Patents

Literature

58results about How to "Good cutting precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

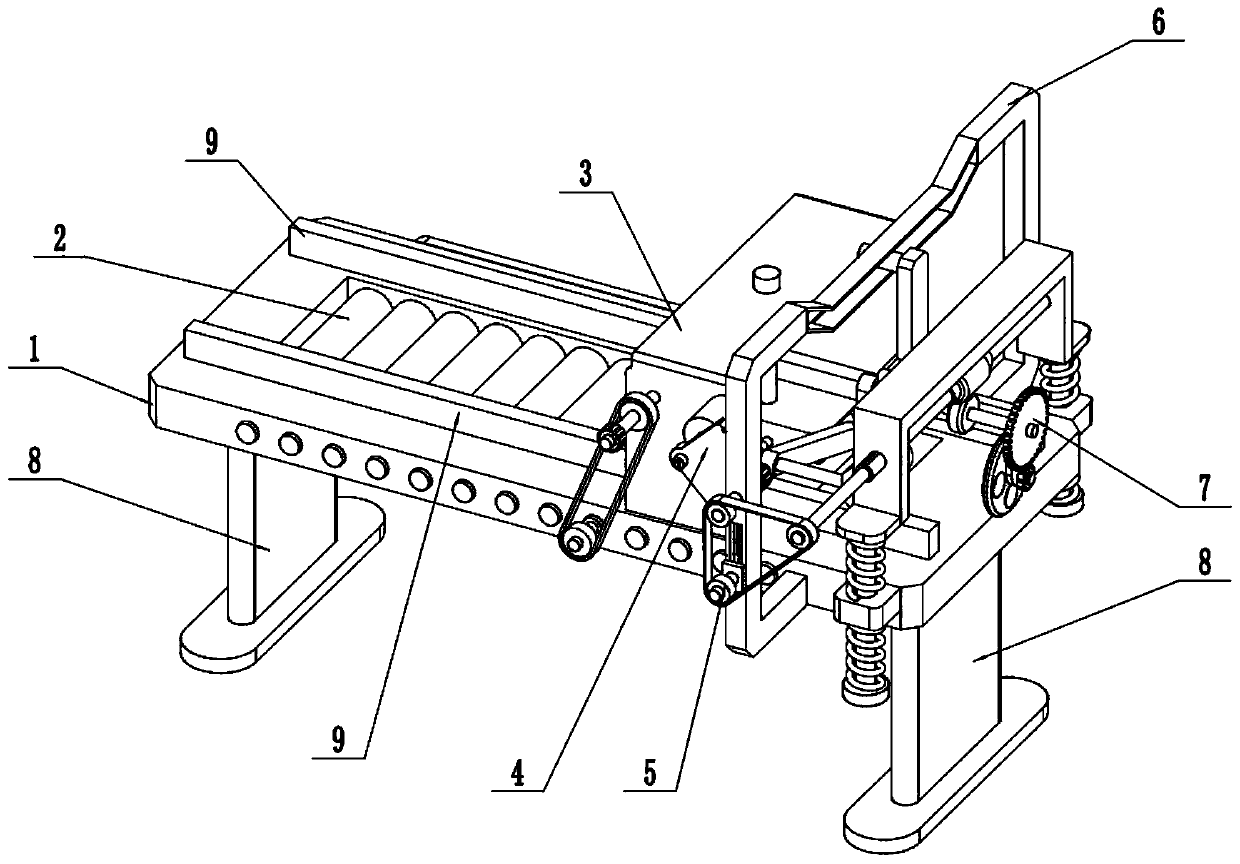

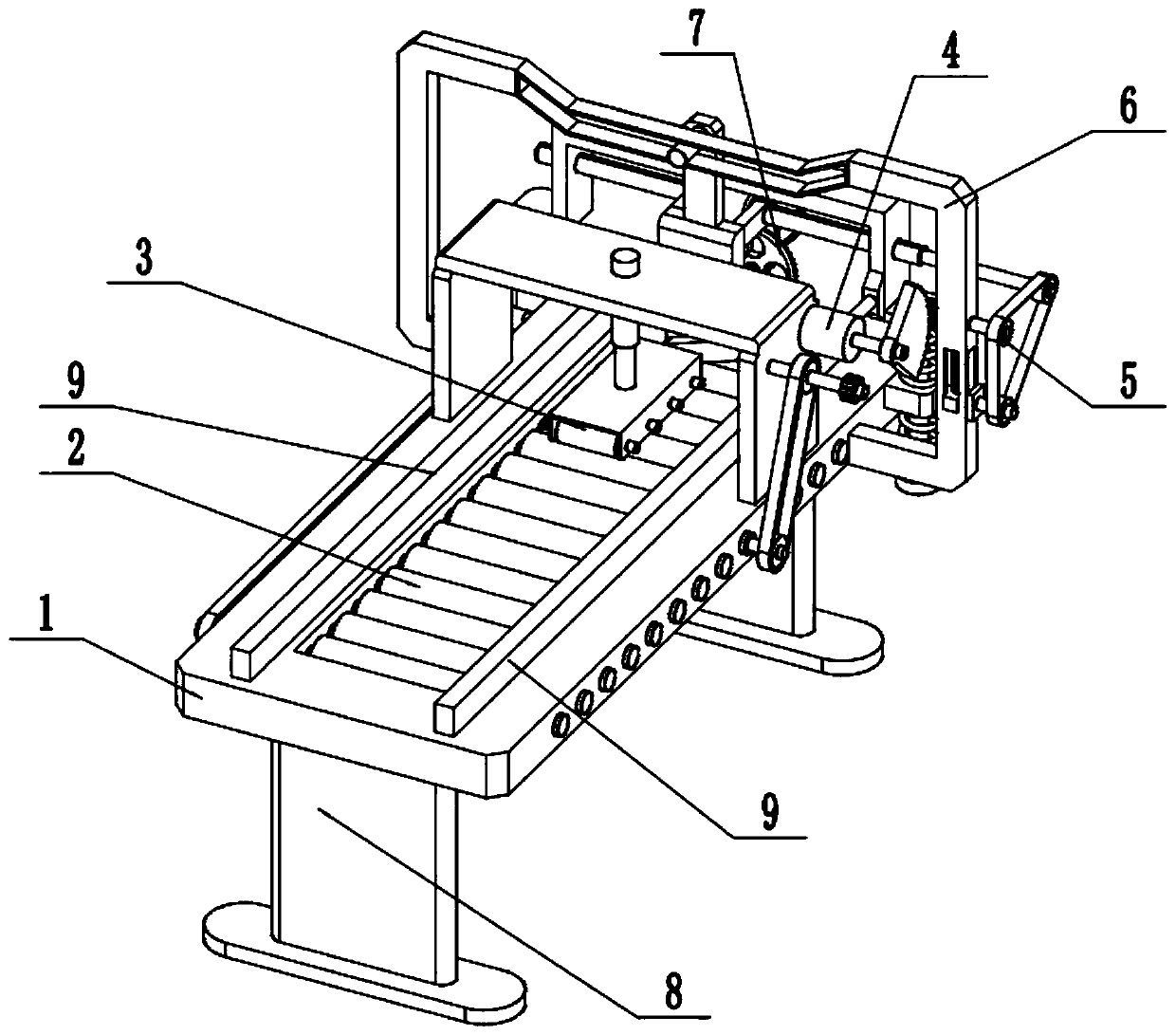

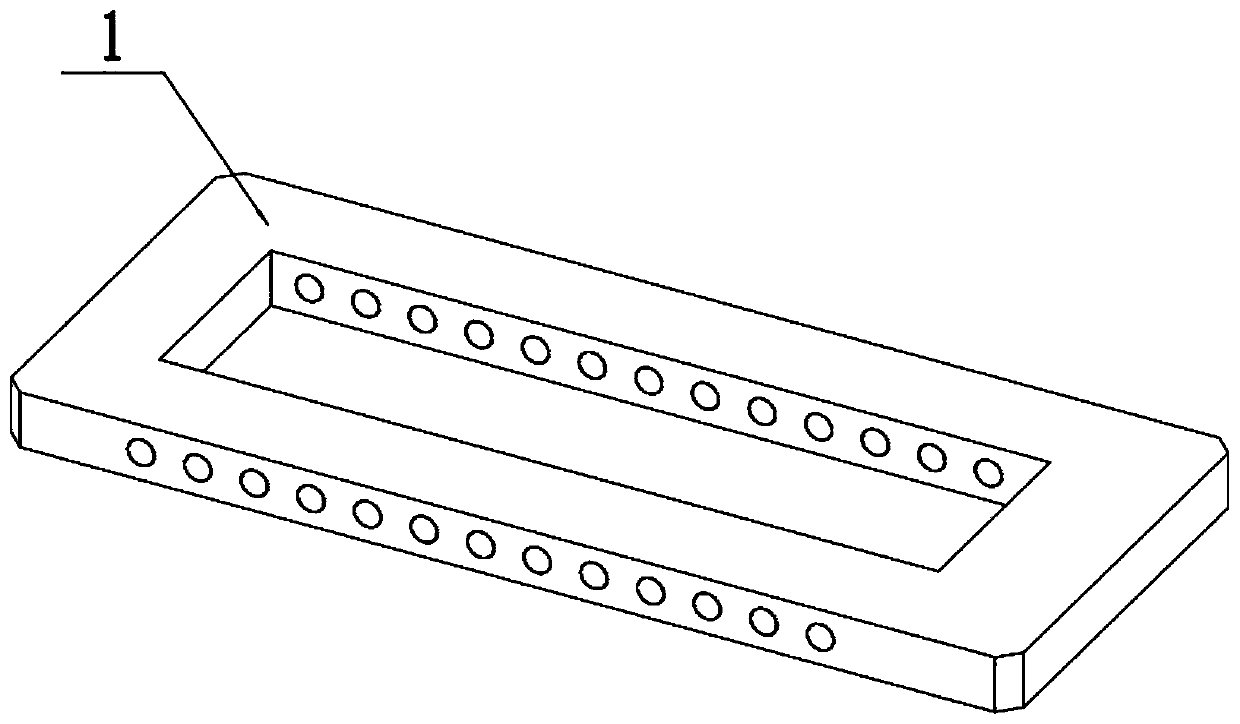

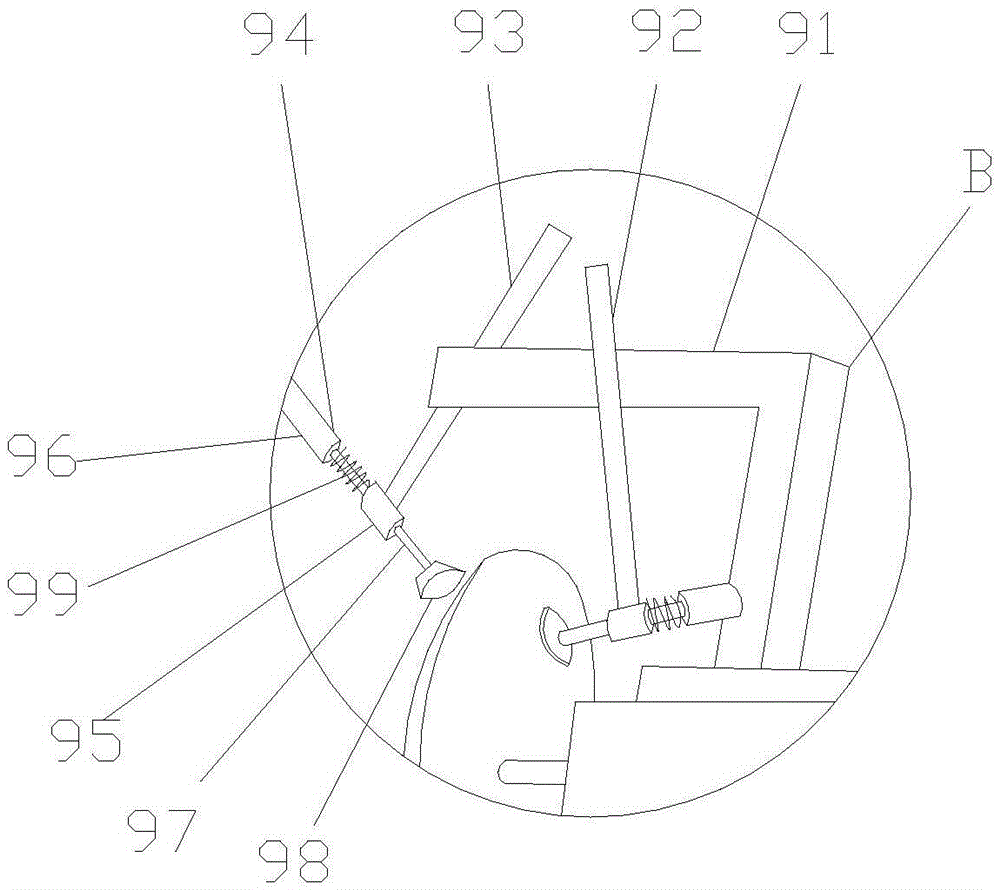

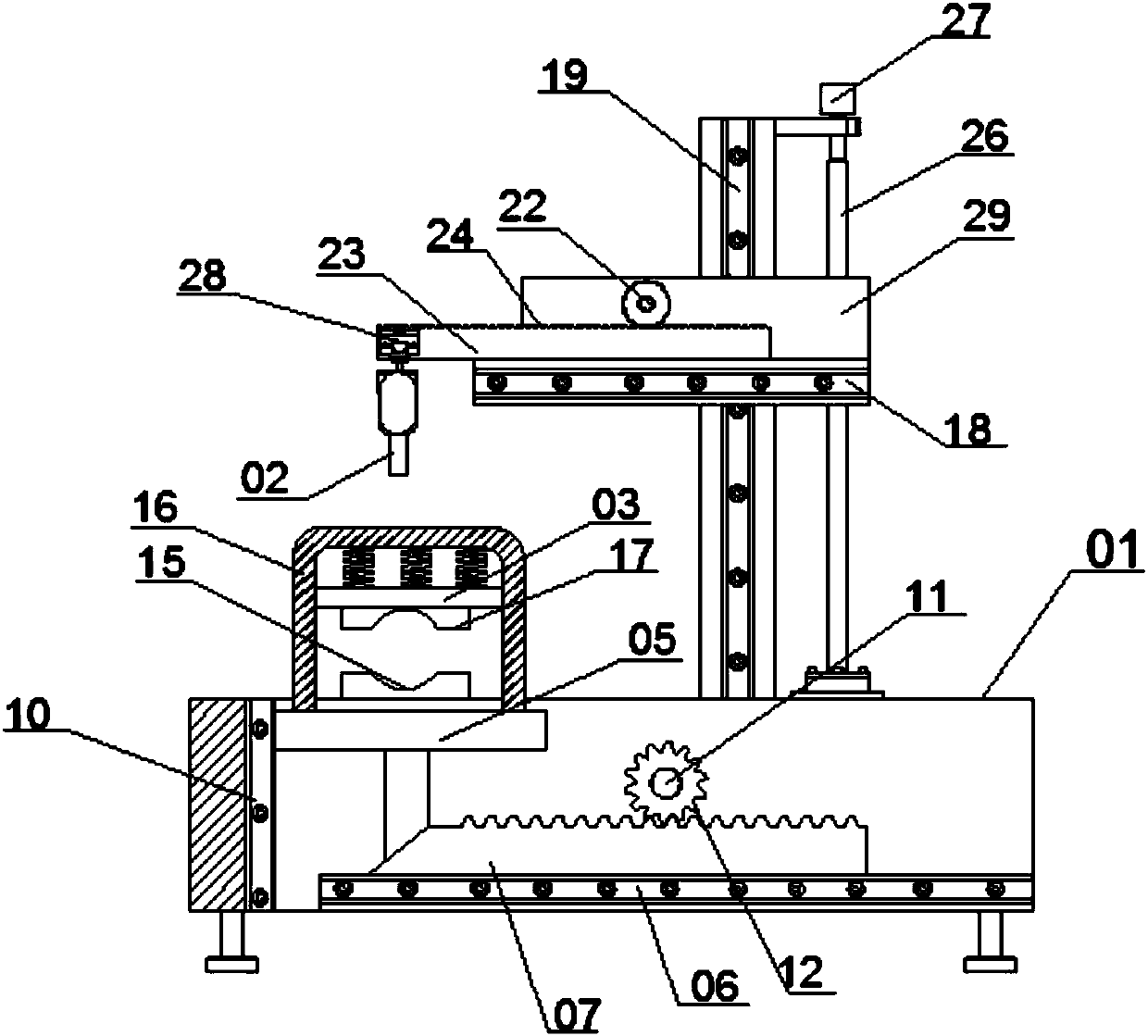

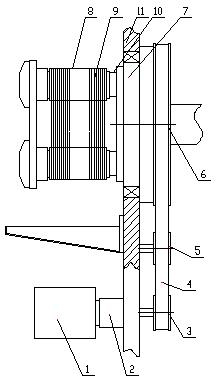

Wood board fixed-length cutting device

InactiveCN110238914AImprove cutting efficiencyImprove stabilityFeeding devicesGripping devicesEngineeringFixed length

The invention relates to the field of wood processing, in particular to a wood board fixed-length cutting device. The wood board fixed-length cutting device comprises a rack, a board conveying roller assembly, a pressure roller, a driving mechanism, a tensioning linkage wheel, a guide frame, a cutting mechanism, supporting legs and side baffles; the supporting legs are fixed at the front end and the rear end of the bottom face of the rack separately; the side baffles are fixed at the left end and the right end of the top face of the rack separately; the board conveying roller assembly is connected in an installation groove in the top face of the rack; the board conveying roller assembly is located between the two side baffles; the pressure roller is arranged at the front end of the top face of the rack; and the board conveying roller assembly is connected to the side end of the pressure roller. According to the wood board fixed-length cutting device, continuous fixed-length cutting is carried out on a wood board by adopting an automatic feeding and fixed length cutting mode, the cutting efficiency is high, and the labor force is low.

Owner:李锋

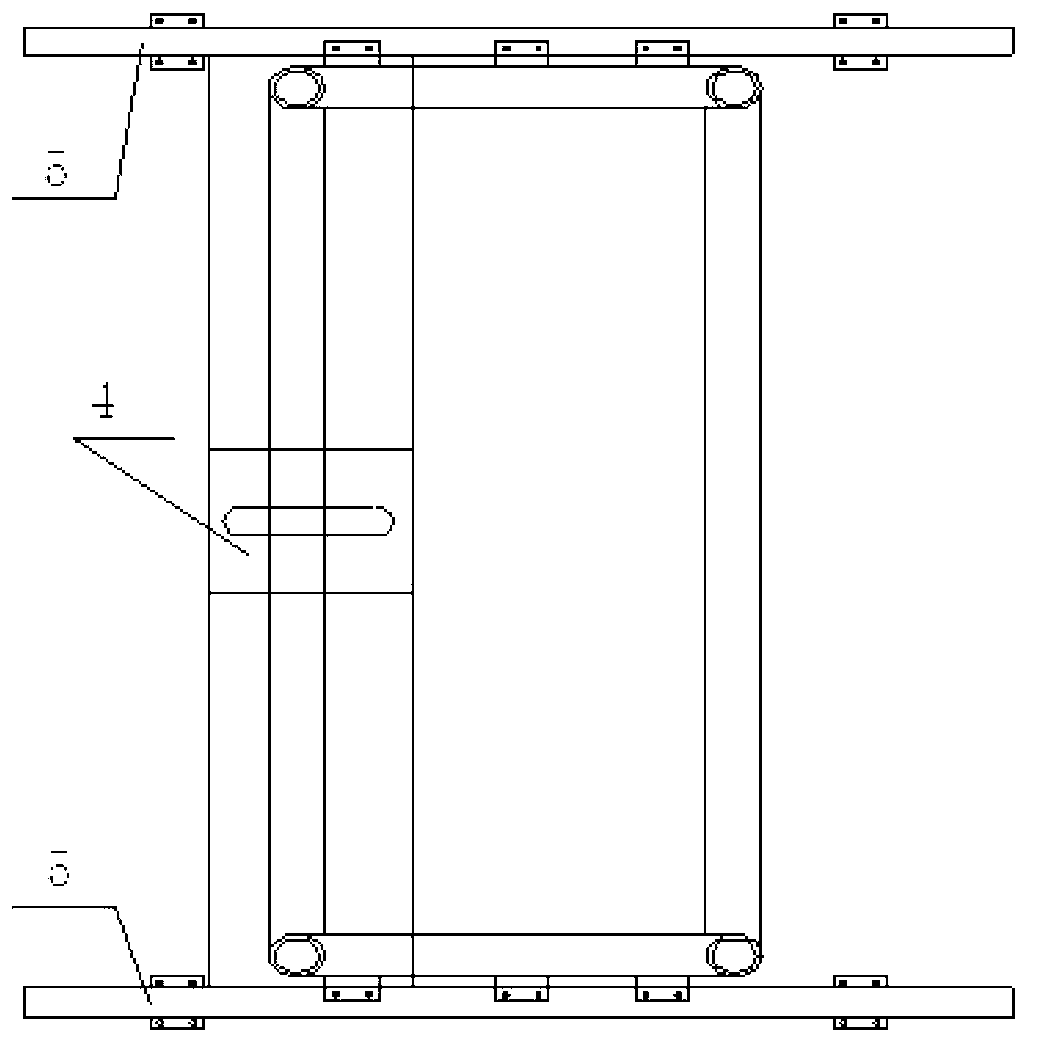

Cloth slitter

InactiveCN105619505APrevent affecting cutting accuracyGood cutting precisionSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention mainly discloses a cloth slitter. According to the technical scheme, the cloth slitter comprises a machine frame, a machine head, a machine tail, a moving device, a cutting device, a knife sharpening device and a PLC control cabinet; a loop bar is arranged between the machine head and the machine tail; the cutting device is connected to the upper side of the moving device; the PLC control cabinet controls the moving device and the cutting device; the cutting device comprises a cutting frame, a first motor, a cutting knife and an air cylinder; the knife sharpening device comprises a supporting frame, a first polishing support, a second polishing support and a pair of polishing modules, wherein the first polishing support and the second polishing support are installed on the two sides of the supporting frame respectively in an inclined mode and are connected to the respective corresponding polishing modules, and the polishing modules are located on the two sides of the cutting knife respectively. The cloth slitter has the advantages of being simple in structure, convenient to operate, accurate in cutting and capable of polishing the cutting knife.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

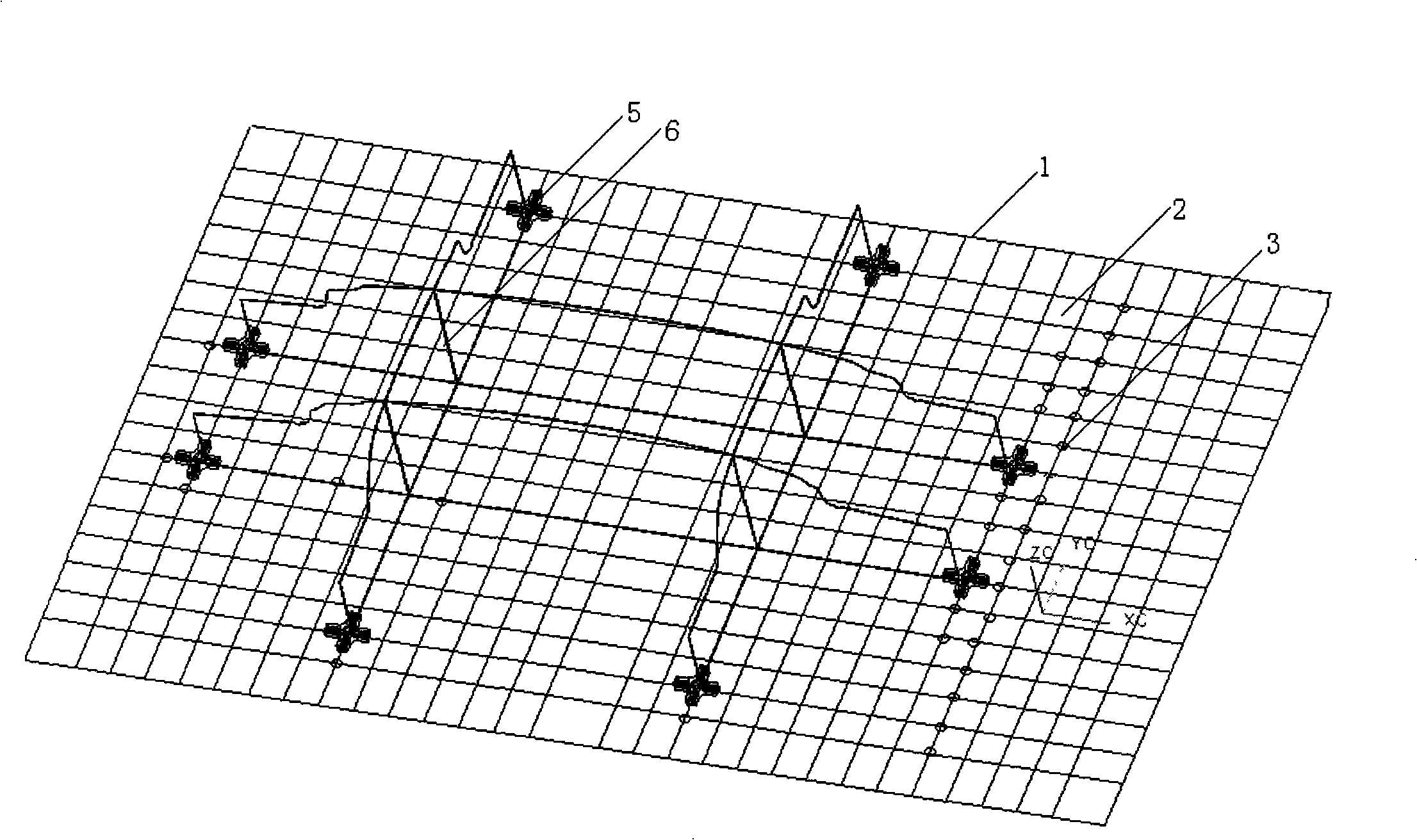

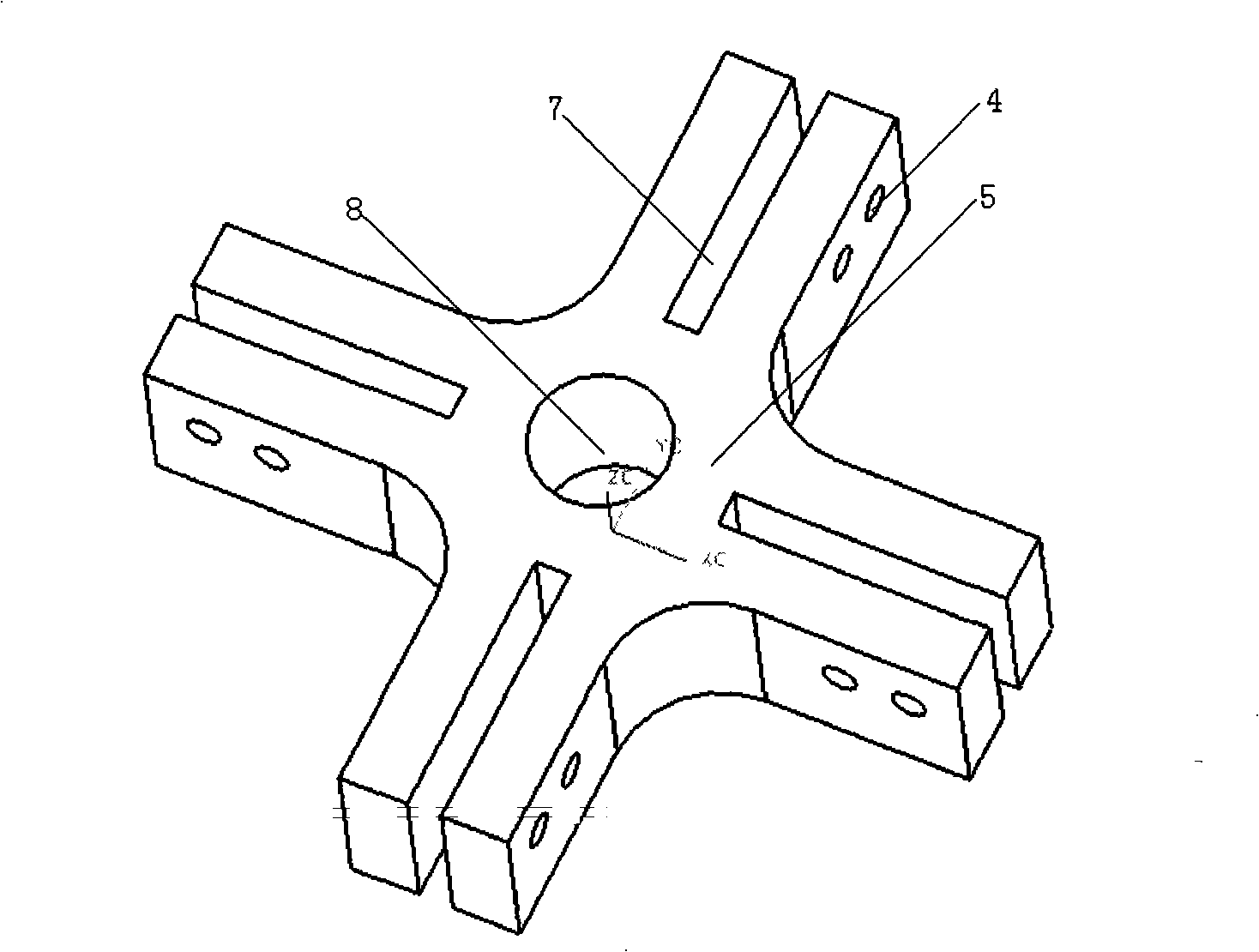

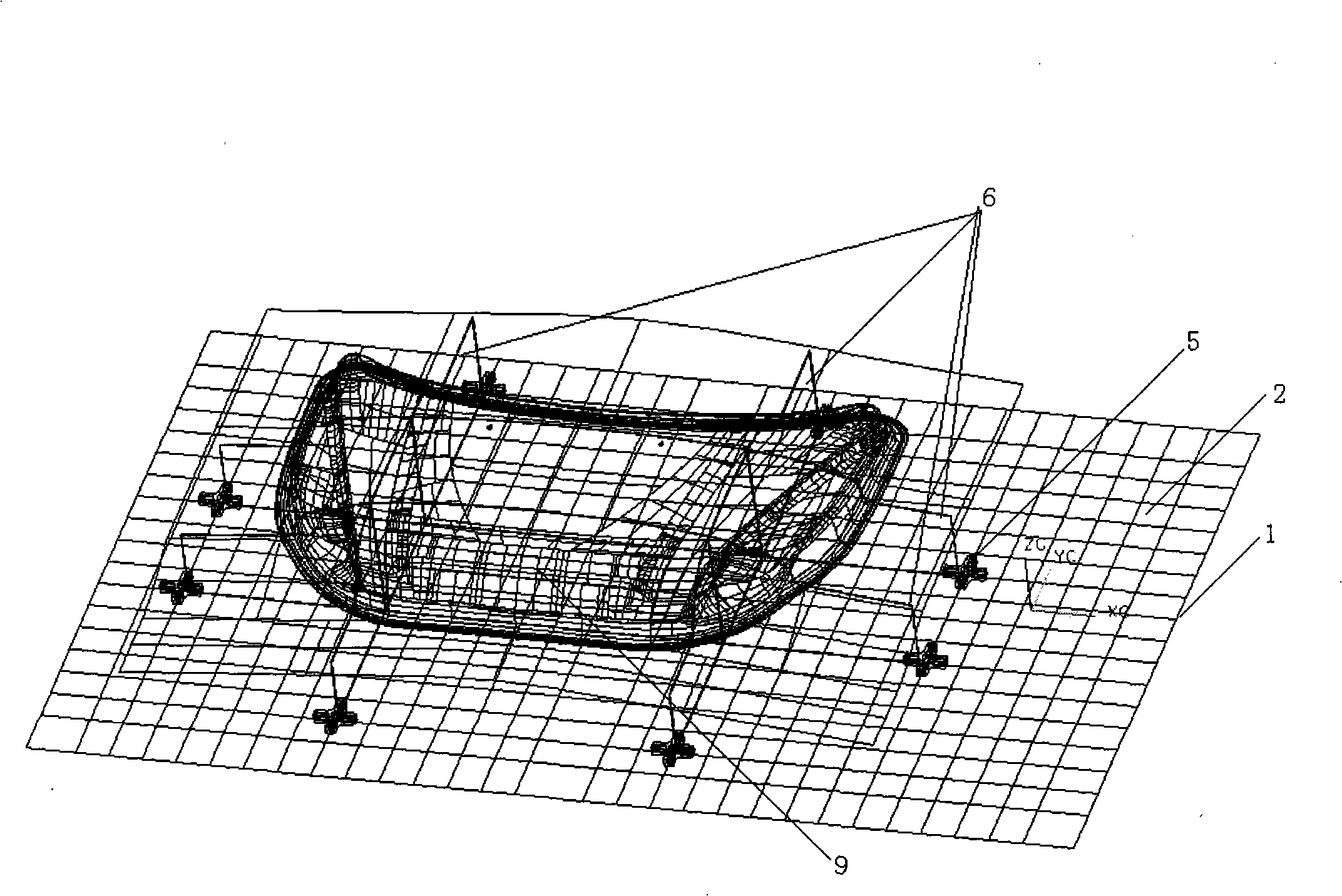

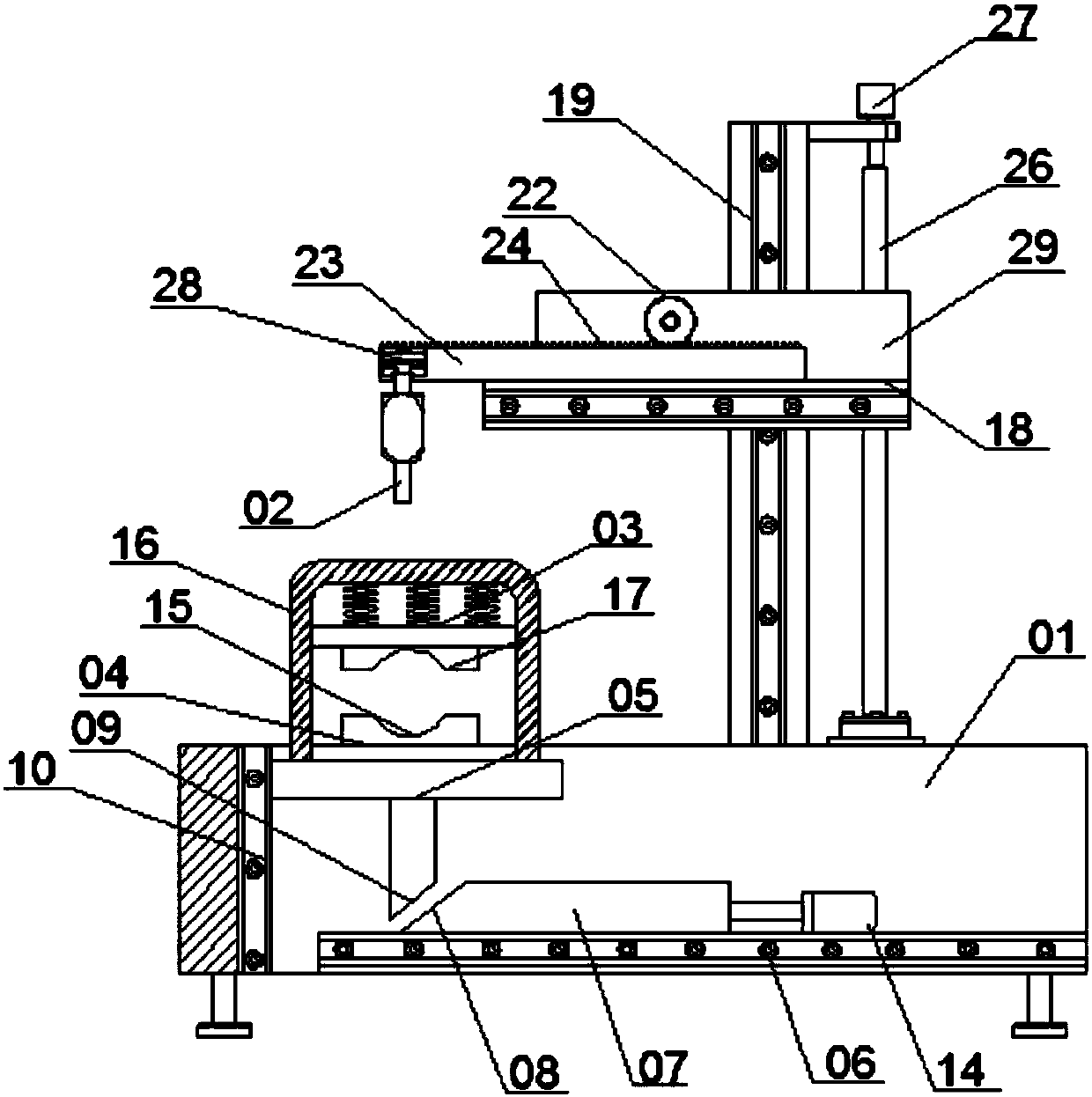

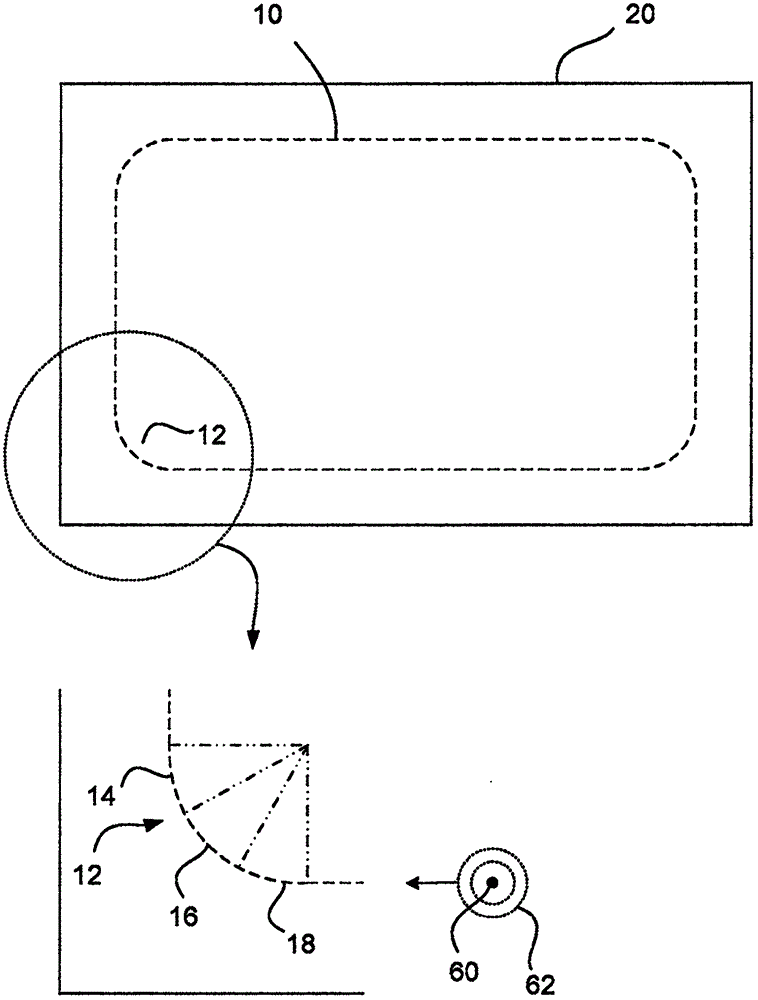

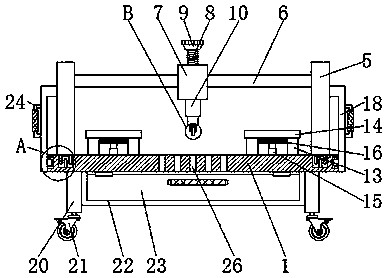

Coordinates platform for accurately locating three-dimensional laser cutting part

ActiveCN101407008AEasy positioning and programming workConvenient and effective positioningWelding/cutting auxillary devicesAuxillary welding devicesMeeting placeRectangular coordinates

The invention discloses a coordinate platform for accurately positioning three-dimensional laser cut parts, which aims to provide a coordinate platform which is convenient and fast, not only accurately and quickly positions three-dimensional laser cut parts, but also does not need the re-positioning in the repeated cutting, so that the parts can be repeatedly and accurately positioned under the machine coordinate system a plurality of times, and the positioning, programming and cutting work for laser cutting can be conveniently performed. The coordinate platform also comprises a positioning bottom plate, of which the shape is similar to that of the operating platform of the laser cutting machine, and a clip plate for positioning the cut parts. The positioning bottom plate is provided with a rectangular coordinate grid with isometric arrangement; meeting points of the coordinate grid are provided with positioning screw holes; clip plate connectors provided with cross clipping grooves are fixed on the positioning screw holes by fastening bolts; according to the shapes of the cut parts, the clip plate connectors are movably distributed on the meeting points of the coordinate grid, and the clip plate is fixed on the positioning bottom plate by the cross clipping grooves of the clip plate connectors so as to fix and support cut parts.

Owner:SICHUAN CHENGFEI INTEGRATION TECH

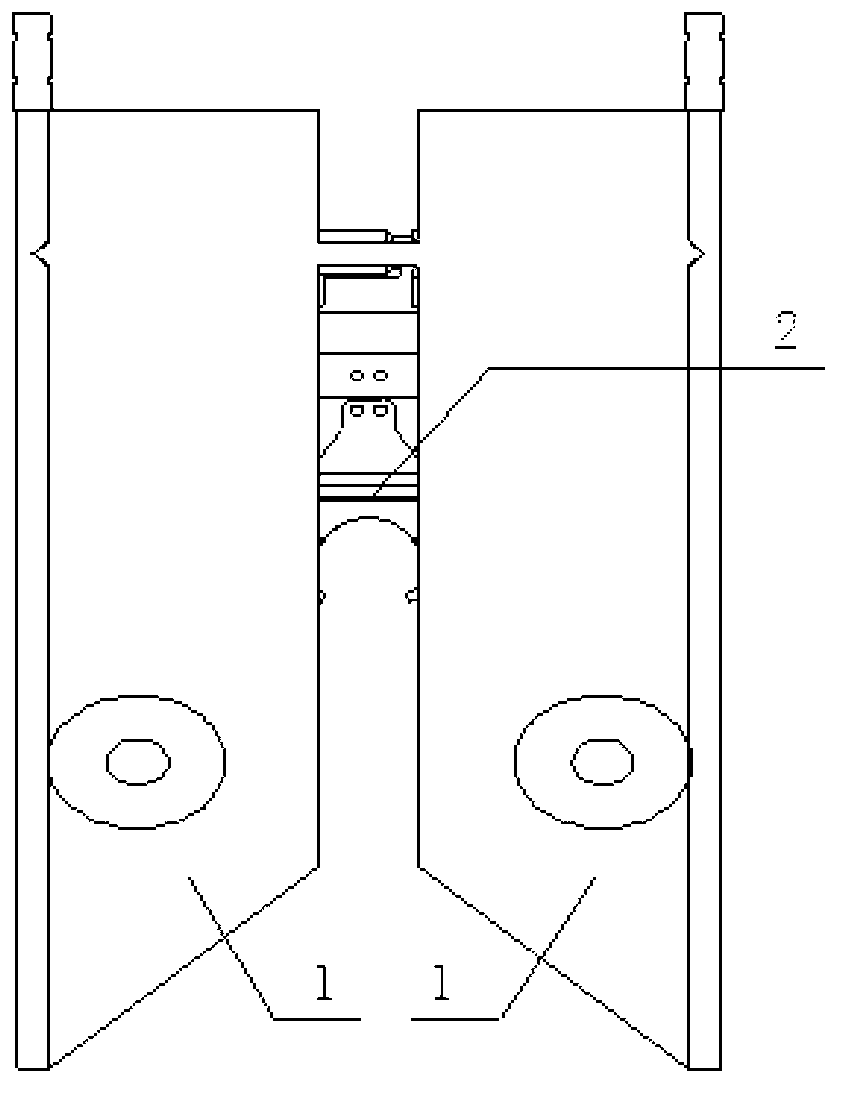

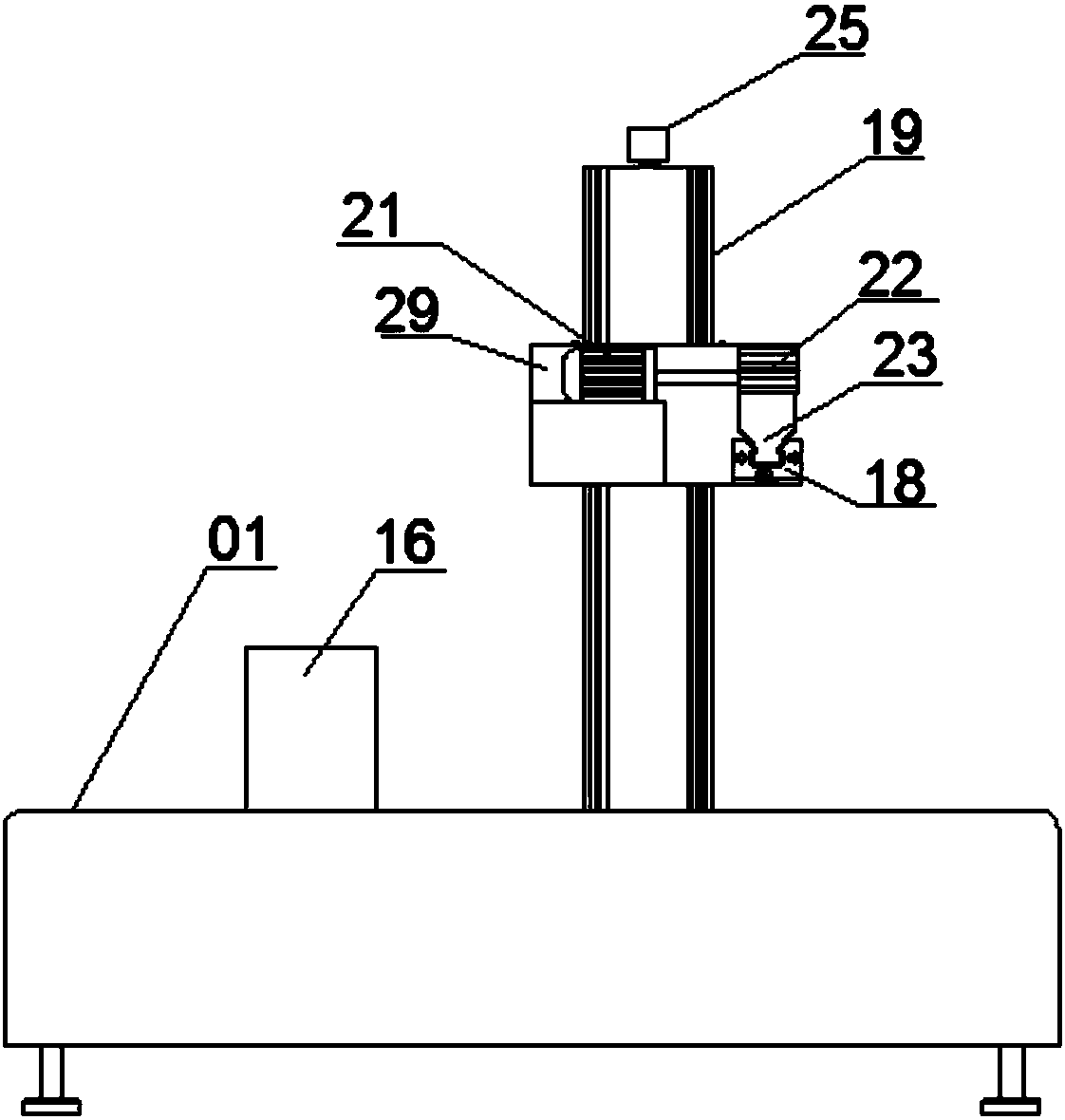

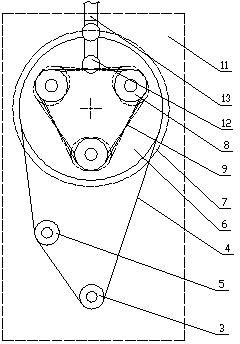

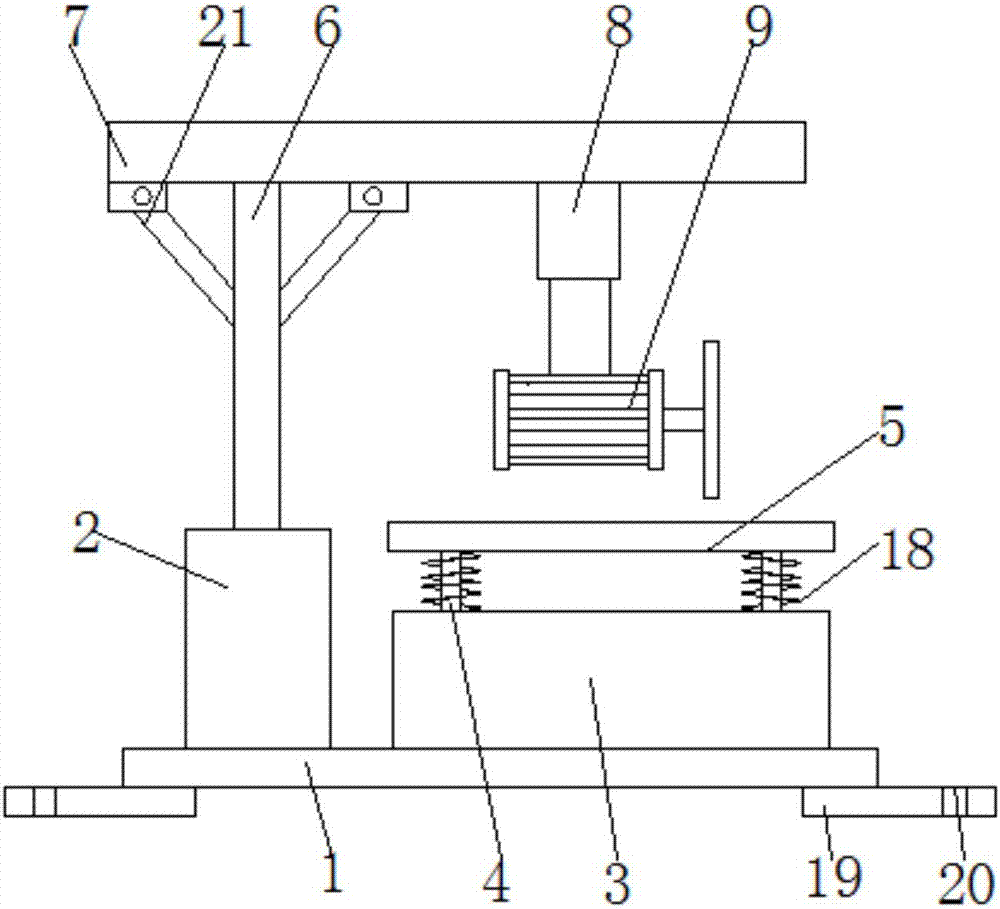

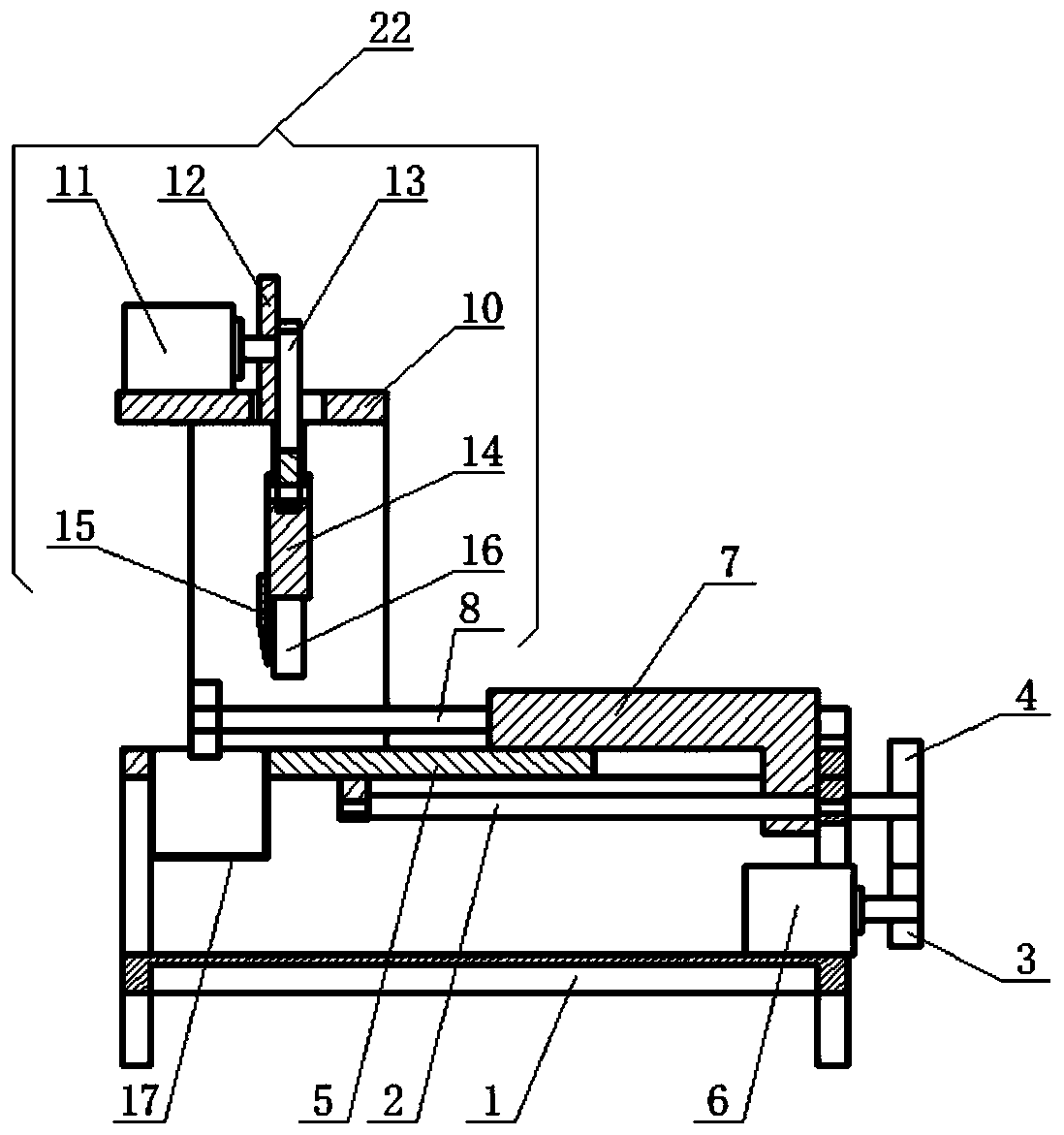

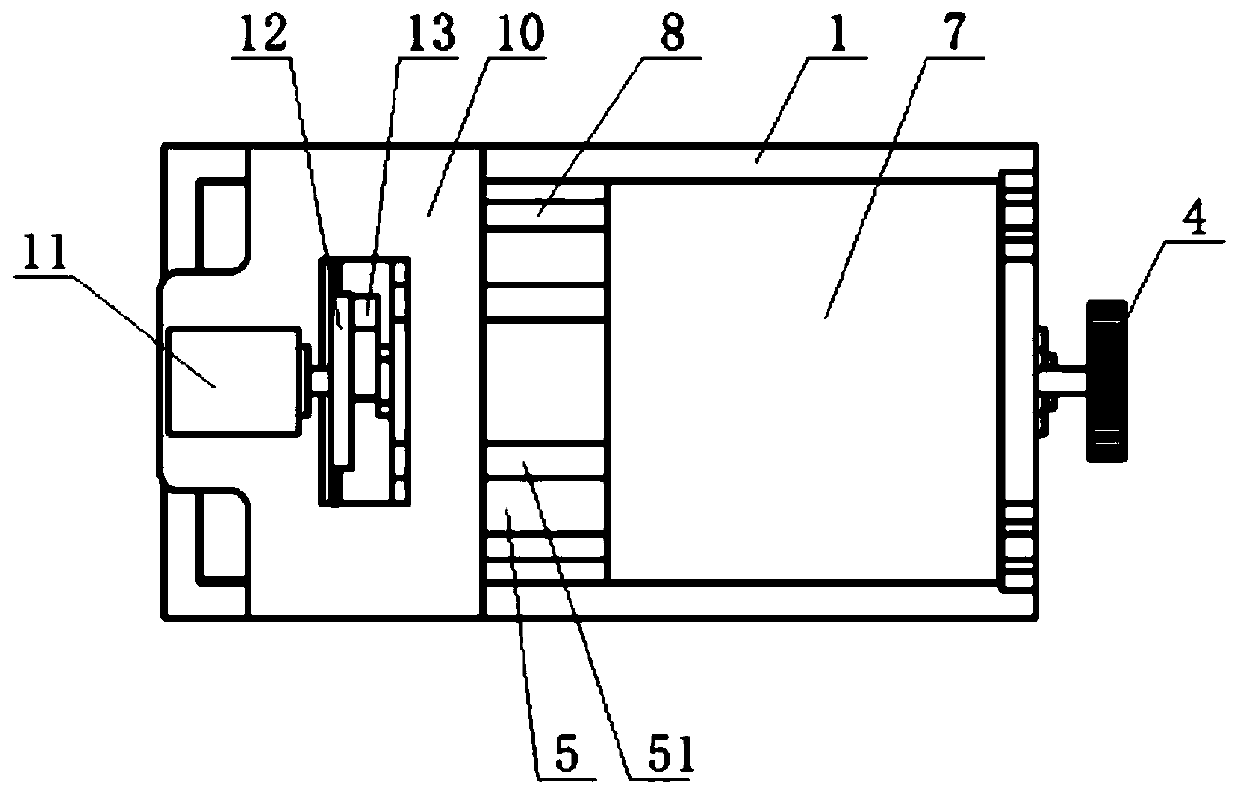

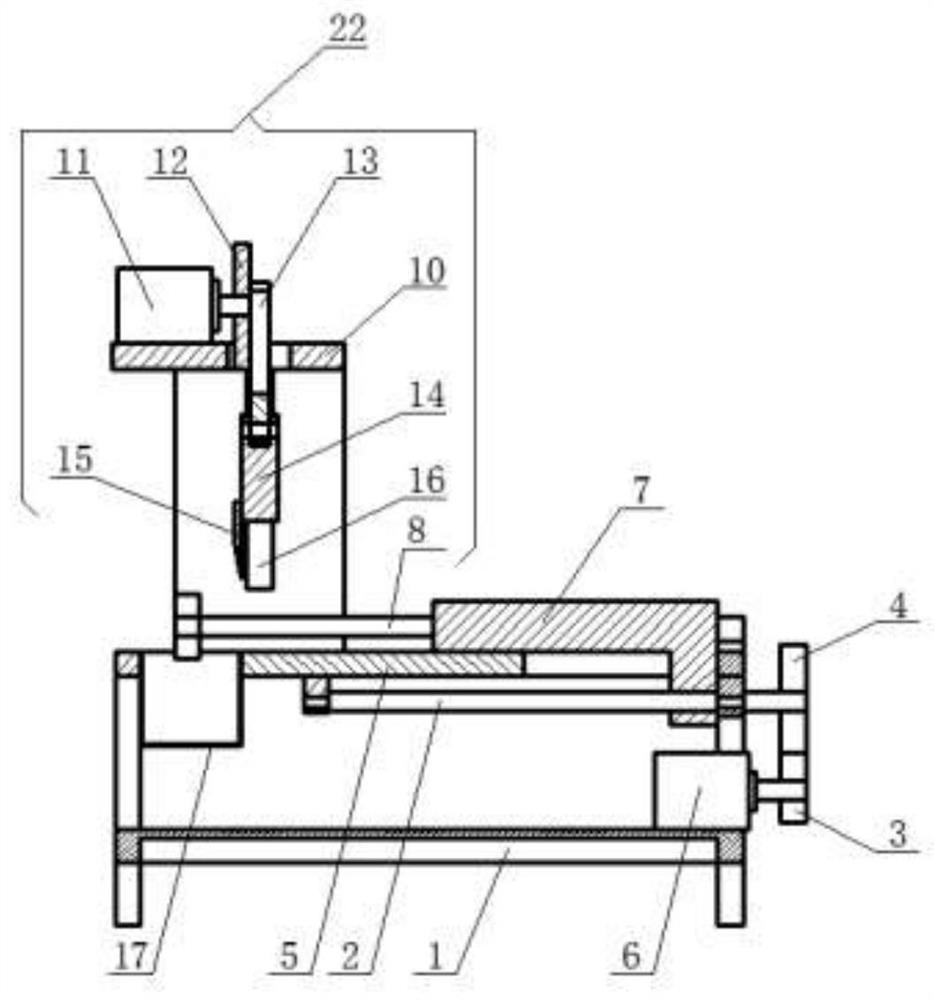

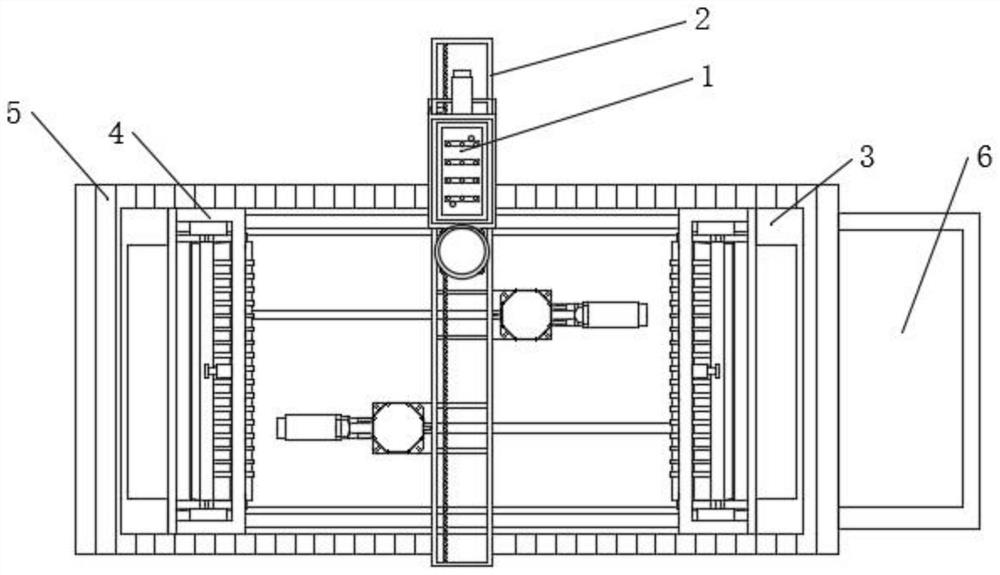

Working platform of multi-wire cutting machine

InactiveCN102049820AEasy accessReduce wearWorking accessoriesFine working devicesWire cuttingEngineering

The invention discloses a working platform of a multi-wire cutting machine, which adopts the scheme that that a metal wire is in point-contact with a workpiece during cutting. The working platform comprises a cutting sleeve (1) mounted on a working platform feeding device, and a working platform (5) equipped with a workpiece (6). The working platform is characterized in that a swinging device capable of enabling the working platform (5) to swing along the cutting center of the working platform (5) is arranged between the cutting sleeve (1) and the working platform (5). The working platform of the multi-wire cutting machine has simple structure, since the working platform capable of swinging in a reciprocating manner is adopted, and the workpiece is in point-contact with the metal wire array to be cut, the length of the contact surface of the metal wire to be cut and the workpiece is reduced greatly, namely the cutting resistance is dissolved, the abrasion of the metal wire to be cut is reduced, and the service life of the metal wire to be cut is prolonged, and at the same time, during the swinging process of the working platform, the grinding material can be enabled to better enter the incision, so that the cutting capacity and the cutting precision are improved.

Owner:HUNAN YUJING MACHINE

Underground anchor cable cutting construction method and cutting device thereof

The invention provides an underground anchor cable cutting construction method and a cutting device thereof. The cutting device comprises a diamond rope, a diamond rope guide fixing wheel arranged in an underground groove, a diamond rope sawing machine fixing base, a driving wheel for driving a diamond rope sawing machine, a remote controller for remotely controlling the diamond rope sawing machine to operate and a diamond rope sawing machine power pump station. The cutting device further comprises a cutting support bottom, a cutting support upper portion and a cutting support fixing portion. The cutting support bottom comprises an anchor cable clamping location guide part, an anchor cable clamping jaw, an anchor cable clamping hydraulic device and a pump station. The cutting support fixing portion comprises a diamond rope sawing machine base fixing part and connection parts which are used for enabling a support to be fixedly connected with the ground. The cutting device can cut underground anchor cables in slurry, can quickly and efficiently cut with good cutting accuracy and completeness, and is high in cutting-off rate and small in cutting size deviation ratio.

Owner:BEIJING FAYAN ENG TECH +1

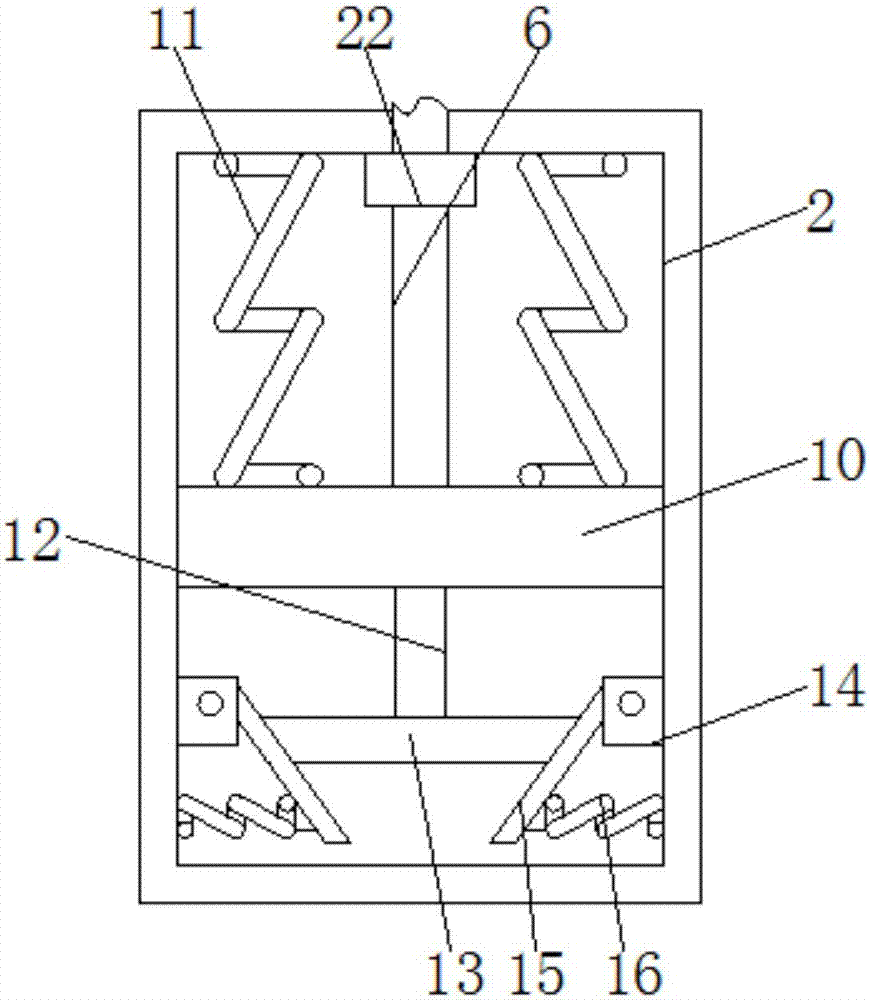

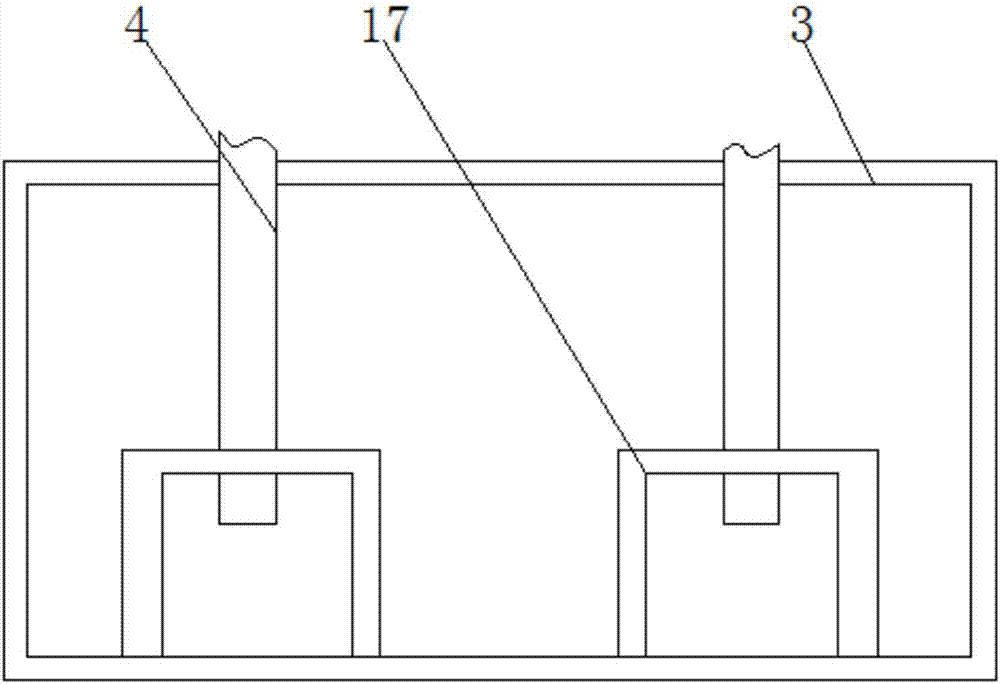

Transmission device for cutting of columns by plasma

InactiveCN107855636ALarge clamping spaceMaintain stabilityPlasma welding apparatusEngineeringPlasma sprayed

The invention discloses a transmission device for cutting a cylinder with plasma, relates to the technical field of plasma cutting, and solves the problem of poor guiding performance in the process of clamping and cutting the cylinder in the prior art; it comprises a processing table, a plasma spray gun, a clamping plasma The clamping device of the spray gun and the XY-axis motion assembly that is arranged on the processing table to drive the plasma spray gun to move along the X-axis direction and the Y-axis direction are characterized in that: the clamping device includes an upper hoop and a lower hoop, It also includes a drive mechanism and a guide mechanism for driving the upper hoop to move along the radial direction of the cylinder. The drive mechanism and the guide mechanism are both arranged in the processing table, the lower hoop is fixedly installed on the processing table, and the upper hoop is installed on the processing table. The lower end of the hoop is provided with a T-shaped connecting block, and the upper hoop passes through the processing table and is connected with the driving mechanism through the T-shaped connecting block. By implementing the technical solution, the driving fixture tooling can move along a fixed direction to clamp cylinders with different diameters, and the guiding performance is good.

Owner:弘毅天承知识产权股份有限公司

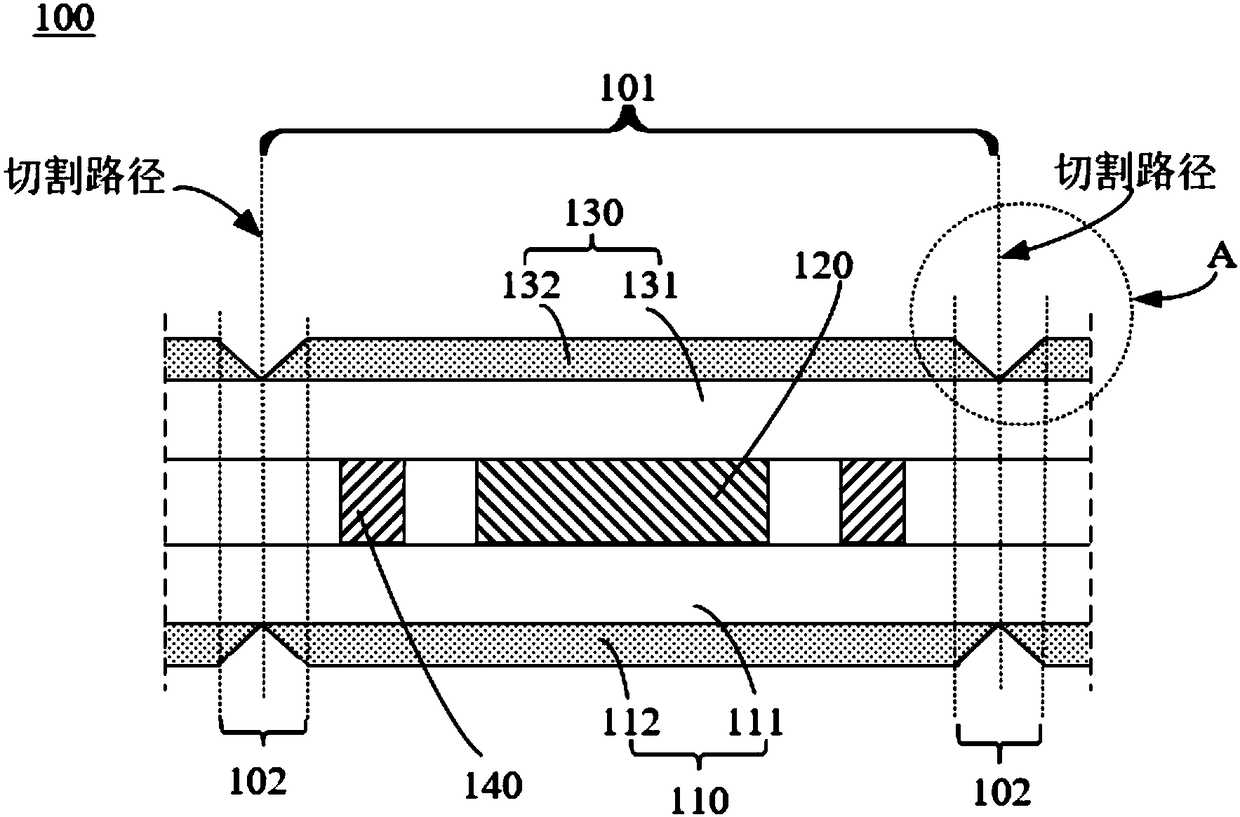

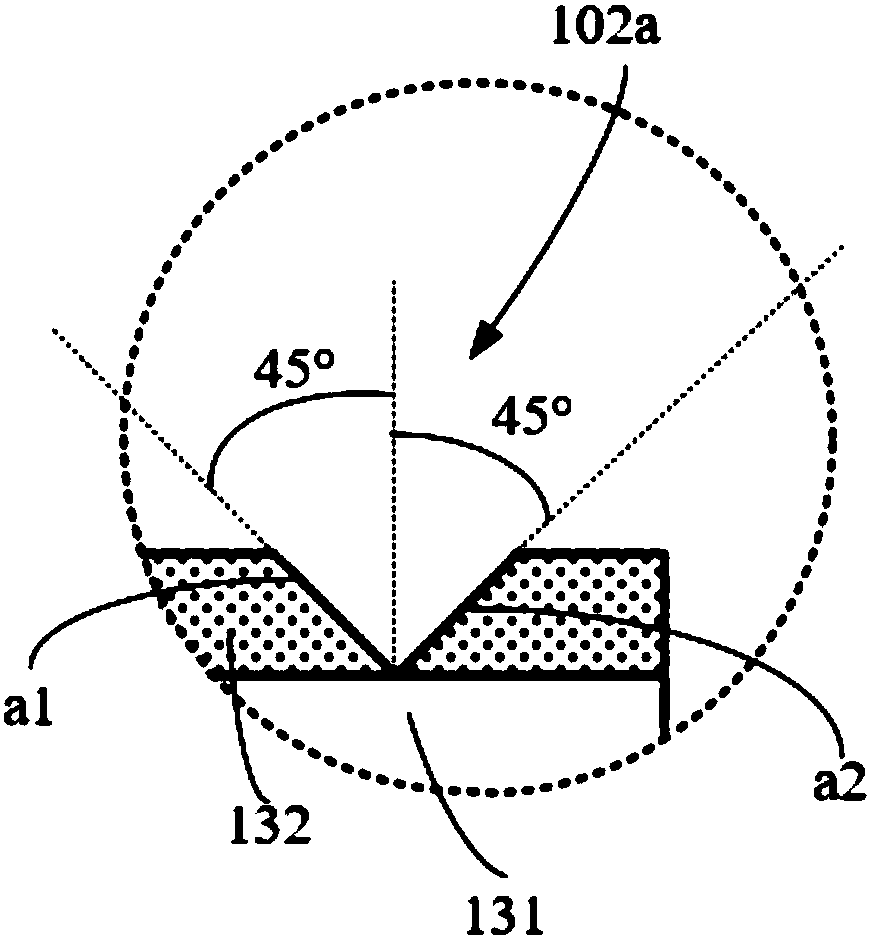

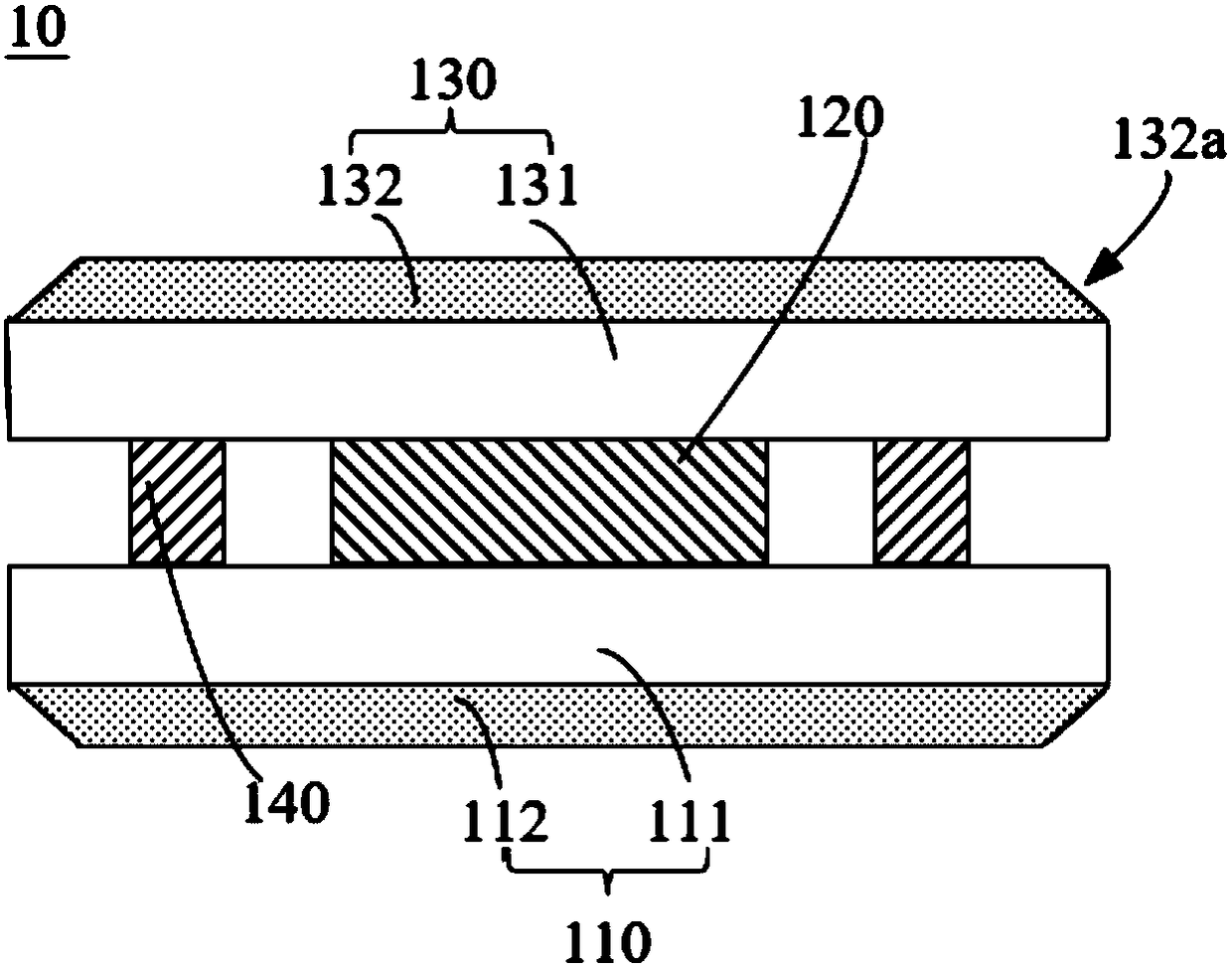

Display mother board, display screens and display terminal

ActiveCN108538862AReduce lateral forceEasy to cut verticallySolid-state devicesSemiconductor devicesEngineeringResin coating

The invention relates to a display mother board, display screens and a display terminal. A plurality of independent display screens are formed on the display mother board; the display mother board comprises a substrate, a functional layer and a packaging cover plate which are sequentially stacked; at least one of the substrate and the packaging cover plate comprises a body layer close to the functional layer and a resin coating stacked on the surface of the body layer; a cutting area is formed on the resin coating along the peripheral edge of each display screen, , and the resin coating in thecutting area is thinner than that of the resin coating in the area where the display screen is located, so that when the display mother board is cut, the resin coating at the cutting route produces small horizontal acting force, a cutting tool can easily and vertically cut the body layer, the cutting accuracy can be improved, and the difficulty of the cutting technology is reduced.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

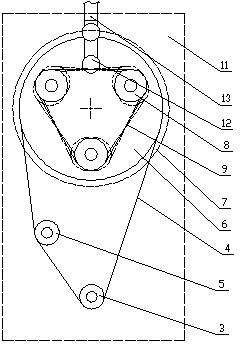

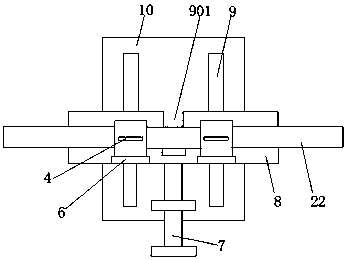

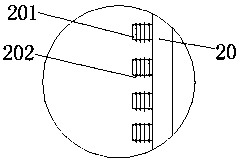

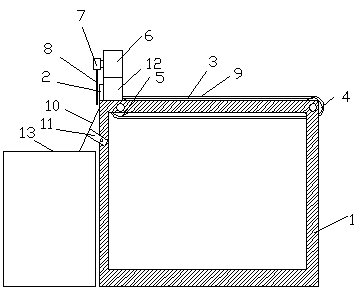

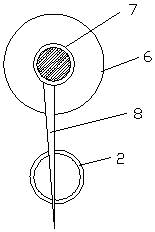

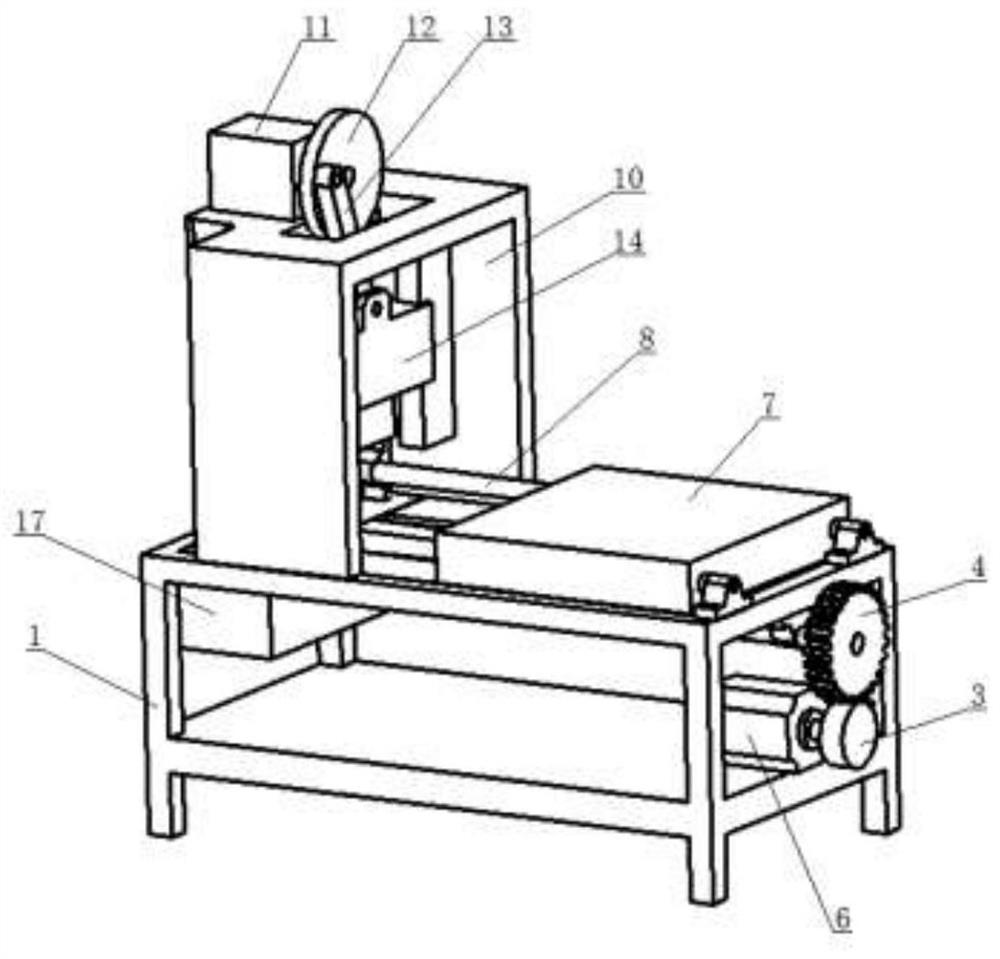

Cutting rollers of multi-wire cutting machine

The invention discloses cutting rollers of a multi-wire cutting machine for point contact of a metal wire and a workpiece during cutting. The multi-wire cutting machine comprises a rack (11), and is characterized in that: the rack (11) is provided with a rocker panel (7) driven by power, and a cutting roller set consisting of the cutting rollers (8) is arranged on the rocker panel (7) through a support seat (10). The cutting roller has a simple structure; the reciprocating swing cutting roller is adopted, and the workpiece is in point contact with a cutting wire array, so the contact face length of the cutting metal wire and the workpiece is greatly reduced, the cutting resistance is weakened, the abrasion of the cutting metal wire is also reduced, and the service life of the cutting metal wire is prolonged; and meanwhile, the abrasive better enters a shear mark in the swing process of the cutting roller, so the cutting capability is improved, and the cutting precision is also improved.

Owner:HUNAN YUJING MACHINE

Methods and apparatus for cutting radii in flexible thin glass

ActiveCN106458693AReduce generationHigh strengthGlass severing apparatusWelding/soldering/cutting articlesLaser beamsCooling fluid

Methods and apparatus provide for: cutting a thin glass sheet along a curved cutting line, where the curve is divided into a plurality of line segments; applying a laser beam and continuously moving the laser beam along the cutting line; applying a cooling fluid simultaneously with the application of the laser beam in order to propagate a fracture in the glass sheet along the cutting line; and varying one or more cutting parameters as the laser beam moves from one of the plurality of line segments to a next one of the plurality of line segments, wherein the one or more cutting parameters include at least one of: (i) a power of the laser beam, (ii) a speed of the movement, (iii) a pressure of the cooling fluid, and (iv) a flow rate of the cooling fluid.

Owner:CORNING INC

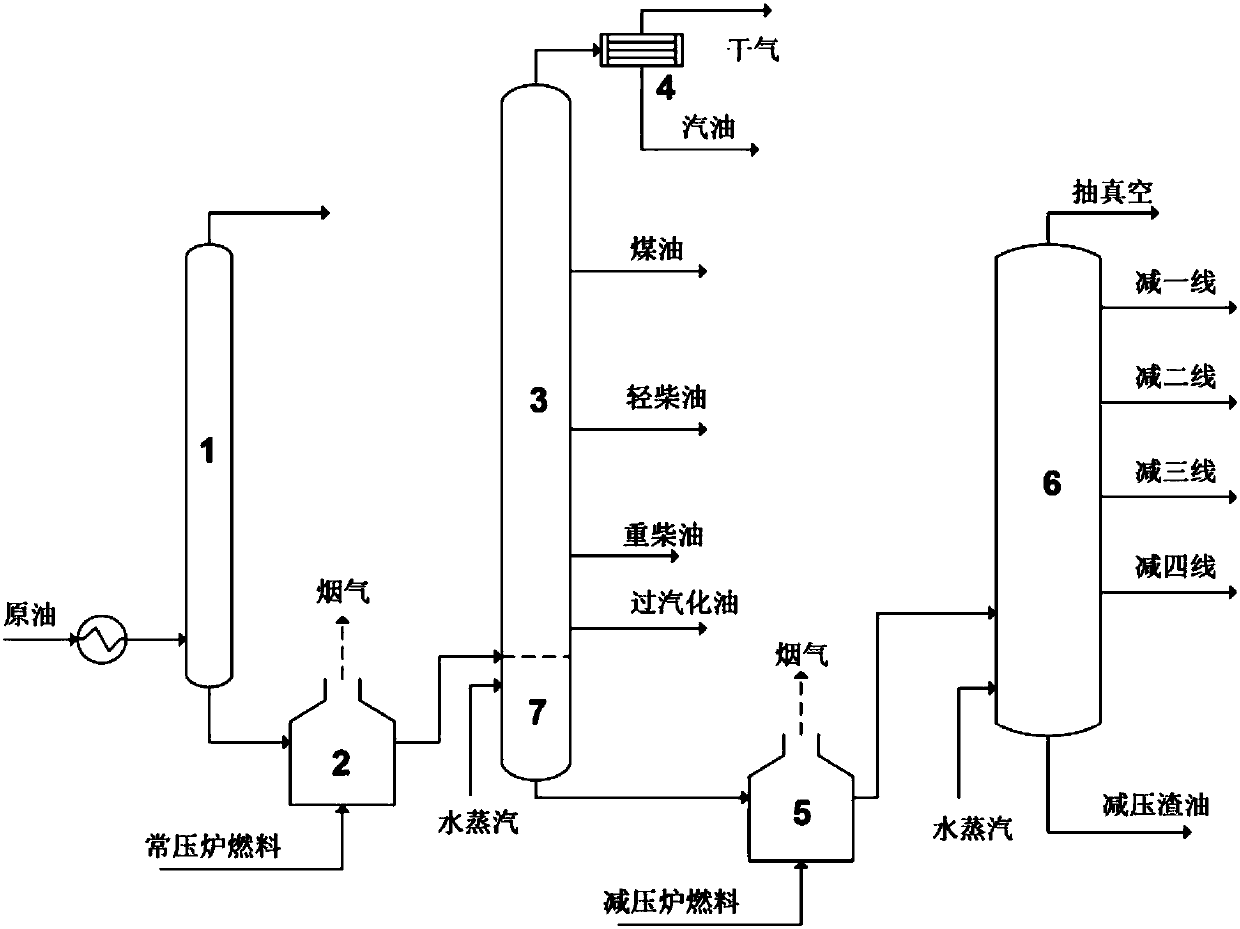

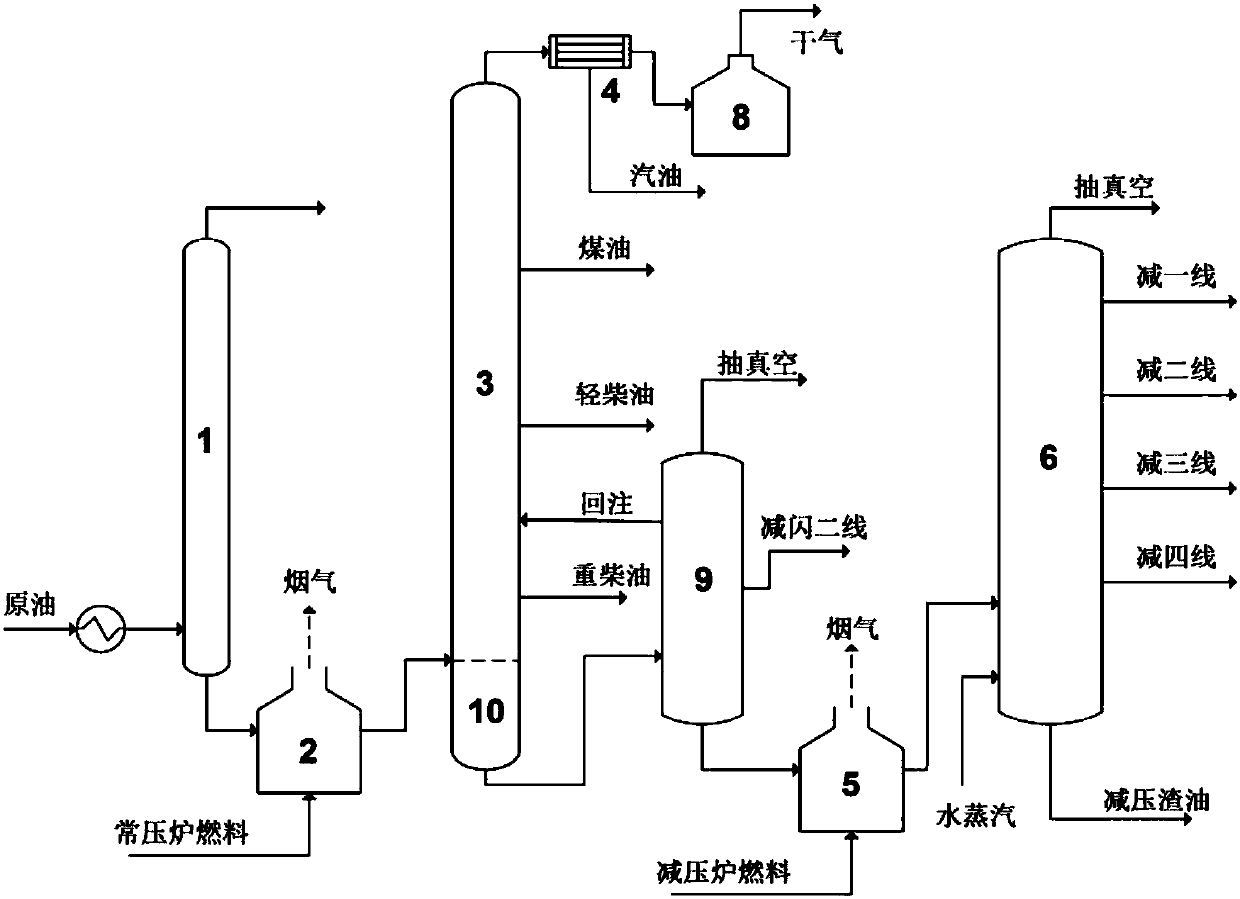

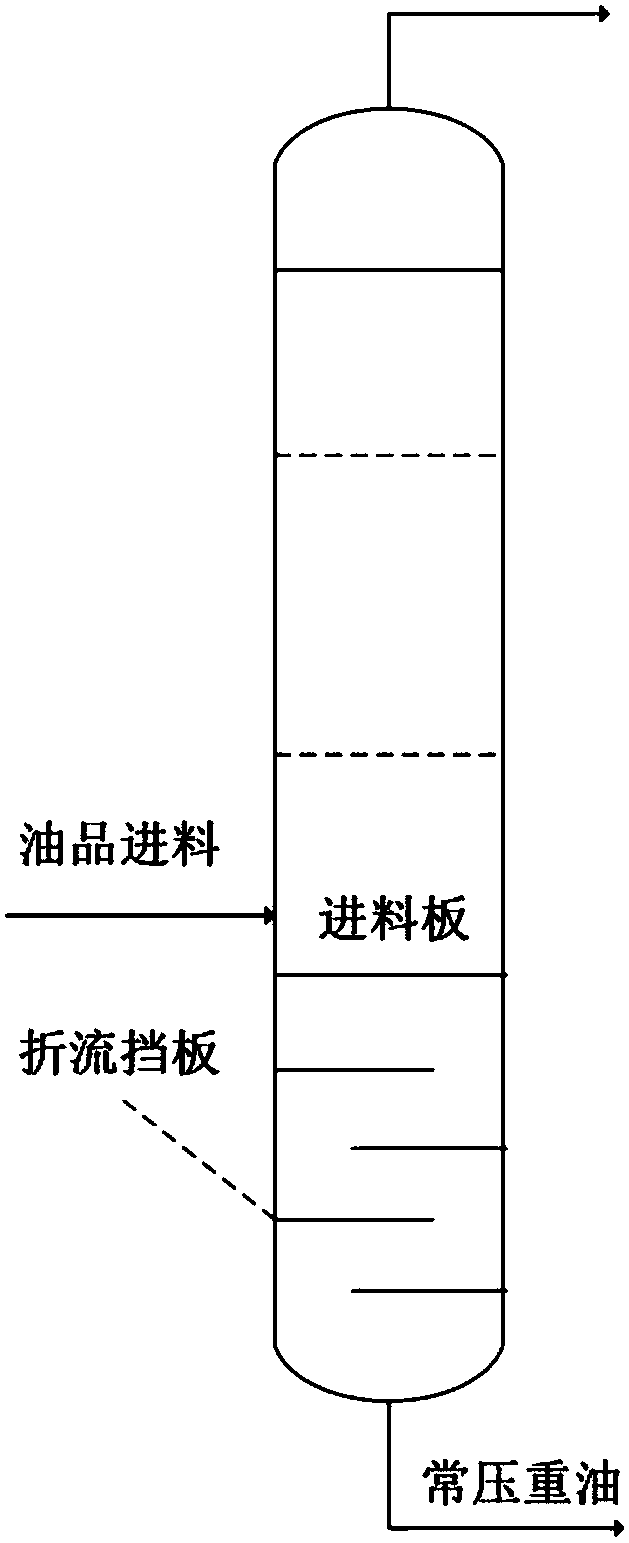

Water-free atmospheric vacuum distillation technology and device

ActiveCN107699273AEasy to separateSolve the problem of low temperature dew point corrosionHydrocarbon distillation control/regulationVacuum distillationReboilerFuel oil

The invention provides a water-free atmospheric vacuum distillation technology and device. The technology is characterized in that a normal-pressure tower and a vacuum tower adopt a four-time gasification and feeding manner; after crude oil is heated through a normal-pressure furnace, materials are fed from a tower kettle of the normal-pressure tower; water steam is not introduced into the tower kettle; each sideline product is heated by adopting a reboiler; alkali washing is carried out on tower top dry gas which is condensed and cooled at a tower top of the normal-pressure tower; a vacuum flashing tower is additionally arranged between the normal-pressure tower and a vacuum furnace; normal-pressure heavy oil from the tower kettle of the normal-pressure tower enters the vacuum flashing tower; the vacuum flashing tower is provided with a plurality of sidelines for drawing out products; the product drawn out from the first sideline is injected into the normal-pressure tower again; the heavy oil of the tower kettle enters the vacuum furnace and is further heated, and then enters the vacuum tower; pressure of the vacuum flashing tower is controlled between the pressure of the normal-pressure tower and the pressure of the vacuum tower. The invention further provides the water-free atmospheric vacuum distillation device. By adopting the device and the technology, provided by the invention, the low-temperature dew-point corrosion problem of the top of the normal-pressure tower can be solved, refinery wastewater is reduced and the diesel oil extraction rate of the normal-pressureheavy oil is improved; serious entrainment of the vacuum tower is alleviated and the decompression and deep drawing vacuum degree is reduced. The long-period, safe, stable and operation performance ofthe device is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

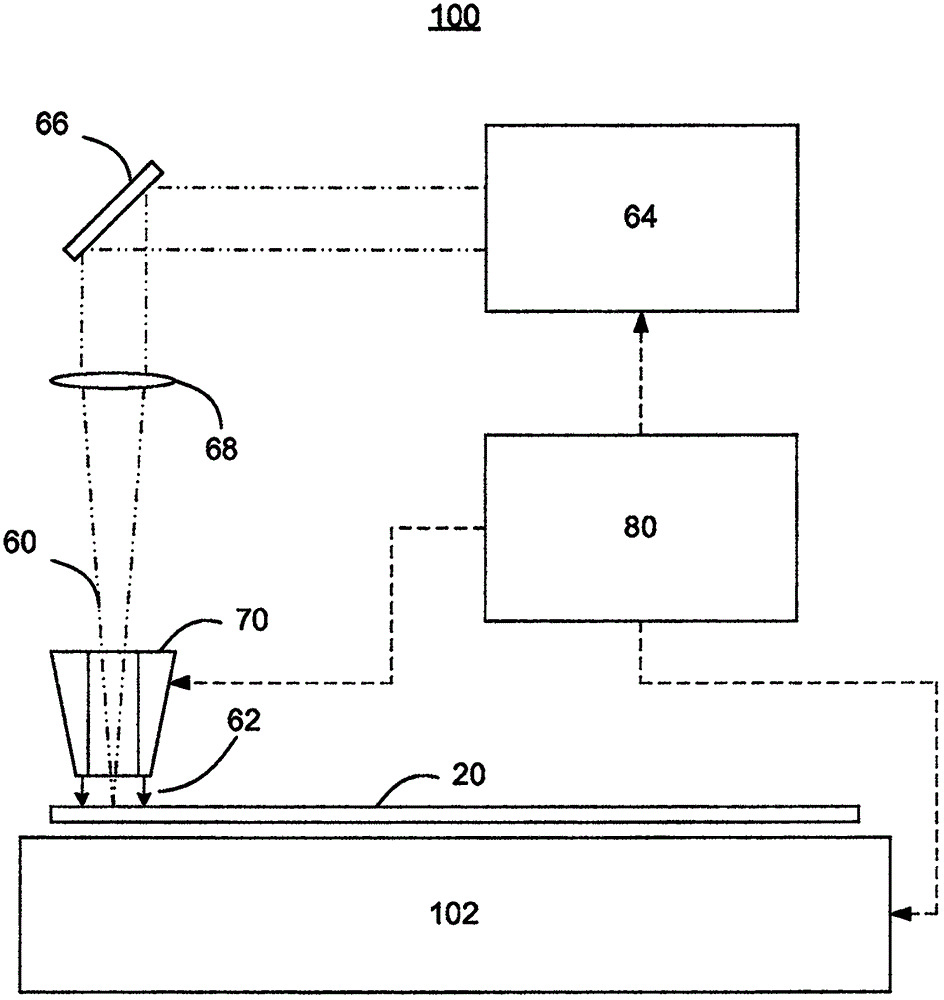

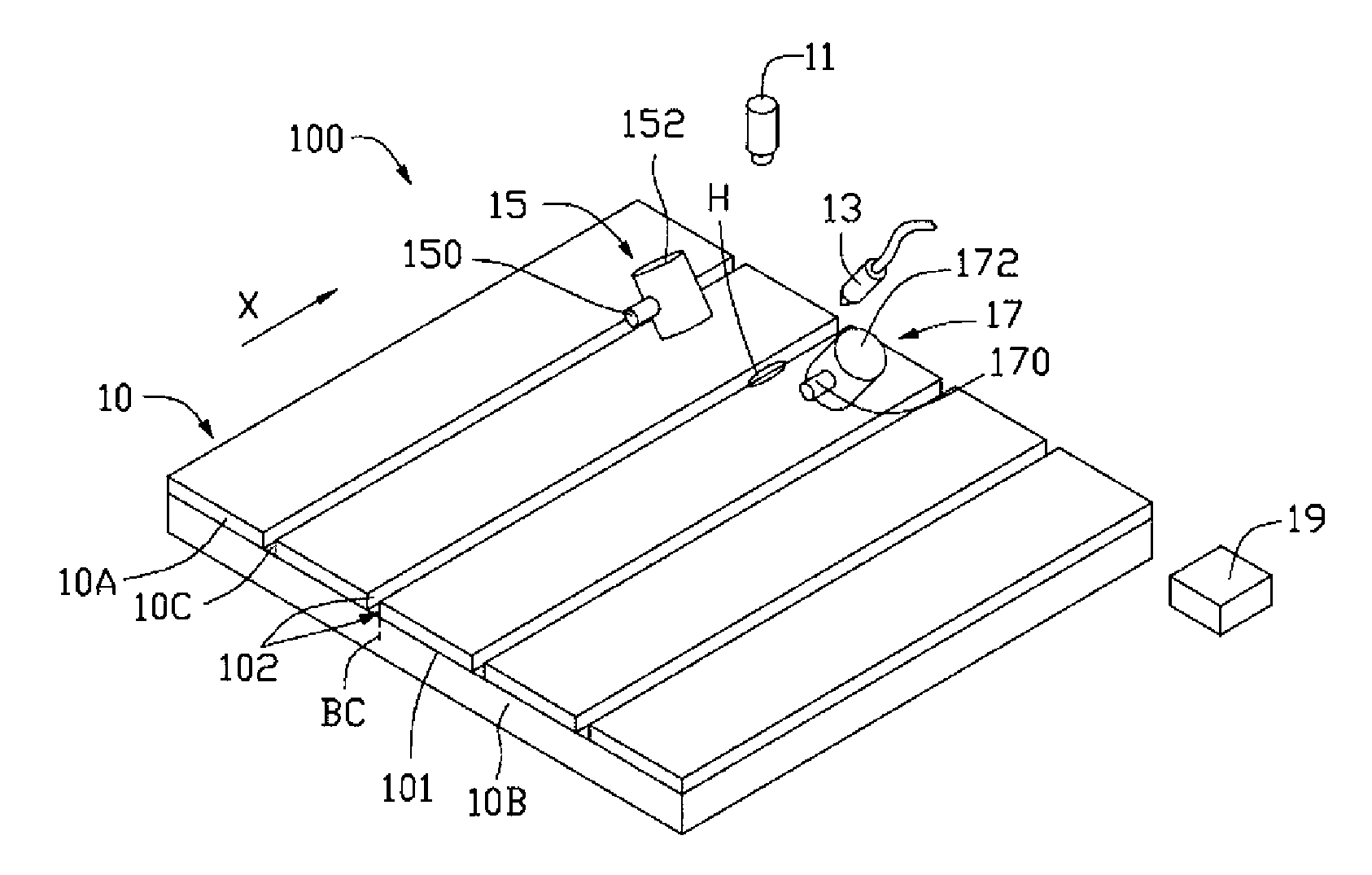

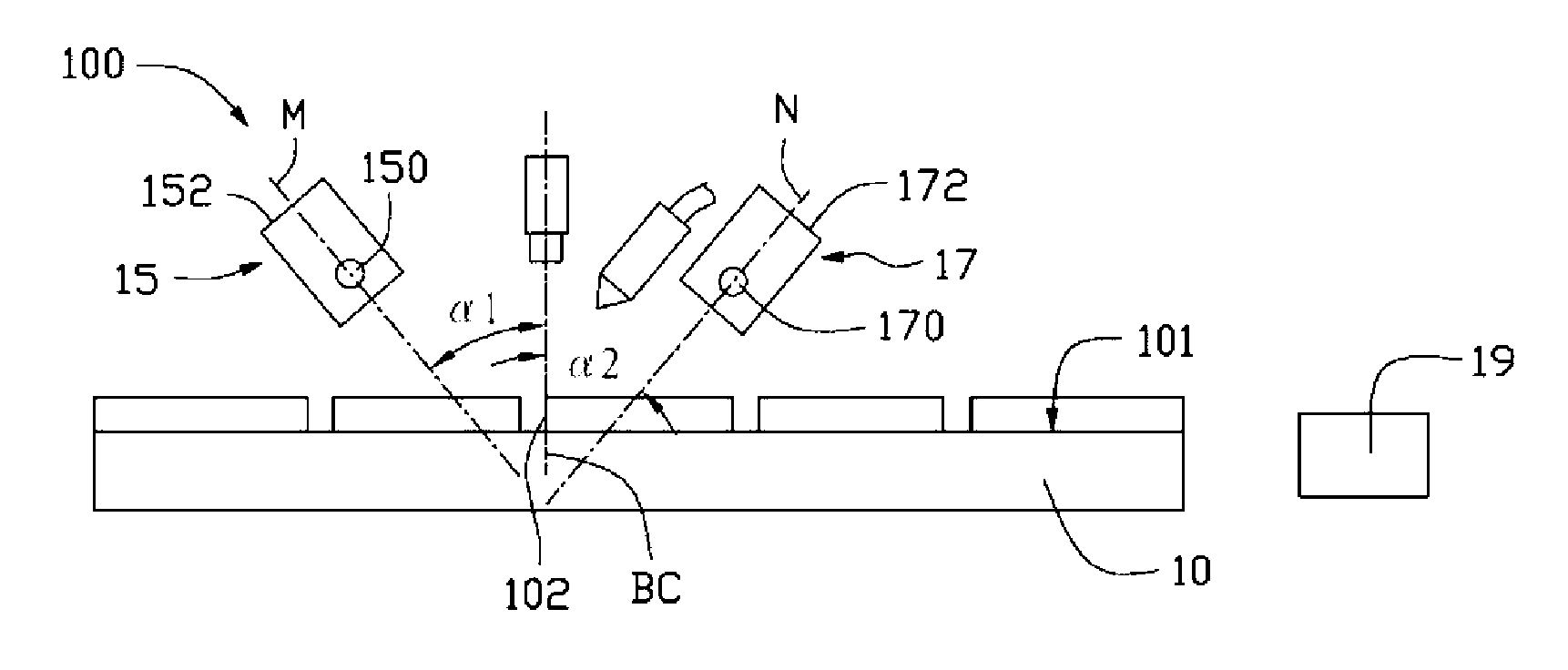

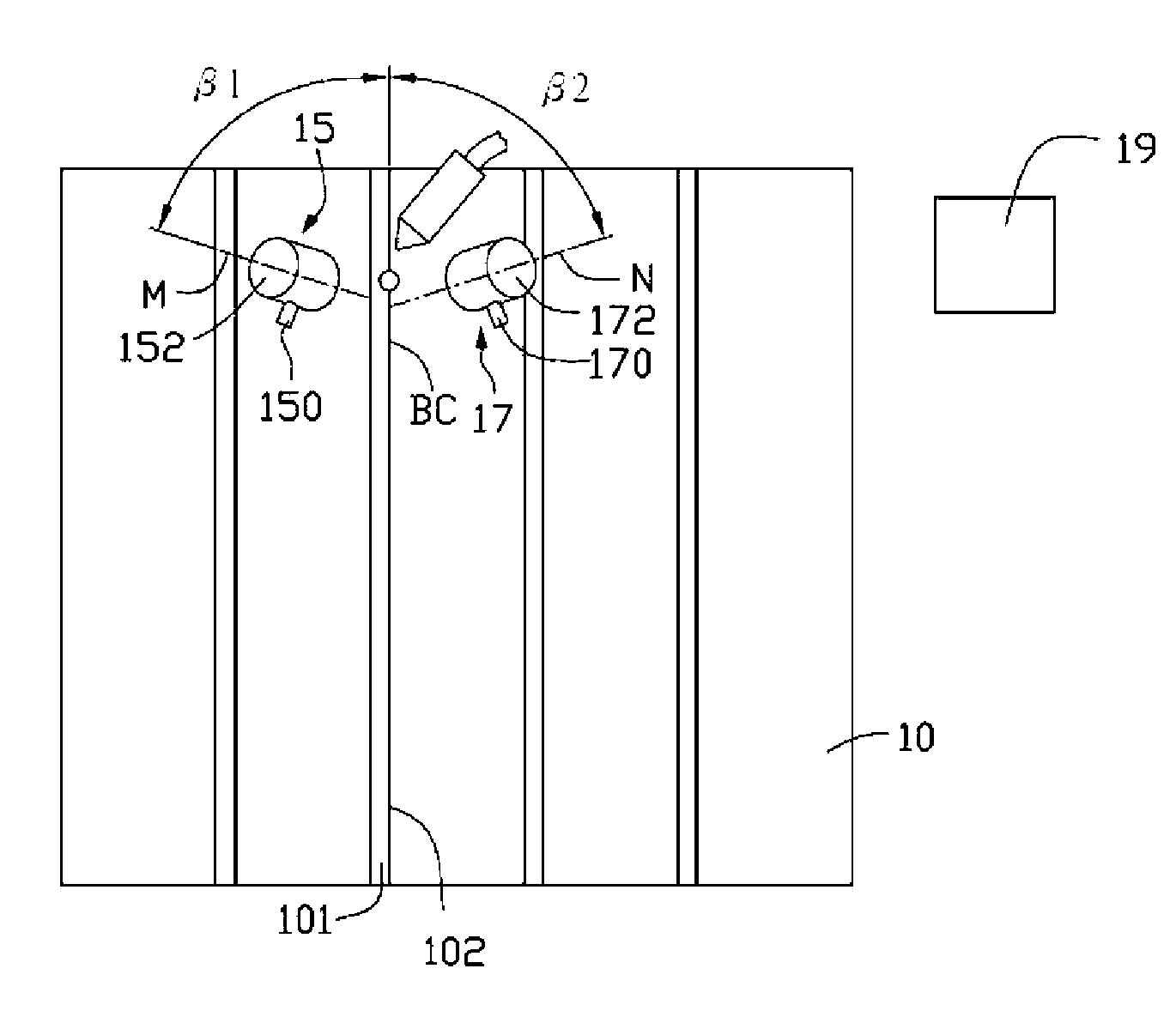

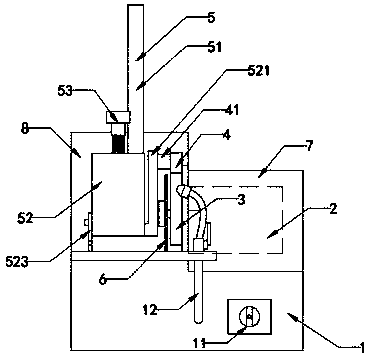

Laser cutting device and laser cutting method

InactiveCN102030468APrecise control over generationGood cutting precisionGlass severing apparatusImaging processingLight beam

The invention relates to a laser cutting device which comprises a laser generating unit, a cooling nozzle, a first image pick-up unit, a second image pick-up unit and an image processing unit. The laser generating unit is used for generating a laser beam. The cooling nozzle is used for generating a cooling medium. The first image pick-up unit comprises a first light source and a first image sensor, and the second image pick-up unit comprises a second light source and a second image sensor. The first light source and the second light source can selectively emit light beams, the light beams emitted by the first light source and the second light source are respectively irradiated on a blind crack from both opposite sides of the blind crack, and the first image sensor and the second image sensor are used for correspondingly sensing the light beams emitted by the first light source or the second light source and reflected on the blind crack to obtain the image of the blind crack. The imageprocessing unit is used for comparing the image of the blind crack with the image of a pre-stored reference blind crack to detect whether the blind crack reaches the preset depth or not.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

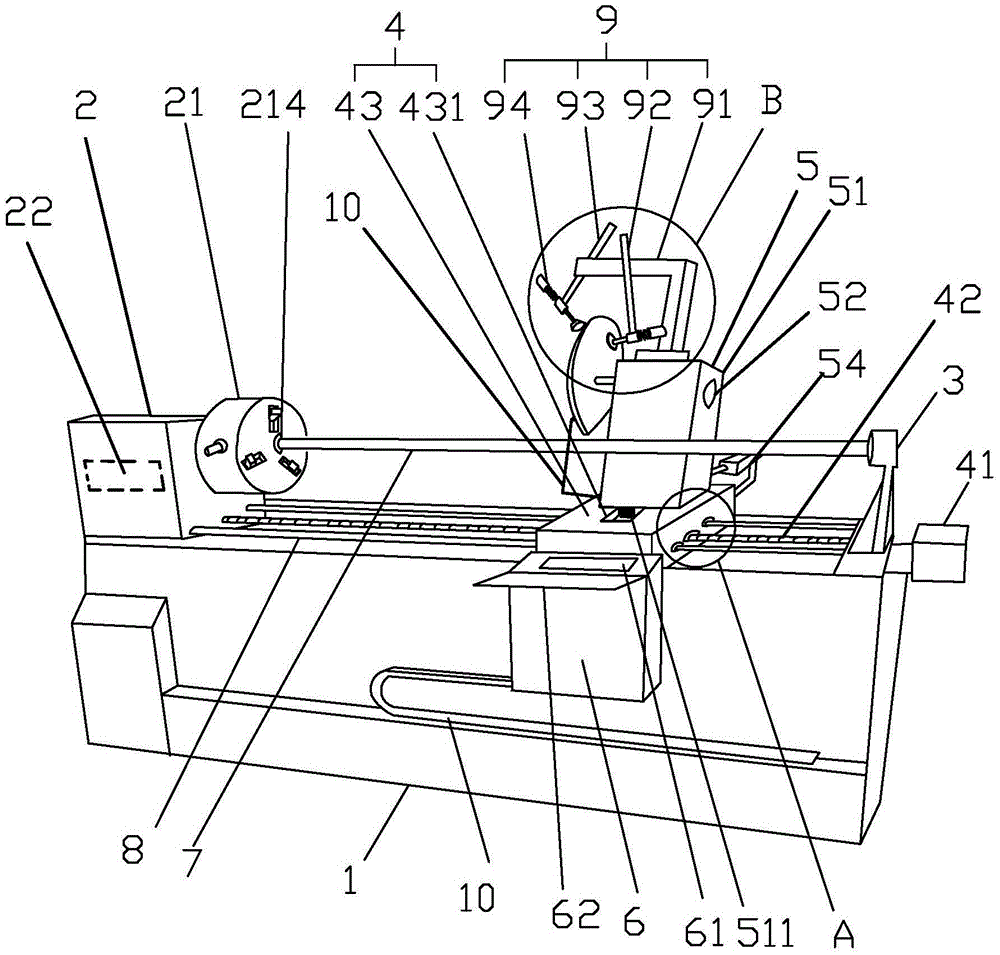

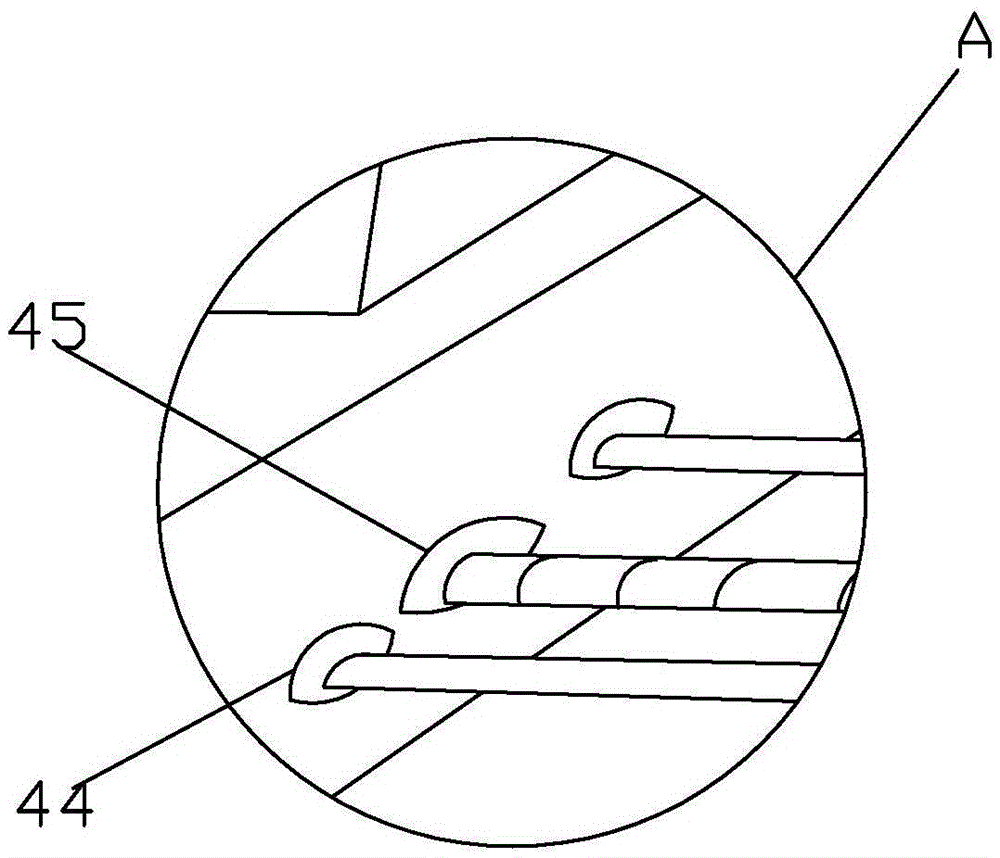

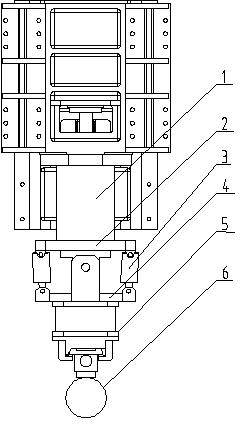

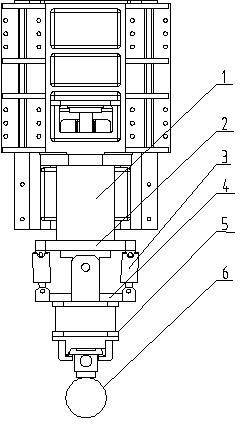

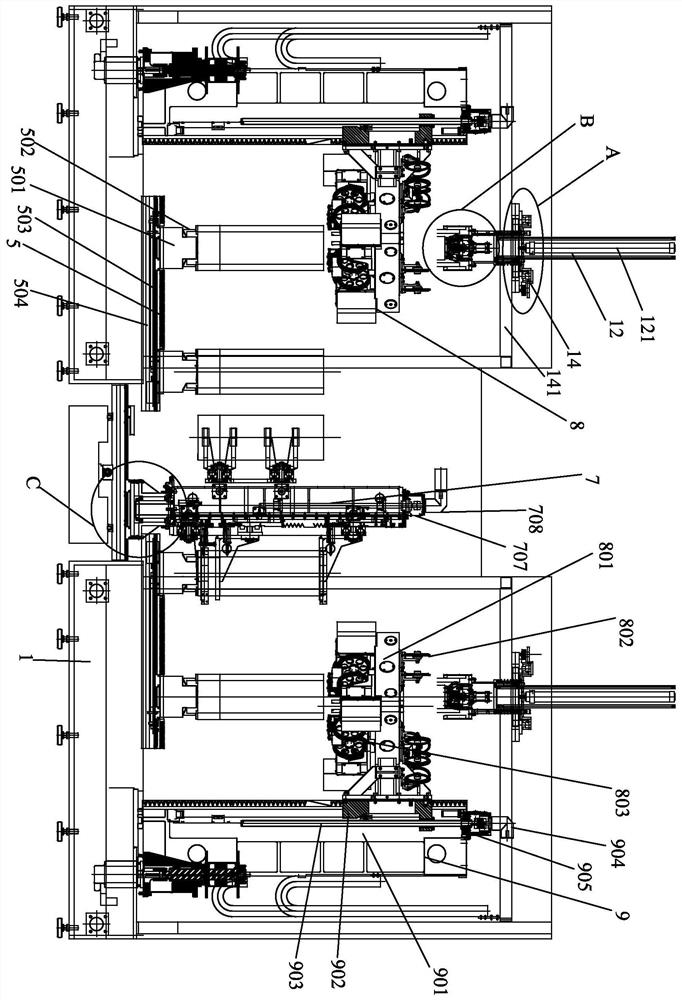

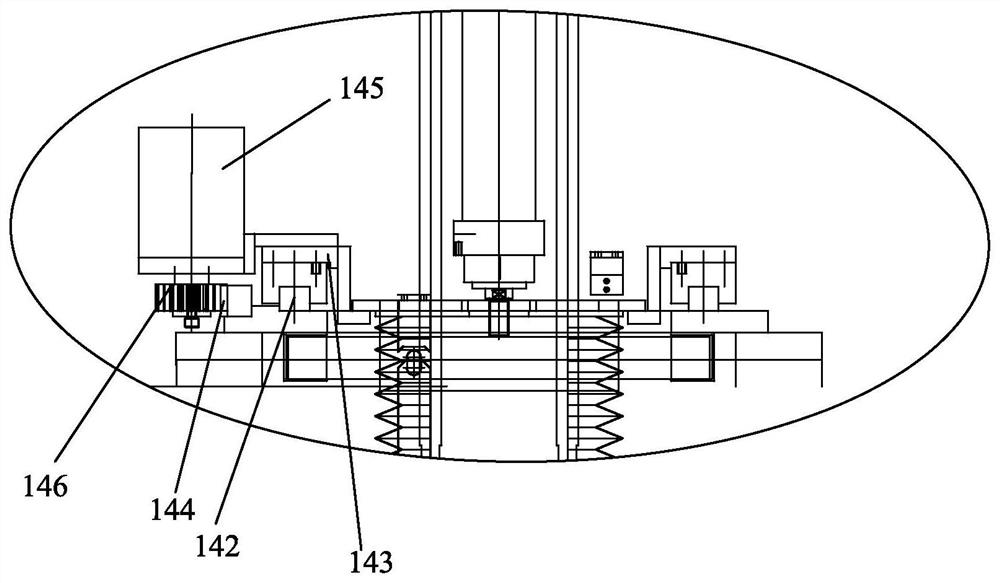

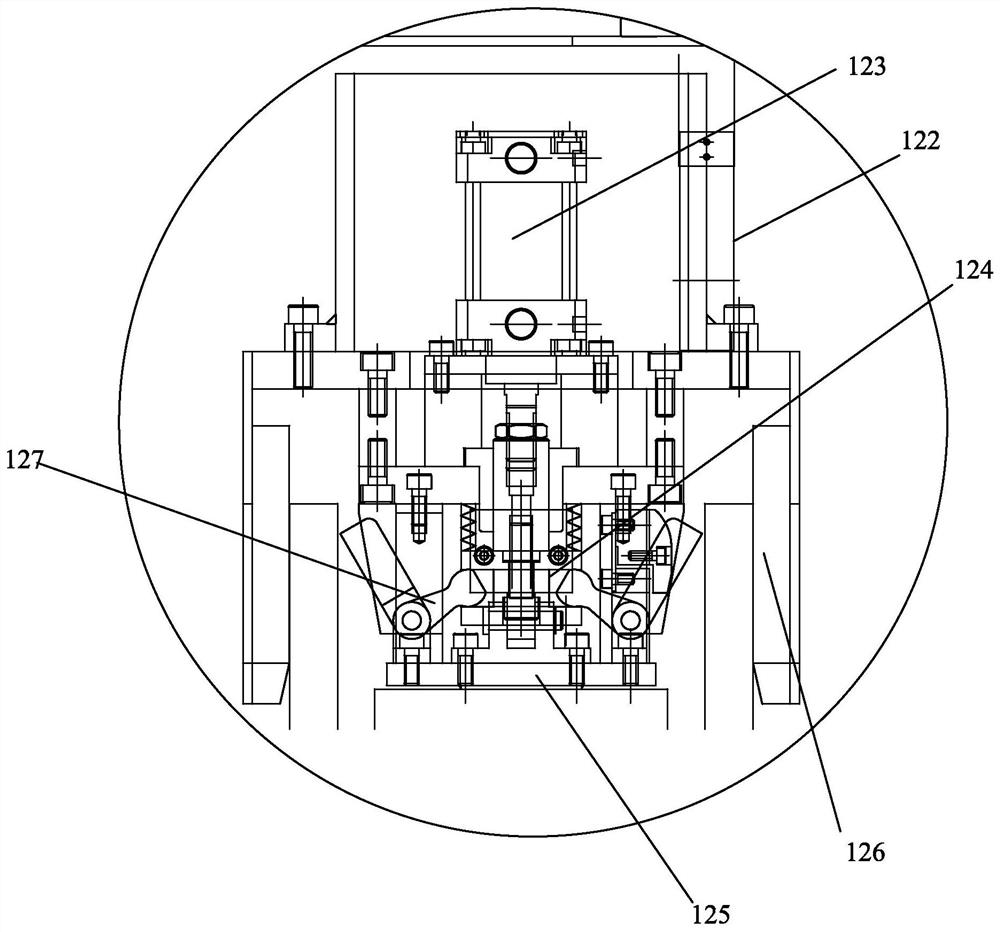

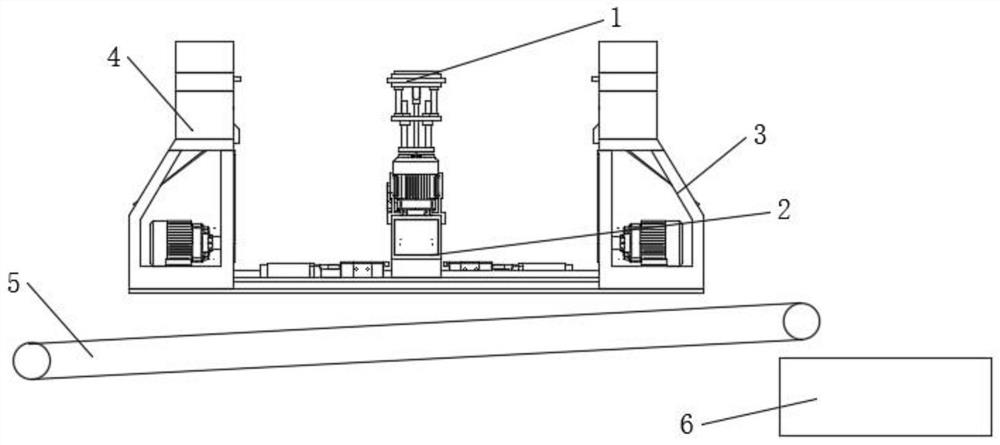

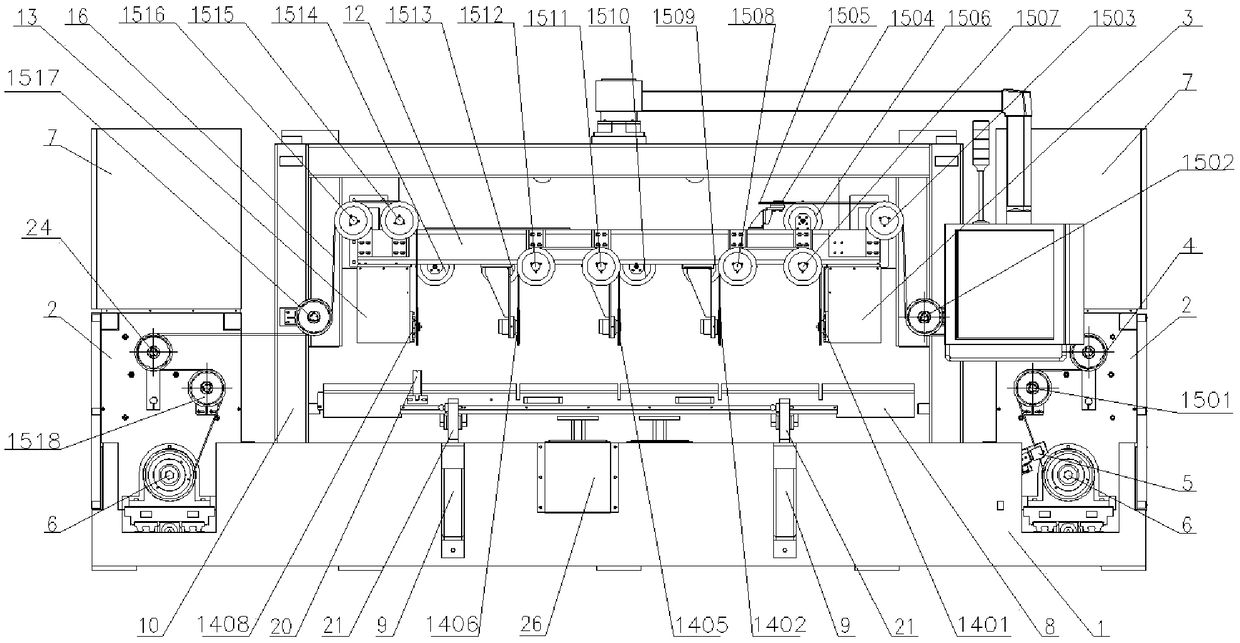

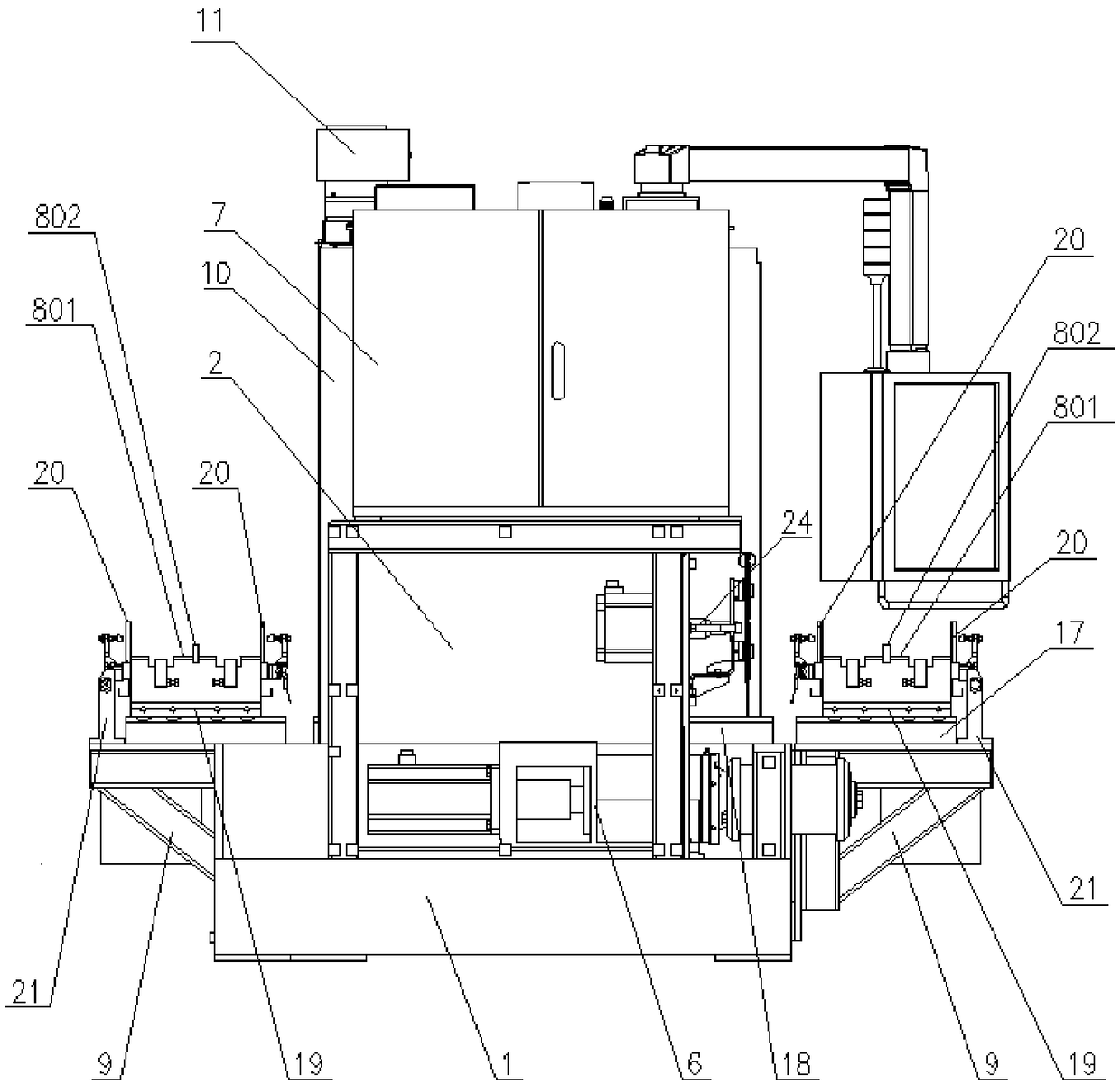

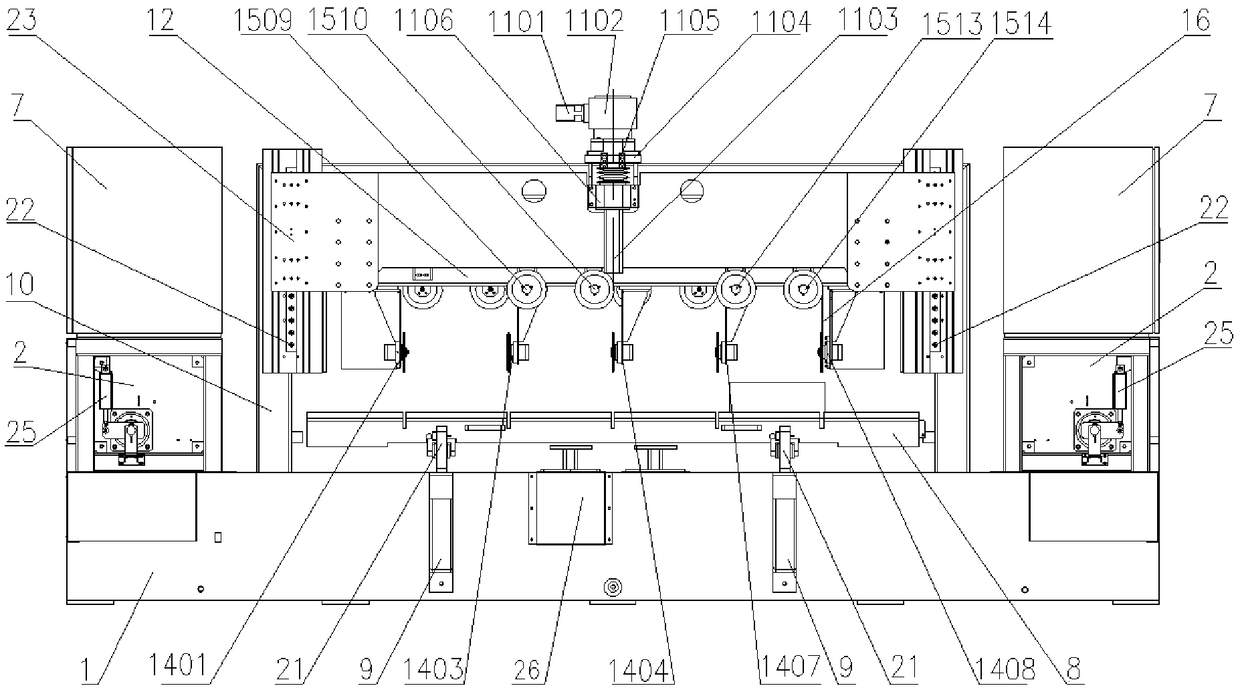

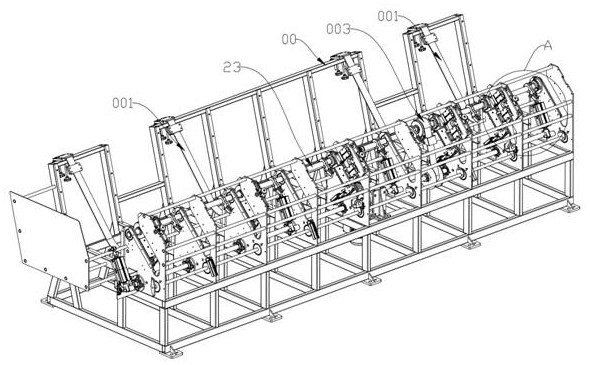

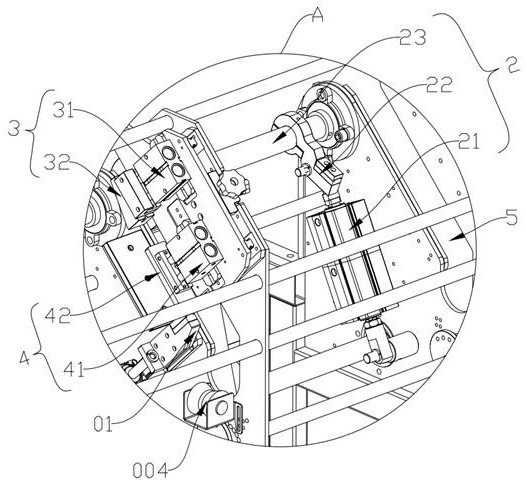

Double-silicon-rod diamond wire squaring machine

PendingCN111619026AImprove flowGood cutting precisionWorking accessoriesFine working devicesRobot handEngineering

The invention provides a double-silicon-rod diamond wire squaring machine comprising a lathe bed extending in the left-right direction. Single-silicon-rod cutting systems are symmetrically arranged onthe left side and the right side of the lathe bed. A feed system and a discharge system are arranged on the front side of the middle portion of the lathe bed. A crystal line detection system used fordetecting silicon rod crystal lines is arranged on the rear side of the middle portion of the lathe bed. A cross slide table system is arranged on the middle portion of the lathe bed and comprises alower slide table system extending in the front-back direction and an upper slide table system extending in the left-right direction. A silicon rod grabbing mechanical hand system used for grabbing silicon rods is installed on the upper slide table system. Two squaring machines share one crystal line detection device and one silicon rod grabbing mechanical hand system, and meanwhile cutting nets of the two squaring machines do not influence each other.

Owner:DALIAN LIANCHENG NUMERICAL CONTROL MACHINE

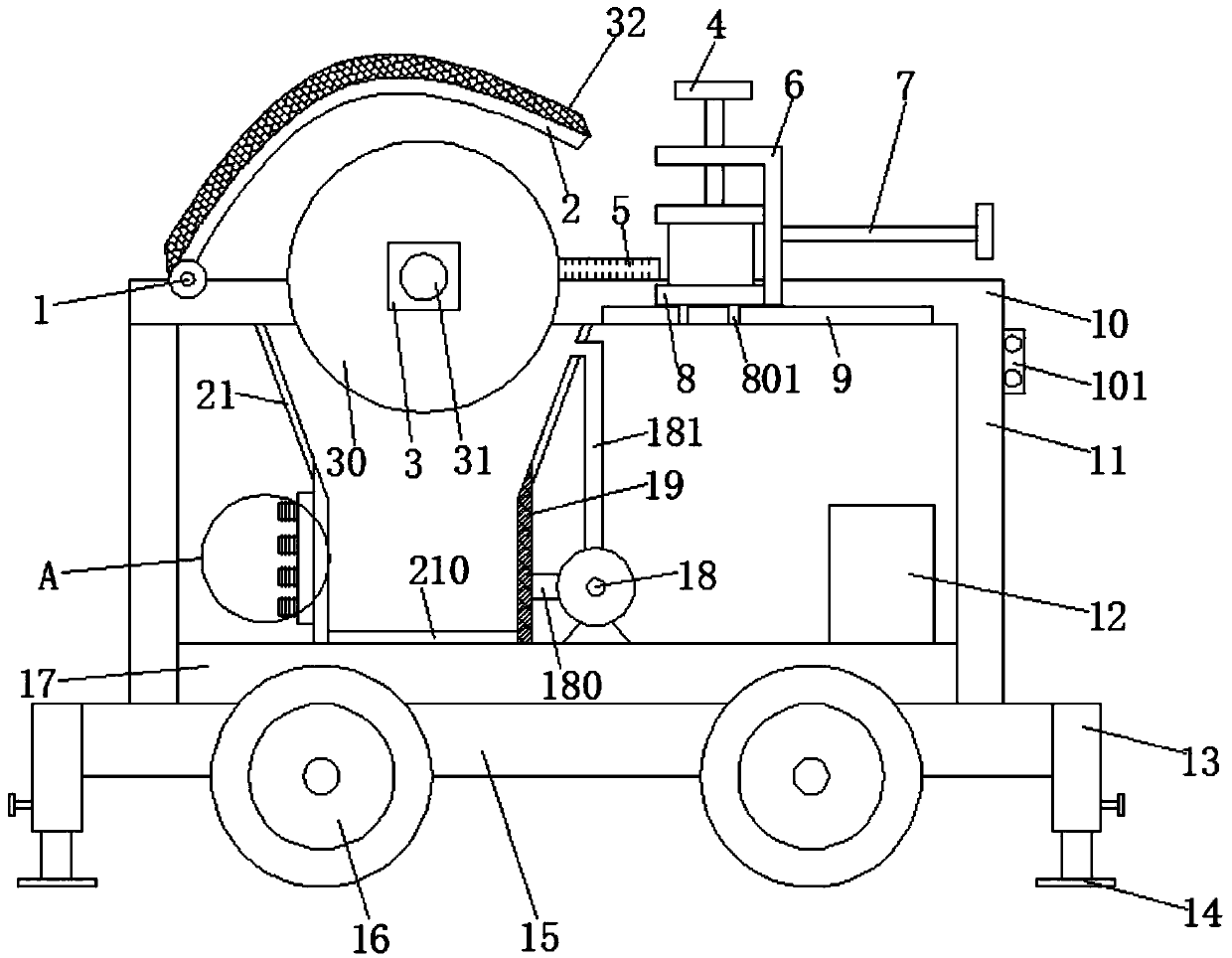

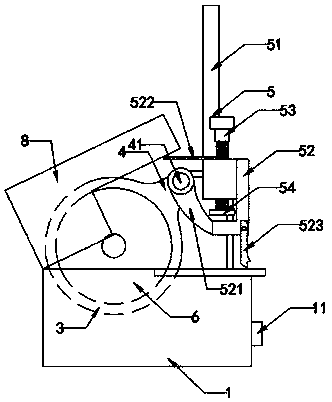

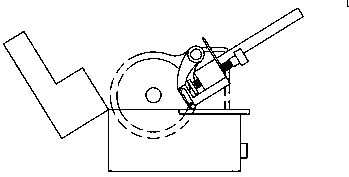

Sectional material cutting machine

InactiveCN108817502AReduce noiseReasonable structural designShearing machinesMaintainance and safety accessoriesEngineeringElectric control

The invention discloses a sectional material cutting machine. The machine comprises a top plate, a side plate, a base, a draught fan, an electromotor, a waste material box, a fixed plate and a material guiding plate, the electromotor is installed on the top plate, and a rotary shaft is installed on the electrode; a cutting piece is installed on the rotary shaft and arranged in a cutting piece groove in the middle of the top plate, and the top plate is connected to one side of a protective cover through a shaft pin; a sectional material fixture is installed on the material guiding plate, a partition plate is fixed to the outer wall of the portion, located on one side of the shaft pin, of the waste material box trough a bolt, and a filtering net board is installed on the side wall of the portion, located on one side of the material guiding plate, of the waste material box; a draught hood cover is connected to the outer side of the filtering net plate, and an electric control cabinet is fixed to the portion, between the draught fan and the side plate, of the fixed plate. The sectional material cutting machine has the advantages of reasonable design, convenient use, high accuracy of cutting sectional materials, good dust-proof and sound-proof effects and the like, and can be widely used and popularized.

Owner:孙中

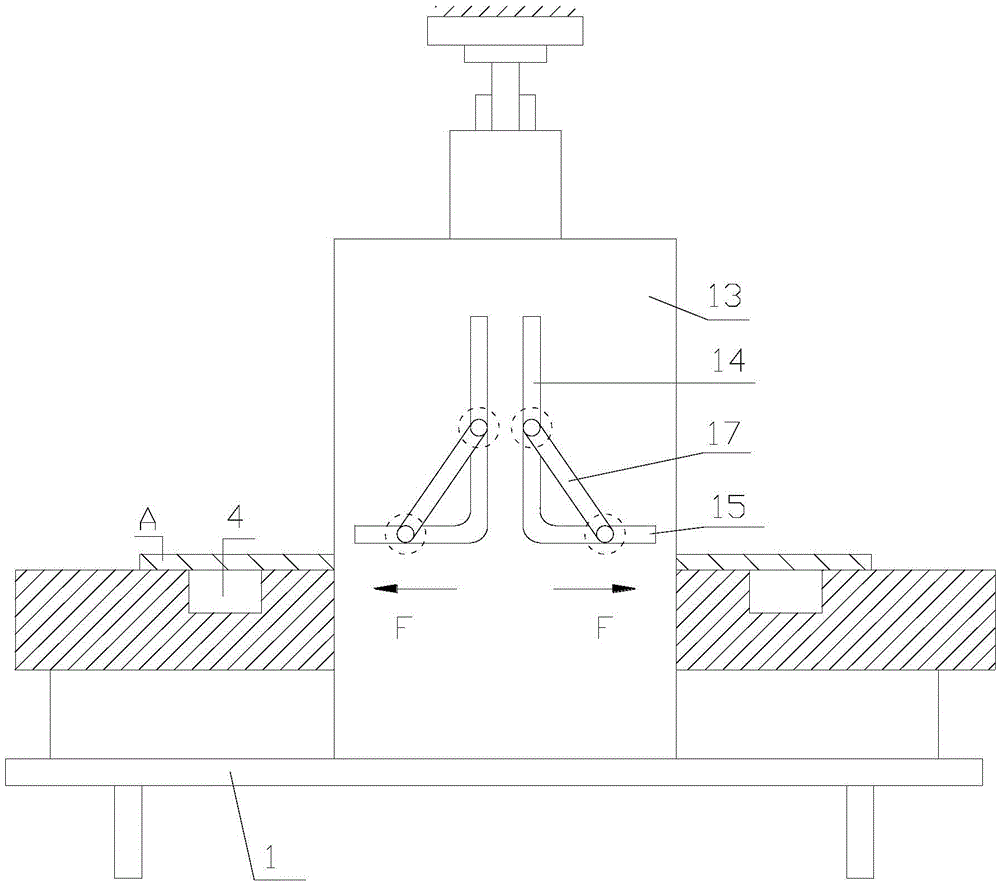

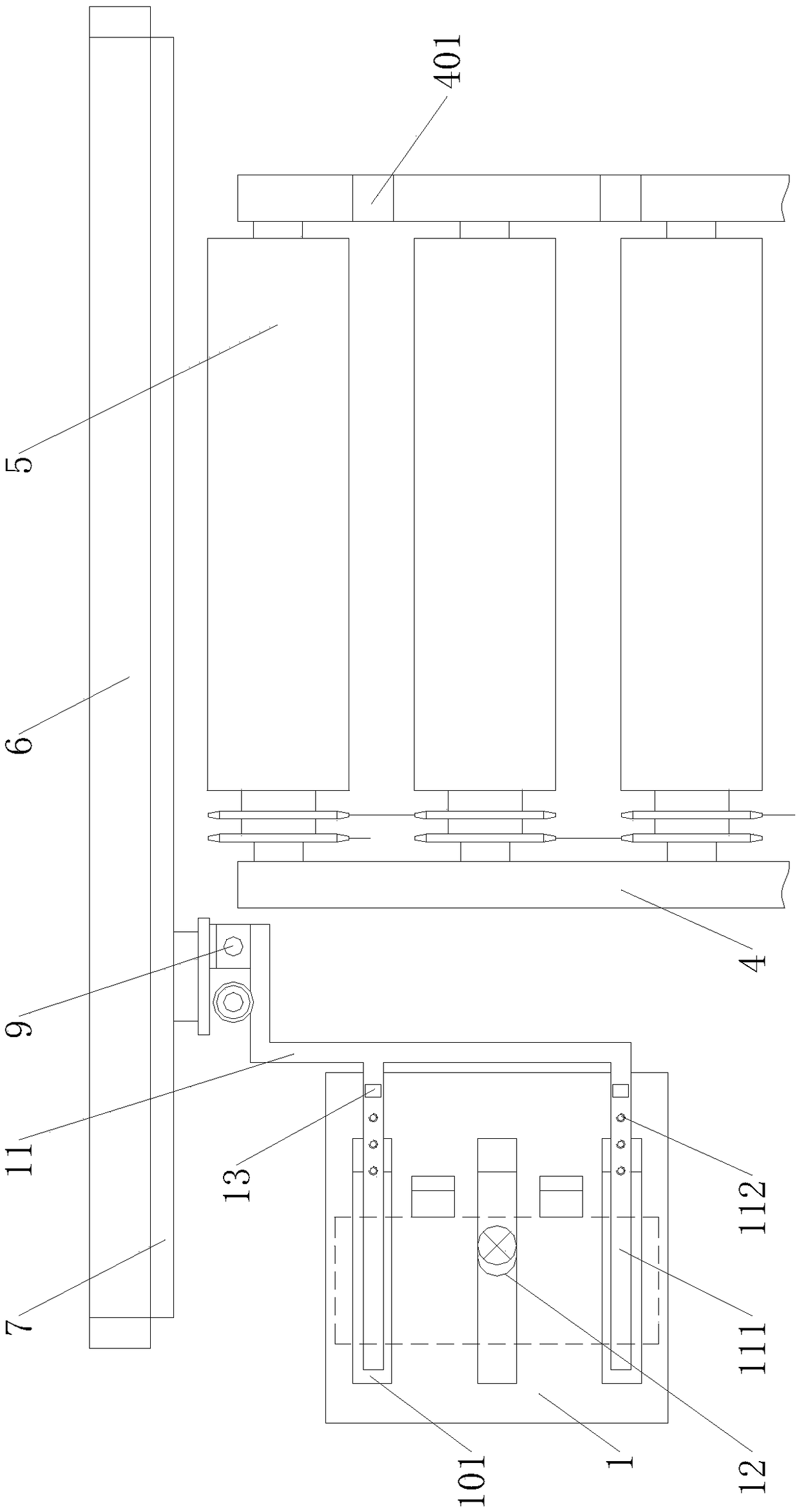

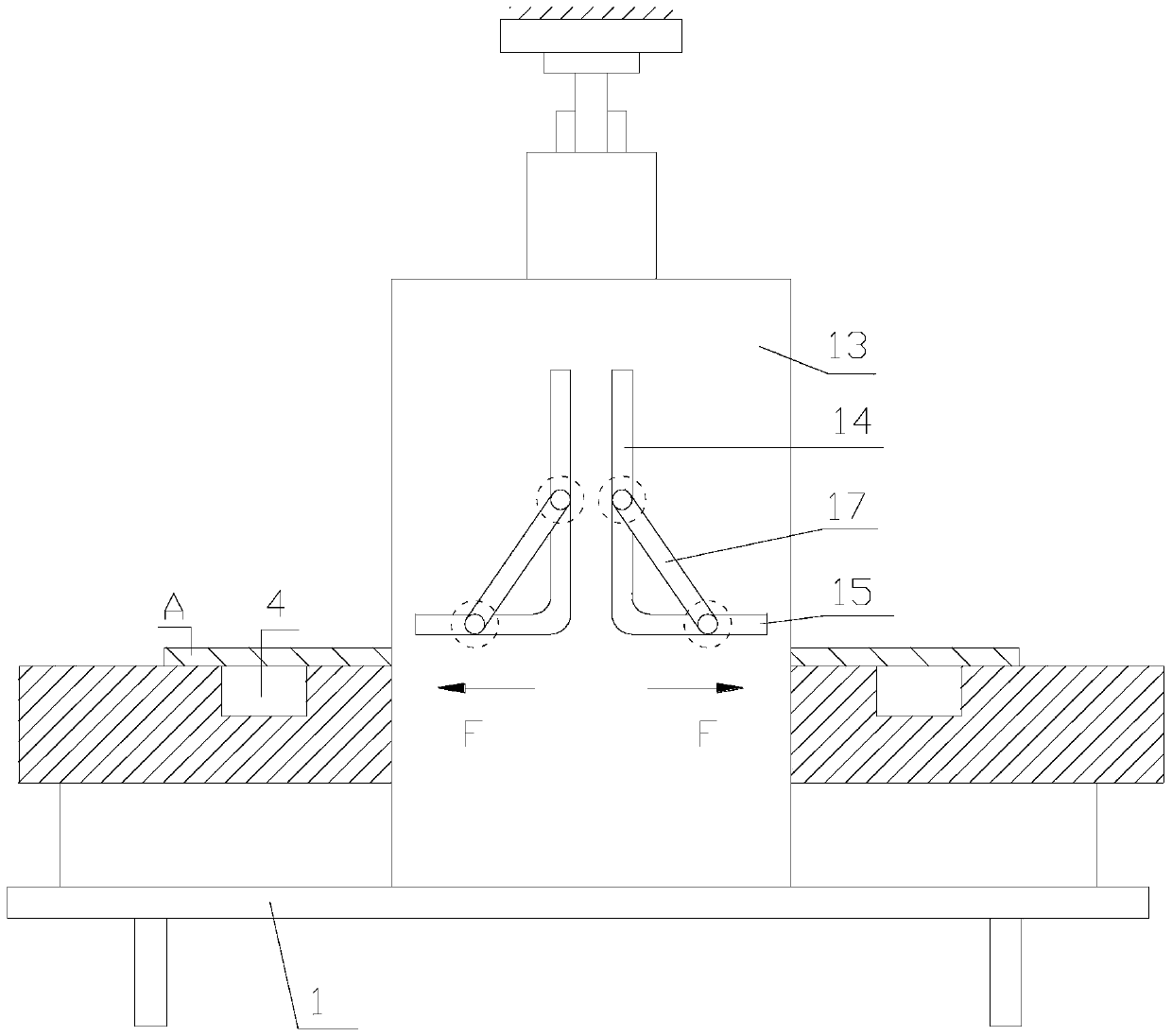

Paperboard cutting system for carton production

The invention discloses a paperboard cutting system for carton production. The paperboard cutting system for carton production comprises a support, two sliding boards, a first driving mechanism, two blades, a second driving mechanism, two auxiliary parts, a distance sensor and a controller. The support is provided with two guide rails which are arranged horizontally in parallel. The two sliding boards are movably mounted on the two guide rails correspondingly. Multiple containing grooves for containing the blades are formed in the upper surfaces of the sliding boards at intervals in the length direction of the guide rails, and the length direction of the containing grooves is perpendicular to the length direction of the guide rails. The first driving mechanism is used for driving the sliding boards to move in the length direction of the guide rails. The first ends of the two blades are both arranged between the two sliding boards. The two blades are arranged symmetrically, and the first ends of the two blades are connected with the support rotationally. The plane where the blades are located is parallel to the length direction of the containing grooves. Each blade and the corresponding sliding board form a cutting module. The paperboard cutting system for carton production has the simple structure and good cutting effect.

Owner:BENGBU ZHONGBANG PACKAGING FACTORY

Aqueous working fluid

ActiveUS20150376533A1Reduced cutting accuracyIncrease the diameterWork treatment devicesBase-materialsWorking fluidWater soluble

A water-soluble working fluid of the invention is used for cutting a brittle material using a wire saw. The water-soluble working fluid is provided by blending water, alkylene oxide adduct of acethylene glycol, and glycols. The water-soluble working fluid of the invention is capable of providing favorable cutting accuracy when the brittle material is cut using a wire, and thus is suitable for cutting out a large-diameter wafer. The water-soluble working fluid of the invention is especially suitably applicable to an abrasive-grain-fixed wire saw.

Owner:IDEMITSU KOSAN CO LTD

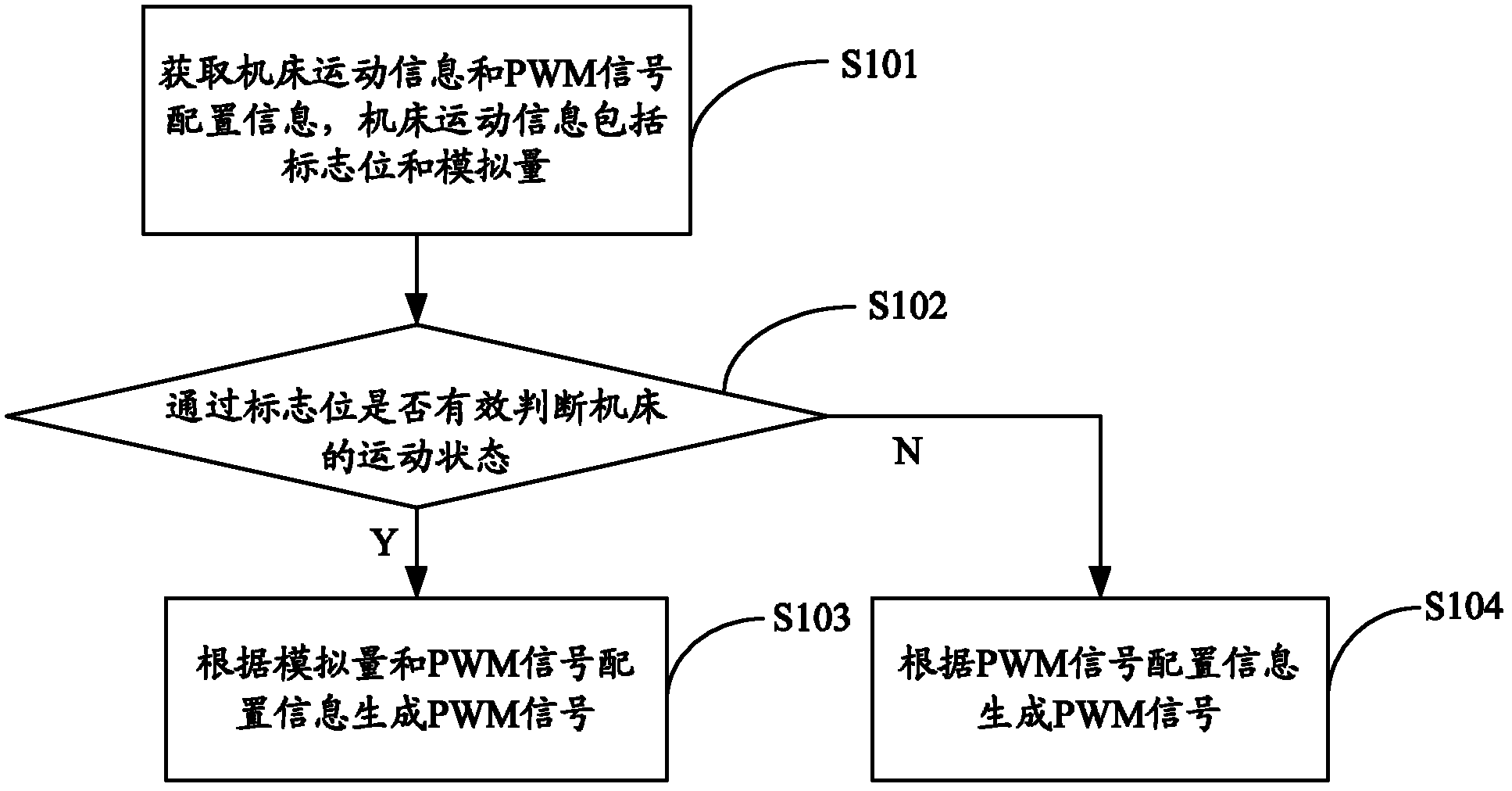

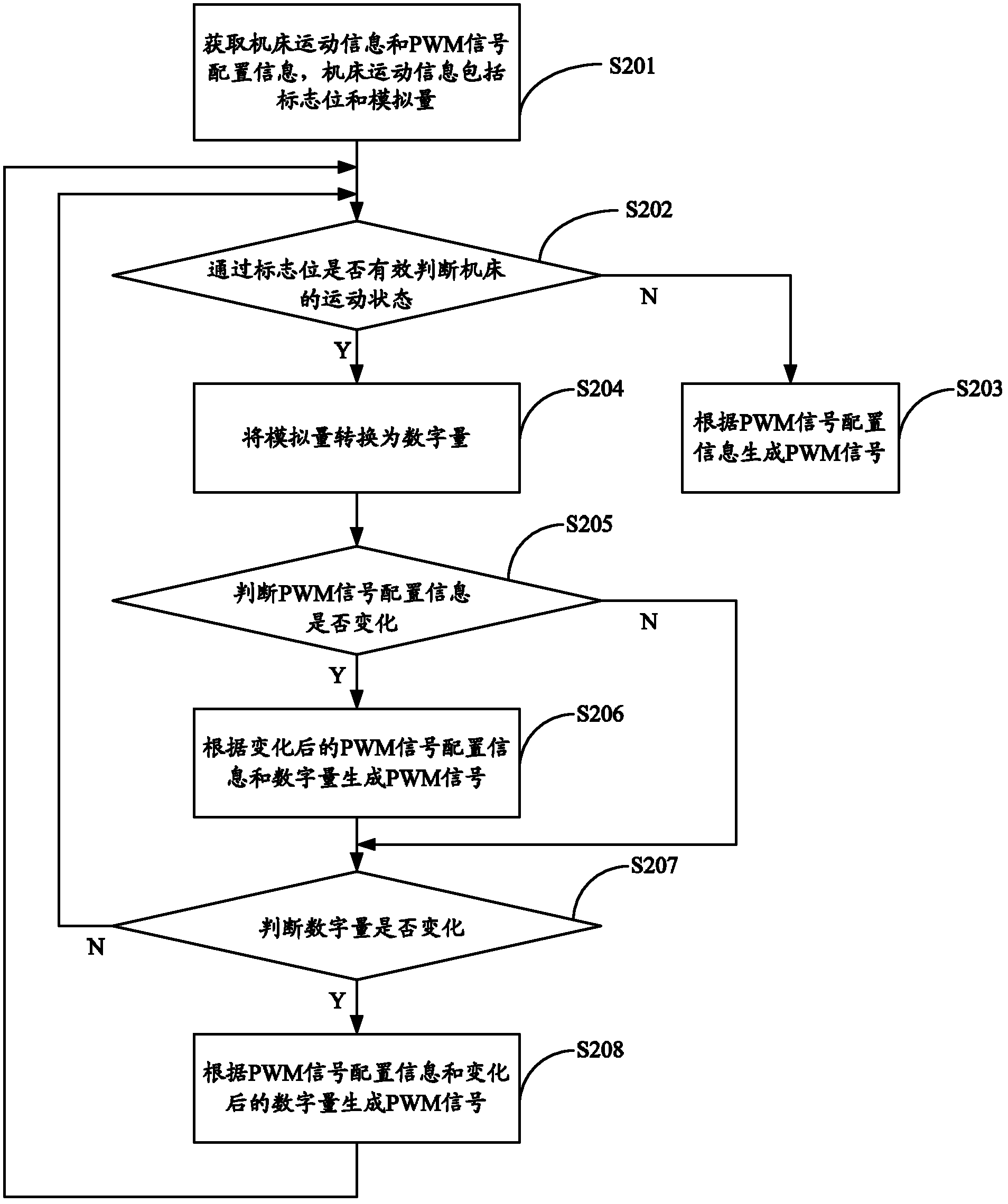

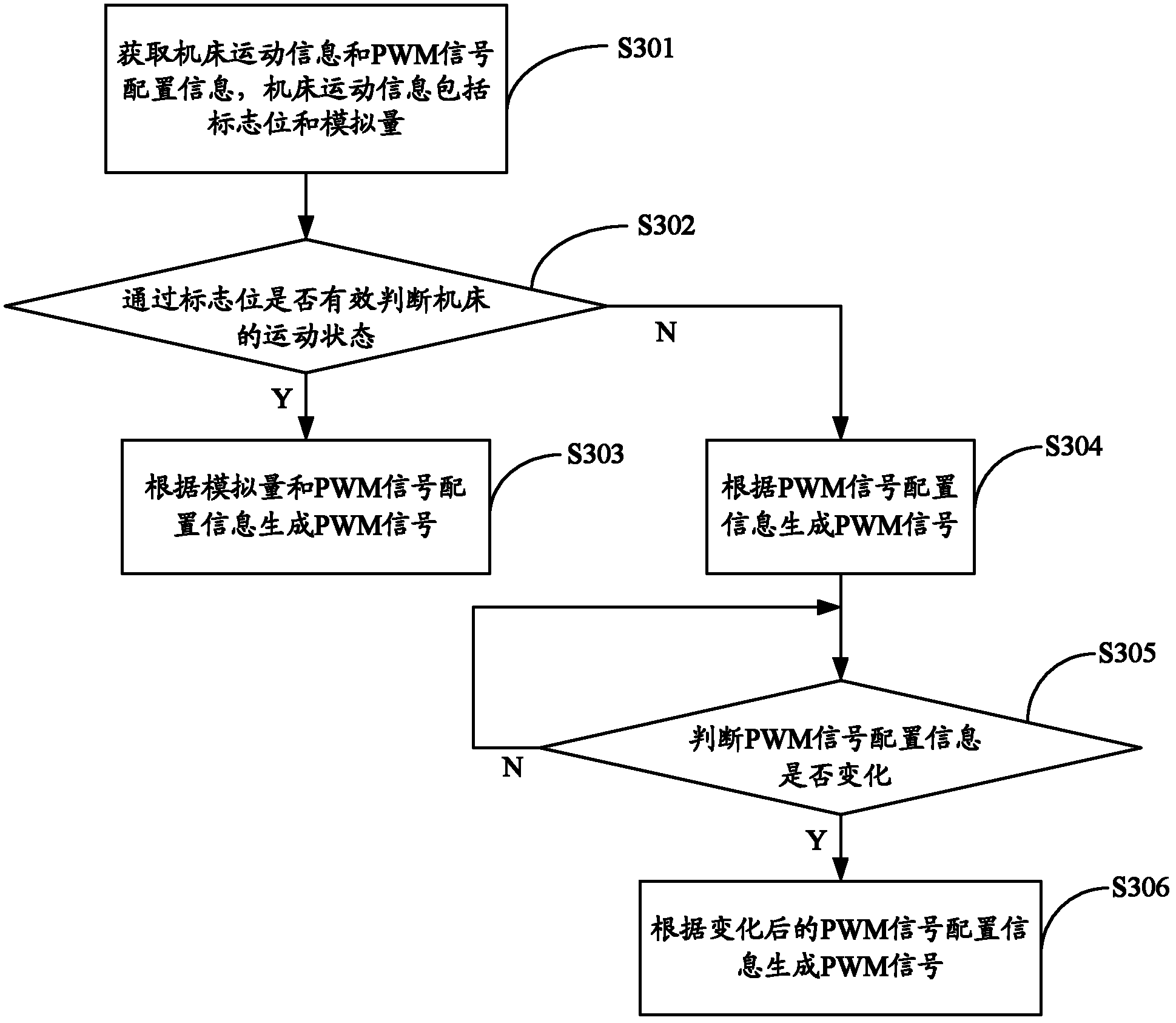

Control method and control system of pulse width modulation (PWM) signals and numerical control laser processing machine tool

InactiveCN103163828AAvoid lagRealize real-time changesLaser beam welding apparatusNumerical controlNumerical controlPwm signals

The invention relates to the field of numerical control laser processing, and provides a control method and a control system of pulse width modulation (PWM) signals and a numerical control laser processing machining tool. The control method of the PWM signals comprises the following steps: acquiring machine tool motion information and PWM signal configuration information, wherein the machine tool motion information comprises zone bit which shows machine tool motion state and analog quantity which changes in proportion with machine tool motion speeds, judging the machine tool motion state according to the zone bit, if the machine tool is in a motion state, the PWM signals are generated according to the analog quantity and the PWM signal configuration information; and if the machine tool is in a static state, the PWM signals are generated according to the PWM signal configuration information. A computer numerical control (CNC) system is used for directly controlling the PWM signals to control a system to carry out change of pulse signal frequency and duty cycle, delay of pulse signals is shortened, lag caused by programmable logic controller (PLC) cycle operation time is avoided, and cutting effect and cutting accuracy are improved effectively.

Owner:HANS LASER TECH IND GRP CO LTD

Steel plate cutting machine good in stability

InactiveCN107186271AImprove stabilityGuaranteed stabilityShearing machine accessoriesSheet steelArchitectural engineering

The invention provides a cutting machine for steel plates with good stability, which relates to the field of cutting machines. The cutting machine for steel plates with good stability includes a base, a casing is fixedly installed on the top of the base, and a box is fixedly installed on the top of the base and located on the right side of the casing, and the casing is far from a side of the base. The side inserts are provided with two insert rods. The steel plate cutting machine with good stability achieves the effect of convenient buffering of the vertical rod through the arrangement of the vertical rod, the sliding plate, the return spring, the rod body, the clamping plate, the movable block, the connecting rod and the shock-absorbing spring, so as to ensure the The stability of the cutting machine for steel plates is improved, which also facilitates the cutting accuracy of the steel plate when cutting the steel plate, so it also improves the efficiency of the cutting machine for steel plates, and also improves the working efficiency of the cutting machine for steel plates, ensuring the steel plate. The service life of the cutting machine also improves the efficiency of the cutting machine for steel plates.

Owner:金陈敏

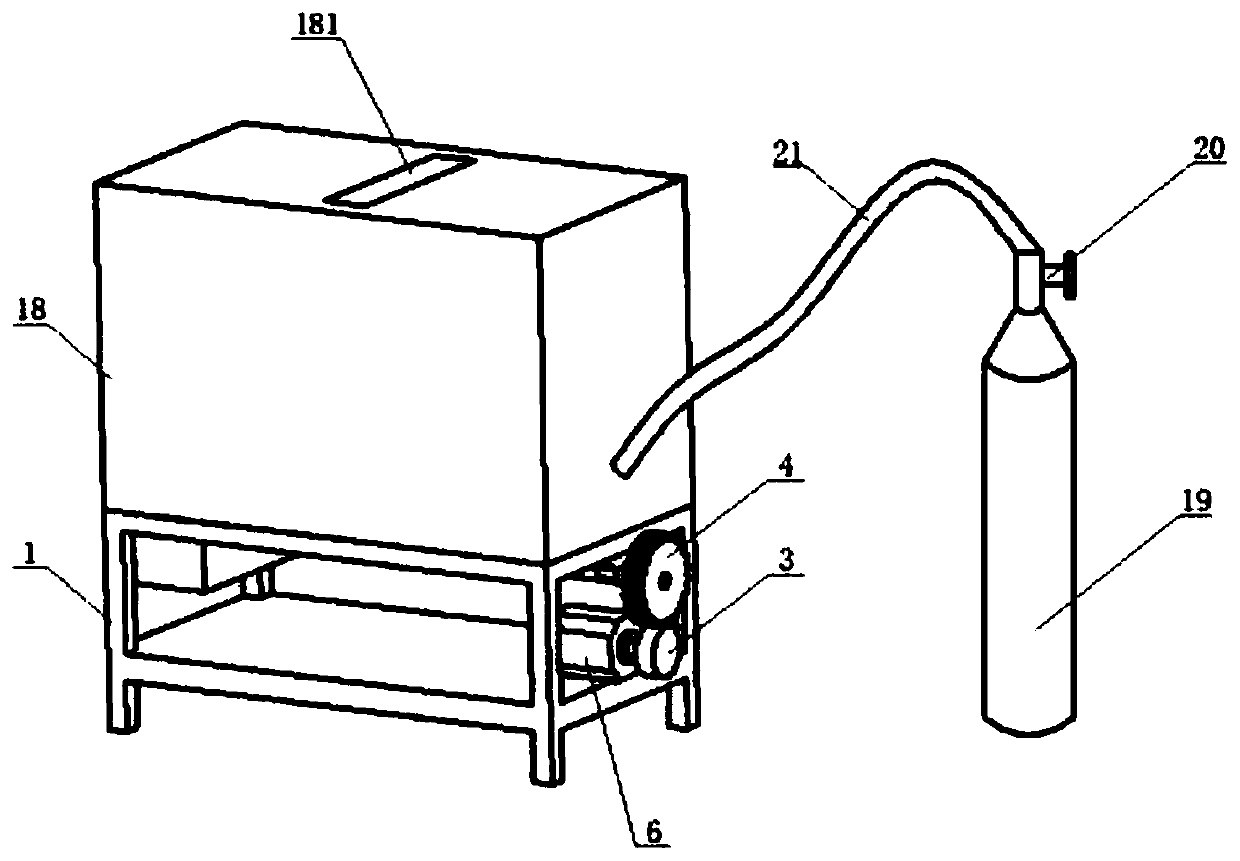

Rice cake slicing machine

InactiveCN109333616AReduce processing noiseGood cutting precisionMetal working apparatusElectric machineryEngineering

The invention provides a rice cake slicing machine. The rice cake slicing machine comprises a machine frame, a conveying assembly and a cutting assembly, wherein the conveying assembly is arranged onthe machine frame, and the cutting assembly is arranged at the end of the machine frame. The rice cake slicing machine is characterized by further comprising a guide pipe, the conveying assembly comprises a conveying belt, a driving wheel and a plurality of driven wheels, wherein the two ends of the driving wheel and the two ends of the driven wheels are movably connected to the machine frame through bearings correspondingly, the conveying belt is wound around the driving wheel and the driven wheels, the driving wheel is driven by a conveying motor, the guide pipe is arranged at the end of theconveying belt, moreover, the guide pipe is arranged on the machine frame, the cutting assembly comprises a cutting motor, a shaft sleeve and one or more cutting knives, the cutting knives are arranged on the shaft sleeve, and the shaft sleeve is arranged on a rotating shaft of the cutting motor. According to the rice cake slicing machine, rotation of the cutting knives is driven through rotationof the cutting motor, so that slicing of a rice cake which is transmitted in the guide pipe is achieved; the rice cake slicing machine is small in processing noise, better in cutting precision, low in cost, reasonable in structural design and capable of being conveniently used for processing.

Owner:ANHUI JIAGUDOU FOOD CO LTD

Paraffin slicing equipment

InactiveCN111203923AReduce labor intensityUniform thicknessMetal working apparatusElectric machineryParaffin wax

The invention discloses paraffin slicing equipment. The paraffin slicing equipment comprises a rack, a conveying lead screw, a driving gear, a driven gear, a driving motor and a slicing mechanism, wherein a cutting board is fixedly connected to the rack, the slicing mechanism and the driving motor are both fixedly installed on the rack, the slicing mechanism is used for cutting paraffin into slices, the driving gear is fixedly connected to an output shaft of the driving motor, one end of the conveying lead screw is installed on the lower surface of the cutting board through a bearing seat, thecoaxial driven gear is fixedly connected to the other end of the conveying lead screw, an ejector block is further in threaded connection to the conveying lead screw, the ejector block is arranged onthe upper surface of the cutting board in a lap joint mode, the driving gear is meshed with the driven gear, and the driving gear is an incomplete gear with gear teeth not completely arranged on theperiphery of the driving gear by a circle. By means of the adoption of the technical scheme, the slicing operation of the paraffin is completed through automatic mechanical equipment, so that the labor intensity of operators is relieved, paraffin slices are good in cutting consistency and uniform in thickness, and the cutting precision is high.

Owner:贵州省水稻研究所 +1

Efficient textile fabric cutting device

InactiveCN109295686ASolve problems that are prone to croppingReduce wasteSevering textilesEngineeringThreaded rod

The invention discloses an efficient textile fabric cutting device which comprises a working table. The two sides of the top of the working table are each provided with a first slide groove. An innercavity of each first slide groove is slidingly connected with a supporting frame. The bottom of each supporting frame is movably connected with a wheel through a rotating shaft. The bottom of each wheel makes contact with the bottom of the inner cavity of the corresponding first slide groove. A supporting rod is fixedly connected with the top of each supporting frame. A slide rod is fixedly connected between the two supporting rods. The surface of the slide rod is slidingly connected with a slide sleeve. Through the cooperation of the working table, the first slide grooves, the supporting frames, the wheels, the supporting rods, the slide rod, the slide sleeve, a threaded rod, a hand wheel, a first electric telescopic rod, a first support, a cutter, a stand column, a top plate, a second electric rod, an antiskid cushion, a second slide groove, a fixed frame and a slider, the problem of cutting deviation in a traditional manual cutting mode can be effectively solved, work efficiency isincreased, and fabric waste can be reduced.

Owner:林友猛

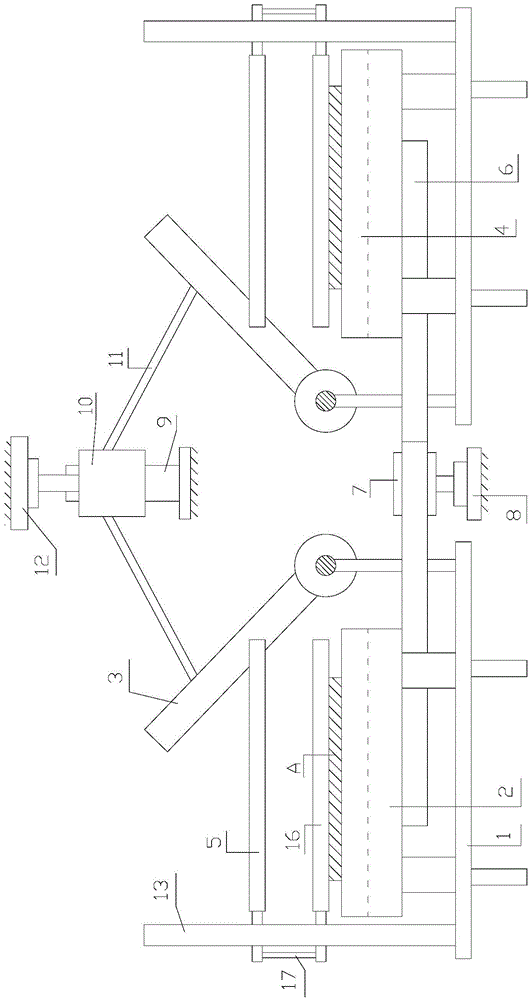

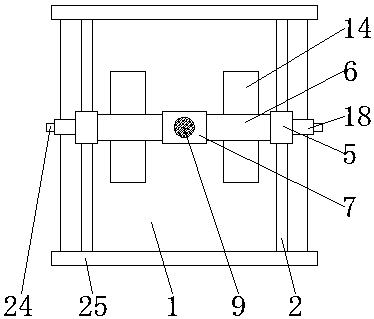

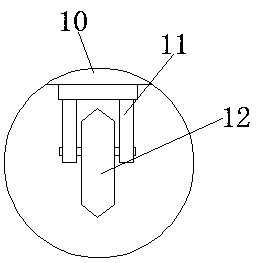

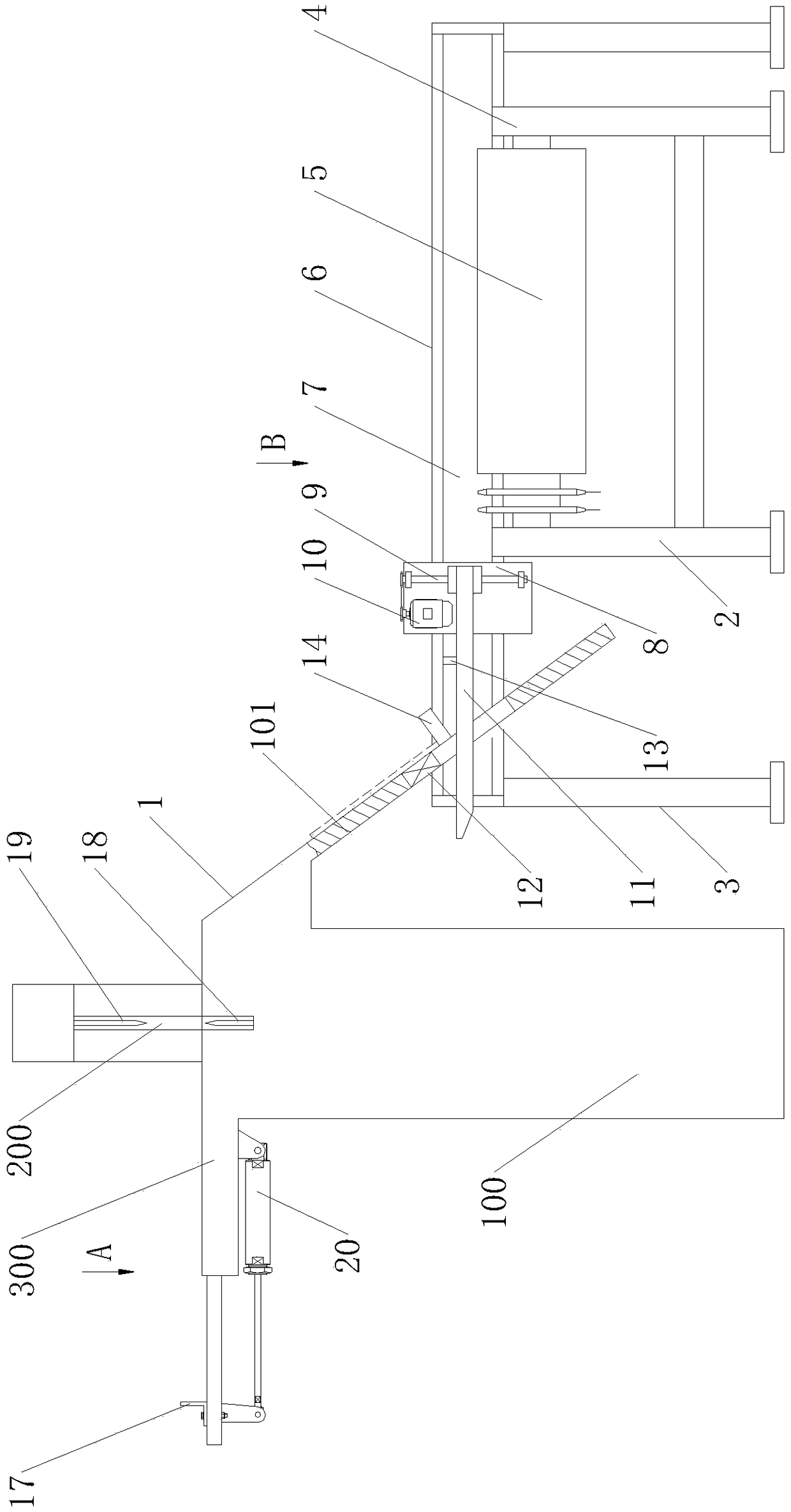

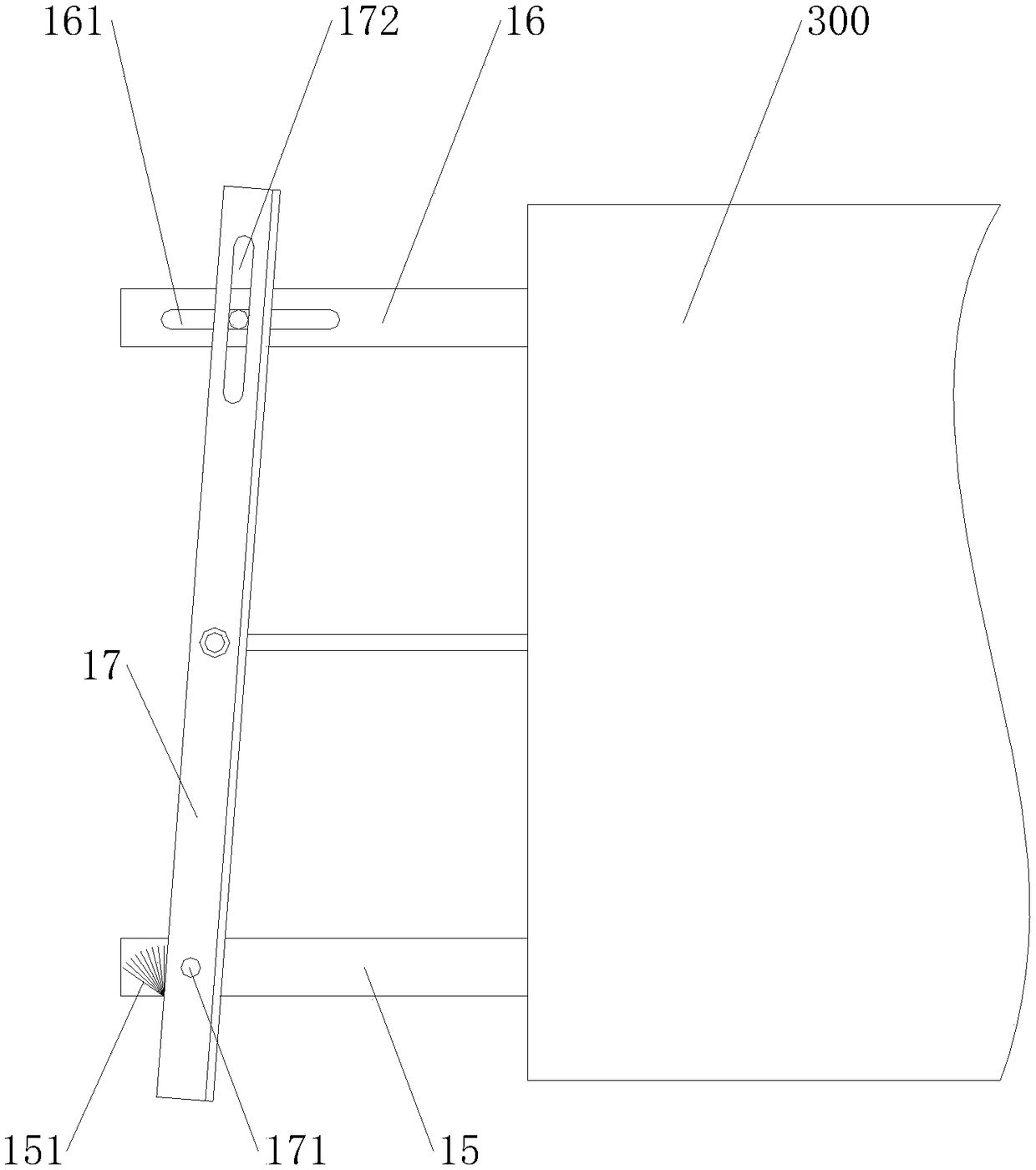

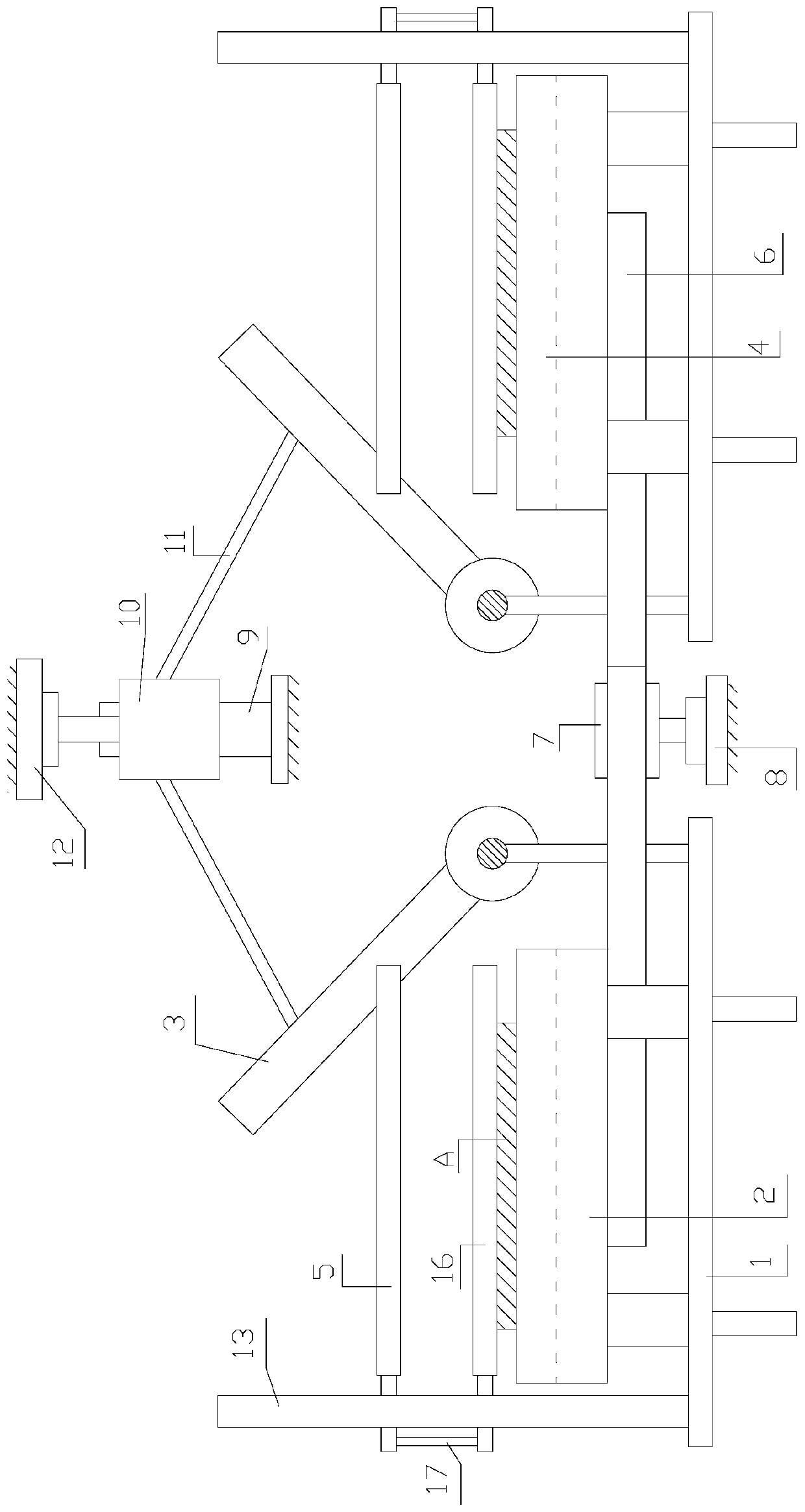

Sheared plate conveying device suitable for skew plate shearing

ActiveCN108817528AEasy cutting workGood cutting precisionShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a sheared plate conveying device suitable for skew plate shearing. The sheared plate conveying device comprises a rack, a cutter set is arranged in the middle of the rack, a feeding platform is arranged on one side of the cutter set, and a skew plate is arranged on the other side of the cutter set. A first extending rod and a second extending rod are connected to the interior of the feeding platform separately, and the end of the first extending rod and the end of the second extending rod are mutually connected through an L-shaped push plate. The two ends of the push plate are connected with the first extending rod and the second extending rod through a circular hole and a first strip-shaped hole respectively, and a second strip-shaped hole matched with the first strip-shaped hole is formed in the second extending rod. The first extending rod is provided with a scale groove matched with the push plate, a conveying device body is arranged on the outer side of theskew plate, and a plate taking device is arranged at the end of the conveying device body. The sheared plate conveying device has the advantages that the shearing precision and the shearing efficiency are high, and the plate is convenient to convey.

Owner:浙江天也智能科技有限公司

Beef slicing device

InactiveCN112704105AImprove consistencyImprove cutting accuracyMeat holding apparatusMetal working apparatusGear wheelElectric machinery

The invention discloses a beef slicing device. The beef slicing device comprises a rack, a pushing lead screw, a driving gear, a driven gear, a driving motor and a slicing mechanism, a cutting board is fixedly connected to the rack, the slicing mechanism and the driving motor are both fixedly arranged on the rack, the slicing mechanism is used for cutting beef into thin slices, the driving gear is fixedly connected to an output shaft of the driving motor, one end of the pushing lead screw is arranged on a lower surface of the cutting board through a bearing seat, the other end of the pushing lead screw is fixedly connected with the coaxial driven gear, an ejector block is further connected to the pushing lead screw in a threaded mode, the ejector block is arranged on an upper surface of the cutting board in a lap joint mode, the driving gear is meshed with the driven gear, and the driving gear is an incomplete gear with gear teeth not completely arranged on a periphery of the driving gear by a circle. In the technical scheme, beef is sliced through an automatic mechanical device, labor intensity of operators is relieved, consistency of beef slicing and cutting is good, slicing thickness is uniform and consistent, and cutting precision is high.

Owner:NANNING UNIV

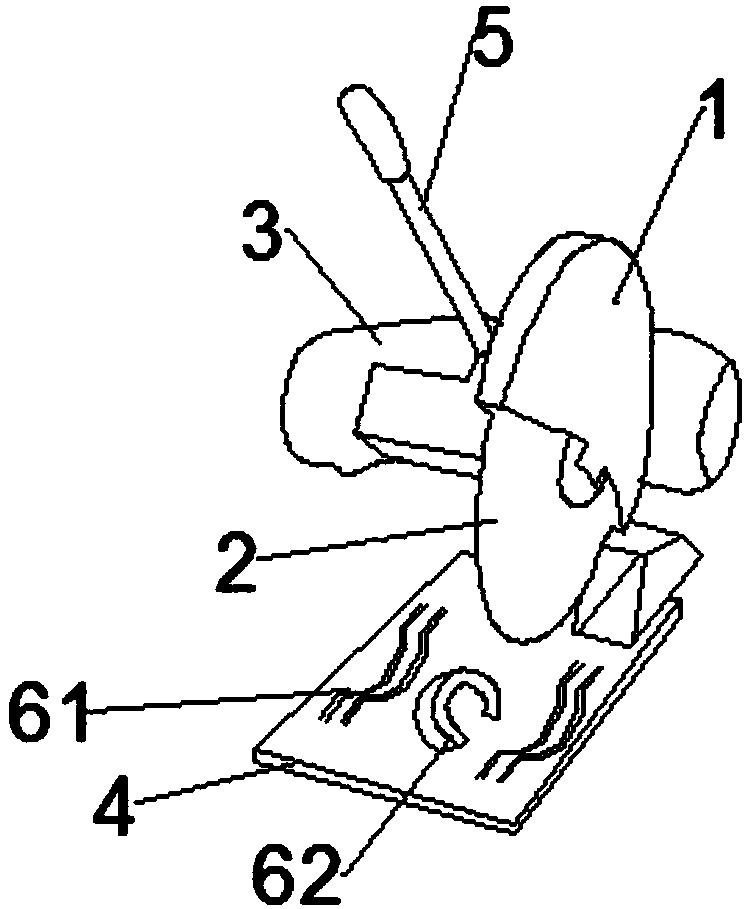

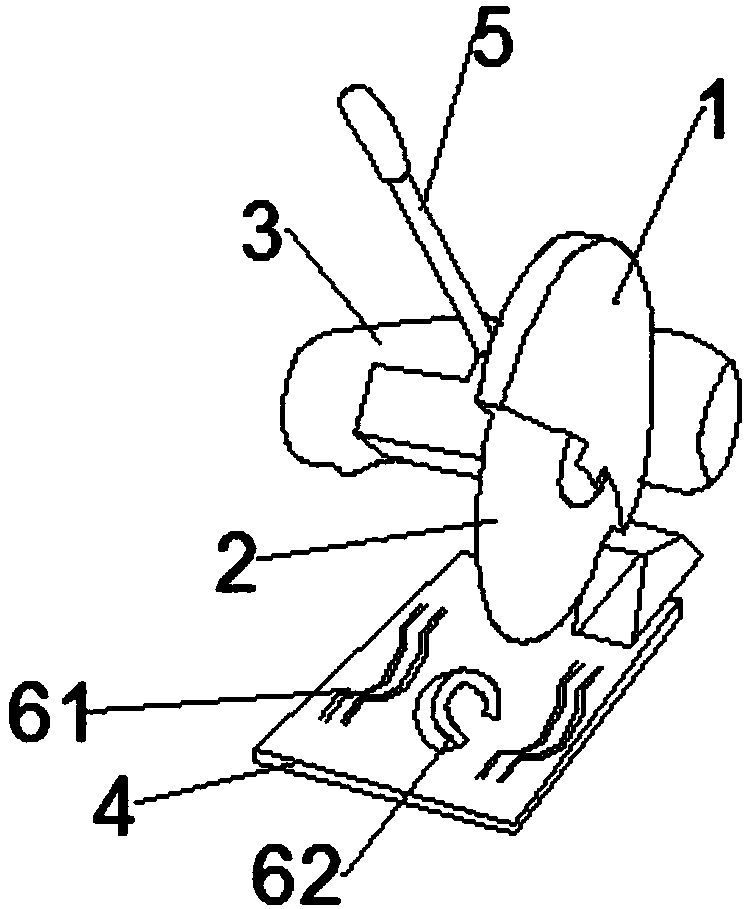

Cutting machine with self-locking type universal wheel

InactiveCN108214256ASimple structureEasy to moveGrinding machinesGrinding work supportsEngineeringSelf locking

The invention provides a cutting machine with a self-locking type universal wheel. The cutting machine with the self-locking type universal wheel comprises a housing, a grinding wheel cutting piece and a machine frame, wherein a half of the housing covers the periphery of the grinding wheel cutting piece. The cutting machine with the self-locking type universal wheel further comprises a safety handle and a cutting base. The safety handle is fixed on the surface of the housing. The lower portion of the safety handle is connected with the cutting base. A cutting fixing device for fixing a profile material is arranged on the cutting base and is installed on the surface of the cutting base. According to the cutting machine with the self-locking type universal wheel, the cutting fixing device is arranged on the cutting base, the cutting machine is provided with the fixing device, the structure is simple, and movement is convenient. The problems that positioning is not accurate enough, positioning is not firm, deviation and other conditions are likely to occur during cutting, and then the cutting effect is affected are solved. High cutting accuracy is guaranteed, and the situation that during cutting of the profile material, longitudinal stress is generated by cutting, and then the profile material deviates is avoided. The whole device is exquisite in structure arrangement and good in use effect.

Owner:NANTONG RUNYA ELECTROMECHANICAL TECH CO LTD

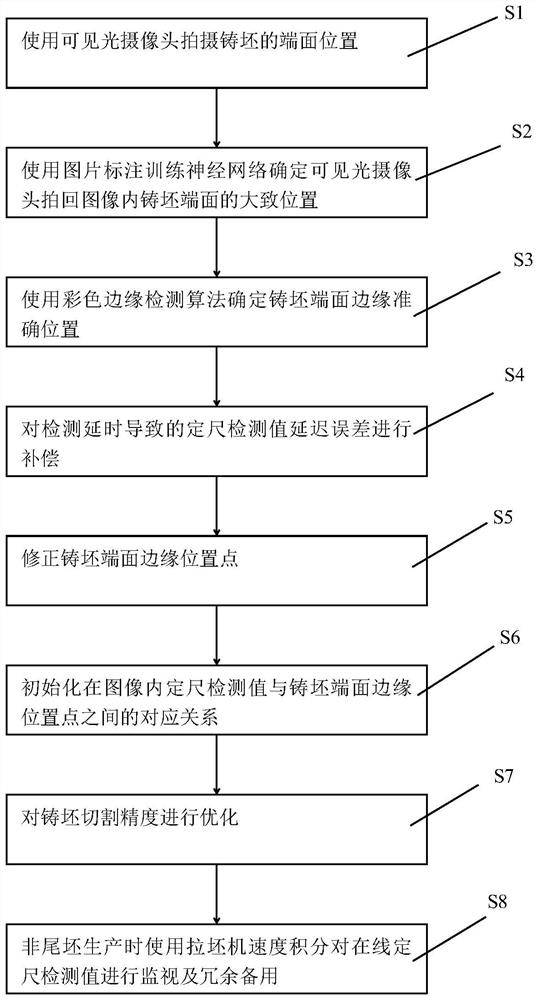

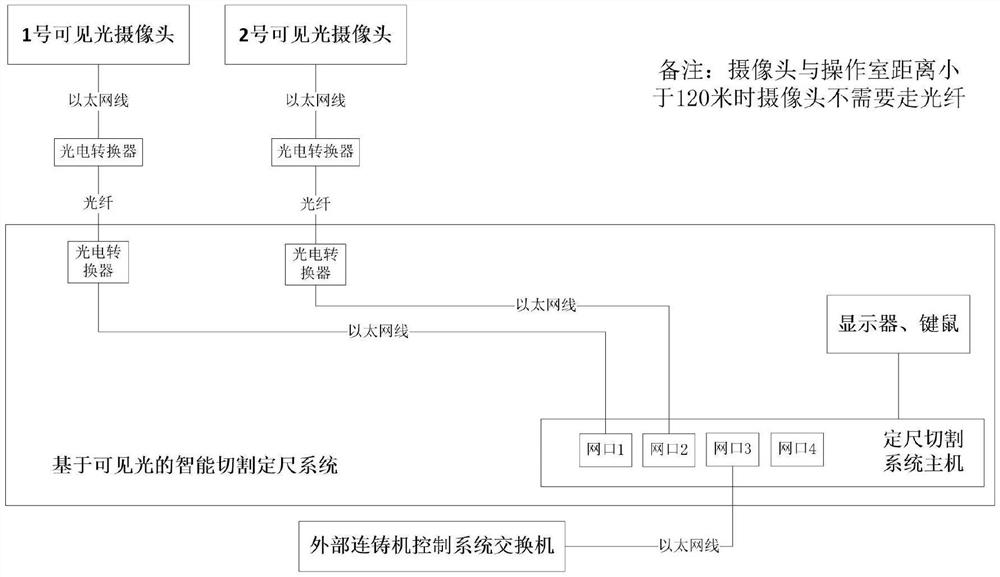

Intelligent cutting and sizing method for continuous casting billet

PendingCN113780646AOvercome the defect that it cannot be applied to the low temperature condition of the continuous casting slab surfaceOvercome the defect of low precisionImage enhancementImage analysisNerve networkEngineering

The invention relates to an intelligent cutting and sizing method for a continuous casting billet. The intelligent cutting and sizing method comprises the following steps that S1, the end face position of the casting billet is shot through a visible light camera; S2, a picture labeling training neural network is used to determine the approximate position of the end face of the casting billet in an image shot by the visible light camera; S3, the accurate position of the end face edge of the casting billet is determined through a color edge detection method; S4, a fixed-length detection value delay error caused by detection delay is compensated; S5, edge position points of the end face of the casting billet is corrected; S6, the corresponding relation between the fixed-length detection value in the image and the edge position point of the end face of the casting billet is initialized; S7, the cutting precision of the casting billet is optimized; and S8, during non-tail blank production, monitoring and redundant standby are carried out on the online fixed-length detection value by using the speed integral of the throwing machine. The method overcomes the defects of a traditional infrared cutting and sizing method and has the advantages of being high in precision and low in cost.

Owner:WISDRI ENG & RES INC LTD

Novel full-automatic edge cutting device for refrigerator liner and machining process thereof

PendingCN112792864AEasy to operateFacilitate workshop layout managementMetal working apparatusElectric machineryDrive motor

The invention discloses a novel full-automatic edge cutting device for a refrigerator liner and a machining process thereof, and relates to the technical field of refrigerator machining equipment. Guiding parts are arranged at the two ends of each lower cutter block mounting plate, a lower cutter block mounting part is arranged at the upper end of each lower cutter block mounting plate, a lower cutter block is arranged at each lower cutter block mounting part, an upper cutter block mounting part is arranged at the position, located below an auxiliary positioning module, of the upper end of each main body frame, and upper cutter blocks are arranged at the upper cutter block mounting parts. A waste sliding plate is arranged on the middle section of each upper cutter block. Linear sliding rails are fixedly arranged at the two ends of the upper side of a lower base plate, guide grooves are formed in the two ends of the lower side of each main body frame, a driving motor is arranged in each main body frame, and a cam is fixedly arranged at the driving end of each driving motor. The novel full-automatic edge cutting device for the refrigerator liner can conduct accurate cutting and has high automation degree and good cutting precision; and the previous one-way cutting is promoted into two-way cutting, so that the shearing efficiency is improved.

Owner:滁州力通机械装备股份有限公司

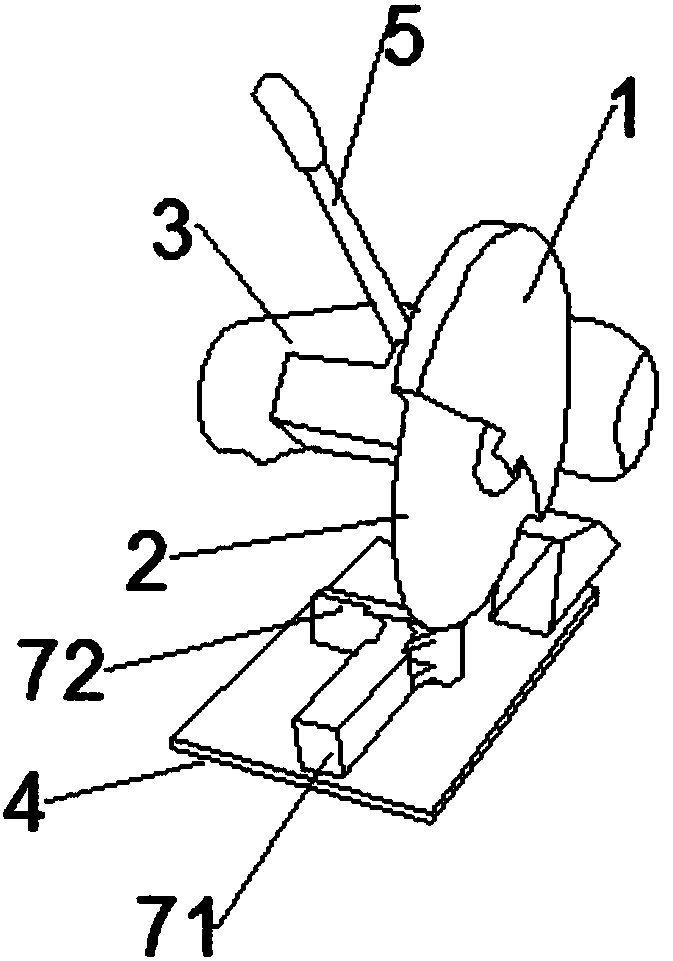

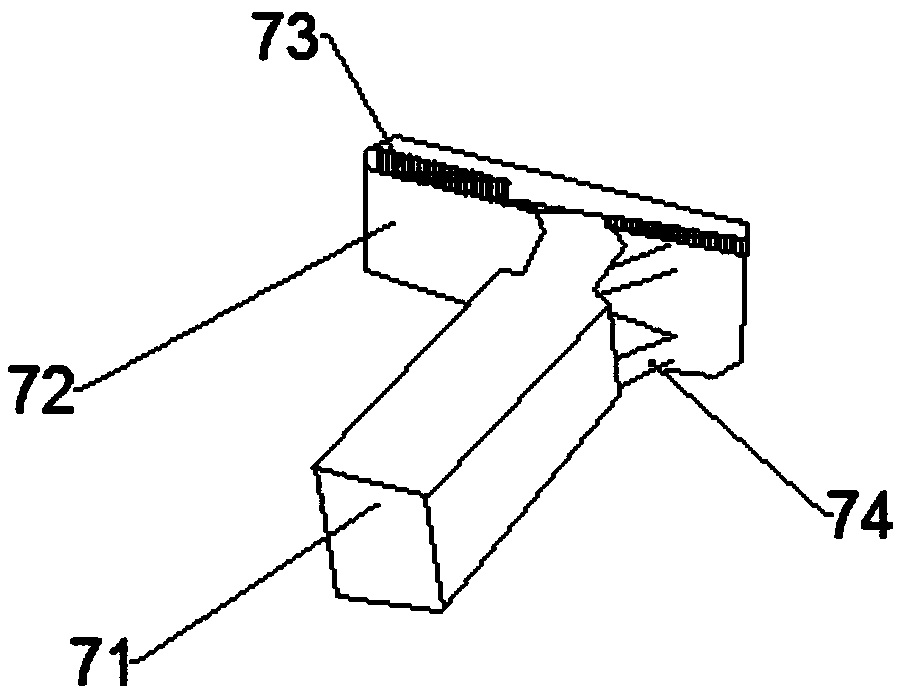

Sheet profile cutting machine

InactiveCN108214257ANo misalignment etc.Simple structureGrinding machinesGrinding work supportsEngineeringGrinding wheel

The invention provides a sheet profile cutting machine. The sheet profile cutting machine comprises a cover shell, a grinding wheel slice and a frame; and the cover shell half covers the grinding wheel slice. The sheet profile cutting machine further comprises a safety handle and a cutting base; the safety handle is fixed on the surface of the cover shell; the cutting base is connected below the safety handle, and is provided with a cutting fixing device for fixing profiles; and the cutting fixing device is mounted on the surface of the cutting base. The sheet profile cutting machine is provided with the cutting fixing device on the cutter base, so that the cutting machine is provided with the fixing device; the structure is simple; the movement is convenient; the problems of weak positioning, instable positioning and influence on the cutting effect by such conditions as easy deflection during cutting can be overcome; accurate cutting precision is guaranteed; such phenomenon as staggering of profiles due to longitudinal stress generated by cutting is not generated during cutting of the profiles; and the whole device is delicate in structural setting and better in use effect.

Owner:NANTONG RUNYA ELECTROMECHANICAL TECH CO LTD

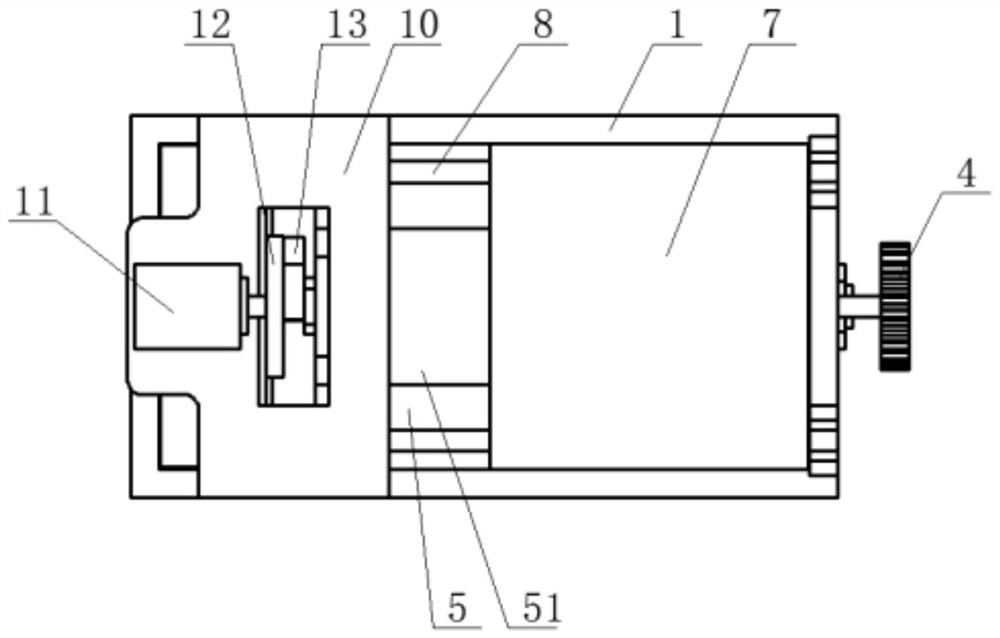

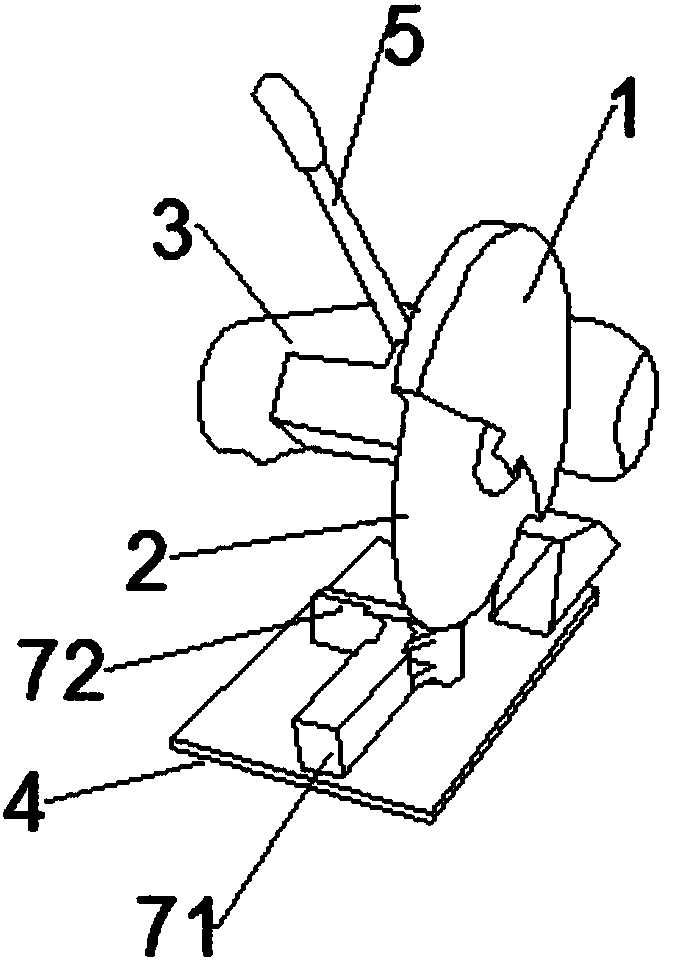

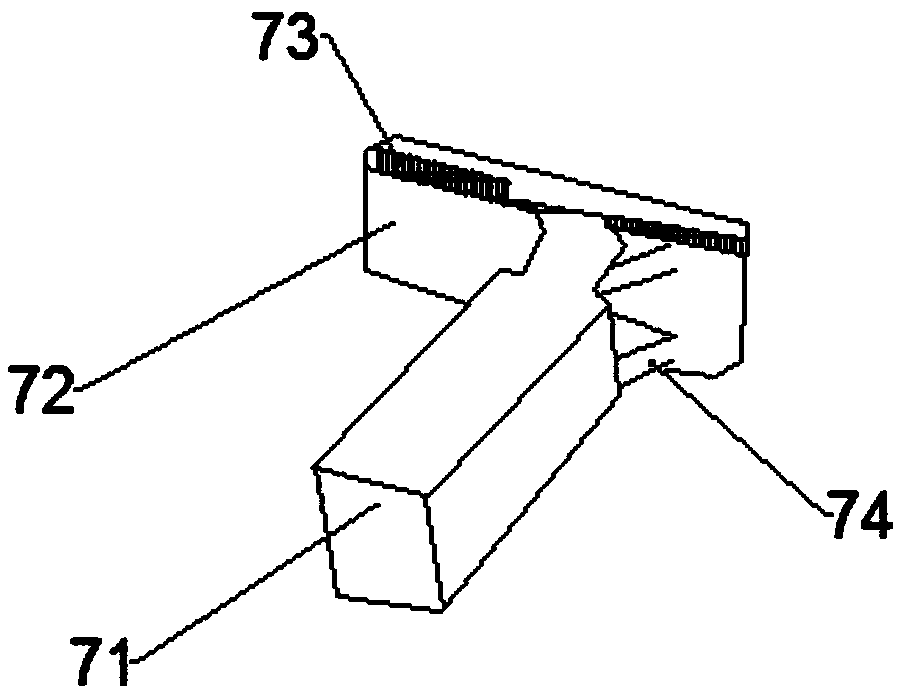

Metal bar cutting machine

PendingCN107639281AEasy to cutGood cutting precisionShearing machinesMaintainance and safety accessoriesSafety coefficientFixed frame

The invention relates to a metal bar cutting machine. The metal bar cutting machine comprises a case (1); the metal bar cutting machine is characterized in that a driving device (2) is arranged on oneside inside the case (1), a fixed frame (3) is fixedly connected to the end, on a main shaft, of the driving device (2), the fixed frame (3) is provided with a protrusion (4) which is provided with ajack post (41), a clamping mechanism (5) is movably connected to the jack post (41), the main shaft is provided with a cutter (6), and the clamping mechanism (5) is provided with a handle (51); a metal bar is clamped through the clamping mechanism (5), the hand-held handle (51) drives the clamping mechanism (5) to rotate by taking the jack post (41) as a fulcrum, and the metal bar is delivered tothe cutter (6) position for cutting. Accordingly, cutting is convenient, the safety coefficient in the cutting process is greatly increased, the cutting precision is good, the cutter and the drivingdevice are protected through a protection cover and a cutter cover, and the service life is prolonged.

Owner:丹阳市协昌合金有限公司

A cardboard cutting system for producing cartons

The invention discloses a paperboard cutting system for carton production. The paperboard cutting system for carton production comprises a support, two sliding boards, a first driving mechanism, two blades, a second driving mechanism, two auxiliary parts, a distance sensor and a controller. The support is provided with two guide rails which are arranged horizontally in parallel. The two sliding boards are movably mounted on the two guide rails correspondingly. Multiple containing grooves for containing the blades are formed in the upper surfaces of the sliding boards at intervals in the length direction of the guide rails, and the length direction of the containing grooves is perpendicular to the length direction of the guide rails. The first driving mechanism is used for driving the sliding boards to move in the length direction of the guide rails. The first ends of the two blades are both arranged between the two sliding boards. The two blades are arranged symmetrically, and the first ends of the two blades are connected with the support rotationally. The plane where the blades are located is parallel to the length direction of the containing grooves. Each blade and the corresponding sliding board form a cutting module. The paperboard cutting system for carton production has the simple structure and good cutting effect.

Owner:BENGBU ZHONGBANG PACKAGING FACTORY

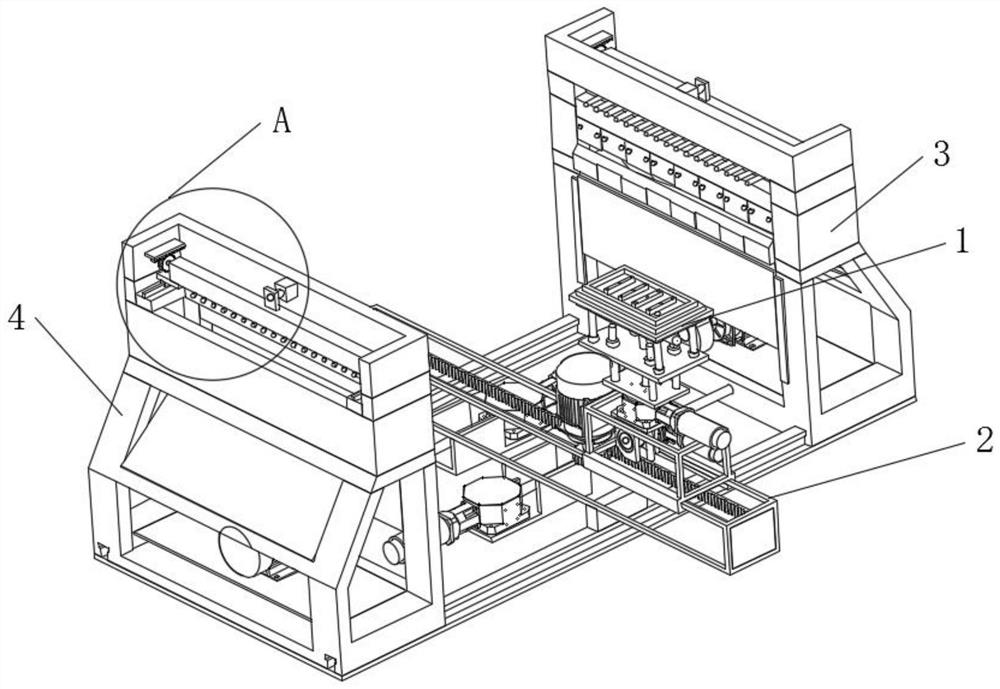

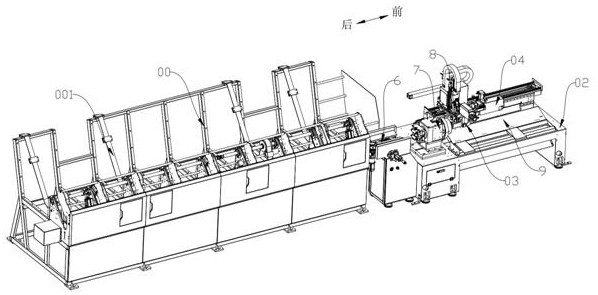

Numerical control polycrystalline silicon diamond wire high-speed cutting-off machine

The invention relates to a numerical control polycrystalline silicon diamond wire high-speed cutting-off machine which comprises a lathe bed and taking-up and paying-off chambers installed at the twoends of the lathe bed. An electric box is fixedly installed on the upper portion of each taking-up and paying-off chamber. Stand columns are installed on the four corners of the lathe bed correspondingly. Two working tables are installed between the two stand columns located on the two sides of the lathe bed through guide rail supports correspondingly. The guide rail supports and the working tables are connected through short steel guide rails. Sliding plates are installed on the two stand columns located on the rear side through linear guide rails correspondingly. The sliding plates drive a cutting wire frame fixed to the lower portions of the sliding plates to move up and down. A first datum motor and a second datum motor are installed at the two ends of the cutting wire frame correspondingly. Multiple diamond wire passing wheels are installed on the two sides of the cutting wire frame. Multiple diamond wire cutting wheels are installed below the cutting wire frame. Diamond wires areguided out from the taking-up and paying-off chamber at one end and sequentially wound around the multiple diamond wire cutting wheels and the diamond wire passing wheels into the taking-up and paying-off chamber at the other end. According to the machine, the diamond wire taking-up, paying-off and distributing quality is improved, and the operation stability and the production efficiency of equipment are improved.

Owner:WUXI SHANGJI AUTOMATION

A material cutting process

ActiveCN113231874BUniform and orderly feedingReduce material jamsMeasurement/indication equipmentsPositioning apparatusStructural engineeringMachining process

The invention discloses a material cutting process, which comprises the following steps: n pieces of material are transported to one side of the material blocking unit and are blocked by the material blocking unit, and the size relationship between the number n of materials and the rated number m of cutting materials is judged, when n When ≤m, the blocking unit releases the material; when n>m, the blocking unit pushes the material back, where n and m are both natural numbers; the released material moves to the detection unit, and the detection unit detects whether the material is cross-stuck , when the material is cross-jammed, the alarm will alarm, and when the material is not cross-jammed, the material will continue to be dropped; the material will be dropped to the limit unit, and the limit unit will control n pieces of material to be evenly arranged along the blanking chute and fall in sequence; The material in the blanking trough is conveyed forward by the feeding unit, and when the material is conveyed forward to the cutting station, it is clamped by the clamping unit; after the material is clamped, the cutting unit cuts it, and several workpieces are obtained by the blanking unit. The unit is unloaded. The material can be discharged evenly, and the cutting accuracy is better.

Owner:FOSHAN LONGXIN LASER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com