Patents

Literature

313 results about "Height increasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

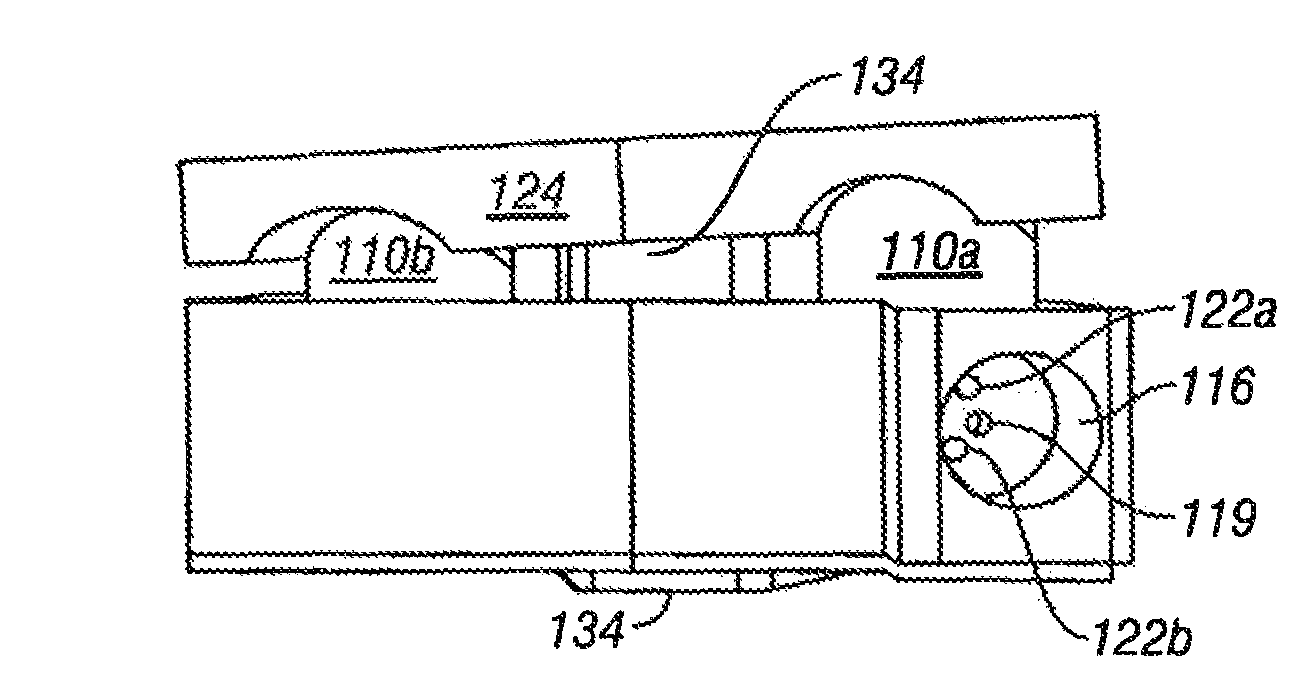

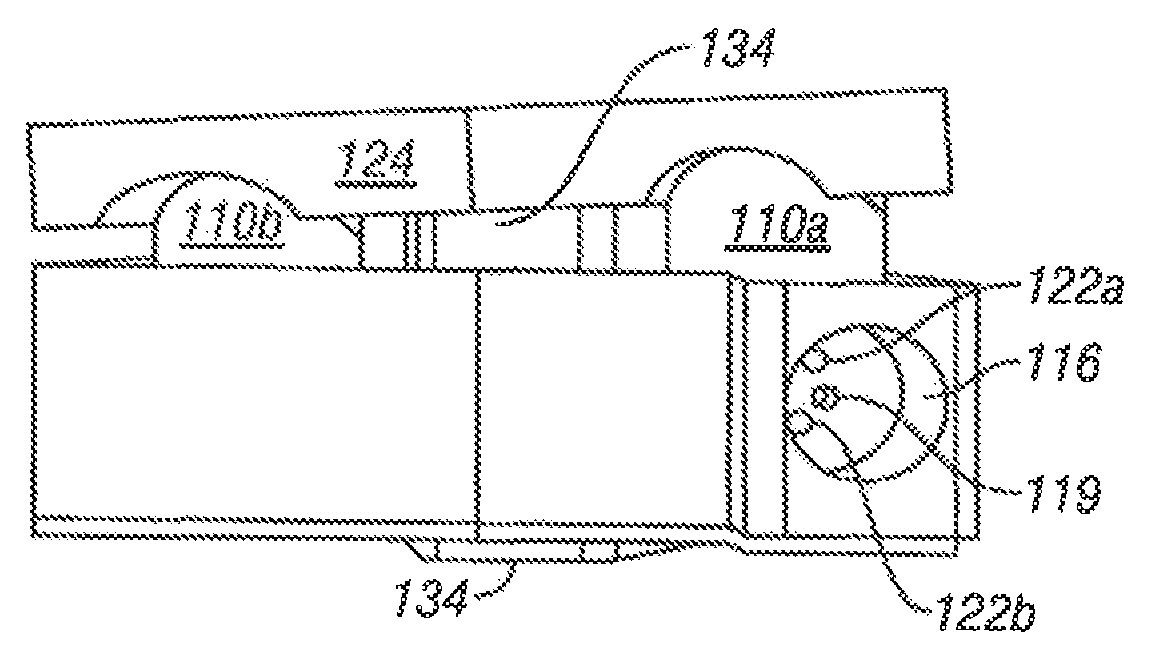

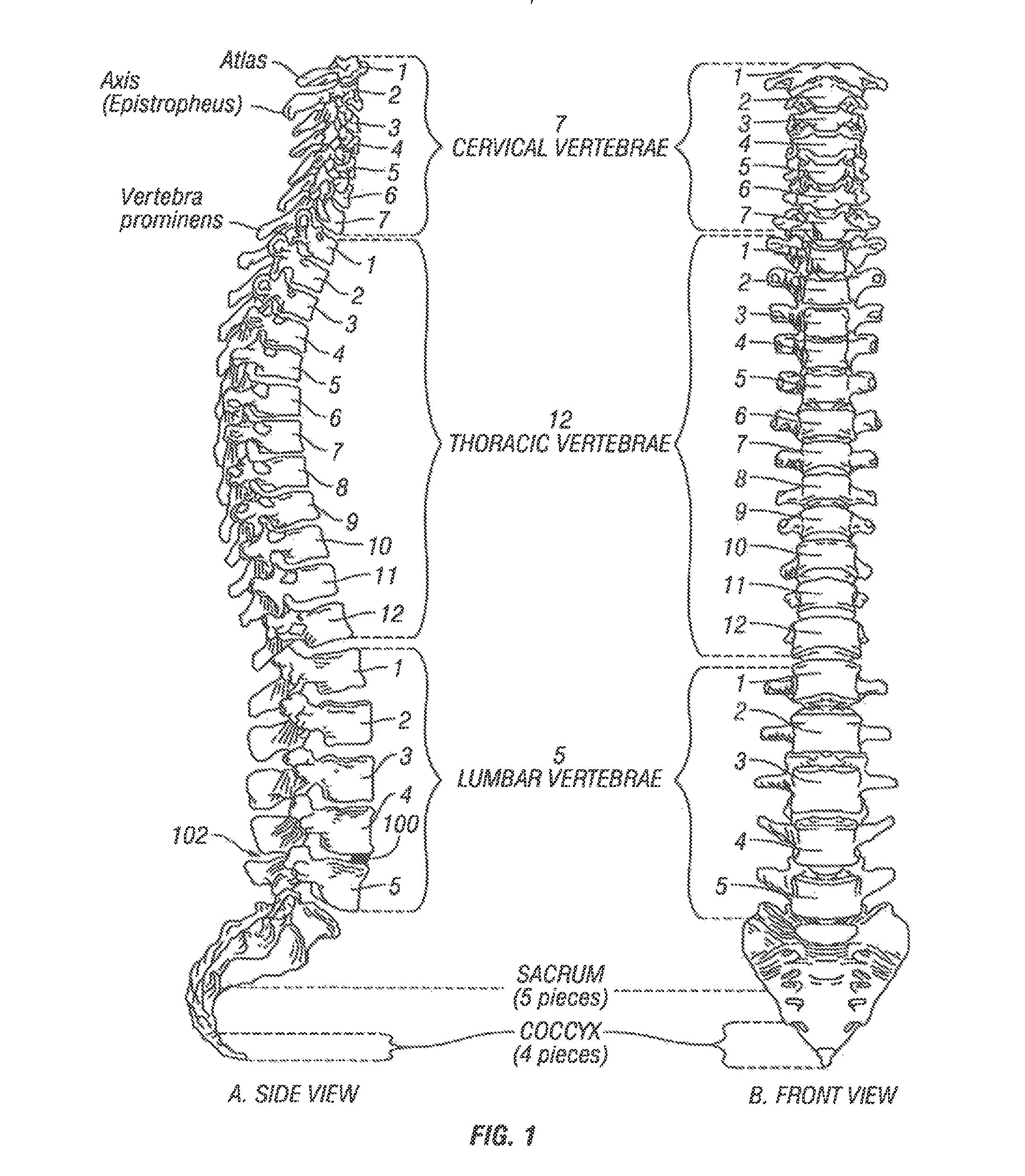

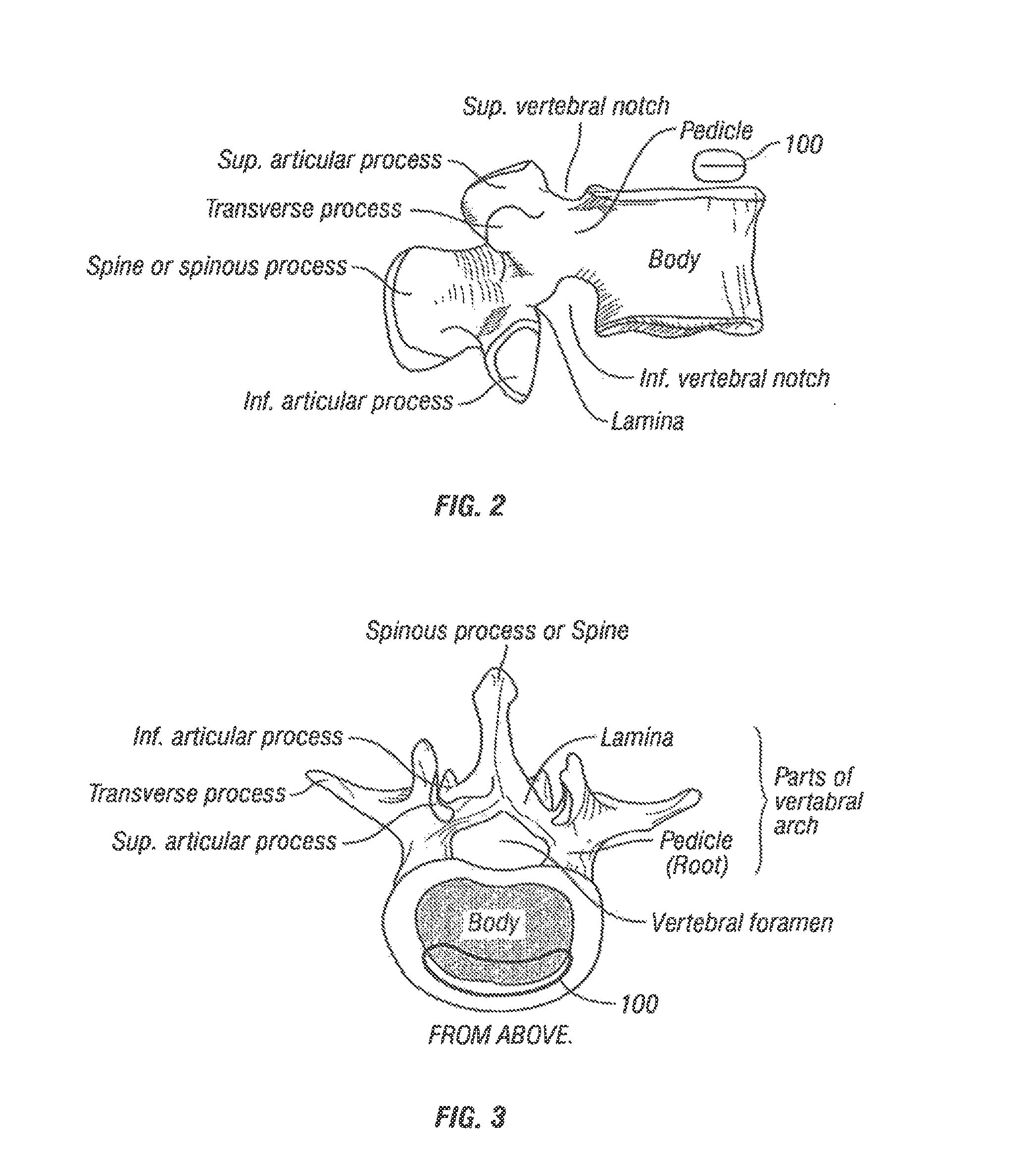

Selectively expanding spine cage, hydraulically controllable in three dimensions for enhanced spinal fusion

A selectively expanding spine cage has a minimized diameter in its unexpanded state that is smaller than the diameter of the neuroforamen through which it passes in the distracted spine. The cage conformably engages between the endplates of the adjacent vertebrae to effectively distract the anterior disc space, stabilize the motion segments and eliminate pathologic spine motion. The cage enhances spinal arthrodesis by creating a rigid spine segment. Expanding selectively, the cage height increases and holds the vertebrae with fixation forces greater than adjacent bone and soft tissue failure forces in natural lordosis. Stability is thus achieved immediately, enabling patient function by eliminating painful motion. The cage shape intends to rest proximate to the anterior column cortices securing the desired spread and fixation, allowing for bone graft in, around, and through the implant.

Owner:HOWMEDICA OSTEONICS CORP

Selectively expanding spine cage with enhanced bone graft infusion

A selectively expanding spine cage has a minimized cross section in its unexpanded state that is smaller than the diameter of the neuroforamen through which it passes in the distracted spine. The cage conformably engages between the endplates of the adjacent vertebrae to effectively distract the anterior disc space, stabilize the motion segments and eliminate pathologic spine motion. Expanding selectively (anteriorly, along the vertical axis of the spine) rather than uniformly, the cage height increases and holds the vertebrae with fixation forces greater than adjacent bone and soft tissue failure forces in natural lordosis. Stability is thus achieved immediately, enabling patient function by eliminating painful motion. The cage shape intends to rest proximate to the anterior column cortices securing the desired spread and fixation, allowing for bone graft in, around, and through the implant for arthrodesis whereas for arthroplasty it fixes to endpoints but cushions the spine naturally.

Owner:HOWMEDICA OSTEONICS CORP

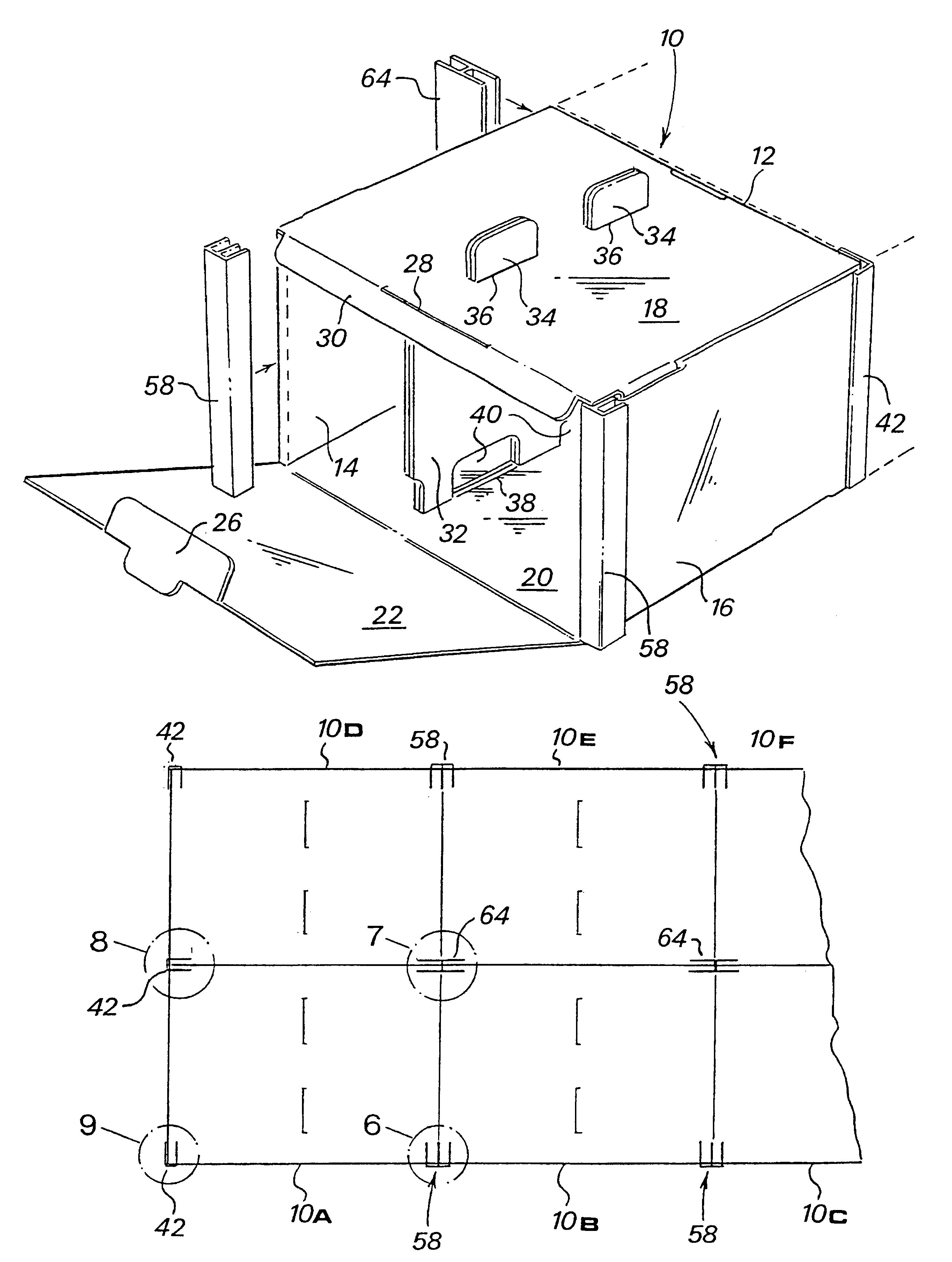

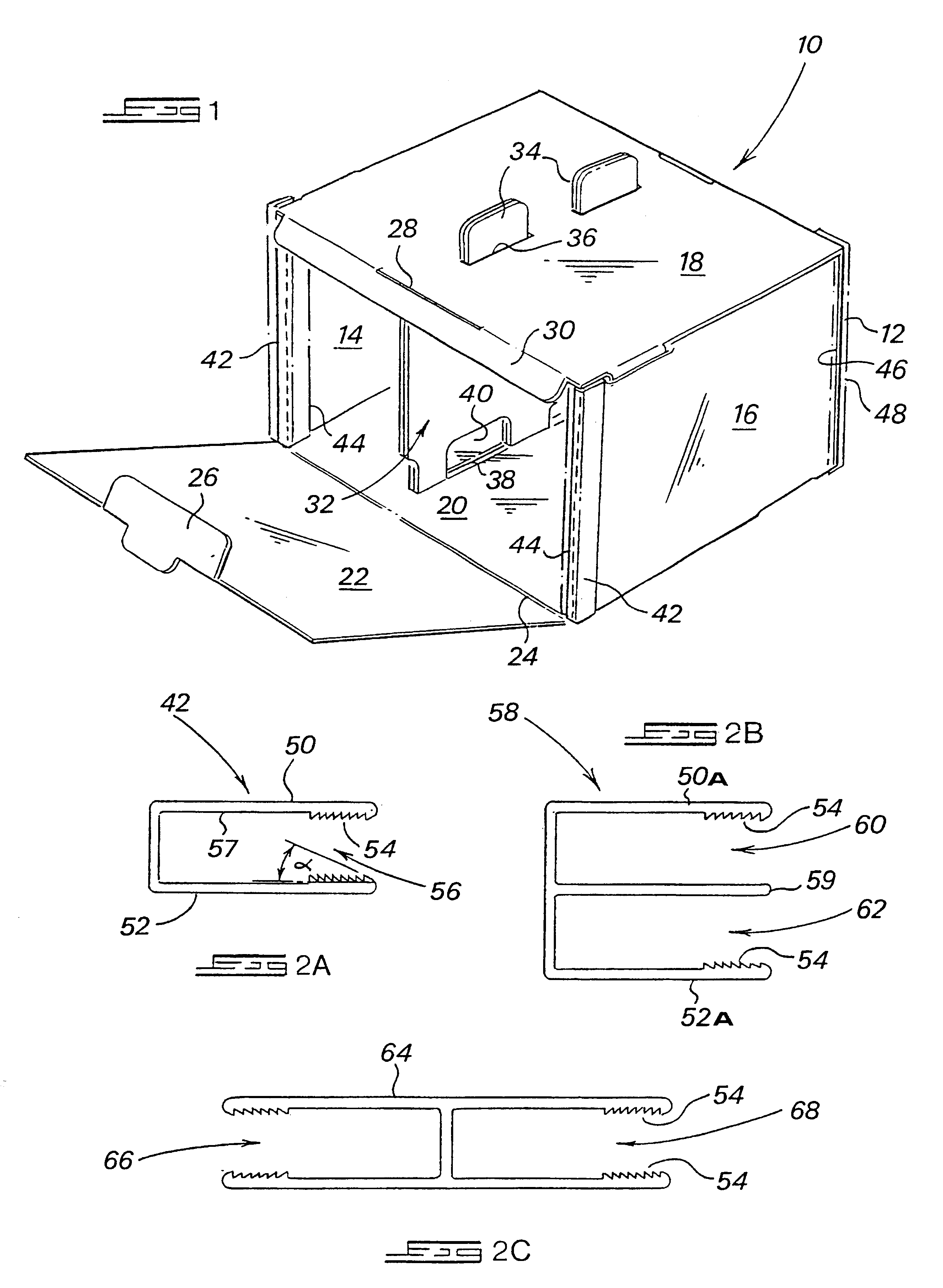

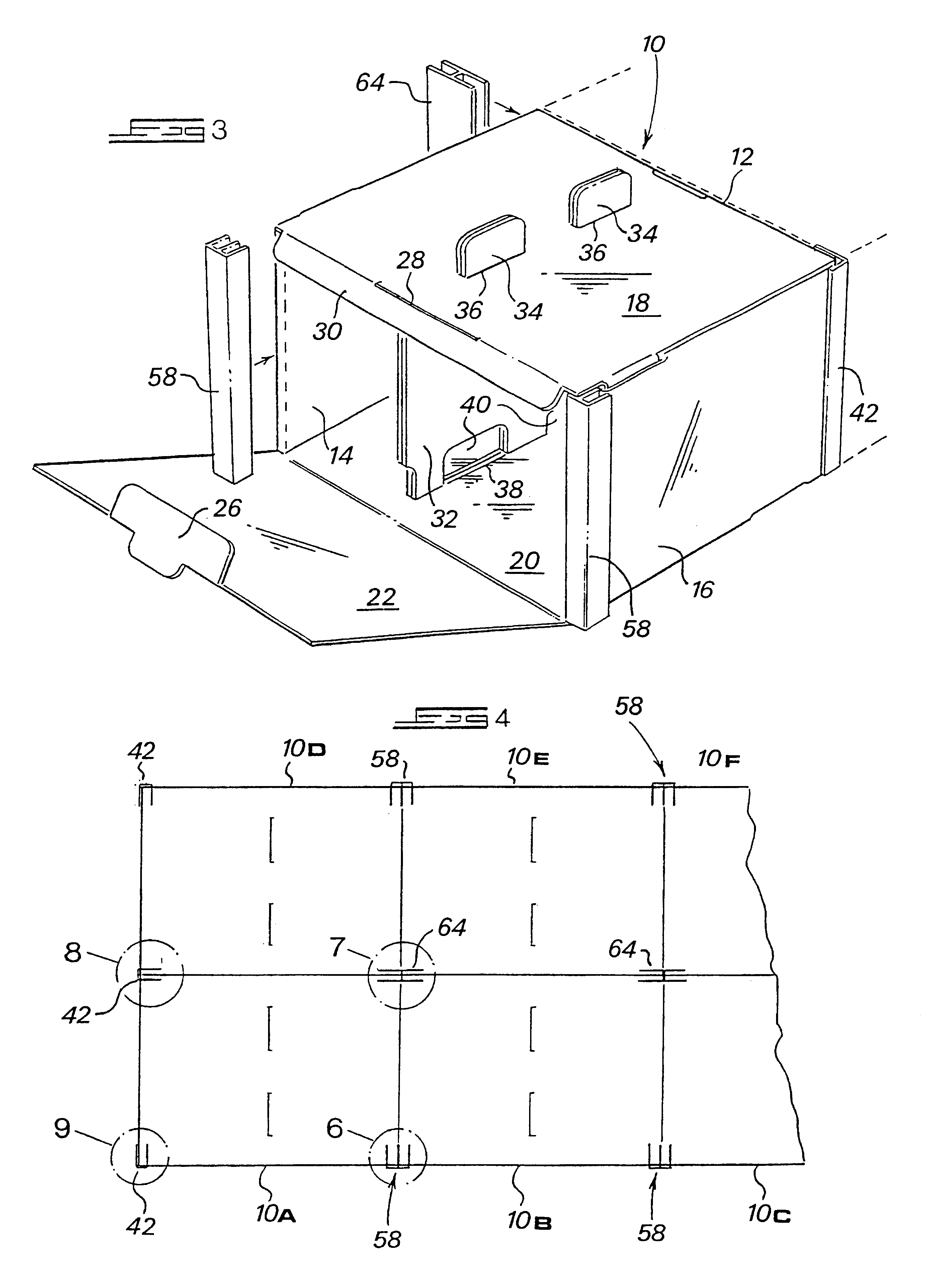

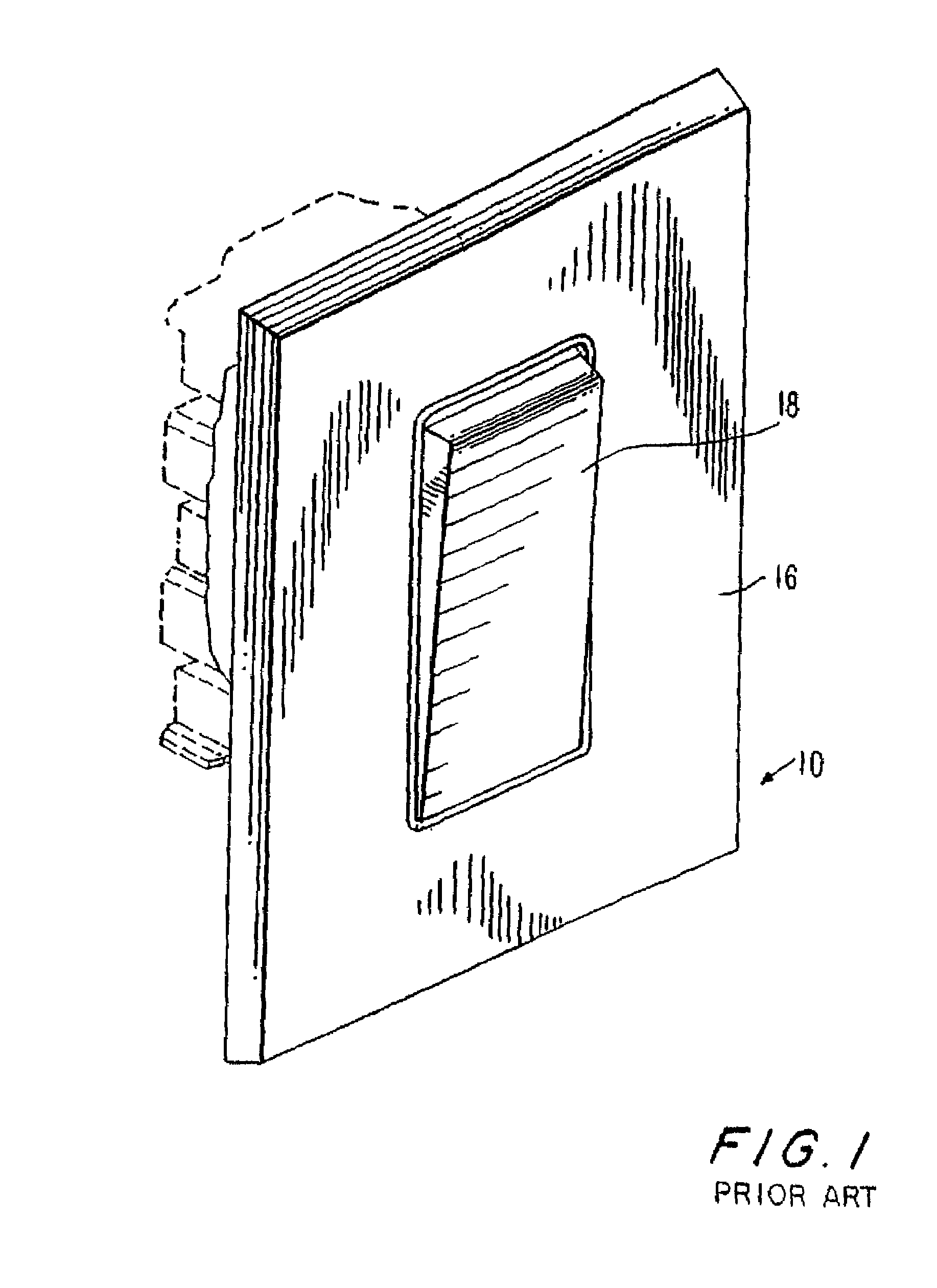

Stackable archive container

A stackable archive container (10) is formed from a cardboard sheet, and comprises, when in the stacked state, two side walls (14, 16), a top wall (18), a bottom wall (20) and a rear wall (12), with a closure flap (22) being hinged to the top or bottom wall. Reinforcing bars (41; 58; 64) are provided on the vertical side edges of the side walls and / or the back wall. The bars are typically extruded from aluminum, and have a U-shaped profile that extends the length of the side edges of the side and / or back walls, and embraces the side edges in a snug push fit. The reinforcing bars may have a U-, H- and / or W-configuration. The profiles enable the stacking height of the containers to be increased, and also serve to interconnect adjacent containers.

Owner:EVERS WILHELMUS JOHANNES ALBERTUS ANTONIUS

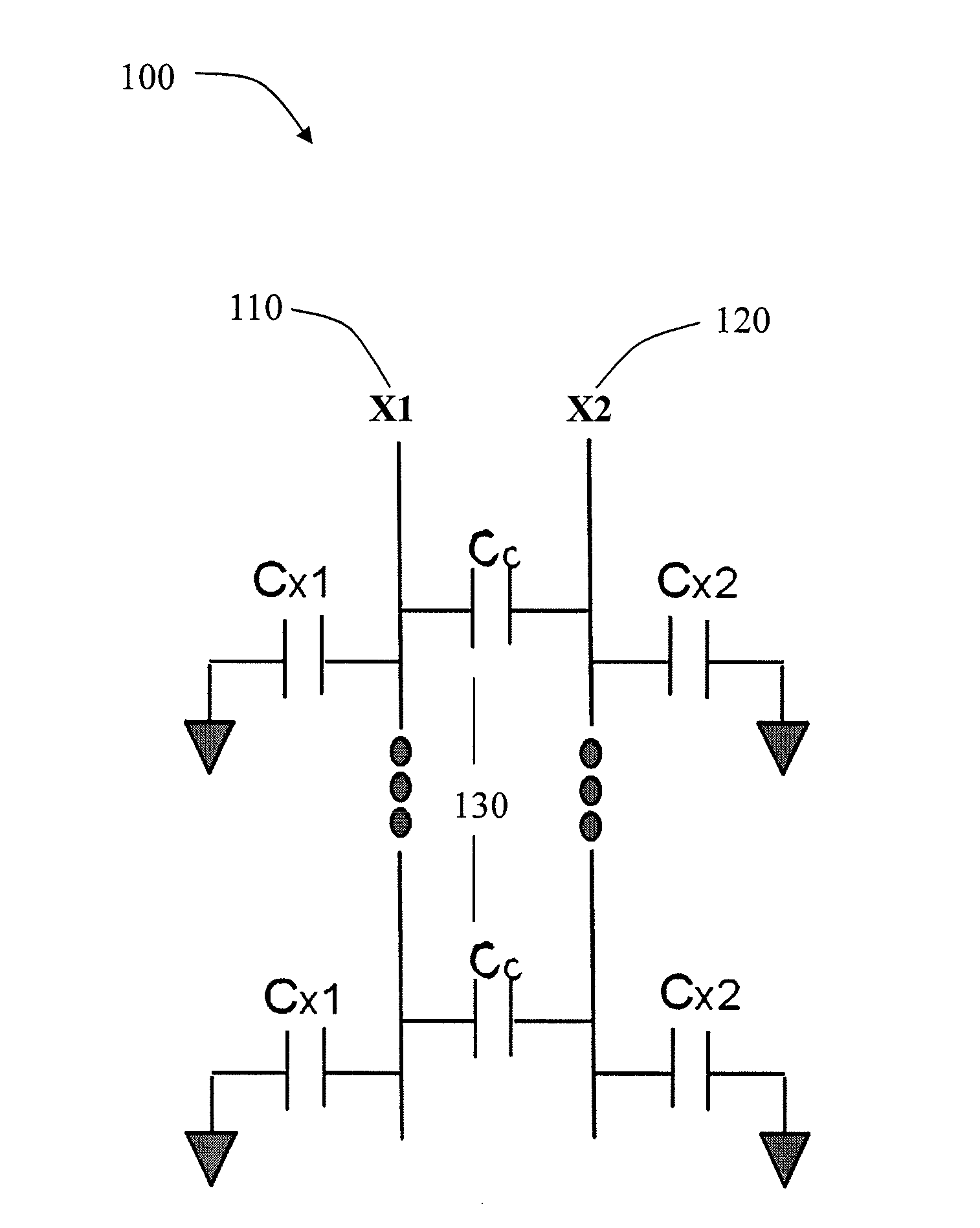

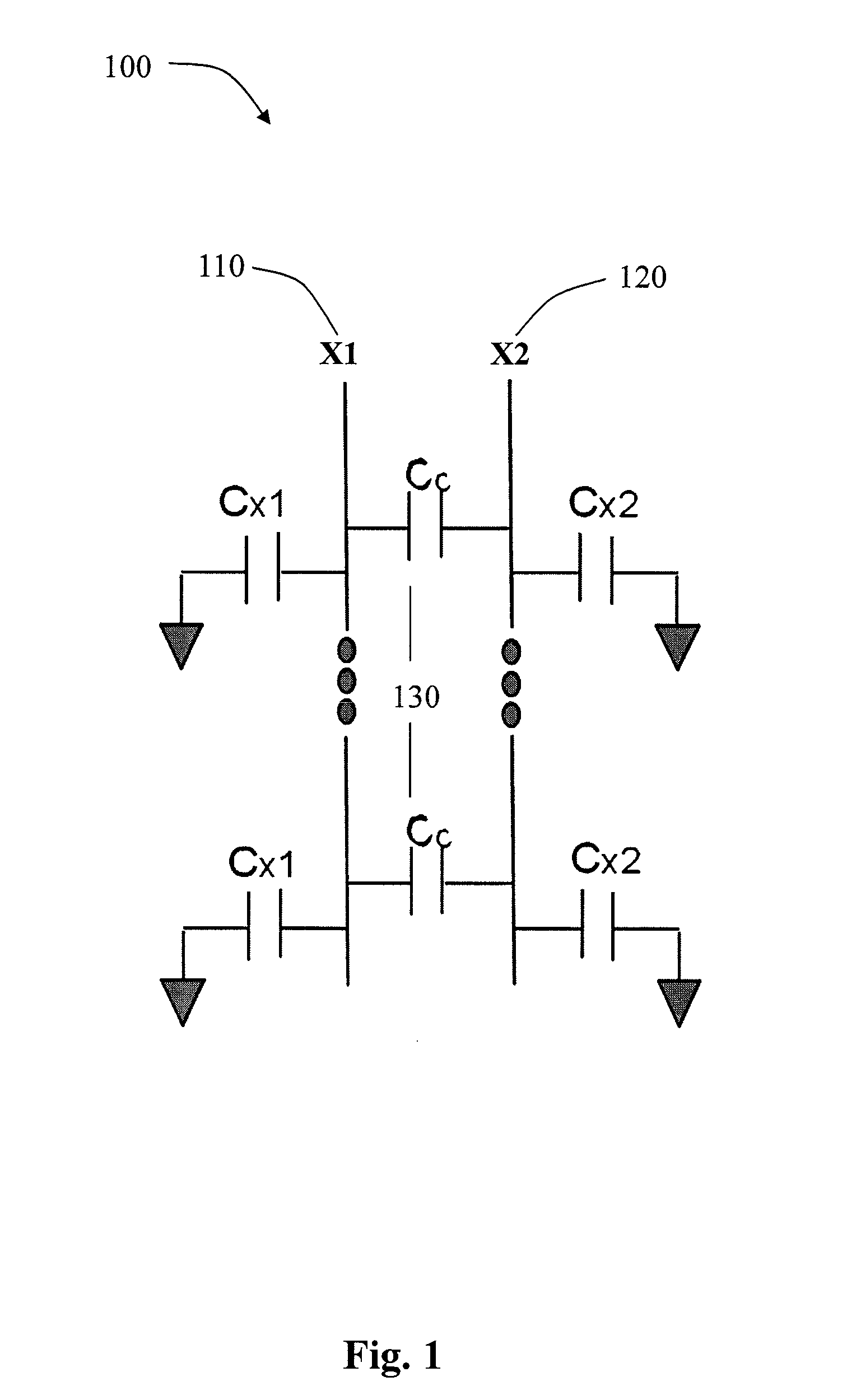

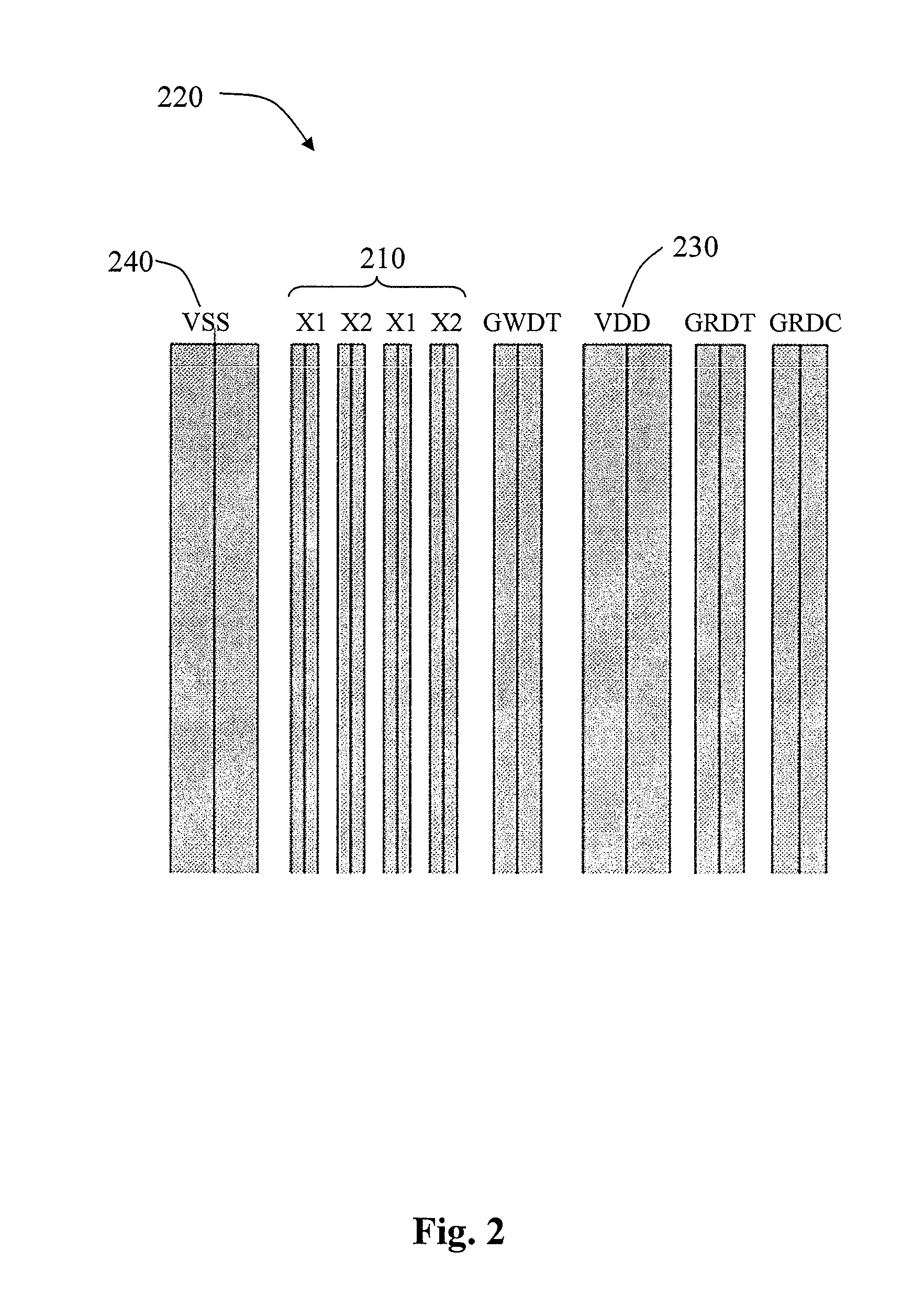

Method and system for an adaptive negative-boost write assist circuit for memory architectures

Disclosed is an adaptive negative bit-line boost write assist technique in which coupling capacitance scales with the number of rows and thereby maintains a constant negative bit-line level. The change in the coupling capacitance in neighboring signals as the height increases is utilized. The change is utilized for negative bit-line voltage generation.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

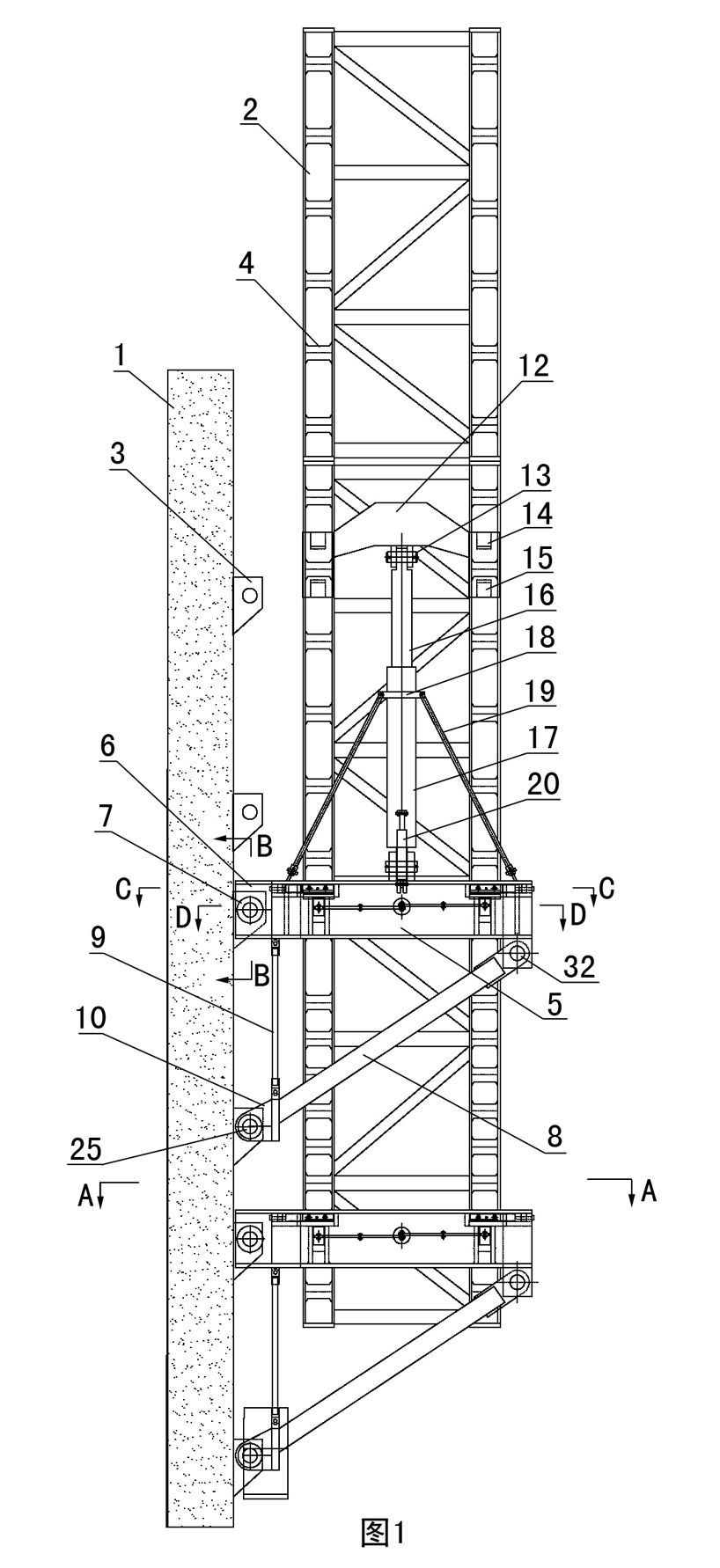

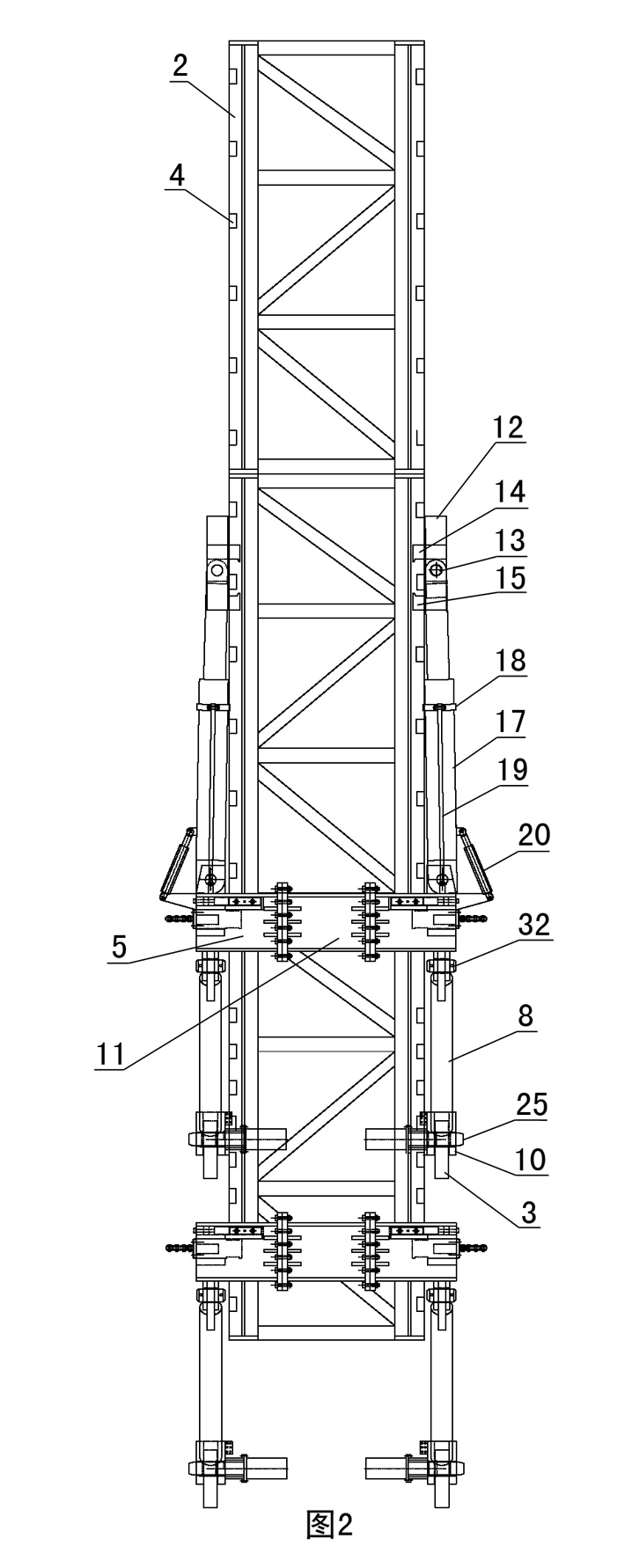

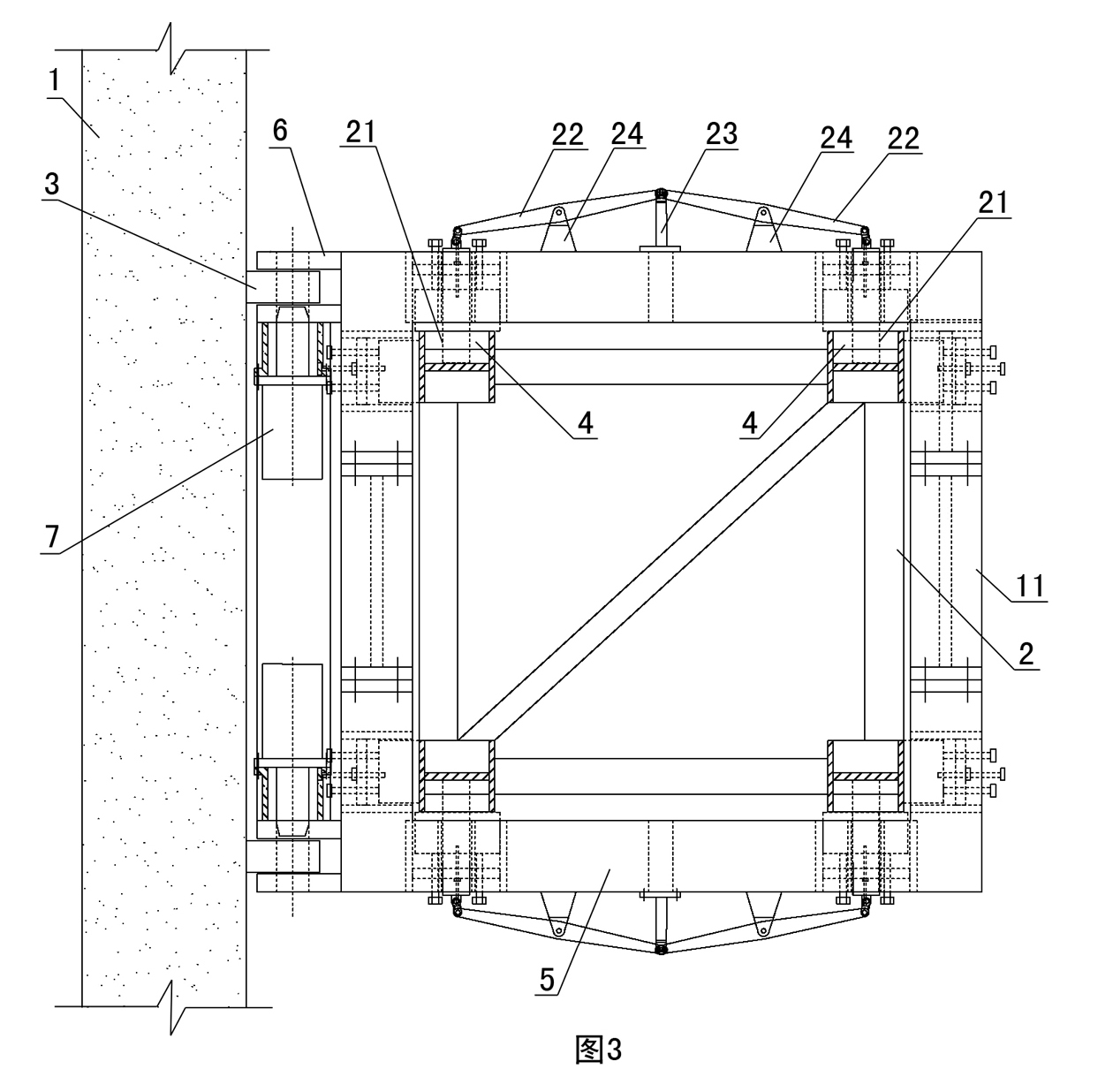

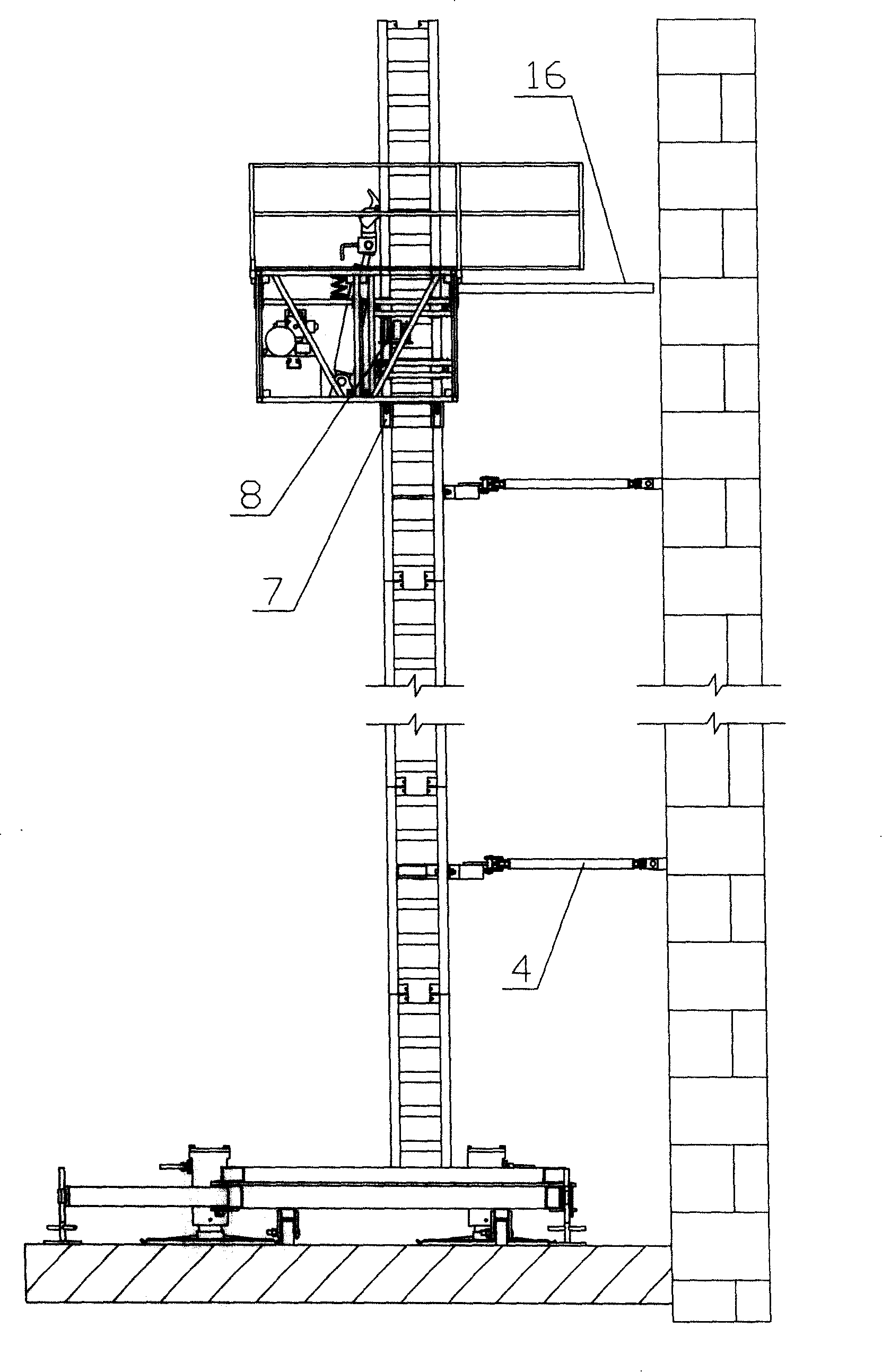

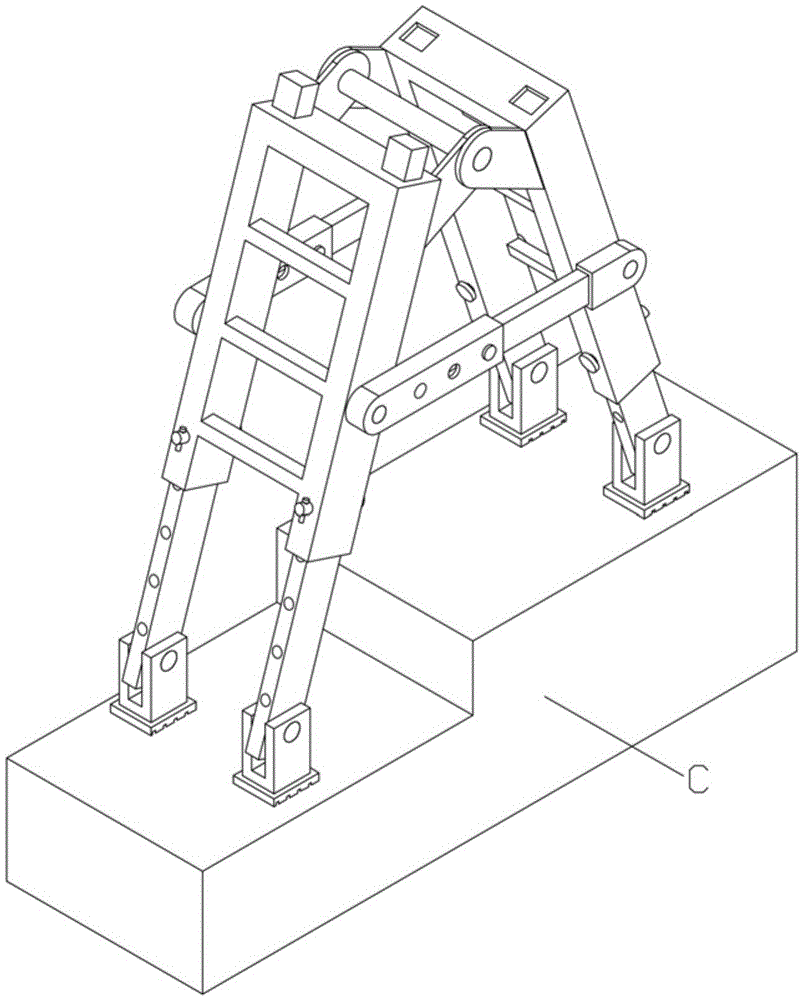

Hydraulic climbing system for wall-attached support frame

ActiveCN102071798AImprove construction efficiencyReduce construction costsForms/shuttering/falseworksScaffold accessoriesSupporting systemArchitectural engineering

The invention discloses a hydraulic climbing system for a wall-attached support frame. The system comprises a support upright post, a support frame device and a hydraulic jacking device, wherein the support frame device is detachably connected with a bracket which is fixed on a core barrel concrete wall and at least comprises an upper support frame device and a lower support frame device; both the upper support frame device and the lower support frame device are provided with upright post supporting devices and upright post clamping devices; climbing step blocks are vertically distributed at intervals on a column of the support upright post; and the support upright post is supported on the upright post supporting device through the climbing step blocks and is connected with the upper support frame device and the lower support frame device through the upright post clamping devices in a clamping way. In the system, an overall elevating template system, a construction steel platform system, a tower crane support system and the like are automatically elevated entirely along with the height increase of a building main body. The system has high safety, short climbing time and high construction efficiency, and can be used repeatedly in different projects.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

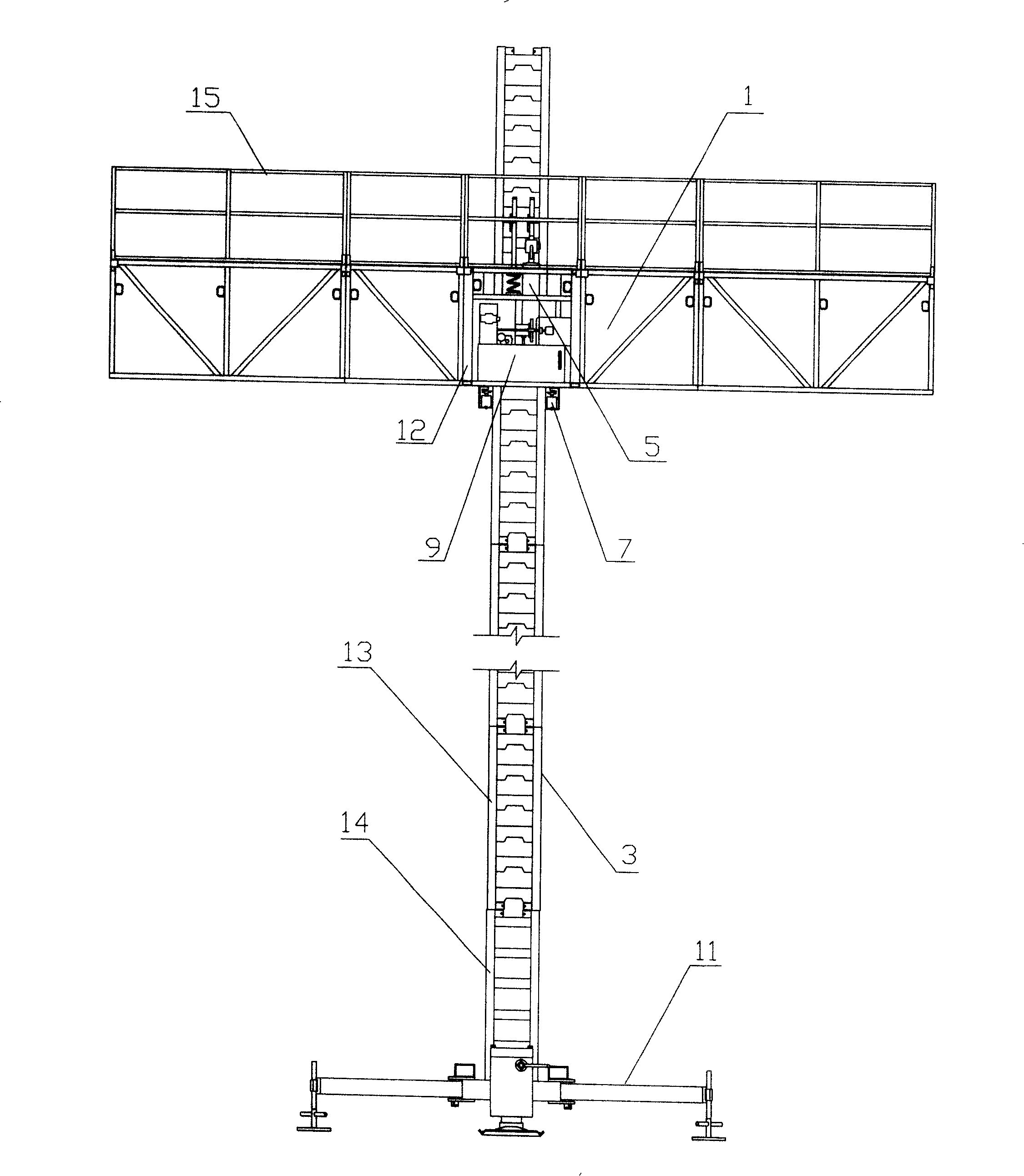

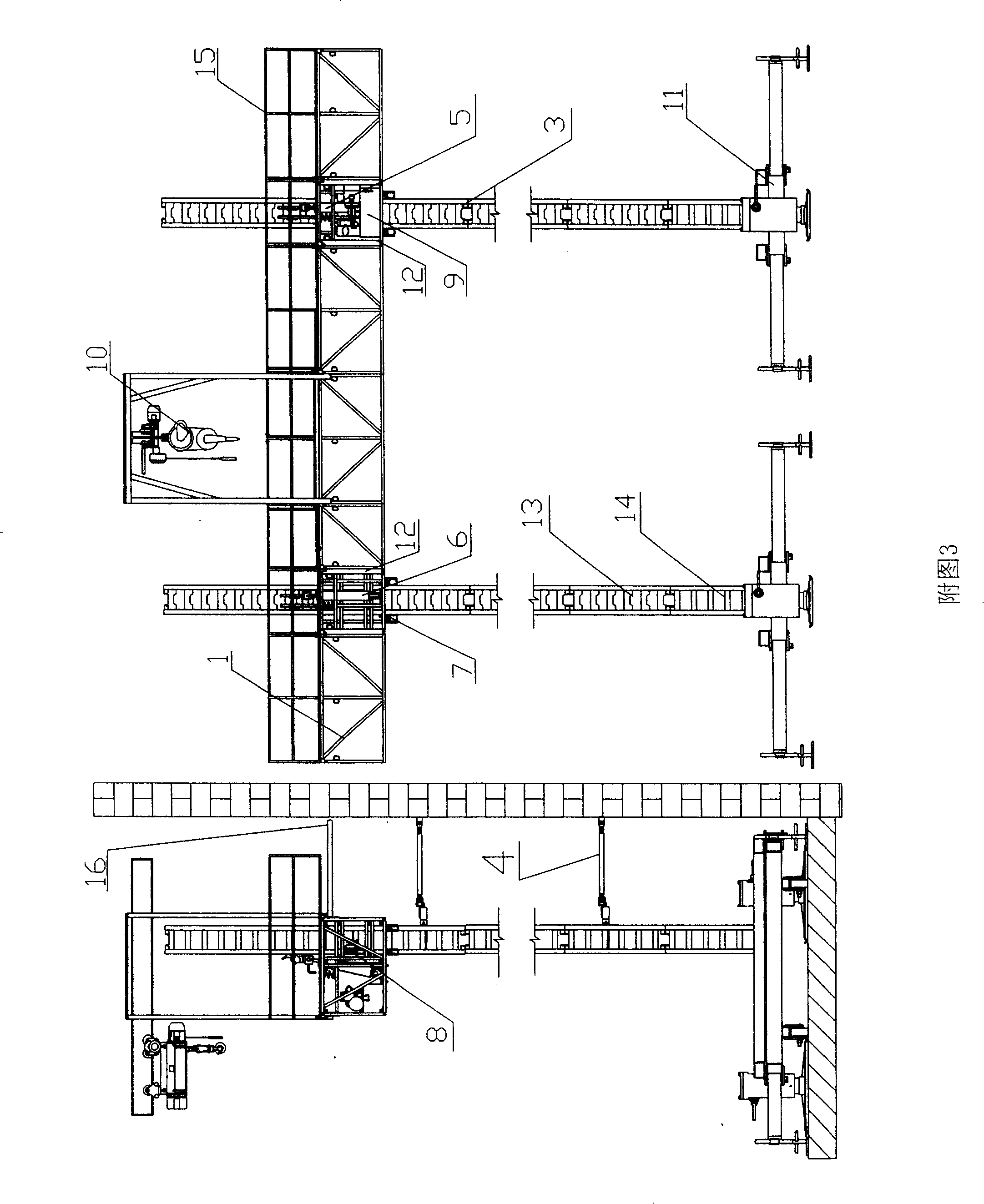

Adhered self-lifting highrise operation platform

InactiveCN101225706ALow costImprove construction efficiencyBuilding support scaffoldsEngineeringBatten

The invention relates to an attached and elevated self-lifting work platform, which uses all kinds of platform standard joints and control platform joints to assemble into a basic platform (1); a plurality of connecting ear plates (21) are welded on the two ends of every platform standard joint, the standard joints are connected with each other by connecting pieces; the attachment support (3), which is in the control platform joint, is the main forcing bearing device in the vertical direction, and is fixed on the support base (11) through a basic joint (14), and the height increases according to the building height, the batten plate (23) of the support standard joint (13) and the inverted U-typed batten plate (24) are horizontally arranged for the lifting of the lifting device. The lifting device and the wedge-shaped safety device are arranged on the control platform joint. The attached and elevated self-lifting work platform has the advantages that the application range is more wider than prior art, and can be used to the construction of the building structures and outer finishing and other elevated operations, and is characterized in diversified, serialized, convenient operation arrangement, very easy installation and disassembly, saving time limit for a project and reducing the project cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

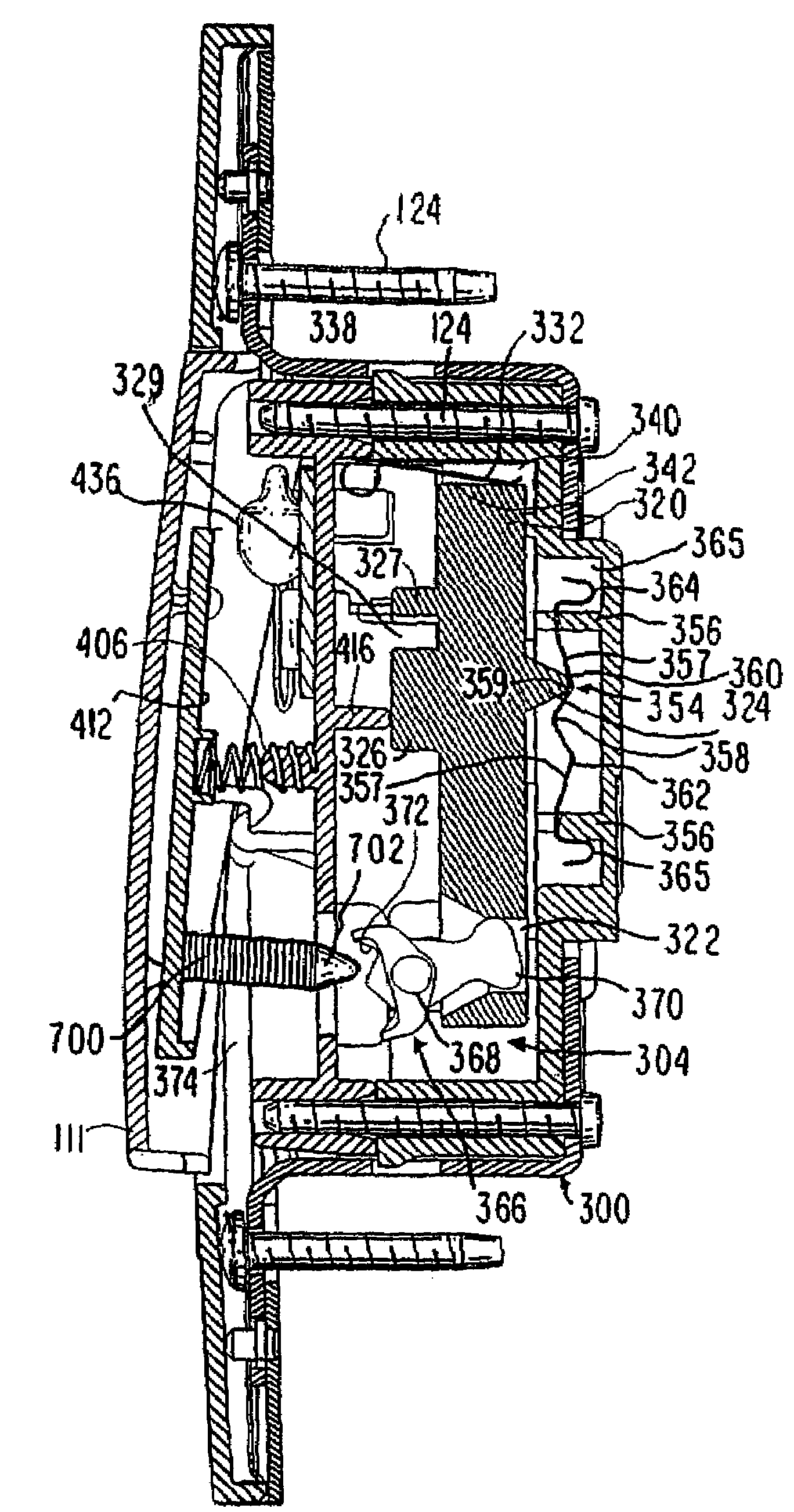

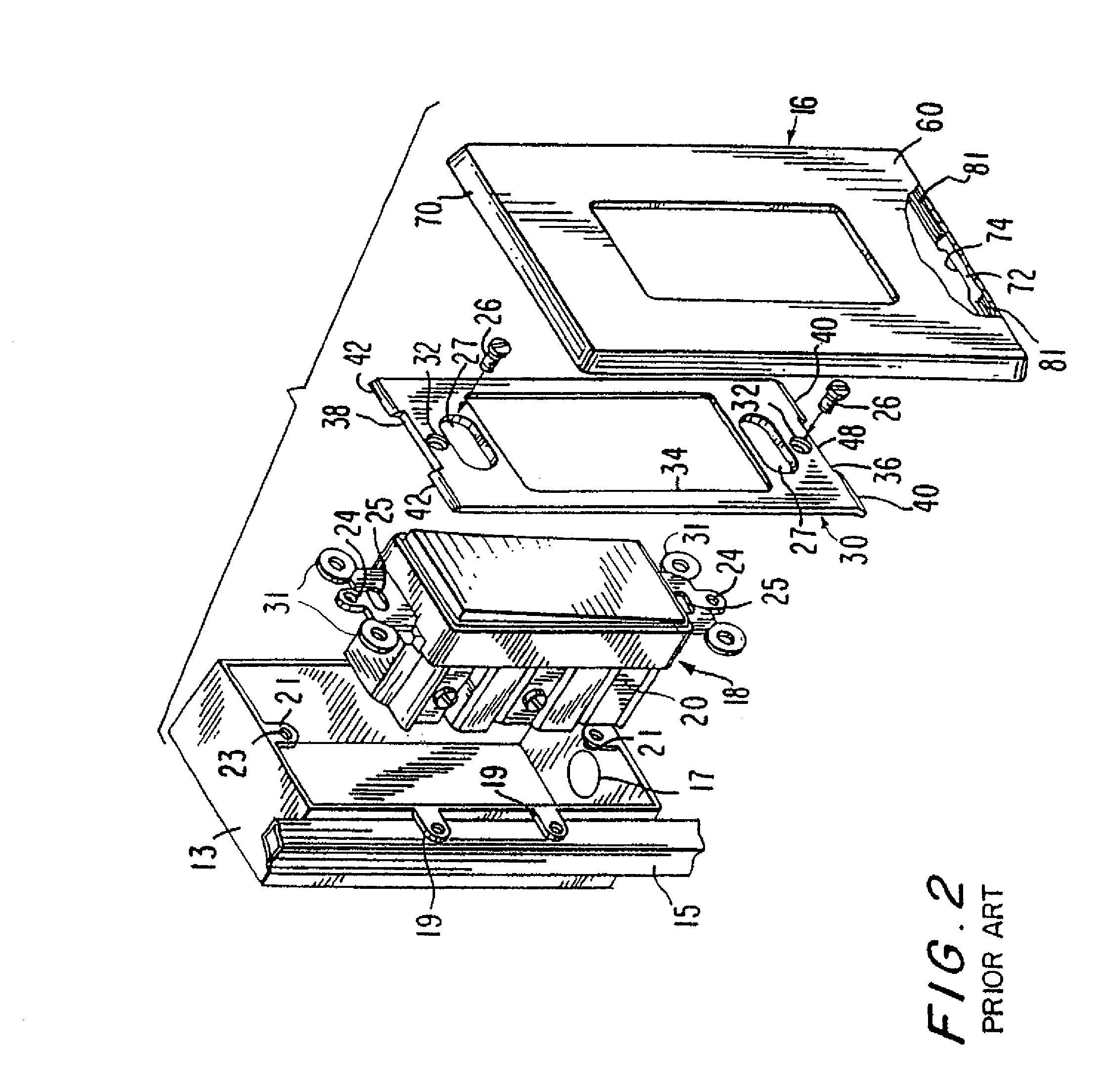

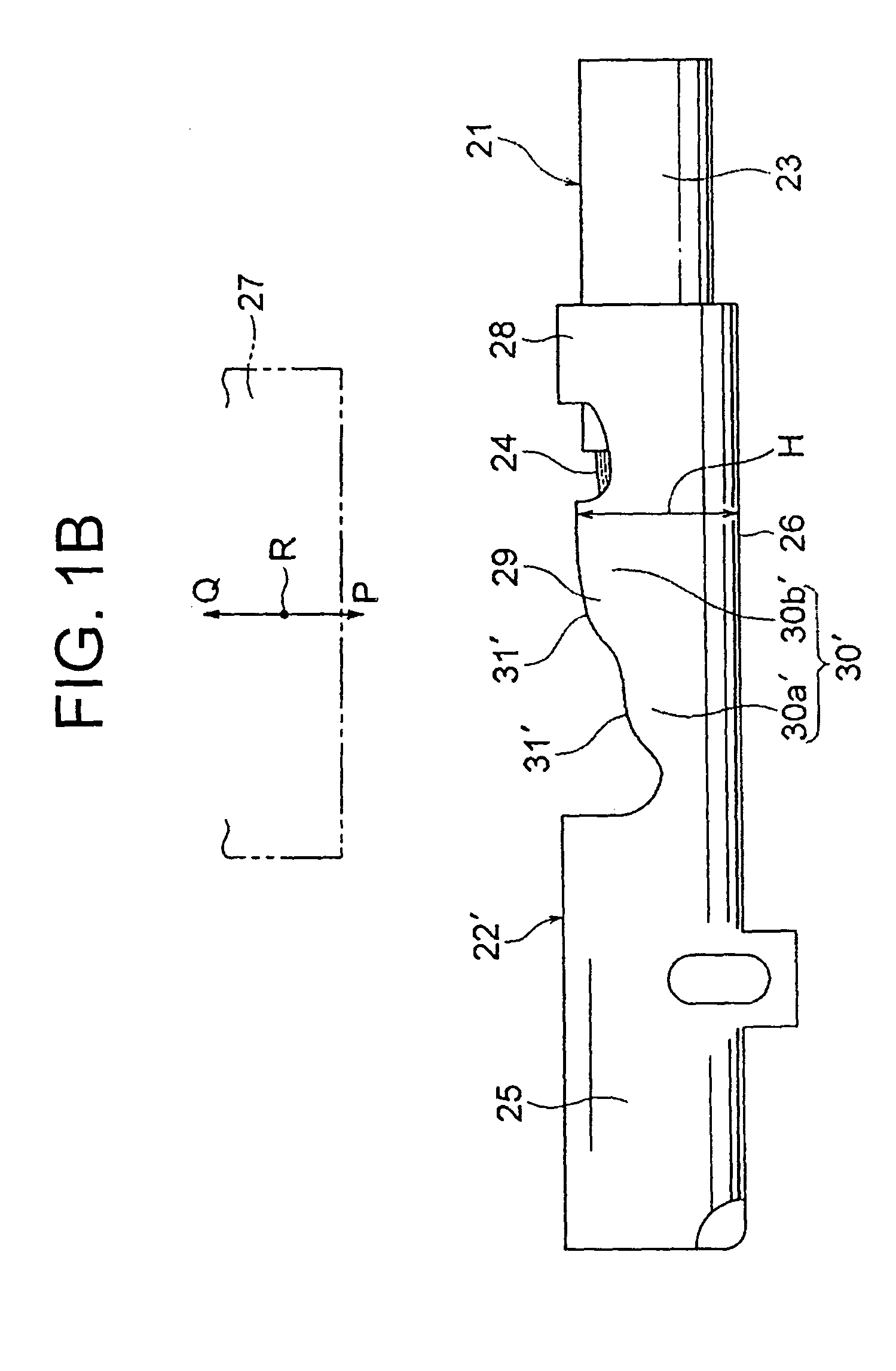

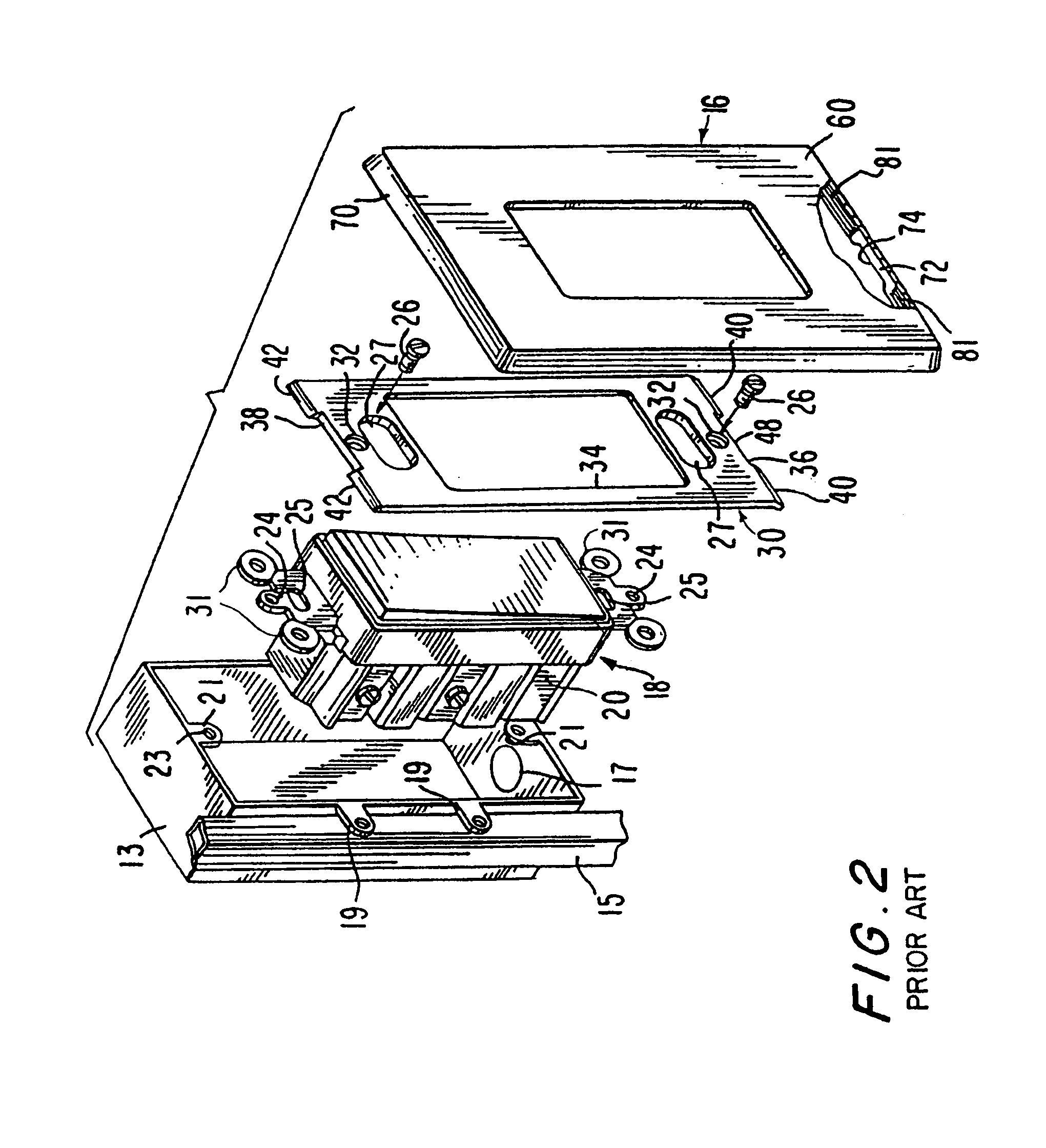

Rocker paddle switch with semi-rigid cam driver

Owner:LEVITON MFG

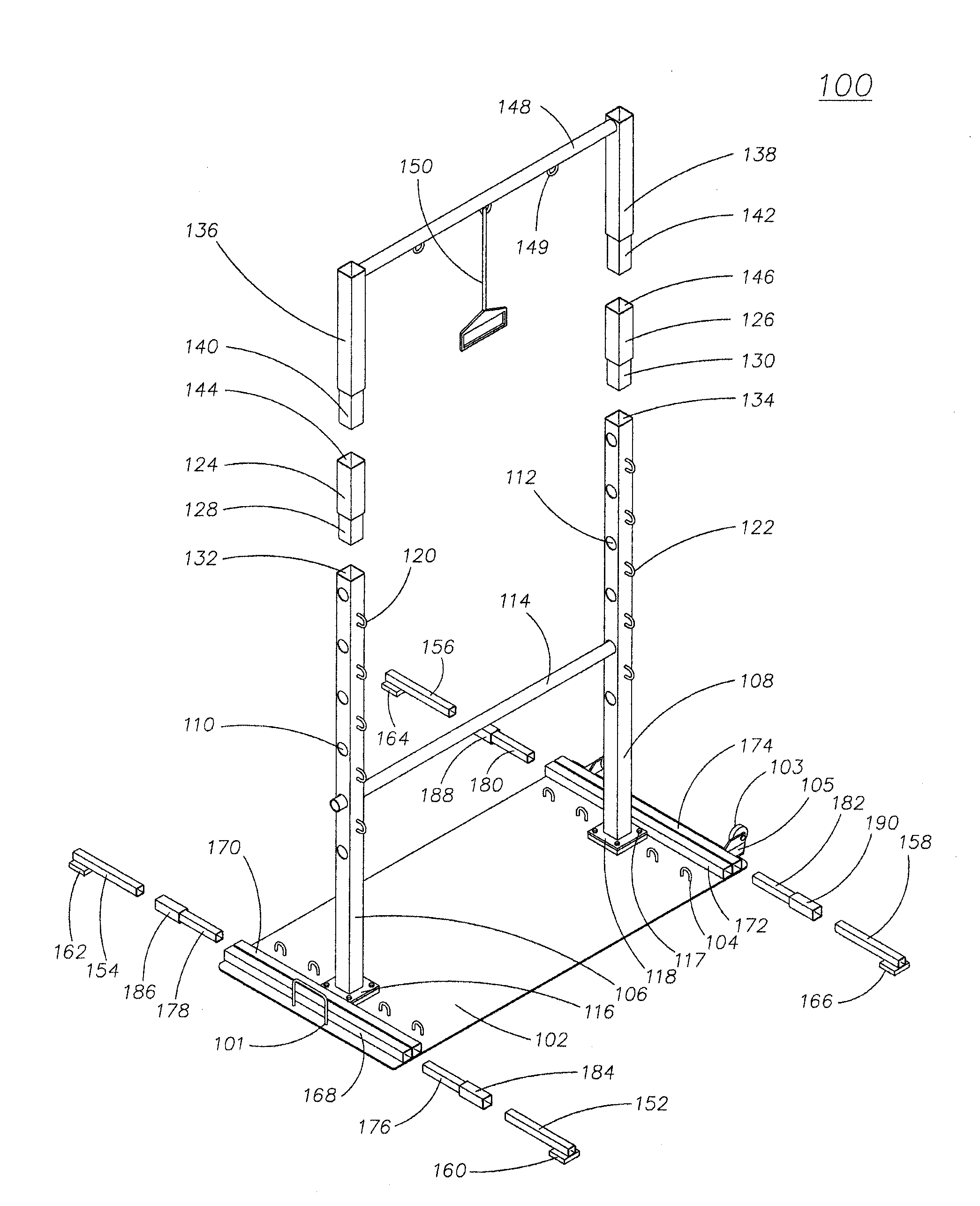

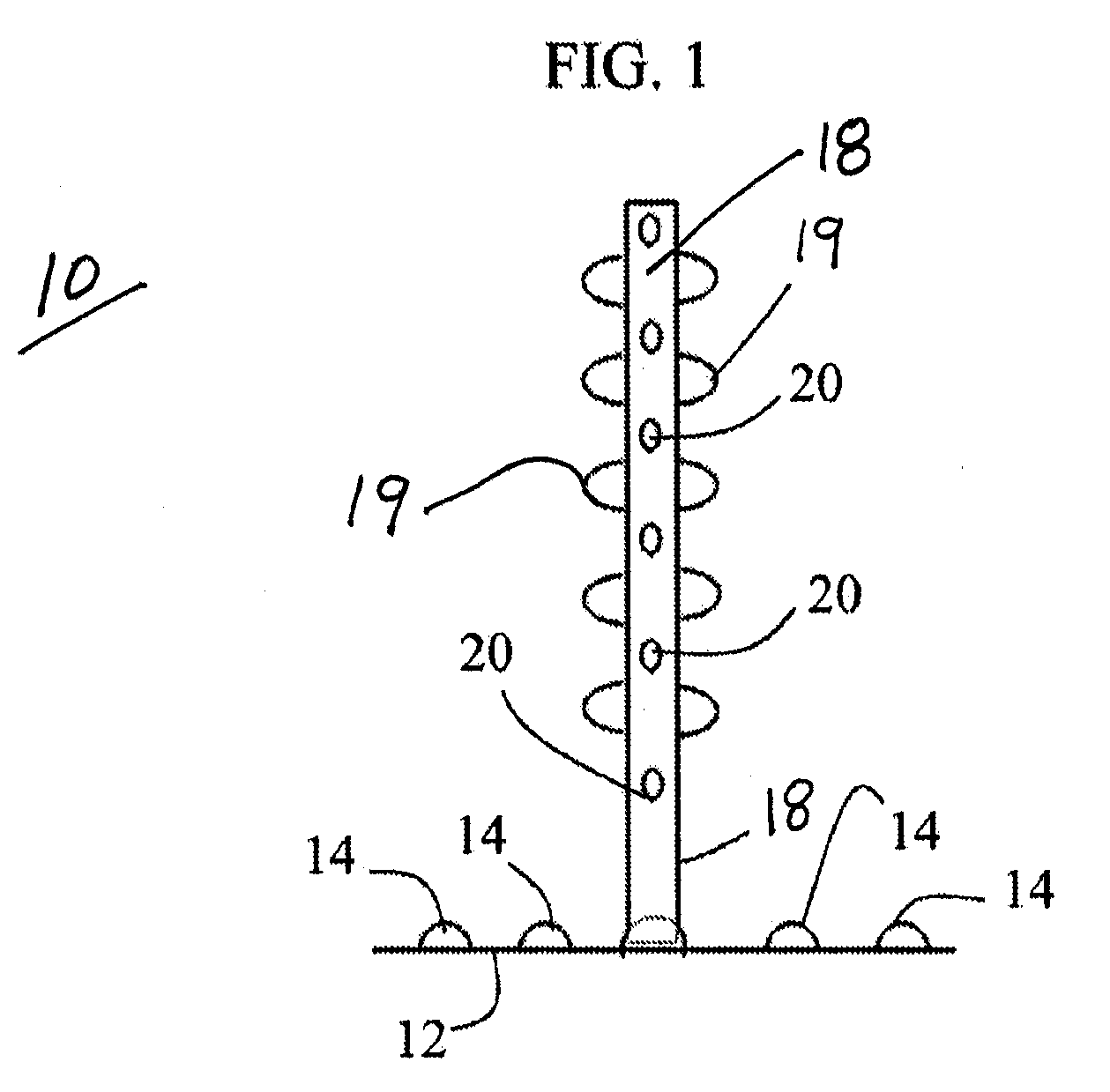

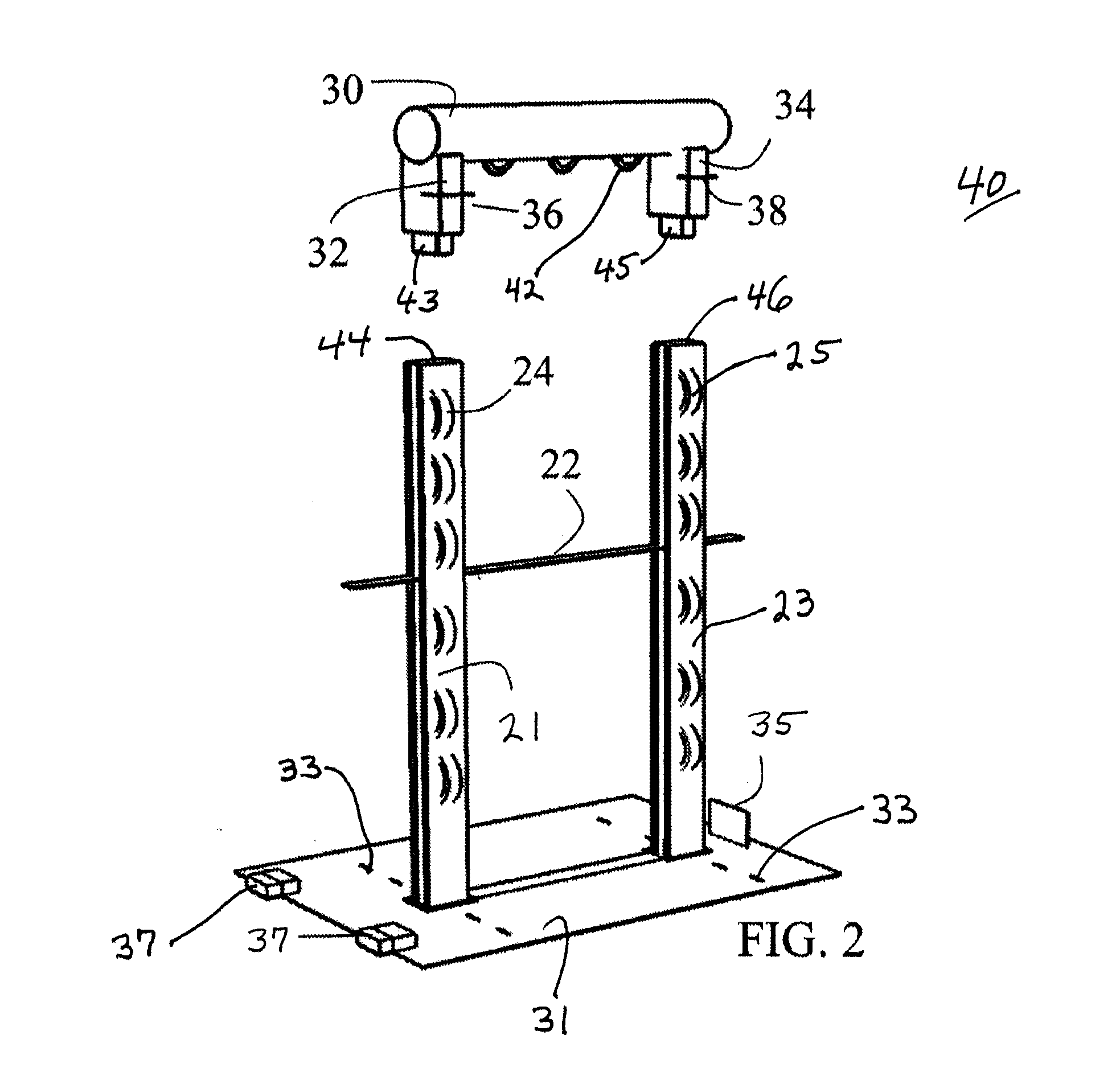

Apparatus for Performing Body Exercises

InactiveUS20110152046A1Improve stabilityIncrease the lengthHorizontal barsMuscle exercising devicesEngineeringIncreased height

Exercise apparatus having vertical towers rigidly attached to a base plate, including tower extensions that slide inside the tops of the vertical towers to increase their height, and further including base stabilizer leg extensions connected to the base plate to further stabilize the apparatus due to increased height.

Owner:ROCHFORD TIMOTHY S

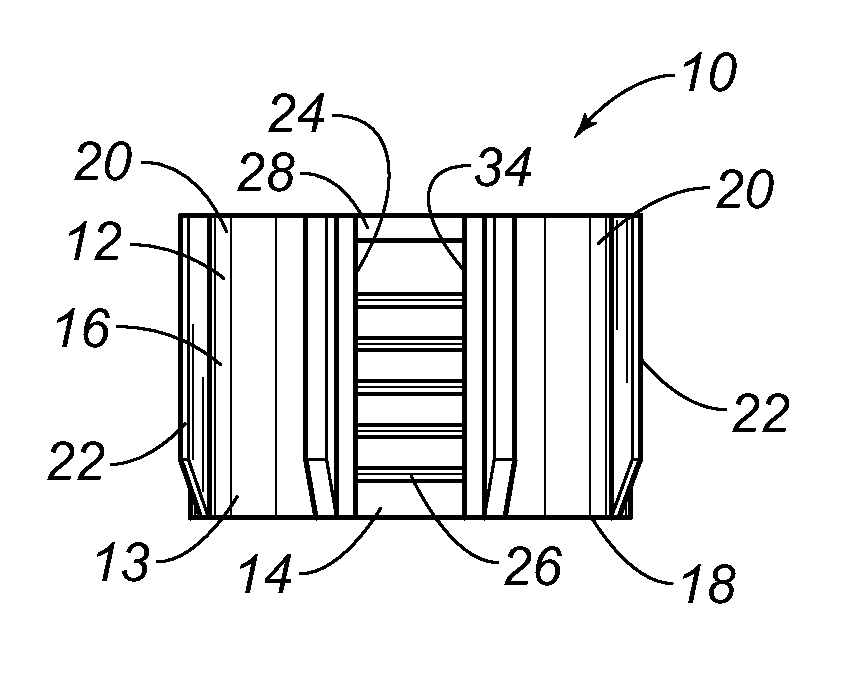

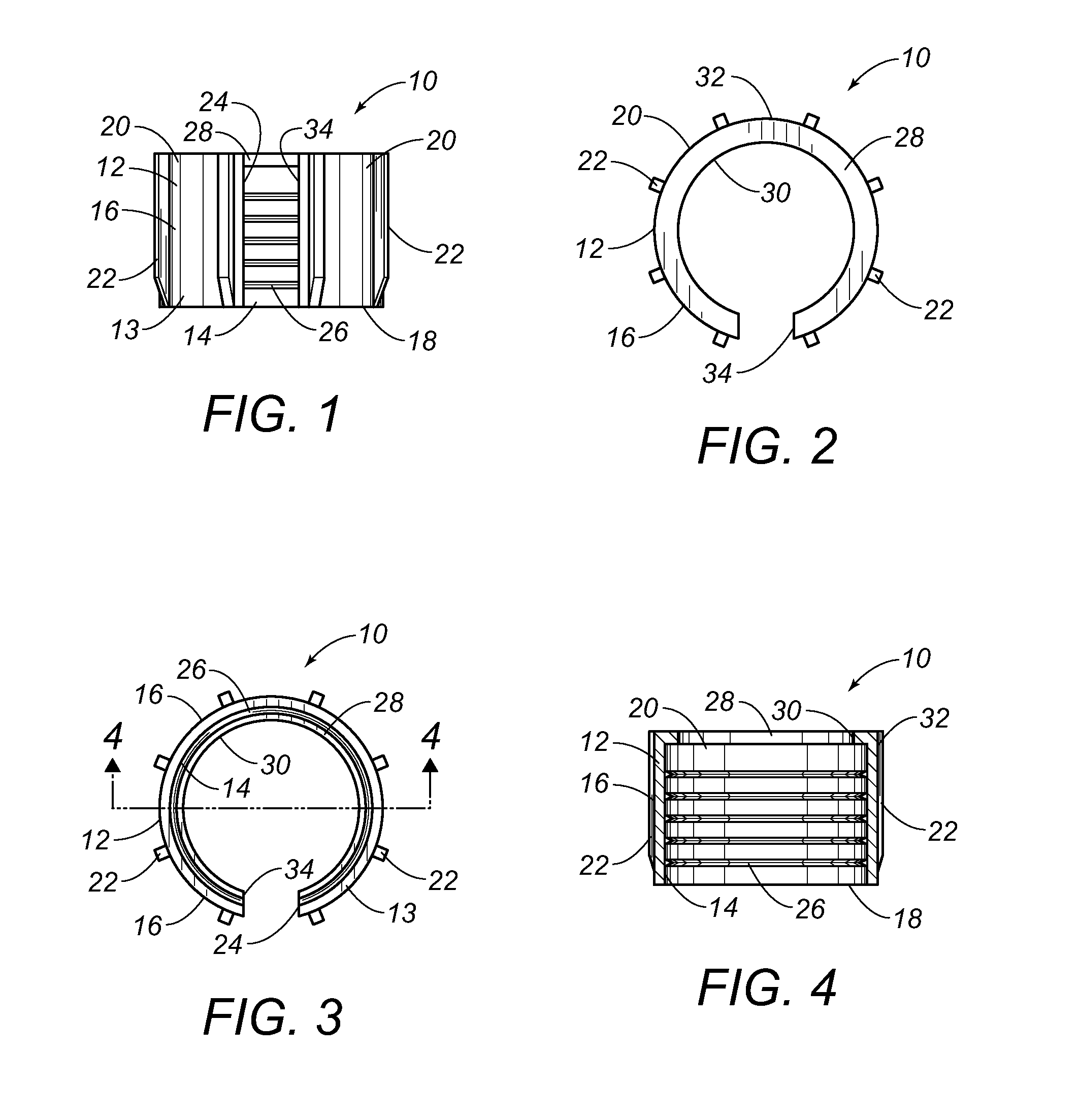

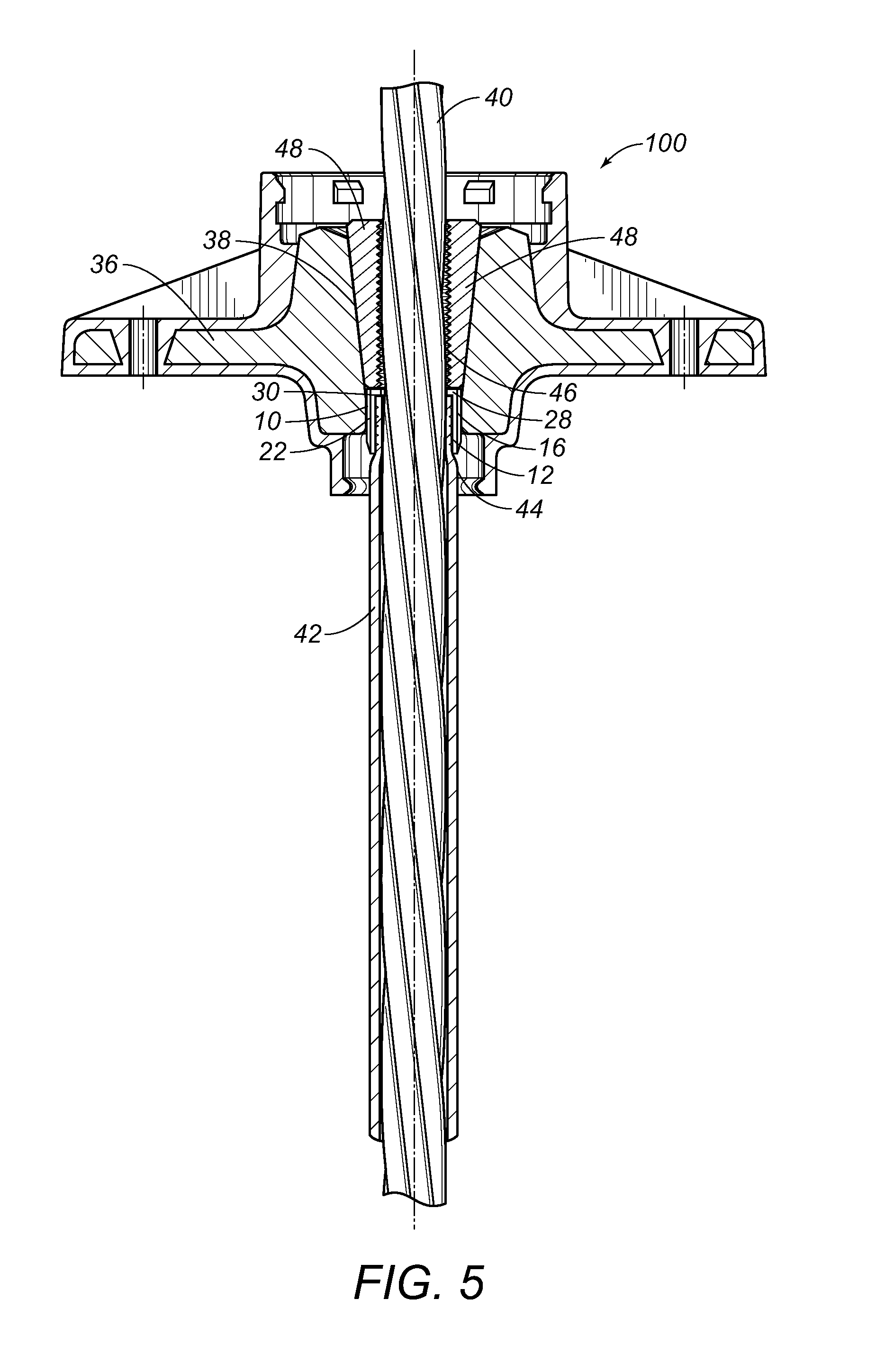

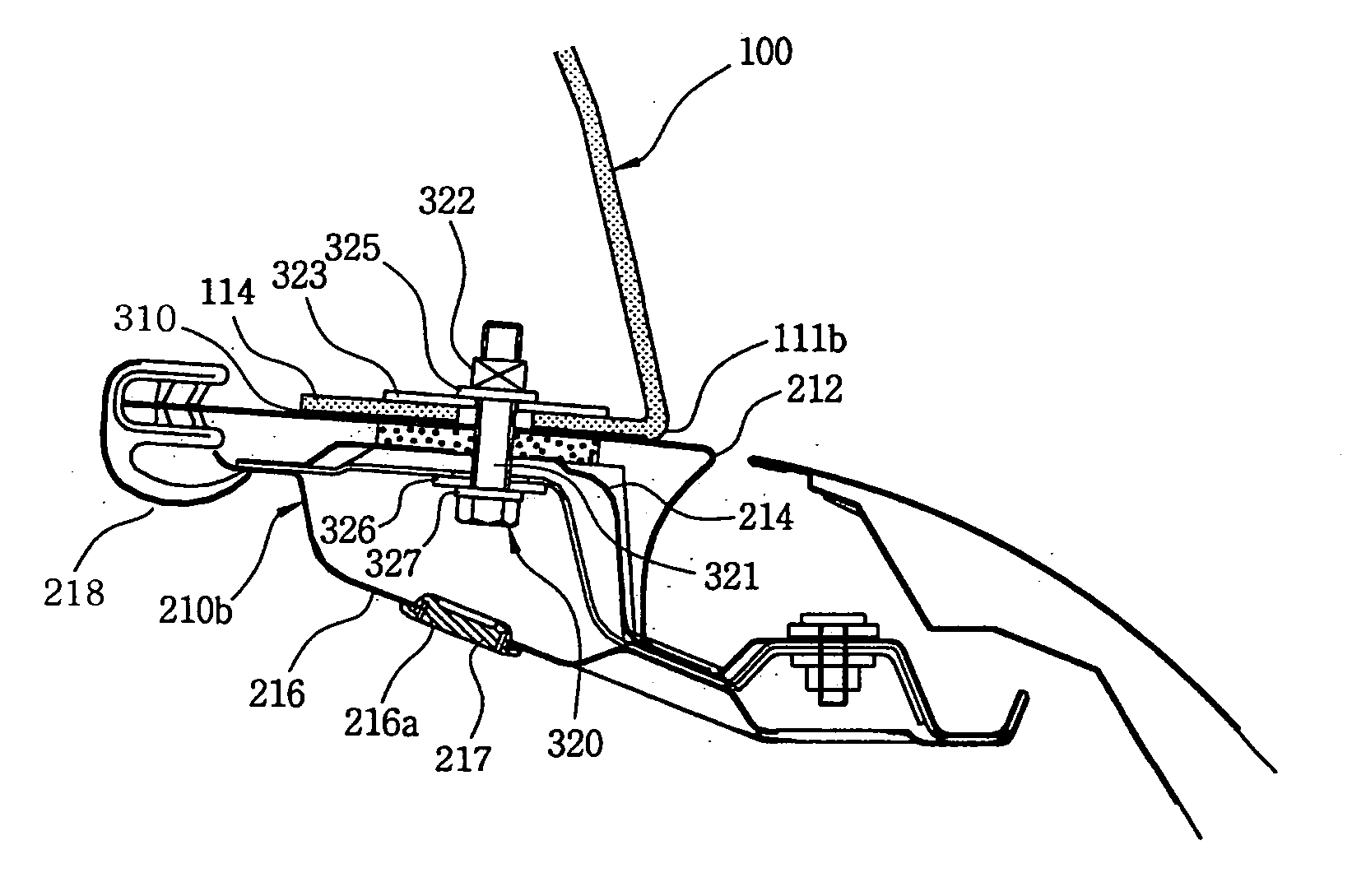

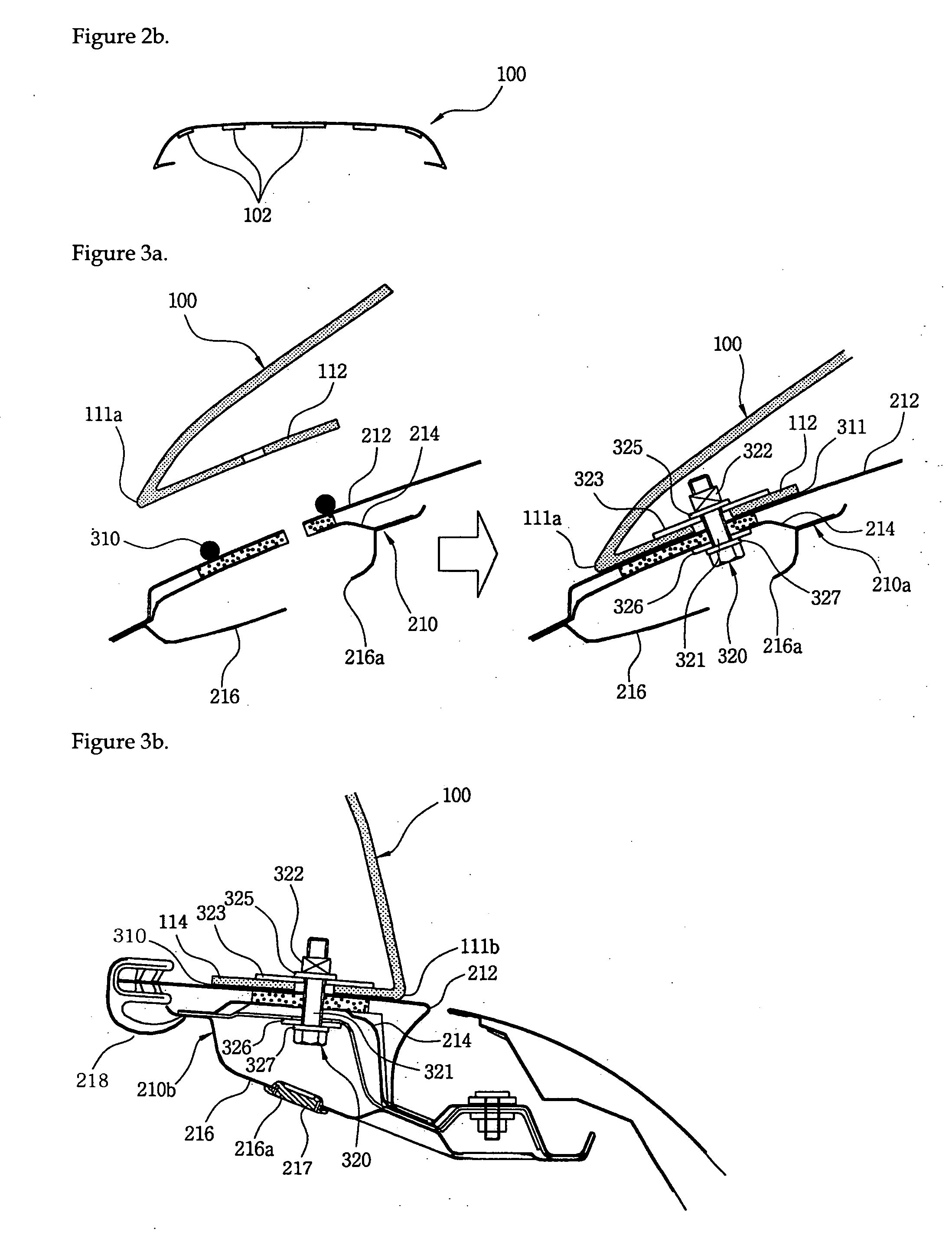

Sheathing retaining cap

ActiveUS7793473B2Snap fastenersRopes and cables for vehicles/pulleyEngineeringMechanical engineering

An article for engaging a sheathing of a sheathed portion of a tendon has a tubular body having an inner surface and outer surface and a first end and a second end, fins extending radially outwardly from the outer surface, a longitudinal split extending through a wall of the tubular body and extending from the first end to the second end, locking ribs extending radially inwardly from the inner surface of the tubular body, and a collar formed adjacent the second end of said tubular body. Each of the locking ribs extends parallel to the other locking ribs. The locking ribs are equally spaced along the inner surface of the tubular body. Each of the fins extends parallel to the other fins. Each of the fins have a height increasing from the first end to the second end of the tubular body.

Owner:SORKIN FELIX L

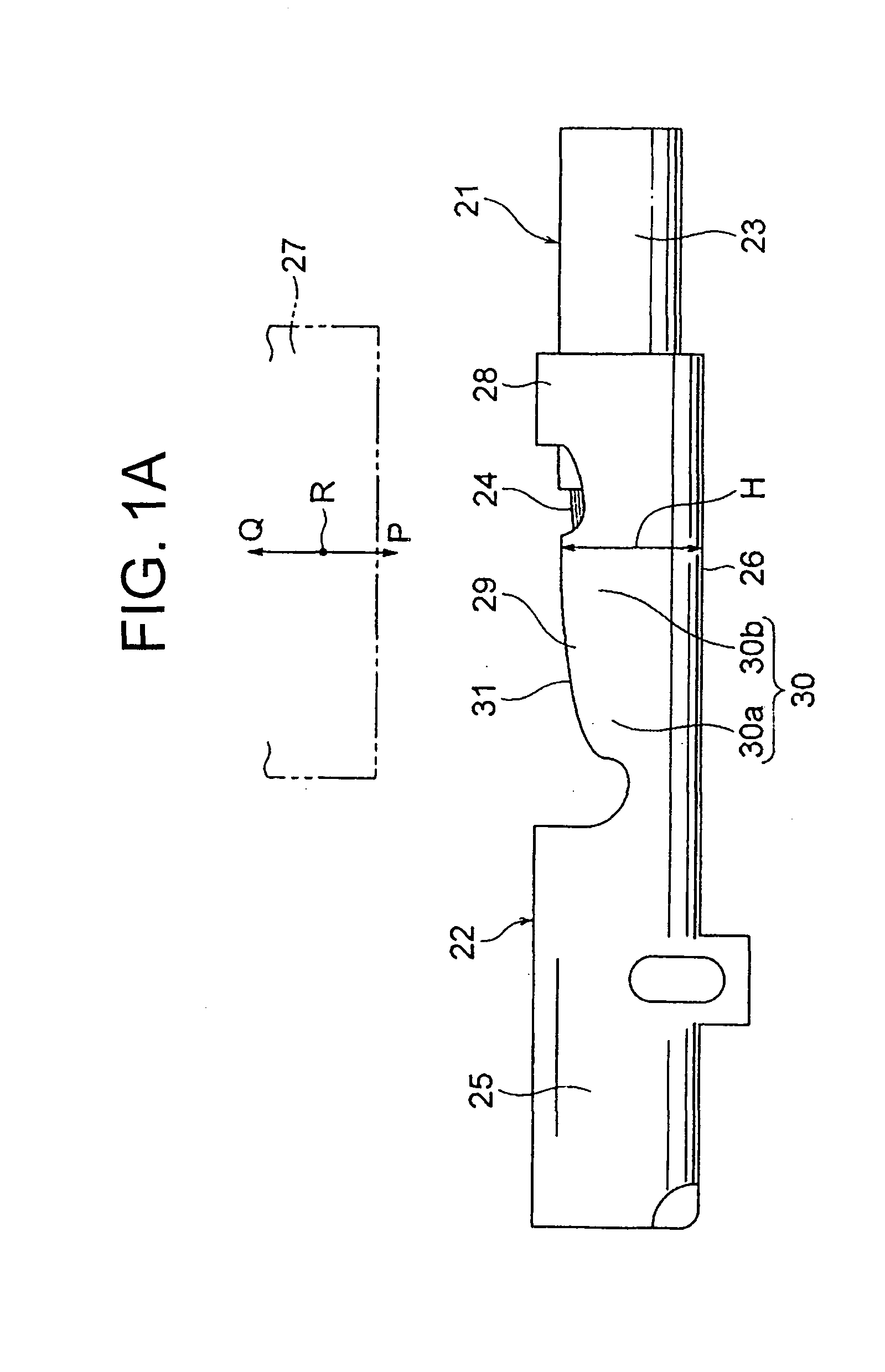

Crimping terminal

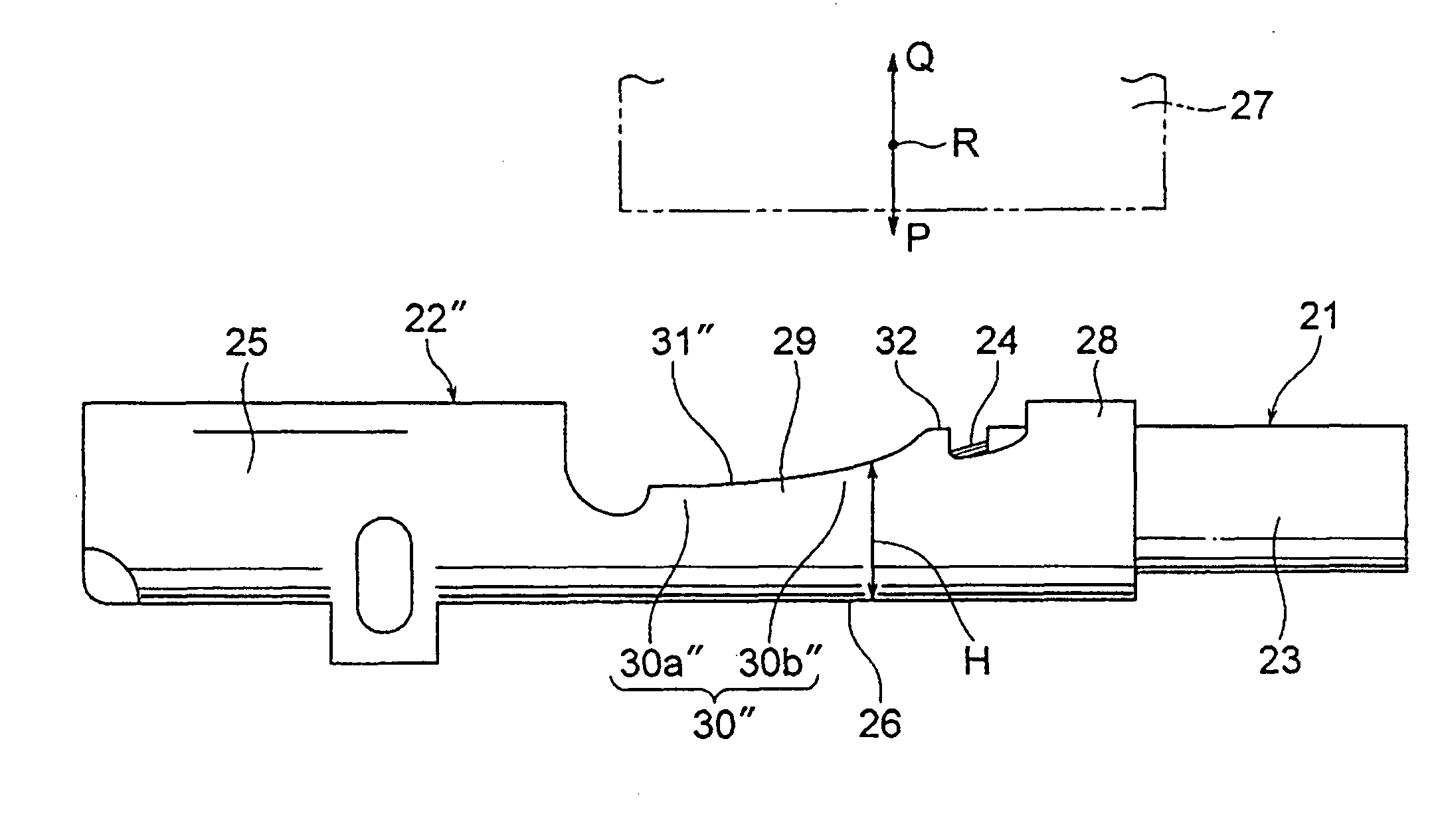

ActiveUS20100144189A1Reduce compressionIncrease crimp heightConnections effected by permanent deformationContact members penetrating/cutting insulation/cable strandsMechanical engineeringCompression ratio

A crimping terminal joined with an aluminum electric wire, in which when the crimping terminal is crimped to the wire, a conduct-purpose crimping portion and a wire-hold crimping portion are formed at a crimping portion of a wire barrel of the crimping terminal. The crimping portion of the wire barrel is formed so as a curvature thereof is projected upwardly in a direction of moving a crimping die and so as a crimp height increases and a compression ratio decreases towards an insulation barrel of the crimping terminal. The curvature is shaped to have a constant degree of curvature, and is shaped to form a quadratic curve as a result of strictly adjusting a crimping force.

Owner:YAZAKI CORP

Rocker paddle switch with flexible cam driver

There is disclosed a paddle switch operated by pushing on the lower portion of a rocker paddle to turn the switch “on” or “off”. The lower edge of the paddle pivots in and out about its upper edge. The switch includes flexible driver means coupled to be driven by the rocker paddle. When the rocker paddle is pushed in, it urges the flexible driver means to rotate a cam means in a first, clock wise direction, or a second, counter clock wise direction. Alternate rotation of the cam drives a slider member having a cam follower back and forth along a linear axis. A shaped leaf spring cooperates with the cam follower to assist in the movement of the slider and determines its rest positions. An indicator such as an LED is used to indicate the state of conduction of the switch. When the rocker paddle is released, it is biased by a spring to pivot back to its initial position. The rocker paddle of the switch is not located within a frame and has a surface along its vertical axis of positive first differential and zero second differential, comprised of a combination of splines which extend between points of varying distances from a datum plane. This surface has zero second differential when the rate of height increase of individual splines is constant.

Owner:LEVITON MFG

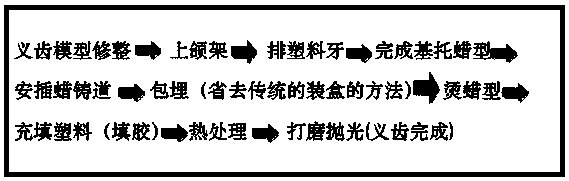

Manufacturing method of removable dentures

ActiveCN107854187AAvoid Coitus HeighteningAvoid Shrinkage Bubble PhenomenonArtificial teethWater bathsDental cast

The invention relates to a manufacturing method of removable dentures. Currently, the removable-denture manufacturing methods in all countries in the world are a thermos-coagulation packing method, need steps such as casing, filling, squeezer pressurizing and water bath polymerization (dental cast cooking pot), are complex in process, time-consuming and labor consuming, are non-uniform in moldingcase pressurizing and are difficult in precise mastering and control of heating speed and heating maintaining time during heat processing. The method has the advantages that the manufacturing flow oftraditional removable dentures is improved, joint height increasing and contraction bubbles of the removable dentures manufactured by the traditional manufacturing process are avoided, and the base-material filling of the partial removable dentures and attachment dentures can be performed; the models of the attachment dentures does not need to be pressurized on a squeezer, and the subfissure or deformation of the fixing-part porcelain teeth of the attachment dentures is avoided.

Owner:程昕

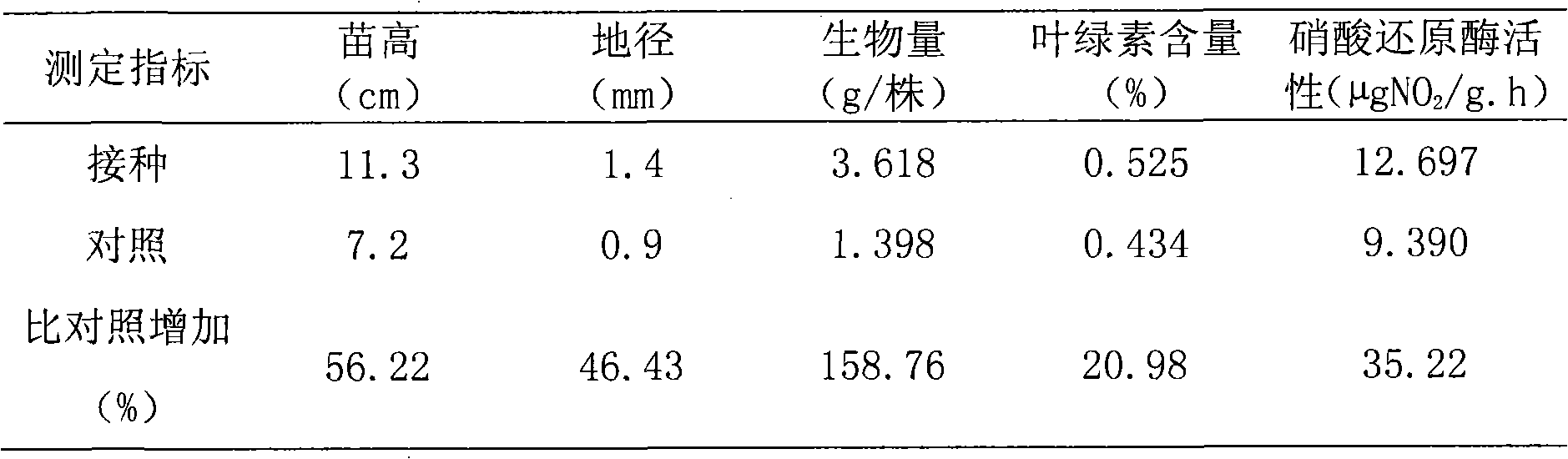

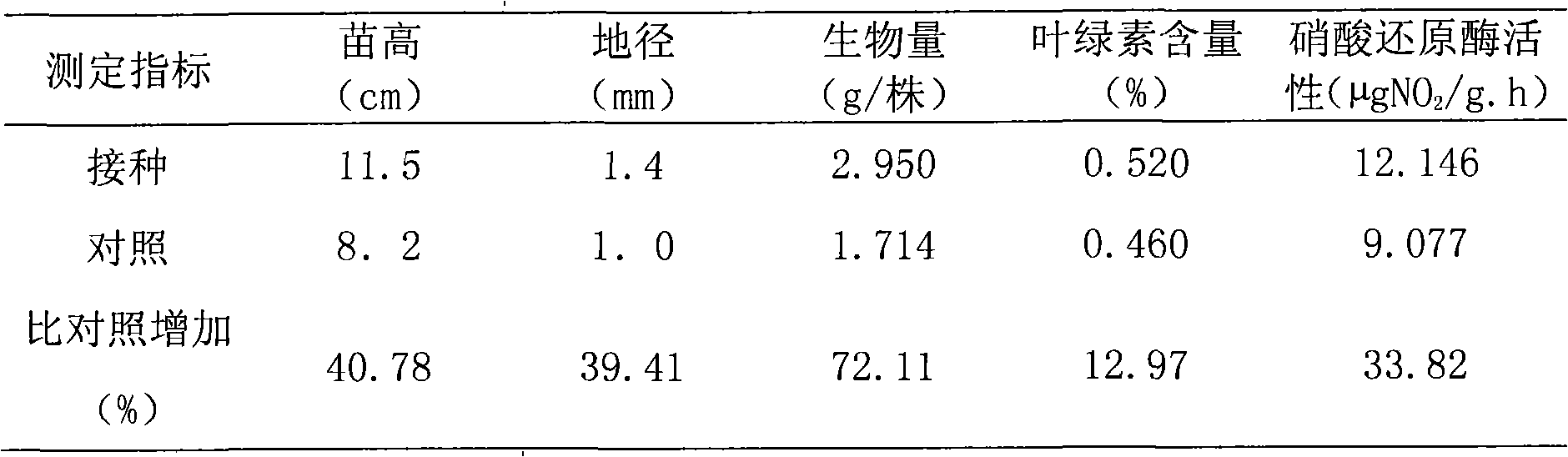

Nitrogen-fixing bacillus megaterium strain DL7 and application thereof

The invention relates to a nitrogen-fixing bacillus megaterium strain DL7 and application thereof. The strain is preserved in the General Microbiological Center of the China Committee for Culture Collection of Microorganisms in June 7, 2010 and has a preserving number as CGMCC NO.3914. The strain is a new nitrogen-fixing strain obtained by using the conventional microorganism separation and purification method for Chinese podocarpus root nodules. In the strain, the nitrogenase activity is 1.5632nmol.g<-1>.h<-1>; after an eucalyptus seedling is planted, the seedling height increases 40.78-56.22 percent, the ground diameter increases 39.41-46.43 percent, the average biomass increases 72.11-158.76 percent, the chlorophyll content increases 12.97-20.98 percent, and the nitrate reductase activity increases 33.82-35.22 percent. The strain can be applied to a biological bacterial fertilizer for promoting eucalyptus seedling growth.

Owner:GUANGXI UNIV

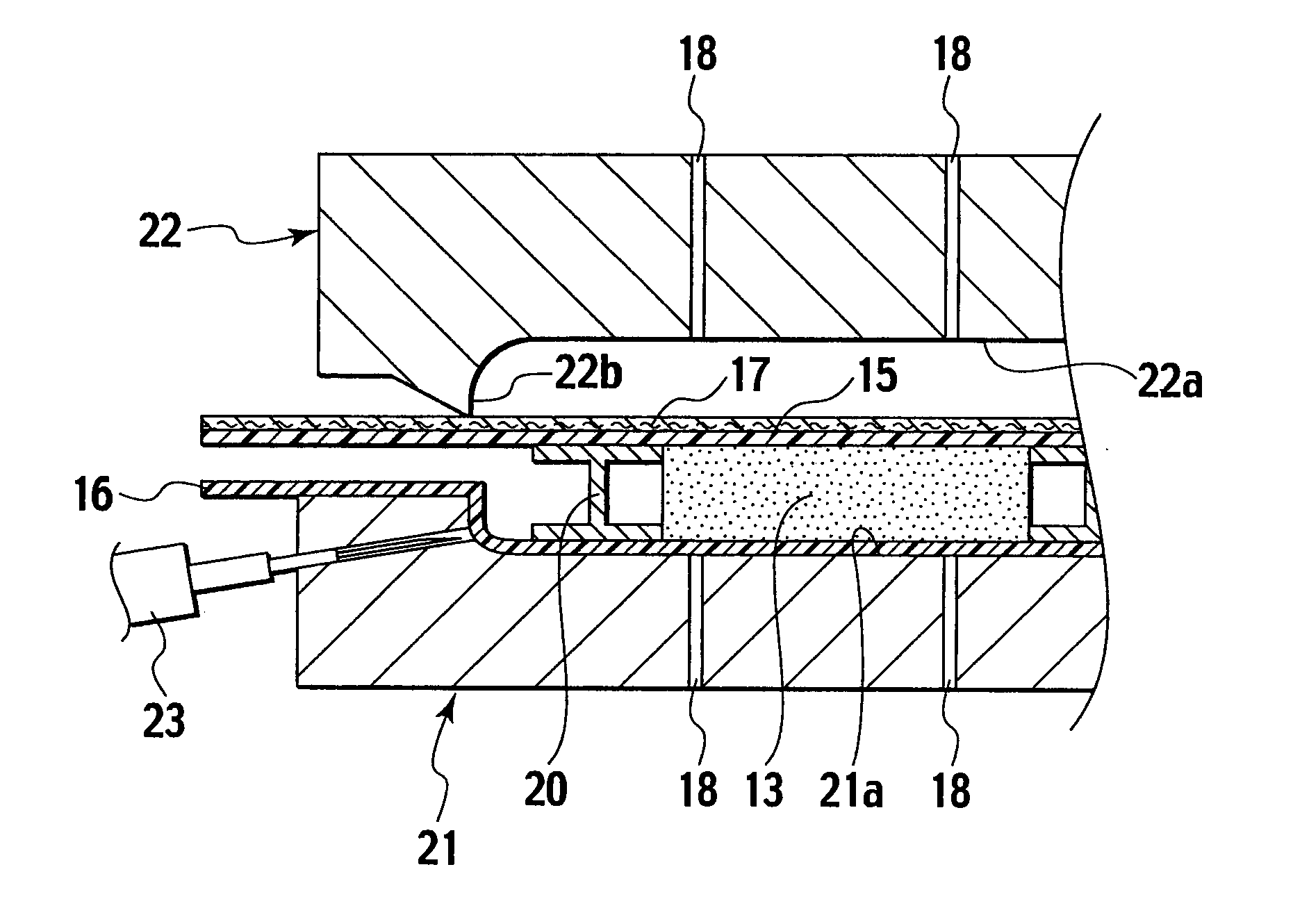

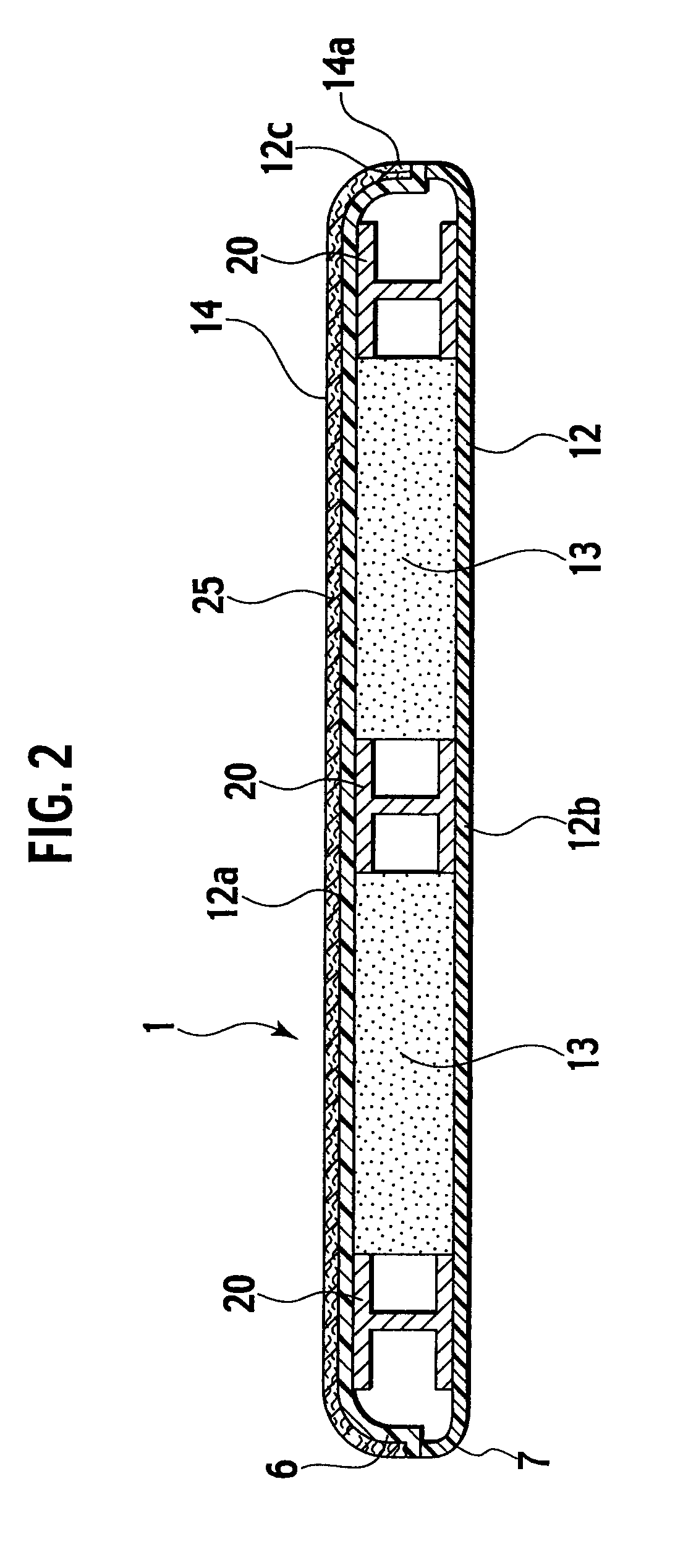

Laminated plate and manufacturing method thereof

A vehicle deck board 1 is molded in such a manner that a lower die 21 and an upper die 22 are clamped together in a state where foamed resins 13 and reinforcements 20 are interposed between a back surface side sheet material 16 and a front surface side sheet material 15, whereby the back surface side sheet material 16 and the front surface side sheet material 15 are welded to each other to thereby form a laminated member 26 with height-increasing bridge members included therein, compressed air is injected into an inside of the laminated member 26 with the height-increasing bridge members included therein, which is formed by welding the back surface side sheet material 16 and the front surface side sheet 15, while individually vacuum-sucking the back surface side sheet material 16 and the front surface side sheet material 15 to the lower die 21 and the upper die 22, and the laminated member 26 concerned is subjected to blow molding.

Owner:MEIWA IND CO LTD

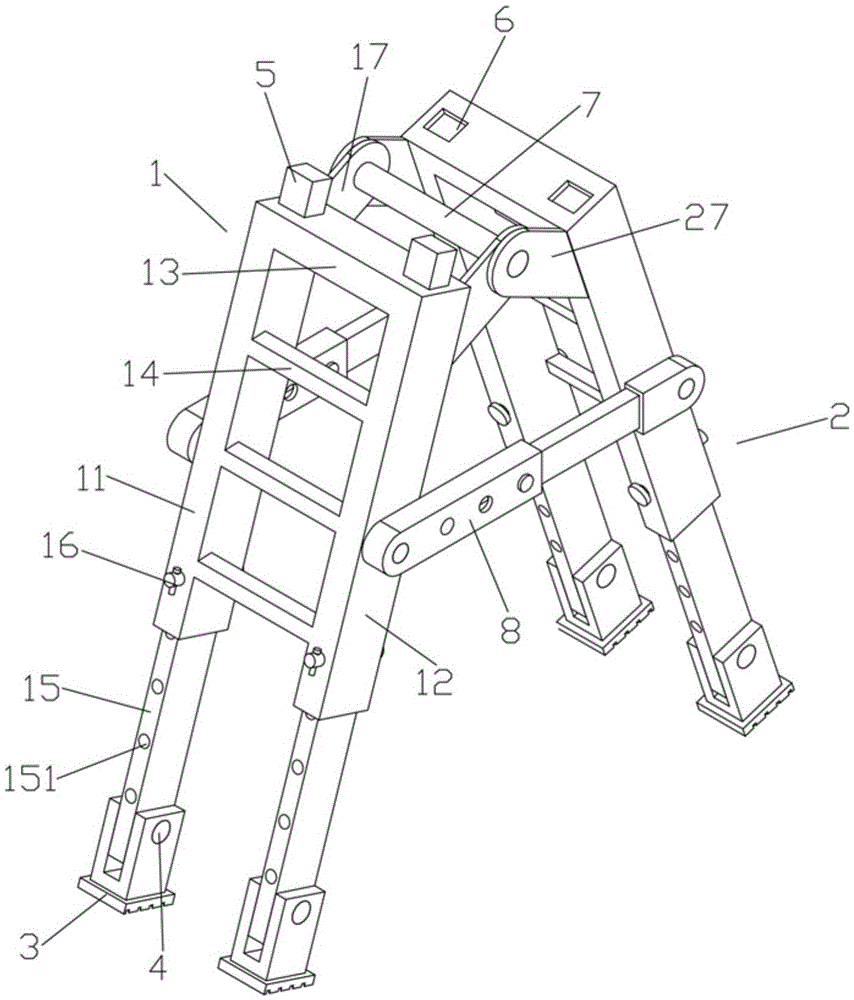

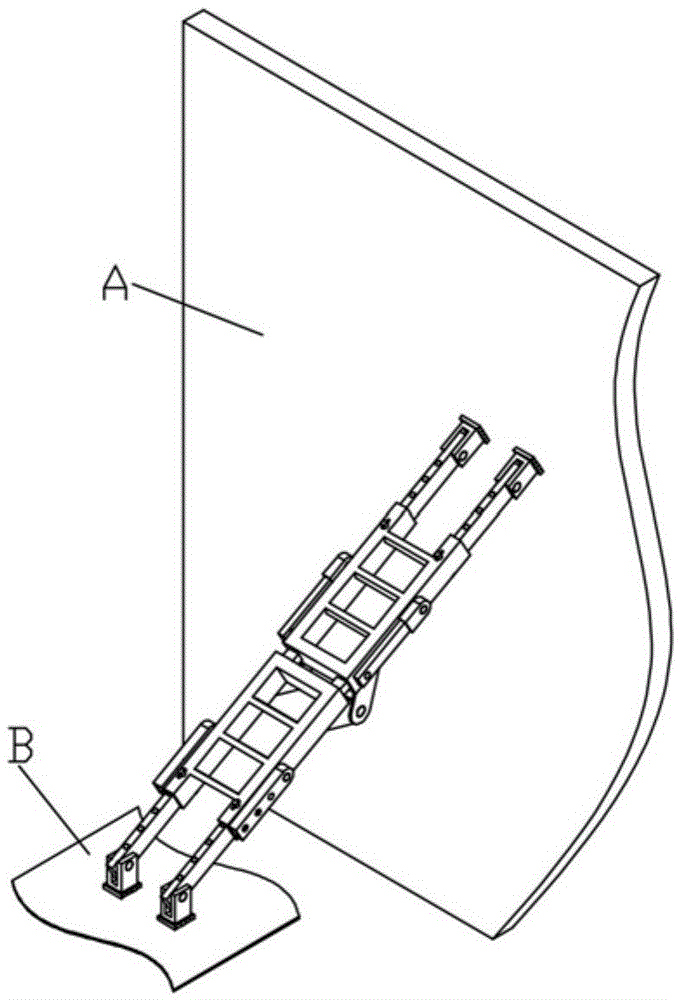

Foldable ladder applicable to various occasions

ActiveCN105649525AEnsure the safety of climbing operationsLaddersEngineeringElectrical and Electronics engineering

The invention discloses a foldable ladder applicable to various occasions. The foldable ladder comprises a first climbing unit and a second climbing unit. The first climbing unit is hinged to the upper end of the second climbing unit. The outer sides of the two sides of the first climbing unit and the second climbing unit are connected through telescopic connecting parts respectively. The foldable ladder has a flat ground state, a step state, a stretching height-increasing state and a vehicle access board state. The foldable ladder applicable to various occasions has the advantages that the foldable ladder is folded during use under a normal situation; when the foldable ladder is used on a slope or steps, the telescopic four corners can timely adjust the support angle of the foldable ladder according to the gradient of the slope or steps, and the climbing safety of a user is guaranteed; the foldable ladder can be stretched and uses a wall face as the support to form a higher ladder so as to satisfy the requirement of high-position operations; the foldable ladder can also by unfolded to serve as an access board for vehicle loading and unloading.

Owner:台州市智诚工业设计有限公司

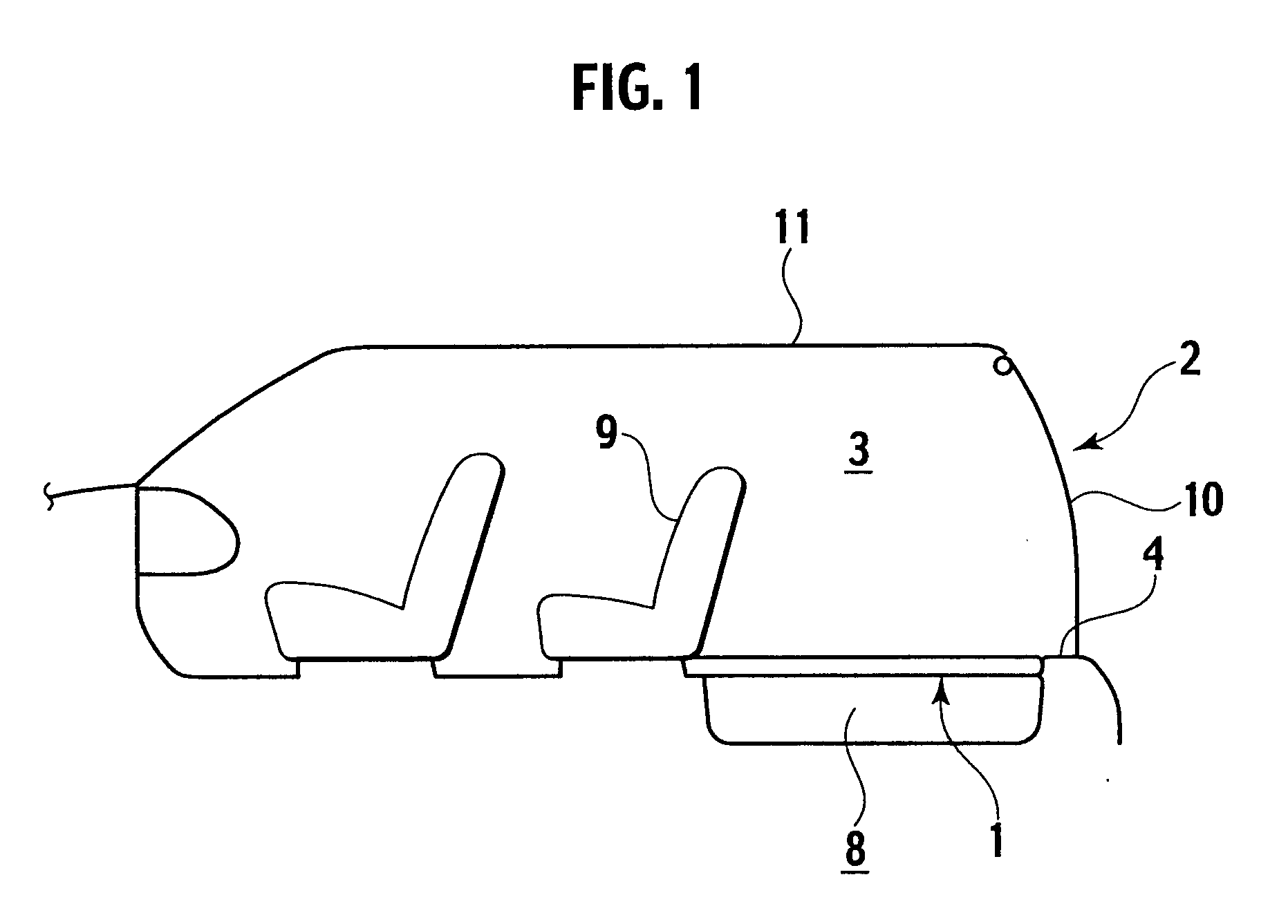

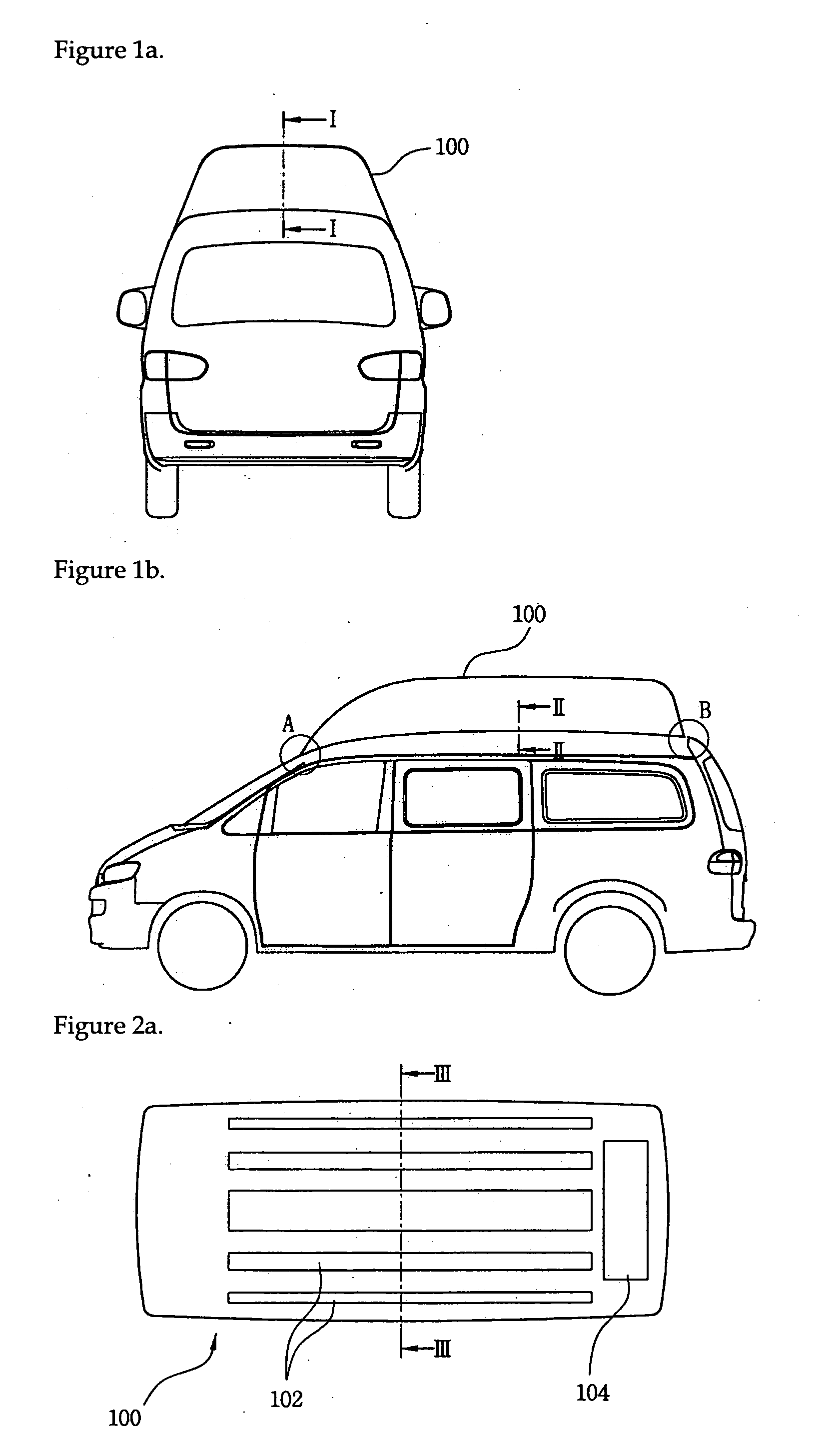

High roof structure of a vehicle

InactiveUS20050082880A1Increased durabilitySimple structureVehicle seatsSuperstructure subunitsFiberAutomotive engineering

A high roof structure of a vehicle includes a high roof formed from a RFP (Fiber Reinforced Plastics) with good durability, forming properties, and a reinforced structure is integrally installed using a predetermined adhering member and engaging member. No welding is needed. An indoor height of a vehicle is increased to a desired size and a desired indoor floor space index is obtained.

Owner:HYUNDAI MOTOR CO LTD

Cutting blade for processing soft metal materials

The invention discloses a cutting blade for processing soft metal materials. The cutting blade comprises an upper surface, a lower surface, a pair of side faces and a blade body which is enclosed by a conical surface for connecting the pair of side faces. The blade body is provided with a blade positioning hole, and the upper surface and the lower surface are connected through the pair of side faces and the conical surface. The conical surface and the upper surface are intersected into a main cutting edge, and the two side faces and the upper surface are intersected into two side cutting edges which are respectively connected on two sides of the main cutting edge. The upper surface is sunk toward the lower surface to form a rake face, a concave curved surface for guiding chips and more than two chip breakers in a shape of an elliptical lug boss. The chip breakers are uniformly distributed in a height increasing stepped shape from a position close to the main cutting edge to the blade positioning hole. The concave curved surface is connected between two adjacent chip breakers; and the rake face extends toward the middle of the upper surface from the main cutting edge and two side cutting edges, and is connected with the concave curved surface. The cutting blade has the advantages of controlling shapes and flow directions of the chips, decreasing the contact between the chips and the upper surface of the blade, and reducing the cutting temperature.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

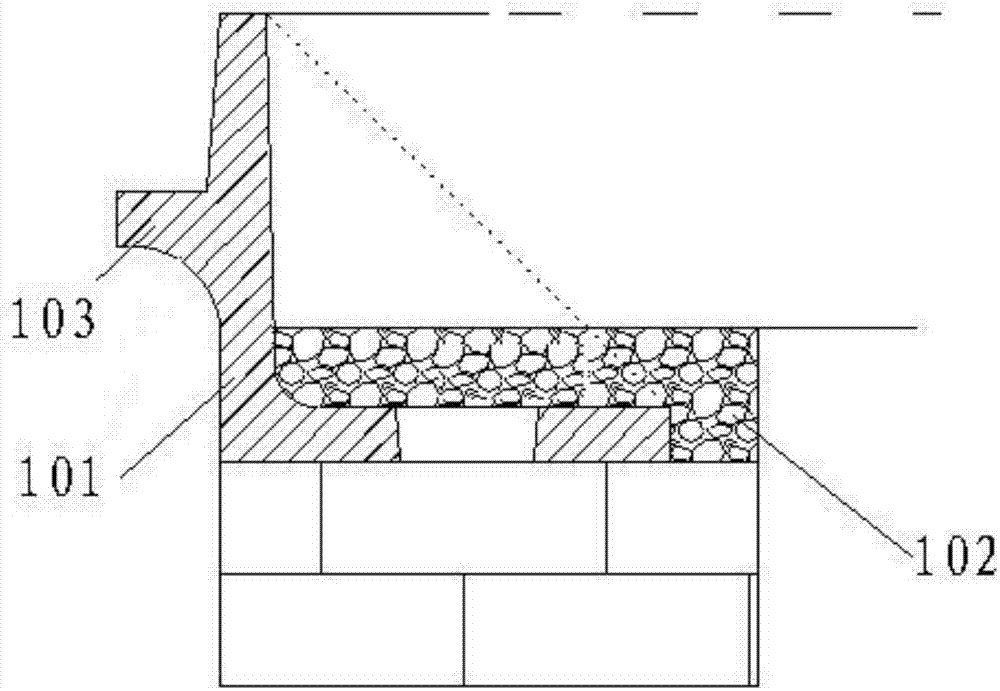

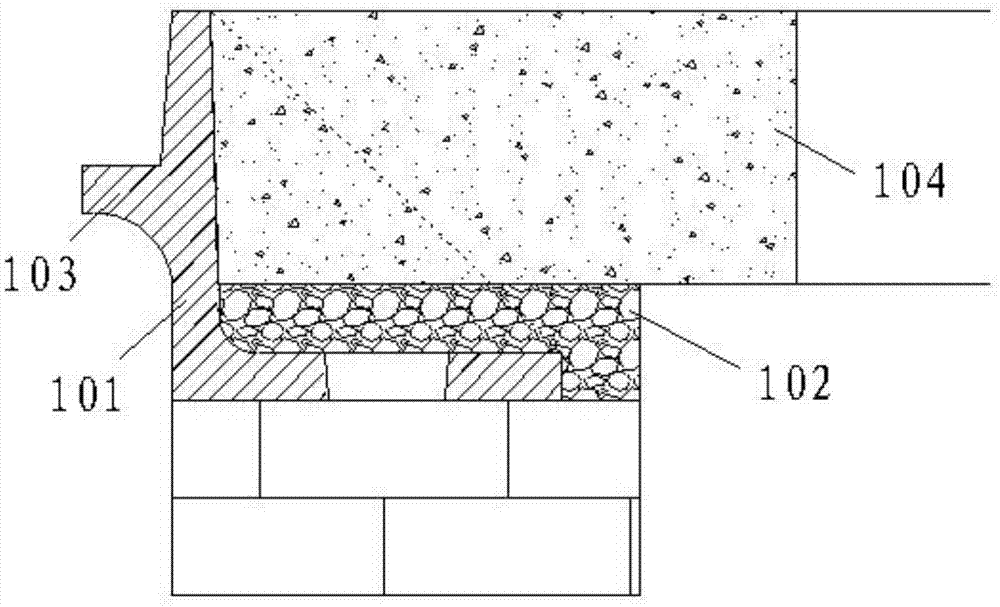

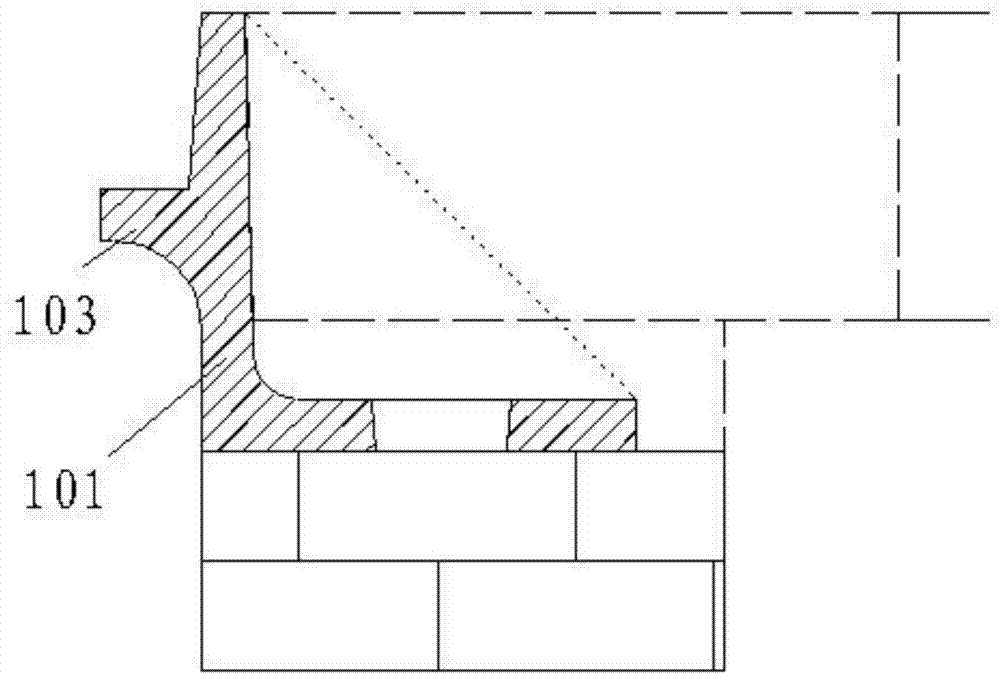

Well lid support seat of road inspection well, support seat assembly and pavement construction method

ActiveCN104775452ALess prone to diseaseAvoid diggingArtificial islandsIn situ pavingsRoad surfaceEngineering

The invention relates to the technical field of road construction, and provides a well lid support seat of a road inspection well. The well lid support seat comprises a support seat body and a lifting support seat used for lifting the height of the well lid support seat, wherein the lifting support seat is connected with the support seat body, and well lid support tables which are respectively the first well lid support table and the second well lid support table are respectively arranged on the inner side walls of the support seat body and the lifting support seat. Before the upper layer asphalt concrete pavement of the well lid support seat of the road inspection well, lower layer asphalt concrete around the well lid support seat does not need to be dug away for well lid support seat height increase, and the lower layer asphalt concrete around the road inspection well can survive at one time, so that the integrality of the pavement around the well lid support seat is good, the quality is ensured, and the damage cannot easily occur; in addition, the digging removal and the repair of the lower layer asphalt concrete are avoided, so that the materials and the cost are reduced. Finally, the well lid support seat does not need the height increase, so that three-day to five-day construction period is at least saved, and the urban road fast passing requirements can be particularly met.

Owner:BEIJING BRIDGE RUITONG MAINTENANCE CENT +1

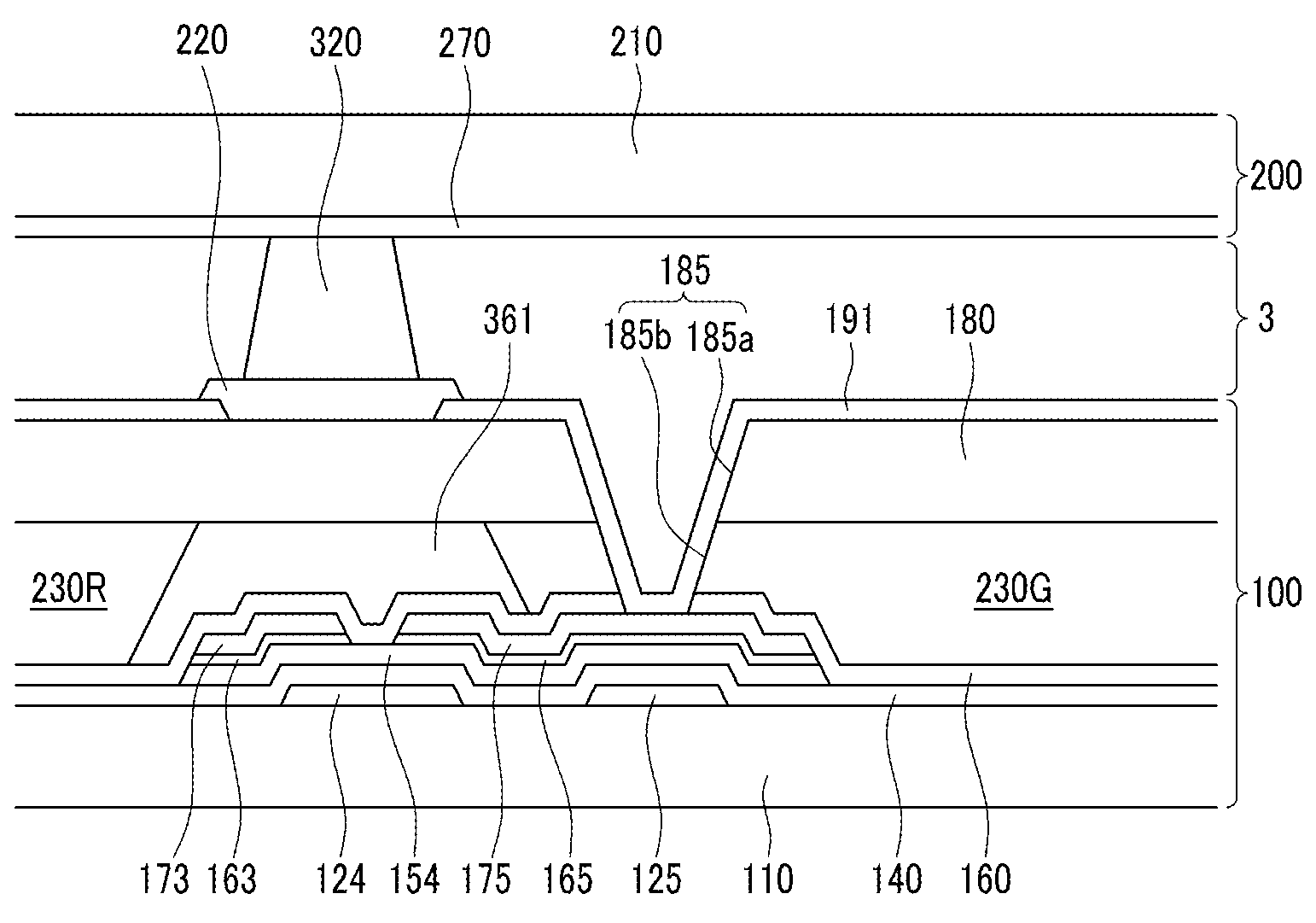

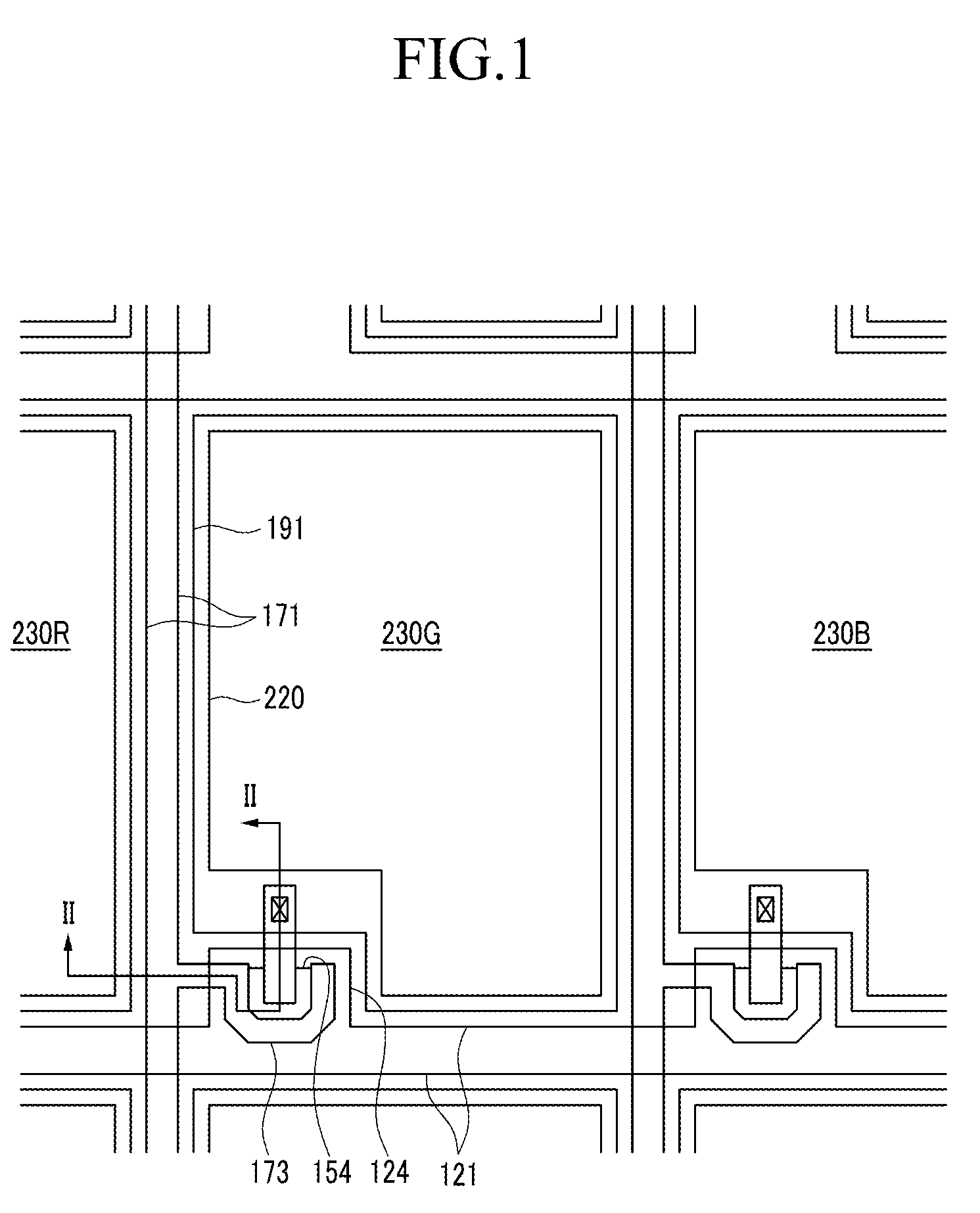

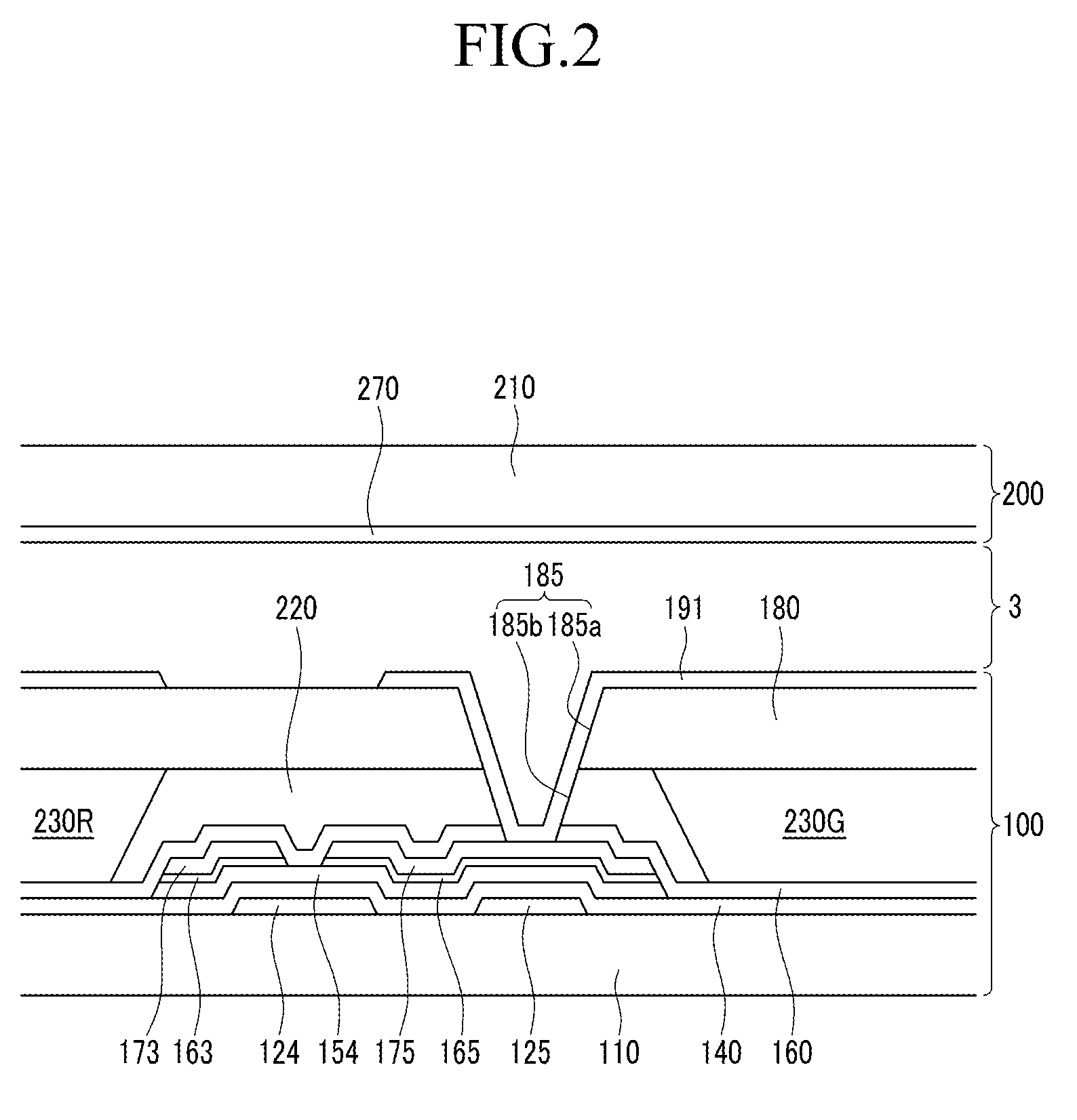

Thin film transistor substrate and method for manufacturing the same

ActiveUS20100019246A1Simple to executeReduce contact lengthSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method for manufacturing a thin film transistor array panel includes; forming a gate line including a gate electrode and a height increasing member on a substrate, forming a gate insulating layer on the gate line and the height increasing member, forming a semiconductor, a data line including a source electrode, and a drain electrode facing the source electrode and overlapping at least a portion of the height increasing member on the gate insulating layer, forming a first insulating layer on the gate insulating layer, a data line and the drain electrode, forming a light-blocking member on a portion of the first insulating layer corresponding to the gate line and the data line, forming a color filter in an area bound by the light-blocking member, forming a second insulating layer on the light-blocking member and the color filter, and patterning the second insulating layer, the light-blocking member or the color filter, and the first insulating layer to form a contact hole exposing a portion of the drain electrode aligned with the height increasing member.

Owner:SAMSUNG DISPLAY CO LTD

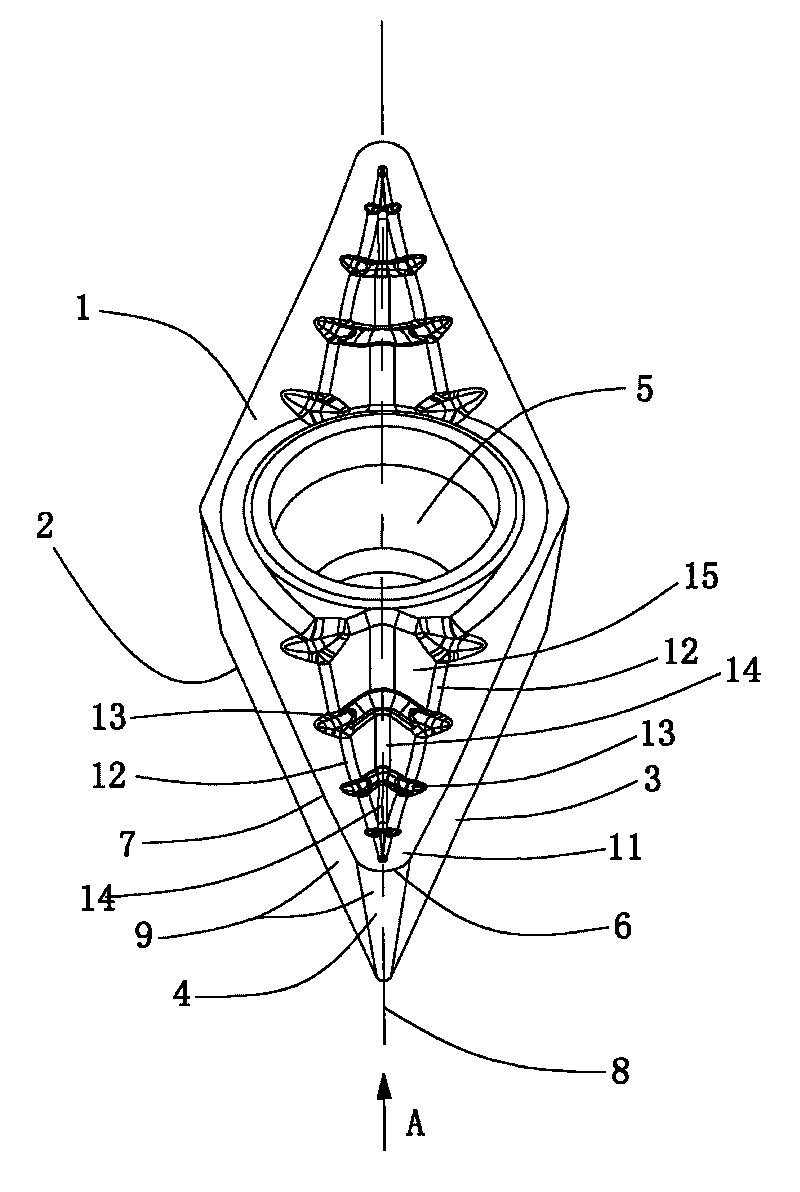

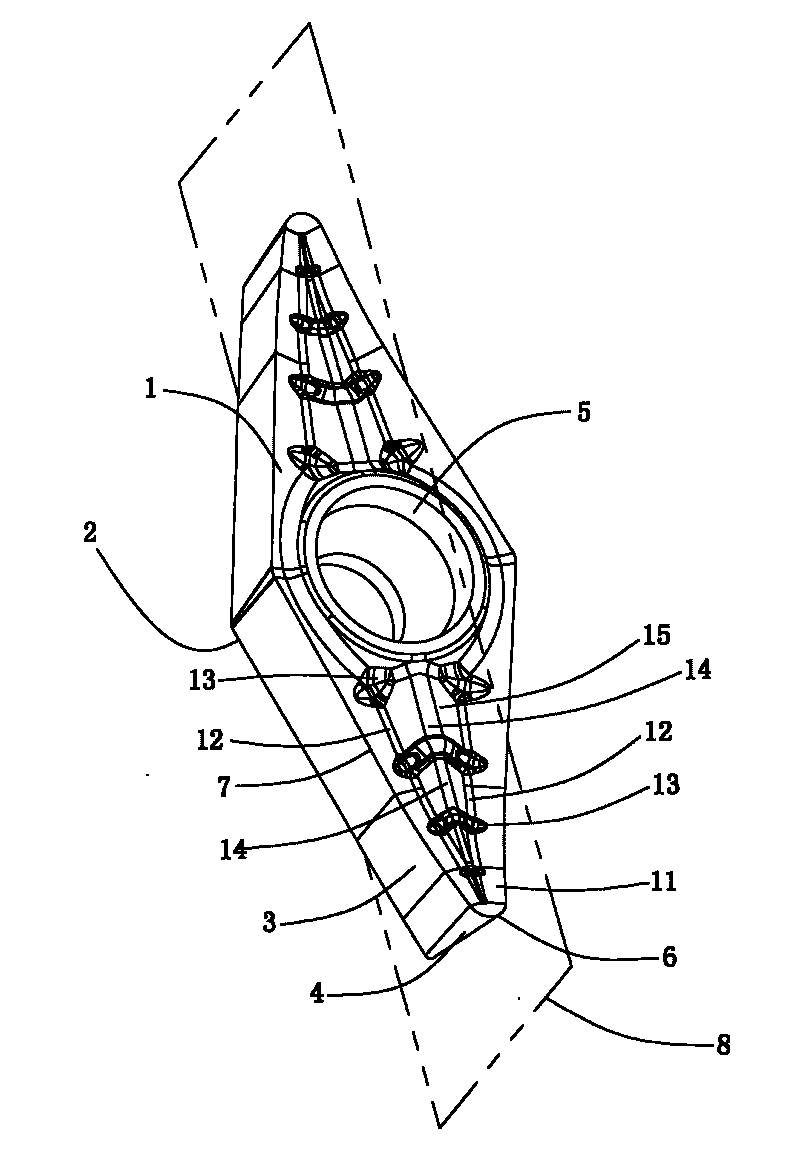

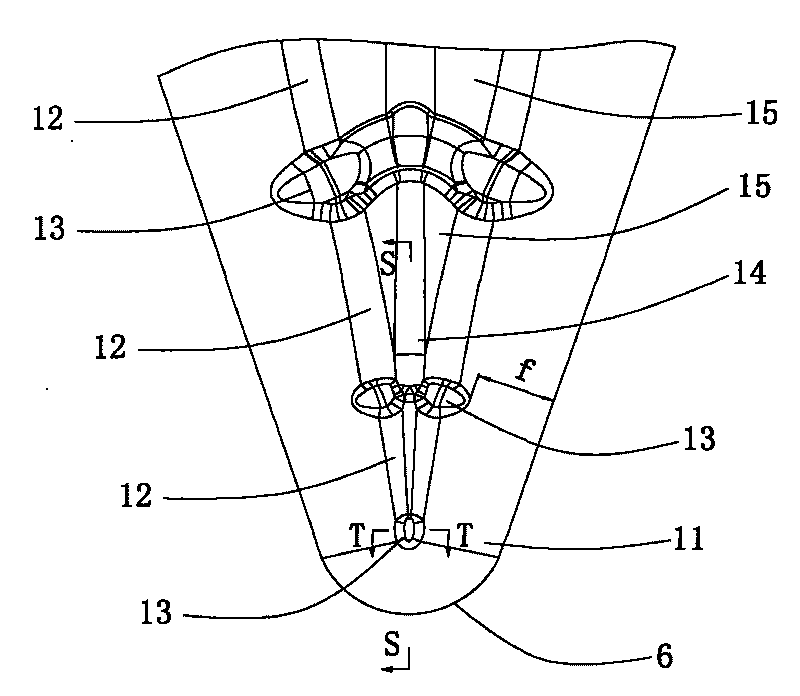

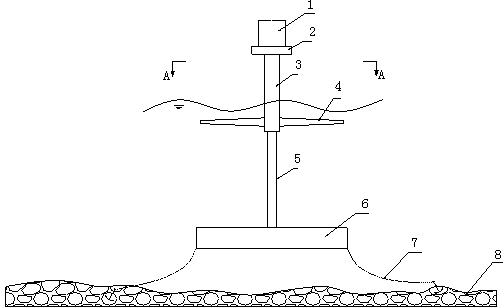

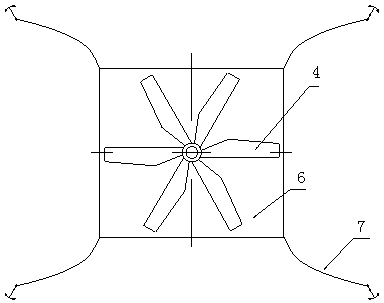

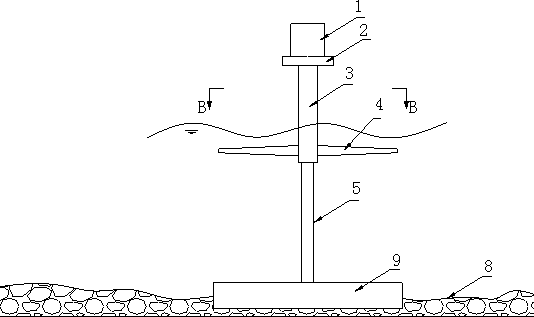

Vertical-axis wave-activated generator

ActiveCN104005903AImprove conversion efficiencyImprove qualityHydro energy generationReaction enginesEnergy transferElectricity

The invention discloses a vertical-axis wave-activated generator. The vertical-axis wave-activated generator comprises vanes, a rotating shaft, a strut, an above-water platform exposed out of the sea level, a generator body, a vane height increasing device, a control device and a base, wherein the generator body, the vane height increasing device and the control device are arranged on the above-water platform. The vanes are fixed to the rotating shaft in the circumferential direction, the upper end of the strut is embedded in and sleeved with the rotating shaft through a bearing, the lower end of the strut is fixedly connected with the base, the above-water platform is fixed to the upper end of the strut, the generator body and the output end of the rotating shaft are in drive connection, the vane height increasing device is arranged at the upper end of the rotating shaft and used for adjusting the draught of the vanes, and the control device is connected with a generator circuit and used for controlling continuous and stable output of electric energy. The arrangement of the vertical-axis wave-activated generator on the sea is independent of the direction of incident waves, the vanes drive the rotating shaft to rotate so as to directly drive the generator body to generate electricity, the complexity of middle link energy transfer, energy storage and voltage stabilization of an ordinary wave-activated generator is omitted, the conversion efficiency and the electricity generating quality of wave energy are improved, and the vertical-axis wave-activated generator is convenient to maintain and low in manufacturing cost.

Owner:SOUTH CHINA UNIV OF TECH

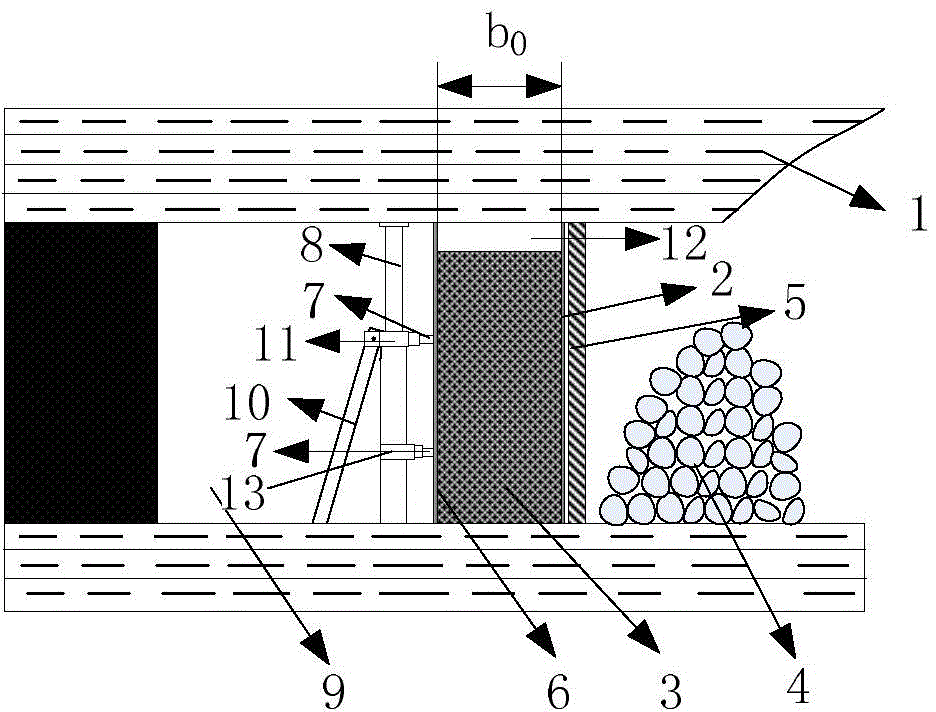

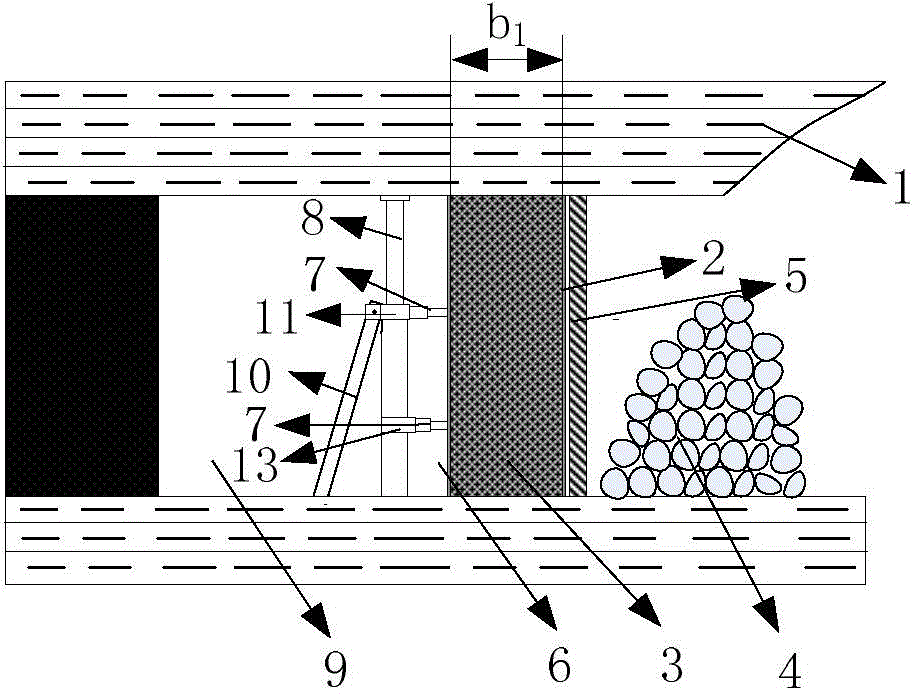

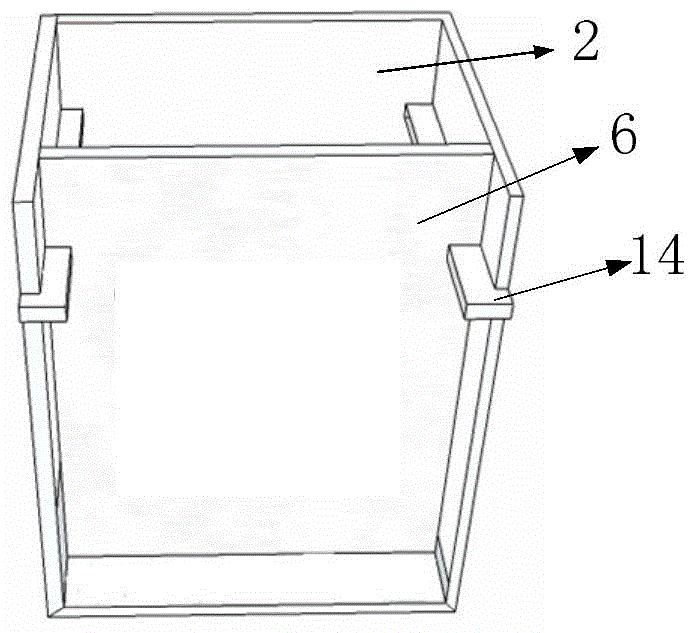

Roof-contacted method for mine gob-side entry paste filling wall body

InactiveCN104405438APrevent air leakagePrevent spontaneous combustionMaterial fill-upCombustionFilling materials

The invention discloses a roof-contacted method for a mine gob-side entry paste filling wall body. The roof-contacted method mainly comprises the following steps: installing a filling template according to a filling design width in a gob or roadway of a pre-filling section, and filling the filling template with a prepared paste-like filling material by using a filling pump; when the height of the filling material reaches 85%-90% of actual filling height, pushing the filling template through pressure of a jack, so that the filling material inside the filling template moves forward and is extruded to rise, after the filling material rises to contact a roof, maintaining the pressure of the jack, moving forward, extruding to rise the filling material, and after the filling material rises to contact the roof, maintaining the pressure of the jack until the filling material is finally solidified. Horizontal thrust is applied before the filling material is solidified, so that the width of a filling body is contracted and the height of the filling body is increased until the filling material is roof-contacted with the top plate of the roadway, and after the filling material is solidified, a gap formed between the wall body and the top plate is completely eliminated, so that the air leakage of the gob is avoided, and the self-combustion of coal is prevented.

Owner:SHANDONG UNIV OF SCI & TECH

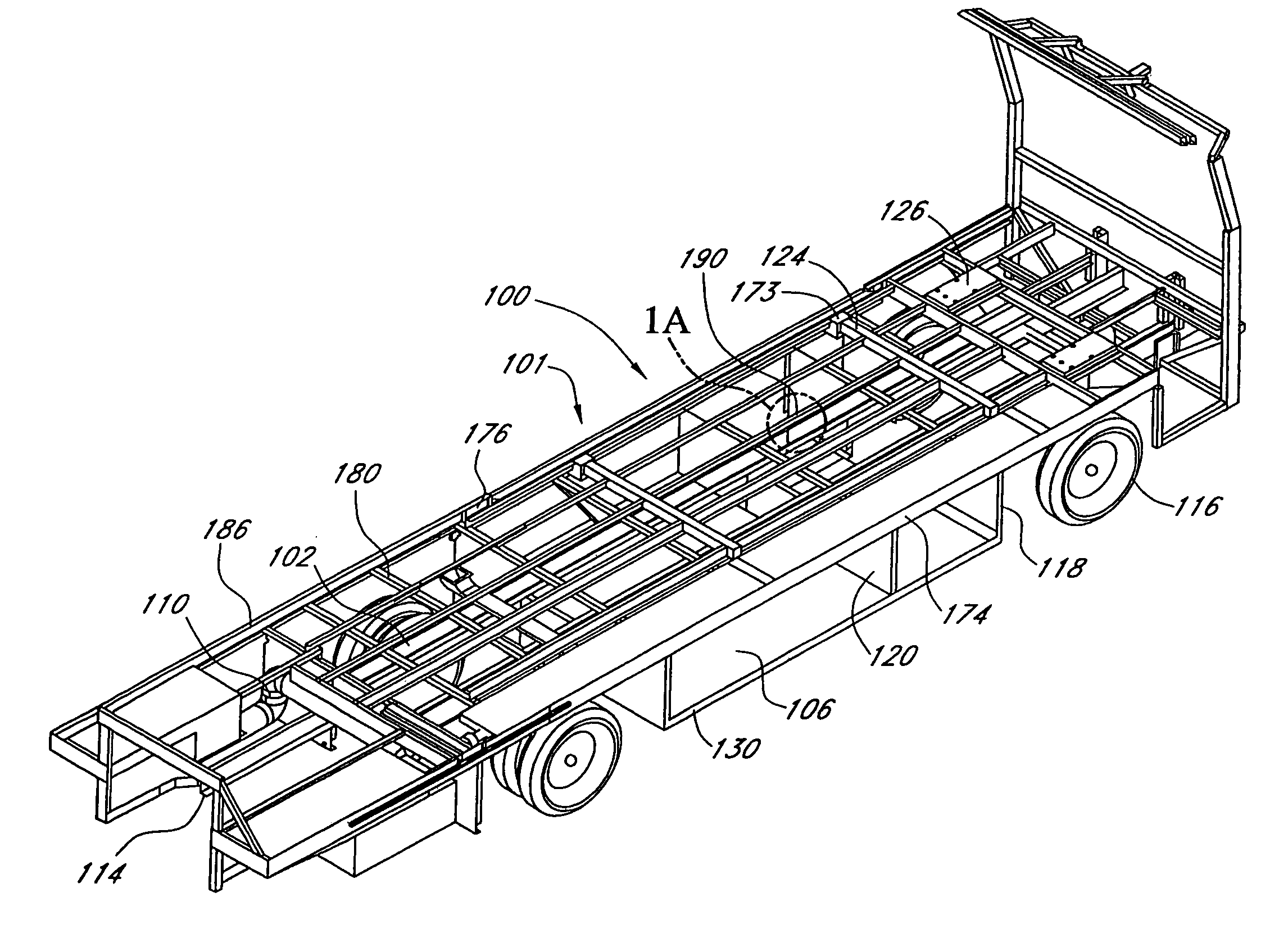

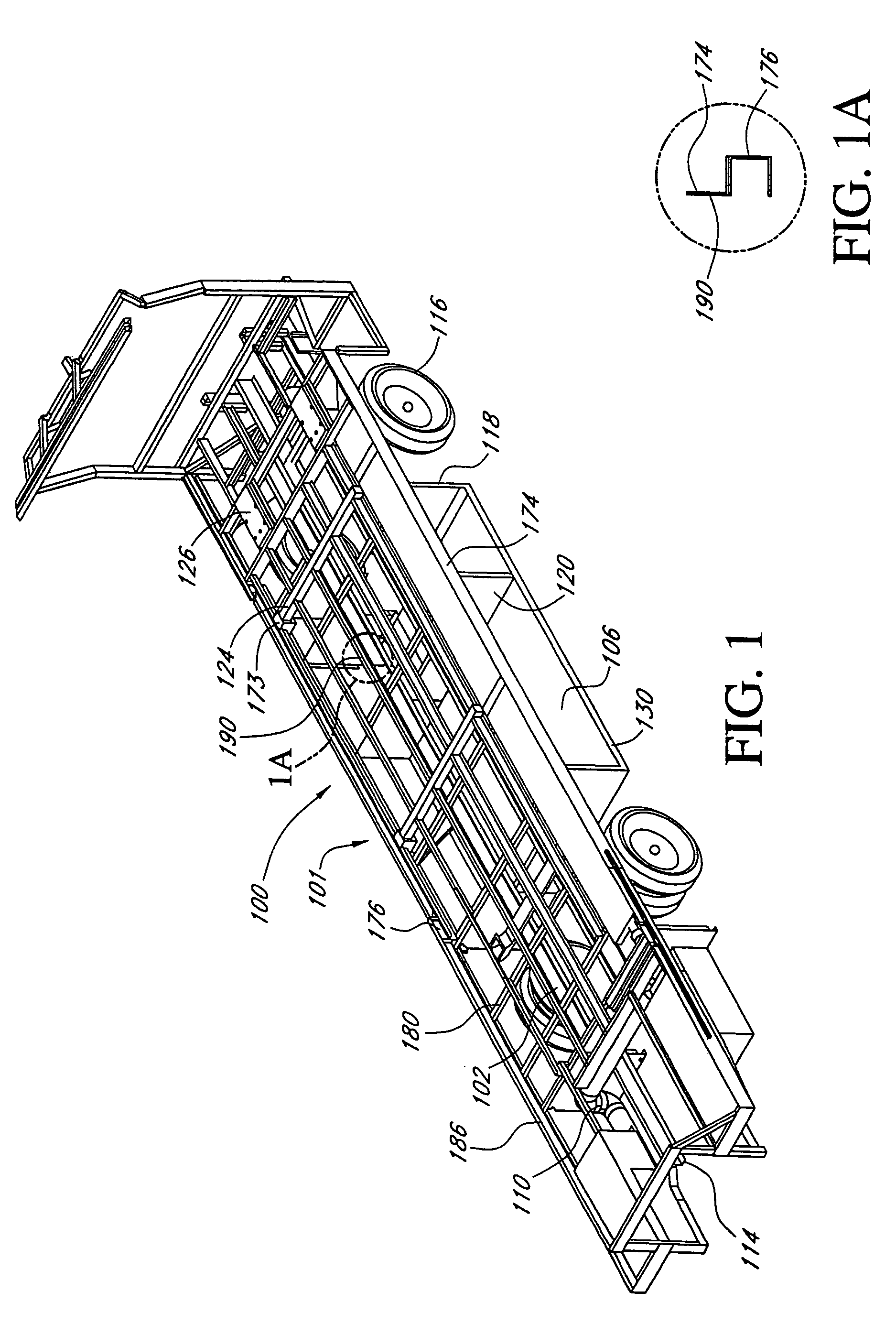

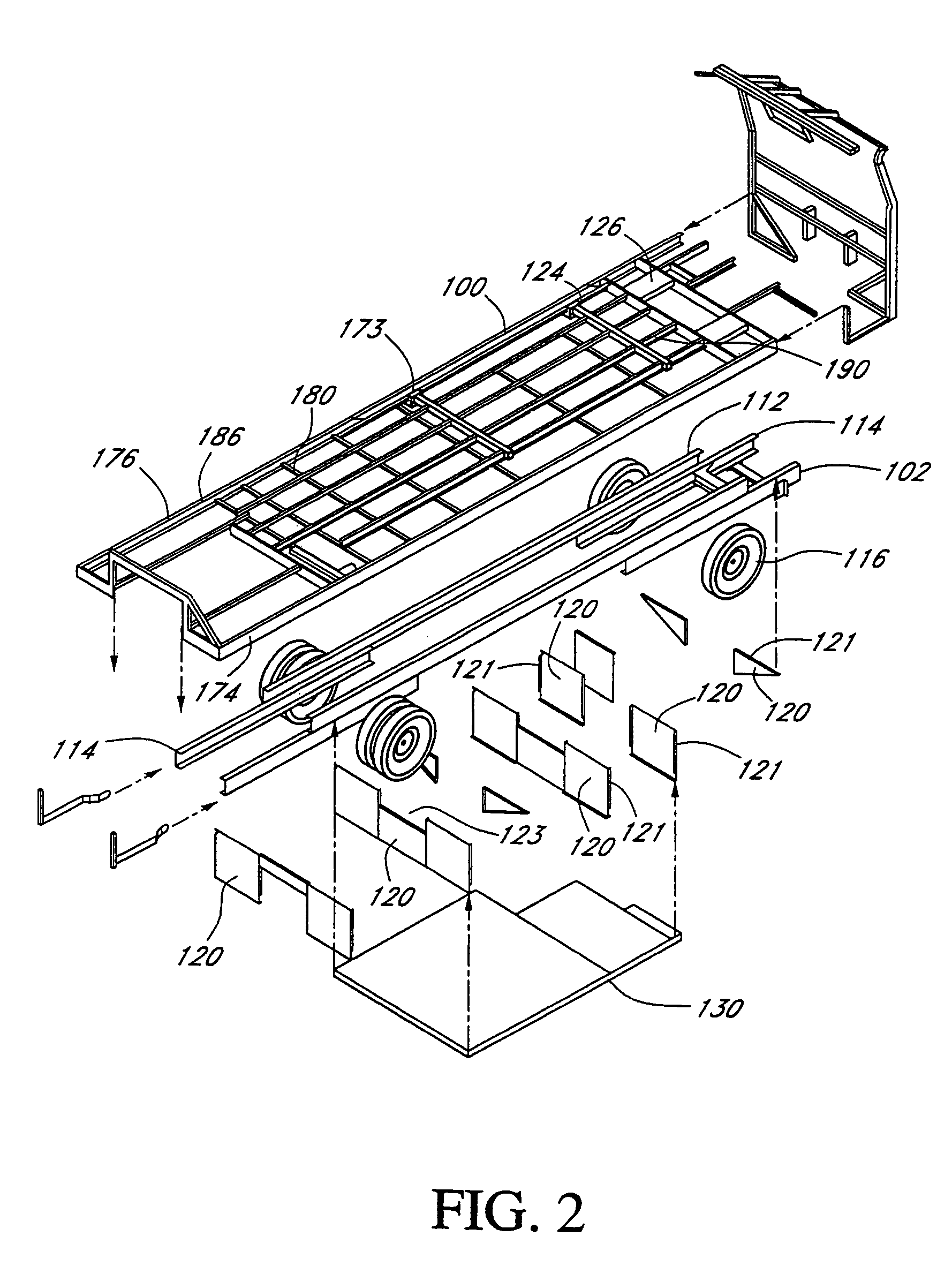

Motorhome with increased interior ceiling height

InactiveUS7021699B2Increase stiffnessUnderstructuresItem transportation vehiclesVehicle frameLiquid water

A vehicle frame with a low profile is designed to be suitable for attaching directly to an incomplete, preassembled motorized chassis to construct a motorhome. The vehicle frame includes planar bulkheads and a storage area floor that are attached to the frame and to the chassis so as to create a three-dimensional space frame that is highly resistant to bending and twisting forces as well as storage areas that extend the width of the motorhome. The motorhome with the frame mounts a heating, ventilation, and air conditioning (HVAC) system as well as heavy holding tanks within or below the plane of the vehicle frame so as to lower the center of mass of the motorhome to thereby improve vehicle handling and safety. Placement of the HVAC system within and / or below the vehicle frame obviates the need to position HVAC components on the roof of the motorhome thereby further lowering the center of mass and eliminating a source of liquid water condensation above the living space of the motorhome. The vehicle frame attached directly to the chassis further facilitates an interior ceiling height in the motorhome of at least 7′6″ while maintaining a total vehicle height not exceeding 13′6″ as well as facilitating construction of slide-out rooms with interior heights of at least 6′1″ thereby allowing adults of above average height to stand up inside the slide-out rooms.

Owner:ALFA LEISURE

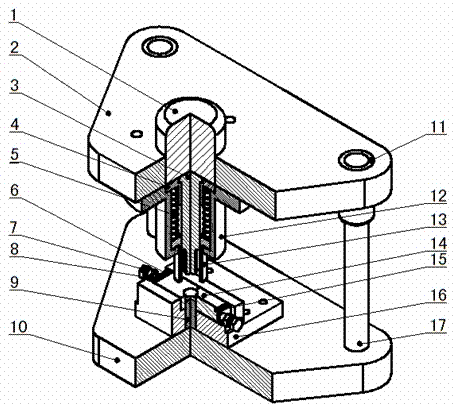

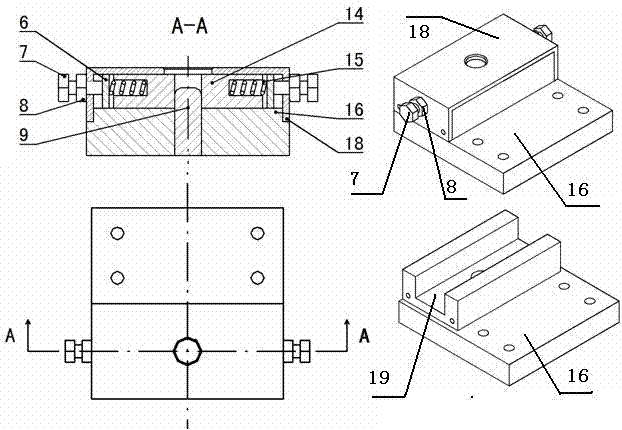

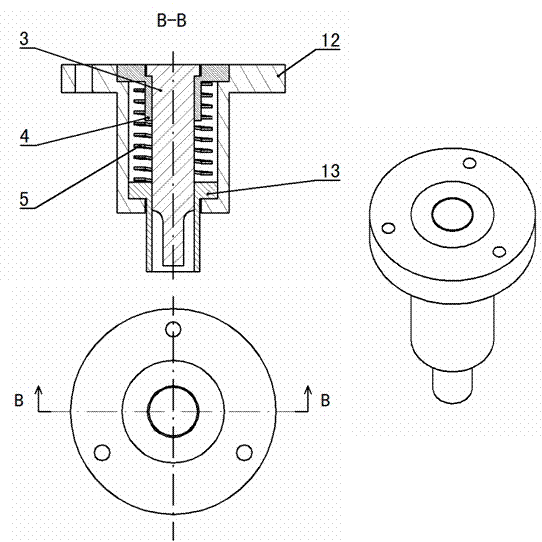

Combined type precision sheet metal stamping and riveting mould

InactiveCN102784841AImprove loading and unloading efficiencyReduce punching forceShaping toolsPunch pressMan-hour

The invention relates to a combined type precision sheet metal stamping and riveting mould, belonging to the field of pressed deformation connection and mould in mechanical engineering. The combined type precision sheet metal stamping and riveting mould comprises a guide device which comprises a postposed guide pillar and a guide sleeve, a precise upper mould and a precision lower mould to realize the precise stamping and riveting process so as to improve the loading and unloading efficiency of the sheet metal in the mould. The combined type precision sheet metal stamping and riveting mould can overcome the quality defects that riveting joints are asymmetric, riveting gaps appear in the riveting process, and that the riveting joints are easy to pull off and realizes a single-gate shearing-free stamping and riveting process; riveting joints with high strength, high rigidity, rotational symmetry and even stress can be formed; and the self-locking ability of the riveting joints is improved. The height increase of the riveting joint at the concave mould is small and the riveting joint at the concave mould is more attractive. The stamping force required by the convex mould is relatively small, so the combined type precision sheet metal stamping and riveting mould is suitable for a general punch press. The combined type precision sheet metal stamping and riveting mould is simple in structure and convenient to operate, saves installing and debugging man-hour, improves the labor productivity and thereby increases the economic benefit.

Owner:JIANGSU UNIV

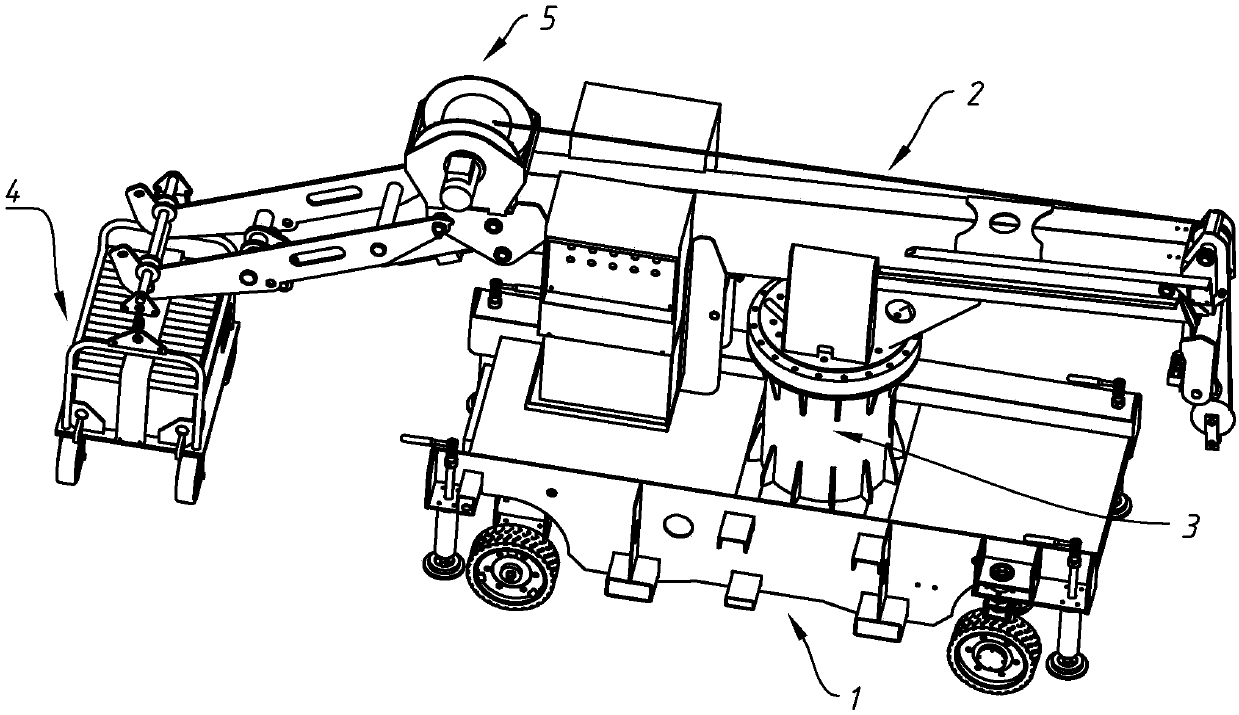

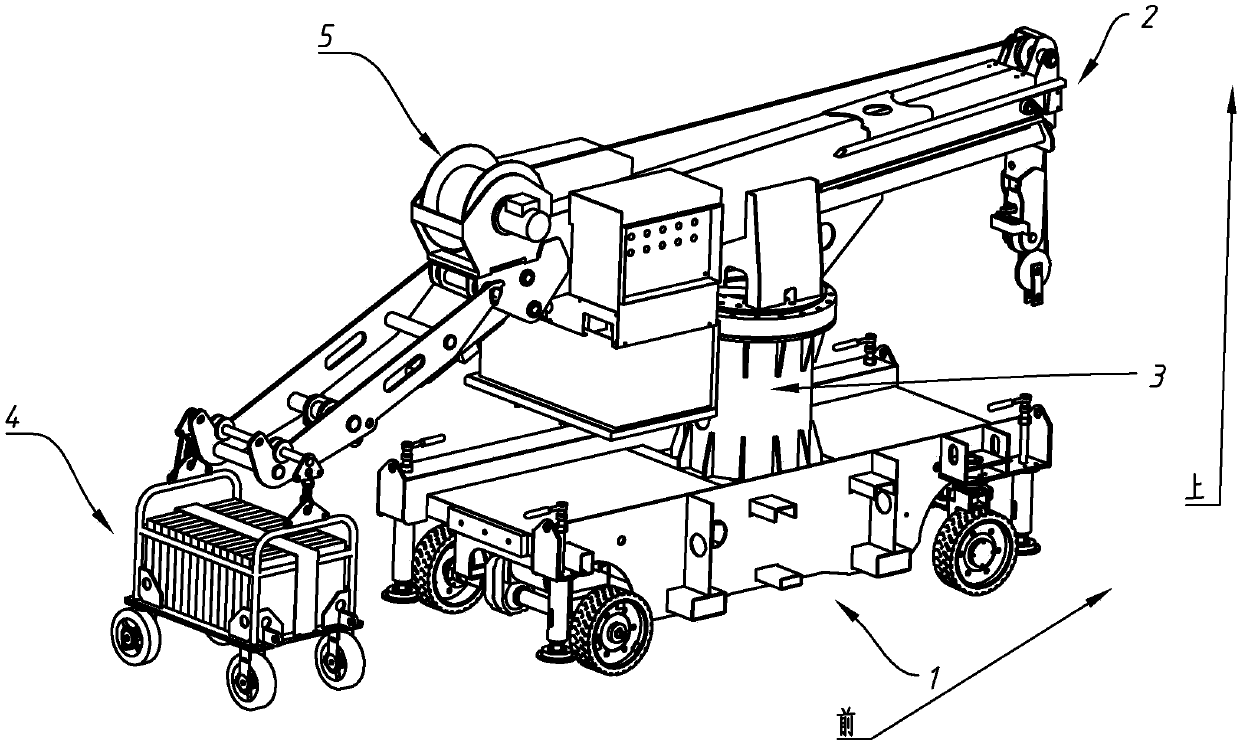

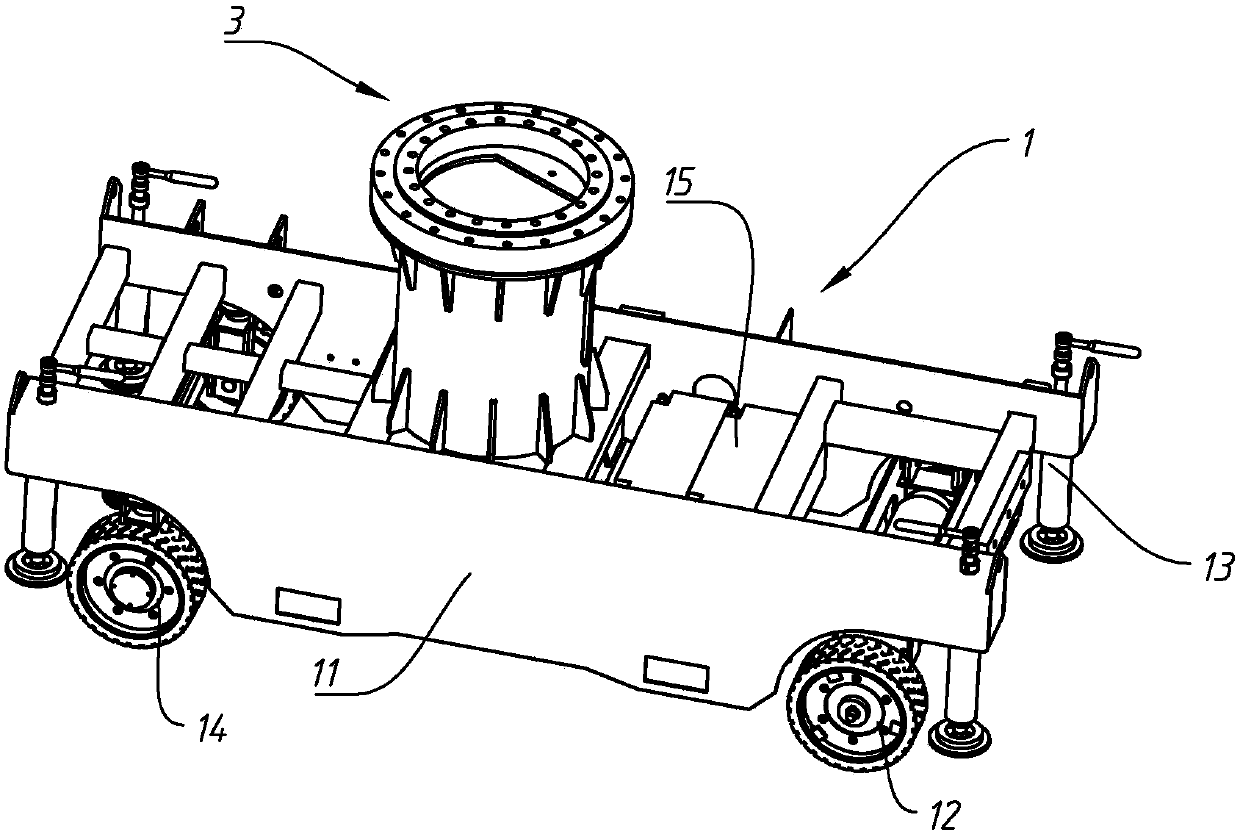

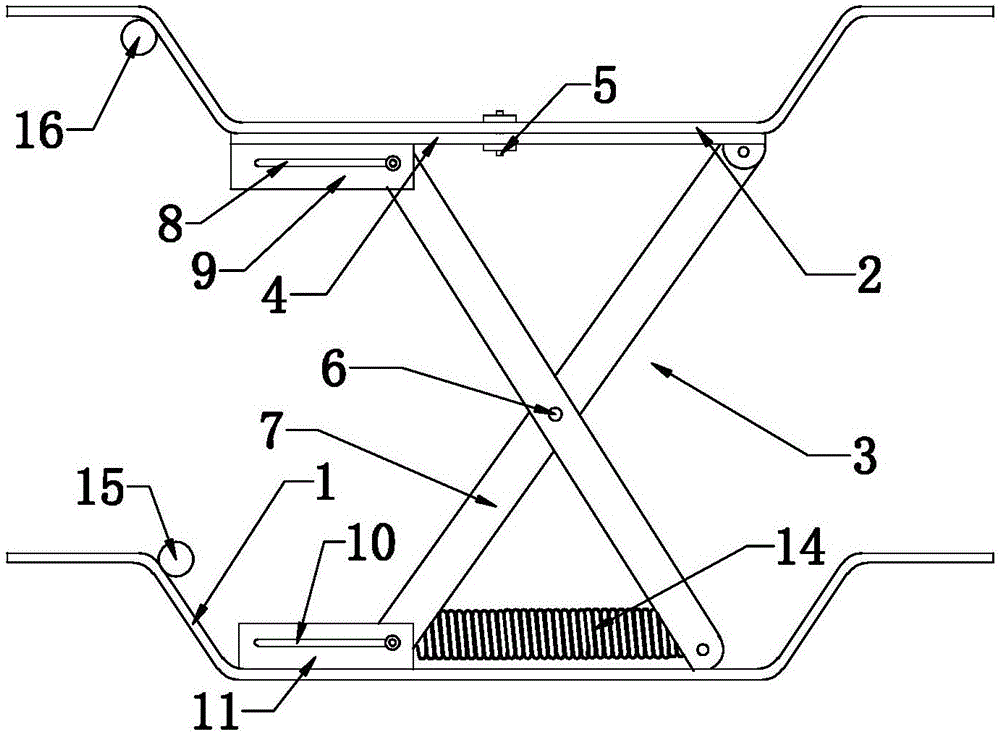

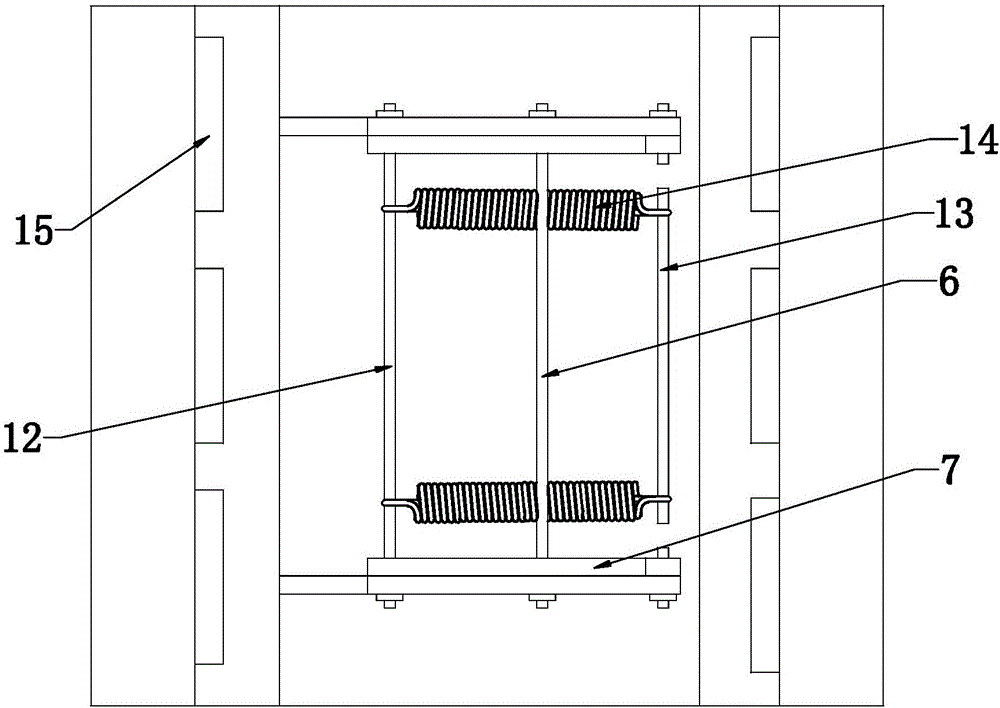

Light crane for building assembling

The invention discloses a light crane for building assembling, and belongs to the technical field of building equipment. A crane in the existing technology is large in size, and cannot enter in some occasions, an existing scaffold, lifting basket and other devices cannot finish material elevating, and a simple hoisting device cannot achieve precise positioning of the mounting work. Driving wheelsdrive a chassis and other devices to freely move on the construction site, position precise positioning is achieved, a telescopic type cantilever crane device is adopted, an independent counterweightdevice is arranged, through a winch device, height increasing of a telescopic type cantilever crane is achieved, the aim that building materials are hoisted to the altitude mounting position from theground or lower layer is accurately achieved, material moving on different floors can be achieved, the structure is simple and practical, production efficiency and construction quality can be greatlyimproved, and building assembly work safety is ensured.

Owner:HANGZHOU SAIQI MACHINERY CO LTD

Seat lifting and rotating adjusting mechanism

InactiveCN106114301ASolve the problem of not being able to rotate 360°Improve versatilityMovable seatsMotor homeEngineering

Owner:富士房车(江苏)有限公司

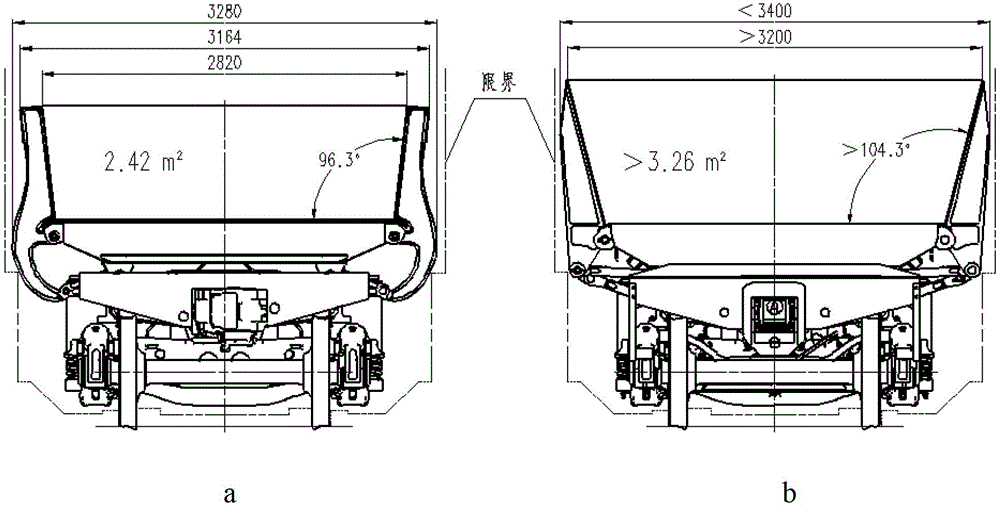

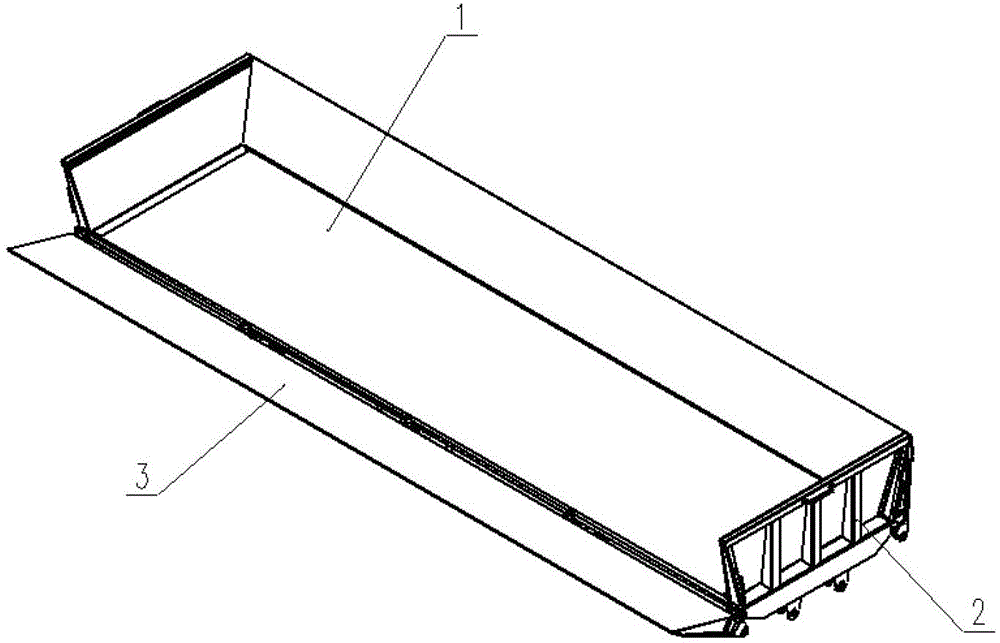

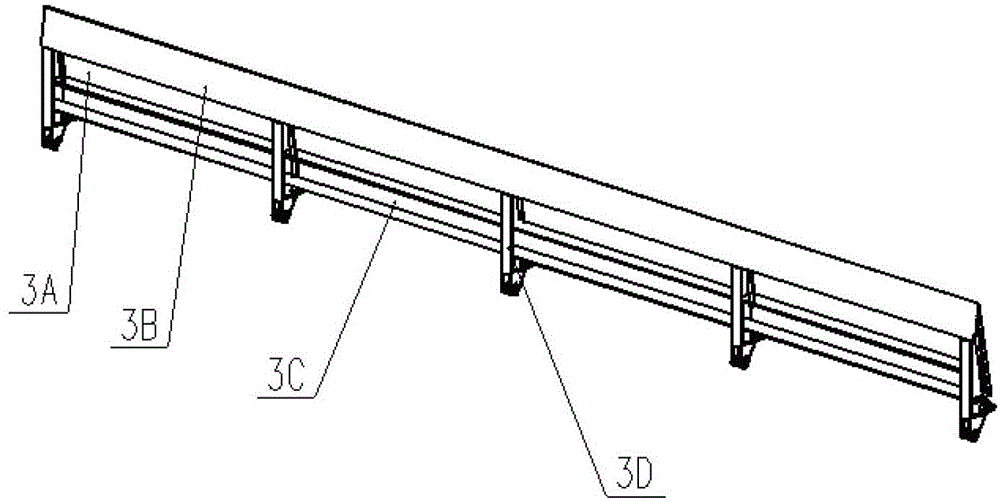

Railway side dump car

The invention discloses a railway side dump car, which is characterized in that the upper cross section of each side door of the side dump car is small, the lower cross section of each side door of the side dump car is large, and the upper cross section is determined by calculation according to the minimum impact load of goods on the side doors. The camber angle of each side door is increased by 8-10 degrees. The height of each side door is increased, and the maximum relative distance between the tops of the two side doors is within the outer width of the lower part of a carriage. According to the railway side dump car disclosed by the invention, through the improvement on the structure of the carriage, the limit is fully utilized, and the lateral dimension of the carriage is increased; and on the premise of meeting the antidumping safety requirement of dumping operation, the internal height of the carriage is increased. The capacity of the carriage is increased through the combination of the modes, the full load need in transporting main trend granular goods is met, and the economic benefit of transportation is improved.

Owner:CRRC YANGTZE CO LTD

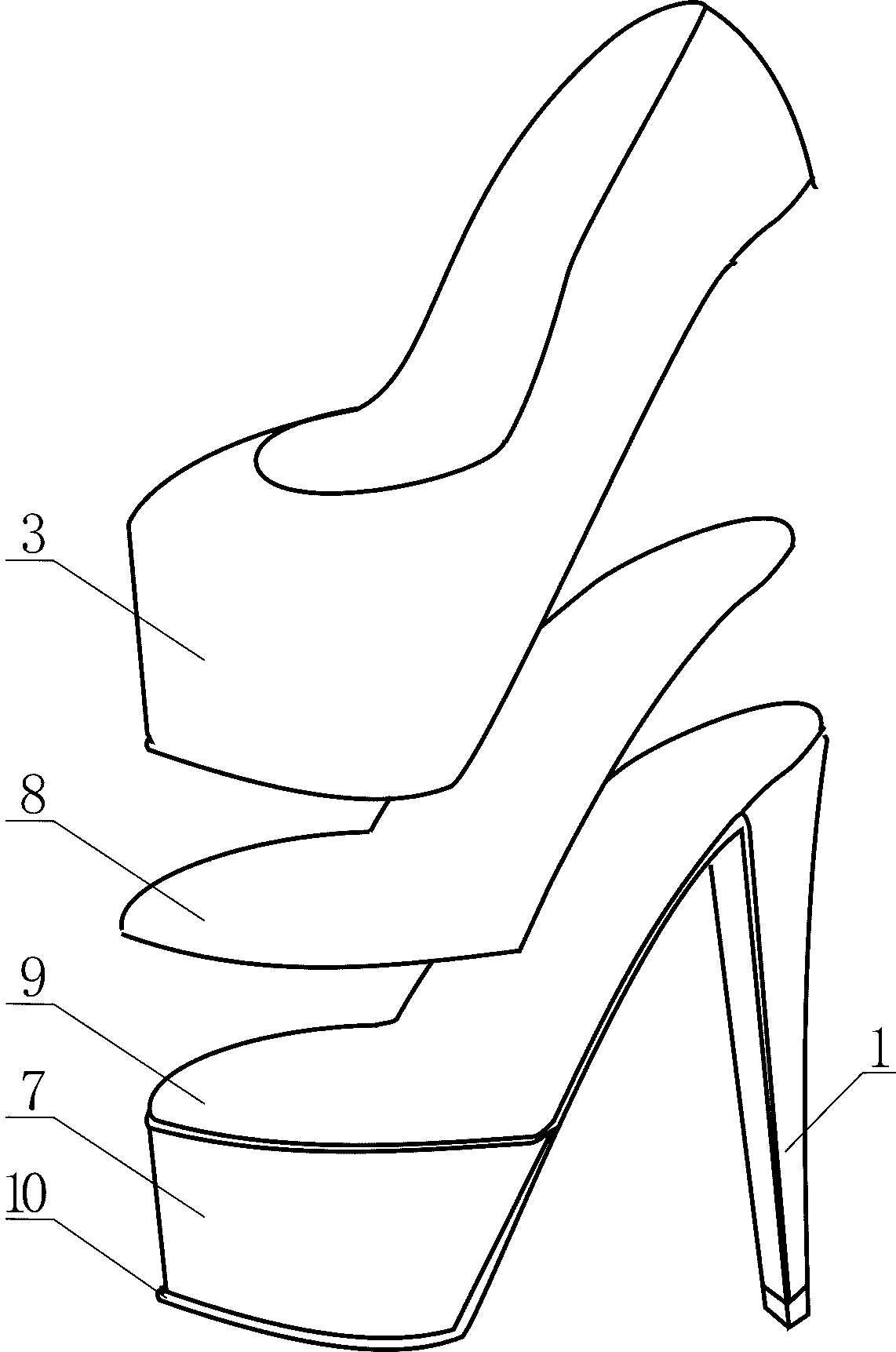

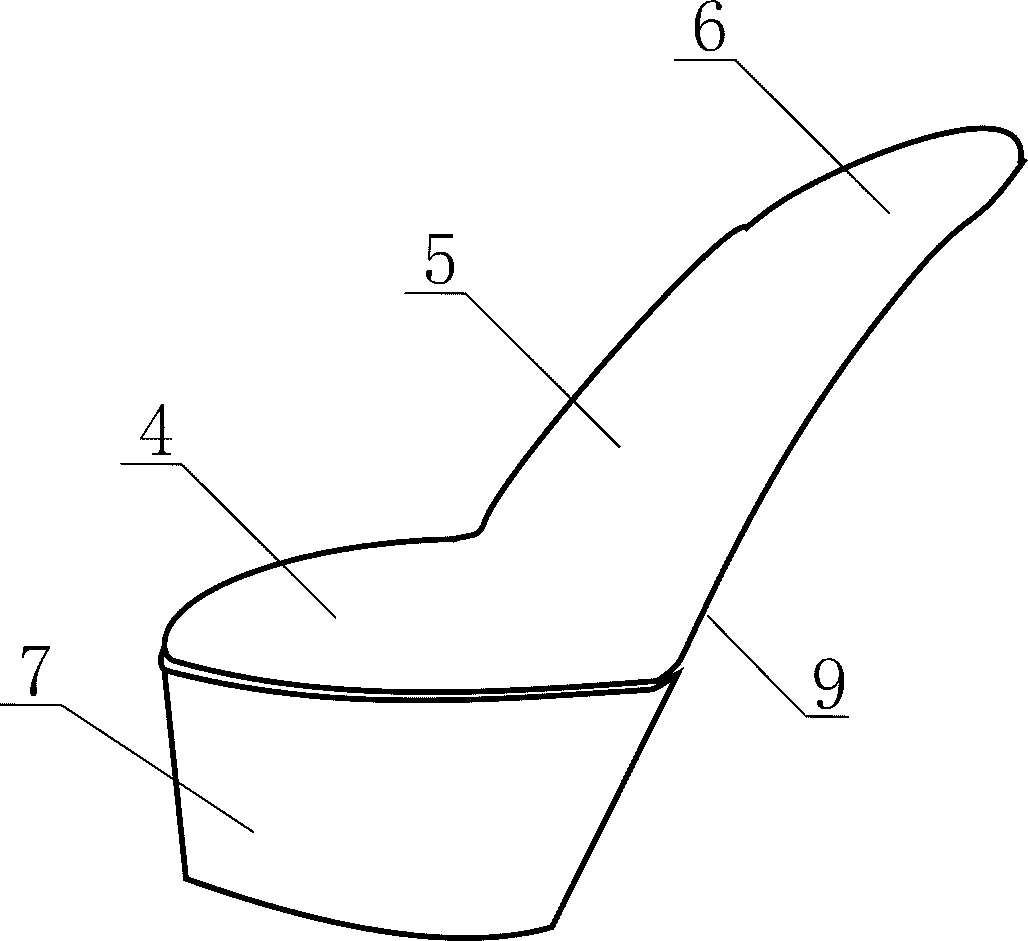

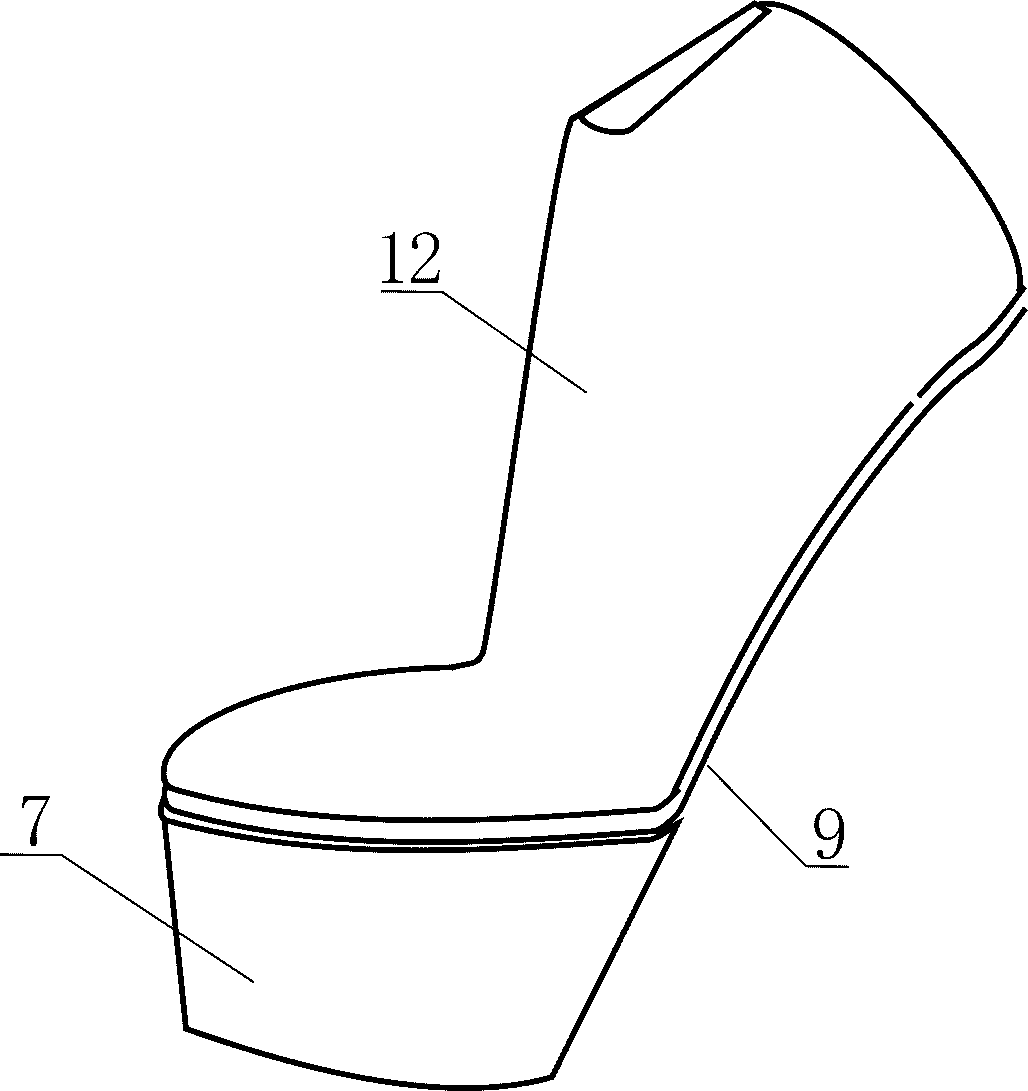

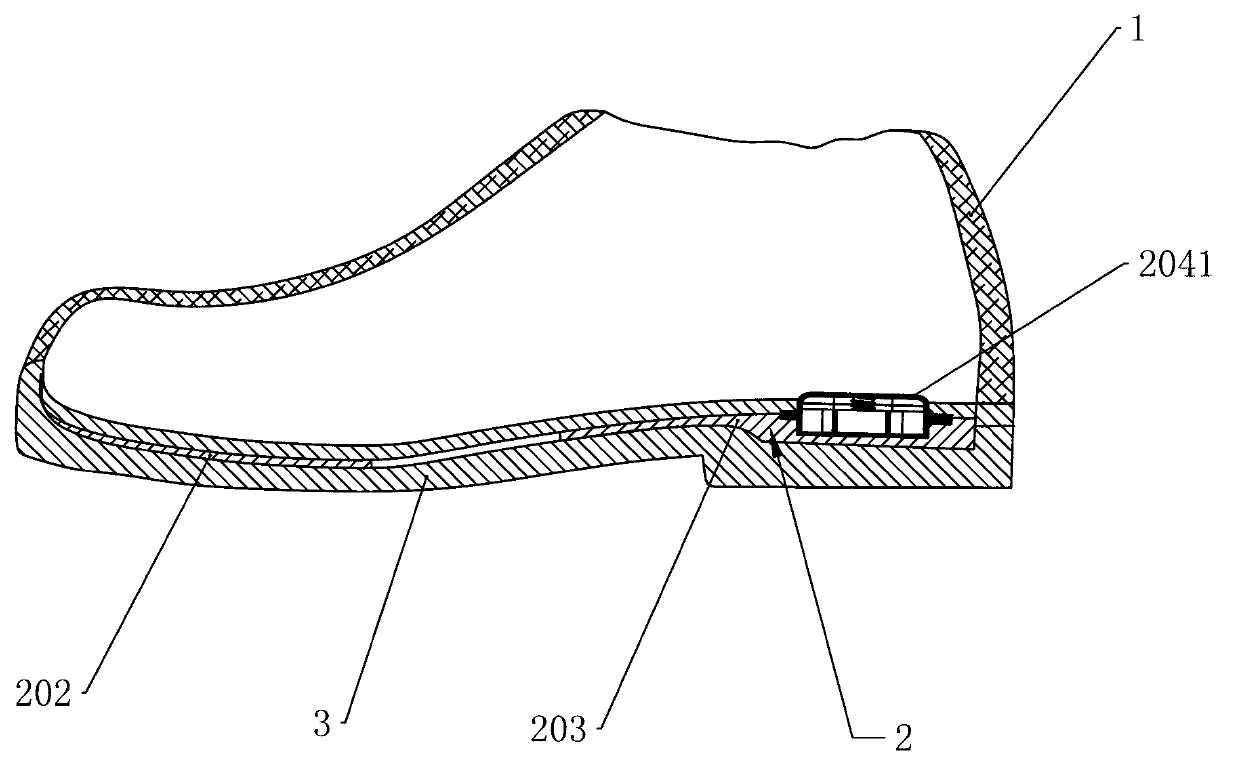

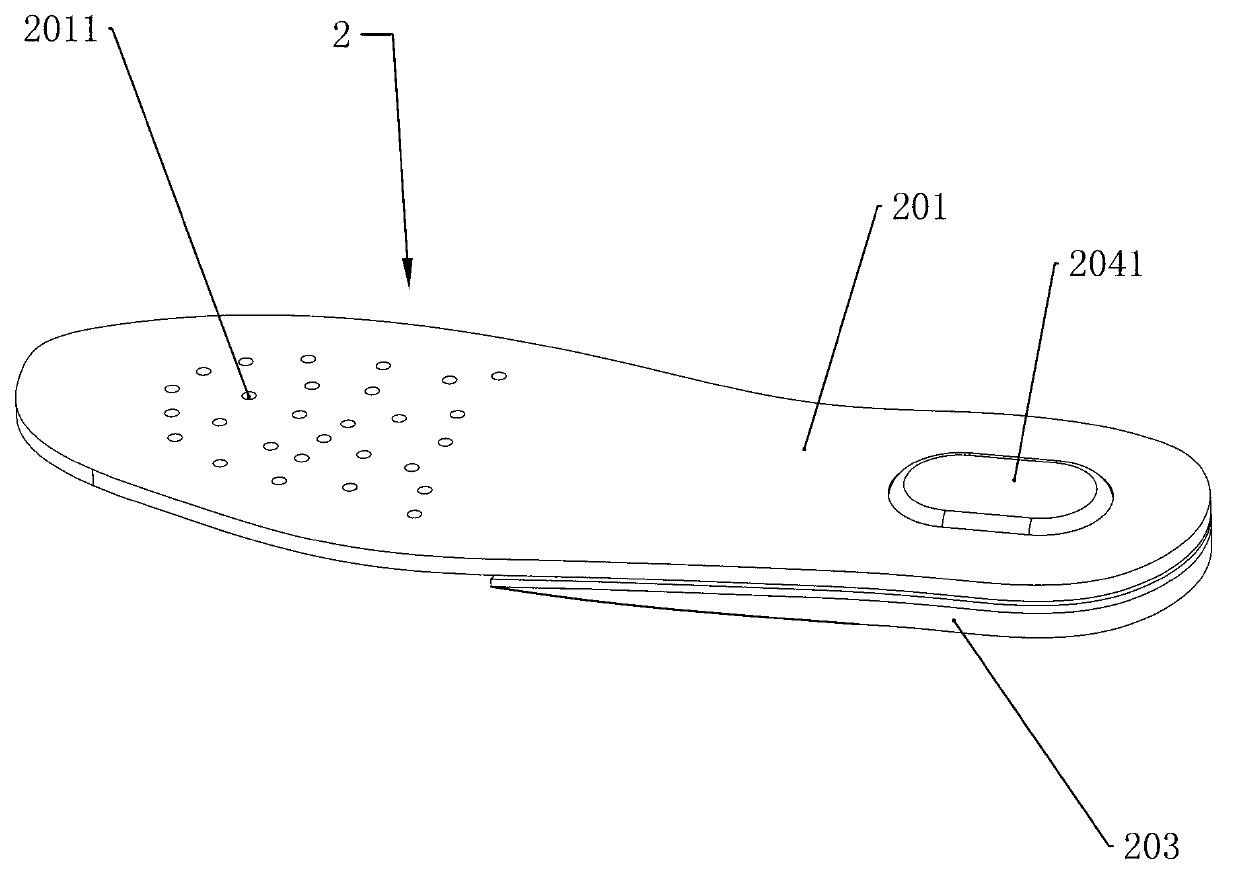

High-heeled shoes with internal height-increasing waterproof platforms covered on front sides and seamless vamps on toe caps and production method thereof

The invention discloses a pair of high-heeled shoes with internal height-increasing waterproof platforms covered on front sides and seamless vamps on toe caps and a production method thereof. The shoes comprise heels, soles and uppers, wherein the soles consist of foot sole sections, foot arch sections and heel sections sequentially; the heels are arranged in the heel sections; the thicknesses of all the sections on the soles are consistent; and the heel sections are higher than the foot sole sections. The shoes are characterized in that: the internal height-increasing waterproof platforms are arranged on the foot sole sections and are covered by the vamps on the toe caps of the uppers; and the vamps on the toe caps of the uppers have a seamless structure of the whole vamps. The thickness of the internal height-increasing waterproof platforms is between 1 and 6cm; and the height of the heels is between 8 and 16cm. The soles are formed by gluing foot pads, insoles and outsoles. The internal height-increasing waterproof platforms are additionally arranged on the foot sole sections of the soles, so that the limitation of the height of the heels is broken through, people can more comfortably wear the shoes, and the height required by the people can be realized. Meanwhile, a form of seamless vamps on the toe caps is adopted, so that the effects of aesthetics, firmness and durability are greatly enhanced.

Owner:伍仲平

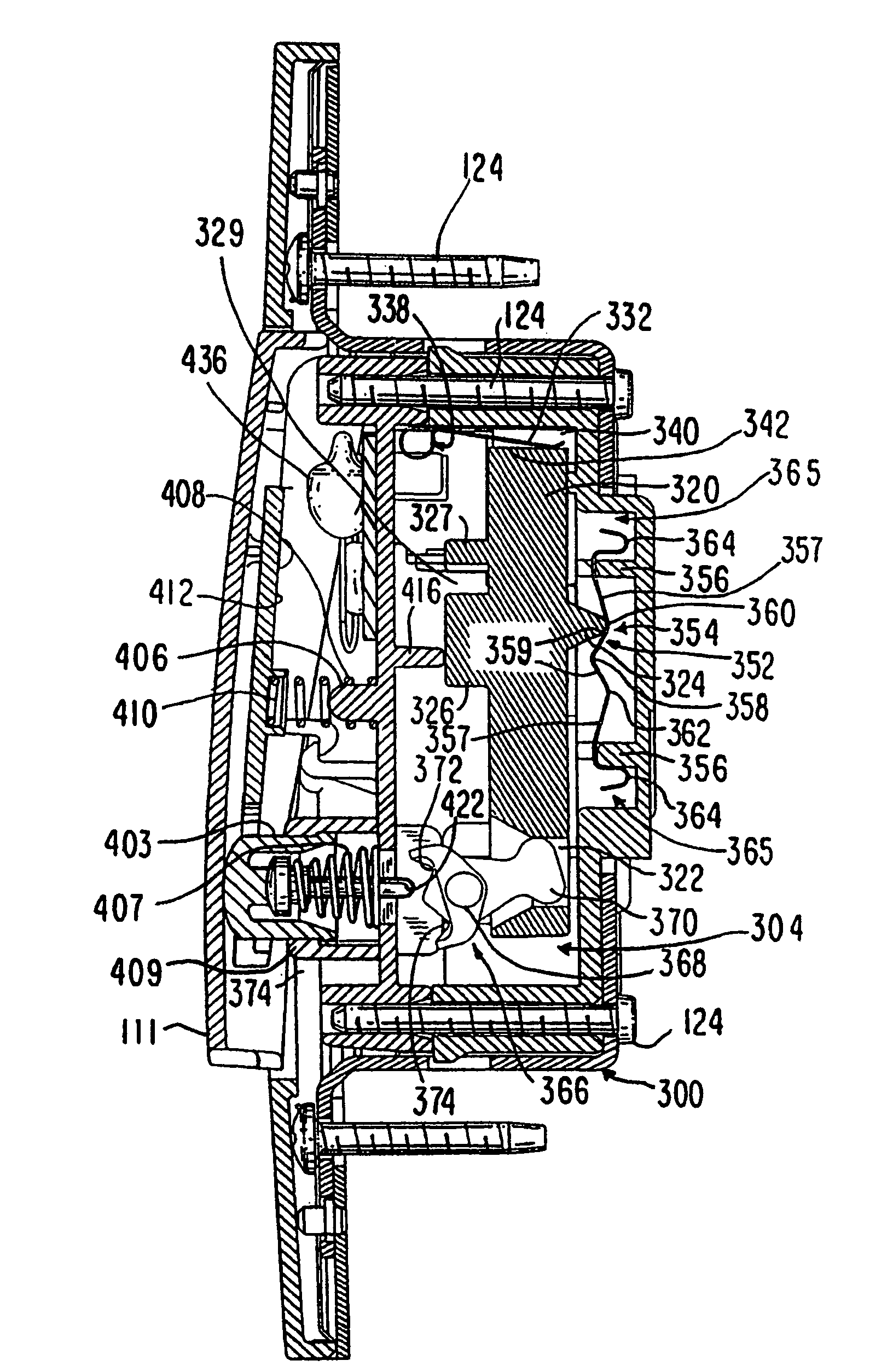

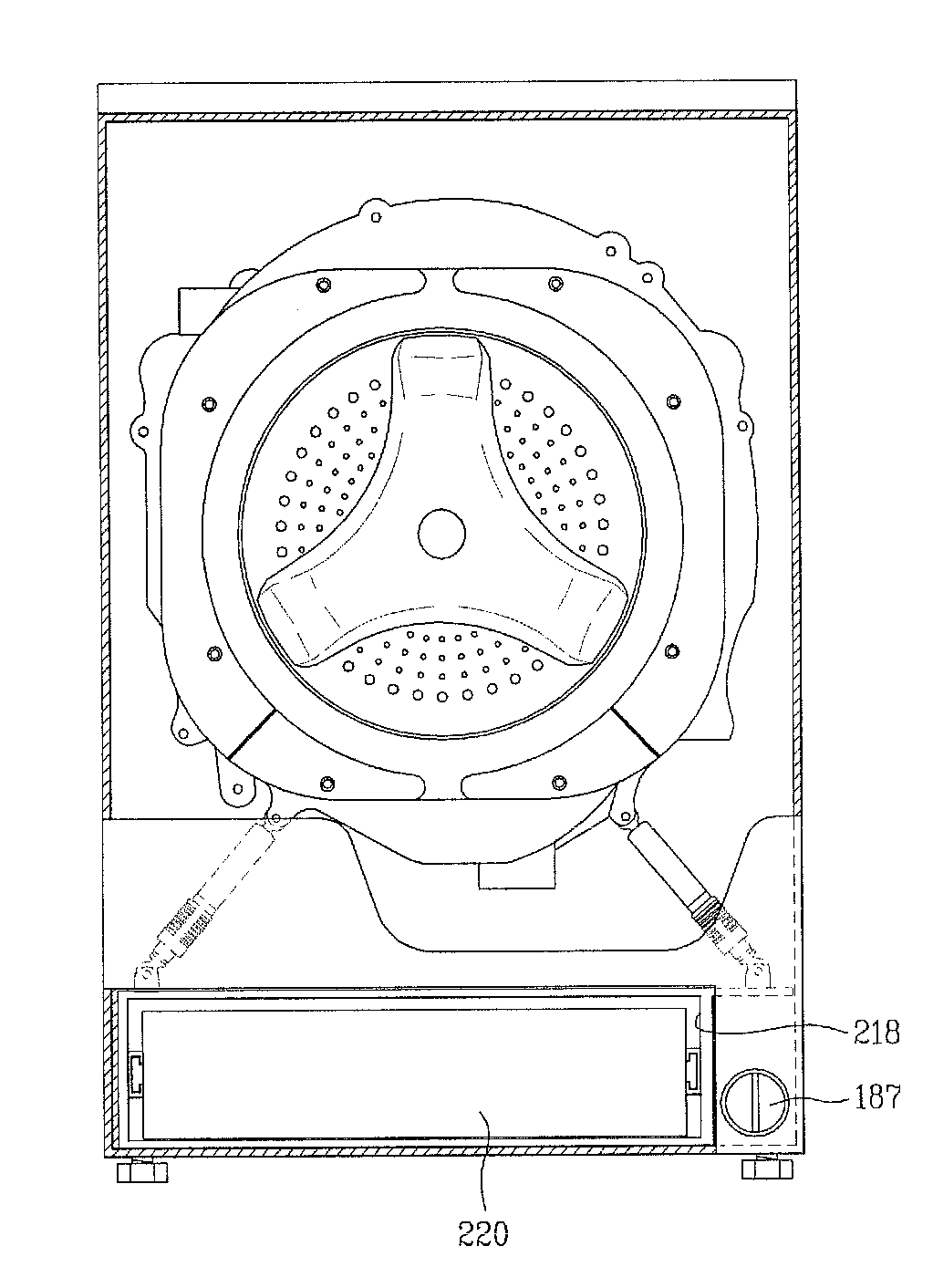

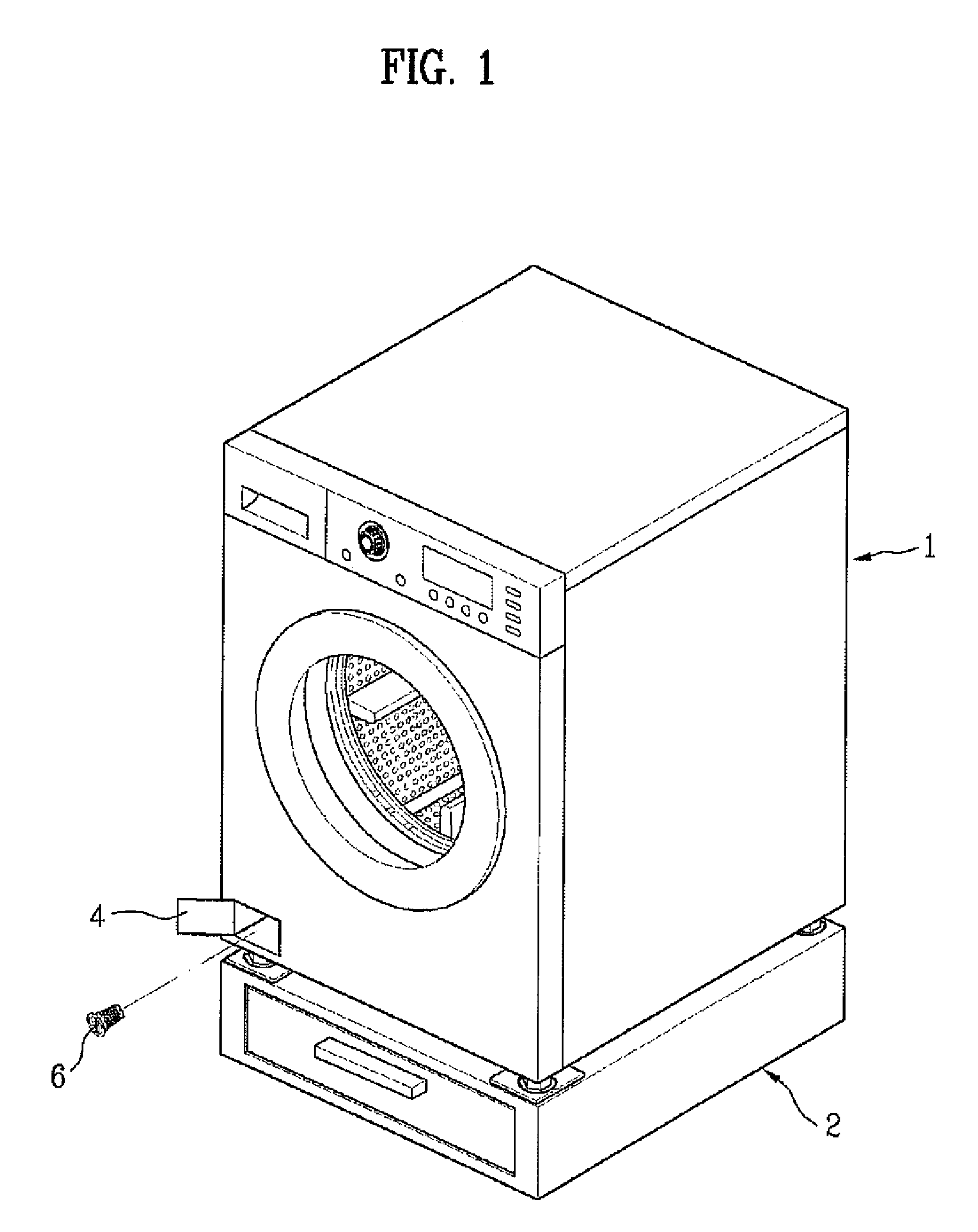

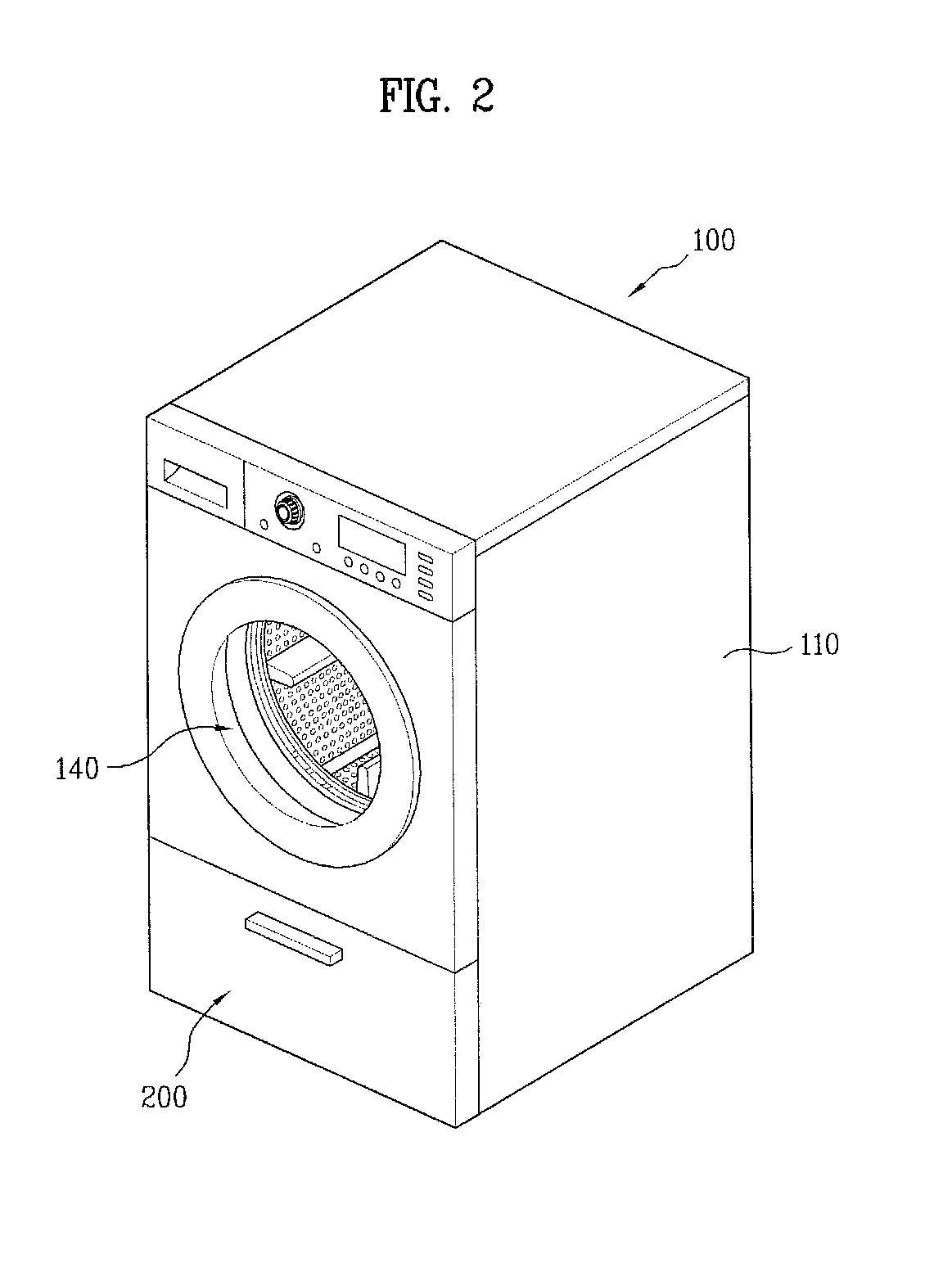

Laundry machine with height increasing member and drainage filter servicing section

ActiveUS8028548B2Improve the level ofGood lookingOther washing machinesControl devices for washing apparatusEngineeringLaundry

A laundry machine includes a height increasing member between a washing tub and an installation surface of a cabinet. The height increasing member includes a housing with an opening to support the washing tub in the cabinet, a body with a storage space that moves in and out of the opening in the housing, and a door panel to hide a servicing section when the body is moved into the opening and to expose the servicing section when the movable body is moved out from the opening. The servicing section may include or otherwise provide access to a filter.

Owner:LG ELECTRONICS INC

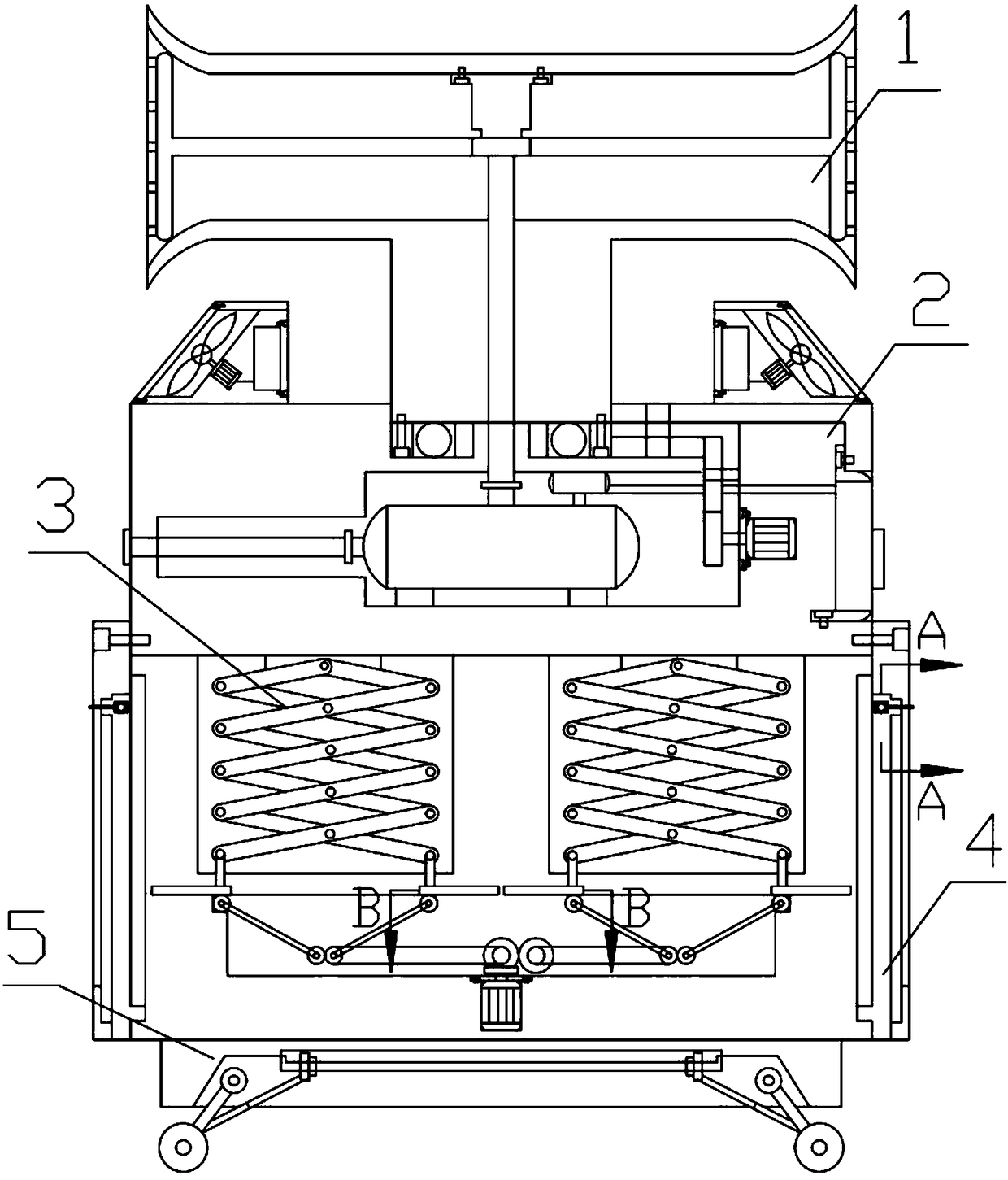

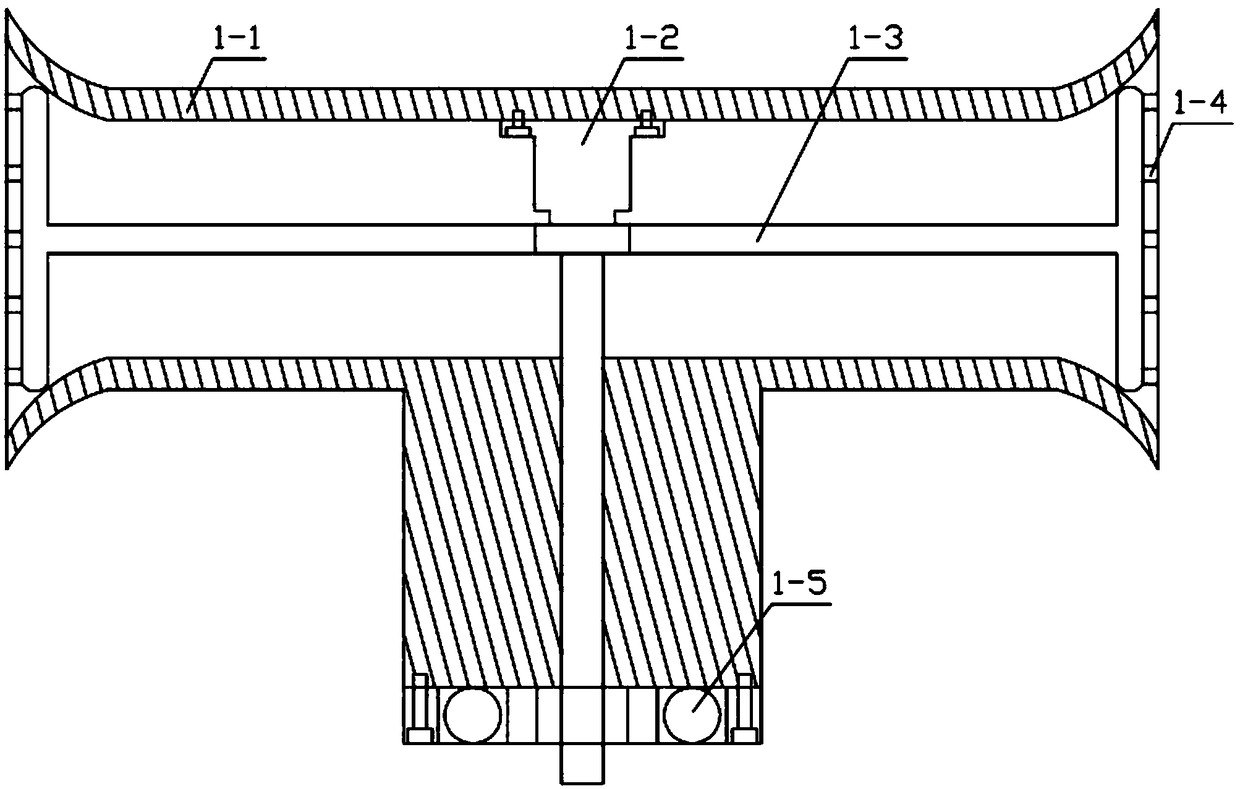

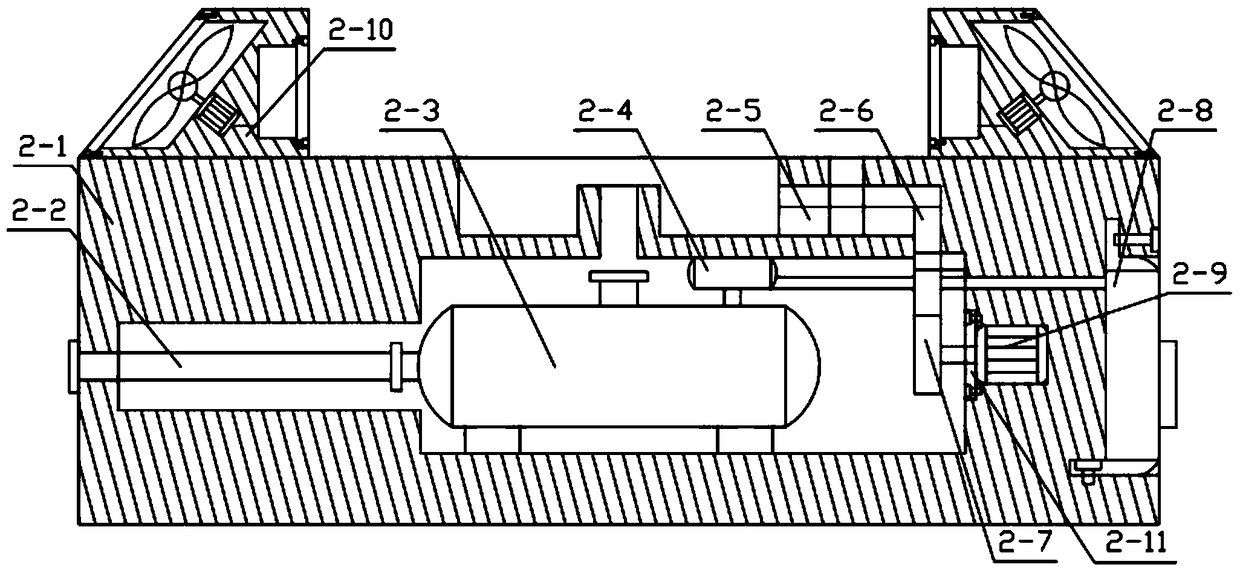

Novel coal mine-used spraying and dust suppression device

InactiveCN109209469AWith double-sided rotating spray functionBasic spray dust suppression functionDust removalFire preventionMechanical engineeringCoal

The invention relates to a coal mine appliance, in particular to a novel coal mine-used spraying and dust suppression device, which comprises a rotary spraying drum, a rotating and spraying mechanism,a height increasing mechanism, auxiliary supporting legs and shrinkable moving wheels. Apart from the basic spraying and dust suppression functions, the device also has a two-face rotary spraying function, the working area is larger, and the device can raise the spray and make the dust suppression effects more comprehensive; the device also has a height increasing function and can be applied to different places; and besides, the device is also provided with a shrinkable moving mechanism, and the use is more convenient. The rotary spraying drum and the rotating and spraying mechanism are in mobile contact connection; the rotating and spraying mechanism is welded with the height increasing mechanism; the rotating and spraying mechanism is connected with the auxiliary supporting legs throughtightening screws; the height increasing mechanism and the auxiliary supporting legs are adapted through grooves; and the height increasing mechanism and the shrinkable moving wheels are welded.

Owner:付耀文

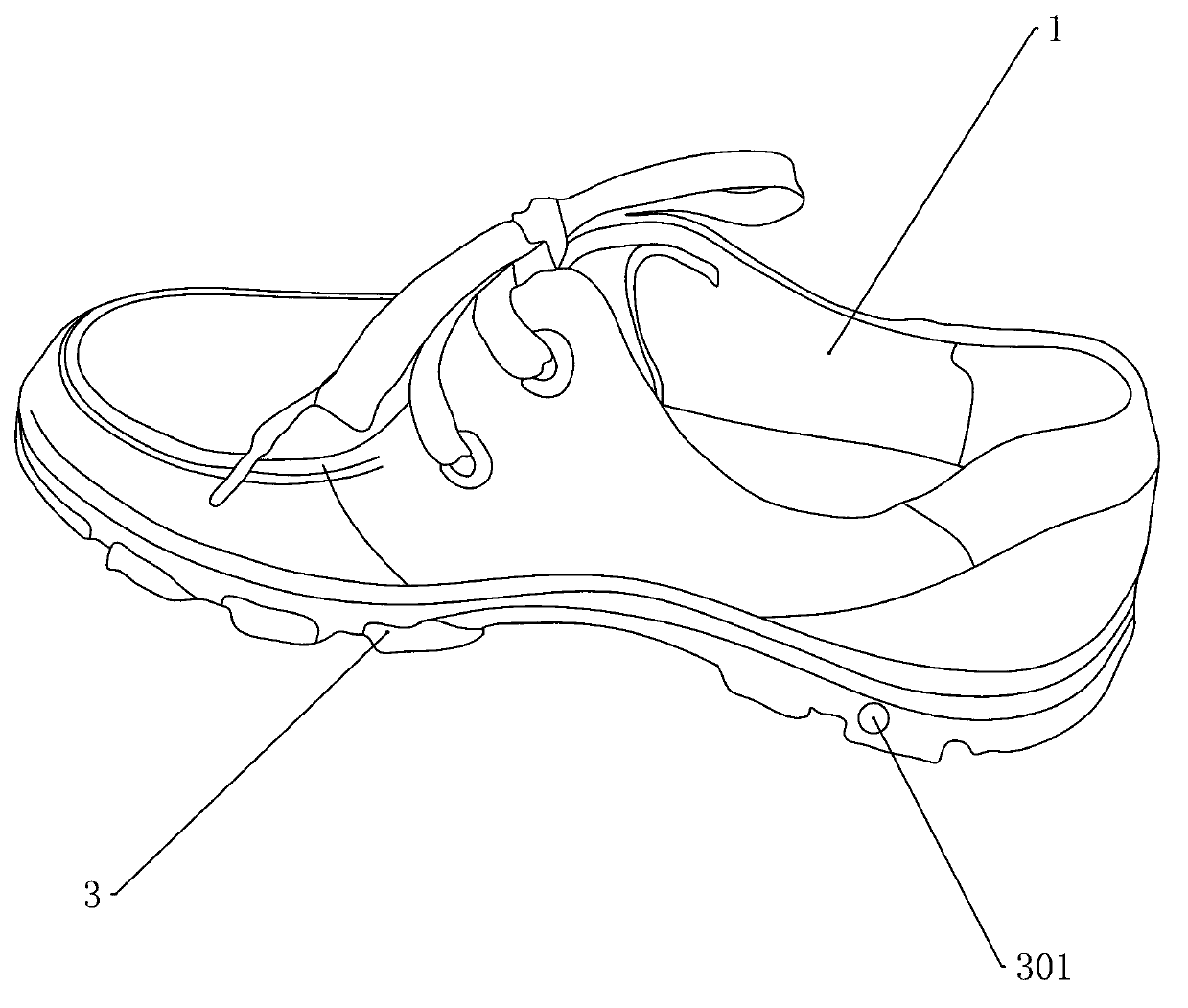

Breathing air change shoes and workmanship thereof

InactiveCN103099379ASimple preparation processImprove pass rateSolesManufacturing technologyAir change

The invention relates to shoes for daily wearing of people, in particular to breathing air change shoes and workmanship thereof. The breathing air change shoes have air changing and perspiring functions. The breathing air change shoes comprise uppers, insole elements and outsoles, and the insole elements are composed of insole base plates, air guide half sole pieces, second half sole pieces and air bag elements. Due to the fact that the air bag elements are connected with the insole base plates by the second half sole pieces to clamp the air bag elements between the insole base plates and the second half sole pieces to form a structure of the insole elements, the insole elements can be independently manufactured, and the workmanship is simple and convenient. Meanwhile, due to the fact that protruded limit protrusion blocks are arranged on the side faces of air bag bodies, the top distances between the limit protrusion blocks and the air bag bodies can be integrally pre-arranged according to requirements, when the insole elements are assembled, the exposed heights of the air bag bodies are kept to be completely consistent, product quality is stable, and percent of pass is high. In addition, due to the fact that the air bag elements are independently arranged on the insole elements, when the thicknesses of insoles are enough (for example, height increasing shoes are manufactured), air bag storage cavities do not need prearranging on heel portions of outsoles, common outsoles can be used to manufacture the breathing air change shoes, and shoe manufacturing technology is simplified.

Owner:管兴无

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com