Patents

Literature

60results about How to "Reduce contact length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

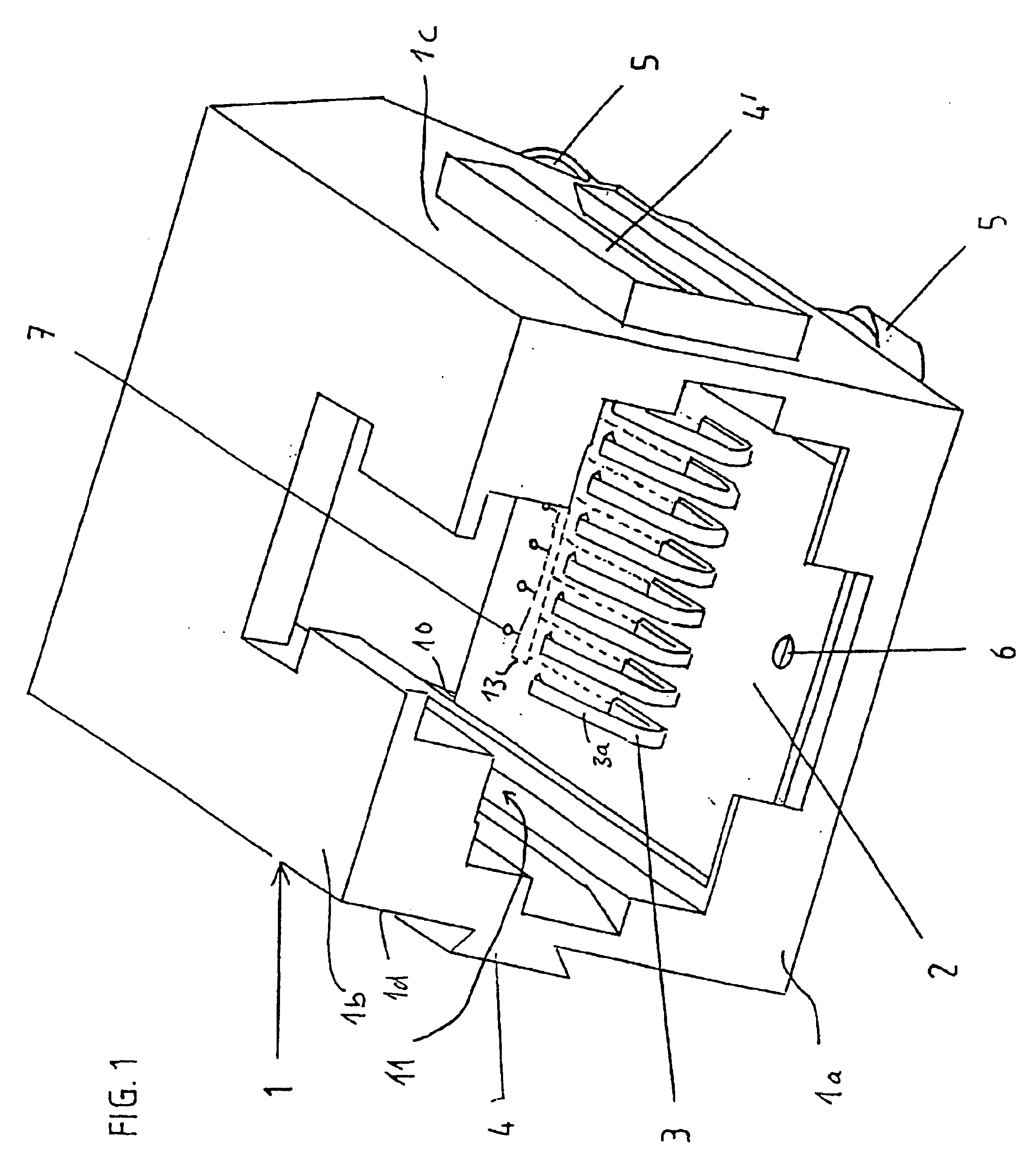

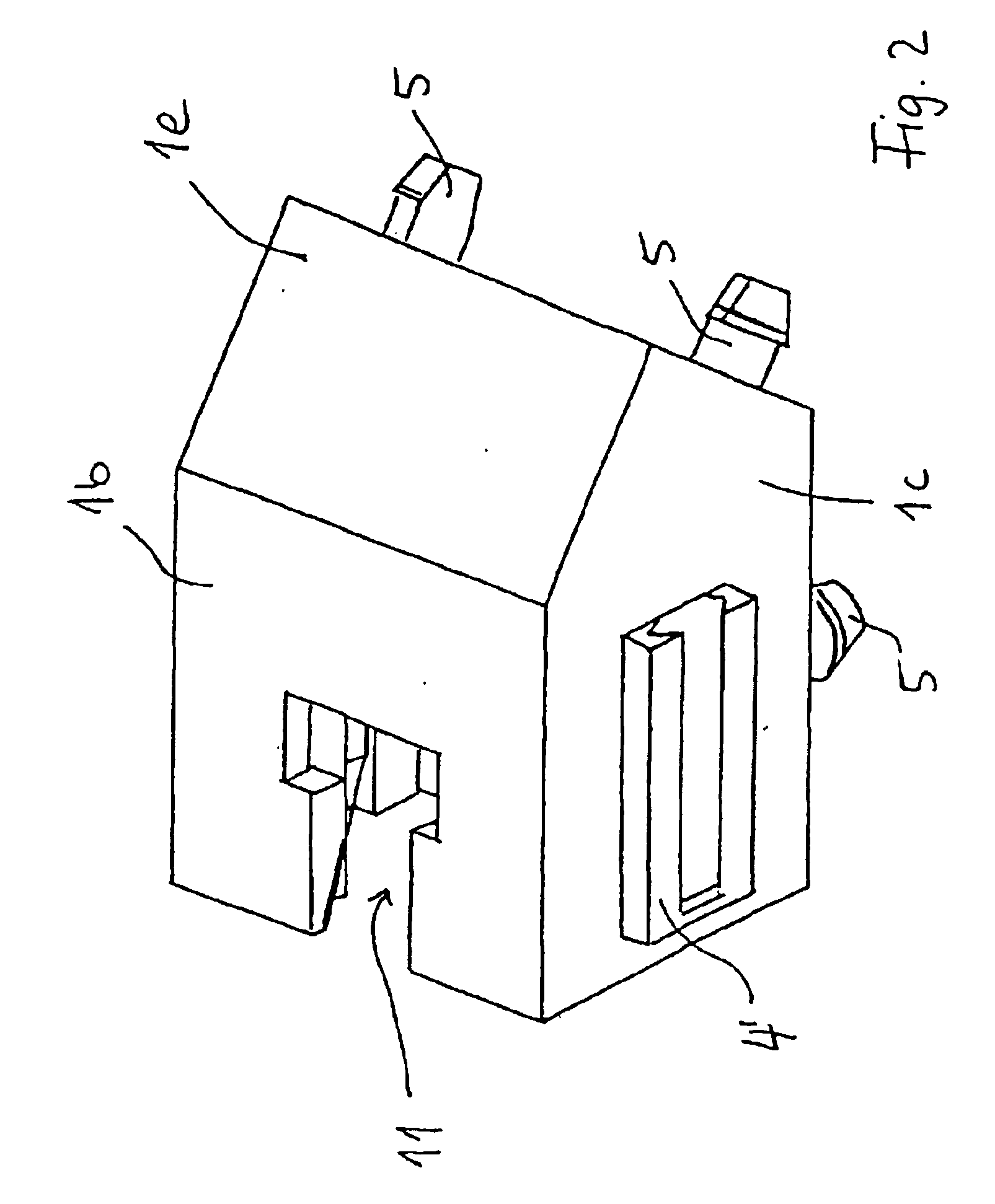

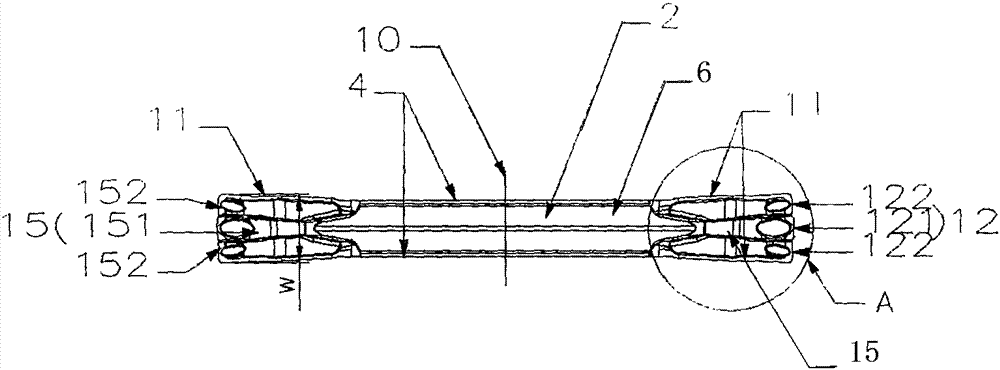

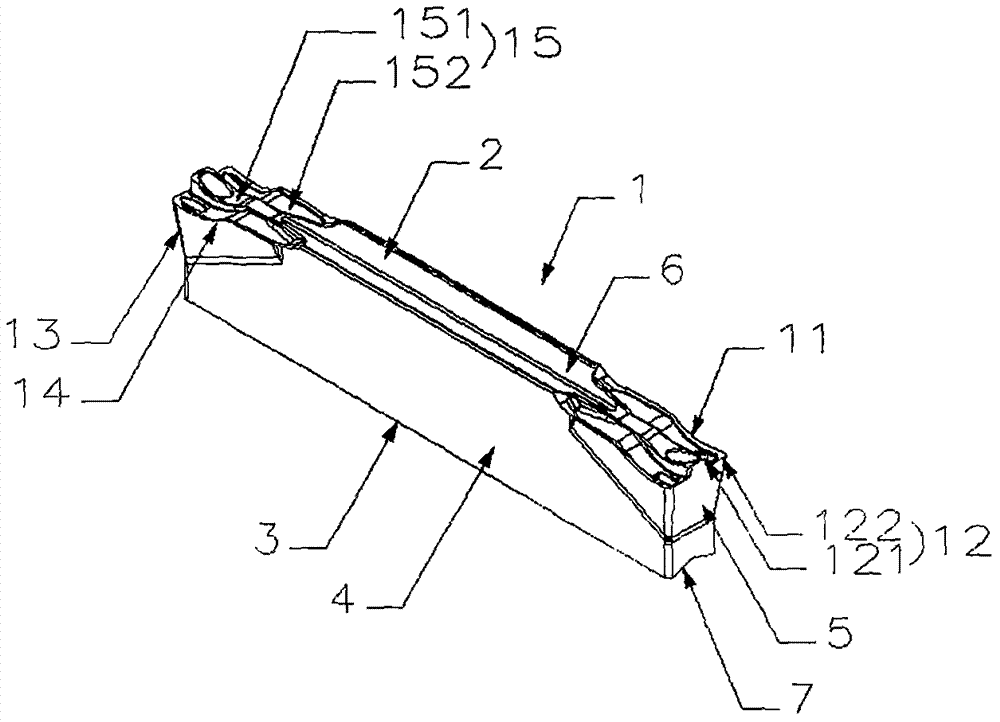

High power data line connection

InactiveUS6840779B2Reduce electrical interferenceReduce distractionsEngagement/disengagement of coupling partsTwo-part coupling devicesEngineeringContact element

A data line connection which comprises a base printed circuit board, a female connector mounted to the base printed circuit board, and a compensation printed circuit board mounted within the female connector. The compensation printed circuit board mounts a plurality of electrically conductive contact elements as well as a compensation circuit for reducing electrical interference. The base printed circuit board includes a further compensation circuit for further reducing electrical interference.

Owner:SETEC NETZWERKE

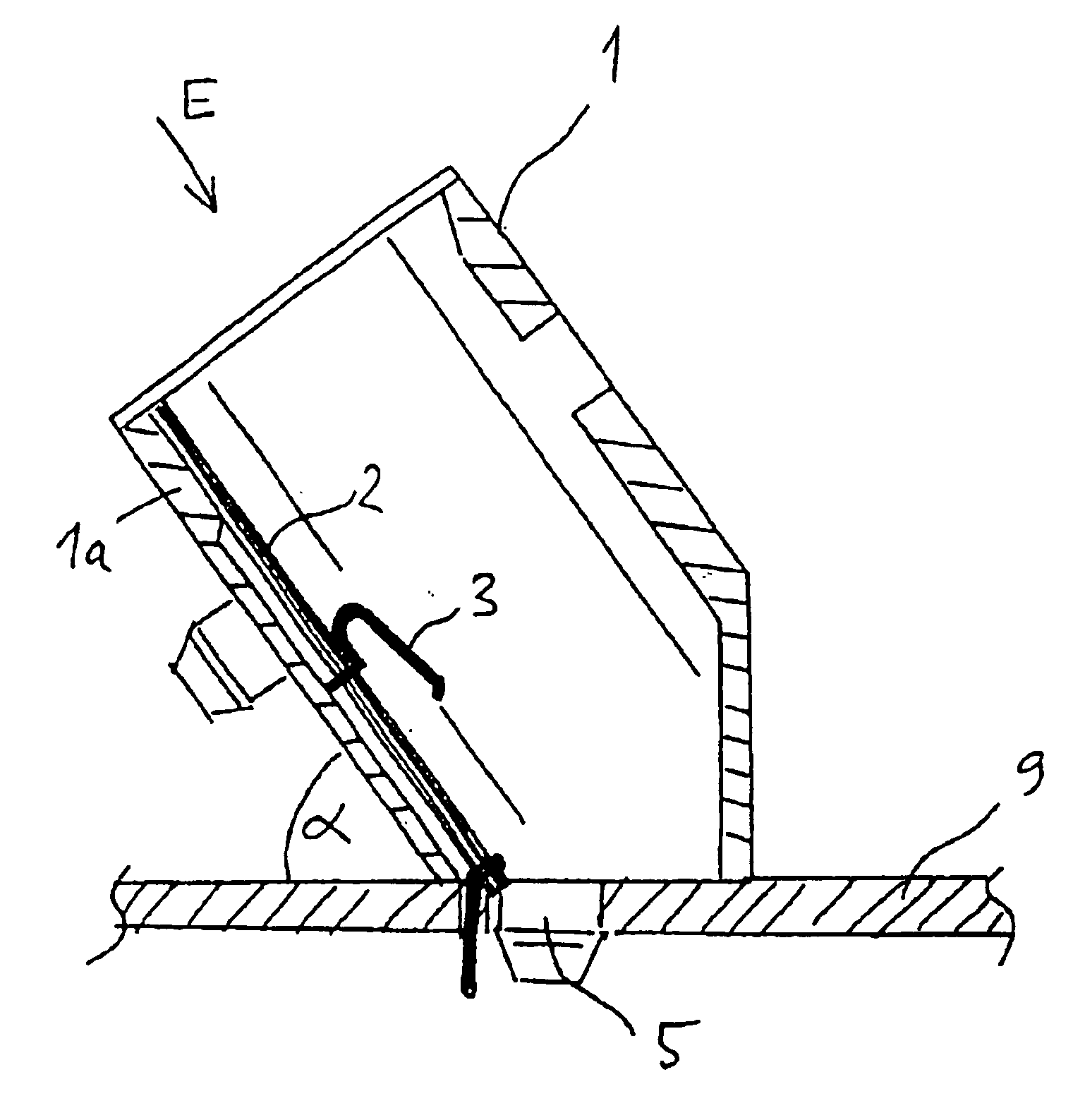

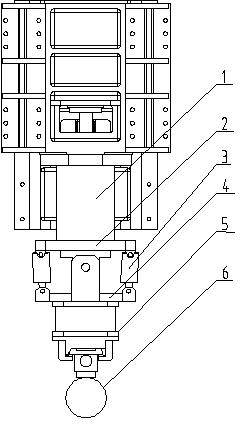

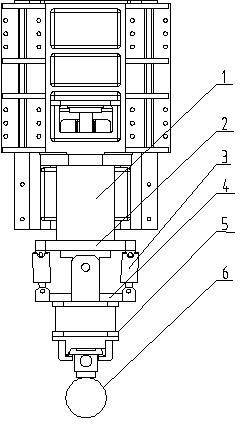

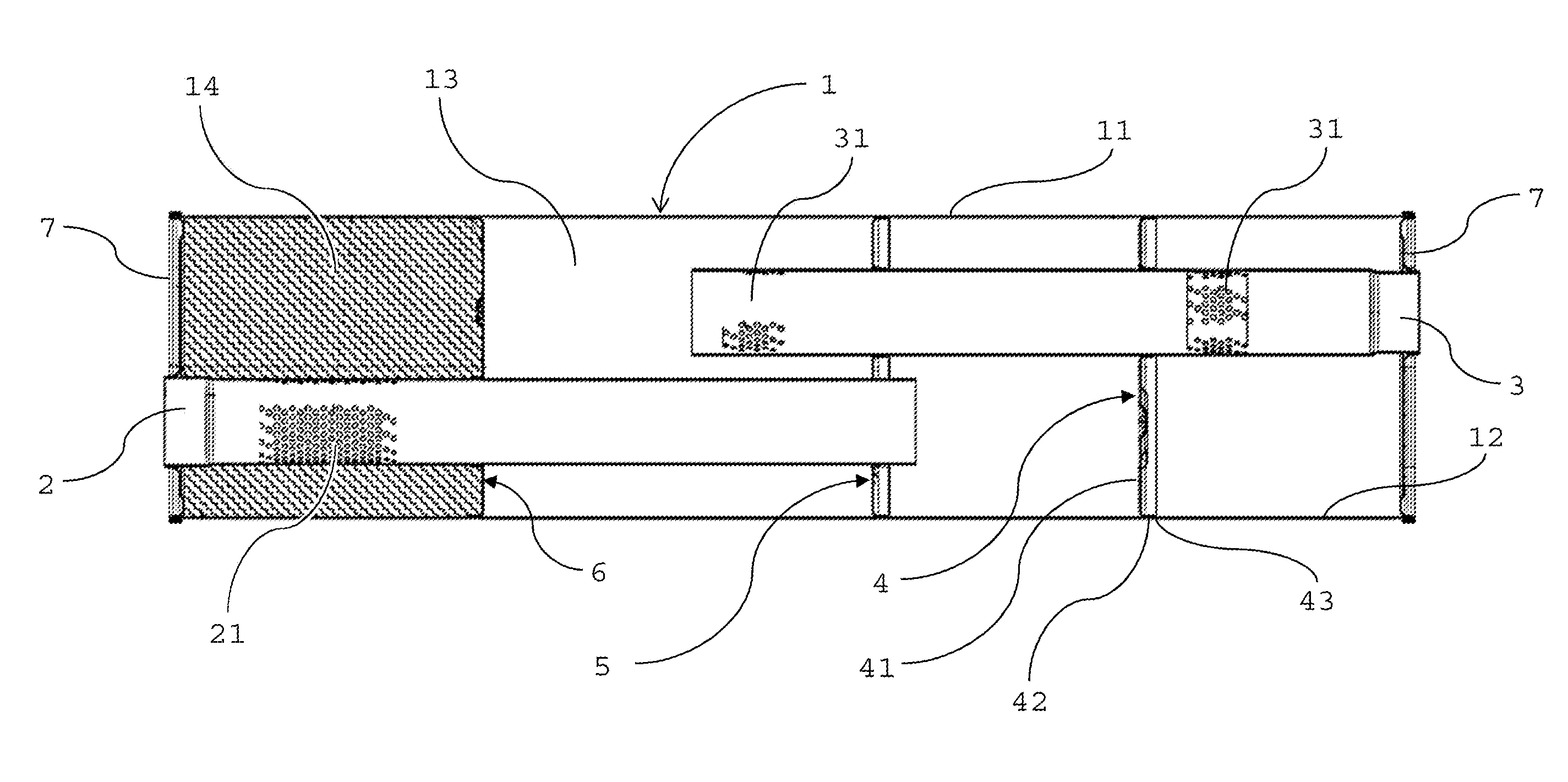

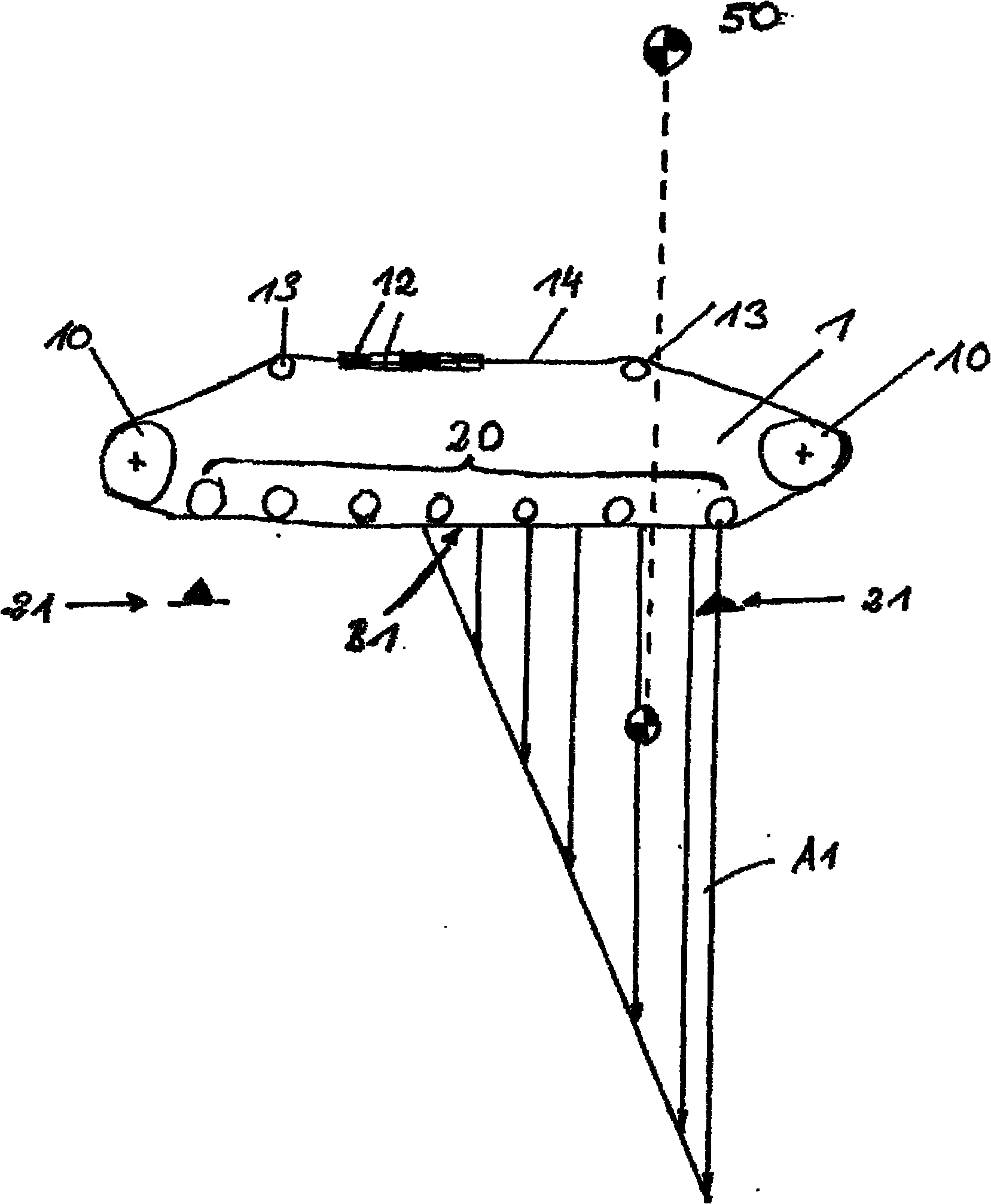

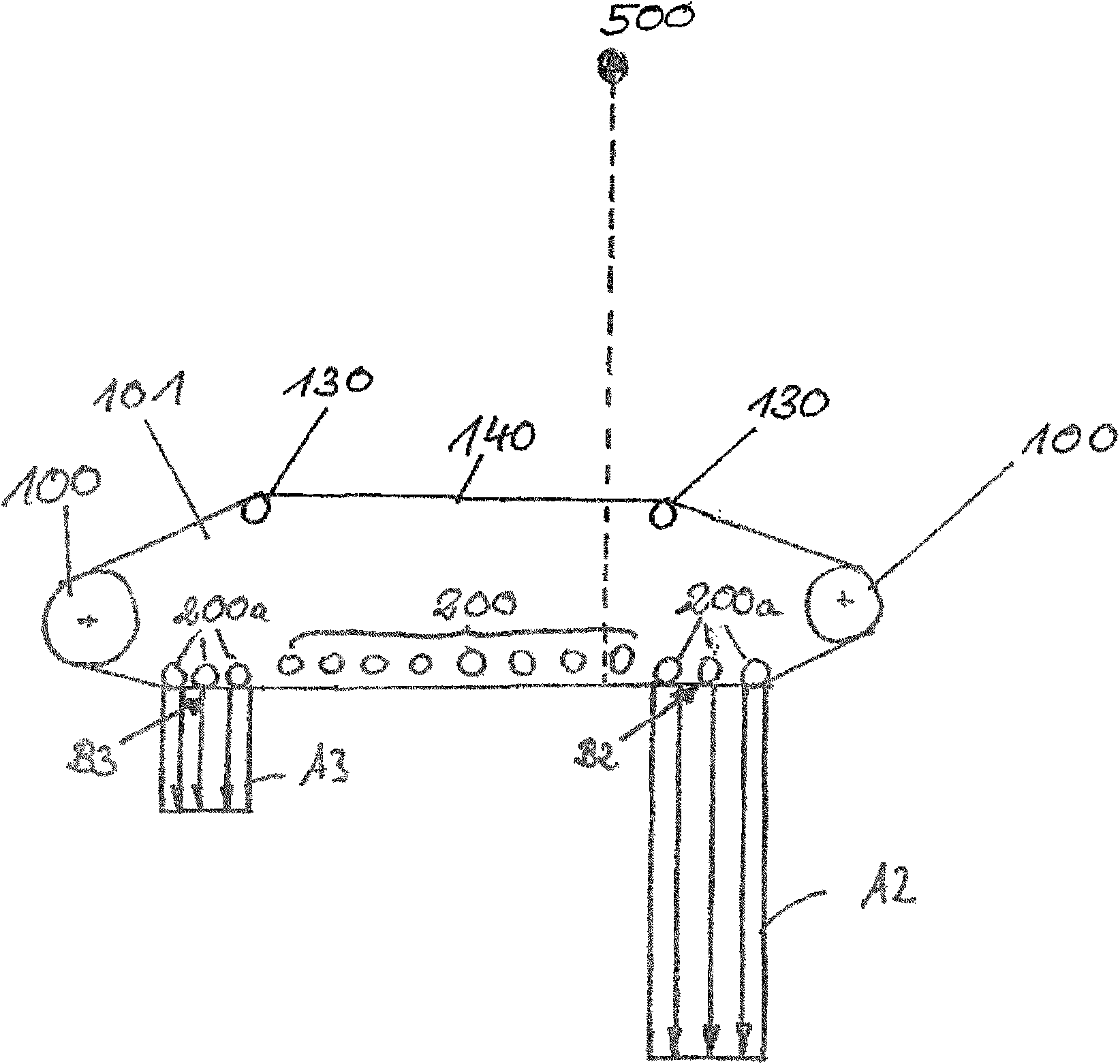

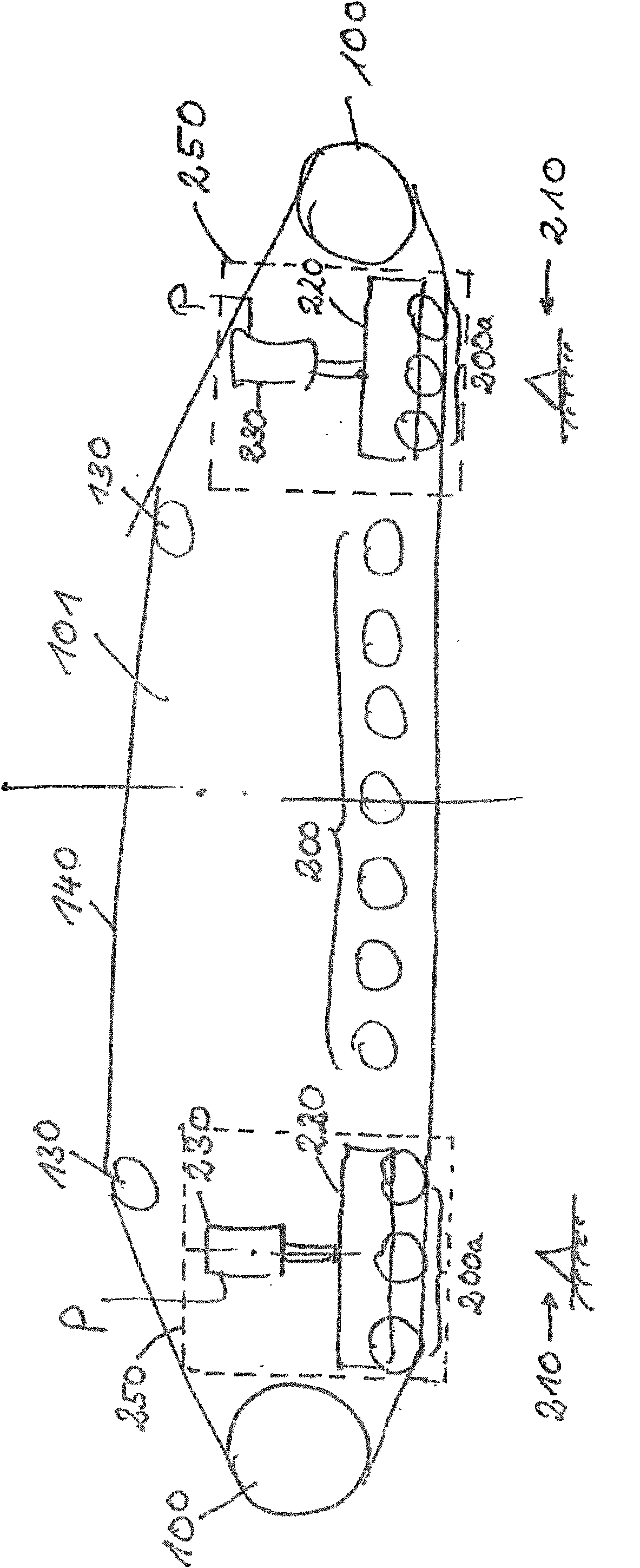

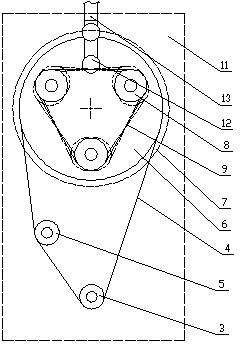

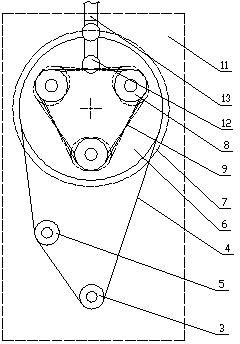

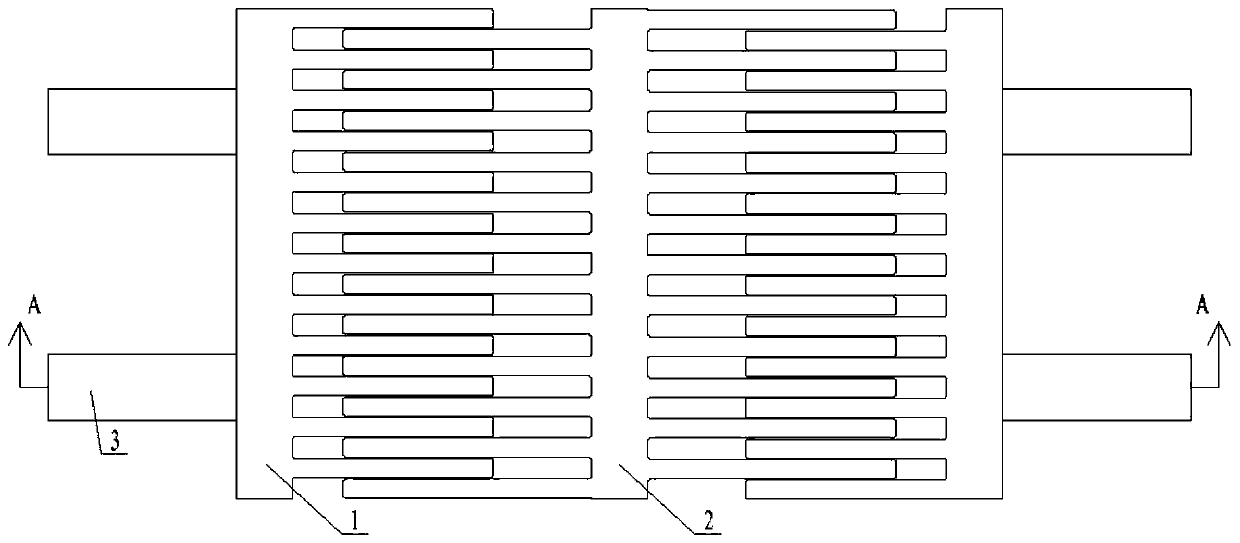

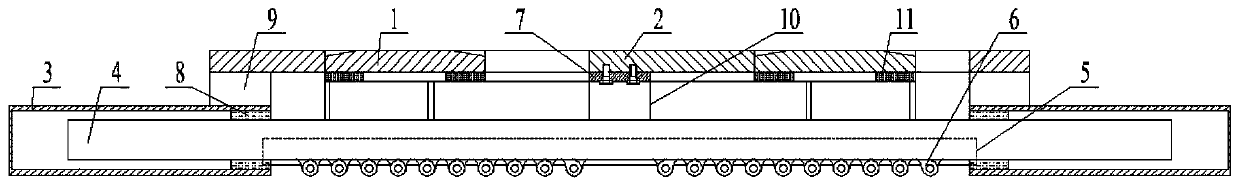

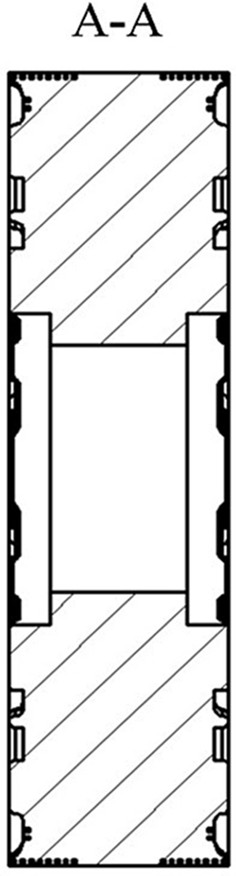

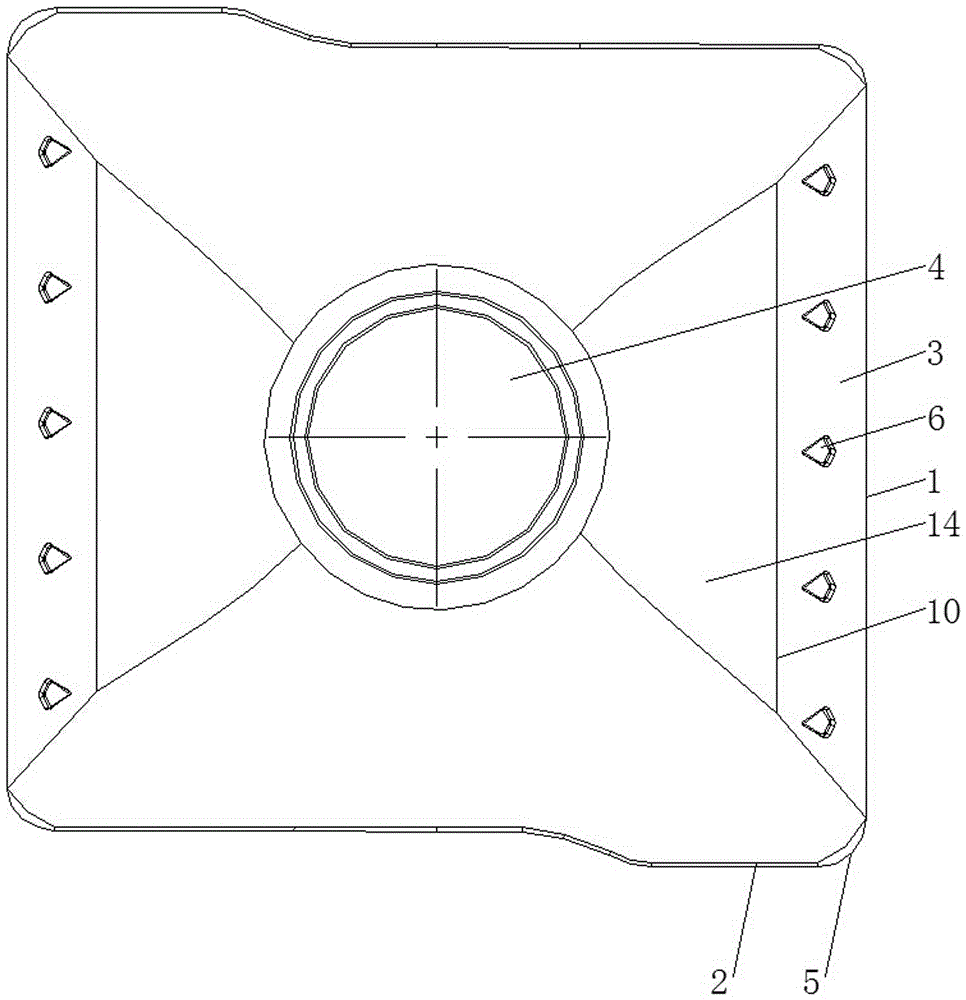

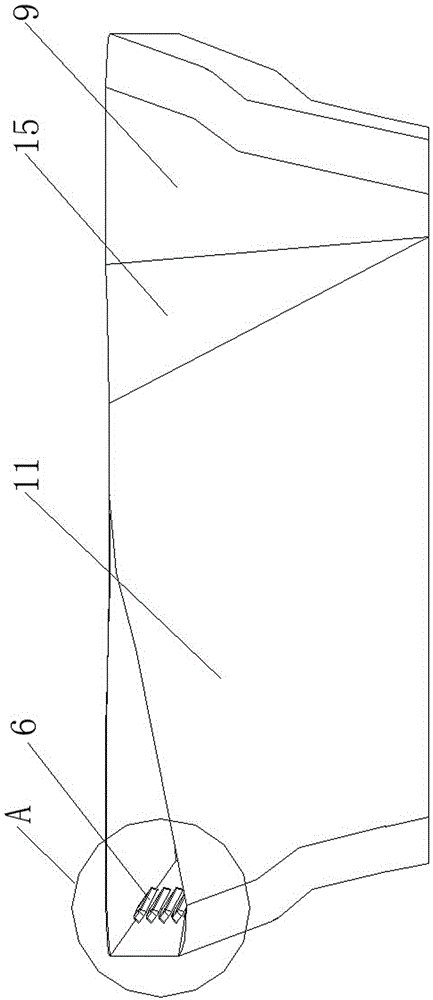

Working platform of multi-wire cutting machine

InactiveCN102049820AEasy accessReduce wearWorking accessoriesFine working devicesWire cuttingEngineering

The invention discloses a working platform of a multi-wire cutting machine, which adopts the scheme that that a metal wire is in point-contact with a workpiece during cutting. The working platform comprises a cutting sleeve (1) mounted on a working platform feeding device, and a working platform (5) equipped with a workpiece (6). The working platform is characterized in that a swinging device capable of enabling the working platform (5) to swing along the cutting center of the working platform (5) is arranged between the cutting sleeve (1) and the working platform (5). The working platform of the multi-wire cutting machine has simple structure, since the working platform capable of swinging in a reciprocating manner is adopted, and the workpiece is in point-contact with the metal wire array to be cut, the length of the contact surface of the metal wire to be cut and the workpiece is reduced greatly, namely the cutting resistance is dissolved, the abrasion of the metal wire to be cut is reduced, and the service life of the metal wire to be cut is prolonged, and at the same time, during the swinging process of the working platform, the grinding material can be enabled to better enter the incision, so that the cutting capacity and the cutting precision are improved.

Owner:HUNAN YUJING MACHINE

Muffler for an exhaust system of an internal combustion engine

ActiveUS20160281559A1Increase dampingIncrease contactSilencing apparatusMachines/enginesInterior spaceEngineering

A muffler for an exhaust system of an internal combustion engine, comprises a housing comprising a shell having an inner wall, an inlet pipe and an outlet pipe, the inlet pipe and the outlet pipe extending into an inner space of the housing, for conveying an exhaust gas stream into and out of the inner space of the housing, at least one baffle arranged in the inner space of the housing, the baffle comprising a baffle plate, the baffle plate having a circumference, and a baffle lip arranged at the circumference of the baffle plate, the baffle lip engaging the inner wall of the shell and having an end portion, wherein the end portion of the baffle lip is curved inwardly away from the inner wall of the shell.

Owner:BOSAL EMISSION CONTROL SYST

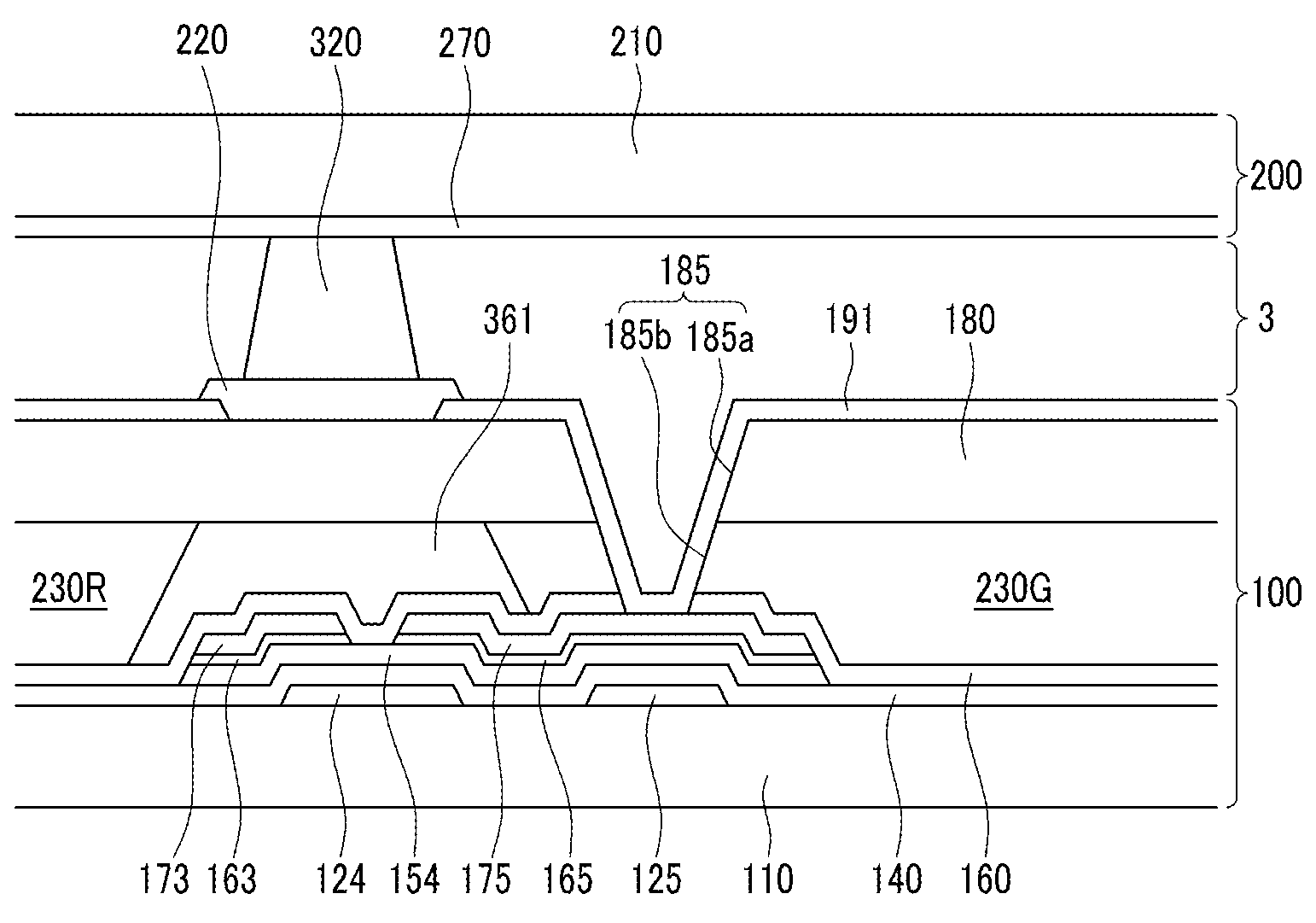

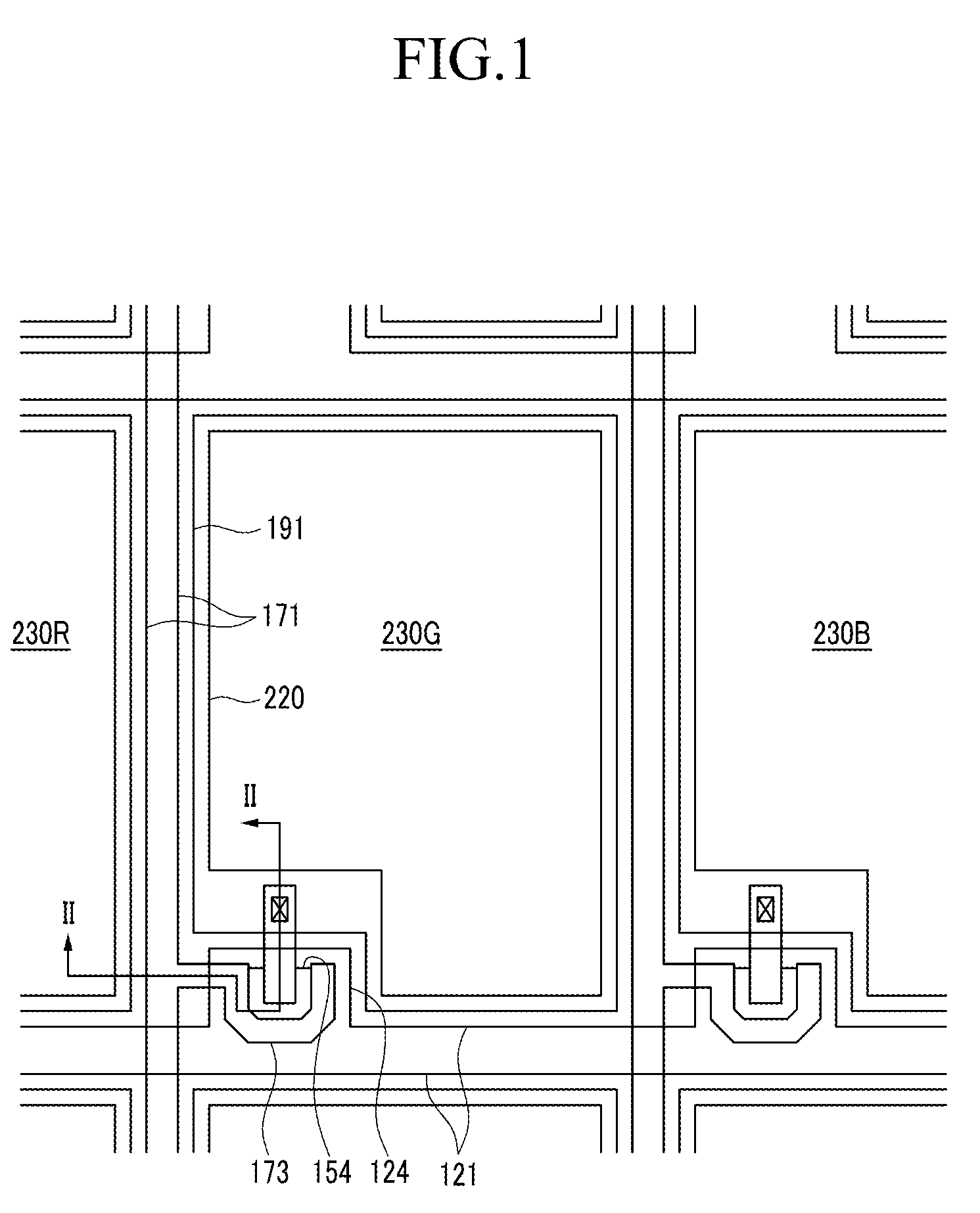

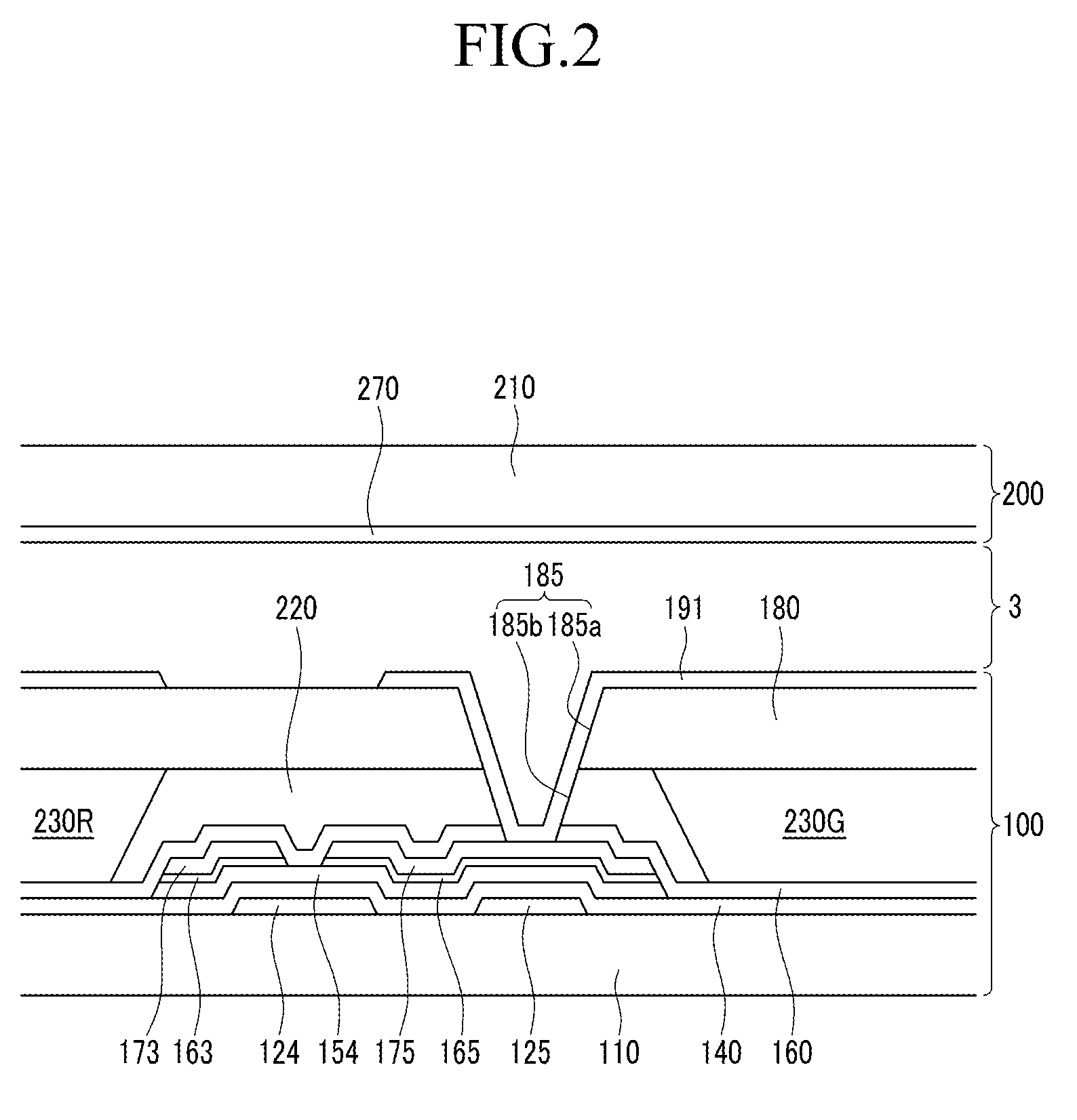

Thin film transistor substrate and method for manufacturing the same

ActiveUS20100019246A1Simple to executeReduce contact lengthSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method for manufacturing a thin film transistor array panel includes; forming a gate line including a gate electrode and a height increasing member on a substrate, forming a gate insulating layer on the gate line and the height increasing member, forming a semiconductor, a data line including a source electrode, and a drain electrode facing the source electrode and overlapping at least a portion of the height increasing member on the gate insulating layer, forming a first insulating layer on the gate insulating layer, a data line and the drain electrode, forming a light-blocking member on a portion of the first insulating layer corresponding to the gate line and the data line, forming a color filter in an area bound by the light-blocking member, forming a second insulating layer on the light-blocking member and the color filter, and patterning the second insulating layer, the light-blocking member or the color filter, and the first insulating layer to form a contact hole exposing a portion of the drain electrode aligned with the height increasing member.

Owner:SAMSUNG DISPLAY CO LTD

Crawler travel gear and crawler-mounted crane

InactiveCN102145716AReduce contact surfaceReduce steering effortStatic/dynamic balance measurementEndless track vehiclesEngineeringMechanical engineering

Owner:LIEBHERR WERK EHINGEN

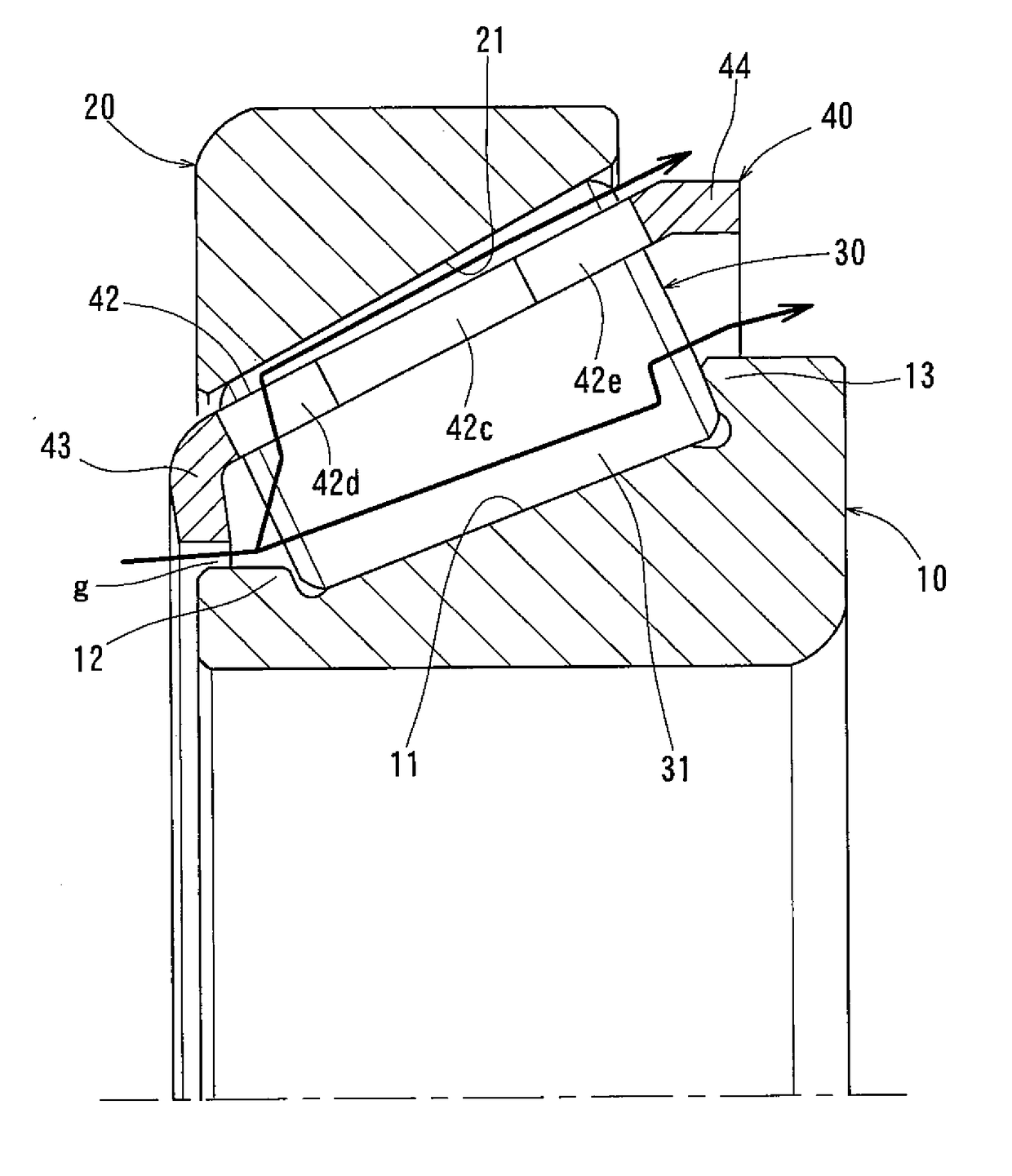

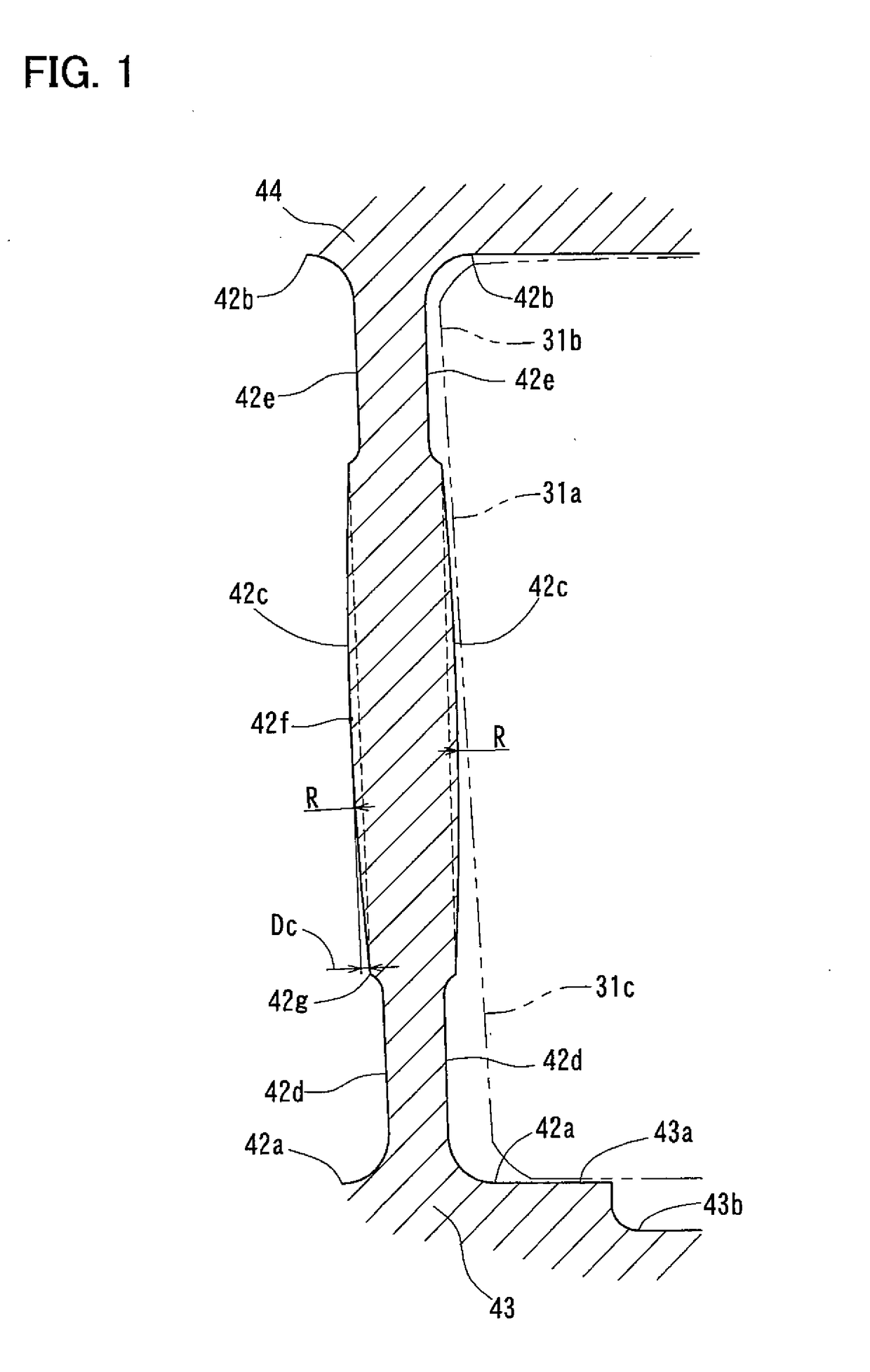

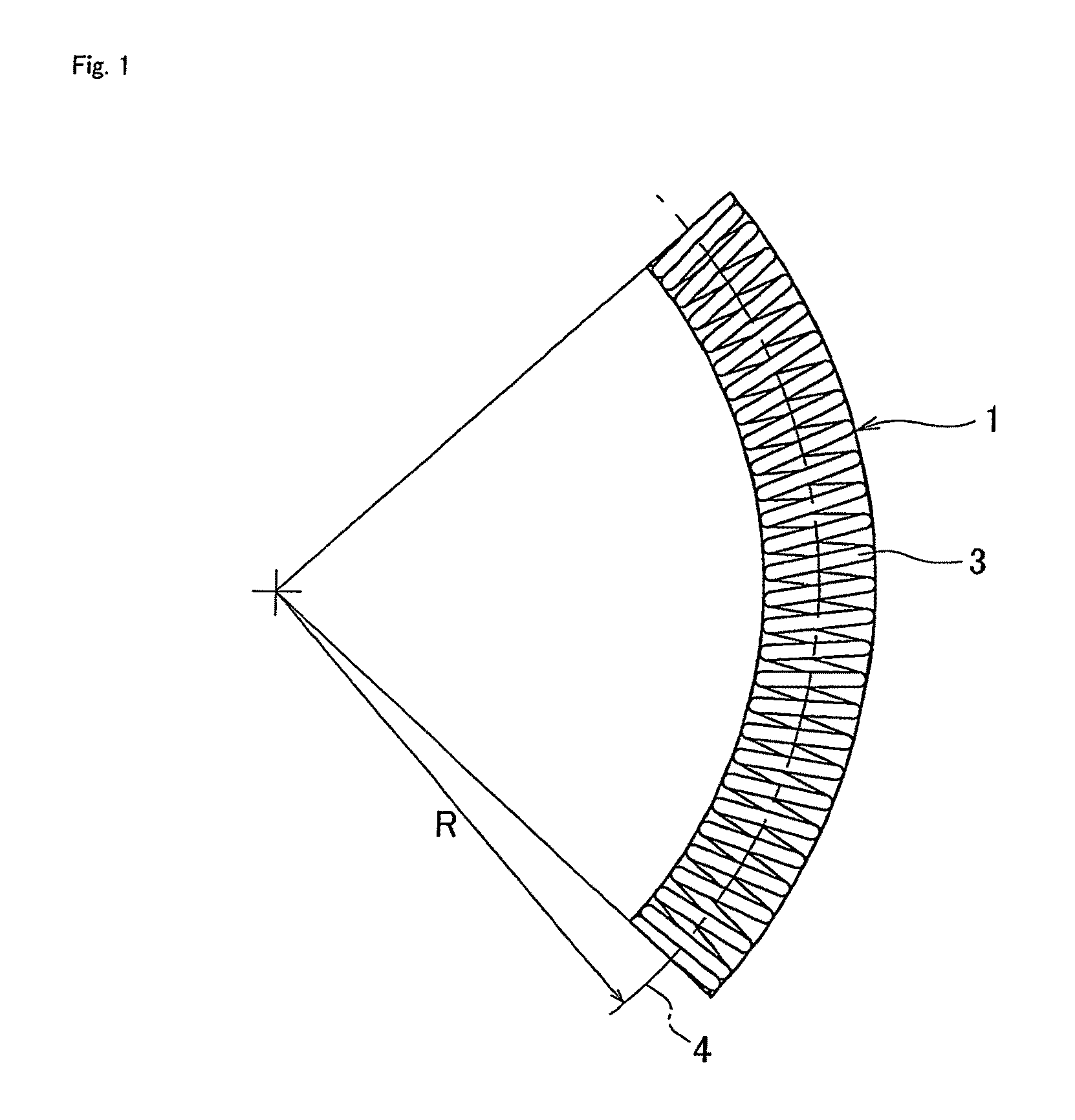

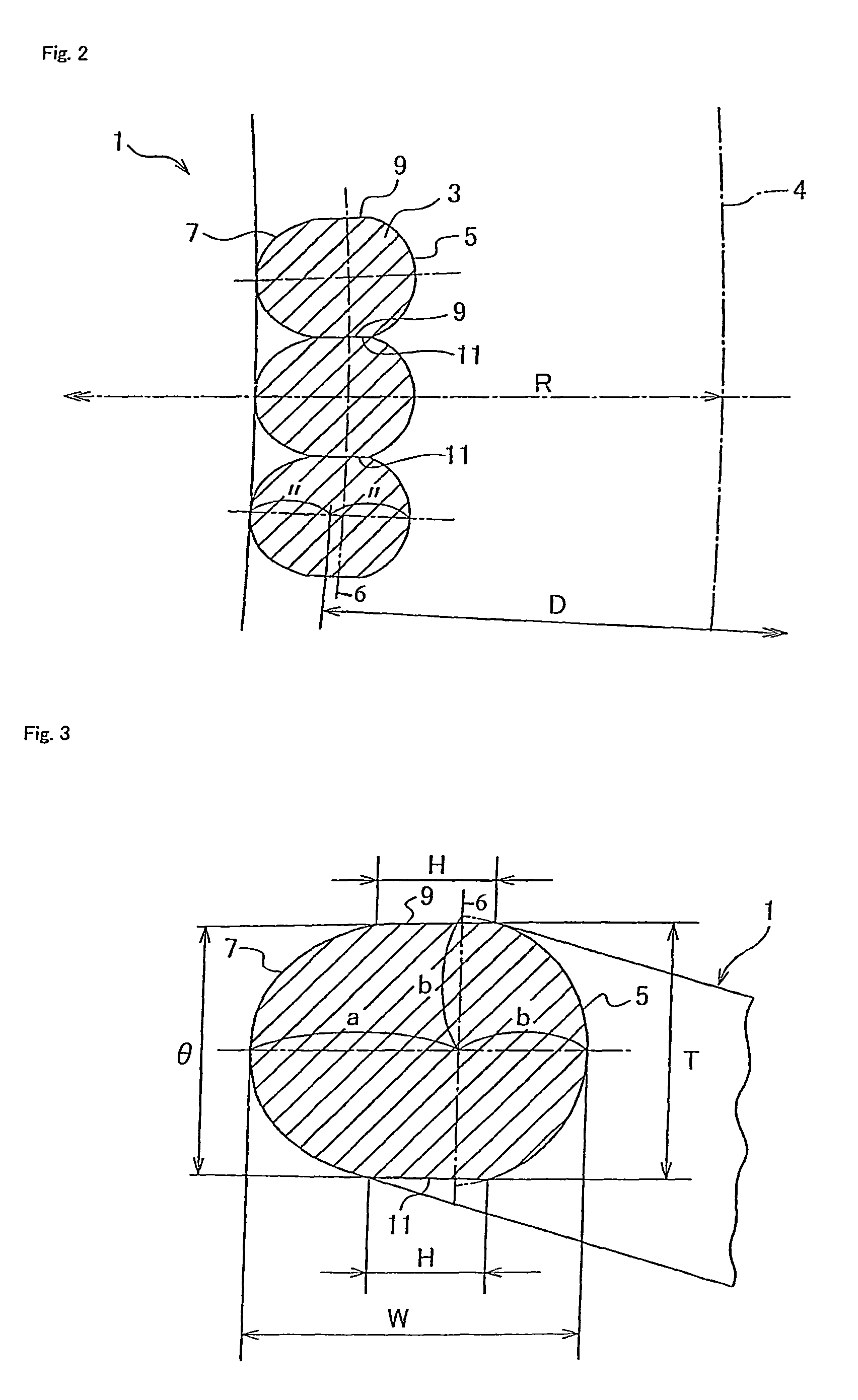

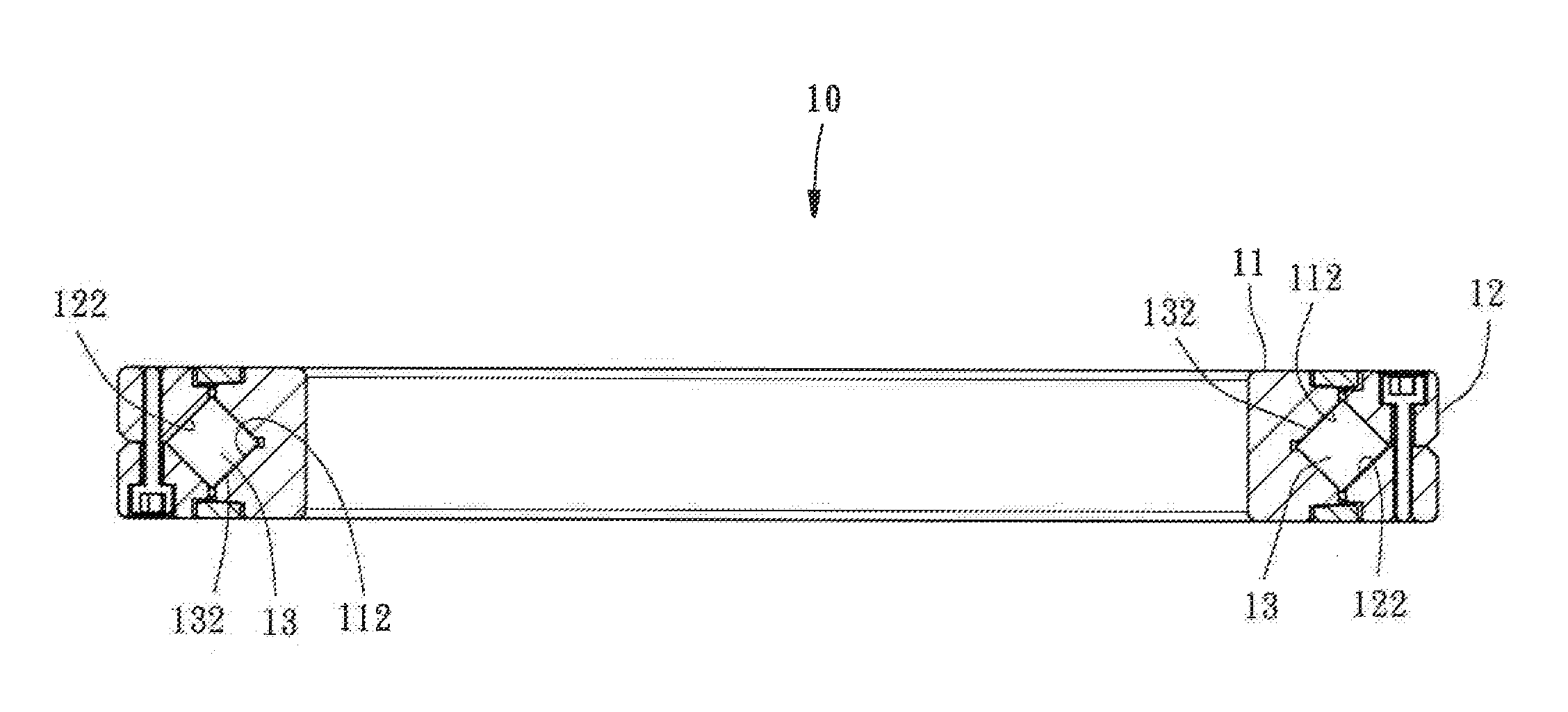

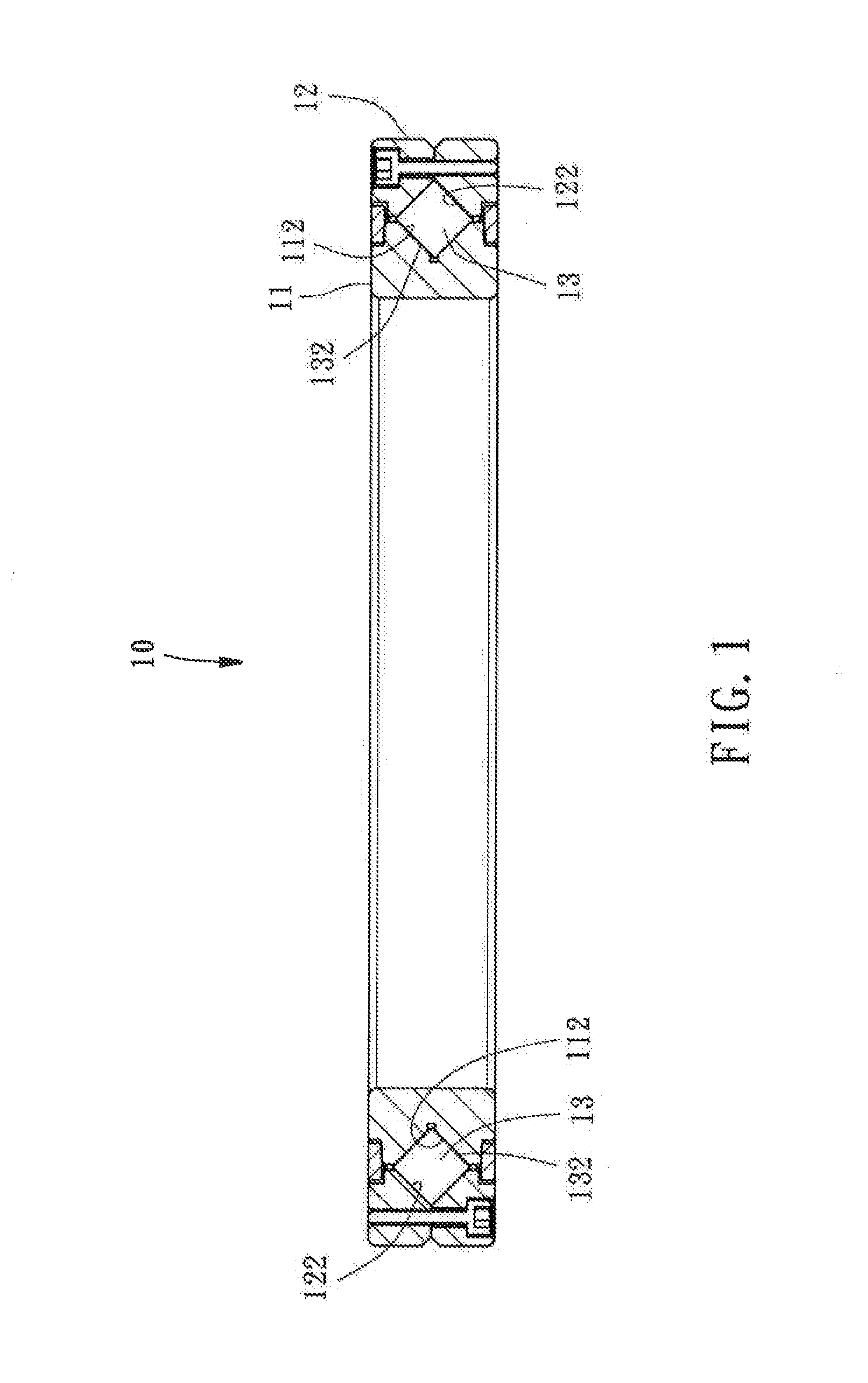

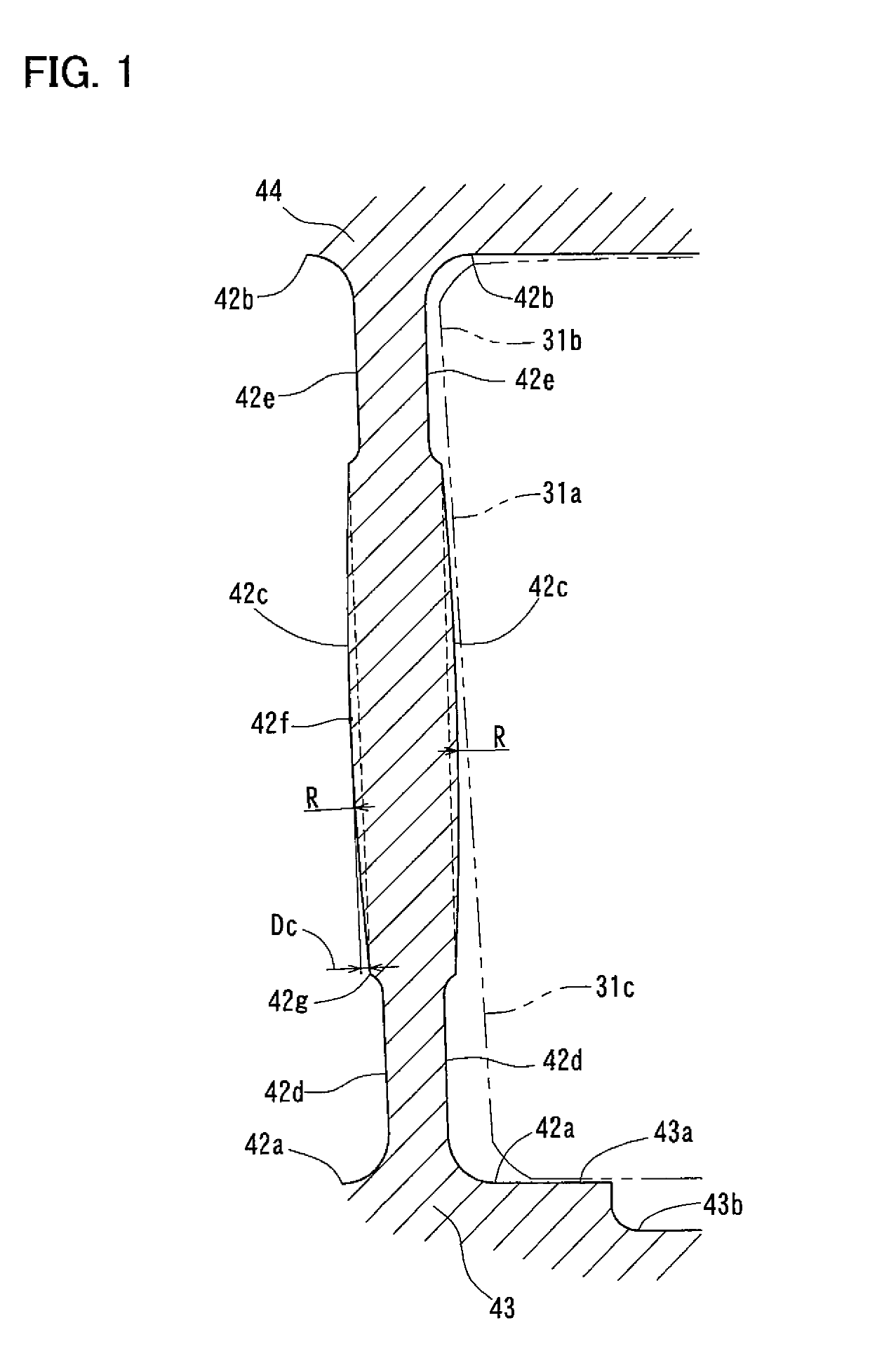

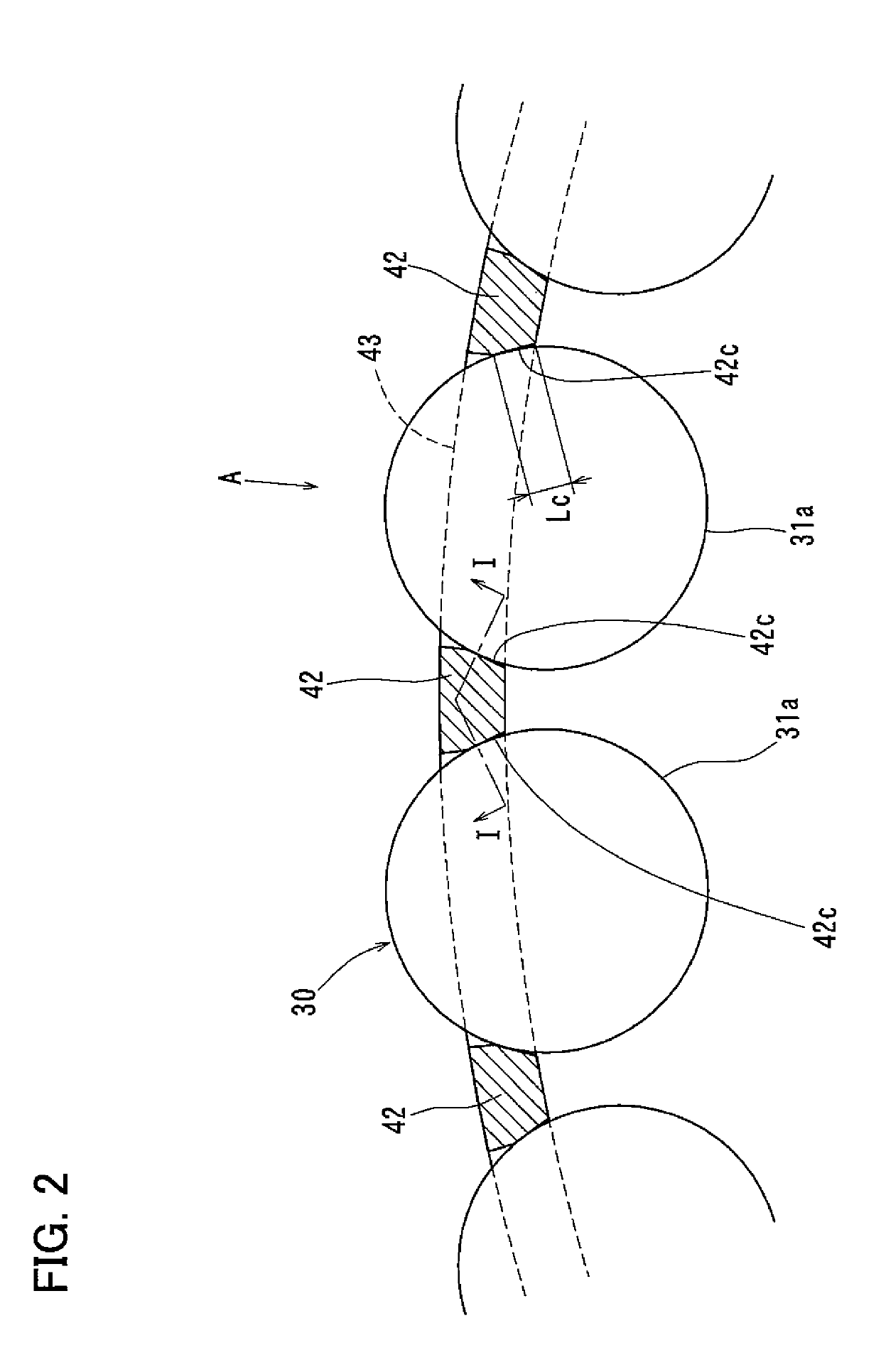

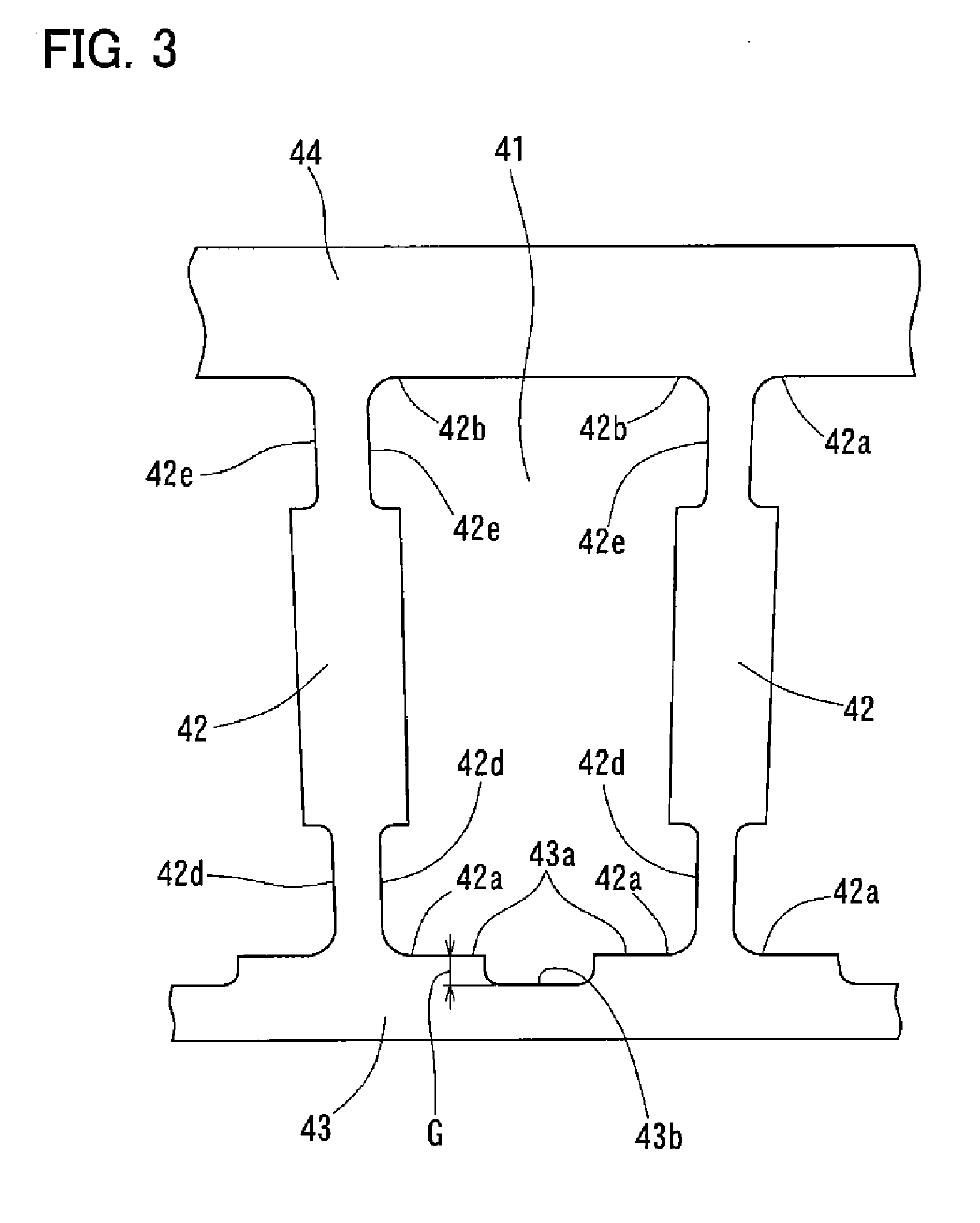

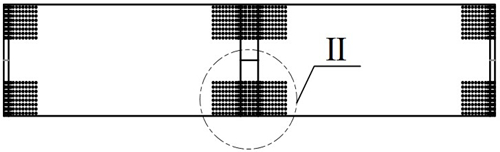

Retainer and tapered roller bearing

ActiveUS20180245627A1Reduces contact lengthReduce rotation torqueRoller bearingsShaftsEngineeringRoller bearing

A retainer of a tapered roller bearing includes crossbars having guide surfaces which circumferentially contact the tapered rollers, and formed with first recessed surfaces and second recessed surfaces which are both in the form of cutouts circumferentially recessed from the respective guide surfaces, to reduce stirring resistance and shear resistance of oil. To reduce the contact lengths between the rolling surface central portions of the tapered rollers and the guide surfaces, the guide surfaces are smoothly convex in the longitudinal direction of the tapered rollers.

Owner:NTN CORP

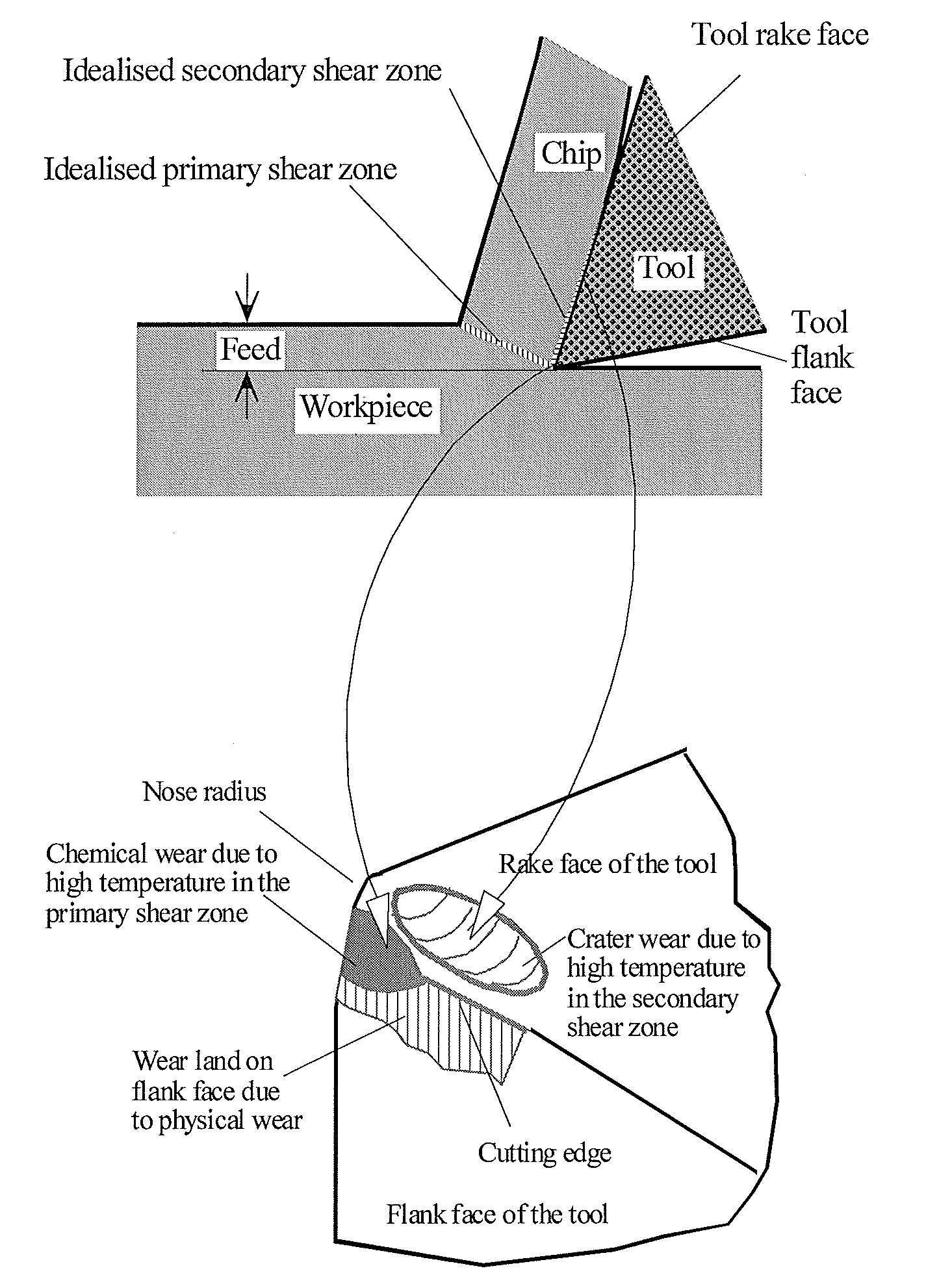

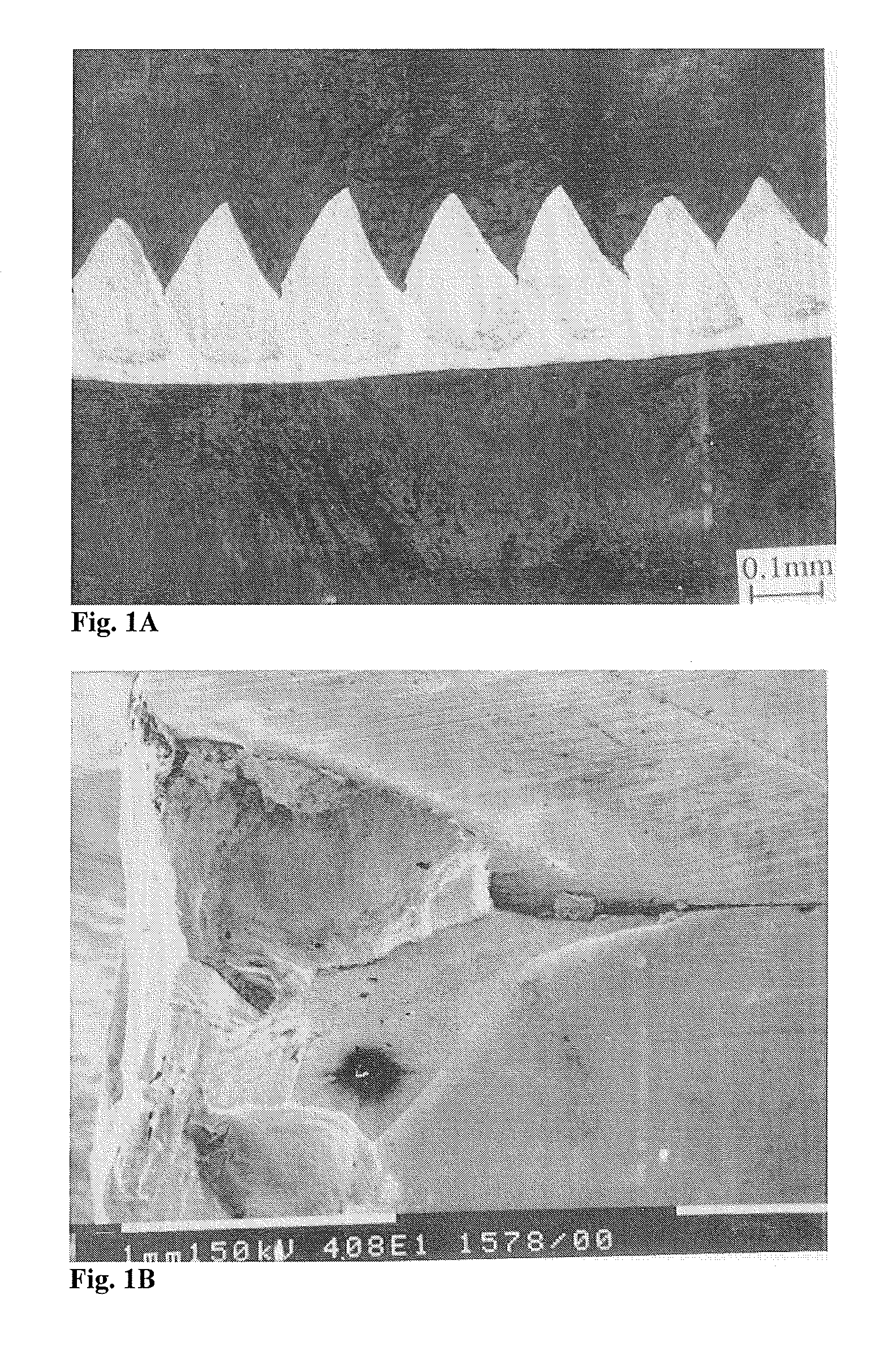

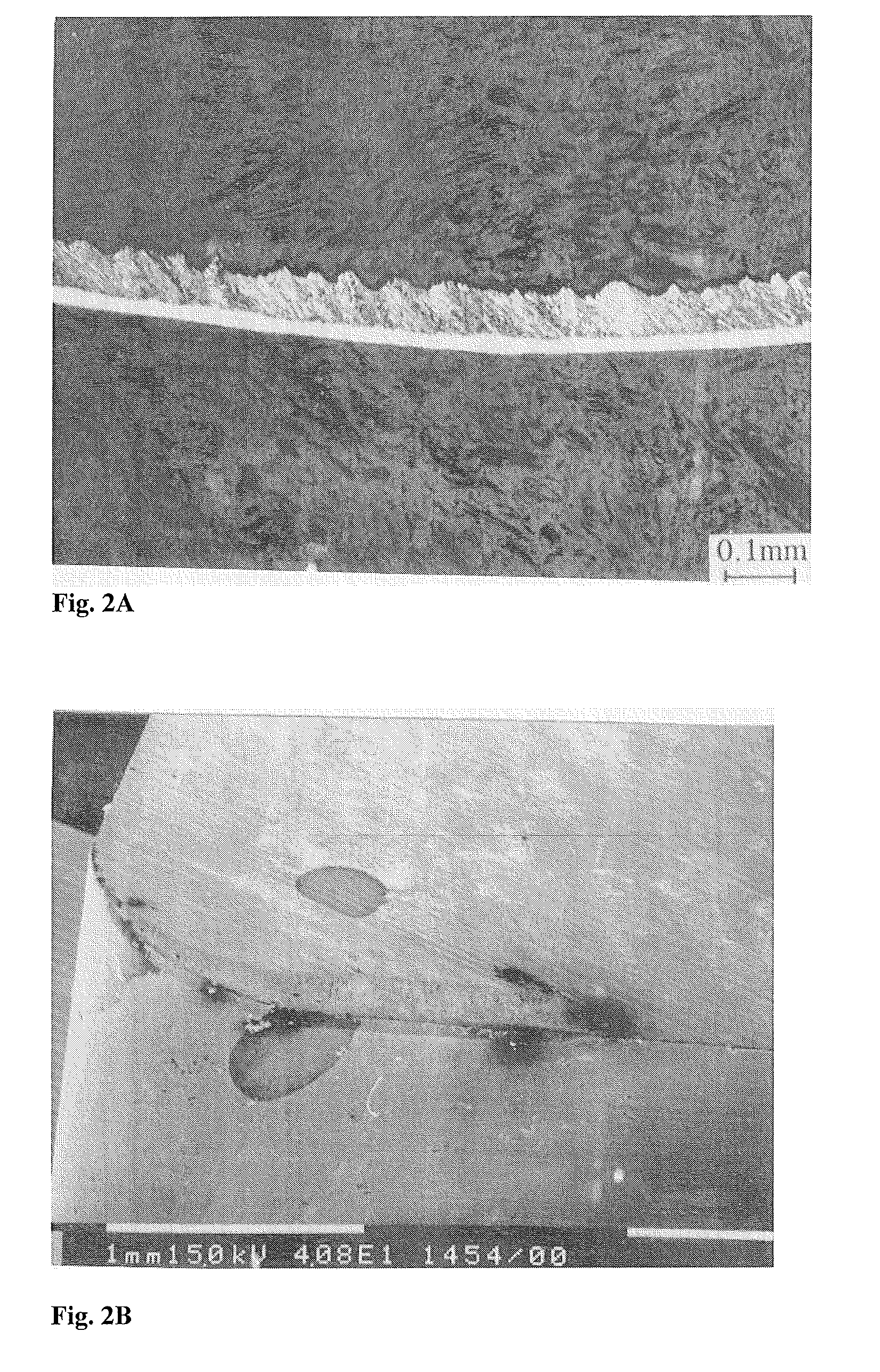

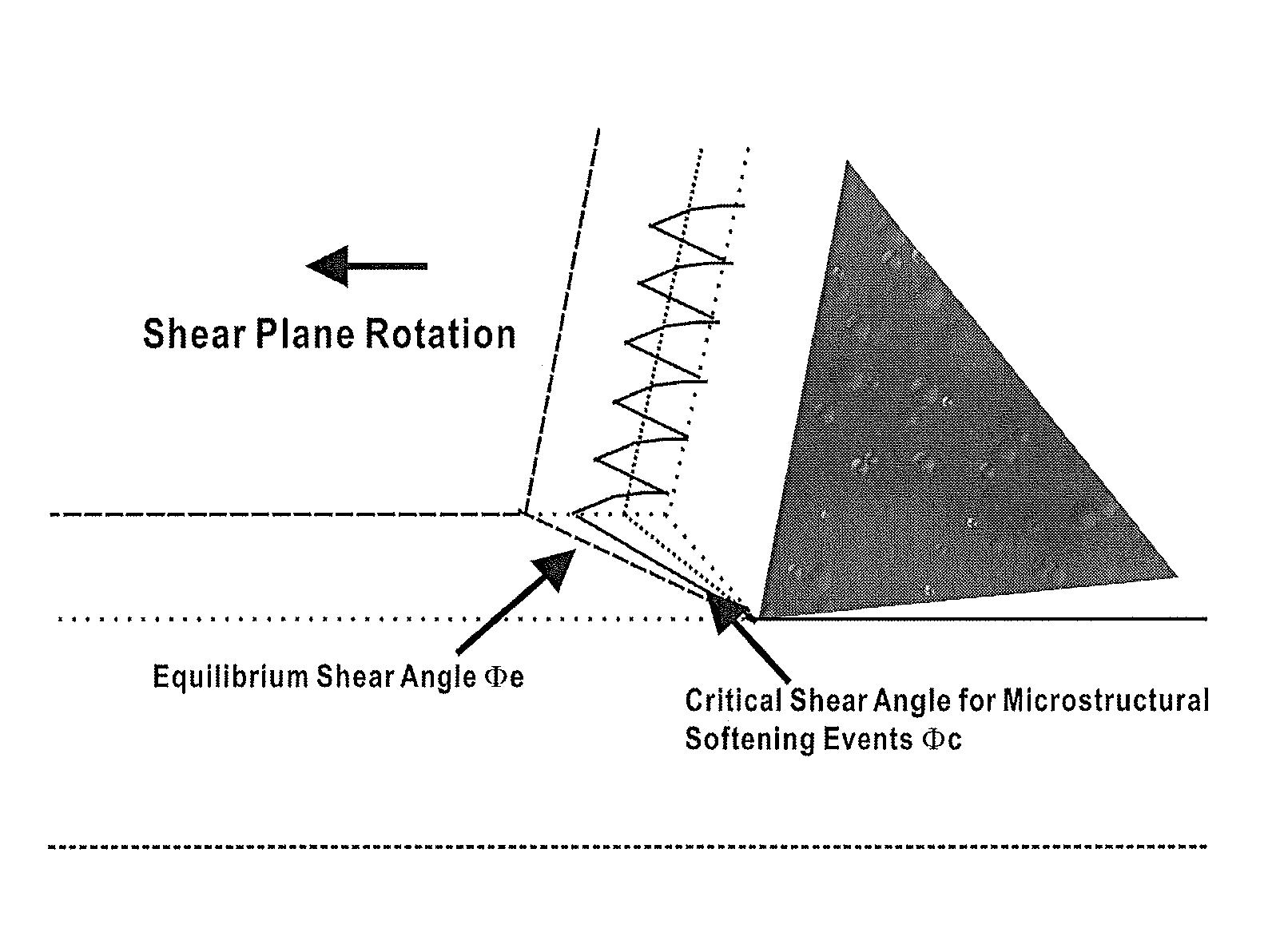

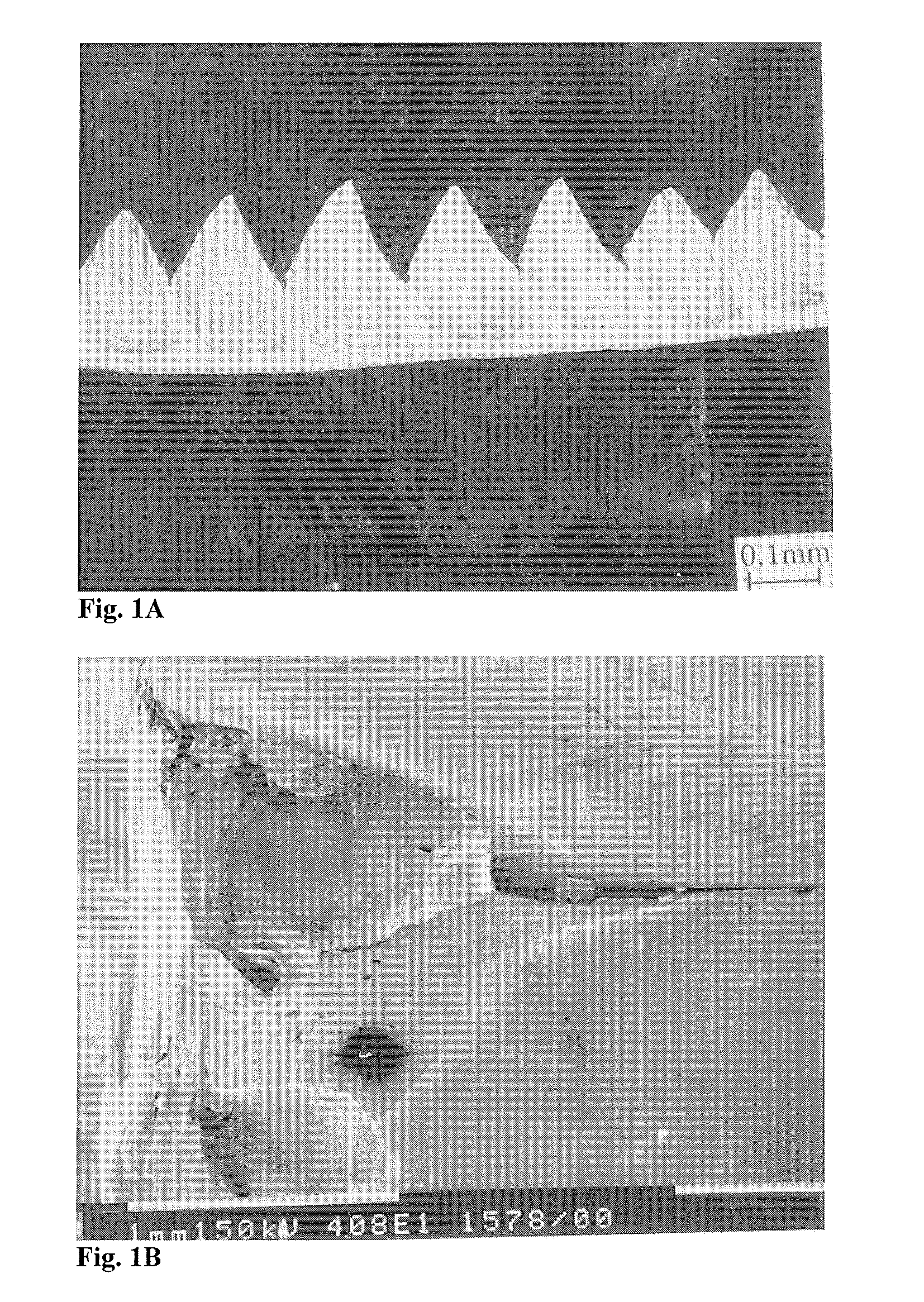

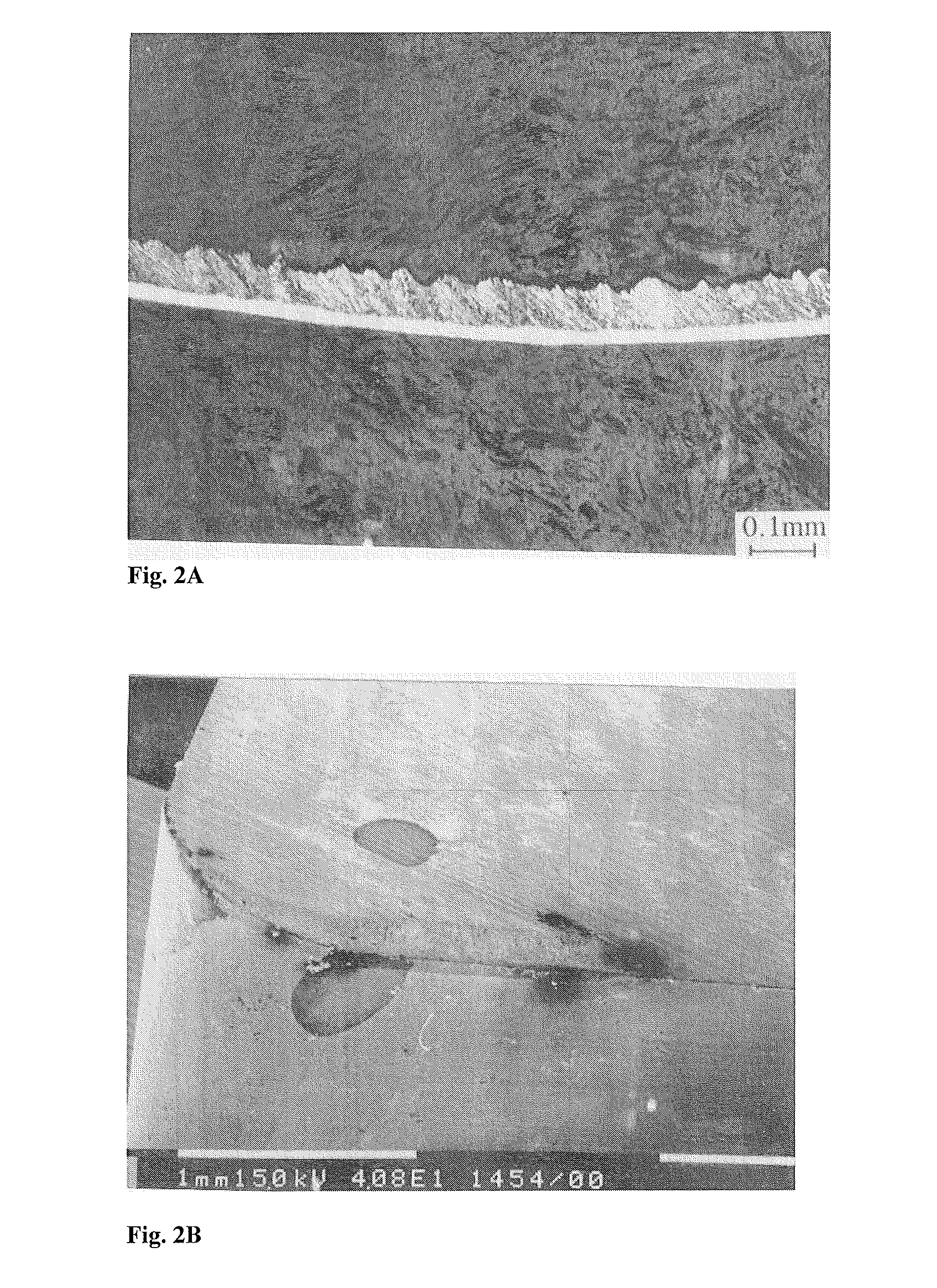

Processes for improving tool life and surface finish in high speed machining

InactiveUS20100086369A1Enhanced grain boundary diffusionReduce wearLathesAutomatic/semiautomatic turning machinesPerformance toolEngineering

Processes for high speed machining of workpiece materials using high performance tools with prolonged tool life and improved surface finish are provided by vibrating the tool and / or the workpiece at a frequency greater than the frequency of shear localization in the primary shear zone or chip segmentation occurring in the absence of tool vibration, with an amplitude sufficient to break up the tool-chip atomic contact, thereby decreasing the tool-chip contact length through decreasing the tool-chip contact time, thereby suppressing accelerated chemical tool wear caused by dissolution of the tool into the workpiece by nanocrystalline grain boundary diffusion and grain boundary sliding mechanisms by preventing shear localization associated with nanocrystalline grain formation in the primary shear zone of the chip, and suppressing oxidation wear of the tool by preventing segmentation of the chip.

Owner:SUBRAMANIAN SUNDARESA V

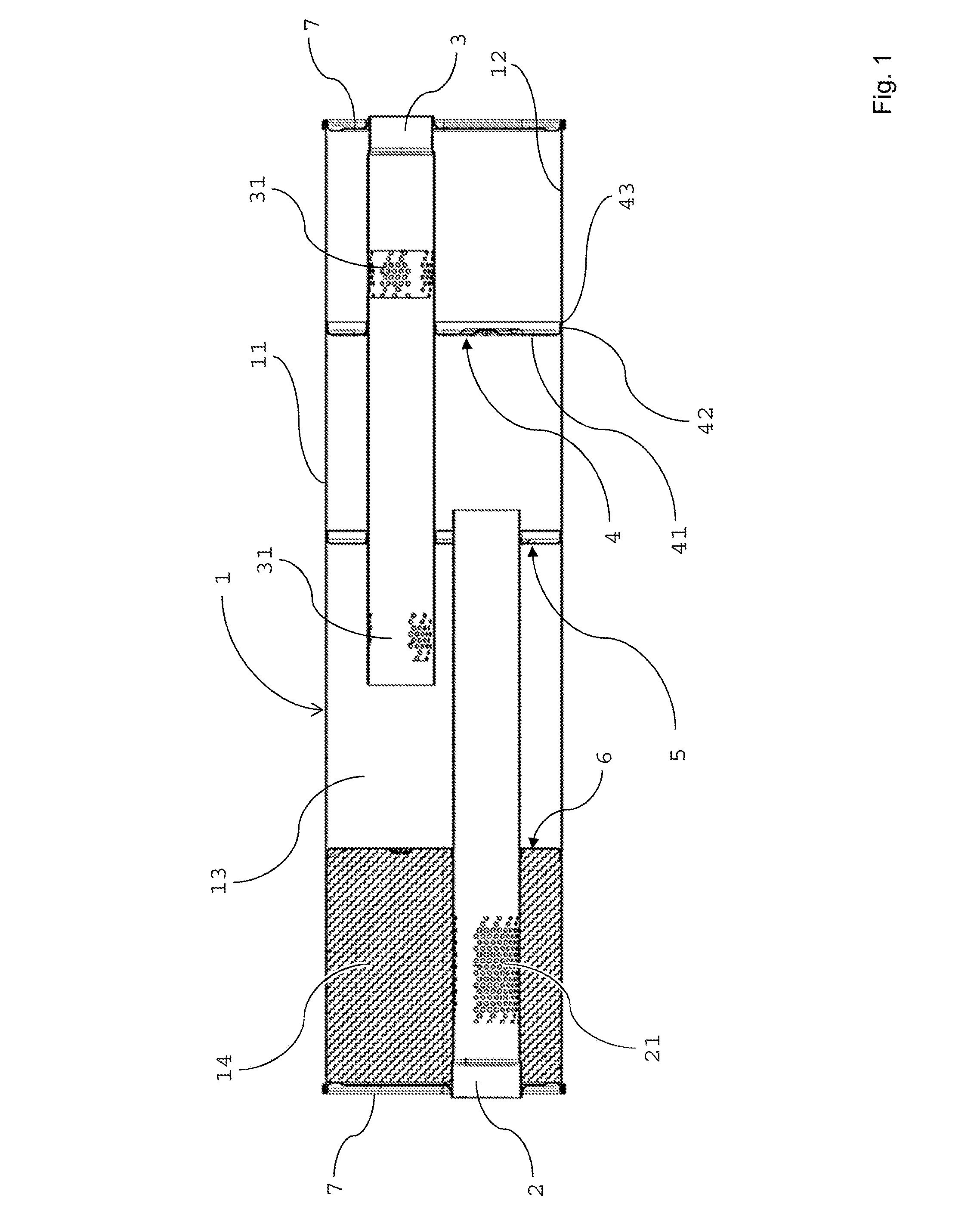

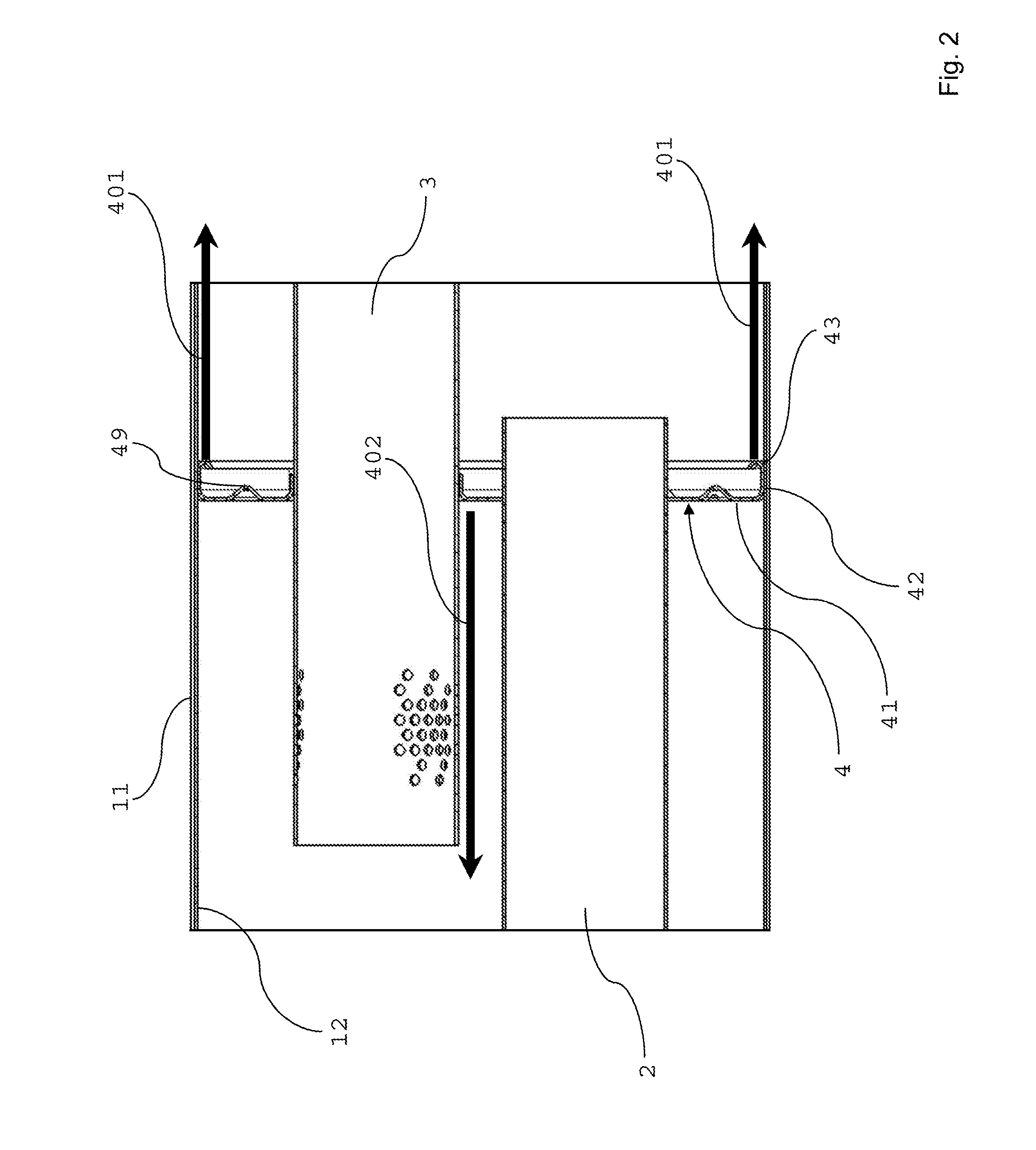

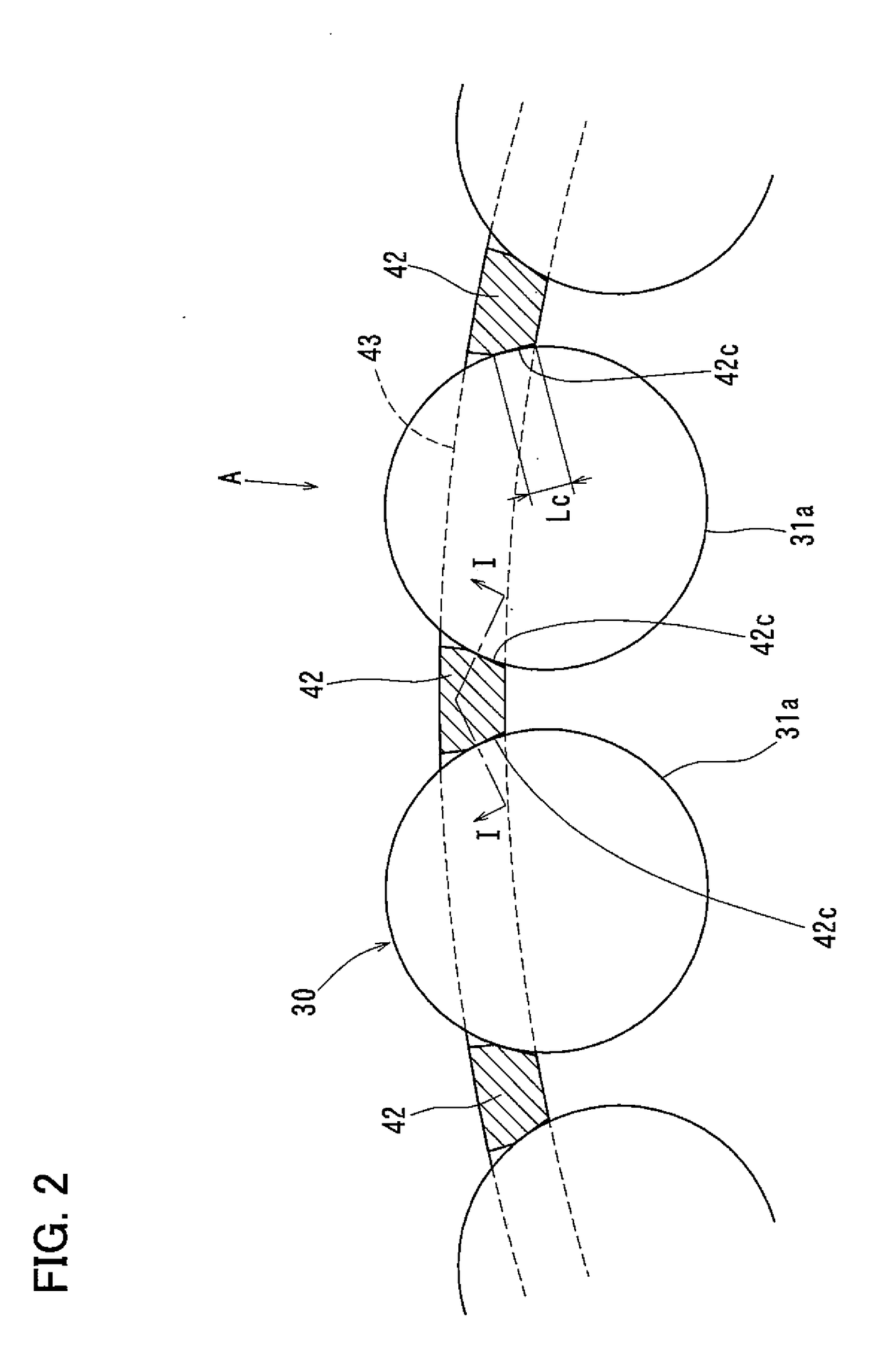

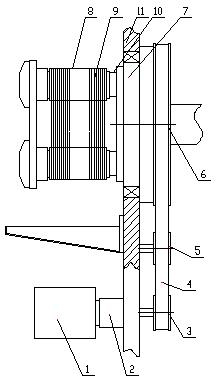

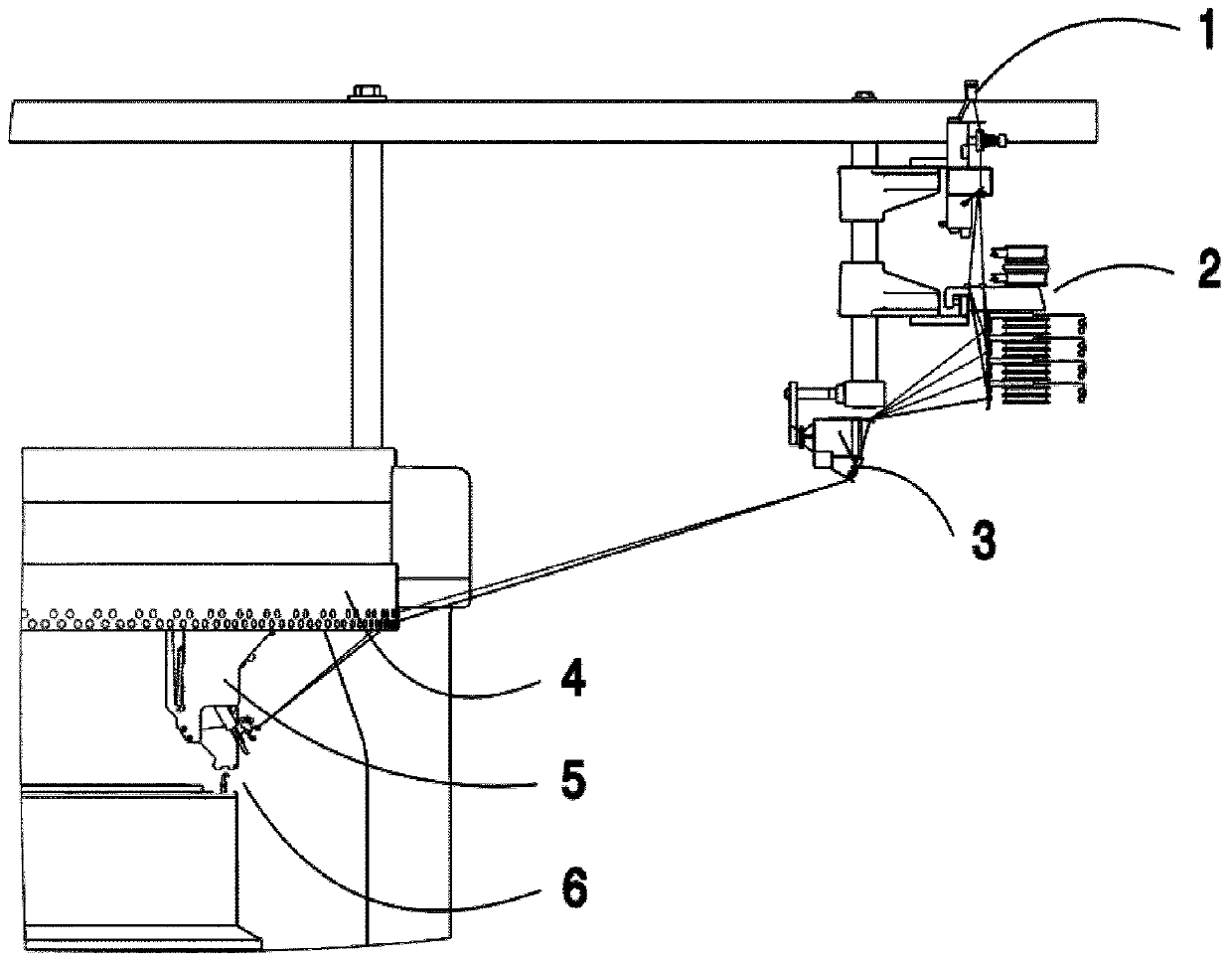

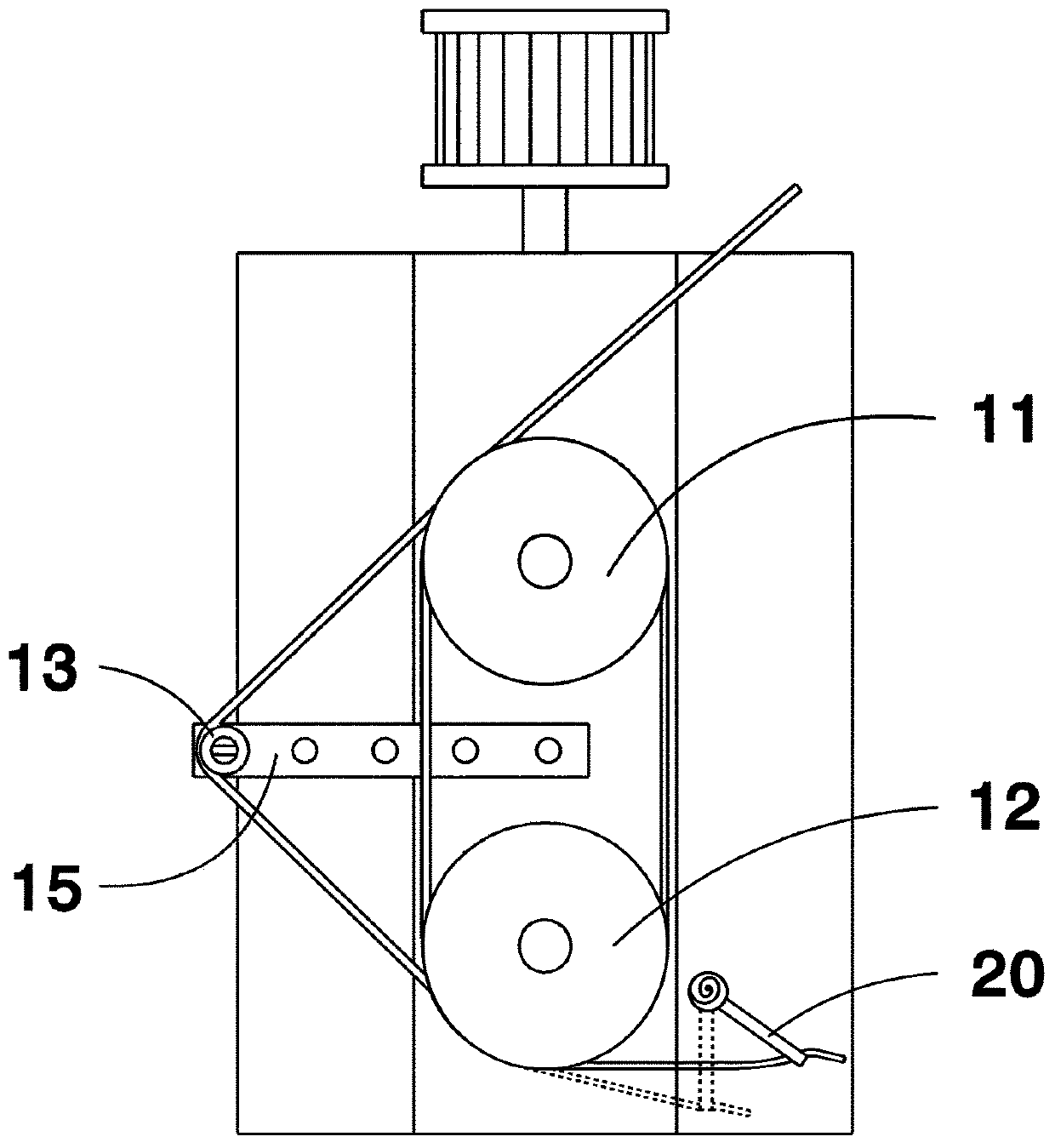

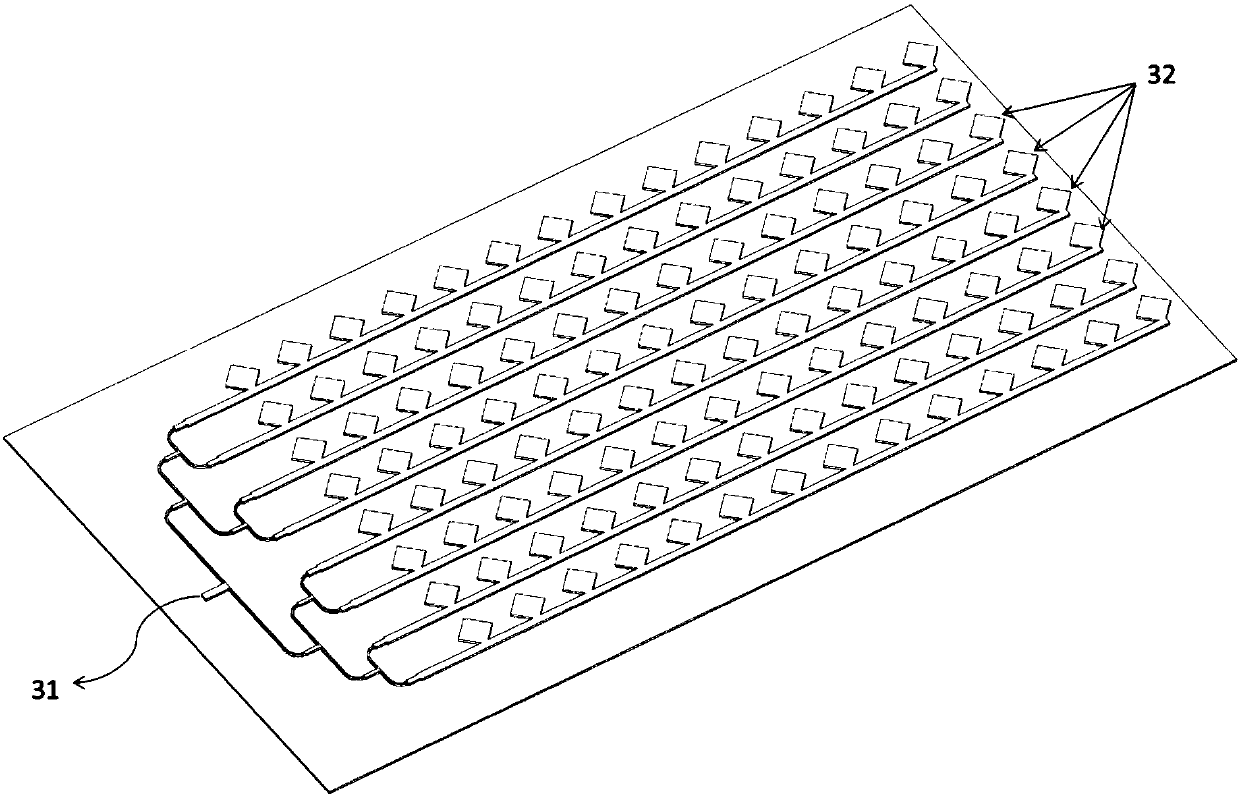

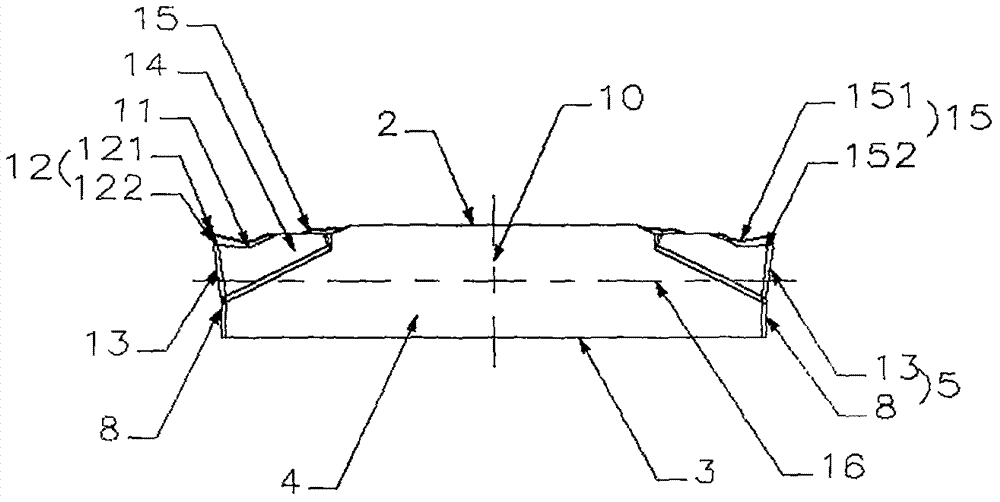

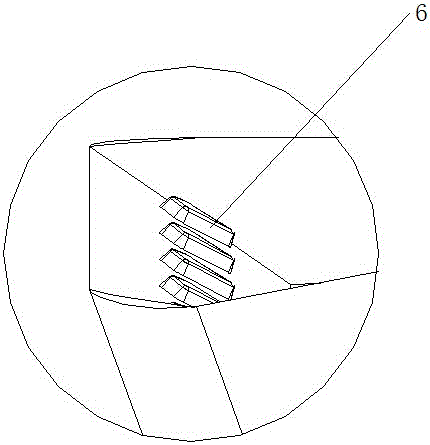

Cutting rollers of multi-wire cutting machine

The invention discloses cutting rollers of a multi-wire cutting machine for point contact of a metal wire and a workpiece during cutting. The multi-wire cutting machine comprises a rack (11), and is characterized in that: the rack (11) is provided with a rocker panel (7) driven by power, and a cutting roller set consisting of the cutting rollers (8) is arranged on the rocker panel (7) through a support seat (10). The cutting roller has a simple structure; the reciprocating swing cutting roller is adopted, and the workpiece is in point contact with a cutting wire array, so the contact face length of the cutting metal wire and the workpiece is greatly reduced, the cutting resistance is weakened, the abrasion of the cutting metal wire is also reduced, and the service life of the cutting metal wire is prolonged; and meanwhile, the abrasive better enters a shear mark in the swing process of the cutting roller, so the cutting capability is improved, and the cutting precision is also improved.

Owner:HUNAN YUJING MACHINE

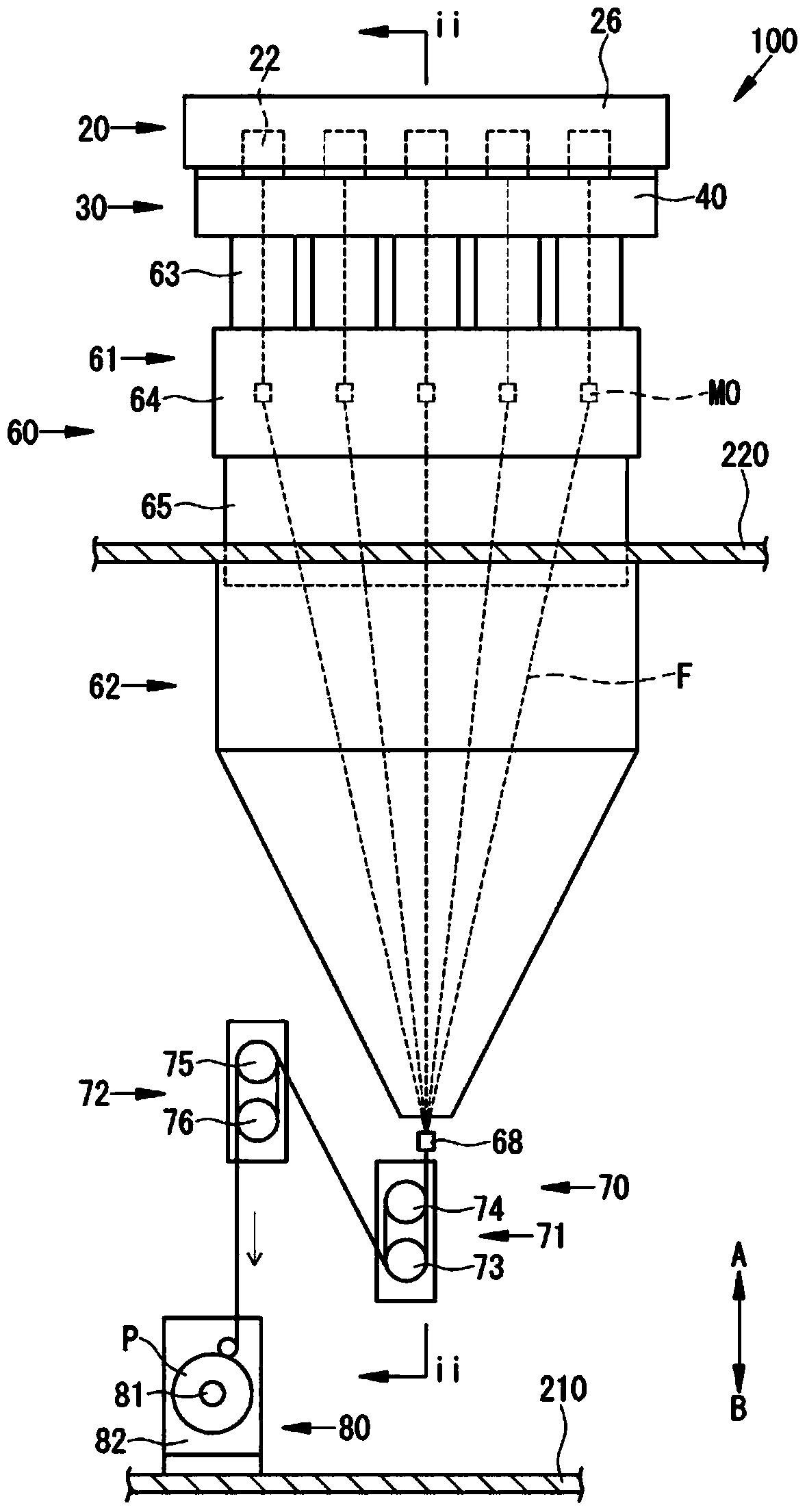

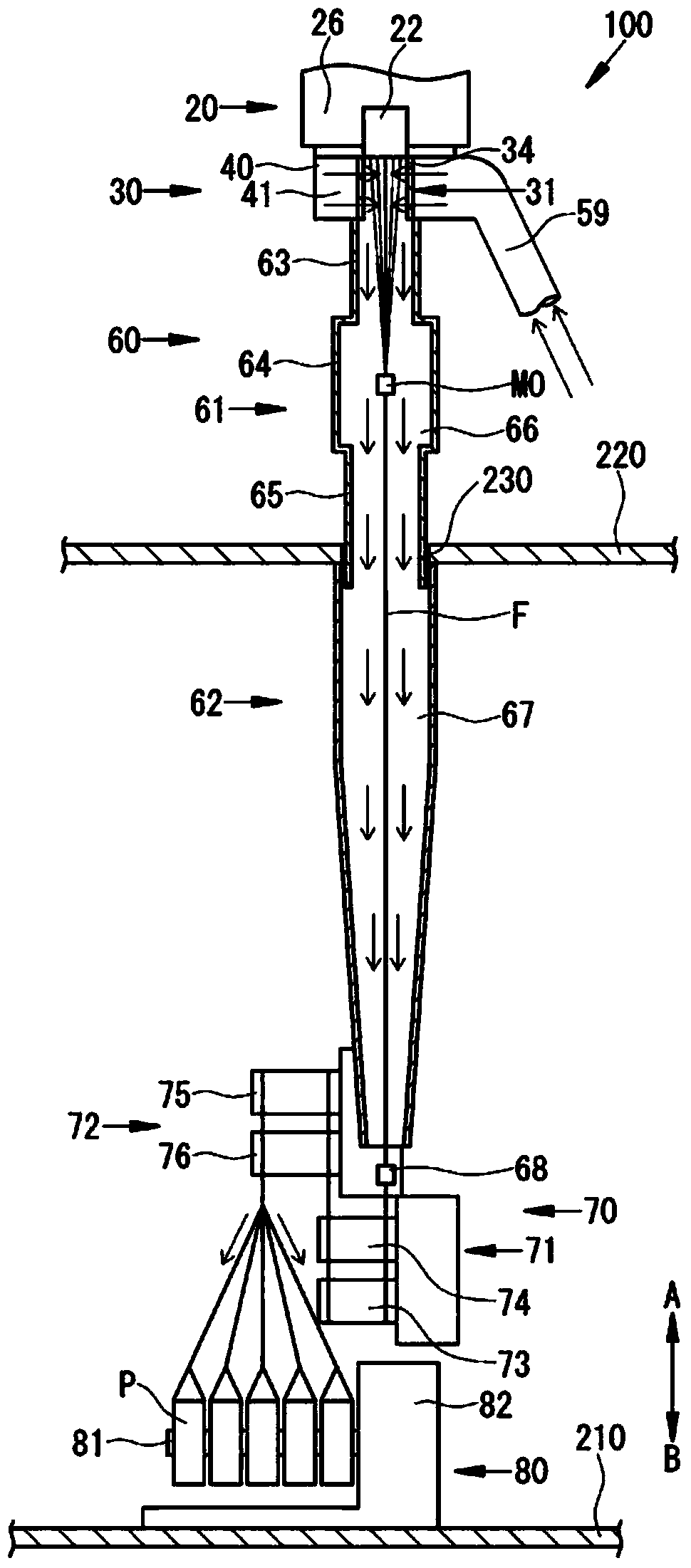

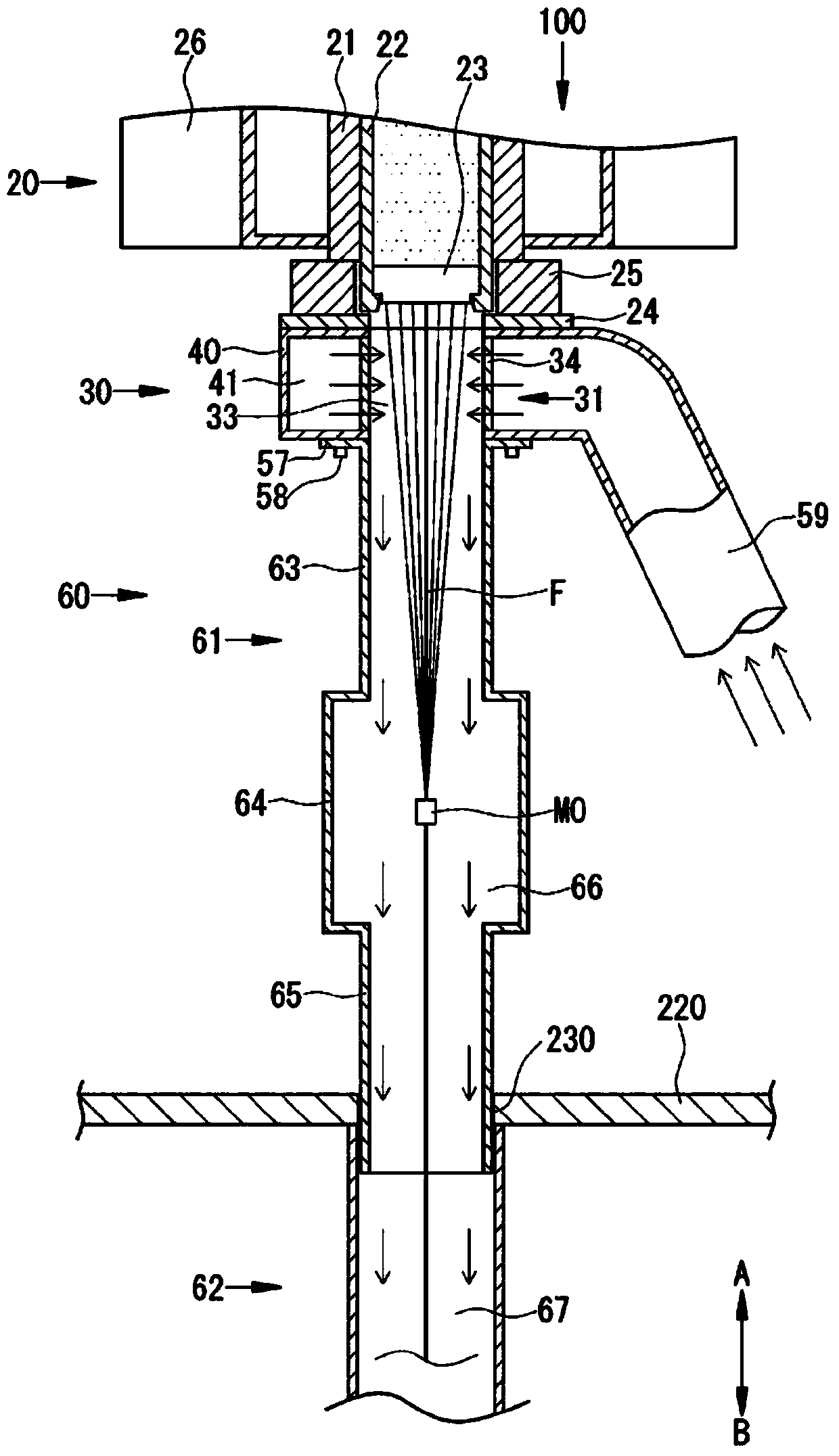

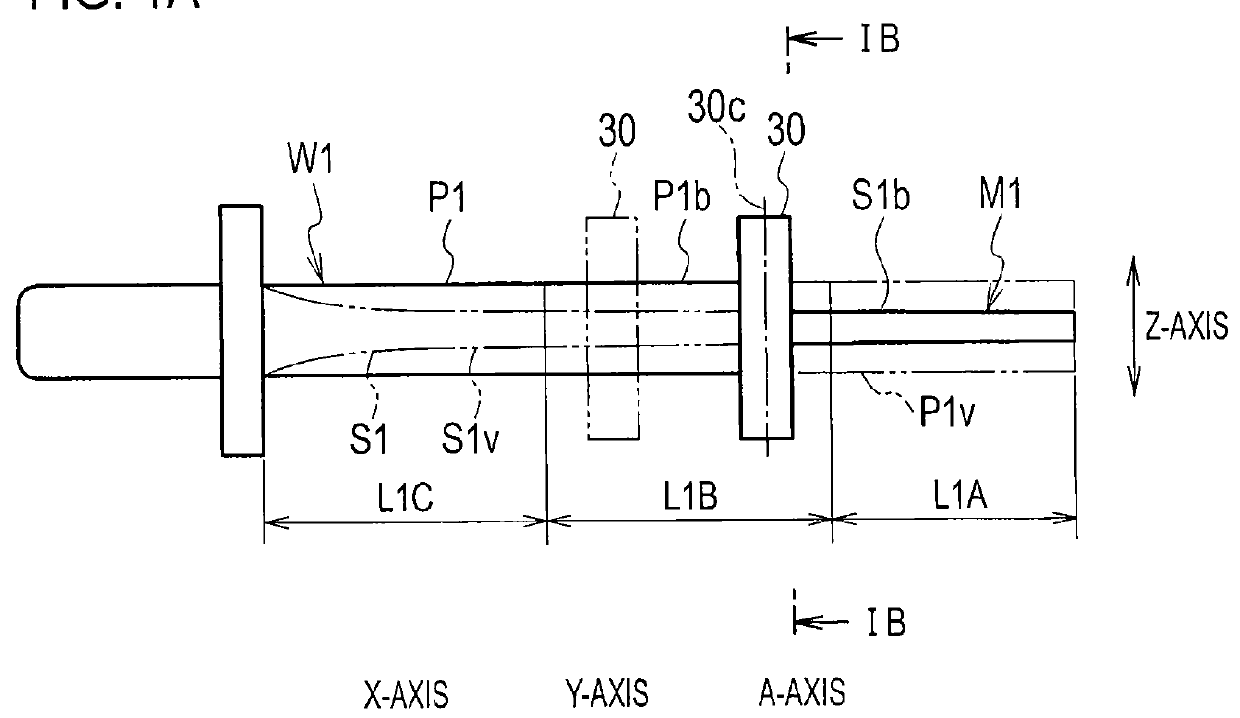

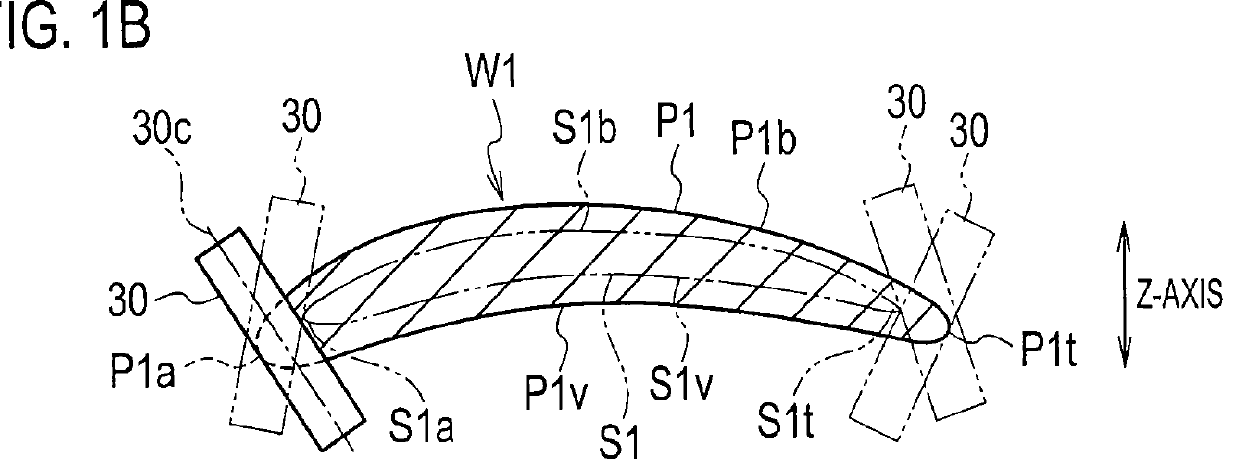

Spinning winding device

ActiveCN103966679AReduce the temperatureReduce temperature changesNew-spun product collectionStretch-spinning methodsSpin outFiber bundle

The invention aims to provide a spinning winding device which, by inhibiting temperature drop of a fiber bundle in a path from a cooling device to a heating stretching device and enabling the temperature of the fiber bundle in front of the heating stretching device to be higher than before, can shorten contact time with a heating roller and contact length required by heating the fiber bundle to above a specified temperature (glass transition point temperature). Specifically, the spinning winding device includes a spinning device which spins out a plurality of fiber bundles from fused material, a cooling device for fiber bundles spinned out by an air cooling spinning device, a heating stretching device which heats at a downstream side of a traveling direction of the fiber bundles of the cooling device and stretches the fiber bundles, and a winding device which winds the fiber bundles at a downstream side of the traveling direction of the fiber bundles of the heating stretching device; and the spinning winding device has a traveling space for the fiber bundles to travel from the cooling device to in front of the heating stretching device, and an attemperator which guides air used by the cooling device for cooling the fiber bundles to inside the traveling space.

Owner:TMT MACHINERY INC

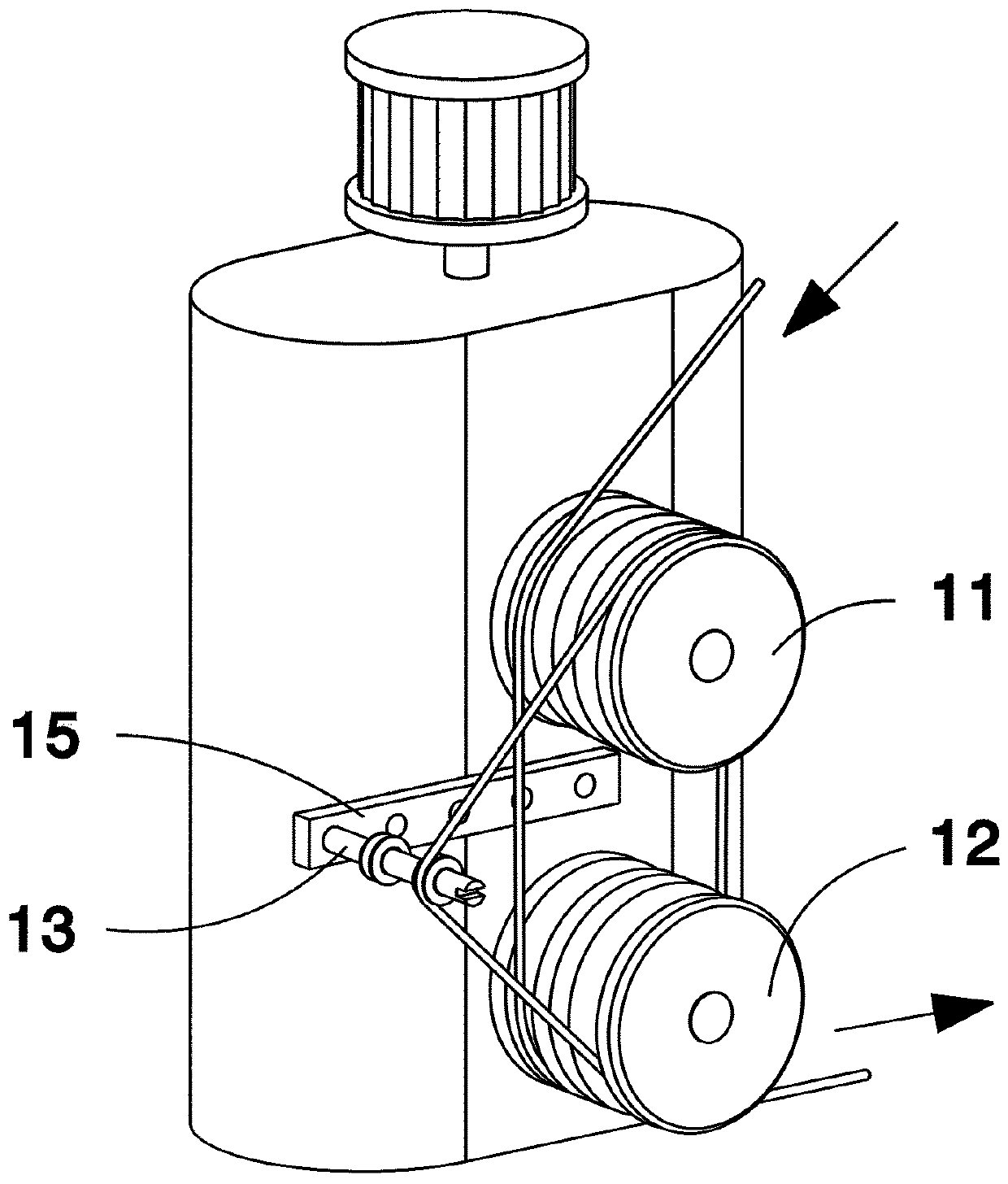

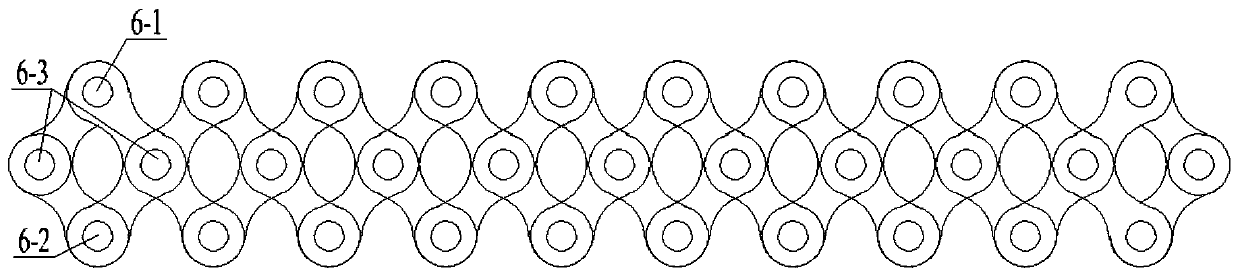

Friction feeder

InactiveCN110073043AReduced friction disturbanceReduce frictionFilament handlingCircular knitting machinesYarnEngineering

The invention relates to a friction feeder for receiving a plurality of threads from one or more corresponding thread delivery devices and feeding at least one of the threads to a thread-processing point of a knitting machine. At least two rollers arranged parallel to each other receive the threads and transport the threads in that the threads are carried along by the rollers by friction on the roller surfaces. A deflecting element is used to adjust the carry-along force applied by the rollers to at least one of the threads, wherein the rollers are arranged in such a way that the threads can be wrapped around both together at least once. The deflecting element can be set in such a way that the deflecting element deflects the thread or threads in a section of the course of the thread wrap between the rollers in such a way that the angle of wrap of the thread or threads around the rollers and thus the contact length of the thread or threads with the roller surfaces can be increased or decreased.

Owner:SIPRA PATENTENTWICKLUNGS & BETEILIGUNGSGMBH

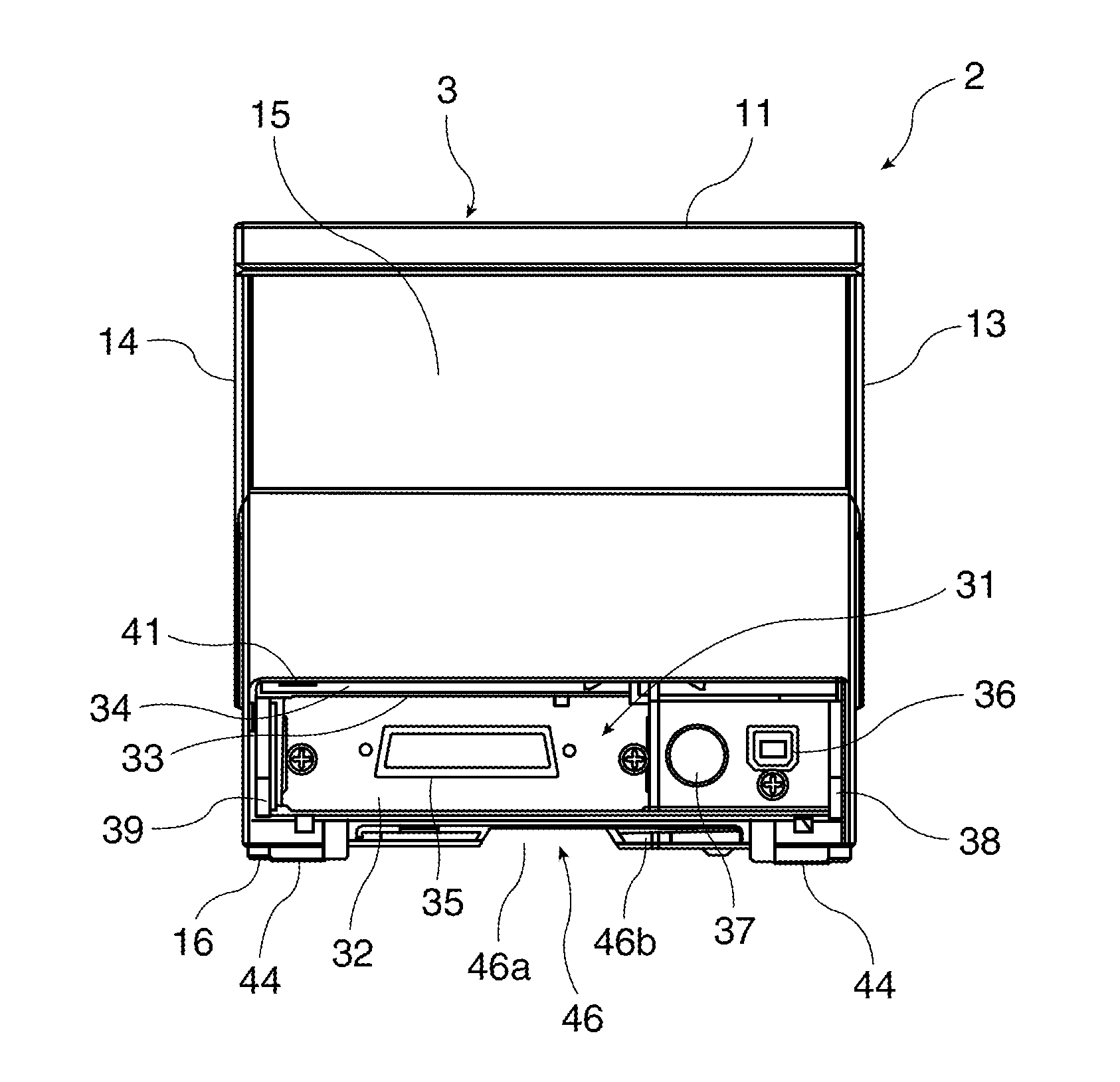

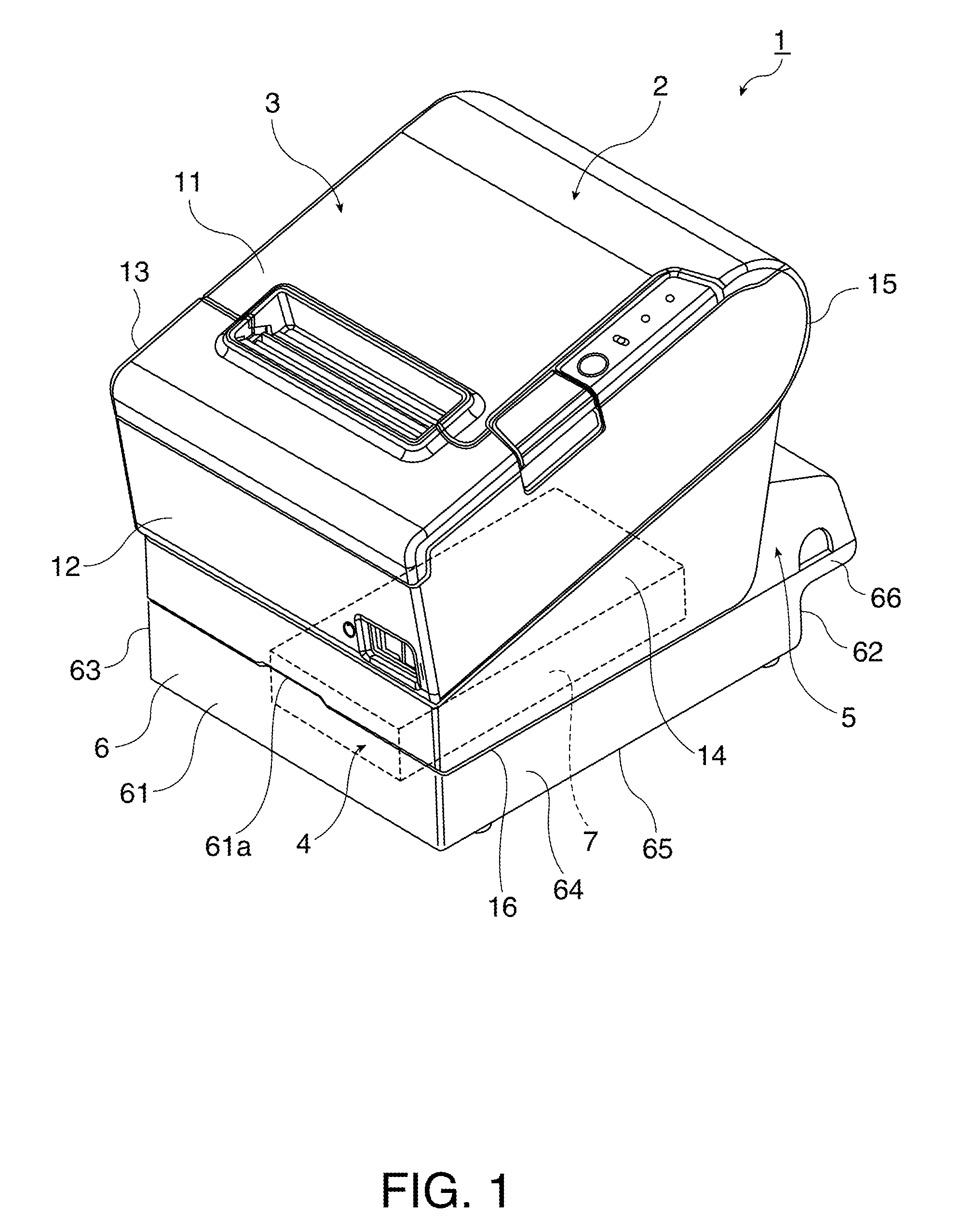

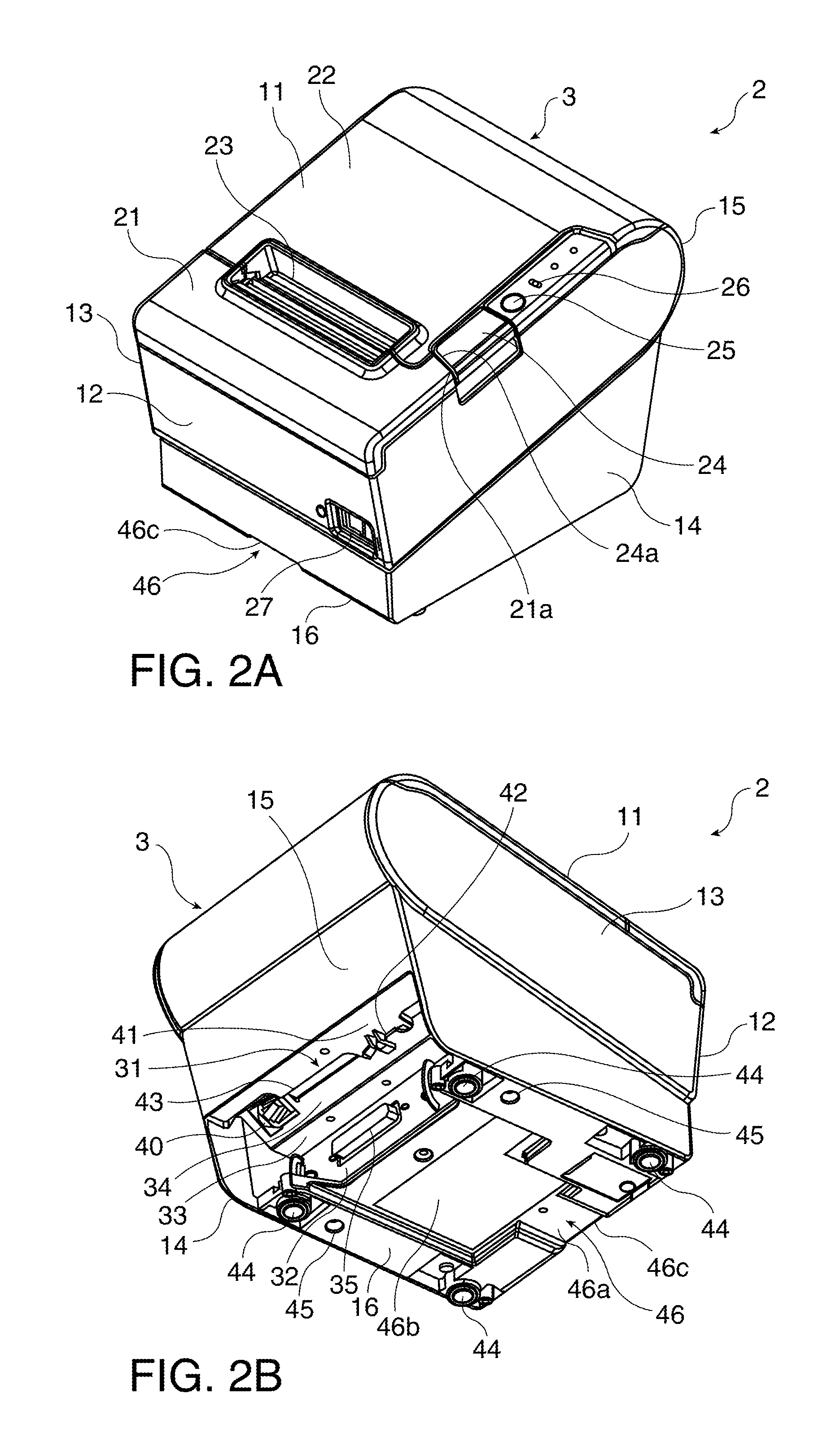

AC adapter unit, storage tray for an AC adapter and electronic device

ActiveUS8194396B2Reduce storage spaceReduce the amount requiredBus-bar/wiring layoutsCable arrangements between relatively-moving partsAC adapterEngineering

An AC adapter unit compactly houses the AC adapter block and DC cable so that radiation noise from the DC cable is not amplified. The AC adapter unit 4 has an AC adapter 7 that includes an AC adapter block 52 and a DC cable 51, and a storage tray 6 that stores the AC adapter 7. The connector-side cable part 51b of the DC cable 51 is stored in the storage tray 6 on the left-side part 6D of the AC adapter block 52. The connector-side cable part 51b has a bundled part 51c with a figure-8 shape when seen from the top opening 6a side of the storage tray 6. The long axis of this bundled part 51c is parallel to the long axis of the AC adapter block 52. Because the DC cable 51 has a figure-8 shaped bundled part 51c, the part that runs parallel to electronic circuit boards inside the AC adapter block 52 is reduced and amplification of radiation noise is reduced.

Owner:SEIKO EPSON CORP

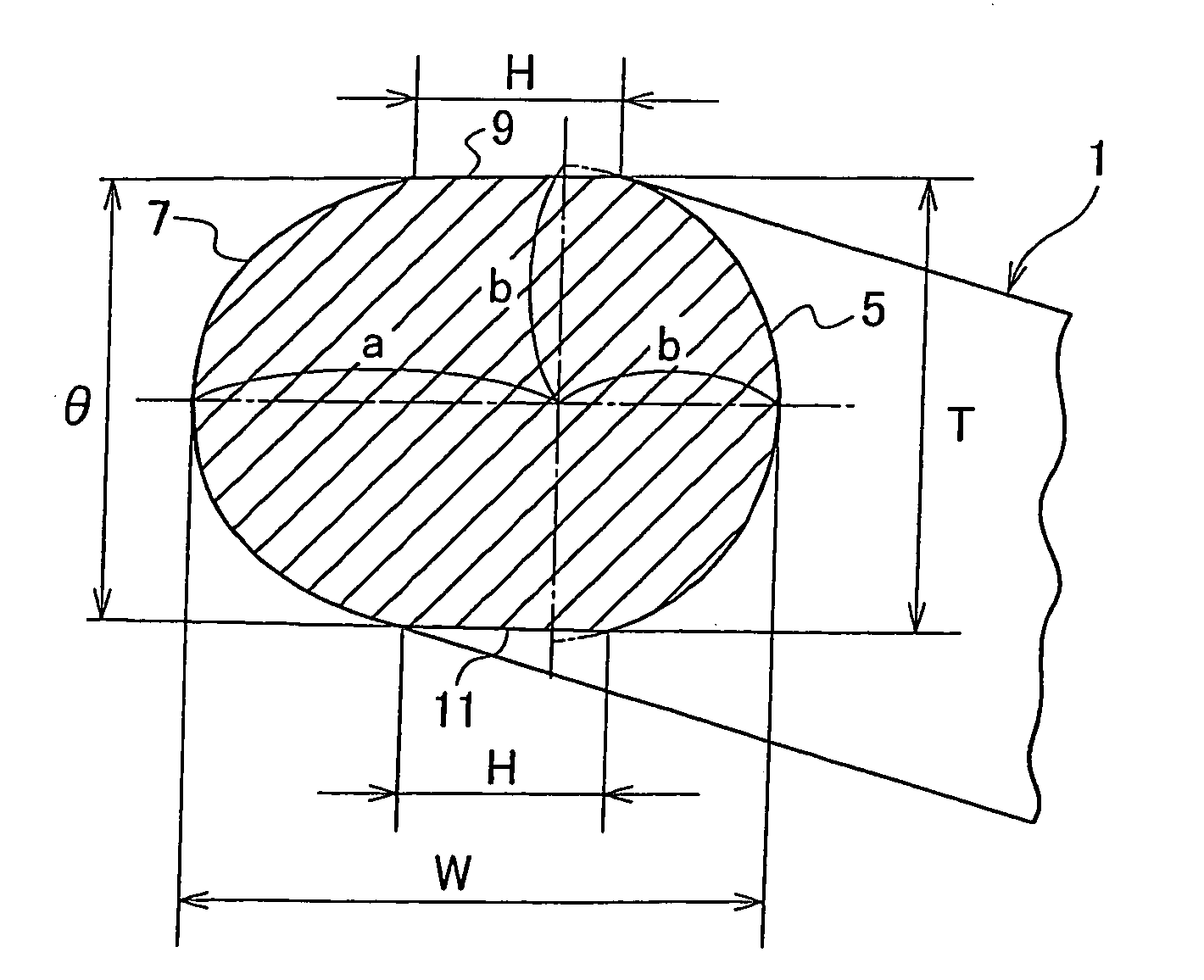

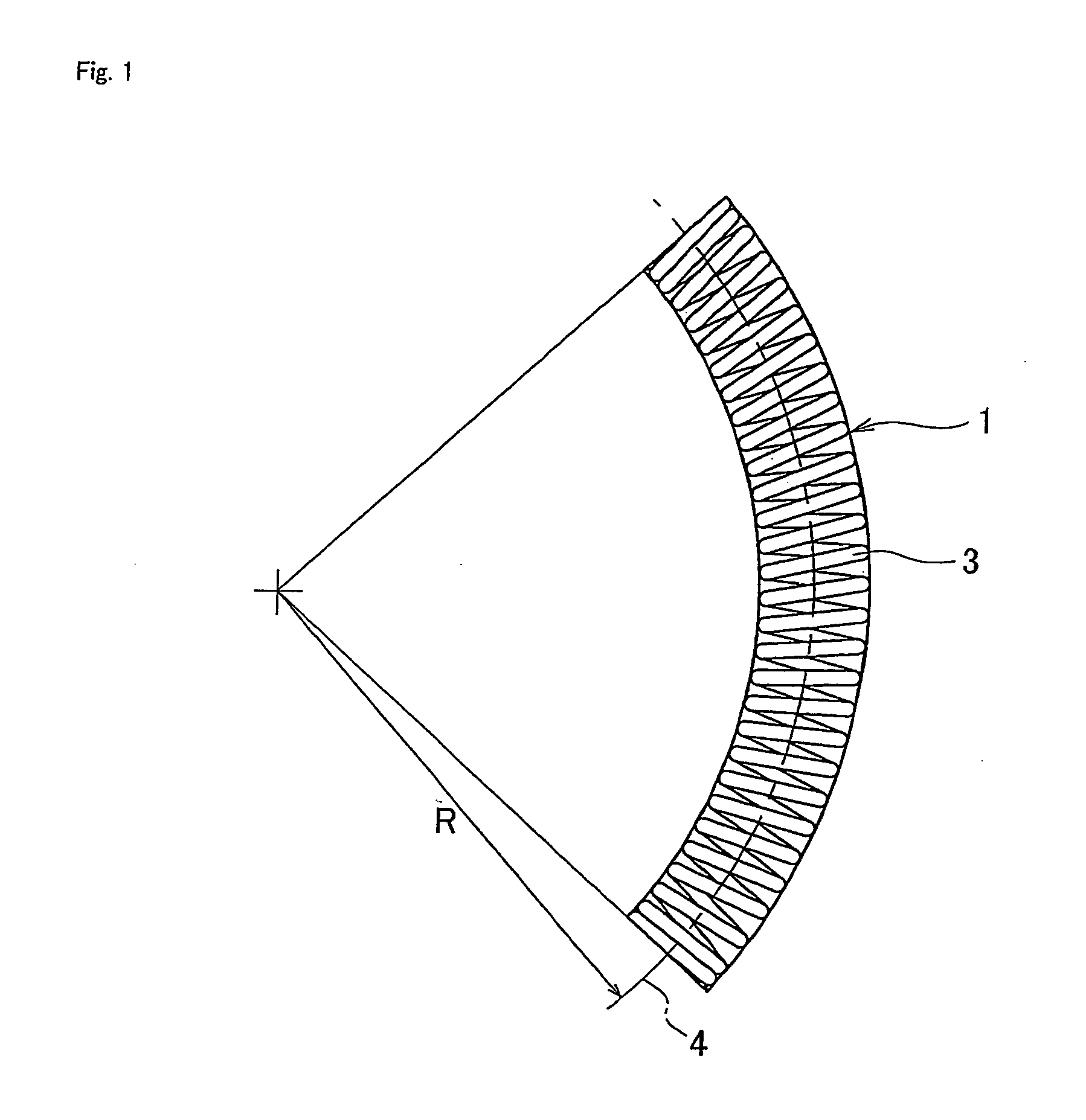

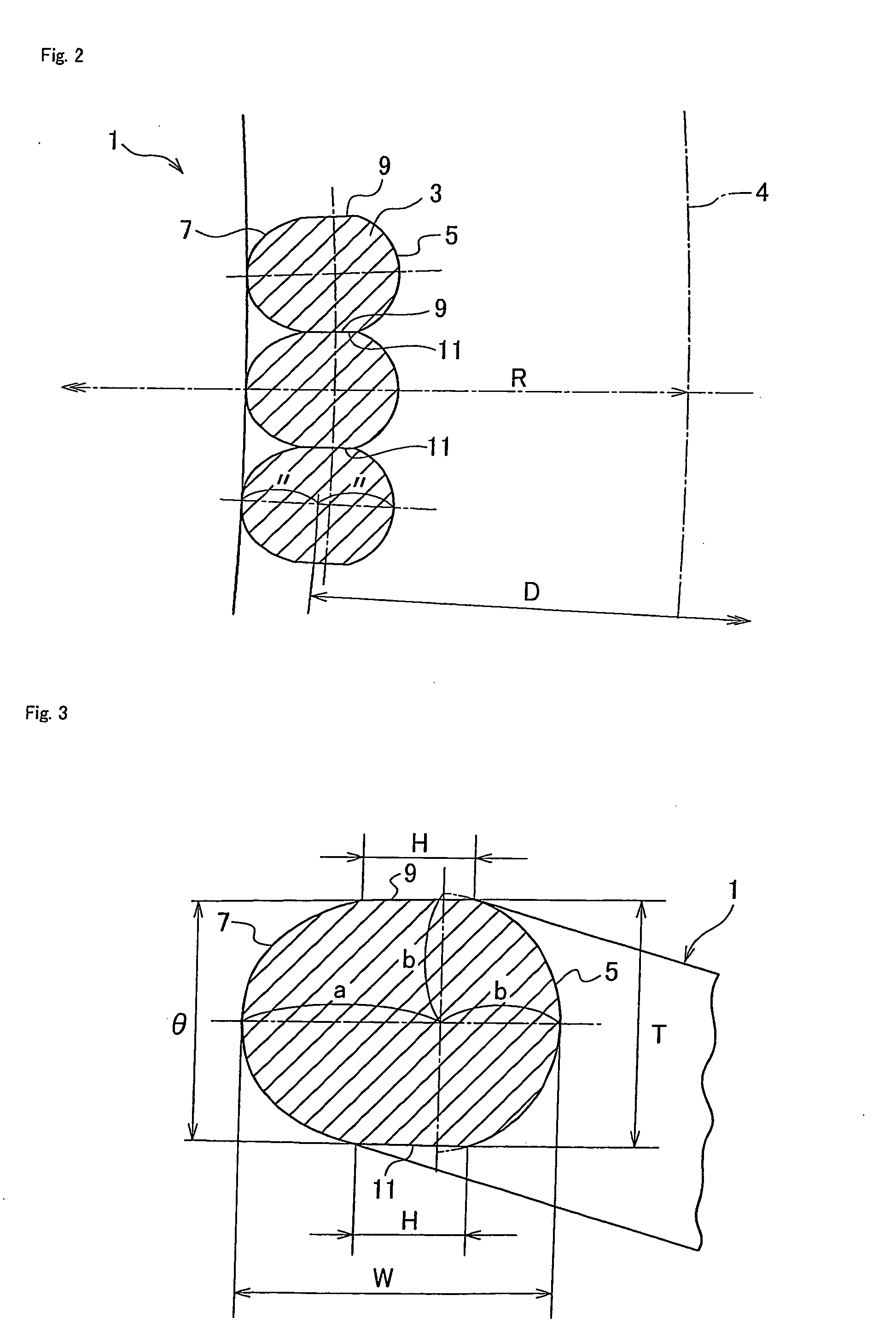

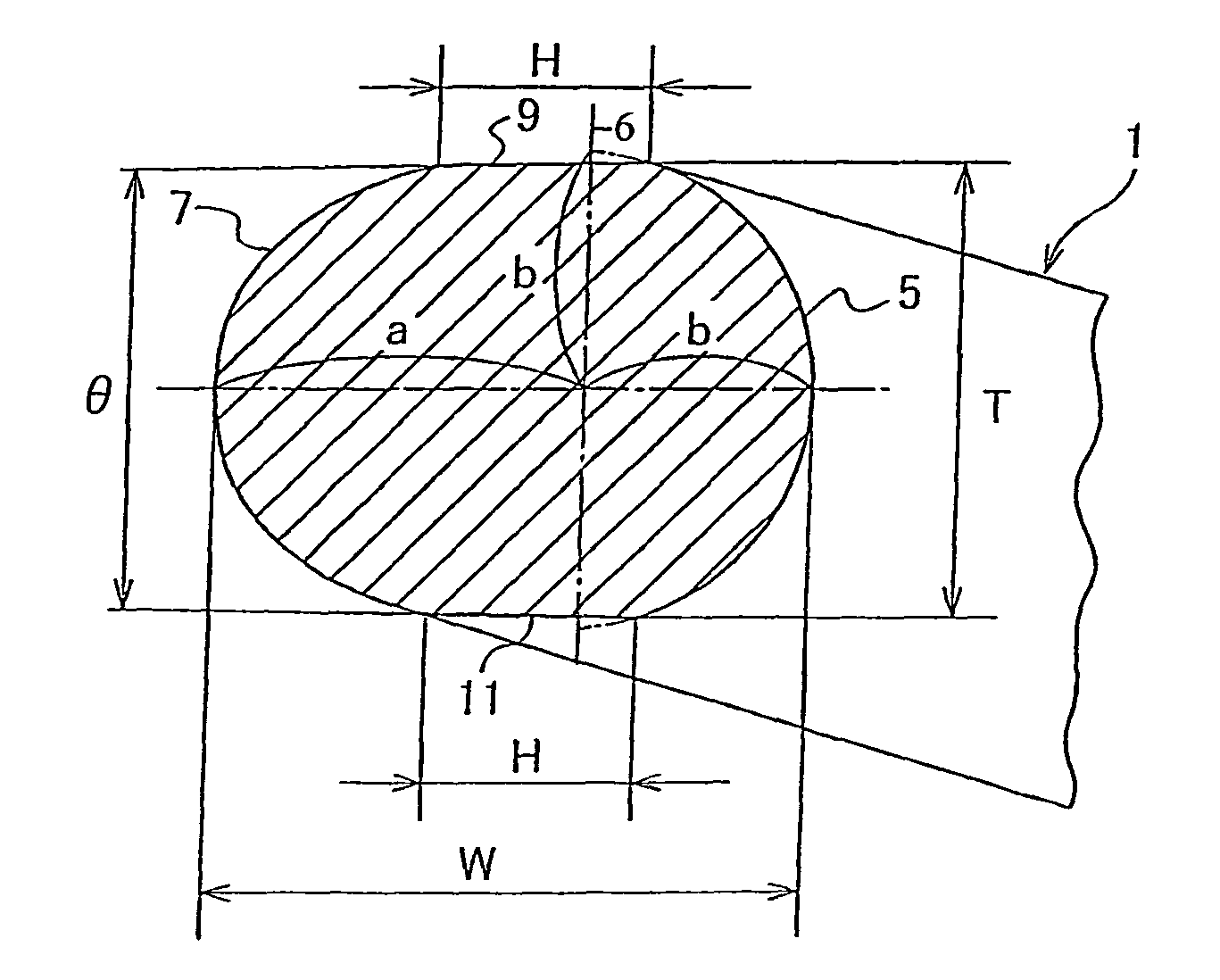

Coil spring

ActiveUS20100090384A1Improve uniformityReducing oblatenessFluid gearingsWound springsLongest DiameterCoil spring

A coil spring has a spring wire wound in a coil shape having an outer diameter side portion and an inner diameter side portion on a peripheral shape in a cross section thereof, one of the outer diameter side portion and inner diameter side portion formed in a semi-circular shape expressed by x2+y2=b2, the other thereof formed in a non-circular shape with a long diameter “a” and a short diameter “b” expressed by (x / a)α+(y / b)α=1, and value of the “α” set in a range of 1.85 to 2.45, and contact faces provided between the inner diameter side portion and the outer diameter side portion on the peripheral shape in the cross section such that each contact face comes into contact with a contact face of an adjacent coil in an axial direction along an axis line of the coil spring.

Owner:NHK SPRING CO LTD

Processes for improving tool life and surface finish in high speed machining

InactiveUS8205530B2Enhanced grain boundary diffusionReduce wearLathesAutomatic/semiautomatic turning machinesPerformance toolEngineering

Processes for high speed machining of workpiece materials using high performance tools with prolonged tool life and improved surface finish are provided by vibrating the tool and / or the workpiece at a frequency greater than the frequency of shear localization in the primary shear zone or chip segmentation occurring in the absence of tool vibration, with an amplitude sufficient to break up the tool-chip atomic contact, thereby decreasing the tool-chip contact length through decreasing the tool-chip contact time, thereby suppressing accelerated chemical tool wear caused by dissolution of the tool into the workpiece by nanocrystalline grain boundary diffusion and grain boundary sliding mechanisms by preventing shear localization associated with nanocrystalline grain formation in the primary shear zone of the chip, and suppressing oxidation wear of the tool by preventing segmentation of the chip.

Owner:SUBRAMANIAN SUNDARESA V

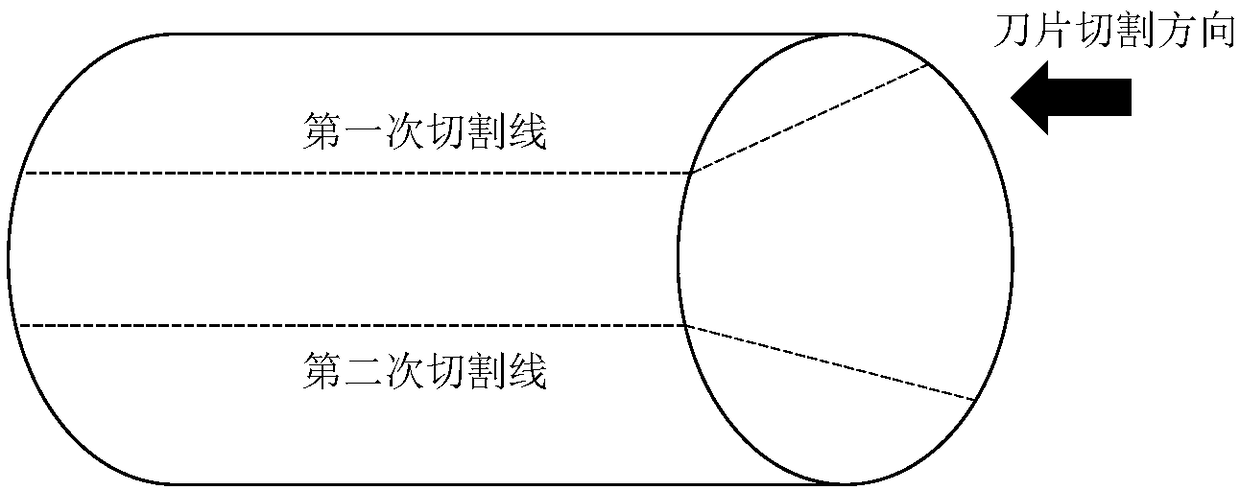

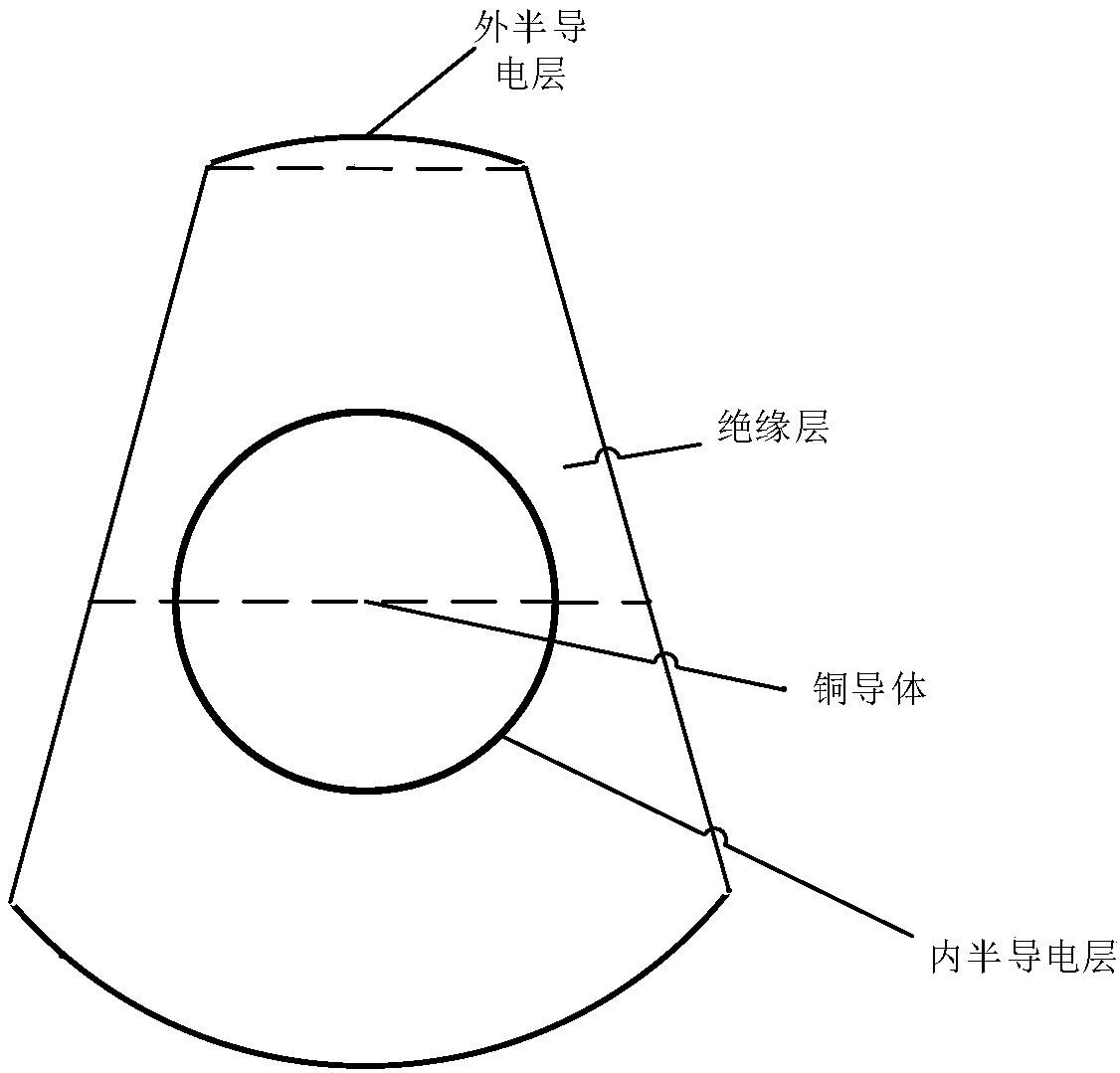

Slicing improvement method based on cross-linked cable slicer

The invention discloses a slicing improvement method based on a cross-linked cable slicer, wherein the slicing improvement method comprises the following steps: selecting a cross-linked polyethylene cable to be sliced, and fixing the cross-linked polyethylene steadily on the slicer; firstly slicing on one side, then changing a certain angle, and making a cable insulating layer present a trapezoidal shape; and slicing the top end of the cable trapezoidal insulating layer according to a ruler of the slicer. By reduction of the contact length between a blade of the slicer and the cross-linked polyethylene insulating layer, the method avoids the problem of reduction of the accuracy because of upwarping due to excessive force in the cutting process or cable arching due to loose clamping. The method also effectively reduces the damage of a sample to the blade.

Owner:SOUTH CHINA UNIV OF TECH

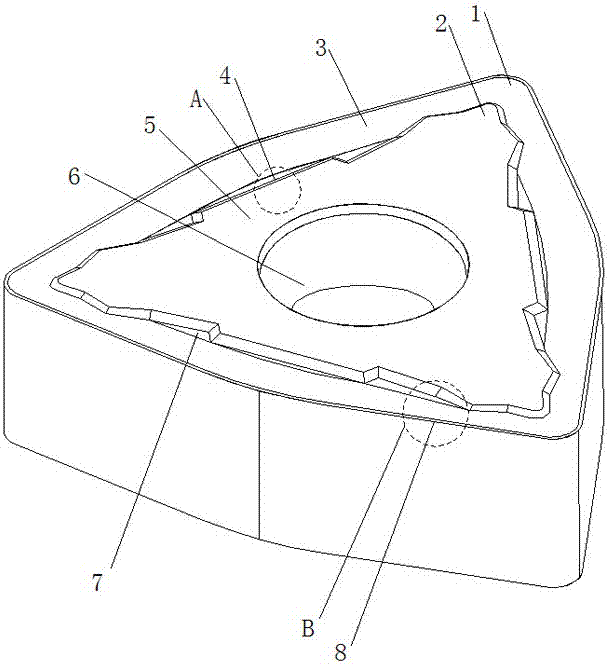

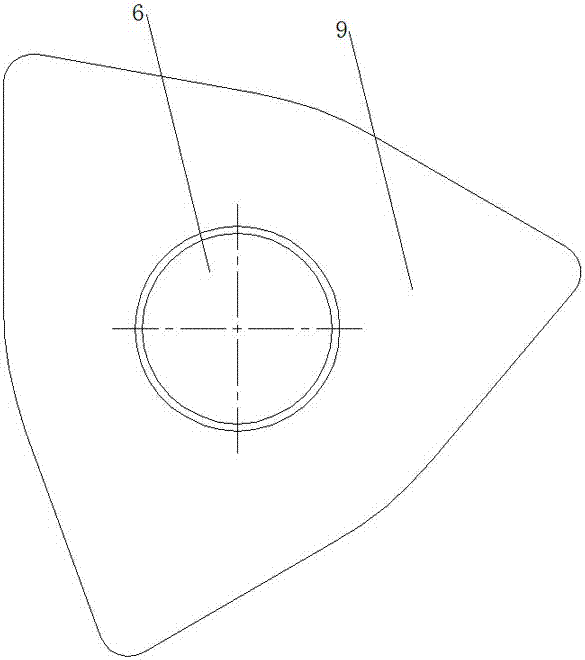

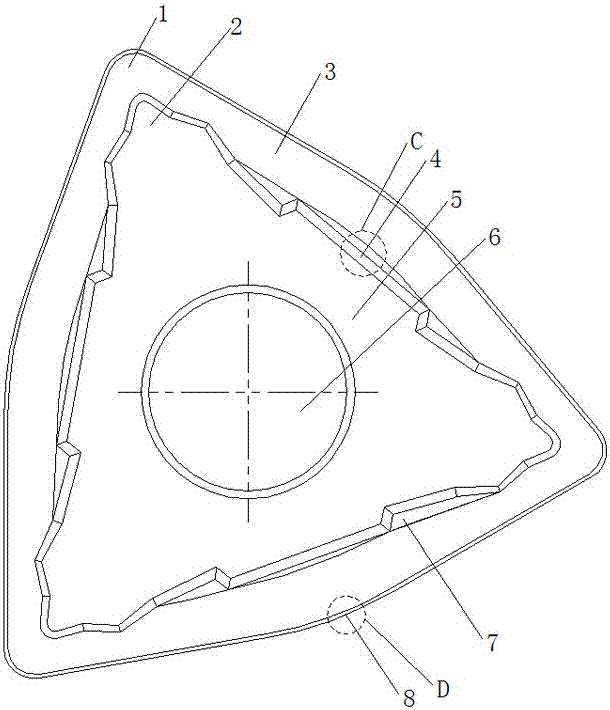

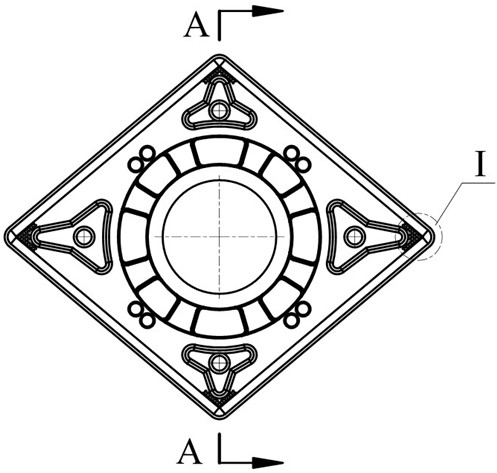

Indexable turning blade for high temperature alloy semifinishing under high-pressure cooling

InactiveCN107214353AReduce wearImprove chip breaking abilityCutting insertsTurning toolsEngineeringHigh pressure

The invention relates to an indexable turning blade for high temperature alloy semifinishing under high-pressure cooling, and belongs to the technical field of turning tools. The turning blade comprises a turning blade body, the shape of the outline of the horizontal cross section of the turning blade body is hexagon, a fastening screw hole is formed in the geometrical center of the hexagonal turning blade body, a front cutter face is arranged on the outer periphery of the top face of the hexagonal turning blade body, and the six vertex angles of the hexagonal turning blade body are composed of three 80-degree angles and three 160-degree angles which are sequentially and alternatively arranged; arc cutter tips are arranged at the three 80-degree angles of the hexagonal turning blade body, negative chamfered edge cutting edges are arranged at the six outer edges of the top face of the hexagonal turning blade body, and protrusions are arranged nearby each arc cutter tip; and fold line step-shaped chip breaker grooves are arranged on the top face of the hexagonal turning blade body and the corresponding positions of the 160-degree angles on the front cutter face, chip grooves are composed of the fold line step-shaped chip breaker grooves and the front cutter face, and the bottom face of the hexagonal turning blade body is a blade installing supporting face. The indexable turning blade is used for high temperature alloy semifinishing under high-pressure cooling.

Owner:HARBIN UNIV OF SCI & TECH

Coil spring

ActiveUS8684342B2Improve uniformityReducing oblatenessFluid gearingsWound springsLongest DiameterCoil spring

A coil spring has a spring wire wound in a coil shape having an outer diameter side portion and an inner diameter side portion on a peripheral shape in a cross section thereof, one of the outer diameter side portion and inner diameter side portion formed in a semi-circular shape expressed by x2+y2=b2, the other thereof formed in a non-circular shape with a long diameter “a” and a short diameter “b” expressed by (x / a)α+(y / b)α=1, and value of the “α” set in a range of 1.85 to 2.45, and contact faces provided between the inner diameter side portion and the outer diameter side portion on the peripheral shape in the cross section such that each contact face comes into contact with a contact face of an adjacent coil in an axial direction along an axis line of the coil spring.

Owner:NHK SPRING CO LTD

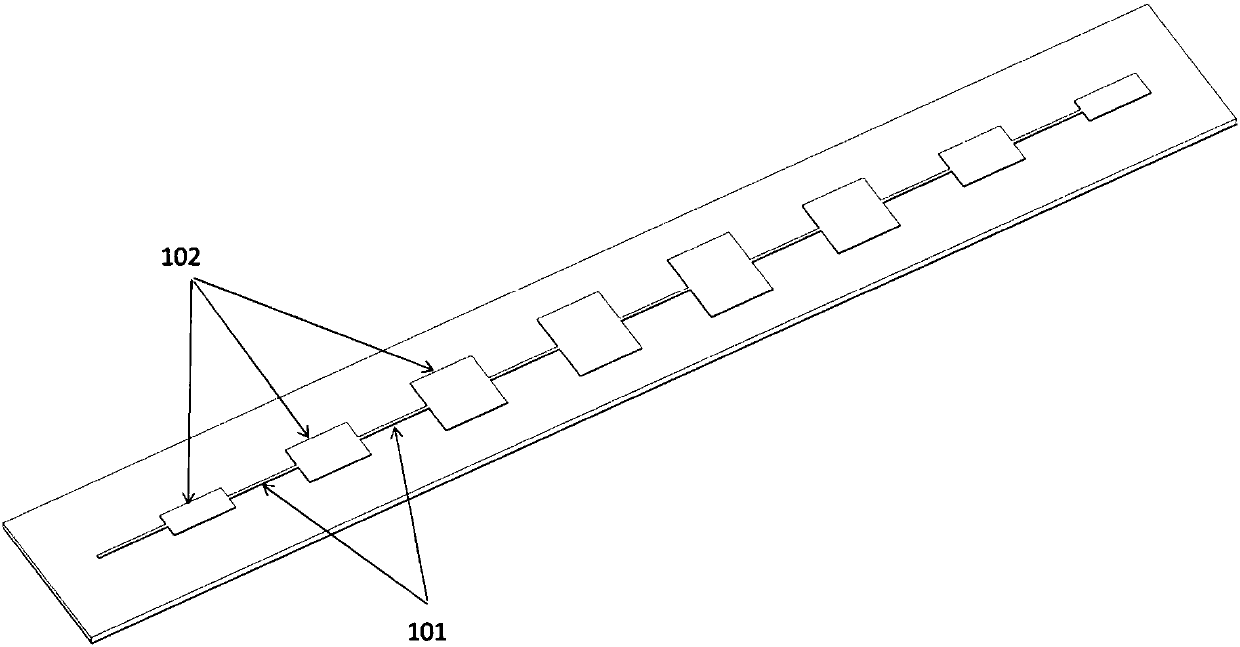

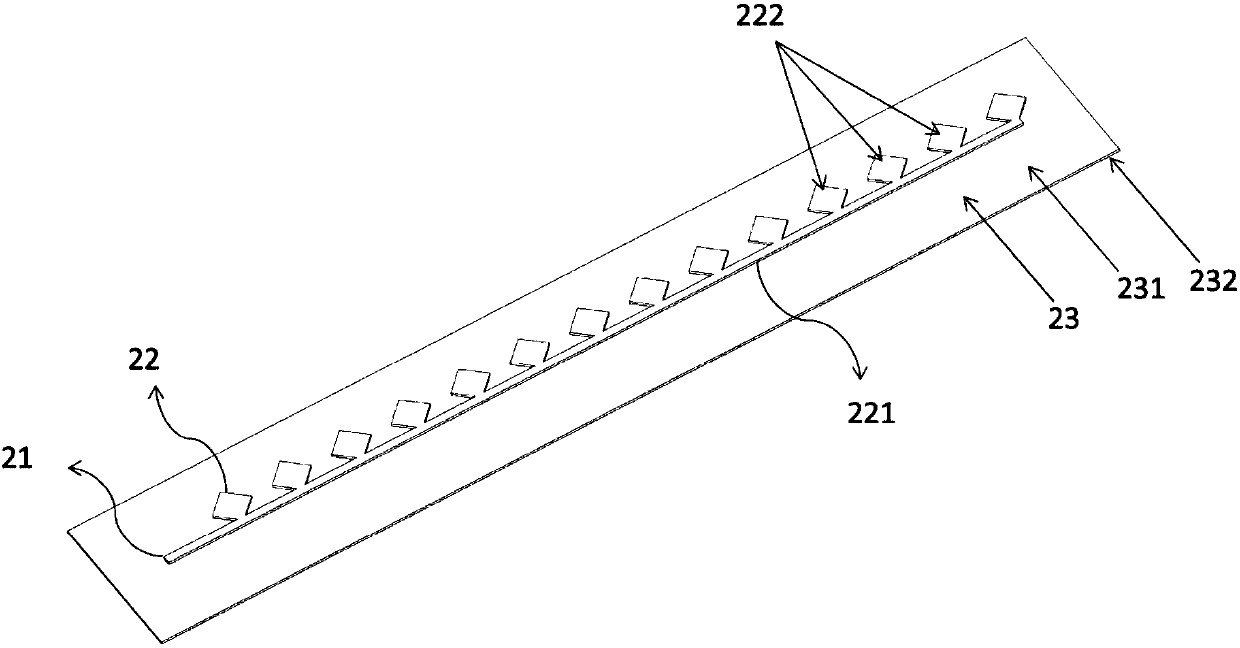

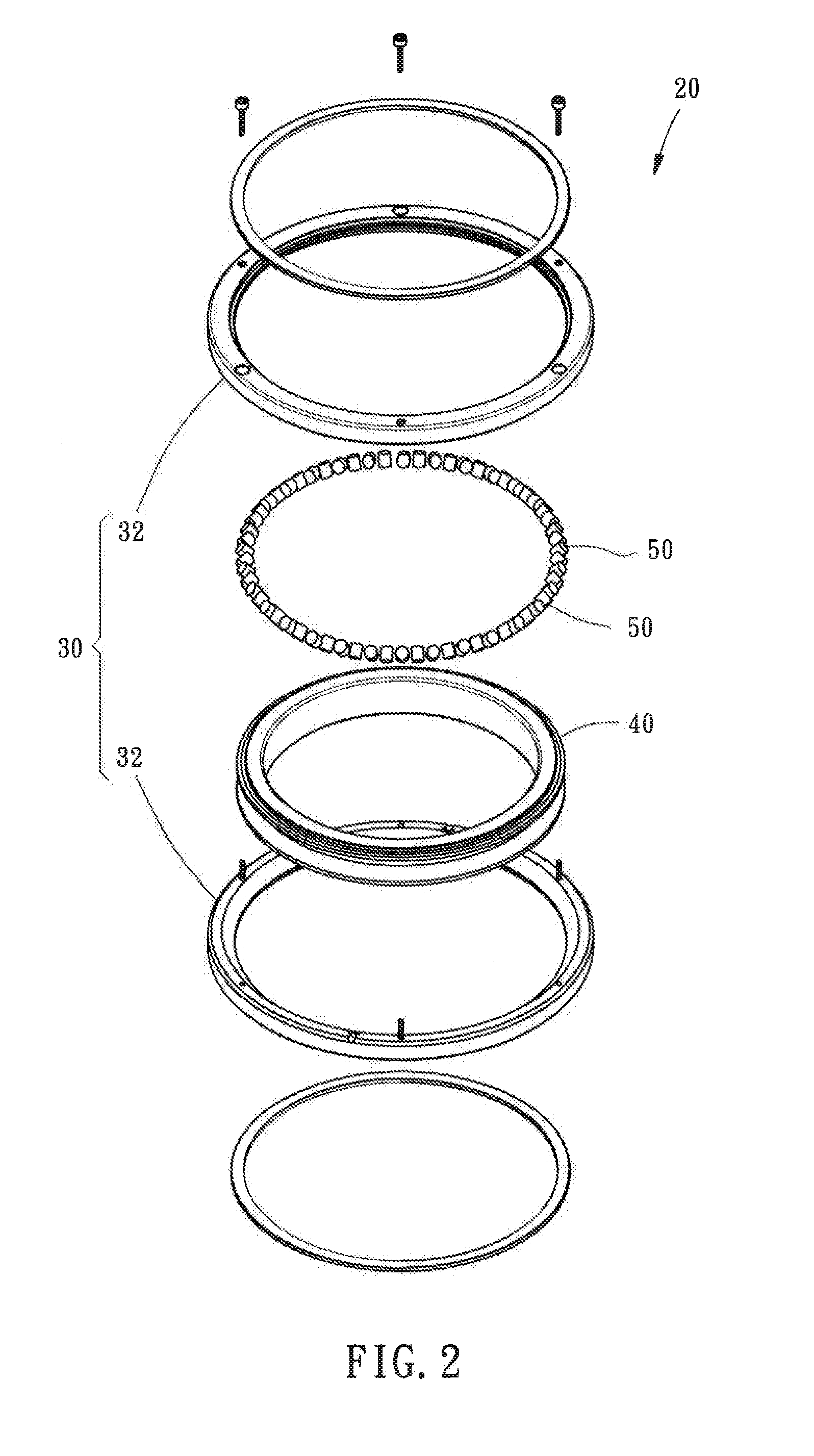

Microstrip antenna structure and method for radiating electromagnetic signals

InactiveCN109768394AReduce contact lengthImprove emission efficiencyAntenna arraysRadiating elements structural formsDielectric substrateElectromagnetic shielding

The invention provides a microstrip antenna structure and a method for radiating electromagnetic signals. The microstrip antenna structure comprises a signal input unit, a signal radiation unit, a grounding unit and a dielectric substrate unit. The signal input unit is used for inputting electromagnetic wave signals. The signal radiation unit is connected with the signal input unit and is used forreceiving and radiating the electromagnetic wave signals into space, and comprises a microstrip line and a plurality of antenna array elements, wherein the antenna array elements are distributed at equal intervals along the microstrip line, and the length of the microstrip line penetrating through the antenna array elements is smaller than the short sides of the antenna array elements. The grounding unit is used for forming a radio frequency ground. The dielectric substrate unit is provided with a first surface and a second surface opposite to the first surface, the signal input unit and thesignal radiation unit are located on the first surface, and the grounding unit is located on the second surface. According to the microstrip antenna structure and the method for radiating the electromagnetic signals, the contact length of the electromagnetic signals between the microstrip lines and the antenna array elements is reduced, and the antenna transmission efficiency and bandwidth are improved.

Owner:北京木牛领航科技有限公司

Roller bearing

ActiveUS20140328555A1Minimize frictional resistanceNot easy to wearRolling contact bearingsShaftsMechanical engineeringRoller bearing

A roller bearing, includes an outer race and an inner race coupled together and rotatable relative to each other, the inner and outer race each defining therein a respective rolling channel, each rolling channel defining two raceway faces abutted at right angles, and rollers accommodated in the rolling channels of the inner and outer races and rotatably kept in contact with the raceway faces of the inner and outer races. The roller bearing is characterized in that the inner and outer races each define a groove between the respective two raceway faces thereof; the ratio between the width of each raceway face and the diameter of each roller is ≧0.45 and ≦0.62, thus, the friction resistance between the rollers and the raceway faces is minimized, and therefore, the roller bearing does not wear easily when rotated at a high speed.

Owner:HIWIN TECH

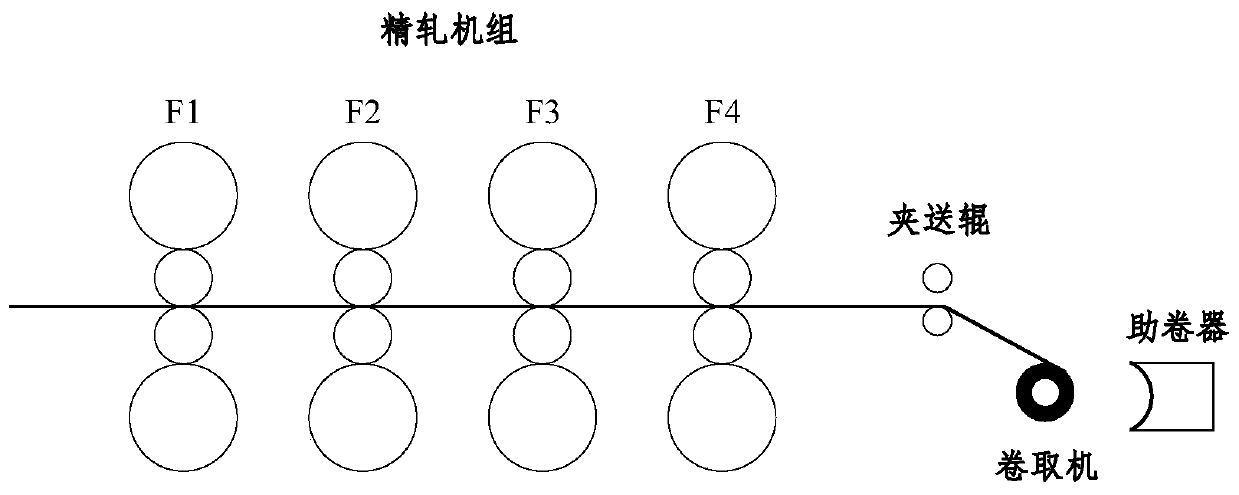

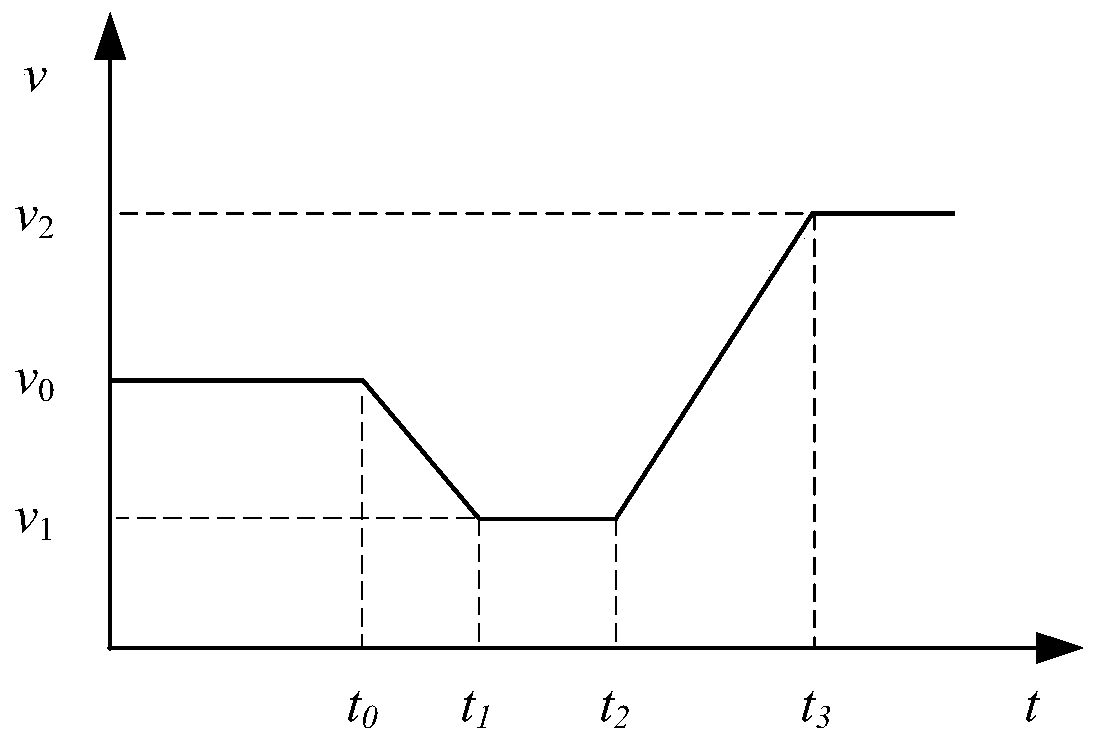

Control method for reducing length of surface scratch caused by coiling machine auxiliary coiling device on aluminum strip

ActiveCN110064663AGuaranteed scratch lengthReduced chafing lengthRoll mill control devicesMetal rolling arrangementsNonferrous metalEngineering

The invention provides a control method for reducing the length of surface scratch caused by a coiling machine auxiliary coiling device on an aluminum strip, and belongs to the technical field of nonferrous metal processing. According to the method, when a finish rolling unit begins rolling, the threading rolling is carried out at a relatively high threading speed; when the aluminum strip head portion enters a last housing rolling mill to generate a biting signal, the position of the aluminum strip head portion is tracked; when the tracking position of the aluminum strip head portion is largerthan the head speed reduction position, the finish rolling unit starts to decrease the speed to the coiling speed; and when the aluminum strip enters a coiling machine and the tension is establishedbetween the coiling machine and the last housing rolling mill, the coiling machine auxiliary coiling device is started, after a swinging arm of the coiling machine auxiliary coiling device is opened,the finish rolling unit starts to rise to the rolling speed, and then the follow-up steady-state rolling is carried out. According to the method, the length of the scratch caused by contact between the auxiliary coiling device and the surface of the aluminum strip in the head auxiliary coiling process can be effectively reduced, the yield of the product is improved, meanwhile, a high-speed threading and head low-speed coiling control method is adopted, so that the production efficiency is ensured while the yield is ensured.

Owner:北京科技大学设计研究院有限公司

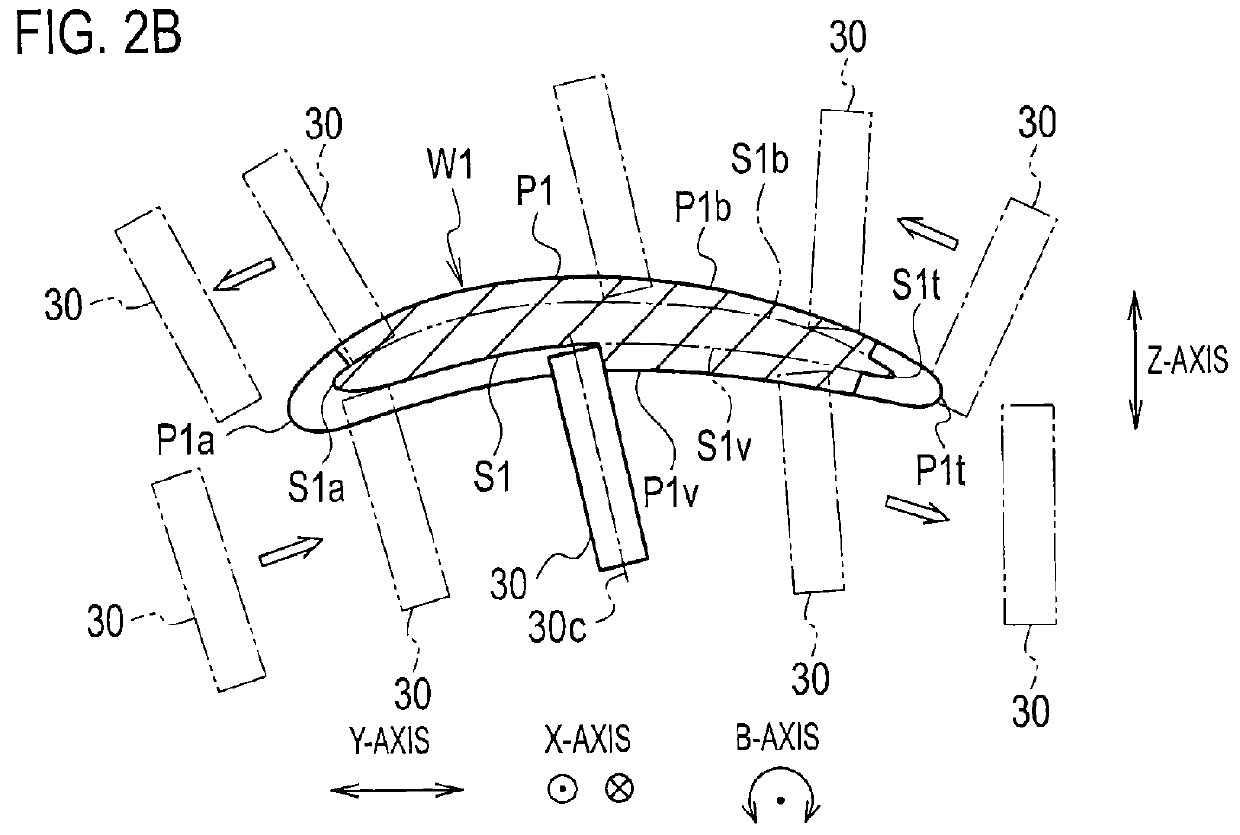

Wing surface finishing method and wing component

ActiveUS20160052071A1Maintain durabilityImprove productivityMilling cuttersWorkpiecesLeading edgeSurface finish

A wing surface finishing method is the one in which after finishing of a leading edge and a trailing edge and finishing of a ventral portion and a back portion in a wing surface of a wing component are separated into separate steps, a finishing end mill is made to approach a ventral portion and a back portion of awing surface corresponding area of a workpiece after a speed of the finishing end mill is increased, finishing processing is applied to the ventral portion and the back portion of the wing surface corresponding area of the workpiece, respectively, and the speed of the finishing end mill is decreased after the finishing end mill is moved away from the wing surface corresponding area of the workpiece.

Owner:IHI CORP

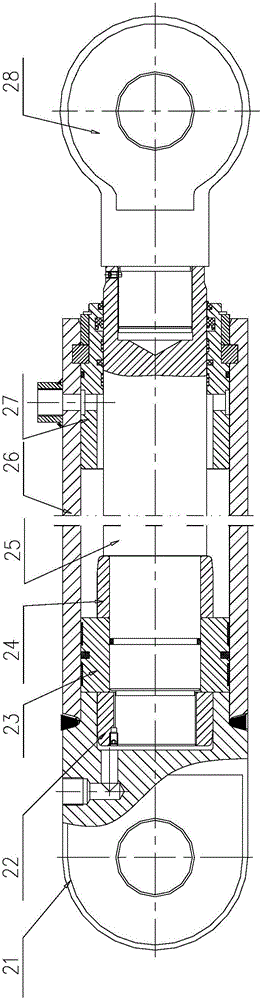

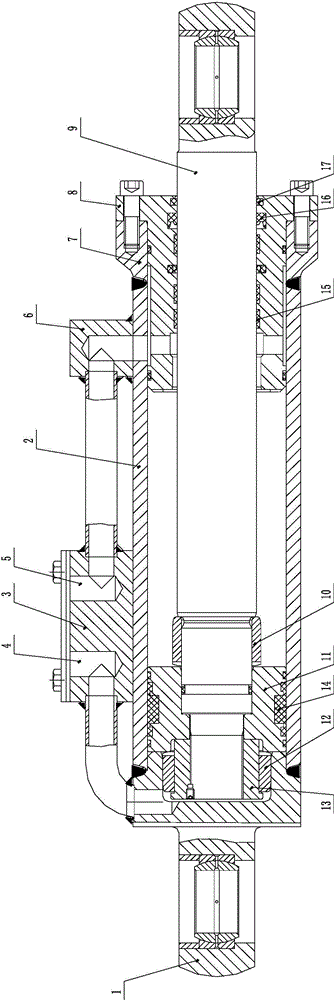

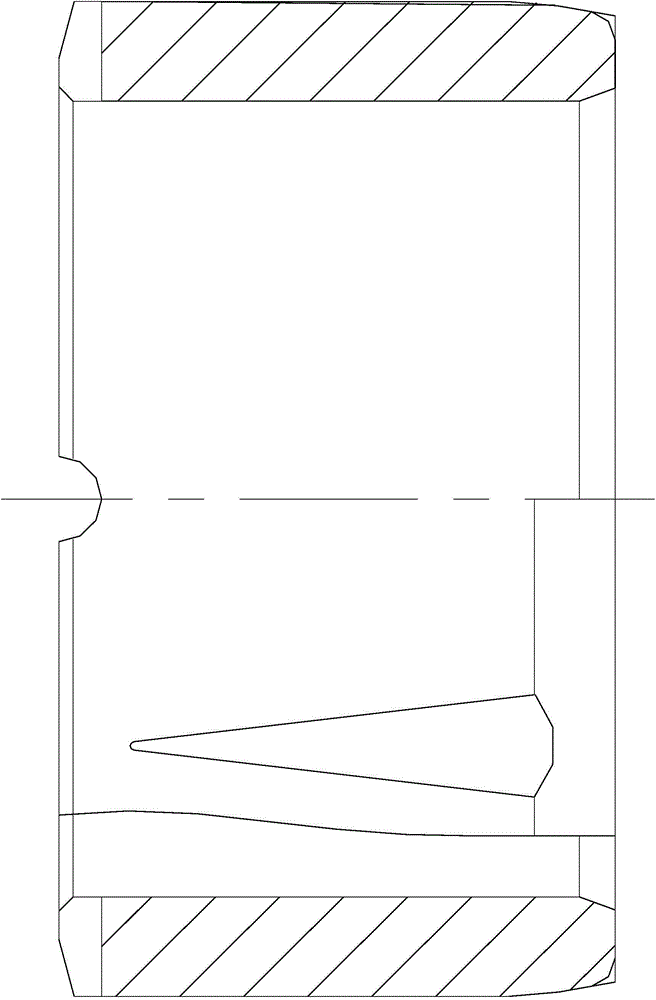

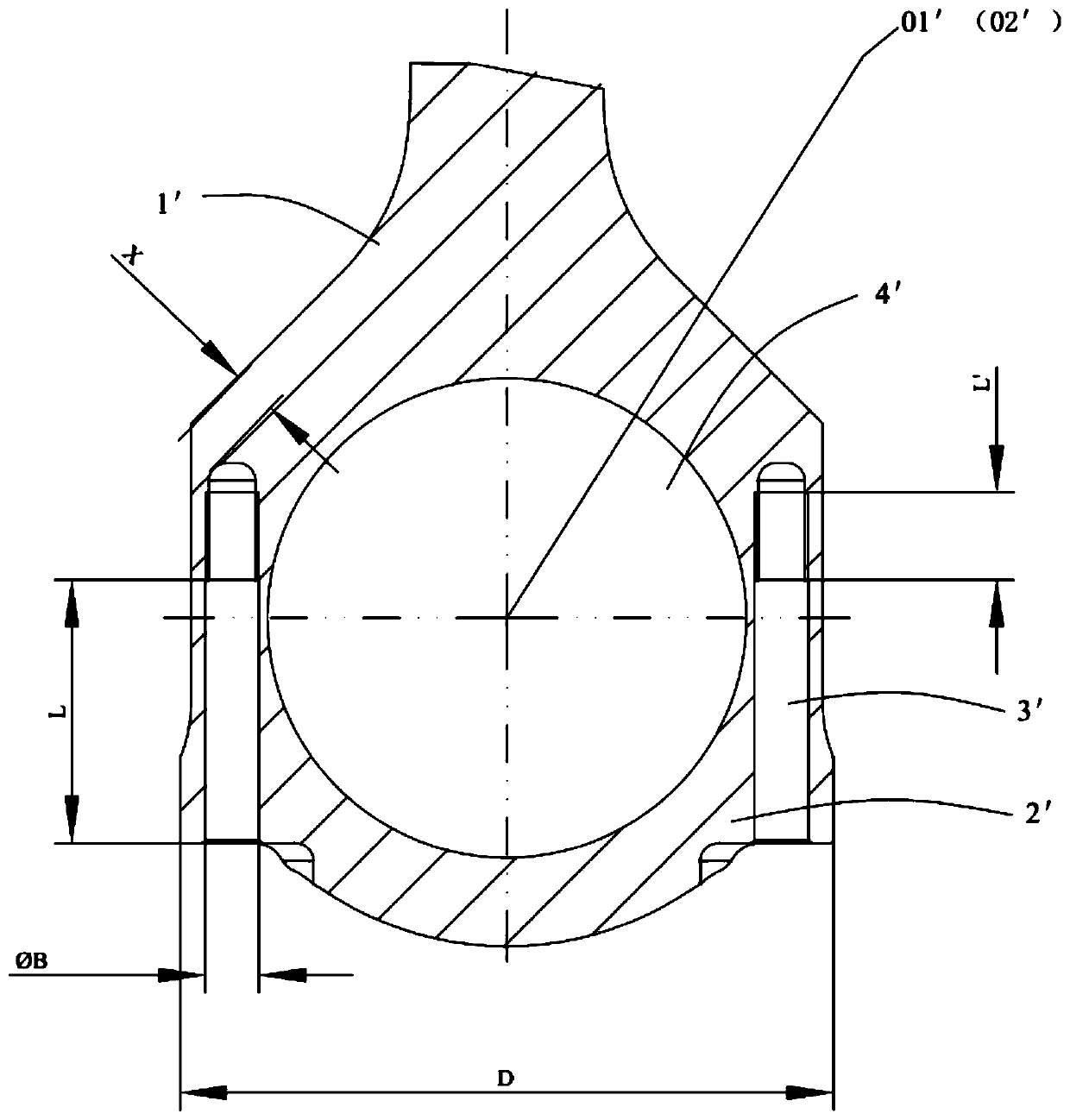

Bucket cylinder

InactiveCN104533874AGood cushioning effectReduced concentricity requirementsFluid-pressure actuatorsEngineeringMechanical engineering

The invention discloses a bucket cylinder, and belongs to the technical field of oil cylinder development. The bucket cylinder comprises a cylinder component and a piston component, wherein the piston component sleeves the inner circumferential surface of the cylinder component; a piston rod of the piston component is adhered to the inner circumferential surface of a small circular inner diameter part of a guide sleeve of the cylinder component; an annular gap is formed between the piston rod and the inner circumferential surface of the large circular inner diameter part of the guide sleeve; the piston of the piston component is adhered to the inner circumferential surface of the cylinder of the cylinder component; the piston rod, a screw nut and a rear buffer sleeve of the piston component, and the cylinder bottom of the cylinder component form a rear buffer; a front buffer sleeve, the piston and the piston rod of the piston component and the and the guide sleeve of the cylinder component form a front buffer. Due to automatic flotation centering of the front buffer sleeve and the rear buffer sleeve, a good buffer effect is achieved, the requirement on the coaxiality of components is low, and the components are easy to process.

Owner:CSIC ZHONGNAN EQUIP

Bolt-free prepressing type large-displacement anti-deflection multidirectional displacement comb plate bridge expansion device

PendingCN109736192AShorten the lengthReduce contact lengthBridge structural detailsEngineeringBuilding construction

Owner:双盛交通科技有限公司

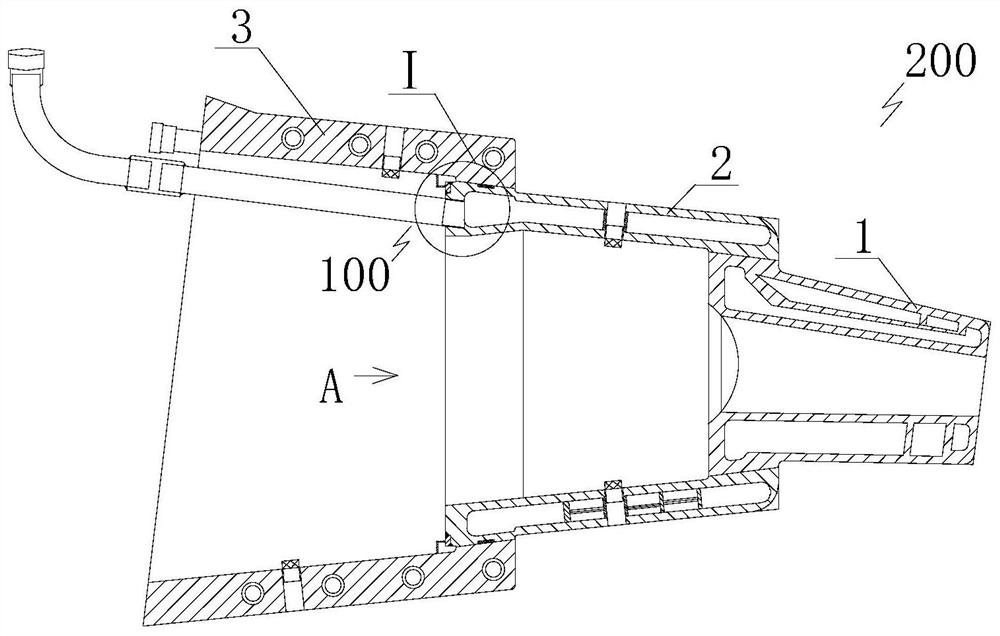

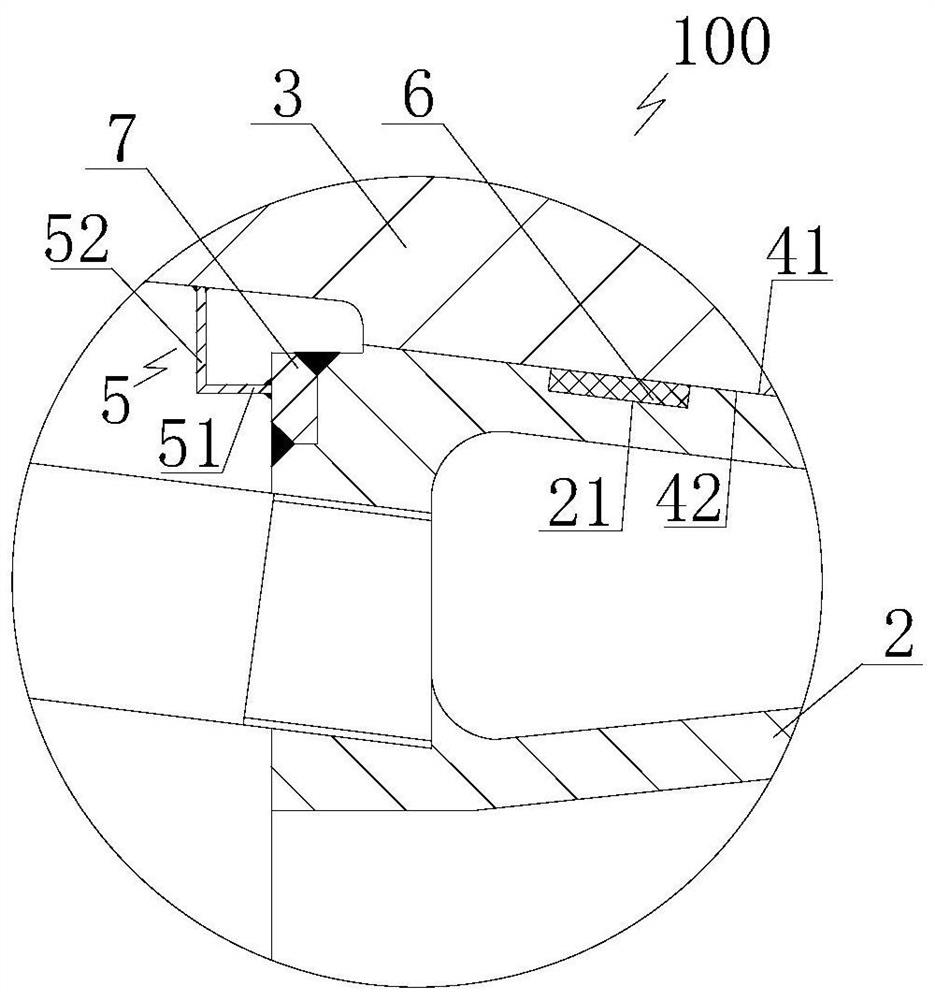

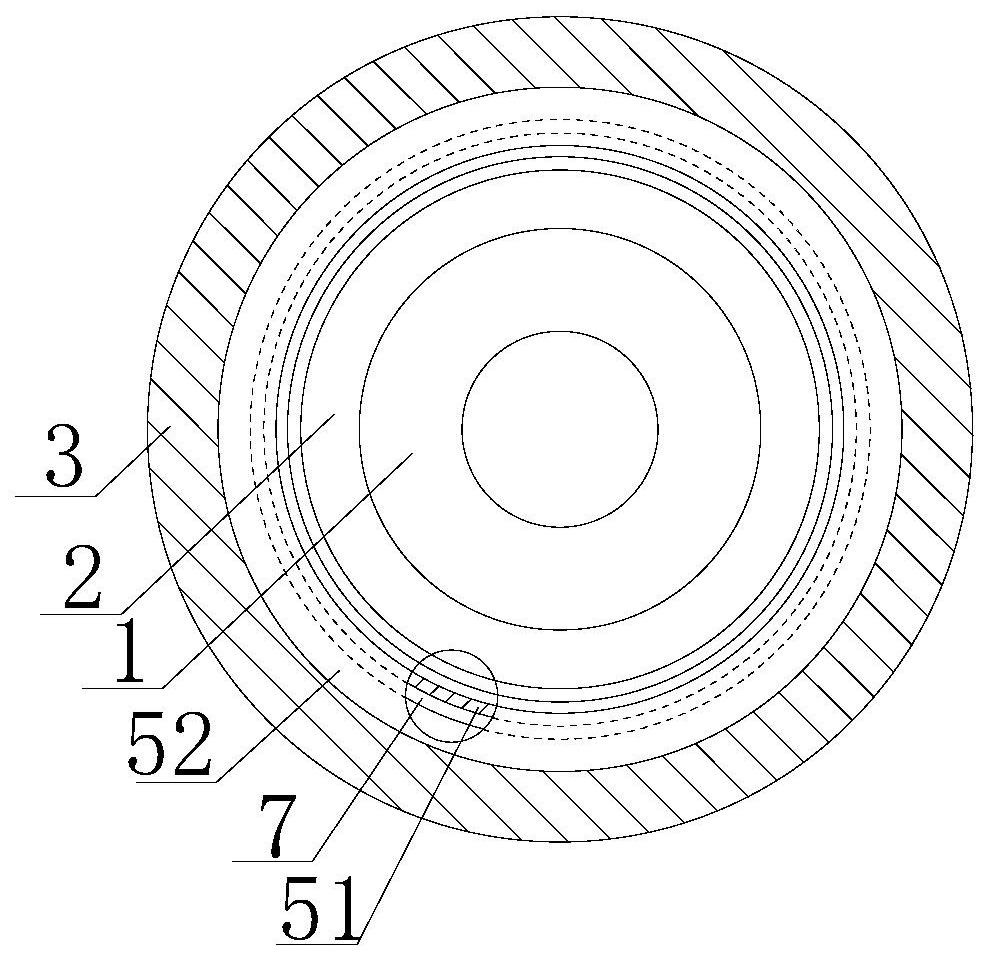

Sealing structure for preventing air leakage of tuyere sleeve joint surface and tuyere sleeve structure

PendingCN111734823AActs as a triple sealFix the leakEngine sealsTuyeresWorking environmentEngineering

The invention relates to a sealing structure for preventing air leakage of a tuyere sleeve joint surface and a tuyere sleeve structure. The sealing structure comprises an inner conical surface arranged on the inner wall of the small-diameter end of a tuyere large sleeve and an outer conical surface arranged on the outer wall of the large-diameter end of a tuyere middle sleeve, the outer conical surface can abut against the inner conical surface in a sealed mode, and a sealing ring is arranged between the outer conical surface and the inner conical surface; the sealing structure for preventingair leakage of the tuyere sleeve joint surface further comprises a sealing ring plate capable of absorbing deformation of the tuyere middle sleeve, the radial inner side of the sealing ring plate canbe fixedly connected with the end face of the large-diameter end of the tuyere middle sleeve in a sealed mode, and the radial outer side of the sealing ring plate can be connected with the inner sideface of the tuyere large sleeve in a sealed abutting mode. According to the sealing structure for preventing air leakage of the tuyere sleeve joint surface, the sealing structure can play a triple sealing role, can effectively solve the problem of gas leakage caused by a gap generated between the joint surfaces of the tuyere middle sleeve and the tuyere large sleeve after the tuyere middle sleeveis upwarped and deformed, effectively improves the working environment of a tuyere area, and is an effective measure for realizing the safety production of a blast furnace.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Groove machining blade

InactiveCN107414110AReduce cutting impactPrevent crashCutting insertsTurning toolsEngineeringMechanical engineering

The invention discloses a groove machining blade. The groove machining blade is defined by an upper positioning surface, a lower positioning surface, two side surfaces and two end surfaces, wherein the two side surfaces and the two end surfaces connect the upper positioning surface with the lower positioning surface. A front cutter surface connecting the upper surface with at least one of the end surfaces is arranged between the end surface and the upper positioning surface. Two side rear cutter surfaces are arranged between the single front cutter surface and the adjacent end surface as well as between the single front cutter surface and the adjacent side surface correspondingly. The side rear cutter surfaces, the end surfaces and the front cutter surface intersect to form a side edge and an end edge correspondingly. The end edge of a double-edged structure is composed of an upper end edge body and a lower end edge body. The groove machining blade has the characteristics of being high in chip breaking ability, high in machining surface quality, long in life and high in cutting efficiency.

Owner:刘辞海

Retainer and tapered roller bearing

ActiveUS10330146B2Reducing stirring resistance of oilReduce shear resistanceRoller bearingsShaftsEngineeringMechanical engineering

A retainer of a tapered roller bearing includes crossbars having guide surfaces which circumferentially contact the tapered rollers. The crossbars are also formed with first recessed surfaces and second recessed surfaces which are both in the form of cutouts circumferentially recessed from the respective guide surfaces to reduce stirring resistance and shear resistance of oil. To reduce the contact lengths between the rolling surface central portions of the tapered rollers and the guide surfaces, the guide surfaces are smoothly convex in the longitudinal direction of the tapered rollers.

Owner:NTN CORP

High-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling

PendingCN112475340AReduce coefficient of frictionIncrease stressCutting insertsTurning toolsDiamond turningEngineering

The invention discloses a high-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling, and belongs to the technical field of cutting tools. The double-sided diamond turning tool blade aims to solve the problems that an existing blade is high in cutting temperature, large in cutting force, difficult in chip breaking, serious in tool wear, low in cutting efficiency and the like in the cutting machining process. The double-sided diamond turning tool blade comprises a double-sided available diamond blade with an included angle of 80 degrees, wherein linear cutting edges are arranged at the edges of a front blade face of the blade; circular protrusions are arranged on the front blade face along the directions of the linear cutting edges, a circular arc-shaped tool nose is arranged at the intersection of every two cutting edges, and a circular groove microstructure is distributed at each circular arc-shaped tool nose; triangular-like chip breaking bosses are arranged at the positions close to the circular groove microstructures, and a circular chip breaking groove is formed in each triangular-like chip breaking boss; and combined microstructures are arranged on a rear blade face of the blade, eight trapezoidal protrusions are distributed in the middle area of the blade, and a flow guide groove is formed between every two adjacent trapezoidal protrusions. The high-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling is used for semi-finish machining and finish machining of a high-temperature alloy material under a high-pressure cooling condition.

Owner:HARBIN UNIV OF SCI & TECH

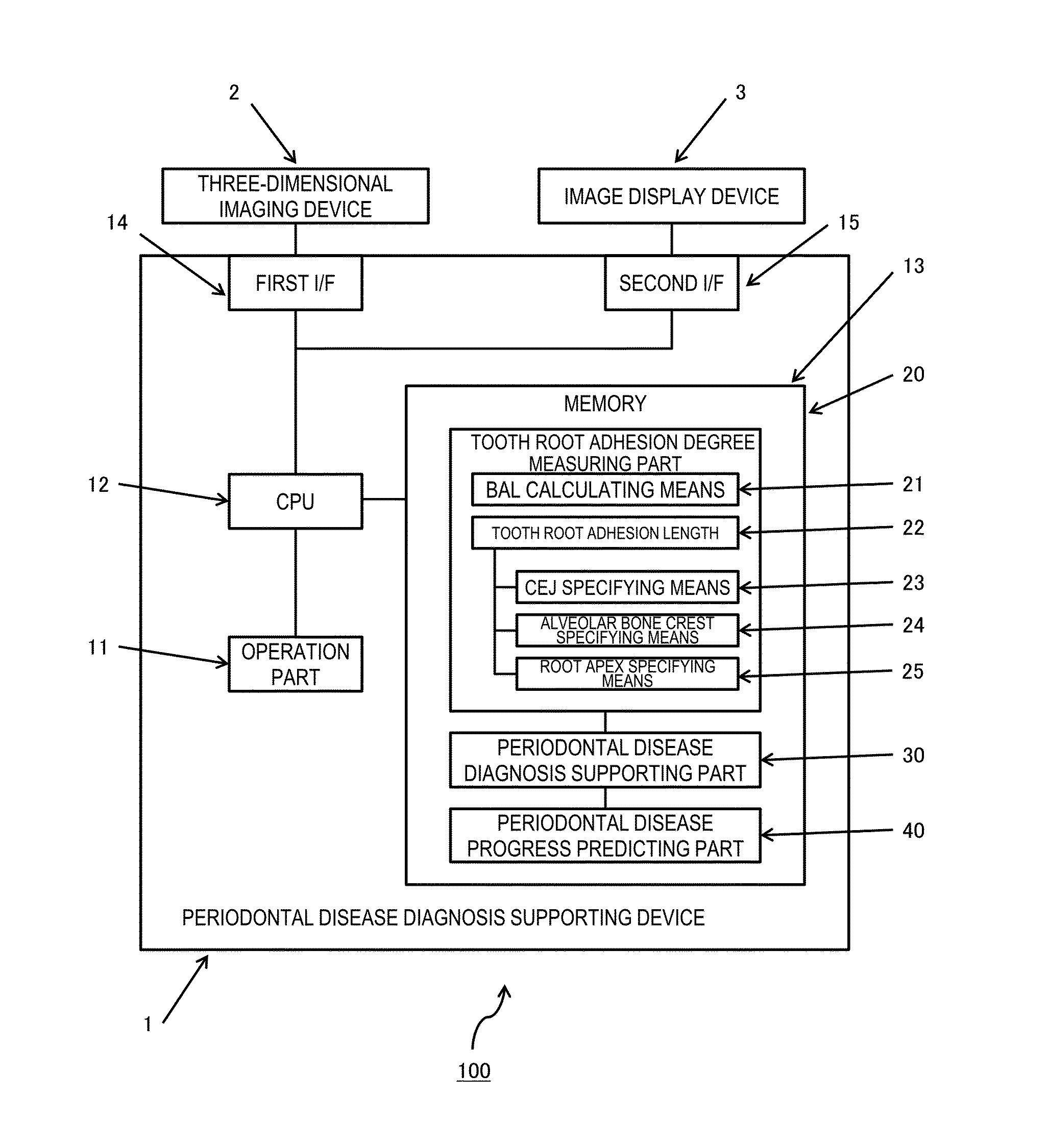

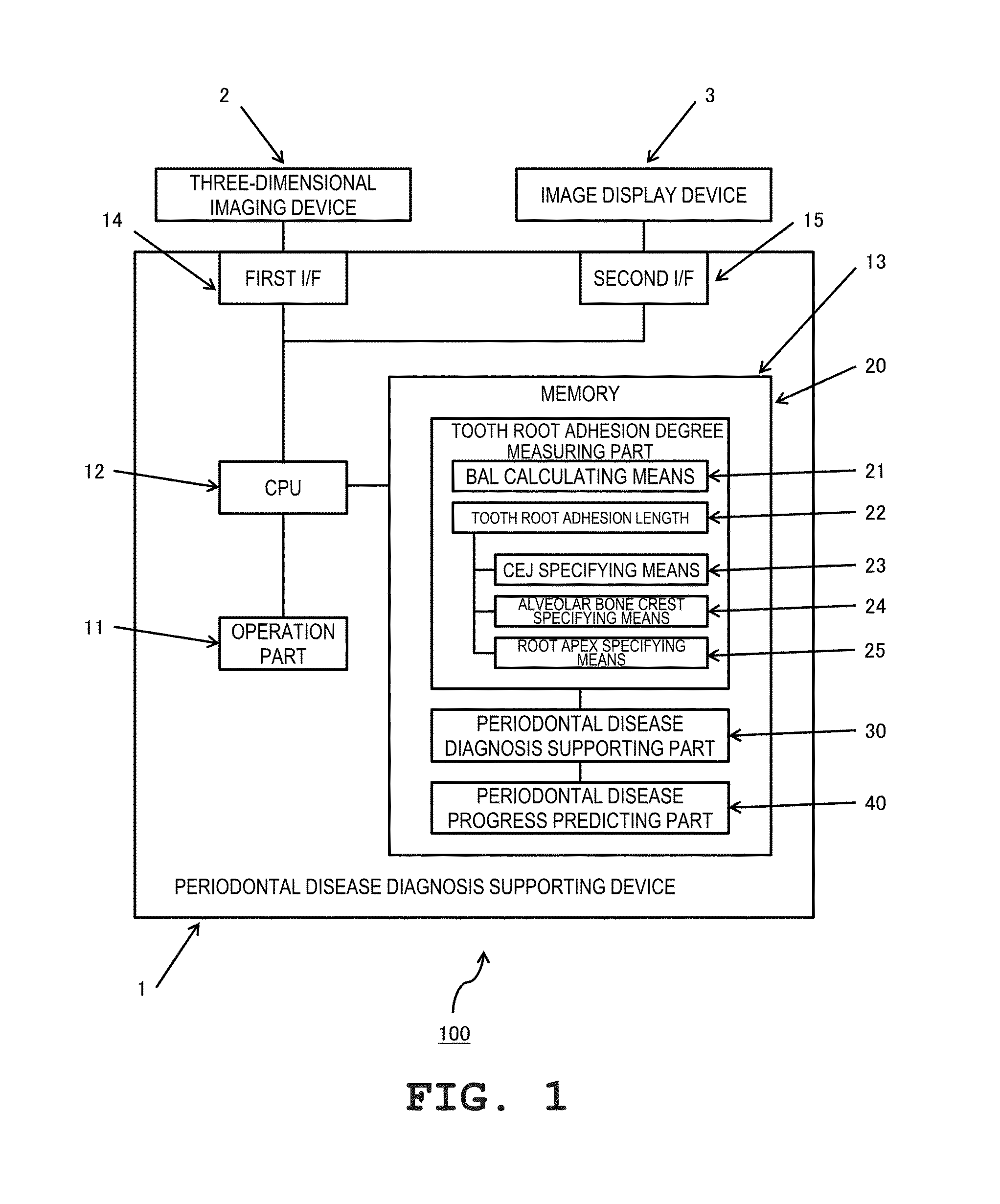

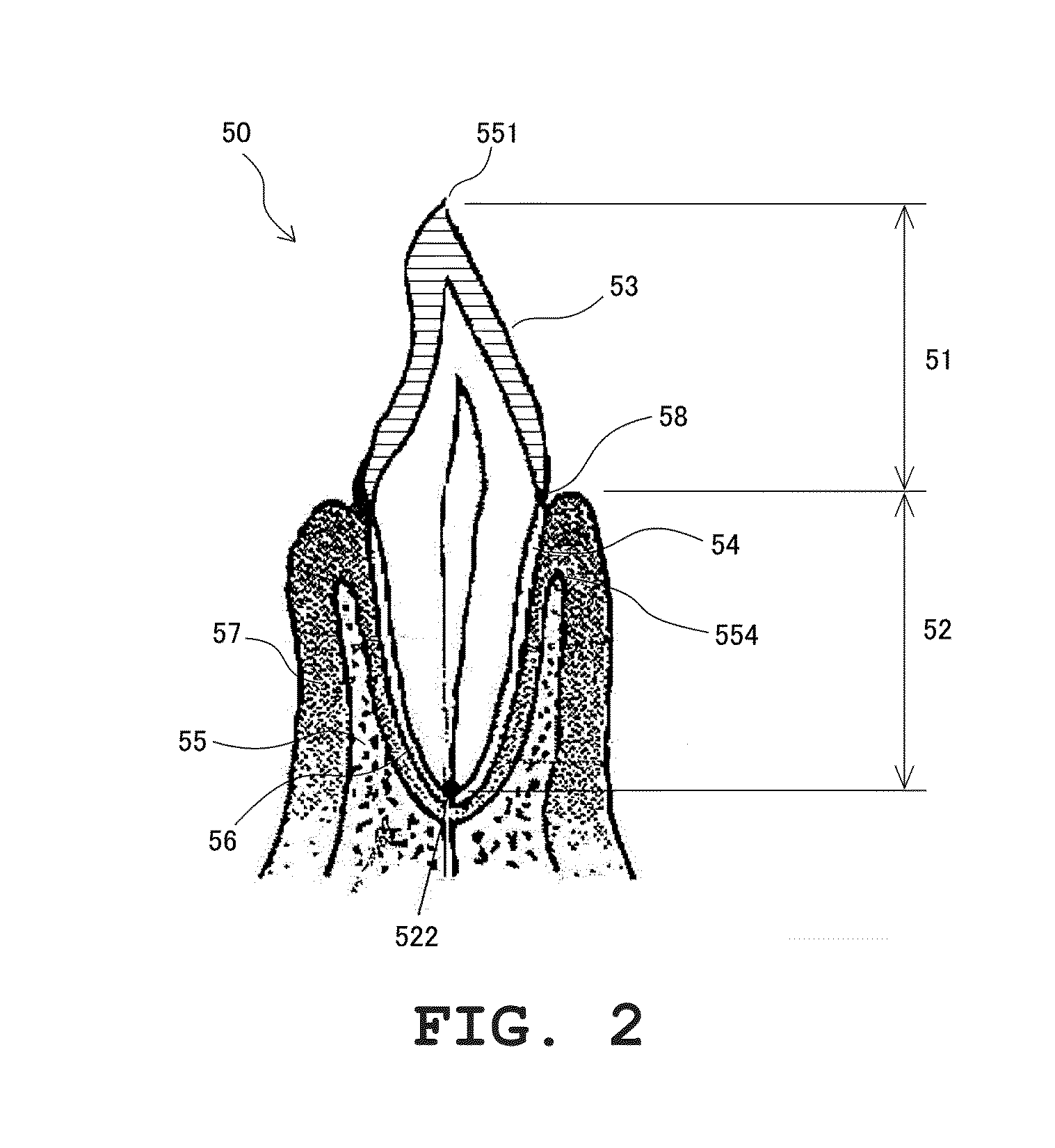

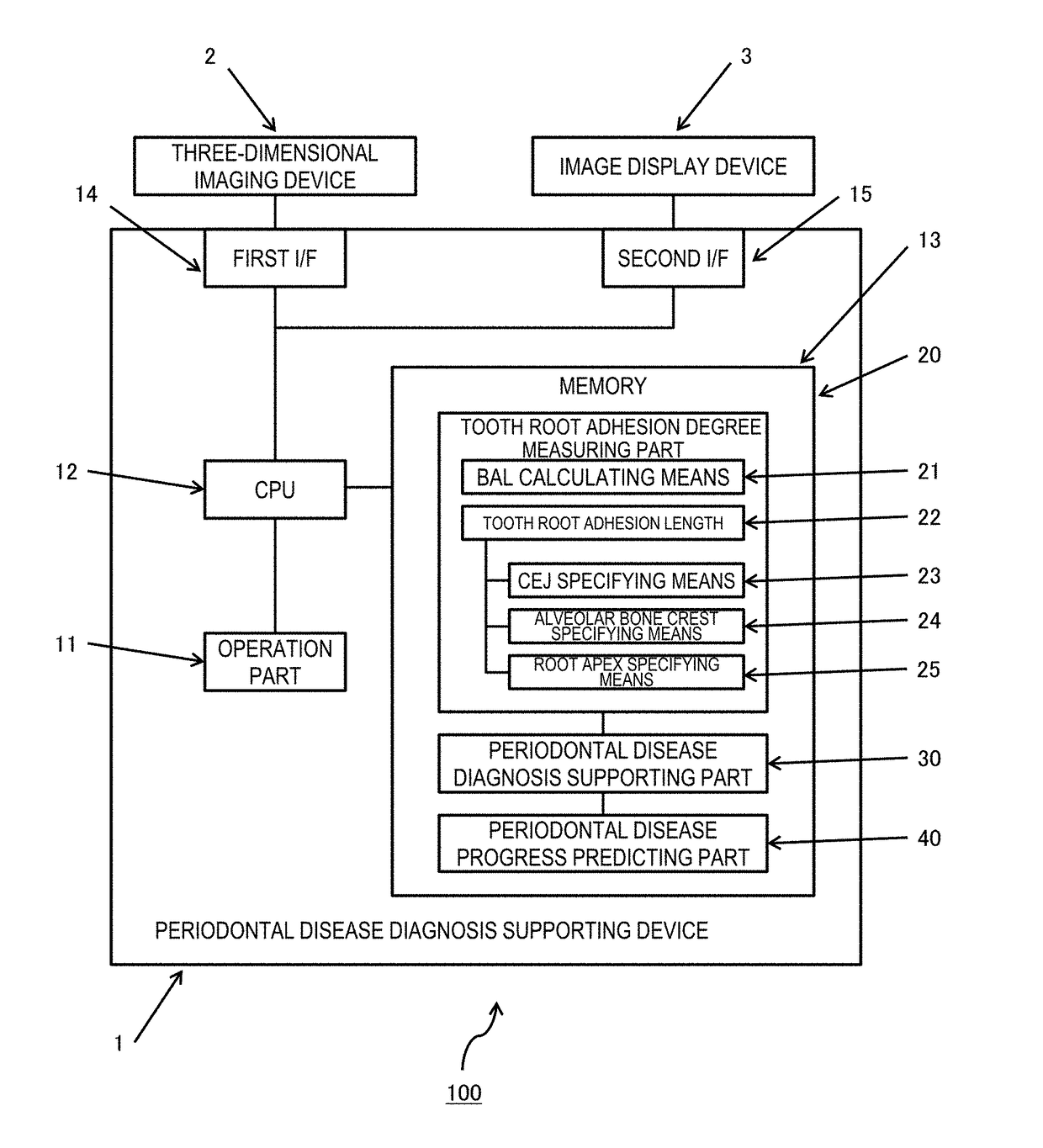

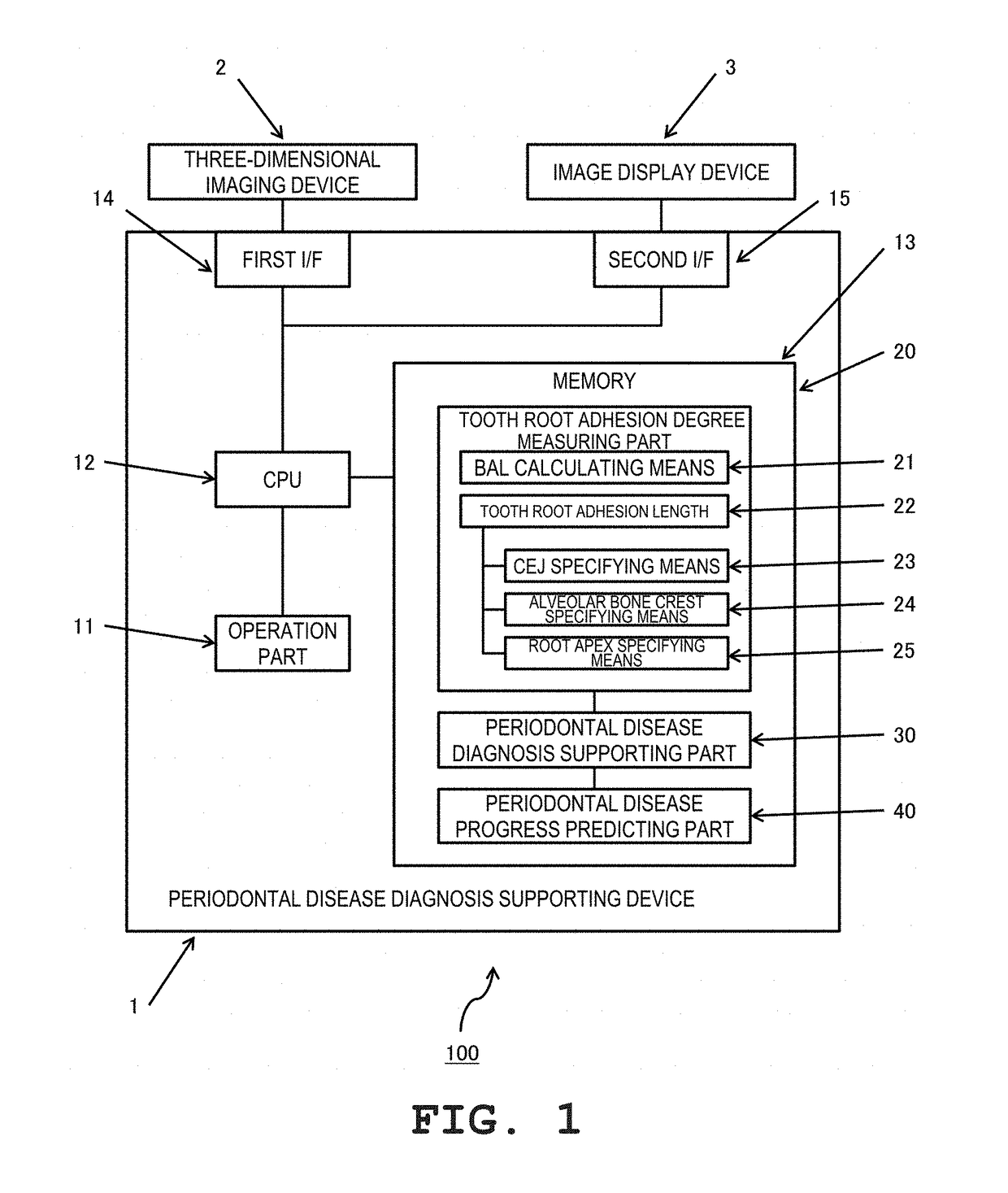

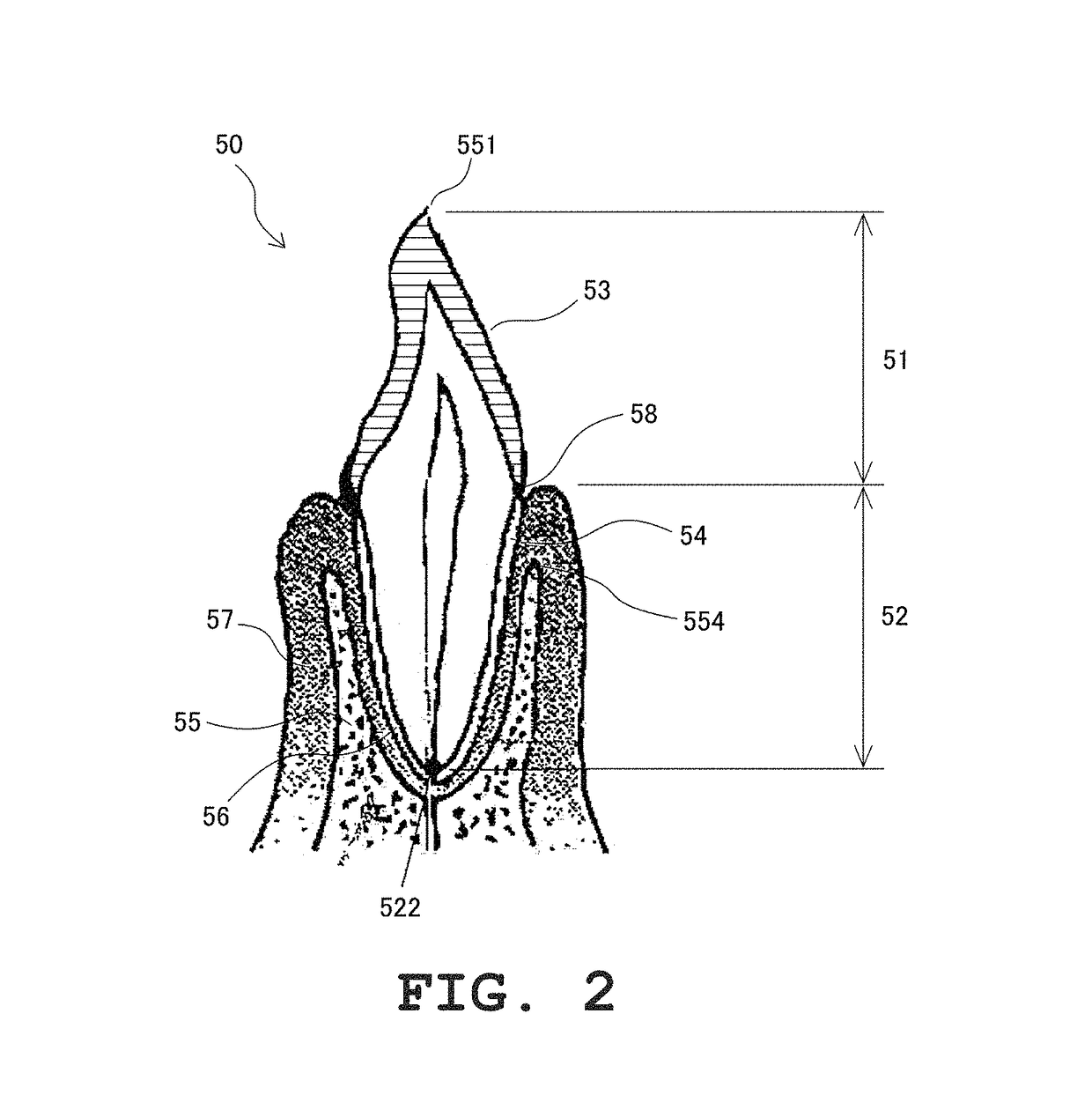

Periodontal disease diagnosis supporting device, periodontal disease diagnosis supporting system, periodontal disease diagnosis supporting program, and periodontal disease diagnosis supporting method

ActiveUS20160183866A1Highly reliable support informationImprove accuracyMedical imagingDental toolsDiseaseSupporting system

In a test for supporting diagnosis of periodontal disease, a test method, whose measurement result has reproducibility and can be an objective index, is achieved and the loss of a tooth is predicted by use of the obtained objective index. A periodontal disease diagnosis supporting device supports diagnosis of periodontal disease by use of a captured three-dimensional image of a tooth part. The device includes a tooth root adhesion degree measuring part for measuring a degree of adhesion between a tooth root and alveolar bone by use of the image. The device further includes a periodontal disease diagnosis supporting part for supporting diagnosis of periodontal disease by use of a measurement result of the measuring part.

Owner:MEDEIA

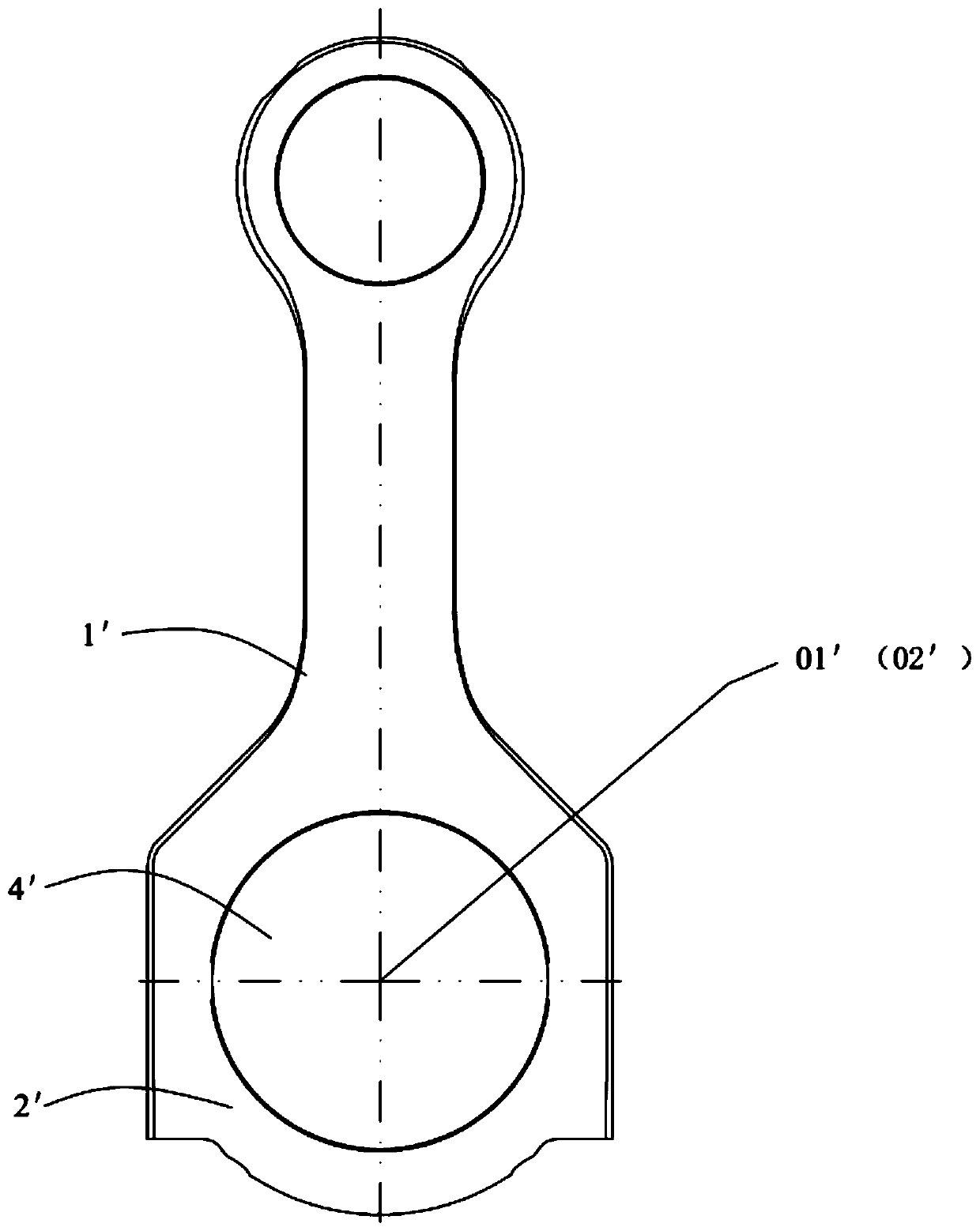

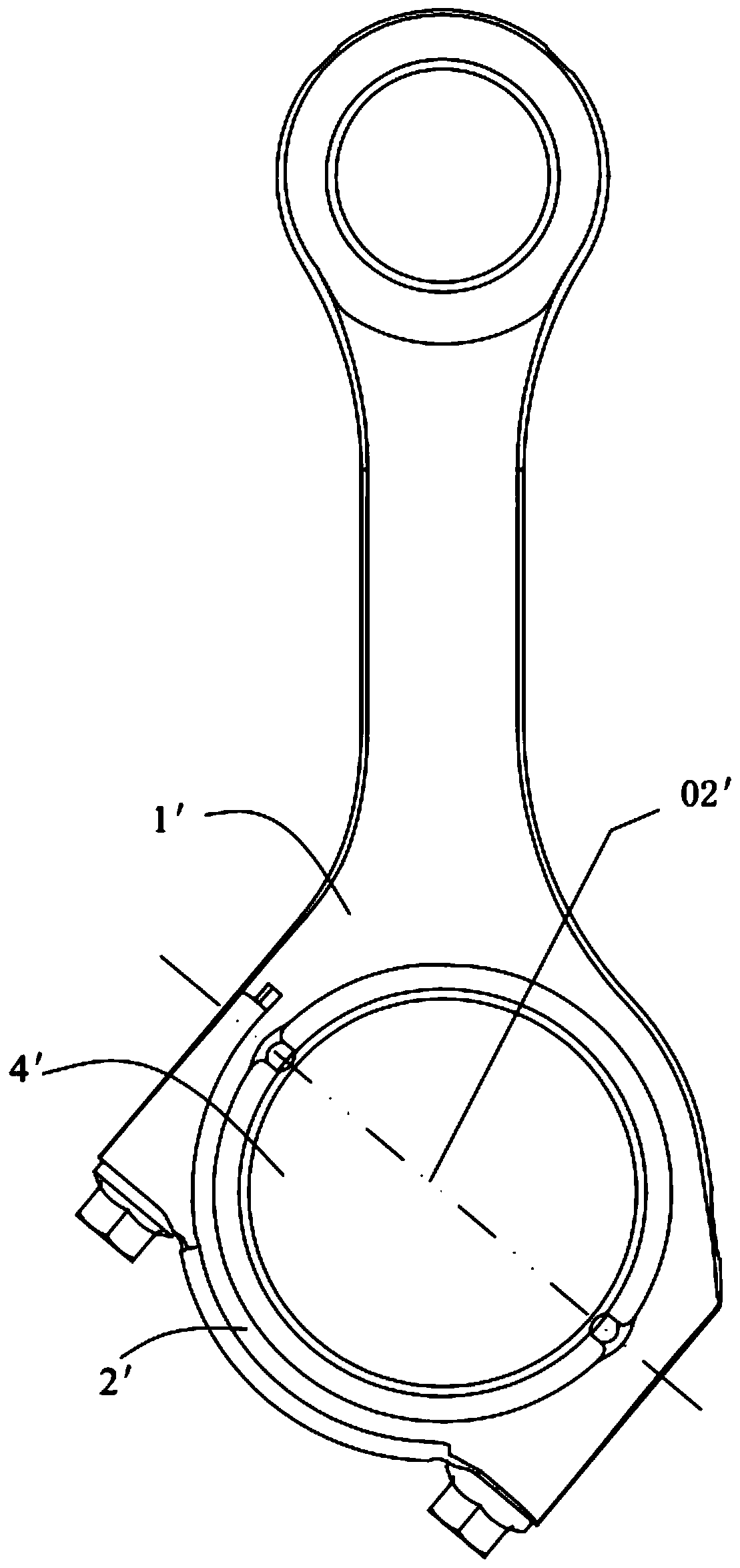

Connecting rod structure and engine

The invention belongs to the technical field of vehicles, and discloses a connecting rod structure and an engine. The connecting rod structure comprises a connecting rod body and a connecting rod cover. The connecting rod body and the connecting rod cover are detachably connected through a connecting rod bolt. A connecting rod large head hole is formed between the connecting rod body and the connecting rod cover. A cutting contact surface between the connecting rod body and the connecting rod cover is not overlapped with the central plane of the connecting rod large head hole and is located onone side, close to the connecting rod cover, of the central plane. According to the connecting rod structure, if the length of the connecting rod bolt is unchanged, the contact length of the connecting rod bolt and the connecting rod body is increased so as to enhance the connecting strength between the connecting rod cover and the connecting rod body; and if the contact length of the connectingrod bolt and the connecting rod body is kept unchanged, the thickness between the bottom of a connecting rod bolt hole and the side wall of the connecting rod body is increased, and the situation thatthe wall thickness between the connecting rod bolt hole and the connecting rod body is too small, and bending deformation happens easily is avoided, so that the rigidity of a connecting rod large head is improved.

Owner:WEICHAI POWER CO LTD

Periodontal disease diagnosis supporting device, periodontal disease diagnosis supporting system, periodontal disease diagnosis supporting program, and periodontal disease diagnosis supporting method

ActiveUS10010299B2Easy to attachDecrease in alveolar bone crestCharacter and pattern recognitionComputerised tomographsSupporting systemOrthodontics

In a test for supporting diagnosis of periodontal disease, a test method, whose measurement result has reproducibility and can be an objective index, is achieved and the loss of a tooth is predicted by use of the obtained objective index. A periodontal disease diagnosis supporting device supports diagnosis of periodontal disease by use of a captured three-dimensional image of a tooth part. The device includes a tooth root adhesion degree measuring part for measuring a degree of adhesion between a tooth root and alveolar bone by use of the image. The device further includes a periodontal disease diagnosis supporting part for supporting diagnosis of periodontal disease by use of a measurement result of the measuring part.

Owner:MEDEIA

High-strength square milling blade for titanium alloy machining

The invention discloses a high-strength square milling blade for titanium alloy machining and belongs to the technical field of tools for cutting machining to solve the problems that when an existing milling blade is used for machining a titanium alloy, the quality of machined surfaces is not high, a tool is abraded seriously, and the machining efficiency is low. The horizontal cross section of the milling blade is square, and a thread installation hole used for being fixedly connected with a cutter rod is arranged at the geometric center position of the milling blade in the thickness direction. The milling blade is provided with two tool noses. The two sides of each tool nose are provided with a main cutting edge and a polishing edge. The two main cutting edges are symmetrically arranged relative to the geometric center of the milling blade, and the two polishing edges are symmetrically arranged relative to the geometric center of the milling blade. Two sets of tapered protrusions are arranged on the front cutter face of the milling blade and are arranged adjacent to the two main cutting edges. A back cutter face comprising the main cutting edges on the milling blade is composed of a main cutting edge rear cutter face and a blade base rear cutter face from top to bottom, and the blade base rear cutter face is an oblique face with the lower portion inclining towards the inner side of the milling blade. The high-strength square milling blade is used for carrying milling on titanium alloy workpieces.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com