Breathing air change shoes and workmanship thereof

A technology for ventilation shoes and airbags is applied in the field of production technology of breathing ventilation shoes, which can solve the problems of difficult quality control, complicated production, high requirements for production personnel, etc., and achieve stable product quality, simple production process, and simplified shoe production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

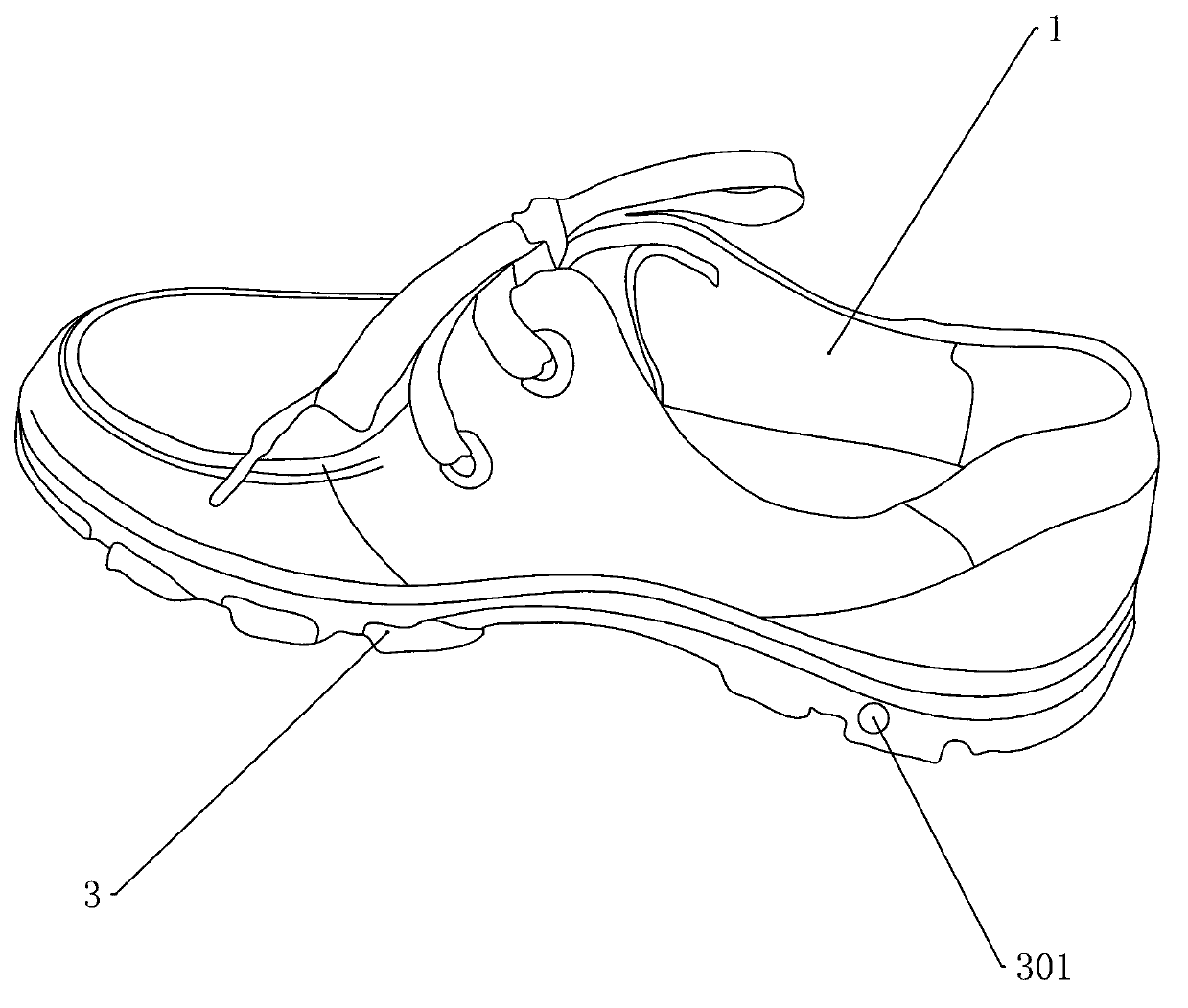

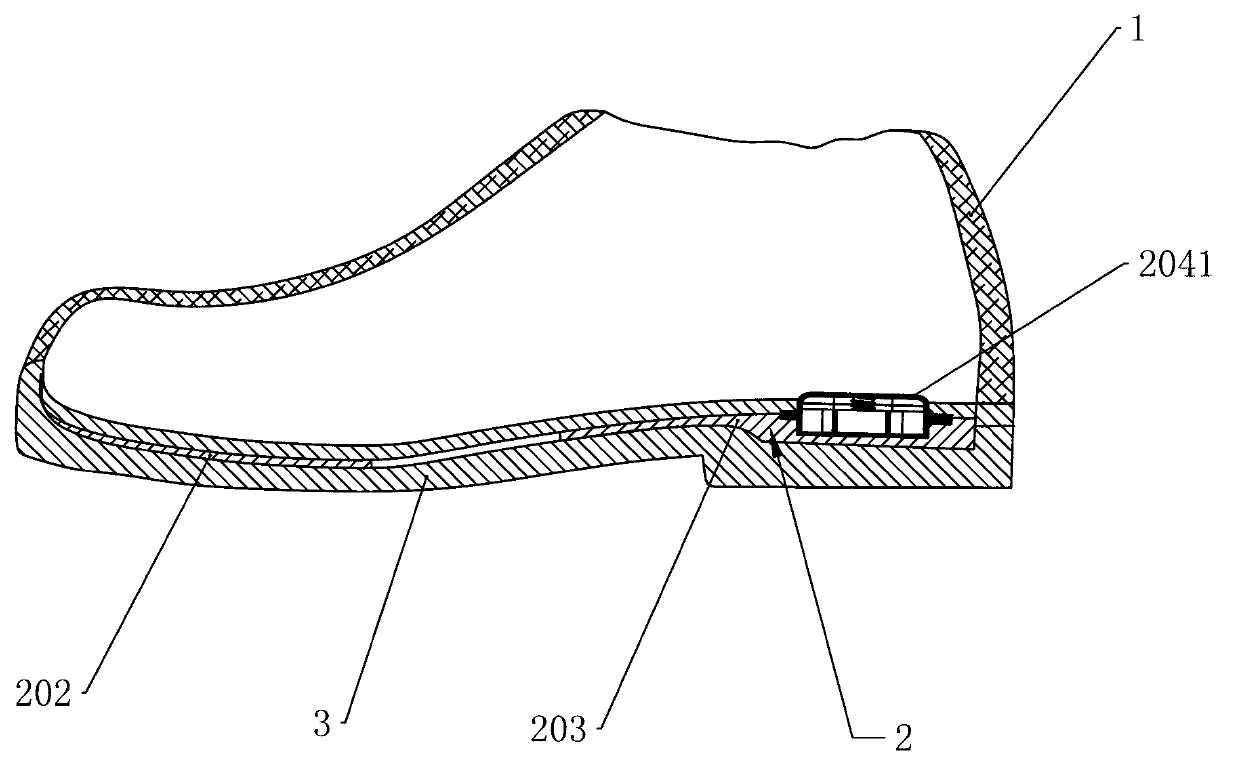

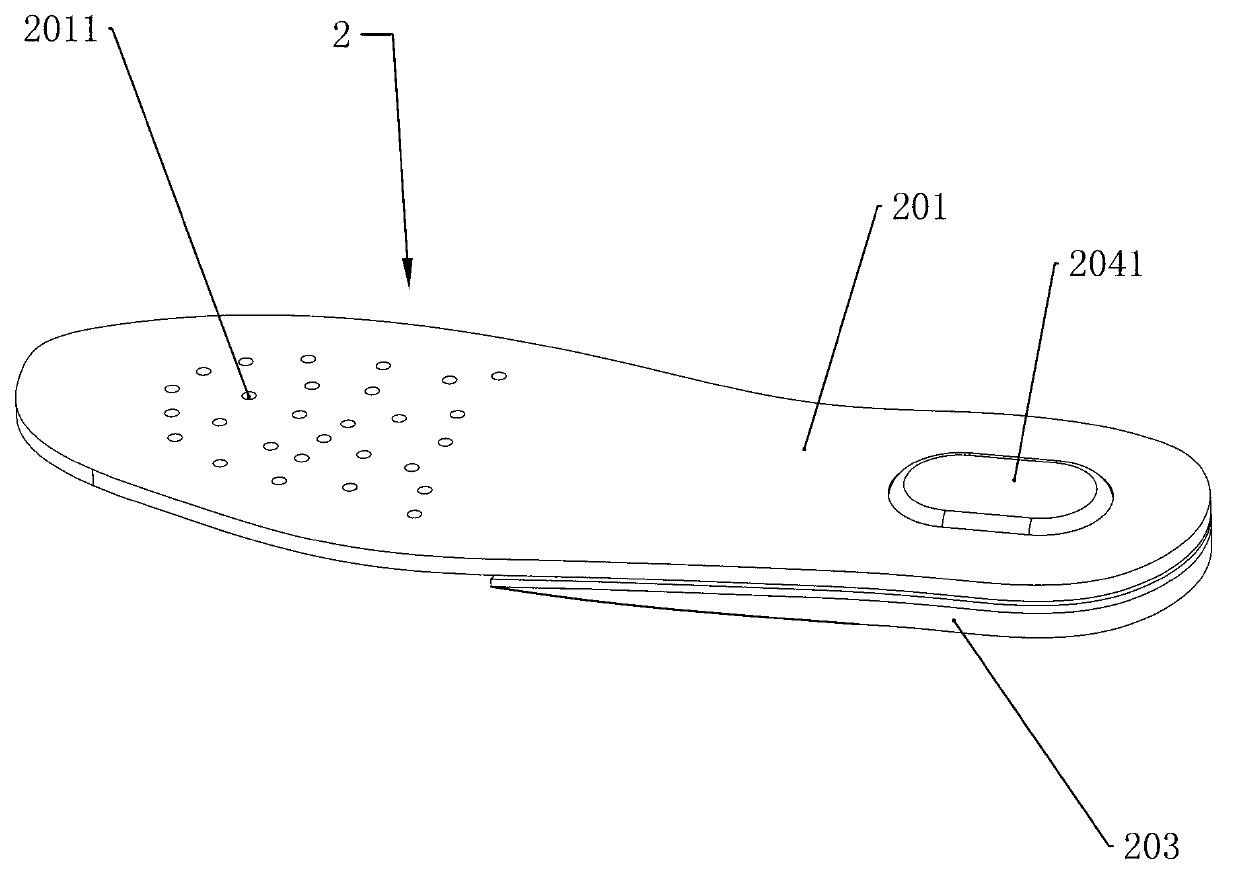

[0024] like figure 1 , 2 As shown, breathing ventilation shoes include upper 1, midsole assembly 2 and outsole 3, such as Figure 3-5 As shown, the midsole assembly 2 includes a midsole substrate 201, an air-guiding front palm 202, a rear half palm 203, and an airbag assembly 204. A plurality of ventilation holes 2011 are evenly distributed on the forefoot of the midsole substrate 201, The heel portion is provided with a first airbag clamping hole 2012; the airbag assembly 204 includes an airbag body 2041, an air guide tube 2042, an exhaust check valve 2045, and an intake check valve 2043; There are interconnected ventilation grooves 2021. In this specific embodiment, the ventilation grooves 2021 are composed of a plurality of parallel wavy grooves. The grooves extend along the length direction and are arranged side by side. There are communication grooves between adjacent wavy grooves. 2022, the air-guiding front palm piece 202 is also provided with a connecting hole 2023 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com