vertical granulator

A granulator and granulation technology, which is applied in the field of manufacturing equipment, can solve the problems of unsightly appearance of the product, reduce the precision of granulation, and affect the quality of the product, and achieve the effect of improving the appearance, sharpness, and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

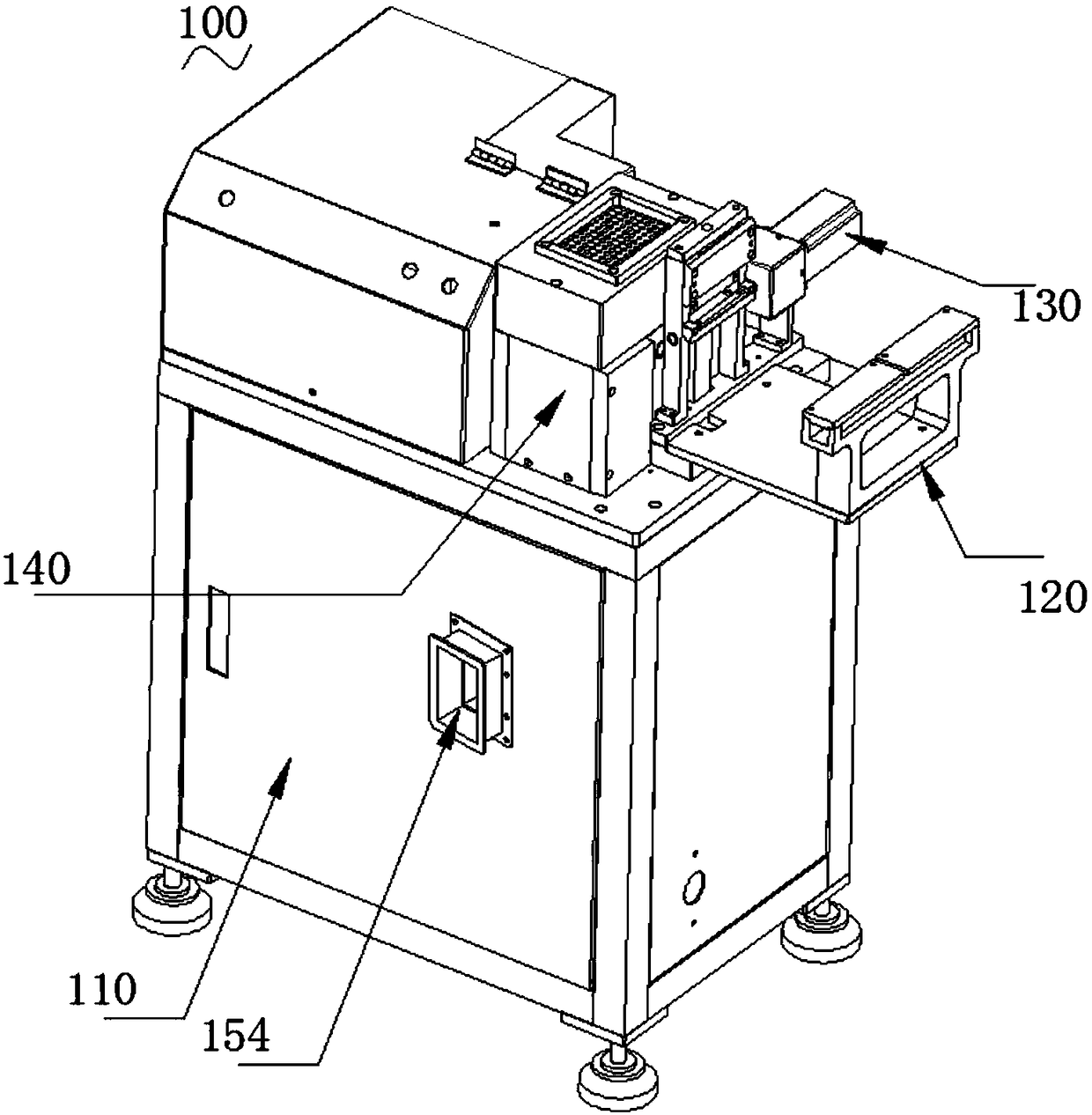

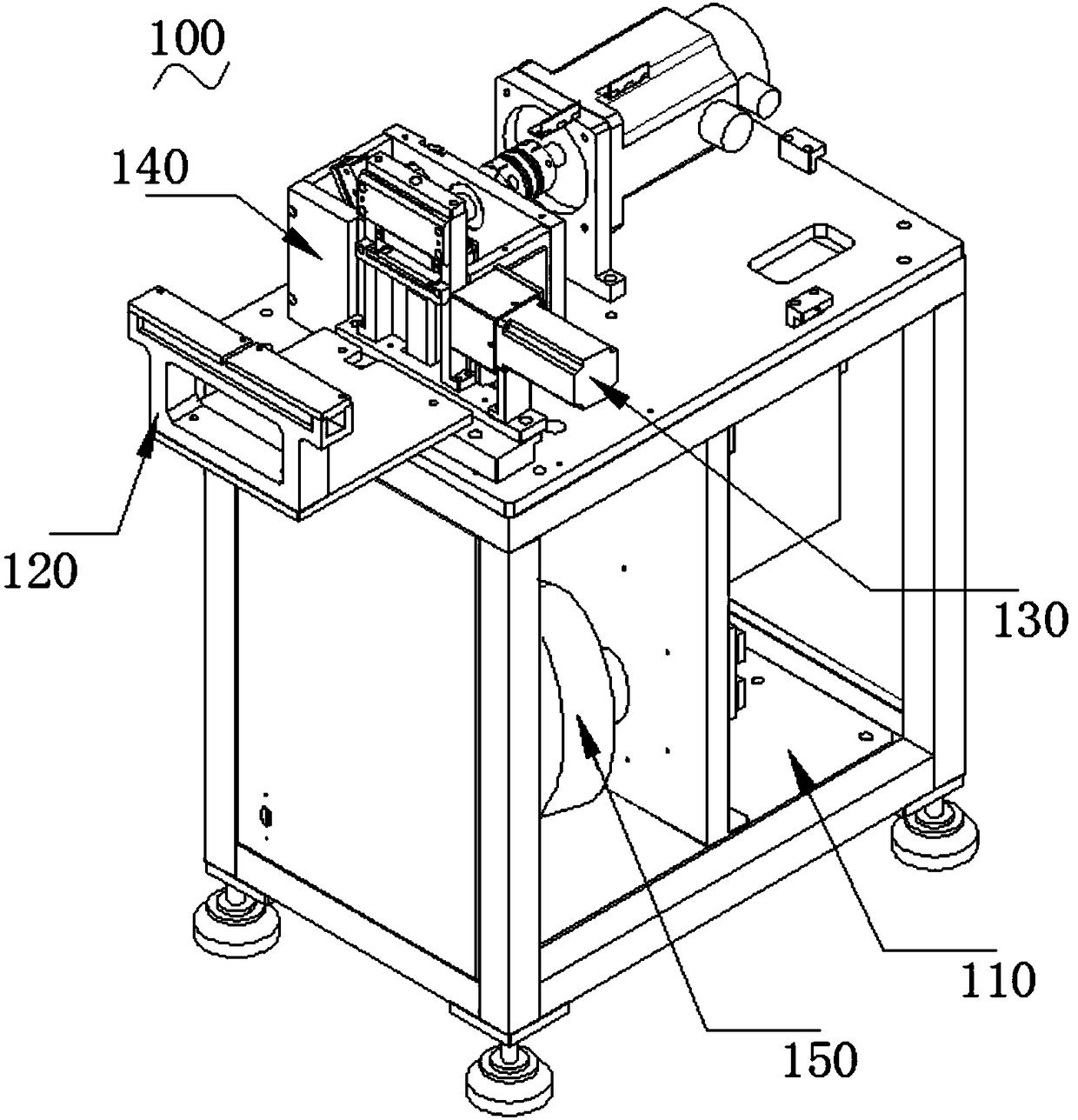

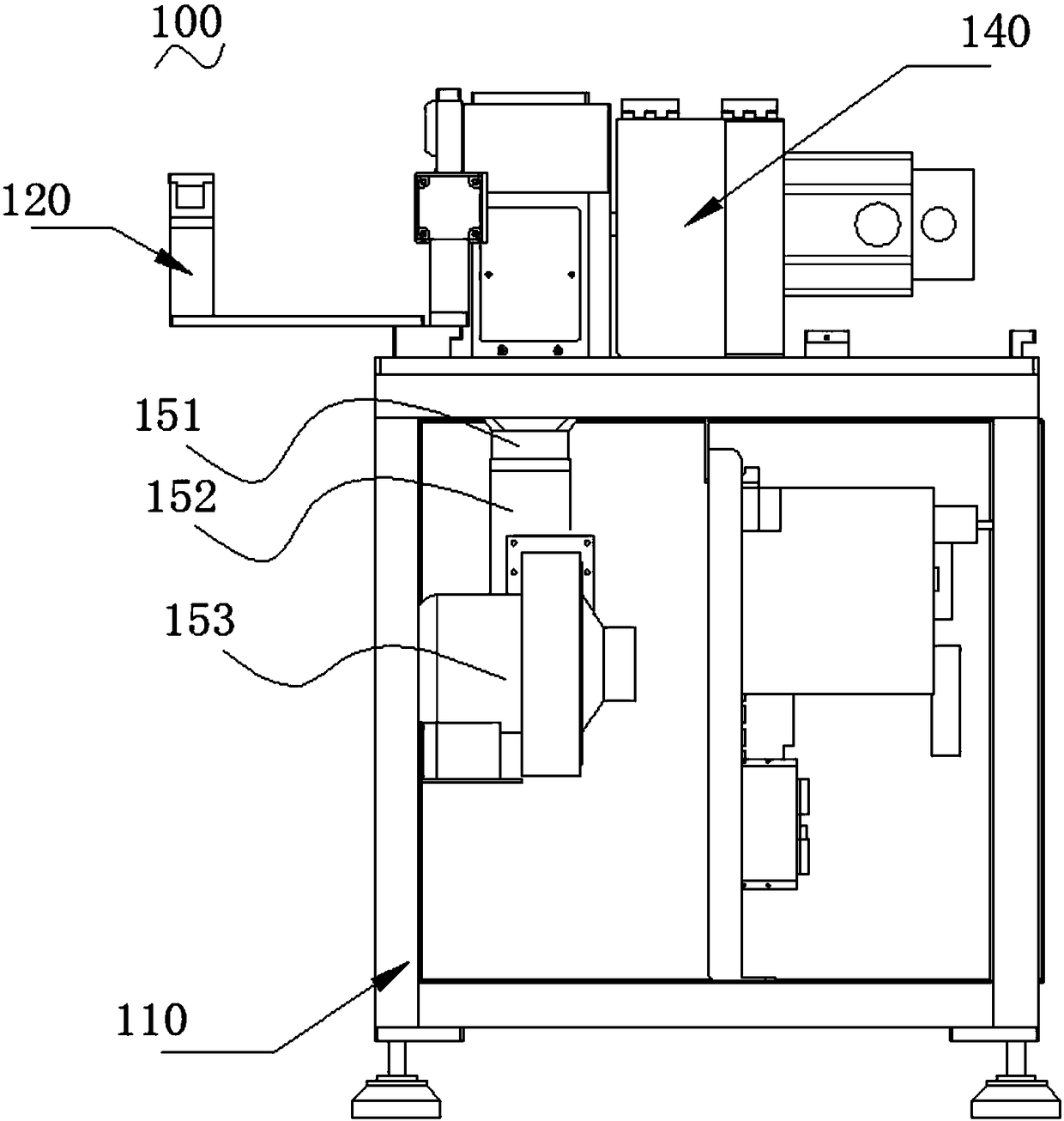

[0039] like Figure 1 ~ Figure 3 Shown are respectively a perspective view, an expanded perspective view and a front view of the present invention.

[0040] The vertical granulator 100 comprises a frame 110 which is hollow inside, a filter mechanism 120 installed above the frame 110, a wire delivery mechanism 130, a granulator 140 and a discharge mechanism 150 installed inside the frame 110; The filter mechanism 120 is located on the side above the frame 110, and is used to filter the nylon thread. The nylon wire is transported from the filter mechanism 120 to the pelletizing mechanism 140, and the pelletizing mechanism 140 is used to cut the nylon wire into nylon sand. Outward output.

[0041] like Figure 4 ~ Figure 6 As shown, they are respectively a perspective view, an expanded perspective view and another perspective view of the pelletizing mechanism of the present invention.

[0042] The pelletizing mechanism 140 includes a flying knife 144 for cutting, and also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com