Cutting rollers of multi-wire cutting machine

A multi-wire cutting machine and cutting roller technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of large resistance and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

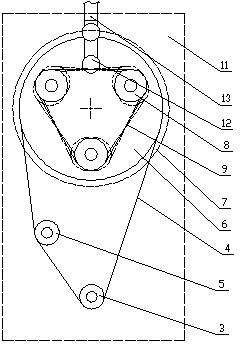

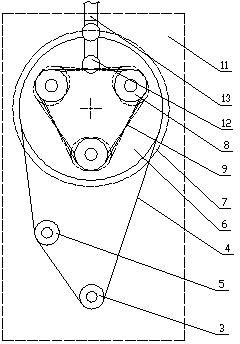

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

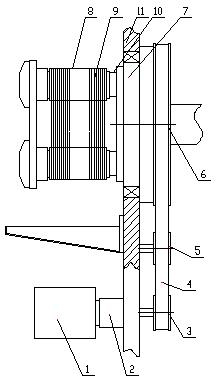

[0013] Depend on figure 1 , figure 2 It can be seen that a cutting roller of a multi-wire cutting machine includes a frame 11, and a rocking plate 7 driven by power is arranged on the frame 11. on board 7.

[0014] In the present invention, the swinging plate 7 rotates along its center in an angle range of -5° to +5° (in this embodiment, -3° to +3°).

[0015] The cutting roller set of the present invention includes three cutting rollers 8 arranged in an equilateral triangle arranged on the rocking plate 7 .

[0016] The power of the present invention is the servo motor 1 installed on the frame 11, the rocking plate 7 is connected with the large synchronous pulley 6, and the servo motor 1 passes through the reducer 2, the small synchronous pulley 3, the synchronous belt 4 and the large synchronous belt Wheel 6 is connected.

[0017] The frame 11 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com