Patents

Literature

35results about How to "Prevent affecting cutting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

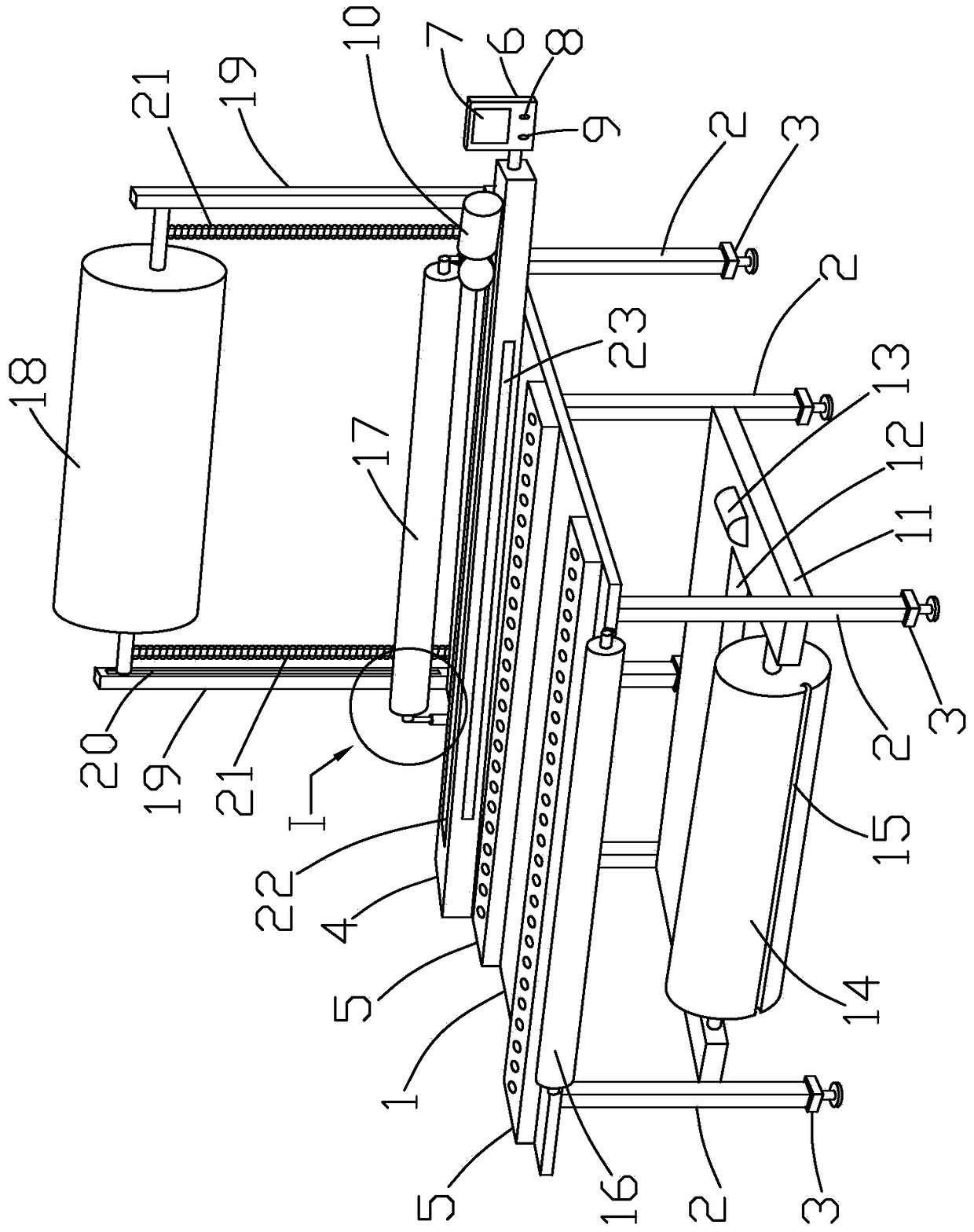

Cloth slitter

InactiveCN105619505APrevent affecting cutting accuracyGood cutting precisionSevering textilesMetal working apparatusEngineeringMechanical engineering

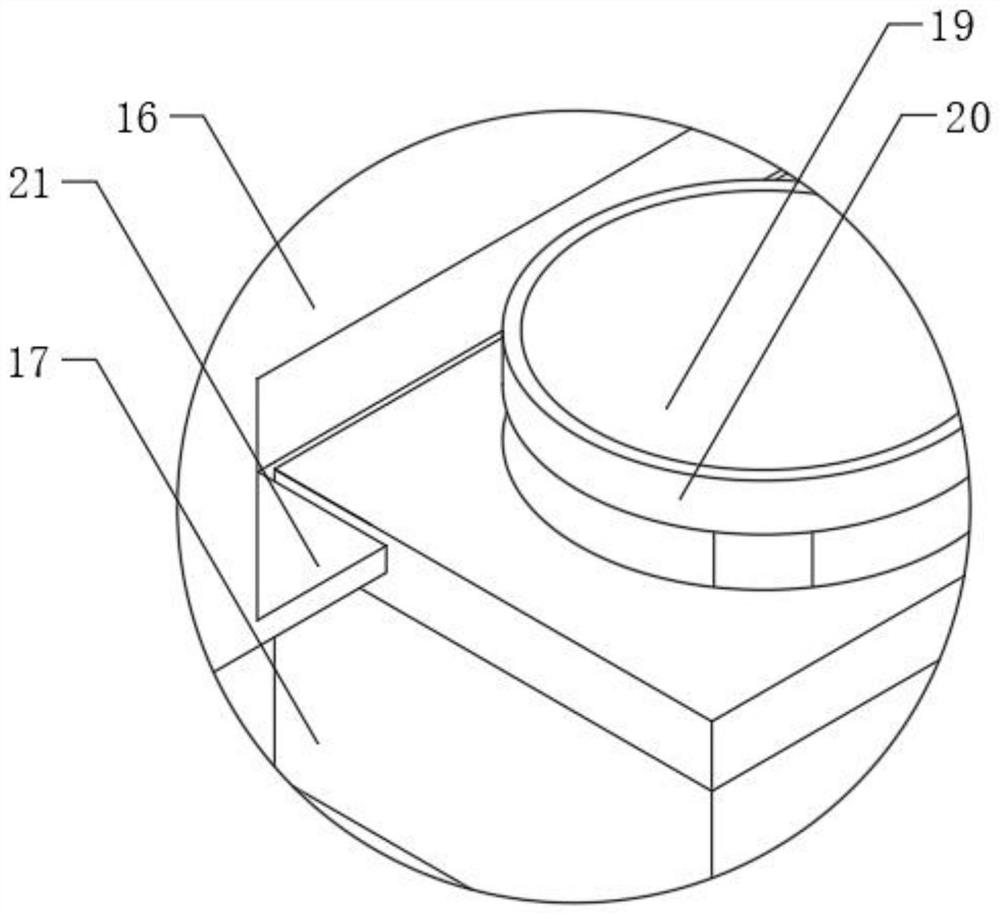

The invention mainly discloses a cloth slitter. According to the technical scheme, the cloth slitter comprises a machine frame, a machine head, a machine tail, a moving device, a cutting device, a knife sharpening device and a PLC control cabinet; a loop bar is arranged between the machine head and the machine tail; the cutting device is connected to the upper side of the moving device; the PLC control cabinet controls the moving device and the cutting device; the cutting device comprises a cutting frame, a first motor, a cutting knife and an air cylinder; the knife sharpening device comprises a supporting frame, a first polishing support, a second polishing support and a pair of polishing modules, wherein the first polishing support and the second polishing support are installed on the two sides of the supporting frame respectively in an inclined mode and are connected to the respective corresponding polishing modules, and the polishing modules are located on the two sides of the cutting knife respectively. The cloth slitter has the advantages of being simple in structure, convenient to operate, accurate in cutting and capable of polishing the cutting knife.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

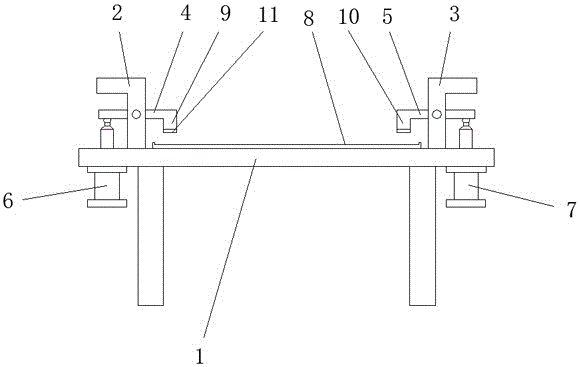

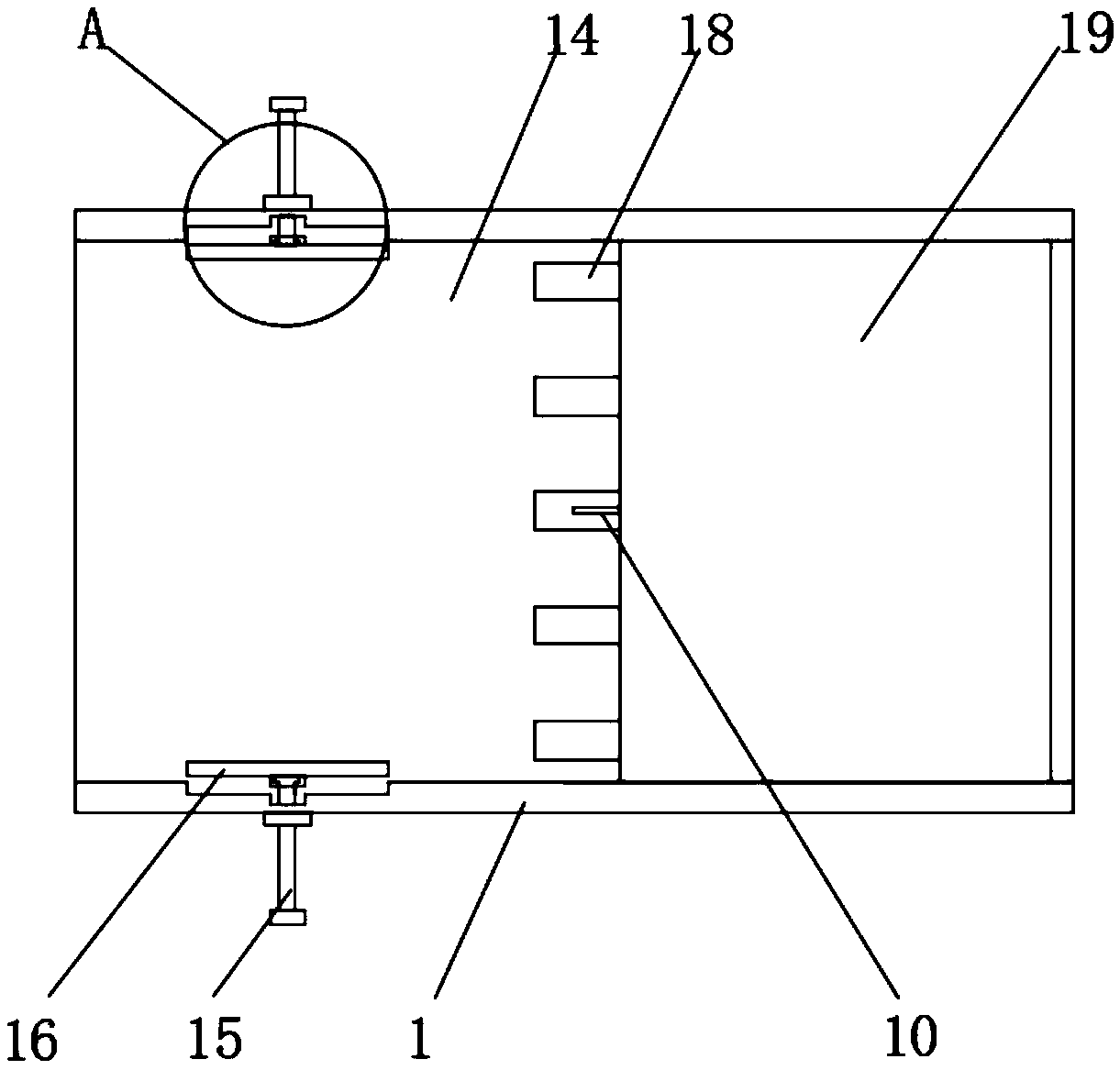

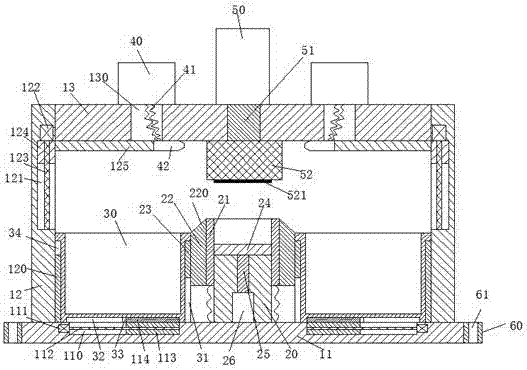

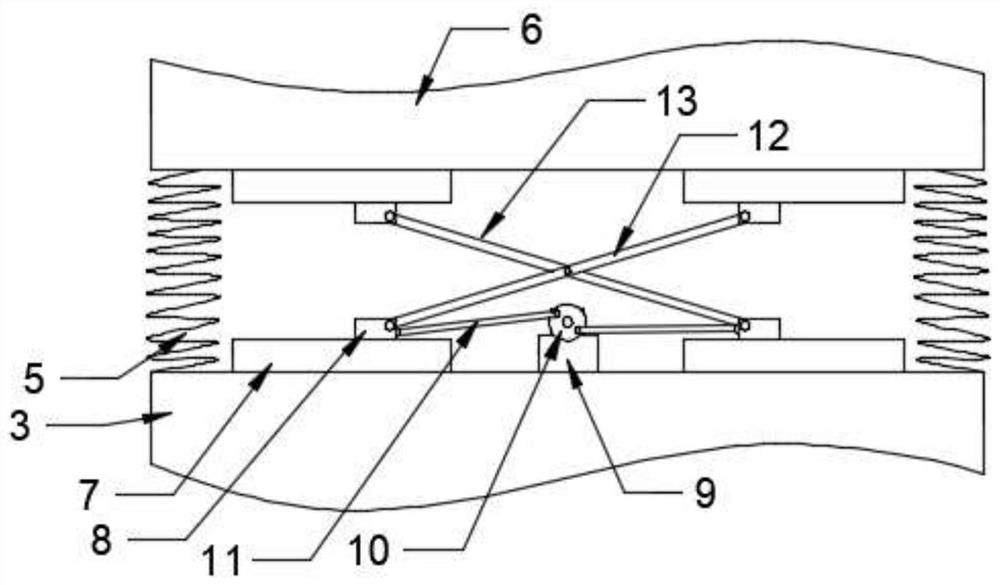

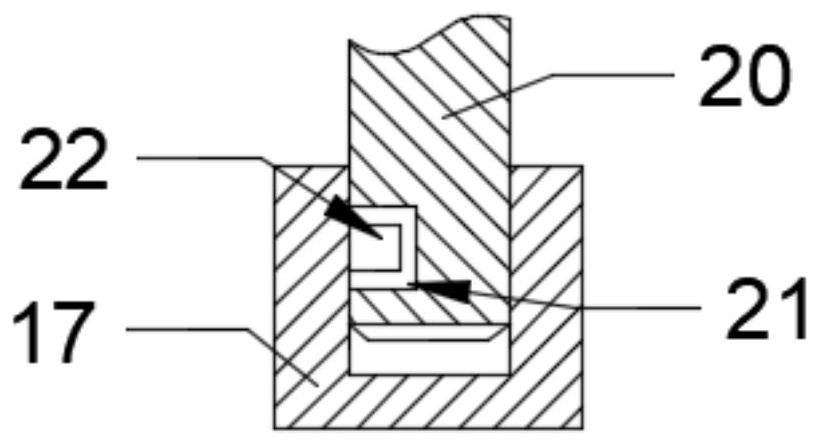

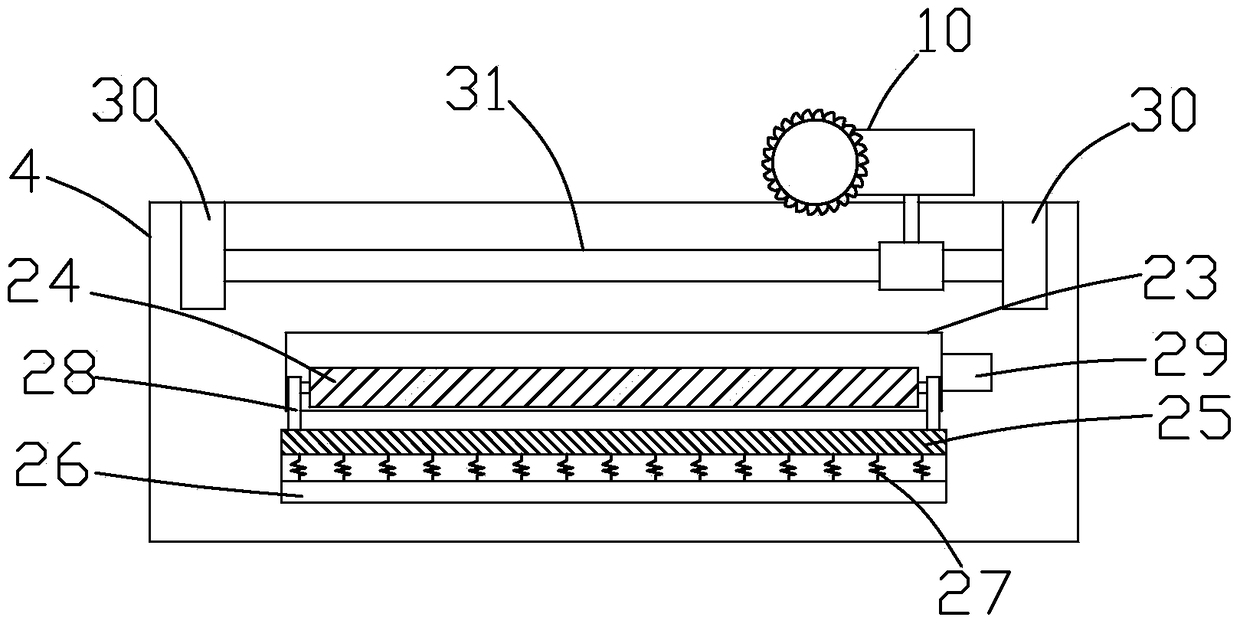

Paper compaction device for paper cutter

InactiveCN106426365AAchieve compaction controlReasonable designMetal working apparatusCardboardMechanical equipment

The invention discloses a paper compaction device for a paper cutter and belongs to the field of compaction mechanical equipment. The paper compaction device comprises a rack provided with a left support and a right support which are distributed symmetrically. The left support is provided with a left compaction plate capable of rotating round the left support. The right support corresponding to the left support is provided with a right compaction plate capable of rotating round the right support. The end, located on the outer side of the rack, of the left compaction plate is hinged to a piston rod of a left telescopic cylinder fixed to the rack. The end, located on the outer side of the rack, of the right compaction plate is hinged to a piston rod of a right telescopic cylinder fixed to the rack. The rack is provided with a paper supporting plate. The paper compaction device is simple in structure and reasonable in design. The bothway cylinders drive the compaction plates to clamp paper, firm fixation of the paper is ensured, the work efficiency is high, and very high market competitiveness is achieved.

Owner:TAICANG XINHE PRINTING & PACKAGING

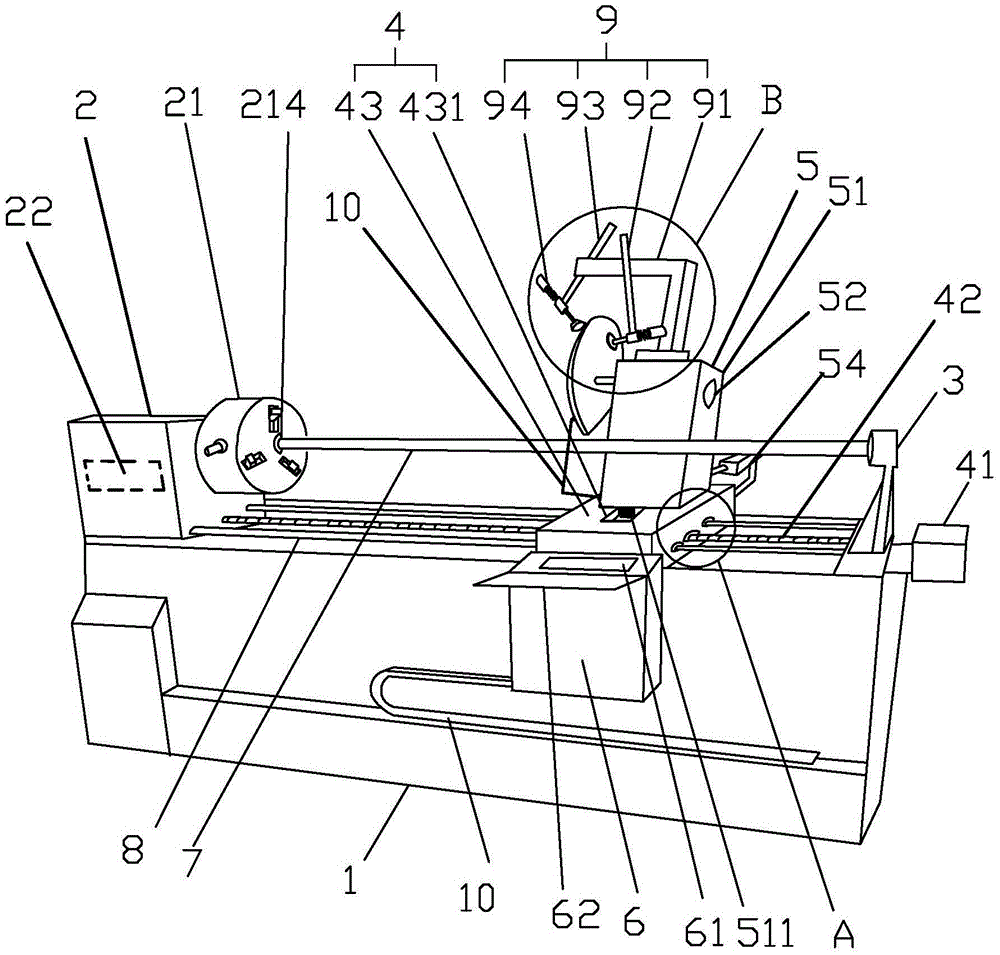

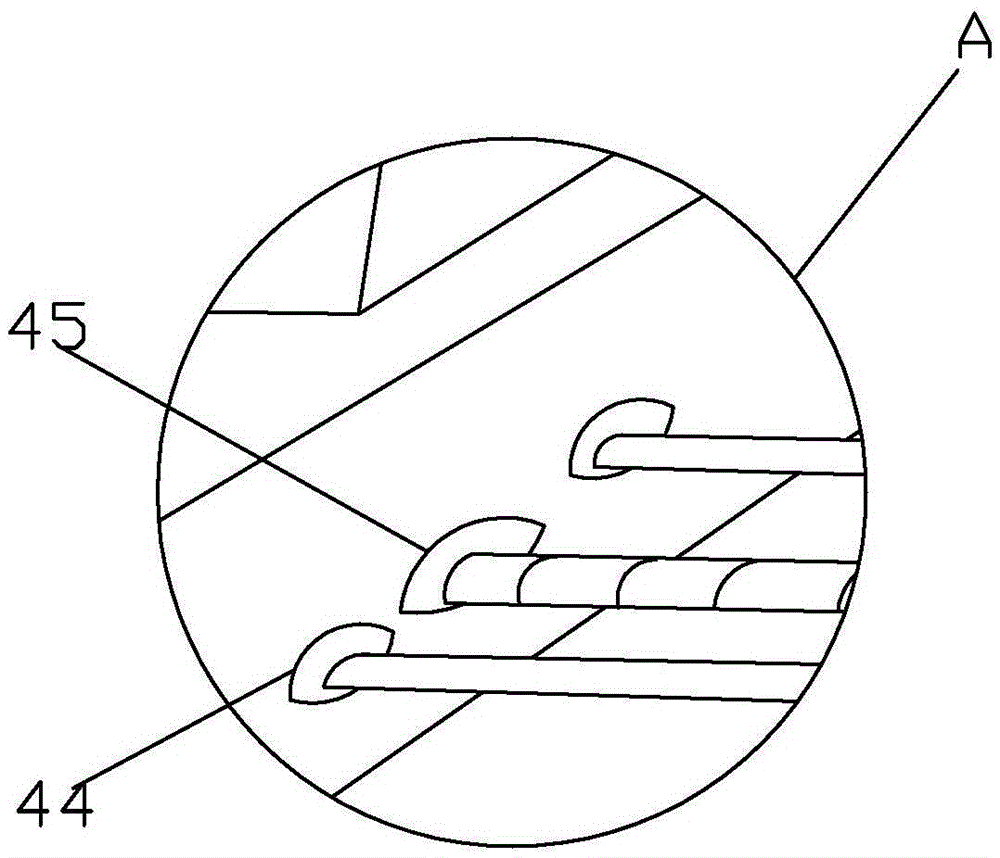

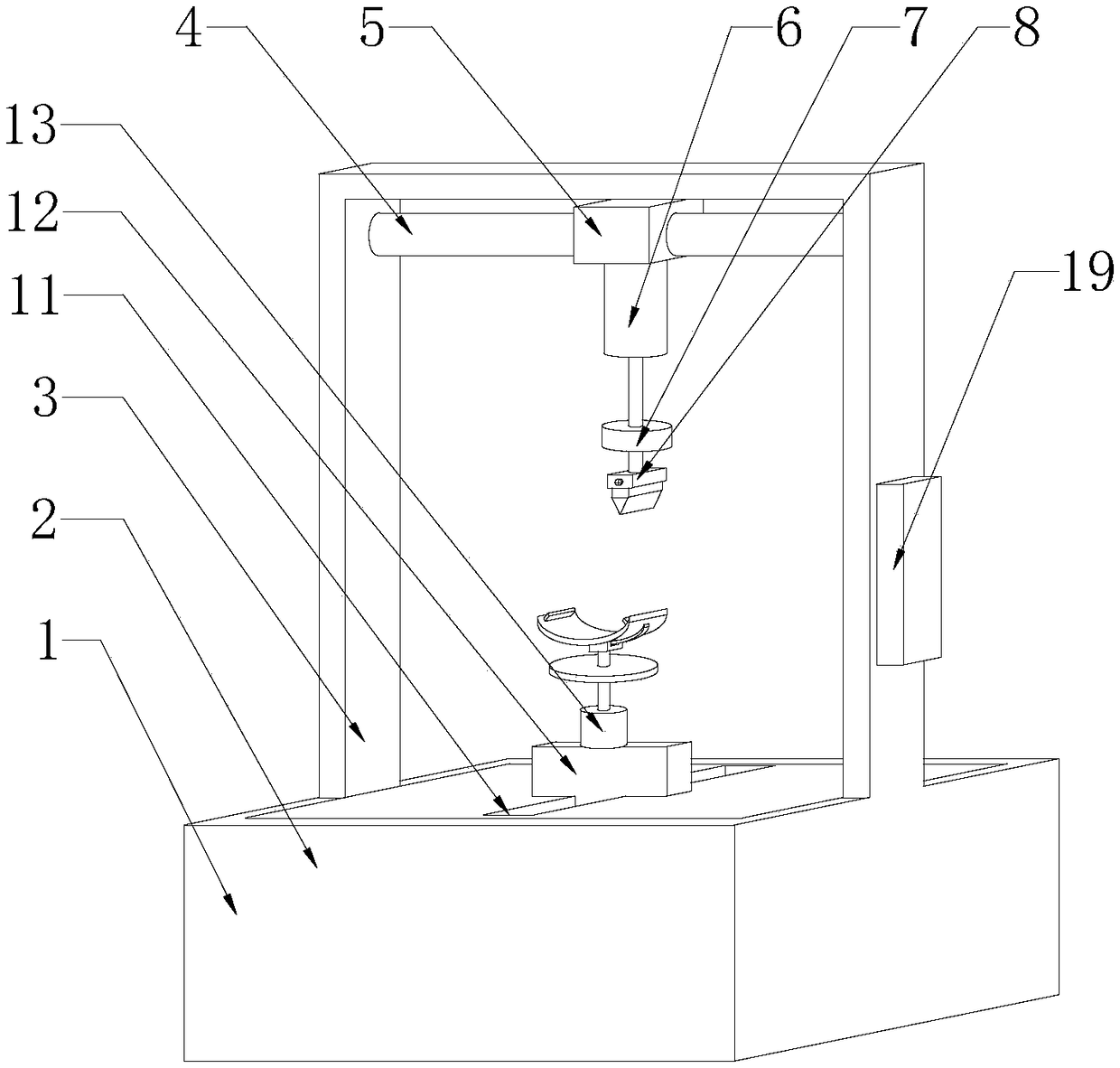

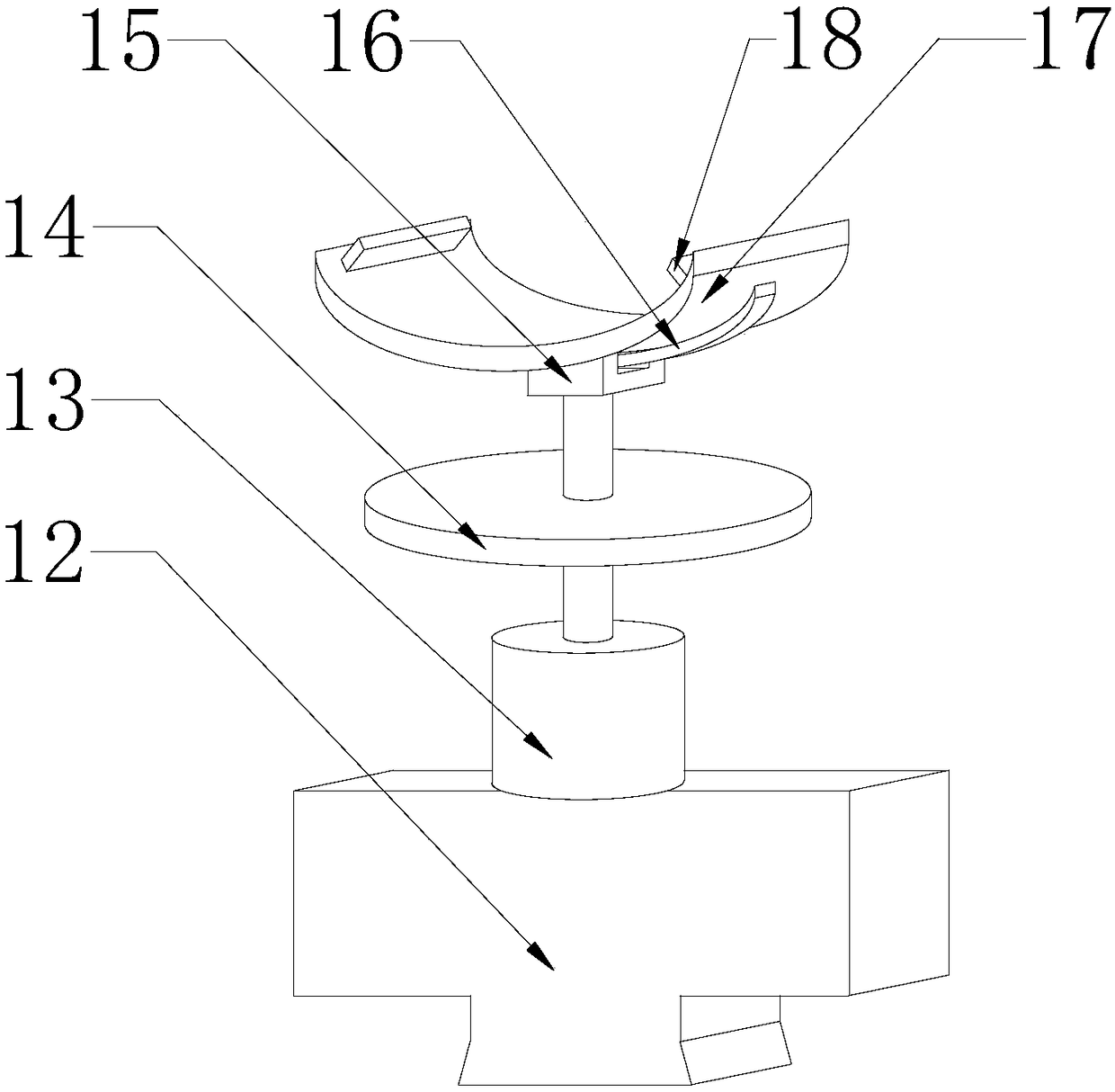

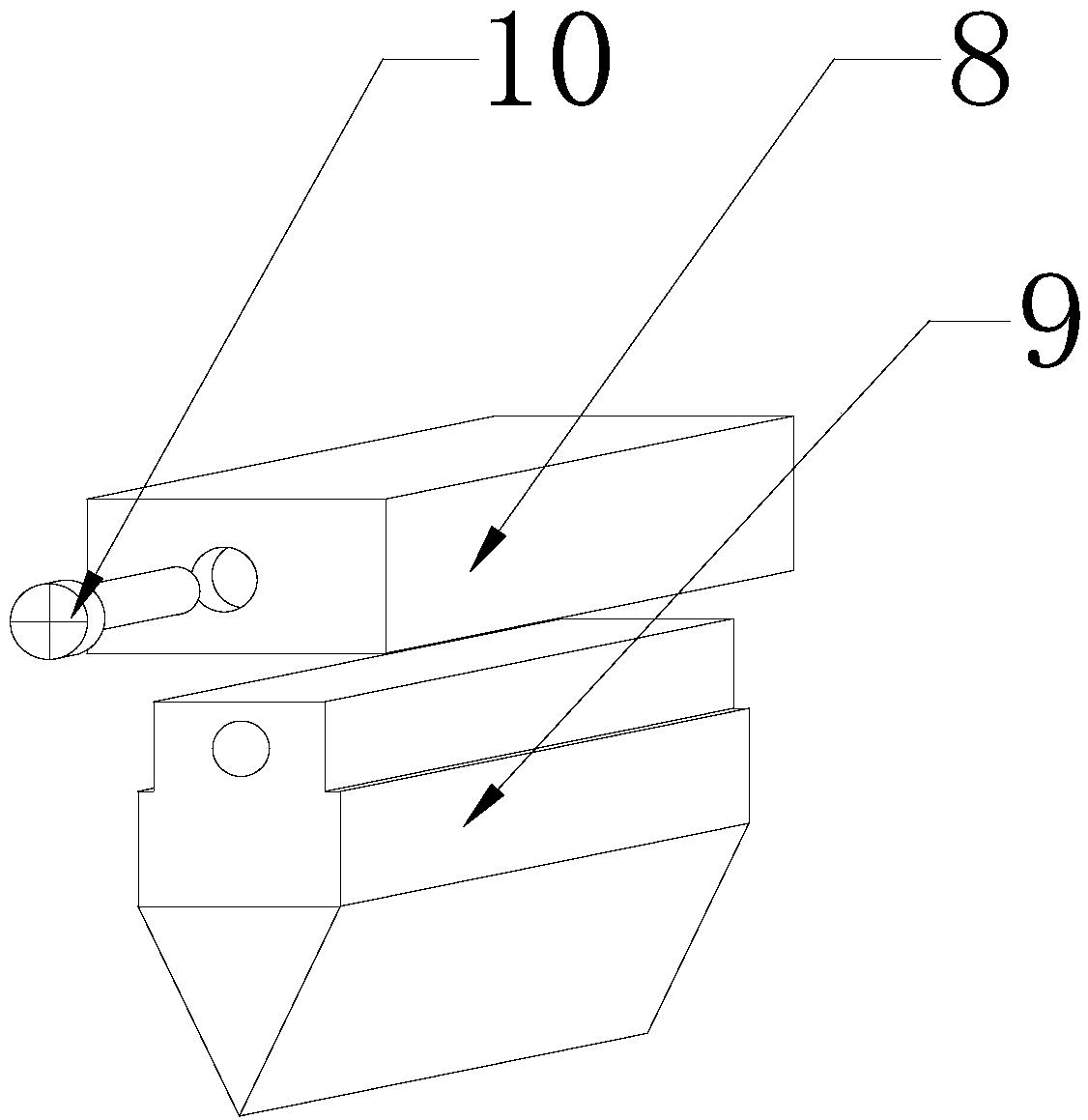

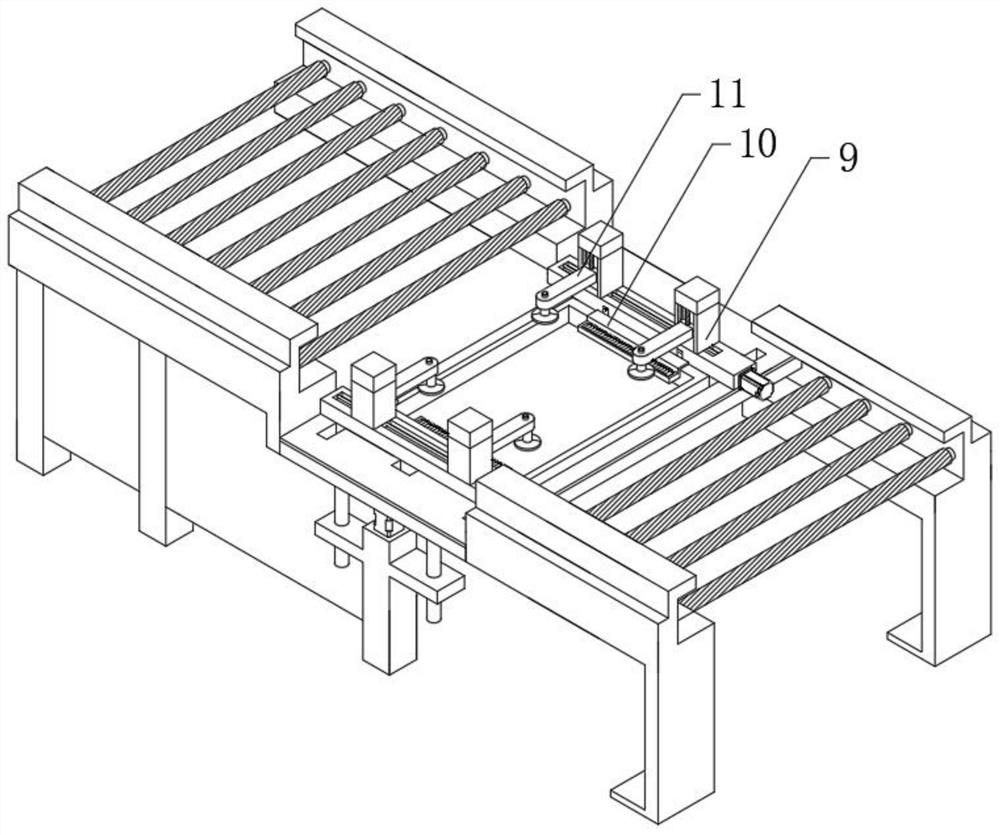

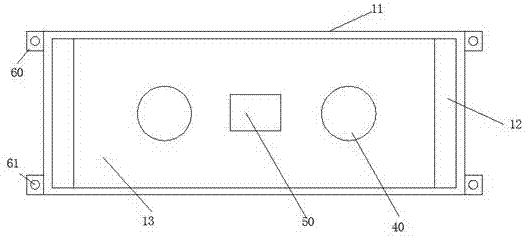

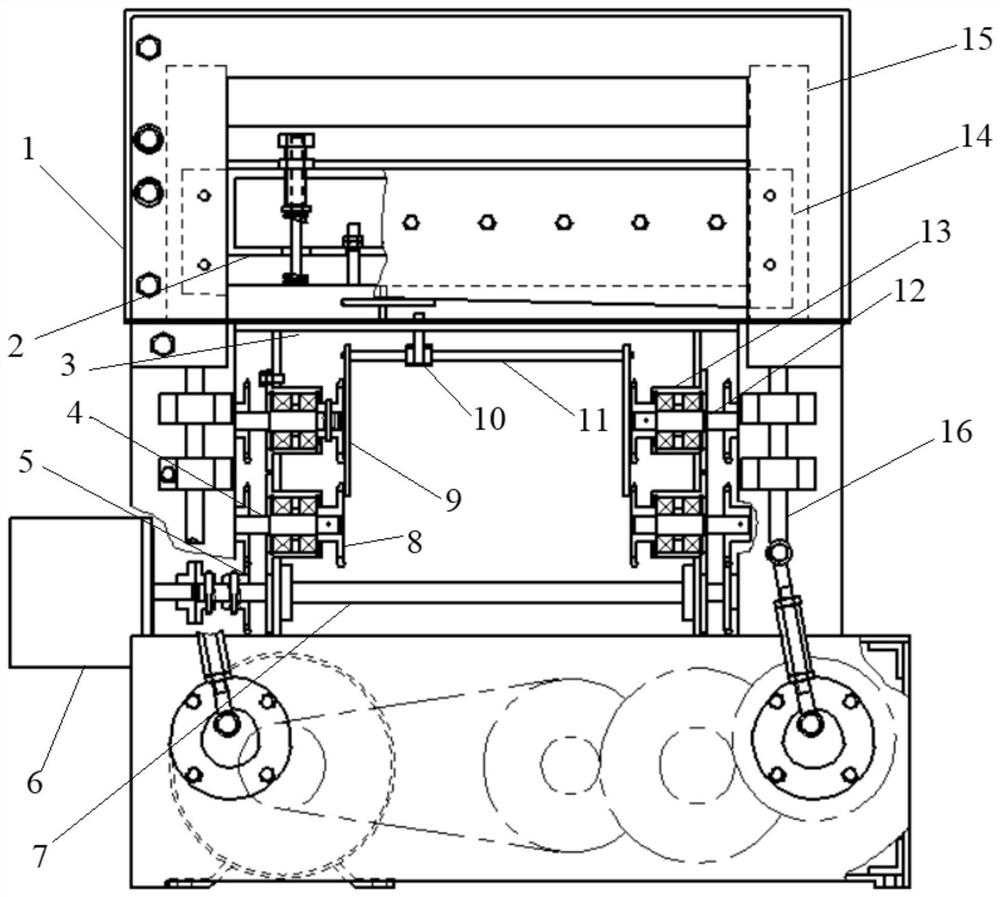

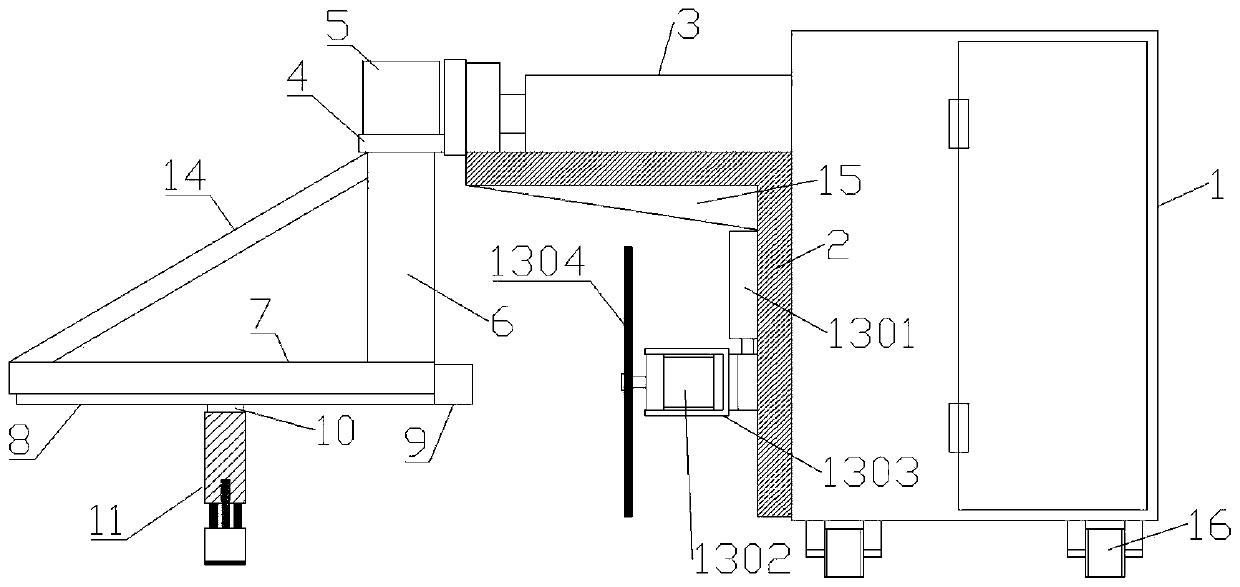

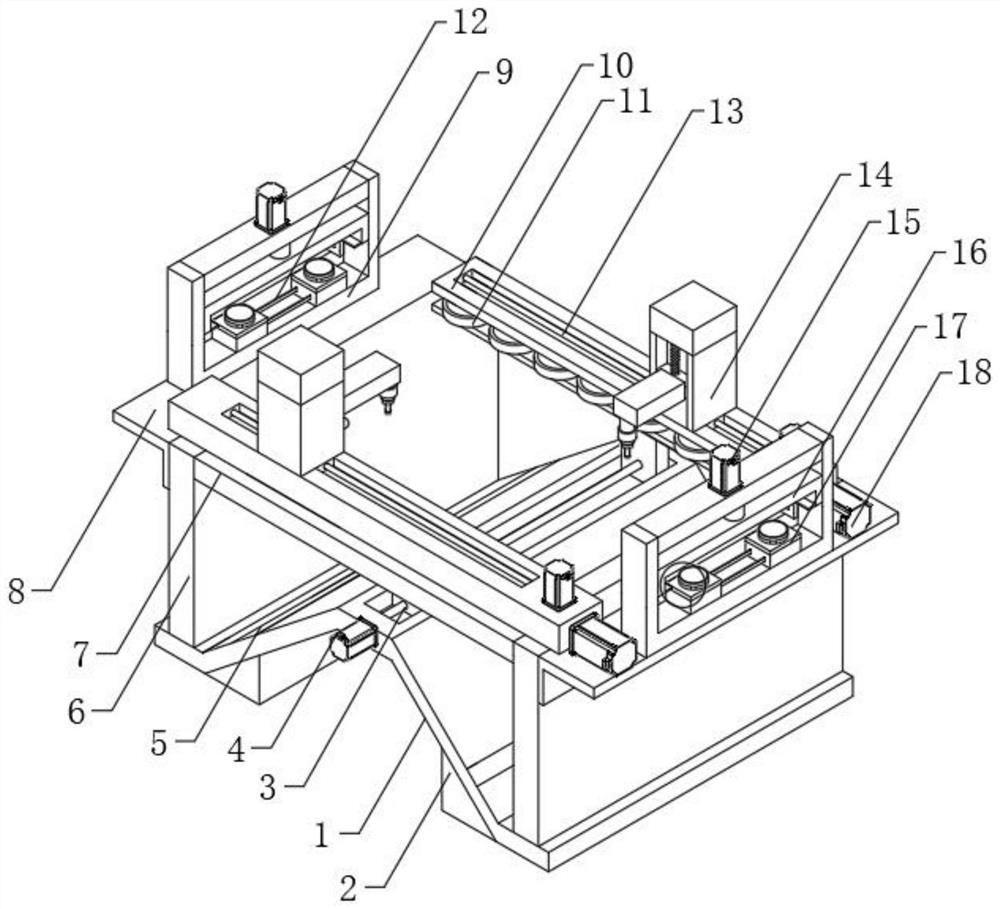

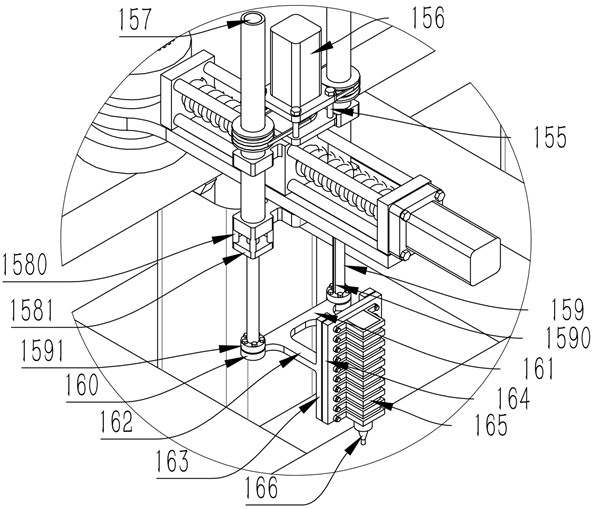

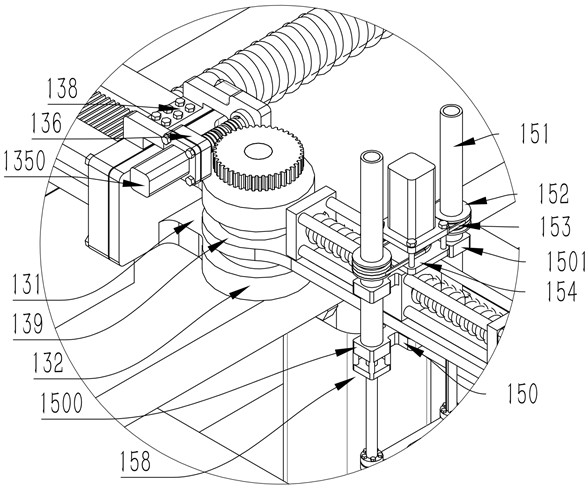

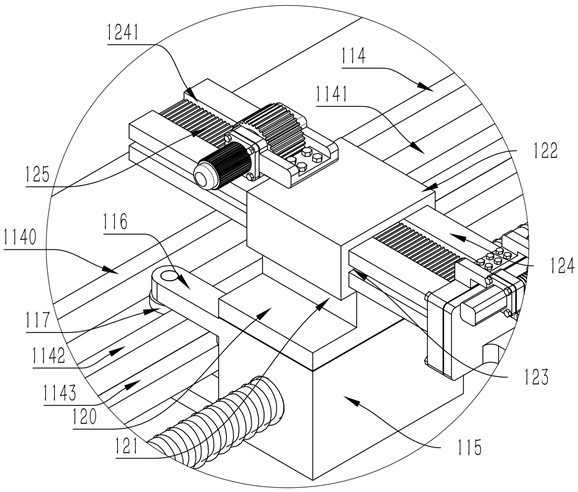

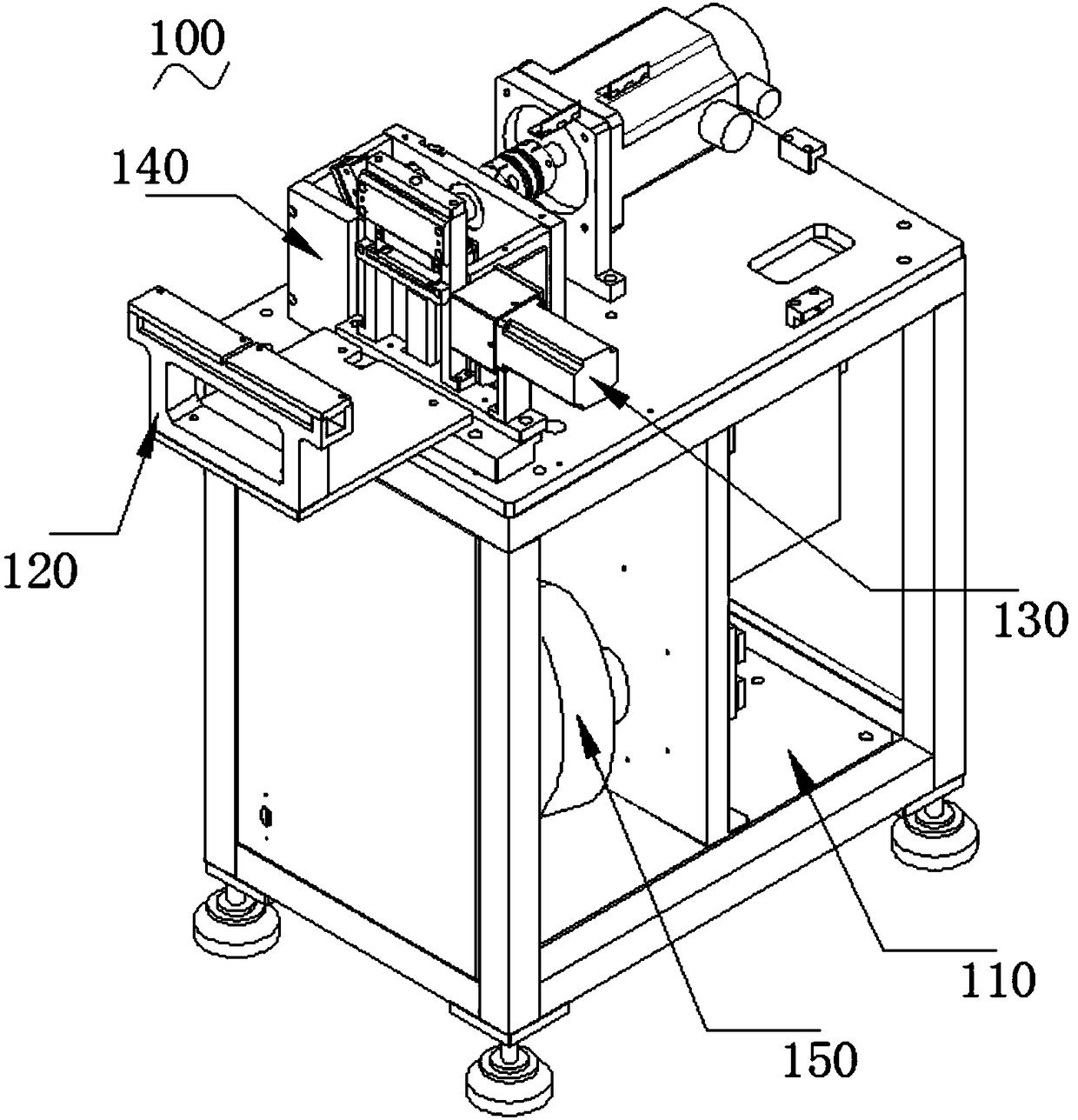

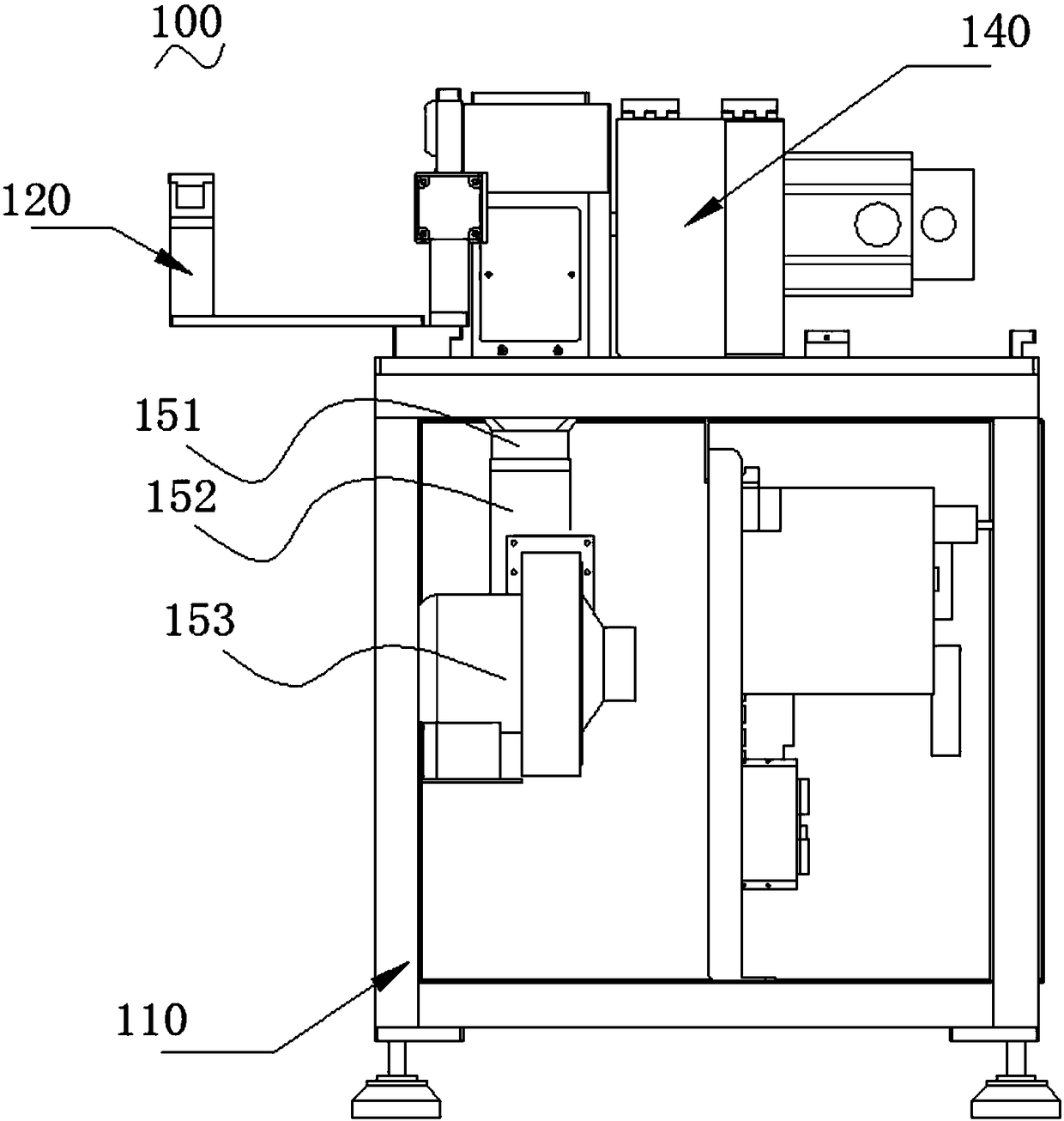

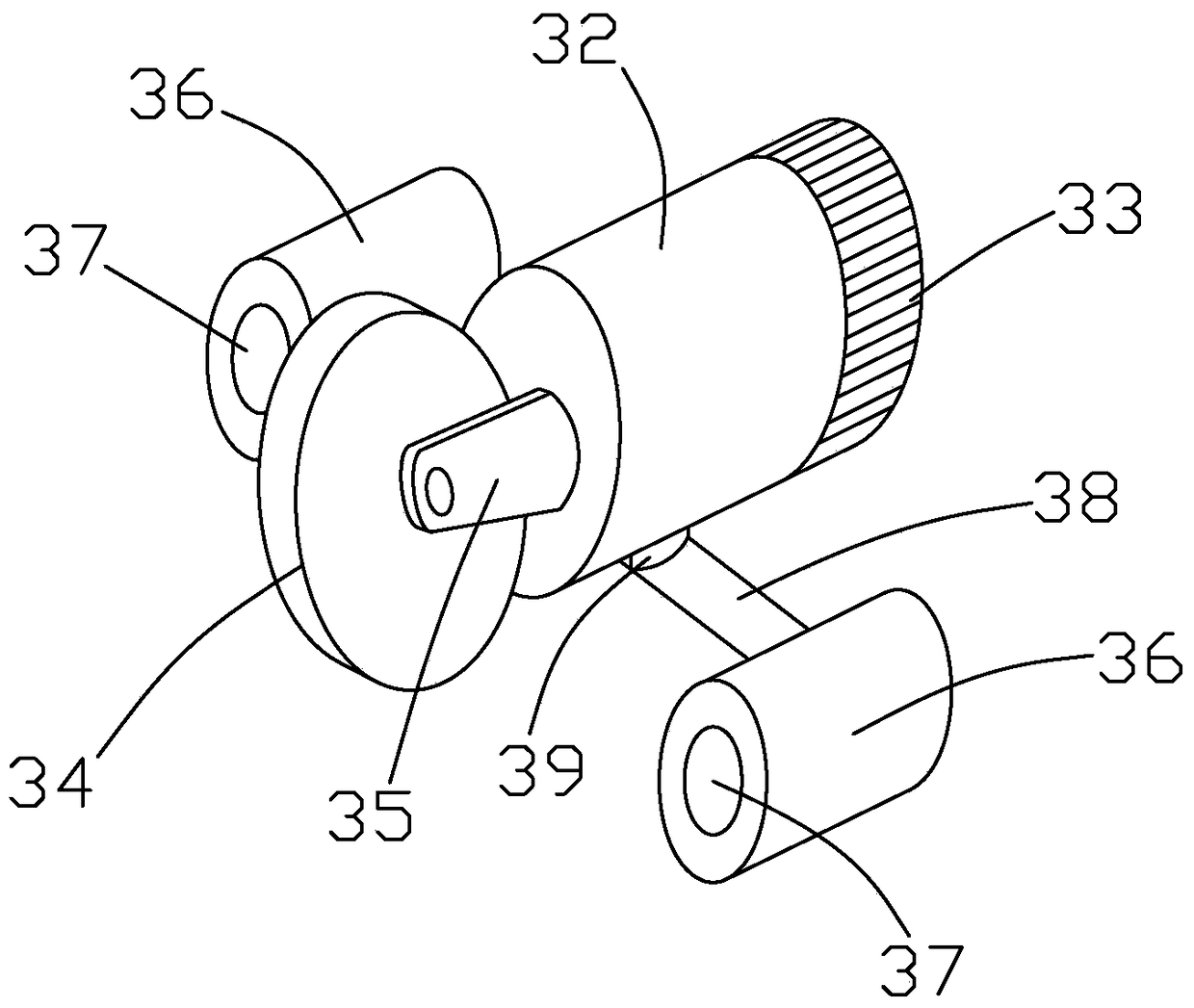

Gantry type pipe and flat plate cutting machine

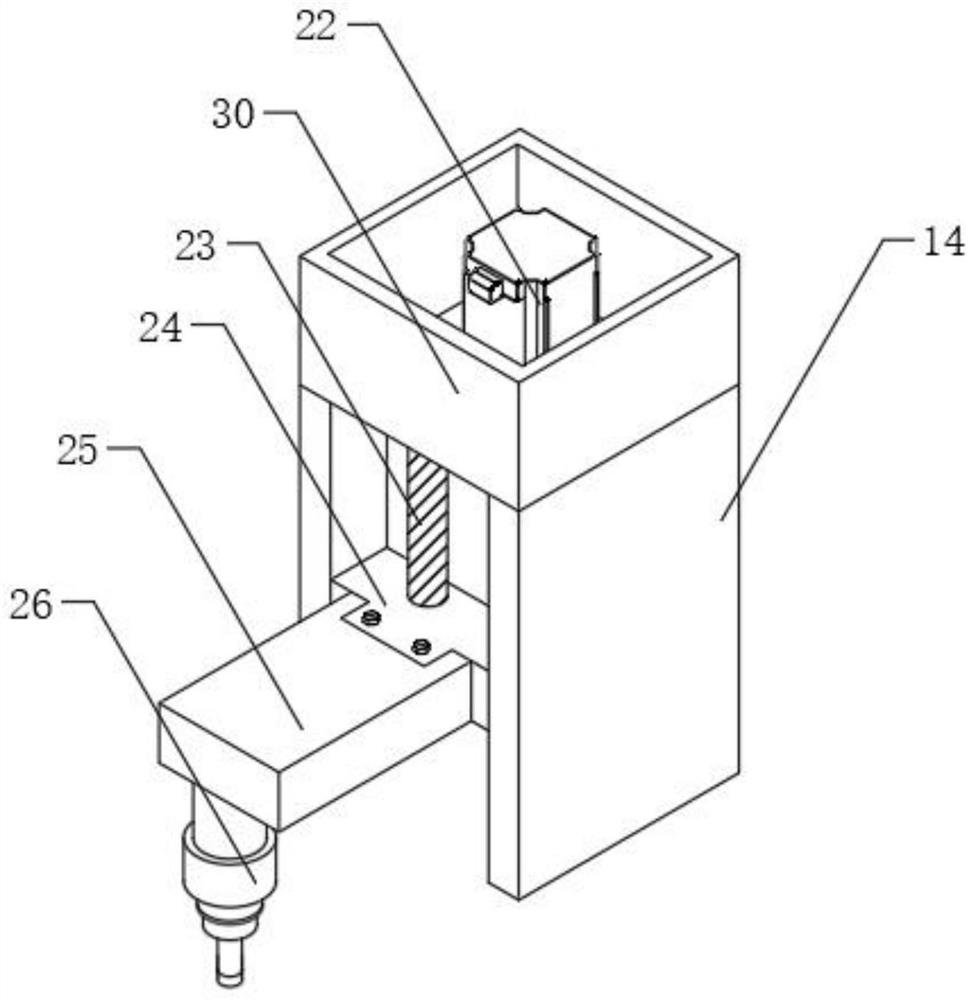

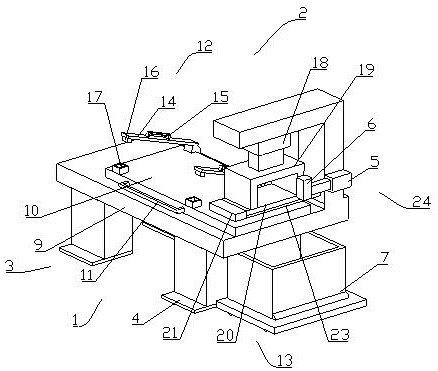

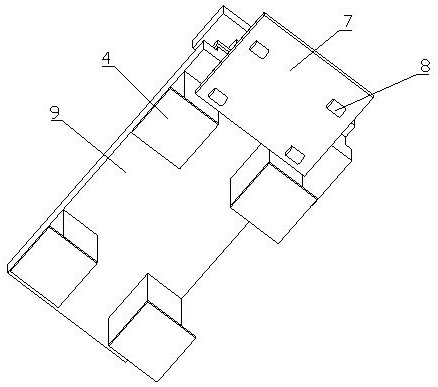

PendingCN108015385AImprove efficiencyVersatileWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDigital control

The invention discloses a gantry type pipe and flat plate cutting machine. The gantry type pipe and flat plate cutting machine comprises a cutting assembly, a plate cutting mechanism, a pipe cutting mechanism and a crossbeam. The crossbeam is provided with a transverse driving unit. The cutting assembly is connected with the crossbeam, and a lifting driving unit is arranged on a cutting assembly installing seat. The transverse driving unit comprises a first gear, a first rack, a first motor and a first track. The plate cutting mechanism comprises a machine frame, a machine table and a longitudinal driving unit. The longitudinal driving unit comprises a second gear, a second rack, a second track and a second motor. The pipe cutting mechanism comprises a feeding track, an end chuck, a movable chuck and a feeding driving unit. The end chuck and the movable chuck each comprise clamping parts, a clamping part installing seat and a chuck body. The gantry type pipe and flat plate cutting machine is provided to meet the machining requirements of pipe products in the digital control cutting machining field, and is easy to control, convenient to use and flexible in clamping, reduces the machining cost of pipe products, and widens the cutting machining range of a digital control cutting machine.

Owner:JIANGSU ZHENGHE HEAVY IND CO LTD

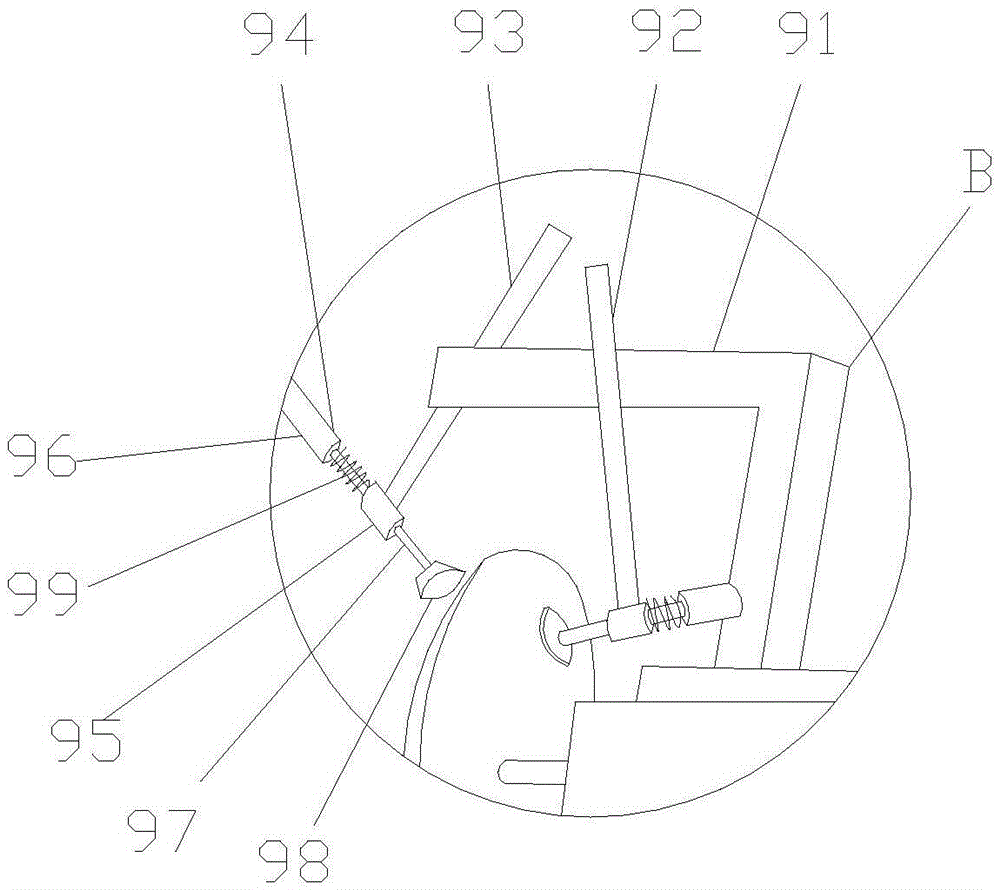

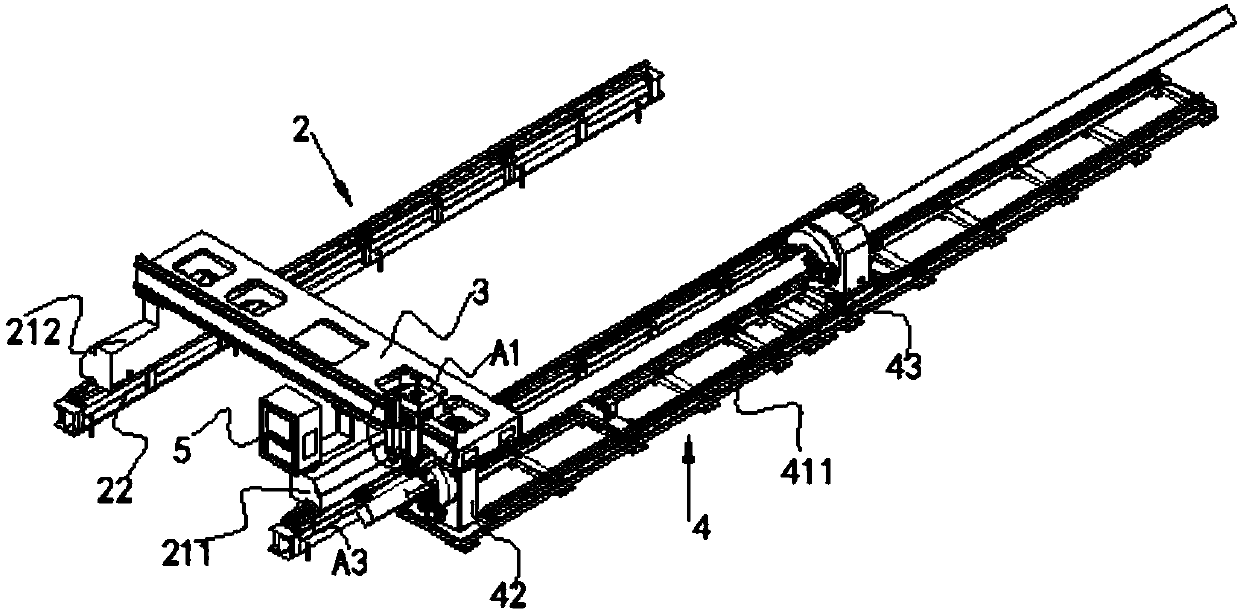

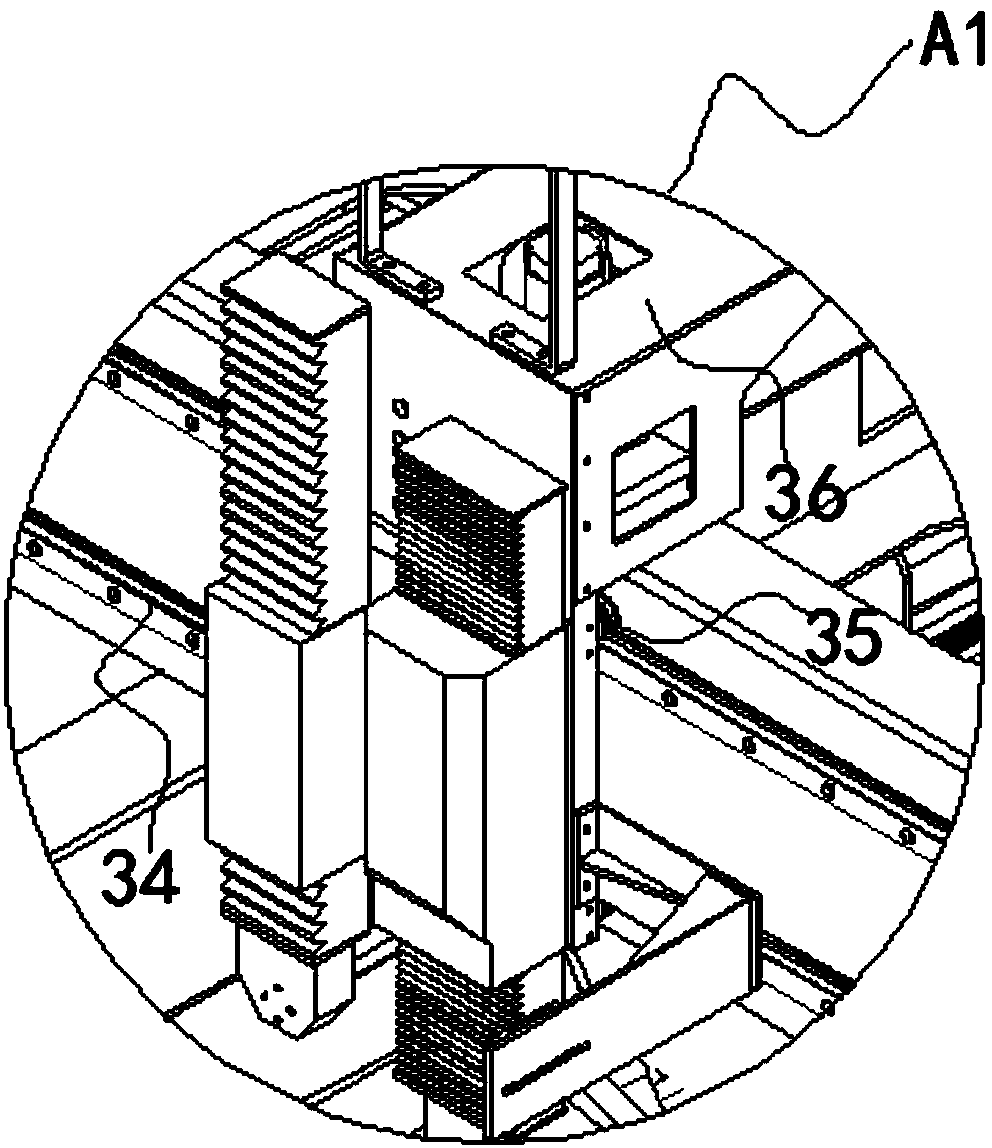

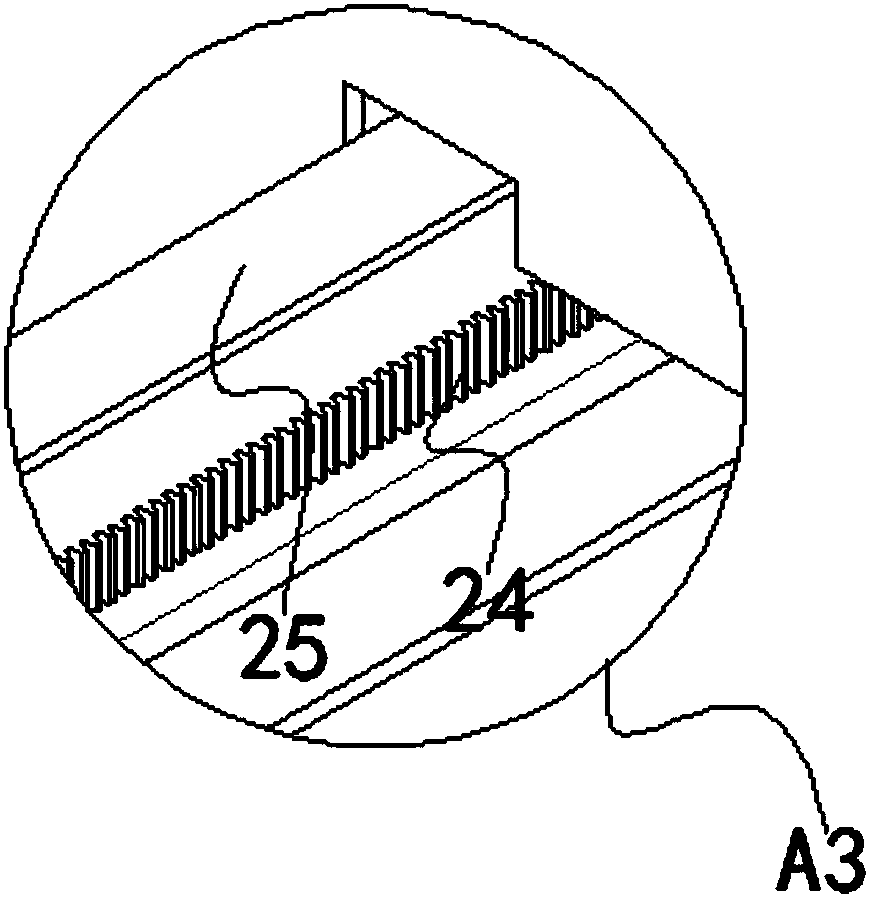

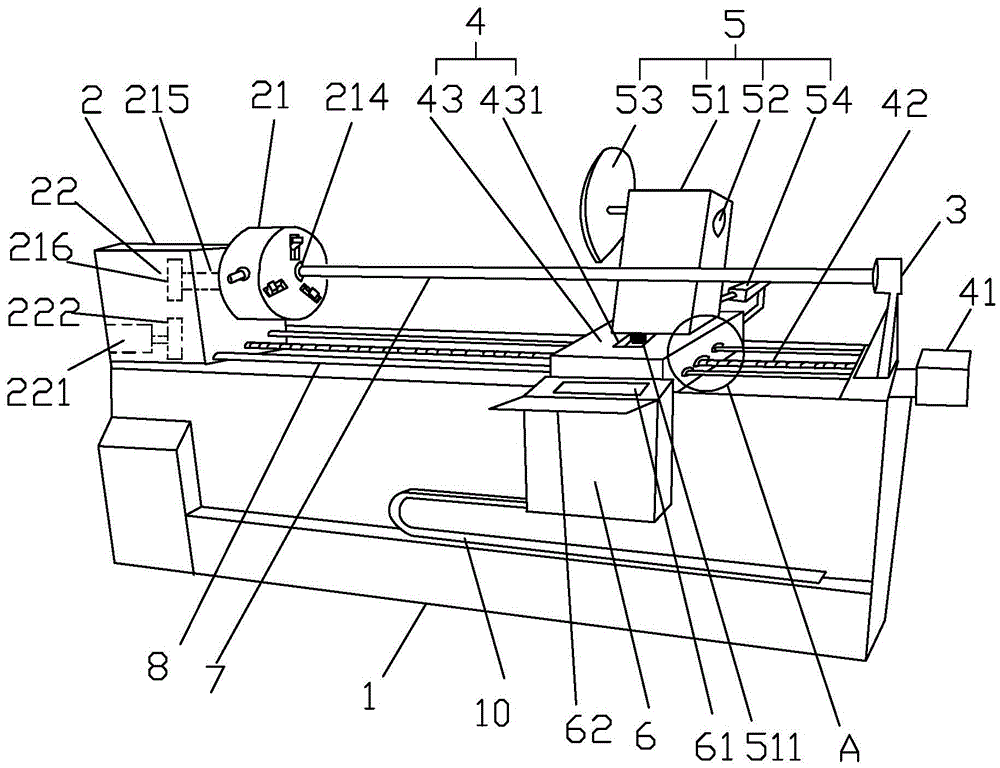

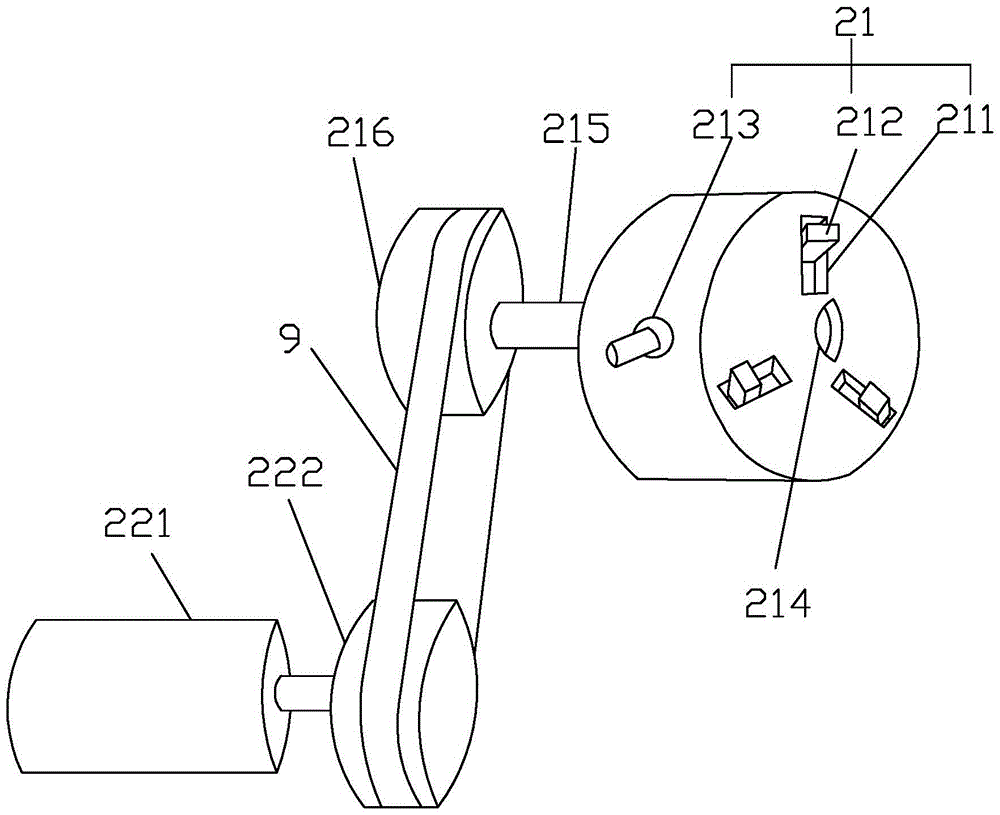

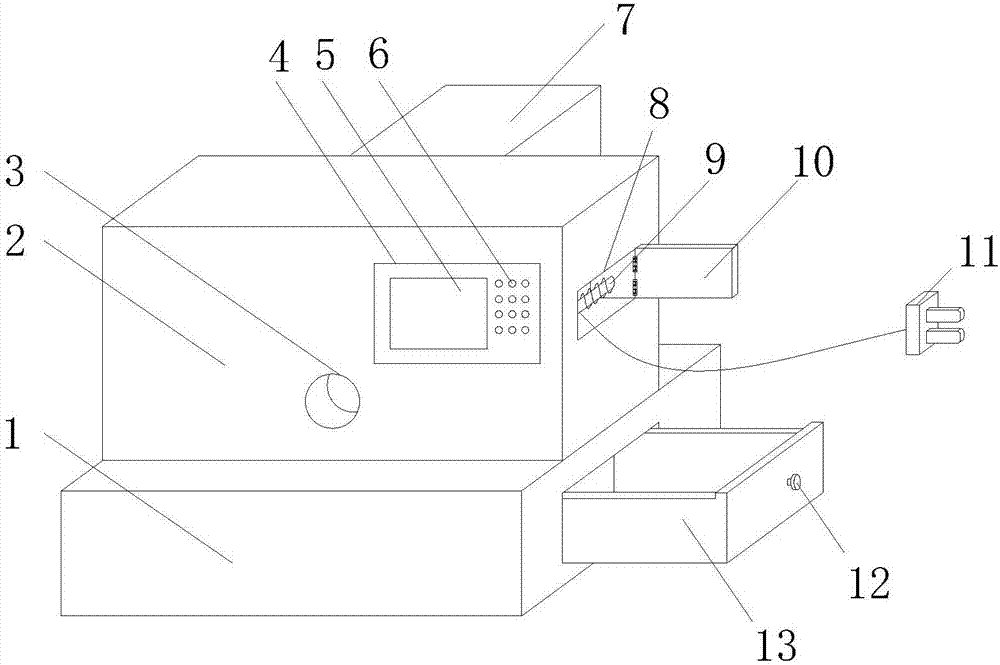

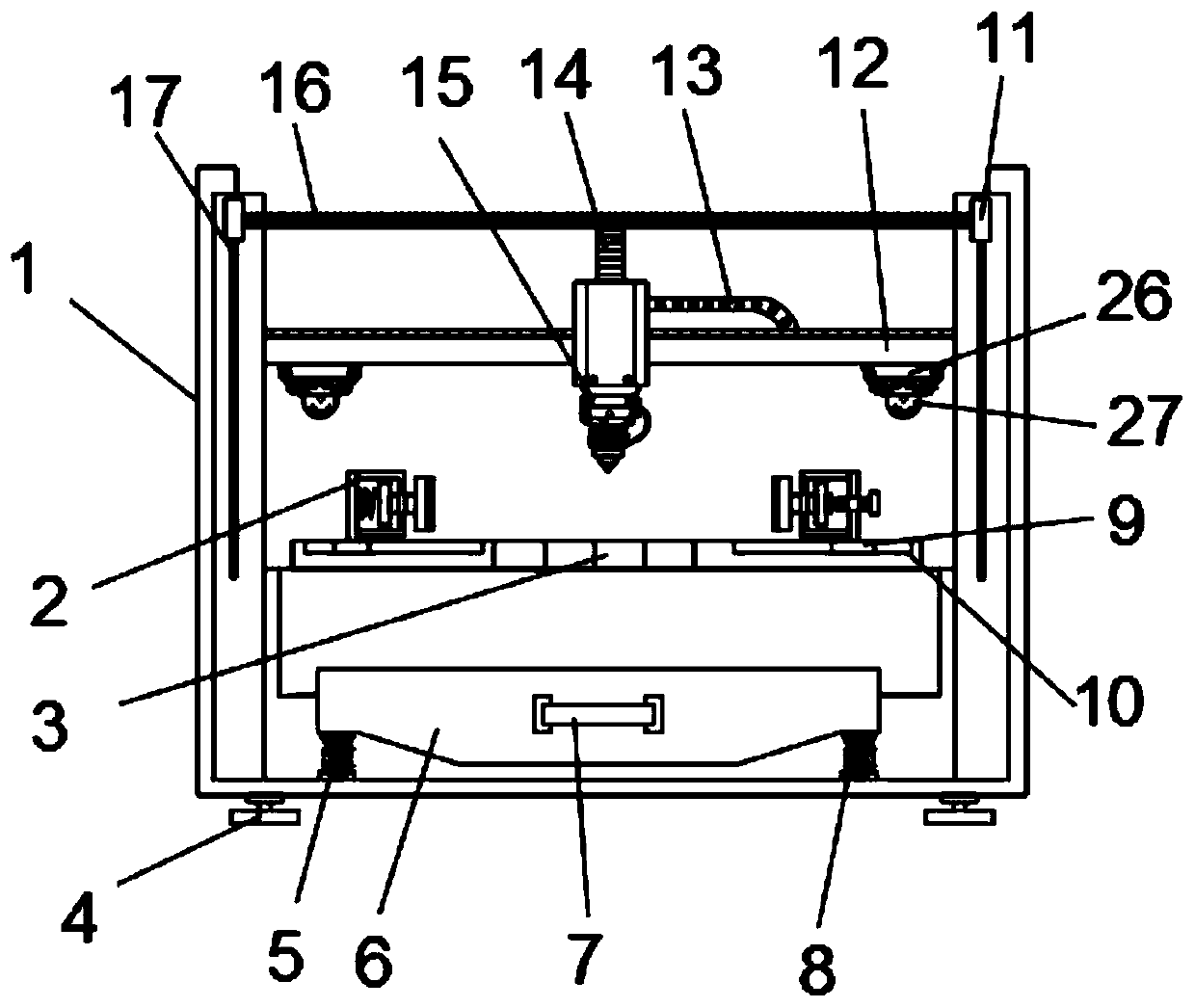

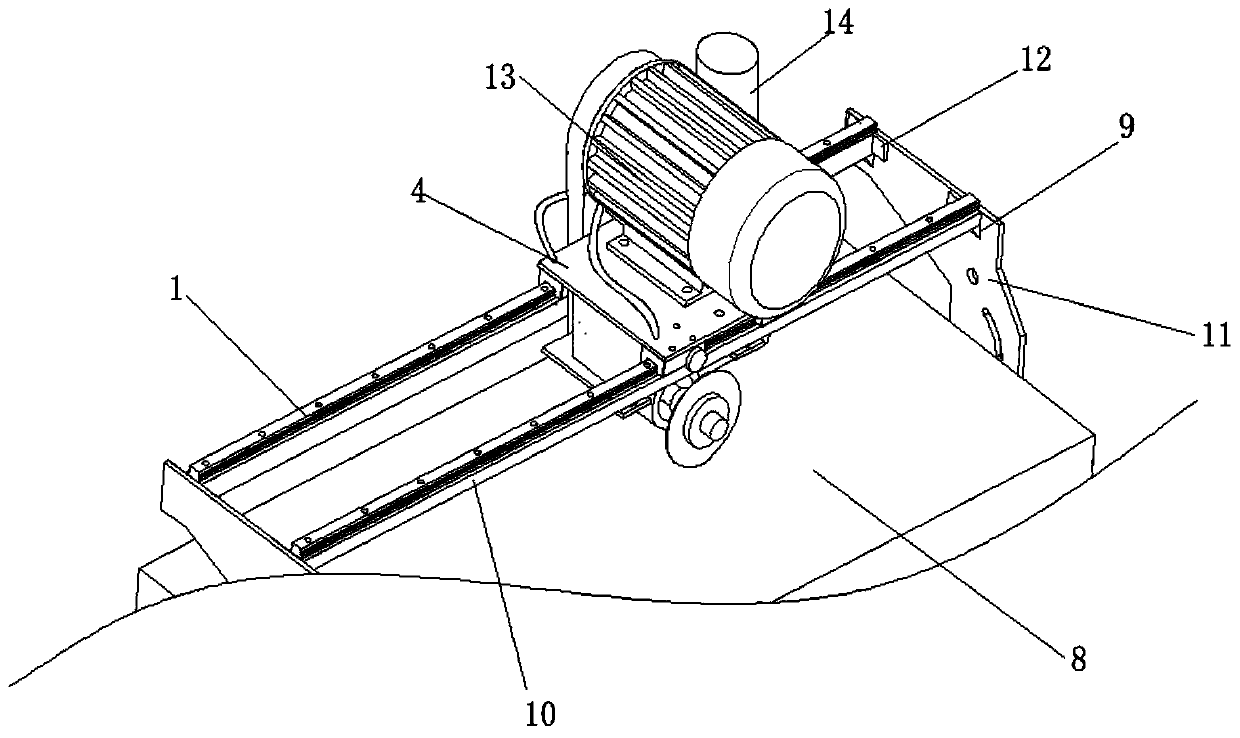

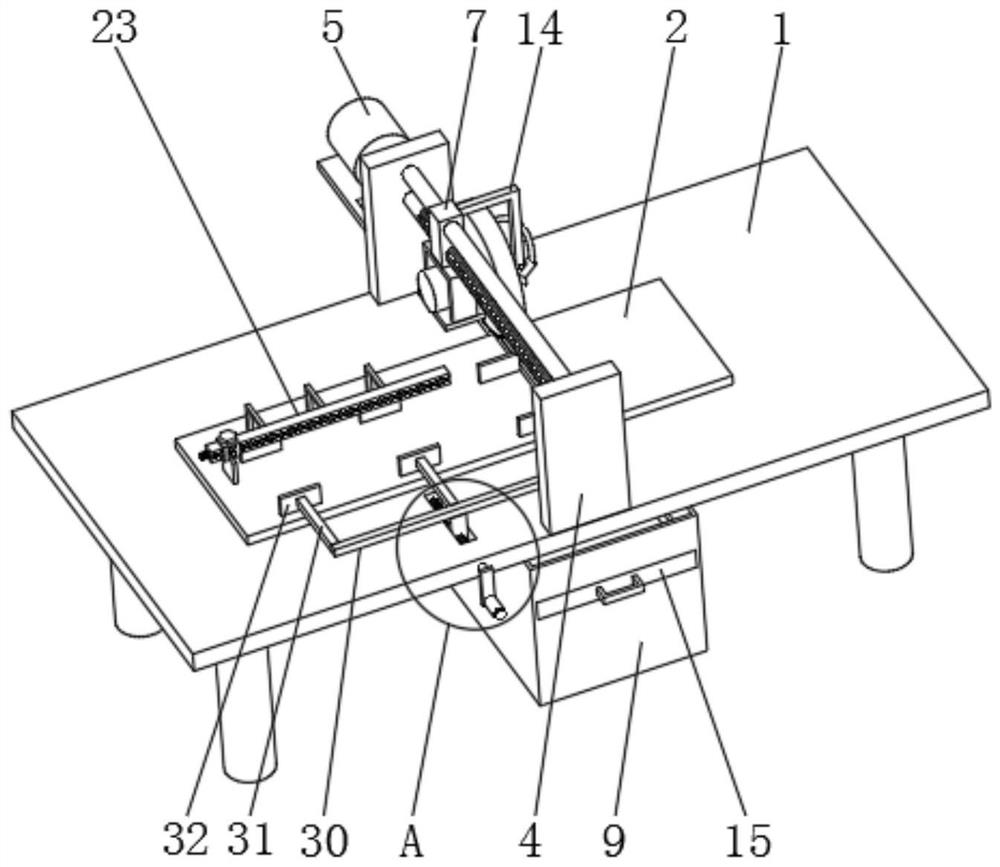

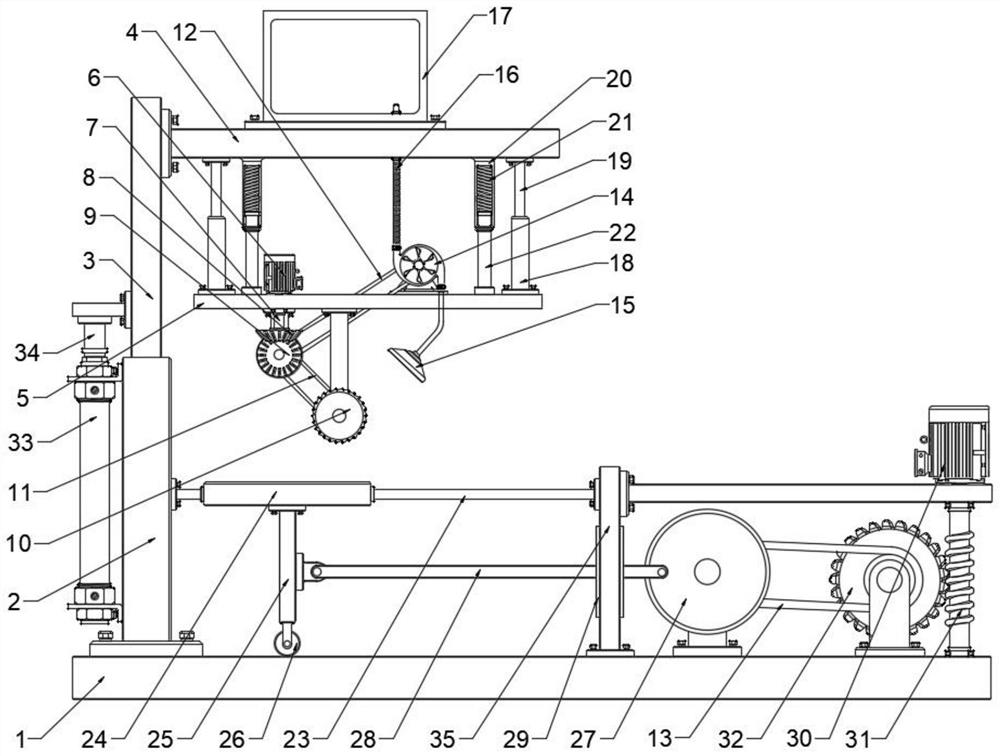

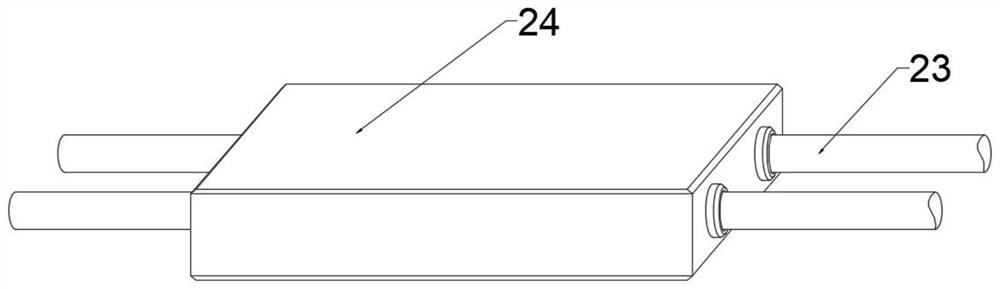

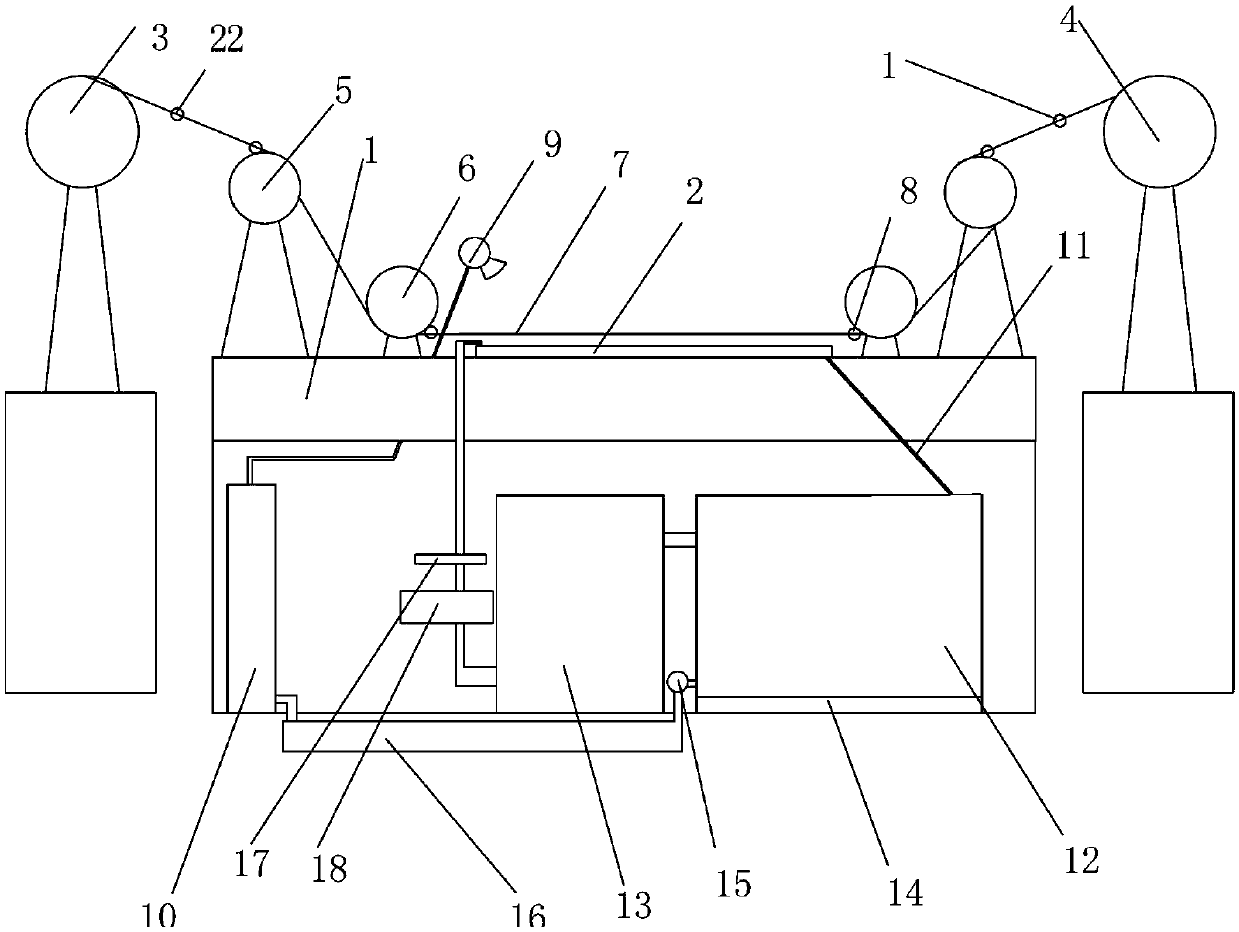

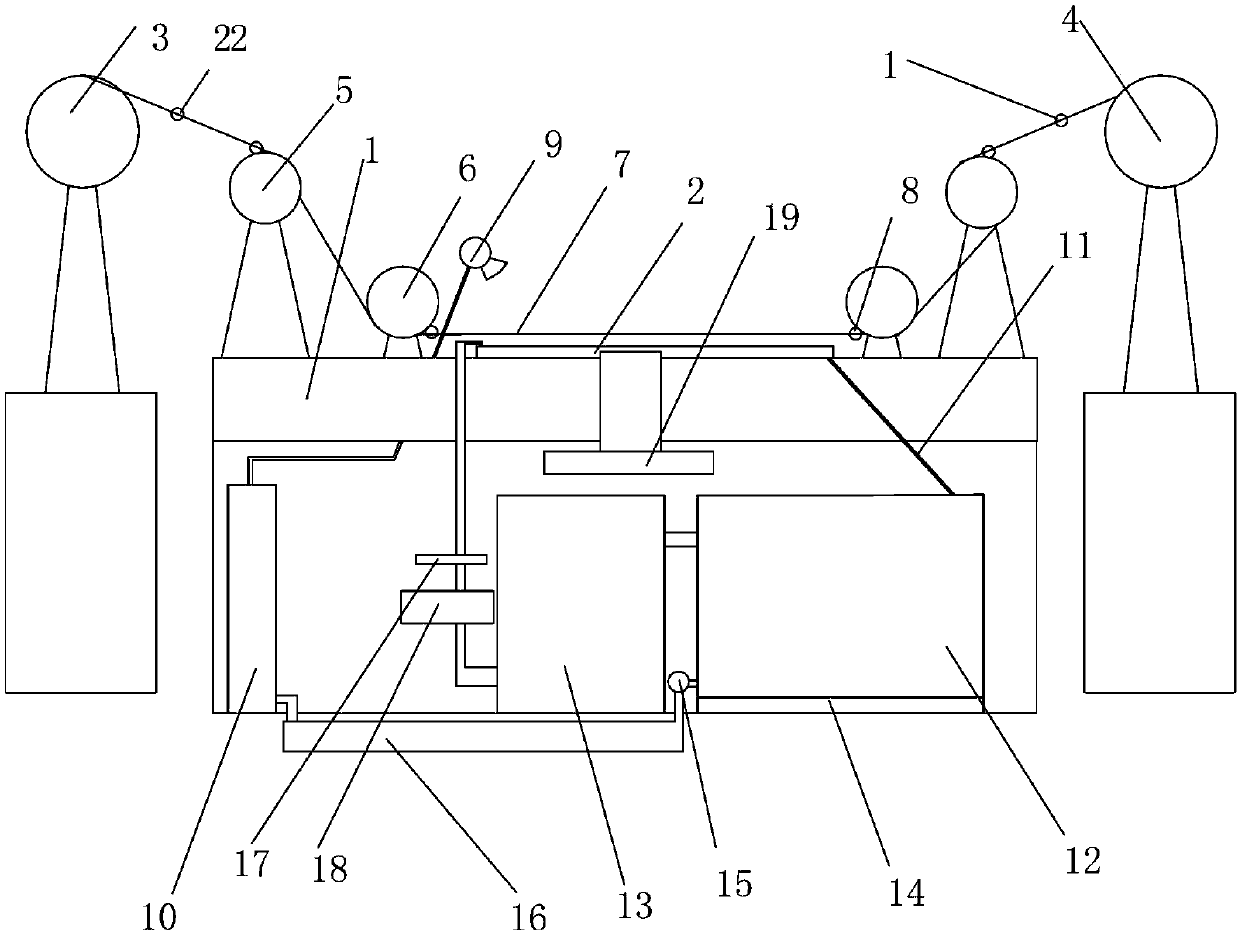

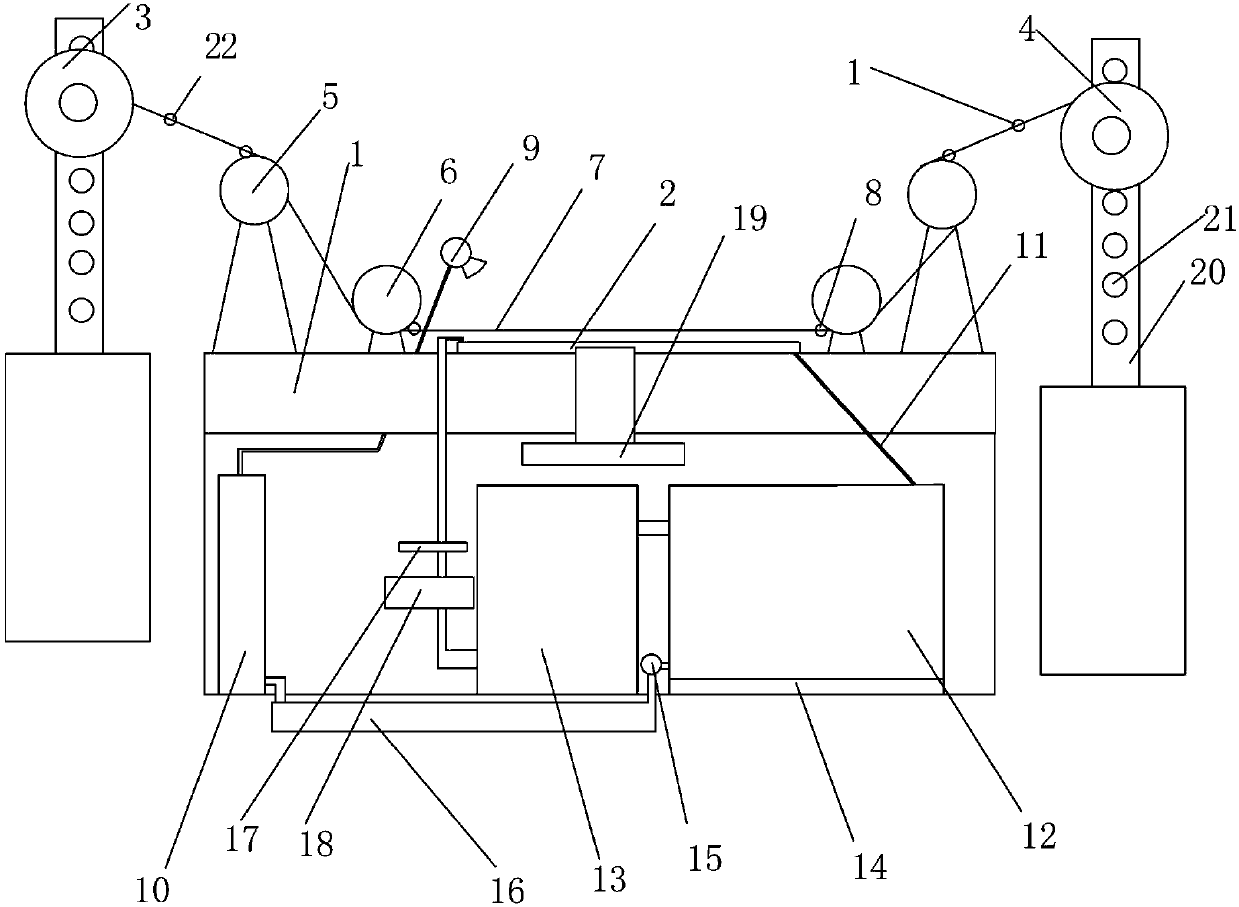

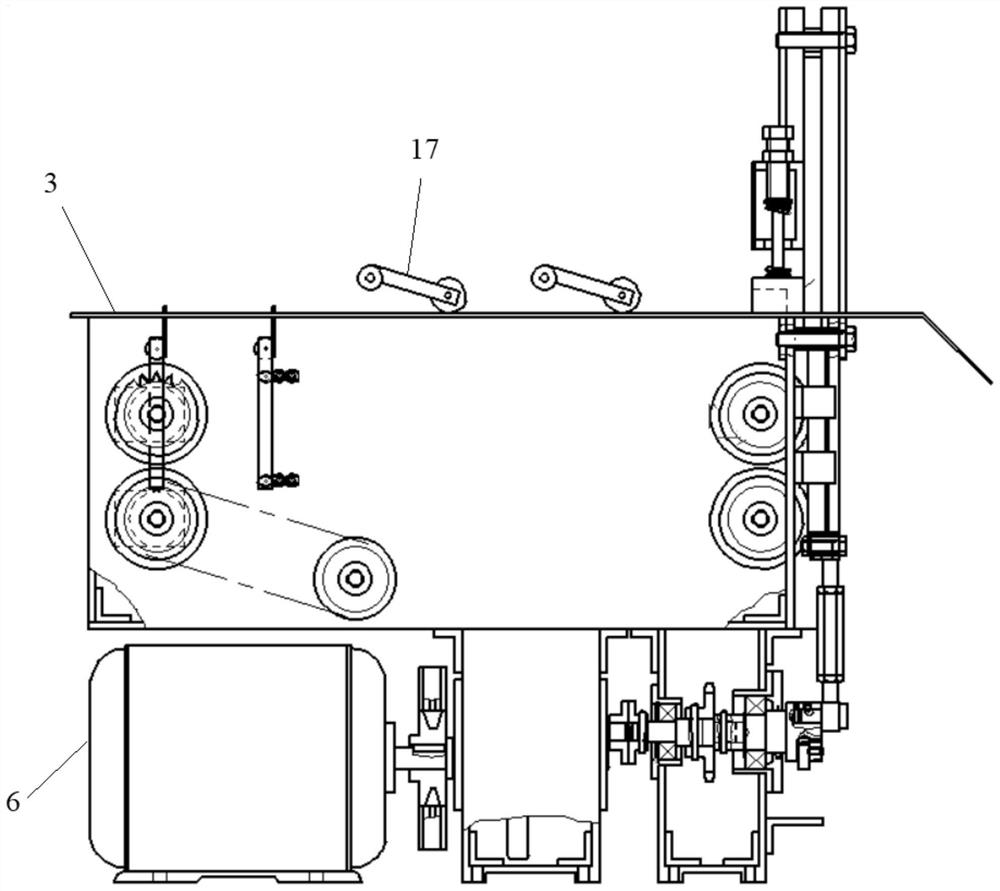

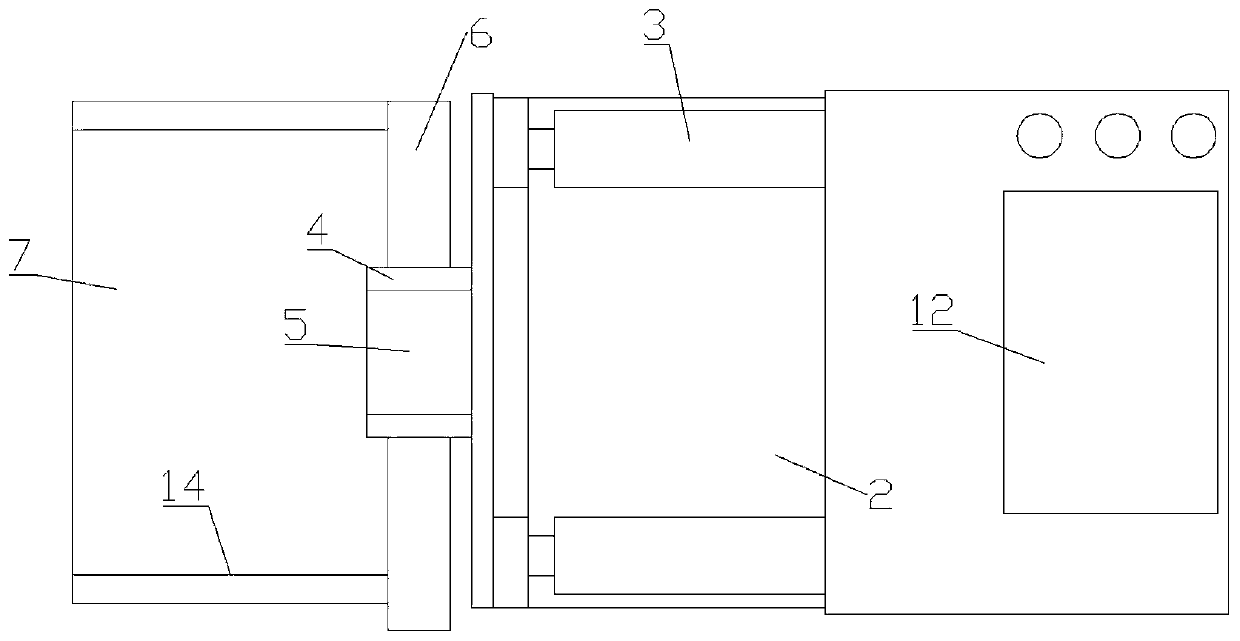

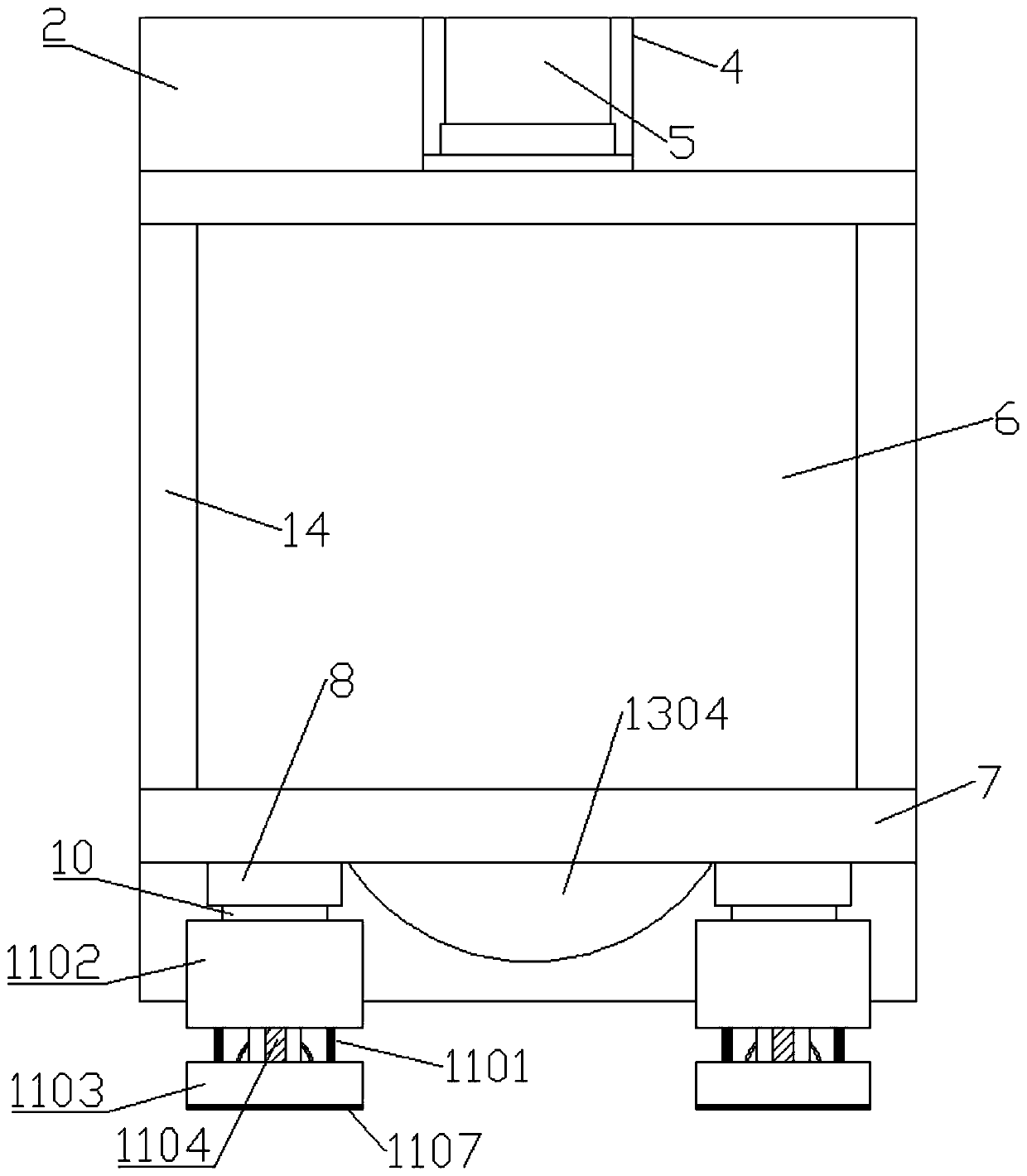

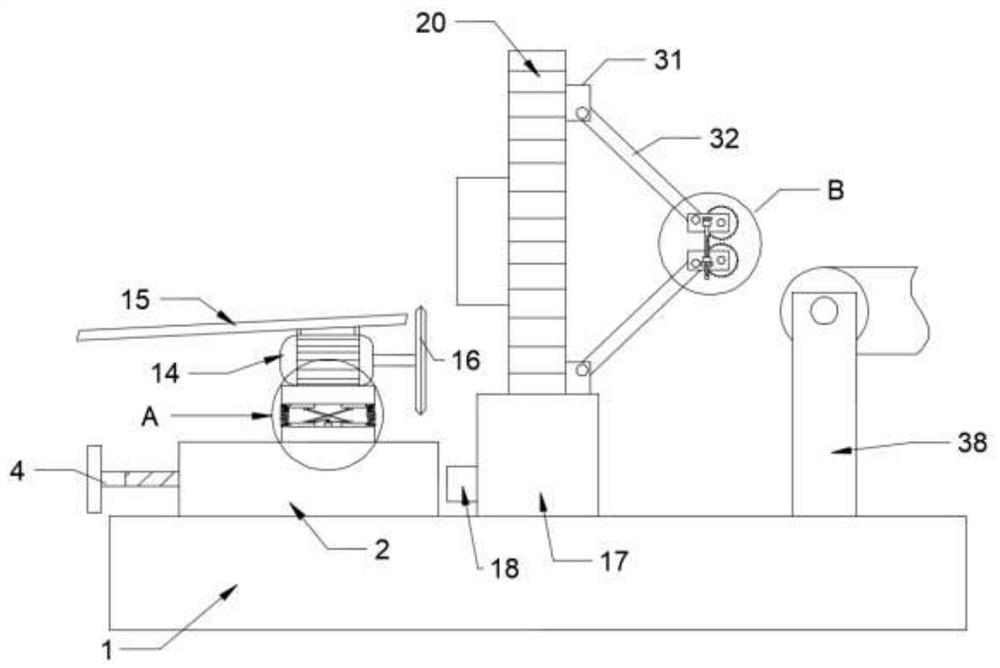

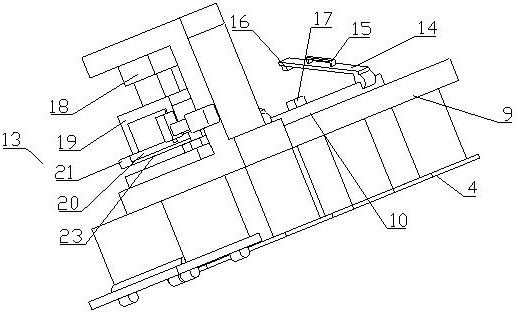

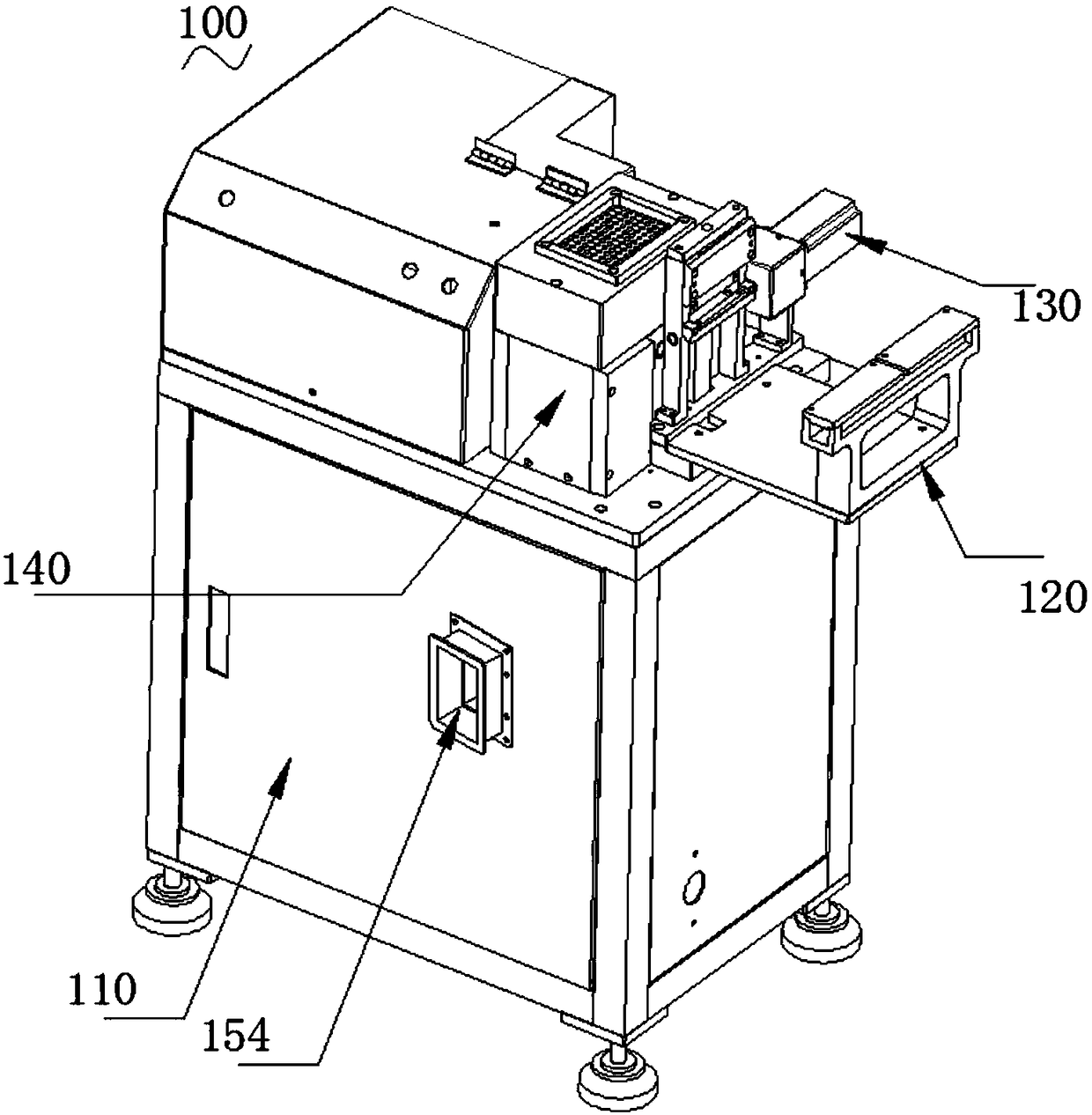

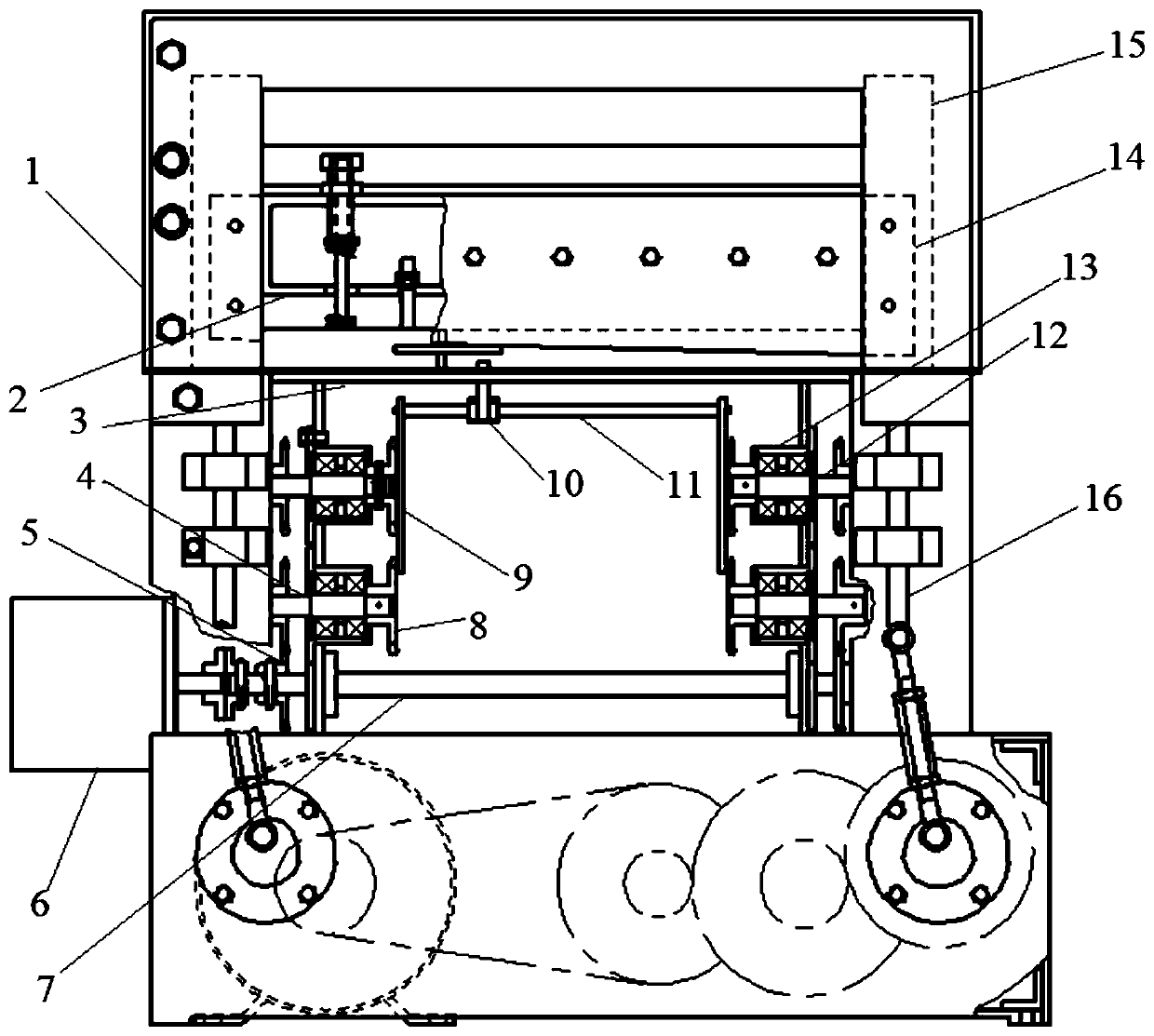

Automatic strip-cutting machine

InactiveCN105479518AHigh precision cuttingSimple structureMetal working apparatusElectric machineryMotor drive

The invention mainly discloses an automatic strip-cutting machine. The technical scheme thereof is as follows: the automatic strip-cutting machine comprises a rack, a head, a tail, a moving device, a cutting device and a PLC control cabinet, wherein the head and the tail are located at the two sides of the rack respectively; the head comprises a clamping chuck and a driver driving the clamping chuck to rotate; a sleeve rod is arranged between the clamping chuck and the tail; the moving device comprises a variable-frequency motor connected to one side of the tail, a screw rod connected with the variable-frequency motor, and a slide plate matching with the screw rod; two guide rails are arranged on the rack, and located between the head and the tail; the screw rod is installed between the guide rails; the variable-frequency motor drives the screw rod to rotate, thus driving the slide plate to move; the cutting device is connected to the top of the slide plate; the cutting device comprises a cutting frame, a first motor, a cutting knife and a cylinder; and a piston rod on the cylinder drives the cutting frame to move back and forth on the slide plate. The automatic strip-cutting machine disclosed by the invention has the advantages of being simple in structure, high in cutting efficiency, convenient to operate, and accurate in cutting.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

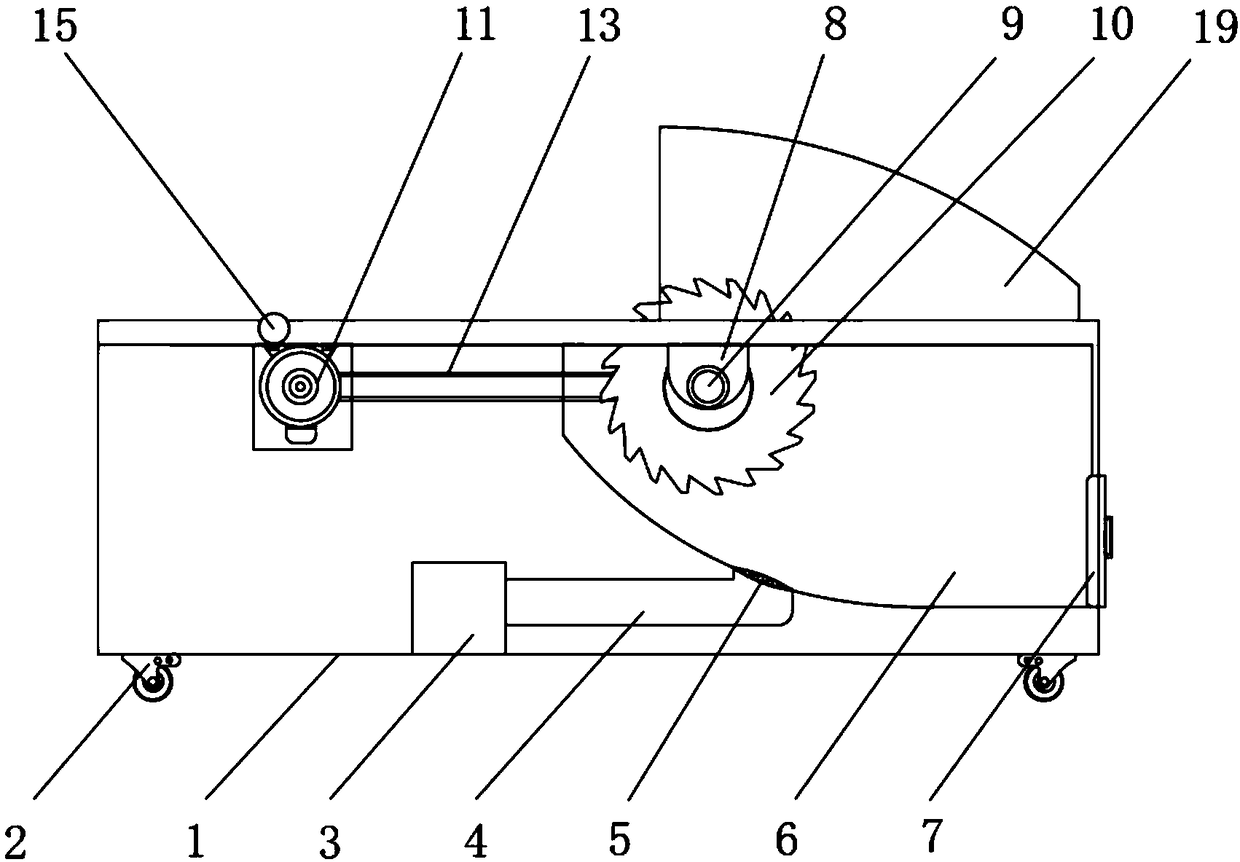

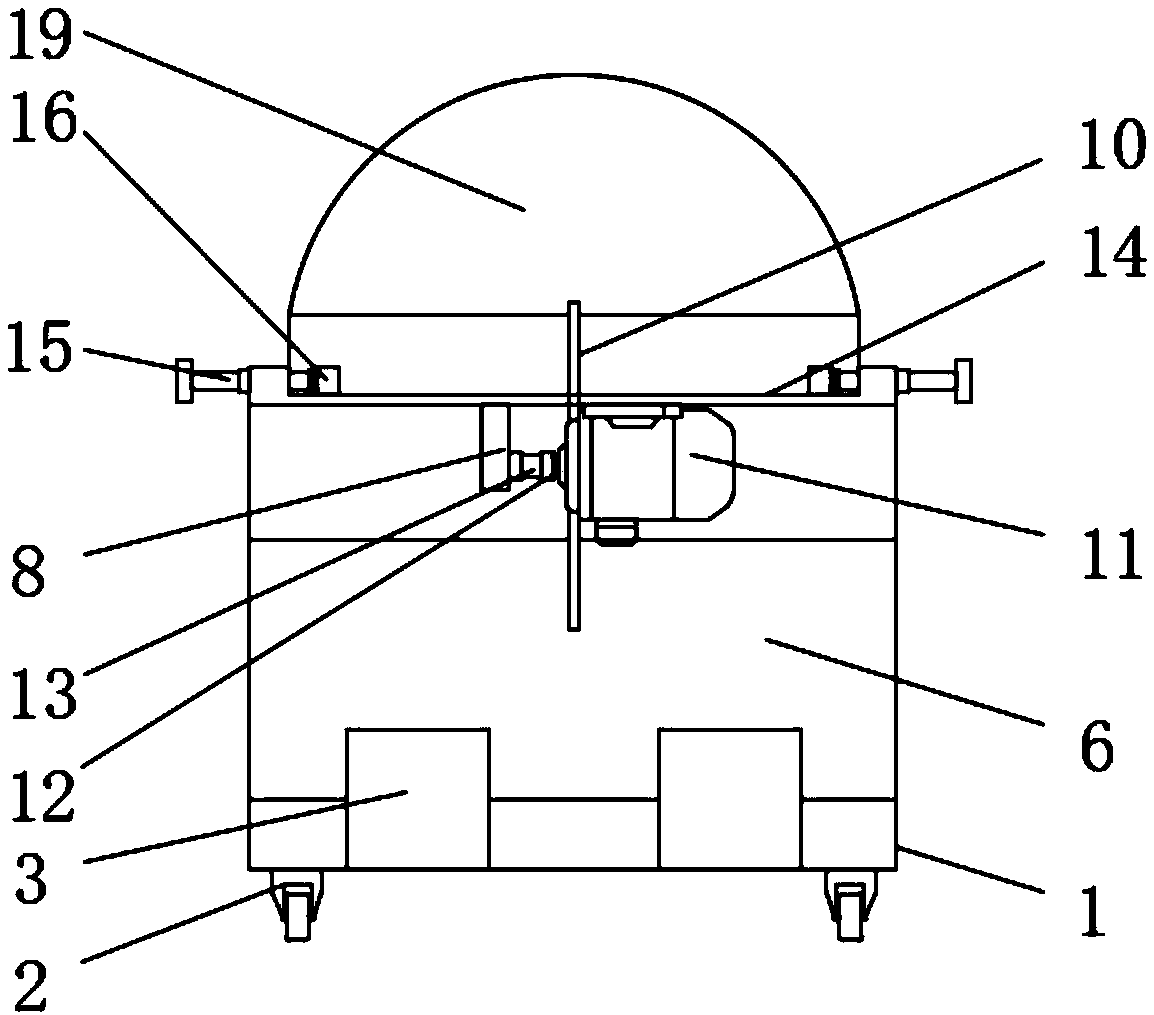

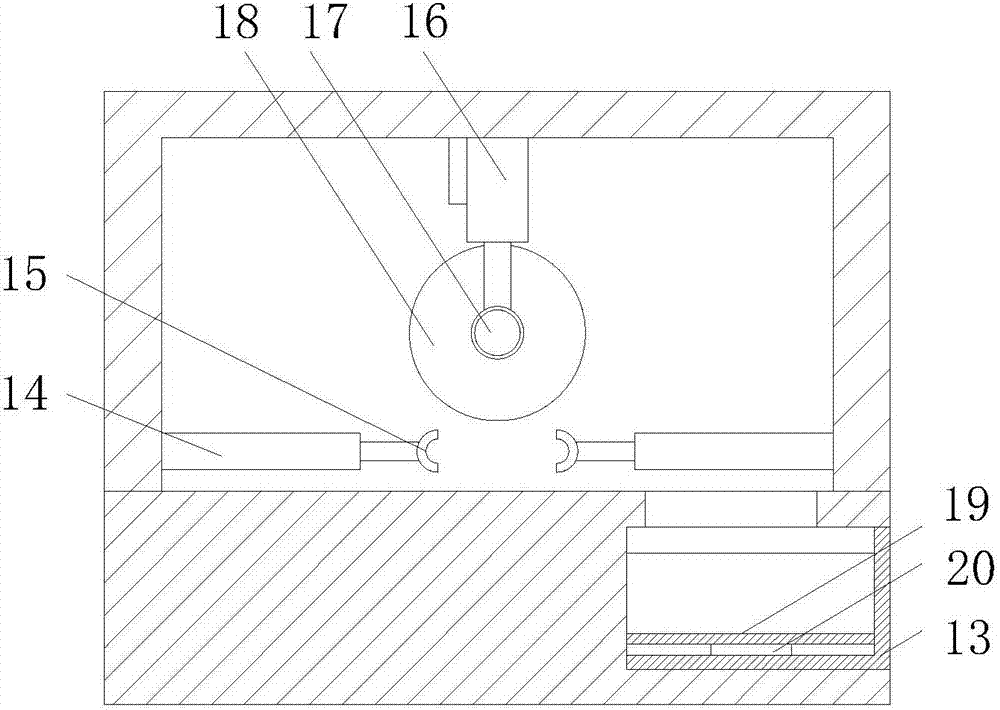

Sawmill convenient in sawdust collection for wooden decorative material

InactiveCN108621255AEasy to collectEasy to fall intoCircular sawsBark-zones/chip/dust/waste removalPulp and paper industryTurbofan

The invention discloses a sawmill convenient in sawdust collection for a wooden decorative material. The sawmill comprises a casing and a dustproof cover, wherein rollers are arranged on the bottom surface of the base; a turbofan is arranged at the bottom of the inner side of the base; the right side of the turbofan is connected with an exhaust tube; the right side of the exhaust tube is connectedwith a filtering net; the filtering net is arranged on the bottom side of a storage cabin; the filtering net penetrates through the bottom side of the storage cabin; a cabin door is rotationally connected with the right side of the storage cabin; the cabin door penetrates through the right side of a casing; a fixing part is fixed at the top end inside the casing; a rotating shaft is rotationallyconnected inside the fixing part; the rotating shaft is connected with a saw blade; the rotating shaft penetrates through the saw blade; a motor is arranged on the left side of the saw blade; the motor is fixed at the top of the inner side of the casing. Due to adoption of the turbofan, the storage cabin, a first limiting groove, a fixing plate and the dustproof cover, the sawmill convenient in sawdust collection for the wooden decorative material is convenient in sawdust collection in a wood plate treatment process, is capable of improving wood plate cutting precision and is convenient and safe to use.

Owner:太湖县佳美装饰工程有限公司

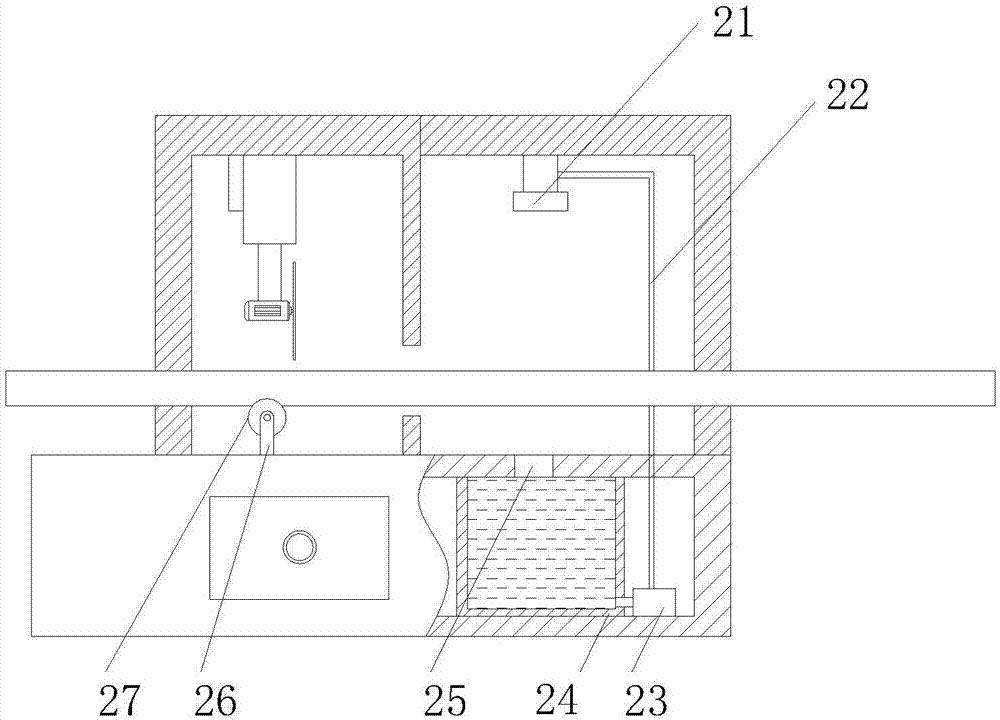

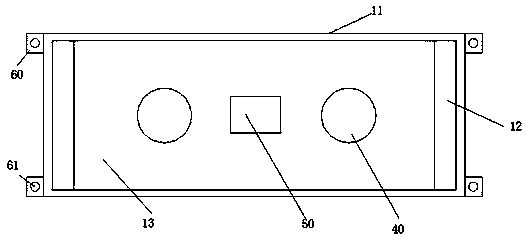

Reinforcement cutting machine capable of cooling and with high safety

The invention discloses a reinforcement cutting machine capable of cooling and with high safety. The machine comprises a base; a machining box is mounted at the top of the base; a push-pull collecting box is mounted on one side of the base; a handle is mounted on one side of the push-pull collecting box; a weight sensor is mounted in the push-pull collecting box; a baffle plate is mounted at the top of the weight sensor; a cooling box is mounted on one side of the machining box; through holes are respectively formed in the cooling box and the machining box; a control panel is inlaid in the machining box; a display screen is mounted on the control panel; an operation button is mounted on one side of the display screen; an accumulator is mounted in the control panel; a circuit main board is mounted on the accumulator; a single-chip is mounted on the circuit main board; a storage tank is formed in one side of the machining box; a wire winding shaft is mounted in the storage tank; an electric wire is mounted on the wire winding shaft; a charge plug is mounted at one end of the electric wire; and a sealing cover is mounted on one side of the storage tank. The reinforcement cutting machine is compact in structure and convenient in use.

Owner:HUNAN QIWEI TECH CO LTD

Numerical control cutting machine capable of rapidly changing cutter

InactiveCN108340022AAdjustable cutting anglePrevent affecting cutting accuracyLarge fixed membersPositioning apparatusNumerical controlPulp and paper industry

The invention discloses a numerical control cutting machine capable of rapidly changing a cutter. The numerical control cutting machine comprises a main body and a motor, wherein a base is fixed at the lower end of the main body, a portal frame is fixed on the two sides of the upper surface of the base, a transverse driving lead screw is connected to the upper end of the inner side of the portal frame, a movable block sleeves the surface of the transverse driving lead screw, a lifting air cylinder is fixedly arranged at the lower end of the movable block, the lower end of the lifting air cylinder is connected with a cutting motor, a cutting head is fixedly arranged below the cutting motor, a cutting knife is embedded in the bottom surface of the cutting head, a fixing screw rod is insertedinto the cutting head, and a longitudinal sliding rail penetrates through the upper surface of the base. According to the numerical control cutting machine capable of rapidly changing the cutter, thecutting knife can be randomly replaced according to the cutting requirements of a workpiece, the cutting knife which meets the requirements is replaced, the fixing screw rod is inserted into the cutting knife, and the cutting knife and the cutting head are fixed, so that the flexibility and the application range are improved; and the numerical control cutting machine is suitable for production and use of the numerical control cutting machine capable of rapidly changing the cutter, and has a good development prospect.

Owner:宁波和丰人力资源服务有限公司

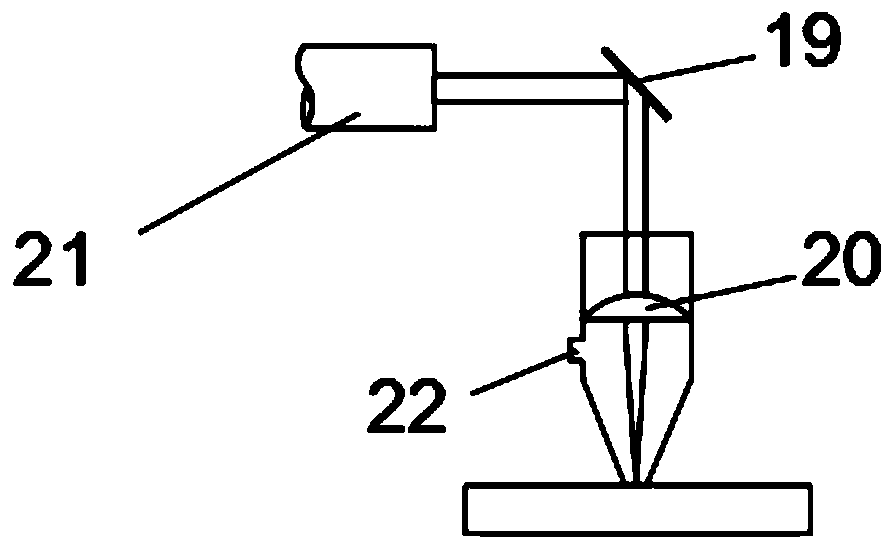

Laser cutting equipment for switch cabinet machining and production

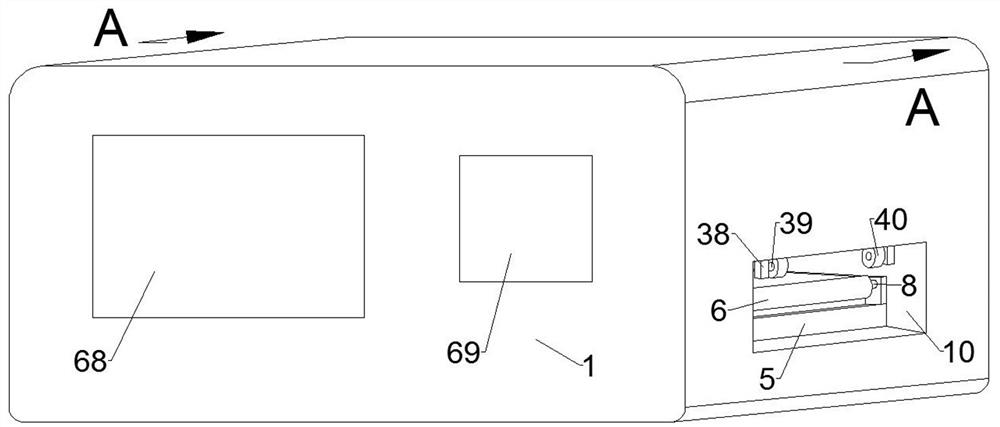

InactiveCN111468839AEffective protectionPrevent affecting cutting accuracyWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingMachining

The invention discloses laser cutting equipment for switch cabinet machining and production, and belongs to the technical field of cutting machine devices. The laser cutting equipment comprises a cutting machine shell, six sets of supporting legs, a laser cutting machine and a workbench, wherein a cutting machine body is fixed to the upper portions of the supporting legs, and an auxiliary protection device is fixedly installed at the upper end of the cutting machine body. An auxiliary clamping device is fixedly installed on the workbench, errors caused by shaking of a switch cabinet in the cutting process of the laser cutting equipment are avoided, and the auxiliary protection device is fixedly installed at the upper end of the cutting machine body, so that damage to eyes of an operator inthe operation process is avoided.

Owner:江苏海潮电气科技有限公司

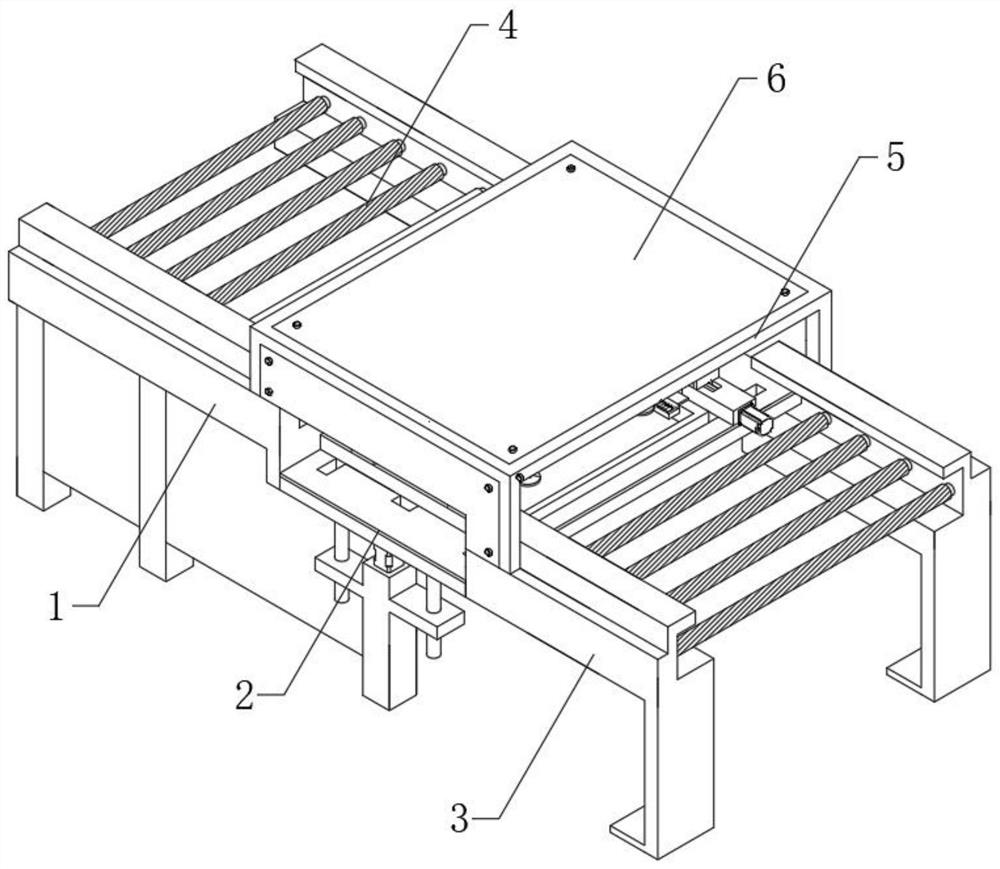

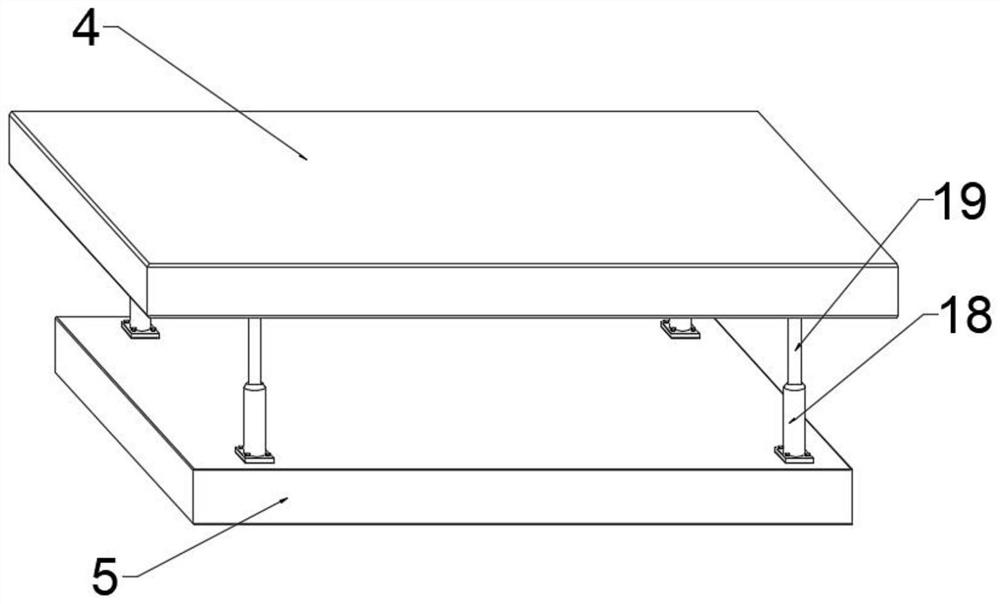

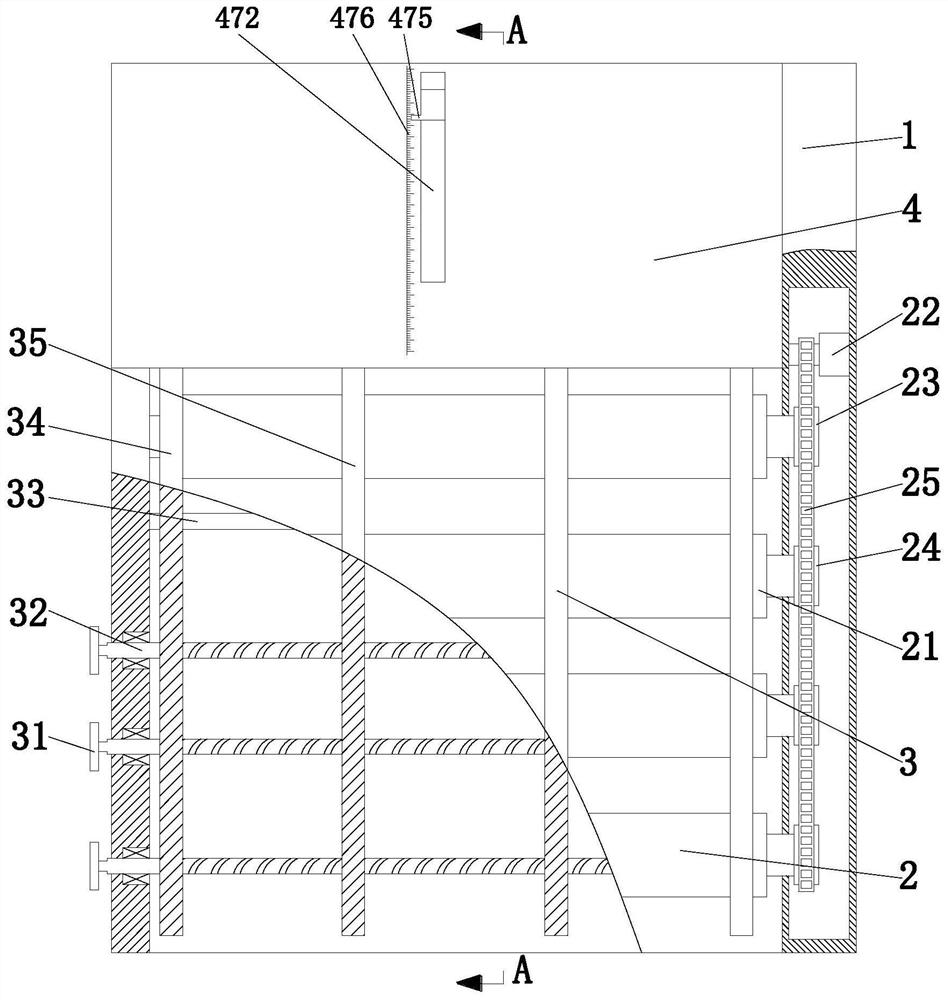

Laser cutting machine for intelligent manufacturing

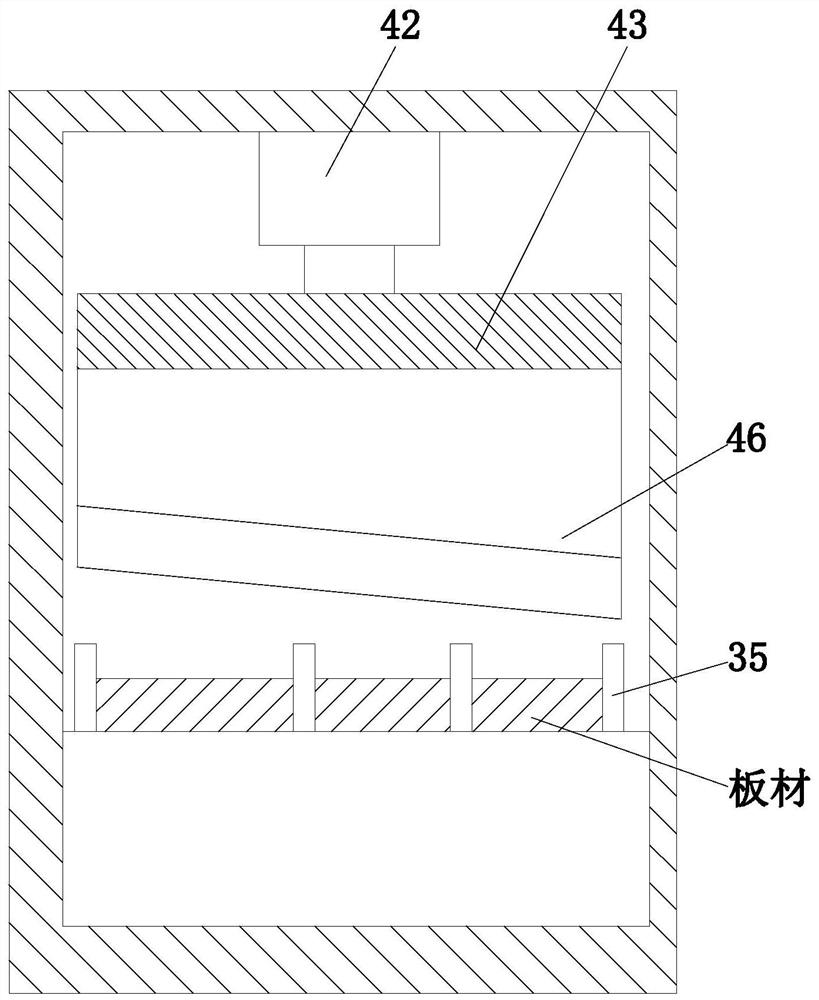

PendingCN113714661AAdjustable distancePrevent affecting cutting accuracyLaser beam welding apparatusHydraulic cylinderElectric machinery

The invention discloses a laser cutting machine for intelligent manufacturing. The laser cutting machine comprises a feeding rack, a machining rack, a discharging rack, a guide roller, a laser frame, a laser cutting base, a movable cutting support, pressing rod bases, a traction plate, a first motor, a second motor and an electric hydraulic cylinder. The two ends of two transverse plate grooves are in sliding connection with the two ends of two supporting transverse plates, a top groove is formed at the top end of each supporting transverse plate, and two pressing rod bases are in sliding connection into the top grooves through small sliding blocks. According to the laser cutting device, the machining rack is arranged between the feeding rack and the discharging rack, the distance between the two supporting transverse plates can be adjusted, and the cutting requirements of plates with different widths are met; and meanwhile, two pressing rod bases capable of being adjusted in a sliding manner are arranged on the supporting transverse plates, the first motor drives a first screw rod to rotate, so that a first sliding block slides in the pressing rod bases, then a pressing rod and a circular pressing piece are driven to press downwards, a cutting point is fixed and limited, and the situation that the cutting precision is affected due to the fact that the plate moves in the cutting process is prevented.

Owner:YULIN NORMAL UNIVERSITY

Tile cutting machine

PendingCN109834856AIncrease stiffnessIncreased load-bearing capacityWorking accessoriesStone-like material working toolsEngineeringMechanical engineering

The invention relates to a tile cutting machine. The tile cutting machine comprises a sliding assembly for driving displacement of a cutting assembly, the sliding assembly comprises sliding rails andsliding blocks sliding on the sliding rails, the sliding rails are square sliding rails, and the sliding blocks are square sliding blocks. According to the tile cutting machine, the sliding rails in the tile cutting machine are the square sliding rails, and the sliding blocks in the tile cutting machine are the square sliding blocks, so that the feeding precision is better in the process of relative sliding, shaking is not prone to occurring, the square sliding rails are better in rigidity and better in bearing capacity and are not prone to being bent, and the cutting precision is ensured.

Owner:四川省万光机械设备有限公司

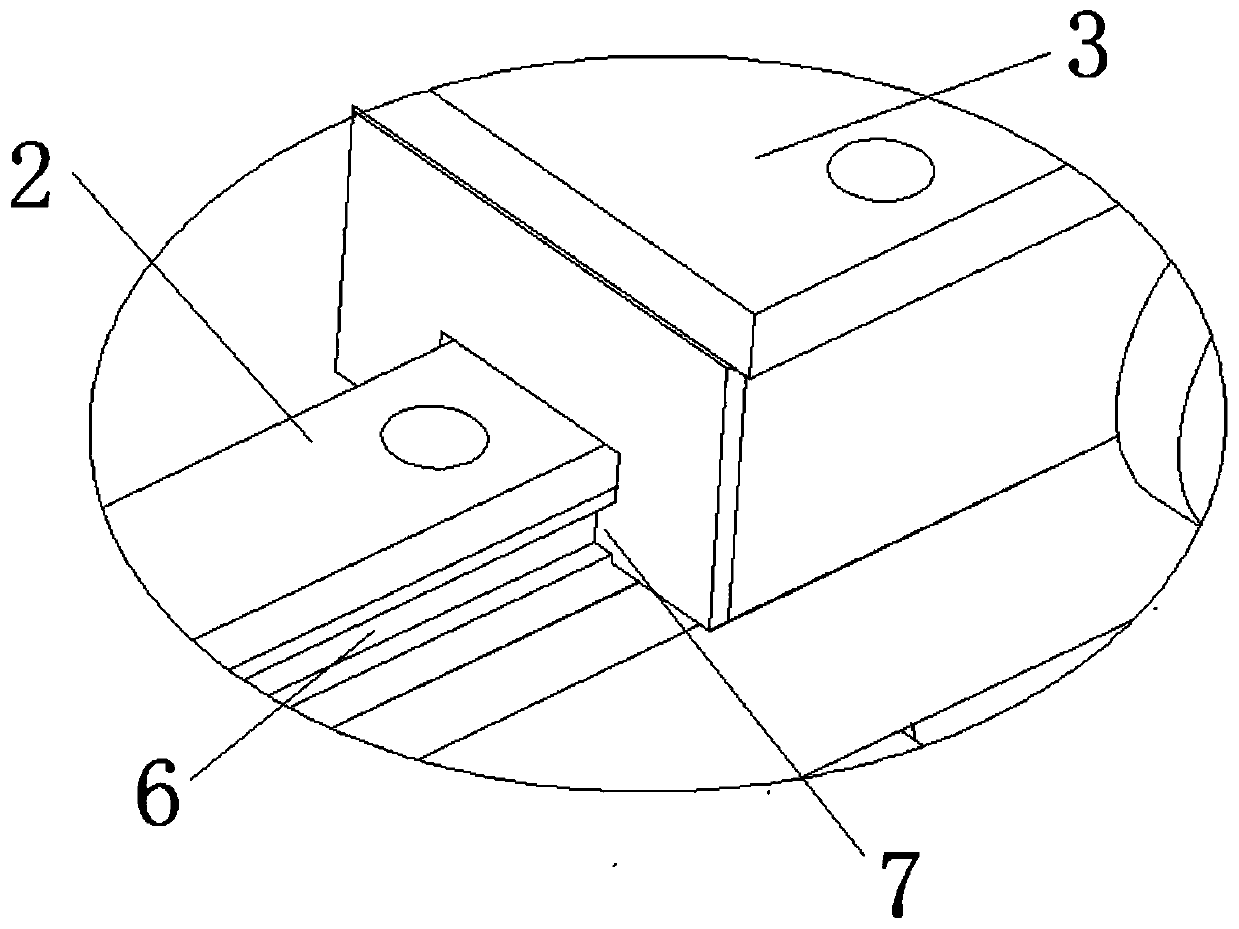

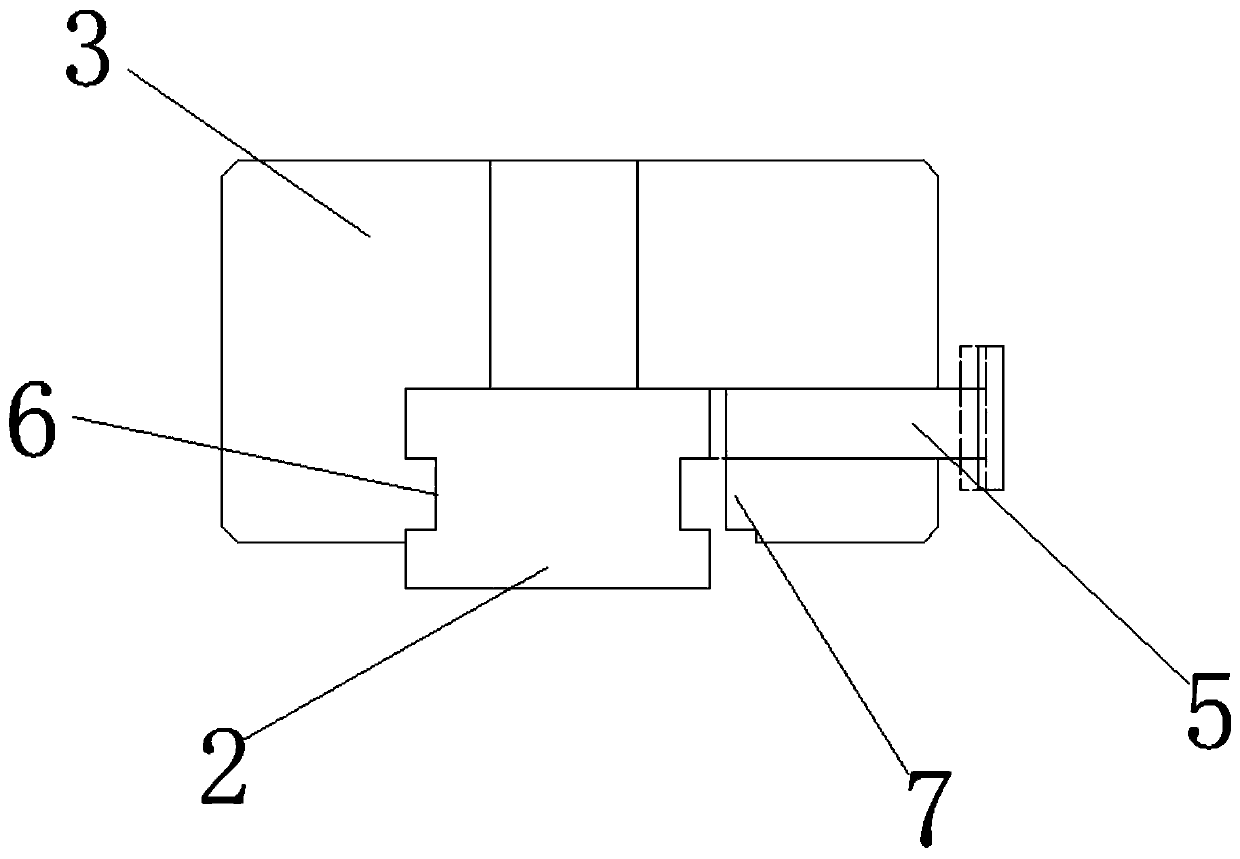

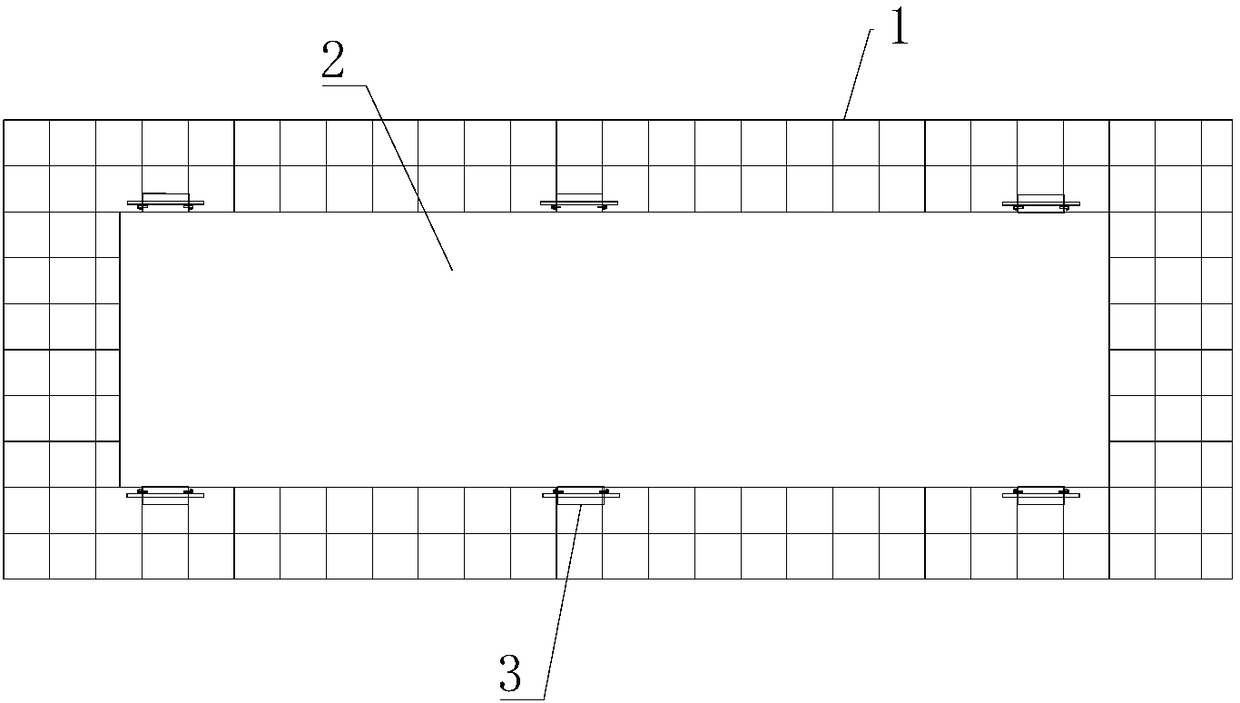

Platform for carrying out numerical-controlled cutting on steel plate based on ships and using method thereof

PendingCN108544260AAvoid bouncingPrevent affecting cutting accuracyPositioning apparatusMetal-working holdersNumerical controlSteel plates

The invention provides a platform for carrying out numerical-controlled cutting on a steel plate based on ships and a using method thereof. The problem that the precision is low when the steel plate is cut in the prior art is solved. The platform comprises an assembly jig which is placed horizontally, wherein a to-be-cut steel plate is placed on the surface of the assembly jig; a plurality of auxiliary parts detachably connected with the assembly jig are arranged on an outer edge of the steel plate; the auxiliary parts are symmetrically arranged at the periphery of the steel plate; the steel plate is fixed to the assembly jig by the auxiliary parts; each of the auxiliary plates comprises a web plate and a face plate, and the web plate and the face plate are perpendicularly and integrally fixed; the web plates are detachably connected with the assembly jig; a plane on which the face plate is located is parallel to a plane on which the steel plate is located; and the face plate is pressed on the edge position of the steel plate and is used for fixing the steel plate to the assembly jig.

Owner:QINZHOU UNIV

Cable tray pre-cutting device for ocean engineering

InactiveCN113319906AReduce labor intensityAffect healthMetal working apparatusPhysical healthWater storage tank

The invention discloses a cable tray pre-cutting device for ocean engineering and relates to the field of cable trays for ocean engineering. The cable tray pre-cutting device comprises a pre-cutting table and a cutting machine arranged on the pre-cutting table, wherein a tray placement table is fixedly mounted at the top of the pre-cutting table; a water storage tank is arranged at the bottom of the pre-cutting table; and a strip-shaped hole is formed in the tops of the pre-cutting table and the tray placement table. Through the arrangement of a movable cutting part, the cable tray pre-cutting device can perform cutting treatment on various brackets of different widths at a time; through the arrangement of an adjusting and fixing part, the purposes of accurately measuring and fixing a tray can be fulfilled, the labor intensity of workers can be reduced, and the cutting and pre-cutting accuracy of the cable tray pre-cutting device can be guaranteed; and through the arrangement of a spraying and cooling part, the purposes of cooling and dust falling can be fulfilled in the cutting process, the situation that the cutting accuracy is influenced by the high-temperature deformation of a cutting blade and a cutting part can be prevented, and the influence of generated smoke dust on the physical health of the workers can be avoided.

Owner:广州从益网络科技有限公司

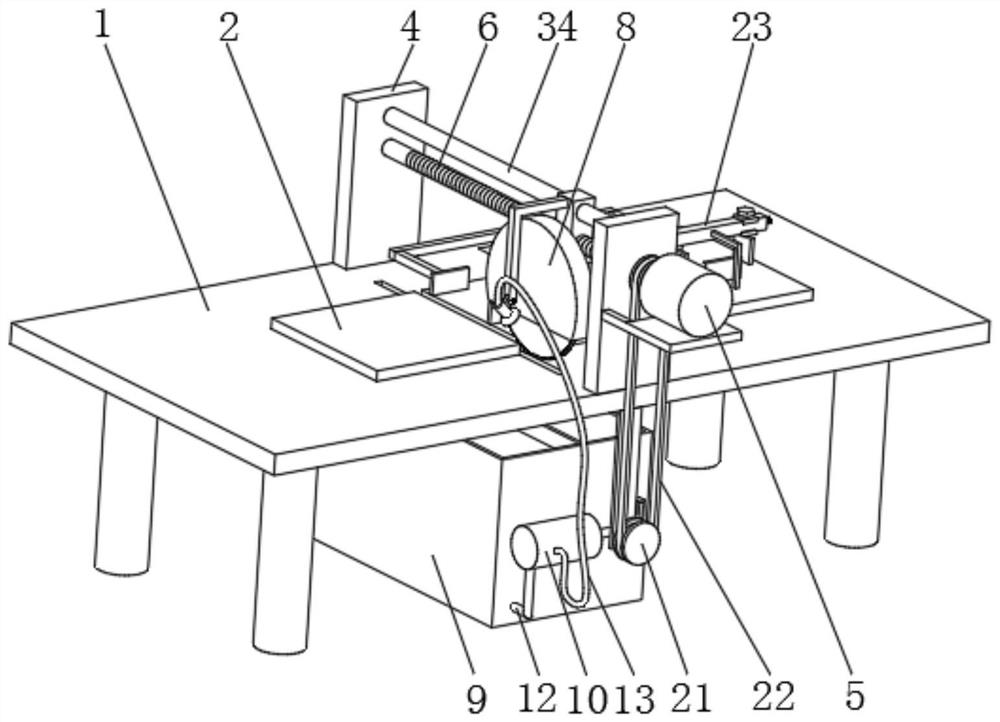

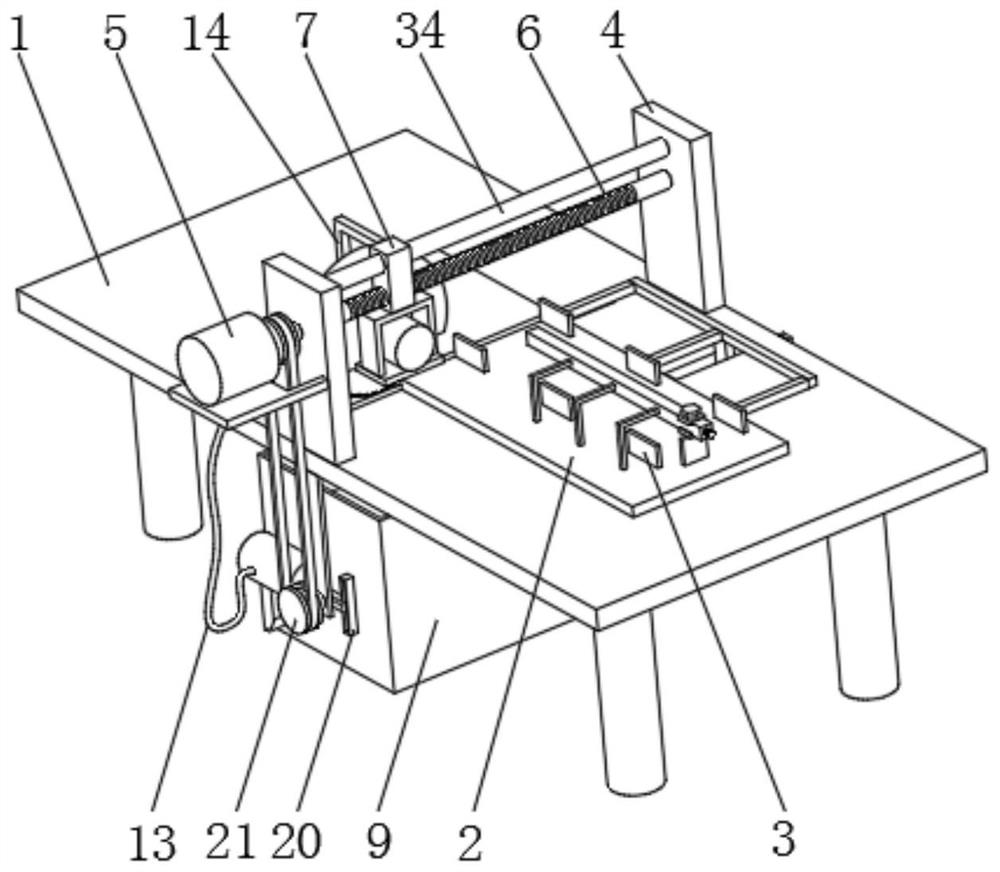

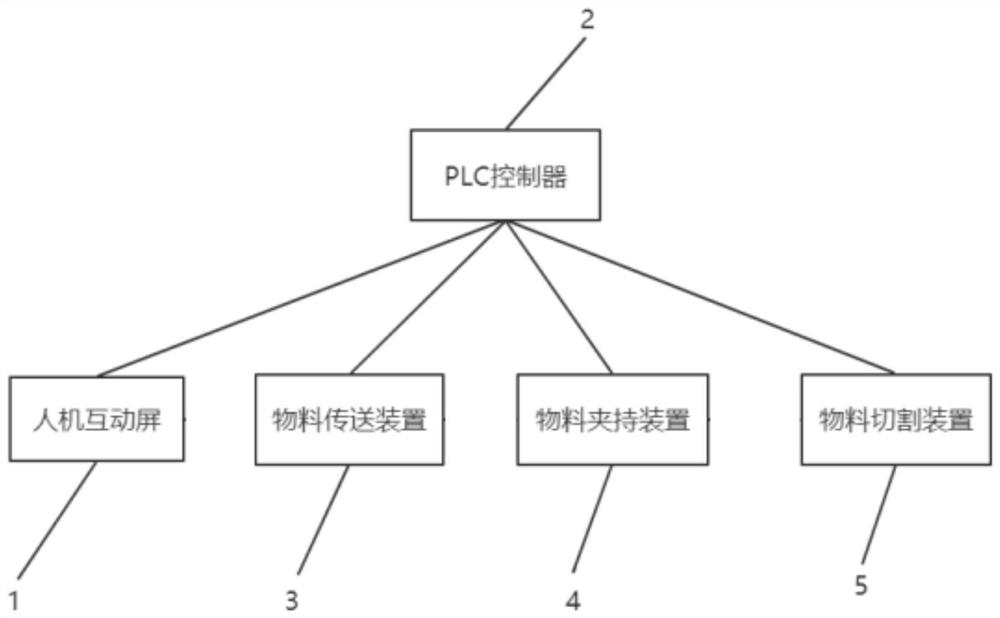

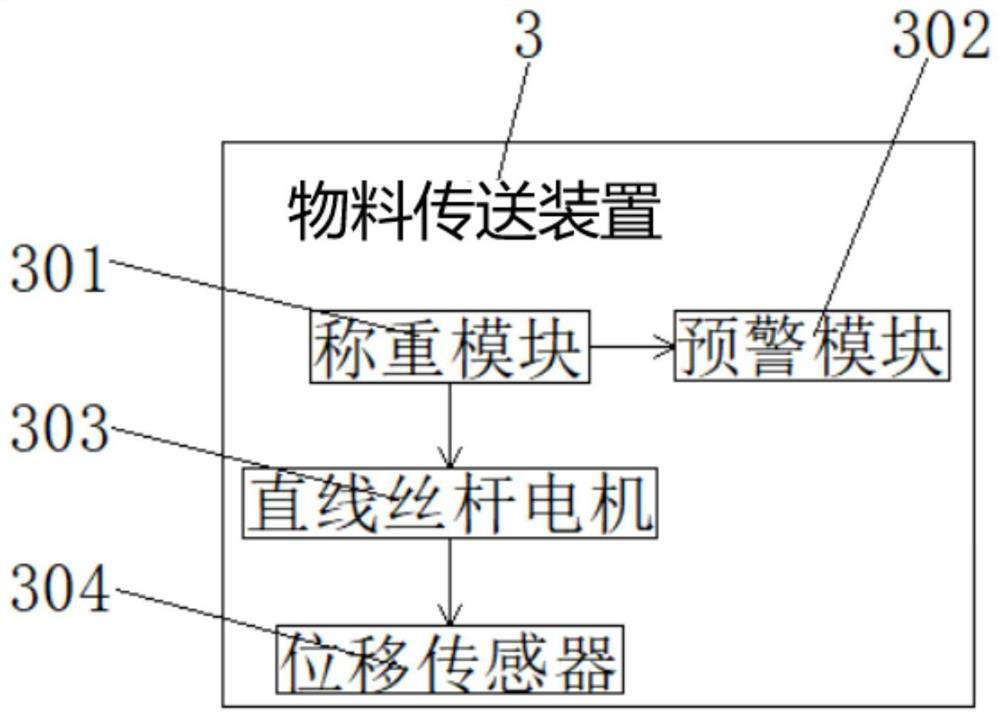

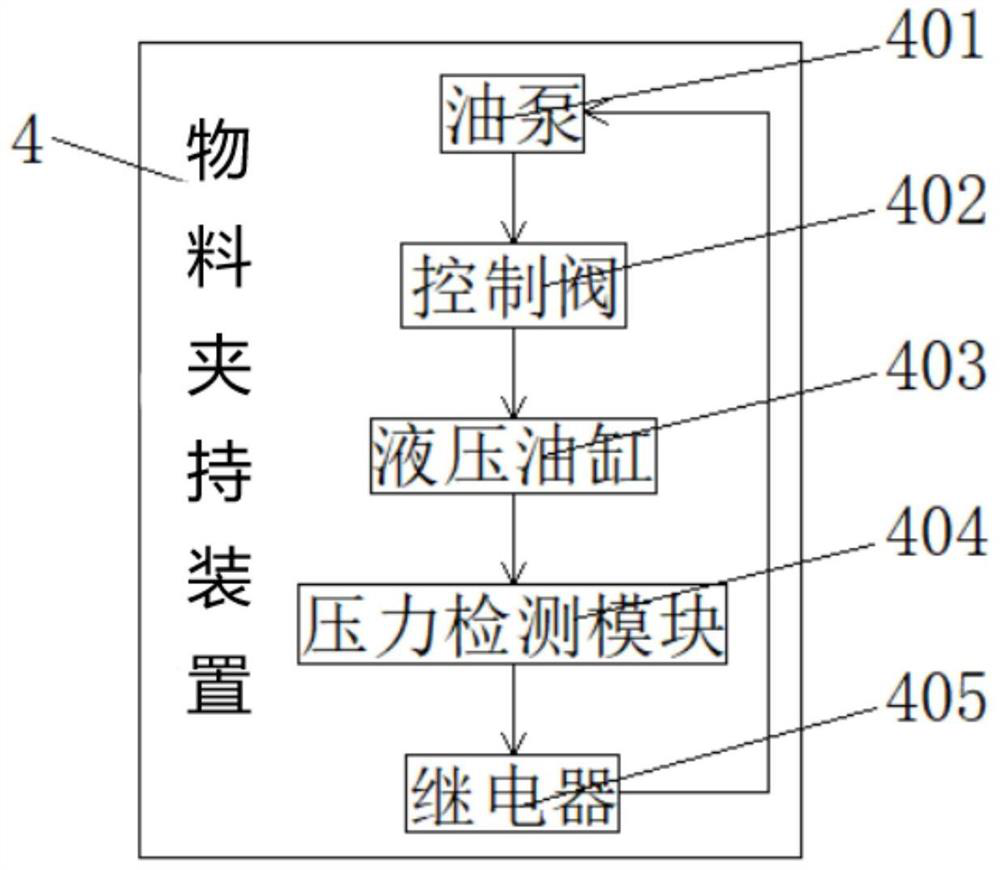

Automatic feeding control system of cutting machine

InactiveCN111889807AImprove convenienceMeasure movement distanceMeasurement/indication equipmentsCleaning using gasesControl systemControl engineering

The invention discloses an automatic feeding control system of a cutting machine. The automatic feeding control system of the cutting machine comprises a man-machine interaction screen, the man-machine interaction screen is in electrical connection with a PLC through a lead, moreover, the PLC is in electrical connection with a material conveying device through the lead, the PLC is in electrical connection with a material clamping device through the lead, and the PLC is in electrical connection with a material cutting device through the lead. The automatic feeding control system of the cuttingmachine is provided with the material cutting device, can effectively detect distance between a material and the cutting machine through an infrared distance sensor, until conveying the material to asuitable position, reminds operators through a loudspeaker, and guarantees accuracy of material cutting of the cutting machine; and a dust collection fan can effectively collect sweeps, can efficiently handle the sweeps and can avoid influence on high efficiency of waste treatment of the cutting machine caused by the sweeps.

Owner:广州心蛙科技有限责任公司

High-precision cutting device for profile machining

InactiveCN112719435AIncreased depth of cutImprove cutting efficiencyMetal sawing devicesMetal sawing accessoriesElastic componentEngineering

The invention relates to a high-precision cutting device for profile machining. The cutting device comprises a base, a first vertical plate, a second vertical plate, a telescopic plate, a fixed plate and a mounting plate; the first vertical plate and the second vertical plate are fixedly mounted on the base; the first vertical plate is vertically glidingly sleeved with the telescopic plate; the fixed plate is fixedly mounted on the telescopic plate; and the mounting plate is arranged at the lower part of the fixed plate through two groups of elastic components. A driving assembly drives a moving assembly to move through a transmission assembly, meanwhile, a cutting assembly and a scrap removing assembly work to cut profiles, in the cutting process, the scrap removing assembly adsorbs scraps generated in the cutting process, the moving assembly drives the profiles to stably move, in the cutting process, an elastic assembly enables the mounting plate to gradually move downwards, the downward moving degree of the mounting plate depends on initial movement of a lifting assembly, and the cutting depth of the profiles is determined, so that the high-precision cutting function of the device on the profiles and the adjustable function for the cutting depth are achieved.

Owner:湖南嘉利塑业有限公司

Environment-friendly pad processing device

InactiveCN107877566APrevent affecting cutting accuracyAchieve lockingMetal working apparatusArchitectural engineeringEnvironmentally friendly

An environmental protection pad processing device of the present invention comprises a seat frame composed of a machine base, a frame bar and a placement plate, two of which are fixedly installed on the machine base correspondingly on the left and right sides, and the seat frame is fixedly installed on the machine base At the upper ends of the two support rods, a first pusher device is fixedly installed at the midpoint of the upper surface of the placement plate, and a first push rod connected with the first pusher device is smoothly installed at the midpoint of the placement plate. The lower end of the push rod is fixedly installed with the end head, and the bottom end surface of the end head is provided with a circular cutting blade. The bottom column is smoothly connected with the casing, the bottom end of the bottom column is fixedly connected with the machine base, an elastic strip is fixedly installed between the lower end of the casing and the machine base, and a As for the push plate, a second push rod is smoothly installed in the bottom column.

Owner:宁波鄞州国康机械科技有限公司

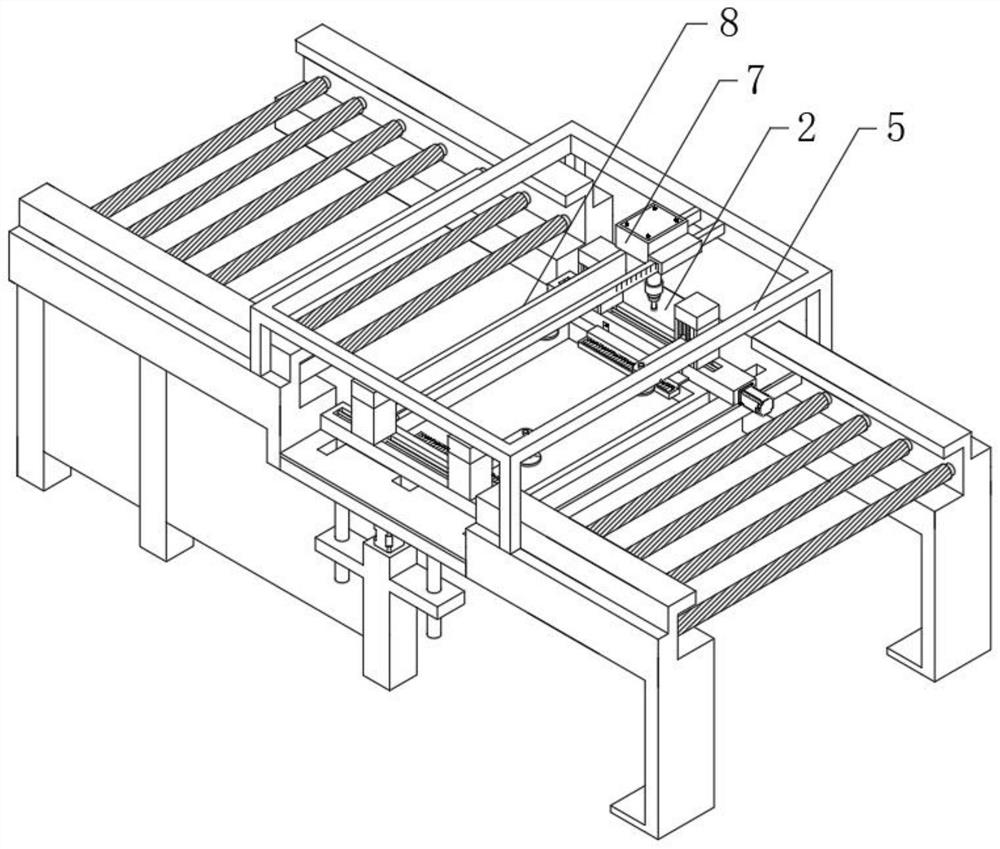

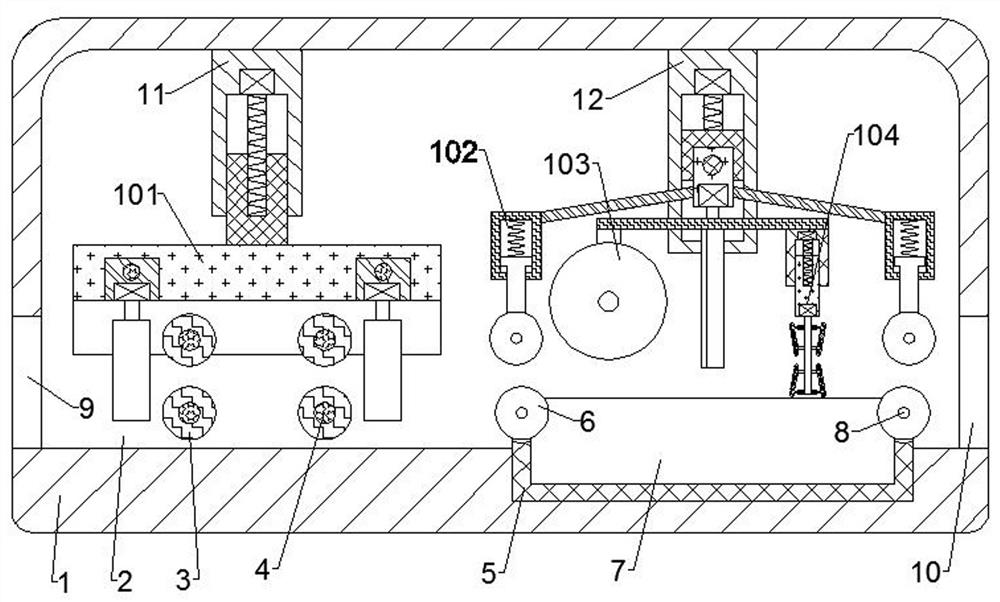

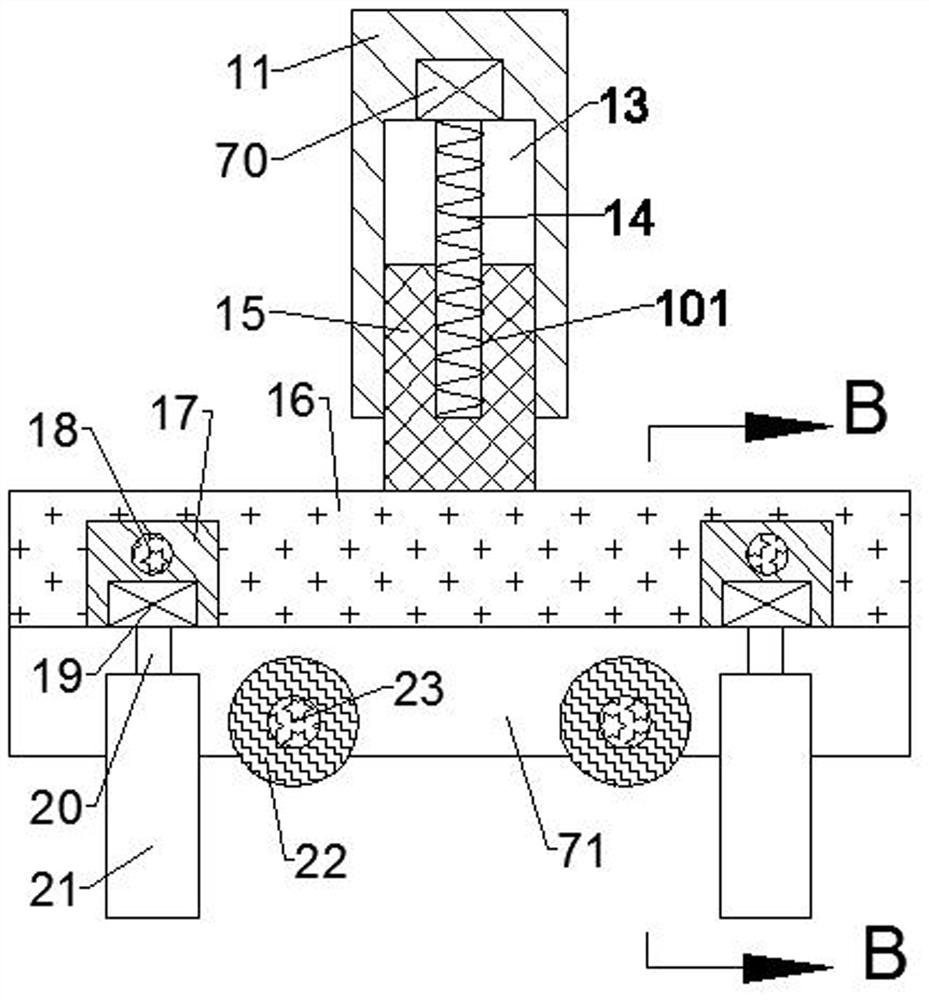

An automatic cutting machine for steel structure profile feeding and fixed length

ActiveCN110524056BControl cutting lengthIncreased labor intensity, etc.Feeding apparatusMetal working apparatusMachineAutonomation

The invention relates to a steel structure profile feeding fixed-length automatic cutting machine. The machine comprises a base, a feeding device, a material distributing device, a cutting device anda discharging device, a feeding cavity and a discharging cavity are formed in the front end of the base from bottom to top, the feeding device and the material distributing device are sequentially installed in the feeding cavity from top to bottom, the cutting device is installed on the upper side of the front end of the base, and the discharging device is installed in the discharging cavity; theadjustable material distributing plate is adopted, so that steel plates with different widths can be fed at the same time; by adjusting the position of the stop block, the steel plate cannot be fed after extending out by a specified length, and the cutting length of the steel plate is controlled; the two ends of the plate are prevented from tilting to influence the cutting precision in a mode of firstly fixing and then cutting; and through discharging of the plates, the conditions that the plates are accumulated on the working platform, efficiency is affected, and the labor intensity of workers is increased are prevented.

Owner:靖江市中元钢构有限公司

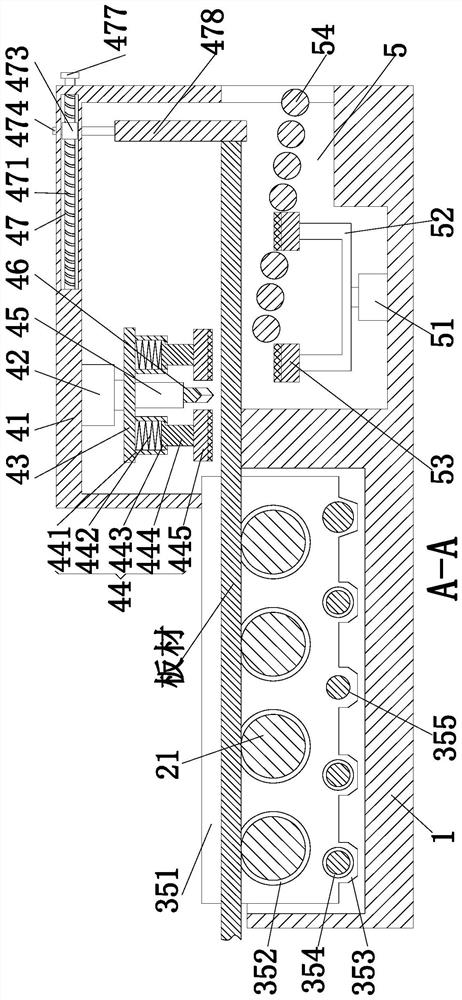

Chamfering equipment used after metal plate cutting

InactiveCN113458793APrevent affecting cutting accuracyFunctions that prevent affecting cutting accuracyOther manufacturing equipments/toolsLarge fixed membersStructural engineeringMachine

The invention discloses chamfering equipment used after metal plate cutting. The chamfering equipment comprises a machine body shell, a working cavity is formed in the machine body shell, first connecting shafts are fixedly arranged in the working cavity, the left positions and the right positions of the first connecting shafts are symmetrical, leveling auxiliary wheels are rotationally arranged on the first connecting shafts, and a leveling device capable of guiding and leveling a metal plate is arranged above the leveling auxiliary wheels. According to the chamfering equipment, arranged leveling wheels cooperate with the leveling auxiliary wheels to press the metal plate, arranged clamping guide wheels are close to each other to clamp the metal plate, the leveling wheels and the clamping guide wheels can rotate at the same time, the functions of pressing, clamping and fixing the metal plate and preventing the metal plate from shaking and affecting subsequent machining, the function of pressing and leveling the surface of the metal plate and the function of feeding the metal plate rightwards are achieved, arranged pressing wheels cooperate with pressing auxiliary wheels so that the metal plate can be firmly pressed, and the function of preventing the metal plate from shaking and affecting the cutting precision during cutting is achieved.

Owner:徐州恒乾紧固件制造有限公司

Wire cutting machine

InactiveCN107790832ASimple structureEasy to operateMeasurement/indication equipmentsLarge fixed membersWire cuttingEngineering

The invention discloses a wire cutting machine which comprises a nut and a lead screw. The nut comprises an outer nut body and an inner nut body. The outer nut body is arranged on the inner nut body in a sleeving manner. The inner nut body is arranged on the outer portion of the lead screw in a sleeving manner and can move on the lead screw. A spiral groove is formed in the inner nut body. An inclined cutting portion is arranged at the end of one side of the lead screw. An elastic locating part embedded in the cutting portion is arranged on the cutting portion. An arc groove carrying out pathguiding on the elastic locating part is formed in the outer nut body. A locating groove with the depth larger than that of the arc groove is formed in one end of the arc groove. A locating bearing isarranged on the contact face of the inner nut body and the outer nut body. The wire cutting machine is simple in structure, convenient to operate, low in price, reliable in performance and capable ofachieving the function of automatic limiting protection.

Owner:南通冒氏智能装备有限公司

Cardboard conveying device and conveying method of a cardboard opening machine for a printing and packaging machine

Owner:XIAN UNIV OF TECH

Plastic dropper mold blanking device and control method thereof

PendingCN113733527AIncrease productivityGuaranteed precisionStructural engineeringManufacturing engineering

The invention discloses a mold, and particularly relates to a plastic dropper mold blanking device and a control method thereof. The plastic dropper mold blanking device comprises a fixed mold plate and a movable mold plate, the movable mold plate is provided with a blanking port, and the shape of the blanking port is matched with the shape of a plastic dropper. A cutting knife can extend into the blanking port to cut a plastic dropper semi-finished product after blow molding, and the shape of the cutting knife is matched with that of the plastic dropper, so that the flash of the plastic dropper semi-finished product can be cut, and the production efficiency is improved. As a first driving mechanism drives the fixed mold plate to move, a second driving mechanism drives the cutting knife to move, a first positioning device is arranged on the first driving mechanism, and a second positioning device is arranged on the second driving mechanism, the action accuracy of the first driving mechanism and the second driving mechanism can be guaranteed, so that the cutting accuracy is guaranteed.

Owner:玉环楚港模具科技有限公司

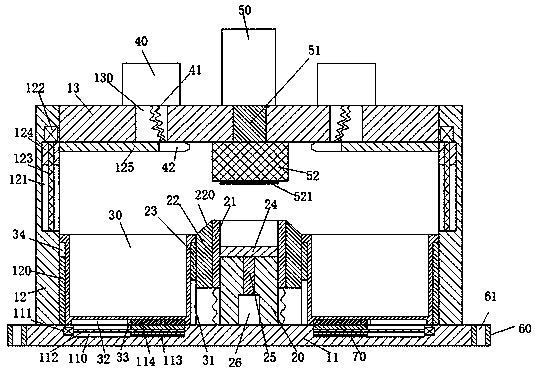

An automatic high-precision pvc wallboard processing equipment

ActiveCN109262710BPrevent affecting cutting accuracyMetal working apparatusElectric machineMechanical engineering

The invention discloses automated high-precision PVC wallboard processing equipment in the field of wallboard processing. The equipment includes a machine body, an L-shaped bracket is fixedly welded to the left side wall of the machine body and includes a vertical member and a horizontal member, and a cutting device is fixed to the left side wall of the vertical member; a horizontal retractable air cylinder is fixed to the upper surface of the horizontal member through bolts, a first motor bracket is arranged at the end of the horizontal air cylinder and fixedly connected with a retractable rod of the horizontal retractable air cylinder, a rotating motor is fixed into the first motor bracket, a vertical connecting board is arranged below the rotating motor, and an output shaft of the rotating motor is fixed to the vertical connecting board. According to the provided automated high-precision PVC wallboard processing equipment, when a cutting motor drives cutting pieces to cut a PVC wallboard, the PVC wallboard can be limited and fixed through limiting blocks, and the situation that the PVC wallboard slants during cutting and the cutting precision is thus influenced is avoided.

Owner:安徽可尔海思新材料科技有限公司

Improved environment-friendly pad machining device

ActiveCN108202358ARun smoothlyReduce operational difficulty and labor intensityMetal working apparatusMechanical engineeringEngineering

The invention provides an improved environment-friendly pad machining device. The improved environment-friendly pad machining device comprises a base frame composed of a base, two frame rods and a storage plate. The two frame are fixedly mounted on the base in a left-right correspondence mode. The storage plate is fixedly mounted at the upper ends of the two frame rods. A first ejection device isfixedly mounted at the midpoint of the upper end face of the storage plate. A first ejection rod which is connected with the first ejection device is smoothly mounted at the midpoint of the storage plate. The lower end of the first ejection rod is fixedly mounted on a tip. An annular cutting blade is arranged on the bottom end face of the tip. A cutting table is mounted on the upper end face of the base and located under the tip and comprises a bottom column and a sleeve. The bottom column is smoothly connected with the sleeve in a matched mode. The bottom end of the bottom column is fixedly connected with the base. An elastic strip is fixedly mounted between the lower end of the sleeve and the base. An ejection plate is further smoothly mounted in the sleeve. A second ejection rod is smoothly mounted in the bottom column.

Owner:NANTONG JIHE RICE CO LTD

Cutting device for latticed column part machining

ActiveCN114083327AImprove securityEnsure personal safetyFeeding apparatusLarge fixed membersStructural engineeringMachining

The invention relates to the technical field of cutting equipment, in particular to a cutting device for latticed column part machining, which comprises a workbench and a guide sliding rail fixed to one side of the workbench and internally provided with a sliding table; a cutting lifting adjusting assembly which is arranged in the guide sliding rail and is used for adjusting the cutting depth up and down; and a material bearing assembly which is arranged on the portion, on one side of the guide sliding rail, of the table body on the workbench and comprises a rotating assembly arranged in the material bearing assembly and used for driving materials to be cut to be rotationally cut and a material clamping assembly arranged in the middle of one side of the material bearing assembly. According to the device, a clamping and conveying assembly is used for clamping and automatically conveying a latticed column part, so that when the latticed column part is cut, the manual use condition and the labor intensity are greatly reduced, meanwhile, the safety of cutting work is improved, and the personal safety of workers is guaranteed.

Owner:安徽科汇钢结构工程有限公司

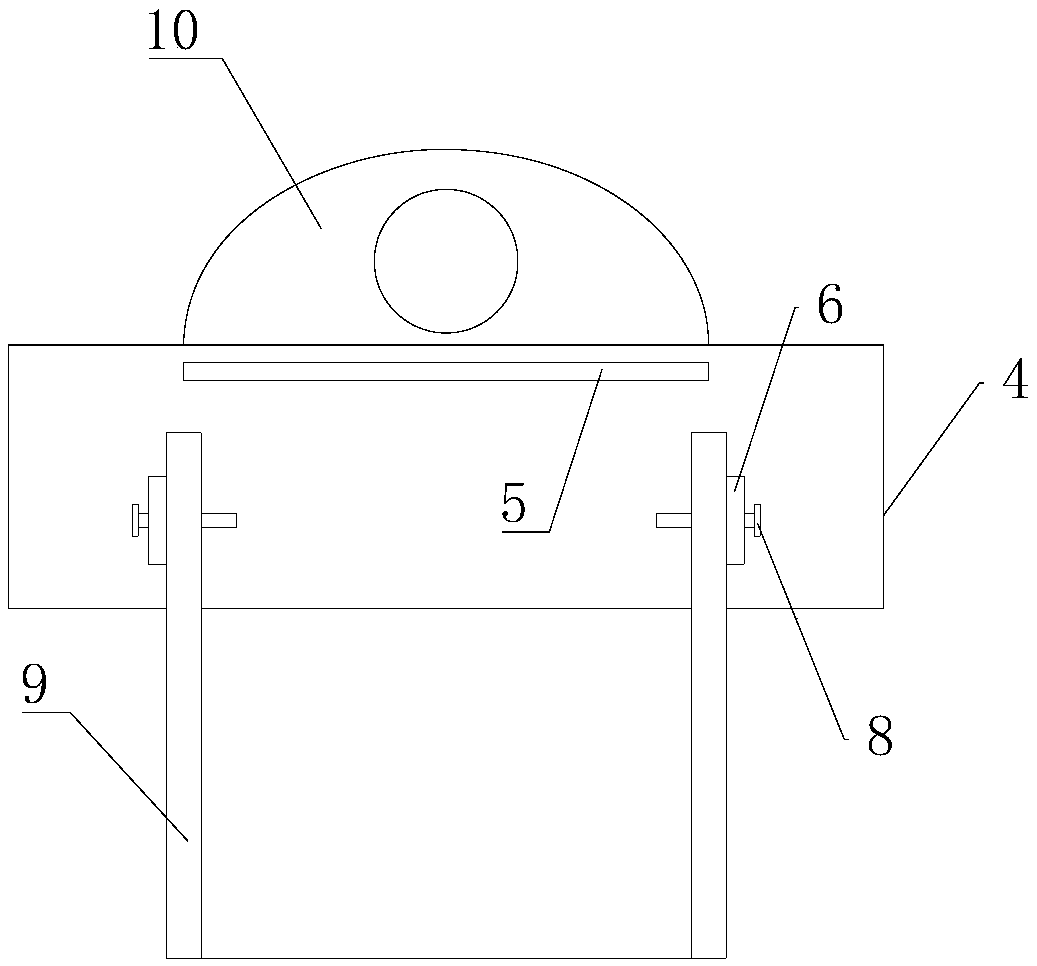

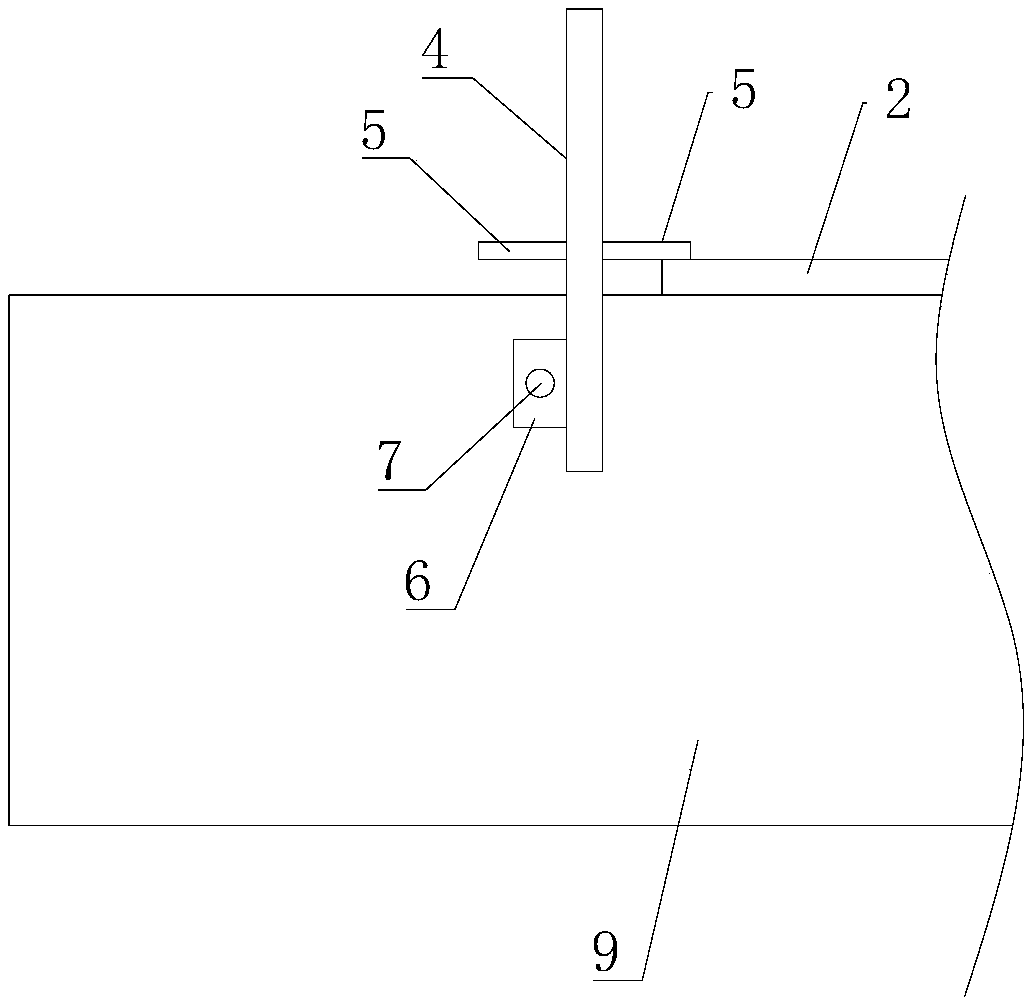

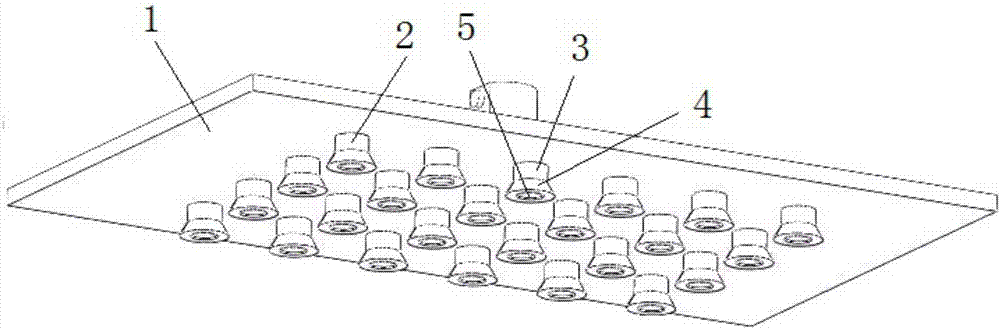

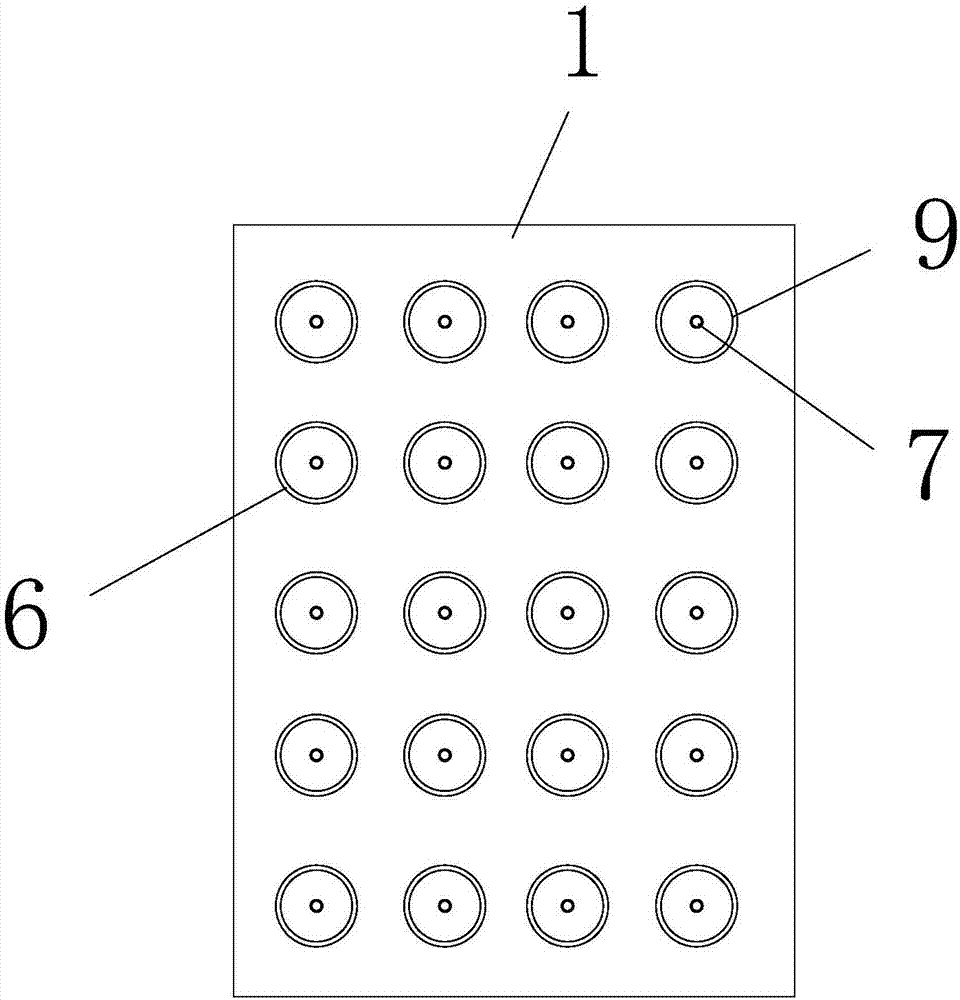

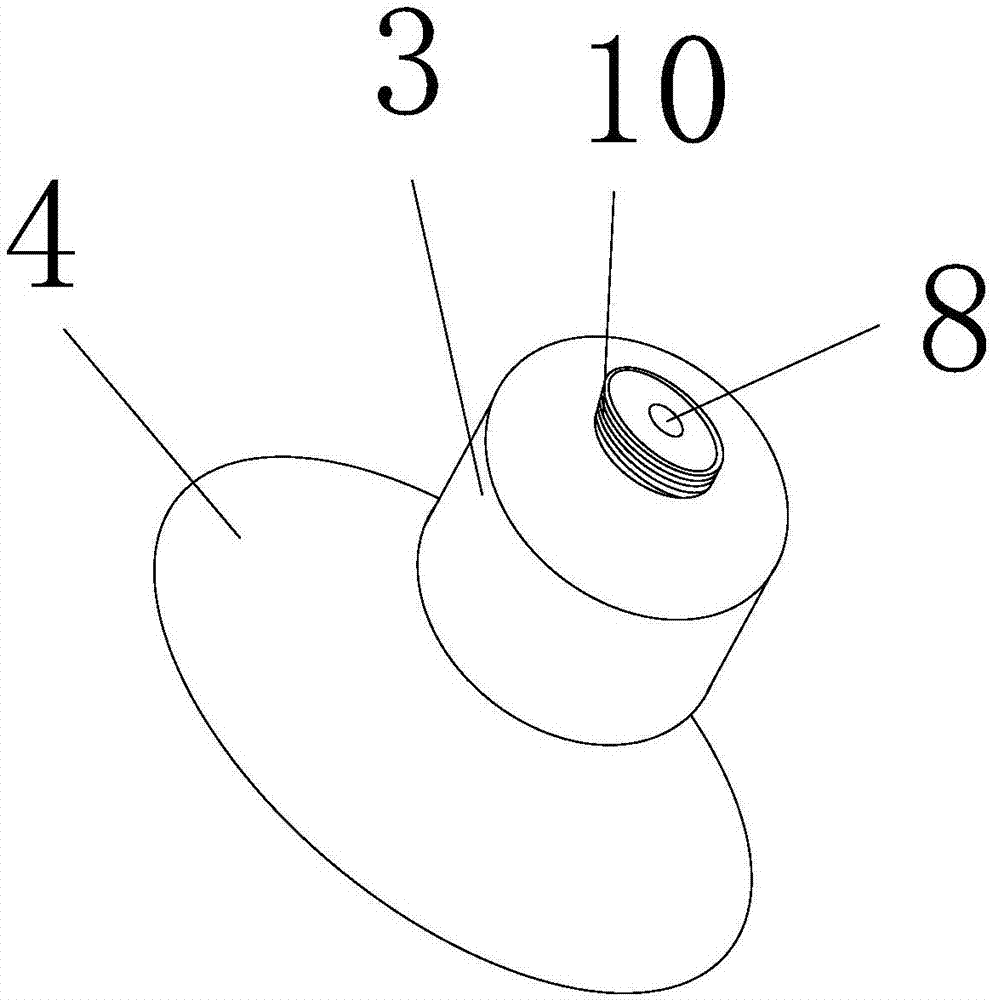

Suction cup clamp for cutting of medium density fiberboard

InactiveCN106903631APrevent affecting cutting accuracyWork holdersMedium density fiberboardEngineering

The invention relates to a suction cup clamp for cutting of a medium density fiberboard. The suction cup clamp comprises a flat plate type material fetching disc and a plurality of suction pieces. Each suction piece comprises a connecting column and a bowl-shaped suction cup, wherein one end of the connecting column is connected with the bottom of the material fetching disc, the other end of the connecting column is connected with the suction cup which is in the shape of a bowl, and a supporting protrusion is arranged at the bowl-shaped bottom of the suction cup and is lower than the suction cup. Compared with a clamping type clamp in the prior art, the board is fixed and moved directly through the suction effect of the suction cup clamp, the suction pieces can be arranged in proper positions of the material fetching disc as required, and when the board is cut one time or several times, cut-off small blocks are still connected with the suction cup, so that repeated positioning and re-clamping are not needed; and during cutting, the supporting protrusions in the suction cups are pressed to fix and support the board, so that the cutting precision is prevented from being affected by deflection of the board.

Owner:WUHAN UNIV OF SCI & TECH

High-precision cutting equipment for automobile part machining and cutting method thereof

InactiveCN113618257AEasy to useCutting efficiency blockVehicle componentsMetal working apparatusStructural engineeringWheel drive

The invention discloses high-precision cutting equipment for automobile part machining and a cutting method thereof. The high-precision cutting equipment comprises an arc-shaped frame body and a sleeve, the top end of a sleeve rod is fixedly connected with a cleaning base, an inner cotton body is fixedly installed inside the cleaning base, and filter screens are fixedly installed in two inclined plates of the arc-shaped frame body. A fixing frame is arranged at the top of a material plate, a supporting base and a pressing plate are arranged at the bottom of the fixing frame, the pressing plate and the supporting base are matched to fix a plate, the cleaning base and the inner cotton body are further arranged at the top of the supporting base, the bottom of the plate can be cleaned, the situation that the cutting precision is affected due to unstable plate fixing caused by particle contamination is prevented, meanwhile, the pressing plate can pull the plate to move up and down, when the position of the plate needs to be changed, the plate and a traction wheel can be driven to be located at the same height, then the traction wheel drives the plate to slide, different positions of the plate are polished, the traction wheel and the plate are not in a contact state during cutting, and the cutting precision is improved.

Owner:重庆市璧山区合成机械制造有限公司

Galvanized pipe laser cutting equipment for municipal railings

PendingCN114273794APrevent sideslipEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringLaser cutting

The invention relates to the technical field of cutting devices, in particular to galvanized pipe laser cutting equipment for municipal railings. Comprising a cutting machine and a fixing assembly, the fixing assembly comprises two clamps and a press mechanism, the press mechanism comprises a longitudinal air cylinder, a connecting frame, a pressing plate and an extension plate, when a galvanized pipe is cut, the two sides of the galvanized pipe are clamped and fixed through the clamps, the galvanized pipe is preliminarily fixed to the cutting machine, and the longitudinal air cylinder moves downwards the connecting frame to enable the pressing plate to press and fix the galvanized pipe; therefore, the galvanized pipe is firmly fixed on the cutting machine, the galvanized pipe is prevented from sideslip when the cutting machine cuts, the cutting precision of the galvanized pipe is improved, and the problems that in the prior art, pipe cutting and manual pipe fixing are unstable, and the cutting precision is reduced are solved.

Owner:重庆市中凯金属制品涂装有限公司

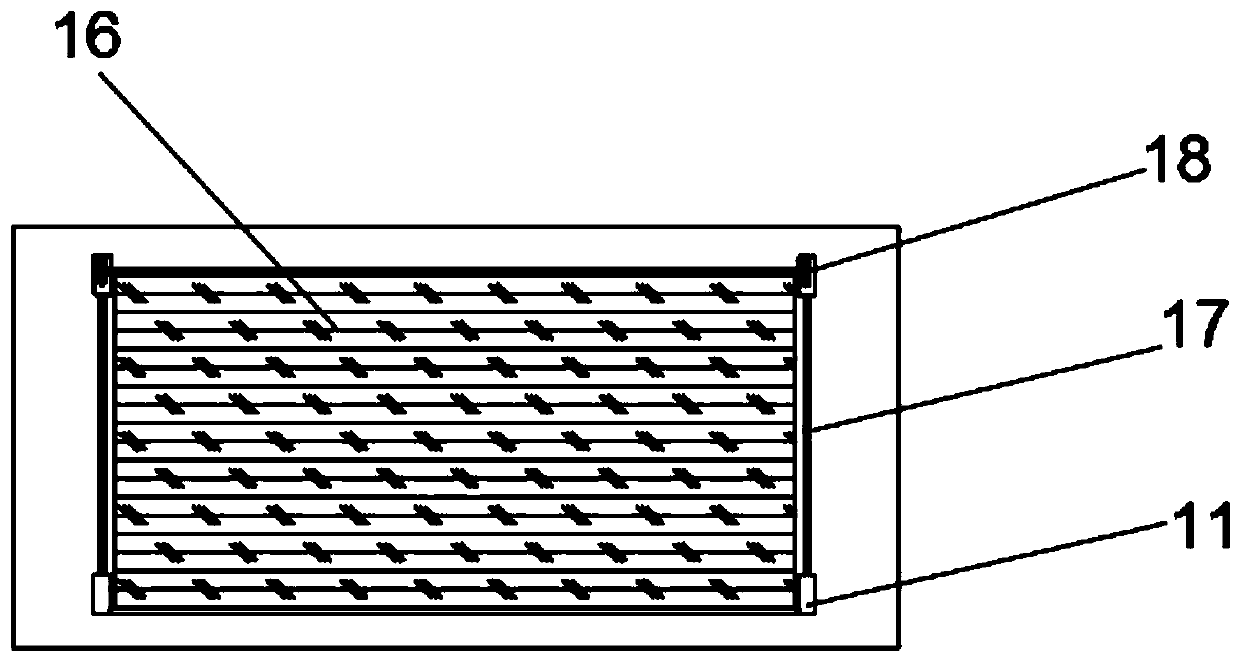

A light guide column laser splitter

ActiveCN112496575BPrevent affecting cutting accuracyAvoid fireLaser beam welding apparatusLight guideEngineering

A light guide column laser slitting device, comprising: a cutting assembly, including a support member, the support member is provided with a pair of translation members, each translation member is provided with a telescopic member, and the telescopic member is provided with an angle adjustment member, and the angle adjustment member is provided with The lateral movement member is provided with a cutting member; the clamping assembly includes a pair of side frame members arranged on both sides of the support member, clamping members are provided at both ends of the side frame member, and the outer side of the side frame member is provided with Move support members. The invention adopts laser to cut the light guide column. During the cutting process, no debris will be generated, so as to avoid fire. During the cutting process, the cutting of multiple light guide columns can be completed. During the cutting process, both ends of the light guide columns can be clamped. During the cutting process, the local clamping and positioning of the light guide columns can be performed to prevent the bending of the light guide columns from affecting the cutting. precision.

Owner:四川恒格光电科技有限公司

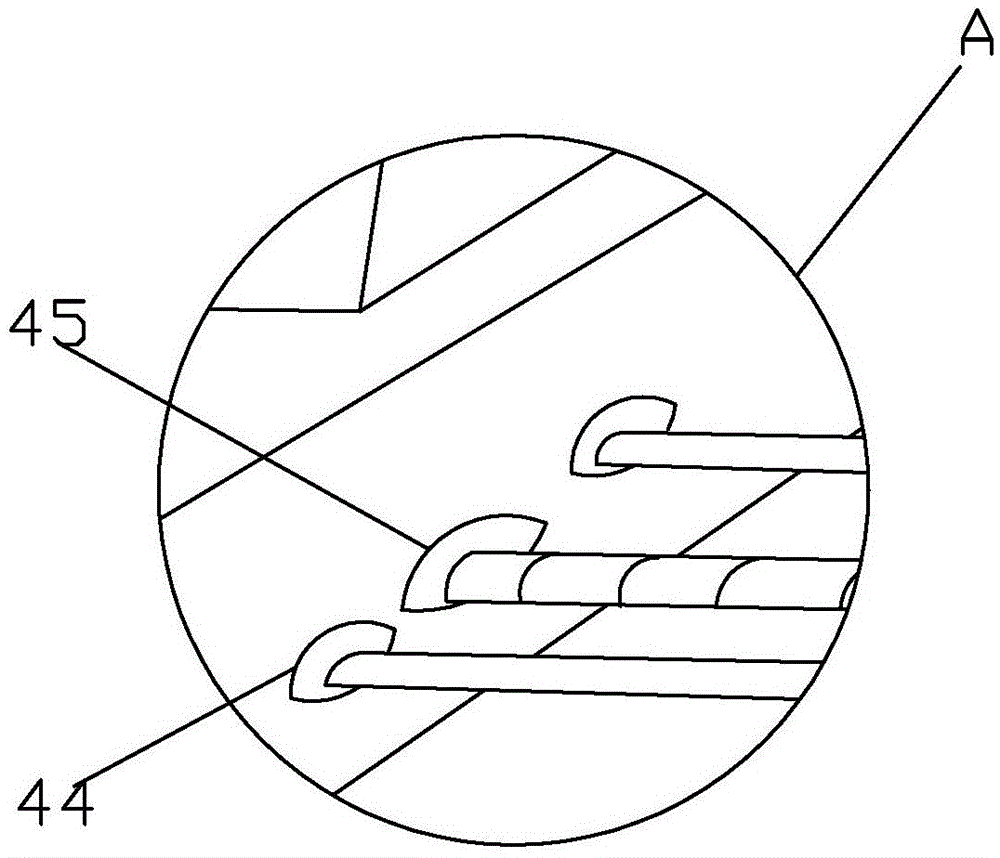

vertical granulator

The invention relates to the field of manufacturing equipment, in particular to a vertical granulator. The vertical granulator comprises a fly cutter used for conducting cutting. The fly cutter comprises a flat and straight installing part, a cutter body obliquely arranged on the side edge of the installing part, and a blade arranged at the bottom of the cutter body. The lower end face of the cutter body is located below the lower end face of the installing part. The installing part, the cutter body and the blade are integrally formed. The plane where the blade is located is perpendicular to the plane where the cutter body is located. A first included angle is formed by the face, close to the outer side, of the cutter body and the face where the blade is located. A second included angle is formed by the face, close to the inner side, of the cutter body and the face where the blade is located. The first included angle ranges from 8 degrees to 12 degrees, and the second included angle ranges from 25 degrees to 35 degrees. According to the vertical granulator, the fly cutter circumferentially moving is adopted, the fly cutter is perpendicular to the material strip conveying direction, and a product obtained through cutting is attractive in appearance and free of inner arc tip, long in service life and high in cutting precision.

Owner:DONGGUAN BOZHAN MACHINERY SCI & TECH CO LTD

A cloth cutting machine for tie processing

ActiveCN105177973BPrecise positioningAvoid the phenomenon of jumping clothSevering textilesMechanical engineeringTextile

The invention discloses a cloth breaking machine for tie processing. The cloth breaking machine comprises a working table and a cloth breaking device. The cloth breaking device comprises a horizontal locating plate, a cloth breaking mechanism and a control panel. A horizontal sliding groove is formed in the top face of the horizontal locating plate. The cloth breaking mechanism is connected into the horizontal sliding groove in a sliding mode. A steam box is arranged at the left side of the cloth breaking device. A supporting table plate is arranged below the working table. A U-shaped groove is fixedly formed in the supporting table plate. A collecting cylinder is connected into the U-shaped groove in a rotating mode. Two supporting rods perpendicular to the working table are arranged at the right side of the cloth breaking device. A discharging cylinder is arranged between the two supporting rods. A second supporting roller is arranged between the horizontal locating plate and the supporting rods. The cloth breaking machine is simple in structure and high in practicality, cloth can be located conveniently, errors are reduced, the situation that because the cloth of a traditional cloth breaking machine is exposed outside and cut, cloth jumping is caused easily can be effectively avoided, the cloth is prevented from wrinkling when rolling to the upper collecting cylinder, the working efficiency of the cloth breaking machine is improved, cutting precision of the cloth is improved, and use is safe and reliable.

Owner:苏州盛泽科技创业园发展有限公司

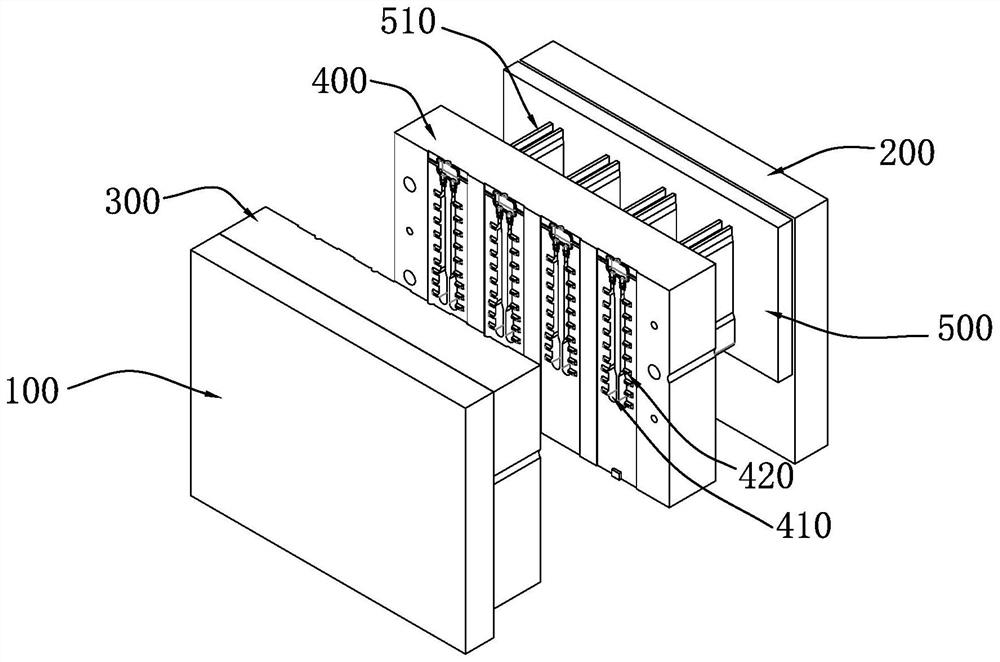

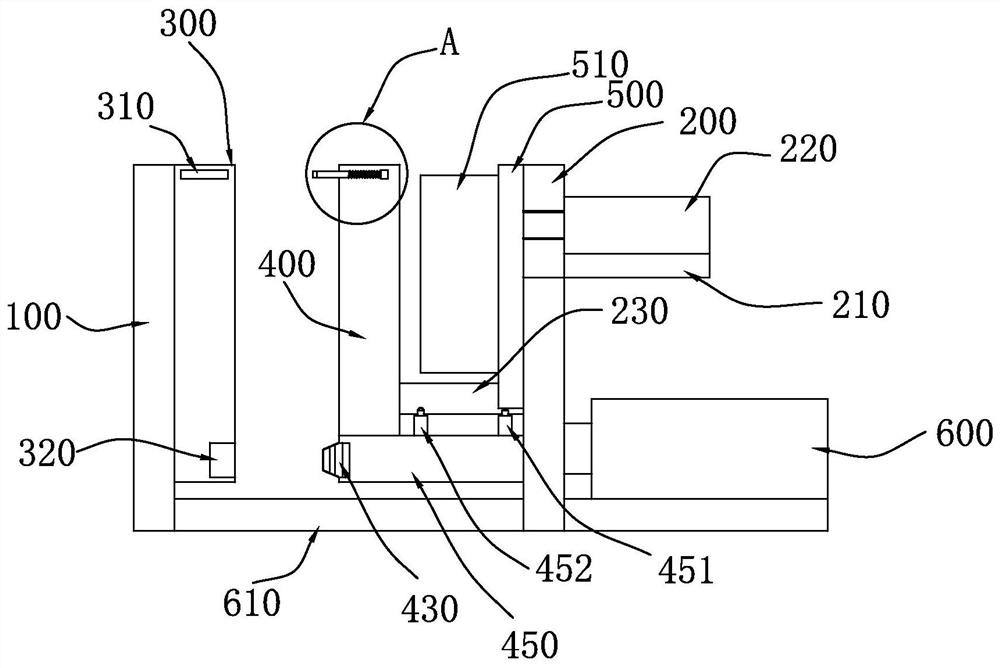

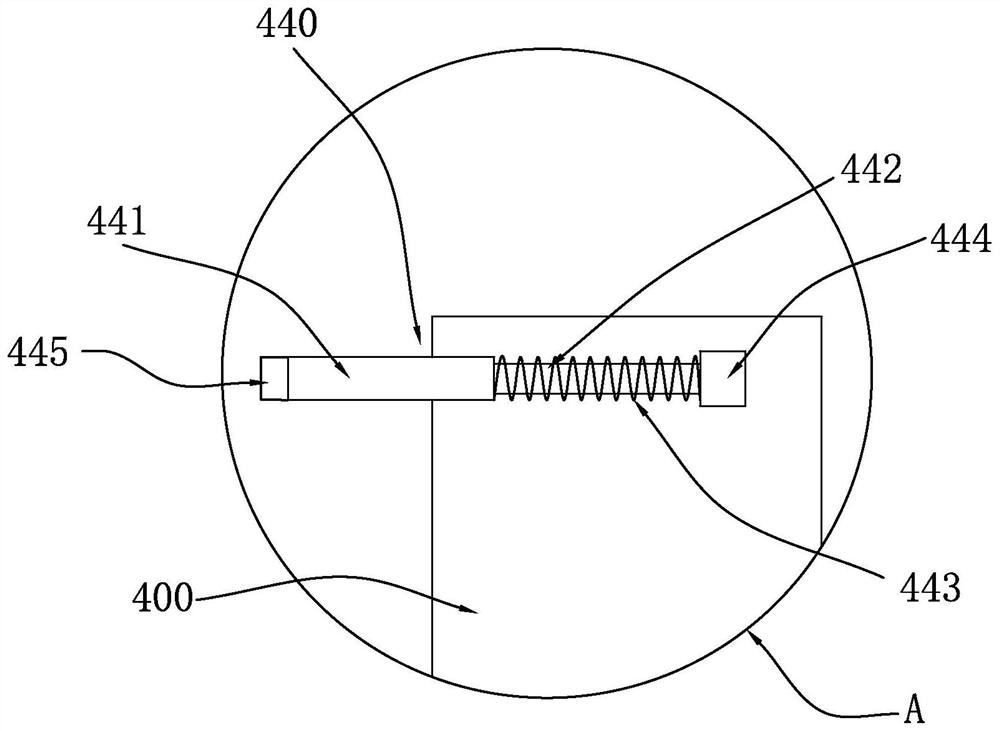

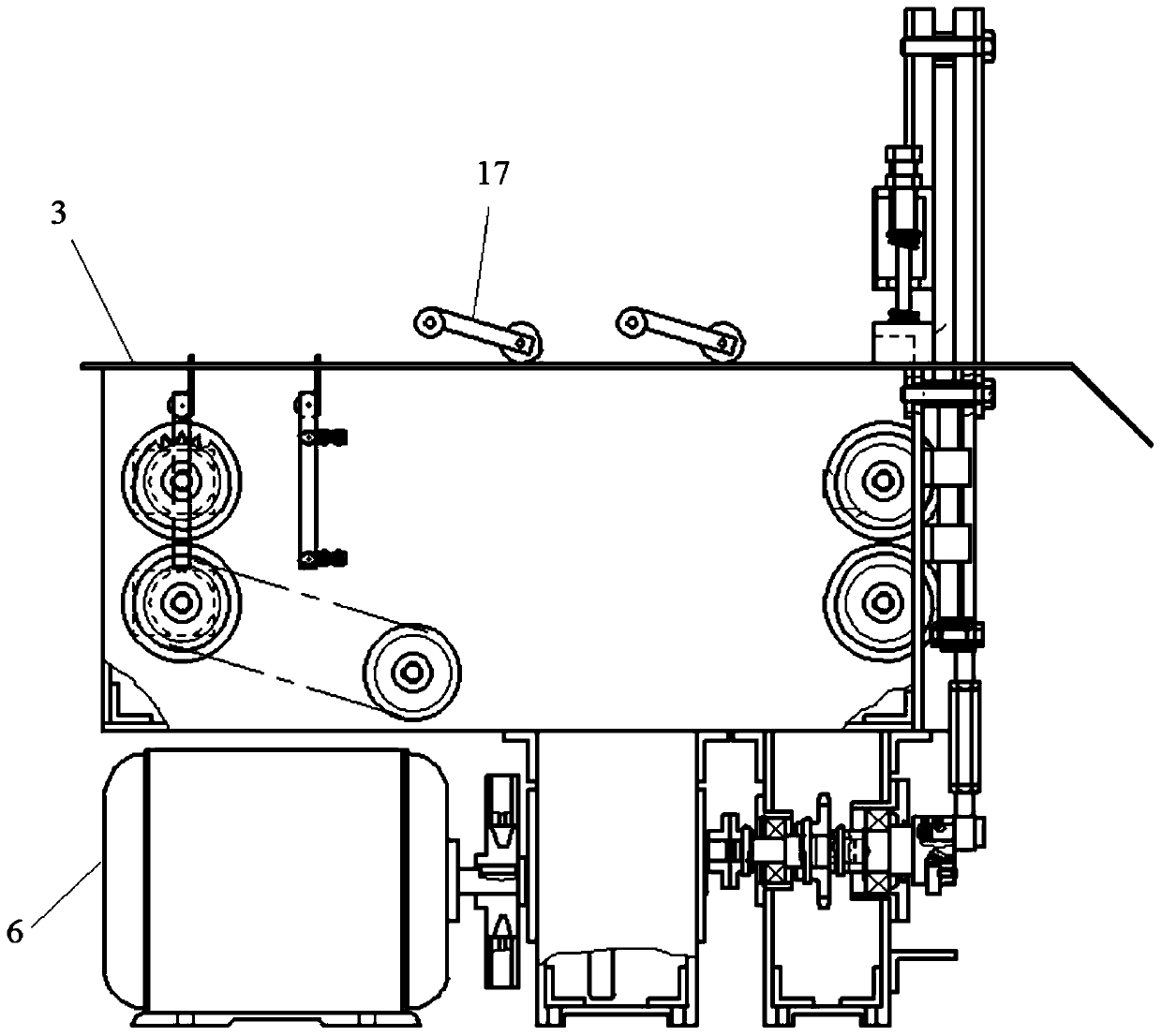

Paperboard slitting machine paperboard conveying device and conveying method for printing packaging machine

The invention discloses a paperboard slitting machine paperboard conveying device for a printing packaging machine. A stepping motor is arranged in a machine frame of the device, an output shaft of the stepping motor is connected with a rotating shaft, the two ends of the rotating shaft are provided with a plurality of first chain wheels, a pairs of first transverse rods are arranged above the first rotating shaft, a plurality of second chain wheels are arranged on the pair of first transverse rods, a pair of second transverse rods are arranged above the first transverse rods, a plurality of third chain wheels are arranged on the pair of second transverse rods, the first chain wheels and the corresponding second chain wheels, as well as the second chain wheels and the corresponding third chain wheels are connected through connecting rods, a third transverse rod is arranged between the two innermost third chain wheels, and a paper pushing device is arranged on the third transverse rod.The invention further discloses a paperboard slitting machine paperboard conveying method for the printing packaging machine. The device and method are used for realizing conveying and accurate positioning of paperboards, so that the production efficiency is improved, and waste is reduced.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com