Patents

Literature

84results about How to "Cut off accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

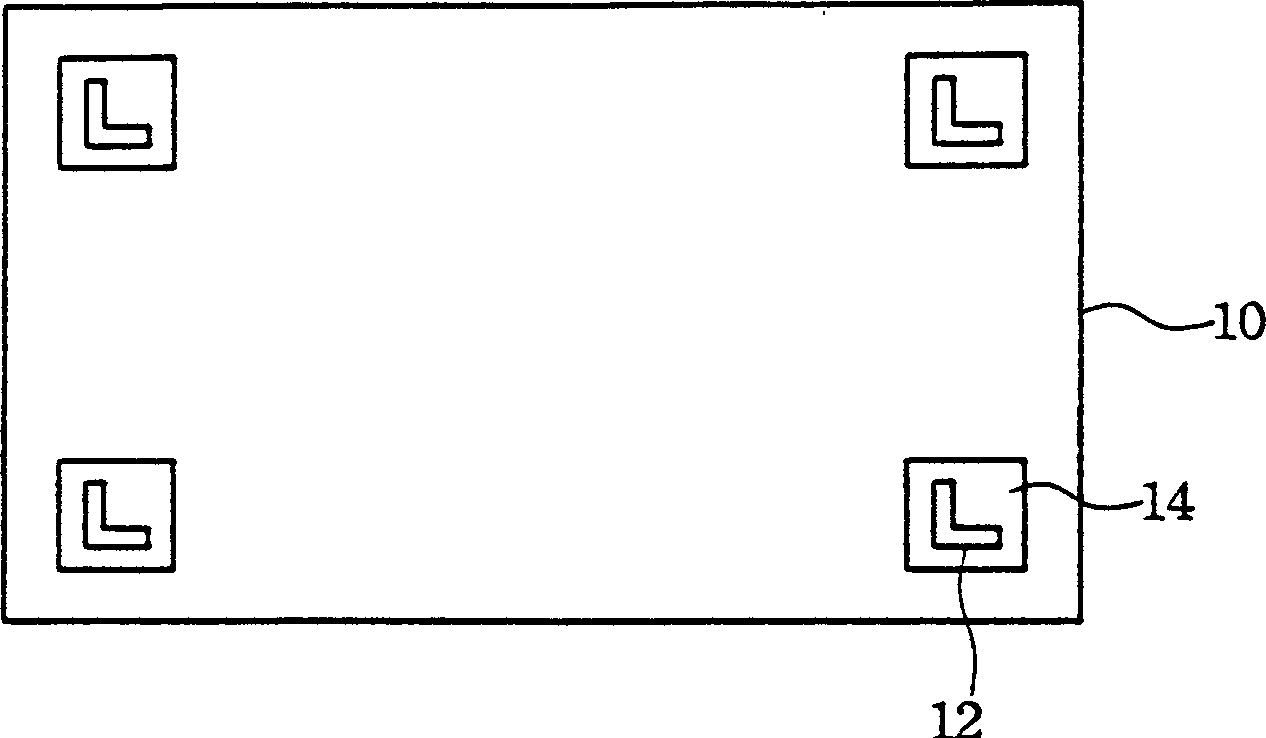

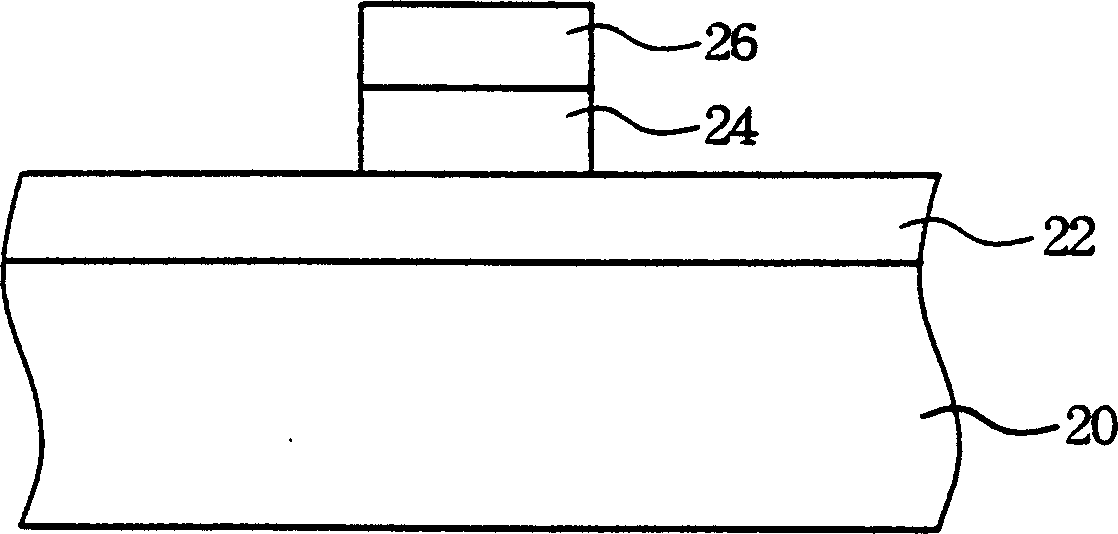

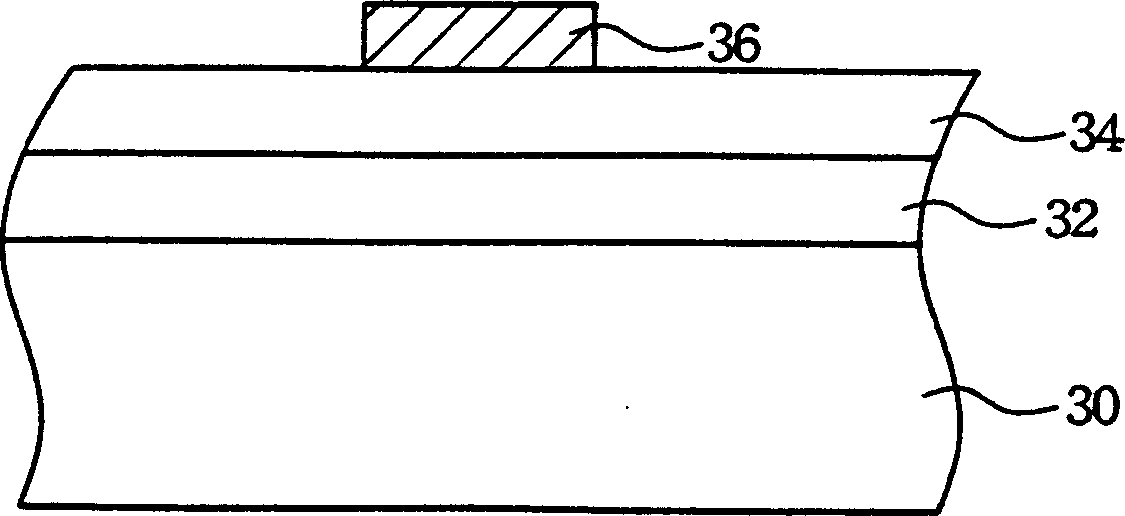

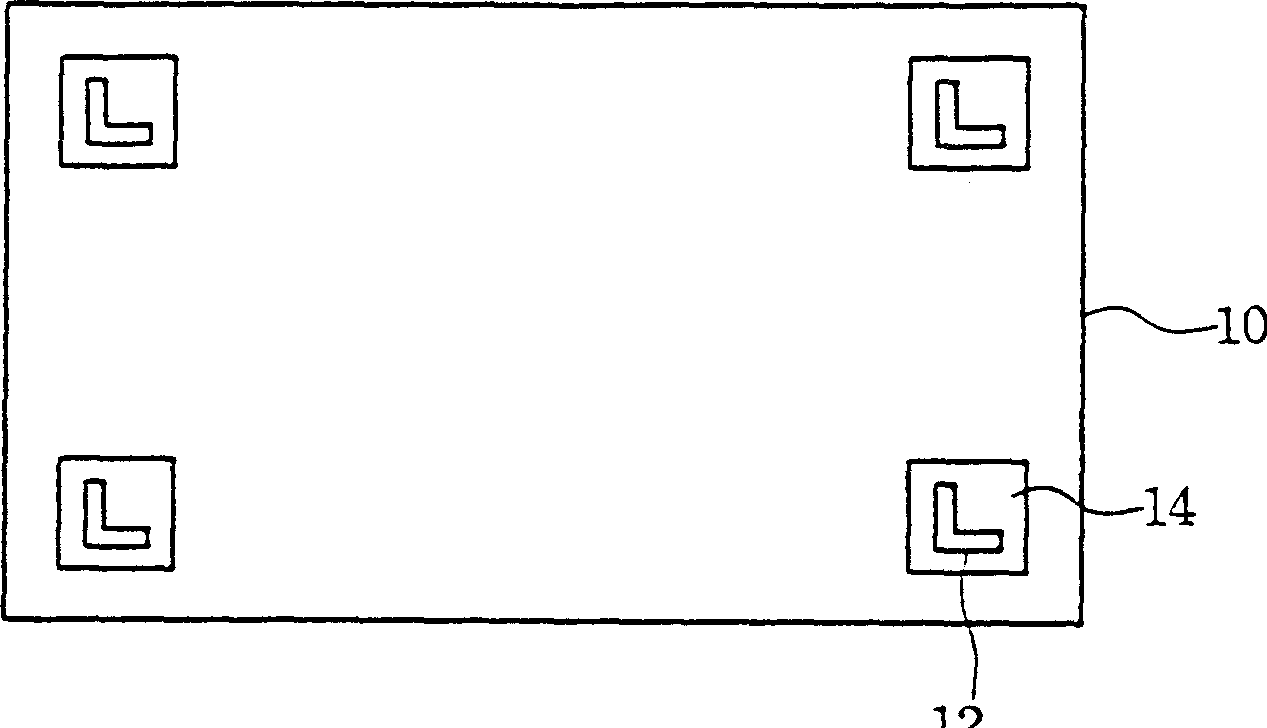

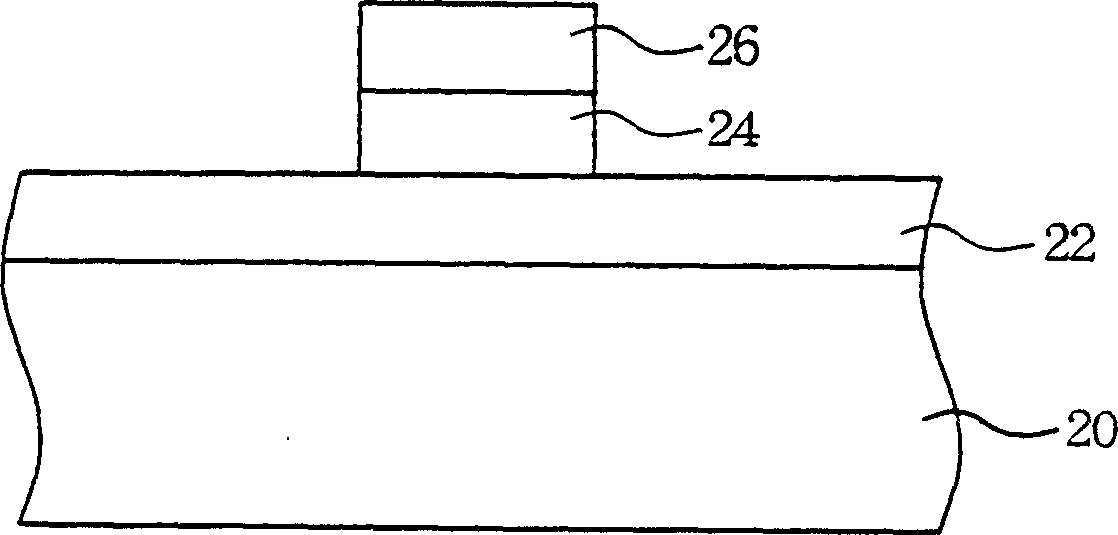

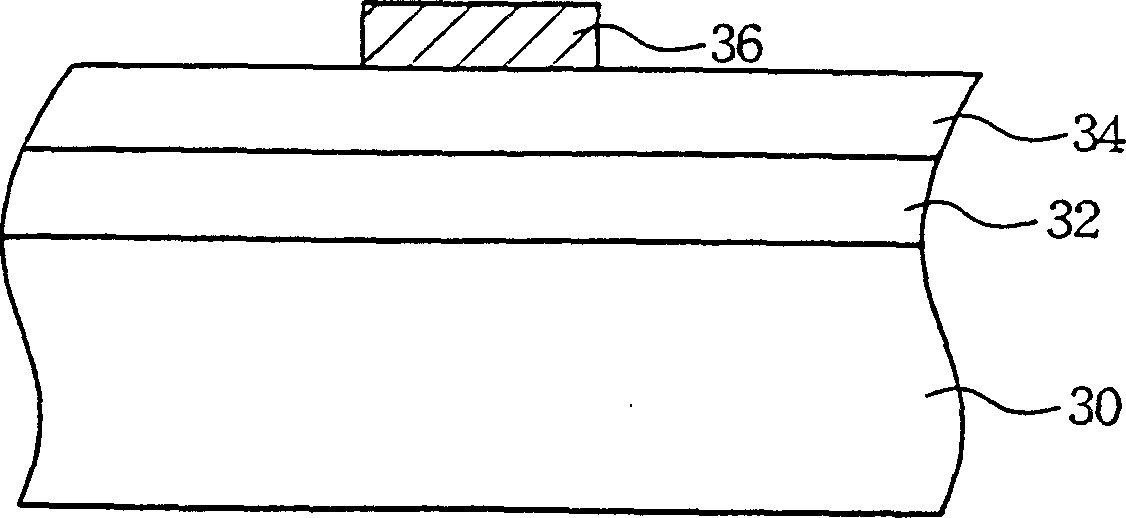

Method for producing alignment mark

InactiveCN1458667AEasy Laser RepairElasticSemiconductor/solid-state device manufacturingTitanium nitrideDielectric layer

During the making of alignment mark, one intermetal dielectric layer is first formed on the upper metal layer of aluminum-copper alloy, one layer of titanium nitride or other low-reflectivity material is then formed, and one metal layer is finally formed on the low-reflectivity material layer. In the metal layer, alignment mark is made, so that the alignment mark has strong contrast to the low-reflectivity material layer and thus is favorable to subsequent repair alignment. In addition, the low-reflectivity material layer may be used also as the metal layer etching stop layer.

Owner:TAIWAN SEMICON MFG CO LTD

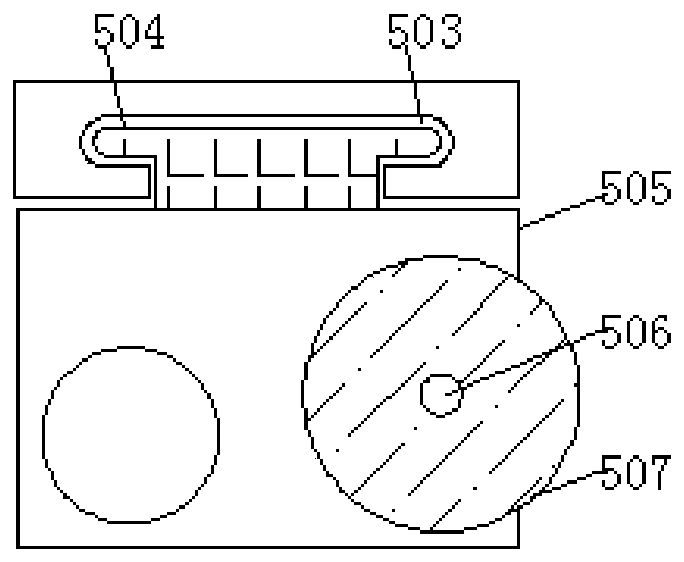

Cutting device for adhesive tape cutting machine

InactiveCN1721148AReduce noiseImprove performanceMetal working apparatusArticle deliveryAdhesive beltEngineering

The present invention relates to a cutting device for adhesive tape cutting machine for arranging a plurality of cutters on said cutting device in radial pattern, the output roller and the cutting device are linked by a gear mesh, thus noise generated when cutting the adhesive tape is apparently reduced, finally the product capability is improved. In order to achieve the purpose, said cutting device comprises a cylinder type shell (52), a plurality of sawtooth blades (56) and fixing shaft (60); wherein, said shell (52) is reversely rotated with the rotation of the output roller (18); said gear blades (56) are arranged on said shell (52) in radial pattern, and are arranged to be capable of being projected and imported corresponding to its inside; said fixing shaft (60) is fixed inside the shell (52) and is used for projecting gear blade in relative direction of the output roller (18) in said a plurality of gear blades (56).

Owner:摩登思标签制品(北京)有限公司

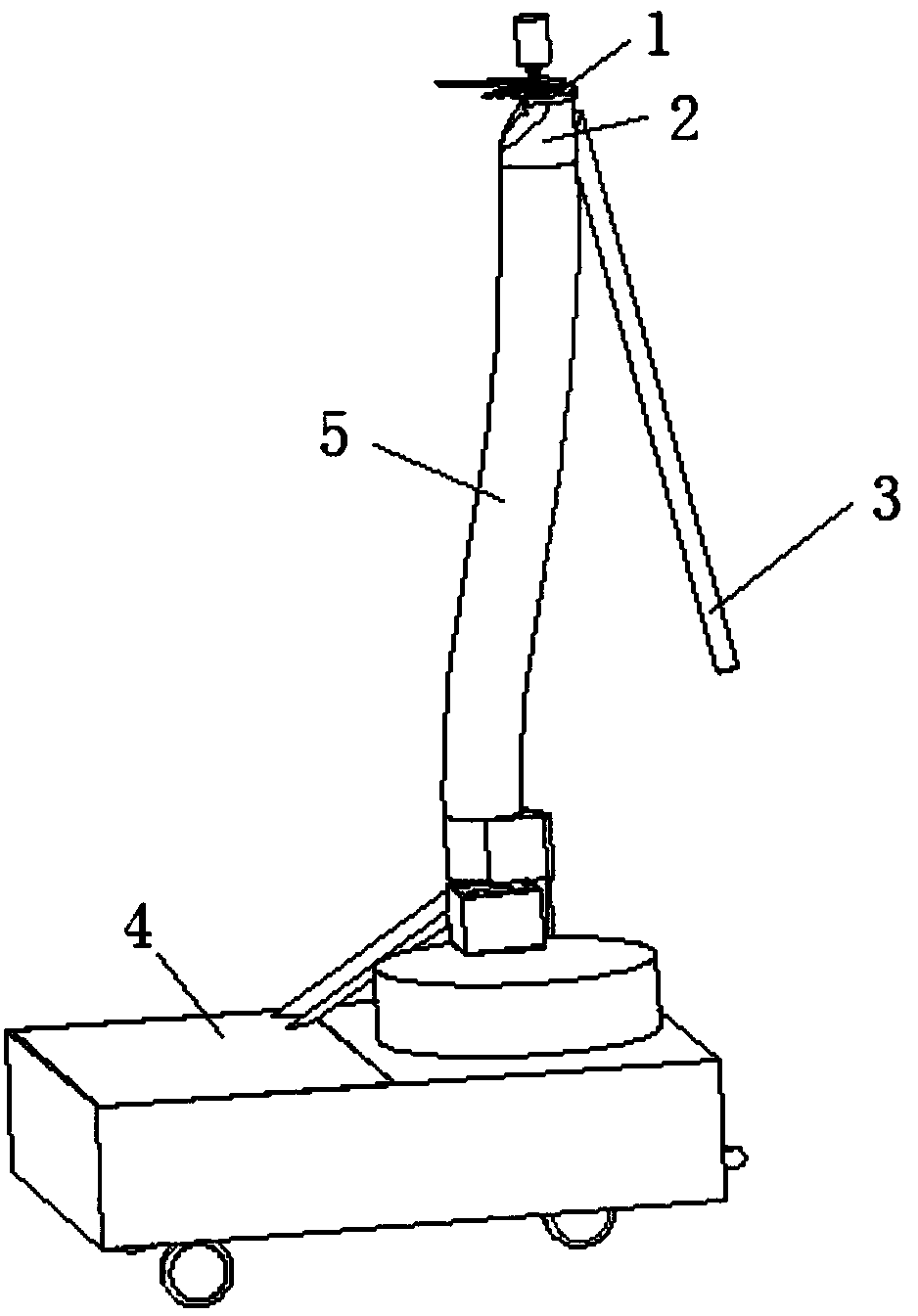

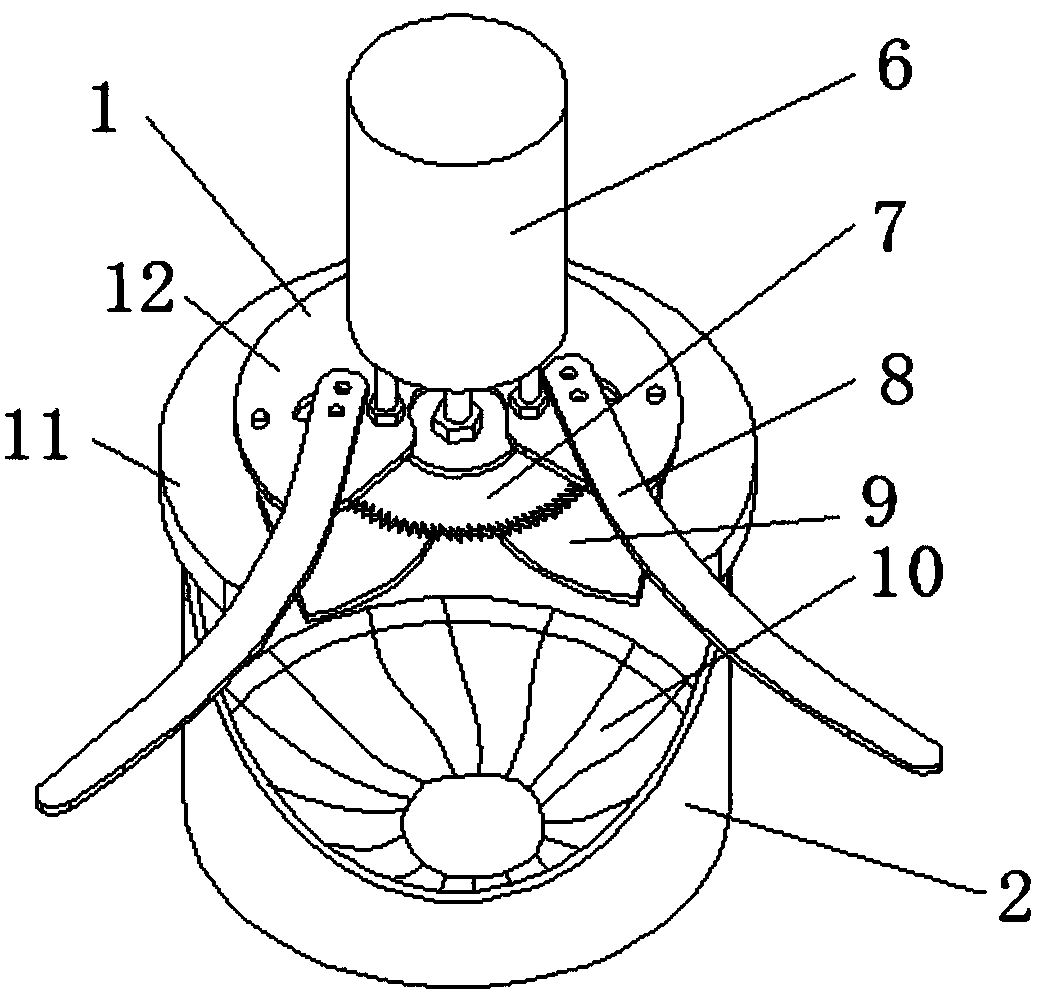

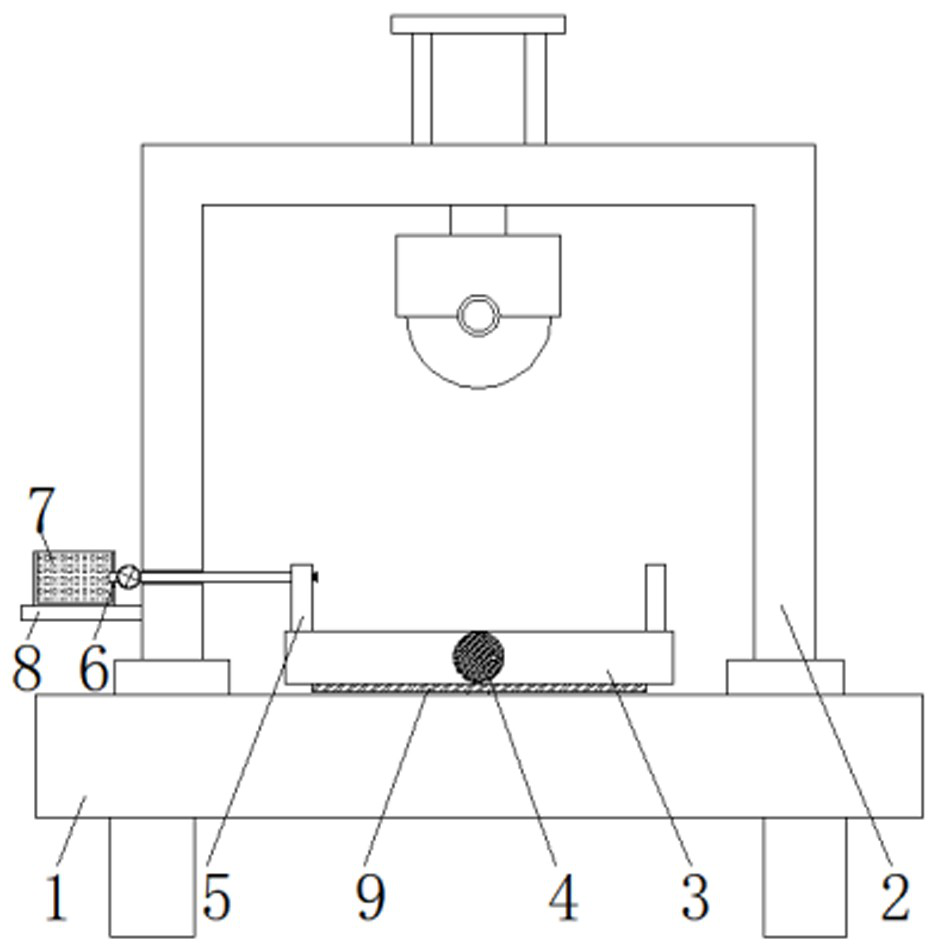

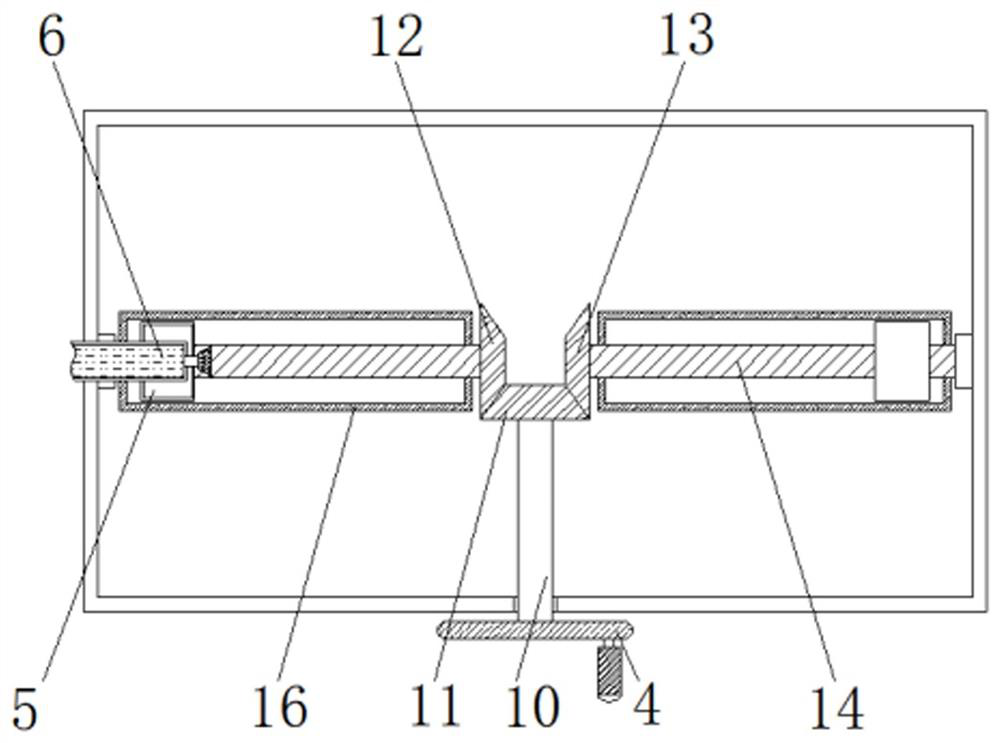

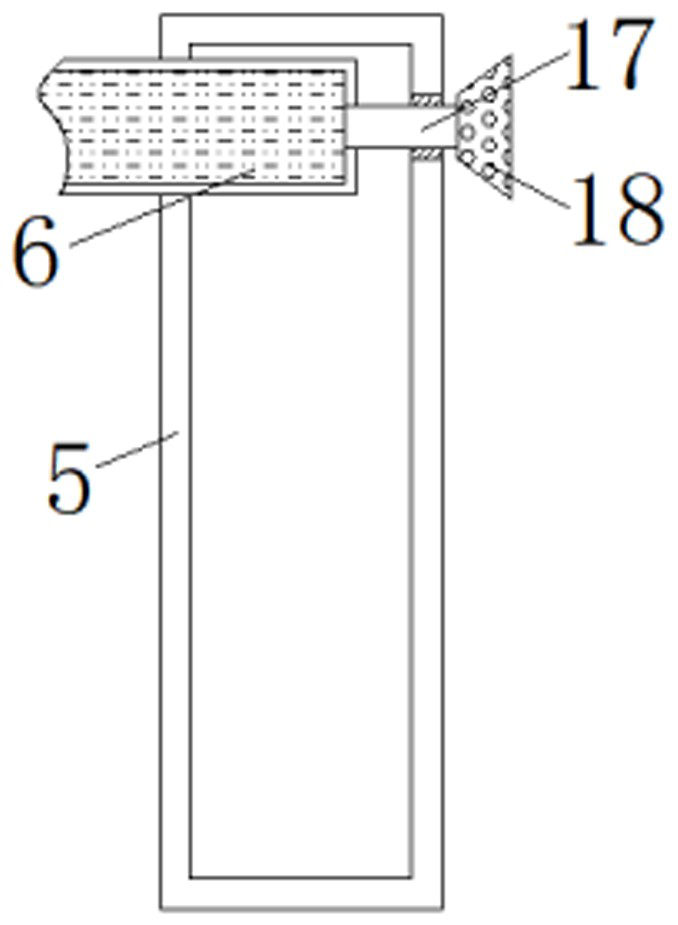

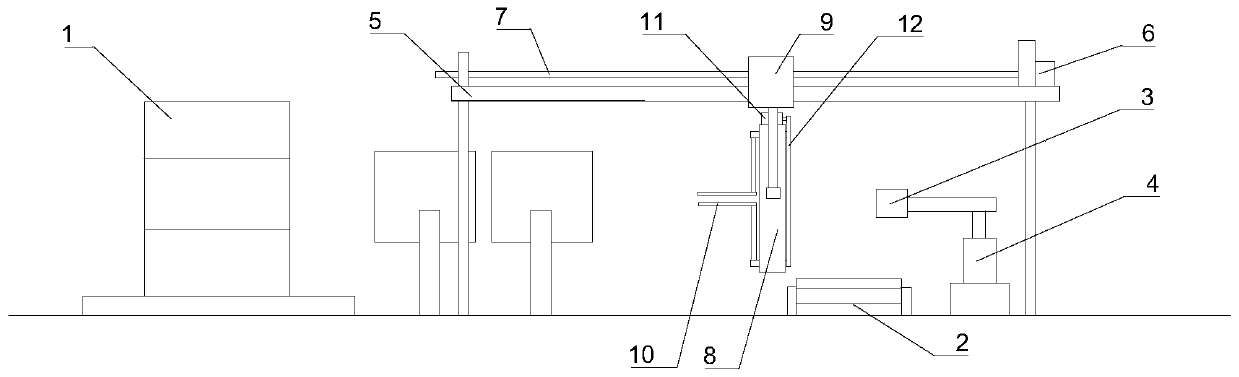

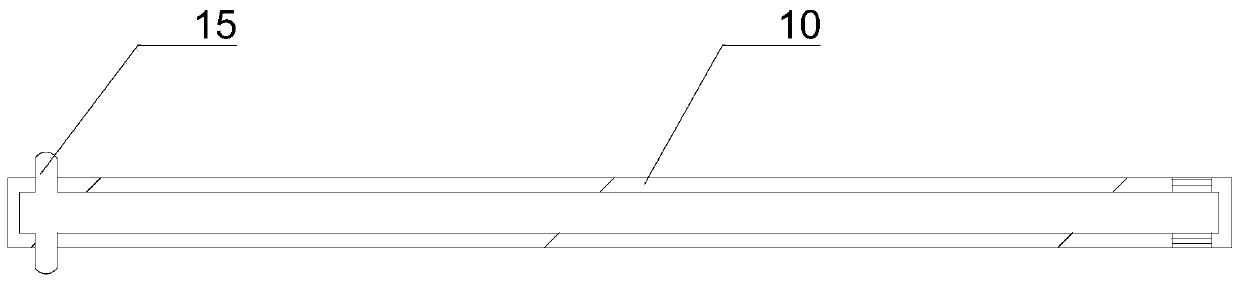

Fruit nondestructive picking and packing machine

InactiveCN107934006AIntegrity guaranteedImprove picking efficiencyPackaging fruits/vegetablesPicking devicesEngineeringHigh-speed steel

The invention discloses a fruit nondestructive picking and packing machine. The fruit nondestructive picking and packing machine comprises a cutting part and a packing part, the cutting part and the packing part are connected through a connecting hose, the bottom of the cutting part is provided with a connecting hard tube, and the connecting hard tube is provided with a handle; the cutting part iscomposed of a high-speed motor and a high-speed steel blade, an upper baffle is arranged above the high-speed steel blade, a lower baffle is arranged below the high-speed steel blade, an upper guiding arm is arranged above the upper baffle, a lower guiding arm is arranged between the lower baffle and the high-speed steel blade, and the lower portion of the lower baffle is connected with the connecting hard tube; and the packing part is composed of a fixed part, a movable part and a collecting device, the movable part is connected with the connecting hose, the collecting device is arranged below the movable part, the fixed part is arranged on one side of the movable part, and a guiding rail is arranged between the movable part and the collecting device. According to the fruit nondestructive picking and packing machine, it can be ensured that fruit picking and packing are completed on the premise of not destroying fruit skin.

Owner:SOUTHEAST UNIV

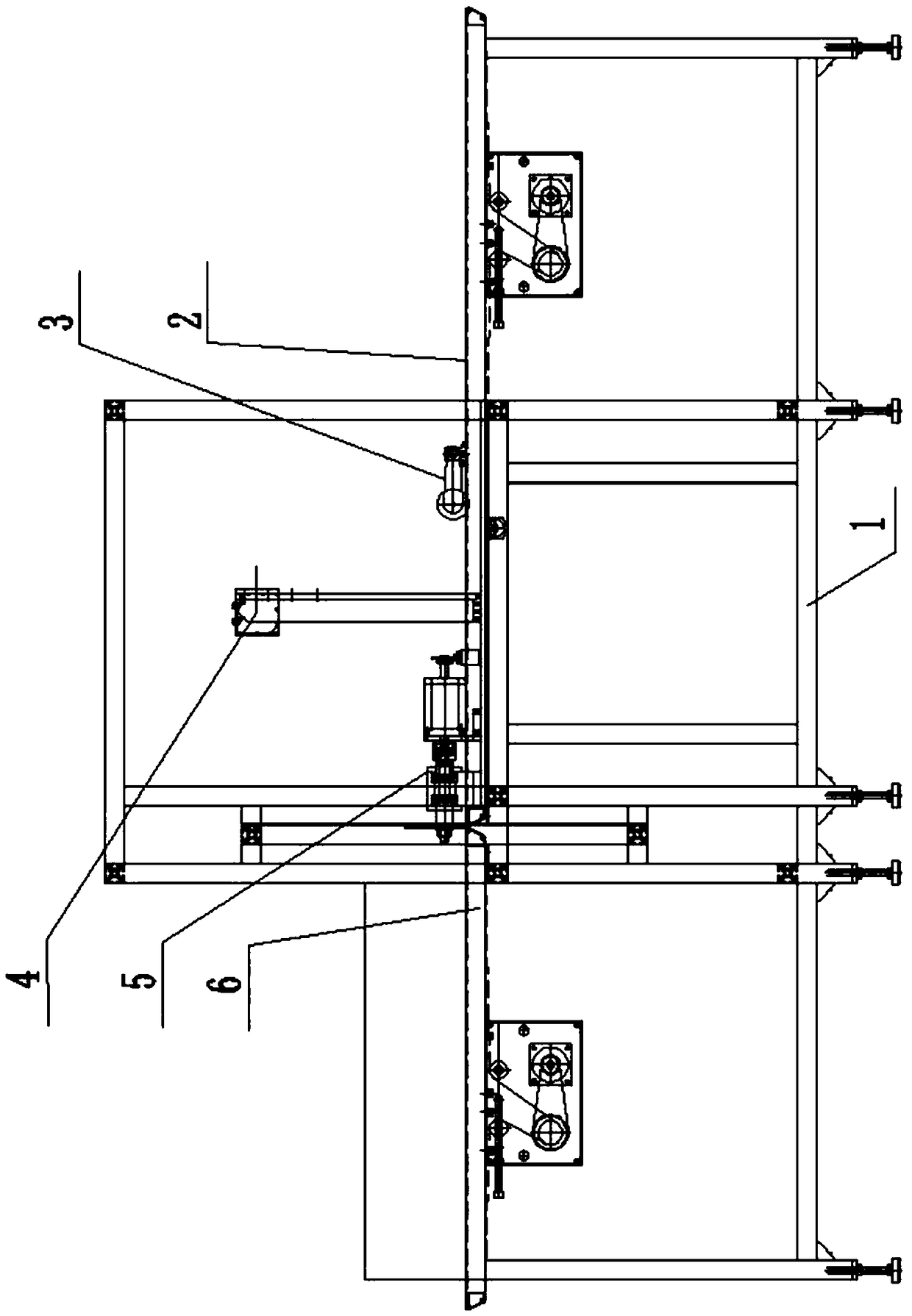

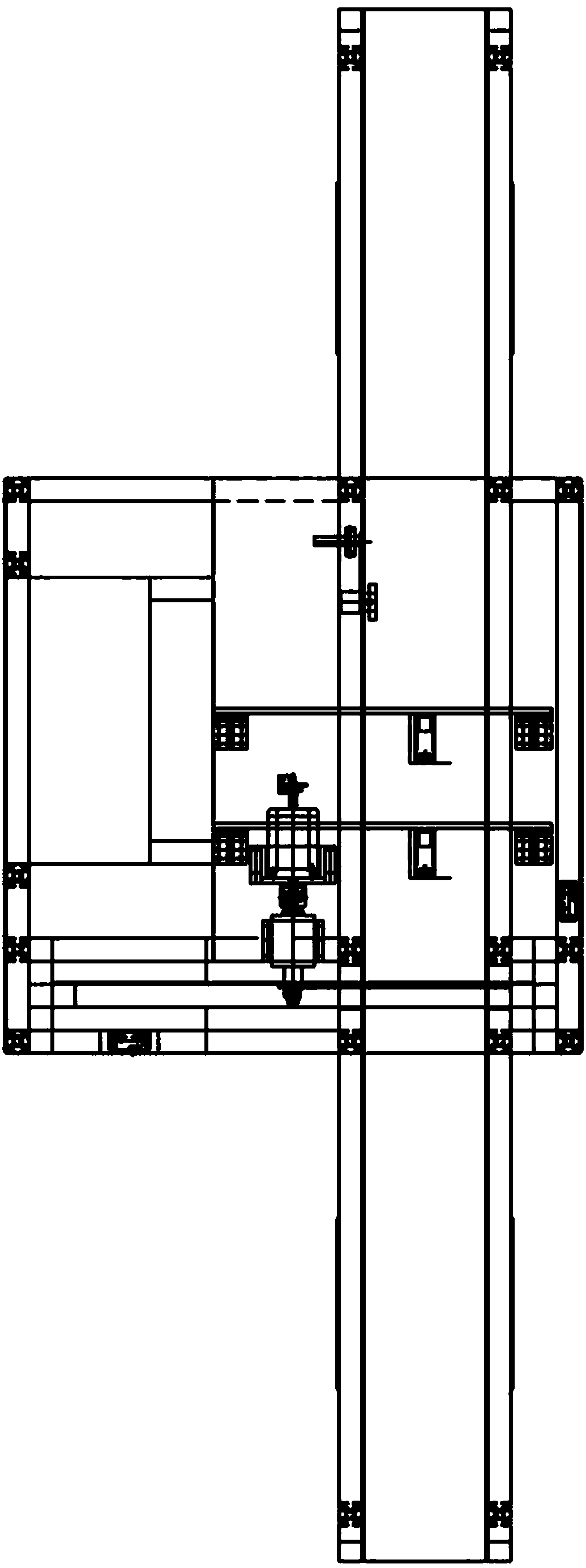

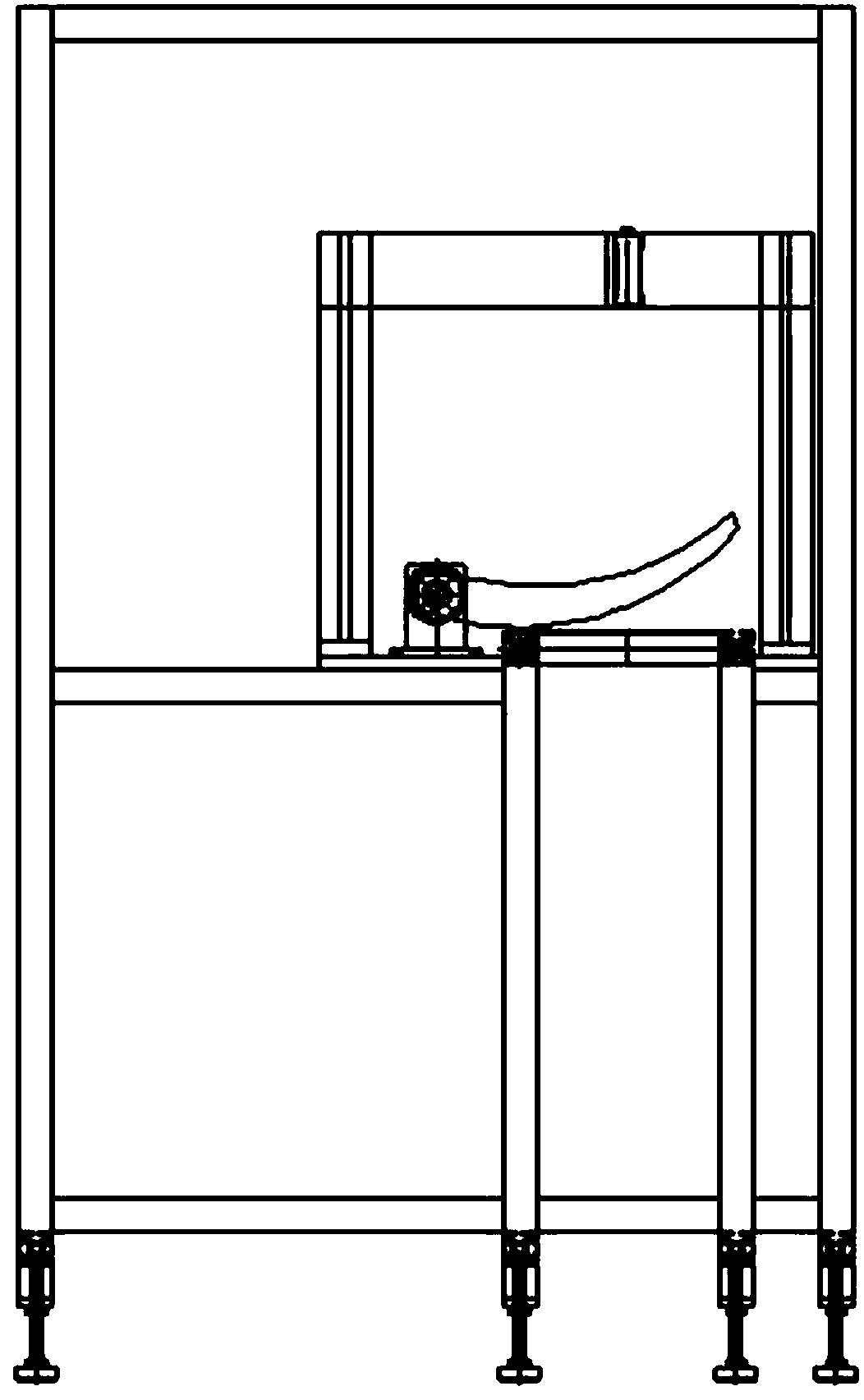

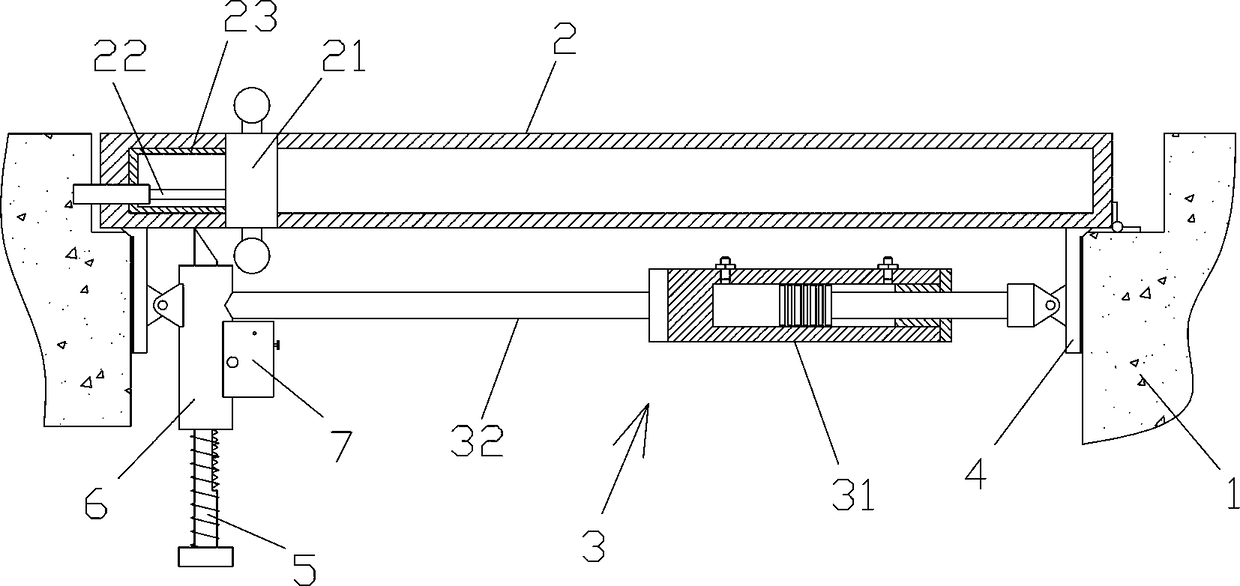

Automatic cutting device for packaging bags

InactiveCN105217099ARealize automatic precise cuttingReasonable structurePackagingArticle deliveryEngineeringMechanical engineering

The invention discloses an automatic cutting device for packaging bags. The automatic cutting device is characterized by comprising a U-shaped support. A horizontal rotating shaft movably penetrates through supporting arms on the two sides of the U-shaped support and is used for holding the coiled packaging bags. A cutting bottom plate is arranged on the part, below the horizontal rotating shaft, of the U-shaped support in a horizontal extension mode and provided with a strip-shaped pressing block parallel with the horizontal rotating shaft. A slot for a single packaging bag to horizontally penetrate through is formed in the lower part of the strip-shaped pressing block, a sliding groove penetrating through the slot downwards is formed in the upper side surface of the strip-shaped pressing block and provided with a cutter, and the blade of the cutter is inserted into the sliding groove downwards and gets close or makes contact with the upper side surface of the cutting bottom plate. The horizontal rotating shaft is connected with a first drive mechanism. The cutter is connected with a linear drive device. The automatic cutting device has the advantages of being simple in structure, convenient to operate, capable of improving the efficiency and lowering the cost and accurate in cutting.

Owner:ANQING XIAOLONGSHAN PLASTIC CO LTD

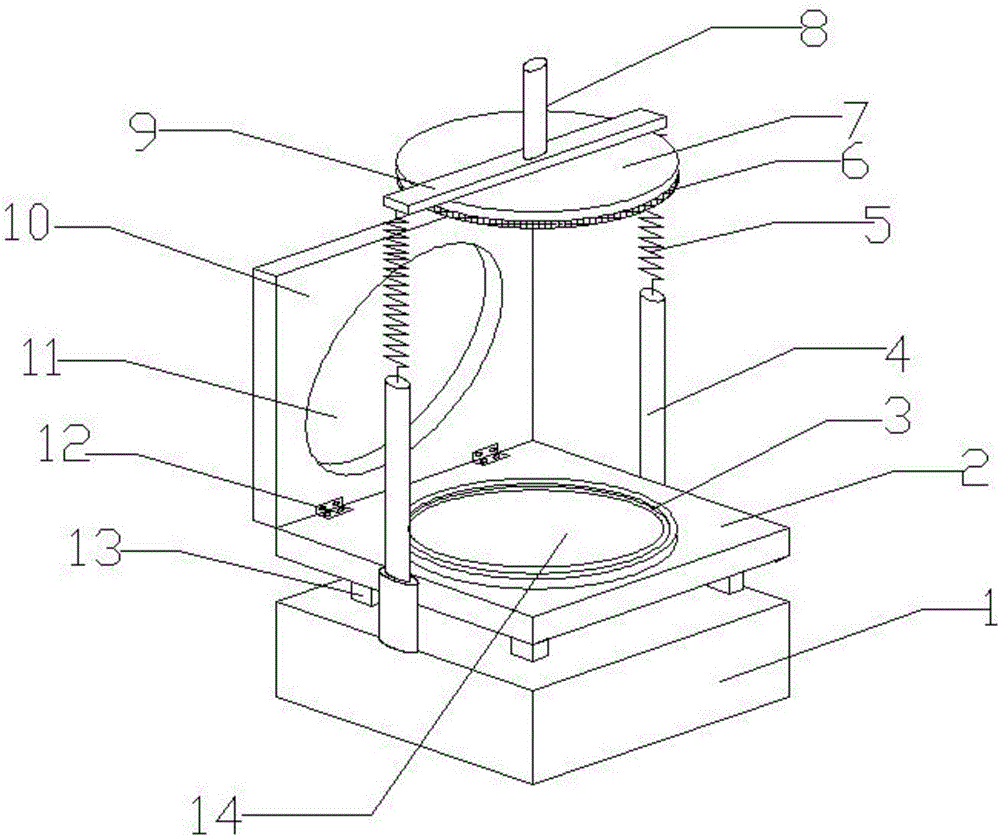

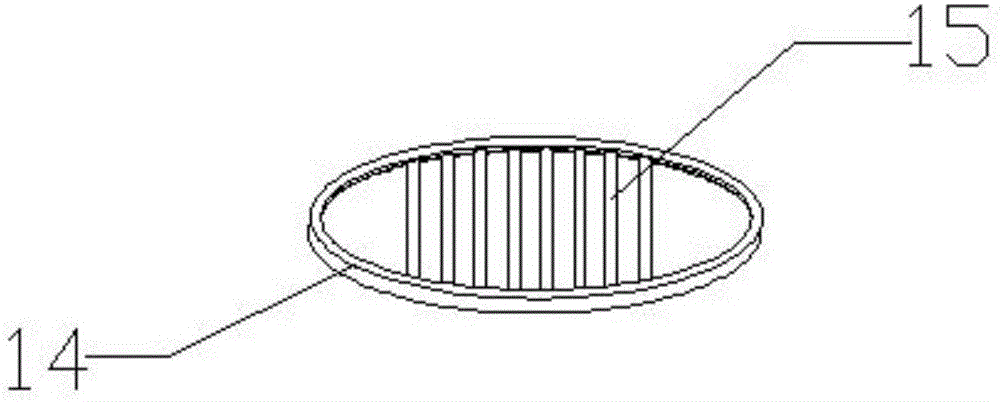

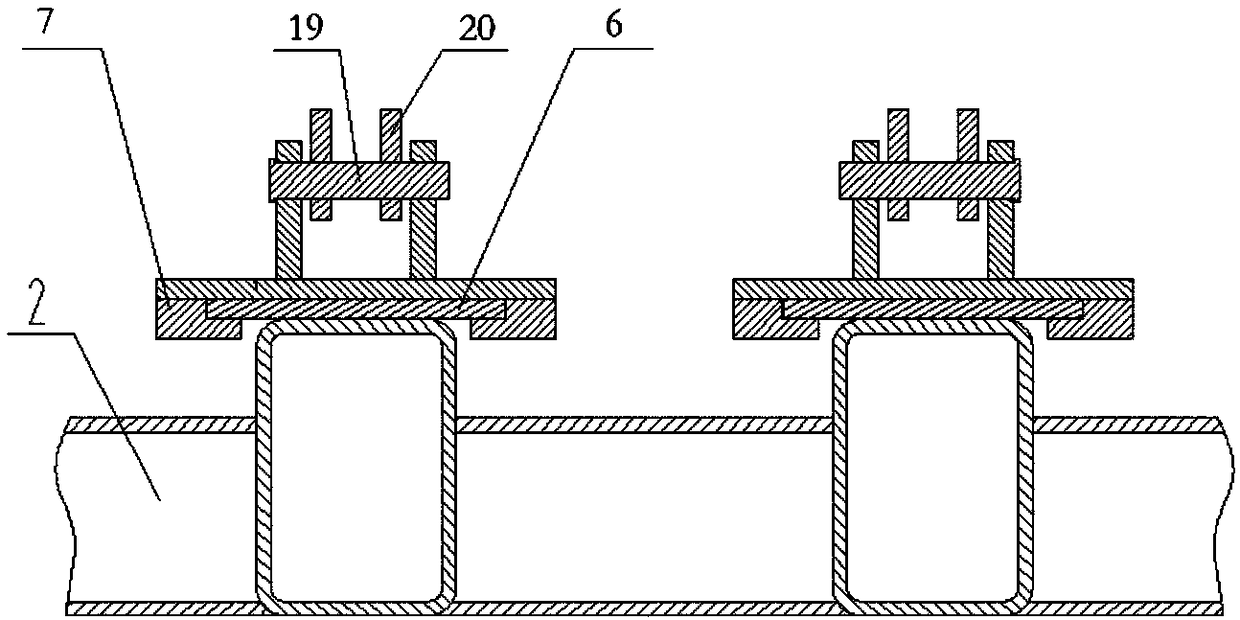

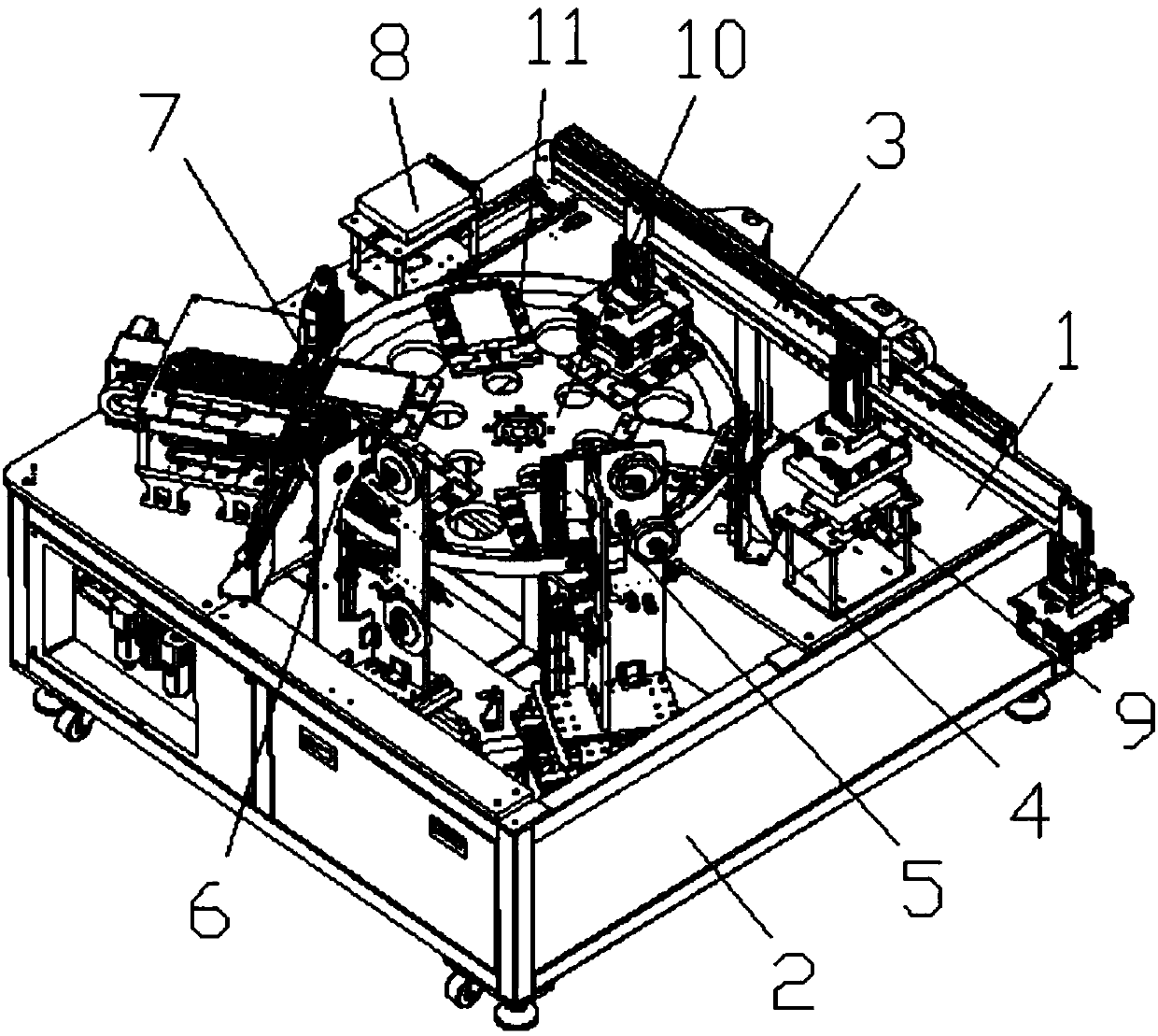

LED wafer expanding machine with membrane cutting device

InactiveCN106025015AEasy to cut offCut off the shortcutSemiconductor devicesEngineeringMechanical engineering

The invention discloses an LED wafer expanding machine with a membrane cutting device. The machine comprises a base, the base is provided with four support columns, a lower pressing mold board is horizontally arranged on the four support columns, a circular wafer expanding disc is arranged at the center of the lower pressing mold board, and heating tubes are arranged in the wafer expanding disc; one side of the lower pressing mold board is provided with an upper pressing mold board, the lower surface of the upper pressing mold board is provided with a circular groove corresponding to the circular wafer expanding disc, the two sides of the lower pressing mold board are provided with supporting rods, the bottoms of the supporting rods are fixed to the base, the tops of the supporting rods are each vertically provided with a spring, the springs are connected with a gland installing plate, the upper surface of the gland installing plate is provided with an air cylinder, the lower surface of the gland installing plate is provided with a gland, and the lower surface of the gland is provided with an annular blade. According to the LED wafer expanding machine with the membrane cutting device, redundant wafer membranes can be conveniently, quickly and accurately cut off, and meanwhile the condition that operating personnel are injured can be avoided.

Owner:汪锐

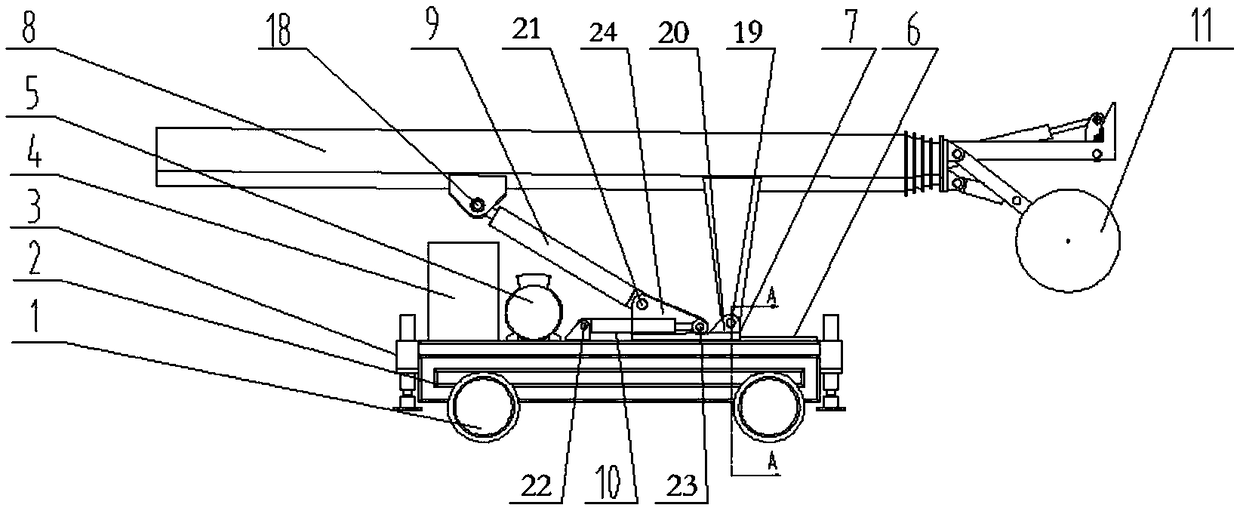

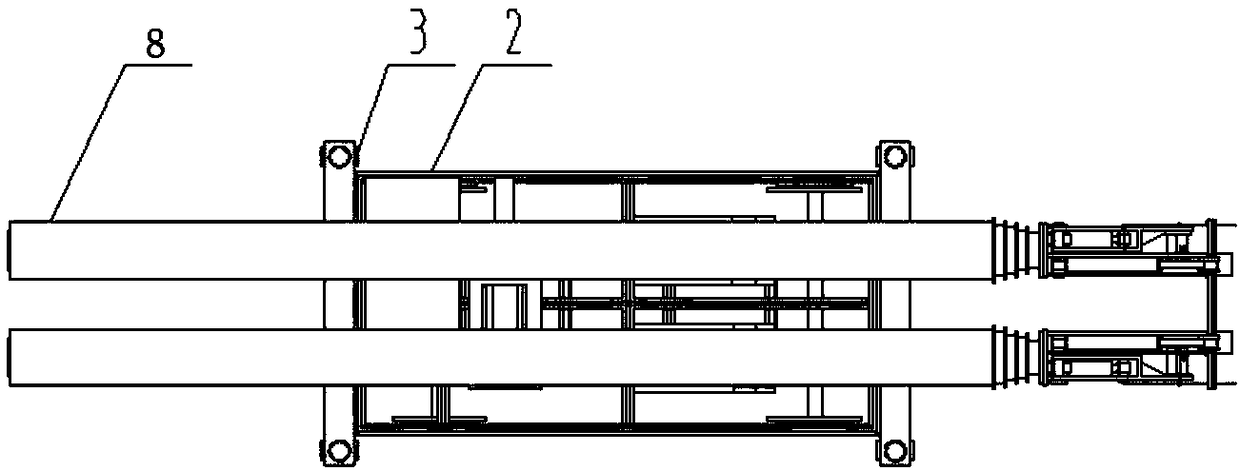

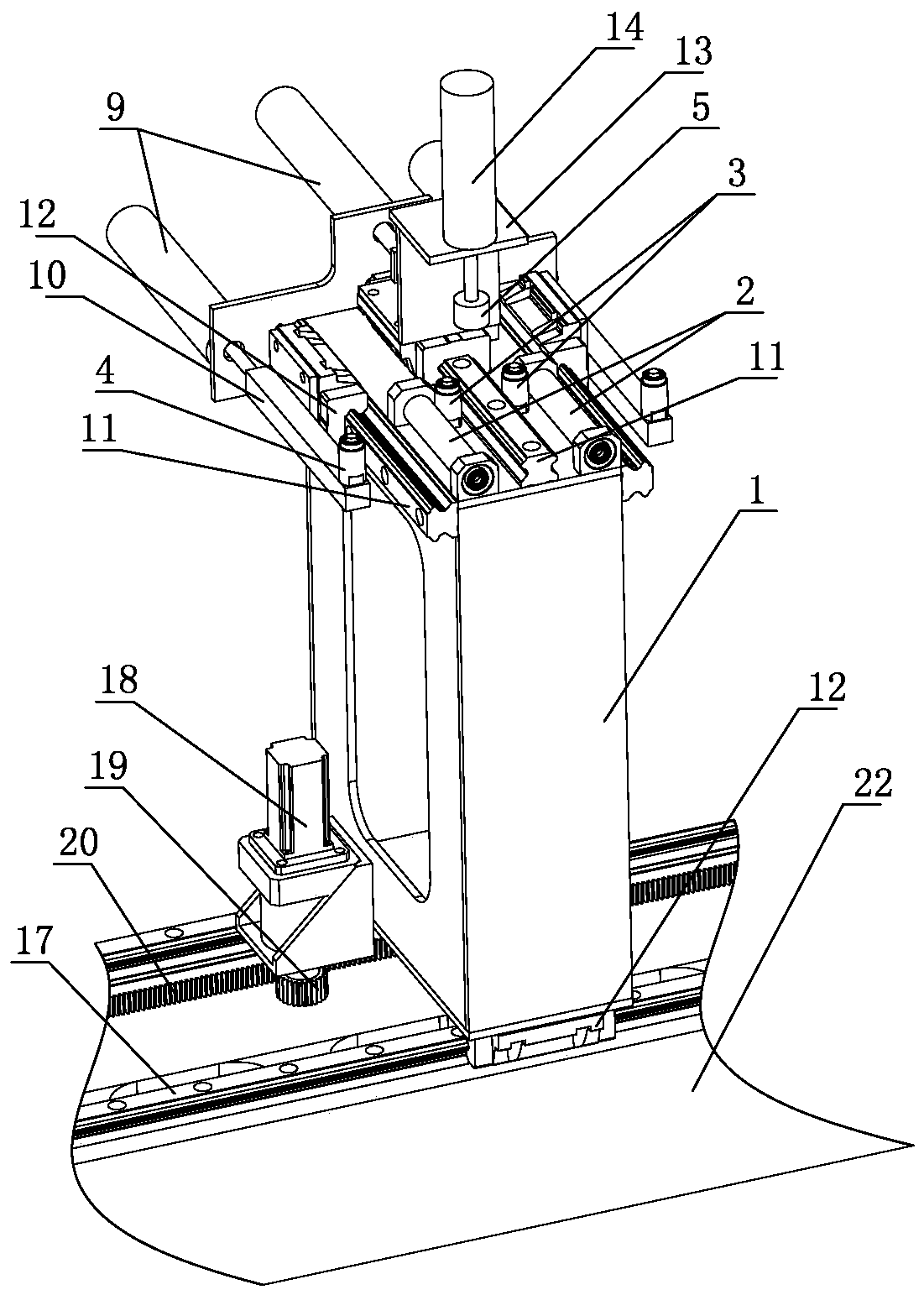

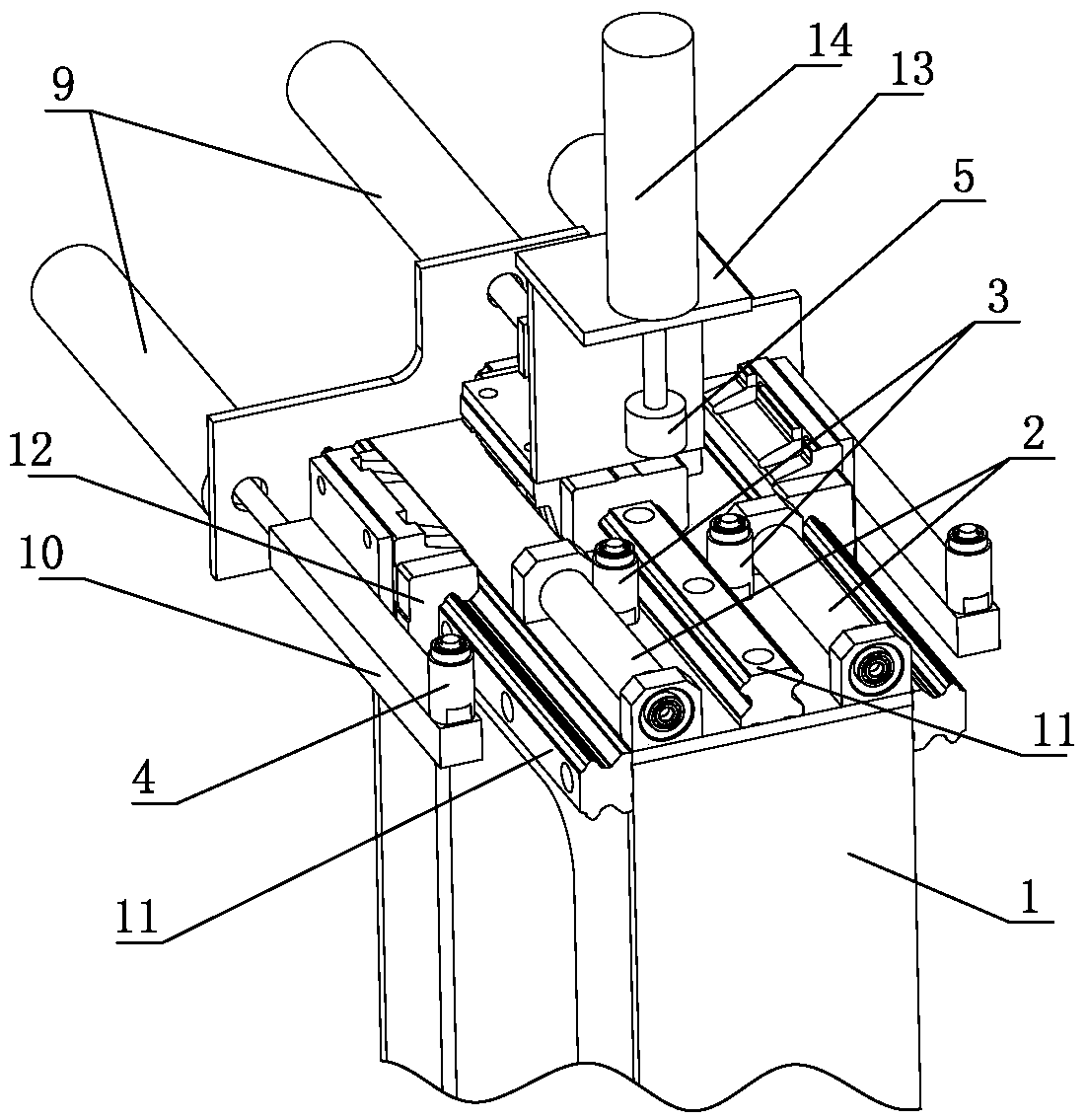

Cutting construction method of anchor cable cutting machine

The invention discloses a cutting construction method of an anchor cable cutting machine. A cutting machine comprises a walking mechanism, a turnover mechanism and a clamping and cutting mechanism; and after the walking mechanism walks in place, the turnover mechanism drives the clamping and cutting mechanism to turn to the position of an anchor cable, after the clamping and cutting mechanism clamps the anchor cable, the anchor cable is cut off through a saw blade, so that the operation of the anchor cable cutting is completed. The cutting construction method of the anchor cable cutting machine has the beneficial effects that the clamping and cutting mechanism can quickly clamp the anchor cable, the saw blade is controlled by a hydraulic motor to adjust the rotating speed of the saw blade,the anchor cable can be cut off accurately and quickly, the cutting machine can conveniently and rapidly move to a required working position, and the working efficiency is improved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

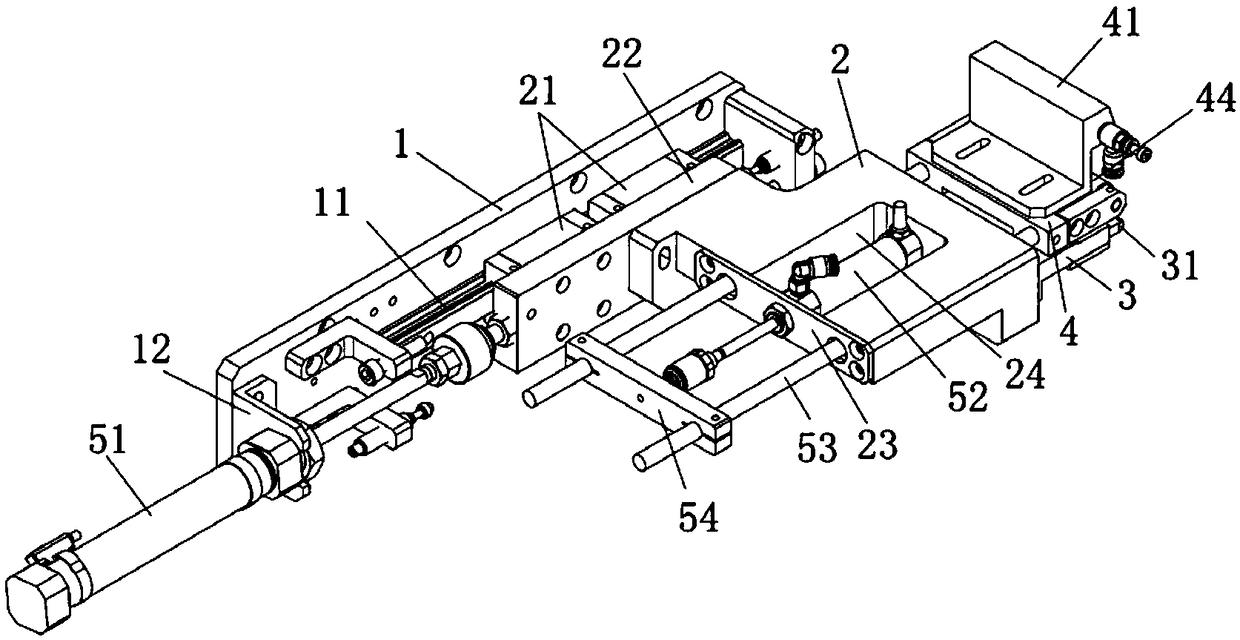

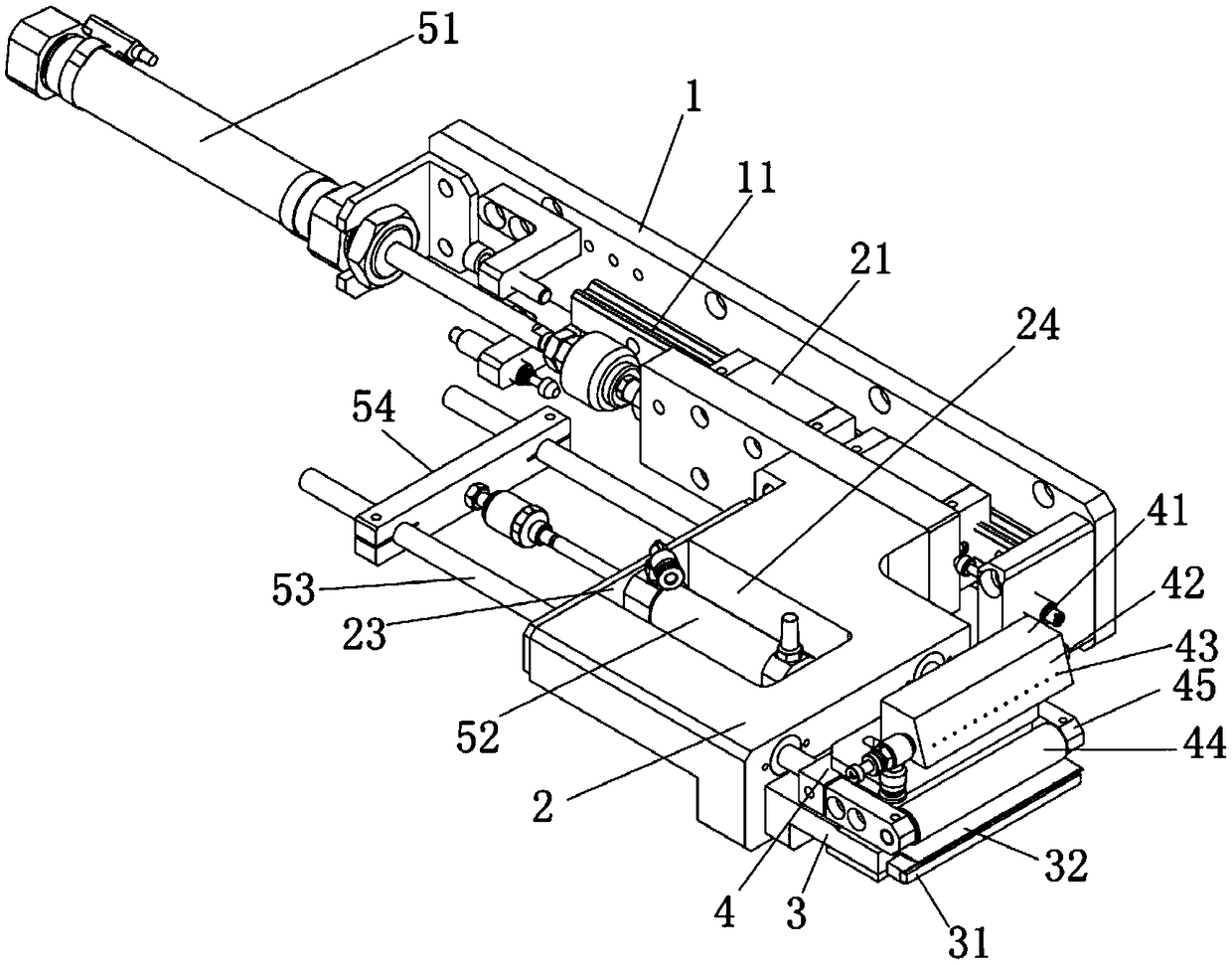

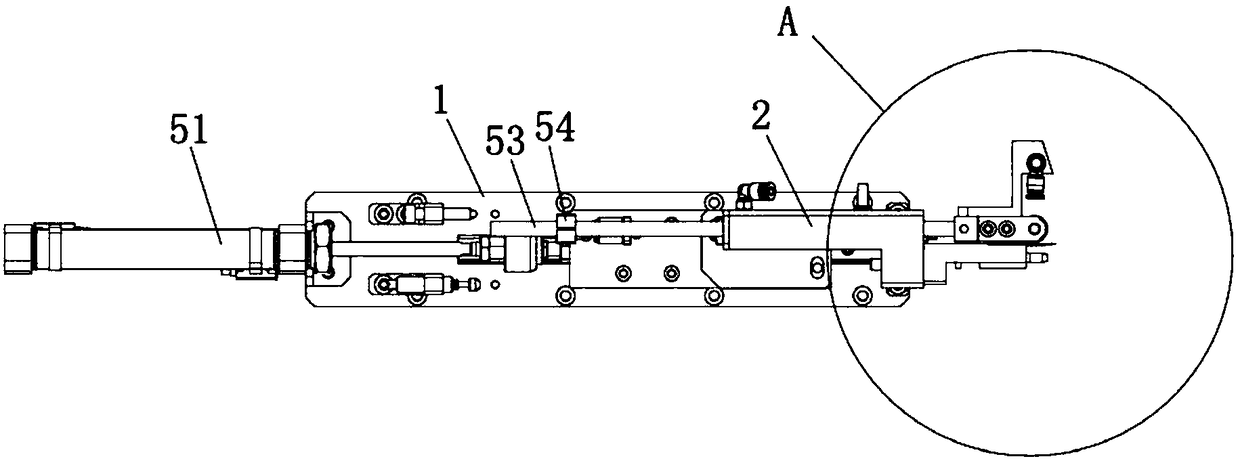

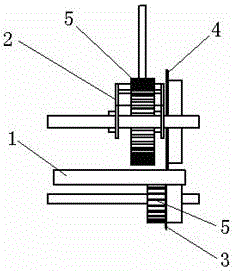

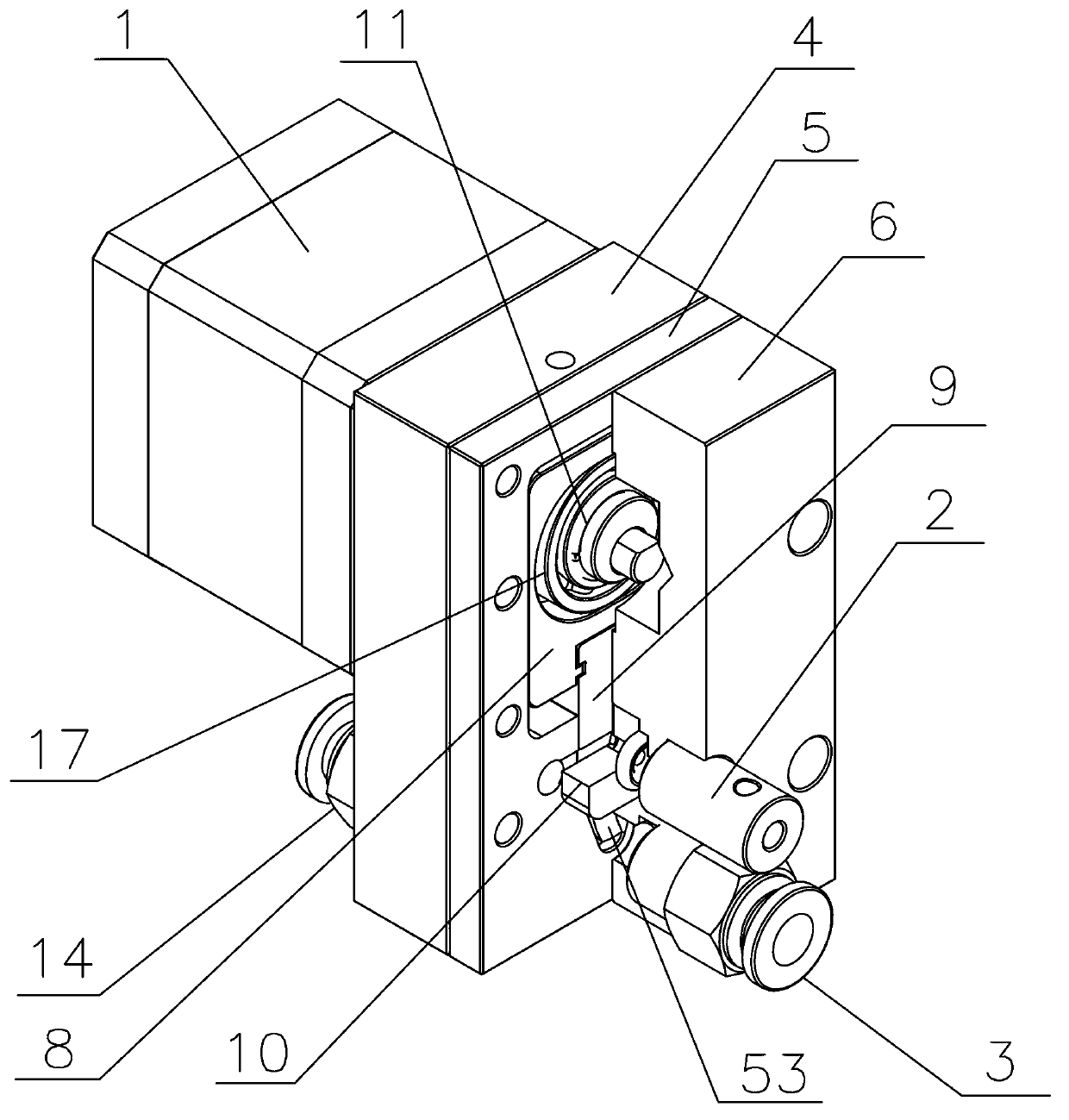

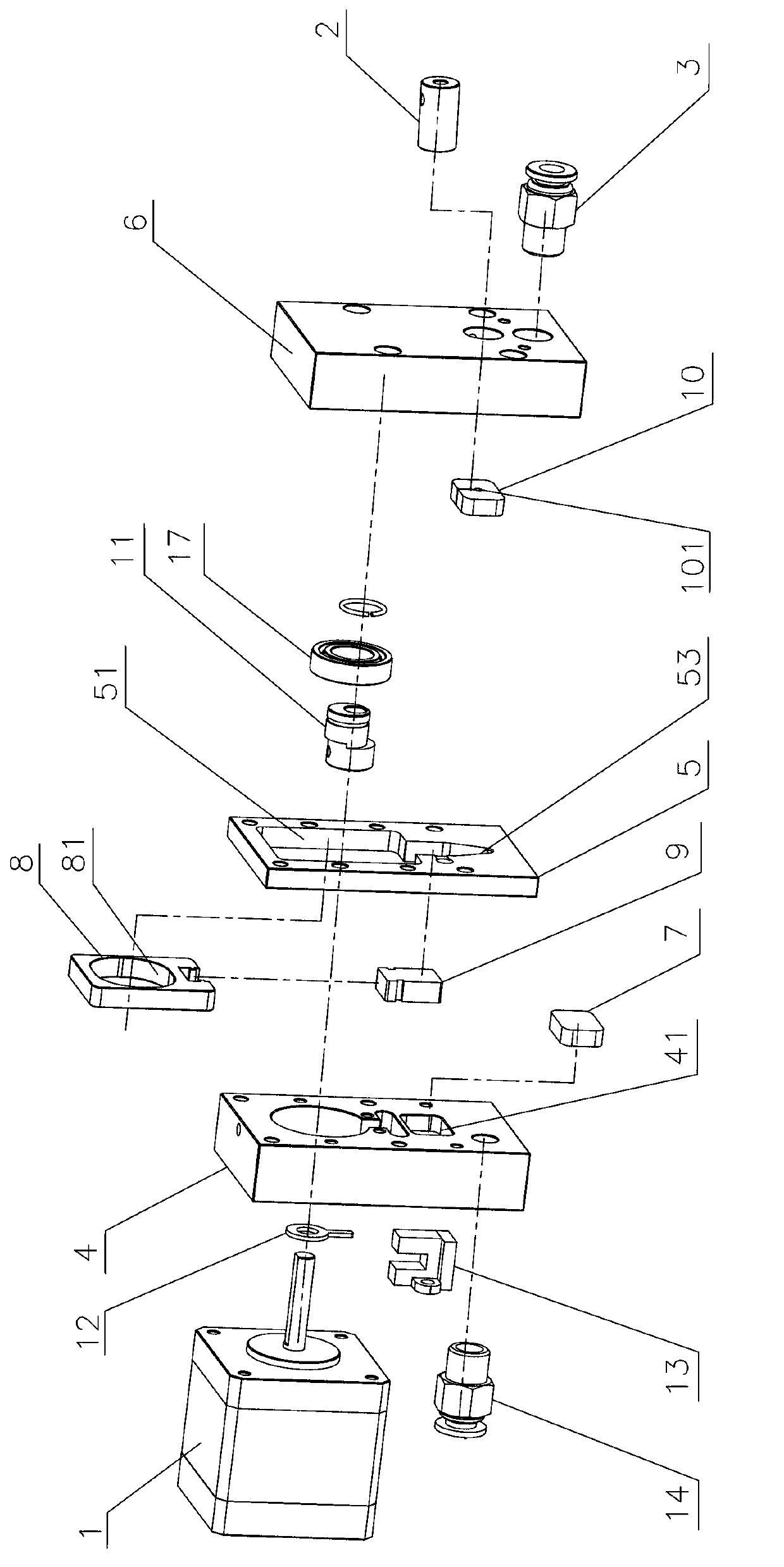

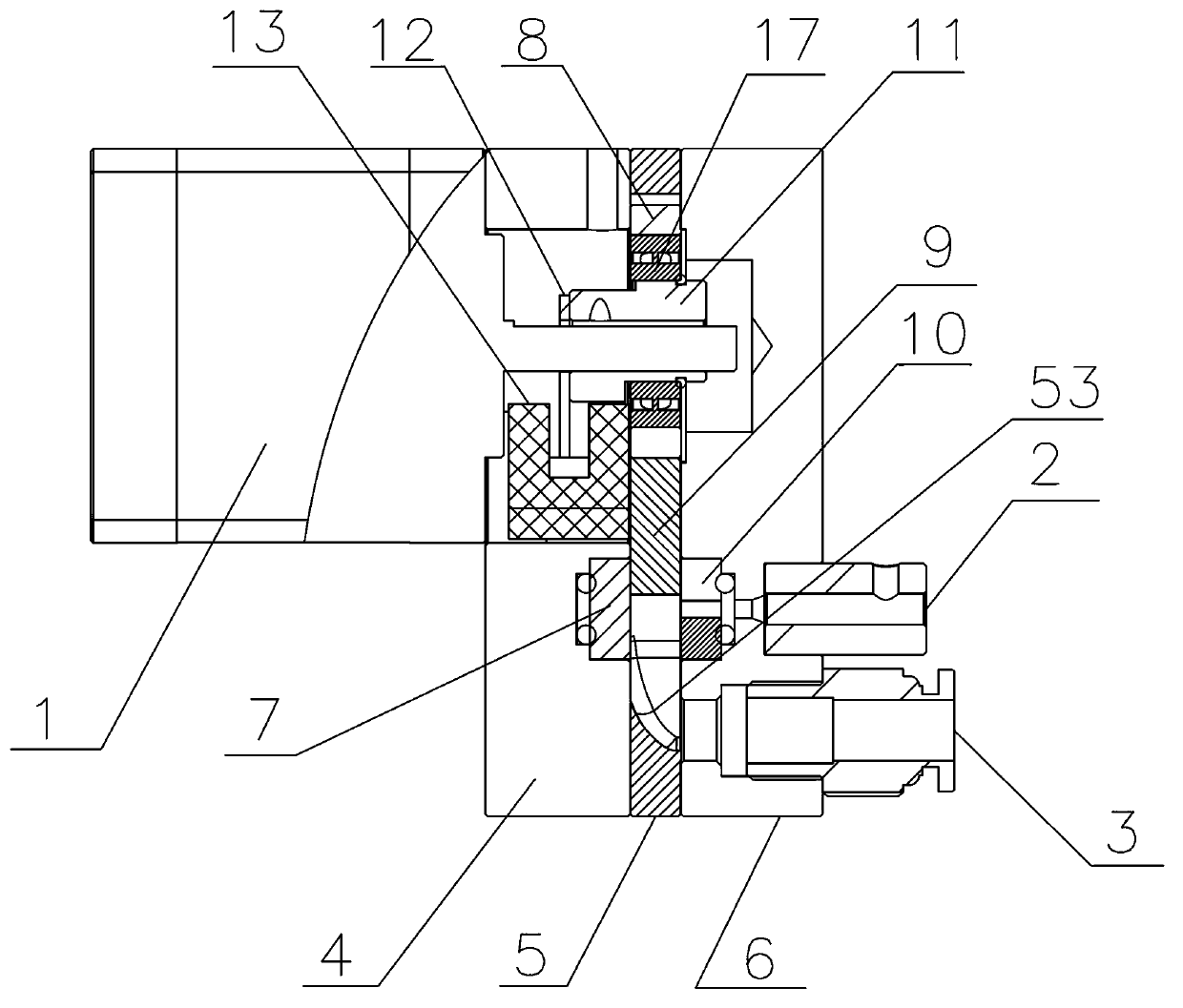

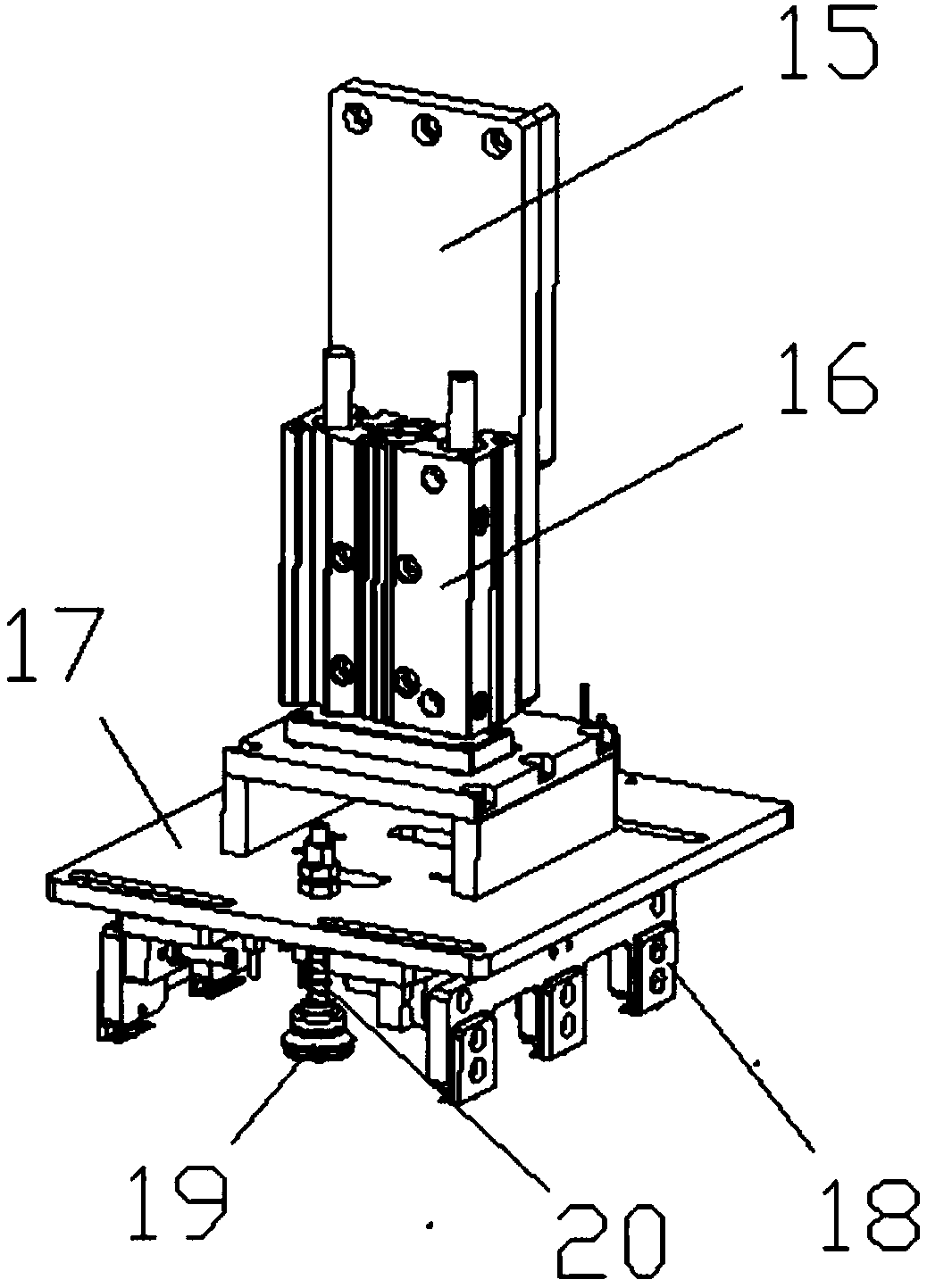

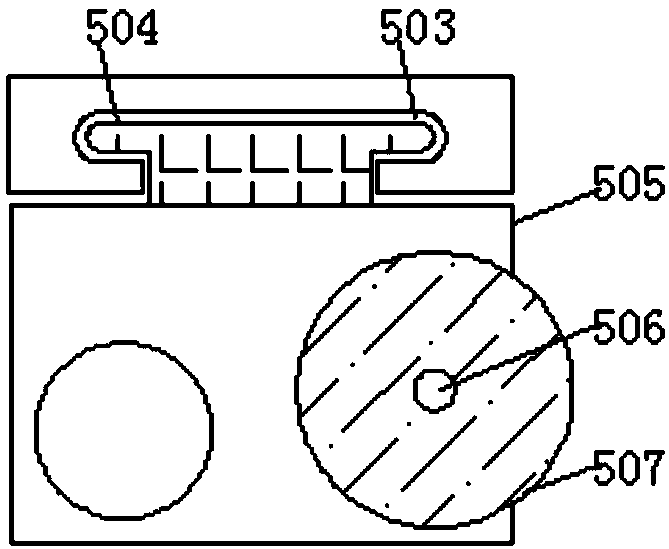

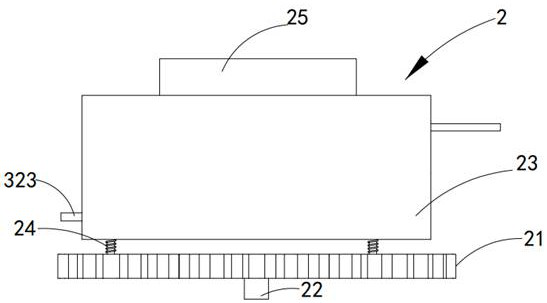

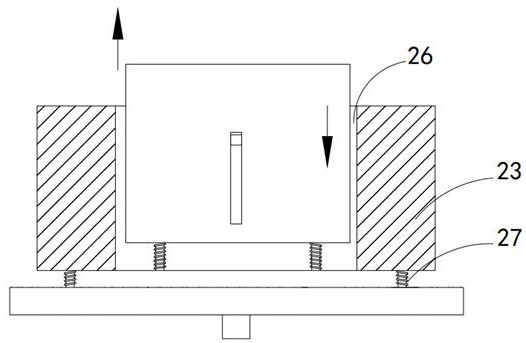

Diaphragm cutting mechanism of lithium battery winding machine

InactiveCN108858307ACut off stabilityCut off accuratelyNon-aqueous electrolyte cellsFinal product manufactureWinding machineEngineering

The invention discloses a diaphragm cutting mechanism of a lithium battery winding machine. The diaphragm cutting mechanism comprises a bracket, a slide seat and a fixing seat. The bracket, the slideseat and the fixing seat are sequentially connected with one another, a support table is arranged on a side of the fixing seat, a cutter for cutting off diaphragms is arranged on the support table, aone-way wheel and a pushing strip are arranged on the upper side and the lower side of the cutter, and a movable seat which is connected with the one-way wheel is arranged on the upper side of the support table, and is provided with a gas blowing seat which is arranged above the one-way wheel; the fixing seat is provided with a movement assembly for driving the movable seat to move on the front side and the rear side of the cutter back and forth; a driving assembly for driving the slide seat to horizontally move is arranged on the bracket. The diaphragm cutting mechanism has the advantages that the diaphragm cutting mechanism is reasonable in structure; the diaphragms on the upper side and the lower side of the cutter can be stably compressed by the one-way wheel and the pushing strip at first and then can be stably and accurately cut off by sawteeth of the cutter, accordingly, the lengths of the diaphragms wound on battery cells are consistent with one another, the consistency and thequality of the battery cells can be improved, and benefits of enterprises can be increased.

Owner:DONGGUAN ZEYUAN MACHINE

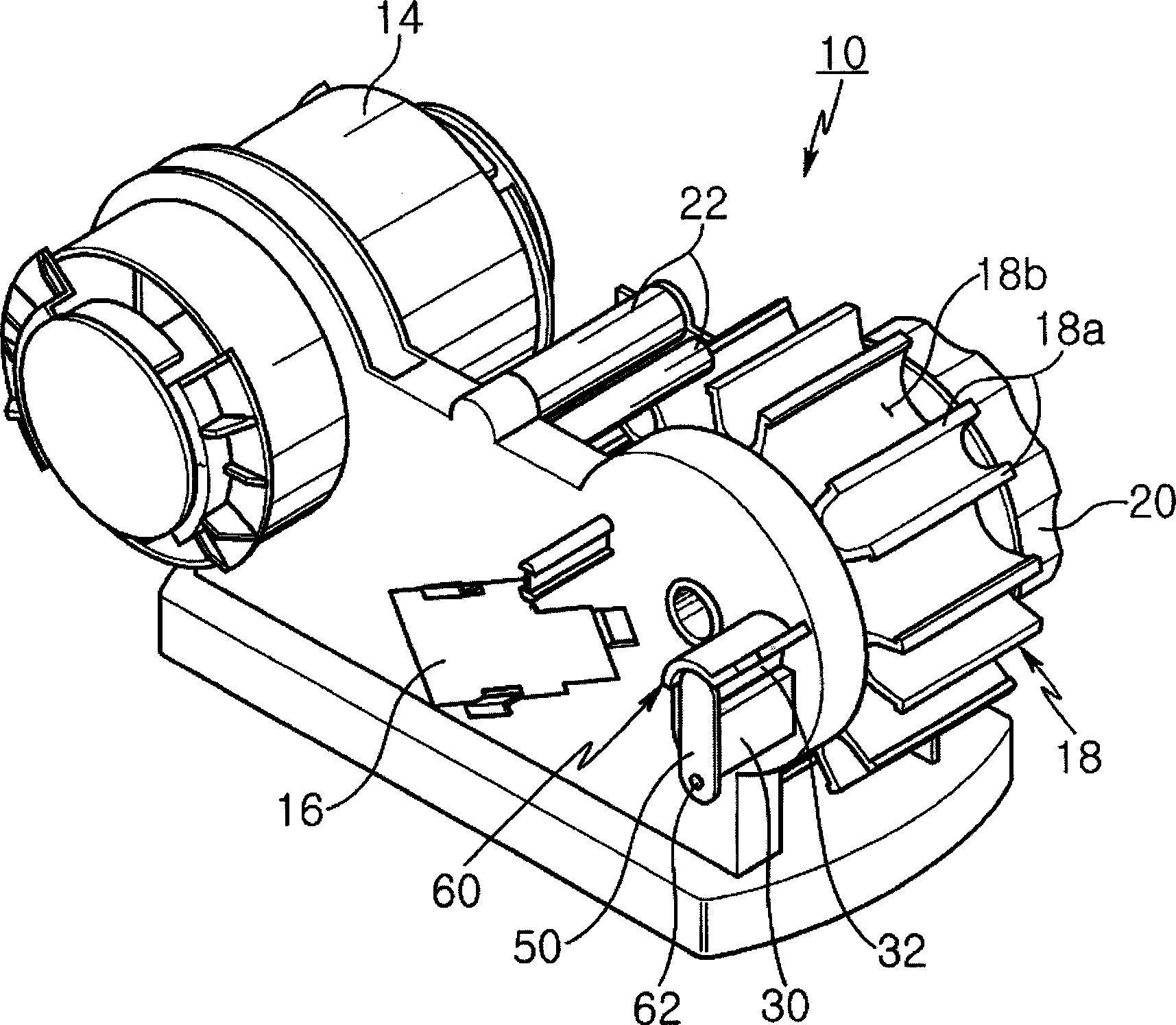

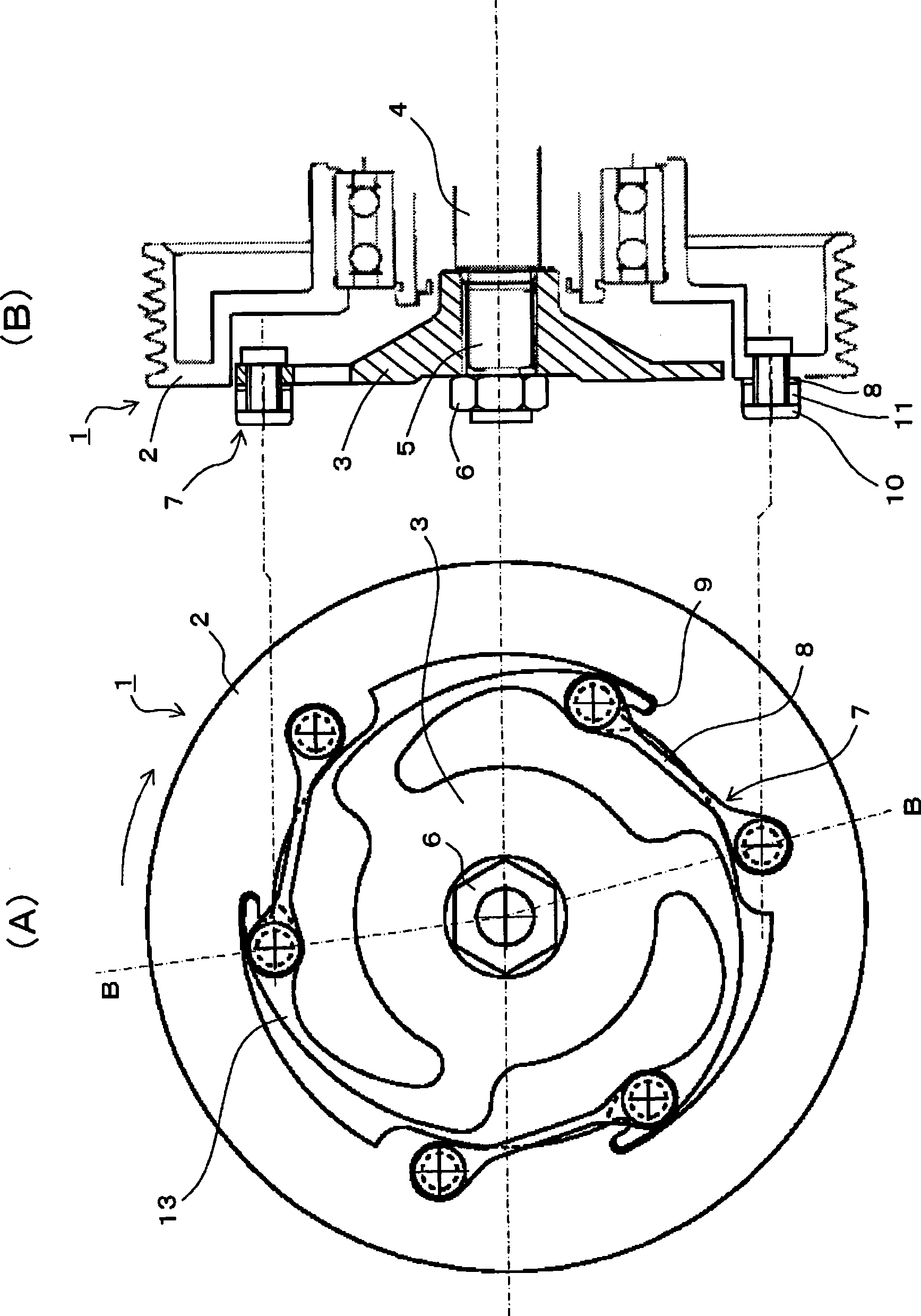

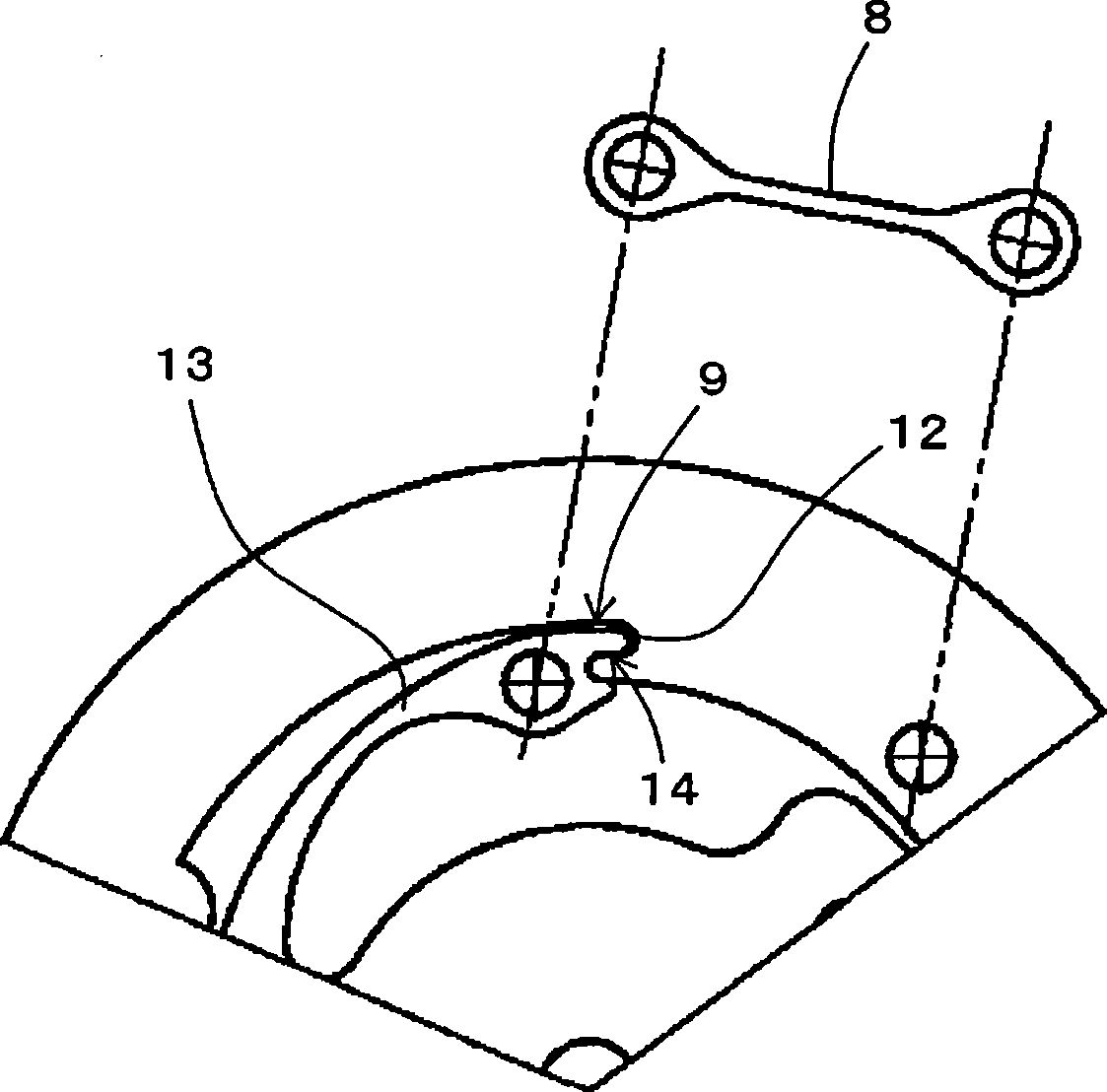

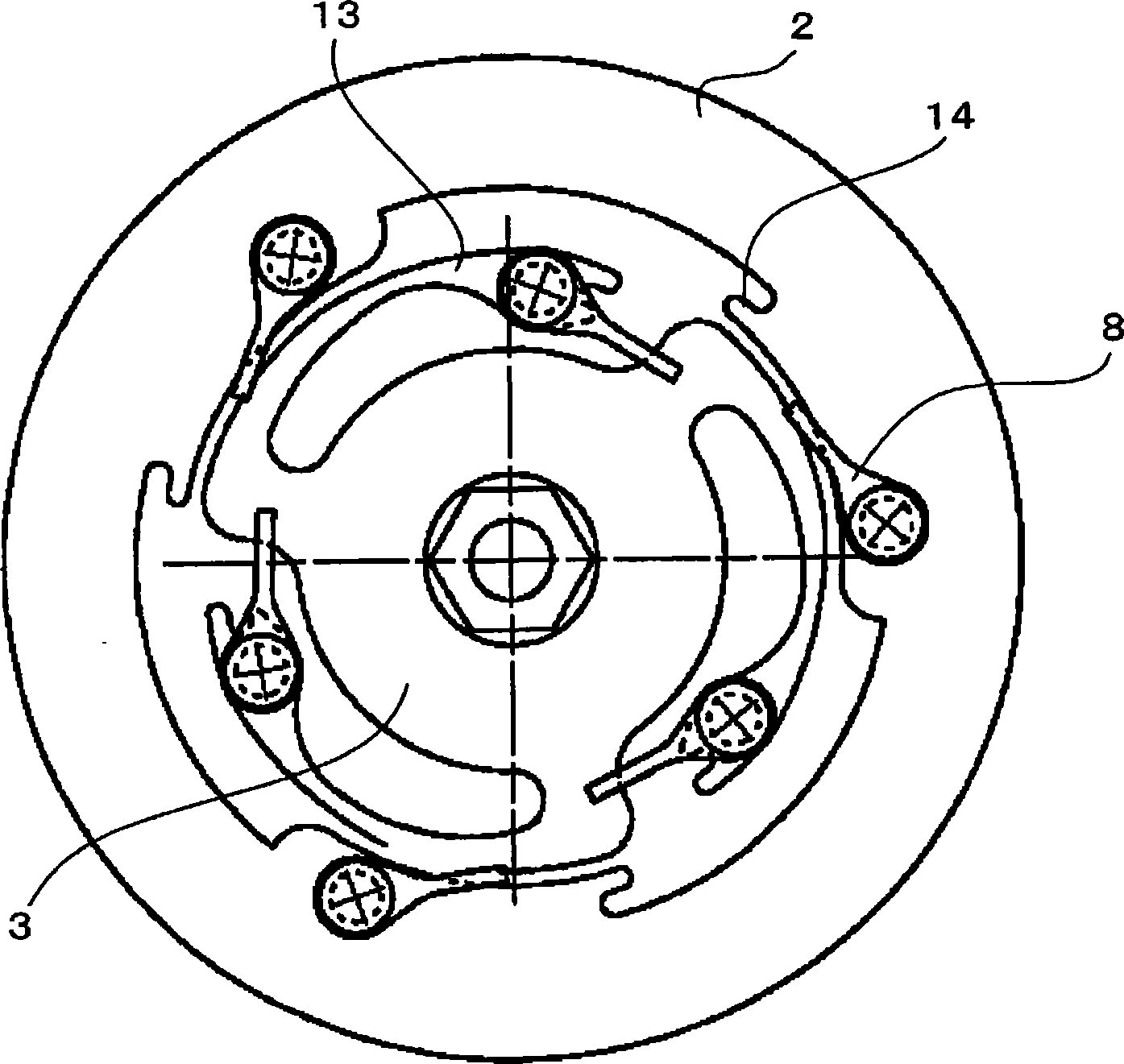

Power transmission device

ActiveCN101512174ASuppress fatigueCut off accuratelyYielding couplingGearingTorque transmissionEngineering

A power transmission device in which a driven body and a driving body for driving the driven body are rotated in the same direction and are connected to each other by a connection section to transmit torque of the driving body to the driven body and in which the transmission of the torque from the driving body is interrupted when a drive load on the driven body exceeds a predetermined level. The connection section is constructed by combining separate elements that are a positive torque transmission member, and a negative torque transmission mechanism or a negative torque transmission member. The positive torque transmission member transmits torque in the normal rotational direction and interrupts transmission of torque from the driving body by breaking itself when a drive load on the driven body exceeds the predetermined level. The negative torque transmission mechanism or the negative torque transmission member can transmit torque in the reverse rotational direction. In the power transmission device, fatigue of materials of the connection section is suppressed and torque is accurately interrupted at a target interruption torque value.

Owner:三电株式会社

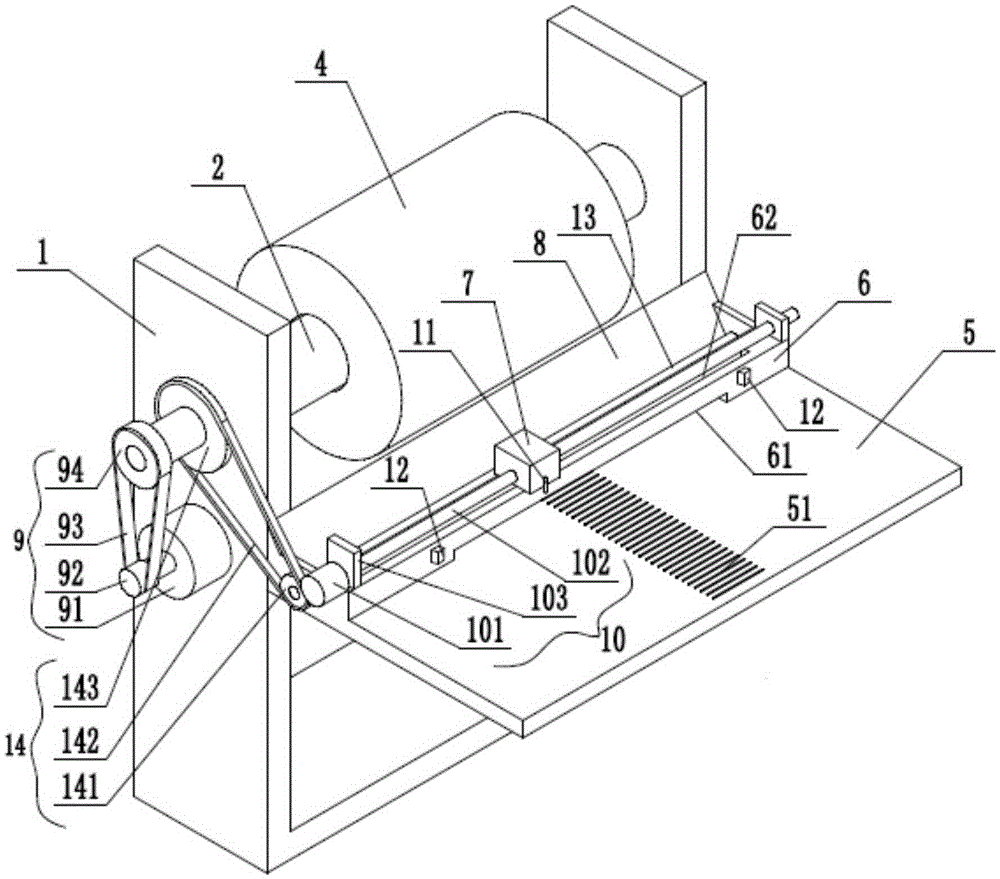

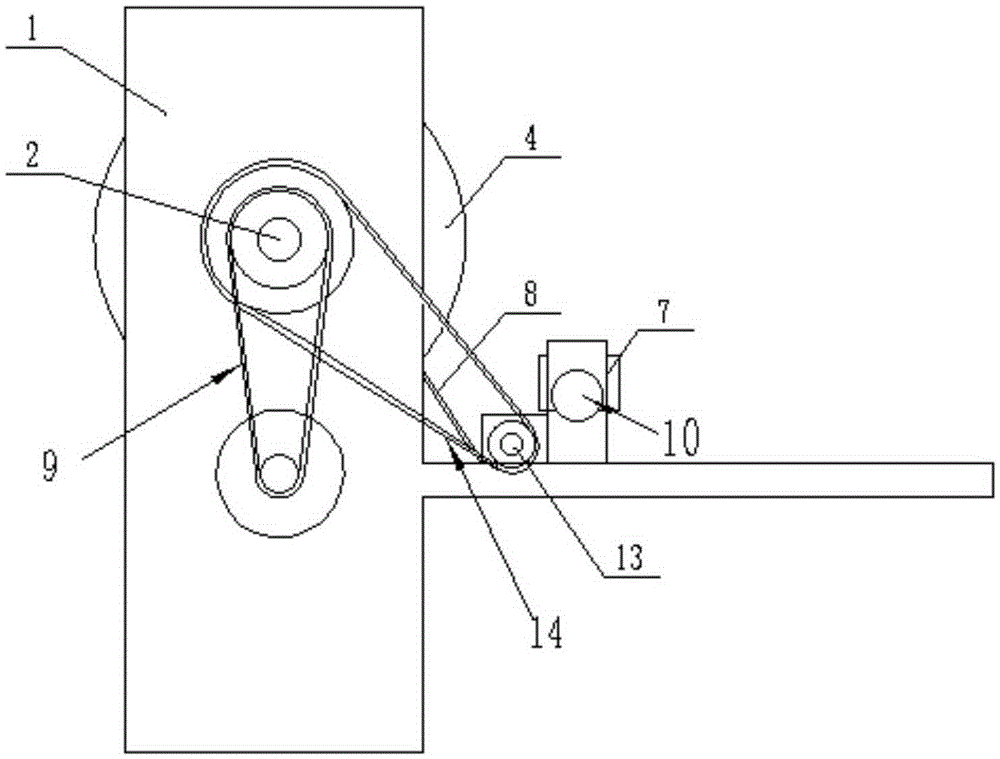

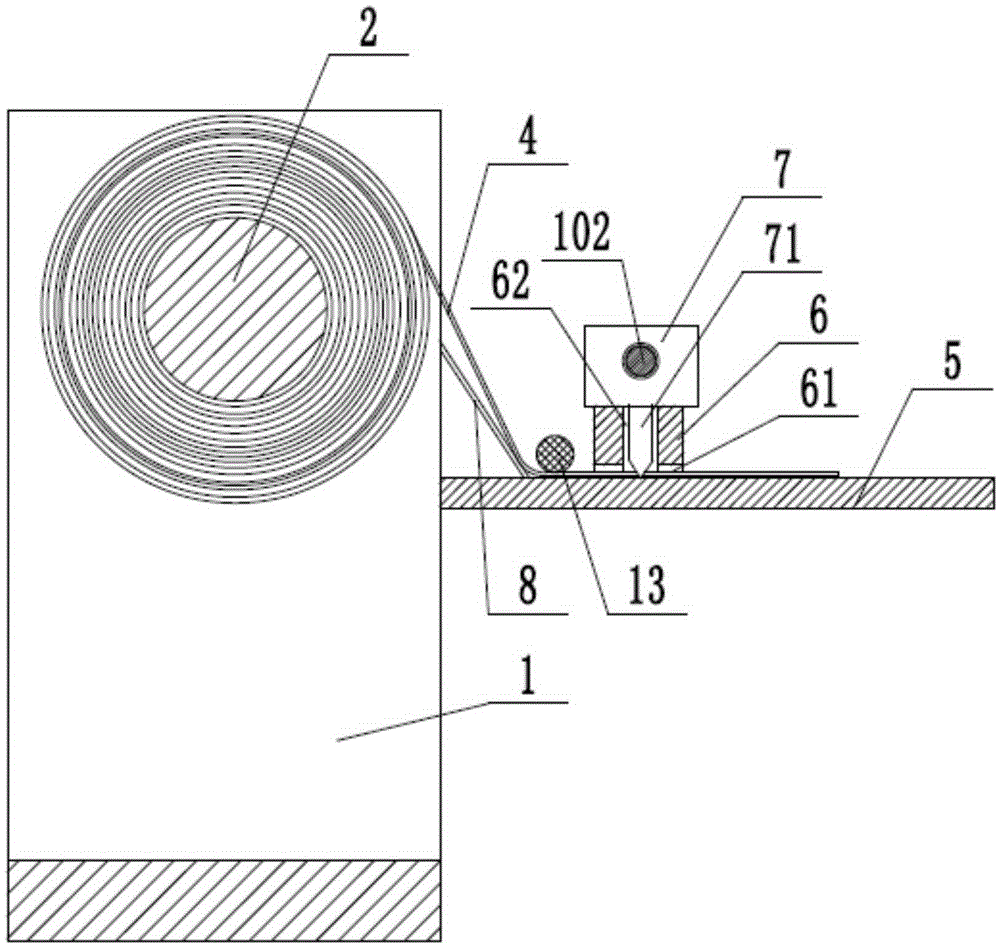

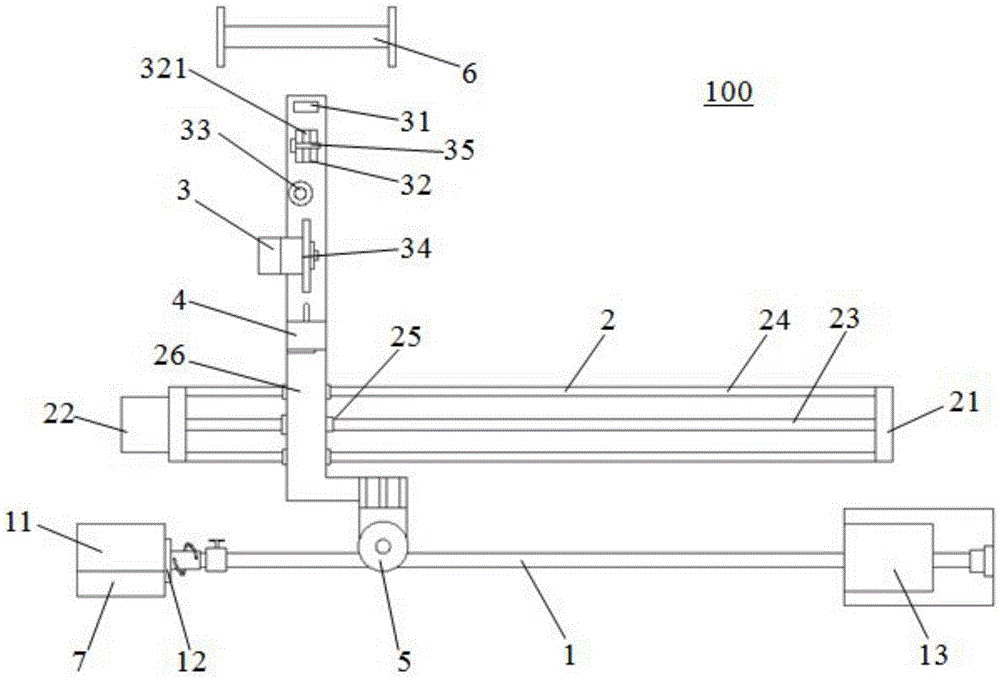

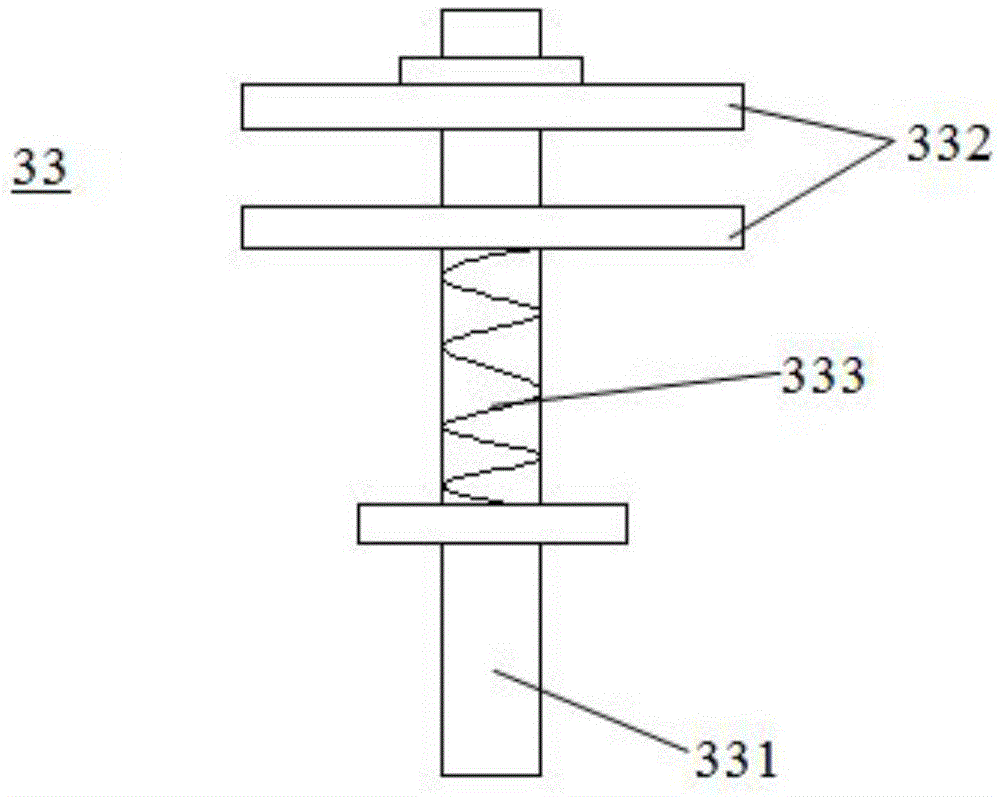

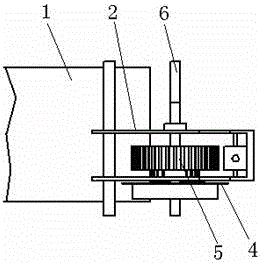

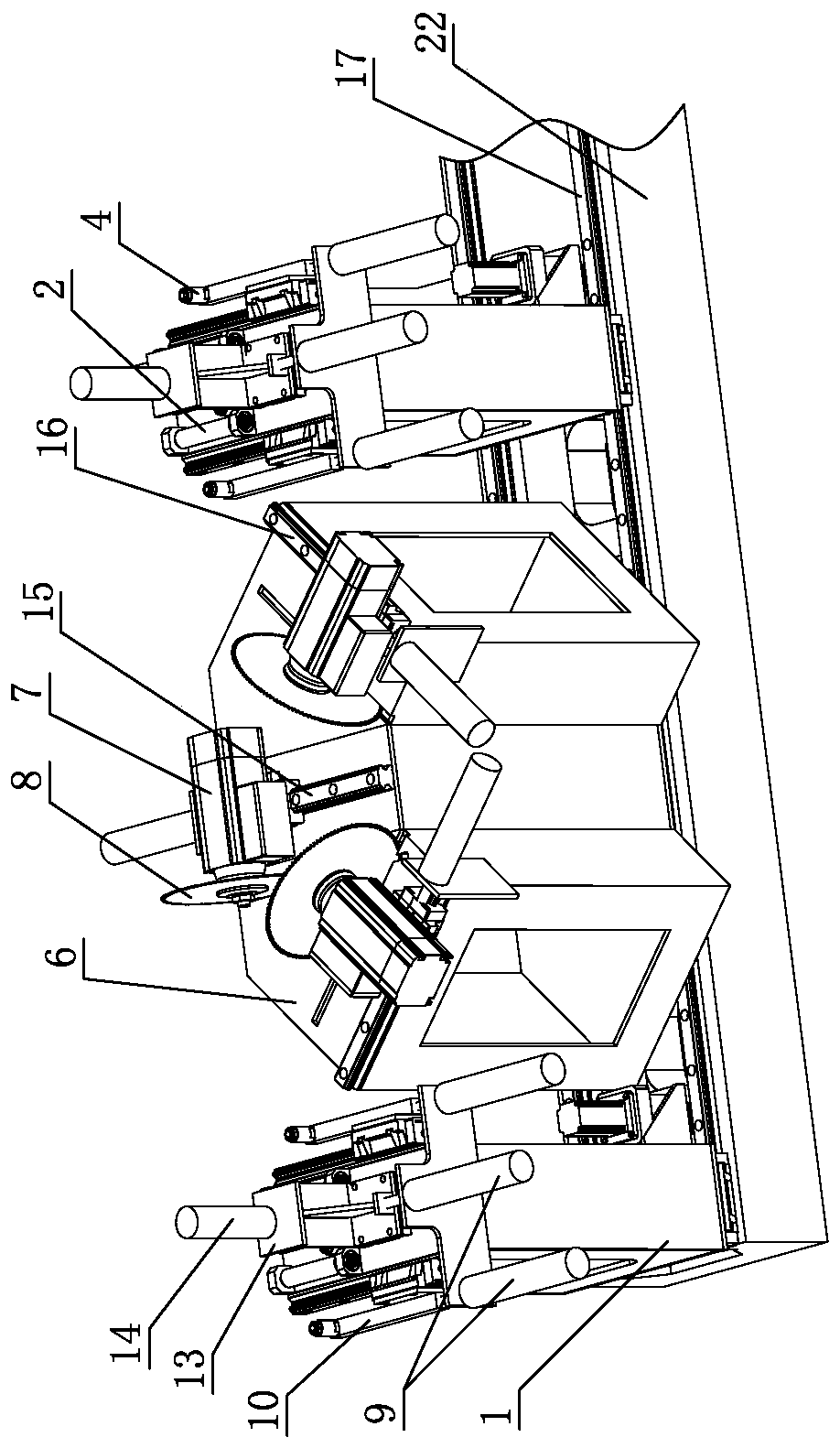

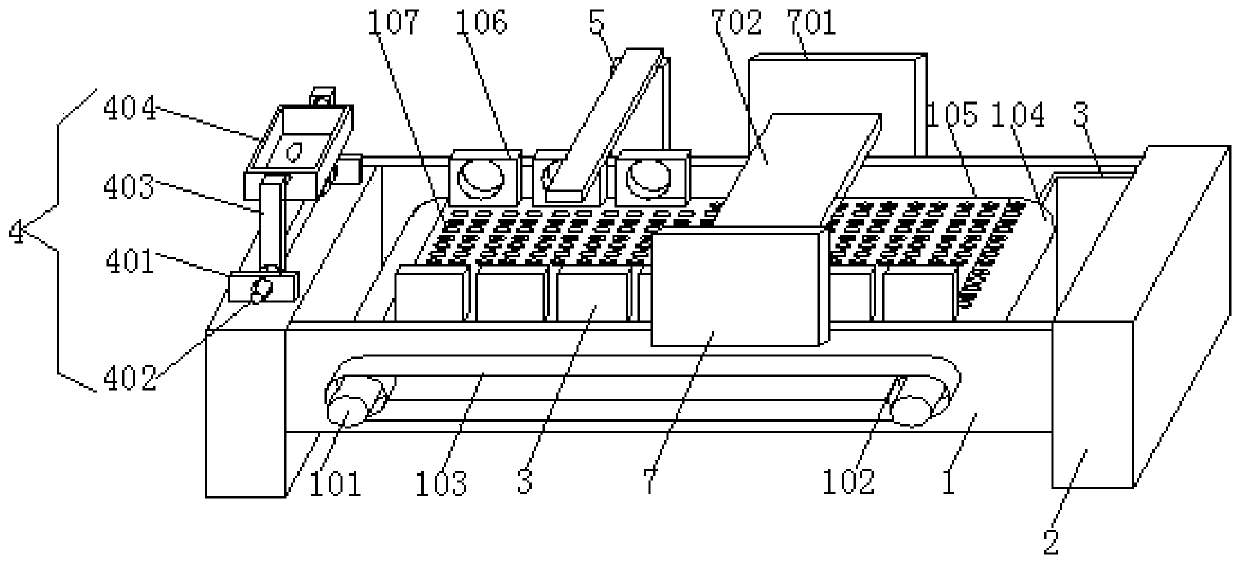

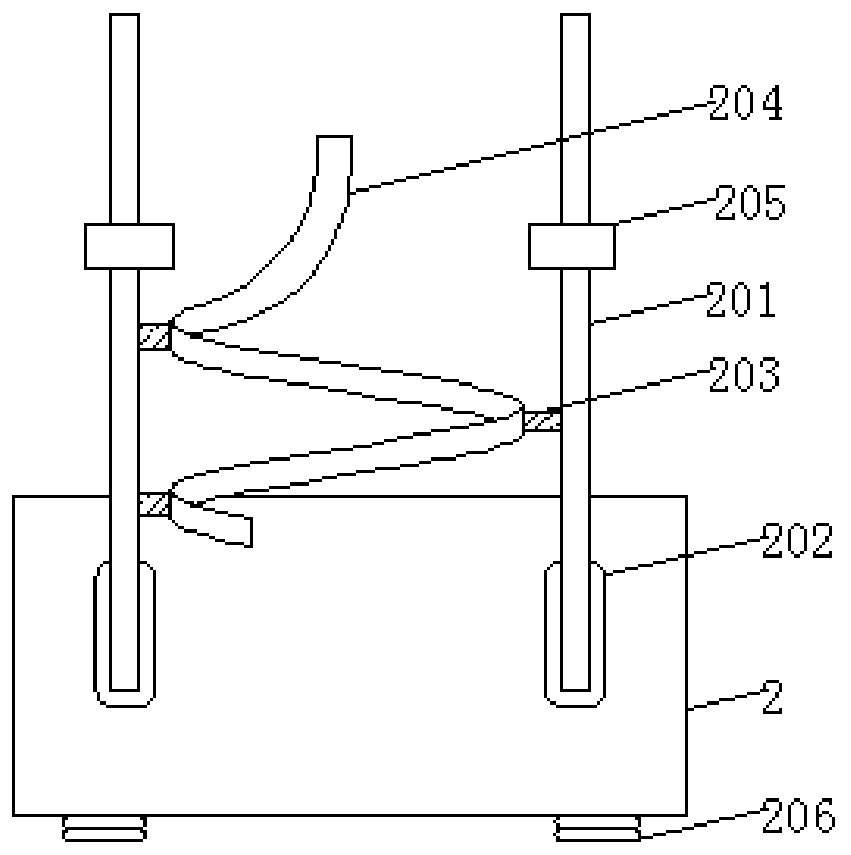

Automatic wire winding machine for spring wires

ActiveCN105665586AEnsure consistencyStable tension controlNon-rotating vibration suppressionElectricityWinding machine

The invention discloses an automatic wire winding machine for spring wires. The automatic wire winding machine comprises a wire winding drive device, a transfer device which is horizontal with the wire winding drive device, a wire cable guide device, a cut-off device, a vibration damping device. The wire cable guide device, the cut-off device and the vibration damping device move on the transfer device., a pay-off rack used for supporting cable coil stock, and a control unit, wherein the control unit is electrically connected to the wire winding drive device, the transfer device, the cut-off device, and the wire cable guide device. According to the automatic wire winding machine, the wire cable guide device, the cut-off device and the wire cable guide device are arranged on the transfer device, and are kept to be synchronous with the movement speed, on a wire winding shaft, of the wire cables, so that the wire cables are guaranteed to be perpendicular to the wire winding shaft all the time during the conveying process. Therefore, the automatic wire winding machine is beneficial for stabilizing tension control, and also guarantees the consistency of elastic force of a spring; the vibration damping device is arranged beside the wire winding shaft, and is synchronous with a cable to move along the wire winding shaft, so that the vibration of the wire winding shaft is further reduced, and therefore, the precision is improved.

Owner:SUZHOU CABLEPLUS ELECTRIC

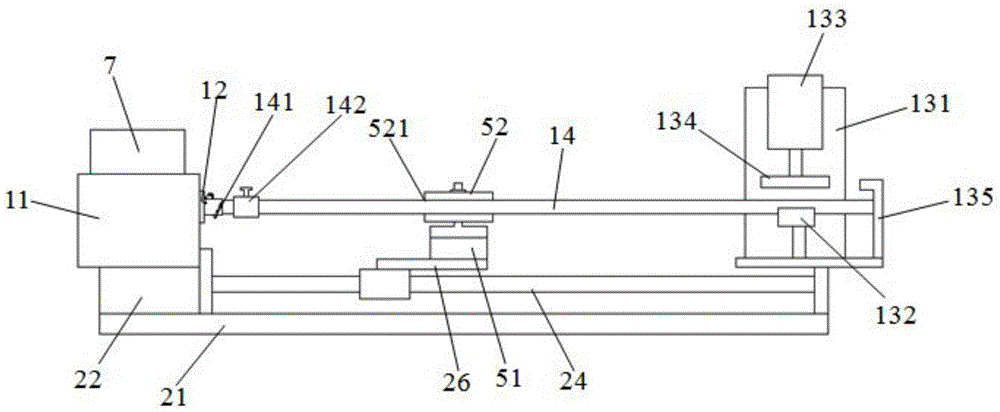

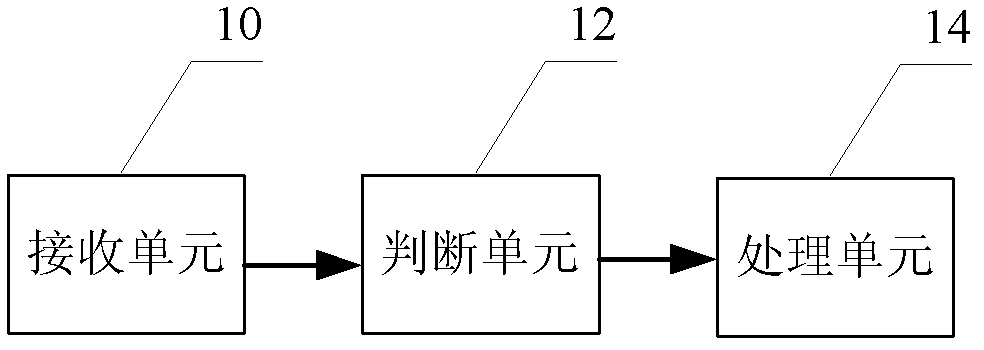

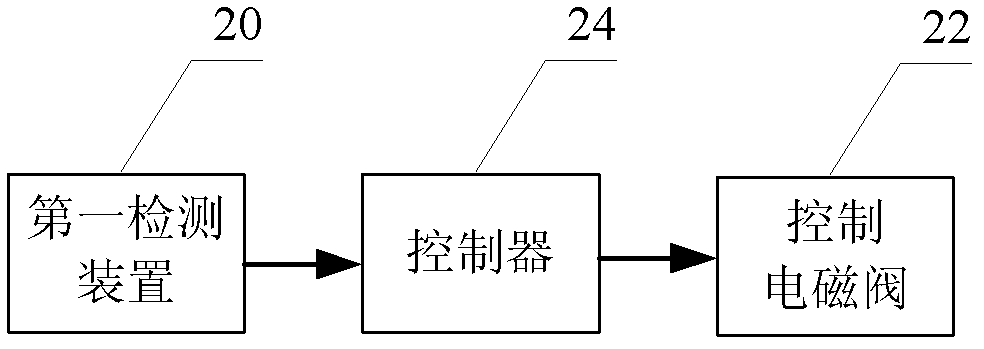

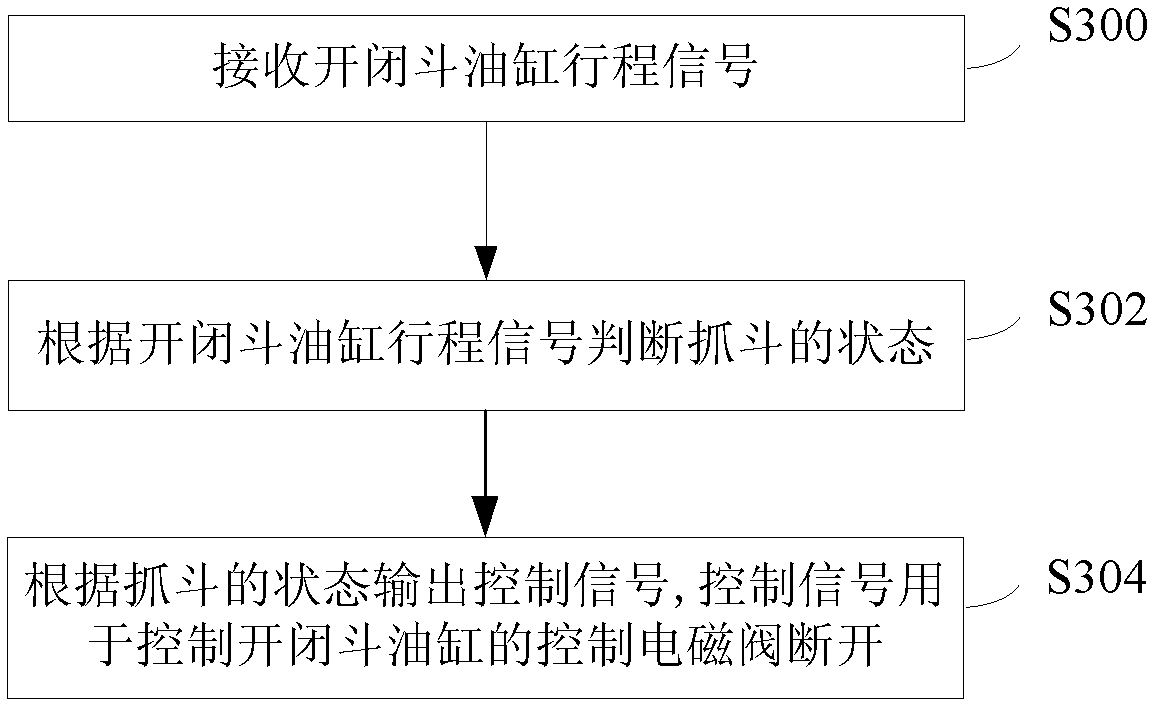

Grab controller, control system and control method as well as engineering mechanical equipment

ActiveCN102628290ACut off accuratelyEliminate lossSoil-shifting machines/dredgersControl systemControl signal

The invention discloses a grab controller, a control system, a control method as well as engineering mechanical equipment. The grab controller comprises a receiving unit, a judging unit and a processing unit, wherein the receiving unit is used for receiving a stroke signal of an opening-closing bucket cylinder; the judging unit is used for judging the state of a grab according to the stroke signal of the opening-closing bucket cylinder; the processing unit is used for outputting a control signal according to the state of the grab; and the control signal is used for controlling a control electromagnetic valve of the opening-closing bucket cylinder to be switched off. The state of the grab is determined through detecting the stroke of the opening-closing bucket cylinder, the control signal is outputted according to the state of the grab, an opening-closing bucket control valve bank needing to be switched off can be switched off in time accurately, and energy loss caused by shutoff pressure of an opening-closing bucket action system is eliminated, thereby the energy-saving and emission-reducing effects are achieved.

Owner:ZOOMLION HEAVY IND CO LTD

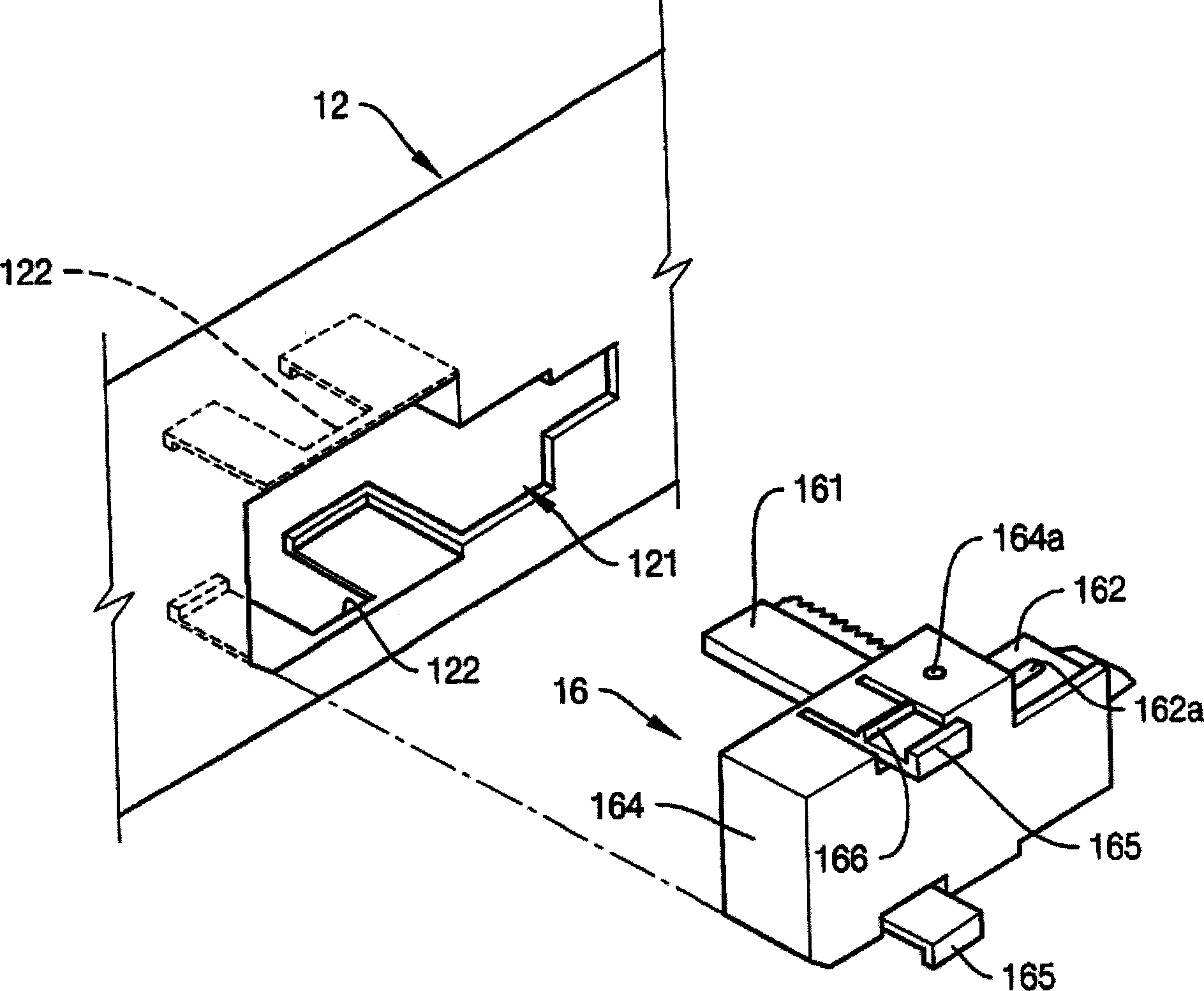

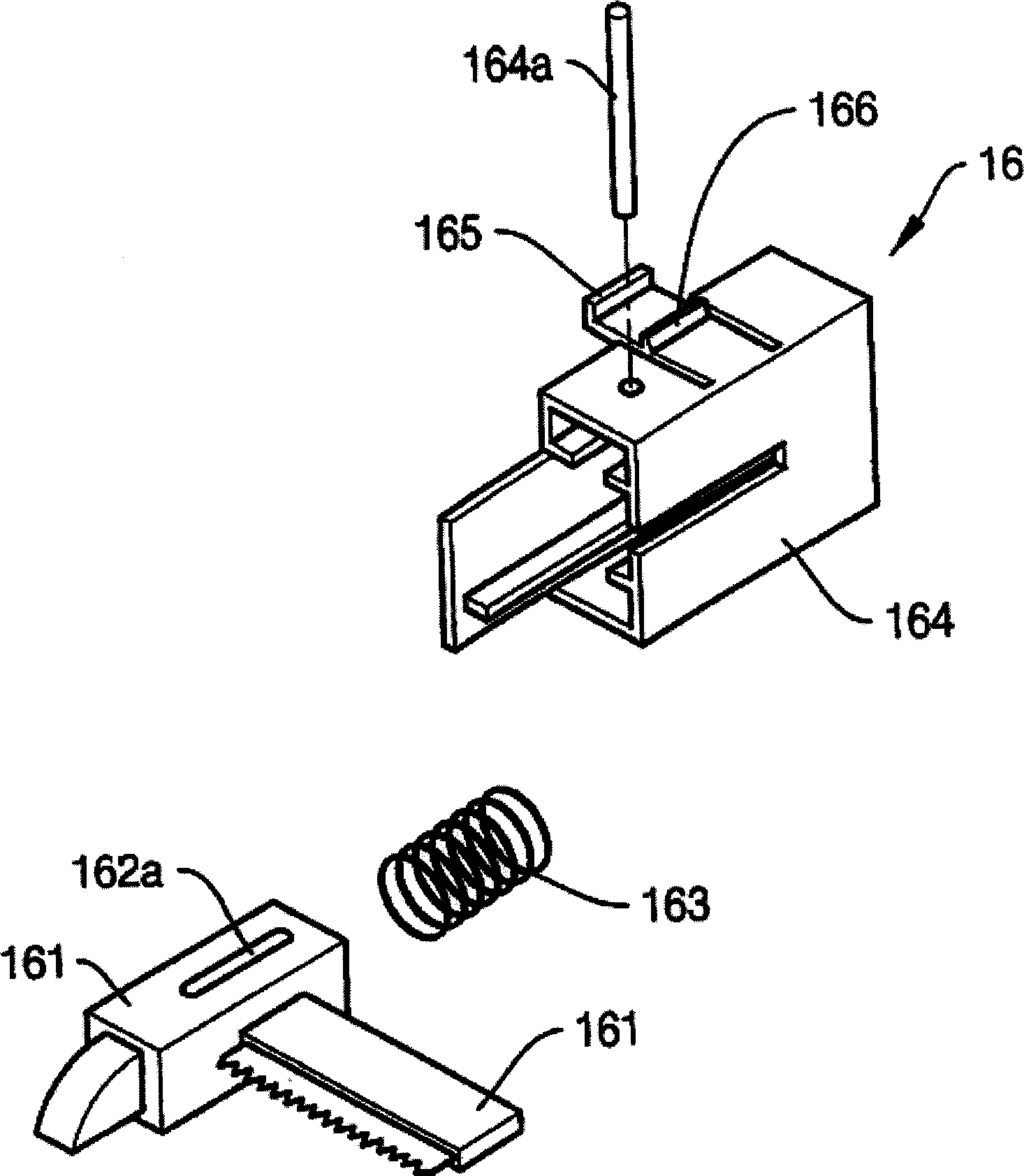

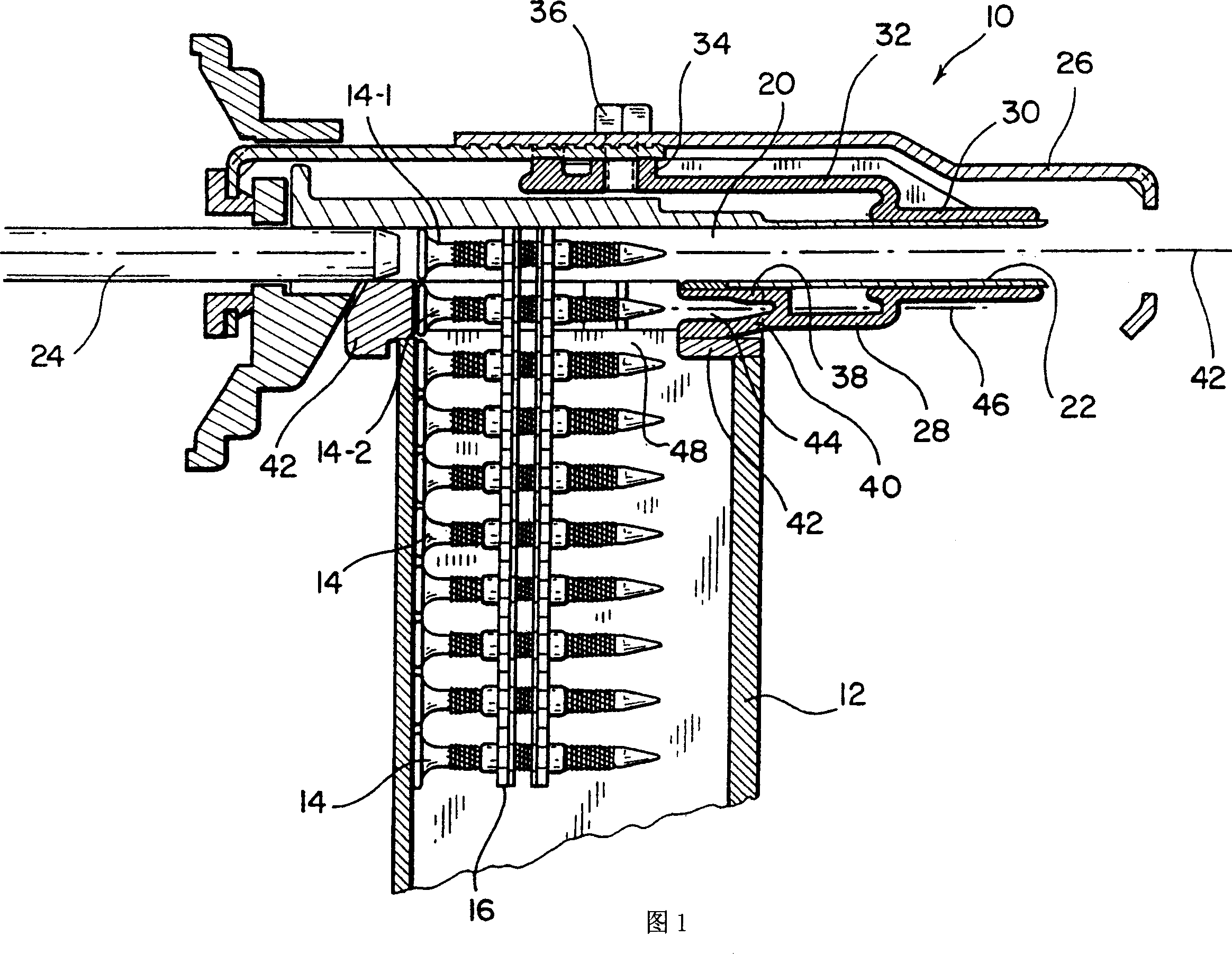

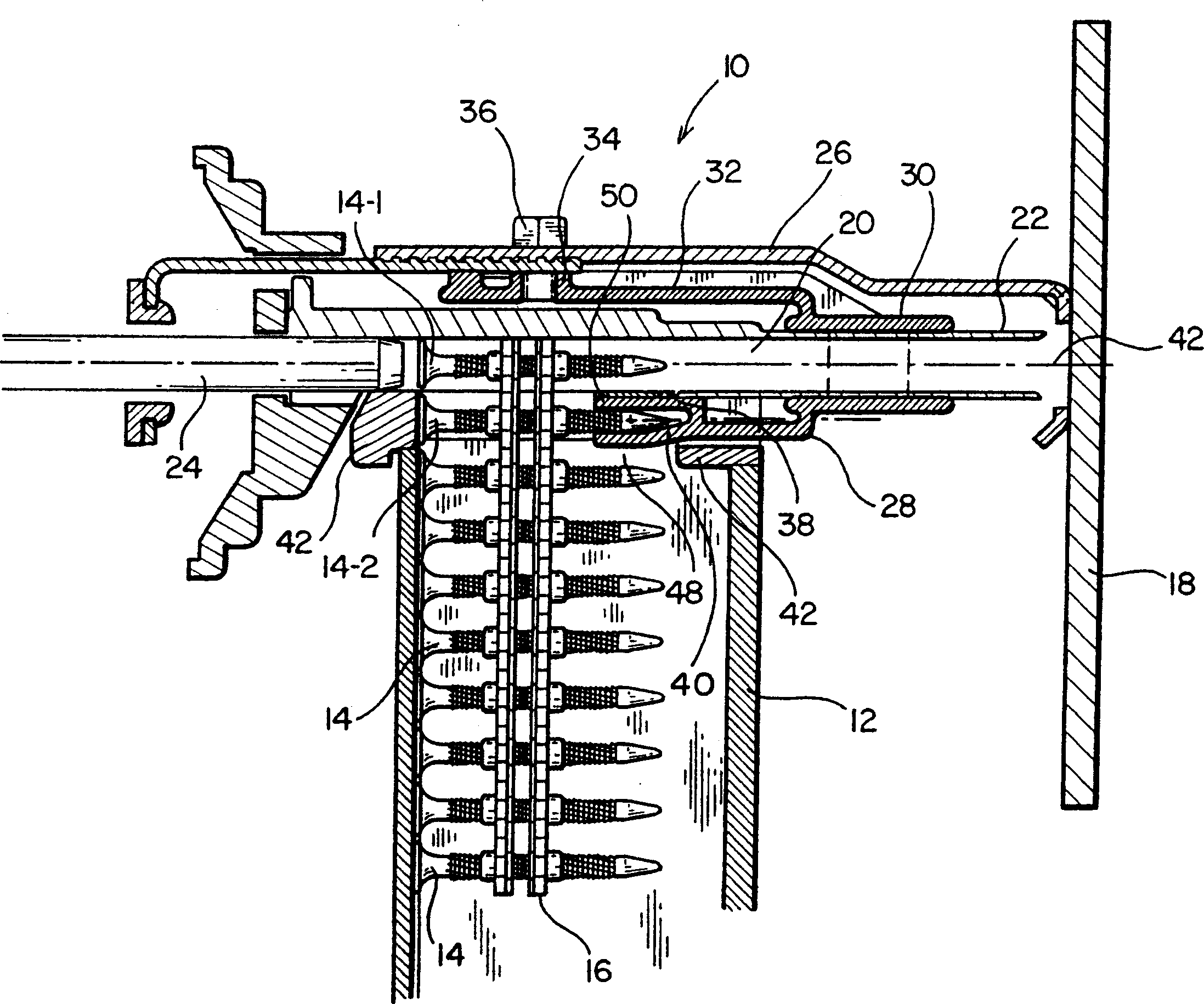

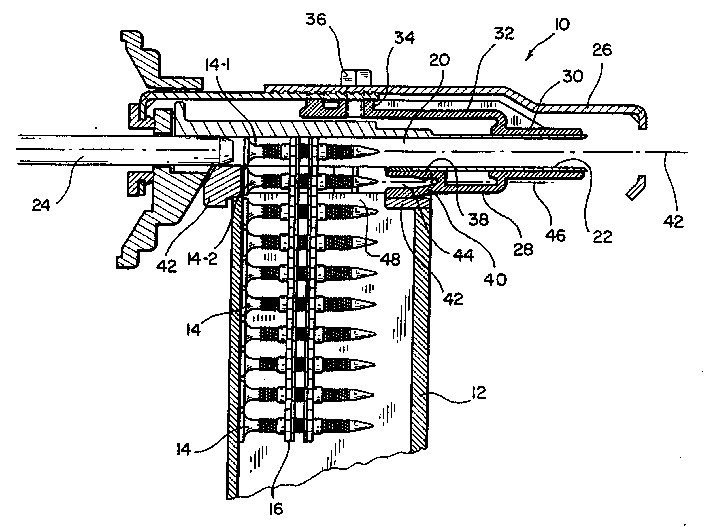

Telescopic supporter for driving tool of fastening component

InactiveCN1406720AImpact reductionCut off accuratelyStapling toolsPortable percussive toolsLeading edgeEngineering

A support device for use within a fastener driving tool is fixedly attached to the tool's workpiece contact element so as to be movable therewith between extended and retracted positions. When the workpiece contact element, and the support device mounted thereon, are moved to the retracted position, a pocket or recessed portion of the support device will envelop a tip portion of a second uppermost fastener disposed within the tool magazine, while the first uppermost fastener is disposed within the tool drive bore, such that the second uppermost fastener, as well as the remaining fasteners within the magazine, is properly supported and stabilized such that shock and vibrational forces, attendant the driving of the first uppermost fastener, are effectively prevented from being transmitted to the second uppermost and remaining fasteners. In addition, the pocket or recessed portion serves to partially close the magazine opening through which the fasteners are serially advanced such that the first uppermost fastener will be maintained coaxially aligned within the tool drive bore, and an upstream leading edge of the pocket or recessed portion also defines a shearing edge for properly shearing those portions of the collation strip which interconnect adjacent pairs of the fasteners within the collated strip of fasteners.

Owner:ILLINOIS TOOL WORKS INC

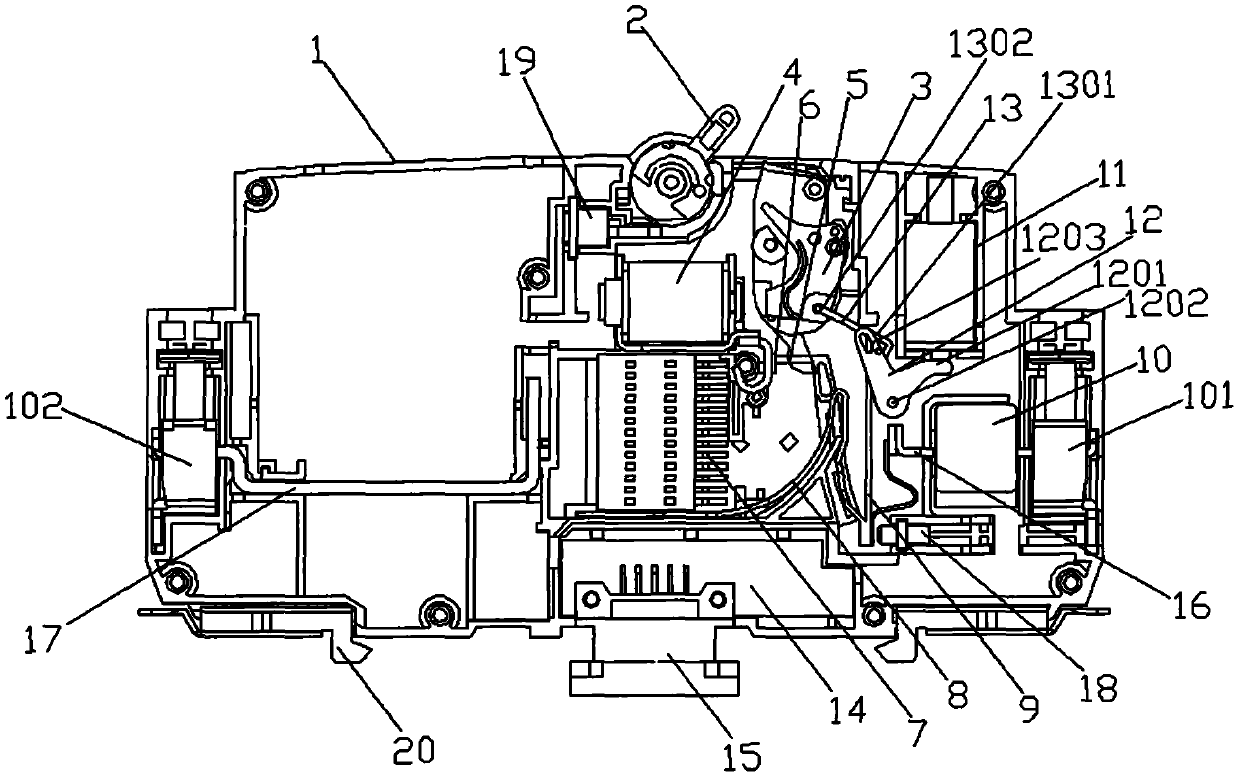

Intelligent circuit breaker

PendingCN110137048ARealize intelligent controlImplement localSwitch terminals/connectionsSwitches with electromagnetic releaseIntelligent controlCircuit breaker

The invention provides an intelligent circuit breaker, which comprises a housing, a first wiring end, a second wiring end, a handle, a tripping linkage mechanism, an electromagnetic tripper, a movingcontact, a static contact, a bimetal sheet, a current transformer, a drive mechanism, a first driving member, a second driving member, a first connecting member, a second connecting member and a circuit board. The moving contact is corresponding to the static contact. The intelligent circuit breaker can solve the problem that a traditional circuit breaker is poor in protection precision and incomplete in protection, realizes a distribution protection function and meanwhile, realizes intelligent control of the intelligent circuit breaker, can carry out on / off control according to power demand,and can also realize local or remote centralized monitoring management, thereby improving power distribution safety and intelligence degree.

Owner:天津市中力神盾电子科技有限公司

Noise-free tobacco leaf unbundling and cutting machine

ActiveCN106418634ACut off accuratelyEfficient solution to cut offTobacco preparationEngineeringUltimate tensile strength

The invention provides a noise-free tobacco leaf unbundling and cutting machine. The noise-free tobacco leaf unbundling and cutting machine comprises a rack, a conveying belt arranged under the rack, an upper hob and a lower hob arranged, wherein the upper hob and the lower hob are arranged at the ends of the conveying belt; the noise-free tobacco leaf unbundling and cutting machine is characterized in that elastic supporting rolling wheels are arranged on the rack, and each elastic supporting rolling wheel comprises an inner supporting ring, an elastic supporting part arranged on the inner supporting ring and a flexible outer ring arranged on the periphery of the elastic supporting part. The elastic supporting rolling wheels are matched with the conveying belt to convey tobacco leaves and other materials in a butt-clamp and rolling mode, when the materials is nonuniform in thickness, material holding conveying force can be increased well, material blocking, deviating and falling are avoided, and tobacco leaf unbundling and cutting are completed efficiently and accurately. The problems of large noise and many faults caused by usage of chains in the prior art are solved fundamentally, and the noise-free tobacco leaf unbundling and cutting machine is safe, reliable, long in service life and convenient to maintain in follow-up period and relieves labor intensity of workers.

Owner:云南申克自动化工程有限公司

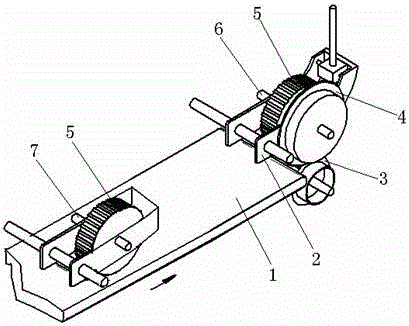

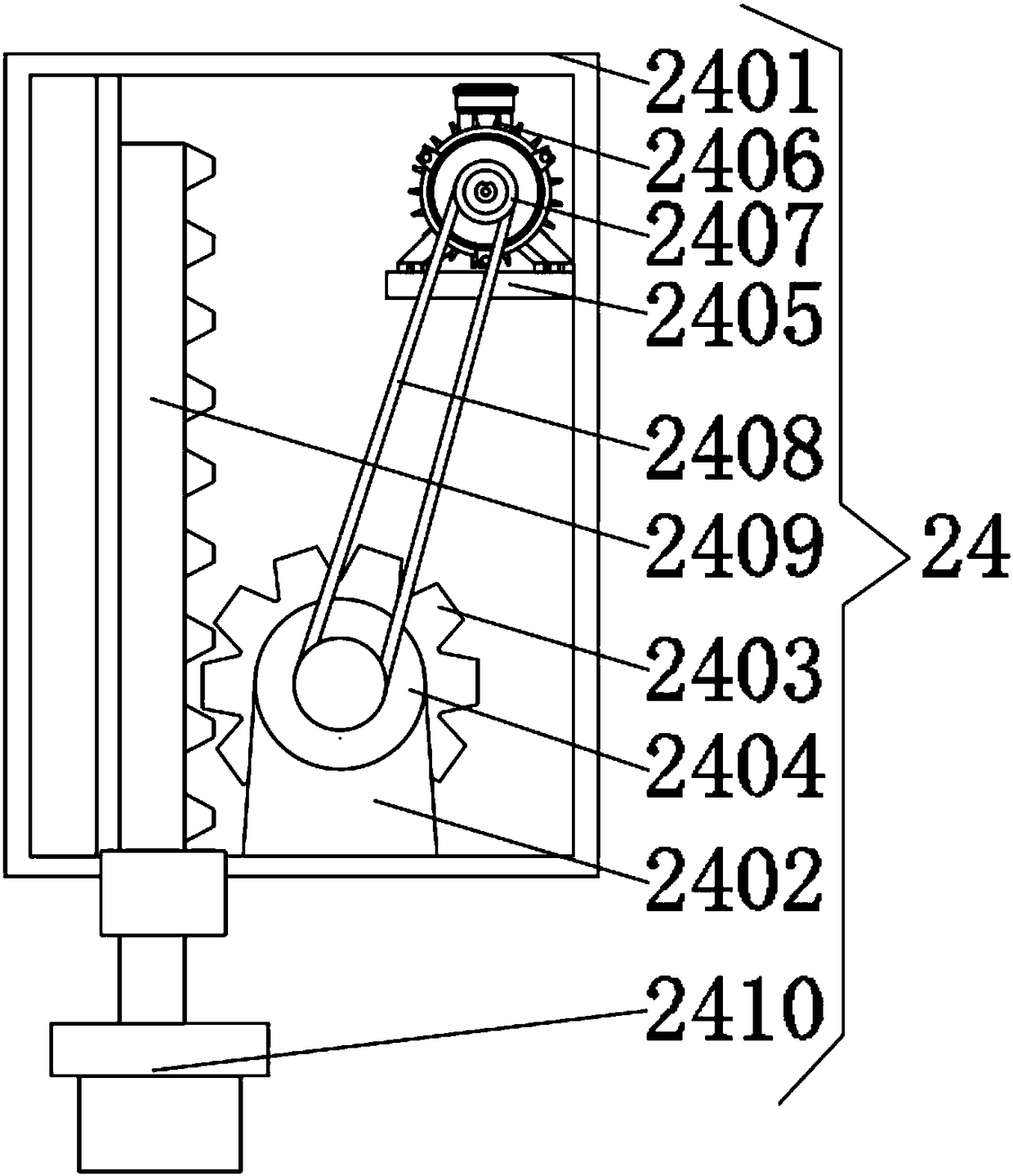

Tin wire cutting machine controllable in tin amount

ActiveCN103100612ACut off accuratelyPrecise tin volume controlSoldering auxillary devicesReciprocating motionWire cutting

The invention relates to a tin wire cutting machine controllable in tin amount. The tin wire cutting machine comprises a motor. A motor shaft of the motor is provided with a wire cutting device capable of being in reciprocating motion in the radial direction relative to the motor. A wire cutting position of the cutting device is provided with a tin wire feeding tube pile for consecutive feeding of wires. A blanking position of the wire cutting device is provided with a tin outlet tube connector. The tin wire cutting machine is precise and quantitative in tin wire, completely uniform in tin amount, reasonable in structure, and capable of discharging cut tin wires quickly, removing tin blocking phenomena, and improving automation working efficiency.

Owner:QUICK INTELLIGENT EQUIP CO LTD

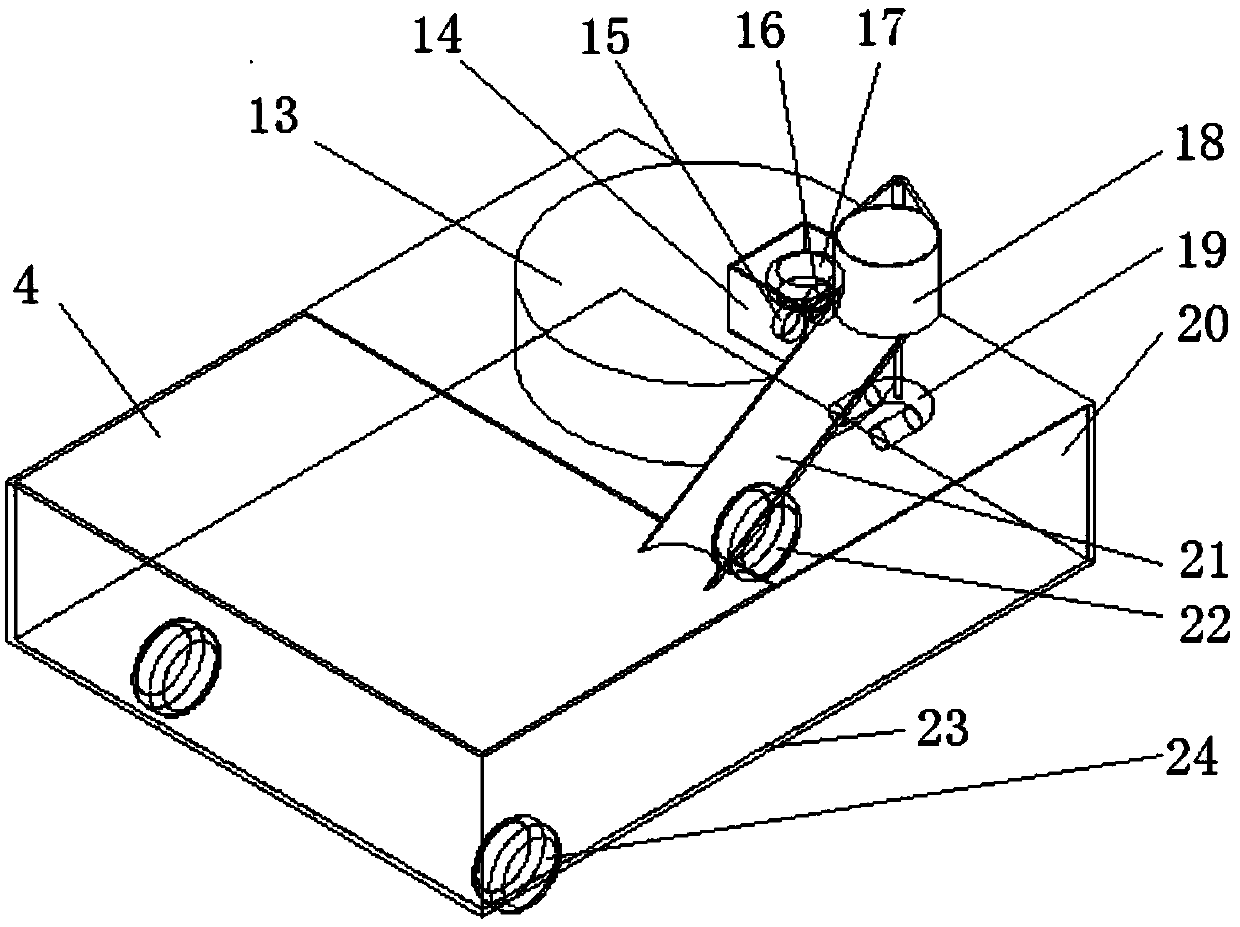

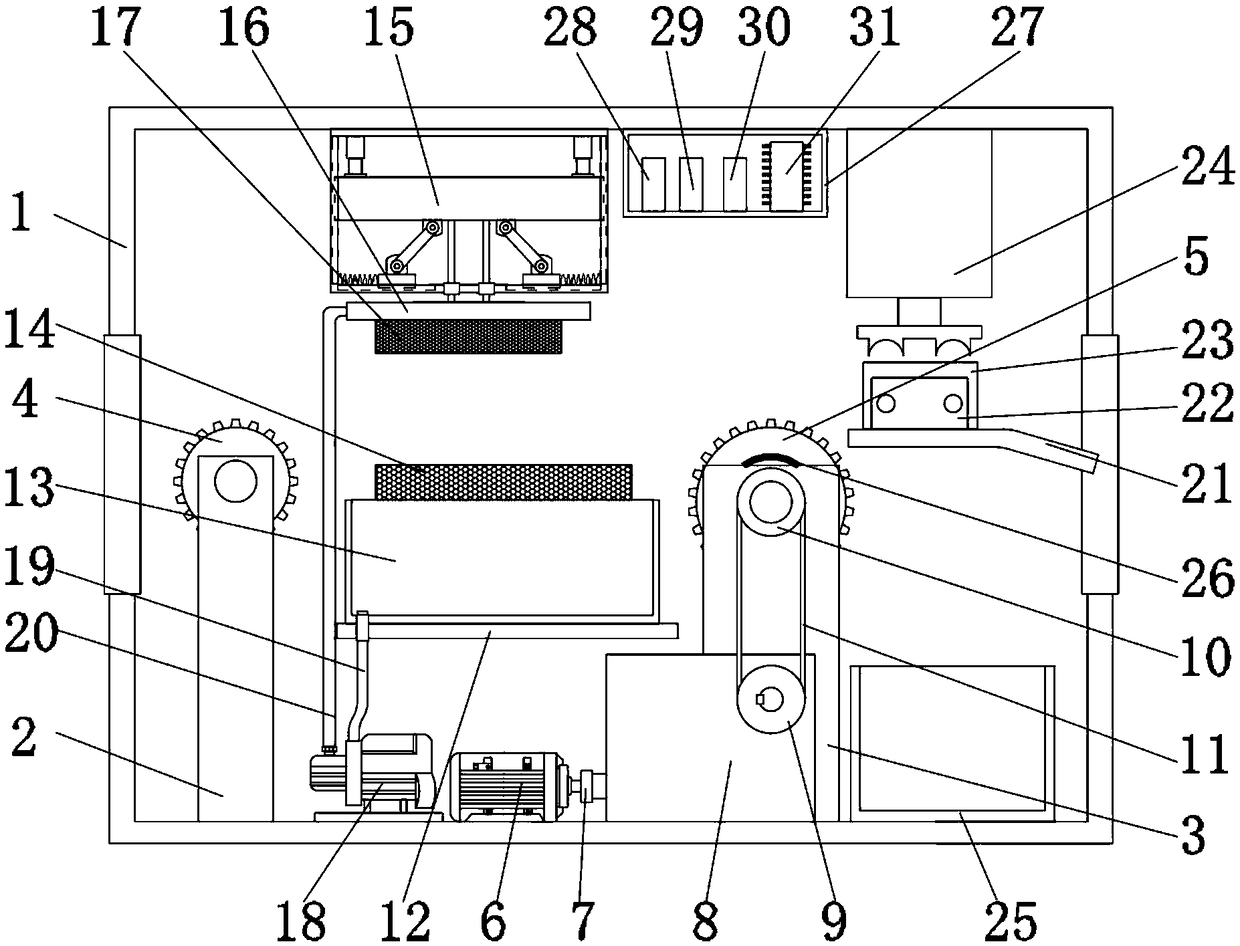

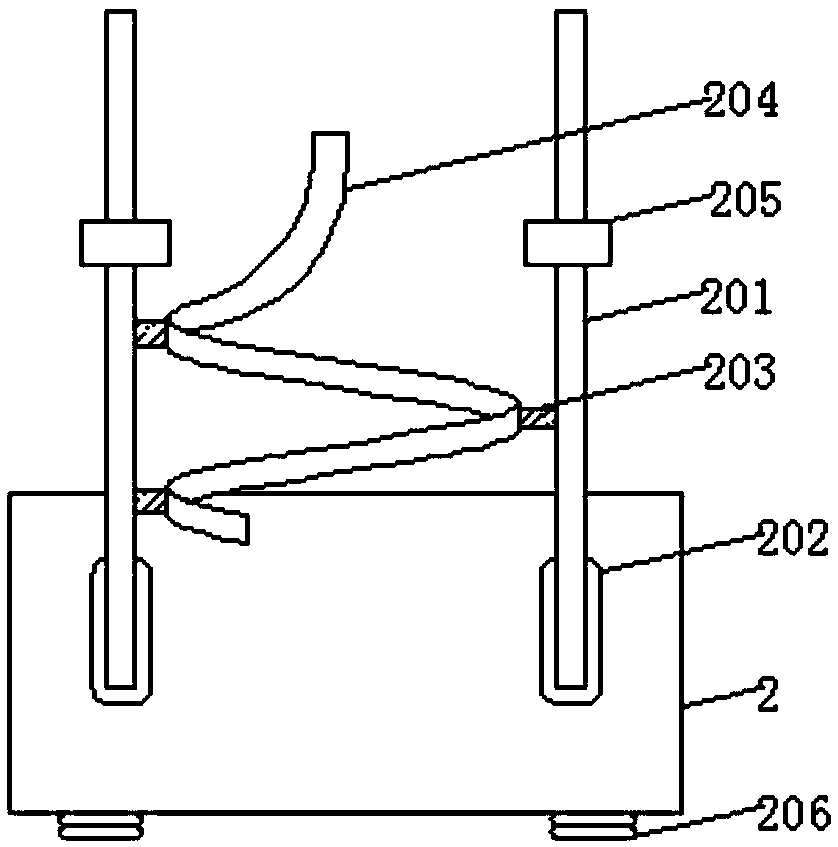

Oiling and cutting-off device for chain

InactiveCN108274236AGuaranteed lengthCut off accuratelyLiquid surface applicatorsOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses an oiling and cutting-off device for a chain. The oiling and cutting-off device for the chain comprises a box body. A first rotary wheel is rotationally connected with the bottom of the inner wall of the box body through a first supporting rod. A second rotary wheel is rotationally connected with the bottom of the inner wall of the box body through a second supporting rod.A first motor is fixedly connected with the bottom of the inner wall of the box body. The output shaft of the first motor is in transmission connection with the second rotary wheel through a speed reducer and a first belt. An oil tank is fixedly arranged between the two opposite sides of the inner wall of the box body through a supporting plate in a connected manner. A telescopic device is fixedlyconnected with the top of the inner wall of the box body. A fixed plate is fixedly arranged between the two opposite sides of the inner wall of the box body in a connected manner. An extrusion base and an extrusion device are fixedly arranged on the top of the fixed plate in sequence in a connected manner. A positioning device is fixedly connected with the position, opposite to the fixed plate, of the top of the inner wall of the box body. The oiling and cutting-off device for the chain relates to the technical field of chain machining. With the oiling and cutting-off device for the chain, itis solved that oiling in the prior art is uneven, oil resources are saved, and meanwhile, it is realized that the chain is quickly cut off as needed.

Owner:湖州众诚链传动制造厂

Method for producing alignment mark

InactiveCN1279583CEasy Laser RepairElasticSemiconductor/solid-state device manufacturingDielectricTitanium nitride

The invention discloses a method for manufacturing an alignment mark (Alignment Mark), which is to first form an inter-metal dielectric (Inter-Metal Dielectric; IMD) layer on a top metal layer (Top Metal Layer) such as an aluminum-copper alloy, and then After forming a layer of low-reflective material such as titanium nitride (TitaniumNitride; TiN), and then forming a metal layer on the low-reflective material layer, and using this metal layer to manufacture alignment marks, so the alignment marks are consistent with the underlying The light-dark contrast between the layers of low-reflective material is obvious, which facilitates the alignment of subsequent laser repairs. In addition, the low reflectivity material layer can also be used as an etching stop layer (Etching Stop Layer) of the metal layer.

Owner:TAIWAN SEMICON MFG CO LTD

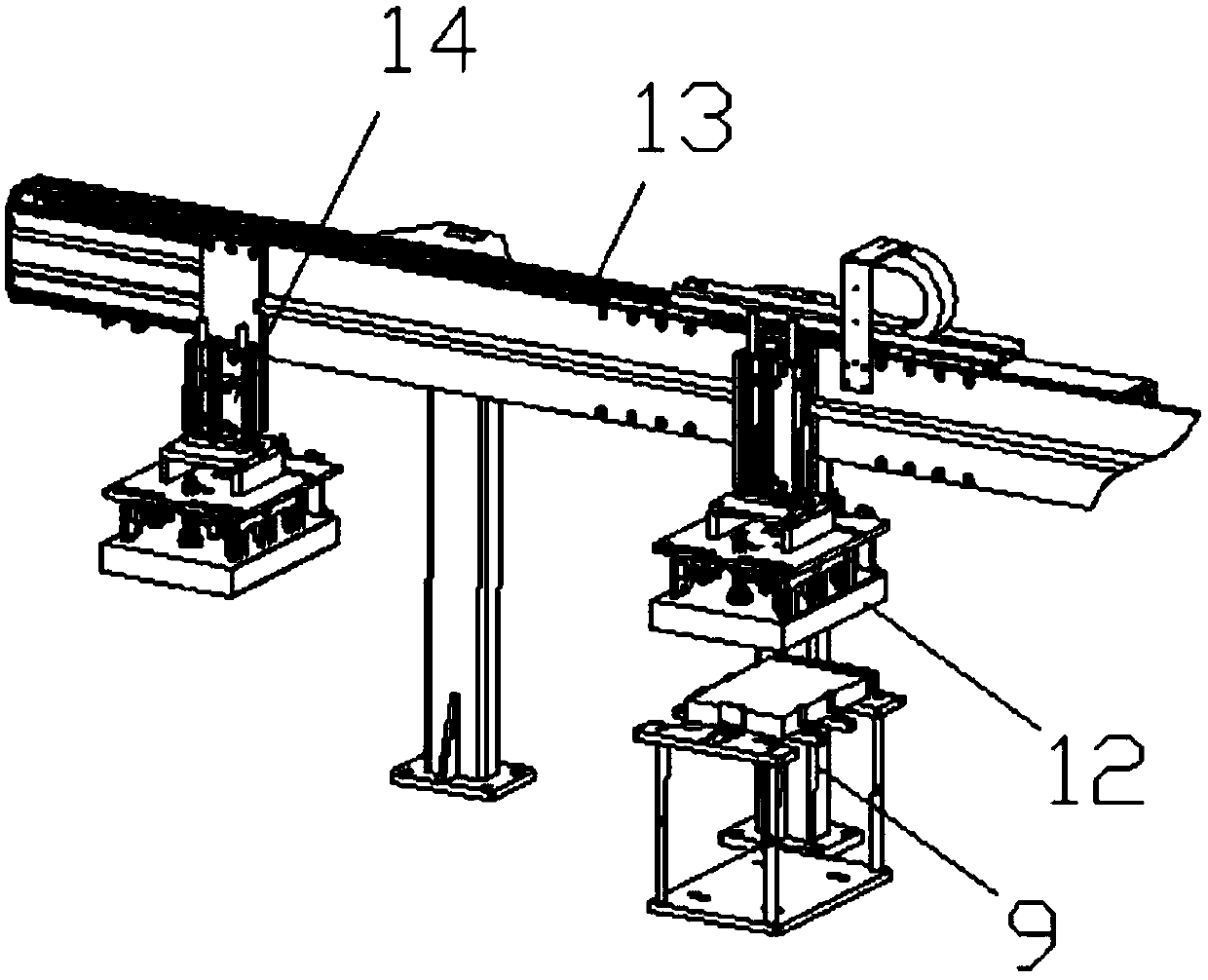

Lithium battery with protection apparatus and assembling machine of lithium battery

ActiveCN107706319AExtended service lifeRealize automatic assemblyAssembling battery machinesFinal product manufactureEngineeringNickel

The invention relates to a lithium battery with a protection apparatus. The lithium battery comprises a battery main body, copper sheets and a cover plate; the upper and lower surfaces of each coppersheet are pasted with a nickel strap and an adhesive tape in sequence; positioning holes are formed in the upper and lower parts of the two ends on the inner side of the cover plate respectively, andan upper protection inserting block and a lower protection inserting block are mounted in the positioning holes in the upper and lower parts by matching with positioning columns respectively; the upper protection inserting block comprises an upper protection block main body matched with one side, close to the cover plate, of the upper part copper sheet; a protection positioning block inserted to the space between the two groups of copper sheets is arranged in the middle position of the upper protection block main body; a protection positioning inserting groove is formed in the lower part of the protection positioning block; the lower protection inserting block comprises a lower protection block main body matched with one side, close to the cover plate, of the lower part copper sheet; and aprotection positioning inserting block is arranged on the lower protection block main body. The protection apparatus, which is mounted on the cover plate and formed by upper protection inserting block and the lower protection inserting block in a buckling manner, is arranged between the battery main body and the cover plate of the lithium battery, so that it is ensured that the copper sheets do not suffer from displacement, thereby prolonging the service life of the lithium battery.

Owner:永康市鹏城电子科技有限公司

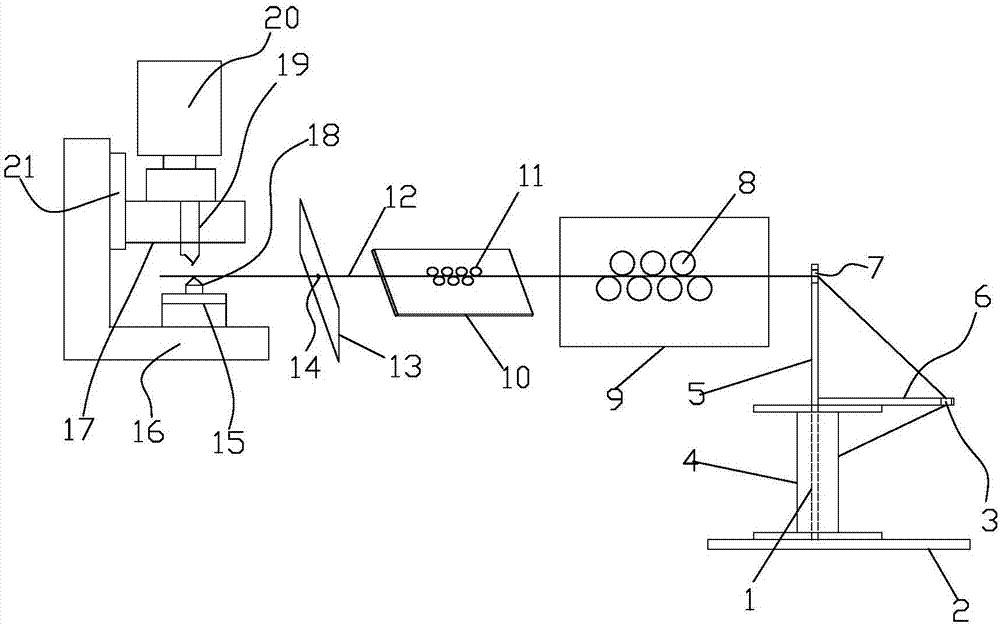

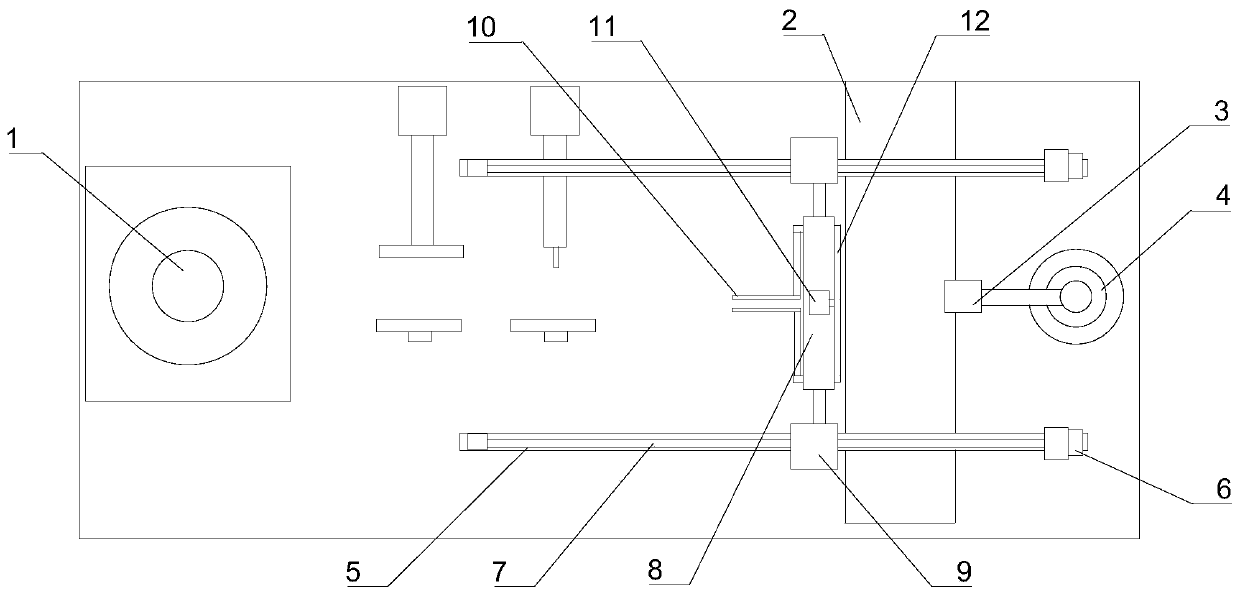

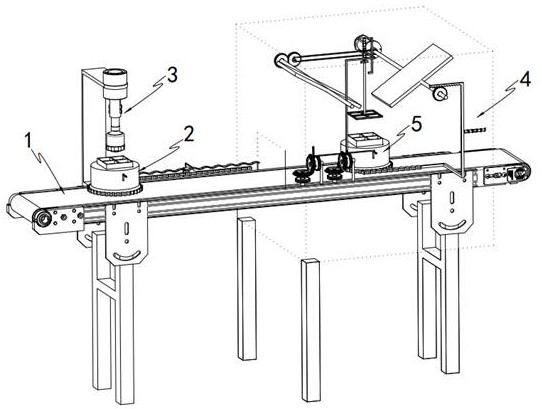

Method for using intelligent cutting-off machine of salmon meat

The invention discloses a method for using an intelligent cutting-off machine of salmon meat. The method comprises the following steps of: a, performing manual feeding: manually placing salmon meat ona belt conveyor A; b, transmitting the salmon meat below a 3D detection device, and automatically scanning the outer contour of the salmon meat and calculating the volume of the salmon meat accordingto the belt transmission speed measured by a transmission distance measuring device of the belt conveyor A through the 3D detection device; c, transmitting the salmon meat below the cutting-off device and cutting off the salmon meat into sections in equal mass by the cutting-off device; and d, transmitting the cut-off salmon meat to a belt conveyor B and placing the manually cut-off salmon meat into a collection box. According to the method disclosed by the invention, automatic detection and cutting-off of the salmon meat are realized, the stability of operating performance is improved, various defects of manual operations are avoided, the quantity of operating personnel is reduced, efficiency is high, precision of cutting-off is high and costs are reduced.

Owner:DALIAN YUN MING AUTOMATION TECH

Glass window frame profile cutting device

PendingCN108161121ACut off accuratelyImprove production and processing efficiencyMetal sawing devicesEngineeringPiston rod

The invention disclose a glass window frame profile cutting device comprising two sets of left-and-right-correspondingly-arranged profile positioning mechanisms; transverse rotating rollers are arranged on positioning machine seats in parallel, the transverse rotating rollers are arranged horizontally, the positioning machine seats are provided with at least a pair of fixed longitudinal positioning vertical rollers, the left and right sides of the positioning machine seats are provided with adjustable longitudinal positioning vertical rollers, and the adjustable longitudinal positioning vertical rollers are connected with linear drive mechanisms in a transmission mode; and upper positioning rollers lock blocks are arranged above the transverse rotating rollers, a cutting-off machine seat is arranged between the two profile positioning mechanisms, the cutting-off machine seat is provided with guide rails corresponding to the transverse rotating rollers, the guide rails are connected with cutting-off motors by sliding blocks, the cutting-off machine seat is provided with cutting-off air cylinders, piston rods of the cutting-off air cylinders are connected with the cutting-off motors,and output ends of the cutting-off motors are provided with cutting saw blades. According to the glass window frame profile cutting device, a window frame profile can be cut accurately, the error isreduced, the cutting efficiency is improved, and the production and processing efficiency of a glass window is improved.

Owner:贾凤鸣

Metal wire releasing and cutting device

The invention discloses a metal wire pay-off and cutting device, which comprises a pay-off mechanism, a straightening mechanism and a cut-off mechanism connected in sequence; The I-shaped wheel is provided with a through hole matched with the vertical rod, the top of the I-shaped wheel is provided with a horizontal bar connected to the vertical rod, the outer end of the horizontal bar is provided with a first guide hole, and the upper end of the vertical rod is provided with a second guide hole. Two guide holes; the straightening mechanism includes a first fixed plate, a second fixed plate and a traction plate arranged in sequence, two sets of first clamping wheels are arranged on the first fixed plate, and two sets of first clamping wheels are arranged on the second fixed plate. Set of second clamping wheels, the traction plate is provided with a threading hole; the cutting mechanism includes an L-shaped base, a fixed block is provided on the L-shaped base, a fixed cone is provided on the fixed block, and the side of the L-shaped base is provided with The connecting block is provided with a support beam, the support beam is provided with a cylinder, and the cylinder is connected with a cutting knife corresponding to the fixed cone.

Owner:HUZHOU NANXUN RONGYE METAL MATERIAL

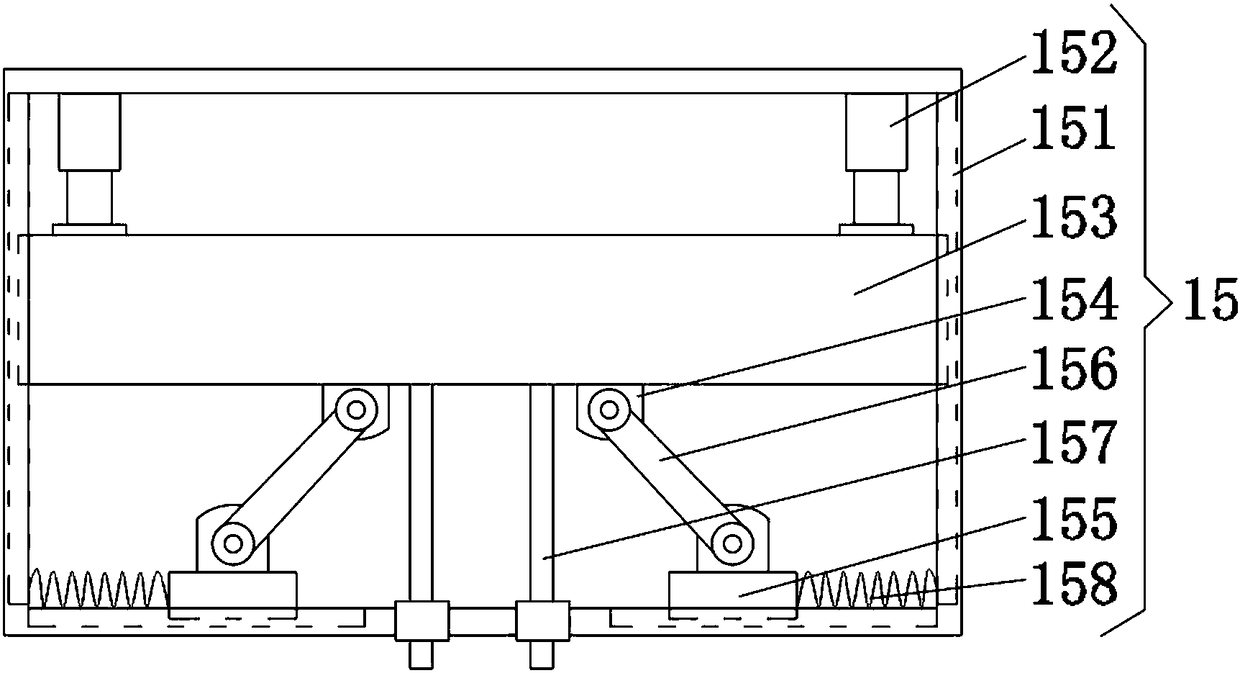

Volume reduction device for recycle treatment of waste ring-pull cans

ActiveCN108908998AAvoid pollutionEasy to collect and organizePressesWaste managementVolume reduction

The invention discloses a volume reduction device for recycle treatment of waste ring-pull cans. The device comprises a working rack, operation boxes are arranged at the two sides of the working rack,and a waste material barrel is arranged at the right side of an inner cavity of the working rack; a feeding device is arranged at the top of the operation box at the left side, a first opening deviceis arranged at the left side of the back face of a support, and a second opening device is arranged at the left side of the front face of the support; a flattening device is arranged at the right side of the working rack. According to the volume reduction device for recycle treatment of the waste ring-pull cans, the two ends of each waste ring-pull can and a can body are cut off and separated from each other through a splitting device, materials different in thickness are treated separately, residual liquid stored in the waste ring-pull cans can also be naturally released, and the situation is avoided that due to splashing, the environment is polluted; the can bodies are ground and flattened through the flattening device, it can be guaranteed that each flattened can body material is in aregular flat shape, and collection and arrangement are conducted conveniently.

Owner:南京萧台东机械制造有限公司

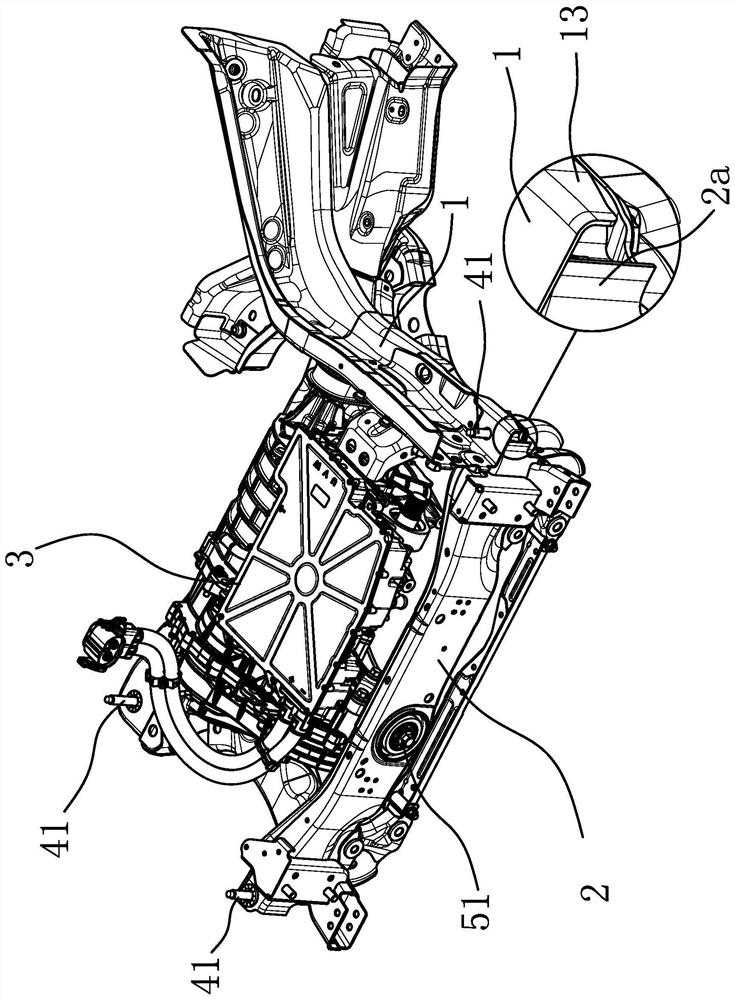

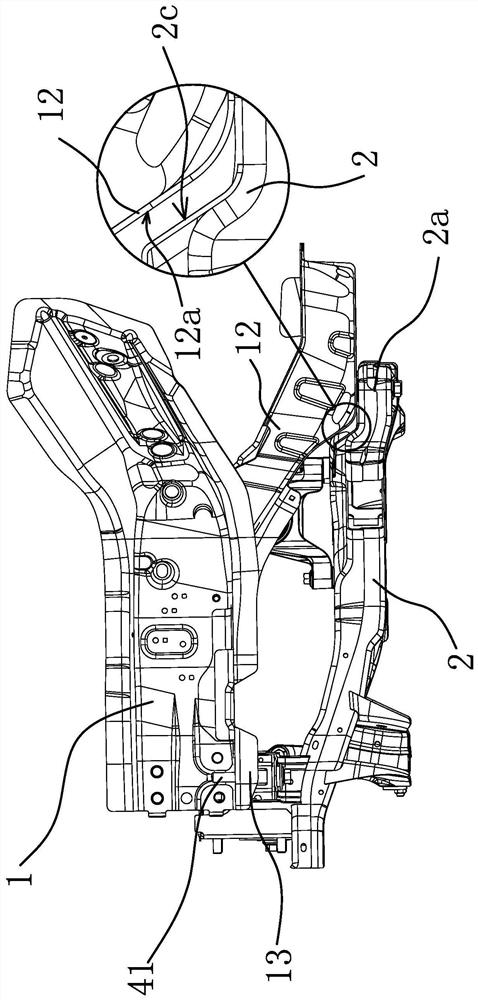

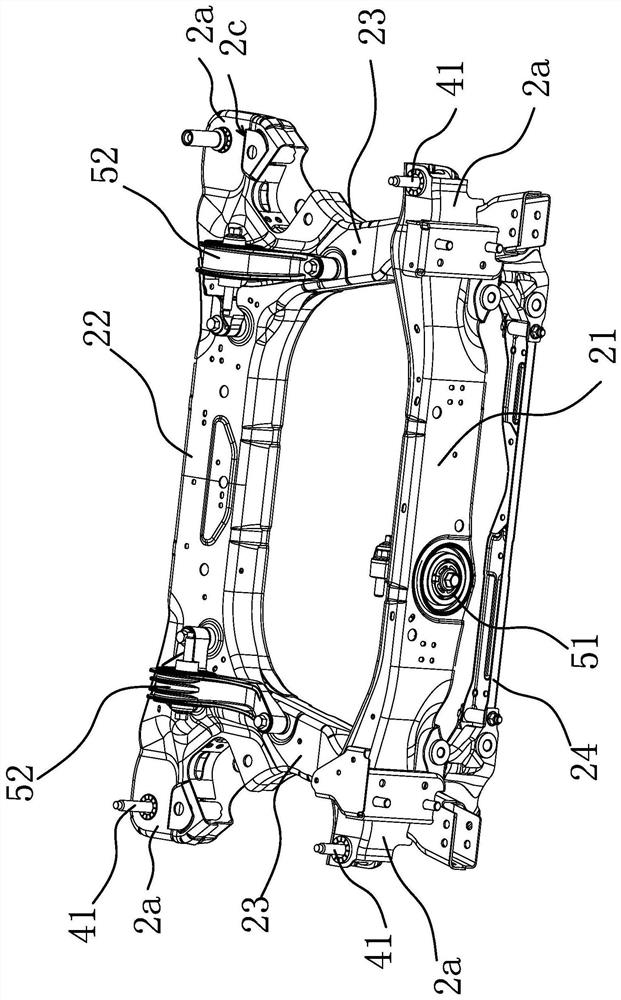

Automobile front suspension framework

ActiveCN111661160AImprove securityPrevent intrusionUnderstructuresJet propulsion mountingVehicle frameControl theory

The invention provides an automobile front suspension framework, belongs to the technical field of automobiles and aims to solve the problems that an existing automobile engine is poor in falling accuracy during collision, inconvenient to maintain in the later period and higher in cost. According to the automobile front suspension framework, two automobile body longitudinal beams which are arranged at intervals are arranged in an engine compartment of an automobile. The front suspension framework comprises an auxiliary frame and a power assembly; the power assembly is connected with the auxiliary frame only through a plurality of suspension structures arranged in the circumferential direction of the power assembly at intervals and is located between the two automobile body longitudinal beams; the auxiliary frame is connected with the two automobile body longitudinal beams only through connecting bolts sequentially penetrating through the auxiliary frame and the automobile body longitudinal beams; the material strength of the auxiliary frame and the material strength of the automobile body longitudinal beams are larger than that of the connecting bolts; and the connecting bolts canbe broken when the auxiliary frame generates longitudinal displacement relative to the automobile body longitudinal beams. When the automobile is subject to collision, an engine and the auxiliary frame sink and fall off, invasion of the engine and the auxiliary frame into a cab is avoided, the accuracy of the breakage of the connecting bolts is higher, and unnecessary breakage is avoided.

Owner:ZHEJIANG LIANKONG TECH CO LTD +1

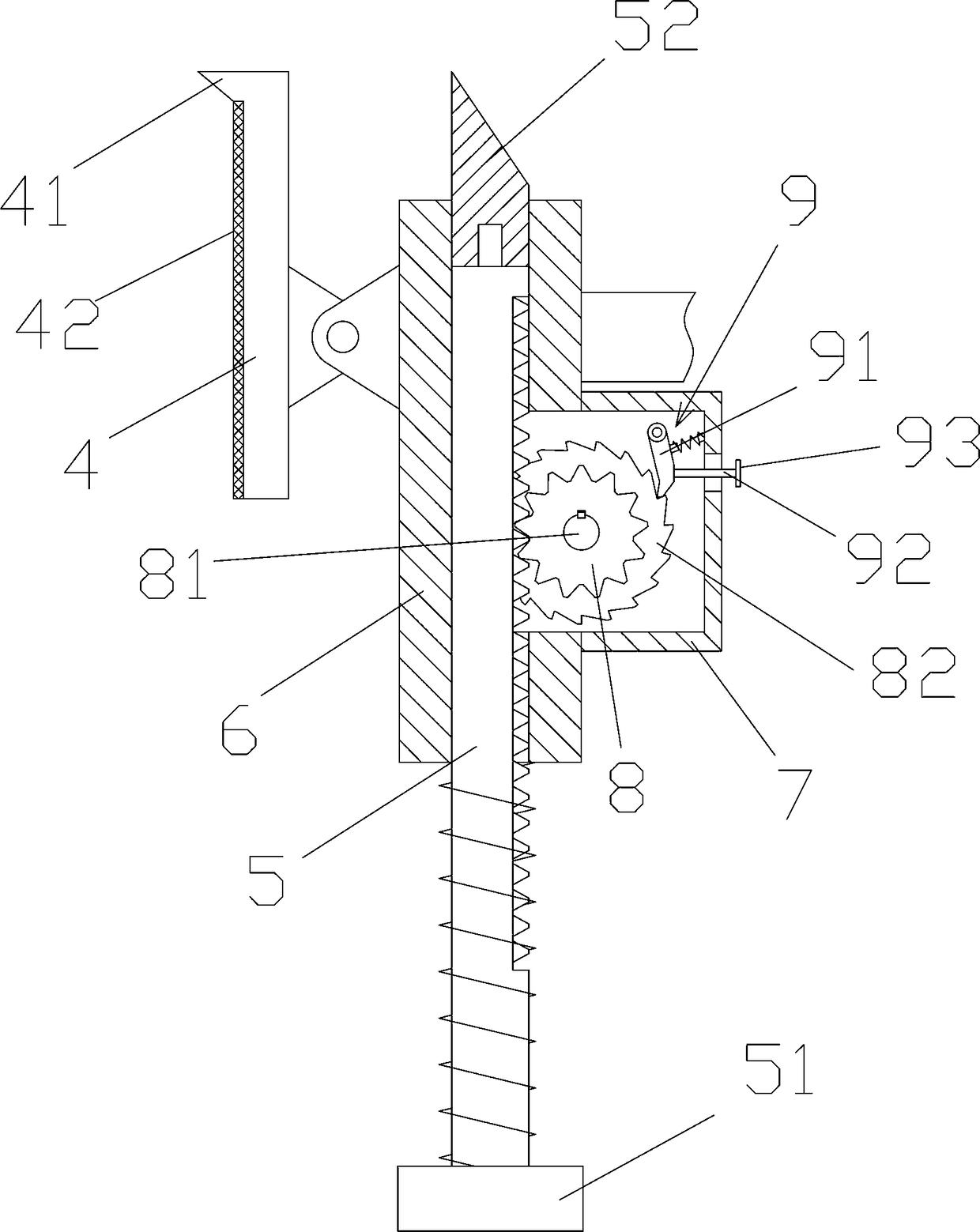

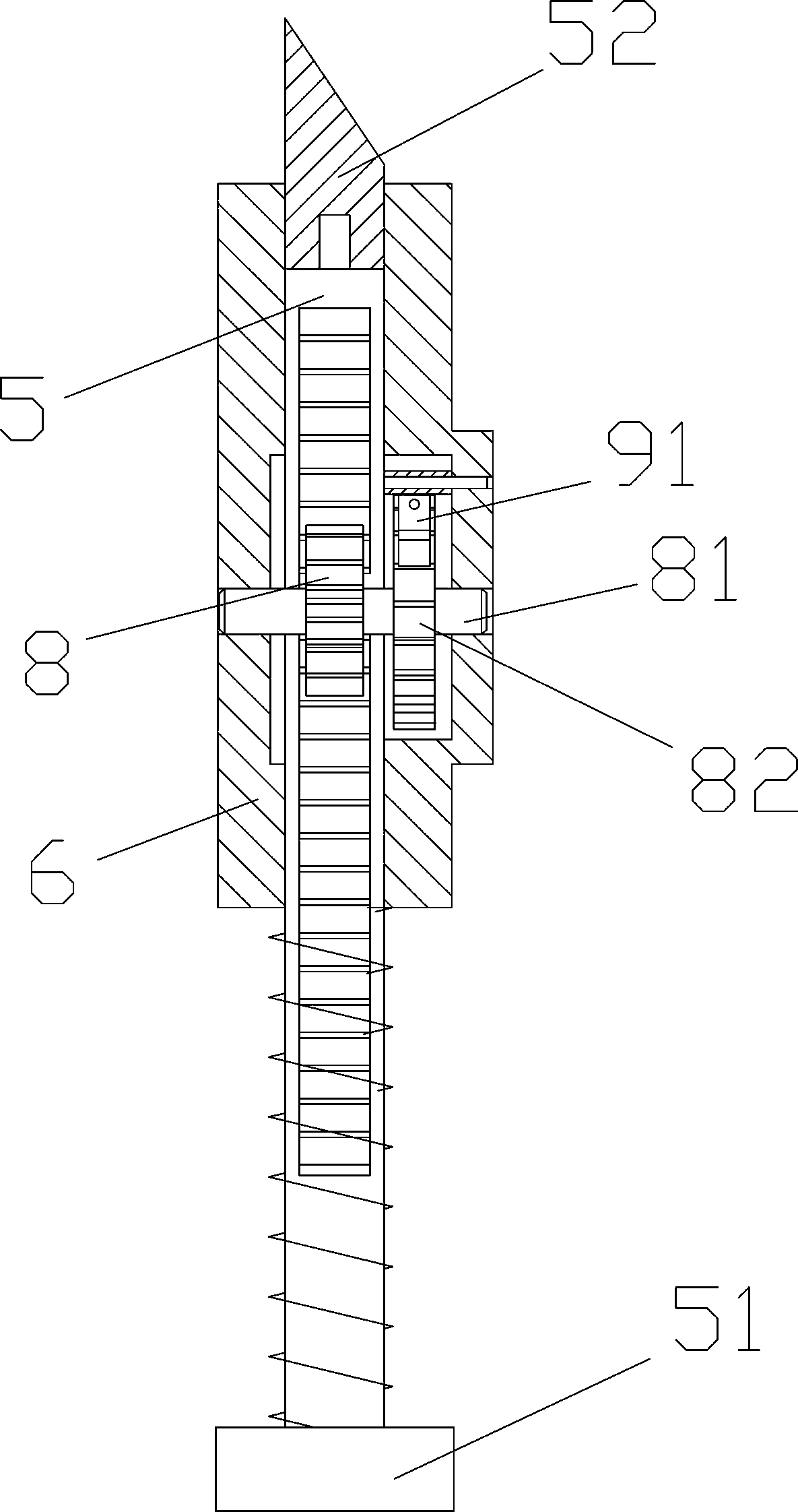

Door breaking device

The invention discloses a door breaking device which comprises a telescopic rod. The two ends of the telescopic rod are each hinged to a crow plate. A shaft sleeve is fixedly connected to the telescopic rod, a wheel box is connected to one side of the shaft sleeve, a spur rack is arranged in the shaft sleeve, the two ends of the spur rack are fixedly connected with a flat spade and a hammering block, a rotating shaft and a non-return mechanism are arranged in the wheel box, the rotating shaft is provided with a ratchet wheel and a gear engaged with the spur rack, the non-return mechanism comprises a spring and a pawl in shaft connection with the interior of the wheel box, the two ends of the spring abut against the inner walls of the pawl and the wheel box, and one end of the pawl is clamped into the ratchet wheel. A lock pin can be rapidly and accurately spaded off, and rapid door breaking is achieved.

Owner:湖北绿筑装配科技有限公司

Full-automatic cut-off machine for stainless steel profile

InactiveCN112122702ACut off accuratelyProtect your healthPositioning apparatusMaintainance and safety accessoriesStructural engineeringSS - Stainless steel

The invention discloses a full-automatic cut-off machine for stainless steel profile. The full-automatic cut-off machine comprises a base, wherein an inverted rack is fixed to the top end of the base;a placing table is fixed to the top end of the base, a first rotating shaft is arranged on the outer wall of the front side of the placing table in a penetrating manner and through a bearing, the first rotating shaft extends to a cavity of the placing table and is rotationally provided with a first bevel gear in a sleeve manner at the tail end, and the two sides of the first bevel gear are in engaged connection to a second bevel gear and a third bevel gear correspondingly; first lead screws rotationally penetrate through the inner walls of the second bevel gear and the third bevel gear, the outer walls of the first lead screws are rotationally sleeved with clamping plates, and sliding grooves allowing the clamping plates to slide are formed in the top end of the placing table; water injection pipes are fixed in cavities of the set of clamping plates, penetrate through the inner wall of one sides of the clamping plates, extends to the outer wall of one side of the rack and are connected to a water tank in an inserted mode at the tail end, and a fixing plate is fixed to the bottom end of the water tank; and connecting pipes are fixed to the surfaces of the sides, located in the cavities of the clamping plates, of the water injection pipes and extend to the outer walls of one sides of the clamping plates, and are fixedly provided with atomizing nozzles at the tail ends of the connecting pipes.

Owner:昆山佳欣成精密机械有限公司

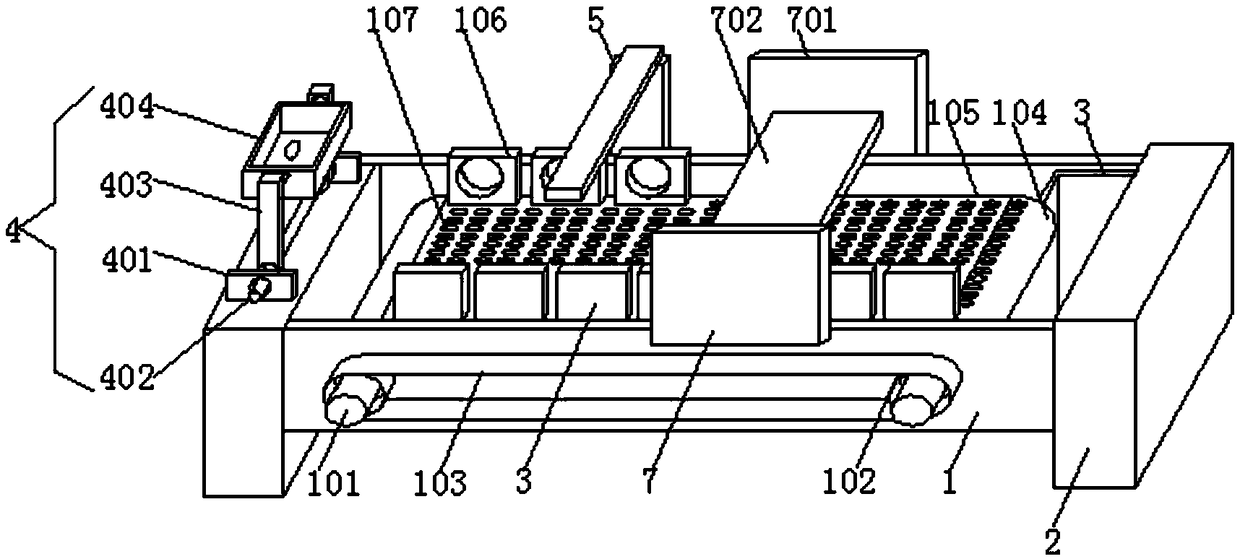

Automatic fruit packaging device

ActiveCN110816942AMove preciselyFast and accurate stretchingWrapping material feeding apparatusPackaging fruits/vegetablesAgricultural engineeringStructural engineering

The invention provides an automatic fruit packaging device. The device comprises a unwinding roller, a conveyor belt, a net fixing mechanism, a net cutting mechanism, a net opening and fixing mechanism and a fruit picking and placing mechanism, wherein the net opening and fixing mechanism comprises a guide rail, a sliding block, a fixing ring and a third drive assembly, the guide rail is arrangedin a horizontal direction perpendicular to the conveyor belt, the guide rail is located between the net cutting mechanism and the fruit picking and placing mechanism, the sliding block is in sliding connection with the guide rail, the third driving assembly is in drive connection with the sliding block, the fixing ring is fixedly connected with the sliding block, the first end of the fixing ring is provided with a plurality of opening rods which can be opened and closed, the first ends of the opening rods are provided with one or more containing holes in the circumferential direction, the containing holes are internally provided with stopping pieces for stopping nets, and the stopping pieces are provided with a contracted state contracted into the containing holes and an extended state inthe process of extending out of the containing holes. According to the automatic fruit packaging device, the fruit can be quickly and accurately sleeved, manual participation is avoided in the whole process, the working efficiency and the working quality are effectively improved, and the labor intensity is reduced.

Owner:HEFEI NORMAL UNIV

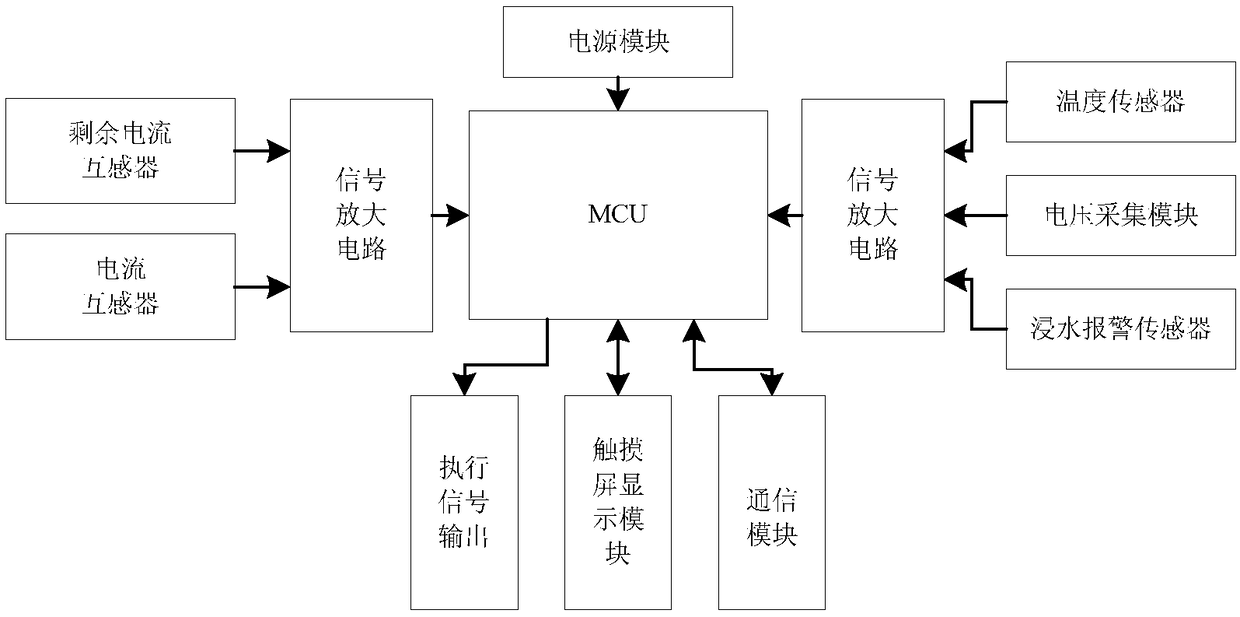

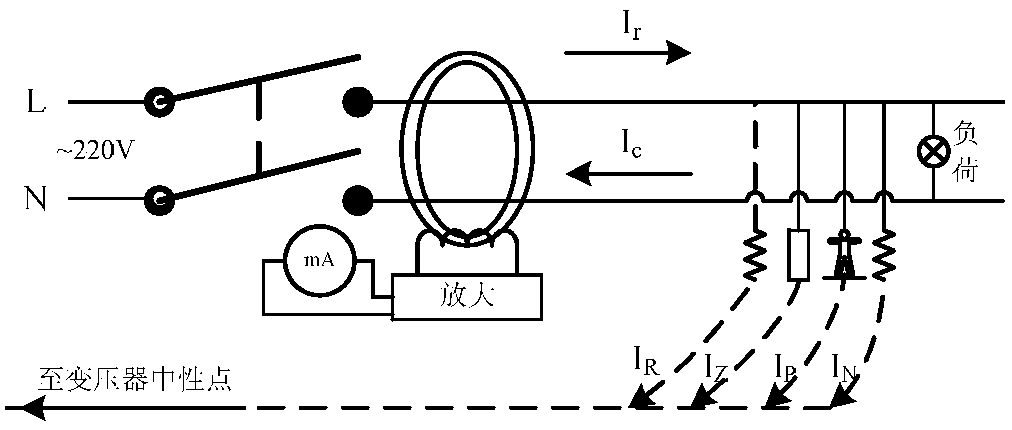

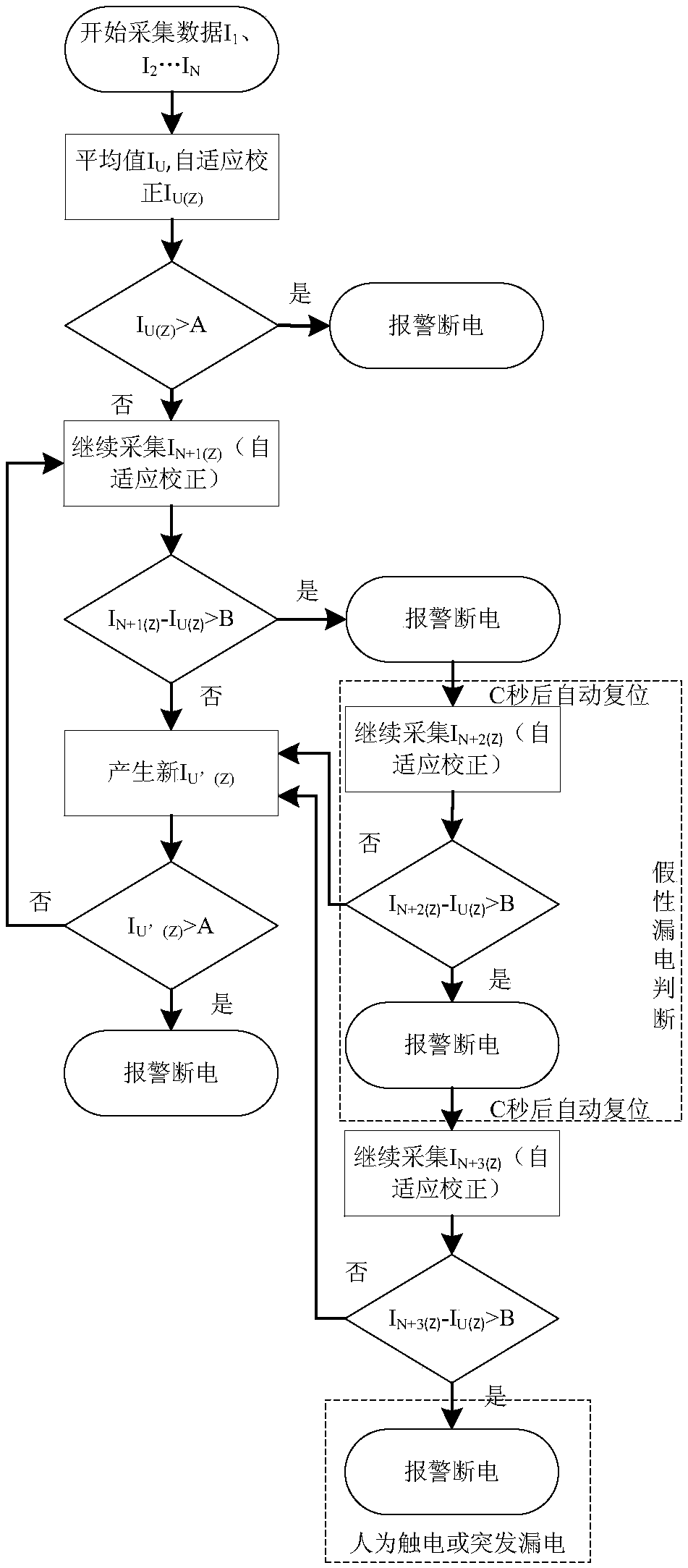

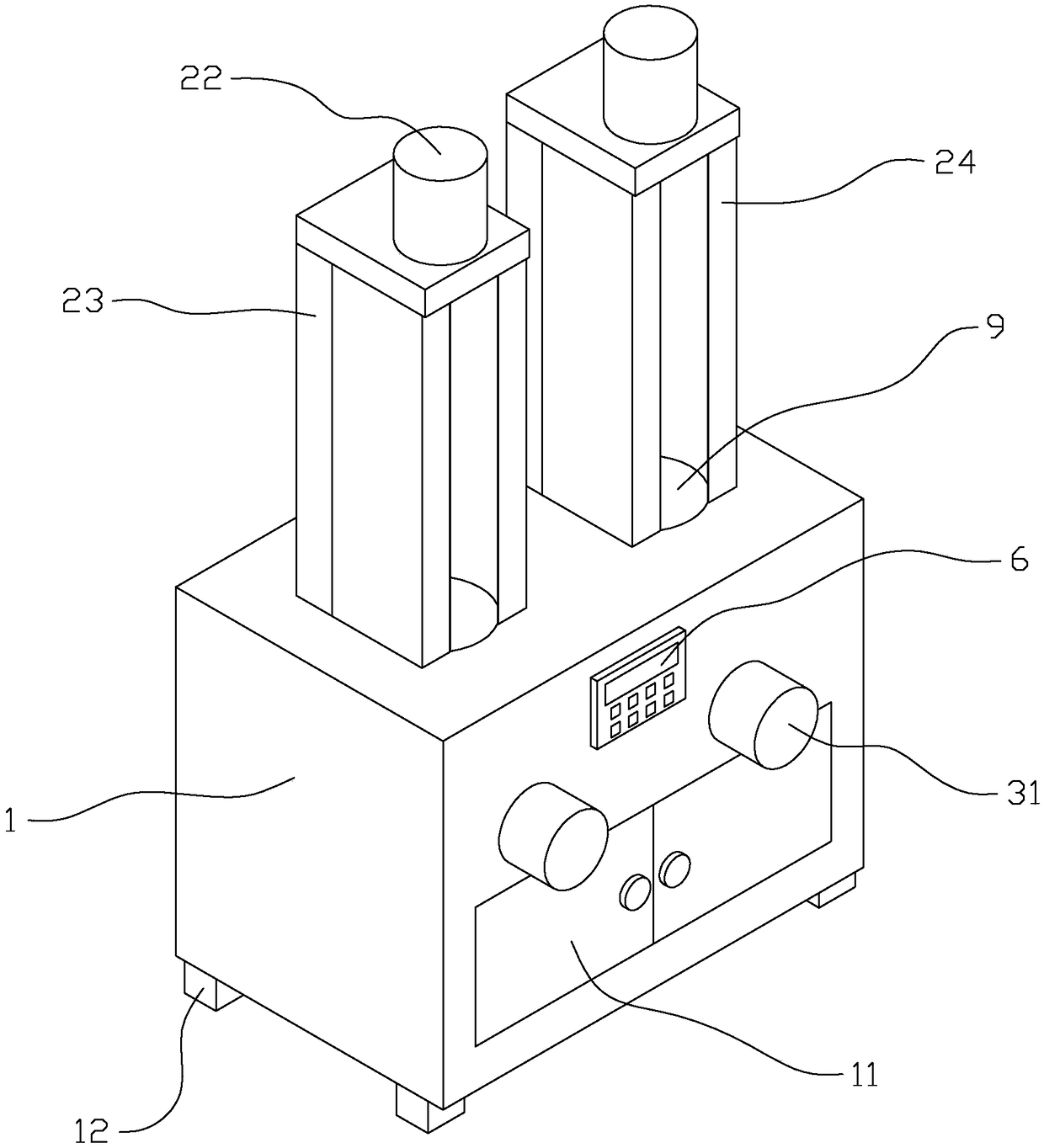

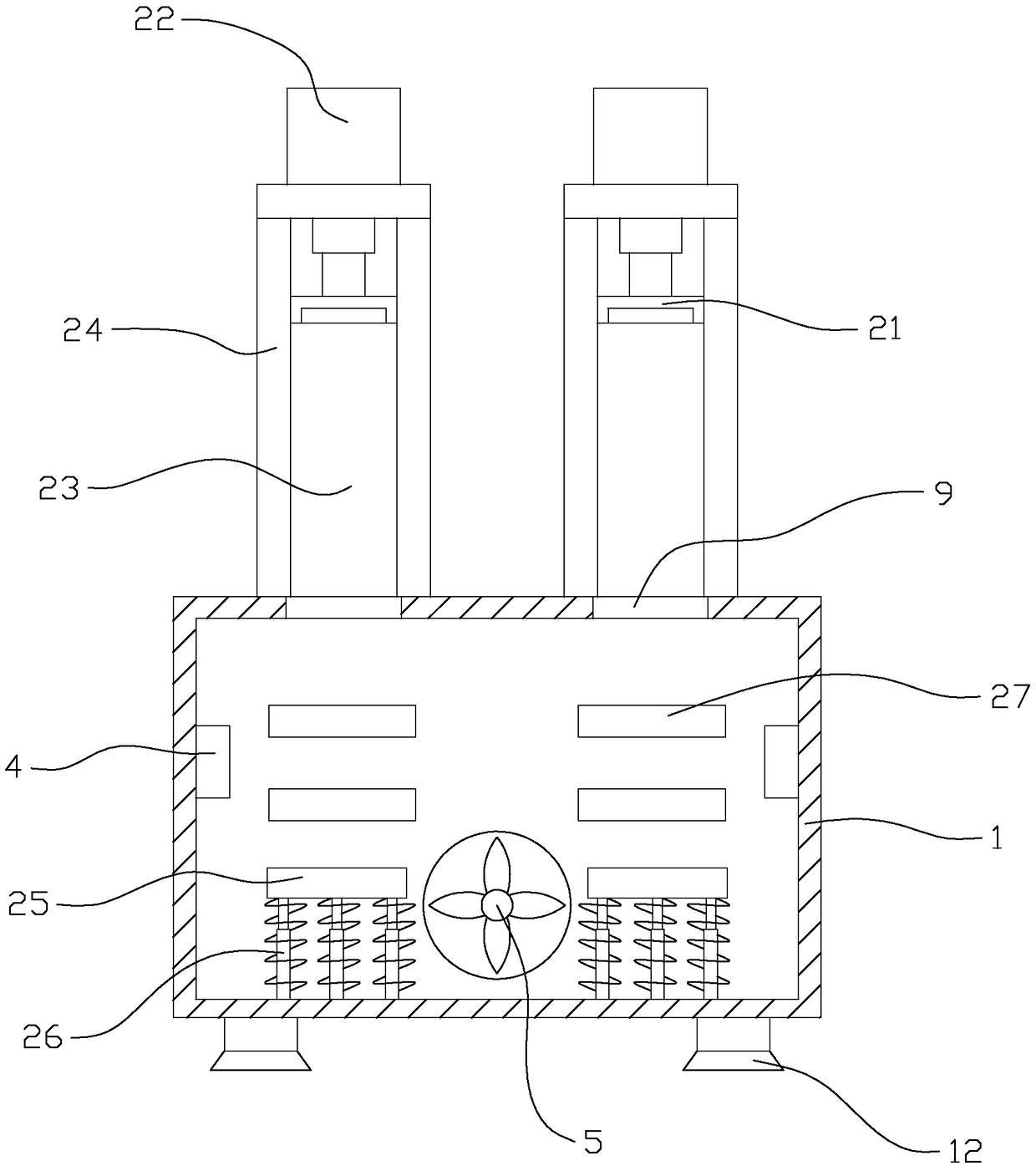

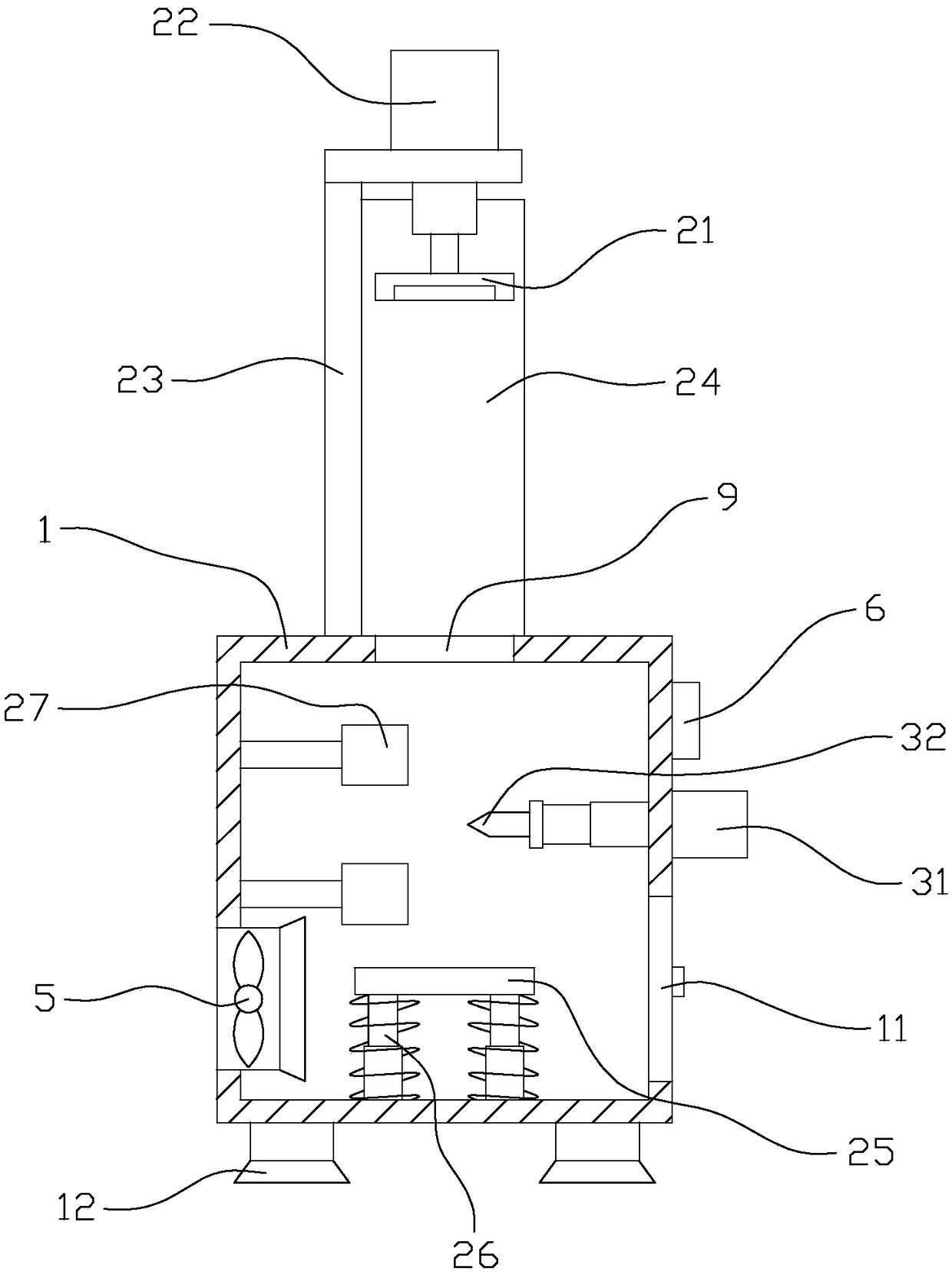

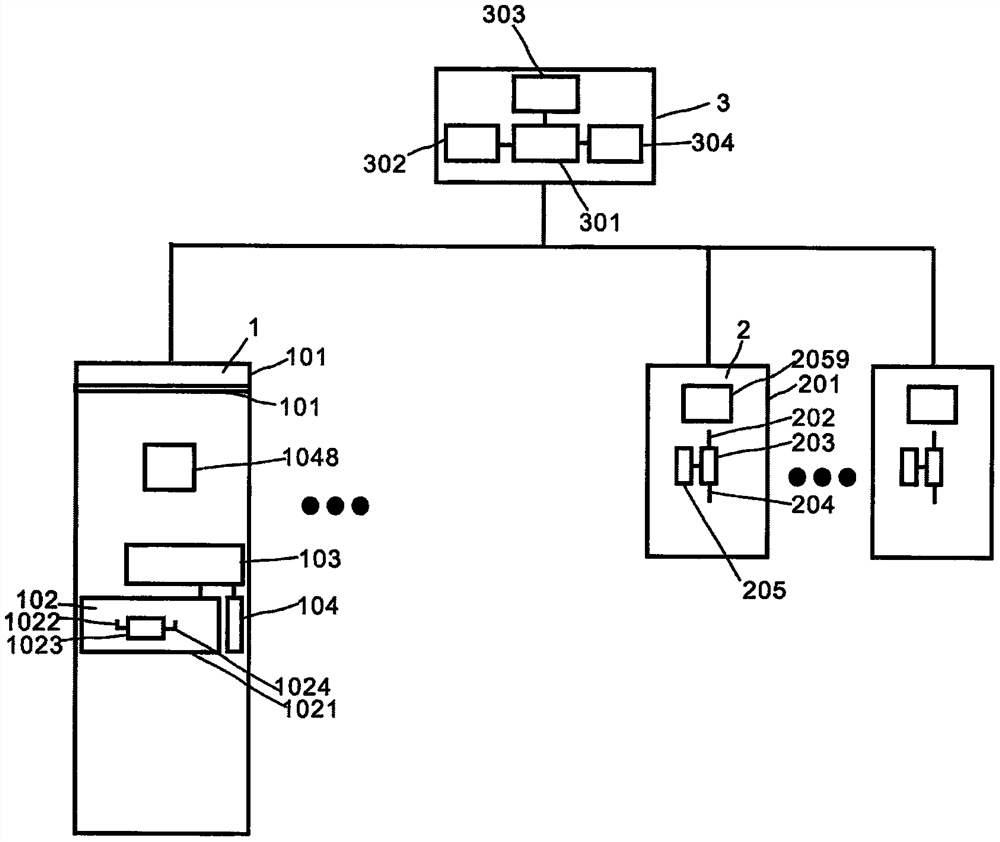

Comprehensive monitoring system and method for electrical safety of traffic signal device

PendingCN109035839AImprove electricity safetyAutomatic control disconnectTraffic control supervisionElectricityTraffic signal

The invention provides a comprehensive monitoring system and method for electrical safety of a traffic signal device. The comprehensive monitoring system comprises a residual current transformer, a current transformer, a voltage acquisition module, a temperature sensor, an immersion alarm sensor, an execution signal output module, a touch screen display module, a communication module, a micro control unit MCU, and a power supply module and a signal amplification circuit which are connected with the micro control unit MCU, wherein the residual current transformer, the current transformer, the voltage acquisition module, the temperature sensor and the immersion alarm sensor are respectively in signal connection with the micro control unit MCU by the signal amplification circuit. According tothe invention, the potential safety hazard of an electrical line of the traffic signal device can be subjected to dynamic tracking monitoring management in real time, automatic power-on and power-offfunctions are achieved, electricity safety of the traffic signal device is improved, and the difficult problem that a residual current circuit breaker cannot be installed in an existing traffic signal control system is completely broken through, thereby meeting the requirements for electrical safety operation and modern management of the traffic signal control system.

Owner:冯国行

Wire pipe cutting device with the dust collecting function

PendingCN109049038ACut off accuratelyAvoid extrusion deformationNon-rotating vibration suppressionMetal working apparatusElectricityEngineering

The invention discloses a wire pipe cutting device with the dust collecting function. The wire pipe cutting device comprises a machine body shell, the machine body shell is provided with an opening soas to allow a wire pipe to enter, a wire pipe positioning device comprises a pressing plate and a bottom plate, the pressing plate is connected with a driving air cylinder, the driving air cylinder is fixed on the machine body shell through a support, the support is provided with two clamping plates which are located on the two sides of the opening, the two clamping plates and the support are matched to limit a line pipe, the bottom plate is connected to the machine body shell through spring shock absorbers, baffle plates corresponding to the opening is arranged in the machine body shell, thebaffle plates are divided into an upper layer baffle plates and a lower layer baffle plates; a cutting device comprises an electric cylinder and a cutting blade connected to an output shaft of the electric cylinder, the electric cylinder is fixed to the machine body shell, the cutting blade is located between the two layers of the baffle plates, a distance measuring sensor is arranged in the machine body shell, a draught fan is further arranged on the rear side of the interior of the machine body shell to draw away dust, an electric control panel is arranged in front of the machine body shell, the draught fan, the distance measuring sensor, the electric cylinder and an electromagnetic valve driving the air cylinder are electrically connected to the electric control panel.

Owner:GUANGDONG DESU TECH

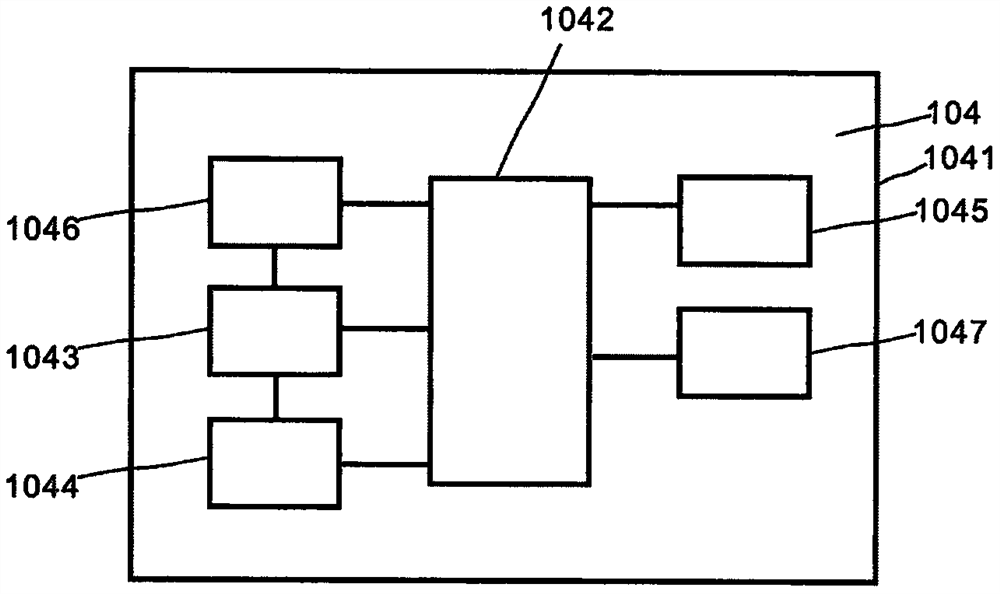

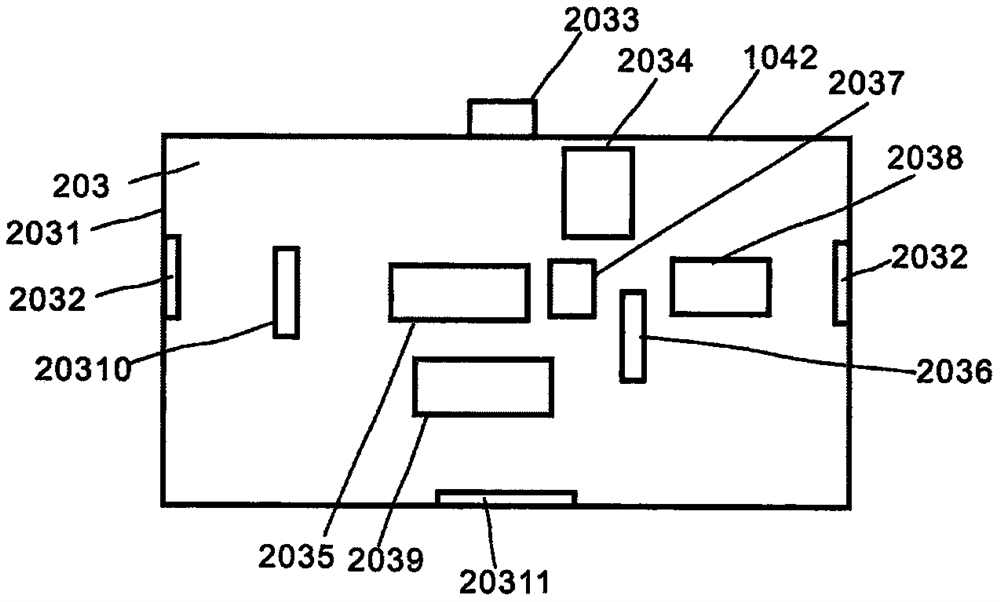

Intelligent power supply and distribution system

PendingCN111697438ACut off accuratelyRealize monitoringBus-bar/wiring layoutsBoards/switchyards circuit arrangementsRemote controlDisplay device

The invention provides an intelligent power supply and distribution system, and the system comprises an intelligent integrated power distribution cabinet, an intelligent power distribution box and a monitoring system. The monitoring system is in communication connection with the intelligent integrated power distribution cabinet and the intelligent power distribution box; the intelligent integratedpower distribution cabinet comprises a cabinet body, a switch unit, an acquisition module and a first intelligent terminal, wherein the first intelligent terminal is connected with the acquisition module and a circuit breaker; the intelligent distribution box comprises a box body, an incoming cable, a composite switch, an outgoing cable and a second intelligent terminal, wherein the second intelligent terminal is connected with the composite switch; the monitoring system comprises an upper computer, a display, a server and a mobile terminal. Through the first intelligent terminal, the circuitbreaker, the second intelligent terminal and the composite switch, the power distribution monitoring, intelligent breaking control and power distribution protection of a power distribution cabinet / box line can be realized; the local and remote monitoring and management of the power distribution system can be realized through the monitoring system, the remote control breaking operation is realized, and the intelligent degree of power supply and distribution is improved.

Owner:天津市中力神盾电子科技有限公司

Forming device for cake blank processing

ActiveCN114794180AIncrease productivitySkip the heavy liftingCharging/discharging ovensDough processingProcess engineeringMechanical engineering

The invention provides a forming device for cake blank processing, which comprises an automatic transmission device, a plurality of groups of bearing mechanisms are sequentially arranged along the transmission direction of the automatic transmission device, and the bearing mechanisms are transmitted from a feeding station to a baking station under the driving of the automatic transmission device. The bearing mechanism is matched with the baking mechanism on the baking station to form cake liquid into cake blanks, and circumferential baking work of each cake blank is completed while a plurality of groups of cake blanks are separated, so that the problems that some cake baking machines can only bake a small amount of cakes at a time, the production efficiency is low, and the production cost is low are solved. The problem that cakes are burnt due to too high temperature caused by non-uniform heating of the cakes in the baking process due to the fact that the cakes need to be taken out of the oven next time after one-time baking is completed is solved.

Owner:安徽品滋味食品股份有限公司

Volume reduction device for recycling and processing waste pop cans and using method

ActiveCN111331909AAvoid pollutionEasy to collect and organizePressesProcess engineeringWaste material

The invention discloses a volume reduction device for recycling and processing waste pop cans and a using method. The volume reduction device comprises a working frame, wherein operation boxes are arranged on the two sides of the working frame; a waste barrel is arranged on the right side of an inner cavity of the working frame; a feeding device is arranged on the top of the operation box on the left side; a first opening device is arranged on the left side of the back surface of the working frame; a second opening device is arranged on the left side of the front surface of the working frame;and a leveling device is arranged on the right side of the working frame. According to the volume reduction device for recycling and processing the waste pop cans, the two ends of the pop cans are cutoff and separated from can bodies through a cutting device, materials with different thicknesses are separately processed, and meanwhile, residual liquid stored in the pop cans can be naturally discharged, so that the environment pollution caused by sputtering is avoided; and the can bodies are rolled and leveled through the leveling device, so that it is ensured that each piece of the can body material subjected to the leveling processing is relatively and regularly flat, and the collection and the arrangement are convenient.

Owner:泉州台商投资区瑞诚文科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com