Transmission device for cutting of columns by plasma

A transmission device, plasma technology, applied in the direction of plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to guarantee cutting stability and cutting precision, increase design cost, complex structure design, etc., to avoid clamping The effect of poor guidance, avoidance of damage, and good cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

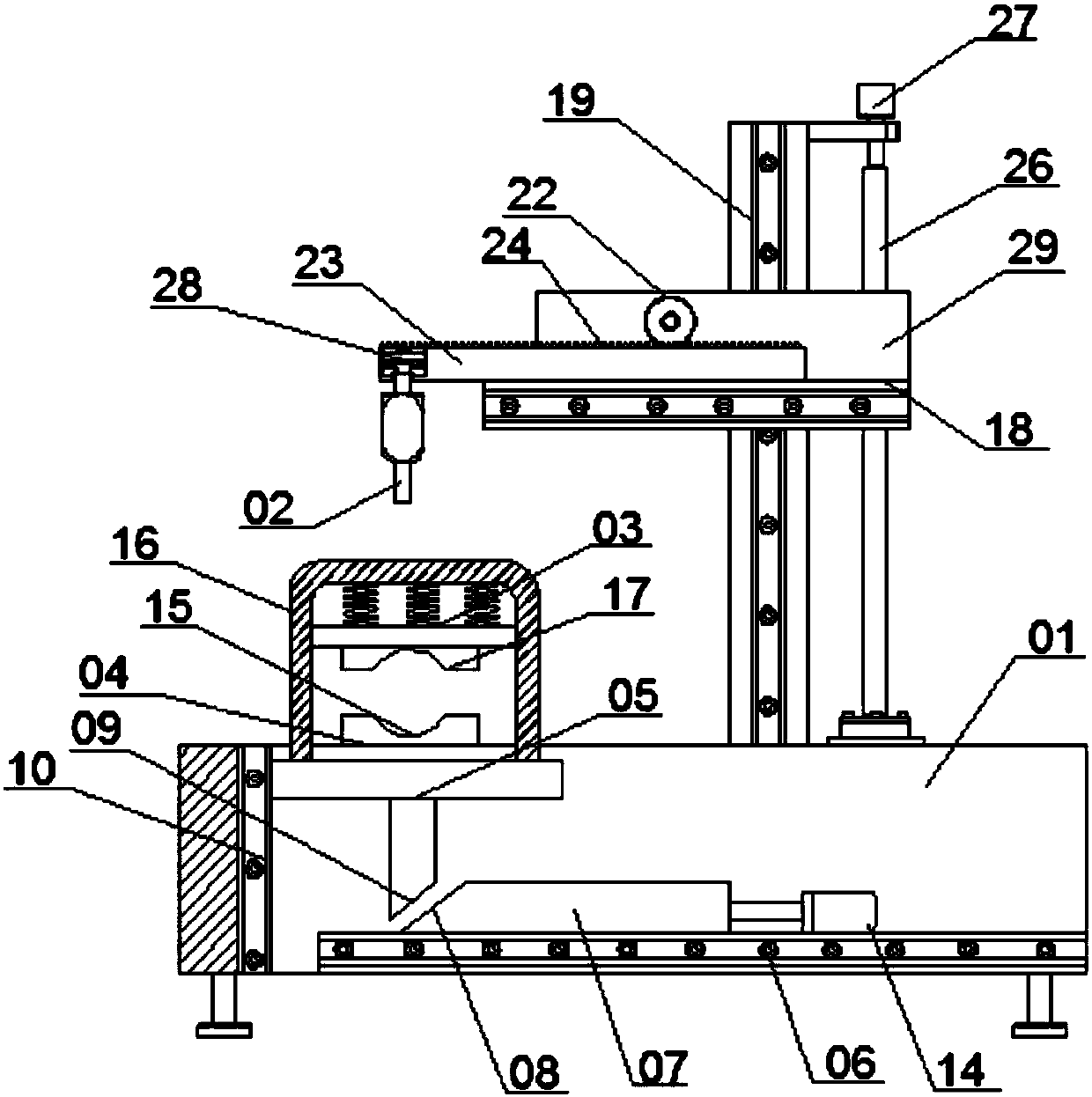

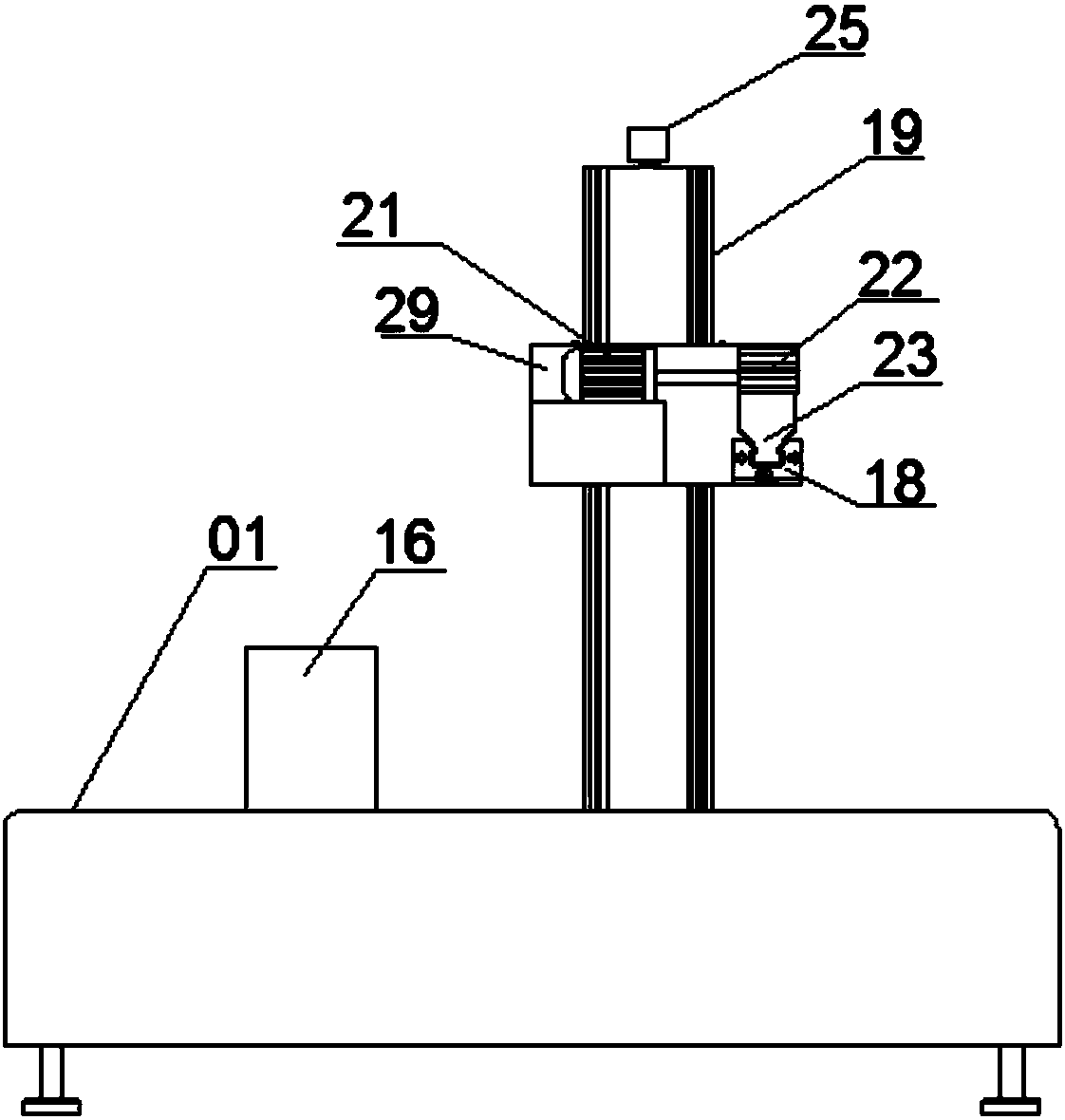

[0030] Please refer to figure 1 and figure 2 As shown, this embodiment provides a transmission device for cutting cylinders with plasma, including a processing table 01, a plasma spray gun 02, and a clamping device for clamping the plasma spray gun 02. The clamping device includes an upper hoop member 03 and a lower hoop Part 04, the upper hoop part 03 and the lower hoop part 04 are all provided with an arc-shaped hoop surface 15, and a polyurethane rubber layer is laid on the arc-shaped hoop surface 15. Polyurethane rubber has good wear resistance and ductility , to avoid damage to the surface of the cylinder when tightening the cylinder, and the hoop with good wear resistance still has good hoop performance after long-term use; and the lower hoop 04 is fixedly installed on the processing table 01, and the upper The hoop piece 03 includes an upper hoop plate 17 and a U-shaped plate 16, the upper hoop plate 17 is connected to the bottom of the U-shaped plate 16 through a com...

Embodiment 2

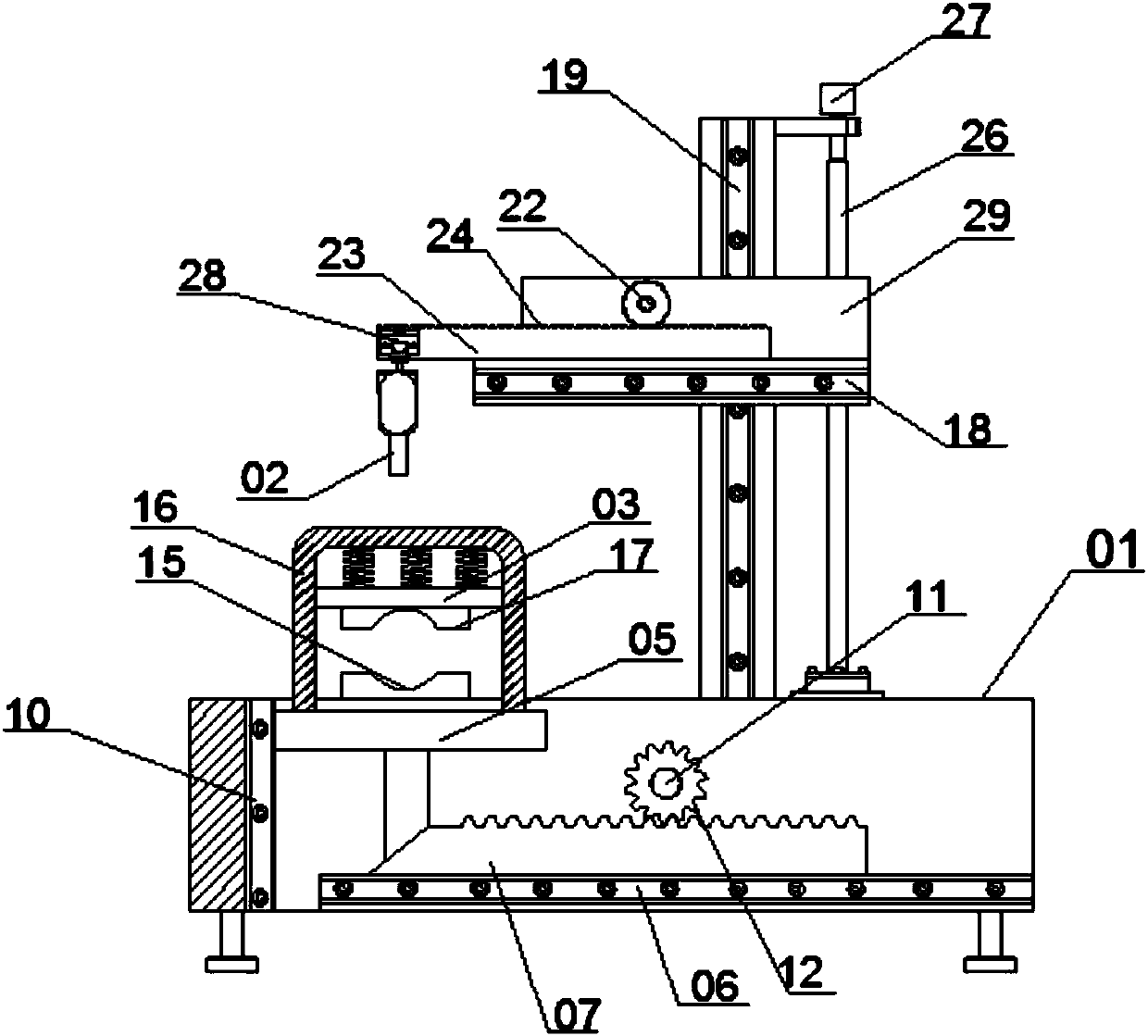

[0043] Please refer to image 3 As shown, embodiment 2 is basically the same as embodiment 1, the difference is that the driver does not use a drive cylinder, specifically, the driver includes a stepper motor 11, a gear A12, and the moving block 07 is provided with a The rack A13 meshed with A12, the output shaft of the stepping motor 11 is connected with the gear A12. The stepper motor 11 drives the gear A12 to rotate and drives the rack meshed with the gear A12 to move along the horizontal guide rail 06. The rack and pinion structure transmits smoothly, and is suitable for fine adjustment of the clamping position when clamping the cylinder to be cut. The driving cylinder 14 directly drives the moving block 07 to drive the upper hoop member 03 to move up and down, and its structure has more stability and precise guidance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com