Novel coal mine-used spraying and dust suppression device

A technology for spraying dust and coal mines, applied in safety devices, dust-proofing, mining equipment and other directions, can solve the problems of great harm, can not meet the actual needs of use, single function, etc., to achieve the effect of convenient use and comprehensive dust reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

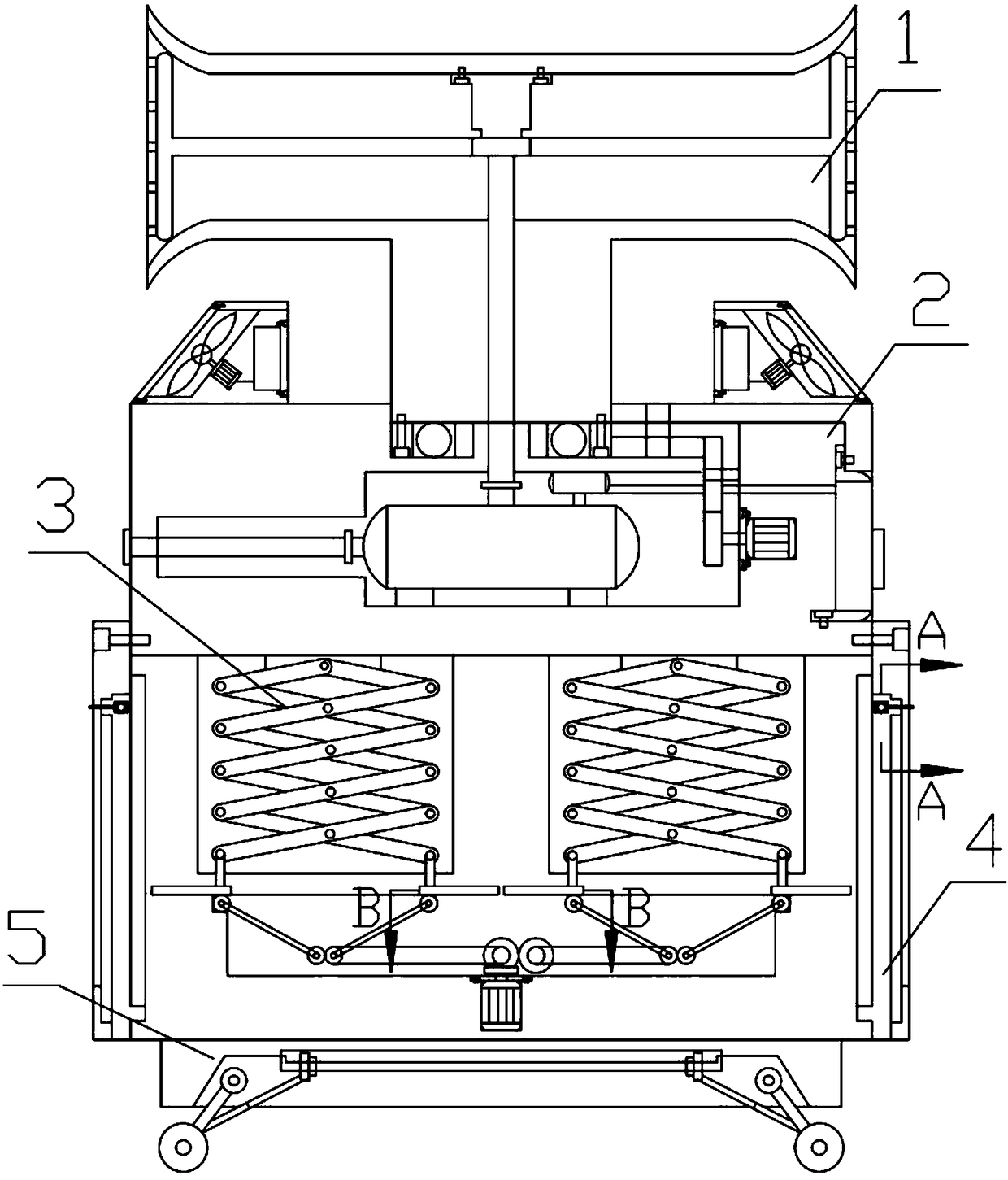

[0033] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 illustrate this embodiment. The present invention relates to a coal mine appliance, more specifically a new type of spray dust suppression device for coal mines, including a rotary Type spray drum 1, rotating and spraying mechanism 2, heightening mechanism 3, auxiliary support leg 4, retractable moving wheel 5, this device not only has the basic function of spraying and dust reduction, but also has the function of double-sided rotating spraying, which makes the working area larger. The device can raise the spray to make the dust reduction effect more comprehensive. The device also has a heightening function, which is suitable for different venues. In addition, the device also has a retractable moving mechanism, which is more convenient to use.

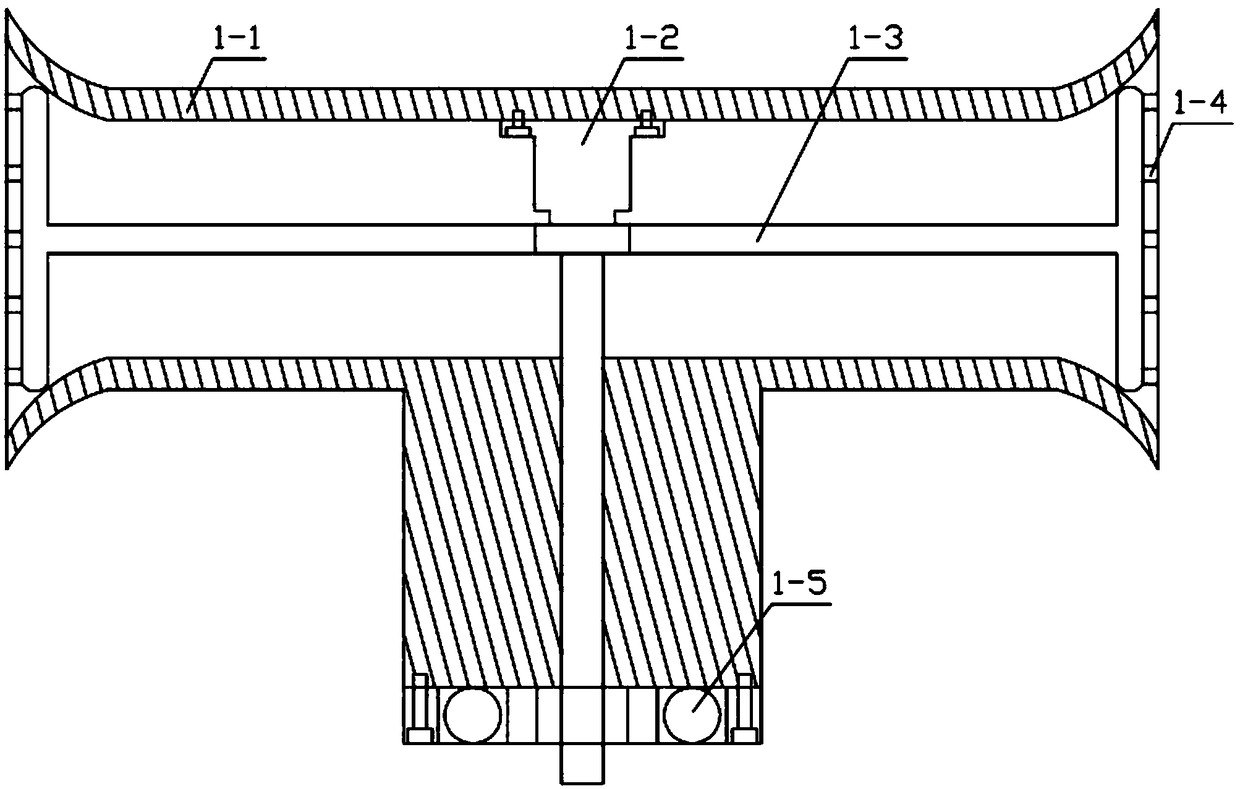

[0034] The rotary spray drum 1 includes a rotary drum 1-1, an electric ball valve 1-2, an outlet pipe 1-3, an atomizing nozzle 1-4, a rotary bearing 1-5, and the el...

specific Embodiment approach 2

[0044] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 illustrate this embodiment, and this embodiment further describes Embodiment 1, and the material of the slewing bearings 1-5 is bearing steel.

specific Embodiment approach 3

[0045] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 illustrate this embodiment, this embodiment will further describe Embodiment 1, the material of the support spring 4-2-2 is carbon steel.

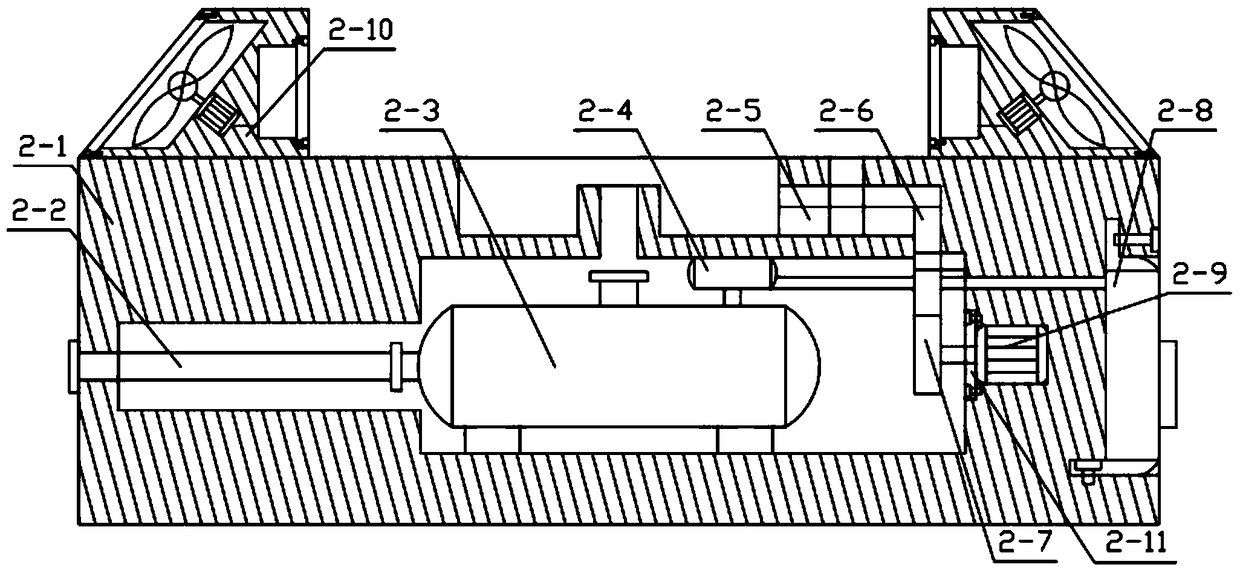

[0046] How to use the device: The device is connected to the water inlet pipe 2-2, the water is pressurized by the high-pressure water pump 2-3, discharged from the outlet pipe 1-3, and passed through the atomizing nozzle 1-4 to make the water form a mist to reduce dust effect, wherein the device detects the dust concentration through the dust concentration sensor 2-8, and transmits the information to the host 2-4 of the dust suppression device. After being controlled by the host 2-4 of the dust suppression device, the high-pressure water pump 2-3 is started, and the electric ball valve 1-2 controls the device. For single side spray or double side spray.

[0047] Start engine one 2-9, engine one 2-9 drives gear three 2-7, drives gear one 2-5 through gear two 2-6, gear o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com