Cutting blade for processing soft metal materials

A technology of metal materials and cutting inserts, applied in metal processing equipment, tools for lathes, turning equipment, etc., can solve the problem of uncut chip curling and good control of flow direction, too smooth connection between tool tip and rake face, The smoothness of the product does not meet the requirements and other problems, so as to achieve the effect of cutting lightly, improving the processing quality and reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

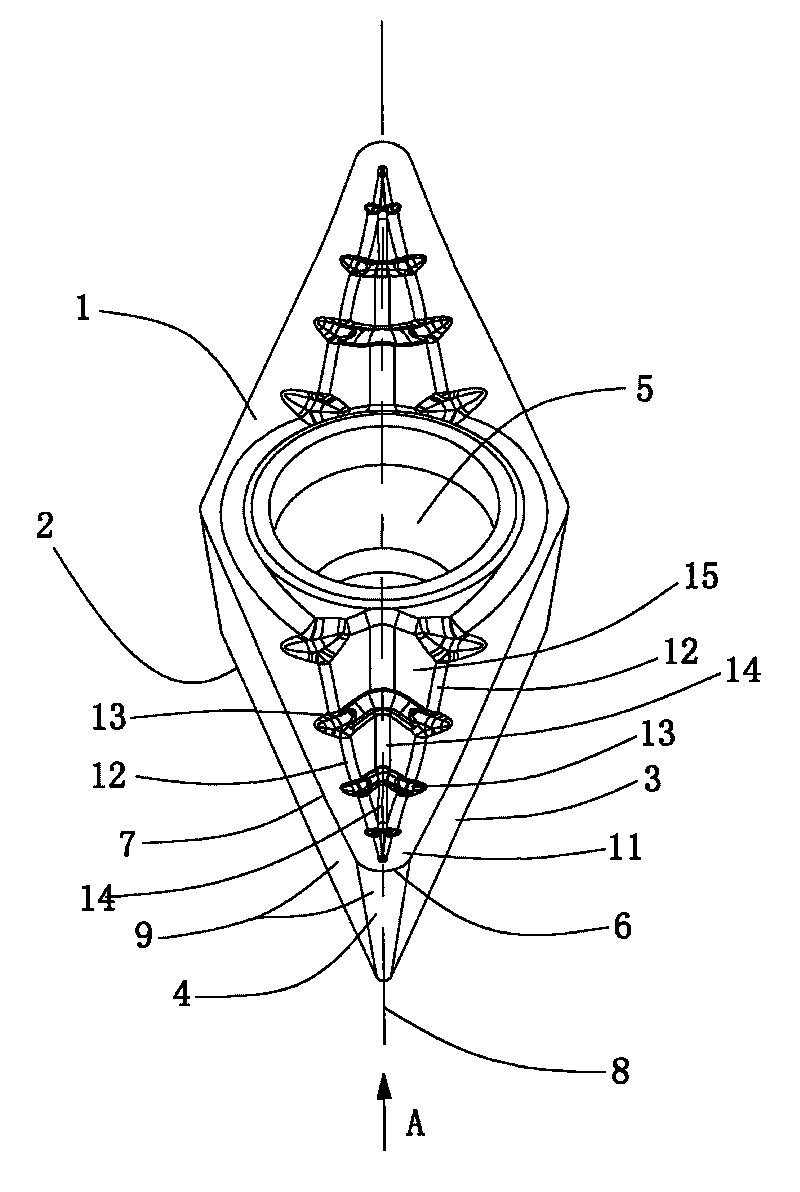

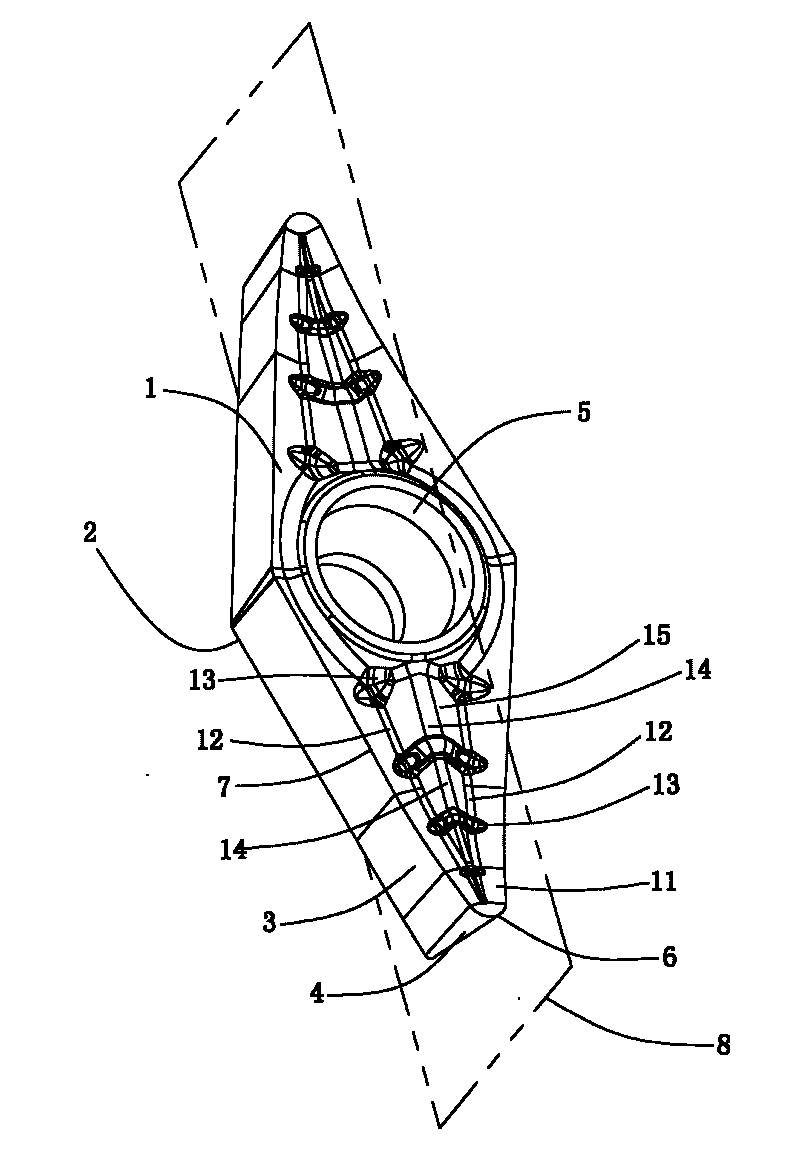

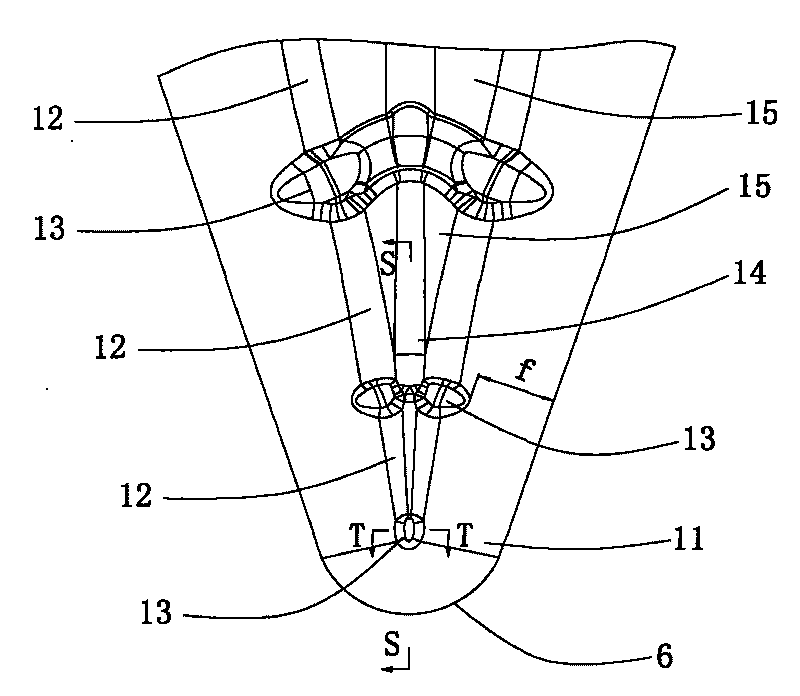

[0029] Such as Figure 1 to Figure 6 As shown, a cutting insert for processing soft metal materials of the present invention has a basic shape similar to a rhombus, including an insert surrounded by an upper surface 1, a lower surface 2, a pair of side surfaces 3 and a conical surface 4 The body, the center of the blade body is provided with a blade positioning hole 5, the upper surface 1 and the lower surface 2 are connected by the pair of side surfaces 3 and the conical surface 4, the conical surface 4 intersects with the upper surface 1 to form a main cutting edge 6, and the two sides 3 and the upper surface The surface 1 intersects to form two side cutting edges 7 respectively connected to the two sides of the main cutting edge 6. The main cutting edge 6 and the two side cutting edges 7 are symmetrically arranged on both sides of the longitudinal vertical section 8 of the insert. The main cutting edge 6 and the side The cutting edge 7 is connected into a space spiral shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com