Wire cutting machine

A technology of cutting machine and wire, which is applied in the direction of metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve the problems of low cutting efficiency, wire vibration, and affecting cutting accuracy, and achieve low production cost, simple structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

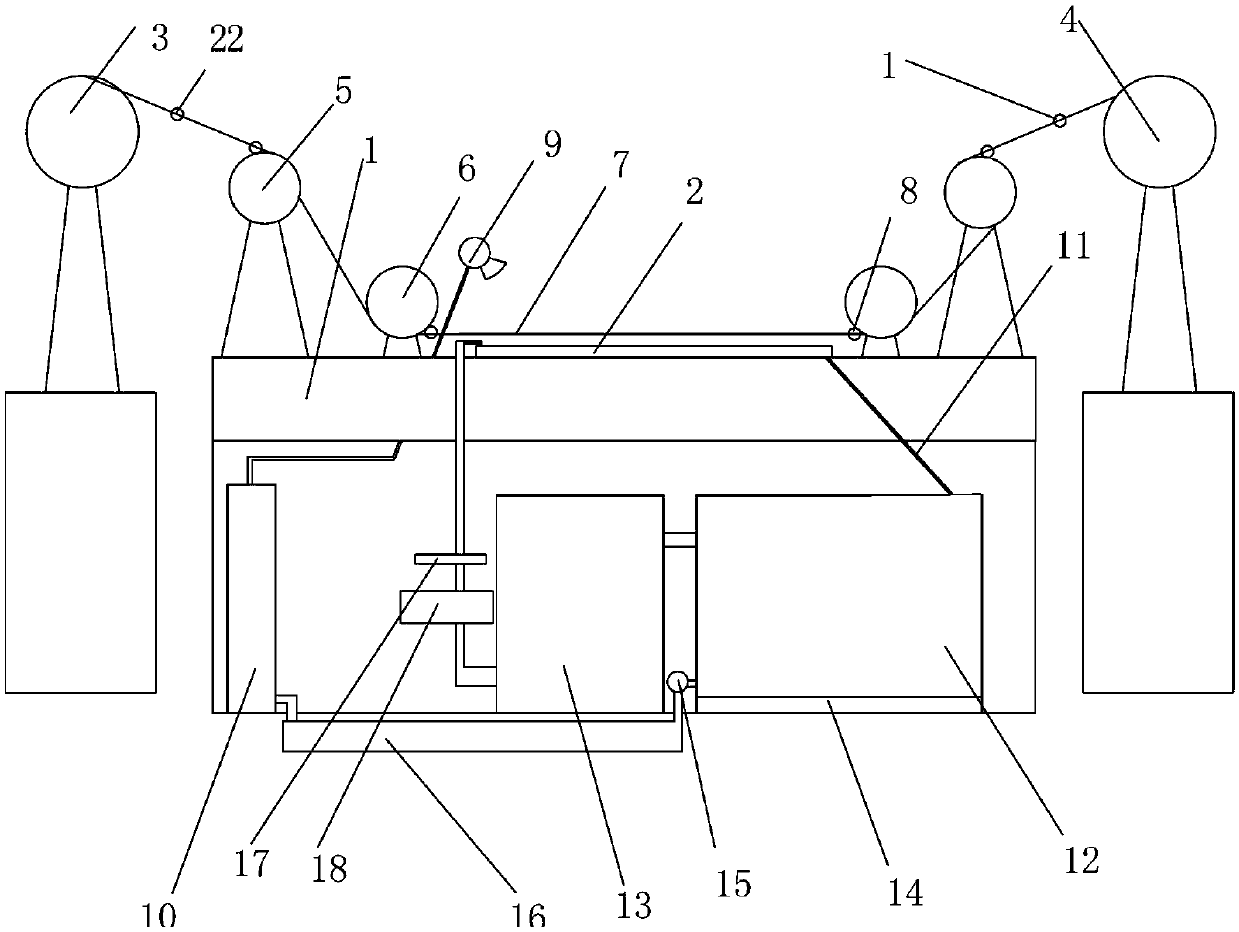

[0017] Such as figure 1 As shown, a wire cutting machine provided by this embodiment includes a bed 1, a workbench 2, a wire storage tube 3, a wire release tube 4, a wire guide wheel 5 and a cutting and cleaning device, and is characterized in that the working The table 2 is set on the bed 1, the wire storage cylinder 3 is detachably arranged on one side of the workbench 2, and the wire discharge cylinder 4 is detachably arranged on the other side of the workbench 2, and the wire storage cylinder 3 and the wire discharge The cylinder 4 controls its working rotation and reversing operation through a servo motor respectively. The godet wheels 5 include more than 3 numbers, and at least 2 of them are placed under the other godet wheels 5 as the bottom godet wheels 6, And the wire guide wheels 5 at the bottom are all parallel to each other on the same straight line, and all the wire guide wheels 5 and the wire storage tube 3 and the wire release tube 4 form a "凵"-shaped structure,...

Embodiment 2

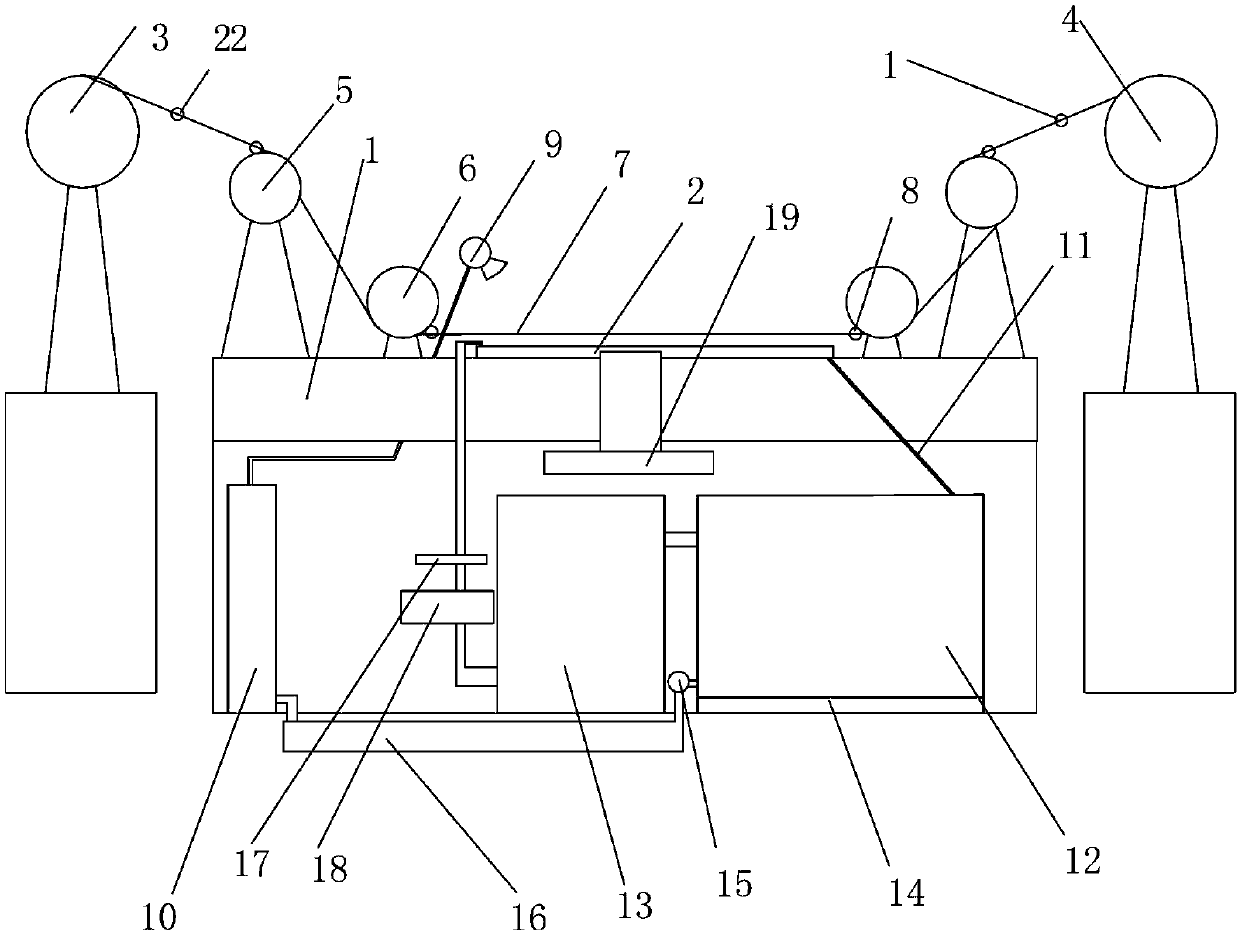

[0021] Such as figure 2 As shown, the general structure of a wire cutting machine provided by this embodiment is the same as that of Embodiment 1, the difference is that, in order to facilitate positioning, the workbench 2 is arranged on the bed 1 through a lifting mechanism 19, and further, The lifting mechanism 19 is an air cylinder or a motor.

Embodiment 3

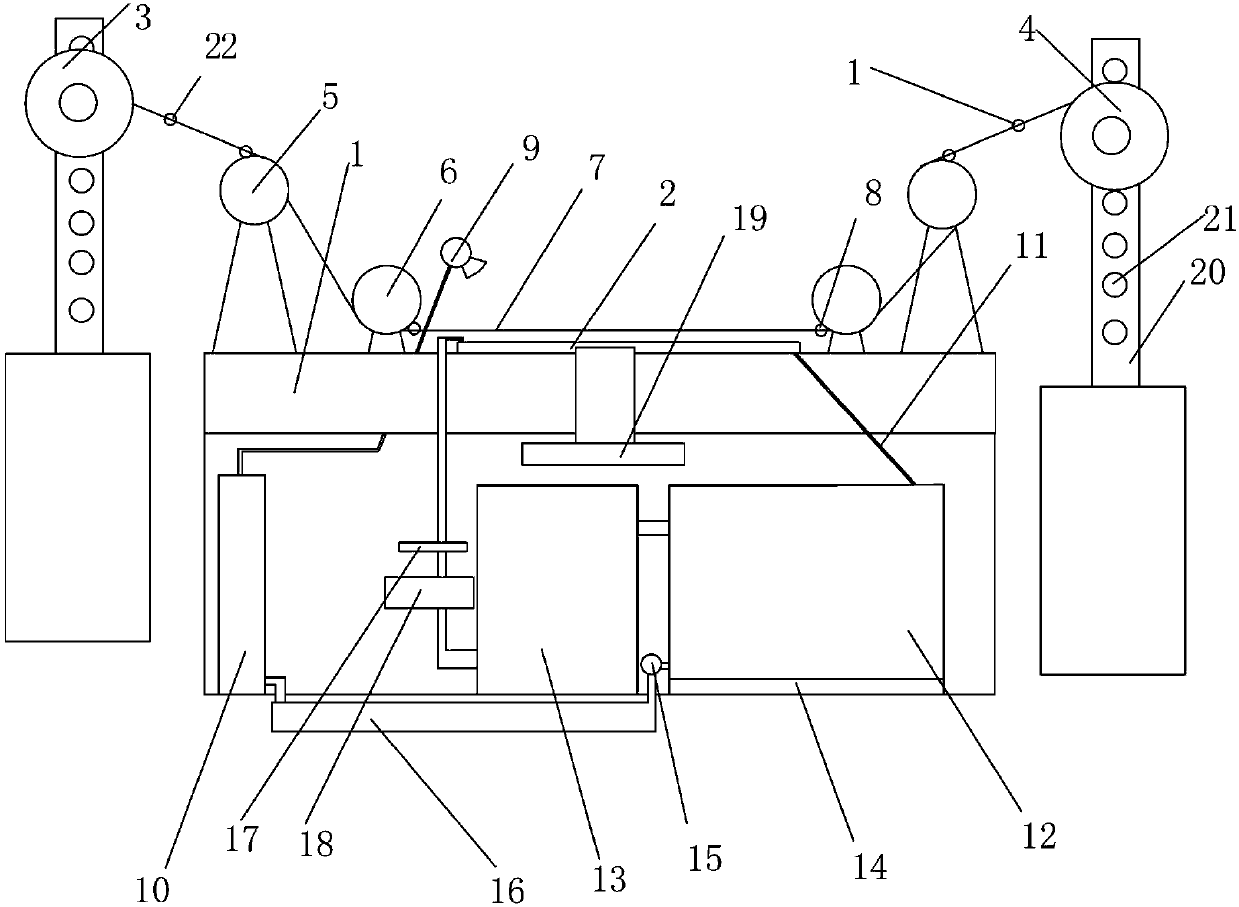

[0023] Such as image 3 As shown, the wire cutting machine provided by this embodiment is further convenient for positioning. A fixing frame 20 is respectively provided on both sides of the bed 1, and the wire storage tube 3 and the wire feeding tube 4 are slidably connected to each other. On the corresponding fixing frame 20 , positioning holes 21 are arranged at intervals in the fixing frame 20 , and the wire storage tube 3 and the wire releasing tube 4 are locked in the positioning holes 21 by locking pieces.

[0024] Further, to prevent jamming, there is a distance difference between the wire storage cylinder 3 and the wire delivery cylinder 4 .

[0025] This embodiment is simple in structure, easy to operate, low in price, low in production cost, and can adjust the height of the workbench according to needs, and monitor the silk thread in real time, and replace it later in case of wear and tear, and position the thread direction to prevent deviation It affects the cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com