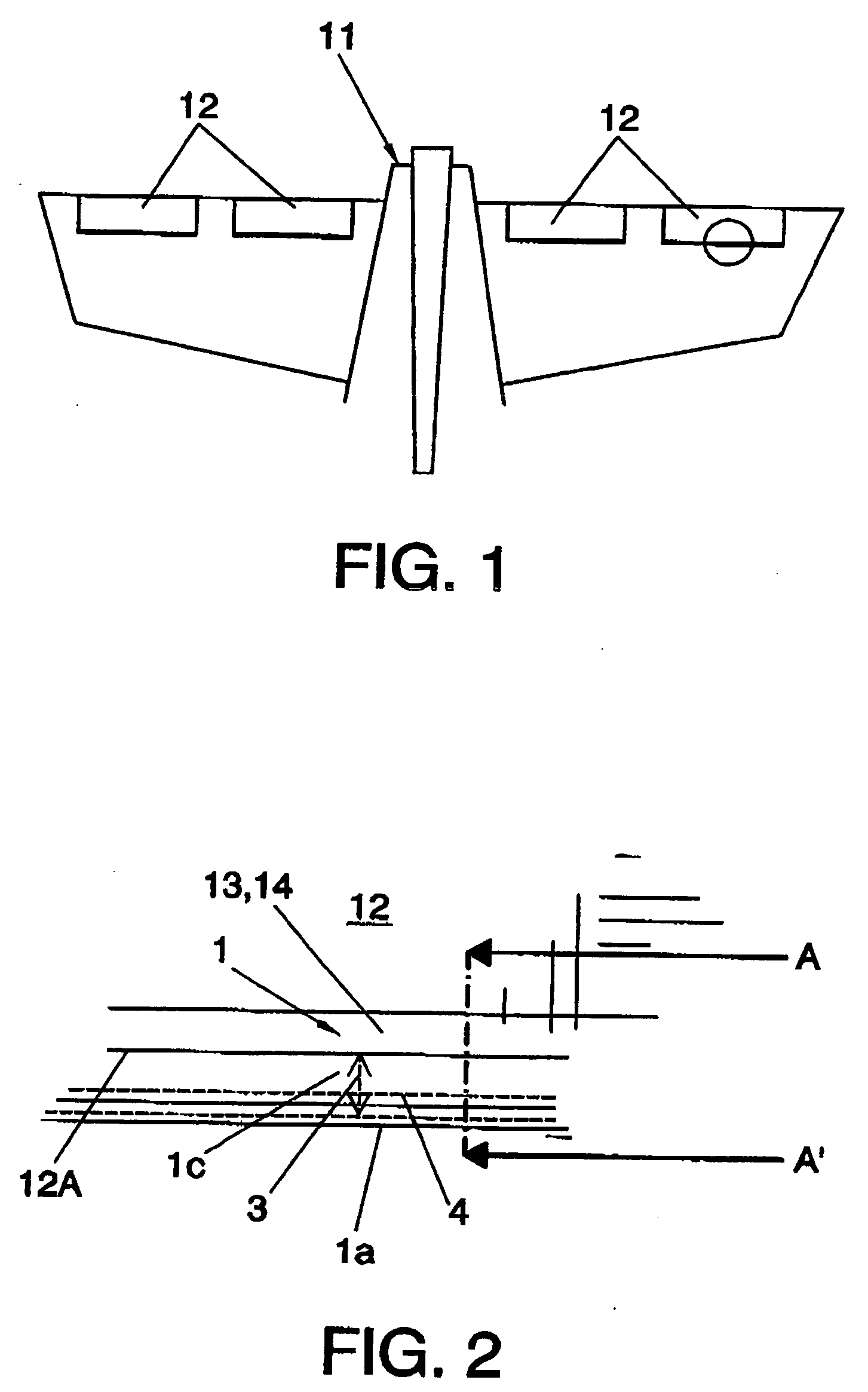

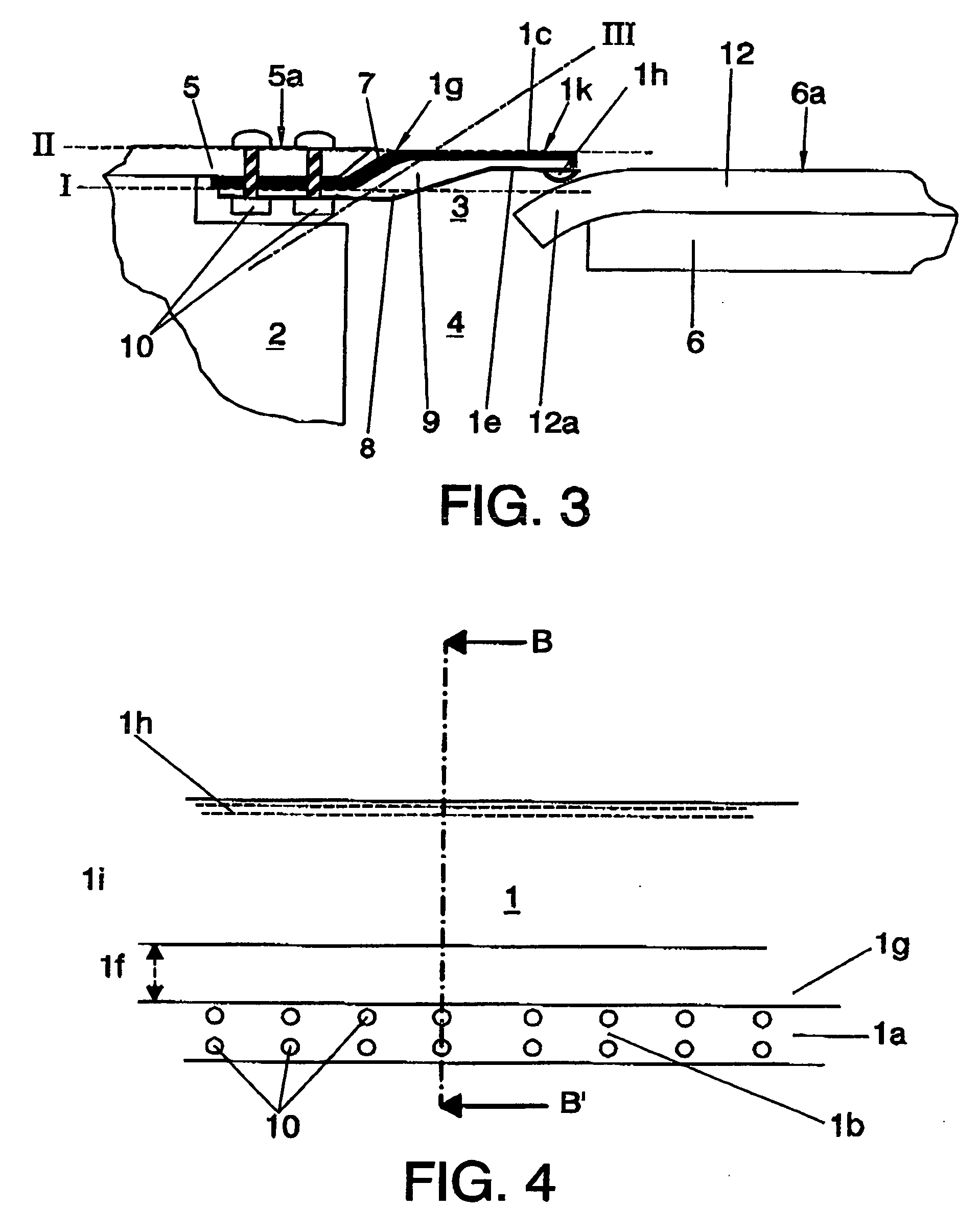

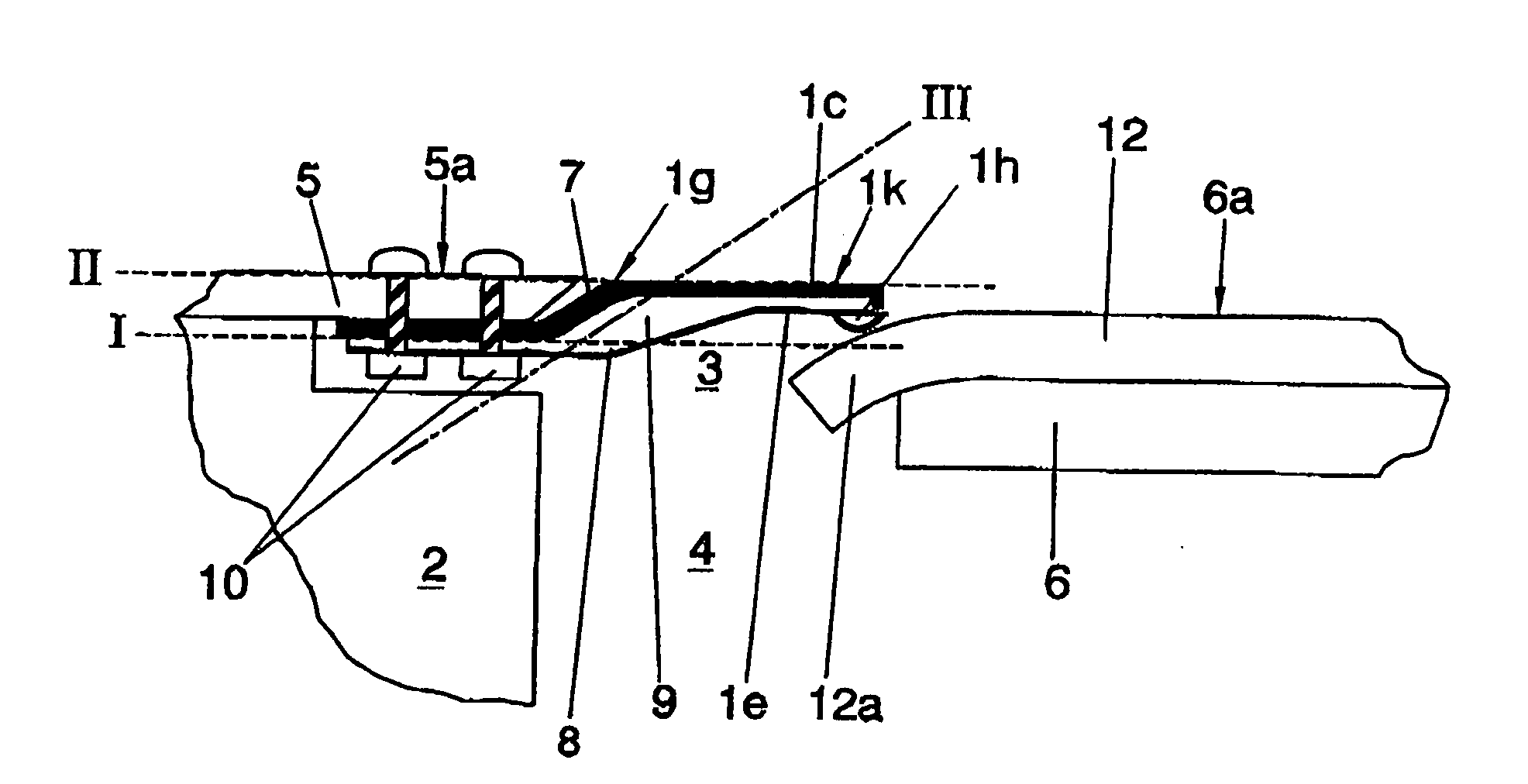

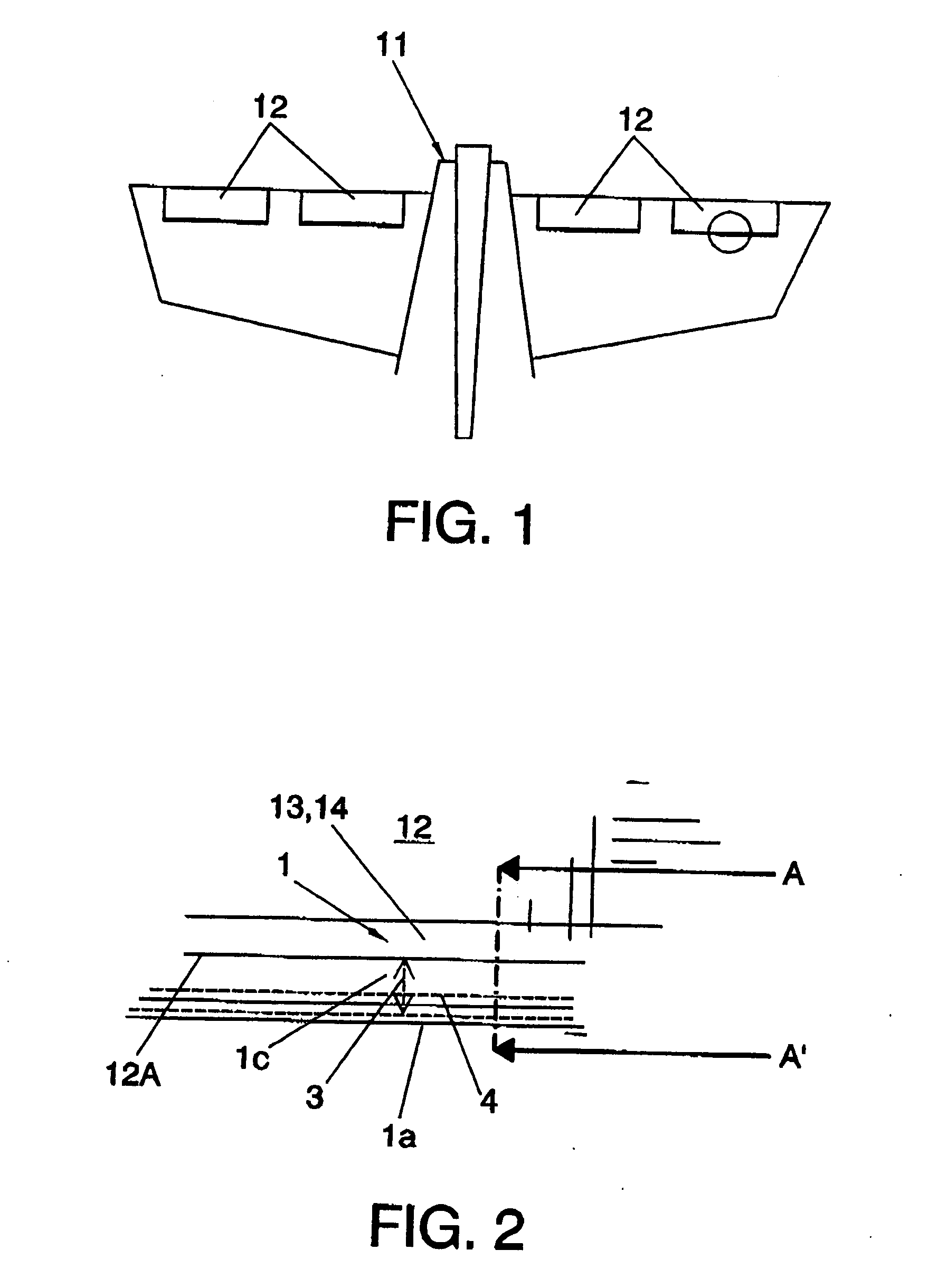

Reinforced cover for gaps in an aerodynamic contour

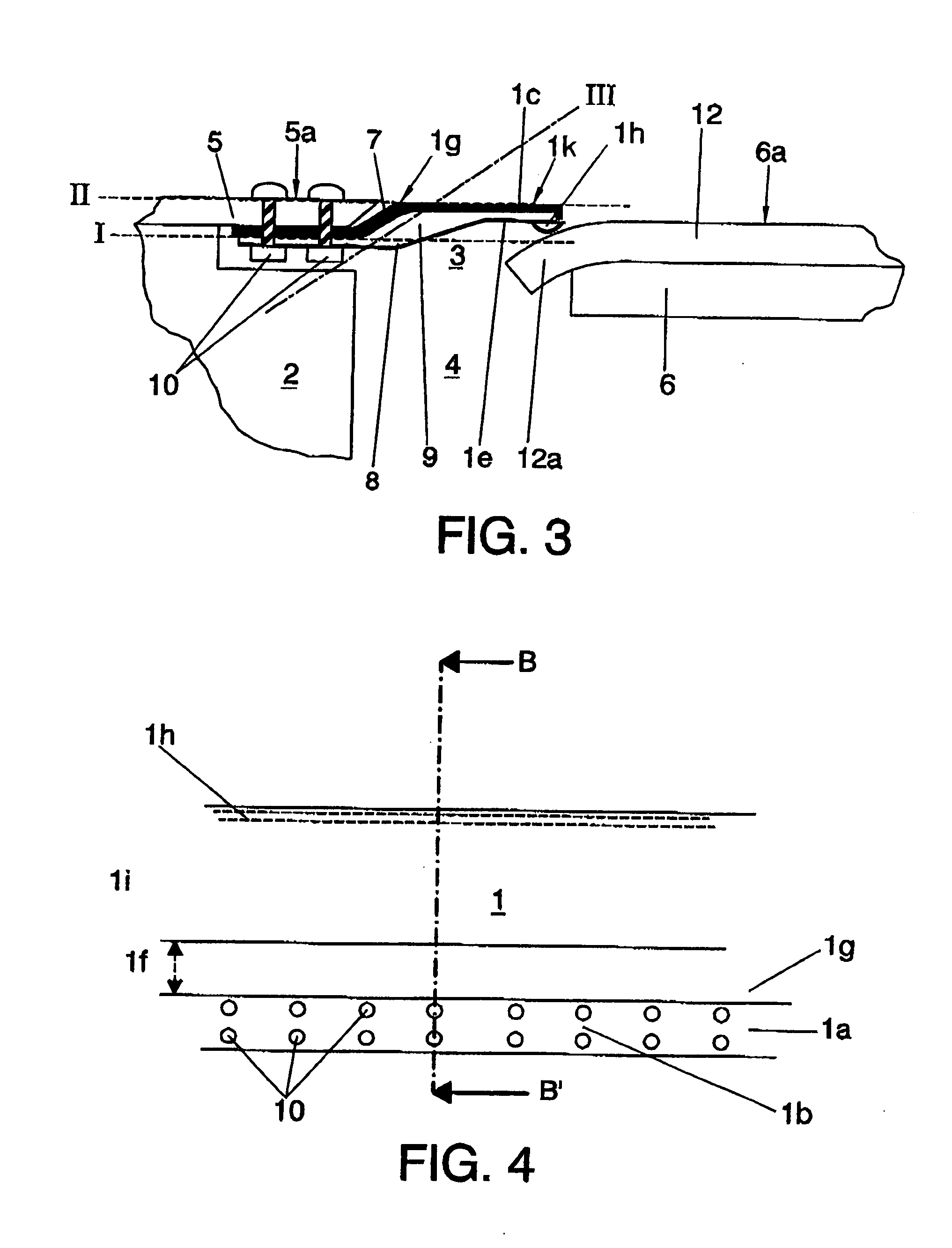

Reinforced cover for gaps in an aerodynamic contour of a vehicle, with a first attachment section la attachable to a structural element 2, 5 of the vehicle 11, on a first axial plane I; a second elastic section 1c which covers a gap 3 which is located between a fixed part 5 and a moving part 6, 12 of the vehicle 11, and provided with a low-friction coating 8 on its inner surface 1e, an outer surface 1k with a fiberglass layer 7a; a main internal body 9 of an elastic material, a flexible transition section 1g between the first and the second section, 1a, 1c; the outer surface 1k of the second section 1c flushing with the outer surface 5a and extending towards the free end 1d as a continuation of the outer surface 5a of the fixed part 5.

Owner:AIBUS ESPAA SL

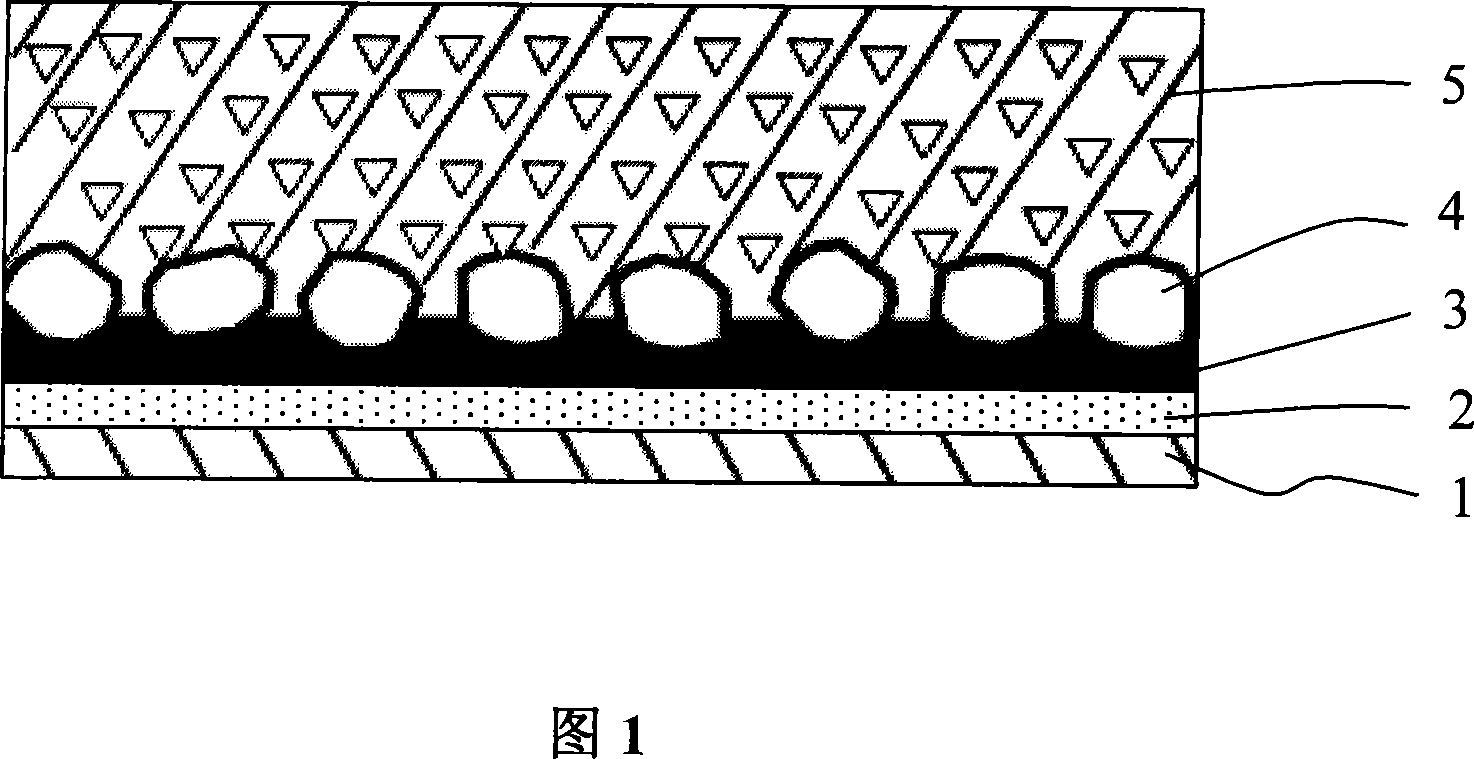

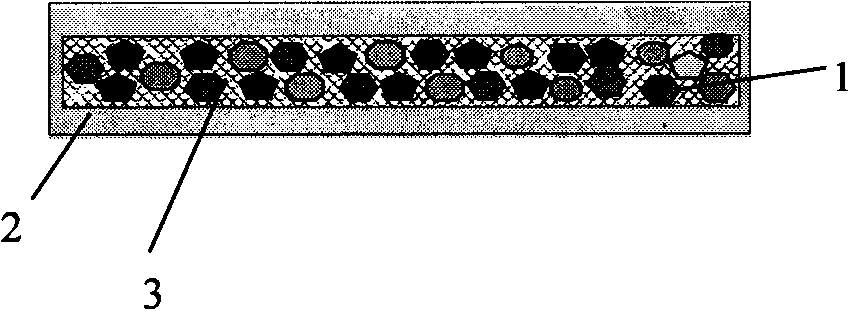

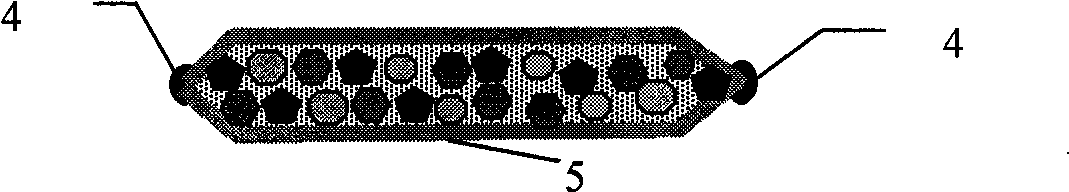

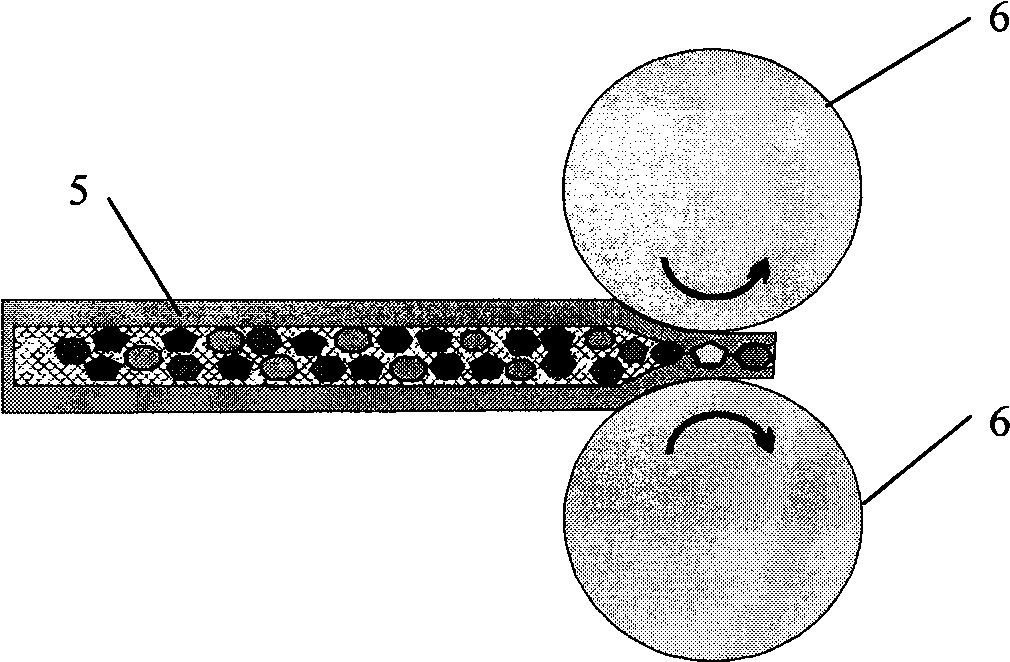

Rubber powder modified asphalt macadam bridge surface waterproof layer and construction method

InactiveCN101220579AImprove adhesionImprove waterproof performanceIn situ pavingsBridge structural detailsChipsealCrack resistance

The invention relates to a rubber powder modified asphalt gravel bridge deck waterproof layer and a construction method thereof. The bridge deck waterproof layer of the invention is arranged between a bridge cement concrete paving layer and a bridge deck asphalt paving layer, and the bridge deck waterproof layer consists of a signal particle diameter gravel layer, a rubber powder modified asphalt layer, and an interlayer interface connection layer from top to bottom. The cement concrete paving layer is gigged and cleaned clearly during the period of construction, and then the interlayer interface connection material, the rubber powder modified asphalt and the signal particle diameter gravel are sprayed sequentially. After the rubber-tyre rolling and health preservation, the traffic can be open to the construction vehicles or the construction of the bridge deck asphalt paving layer starts. The bridge deck waterproof layer of the invention has the advantages of good waterproof effect, high interlayer cohesive performance, good high-temperature stability, good low-temperature crack resistance and excellent fatigue resistance, and efficient property of absorbing and reducing the interlayer stress.

Owner:徐培华

Reinforced cover for gaps in an aerodynamic contour

ActiveUS20080121758A1Reduce weightReduce thicknessAircraft controlWing adjustmentsGlass fiberEngineering

Reinforced cover for gaps in an aerodynamic contour of a vehicle, with a first attachment section 1a attachable to a structural element 2, 5 of the vehicle 11, on a first axial plane I; a second elastic section 1c which covers a gap 3 which is located between a fixed part 5 and a moving part 6, 12 of the vehicle 11, and provided with a low-friction coating 8 on its inner surface 1e, an outer surface 1k with a fiberglass layer 7a; a main internal body 9 of an elastic material, a flexible transition section 1g between the first and the second section, 1a, 1c; the outer surface 1k of the second section 1c flushing with the outer surface 5a and extending towards the free end 1d as a continuation of the outer surface 5a of the fixed part 5.

Owner:AIRBUS OPERATIONS SL

High wear resisting iron-based composite material and preparation method thereof

The invention relates to a high wear resisting iron-based composite material and a preparation method thereof. The method comprises the following steps: 1) large-size electric smelting zirconium corundum particles are used; 2) the electric smelting zirconium corundum particles are prepared into zirconium corundum particle ceramic blocks and cooled for standby application; 3) the obtained zirconium corundum particle ceramic blocks are arranged on the top of a resin sand mould cavity for an infiltration casting process, and a box is opened to take out pieces; and 4) heat treatment is carried out on the obtained zirconium corundum particle enhanced iron-based composite material. The method disclosed by the invention has the following advantages: 1, the process is simple and can be realized through an ordinary casting method, and the thickness of the composite layer can be adjusted in a wider range; 2, air holes and slag inclusion in the production process of the composite material can be effectively avoided; and 3, the production process is mechanized easily, the production cost is low, and the production efficiency is high.

Owner:YANGZHOU ELECTRIC POWER EQUIP MFG FACTORY CO LTD +1

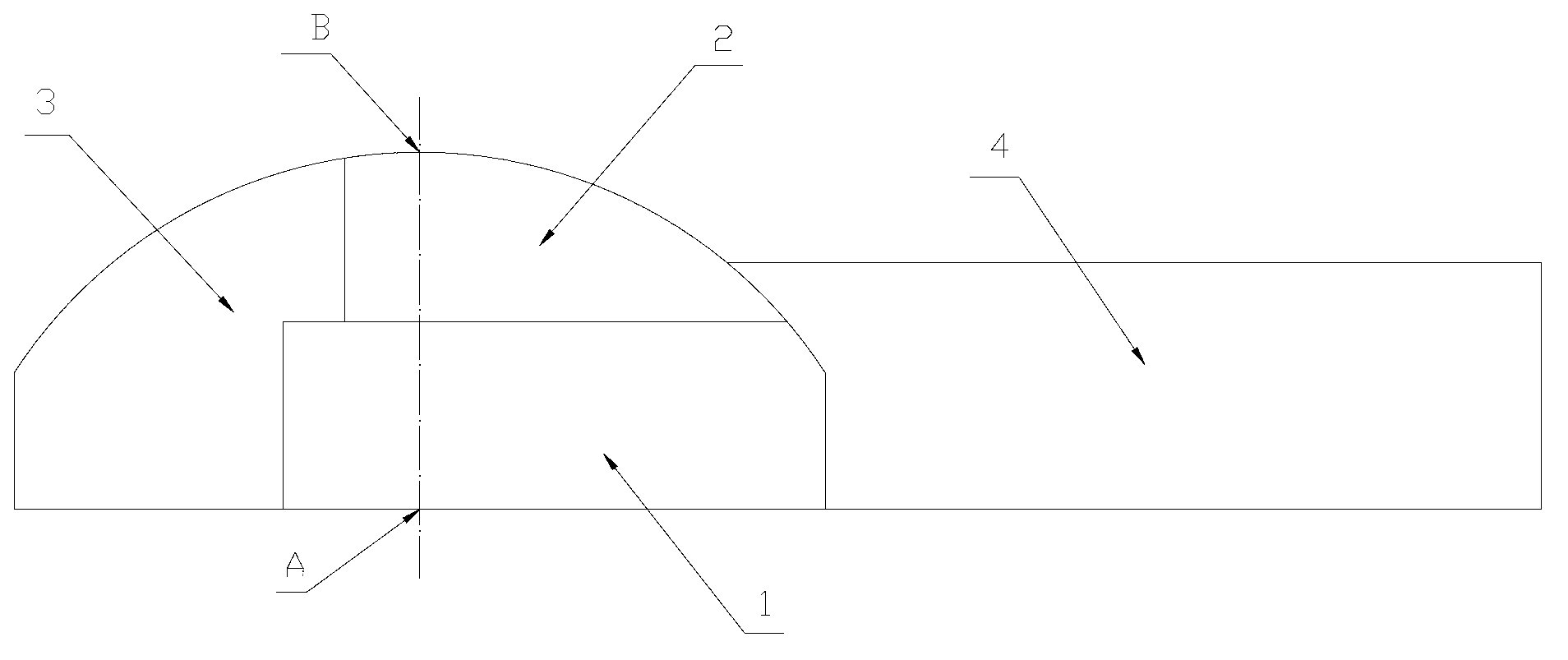

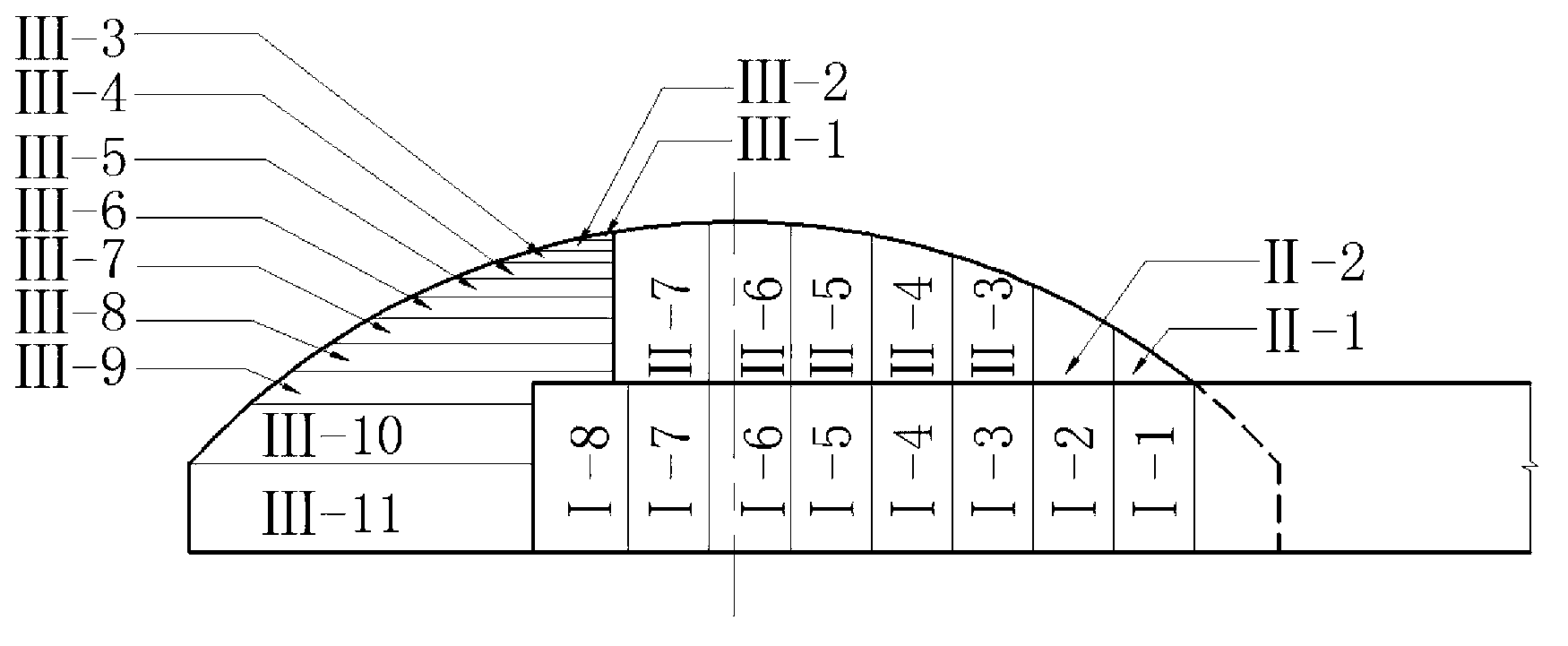

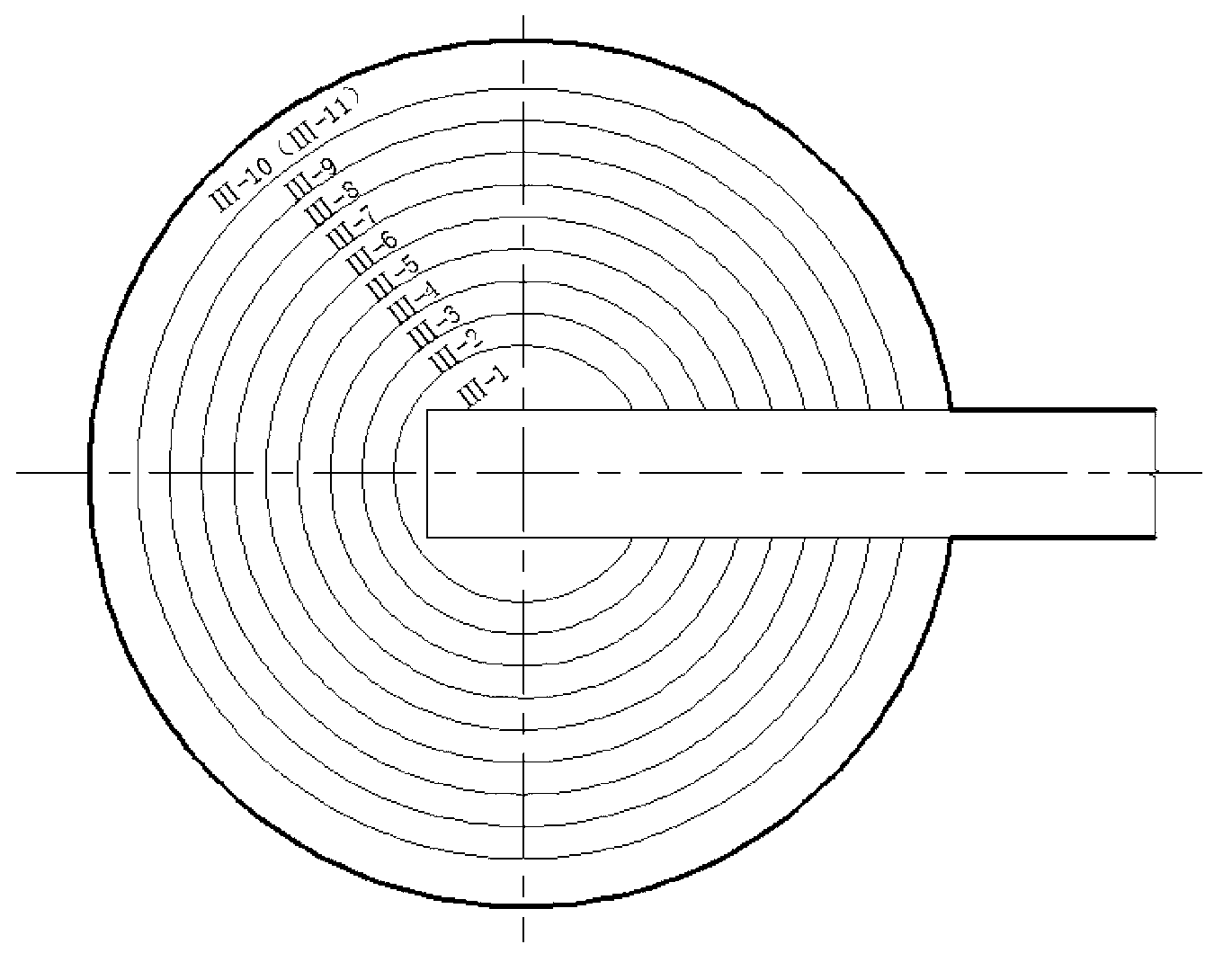

Excavation and construction method of underground cavity ball coronary dome

ActiveCN103256053AEnsure surrounding rock stabilityEasy and accurate workUnderground chambersTunnel liningPart iiiWire rope

The invention relates to an excavation and construction method of an underground cavity ball coronary dome. The excavation and construction method includes the following steps: S1, a channel is constructed; S2, a dome part I is excavated, primary support is conducted on the dome part I, S3, a dome part II is excavated, primary support is conducted on the dome part II, S4, a dome part III is excavated, a steel wire rope which is connected with the central point of the bottom of the dome and the central point of the top of the dome is used as a center, the vertical layered construction height marked on the steel wire rope is used as a control height, and the dome part III is constructed in a layering and loop mode from top to bottom. Each layer is excavated in a segmentation mode, and the primary support is conducted on each segment. The excavation and construction method of the underground cavity ball coronary dome has the advantages that geology is ascertained through an advance pilot tunnel, therefore, reinforcing supporting measures can be made in advance, and the stability of surrounding rock is guaranteed. An annular excavation method in which a dome central line is used as a standard from top to bottom is adopted, the line type control of a fracture surface is benefited, the construction space is enlarged, mechanical operation is convenient, and construction efficiency is high.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD

Peltateleaf begonia herb and rhizome type grape cultivation method

The invention relates to a peltateleaf begonia herb and rhizome type grape cultivation method, which is favorable for improving the grape quality, effectively controlling the yield and realizing excellent quality, stable yield, long life and beautiful appearance of the grapes. The method comprises the following steps: (1) in the first year, carrying out trench planting, namely, shearing the seedling for fix planting to leave two buds, cultivating one or two young sprouts, and in winter shearing the cultivated annual shoot to leave 0.5m of the annual shoot, pressing the left annual shoot on the ground surface and fixing the left annual shoot on a first strip of iron wire, wherein when trench planting is carried out, the fix planting furrow width is 0.5 meter, the furrow depth is 0.5 meter, the plant spacing is 0.5 or 1.0 meter and the row spacing is between 2.2 and 2.5 meters; (2) in the second year, straightly binding the young sprouts germinated from the bud eyes upward to ensure that the young sprouts are distributed uniformly on the trellis surface, and when carrying out shearing in winter, leaving three buds; and (3) in the third year, straightly binding the young sprouts germinated from the bud eyes upward to ensure that the young sprouts distributed are uniformly on the trellis surface and each bearing shoot have three young sprouts, and when carrying out shearing in winter, shearing all the parts which are provided with two annual shoots, and shearing another annual shoot to leave three buds.

Owner:内蒙古阳光田宇葡萄酿酒有限公司

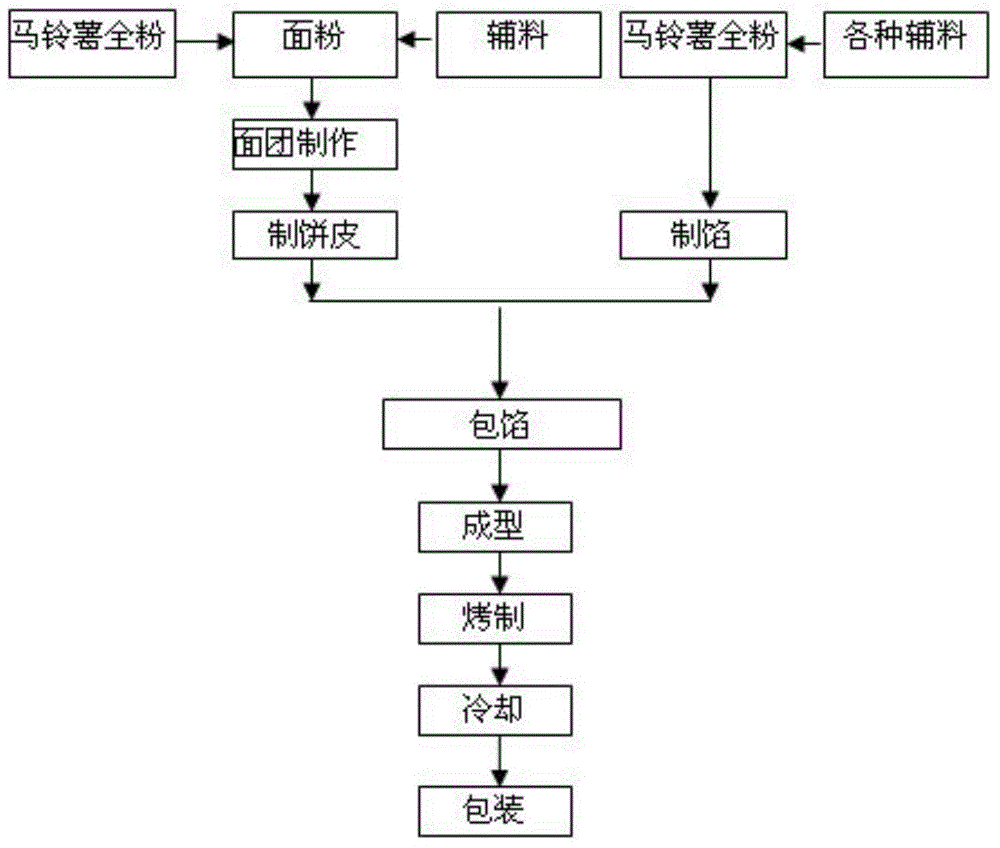

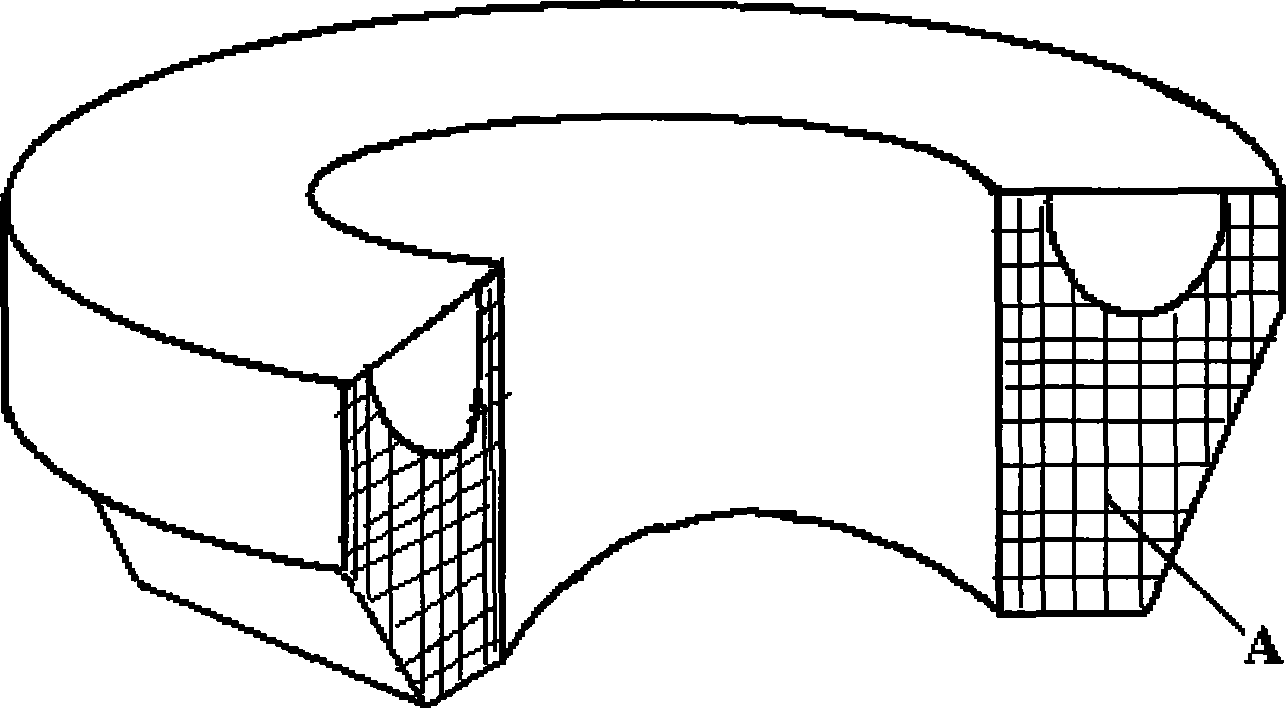

Potato mooncake and preparation method thereof

InactiveCN104663833AReduce heatRich materialDough treatmentBakery productsBiotechnologyMonoglyceride

The invention provides a potato mooncake. A cake crust comprises the following components in parts by weight: 50-75 parts of flour, 25-50 parts of potato granules, 50-80 parts of high fructose corn syrup, 10-40 parts of plant oil, 0.1-1 parts of monoglyceride, 0.1-0.3 part of sodium carbonate, and 5-8 parts of water; a stuffing comprises the following components in parts by weight: 100 parts of potato granules, white granulated sugar, melon seed kernels, peanut kernels, sesame, walnut kernels, pinenut kernels, plant oil, rose wine, water and the like. The potato mooncake has the advantages that the stuffing and the cake crust use the potato granules as the main raw materials, so the fatty content of the potato mooncake is reduced, the difficulty in industrial processing is decreased, and the industrial processing efficiency is improved; the mechanical operation is convenient, the qualitative and quantitative standard processing is realized, and the potato mooncake is suitable for industrial production of large, medium and small cake processing enterprises.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

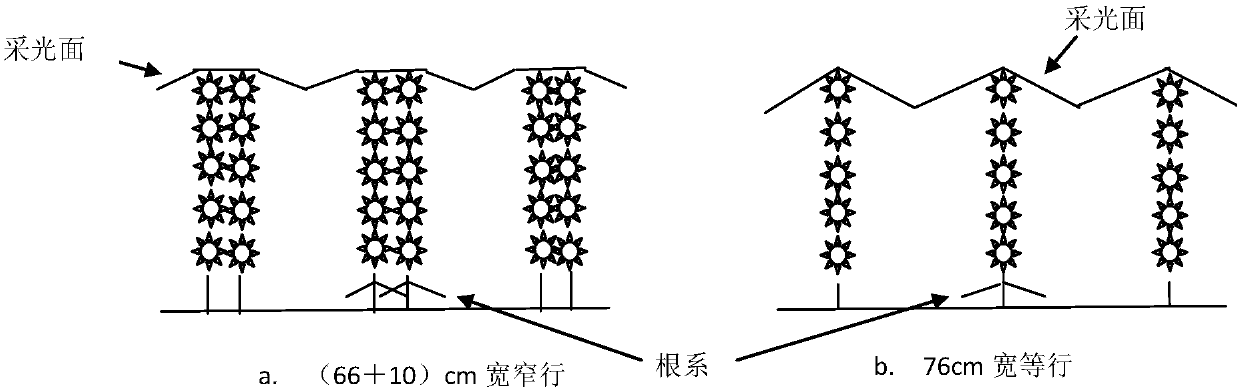

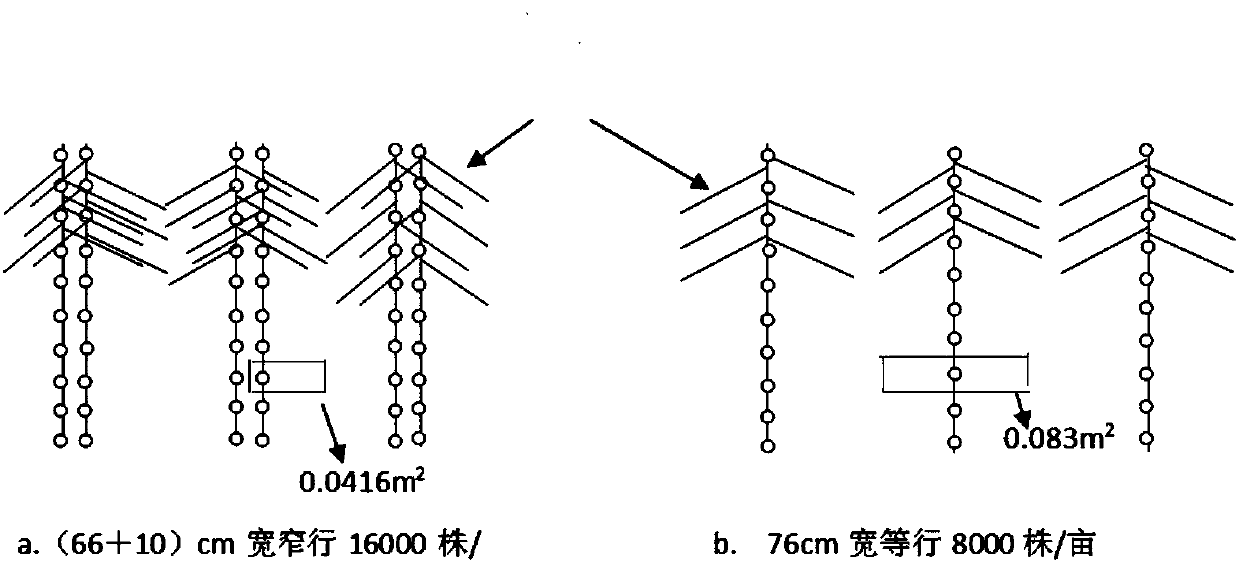

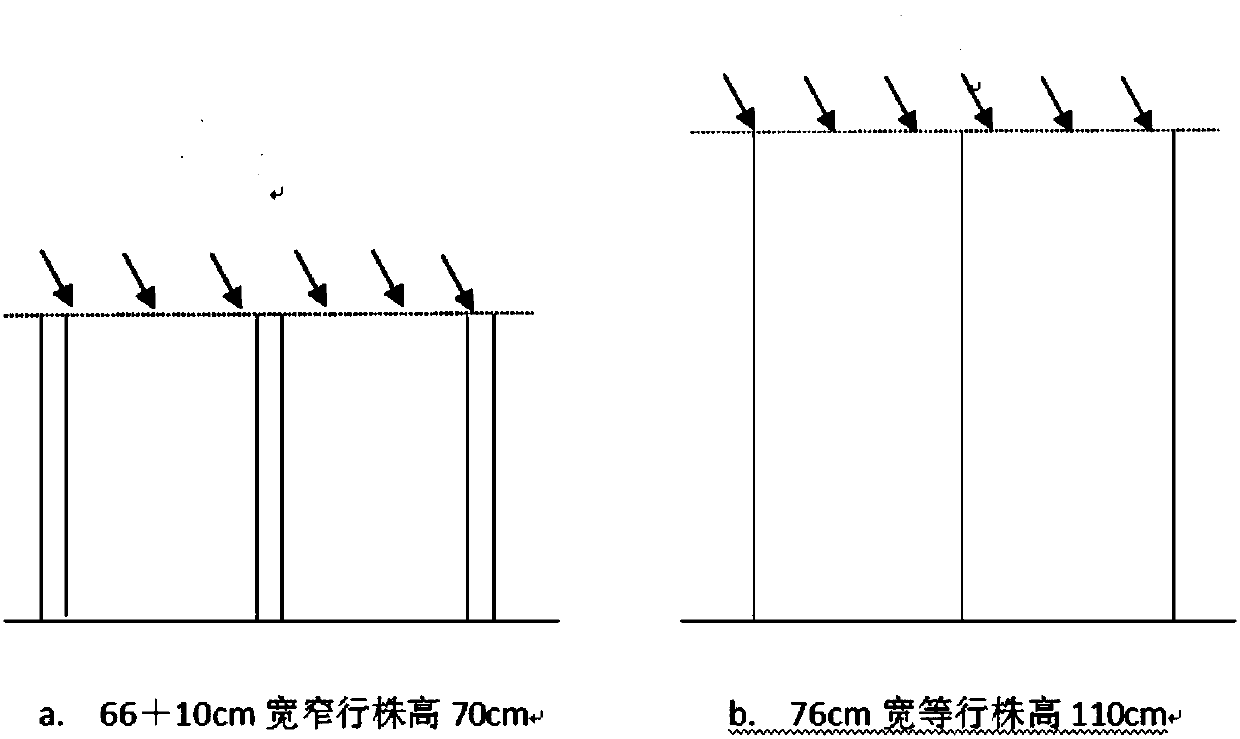

Production method for wide-early-superior raw cotton in cotton region in Northwest China

ActiveCN107996339AAvoid interspersedGood ventilation and light transmissionFertilising methodsCotton cultivationForeign matterAgricultural science

The invention discloses a production method for wide-early-superior raw cotton in a cotton region in Northwest China. The method includes the following steps of 1, fission type elite seed production,wherein variety selection,10-ten-thousand-times fission type seed reproduction, and grain selection according to the grain size are conducted; 2, planting in rows with the equal width and conducting the following matching technologies: the variety selection and rational early sowing technology, the edge film widening and lighting technology, the sowing row no-covering-soil and film no-covering-soil technology, the appropriate seedling water dropping technology, the first water late-drop technology, the plant-height increasing and appropriate tip pruning delay technology, and the cotton-flowering and boll-forming fertilizer re-application technology; 3, an early-sowing and early-ripening matching technology; 4, superior raw cotton quality control technologies which includes the technology of uncovering mulching films in the optimum period and preventing pollution, the technology of spraying an appropriate amount of disleave agent and ripener in the appropriate period, the technology ofremoving field weeds and foreign matters and the technology of harvesting in the appropriate period. The method is feasible, operation is simple and convenient, conversion from short-dense-early 'getting cotton by temperature' to tapping of the potential of light, temperature and environment resources is achieved, and support is provided for high-yield, high-efficiency and high-quality cotton.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

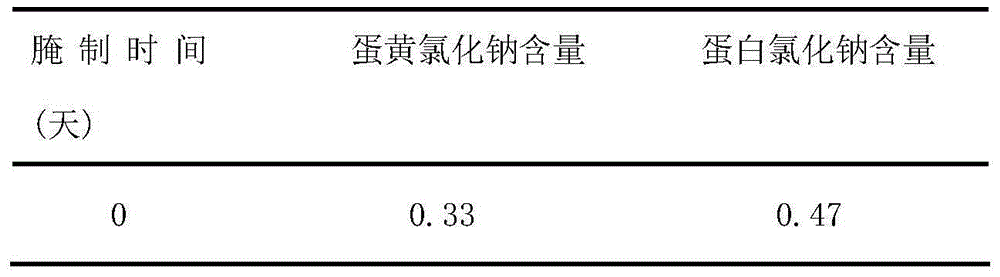

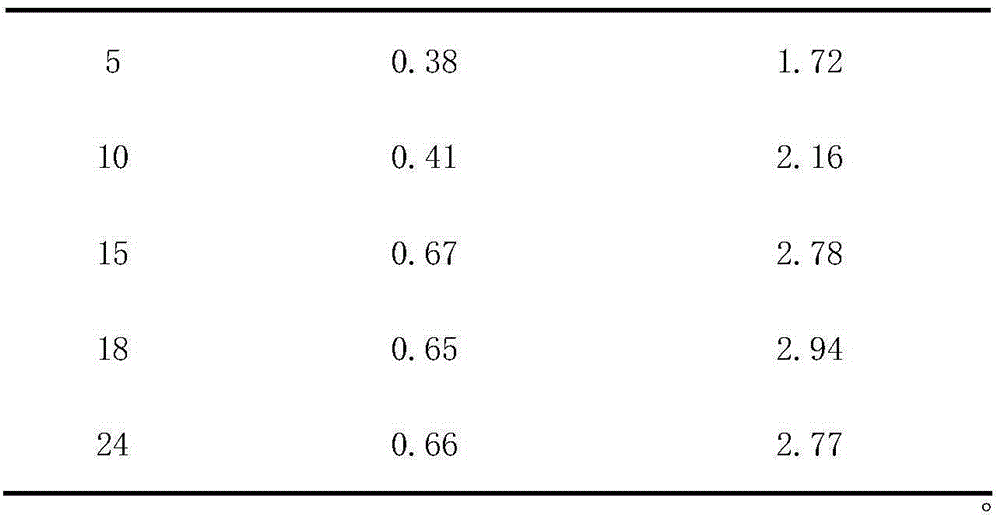

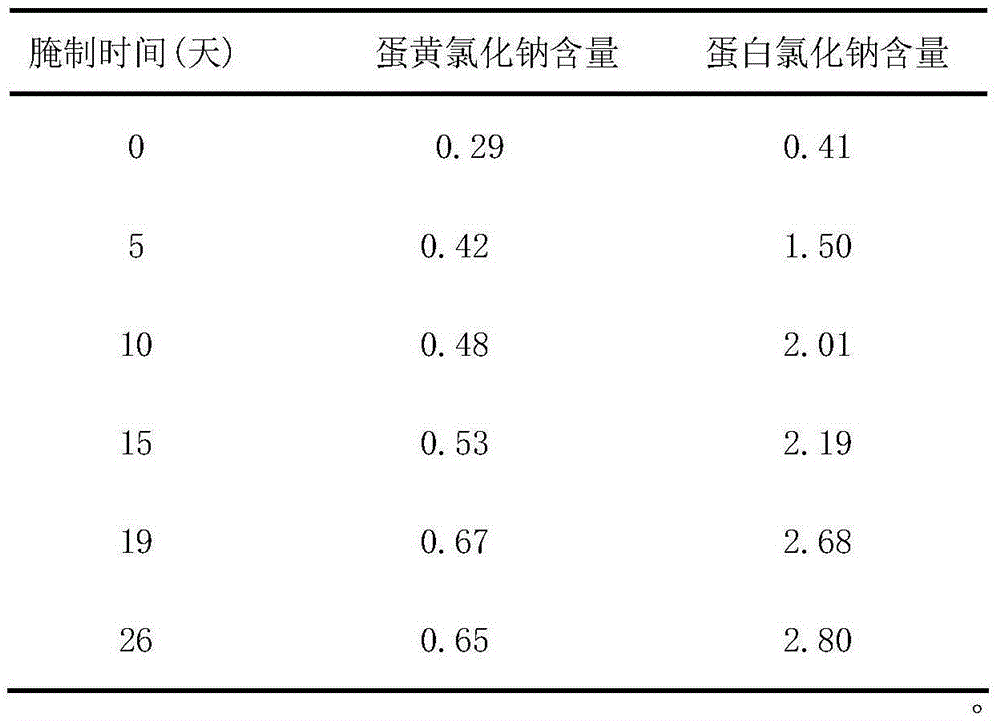

Method of pickling salty preserved eggs

The invention provides a method of pickling salty preserved eggs. The salty preserved eggs are formed by pickling salted eggs and preserved eggs through a sectional type design. According to the cooked salty preserved eggs, egg white is yellowish-brown preserved-egg gel and is crystal clear and high in resilience, and the salty preserved eggs have a preserved egg flavor; yolks are floppy, can produce oil and have the salted egg feature; one duck egg has two flavors.

Owner:JIANGXI ACAD OF AGRI SCI

Low-fat flavour chilli sauce and method for making same

A low-oil fragrant hot paste with different tastes is prepared from primary raw material, stabilizing material and fragrant hot material in weight ratio of (60-75):(24-37):(1-3) through mixing, stirring, steam heating to 50-100 deg.C, grinding by colloid mill 2-3 times, loading in sterilized containers, and sealing. Its advantages are low content of oil, rich nutrients, and optimal color, smell and taste.

Owner:杨辉

Method for rapidly and directly reducing haematite or limonite into ferrous powder

The invention relates to a method in which hematite or limonite are quickly reduced and made into iron powder, which aims to use iron ore difficult to be magnetically separated as a raw material to reduce the cost. The method is characterized in that hematite ore or limonite ore are crushed and then washed and magnetically separated; iron ore powder, coal powder and lime powder are mixed according to the proportion, and calcium fluoride and adhesive are added to be pressed into flans with pores, and the flans are dried; the structure of a kiln car surface is improved, and a sagger is made; the pressed and dried flans are hoisted to the kiln car surface after being put orderly, and the sagger is covered outside the flans; a tunnel kiln is used for calcinating the flans, and two ends of the tunnel kiln are covered with air sealing machines; after the kiln car travels out of the tunnel kiln, a motor hoist is used to hoist the sagger, calcinating blocks are pushed into a water pool to be quickly cooled and automatically ground, and the iron powder and dregs are fished out to directly enter a ball mill to be wetly milled and be pressed into blocks or bagged after the separation of a magnetic separator and the drying.

Owner:王号德

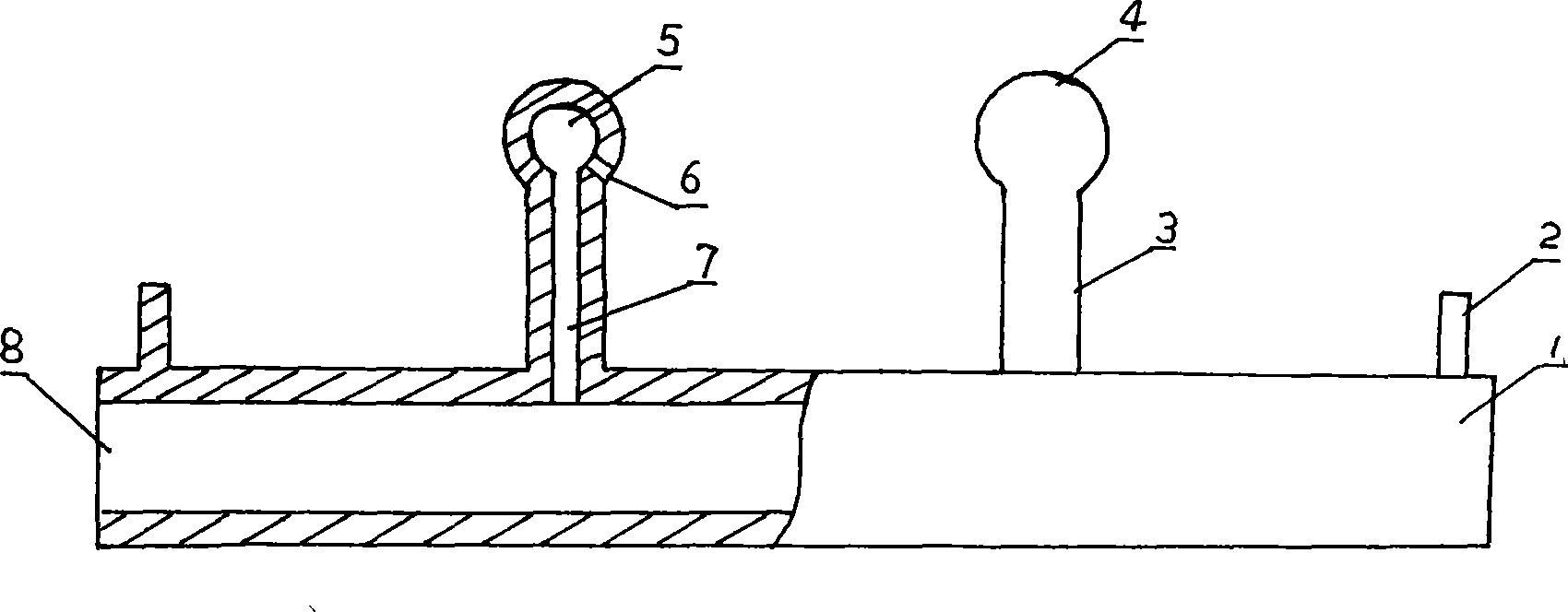

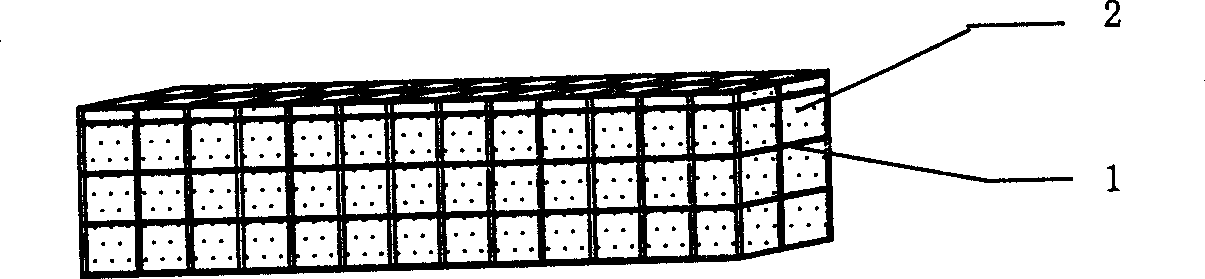

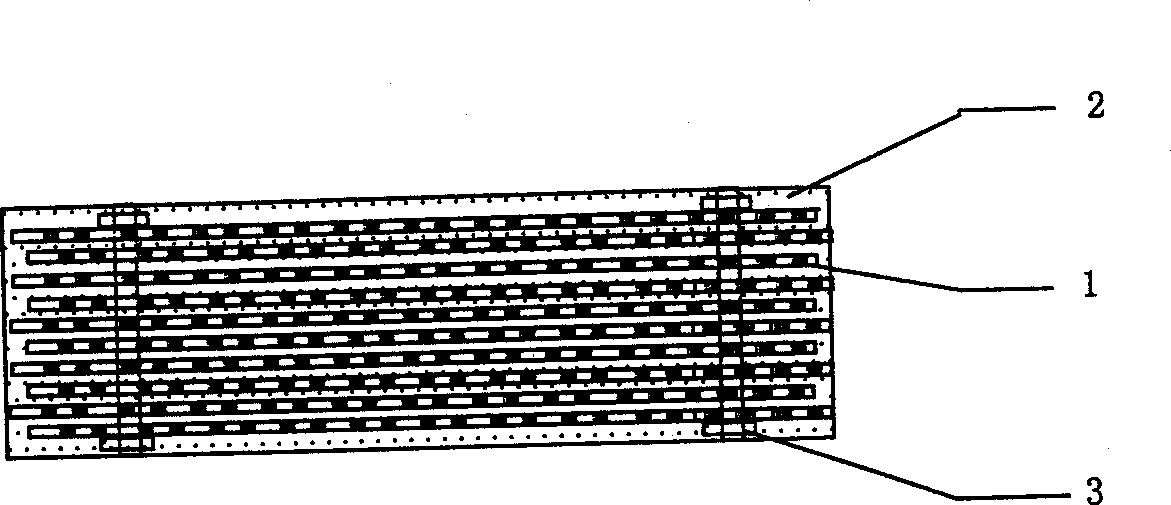

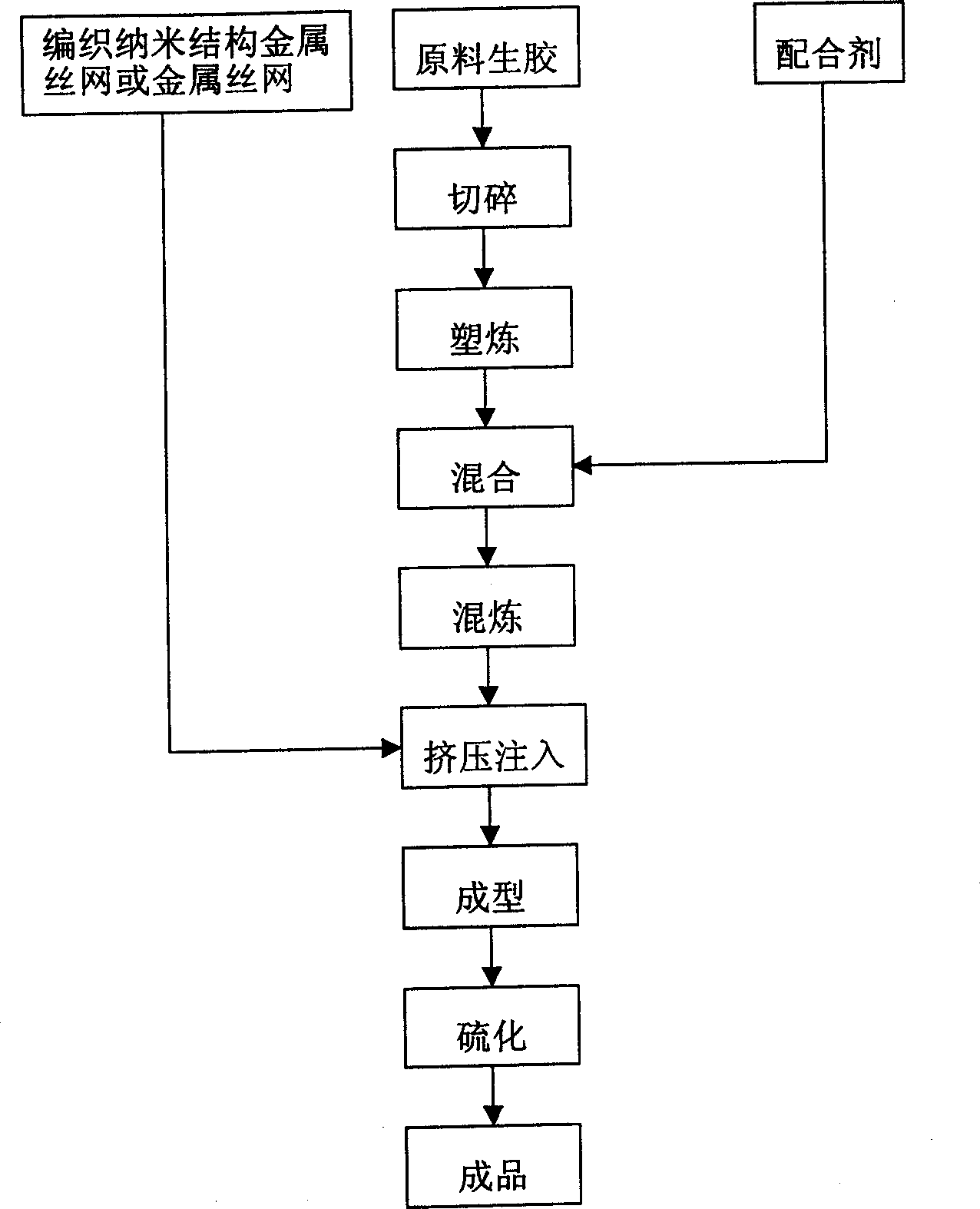

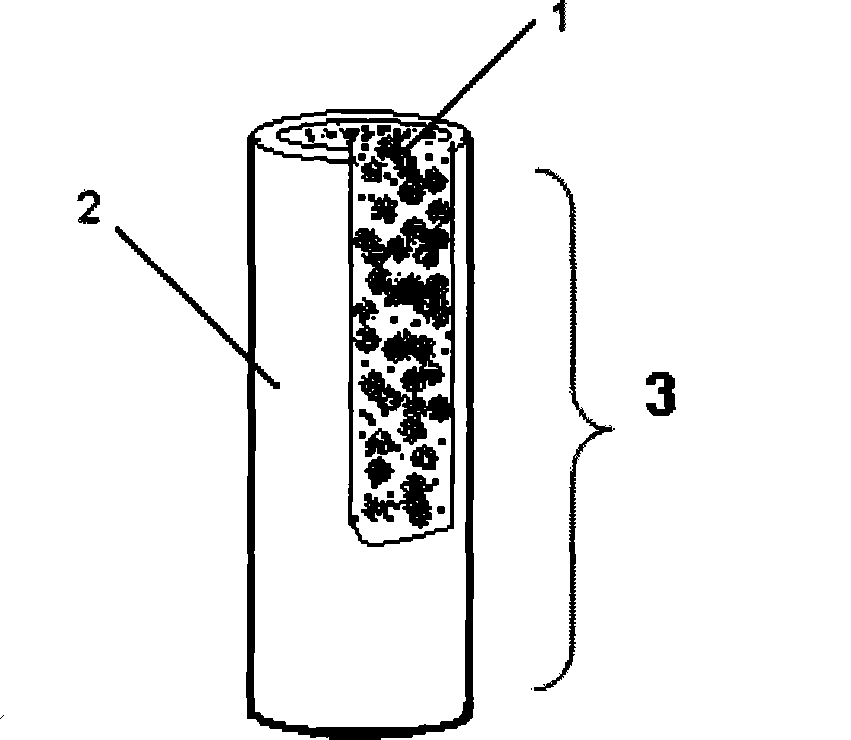

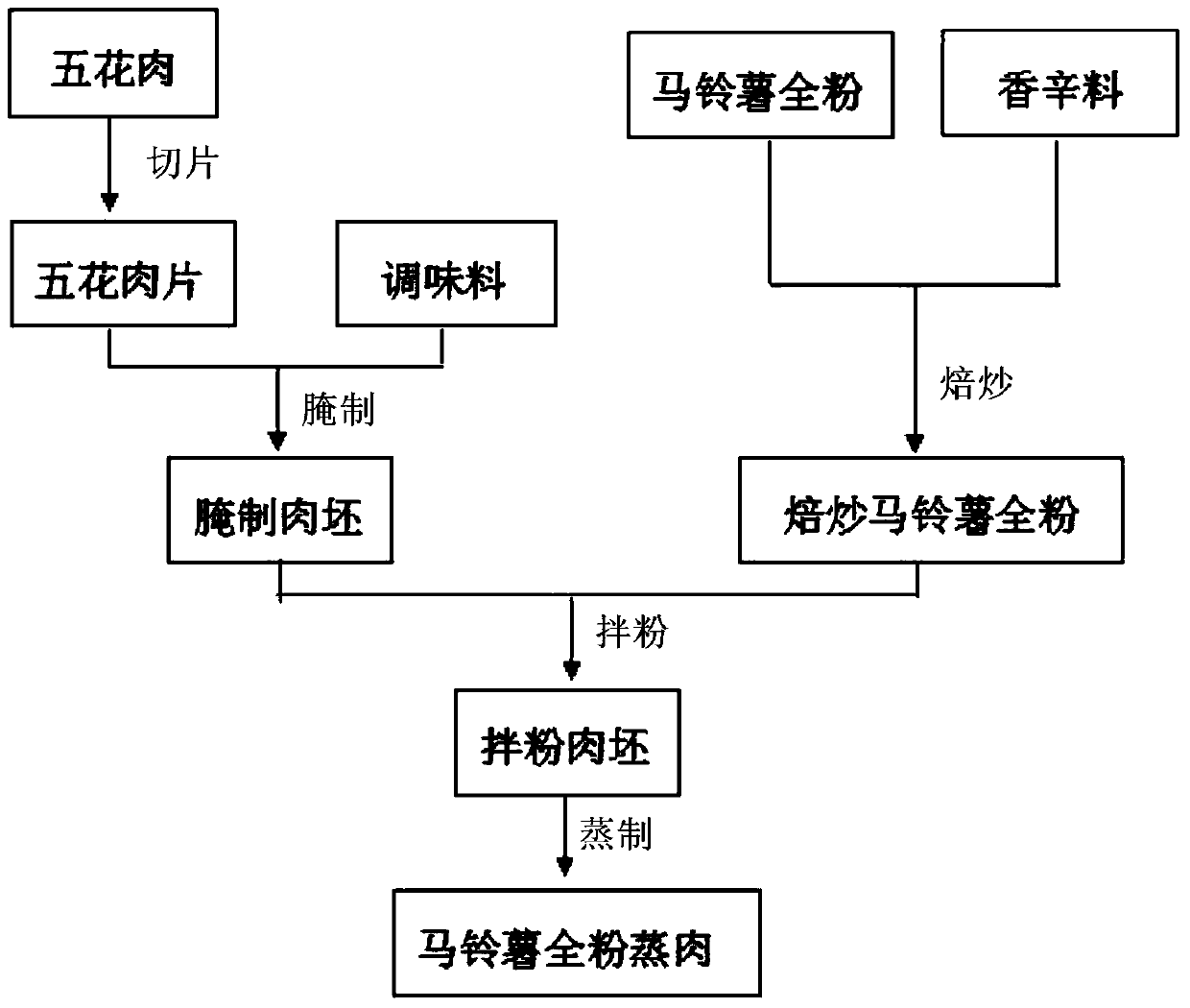

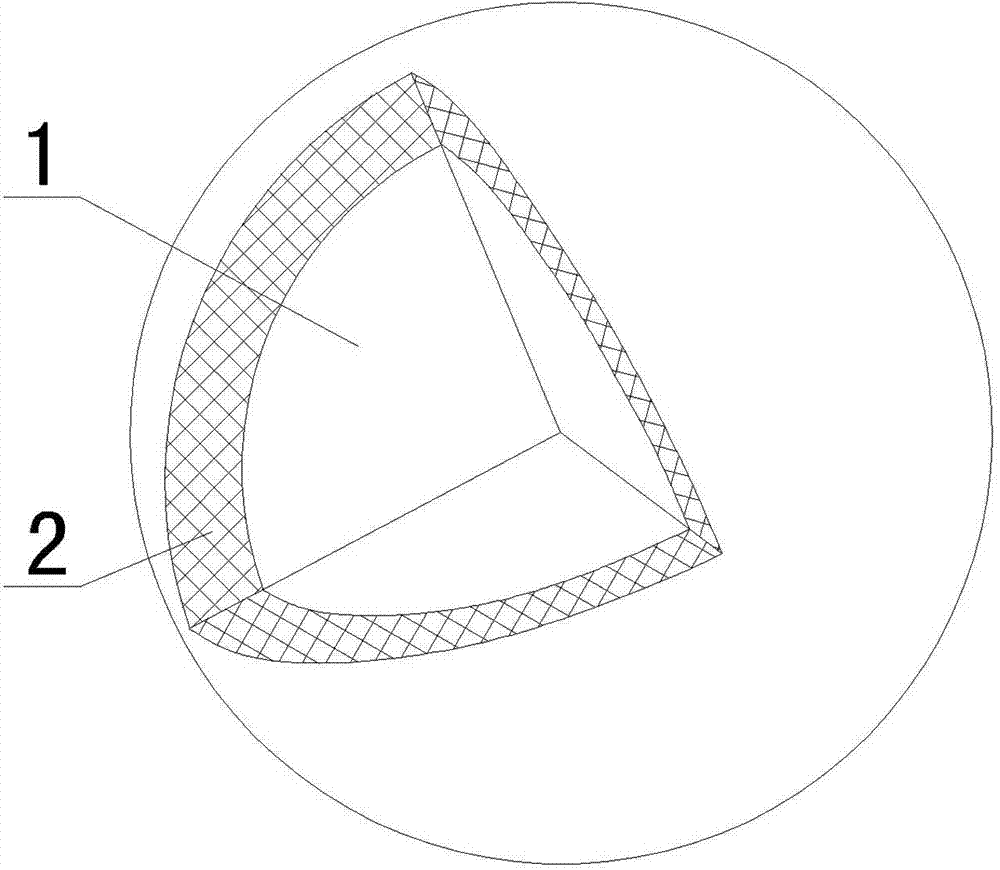

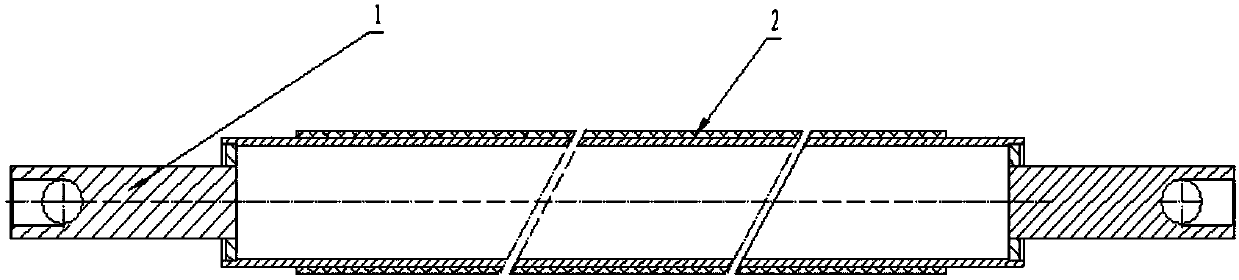

Composite lining with metal wire screen in nanometer structure and its production process

The present invention discloses a kind of nano structure wire gauze composite lining plate and its preparation process. Said lining plate is made up by using wire gauze and compounded filing materialthrough a compositive process. Said wire gauze can be integrally braided, also can be a multilayer structure pieced by using single-layer of wire gauze, said wire gauze can be placed in the interior of compounded filling material, then they are combined into a whole body. Said composite lining plate possesses high wear-resistance, water-resisting property, vibration-absorbing property and corrosion-resisting property, etc..

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

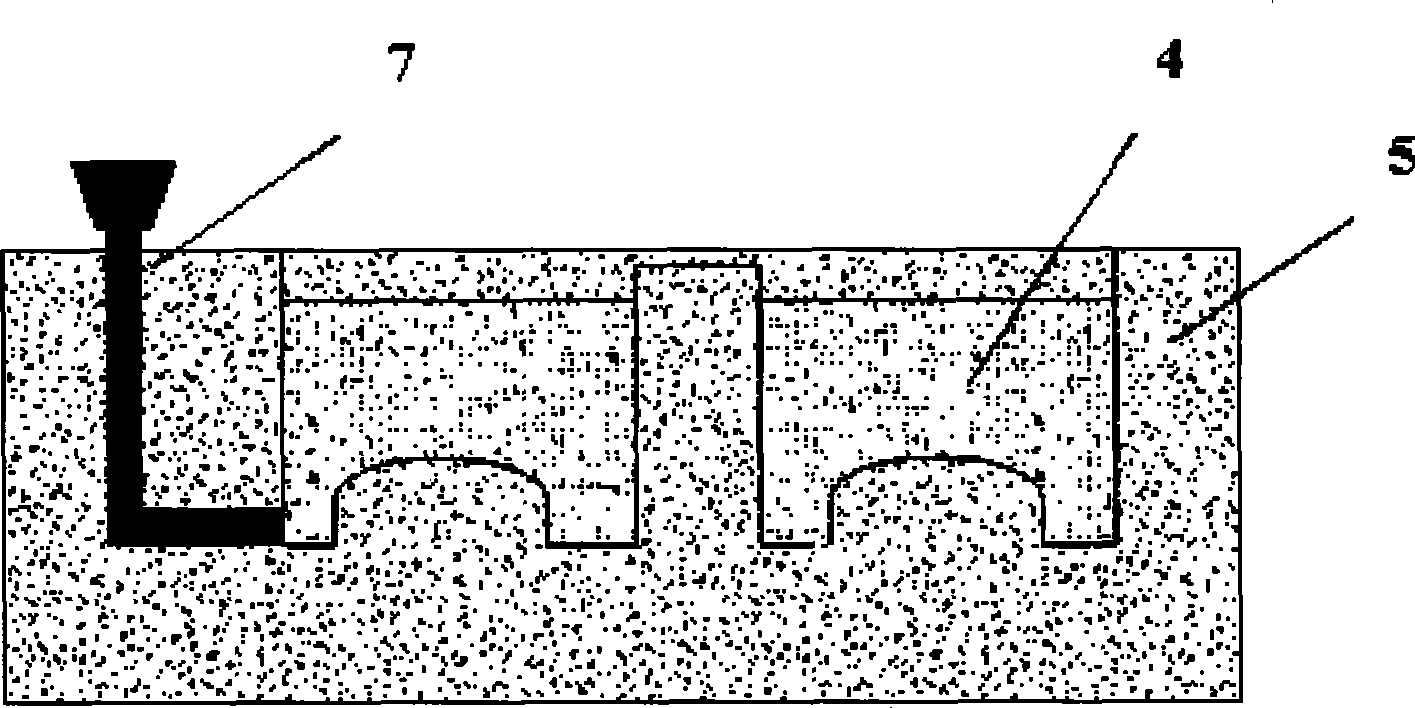

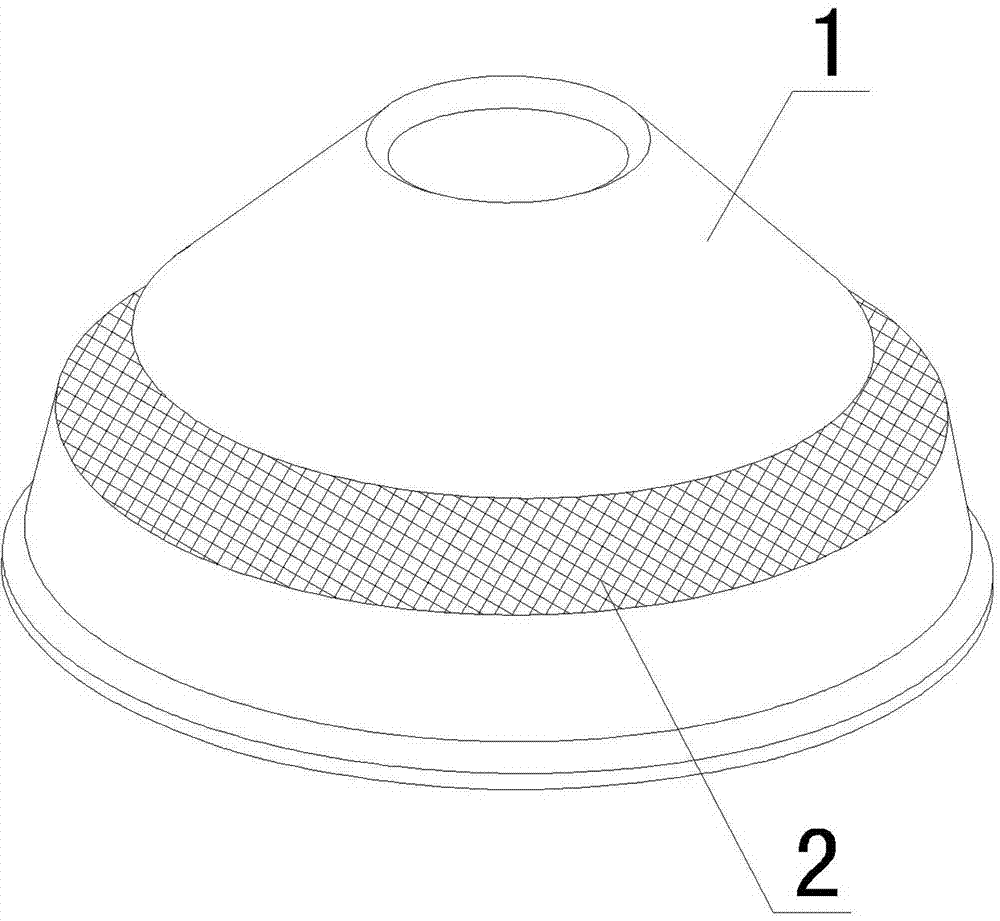

Method for preparing primary column shaped horniness phase composite wear-resistant grinder dish

The invention discloses a method for preparing a composite wear resistant abrasive disk with a protogenous columnar hard phase. The wear resistant abrasive disk prepared by the method is formed by pouring and compounding a high hardness columnar alloy hard phase and a high tenacity base metal. The method comprises the following steps: weaving an alloy powder core wire material into a framework similar to the shape of the abrasive disk, and pouring smelted high temperature base material molten steel into a die cavity of an abrasive disk casting mould; putting the woven framework similar to the shape of the abrasive disk into the casting die cavity filled with the high temperature base metal molten steel quickly, performing cast-infiltration, sintering or melting on the woven alloy powder core wire material framework by using the heat of the high temperature base metal molten steel so as to generate a highly-dispersed high hardness columnar alloy hard phase in situ; and cooling the phase at room temperature to produce the composite wear resistant abrasive disk using high-tenacity and high-strength metal as a base and containing the metallurgically-combined protogenous columnar hard phase. The composite wear resistant abrasive disk with the protogenous columnar hard phase has ultra wear resistance and good impact resistant toughness, and the service life of the abrasive disk is close to or exceeds the imported products of the same type.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

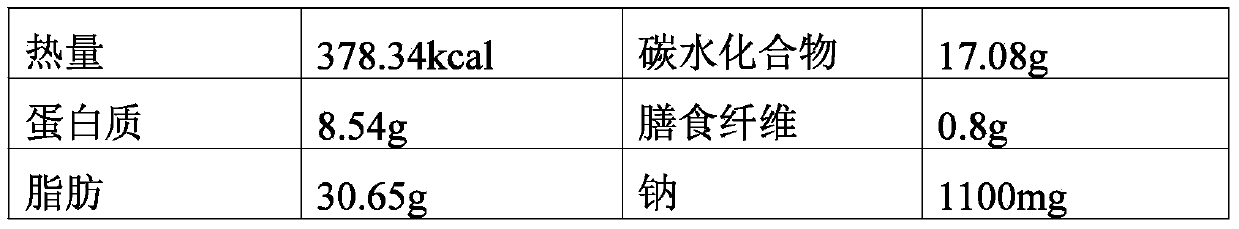

Pork steamed with total potato flour and processing method of pork steamed with total potato flour

InactiveCN104055130AFit for consumptionIncrease dietary fiber contentFood ingredient functionsFood preparationMonosodium glutamateAmomum tsaoko

The invention discloses pork steamed with total potato flour and a processing method of the pork steamed with total potato flour. The pork steamed with the total potato flour is prepared from the following main materials and condiments in parts by weight: 80-120 parts of streaky pork, 10-45 parts of the total potato flour, 0.5-1 part of edible salt, 2-3 parts of white sugar, 0.1-0.4 part of aginomoto, 3-4 parts of light soy sauce, 1-2 parts of bean paste, 1-2 parts of cooking wine, 1-2 parts of fermented bean curd juice, 1-3 parts of bruised shallot, 1-3 parts of bruised ginger, 0.1-0.2 part of cinnamon powder, 0.1-0.2 part of star aniseed powder, 0.1-0.2 part of pepper powder, 0.01-0.02 part of ground cloves powder, 0.05-0.1 part of fennel powder, 0.05-0.1 part of amomum tsaoko powder and 0.01-0.02 part of dried tangerine or orange peel powder, wherein the total potato flour is formed by roasting and frying potato flour with spices.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

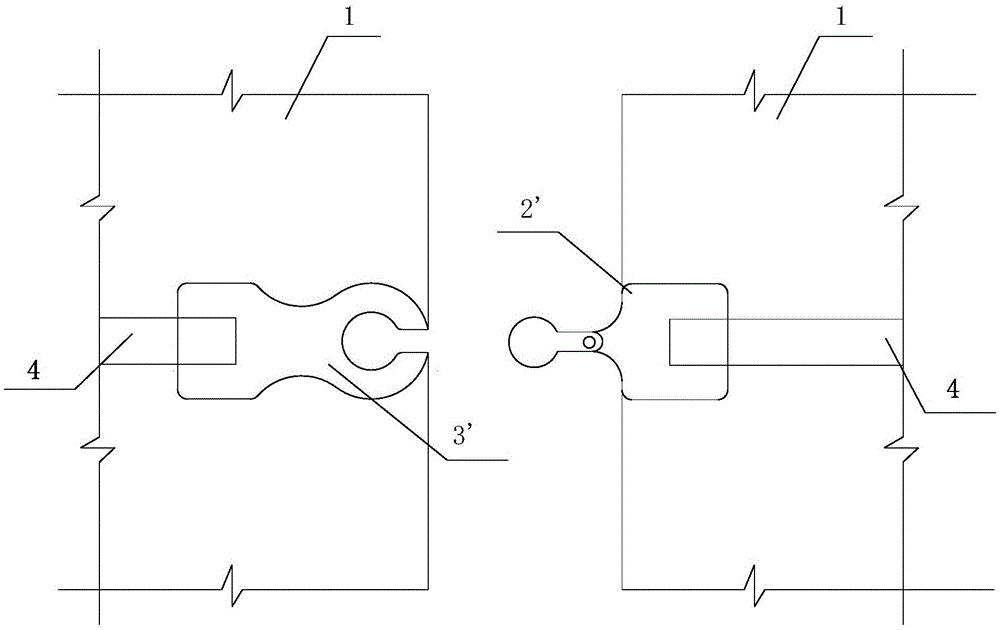

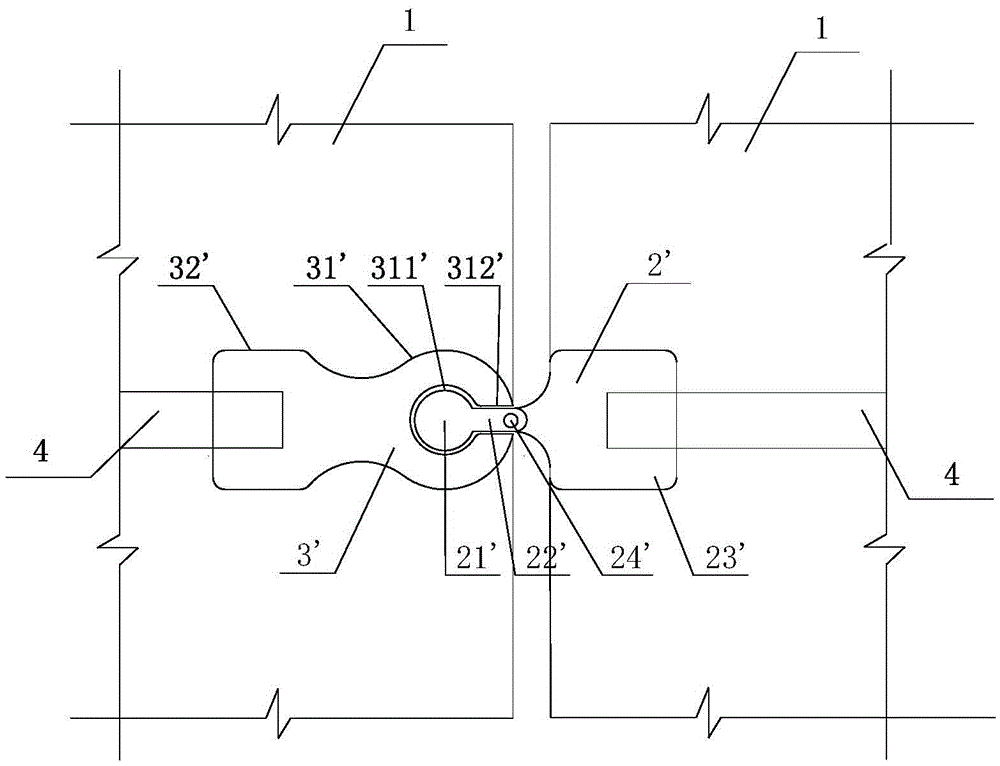

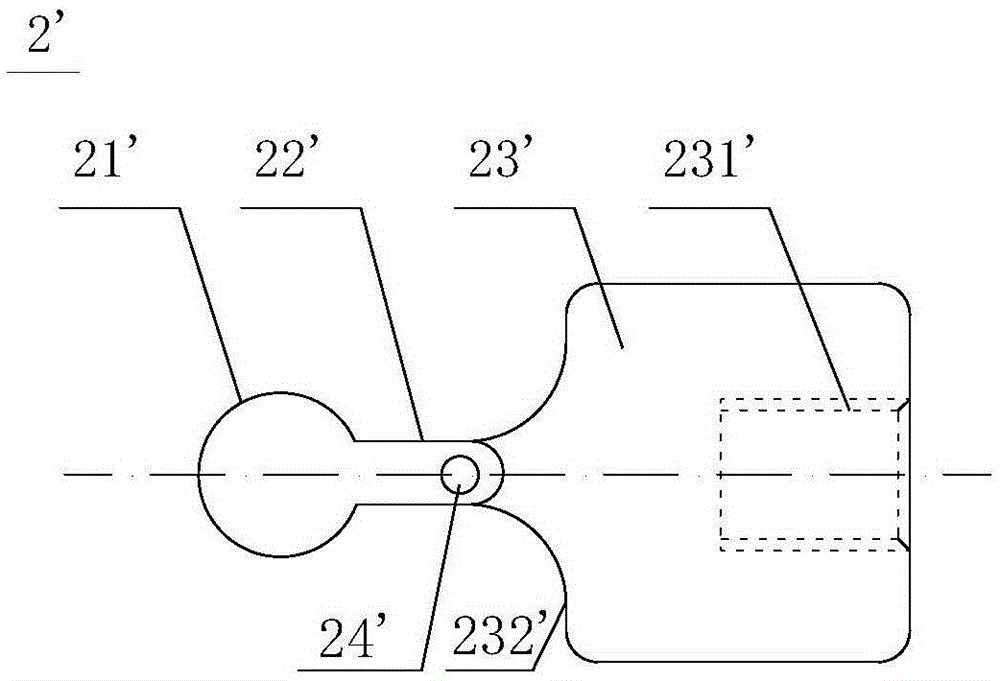

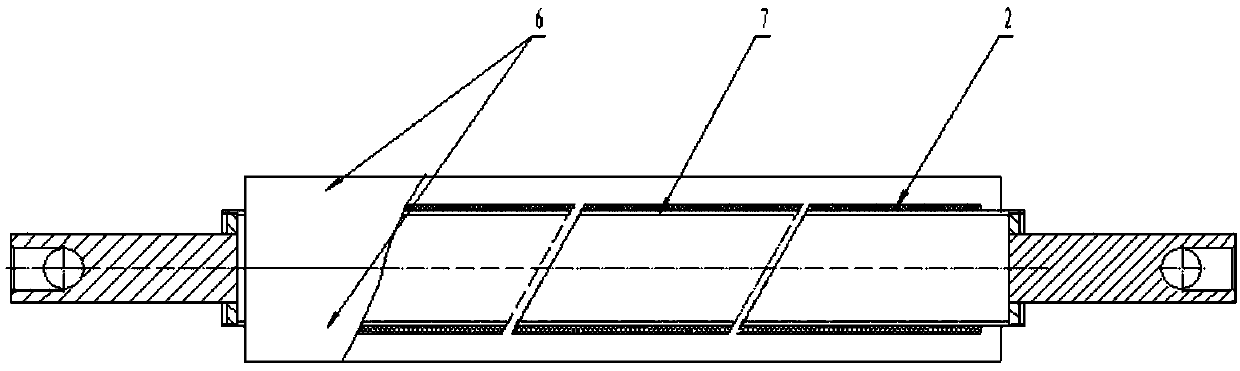

Segment longitudinal seam connecting assembly, tunnel segment structure and construction method

ActiveCN105484764ACapable of toleranceEasy connection and constructionUnderground chambersTunnel liningButt jointEngineering

The invention discloses a segment longitudinal seam connecting assembly, a tunnel segment structure and a construction method. The segment longitudinal seam connecting assembly comprises a longitudinal seam male part and a longitudinal seam female part, wherein the longitudinal seam male part comprises a gradient section cylinder, a connecting plate and a base, one end of the connecting plate is fixedly connected to the side face of the gradient section cylinder, and the other end of the connecting plate is connected with the base; the longitudinal seam female part comprises a front section and a rear section, a gradient section cylindrical cavity matched with the gradient section cylinder is formed in the front section, a through hole matched with the connecting plate in shape and size and communicated with the gradient section cylindrical cavity is formed in one end, away from the rear section, of the front section, the longitudinal seam female part is wholly pre-buried into a segment, a groove capable of containing the longitudinal seam male part is formed in the segment, and the longitudinal seam female part is located at one side of the groove. The tunnel segment structure has certain tolerance capacity, is adaptive to construction environment and capable of achieving simultaneous butt joint of segments in the longitudinal and circumferential directions, and has the advantages of being fast and convenient to construct and easy to construct automatically.

Owner:SHANGHAI CONSTRUCTION GROUP

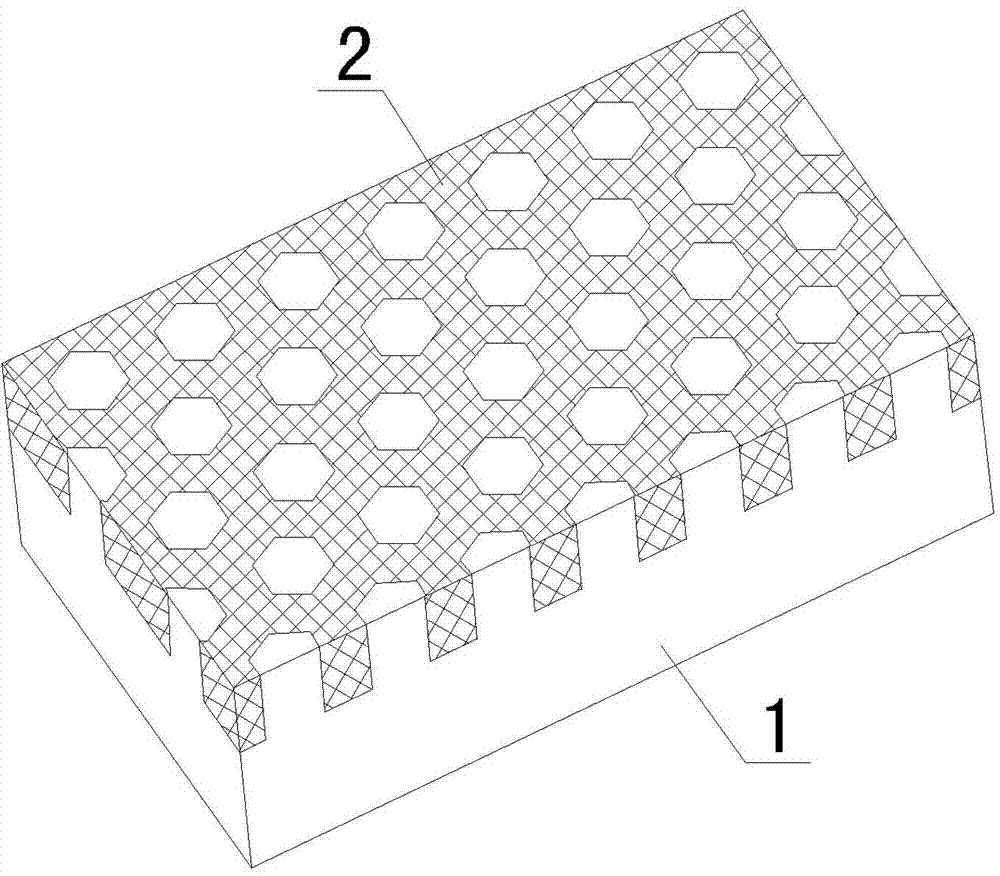

Composite wear-resistant part preparation method

The invention provides a composite wear-resistant part preparation method. The composite wear-resistant part preparation method comprises the following steps that firstly, the wear surface and the failure mode of a wear-resistant part under working condition are determined, and a ceramic reinforcement configuration is designed, wherein the thickness of the ceramic reinforcement configuration ranges from 3 mm to 80 mm, and the configuration can be in a bar shape, a plate shape or a porous shape to guarantee that the absolute distance from an arbitrary point in ceramic reinforcement to molten metal is smaller than 10mm at the moment of casting; secondly, the ceramic reinforcement is prepared; thirdly, a metallic matrix is cast to enable the ceramic reinforcement and the metallic matrix to be mutually combined to form a composite wear-resistant part, ceramic particles forming the ceramic reinforcement are evenly distributed on the wear surface of the wear-resistant part, and the ceramic particles are firmly coated by the metallic matrix. According to the composite wear-resistant part preparation method, the production technology is more simplified, the mechanized operation is facilitated, the ceramic particles are enabled to be evenly distributed on the wear surface of the wear-resistant part, and therefore the service life of the product is effectively prolonged.

Owner:GUANGDONG INST OF NEW MATERIALS

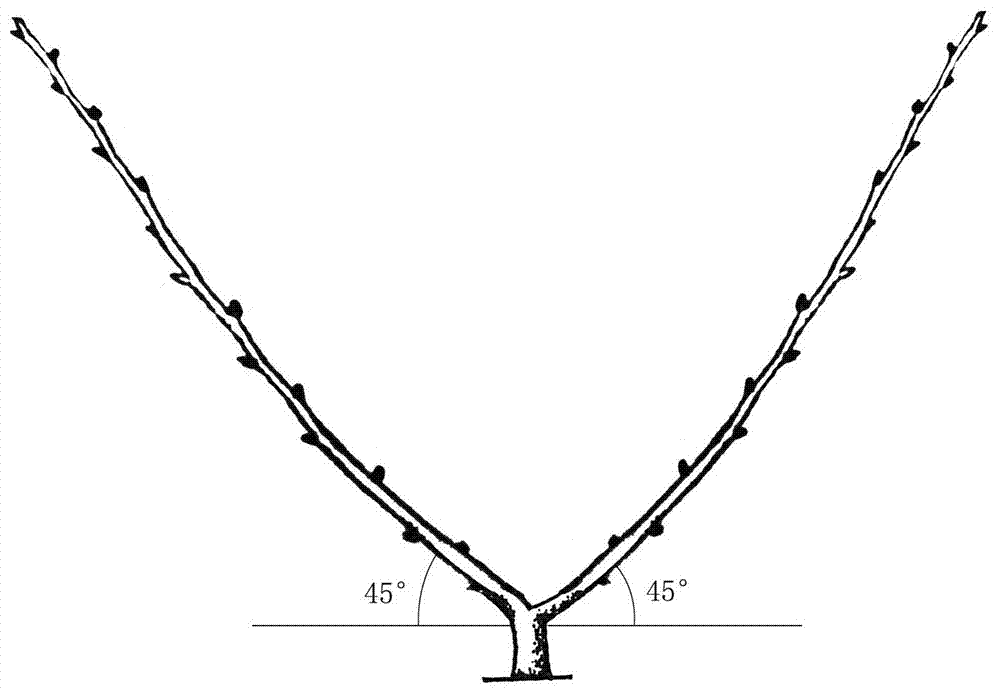

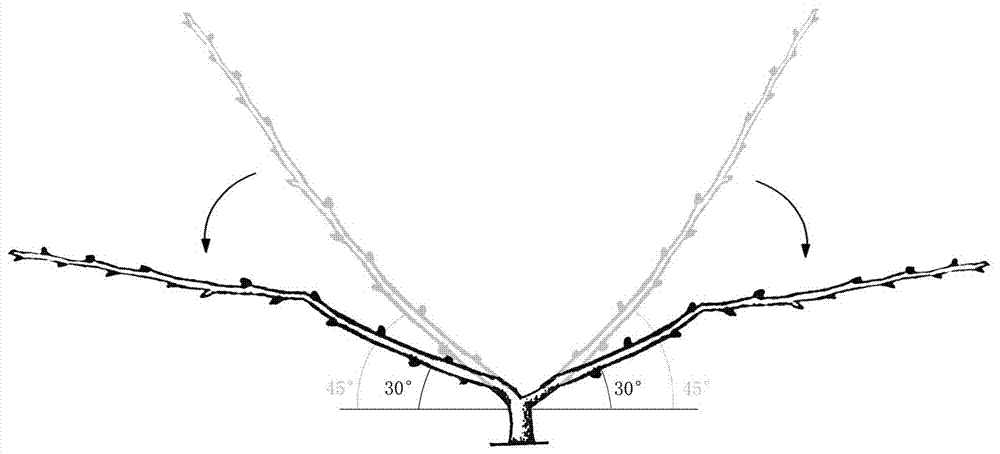

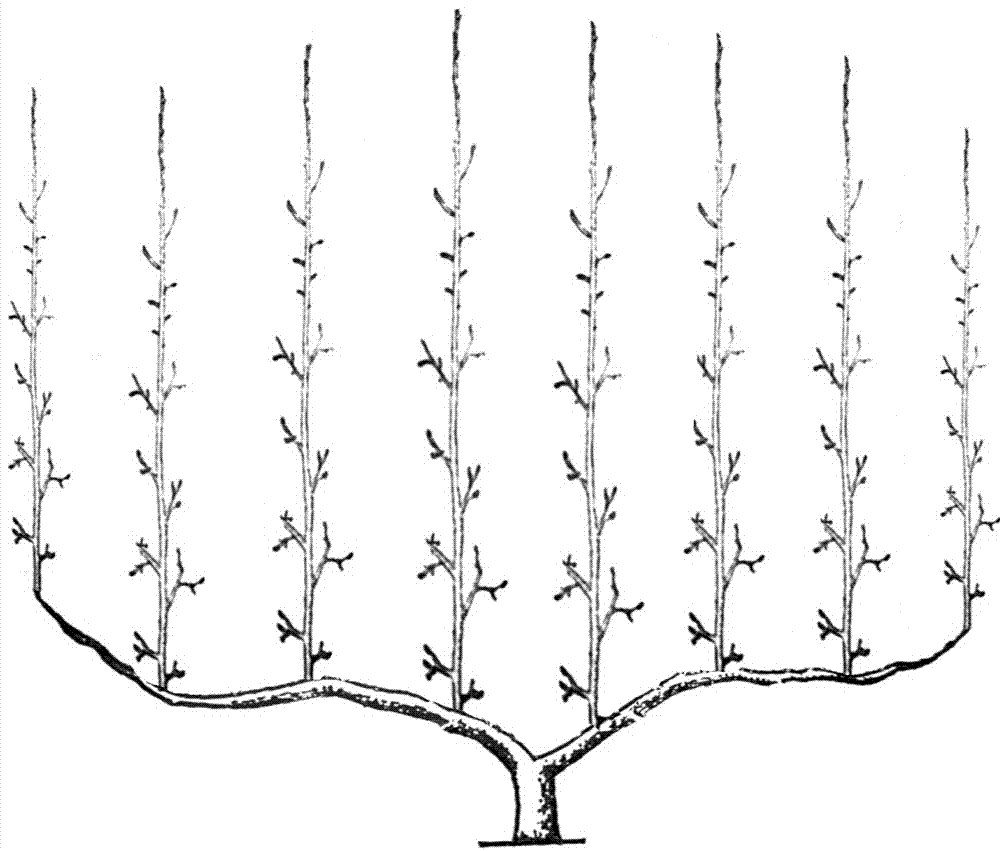

Comb-shaped fence wall tree shape of pear tree and shaping method of shape

ActiveCN107278786ALittle difference in qualityIncrease productionCultivating equipmentsFruit treeMain branch

The invention belongs to the technical field of pomology, and relates to a comb-shaped fence wall tree shape of a pear tree and a shaping method of the shape. The total height of the pear tree does not exceed 3.5 m, the height of the central trunk of the pear tree is 0.3-0.4 m, two main branches are arranged on the two sides of the central trunk and are 1.5 m long, the included angle of the base part of each main branch and the horizontal direction is 30 degrees, the front end of each main branch is in a horizontal state, a plurality of straight fruiting branches are arranged on each main branch and spread on the main branch in a combtooth-shaped mode, and the distance between the fruiting branches is 0.3 m. By means of the tree shape, the plane fruiting of the shed-frame-shaped pear tree is changed into the compact type three-dimensional fruiting, the tree bears more fruits, the quality differences of fruits at different positions are small, and the yield is higher.

Owner:ZHENGZHOU FRUIT RES INST CHINESE ACADEMY OF AGRI SCI

Method for producing metal and diamond composite body

InactiveCN101480744AAvoiding problems with reduced sintering qualityQuality improvementSoldering apparatusMetal rolling arrangementsHardnessLarge deformation

The invention discloses a method for manufacturing a composite body of metal and diamond, comprising the following steps: diamond grits and metal powder bonds are arranged between two metal plates which can be copper plates or low-carbon steel plates, the metal plates are rolled to be in a flat pipe shape, braze welding and sealing are carried out on the round seaming part to manufacture a prefabricated piece, and multi-time cold rolling is carried out so that the thickness of the metal plates in a flat pipe shape is a little bigger than that of a particle and the metal plates in a flat pipe shape are sintered at the temperature ranging from 700-900 DEG C. The invention abandons a traditional powder metallurgy like method, instead, the capability feature that great difference exists between the rigidity of the diamond and the rigidity of the copper plate or the low-carbon plate is utilized, thereby the diamond embedded into a copper block or a low-carbon block in the rolling process and the combination of a little amount of metal powder bonds and high-speed flow deformation and large deformation rate which are unique in the rolling process enable the metal plates to be mutually welded so that the problem in the traditional method that the metal powder is prone to be oxidized to cause the sintering quality to be reduced is avoided. The invention is favorable for the mechanized and automated manufacturing and lowers the manufacturing cost.

Owner:YANSHAN UNIV

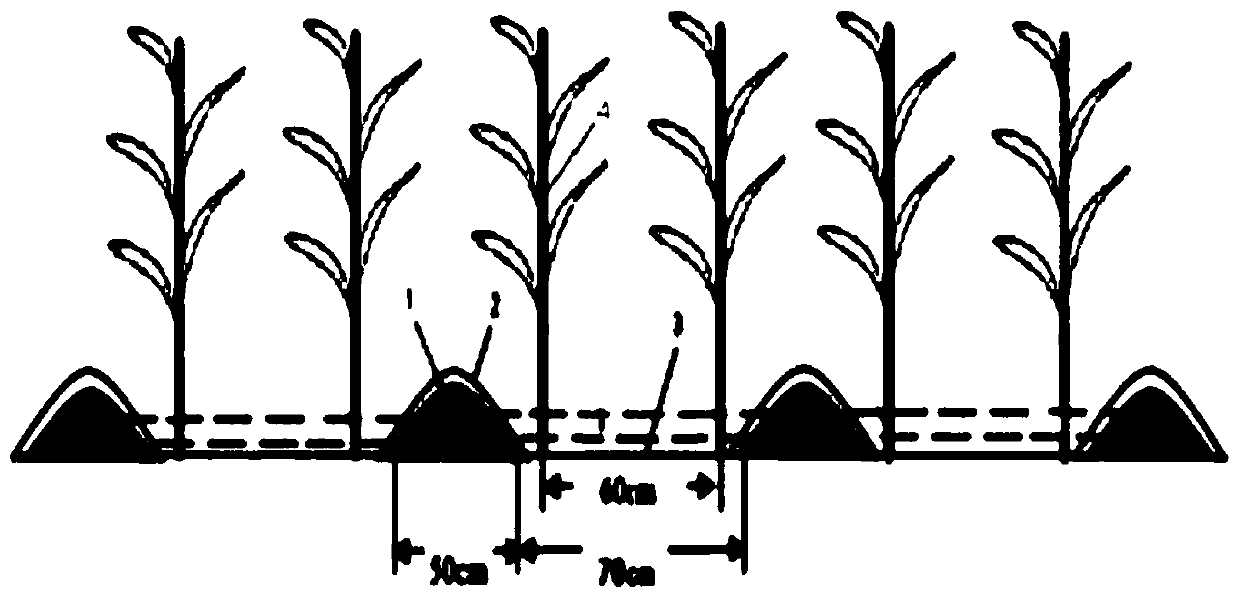

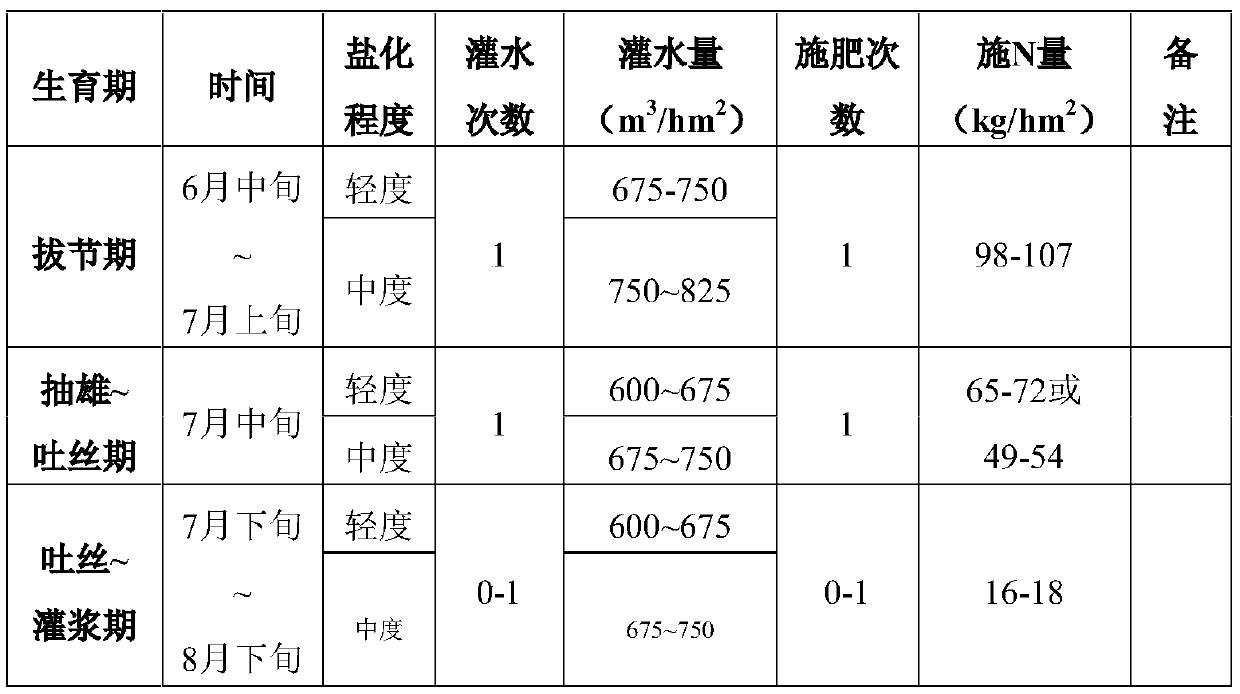

High-efficiency corn cultivation method in saline-alkali land

InactiveCN110169320AImprove germination rateImprove seedling retention rateOther chemical processesCereal cultivationEcological environmentWater-use efficiency

The invention belongs to the field of crop planting, in particular to a high-efficiency corn cultivation method in saline-alkali land. The high-efficiency corn cultivation method in the saline-alkaliland includes the following specific cultivation steps: soil improvement, flat land preparation and application of base fertilizer, corn sowing and film covering, irrigation and fertilization. The method achieves the aim of improving corn emergence rate, seedling preservation rate, water and fertilizer utilization efficiency and further improving corn yield by improving the corn planting method and optimizing the irrigation and fertilization system, breaks through the technical bottleneck of difficult corn planting and improvement in saline-alkali land in low-lying areas, and can play a technical supporting role in efficient improvement and utilization of saline-alkali land and improvement of ecological environment. On the one hand, ridge film furrow planting can effectively reduce the evaporation and consumption of soil moisture, and thus water collection and moisture preservation are favorable, so that crop yield and water use efficiency are improved; on the other hand, the utilization of groundwater can be further promoted, the groundwater level is lowered, and the phenomenon of soil salinization is reduced.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT NINGXIA ACAD OF AGRI & FORESTRY SCI NINGXIA KEY LAB OF SOIL & PLANT NUTRITION

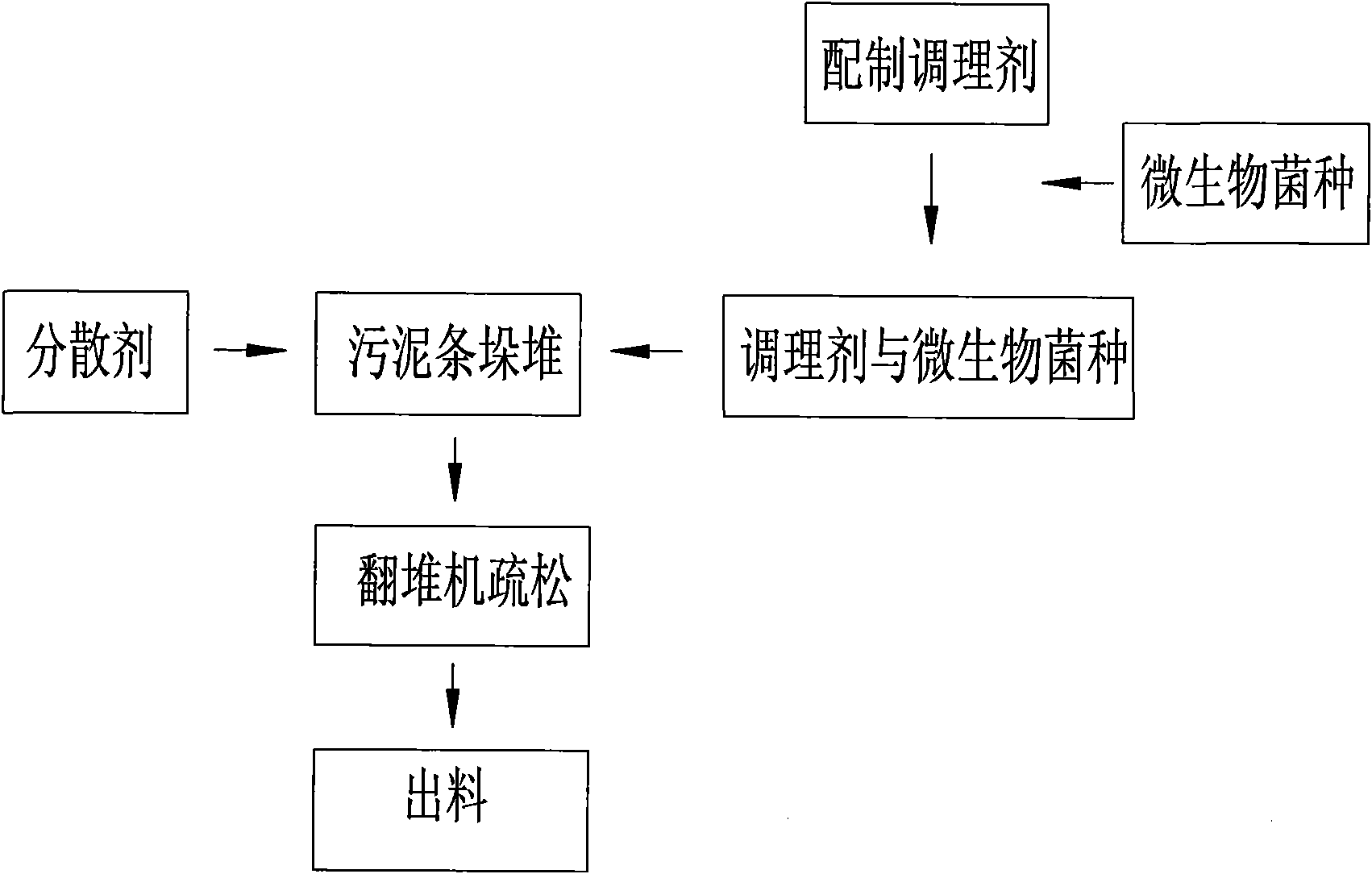

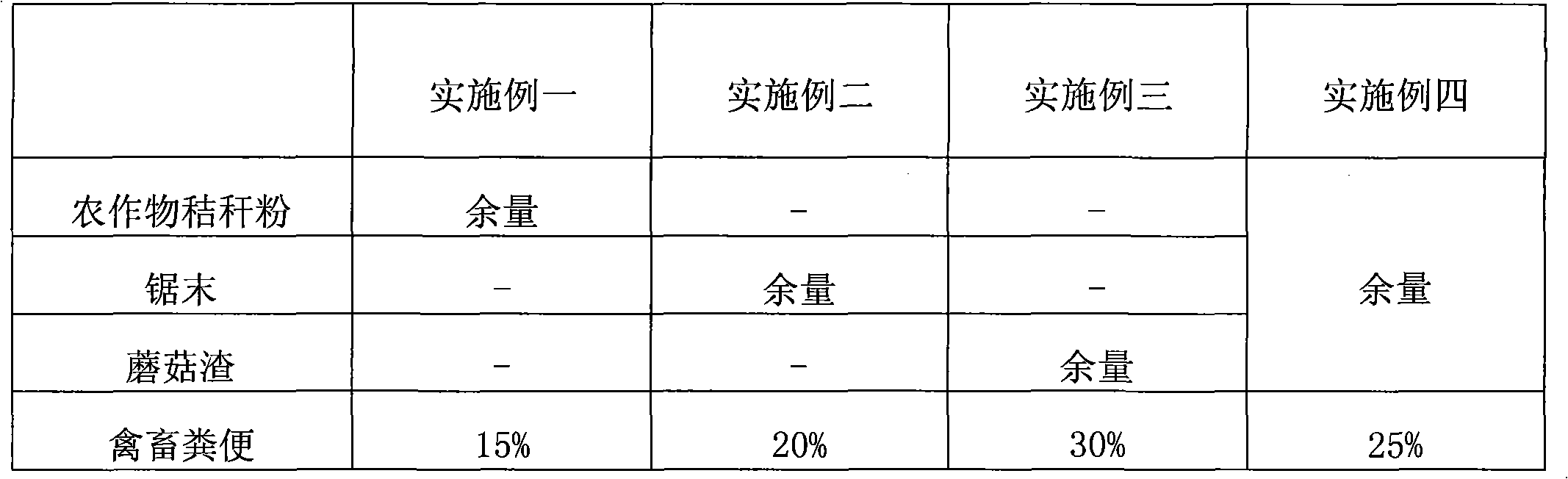

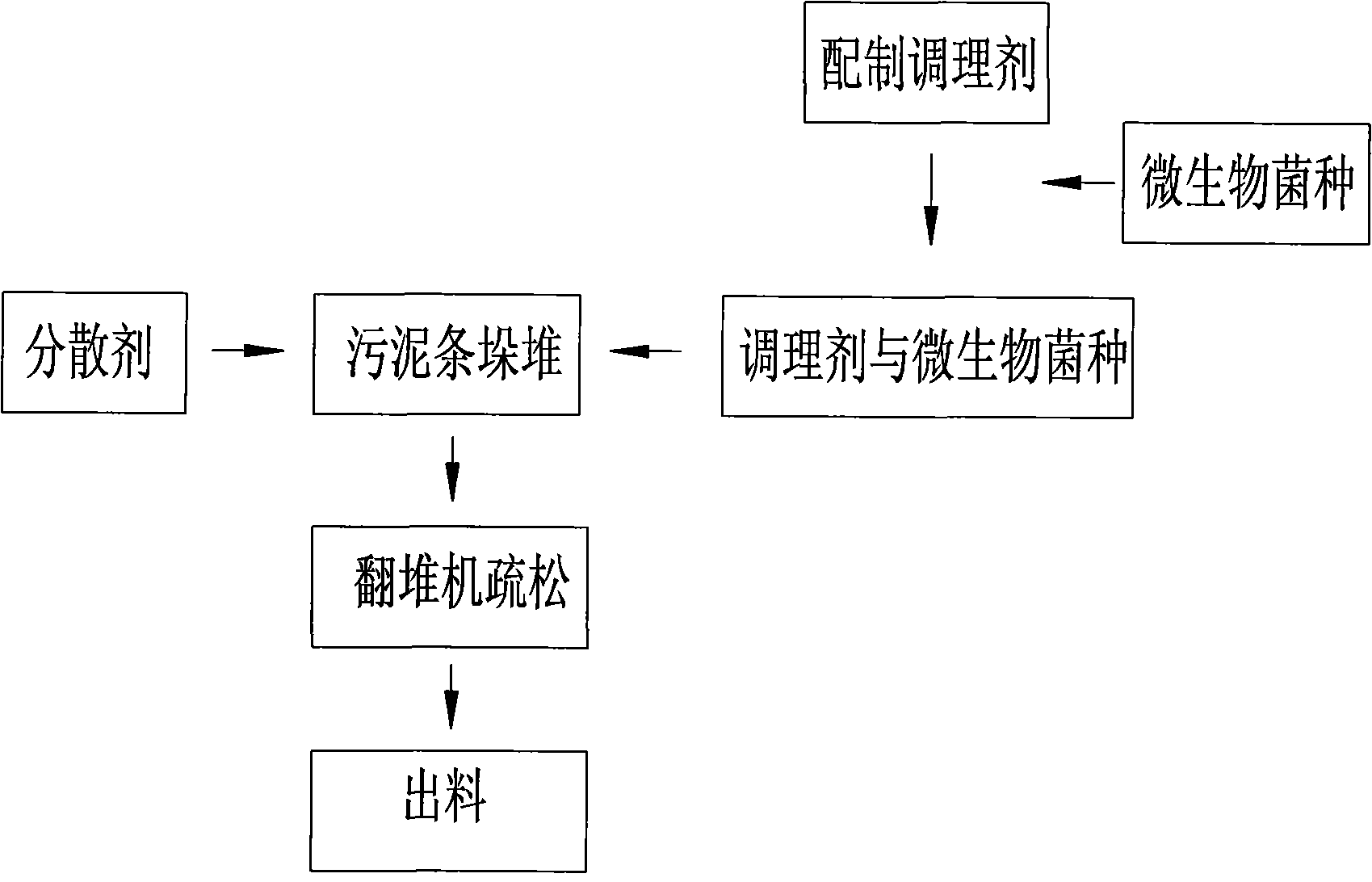

Method for innocent treatment of sludge in sewage plant

The invention discloses a method for the innocent treatment of sludge in a sewage plant, which comprises the following treating steps of: (1) piling sludge on the cement-hardened ground into windrows; (2) uniformly spreading conditioner on the windrows, wherein the weight part ratio of the sludge to the conditioner is 600-800:400-200; (3) preparing nutriment, wherein the nutriment comprises the following component in parts by weight: 5-8 parts of starch, 0.5-1 part of sugar and 0.5-1 part of ethanol of which the volume content is 40%; (4) uniformly mixing the nutriment with compound microorganism microbial inoculum according to the weight ratio of 1-2:1-2; (5) directly spreading the mixture of the nutriment and the compound microorganism microbial inoculum in step (4) on the windrows, wherein the weight ratio of the sludge to the mixture is 600-800:1-2; and (6) using an upender to upend and stir the windrows, and thus finishing the overall treatment 10-15 later. The method is simple in treating process, is applicable to large-scale treatment, and has high innocent treatment degree.

Owner:吴立阳

Method for preparing crop straw feed based on composite puffing and biological processing technology

InactiveCN103798512ASimple processReduce energy consumptionAnimal feeding stuffBiotechnologyLactic acid bacterium

The invention relates to a method for preparing crop straw feed based on composite puffing and biological processing technology. The method is characterized by comprising the steps of crushing crop straws, chemically preprocessing the crushed crop straws, puffing the chemically preprocessed straws so as to destroy the wood fiber structure of the straws and to realize safety and no toxicity and side effect, and adding mixed strains such as yeast and lactic acid bacteria into the puffed material for solid fermentation so as to produce mycoprotein. Therefore, the content of crude protein of the straw feed can be increased from 2 to 4 percent to 8 to 12 percent, and the digestion rate can be increased from 30 to 45 percent to more than 60 percent. The method has the advantages of simplicity in process, low energy consumption, high applicability and easiness in industrialization.

Owner:NANJING AGRICULTURAL UNIVERSITY

Seabuckthorn leaf instant tea and preparation method

The present invention relates to a seabuckthorn leaf instant tea, it is a seabuckthorn instant tea powder made up by utilizing water extract of seabuck thorn leaf through the processes of drying and blending. Its preparation method includes the following steps: making the seabuckthorn leaf undergo the processes of steaming to retain its green colour, rolling and stir-drying, soaking in boiling water, extracting, filtering, concentrating, drying, blending and forming to obtain the product which can be directly drunk, and can be mixed with auxiliary materials of fruit juice and sugar for drinking so as to meet requirements of different consumers. In its processing course the impurities of scales, heavy metal, sand and pesticide residue can be completely removed with tea dregs, so that it is a pure clean beverage.

Owner:SHANXI UNIV

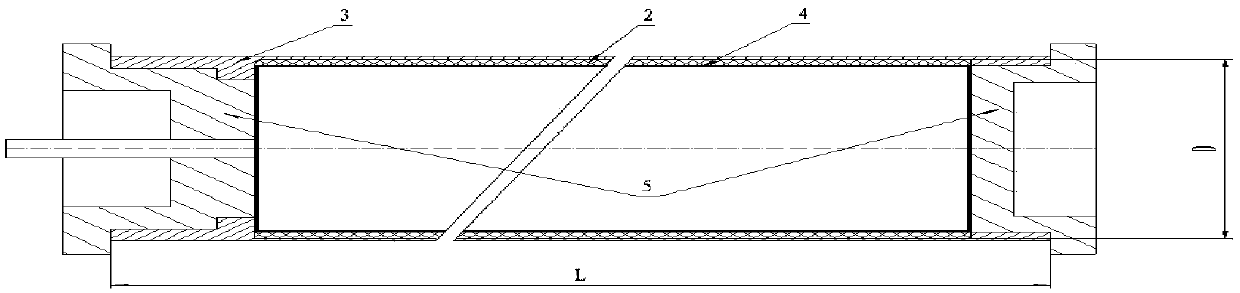

Solid rocket engine combustion chamber shell adiabatic layer forming method

ActiveCN109605625ANo distortionThere is no problem with exhaustDomestic articlesVulcanizationCombustion chamber

The invention relates to a solid rocket engine combustion chamber shell adiabatic layer forming method, and belongs to the field of adiabatic layer forming technologies. The solid rocket engine combustion chamber shell adiabatic layer forming method comprises the steps that according to the design structure of an engine combustion chamber shell, an adiabatic layer prefabricated part which is not completely vulcanized is prepared, and the outer diameter of the adiabatic layer prefabricated part which is not completely vulcanized is less than the inner diameter of the engine combustion chamber shell; the adiabatic layer prefabricated part which is not completely vulcanized is bonded to the inner wall of the engine combustion chamber shell through a heat vulcanization adhesive; and hot pressing vulcanization is conducted, and thus the engine combustion chamber shell with an adiabatic layer is obtained. Through internal support tension of the adiabatic layer prefabricated part and a good isolation gap between the adiabatic layer prefabricated part and the inner wall of the combustion chamber shell, the problems of sheet pasting warp and unsmooth exhaust of sheet rubber are effectivelysolved, and bonding reliability of the interface of the adiabatic layer and the shell is improved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

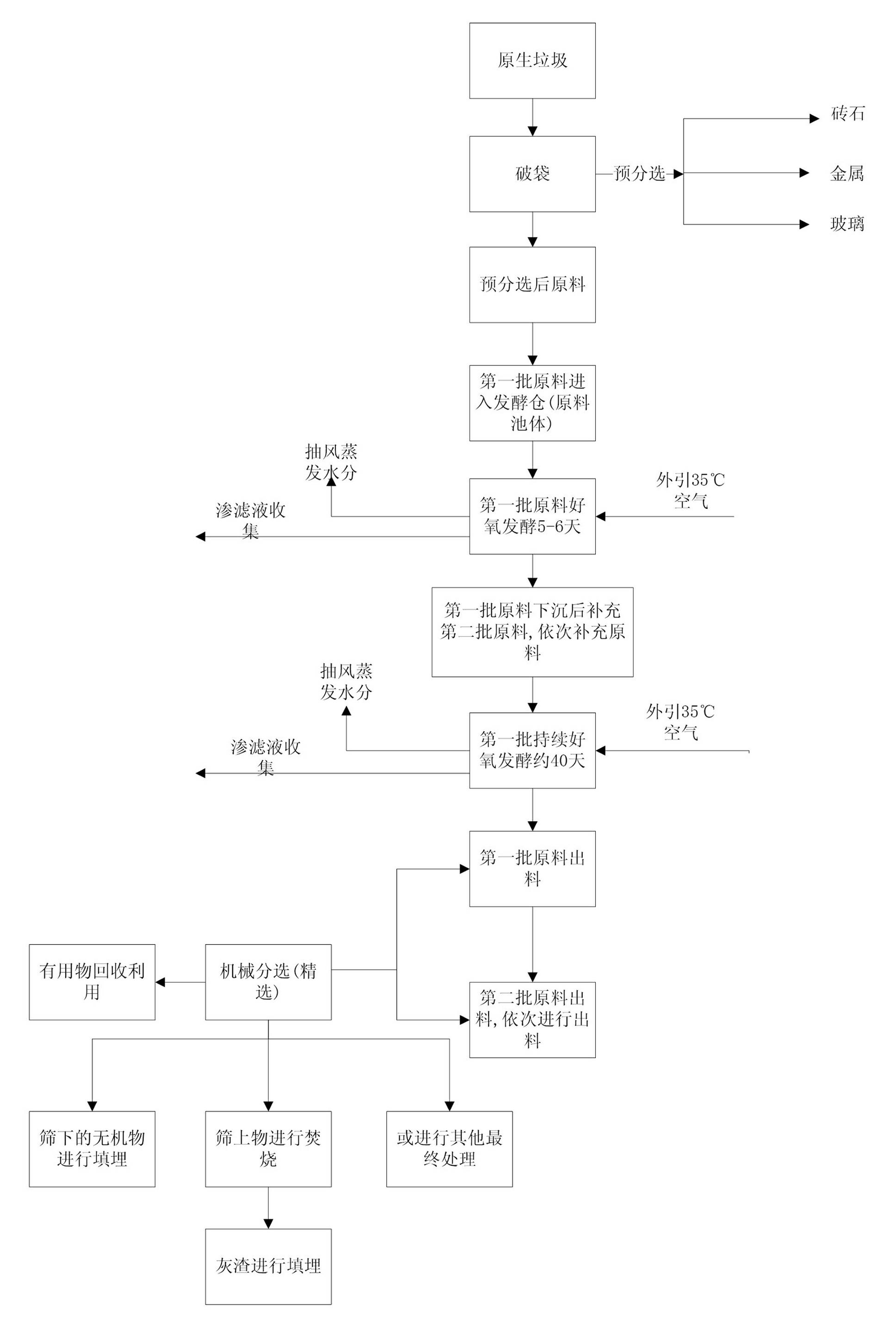

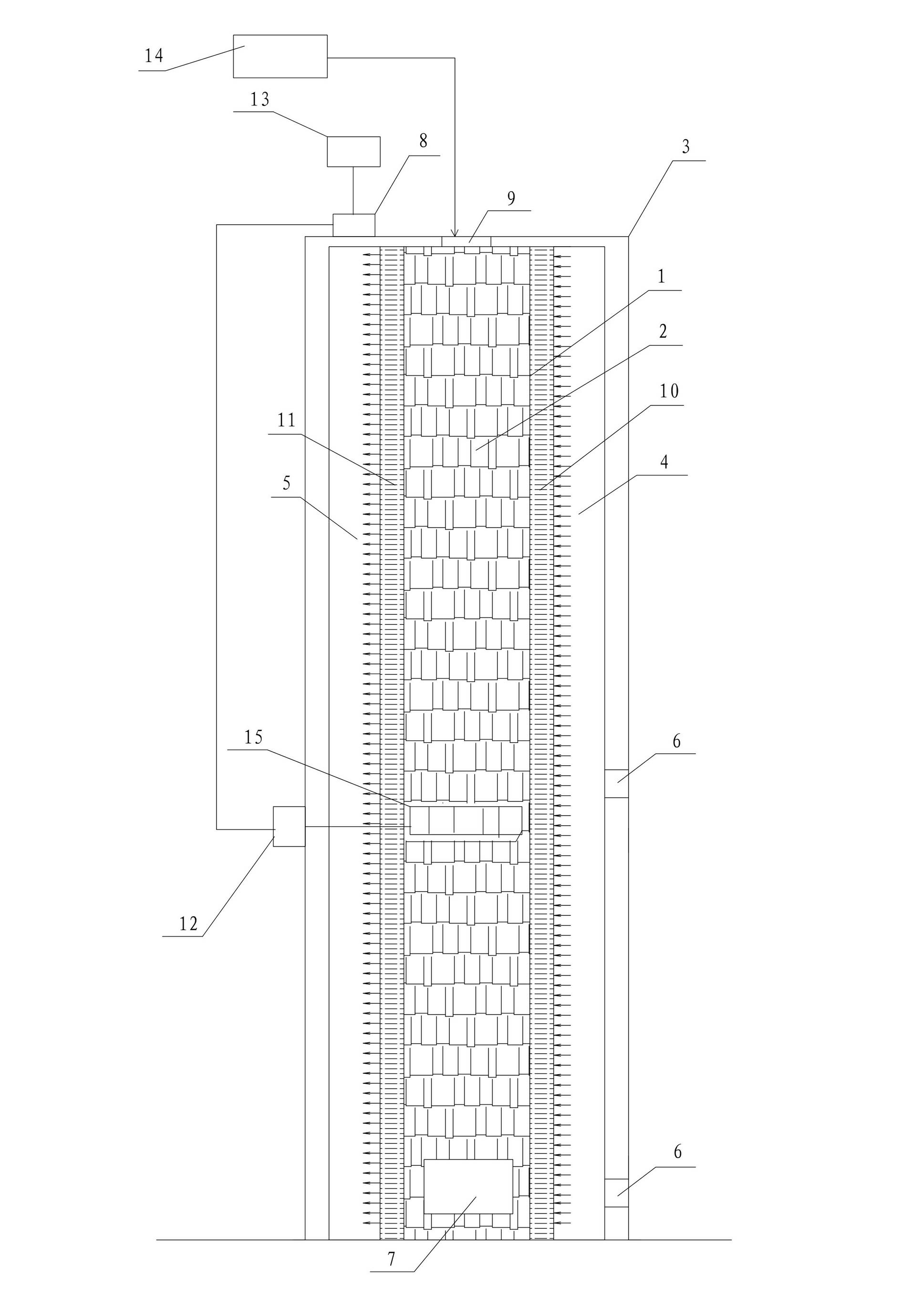

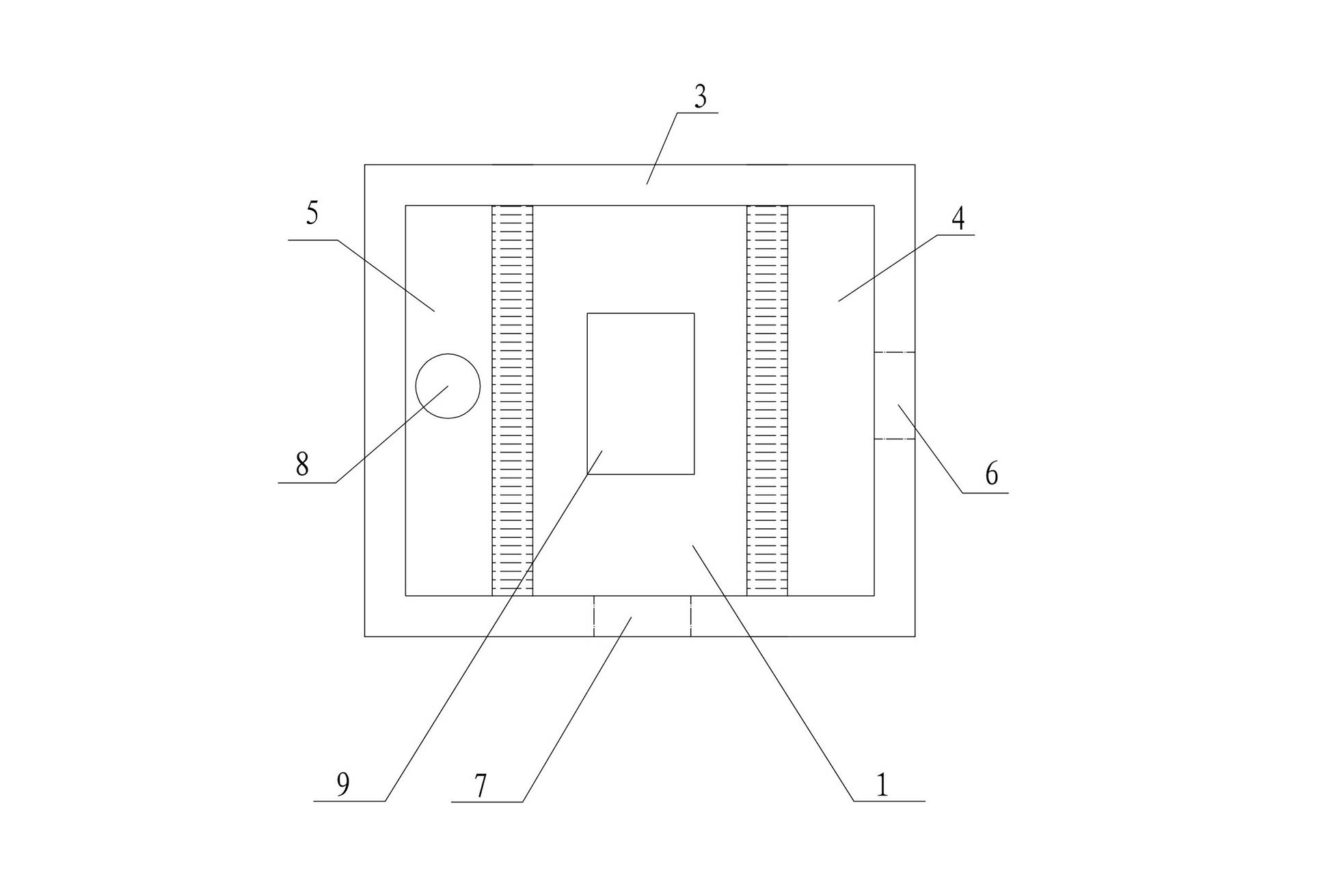

Device and method for large-scale pretreatment of domestic garbage

ActiveCN102626710AReduce moistureImprove low heatSolid waste disposalAutomatic controlSmall footprint

The invention discloses a device and a method for large-scale pretreatment of domestic garbage. The device comprises a vertical cylinder, an air suction component, a double-screw discharge component and a temperature automatic control component, wherein the air suction component is matched with the vertical cylinder; a raw material cavity, an air inlet duct and an air outlet duct are arranged in the vertical cylinder; the air inlet duct and the air outlet duct are oppositely arranged at the two ends of the raw material cavity; the face of the air inlet duct facing the raw material cavity is provided with a plurality of air inlet holes which are communicated with the raw material cavity; the face of the air inlet duct far away from the raw material cavity is provided with more than one air inlet; the face of the air outlet duct facing the raw material cavity is provided with a plurality of air outlet holes which are communicated with the raw material cavity; and the face of the air outlet duct far away from the raw material cavity is provided with more than one air outlet. According to the method, the garbage material is continuously filled into the raw material cavity of the vertical cylinder lot by lot, fermented by intake air and continuously discharged lot by lot. The device has the advantages of simple and compact structure, small floor area and the like; and large-scale, industrial, engineered and continuous flow line production of the pretreatment of the domestic garbage can be realized.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Method for cultivating pleurotus eryngii via bottles in greenhouse by using mushroom grasses

The invention discloses a method for cultivating pleurotus eryngii via bottles in a greenhouse by using mushroom grasses, belonging to the method for cultivating edible mushrooms by using mushroom grasses in mushroom production. With the adoption of the method, six kinds of mushroom grass seeds comprising miscanthus floridulus, neyraudiareynediana, arundo donax linn, grassiness, dicranopteris pedata, and Jujuncao are combined with auxiliary materials comprising bran, corn starch and lime; and the method of cultivating pleurotus eryngii via bottles in the greenhouse by using mushroom grasses is implemented by six formulas. According to the method, the fresh grasses such as grassiness, Jujuncao, miscanthus floridulus, neyraudiareynediana, arundo donax linn and dicranopteris pedata are directly used as the raw materials, the processes of drying and water are eliminated, so that the production cost is saved, and the method has the following advantages of being high in yield and short in production period, and improving the economic benefit. Compared with the cultivation by using cottonseed hulls in the prior art, the method has the advantages that the product quality can be improved. Compared with the cultivation by using dry mushroom grasses in the prior art, the method has the advantages that the costs spent on drying and storing mushroom grasses can be saved. Compared with the cultivating by using plastic thin films, the method has the advantages that the mechanical operation is facilitated, the yield is high and the production period is short and the like.

Owner:FUJIAN ZHENGYUAN JUNCAO INT COOP CO LTD

Follicular extraction method and device

ActiveUS20090088776A1Diminish and even eliminate shortcomingUnable to easily cut and inciseSkin implantsSurgical needlesHair follicleBiomedical engineering

A method and device for the extraction of follicular units from a donor area on a patient. The method includes scoring the outer skin layers with a sharp punch, and then inserting a blunt punch into the incision to separate the hair follicle from the surrounding tissue and fatty layer. The method and device will significantly decrease the amount of follicular transection and increase the rate at which follicular units can be extracted.

Owner:HSC DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com