Forming device for cake blank processing

A molding device, a technology for cake embryos, applied in application, oven loading/unloading, dough handling, etc., can solve the problems of uneven heating of cakes, low production efficiency, and high temperature of cakes, avoid difficult demoulding, and improve production. Efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

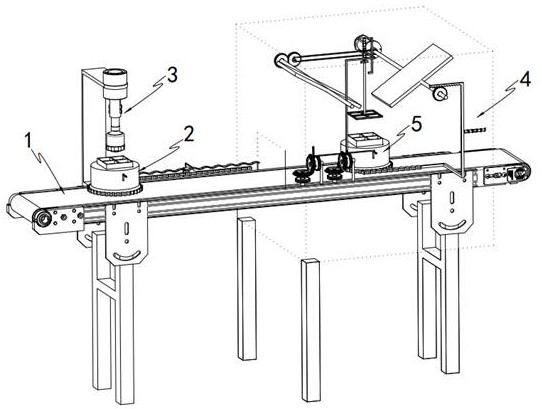

[0048] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 14 As shown, a forming device for cake embryo processing includes an automatic transmission device 1, and the automatic transmission device 1 is sequentially provided with several groups of bearing mechanisms 2 along its transmission direction, and the bearing mechanism is driven by the automatic transmission device 1 2 Transfer from feeding station 3 to baking station 4;

[0049] The carrier mechanism 2 cooperates with the baking mechanism 5 on the baking station 4 to form the cake liquid into the cake embryo, and separates several groups of cake embryos while completing the circumferential baking of each cake embryo. The carrier mechanism 2 include:

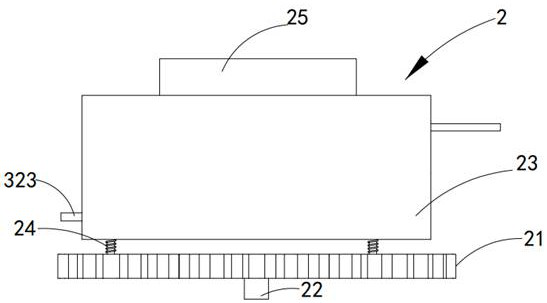

[0050] a carrying plate 21, the carrying plate 21 is a gear structure and is rotatably arranged on the automatic transmission device 1 through a first rotating shaft 22;

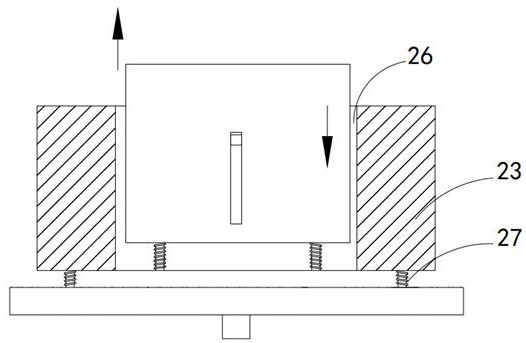

[0051] a base 23, the base 23 is fixedly connected to the upper end of the carrying...

Embodiment 2

[0083] like Image 6 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0084] further, as Figure 12 As shown, the adjustment assembly 32 includes:

[0085] a driving rack 321, the driving rack 321 is fixedly mounted on the frame and meshes with the carrying plate 21 for transmission;

[0086] The corrugated rail 322 is located above the driving rack 321 and is installed on the rack. The corrugated rail 322 drives the bumps 323 on the base 23 to drive the cake liquid in the cake mold frame 25 to fluctuate up and down.

[0087] In this embodiment, by arranging the adjusting assembly 32 to cooperate with the bearing mechanism 2, when the driving rack 321 moves to the corrugated track 322, several g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com