Working platform of multi-wire cutting machine

A multi-wire cutting machine and workbench technology, applied in work accessories, fine work devices, manufacturing tools, etc., can solve problems such as high resistance and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

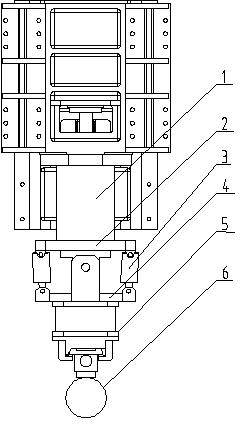

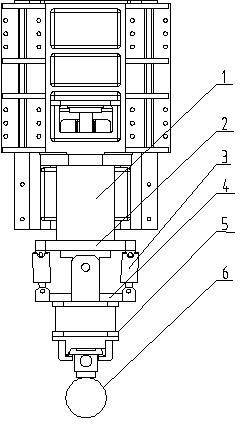

[0012] Depend on figure 1 It can be seen that a workbench of a multi-wire cutting machine includes a cutting sleeve 1 installed on the feeder of the workbench, a workbench 5 on which a workpiece 6 is installed, and a device that can be used between the cutting sleeve 1 and the workbench 5. The rocking device that the workbench 5 swings along the cutting center of the workbench 5.

[0013] The swinging angle range of the rocking device of the present invention along the cutting center of the workbench 5 is -5° to +5° (-5° to +5° in this embodiment).

[0014] In order to ensure that the force on the workpiece is balanced during cutting, the present invention includes a fixed plate 2 installed on the cutting sleeve 1 and a connecting plate 4 installed on the workbench 5, and the connecting plate 4 is hinged on the fixed plate 2 , the fixed plate 2 is symmetrically provided with the cylinder body of the hydraulic cylinder 3 along both sides of the cutting center of the workbench ...

Embodiment 2

[0018] The rocking device of the present invention includes a fixed plate 2 installed on the cutting sleeve 1, a connecting plate 4 installed on the workbench 5, the connecting plate 4 is hinged on the fixed plate 2, and the fixed plate 2 cuts along the cutting of the workbench 5. The cylinder body of the hydraulic cylinder 3 is arranged on one side of the center, the piston rod of the hydraulic cylinder 3 is connected with the connecting plate 4, and the swing angle ranges from -3° to +3°.

[0019] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com