Full-automatic cut-off machine for stainless steel profile

A fully automatic, stainless steel technology, used in maintenance and safety accessories, metal processing machinery parts, clamping, etc., can solve problems such as adverse health effects of workers, steel cutting offset, steel shaking, etc., to improve safety and The effect of stability, body health protection, quick installation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following further describes the present invention in conjunction with specific embodiments, but the following embodiments are only preferred embodiments of the present invention, not all of them. Based on the examples in the implementation manners, other examples obtained by those skilled in the art without creative work shall fall within the protection scope of the present invention. The experimental methods in the following examples are conventional methods unless otherwise specified. The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0024]Example:

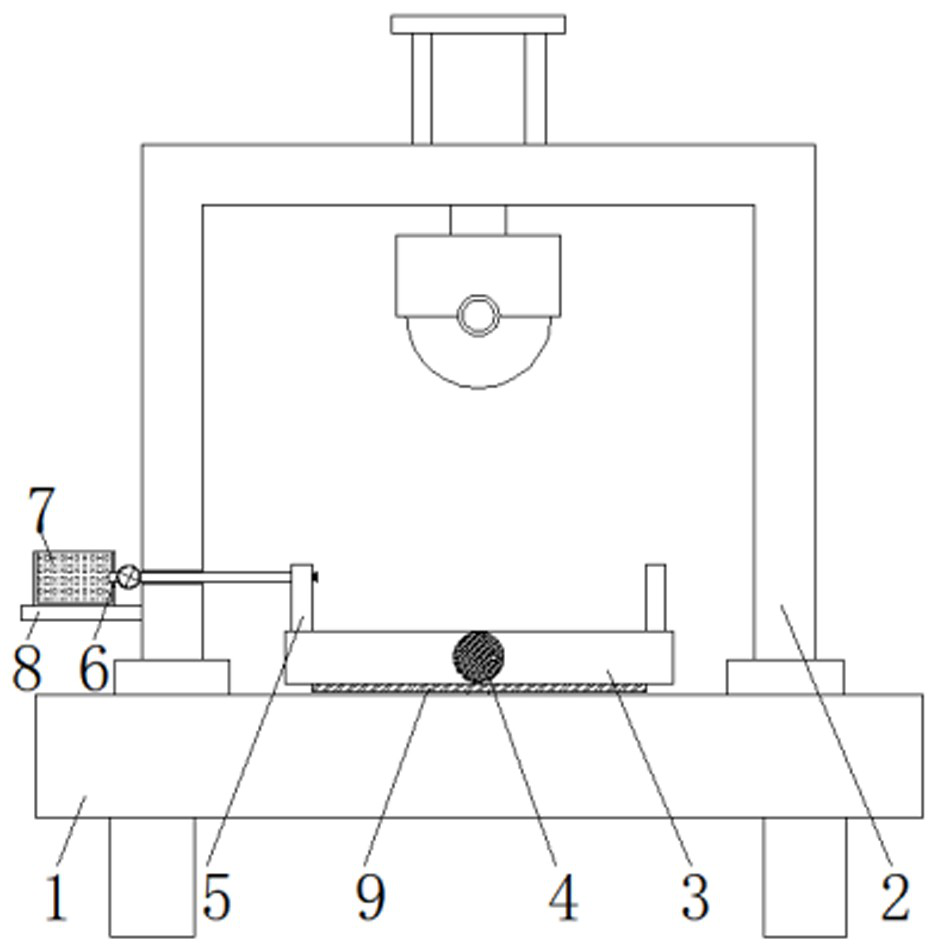

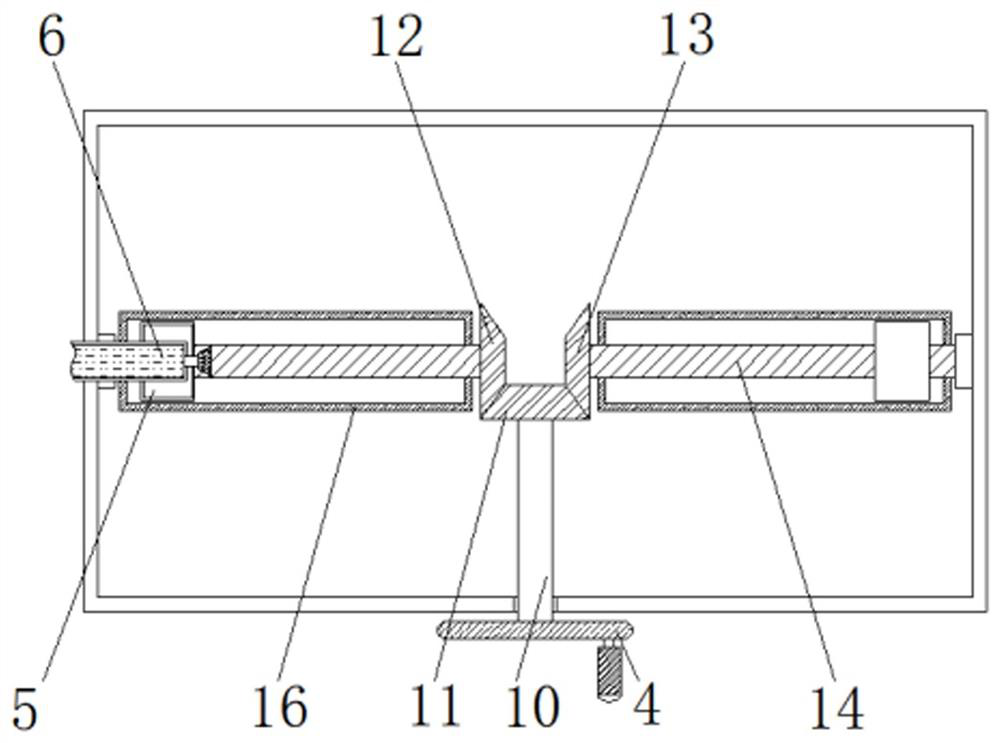

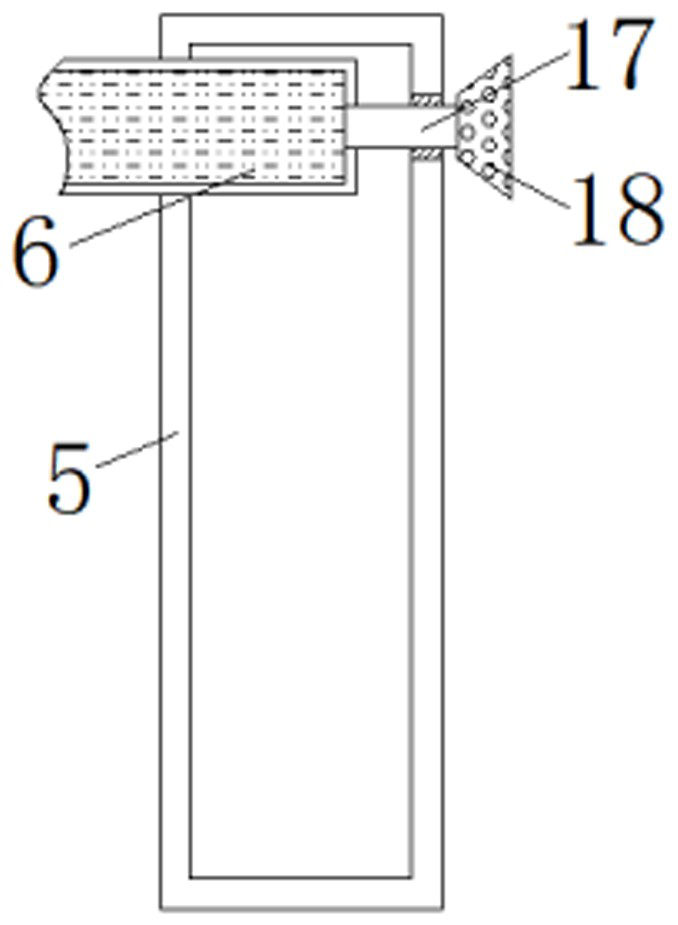

[0025]Such asFigure 1-Figure 3As shown, a stainless steel profile automatic cutting machine includes a base 1, an inverted frame 2 is fixed at the top of the base 1, a placement table 3 is fixed at the top of the base 1, and a bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com