Horizontal deeply-concealed wear-resistant tongue rail and stock rail structure

A technology of basic rails and sharp rails, applied in tracks, roads, buildings, etc., can solve problems such as crushing, prone to side wear, and block falling, so as to improve service life, reduce lateral force, enhance structural strength and The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

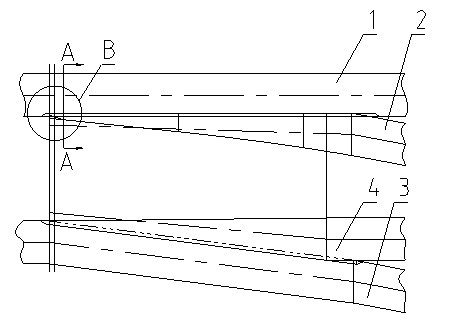

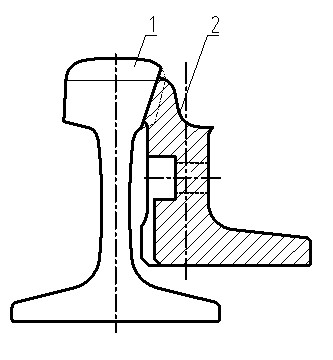

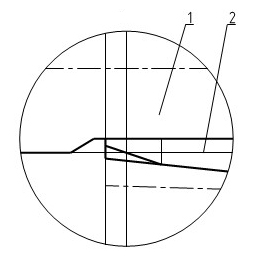

[0014] Embodiment 1: with reference to attached Figure 1-5 . A horizontal deep wear-resistant switch rail and basic rail structure, which includes a switch rail and a basic rail, and is characterized in that: the working edge of the close-fitting section of the basic rail has a horizontal planing depth of 6mm, and the For the switch rail of this technology, at the same position from the tip of the switch rail, the width of the switch head is increased by 6mm, the slope of the working side of the switch rail is 1:5, and the slope of the non-working side is 1:3, so as to reduce the side Axial force, so as to enhance the structural strength and bearing capacity of the switch rail. The transition from the tip gauge of the switch rail to the straight standard gauge is completed within the planing range of the head of the straight switch rail. Within the range of the front end of the basic rail, complete the transition from the tip gauge of the switch rail to the standard gauge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com