A pcb board bracket for automatic optical inspection machine

A PCB board and automatic optics technology, applied in the field of brackets, can solve the problems of reduced detection coverage, easy clamping of devices, and easy blocking of fixtures, etc., to achieve the effect of improving detection coverage, not easy to damage, and large clamping space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

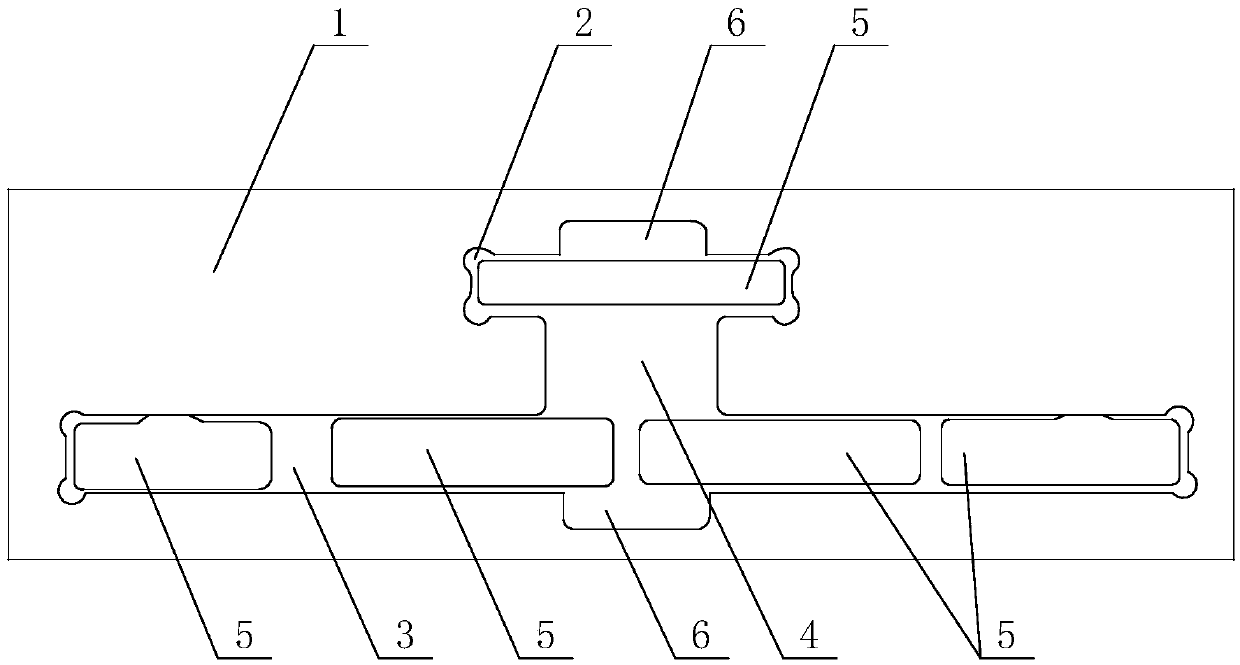

[0017] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of a PCB board bracket for an automatic optical inspection machine of the present invention.

[0018] In this embodiment, a PCB board bracket for an automatic optical inspection machine includes a black bracket body 1 made of synthetic stone, and the PCB board is a combination of soft and hard boards, corresponding to the bracket body 1. The upper part is opened with a first cavity 2 for carrying the first hard plate, the lower part of the bracket body 1 is opened with a second cavity 3 for carrying the second hard plate, and the bracket body 1 is located in the first cavity 2 Between the second cavity 3 and the flexible board cavity 4 for carrying the flexible board, the first cavity 2 and the second cavity 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com