A cloth cutting machine for tie processing

A cloth breaking machine and cloth breaking technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of reducing the flatness of the cloth, prone to deviation in cutting, and reducing the cutting accuracy, so as to prolong the service life and improve the safety. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

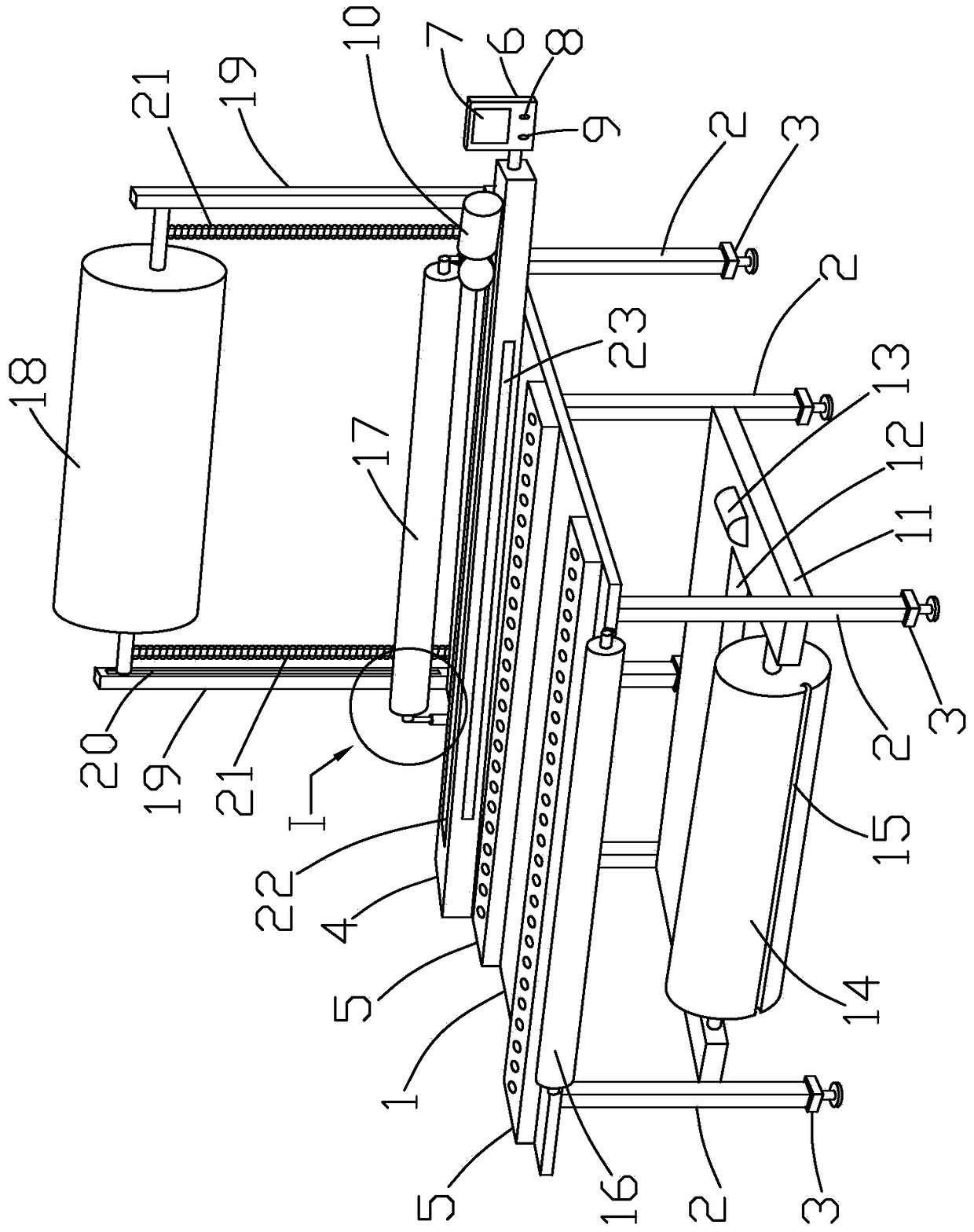

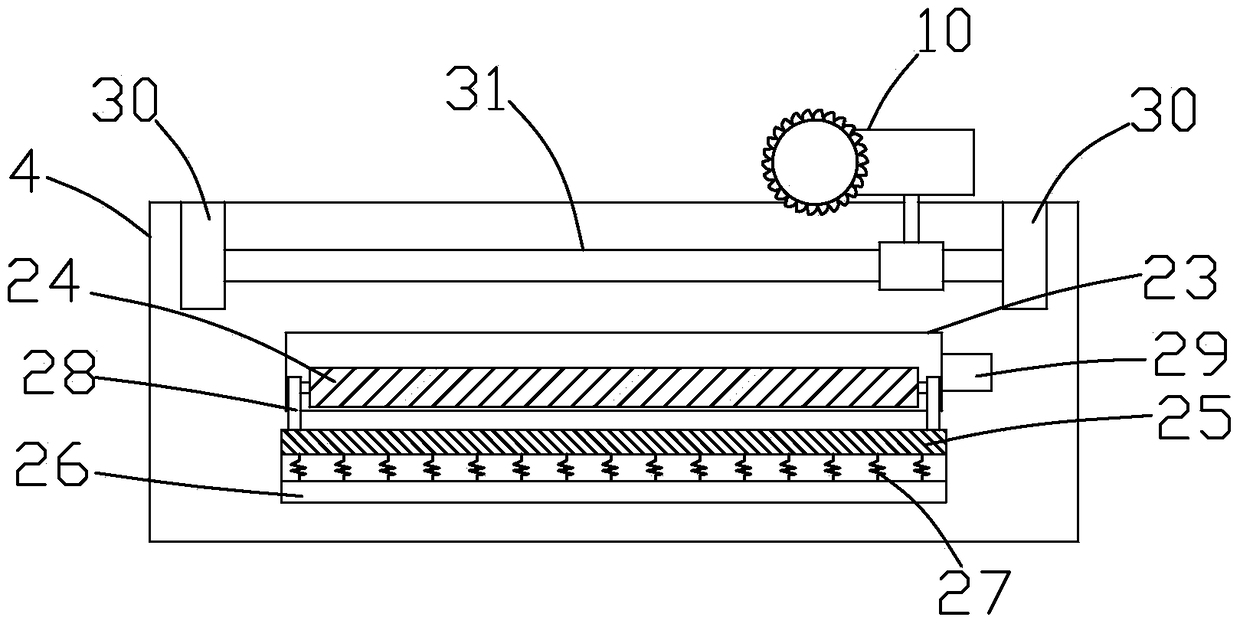

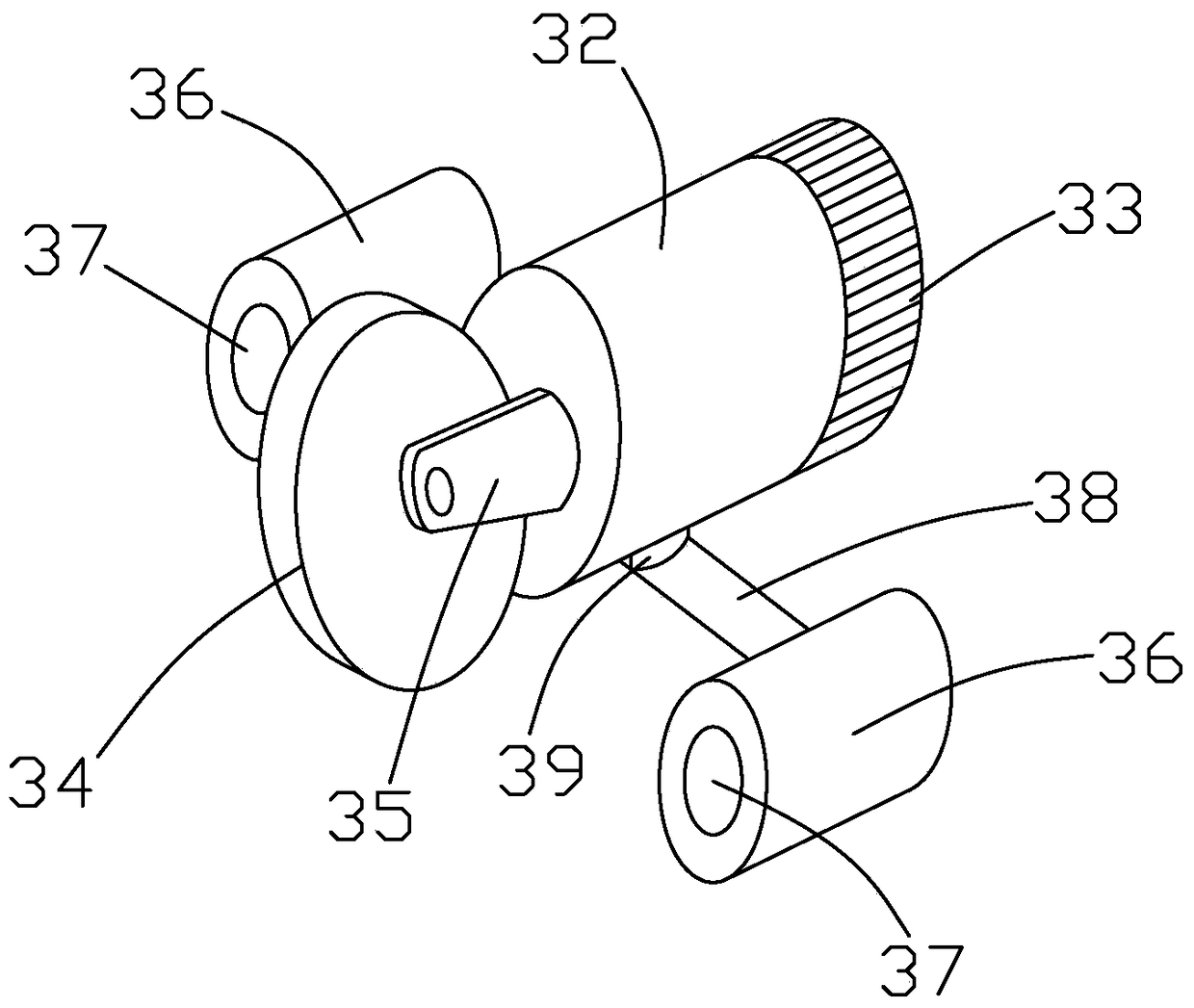

[0028] Such as Figure 1 to Figure 5As shown, it is a cloth cutting machine for tie processing according to the present invention. The cloth cutting machine includes a workbench 1 and a cloth breaking device. At least six support legs 2 are evenly arranged on the bottom surface of the workbench 1. The bottom of the support legs 2 A buffer pad 3 is provided, which can effectively reduce the vibration generated by the motor on the workbench 1, thereby reducing the impact of vibration on the cloth breaking mechanism 10 and improving the accuracy of cloth breaking. The cloth breaking device is located on the top surface of the workbench 1 Above, the cloth breaking device includes a horizontal positioning plate 4, a cloth breaking mechanism 10 and a control panel 6, the horizontal positioning plate 4 is fixedly connected to the workbench 1, the control panel 6 is rotatably connected to the end of the horizontal positioning plate 4, and the control panel 6 A display window 7, a swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com