Steering frame of railway track car with flaw detection devices

A flaw detection device and technology for railway tracks, which are applied to bogies, railway car body parts, railway vehicle shape measuring instruments, etc. The effect of eliminating hidden dangers of driving safety, good running quality and high accuracy of flaw detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

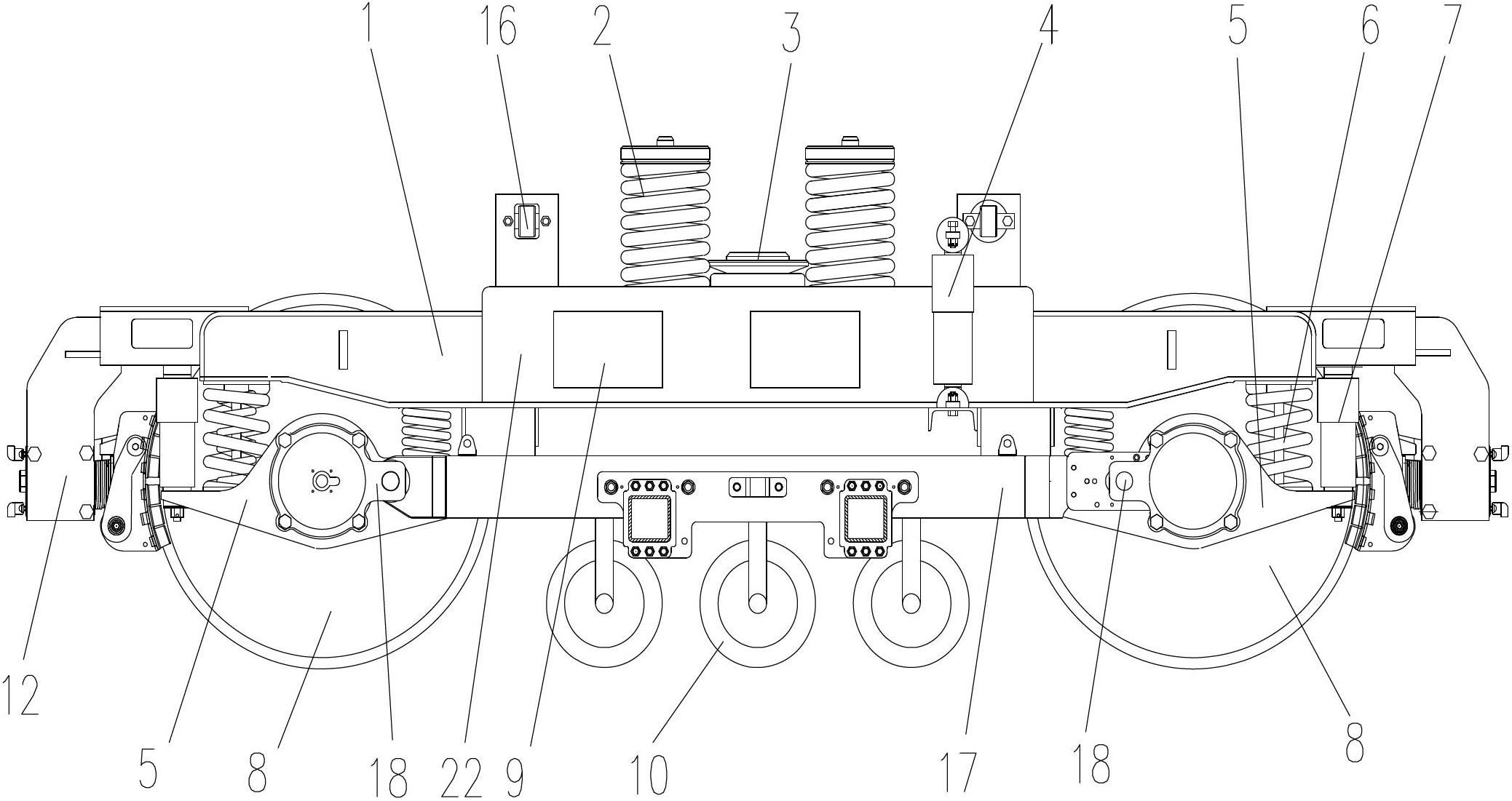

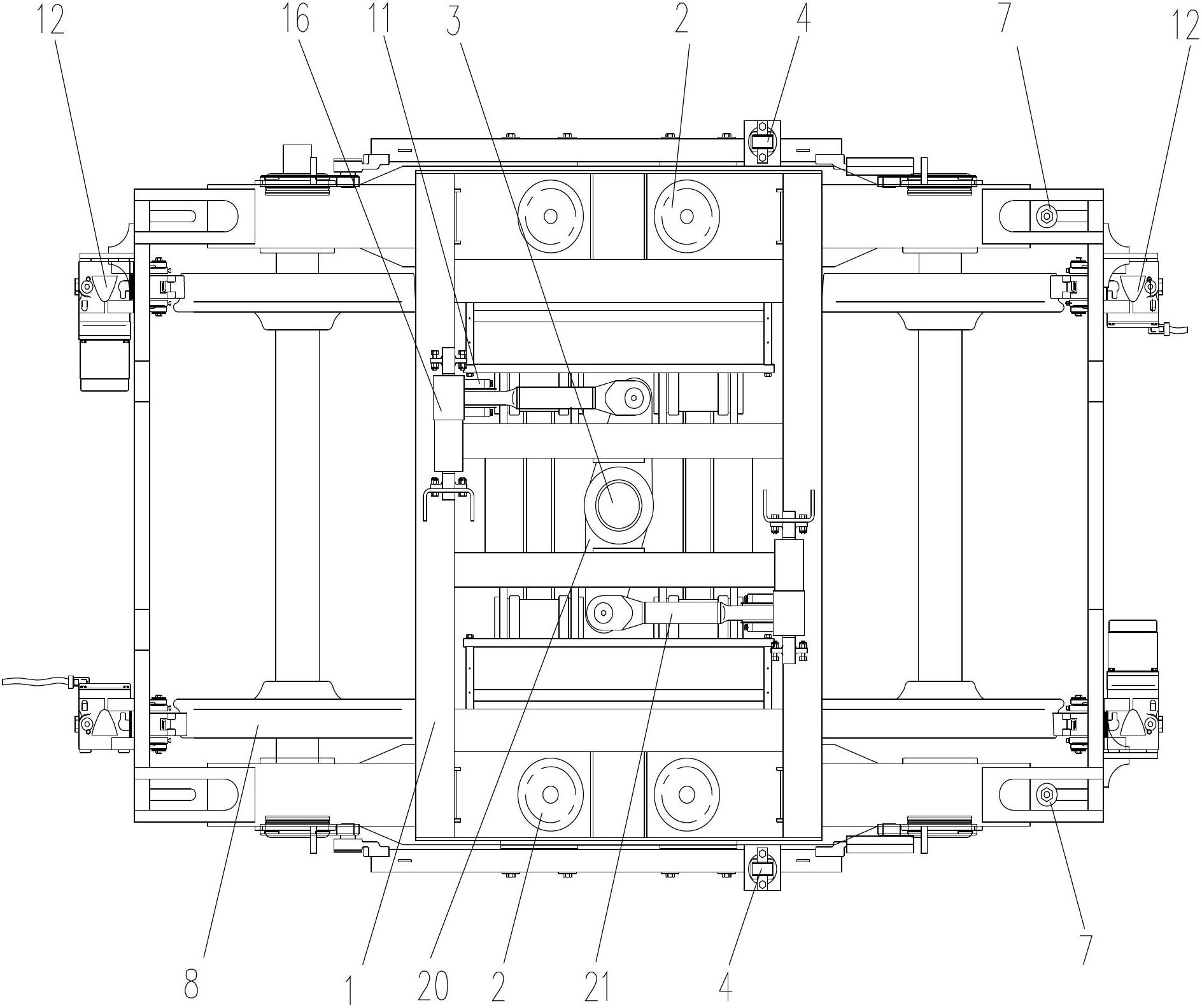

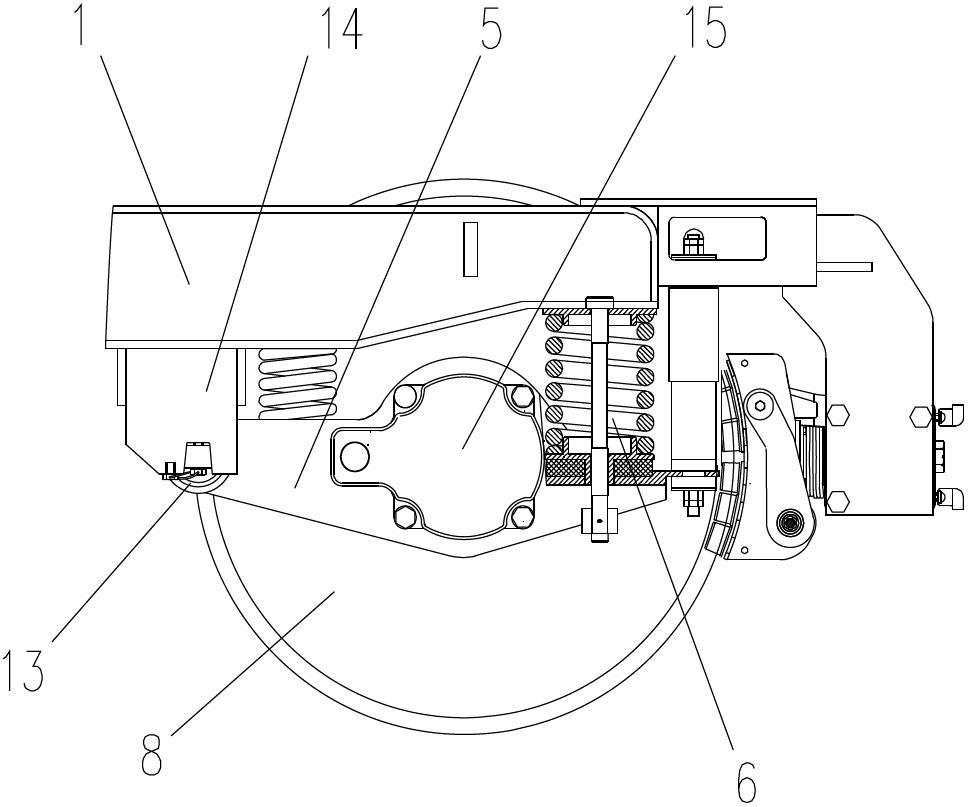

[0021] Attached below figure 1 , 2 , 3, 4, 5 describe an embodiment of the present invention.

[0022] A railway car bogie with a flaw detection device, the bogie includes a frame 1, and the upper part of the frame 1 is provided with a traction seat 11 connected to the car body through a traction device 3, specifically, the traction device 3 and the rotating arm 20 Connected in the middle, one end of the rotating arm 20 is connected to one end of the traction rod 21, the other end of the connecting rod 21 is connected to the traction seat 11 on the frame 1, and the traction device 3 is a Z-shaped central pin; the lower part of the frame 1 is provided with The elastic node seat 14 connected with the axle box 5, the axle box 5 is connected with the elastic node seat 14 through the elastic node 13, the axle box 5 is connected with the wheel set 8, and the support spring provided on the frame 1 2. The lateral shock absorber 16 and the secondary vertical shock absorber 4 constitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com