Display mother board, display screens and display terminal

A technology for display screens and motherboards, applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as edge chipping and cracks at cutting sites, reduce difficulty and improve cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

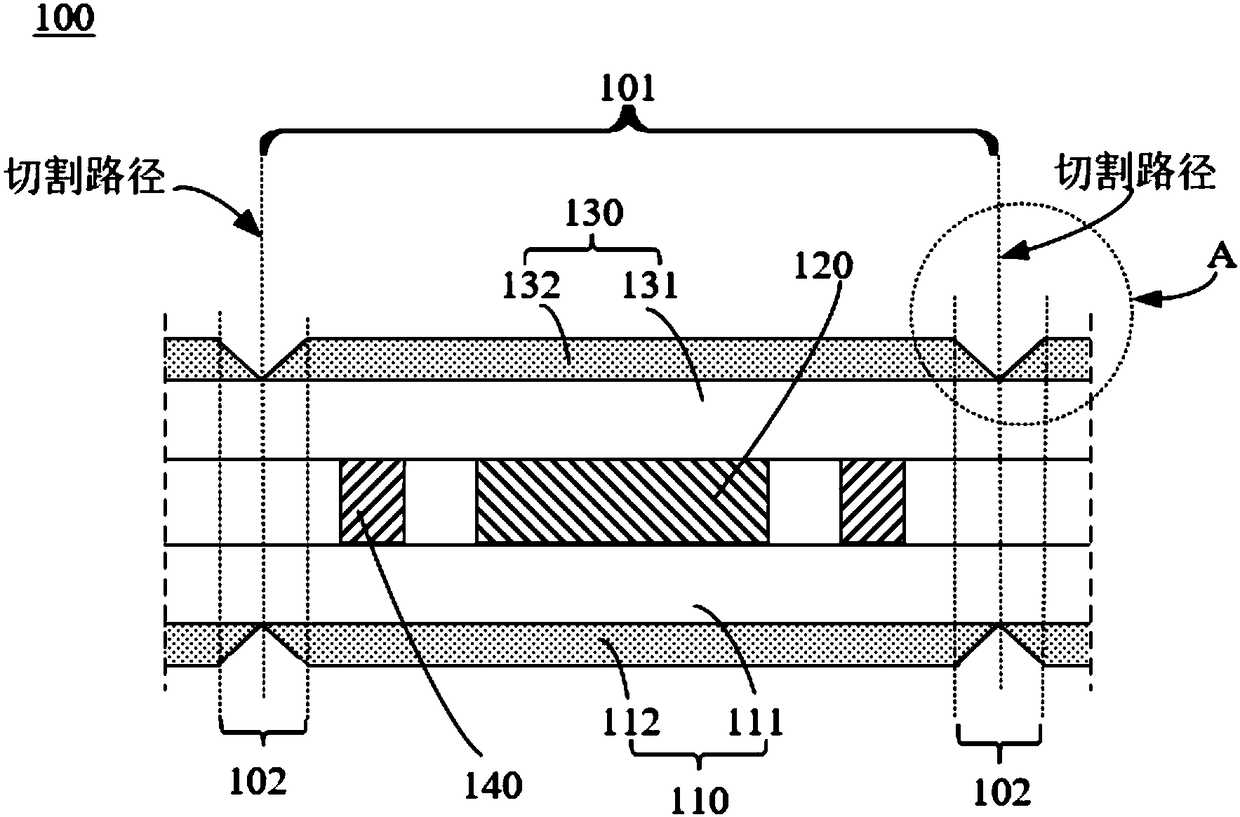

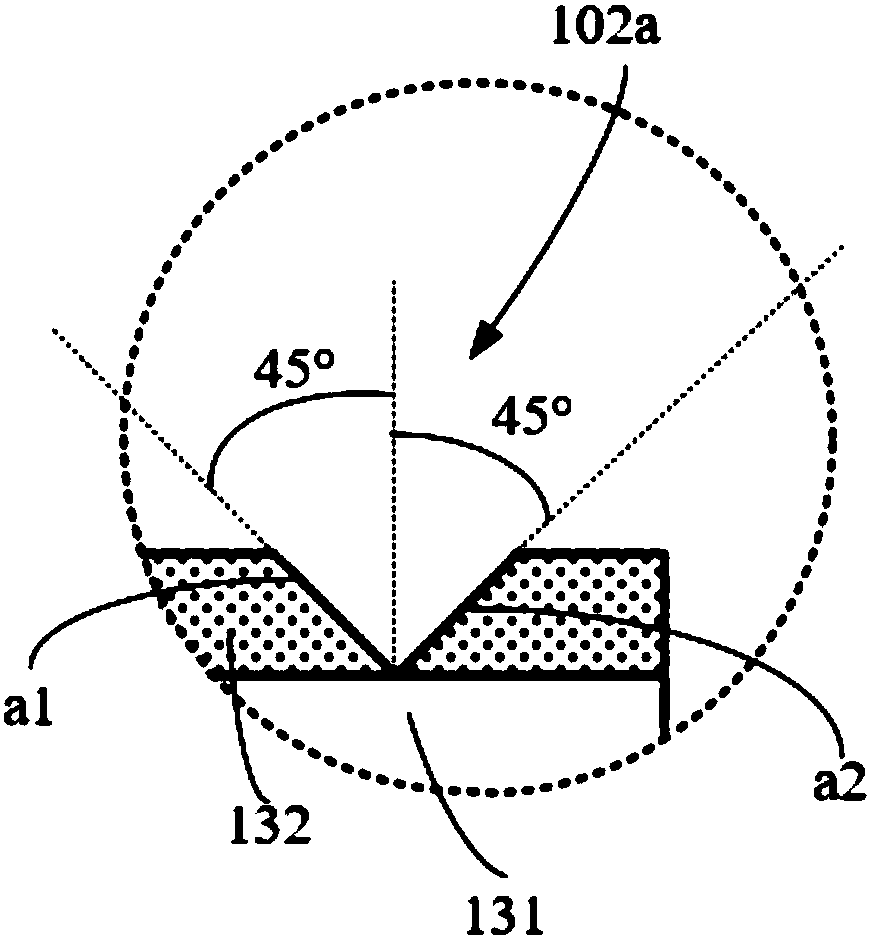

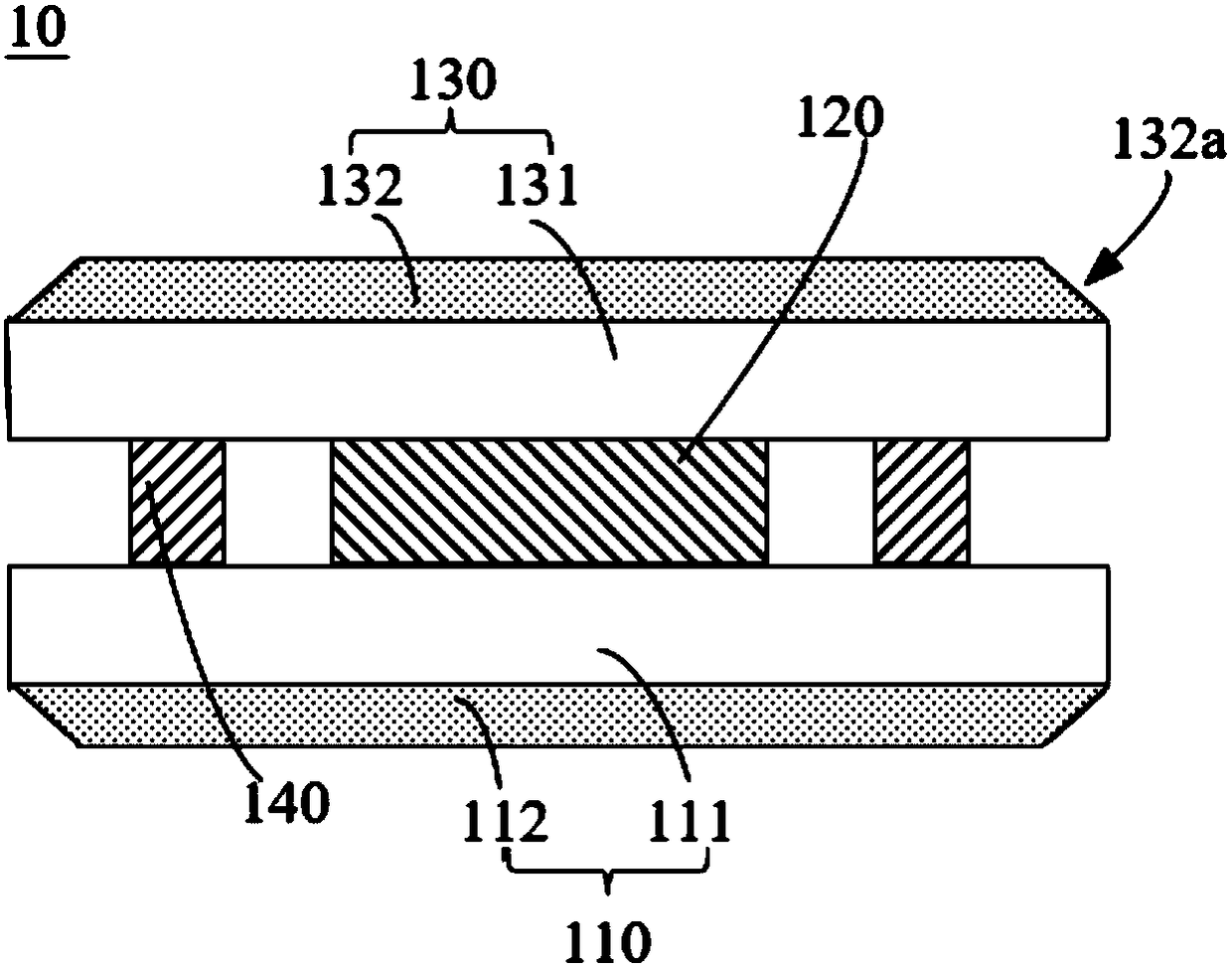

[0022] Please refer to figure 1 , the embodiment of the present invention provides a display motherboard 100 . Several independently arranged display screens 10 are formed on the display motherboard 100 . The display motherboard 100 includes a base substrate 110 , a functional layer 120 and a packaging cover 130 which are stacked in sequence. At least one of the base substrate 110 and the package cover 130 includes: a body layer and a resin coating layer stacked on the surface of the body layer. Wherein, the body layer is disposed close to the functional layer 120 , and the resin coating is located on the surface of the body layer away from the function layer 120 . A cutting area 102 is formed on the resin coating along the peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com