Patents

Literature

265results about "Charging/discharging ovens" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

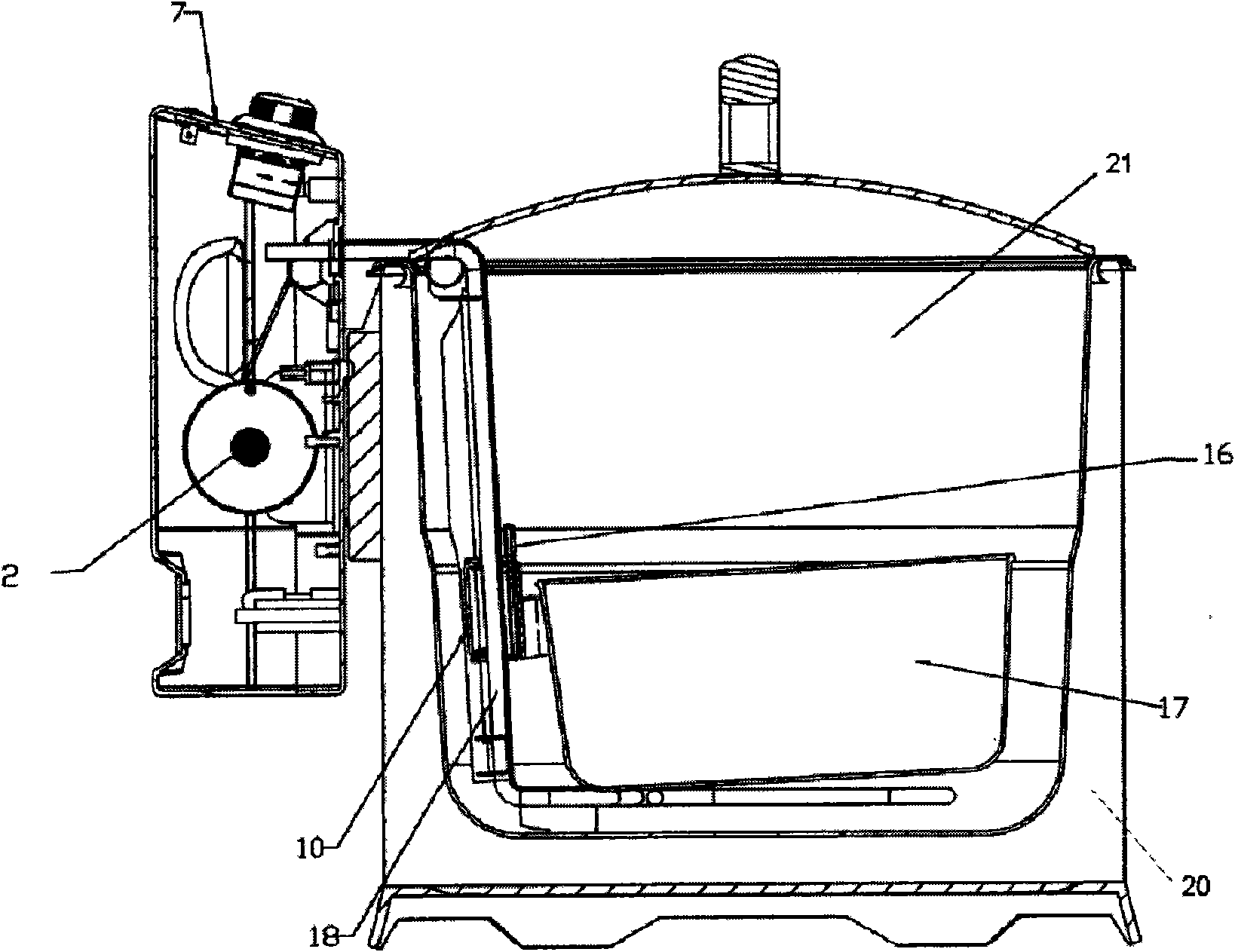

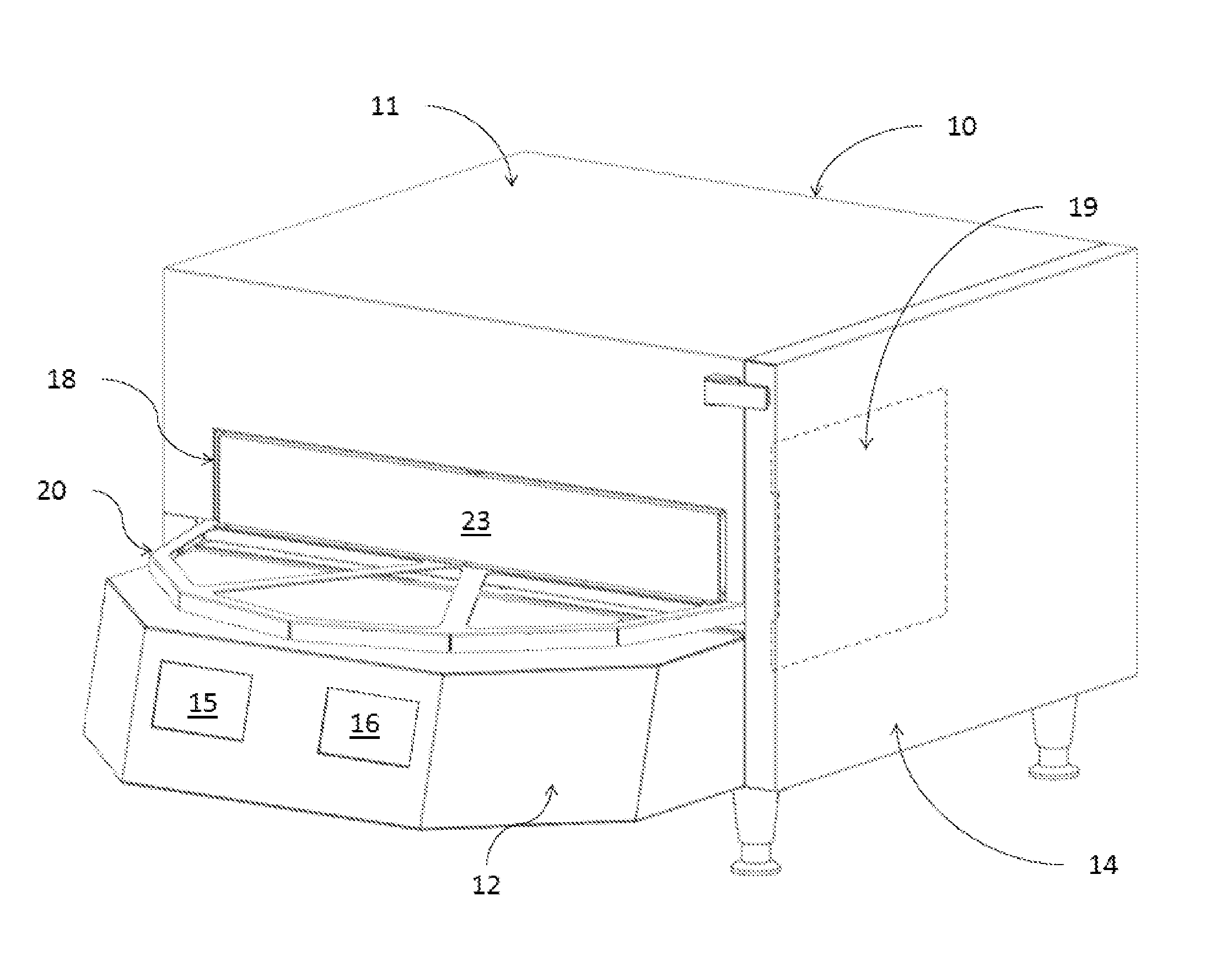

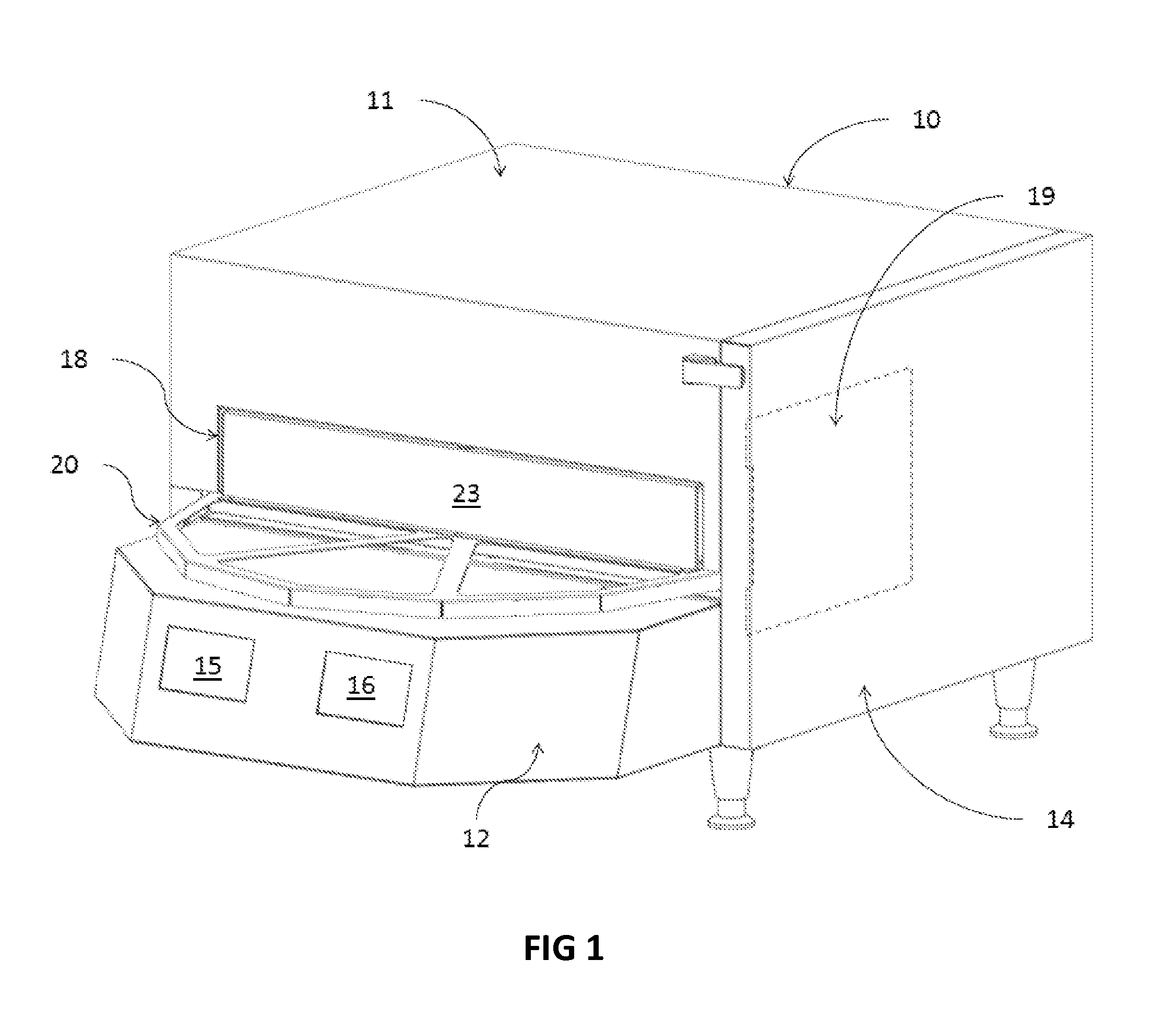

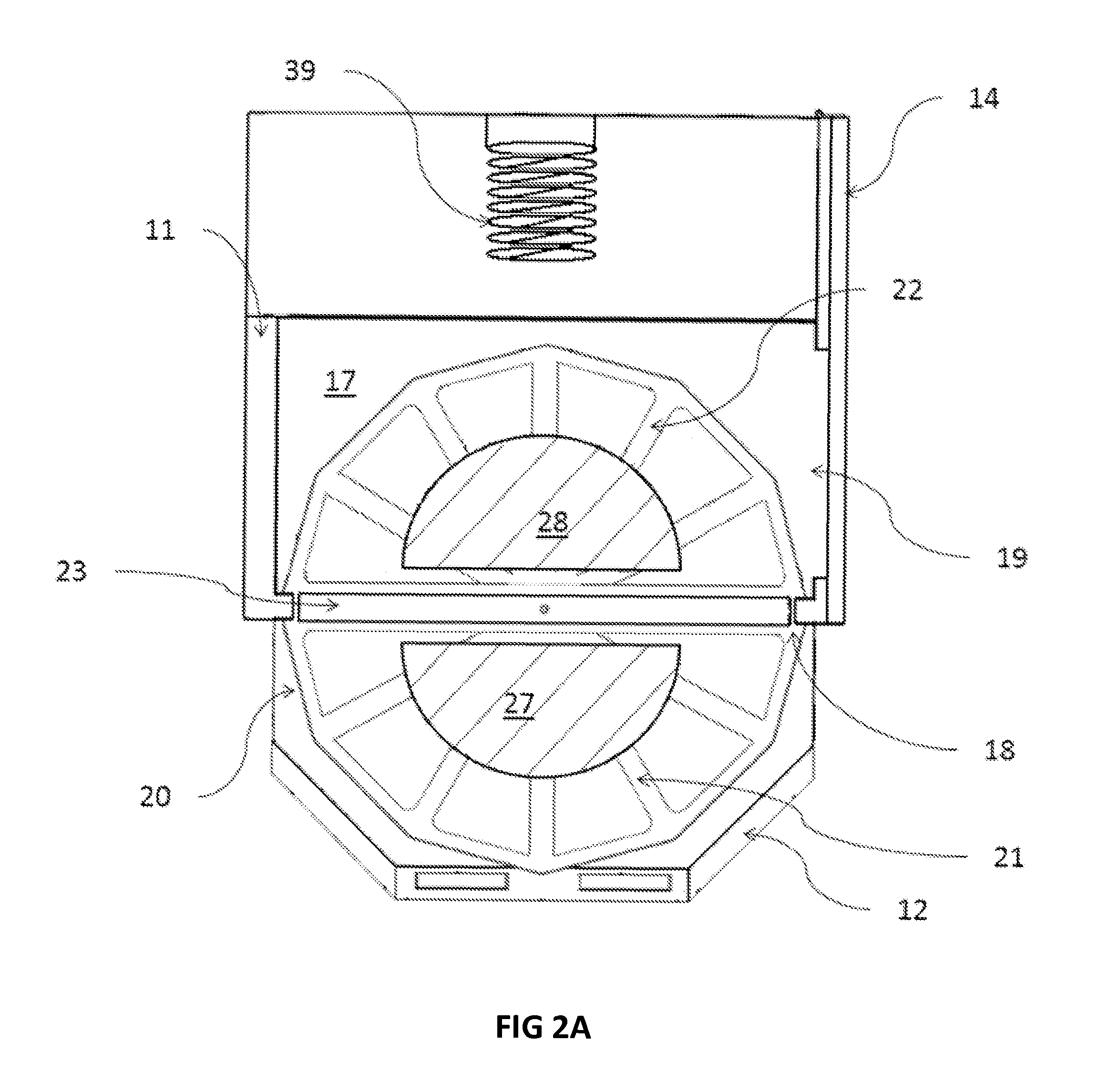

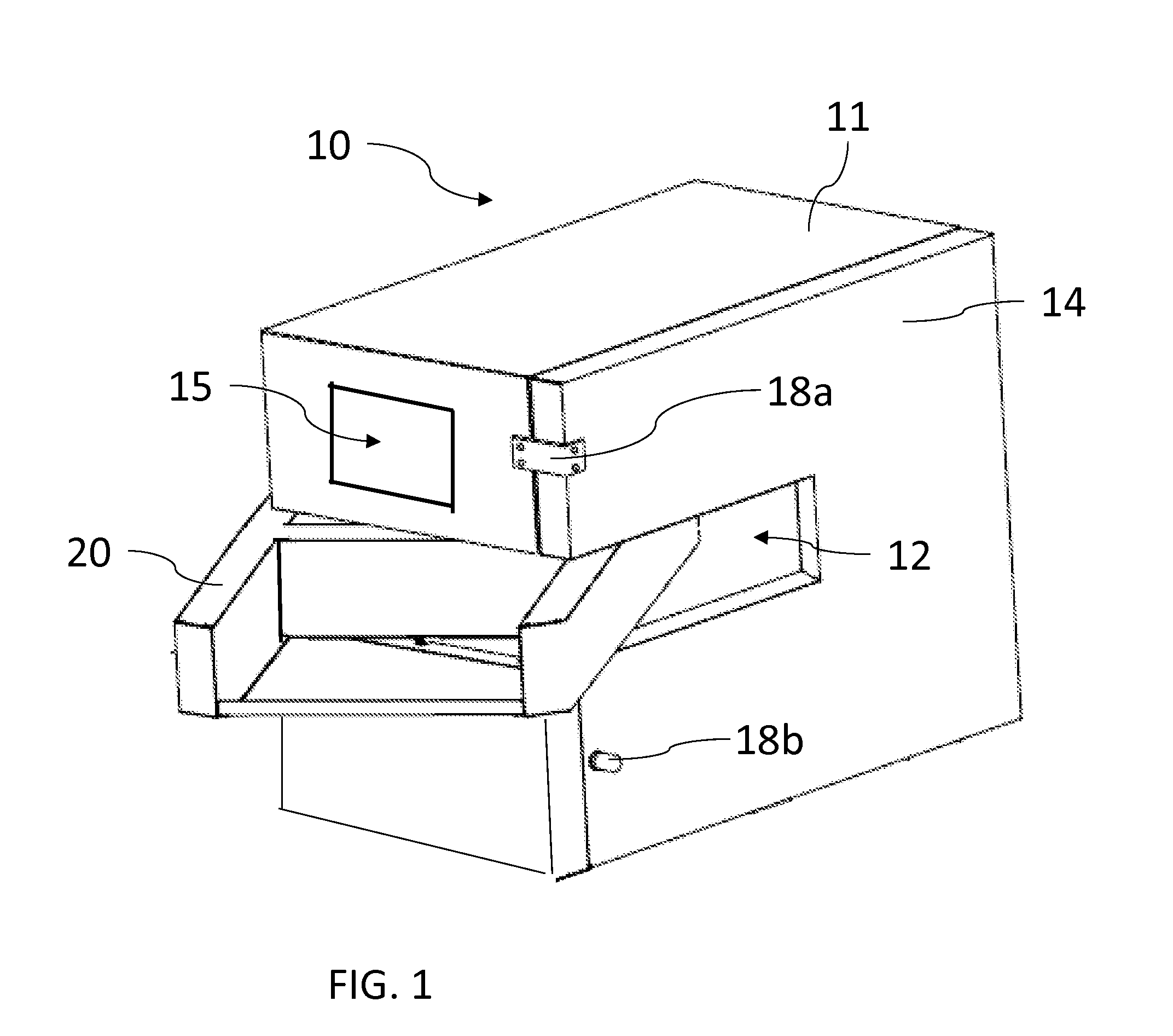

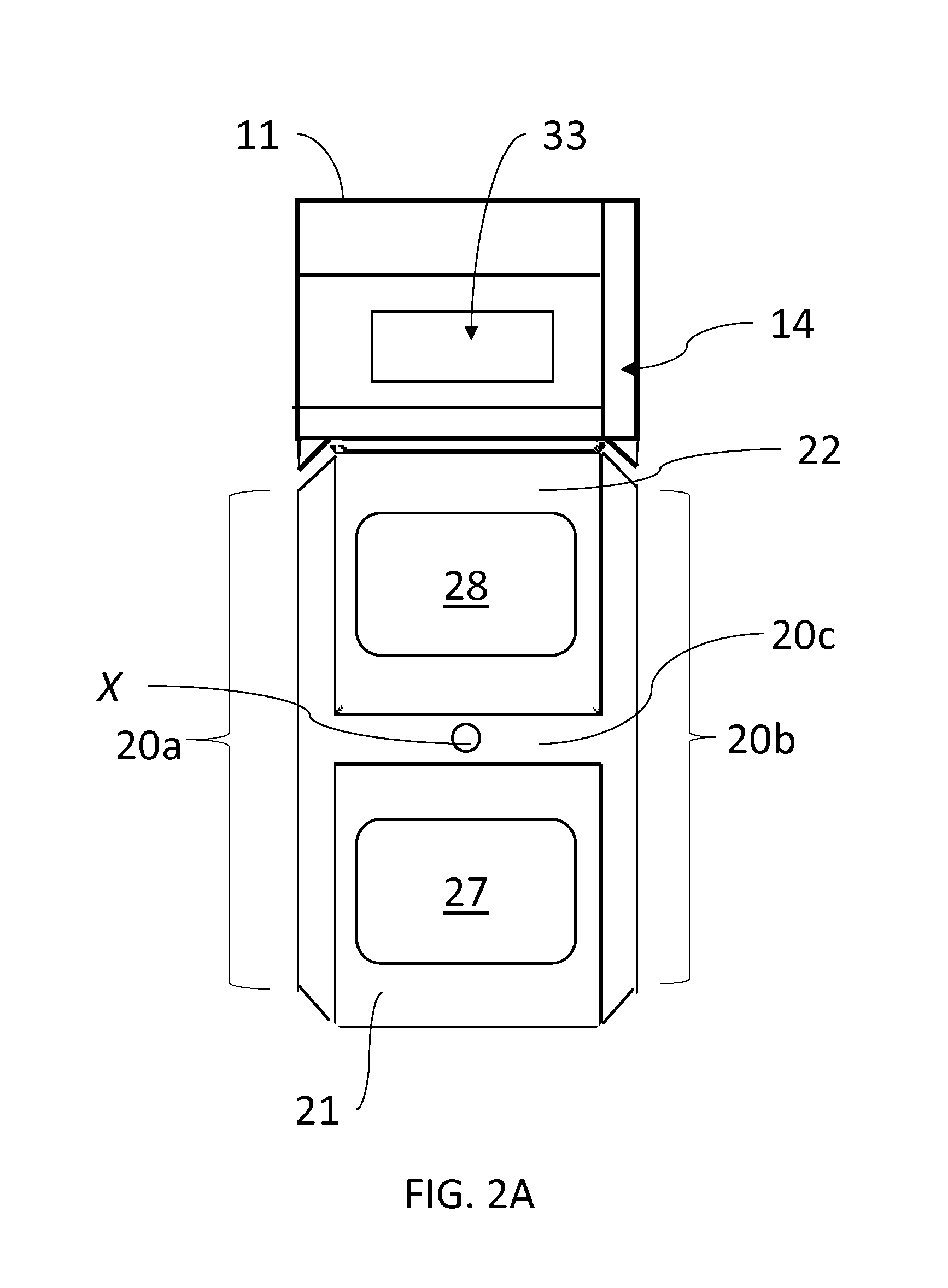

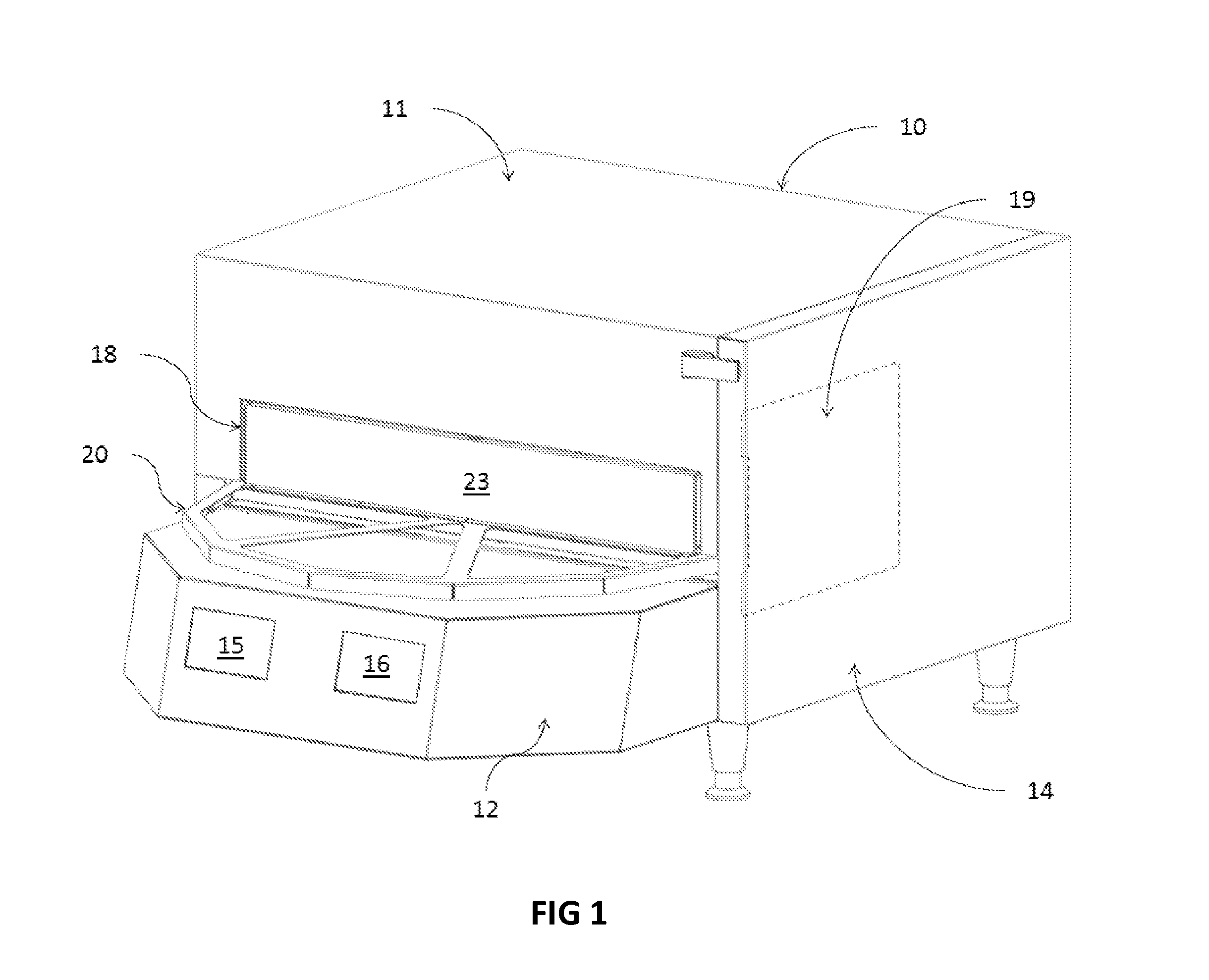

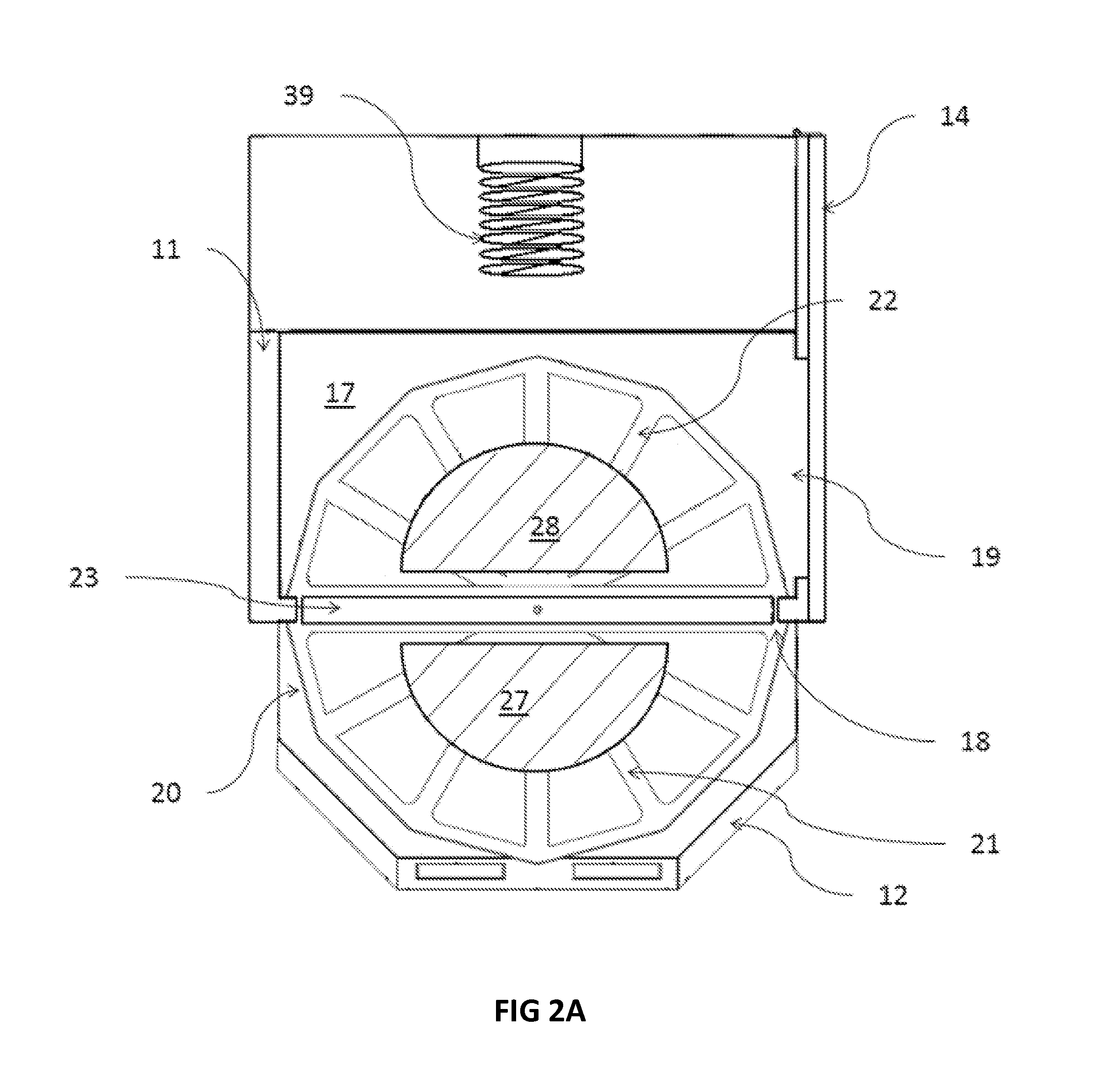

Oven having an H-shaped rotating door

ActiveUS9480364B2Prevent escapeDomestic stoves or rangesStoves/ranges shelves or racksMechanical engineeringFood item

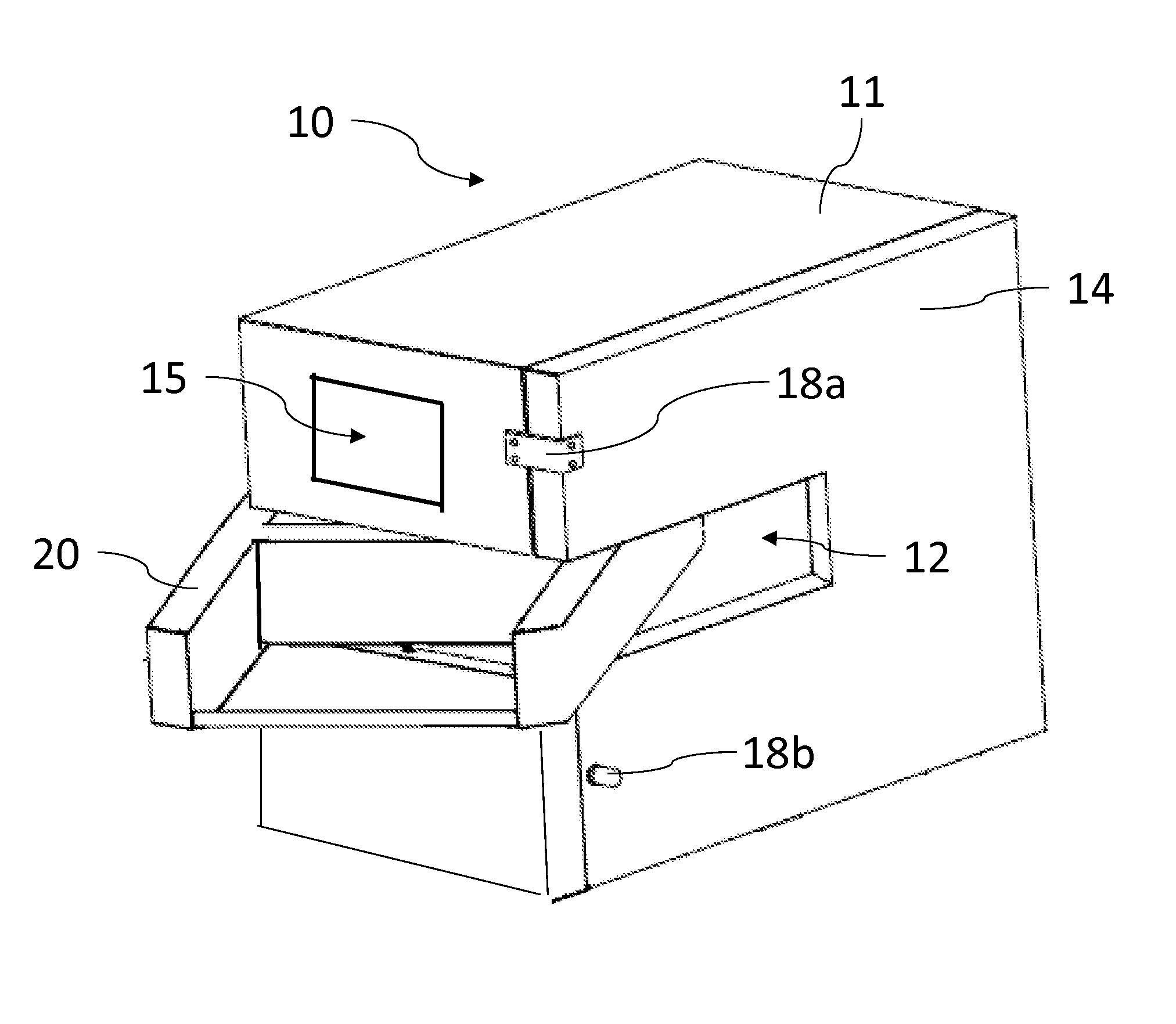

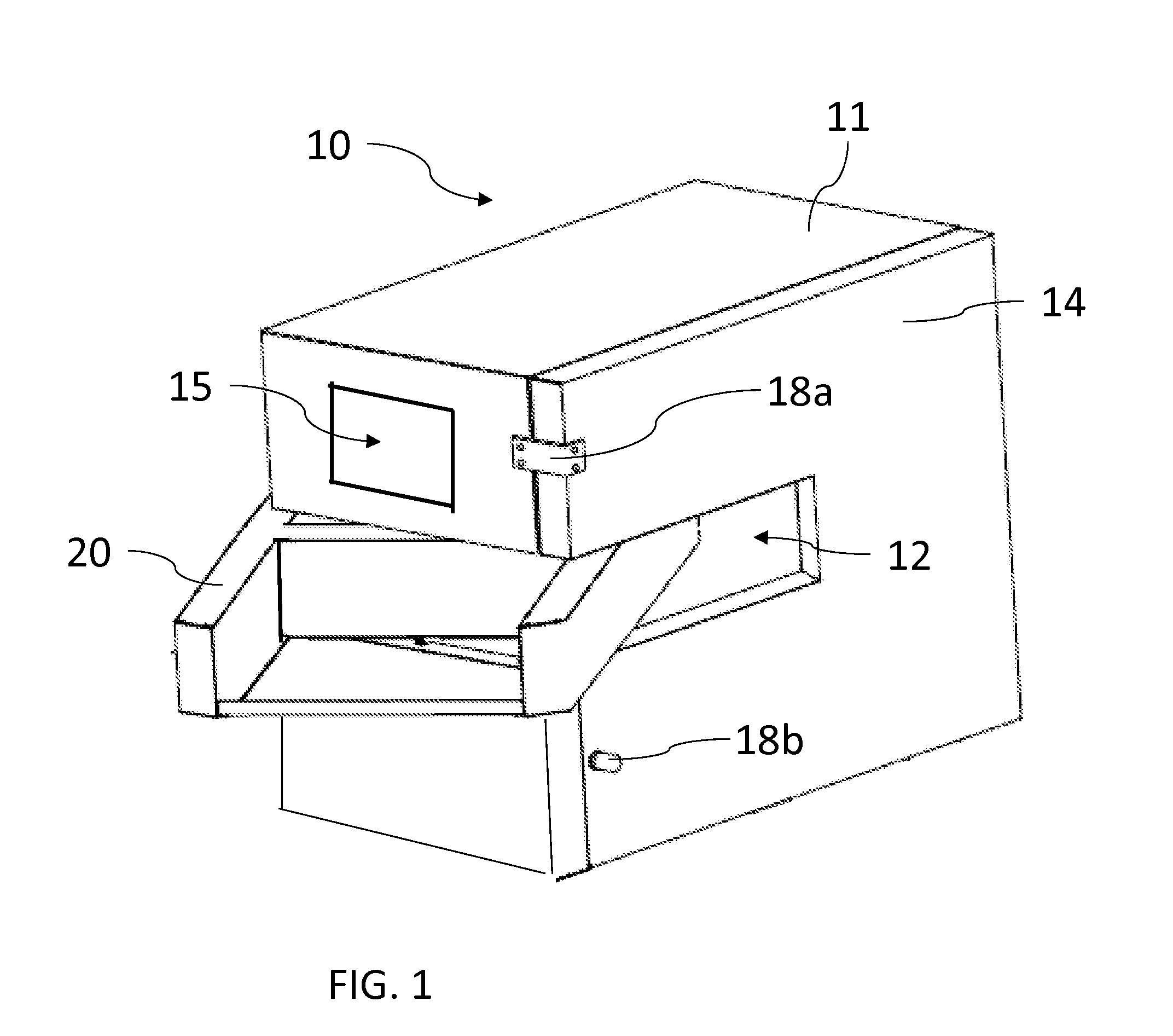

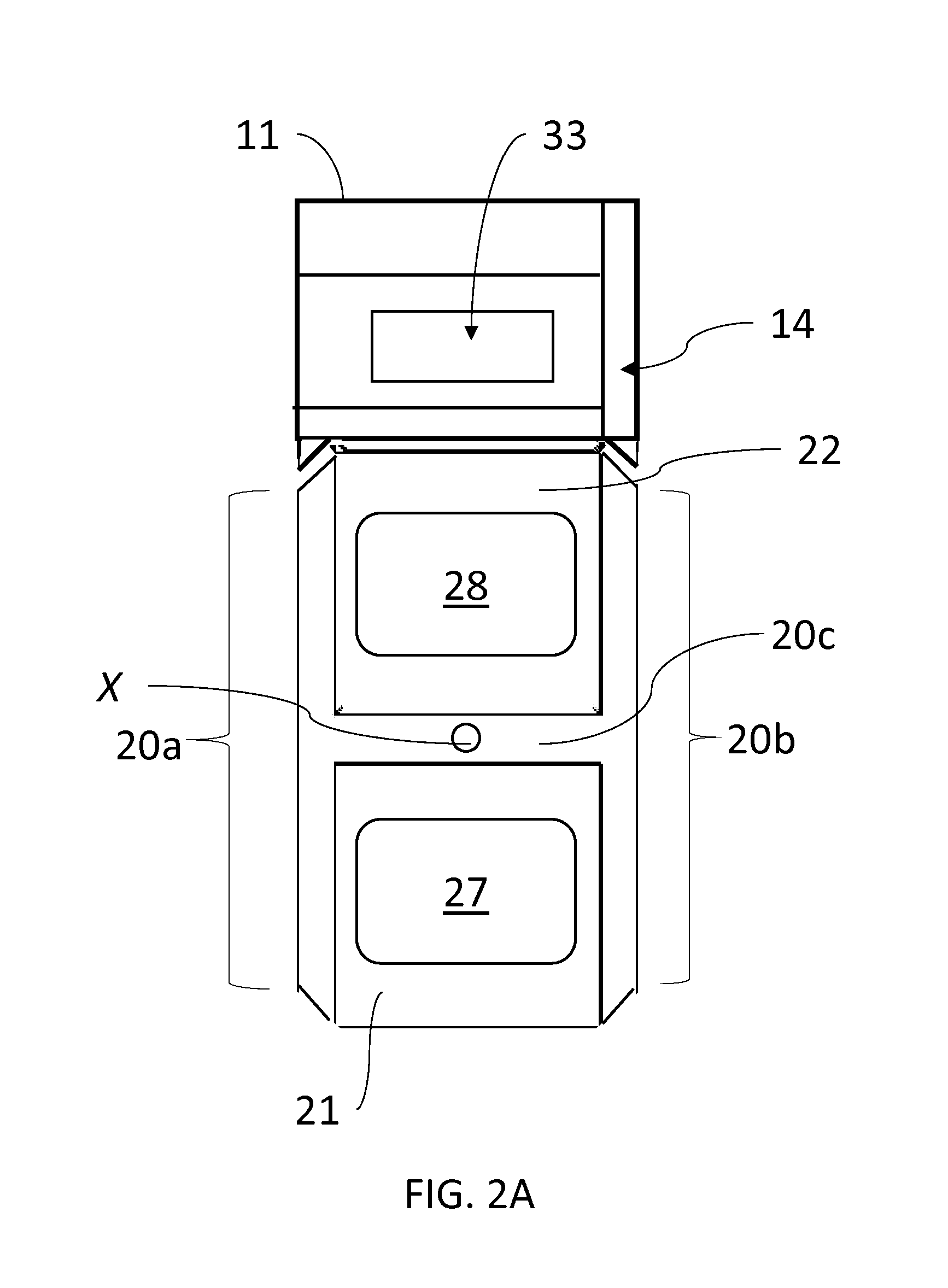

An oven comprising a housing, a cavity, an H-shaped rotating door, a motor and a heat source is disclosed. The cavity, which includes an opening, is located within the housing. The H-shaped rotating door, which can be rotated by the motor, includes a first food loading section and a second food loading section. The H-shaped rotating door also serves as a cover to prevent heat within the cavity from escaping through the opening. The heat source provides heat to the cavity to heat up any food item placed on one of the food loading sections located within the cavity.

Owner:OVENTION

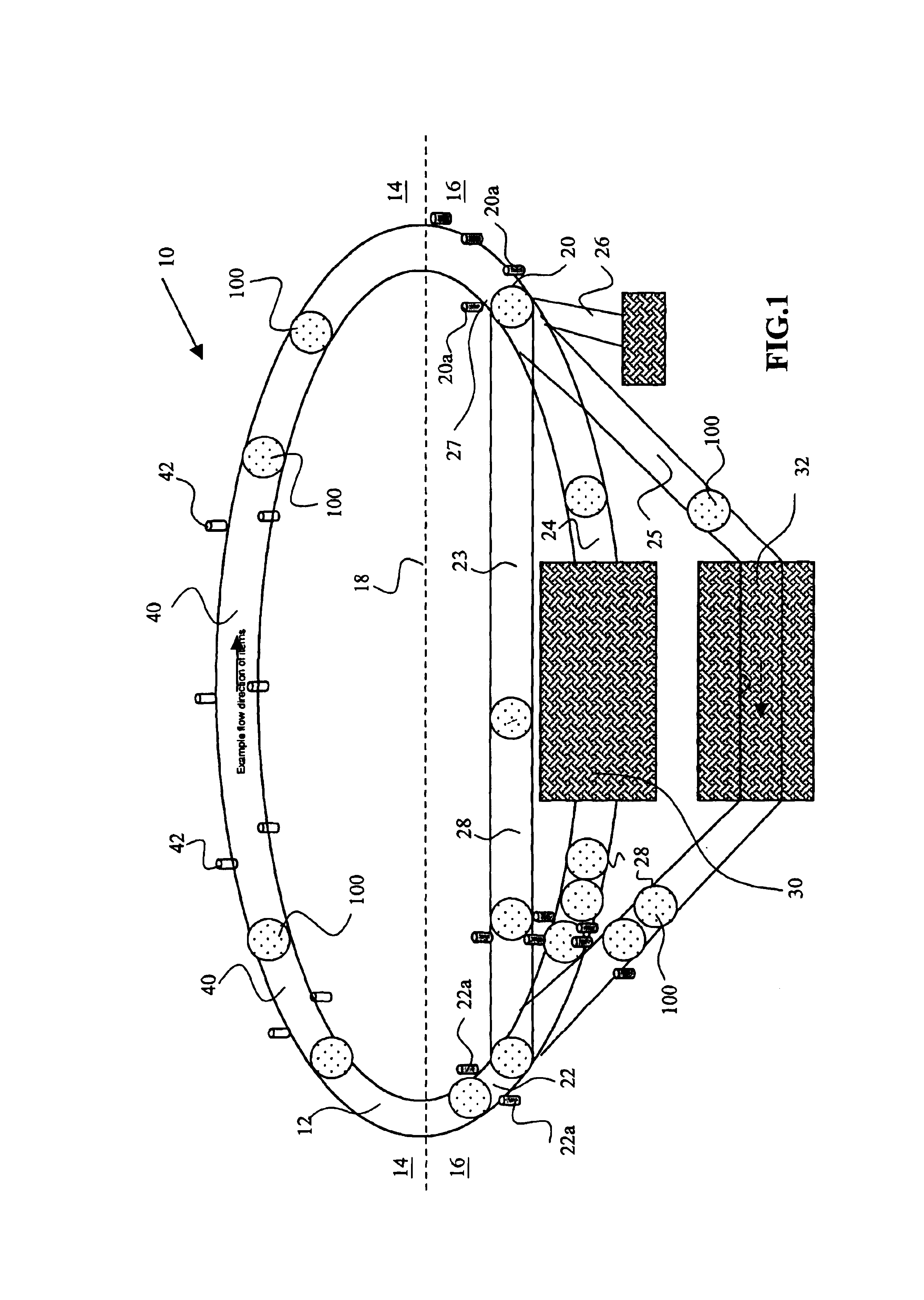

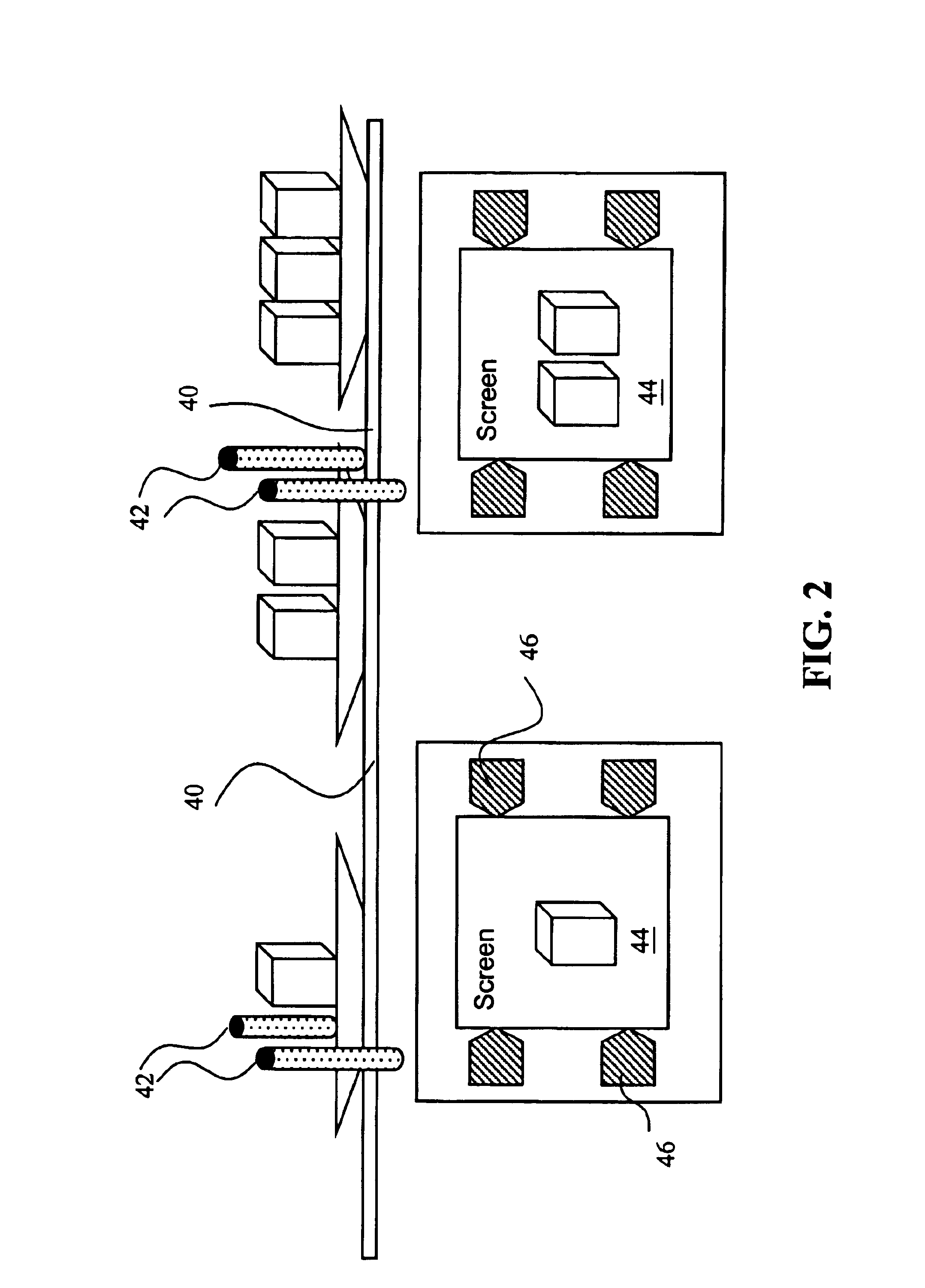

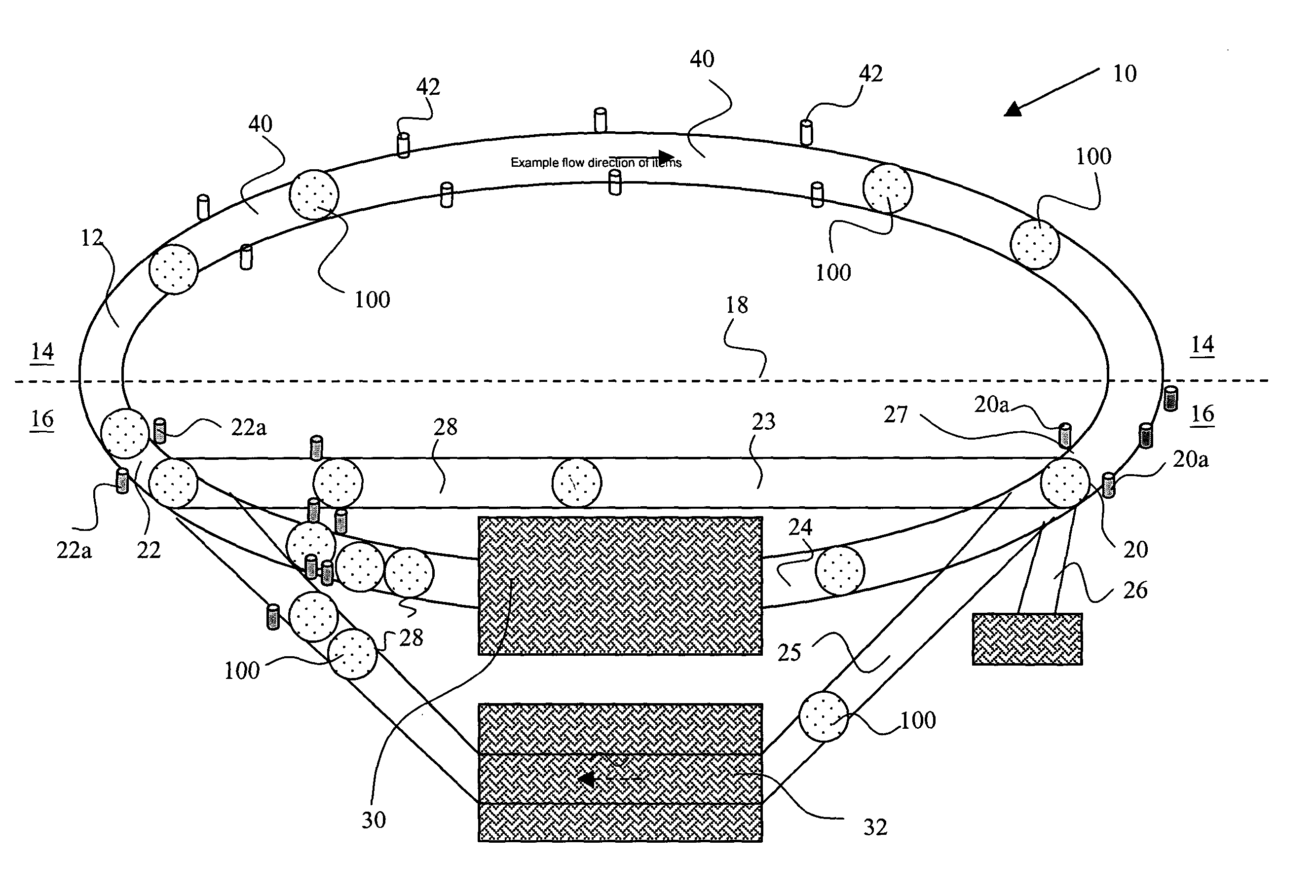

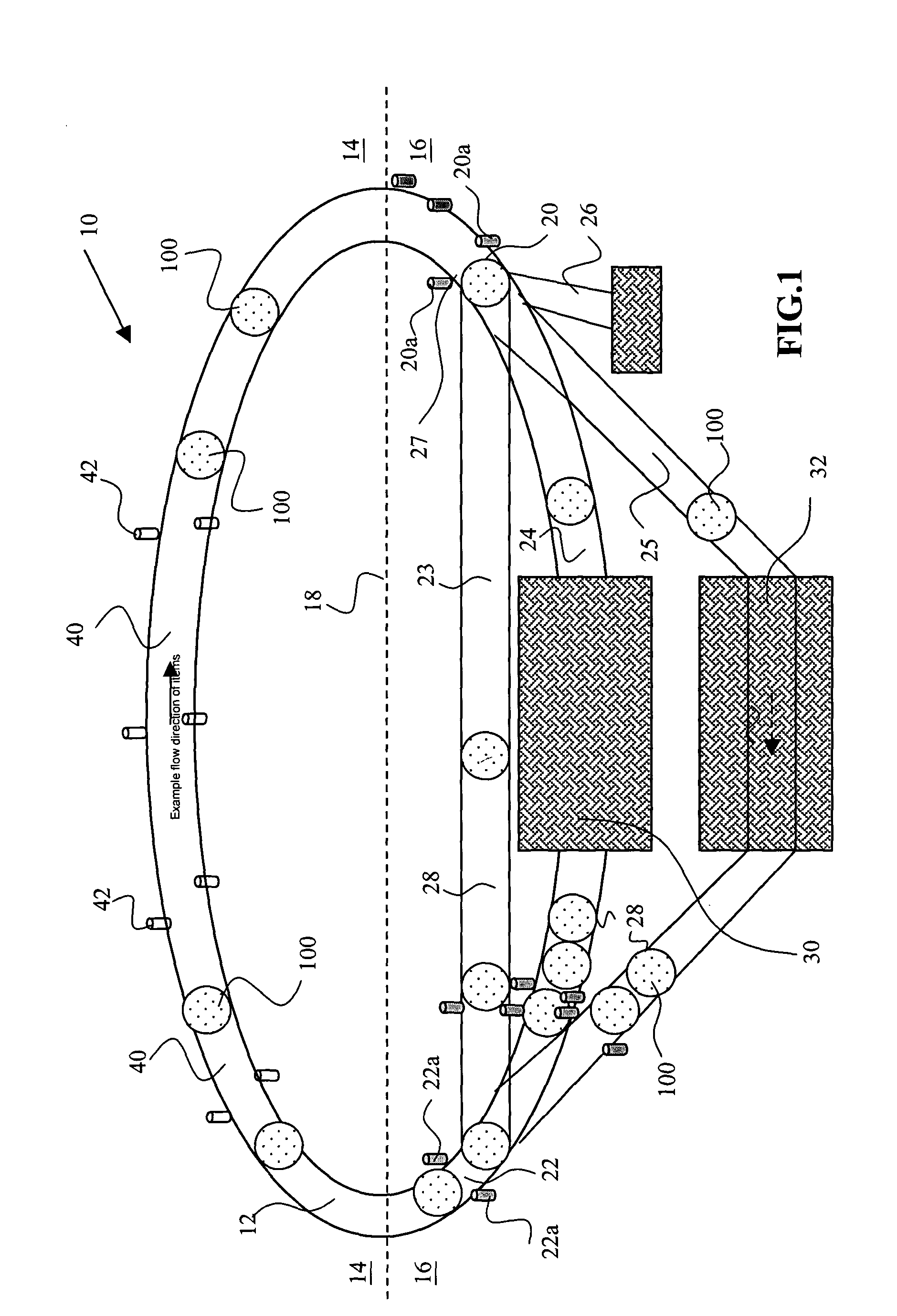

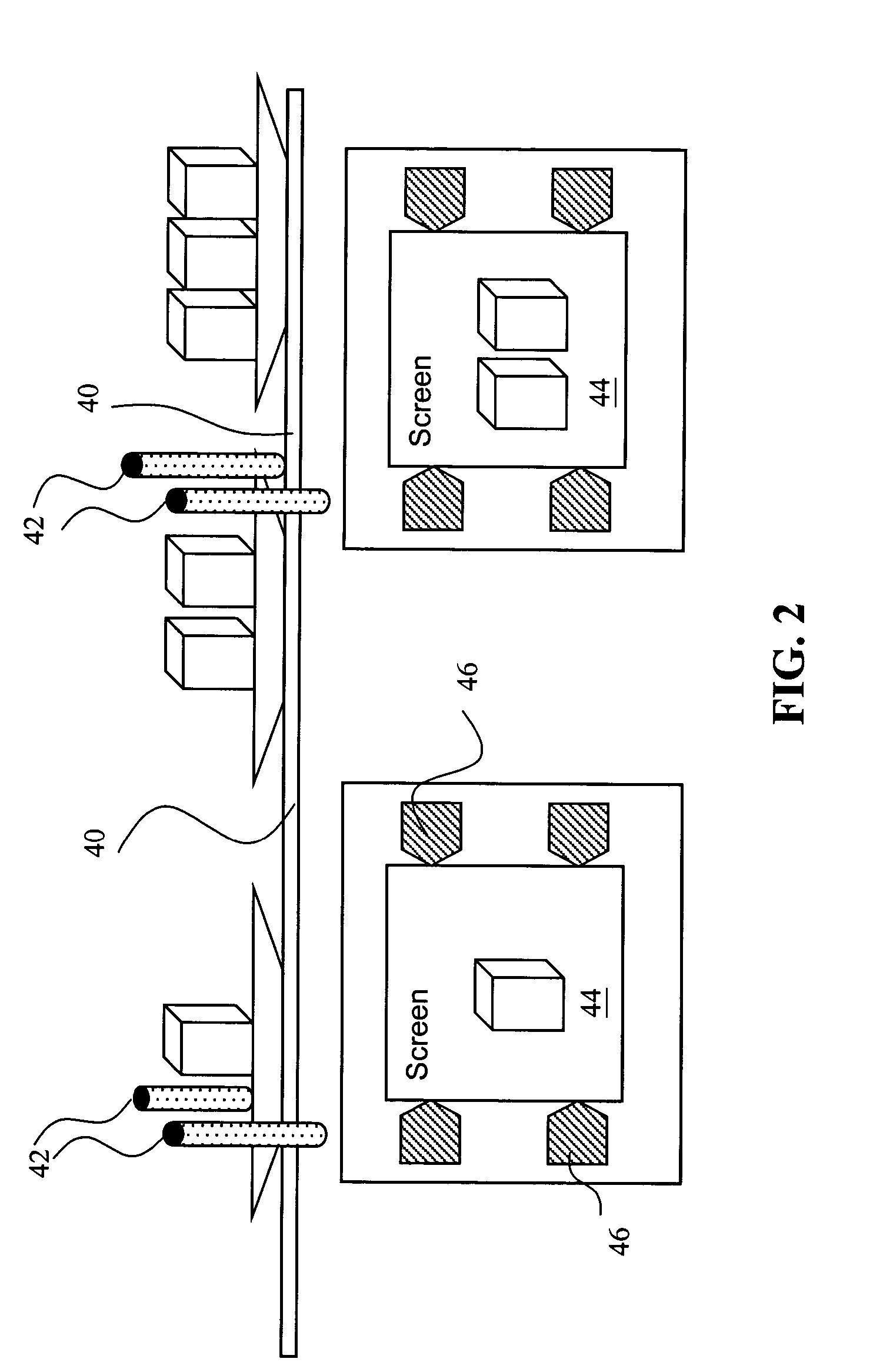

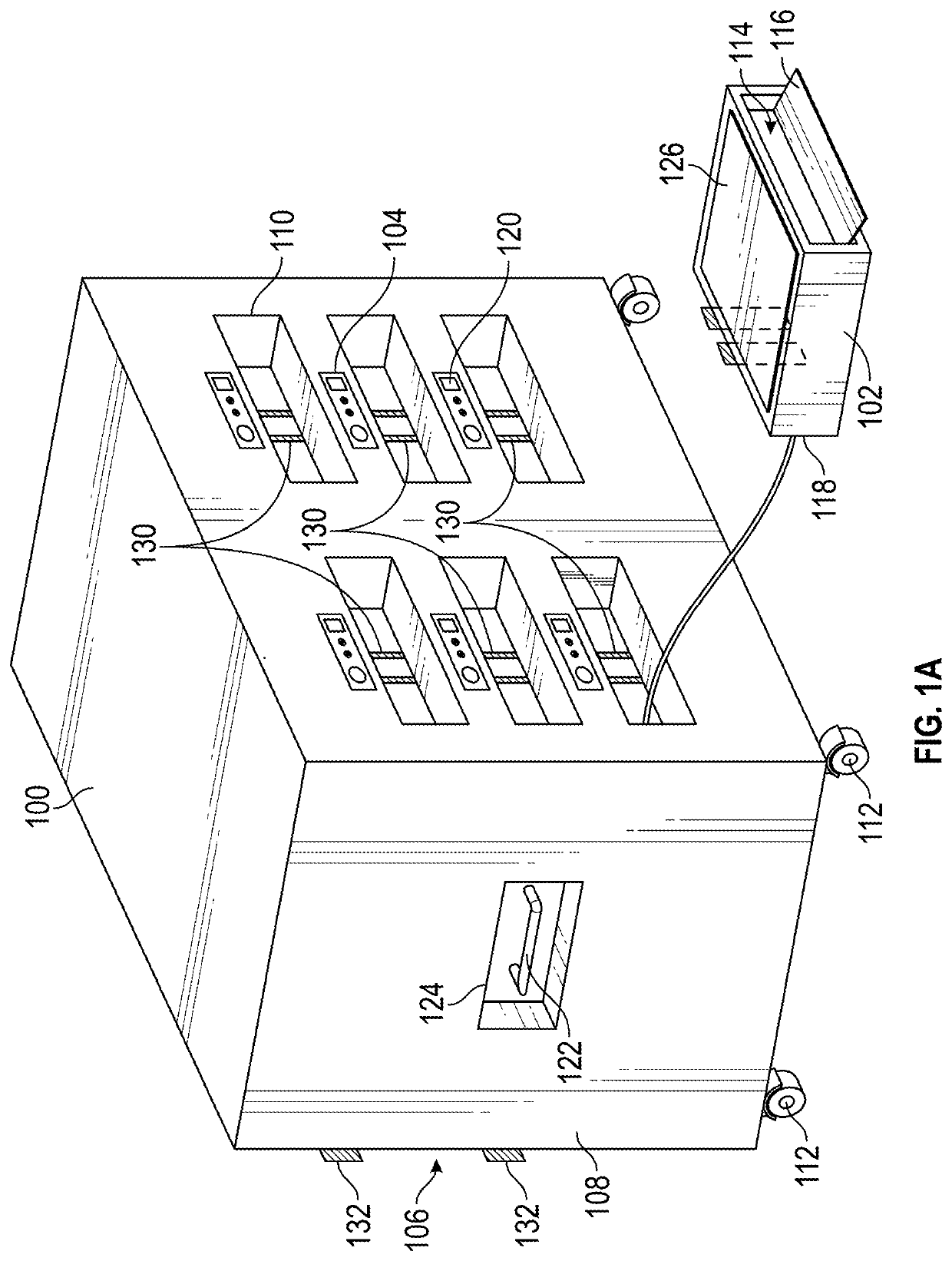

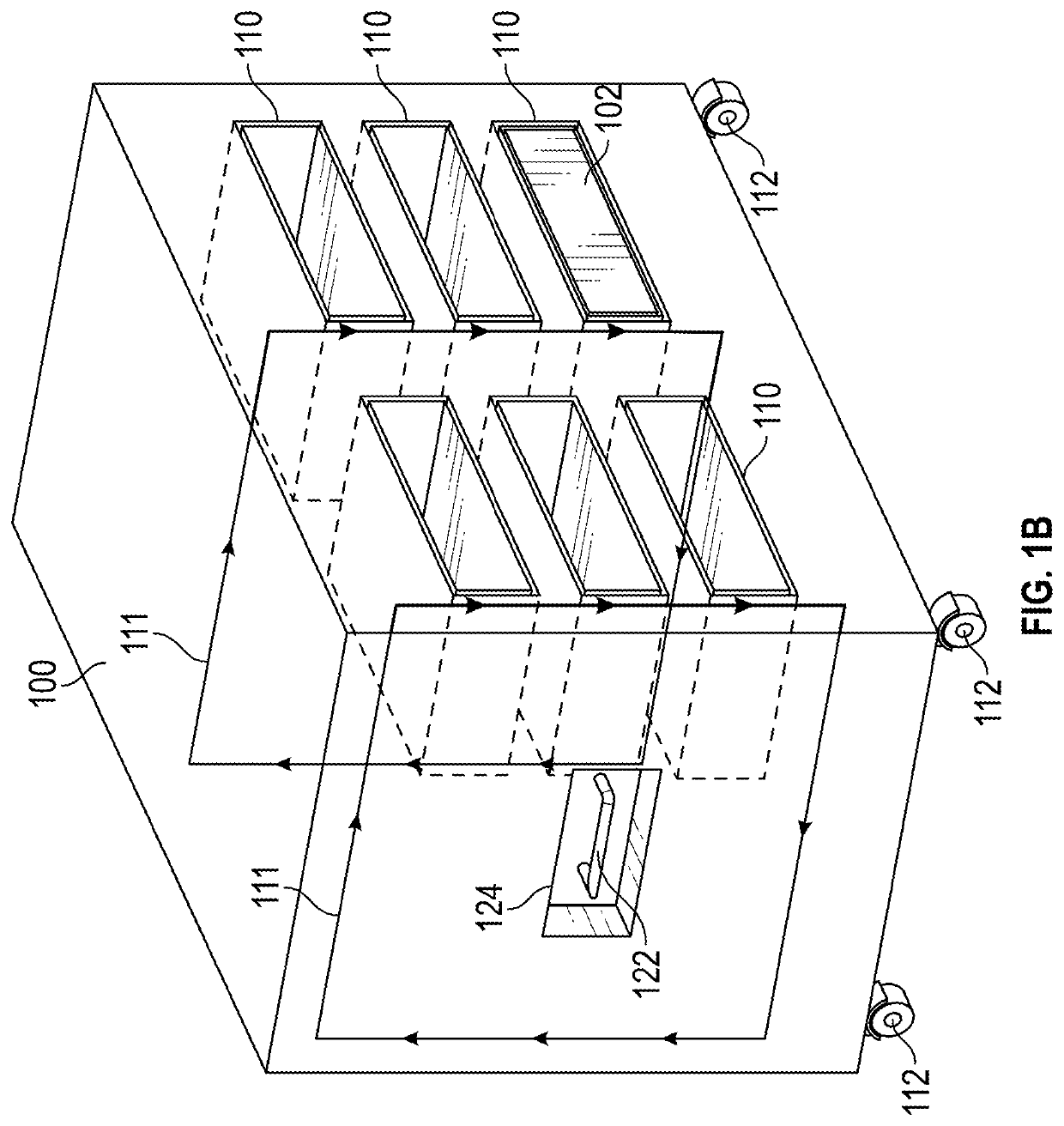

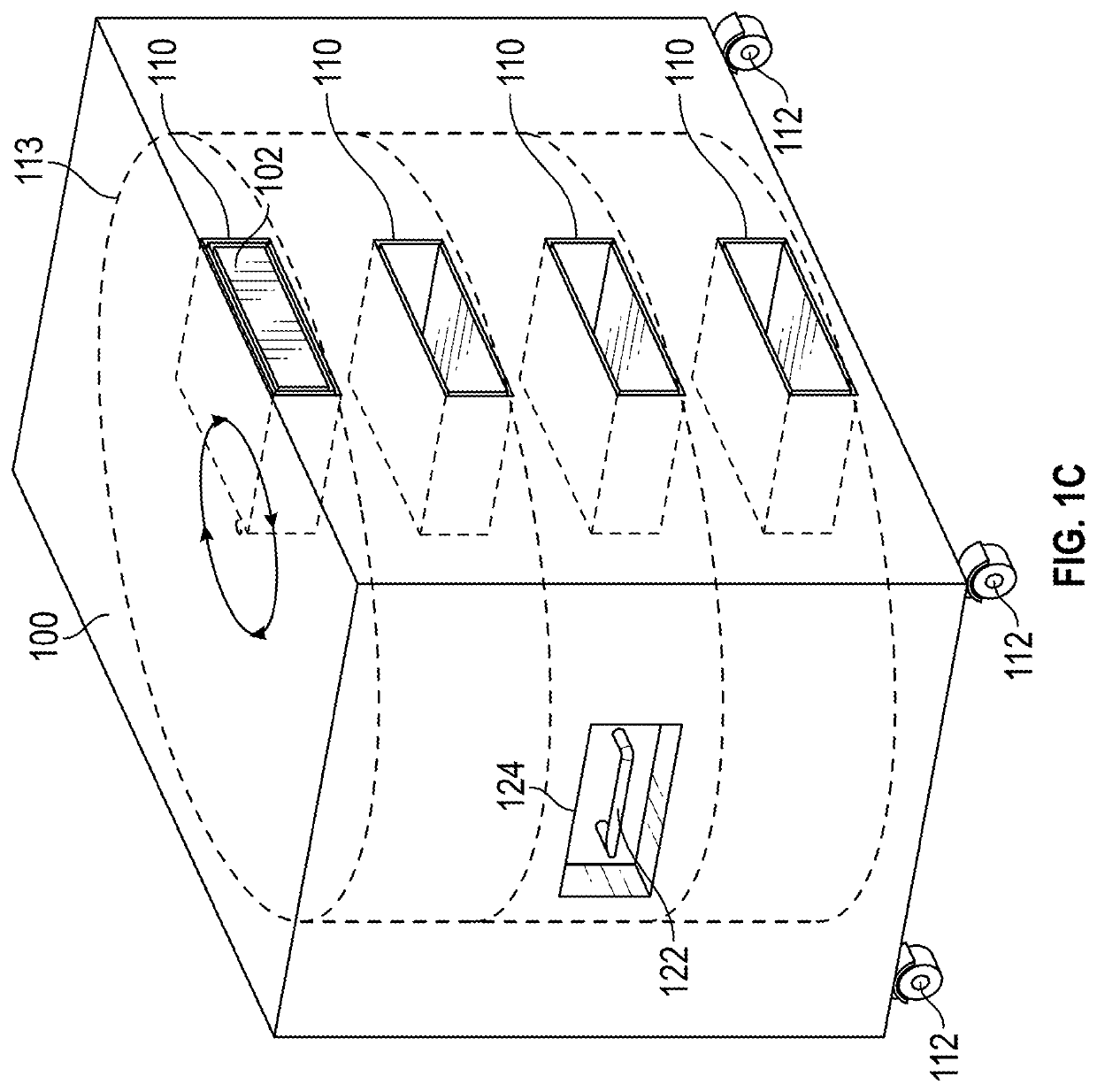

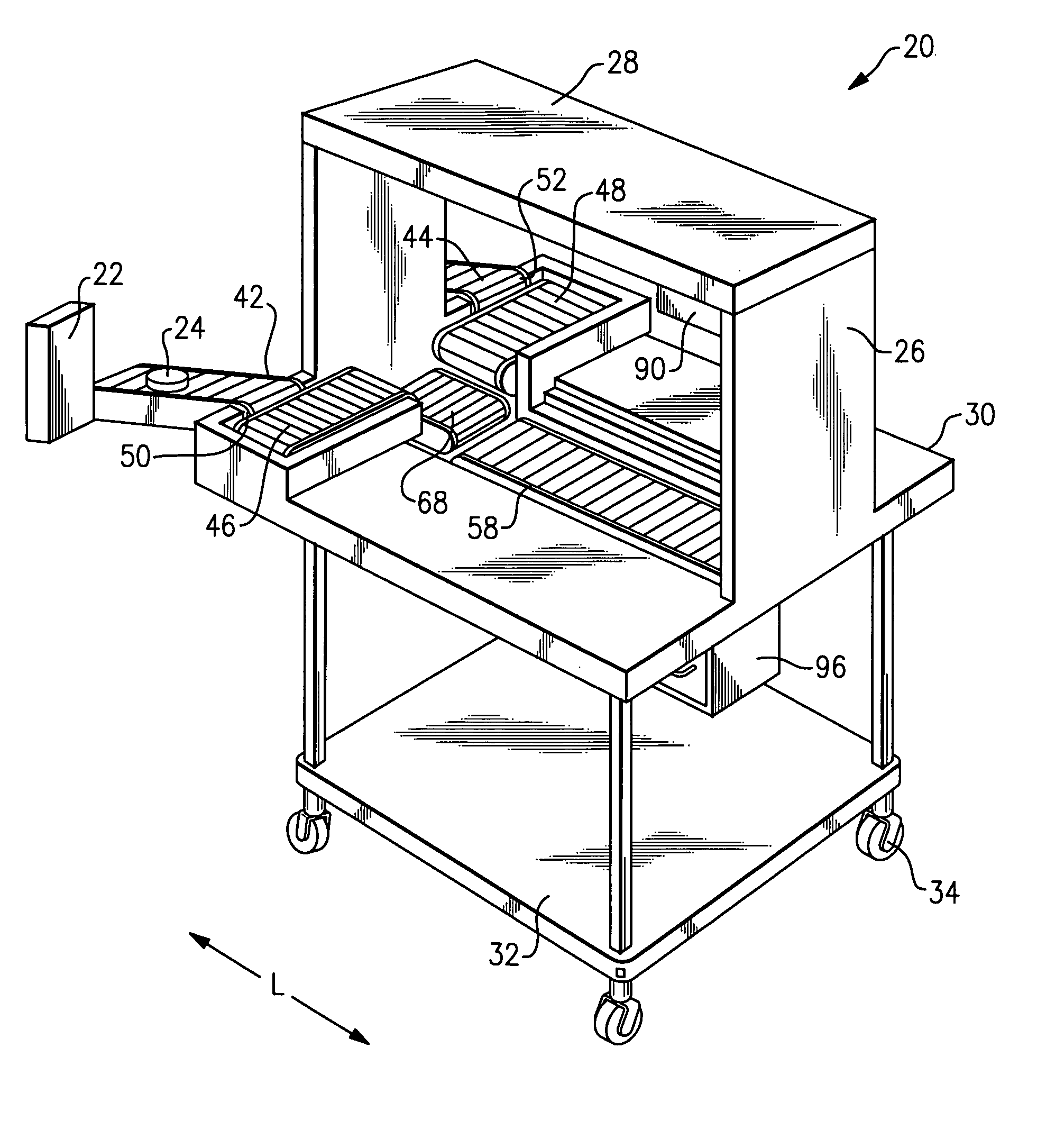

Apparatus, method and system for food management and food inventory

InactiveUS6930296B2Avoid unnecessary workEfficient and effectiveAutomatic control devicesFurnace typesEngineeringFood handling

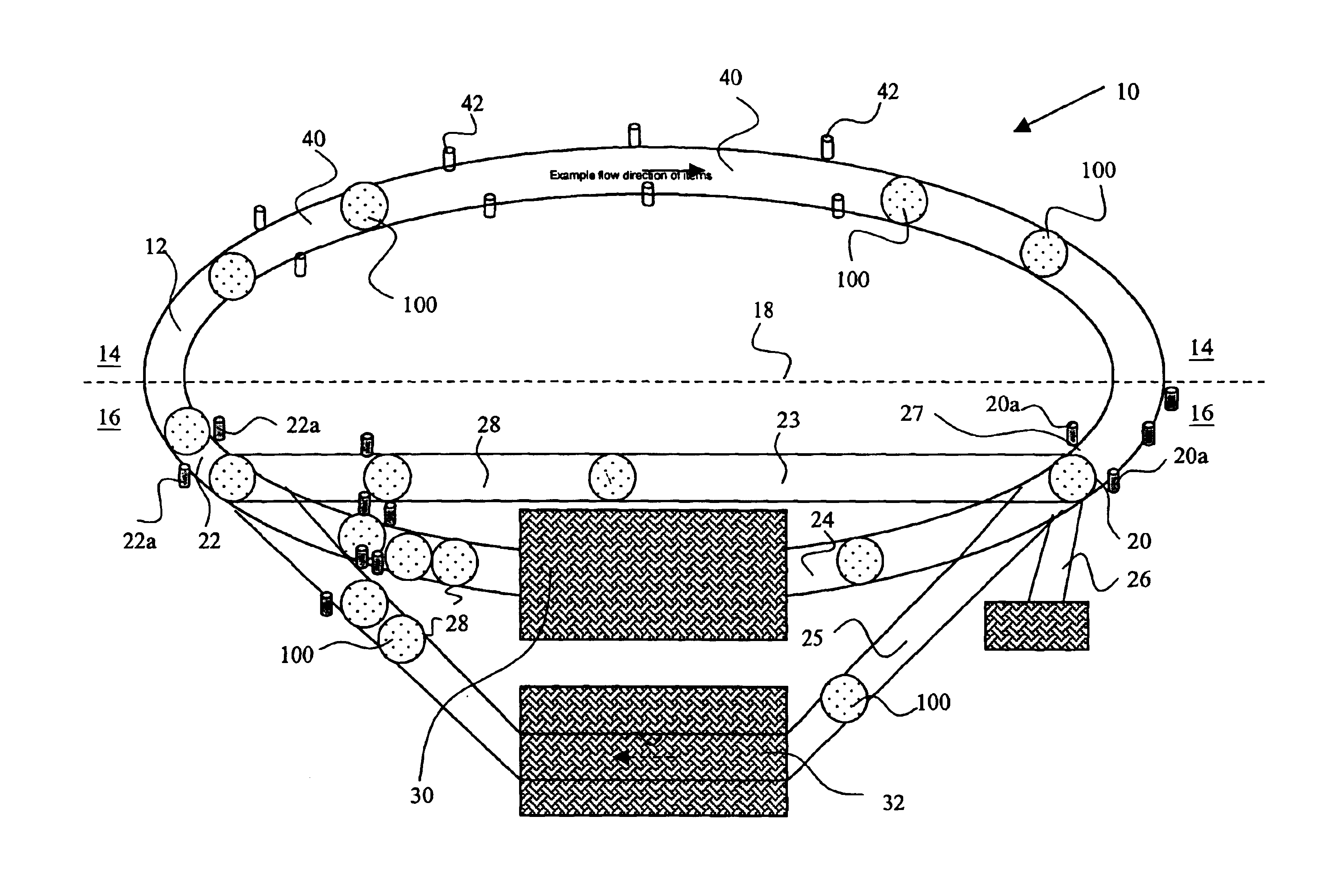

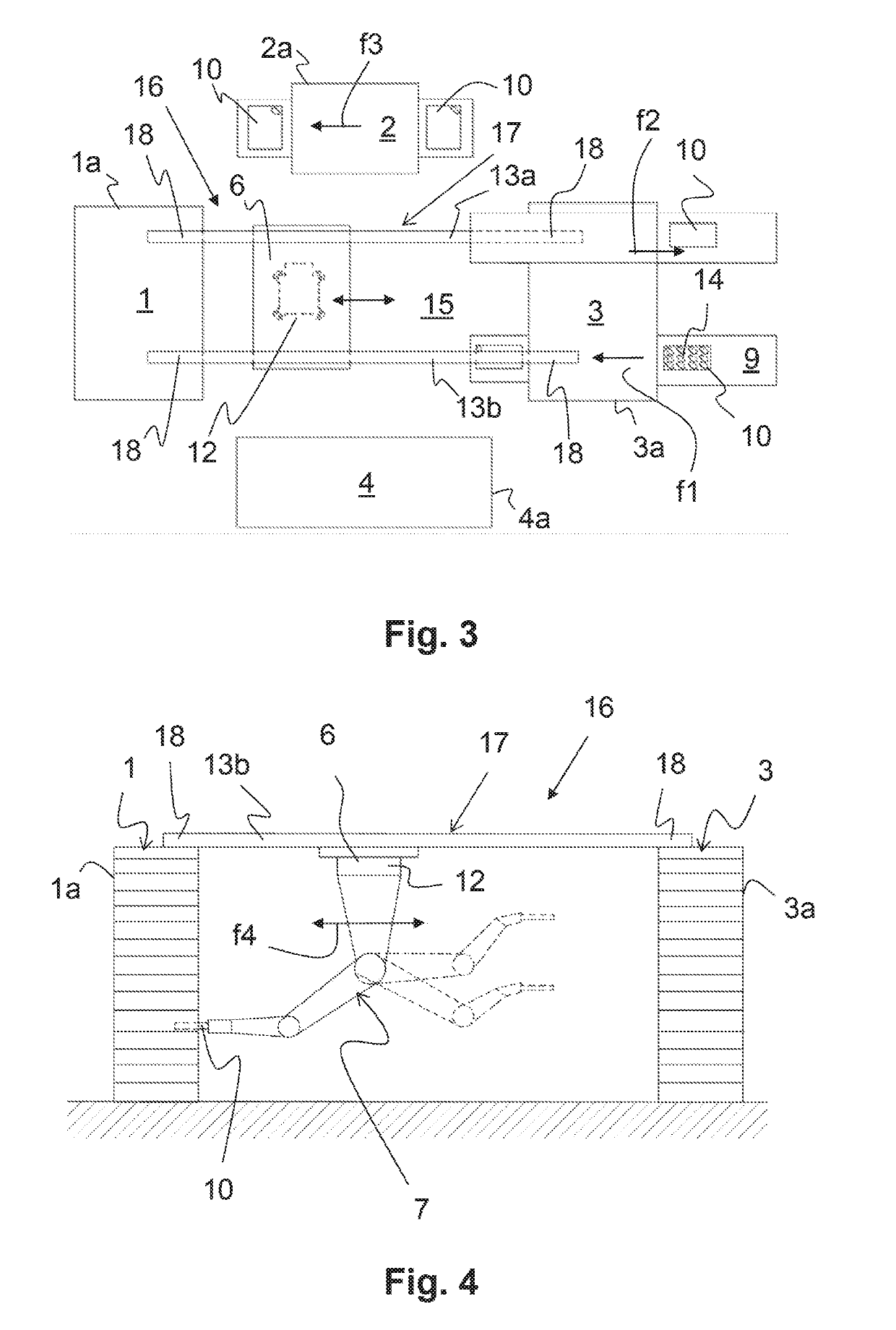

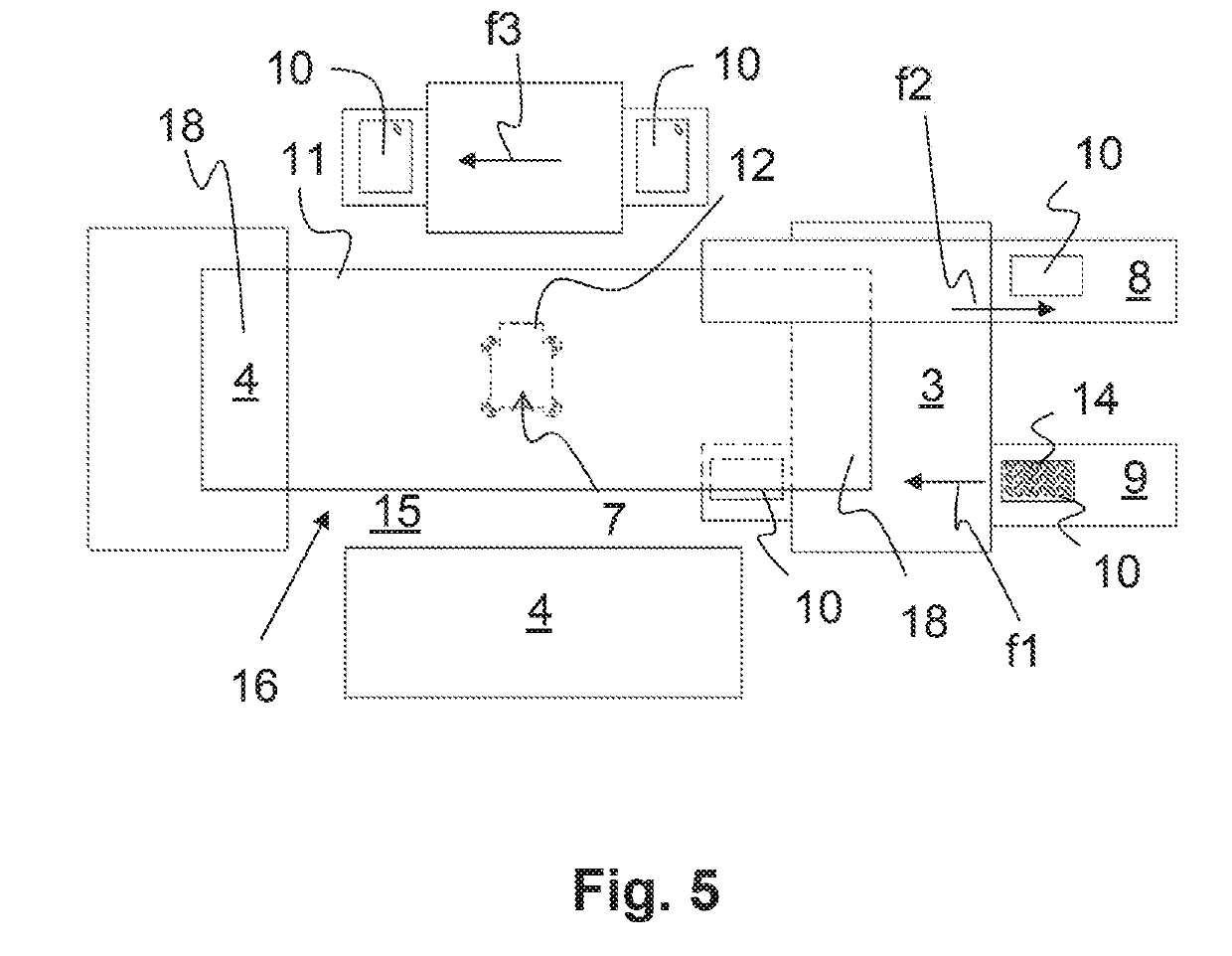

An automated food handling system for food servings comprising a transfer means for transporting food servings therealong; a plurality of treatment modules coupled in parallel to the transfer means; means for sensing and recognizing the type of food servings being transported on the transfer means; and means for automatically diverting the food serving from the transfer means into one of the treatment modules. The treatment modules may be machines that bring the food servings to the desired temperature. An inventory system is also provided.

Owner:NATURE FOOD HLDG

Apparatus, method and system for food management and food inventory

InactiveUS20050051528A1Prevent drying outAvoid unnecessary workAutomatic control devicesFurnace typesEngineeringFood handling

An automated food handling system for food servings comprising a transfer means for transporting food servings therealong; a plurality of treatment modules coupled in parallel to the transfer means; means for sensing and recognizing the type of food servings being transported on the transfer means; and means for automatically diverting the food serving from the transfer means into one of the treatment modules. The treatment modules may be machines that bring the food servings to the desired temperature. An inventory system is also provided.

Owner:NATURE FOOD HLDG

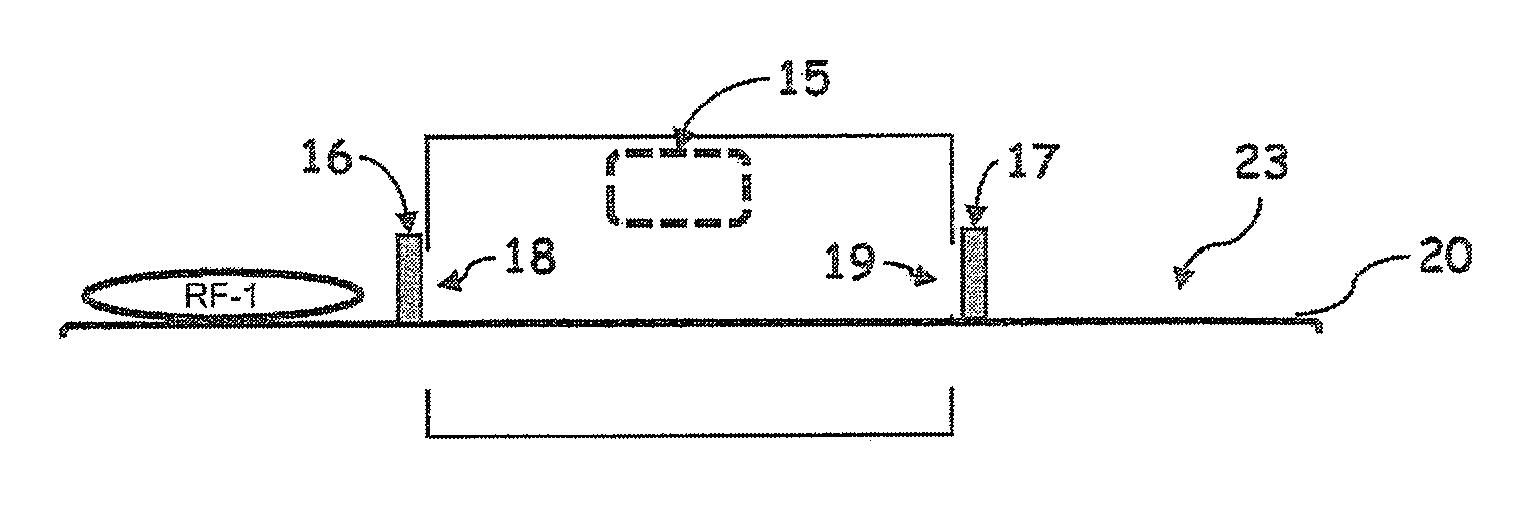

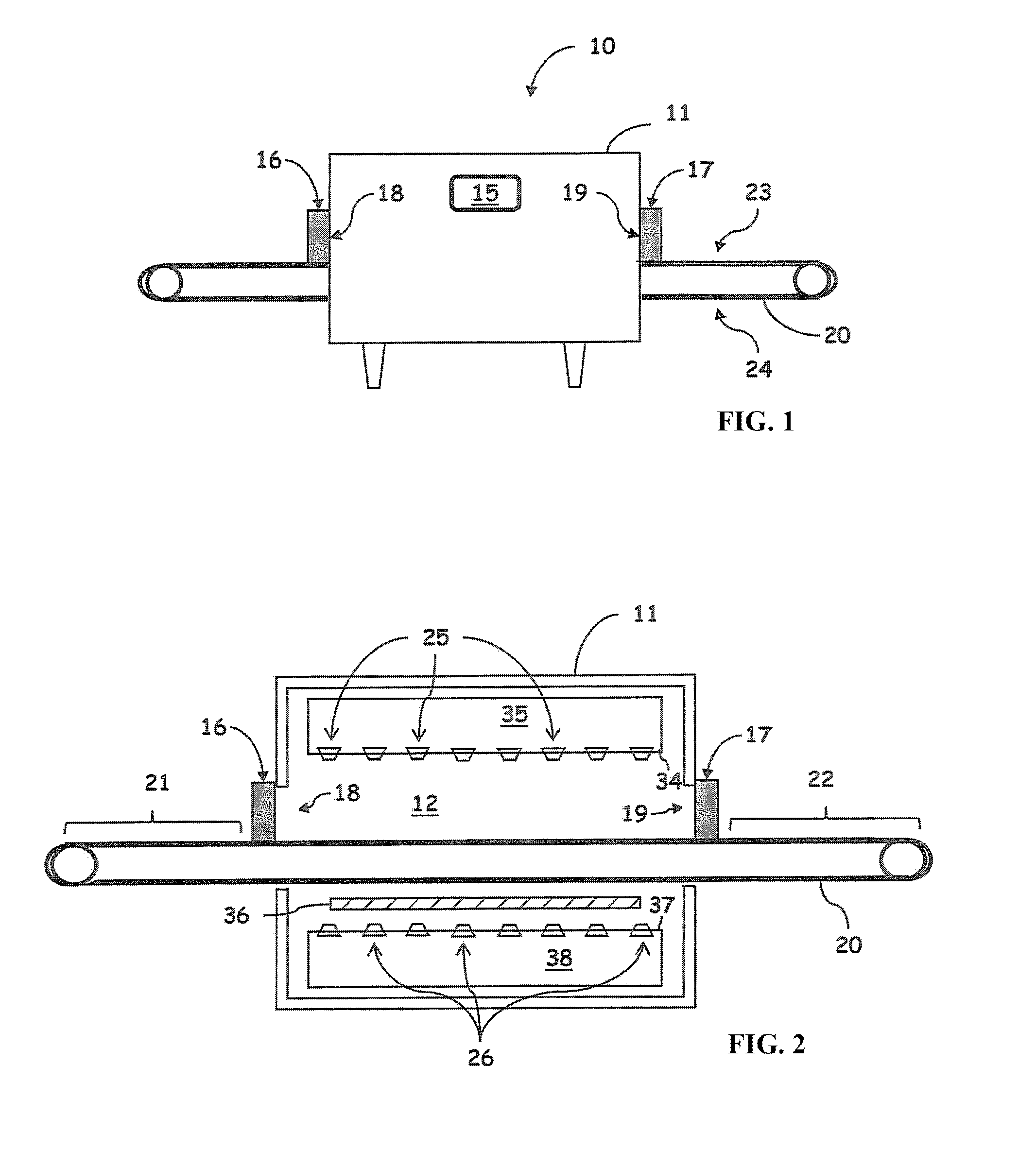

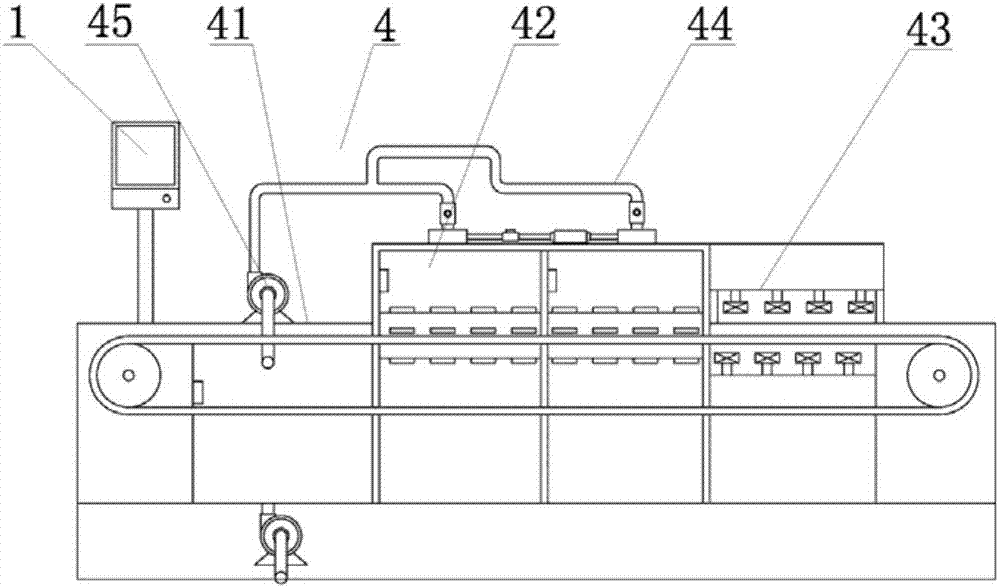

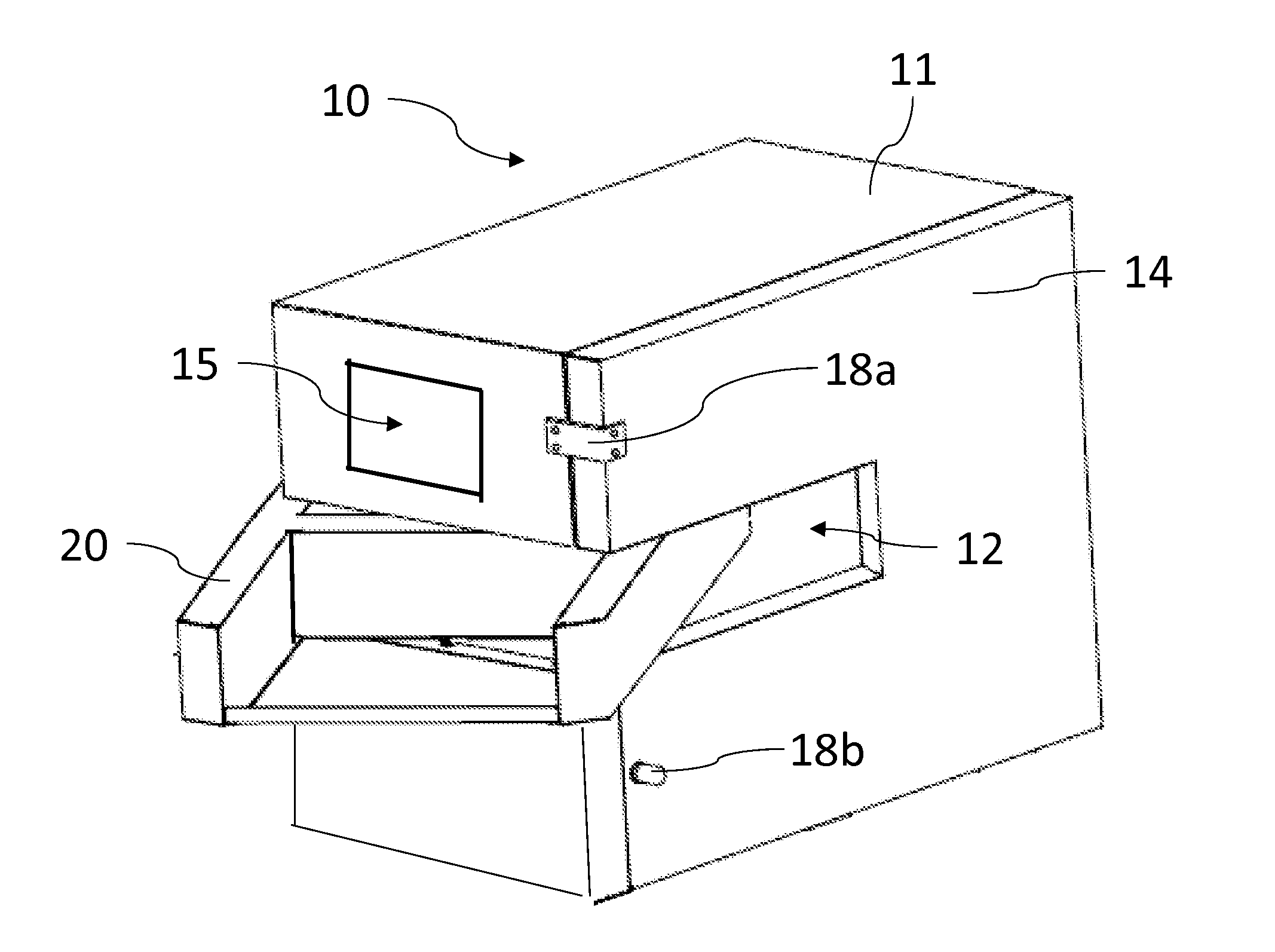

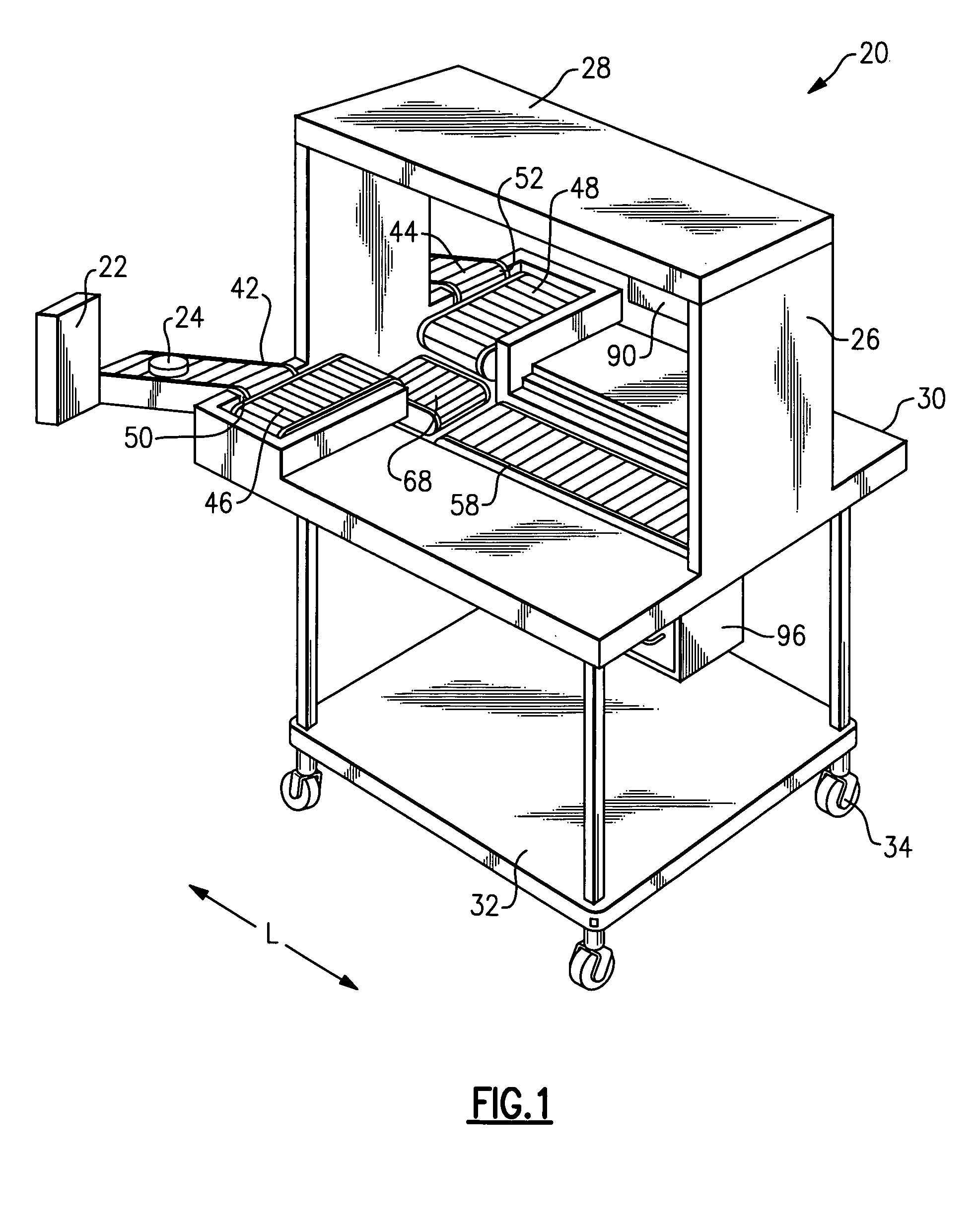

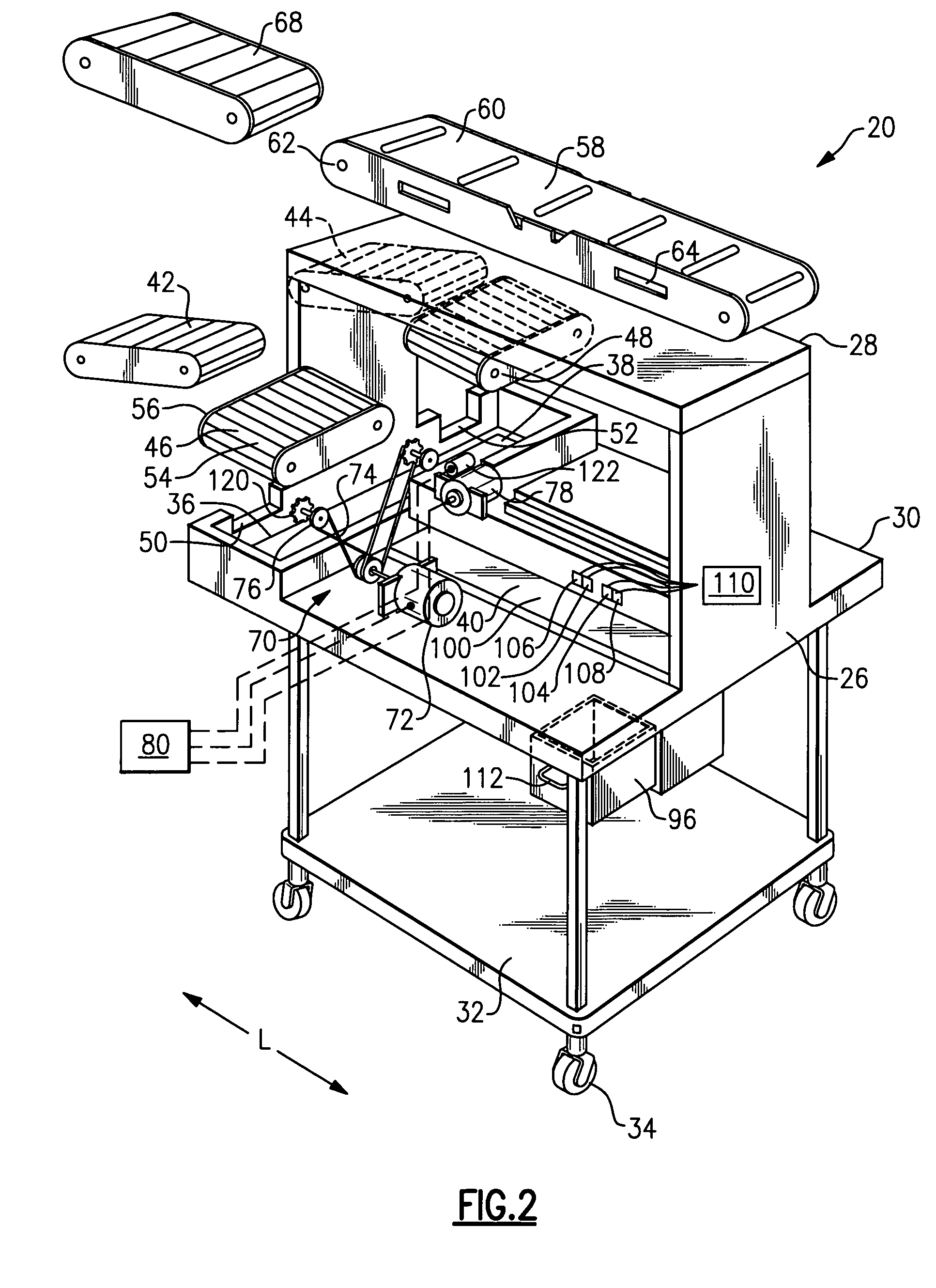

Conveyor oven

A conveyor oven is disclosed. The conveyor oven includes a housing, a conveyor belt, a first and second doors, and a heat source. The housing includes a cavity and a first and second openings. The conveyor belt is configured to receive and transport food items in and out of the cavity through the first and second openings. The conveyor belt includes a loading section and an unloading section for food. The first and second doors cover first and second openings, respectively, in order to prevent heat within the cavity from escaping through the first and second openings during operation. Configured to provide different cooking times and thermal profiles to various types of food items, the heat source provides heat to the cavity for heating up any food item placed on a portion of the conveyor belt located within the cavity.

Owner:OVENTION

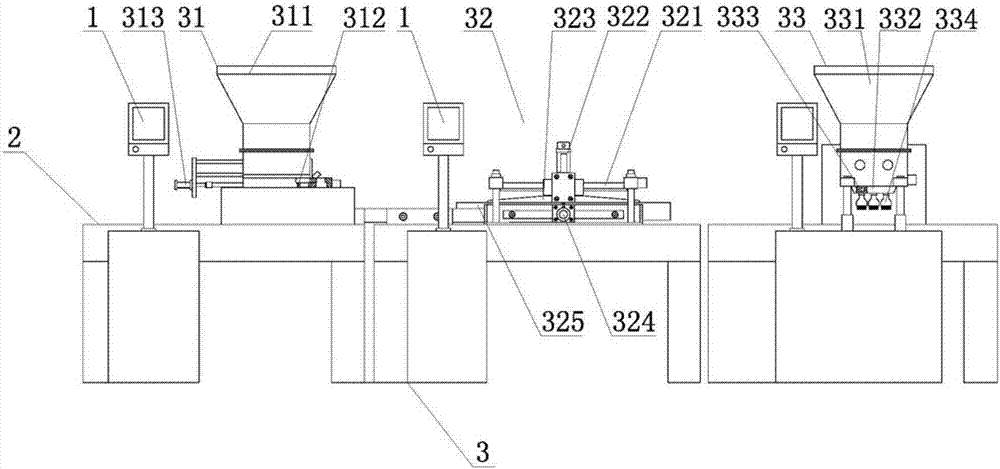

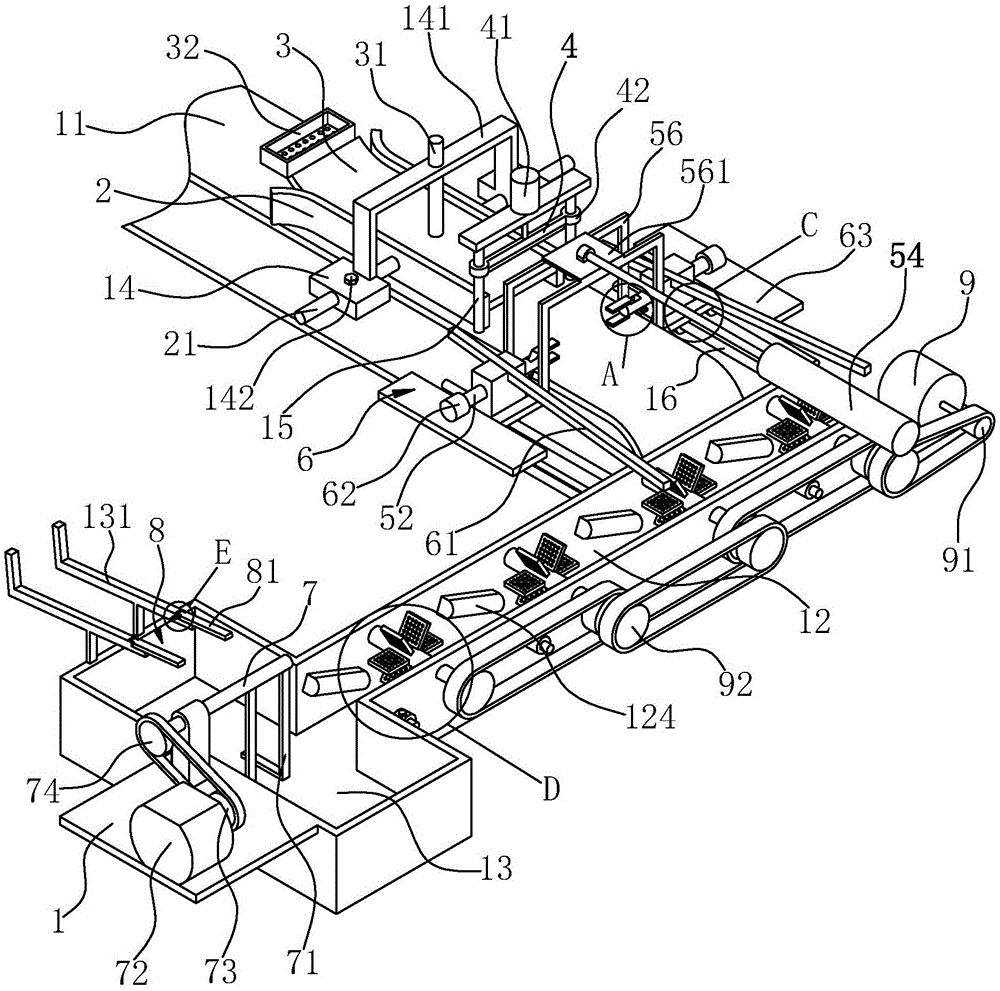

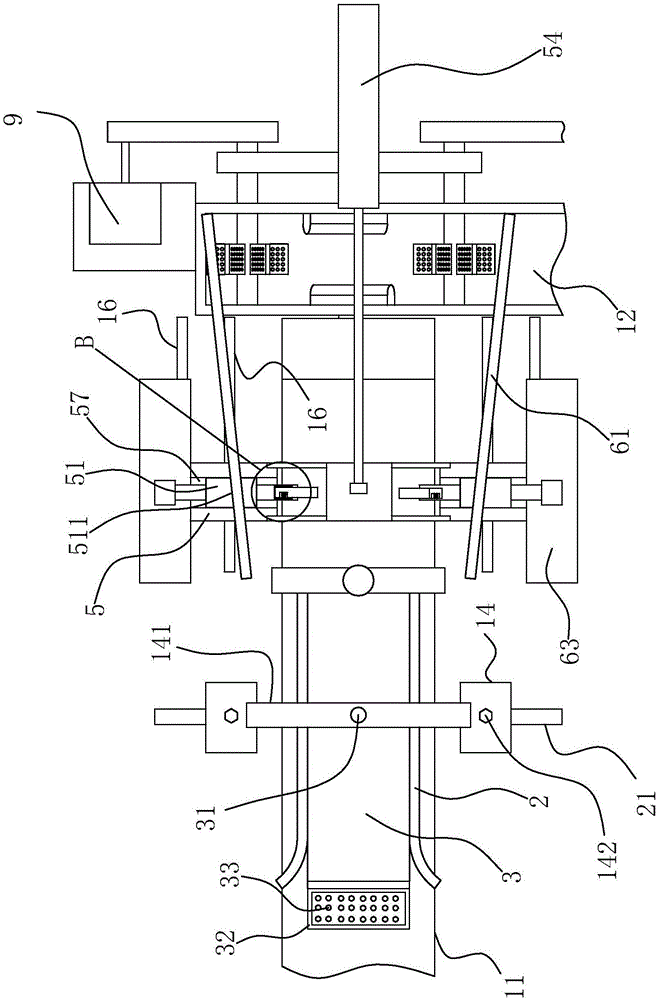

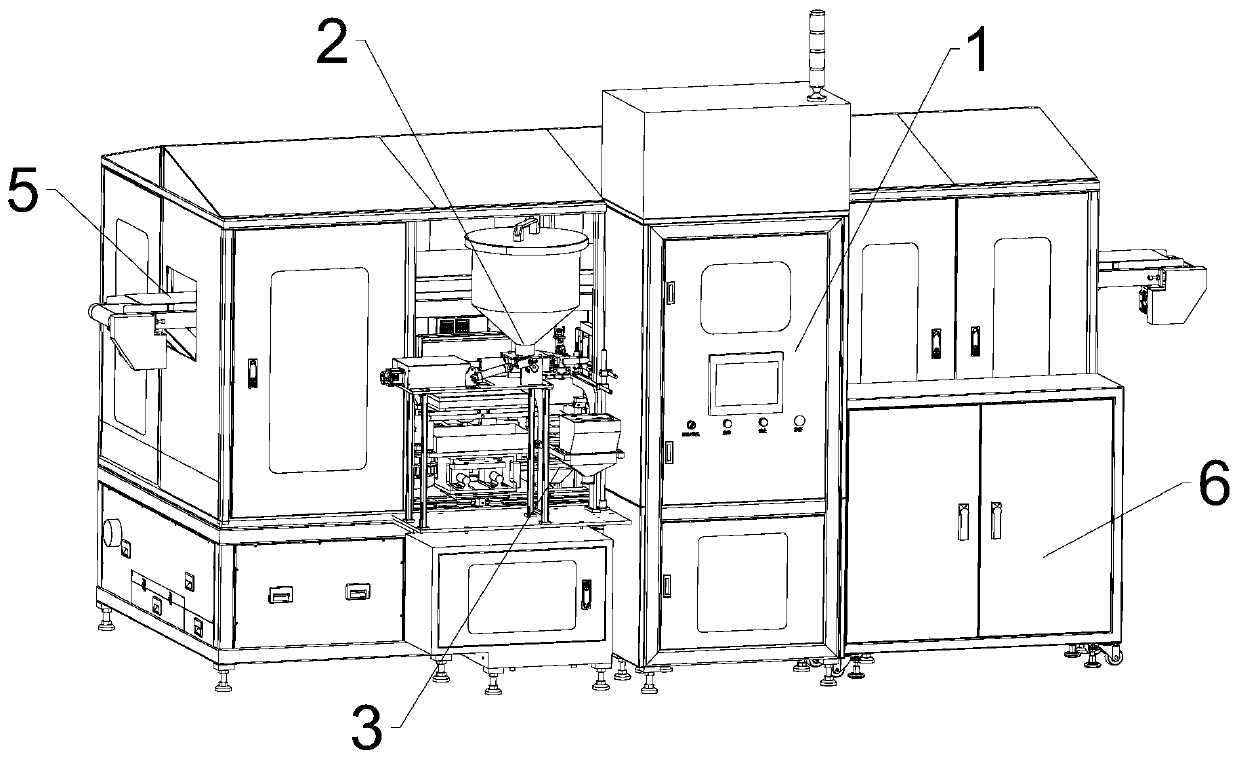

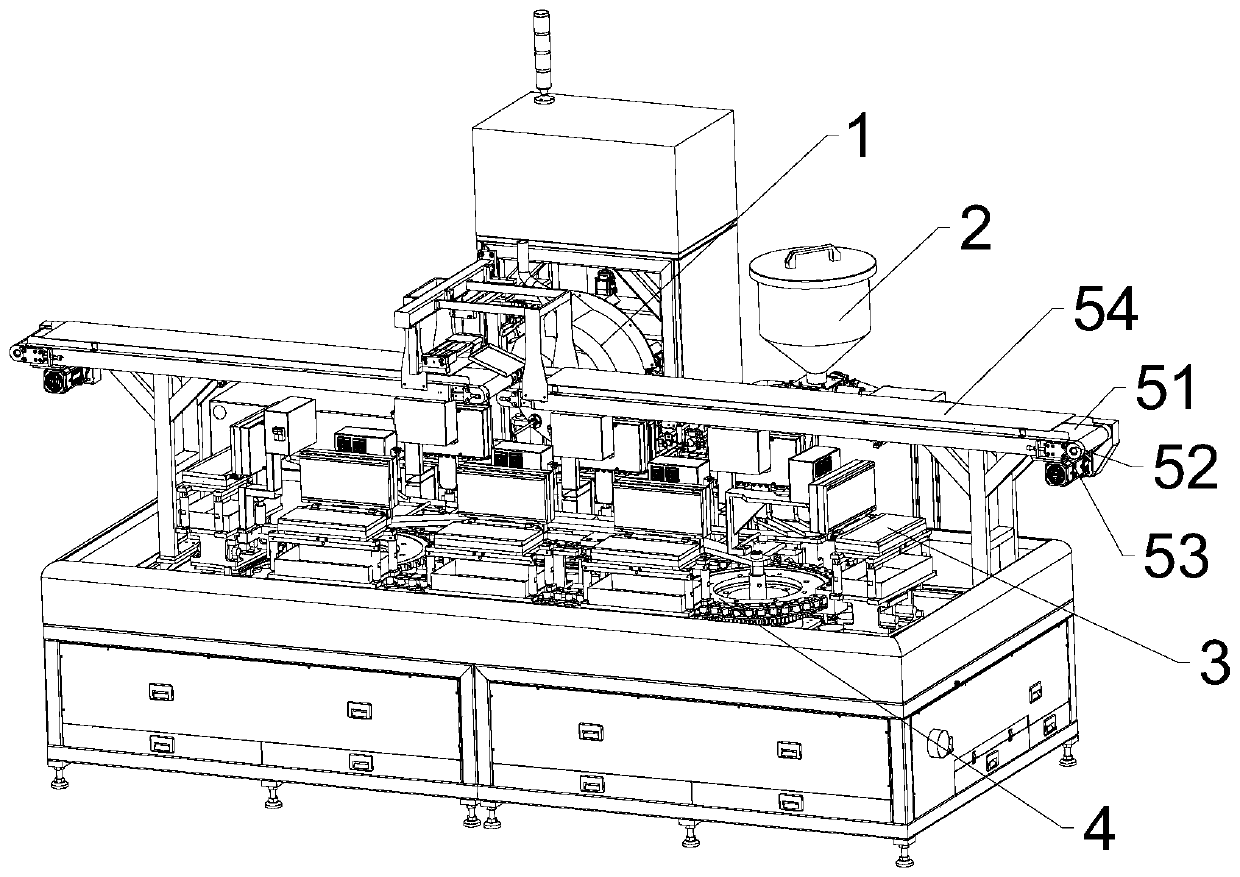

Molding technology of baked foods, production system for baked foods, and baked foods

ActiveCN107455416ARealize mass productionFit for consumptionDough treatmentFood processingProduction lineBaked goods

The invention discloses a molding technology of baked foods, a production system for baked foods, and baked foods, and belongs to the technical field of food production. The molding technology of the baked foods comprises the following steps of successively performing quantitative feeding, vibrating-leveling, quantitative grouting, multi-stage transition baking, multi-station cooling and counting-boxing, and carrying out sealing and molding. The baked foods comprise the following raw materials in parts by weight: 40-50 parts of walnut kernels, 40-50 parts of spina date seeds, 1-3 parts of black sesame seeds, 4-5 parts of longan flesh, 90-100 parts of flour, 50-60 parts of butter, 20-30 parts of white sugar, 20-30 parts of brown sugar, 50-60 parts of eggs, 2-3 parts of baking powder, 4-5 parts of soda powder, and 120-140 parts of water. The invention has the following beneficial effects: the baked foods are rich in nutrition, and satisfies living needs of current people; moreover, production-line mass production is realized by the molding technology and the production system used for producing the baked foods so that production efficiency and production quality are improved with cost reduced.

Owner:ANHUI NONG ANKANG FOODS LTD CO

Oil frying equipment

InactiveCN101611733AAvoid the phenomenon of uneven raw and cookedQuality assuranceOil/fat bakingCharging/discharging ovensEngineeringMechanical engineering

Owner:ZHENGZHOU GUXIANGQING FOOD TECH

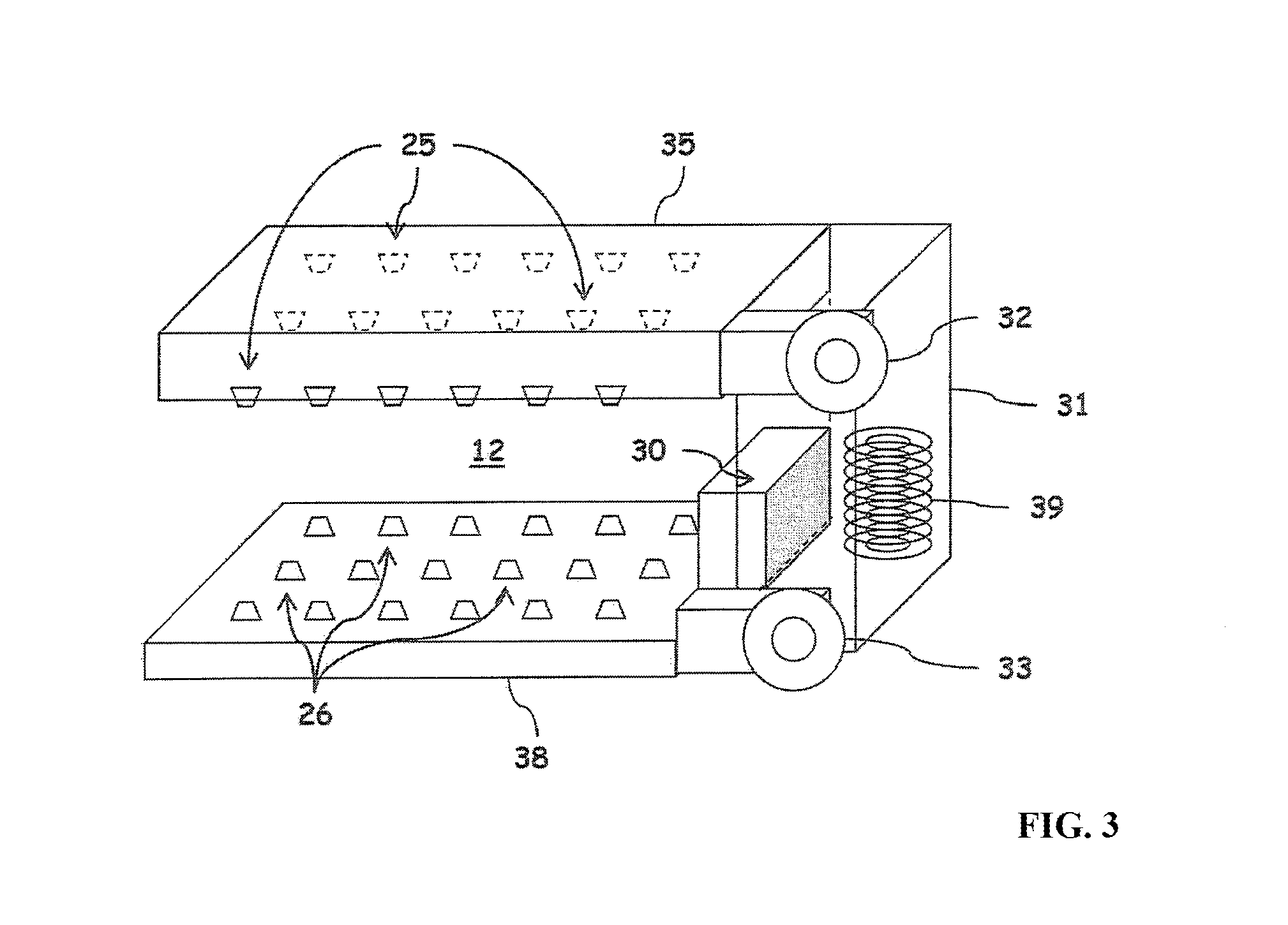

Configurable oven rack system

InactiveUS20200200393A1Assisted movementDomestic stoves or rangesStoves/ranges shelves or racksEngineeringFood item

An oven to facilitate heating a food item is disclosed that includes an oven box one or more upper heating elements, and one or more lower heating elements. The oven box has a floor, a ceiling spaced across a height of the oven box from the floor, and at least one side wall that extends between the floor and the ceiling to at least partially delineate an interior of the oven box from an exterior thereof. The one or more upper heating elements are spaced proximate the ceiling relative to the one or more lower heating elements. The one or more lower heating elements are spaced proximate the floor relative to the one or more upper heating elements. The one or more lower heating elements are arranged in a first pattern and the one or more upper heating elements arranged in a second pattern. The first pattern is different than the second pattern.

Owner:ZUME INC

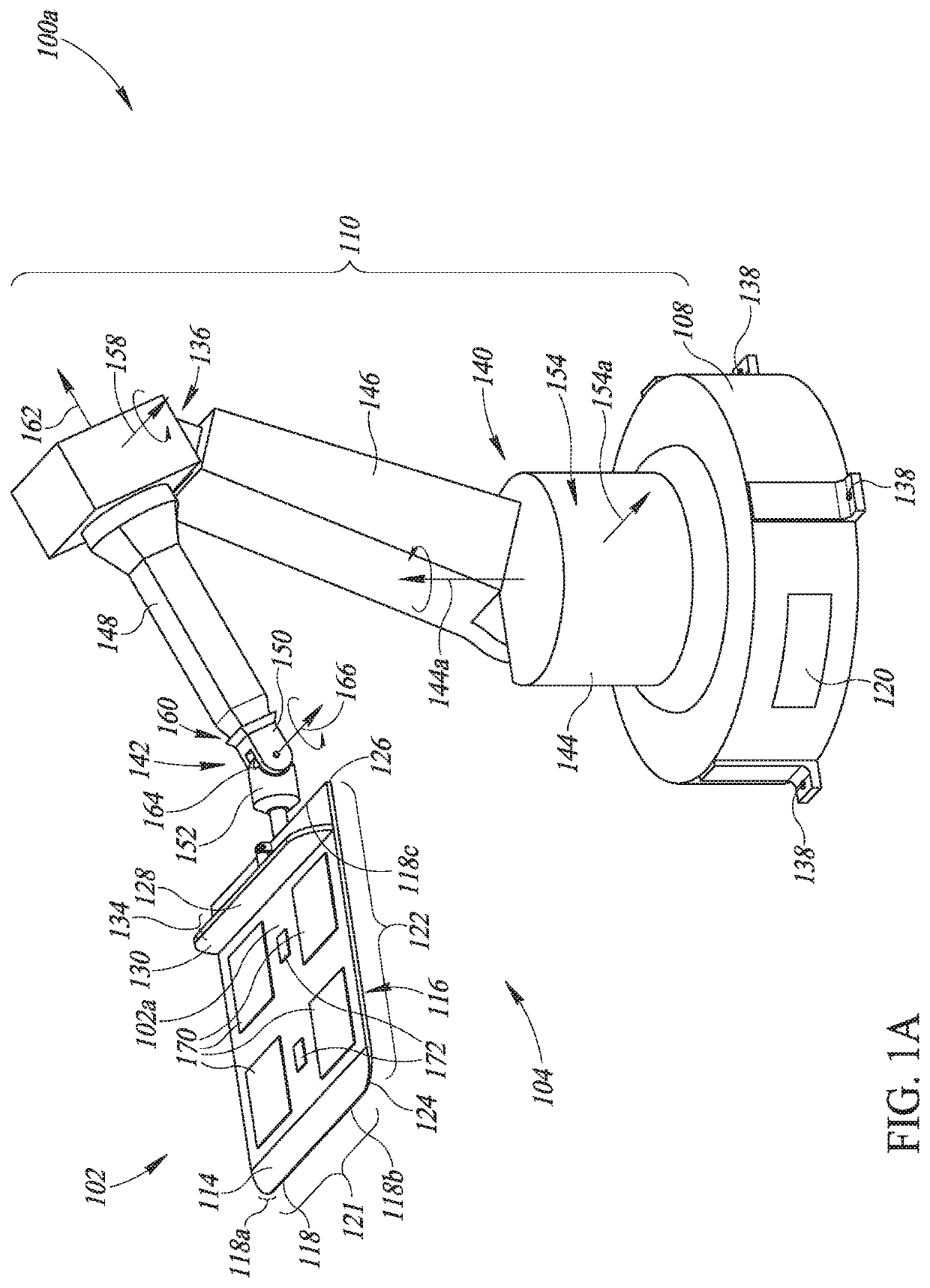

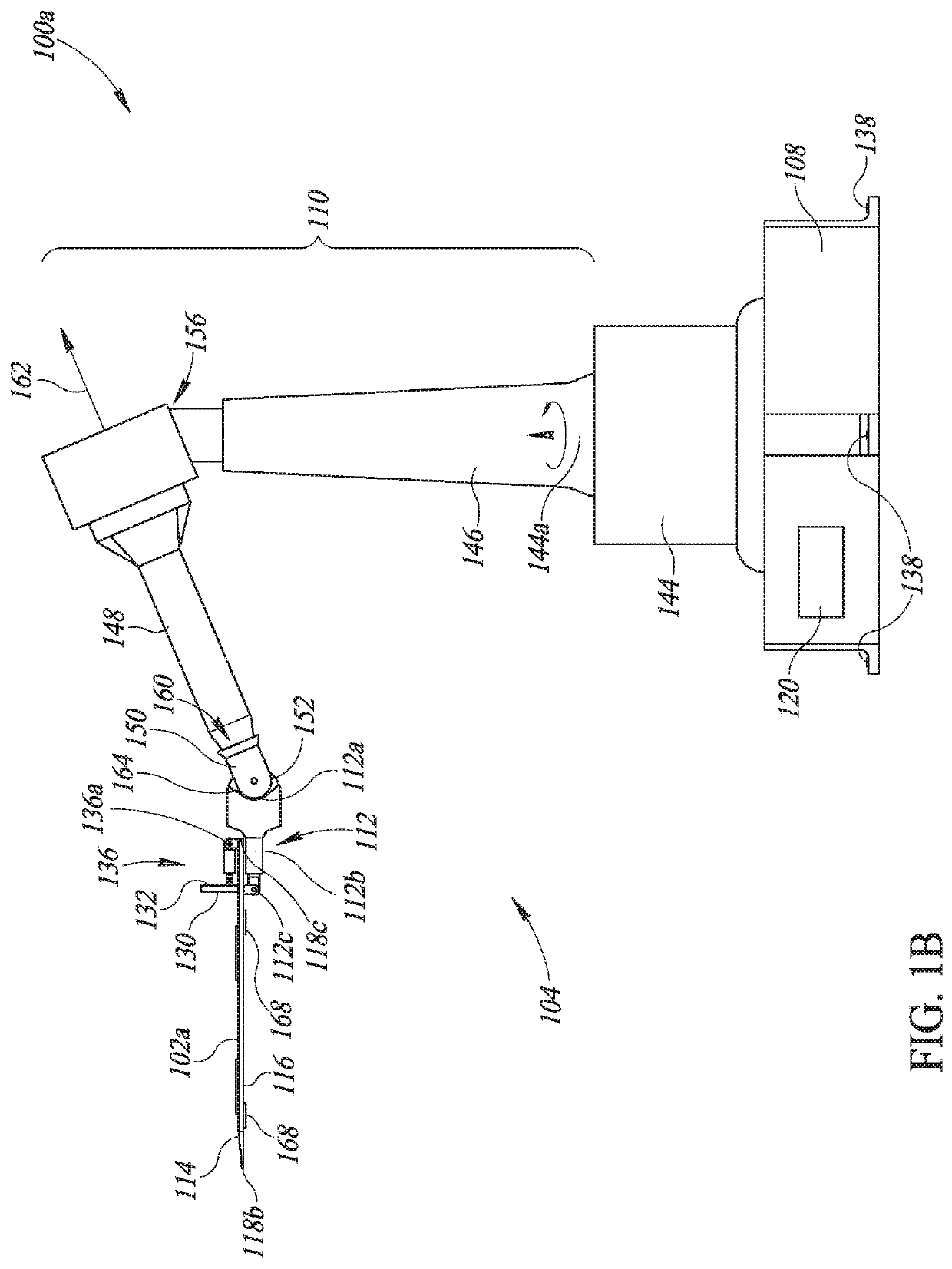

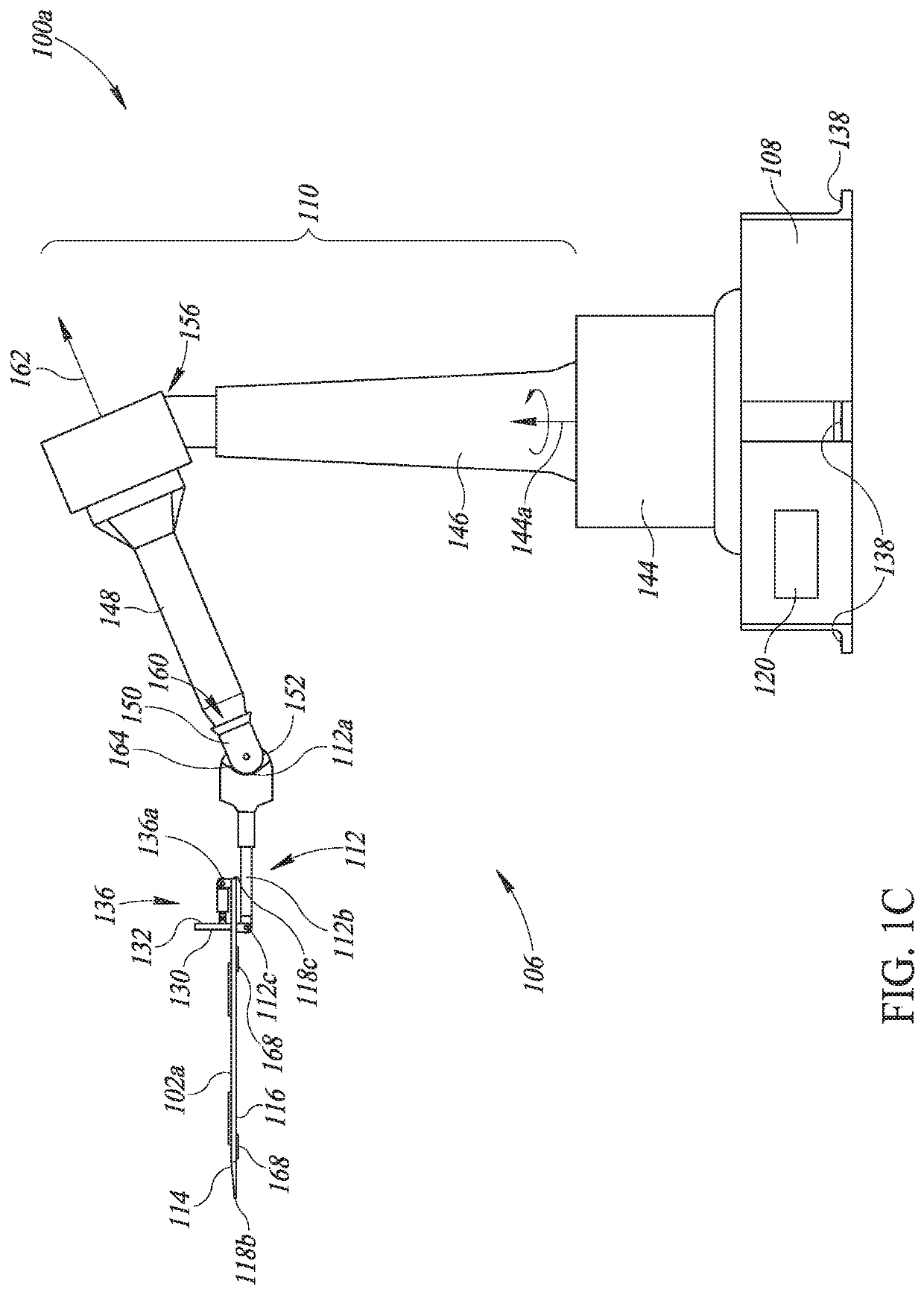

Oven having a rotating door

ActiveUS9326639B2Prevent escapeDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

Owner:OVENTION

Oven having an h-shaped rotating door

ActiveUS20150164271A1Prevent escapeDomestic stoves or rangesStoves/ranges shelves or racksElectric machineryIngested food

An oven comprising a housing, a cavity, an H-shaped rotating door, a motor and a heat source is disclosed. The cavity, which includes an opening, is located within the housing. The H-shaped rotating door, which can be rotated by the motor, includes a first food loading section and a second food loading section. The H-shaped rotating door also serves as a cover to prevent heat within the cavity from escaping through the opening. The heat source provides heat to the cavity to heat up any food item placed on one of the food loading sections located within the cavity.

Owner:OVENTION

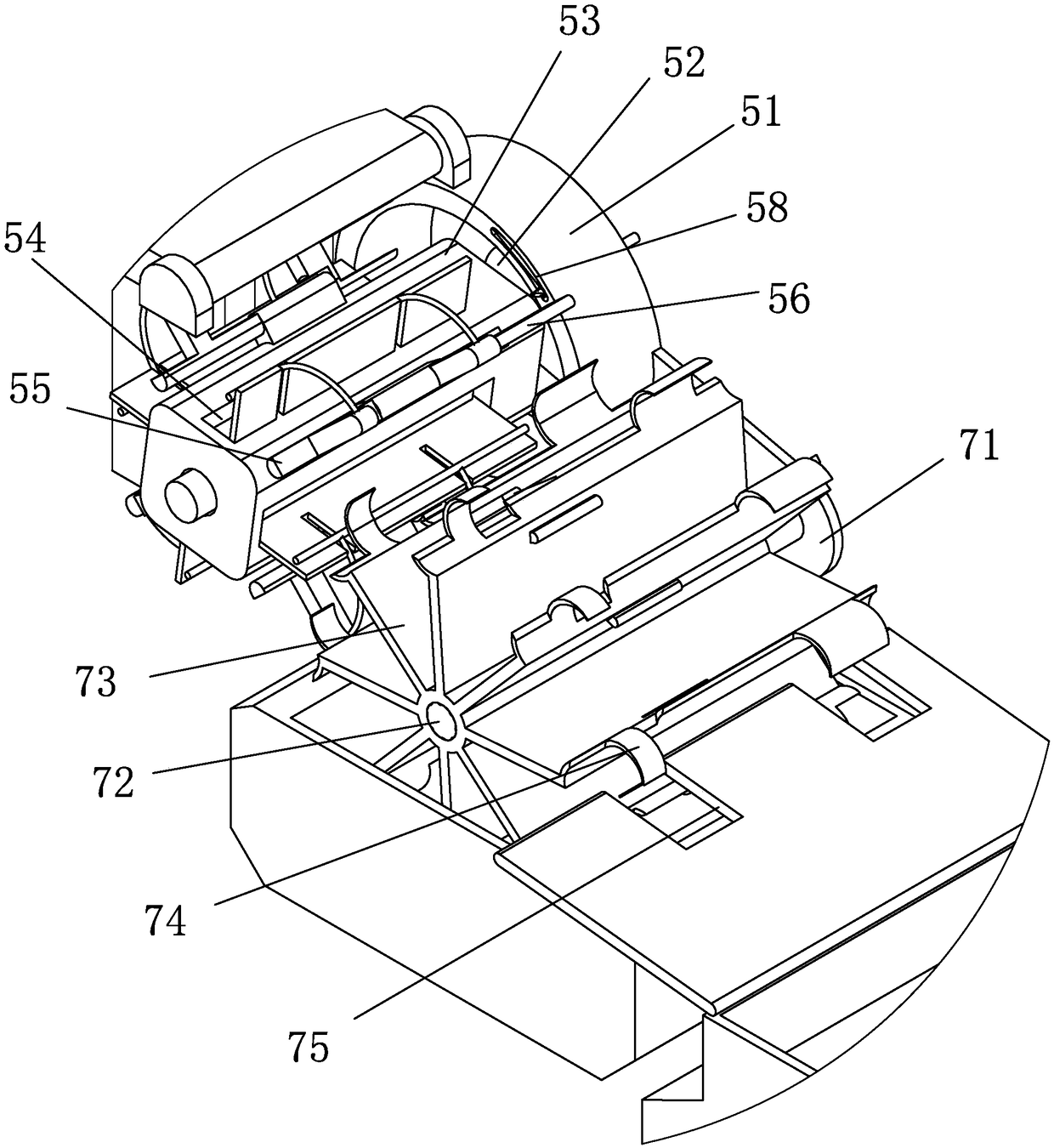

Automatic processing machine for fried bread sticks

InactiveCN105076278AHigh degree of automationImprove processing efficiencyDough shaping and cutting apparatusBaking plantsEngineeringMechanical equipment

The invention provides an automatic processing machine for fried bread sticks, belongs to the technical field of food mechanical equipment, and solves the problems that the conventional automatic processing machine for fried bread sticks is low in efficiency, and fried bread sticks produced by the conventional automatic processing machine are poor in quality. The automatic processing machine for fried bread sticks comprises a rack, wherein a transmission belt is arranged on the rack; the rack is connected with two side plates and a pressing plate; the rack is connected with a cutter and movable plates in a sliding manner; a movable block is connected onto each of the movable plates in a sliding manner; a material grabbing rod is connected onto each of the movable blocks in a rotating manner; a clamping jaw is arranged at one end of each material grabbing rod; the rack is fixedly connected with an oil groove; a plurality of rotating shafts are connected to the interior of the oil groove in a rotating manner; a plurality of material stirring plates are fixedly connected onto the outer circumferential wall of each of the rotating shafts; a material turning block is connected onto each of the two opposite groove walls of the oil groove; a feeding groove is fixedly connected with one end part of the oil groove on the rack; two material placing rods are fixedly connected to a position above the feeding groove on the rack. According to the automatic processing machine for fried bread sticks, paste can be automatically processed into fried bread sticks, and the degree of automation and efficiency are high.

Owner:ZHEJIANG OCEAN UNIV

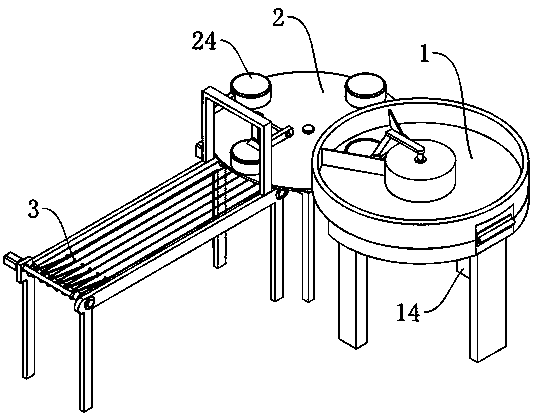

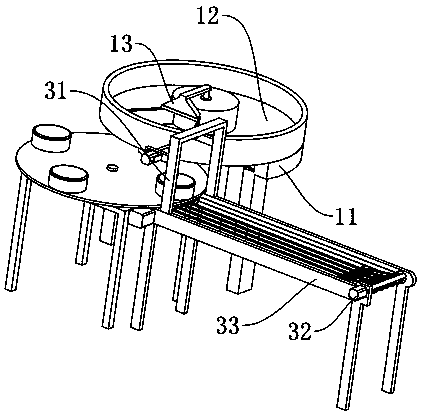

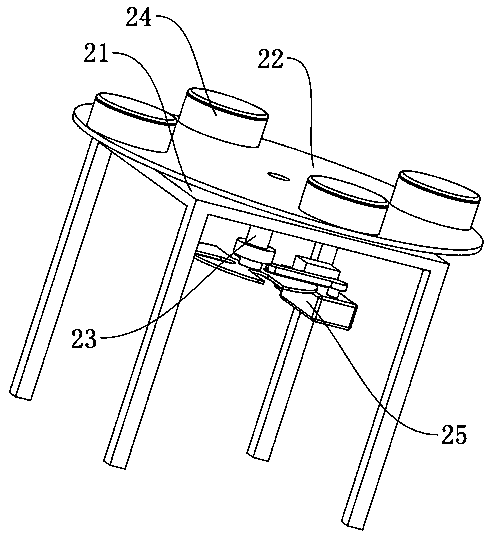

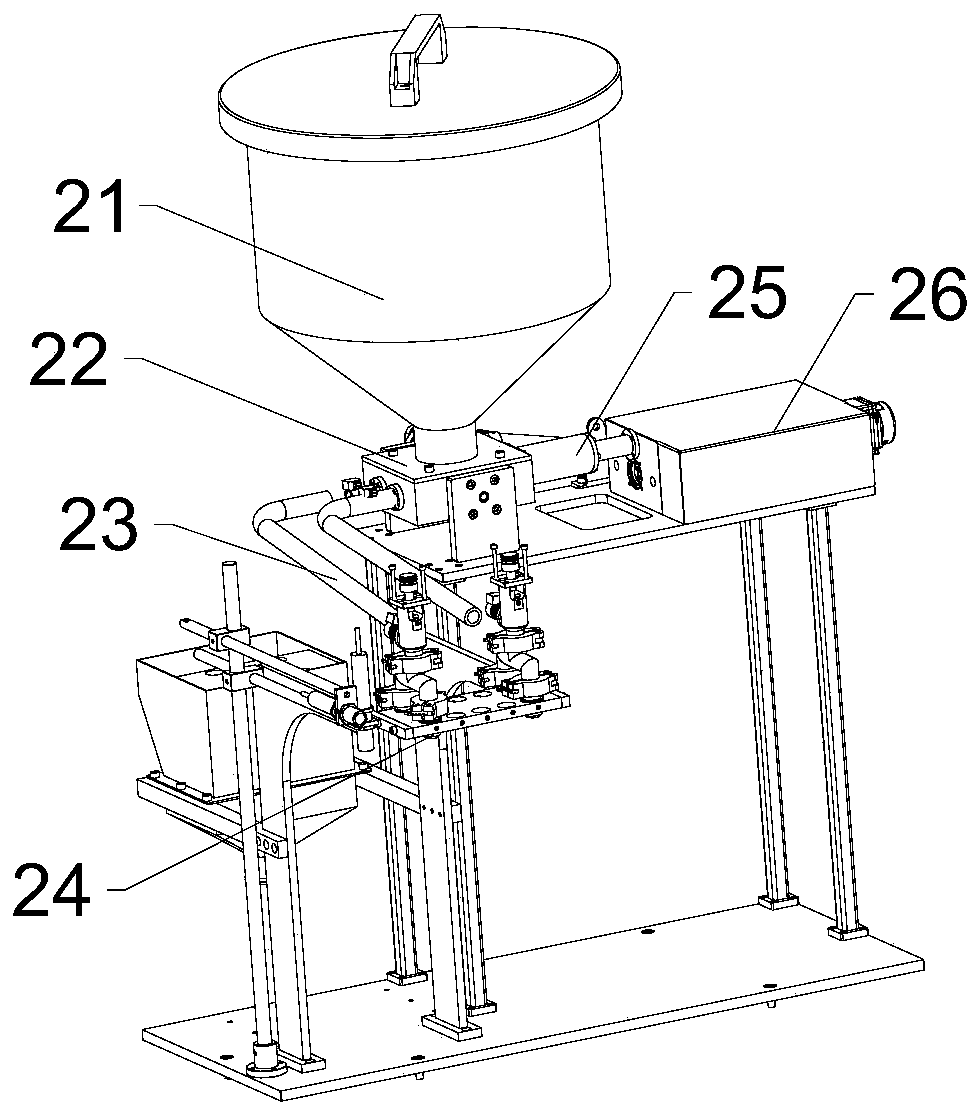

Automatic pancake forming equipment

InactiveCN109452332AIncrease production speedOil/fat bakingPancakes bakingEngineeringFood processing

The invention relates to the field of food processing, in particular to automatic pancake forming equipment. The equipment comprises a batter feeding device, a pancake forming device and a pancake discharging device, the pancake forming device comprises a workbench, a rotating disc and a first driving component used for driving the rotating disc to rotate, the rotating disc is horizontally arranged at the top end of the workbench, the first driving component is arranged at the bottom end of the workbench, the bottom end of the rotating disc is provided with a rotating shaft used for connectingthe first driving component, the rotating shaft passes through the workbench and is in transmission connection with the first driving component, the rotating shaft is in shaft connection with the workbench, the top end of the rotary disc is provided with four heating components at equal intervals for heating batter to form pancakes, the heating components are of a circular structure, the batter feeding device is arranged at one side of the workbench, the pancake discharging device is arranged at the other side of the workbench, and the pancake discharging device is arranged adjacent to the batter feeding device, thereby completing the automatic production of the pancakes and accelerating the production speed.

Owner:李和菊

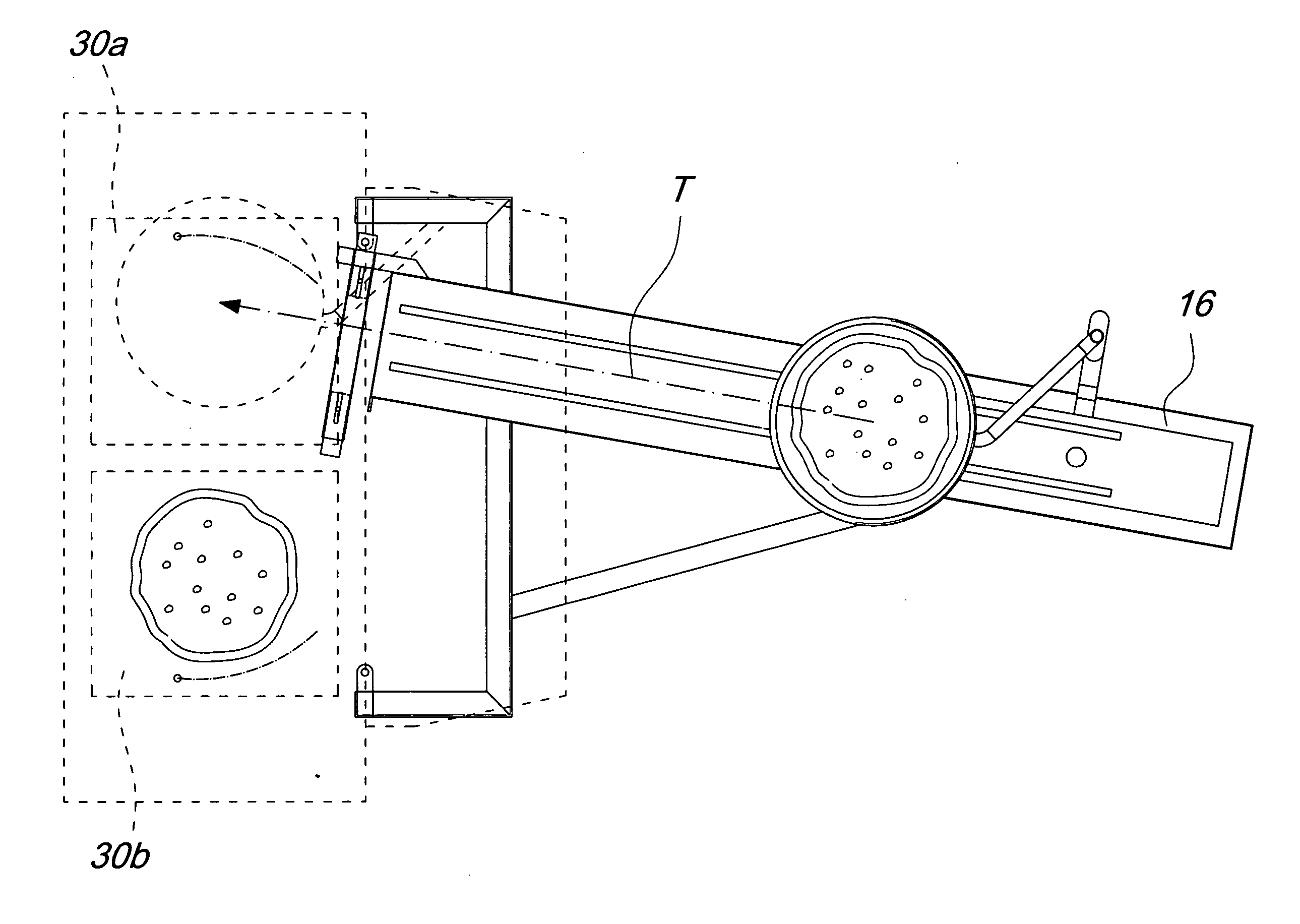

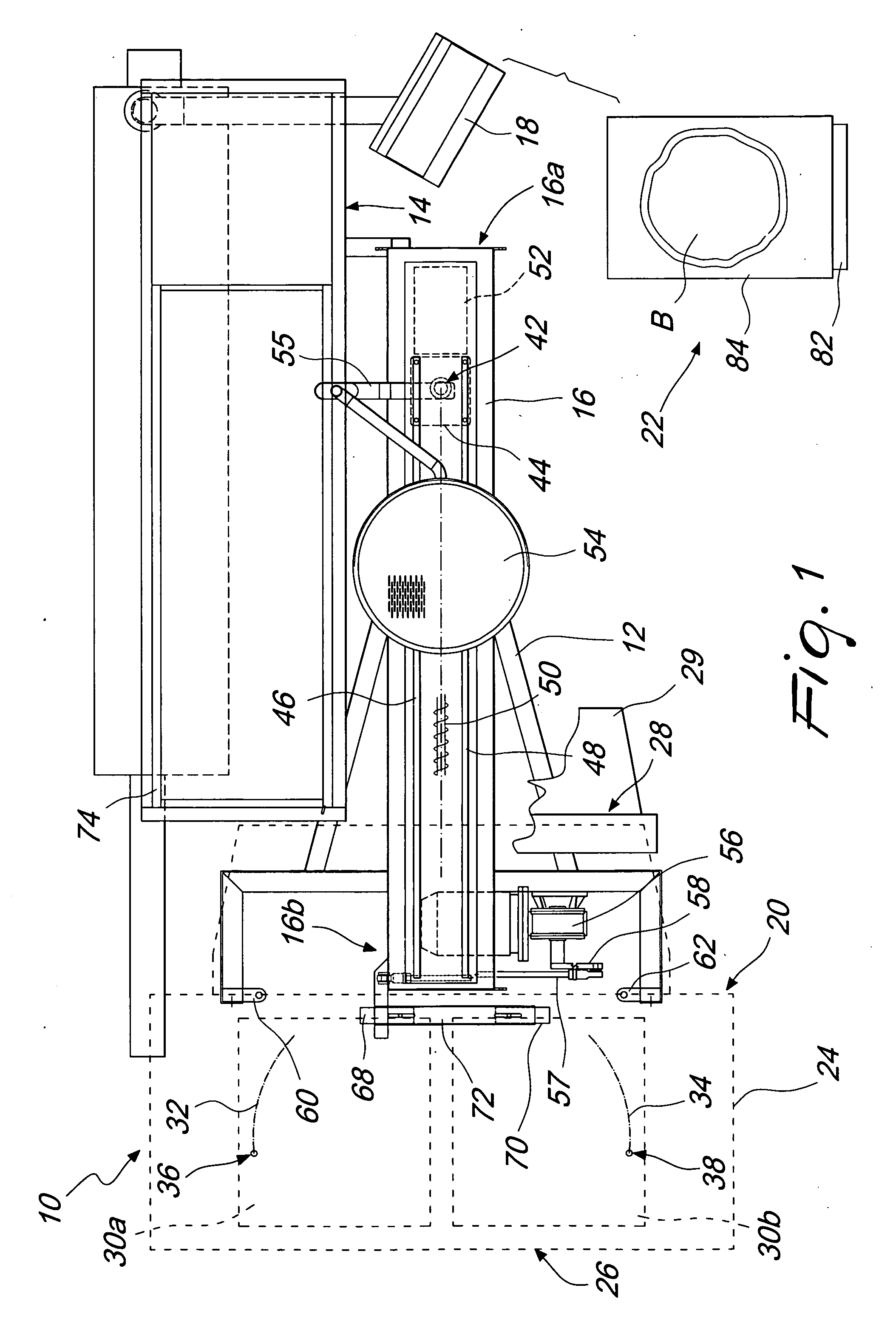

Oven having a rotating door

ActiveUS20140033932A1Prevent escapeDomestic stoves or rangesLighting and heating apparatusMechanical engineering

An oven comprising a housing, a cavity located within the housing, and a rotator having a first food loading section and a second food loading section is disclosed. The cavity includes a single opening for loading a food item into the cavity. If one of the first food loading section and the second food loading section is located outside of said cavity, then the other of the first food loading section and the second food loading section is located within said cavity. A first cook setting of the oven when the first food loading section is within the cavity and a second cook setting of the oven when the second food loading section is within the cavity are independently controllable. The first food loading section and the second food loading section may be separated by a divider, which prevents heat from escaping from the cavity through the opening.

Owner:OVENTION

Egg roll processing equipment

PendingCN111150008ARealize automatic productionIncrease productivityOil/fat bakingPancakes bakingBiotechnologyMechanical engineering

The invention discloses egg roll processing equipment. The egg roll processing equipment comprises a baking plate mechanism, a baking plate circulating mechanism and an egg roll forming mechanism, wherein the baking plate mechanism comprises a plurality of baking plates which are provided with grouting positions and rolling positions and used for making egg roll wrappers from a slurry dripping onto the baking plates by a grouting mechanism; the plurality of the baking plates are fixedly arranged on the baking plate circulating mechanism; the baking plate circulating mechanism drives the bakingplates to circularly rotate and controls the baking plates to be opened and closed; and the egg roll forming mechanism is arranged at the rolling positions and used for rolling egg roll wrapper on the baking plates to form egg rolls. The egg roll processing equipment provided by the invention comprises the grouting mechanism, the baking plate mechanism, the baking plate circulating mechanism, theegg roll forming mechanism and a discharging mechanism; automatic production of egg rolls is achieved; and the production efficiency is greatly improved. The baking plate mechanism is fixedly arranged on the baking plate circulating mechanism; opening and closing of the baking plates are achieved under driving of the baking plate circulating mechanism; the baking plate mechanism is matched with the grouting mechanism to make the egg roll wrappers; and the consistency of the egg roll wrappers is effectively improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

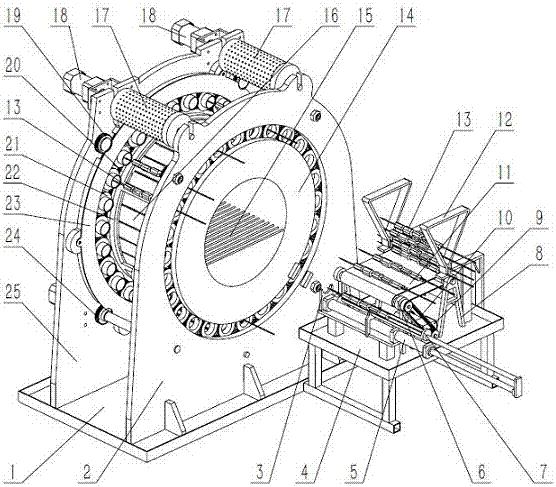

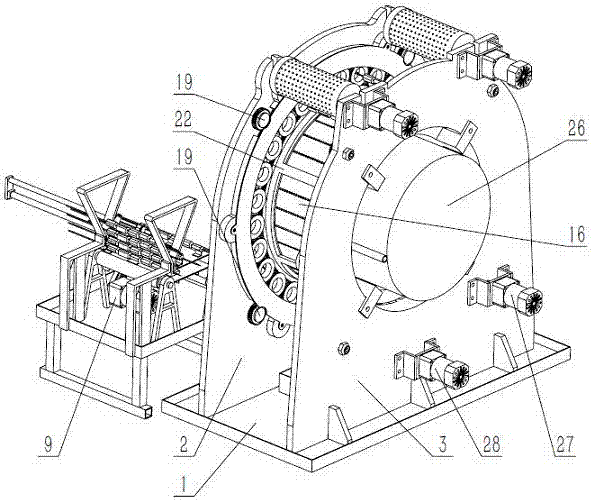

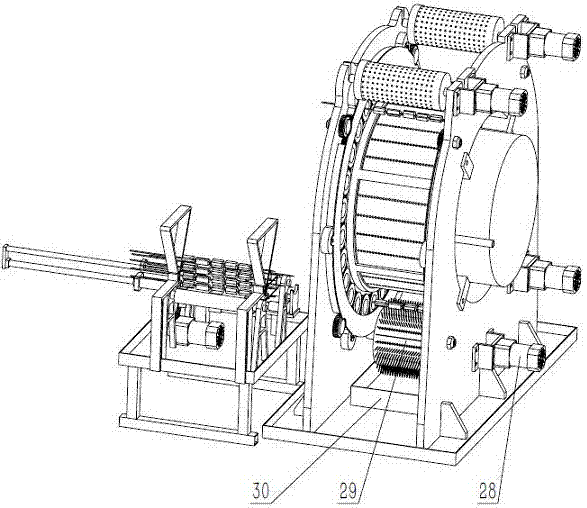

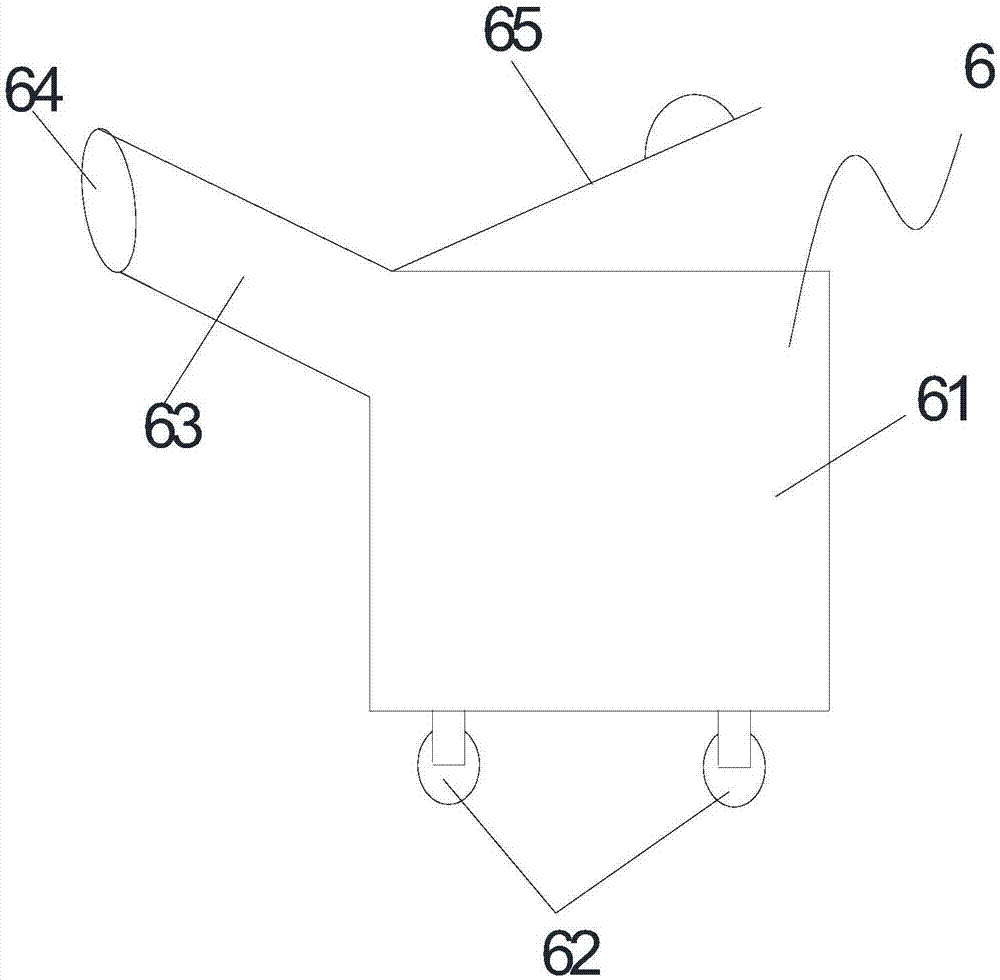

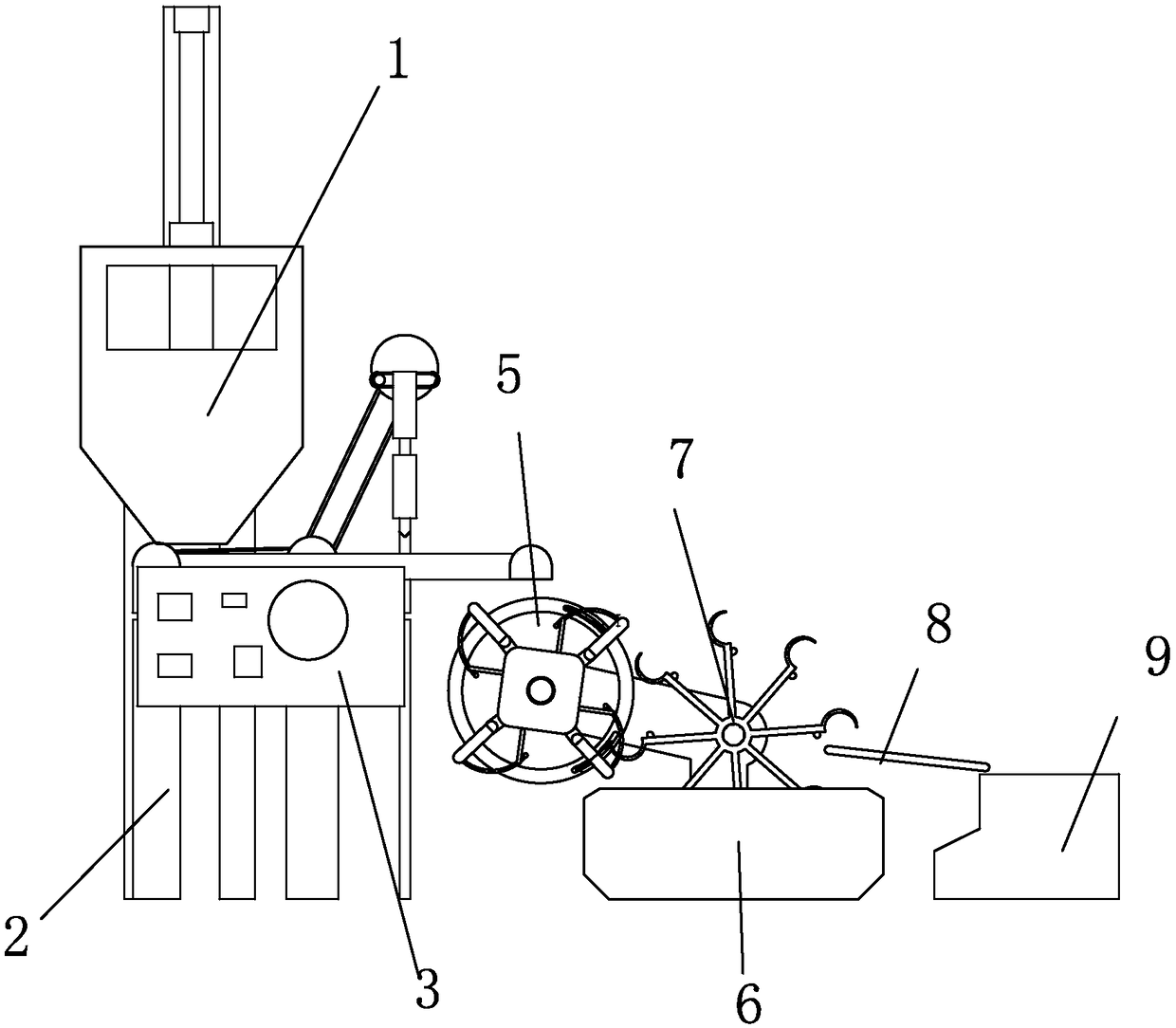

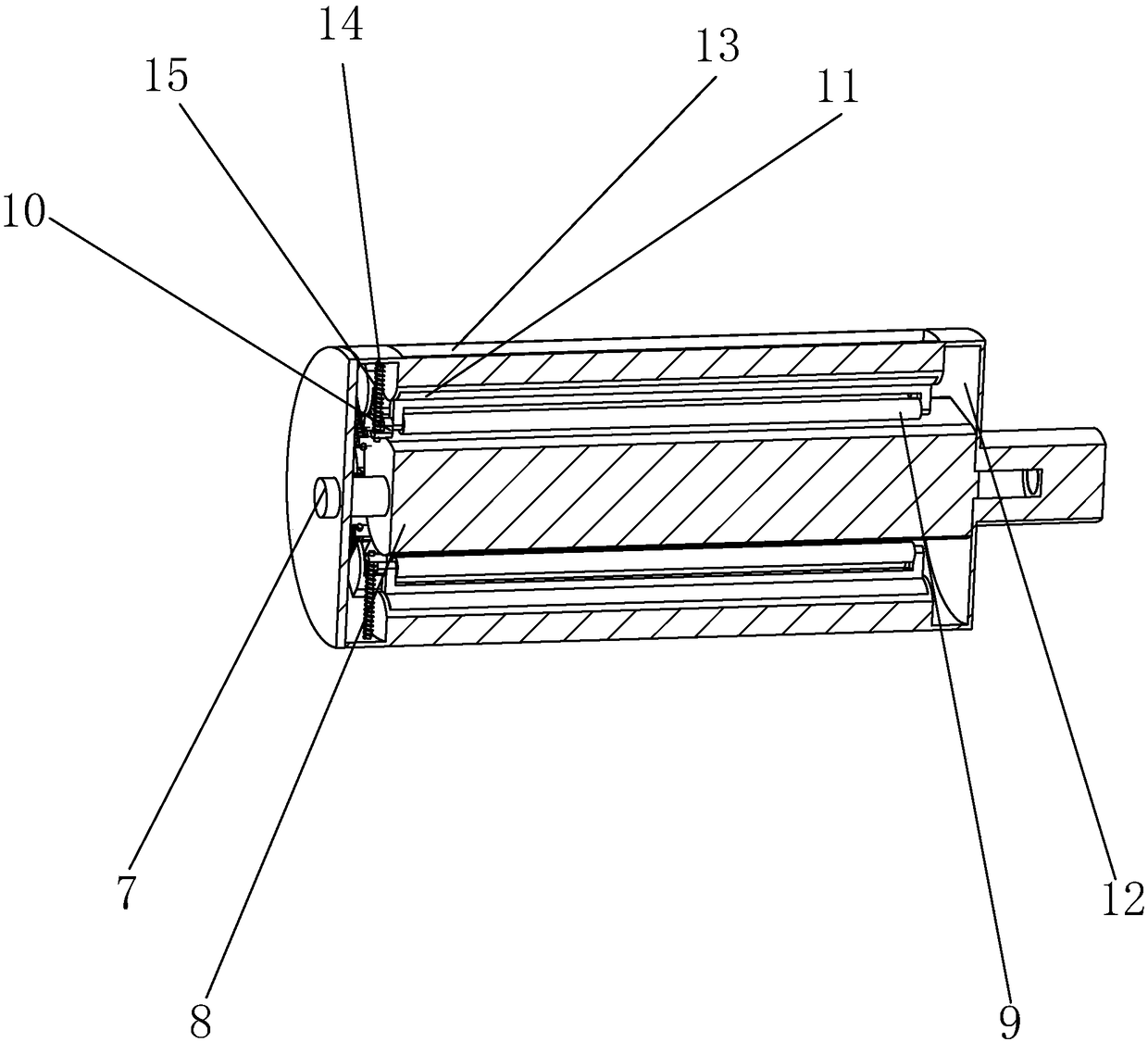

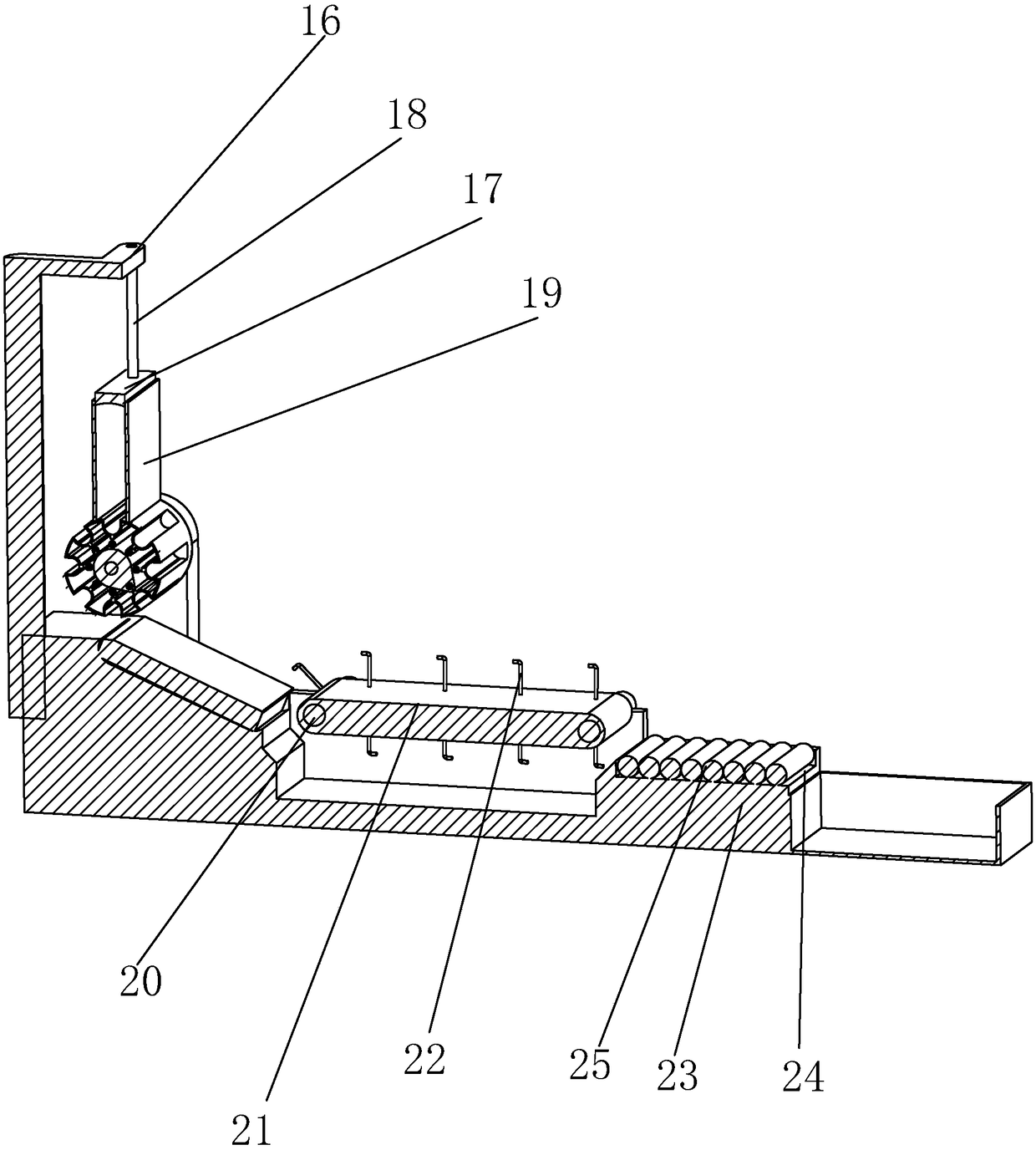

Automated kebab barbecue processing equipment

ActiveCN106879655ARealize automatic revolutionEvenly heatedBaking surface cleaning/greasingCharging/discharging ovensGear wheelAdditive ingredient

The invention discloses automated kebab barbecue processing equipment. The purpose of automatic 360-degree overturning of kebab is finally achieved by arranging a big gear ring, a small gear ring and small gears evenly arranged between the big gear ring and the small gear ring, and by driving the small gears to revolve around the axis of the small gear ring and meanwhile driving the small gears to rotate through the big gear ring so that the kebab can be heated evenly, and the barbecue quality is high; meanwhile the equipment is further provided with a material conveying related mechanism, automatic getting-on-equipment of the kebab can be achieved, manual operation is reduced, and not only can the barbecue processing efficiency of the kebab be improved, but also the problems of uneven barbecue processing caused by a personnel quality problem and the like are avoided to a great extent; besides, the automated kebab barbecue processing equipment is further provided with an automatic ingredient adding structure and an oil brushing device, the manual operation is reduced as well to a great extent, the manpower cost is saved, and the work efficiency is improved.

Owner:台山市冠荣金属制品有限公司

On-demand robotic food assembly equipment, and related systems and methods

PendingUS20200238534A1Reduce labor costsReduce variationProgramme-controlled manipulatorBaker's peelsEngineeringAssembly line

A piece of equipment for on-demand food preparation, for instance on an assembly line, that can use an end-of-arm tool to retrieve and deposit food items on a horizontal surface, such as the surface of a conveyor. The end-of-arm tool may include a peel, in which the peel can be translated from a retracted position to an extended position to transfer food items. The piece of equipment may translate the peel quickly into the extended position to facilitate the retrieval of food items from the horizontal surface. The piece of equipment may be rotated to position the robotic appendage and the peel in a desired direction. The peel may include a push bar that may be movable between a withdrawn position and a push position to selectively push items off of the peel.

Owner:ZUME INC

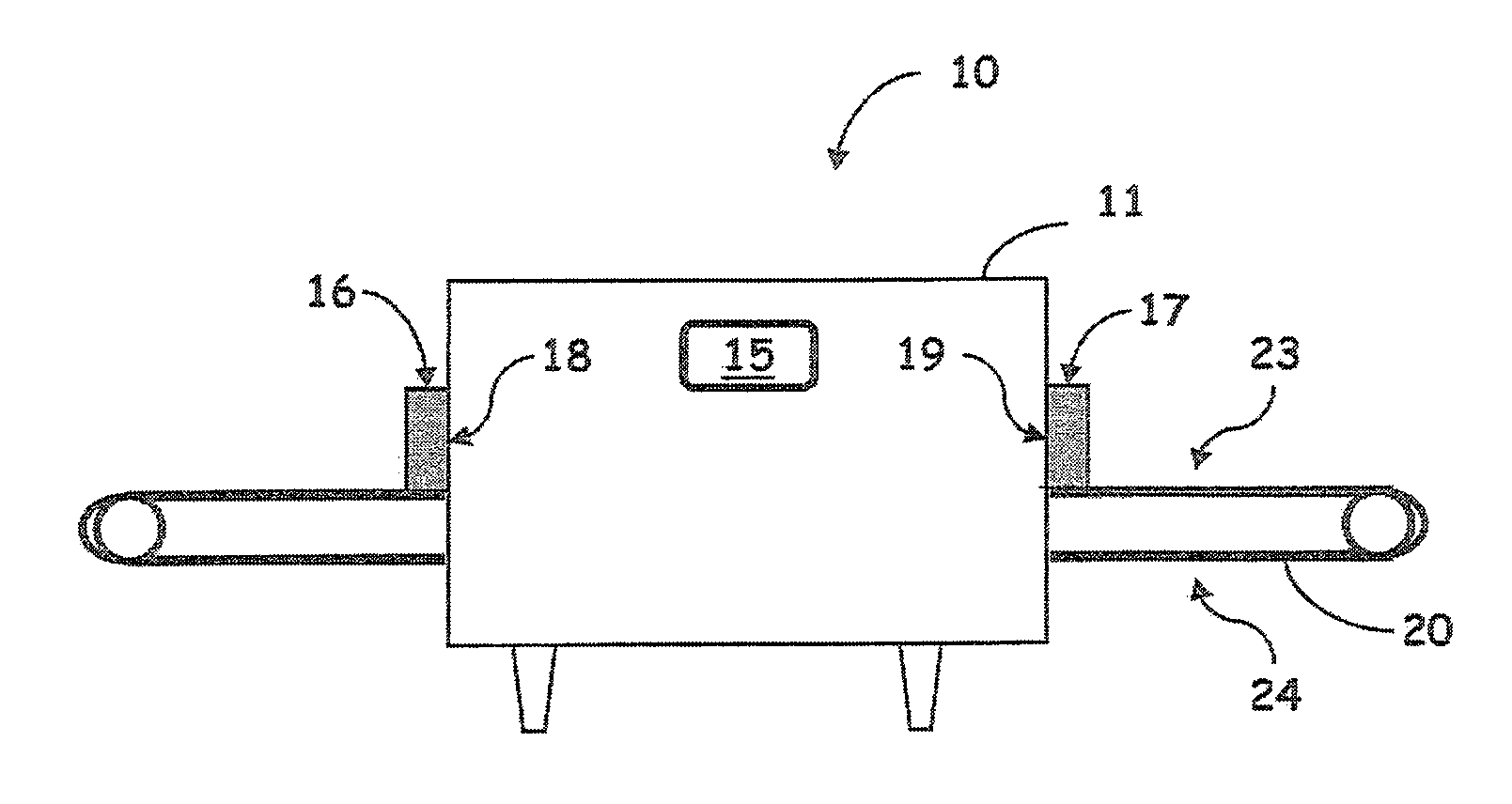

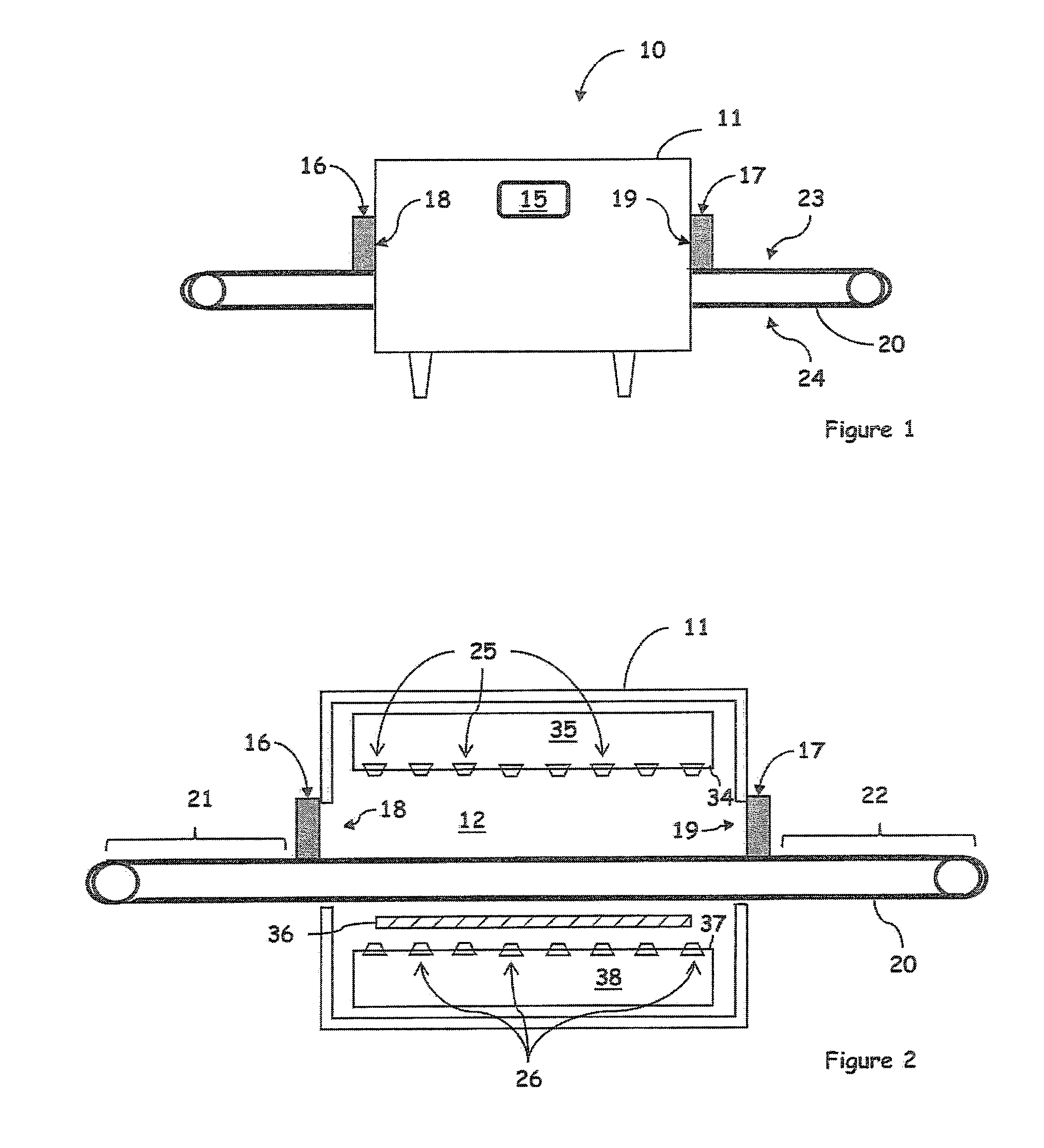

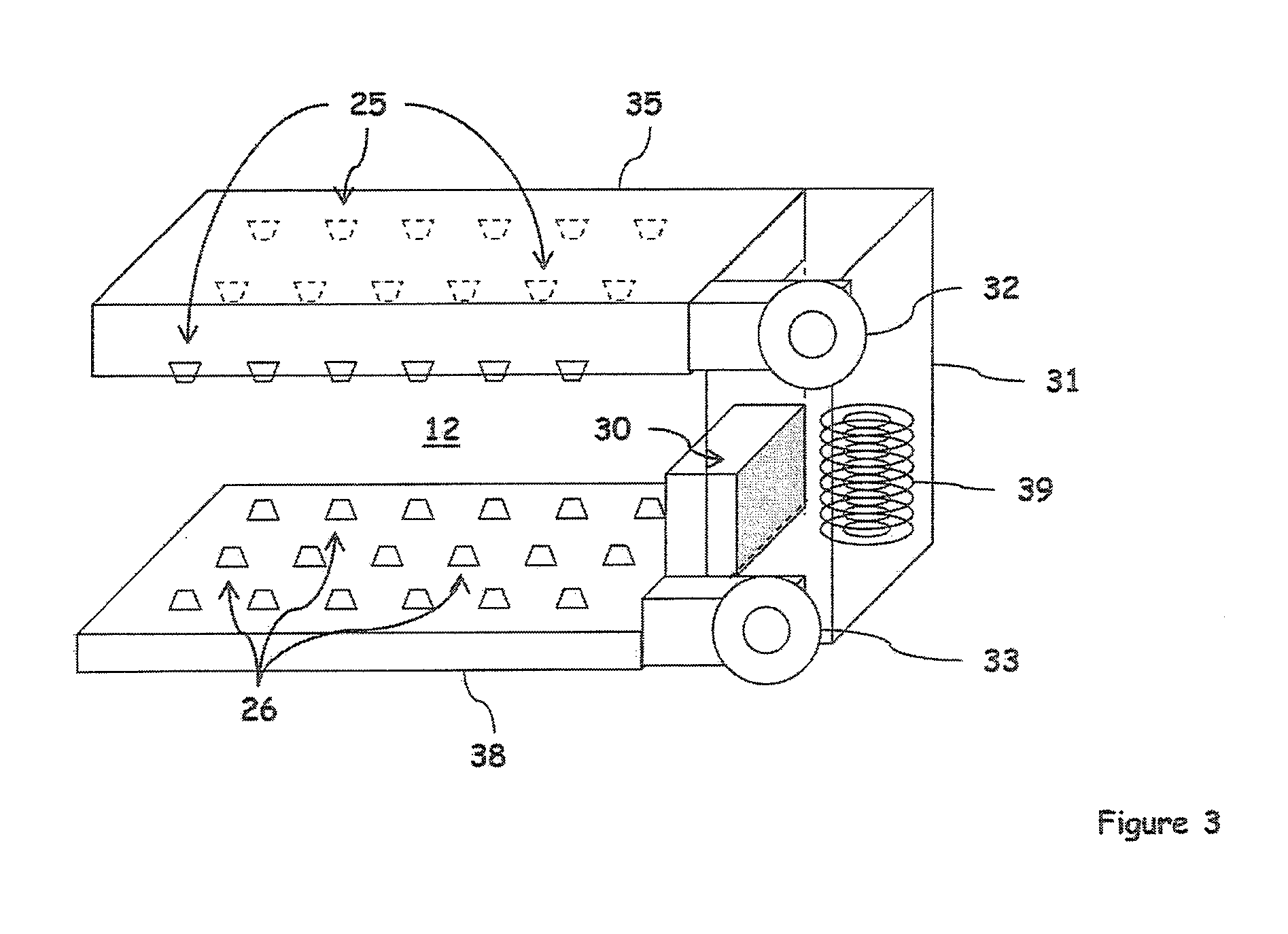

Conveyor Oven

ActiveUS20130213380A1Prevent escapeDomestic stoves or rangesLighting and heating apparatusEngineeringConveyor belt

A conveyor oven is disclosed. The conveyor oven includes a housing, a conveyor belt, a first and second doors, and a heat source. The housing includes a cavity and a first and second openings. The conveyor belt is configured to receive and transport food items in and out of the cavity through the first and second openings. The conveyor belt includes a loading section and an unloading section for food. The first and second doors cover first and second openings, respectively, in order to prevent heat within the cavity from escaping through the first and second openings during operation. Configured to provide different cooking times and thermal profiles to various types of food items, the heat source provides heat to the cavity for heating up any food item placed on a portion of the conveyor belt located within the cavity.

Owner:OVENTION

Heated holding compartment for food

A food item is cooked in a cooking device and transferred to a heated holding table by two exit conveyors. The food item then falls onto one of two transfer conveyors that move perpendicularly to the direction of movement of the exit conveyors. The food items travel on the transfer conveyors and then fall onto a main conveyor. The main conveyor moves in a direction that is parallel to the direction of movement of the exit conveyors. If the food item has not been manually removed from the main conveyor after a predetermined amount of time, the food item falls off the main conveyor and into a drawer waste chute for disposal.

Owner:RESTAURANT TECH

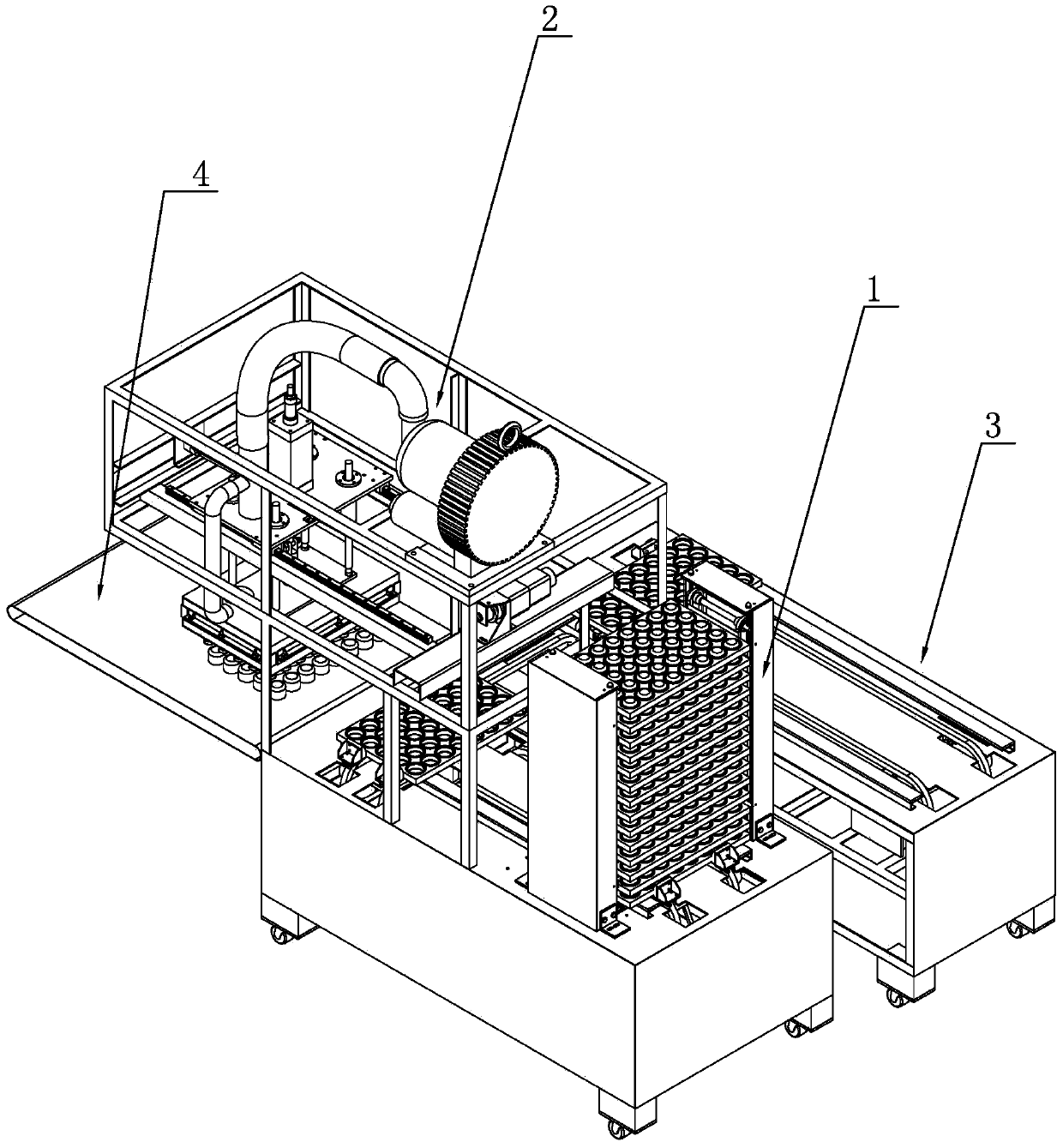

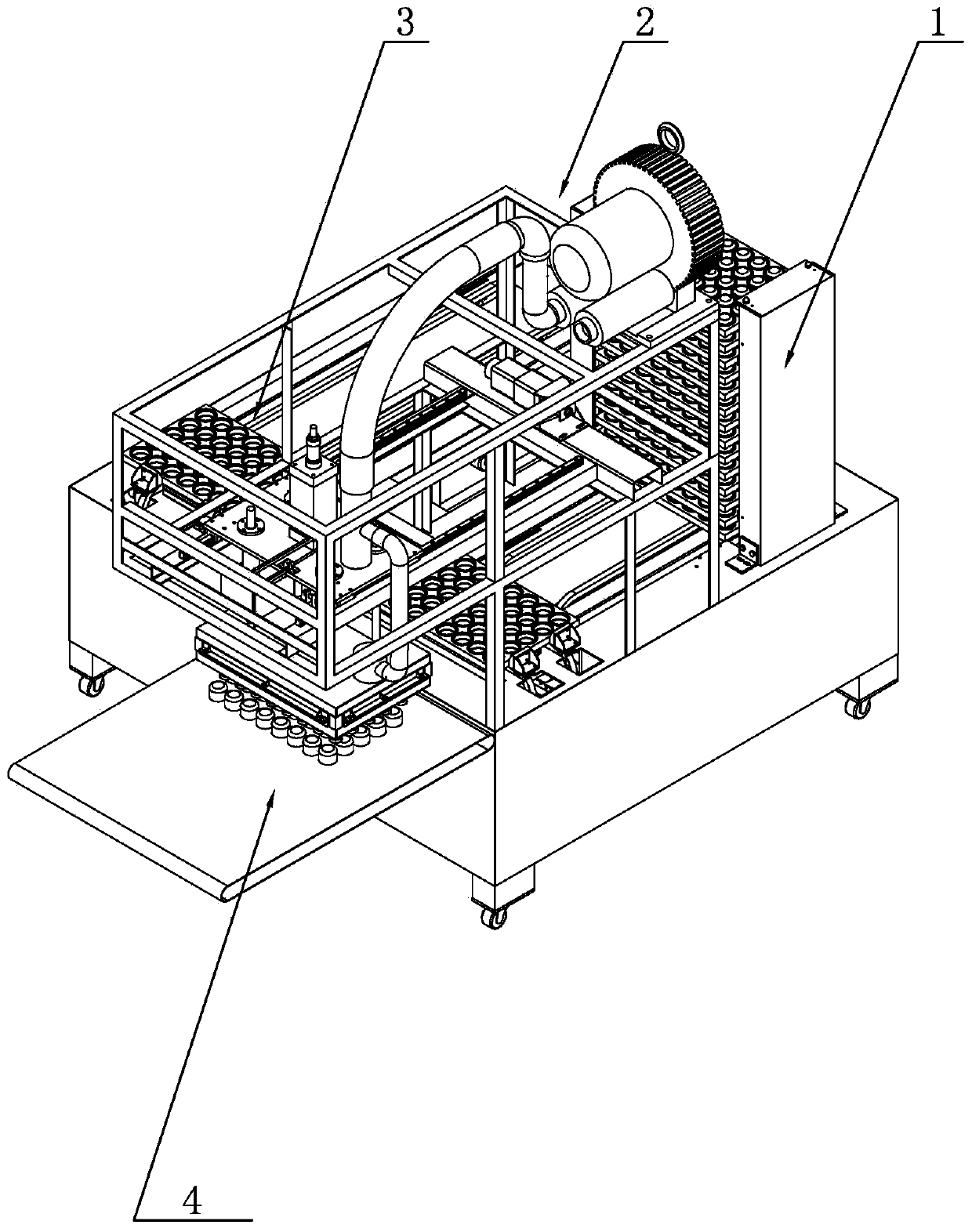

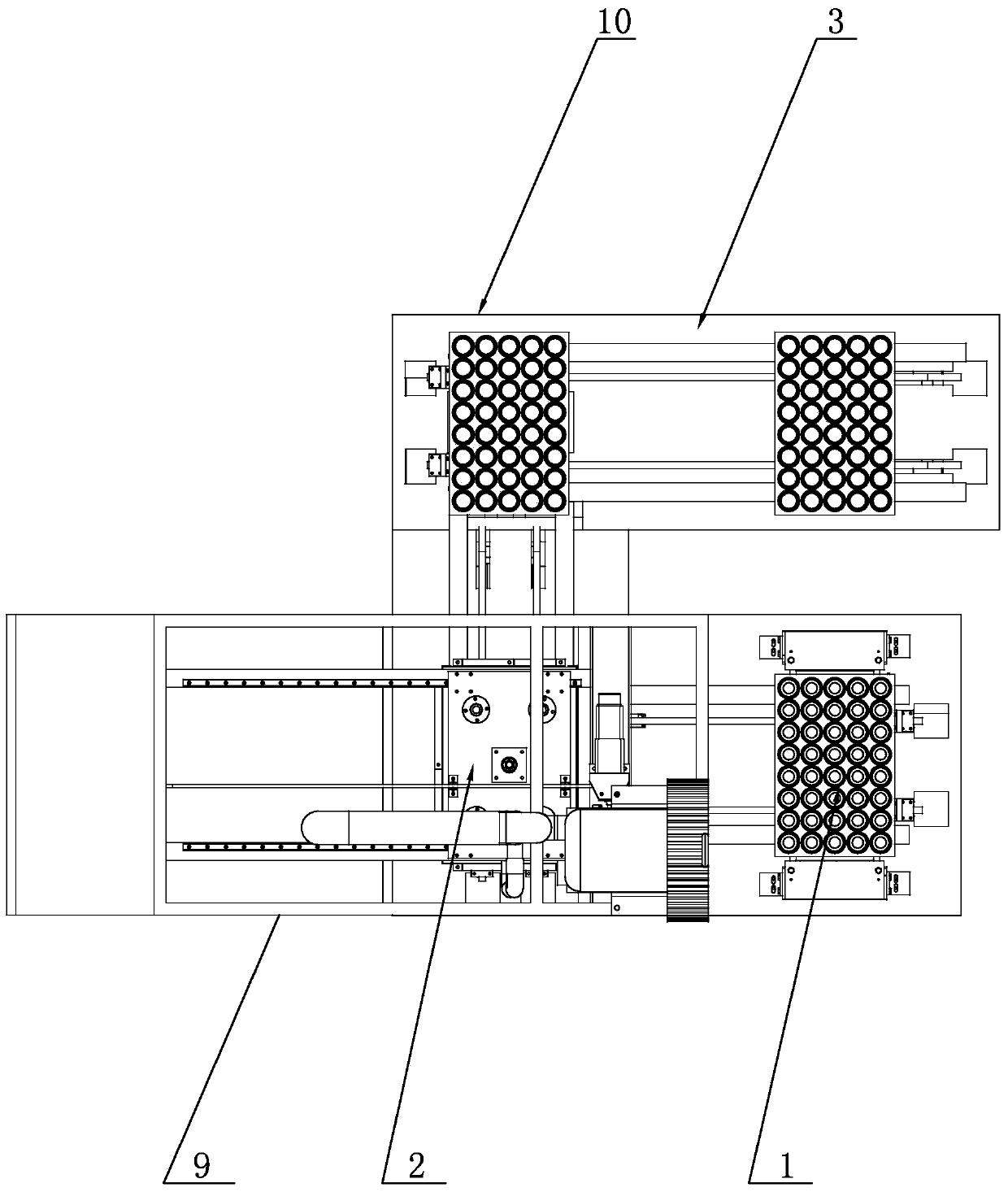

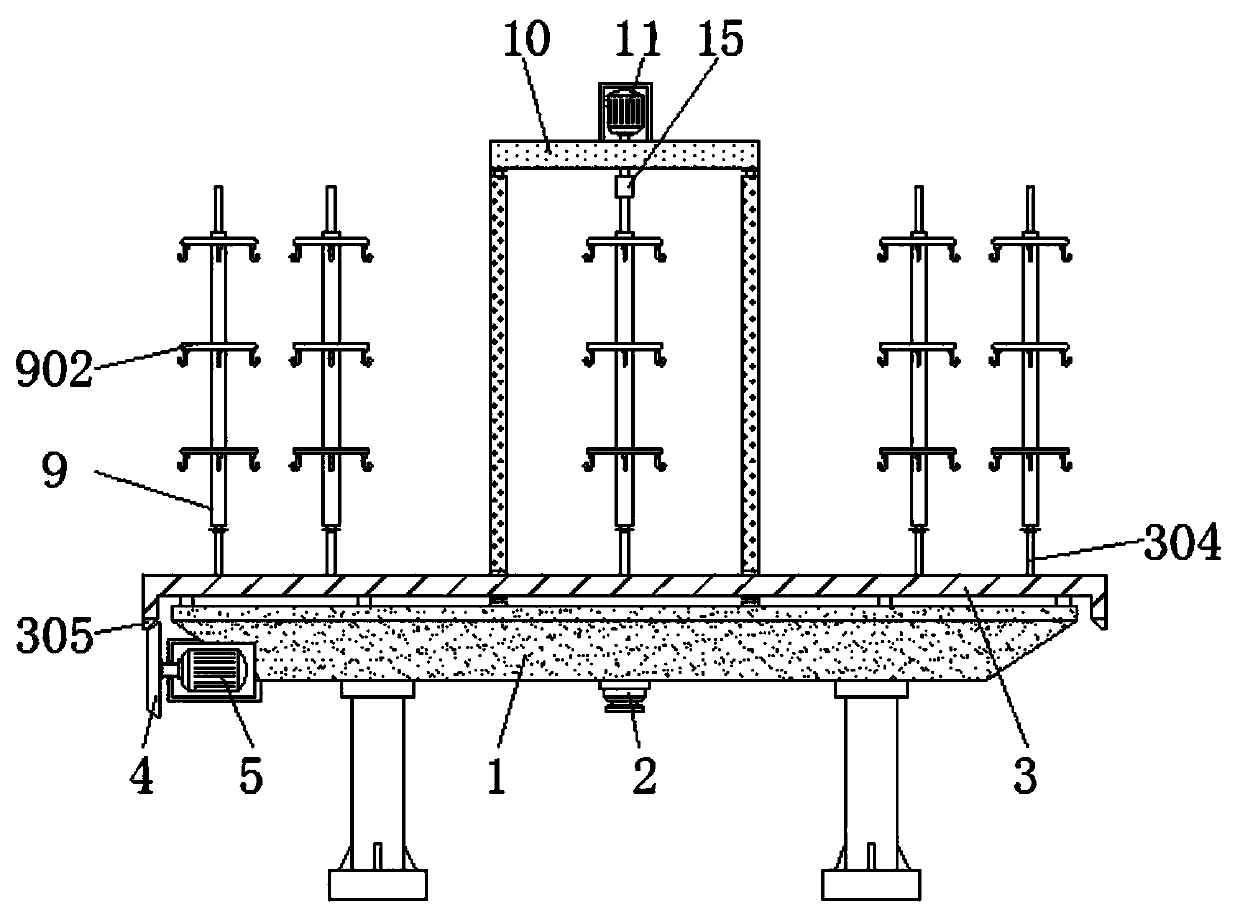

Device and method for discharging and recovering baking tray and separating food from baking tray

InactiveCN103734207ARealize reciprocating motionAddresses the defect of passing one by oneConveyorsCharging/discharging ovensCooking & bakingProcess engineering

The invention relates to a device and method for discharging and recovering a baking tray and separating food from the baking tray. The device comprises an automatic tray arranging unit, a movable food absorbing unit and a movable baking tray recovery unit. The movable baking tray recovery unit is formed by combining a first conveying unit, a second conveying unit and a third conveying unit, wherein the first conveying unit, the second conveying unit and the third conveying unit are identical in structure. The automatic tray arranging unit, the movable food absorbing unit, the first conveying unit and the second conveying unit are arranged in a first machine frame, and the third conveying unit is disposed in a second machine frame. Automatic discharging and recovering of the baking tray are effectively achieved, the process of separating the food from the baking tray is automated, time and labor are saved, labor cost is lowered, and production efficiency is improved.

Owner:YANG JENQ MACHINERY

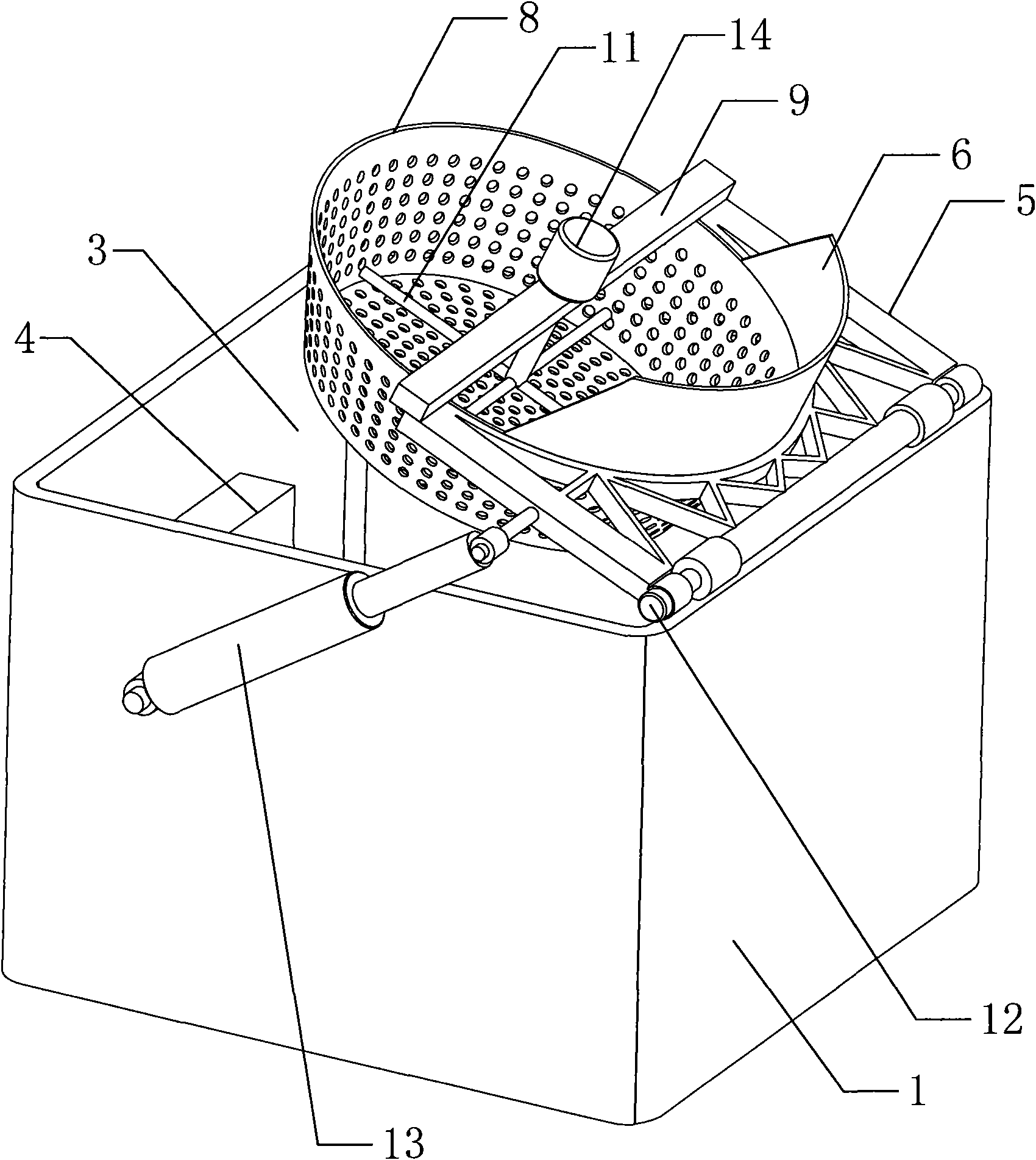

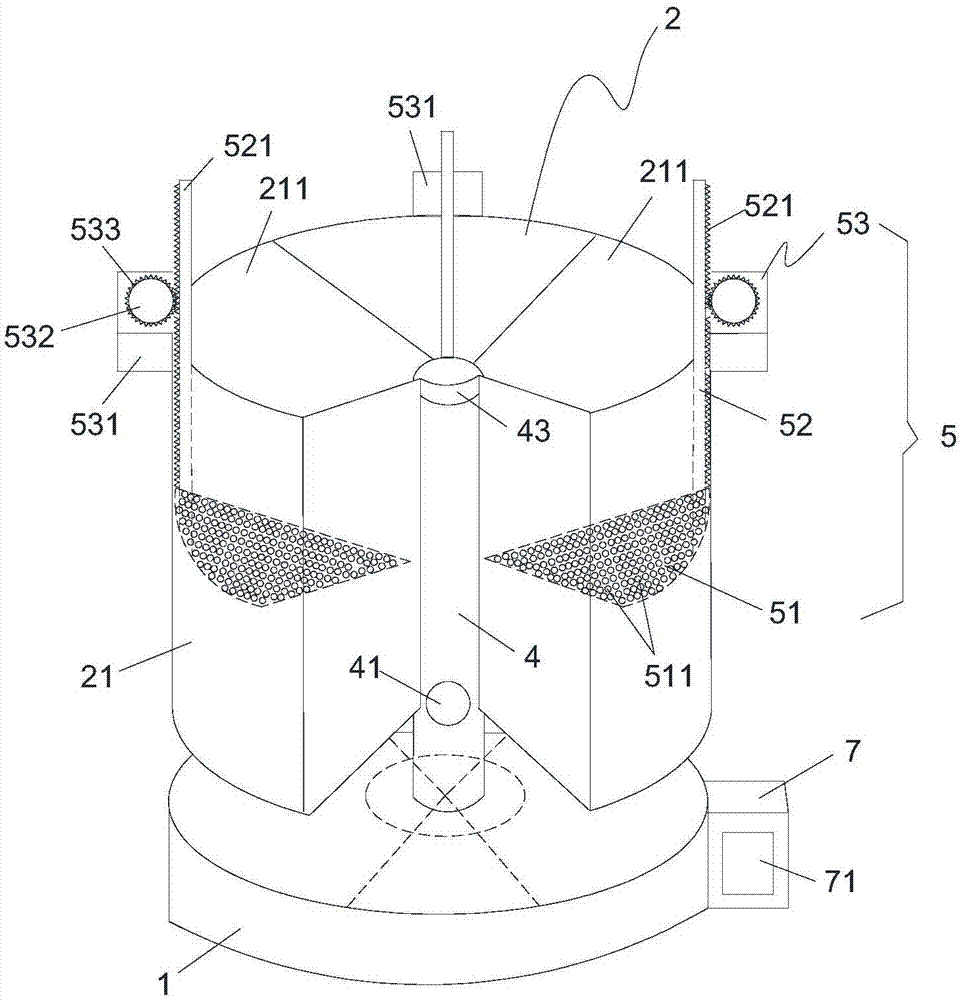

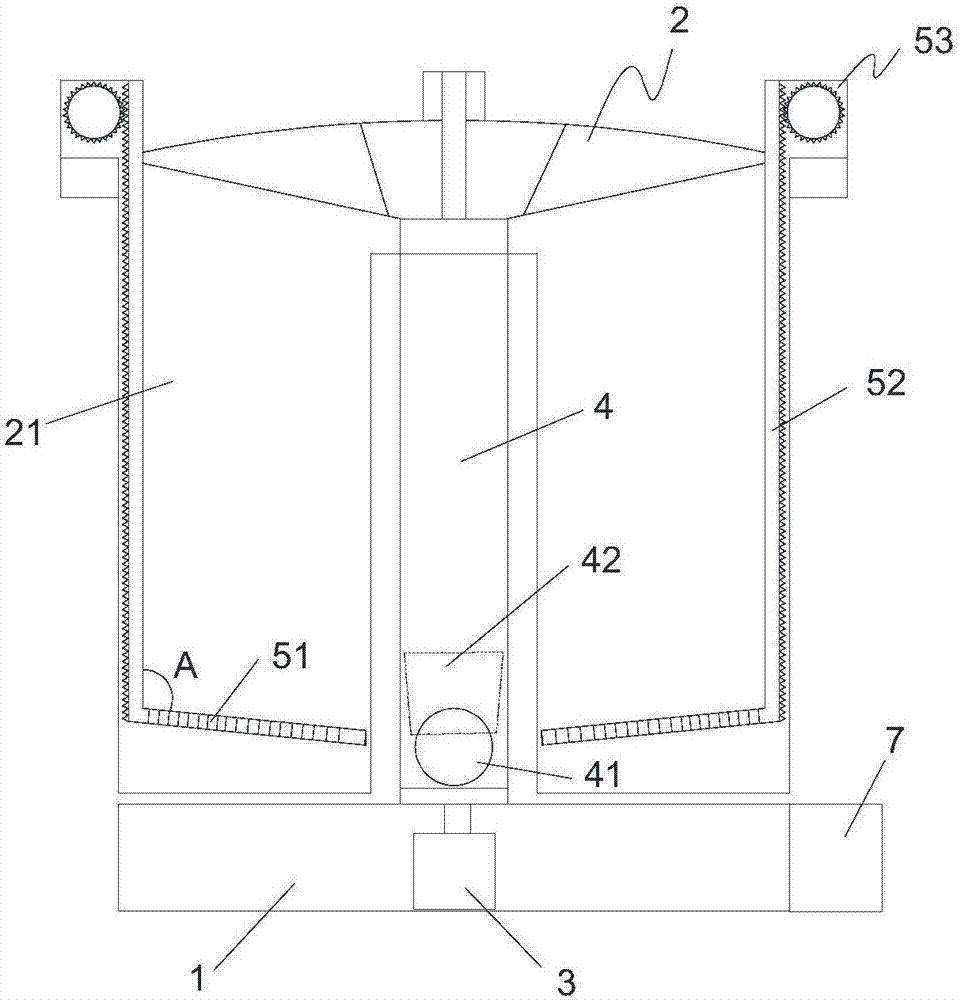

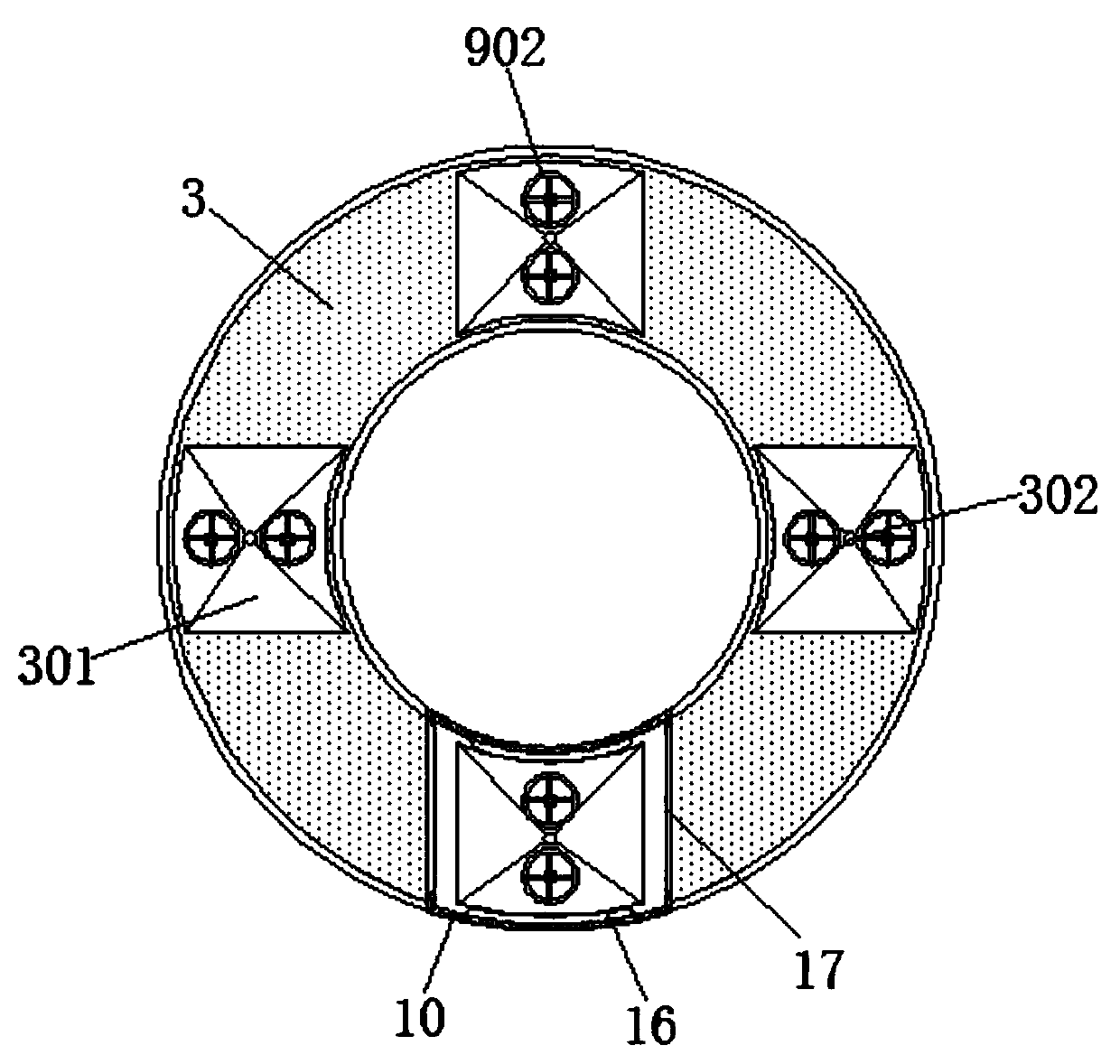

Regional rotary water flowing type croquette deep frying equipment

PendingCN107094823AGreat tasteNo burningOil/fat bakingCharging/discharging ovensDeep fryingWater flow

The invention relates to regional rotary water flowing type croquette deep frying equipment. The regional rotary water flowing type croquette deep frying equipment comprises an induction cooker base and a deep fryer component and is characterized in that the induction cooker base is divided into four regions, and at least three induction cookers are arranged at the bottom of the induction cooker base of the three sequentially-spliced regions in the four regions; a drive motor is arranged in the induction cooker base, and a hollow discharge sleeve is fixed on the rotary shaft of the drive motor; the top of the discharge sleeve is open; a discharge outlet is formed in the lower lateral wall of the discharge sleeve, an arc-shaped guide plate is arranged on the lower inner wall of the discharge sleeve, and the arc-shaped guide plate can exactly guide croquettes to be discharged from the discharge outlet; three columnar deep fryers are sequentially spliced and fixed on the lateral wall of the discharge sleeve, a fishing component is arranged on each of the three columnar deep fryers, and each fishing component comprises a sector-shaped fishing plate, a lifting rod and a drive mechanism. By the regional rotary water flowing type croquette deep frying equipment, regional croquette deep frying can be achieved, and the taste of the croquettes can be increased.

Owner:程梅雪

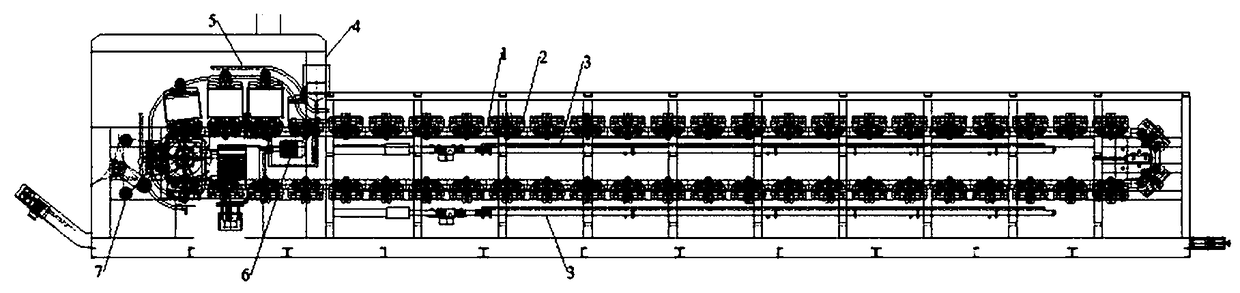

Wafer biscuit baking oven

InactiveCN108323542AGuaranteed uptimeEasy to operateBaking plantsCharging/discharging ovensEngineeringSlurry

The present invention discloses a wafer biscuit baking oven. The wafer biscuit baking oven comprises a wafer biscuit conveying chain assembly, a plurality of wafer biscuit molds arranged on the waferbiscuit conveying chain assembly, two fuel gas assemblies respectively arranged on the bottom end and in the middle of the wafer biscuit conveying chain assembly, a machine box arranged at one end ofthe wafer biscuit conveying chain assembly and partially wrapping the wafer biscuit conveying chain assembly, a mold opening and closing assembly arranged in the machine box, a slurry feeding assemblyarranged in the machine box, and a material discharging and slice receiving assembly. The interactions of the wafer biscuit conveying chain assembly, wafer biscuit molds, fuel gas assemblies, mold opening and closing assembly, slurry feeding assembly and material discharging and slice receiving assembly realize an effect of integrally, continuously and synchronously completing automatic baking ofthe wafer biscuit slices; each 90-degree rotation of a left star wheel and a right star wheel can complete the baking of the wafer biscuits; and the wafer biscuit baking oven is simple and convenientin operations, stable in whole machine operation and low in maintenance costs.

Owner:肇庆市万顺达食品机械制造有限公司

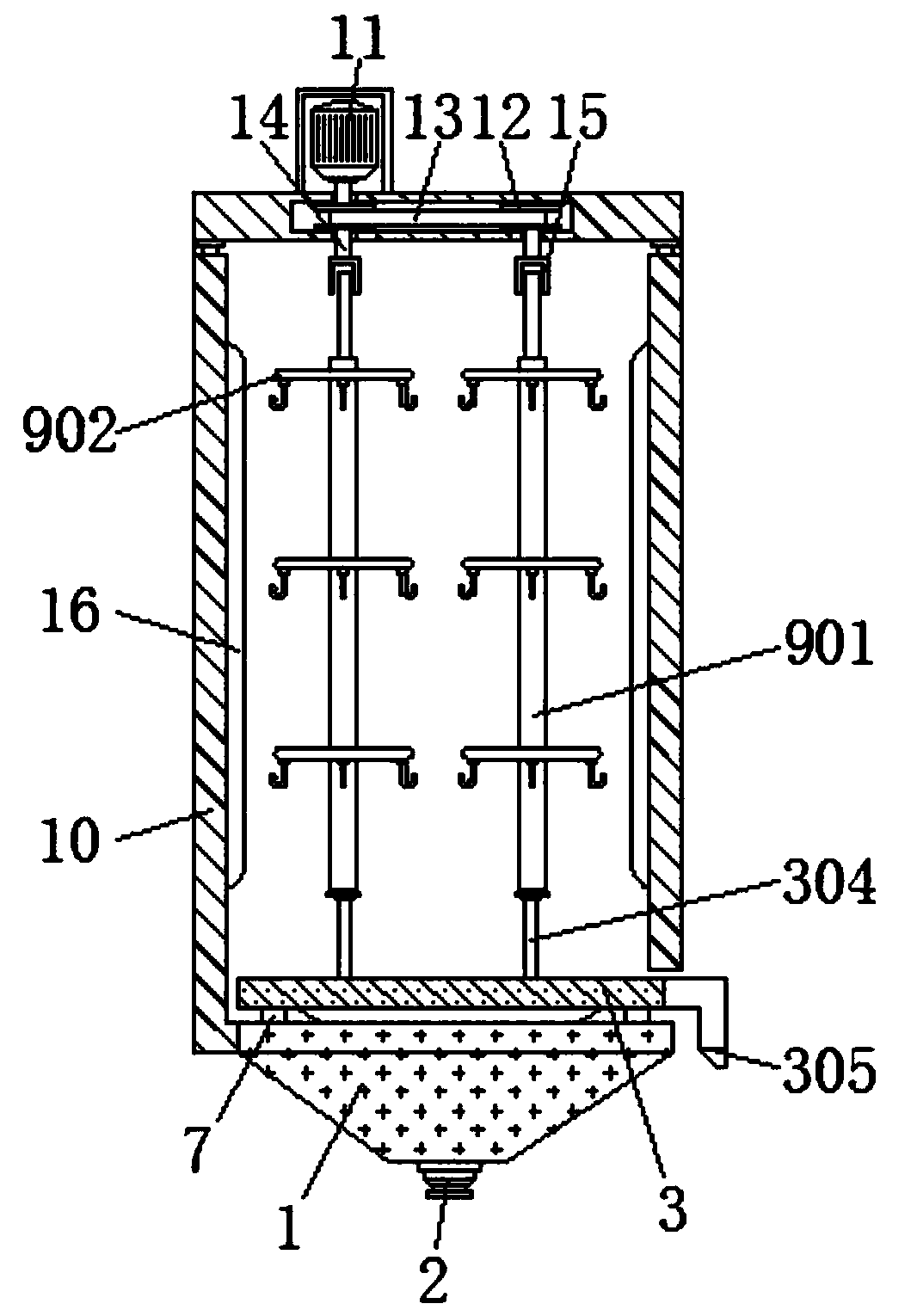

Baking device for pressed spicy salted duck processing convenient for centralized loading and unloading

ActiveCN109832307AConvenient centralized loading and unloadingEasy accessCharging/discharging ovensSpecial goods bakingDrive wheelGear wheel

The present invention discloses a baking device for pressed spicy salted duck processing convenient for centralized loading and unloading. The baking device comprises a supporting bracket, a first motor, a second motor and baking lamps, a material discharge opening is formed in a lower side of the supporting bracket, besides, a drive plate is arranged at an upper side of the supporting bracket, abevel gear is arranged a left side of the supporting bracket, connecting grooves are formed in the supporting bracket, besides, insides of the connecting grooves are provided with connecting rings, vertical shafts are arranged under driving wheels, besides, the vertical shafts are located inside a baking oven, besides, lower sides of the vertical shafts are connected with clamping pieces, the baking lamps are located inside the baking oven, and besides, the baking oven is provided with oven doors. The baking device for the pressed spicy salted duck processing convenient for the centralized loading and unloading can hang pressed spicy salted ducks needing to be baked in batches on baking brackets, thus is convenient for the drive plate to drive the pressed spicy salted ducks on the baking brackets successively into the baking oven to be baked, reduces labor intensity of workers and at the same time can also prevent the workers from being harmed by high temperatures in the baking oven during the work process.

Owner:HUNAN UNIV OF ARTS & SCI

Oil-frying device

InactiveCN109329330AReduce wasteIncrease distanceOil/fat bakingCharging/discharging ovensEngineeringLarge distance

The present invention relates to the technical field of food production and particularly discloses an oil-frying device. The oil-frying device comprises an oil-frying pot; the oil-frying pot is internally provided with an oil-frying basket; the upper side of the oil-frying basket is fixedly provided with a telescopic cylinder; an output end of the telescopic cylinder is fixedly connected with a rotating roller frame; the rotating roller frame is rotatably connected with a rotating roller; a first chain and a second chain are wound around the rotating roller; both ends of the first chain and the second chain are respectively fixedly connected to the four end points of the top part of the oil-frying basket; and the top part of the side wall of the oil-frying pot, parallel to the rotating roller, is rotatably connected with a plurality of inverted L-shaped baffle bars. The oil-frying device realizes automatic material discharging of oil-fried materials, reduces workload and improves the work efficiency. At the same time, the oil-frying basket can completely enter into the oil-frying pot, so that the materials to be oil-fried in the oil-frying basket can be fully oil-fried to ensure the oil-frying quality; besides, the oil surface in the oil-frying pot has a large distance to the mouth of the oil-frying pot; hot oil is not easy to spill; scalding of workers is avoided; and at the same time, waste of oil is also reduced.

Owner:CHONGQING NIANJI FOOD

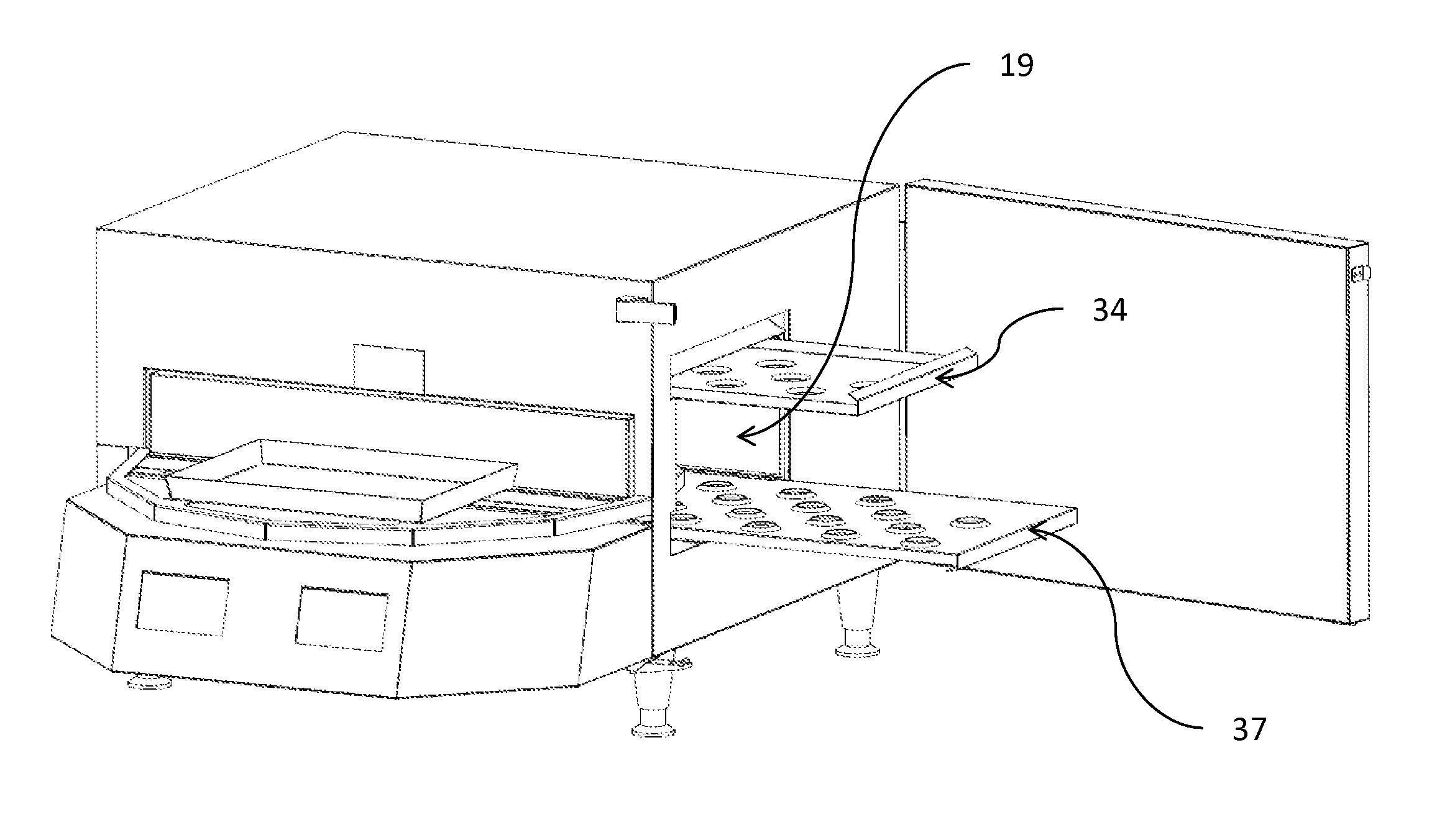

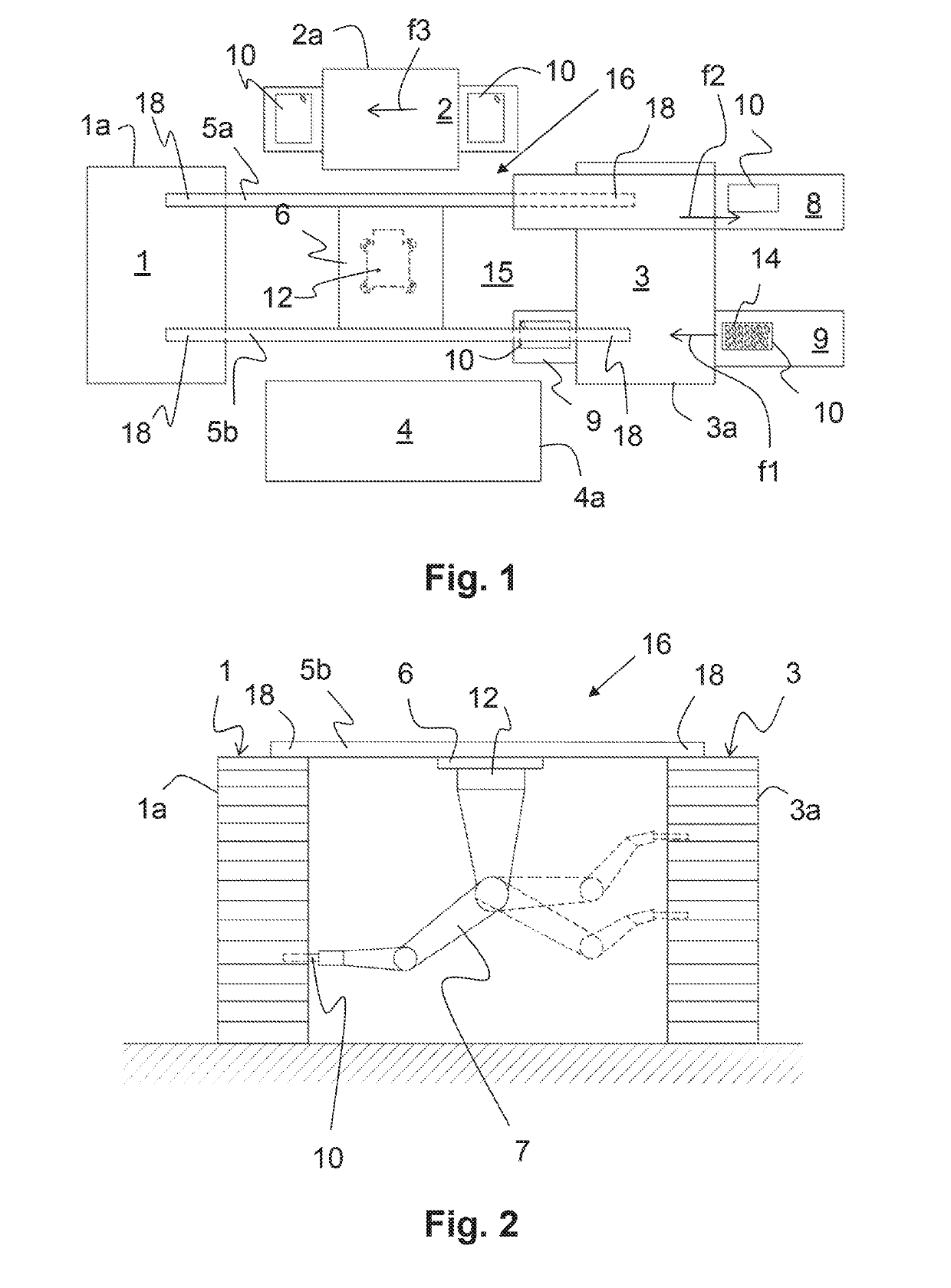

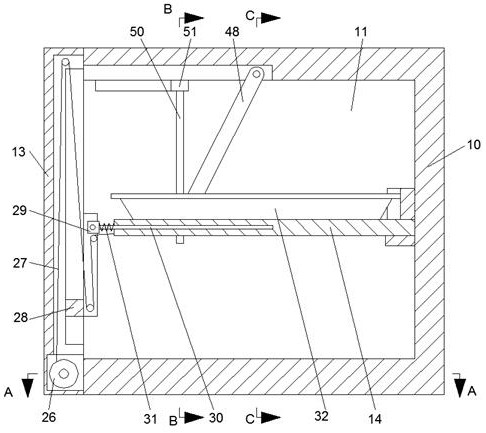

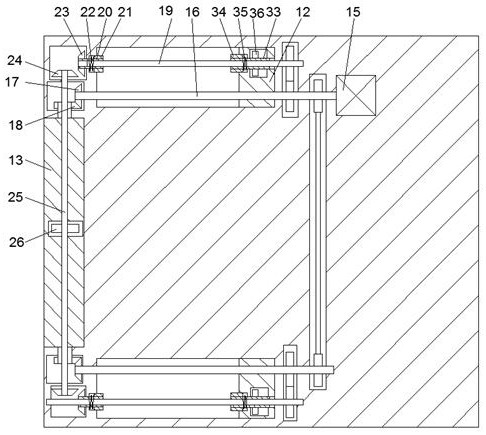

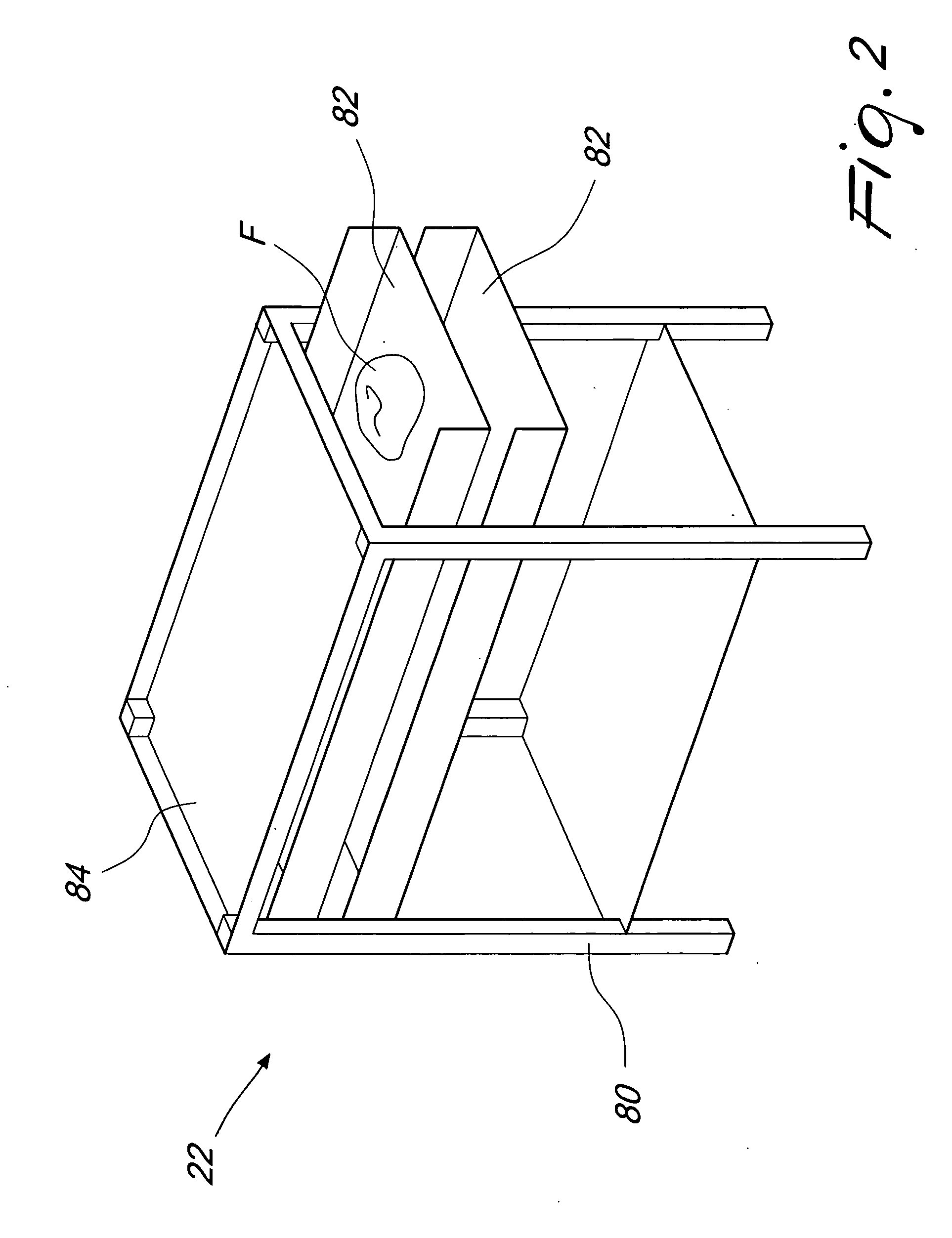

Device for storing, baking, and discharging bakery goods

ActiveUS20190297899A1Space minimizationLittle effortBaking plantsManipulatorCooking & bakingEngineering

A device for storing, baking, and discharging bakery goods includes a plurality of stations with each station having a housing. The plurality of stations include a storage station for receiving a carrier loaded with bakery goods, a baking station for baking the bakery goods located on the carrier, and a discharging station on which bakery goods can be presented and removed. A robot transports the carrier between the plurality of stations. A carrying device provides suspended mounting of the robot, and the carrying device is supported by at least two of the plurality of stations.

Owner:R WEISS VERPACKUNGSTECHN

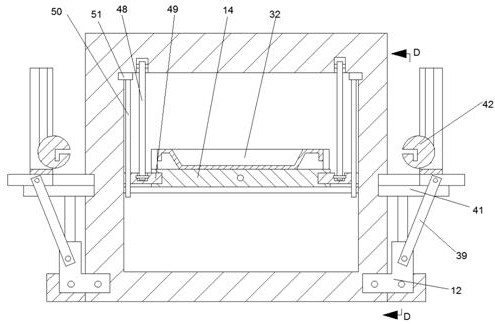

Oven device for preventing scalding during taking and placing in heat exchange mode

InactiveCN111904295AWon't burnRoasters/grillsCharging/discharging ovensElectric machineryEngineering

The invention discloses an oven device for preventing scalding during taking and placing in a heat exchange mode. The oven device comprises a machine body, a baking cavity is formed in the machine body, an oven door is installed on the left side of the baking cavity, a connecting mechanism is arranged on the oven door, and side sliding blocks are installed on the front portion and the rear portionof the machine body in a front-back symmetry and left-right sliding mode. A support mechanism is arranged on the side sliding block, a lifting mechanism is arranged on the upper portion of the bakingcavity, when a baking tray in the oven needs to be taken out, the oven can be driven by a motor to be opened, the oven door does not need to be touched by hands, after the oven door is opened, a support provided with a heat insulation handle can move to an inlet of the oven, and then the baking tray is forwards pushed out of the oven. The side edge of the baking tray is connected with the heat insulation handle, and then the baking tray is lifted upwards to leave the high-temperature area of the oven, so that people cannot be scalded even if forgetting to wear heat insulation gloves when holding the baking tray.

Owner:诸暨太普厨卫科技有限公司

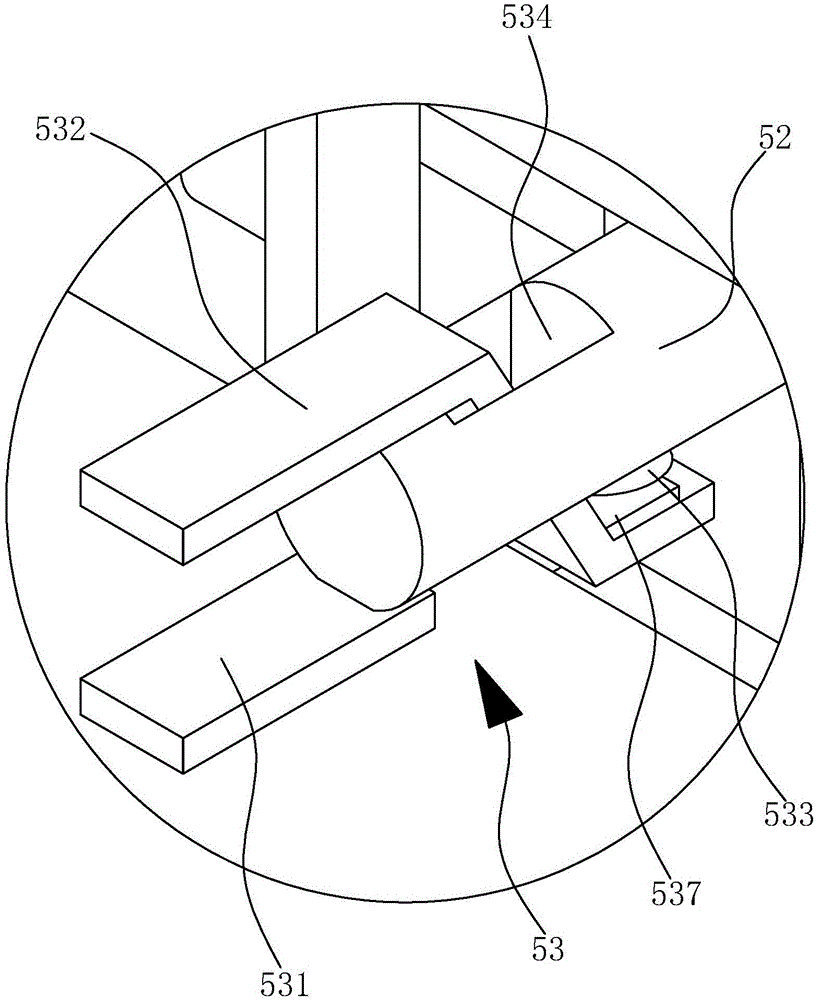

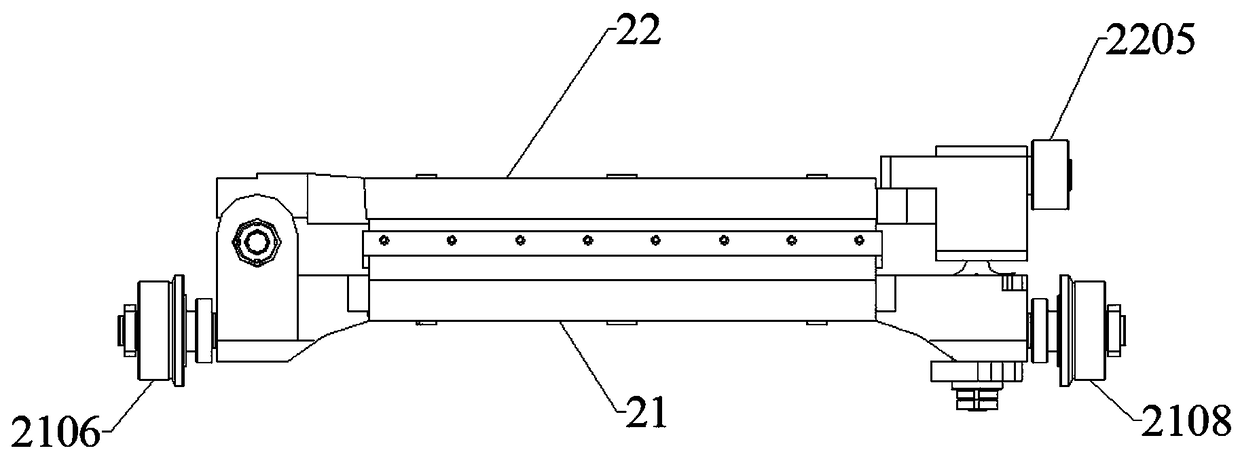

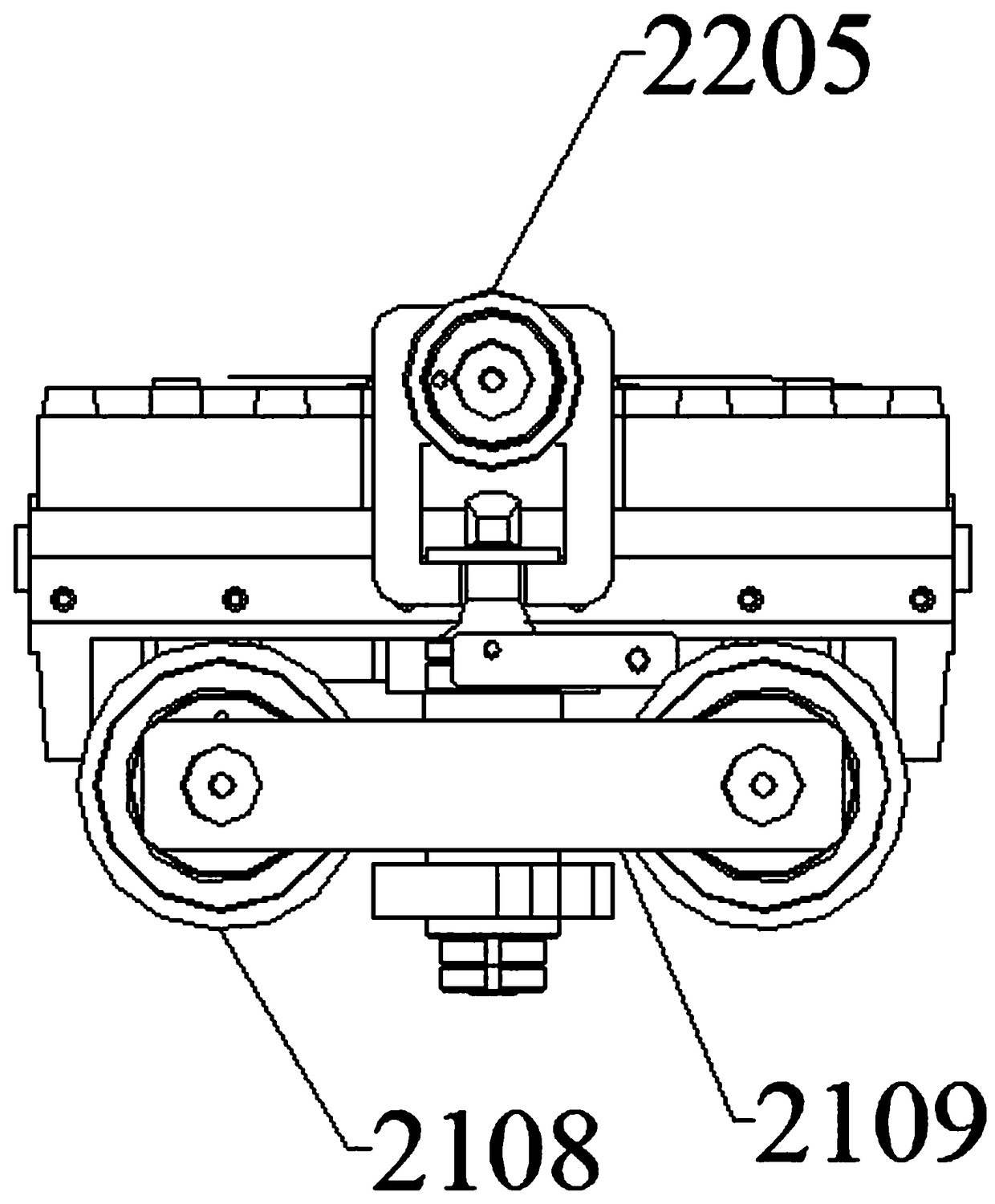

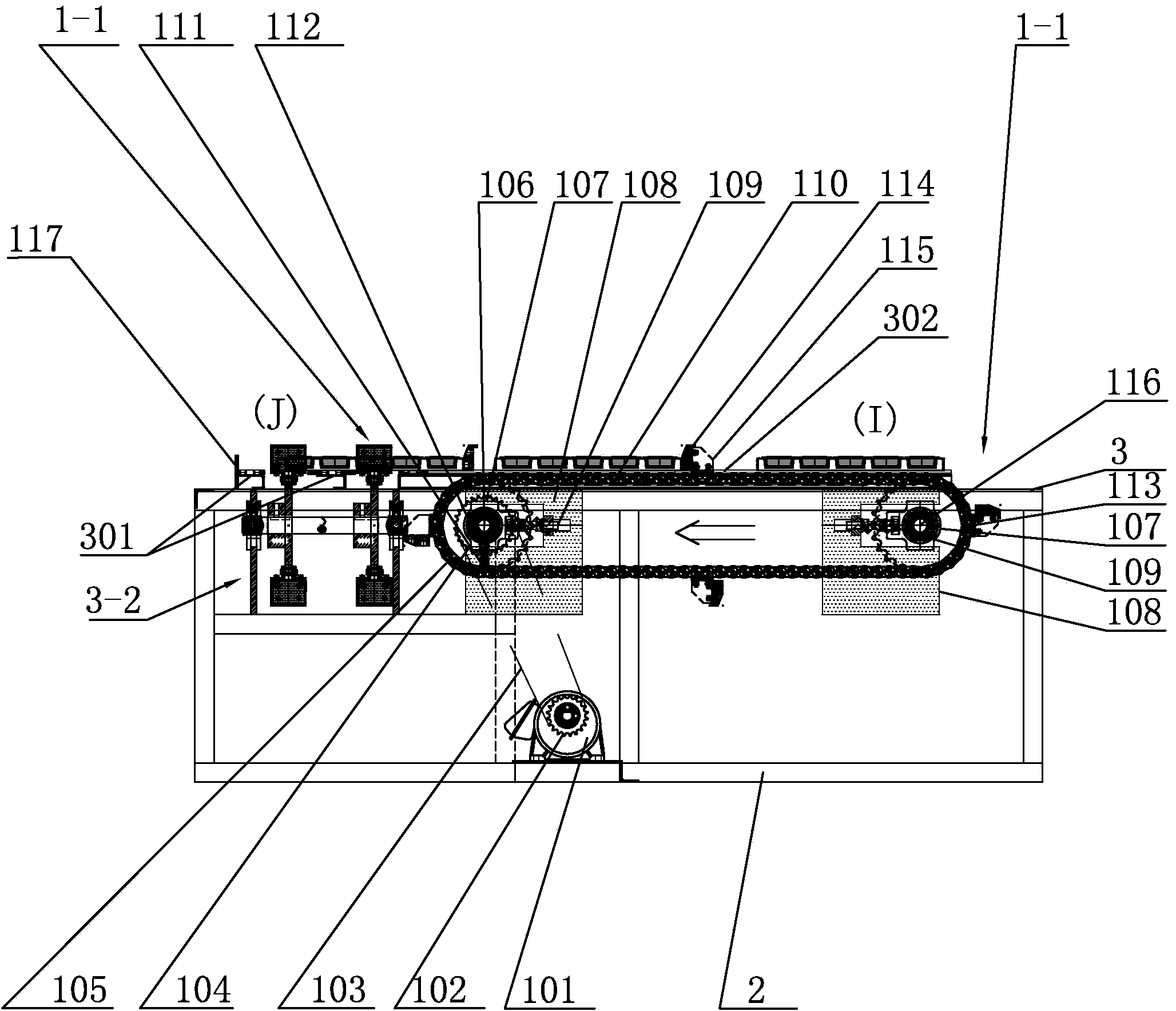

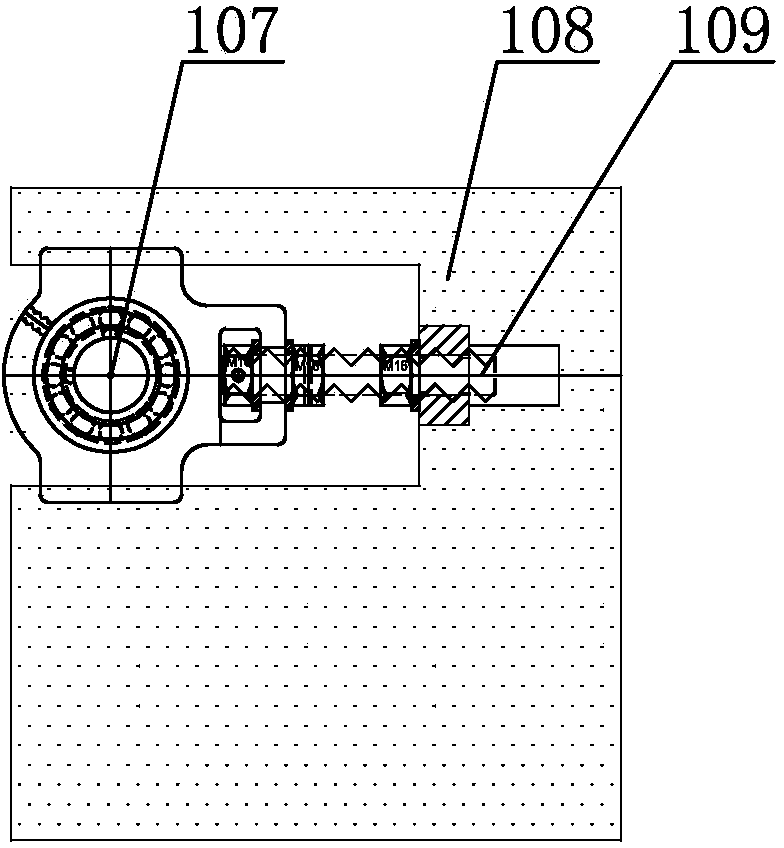

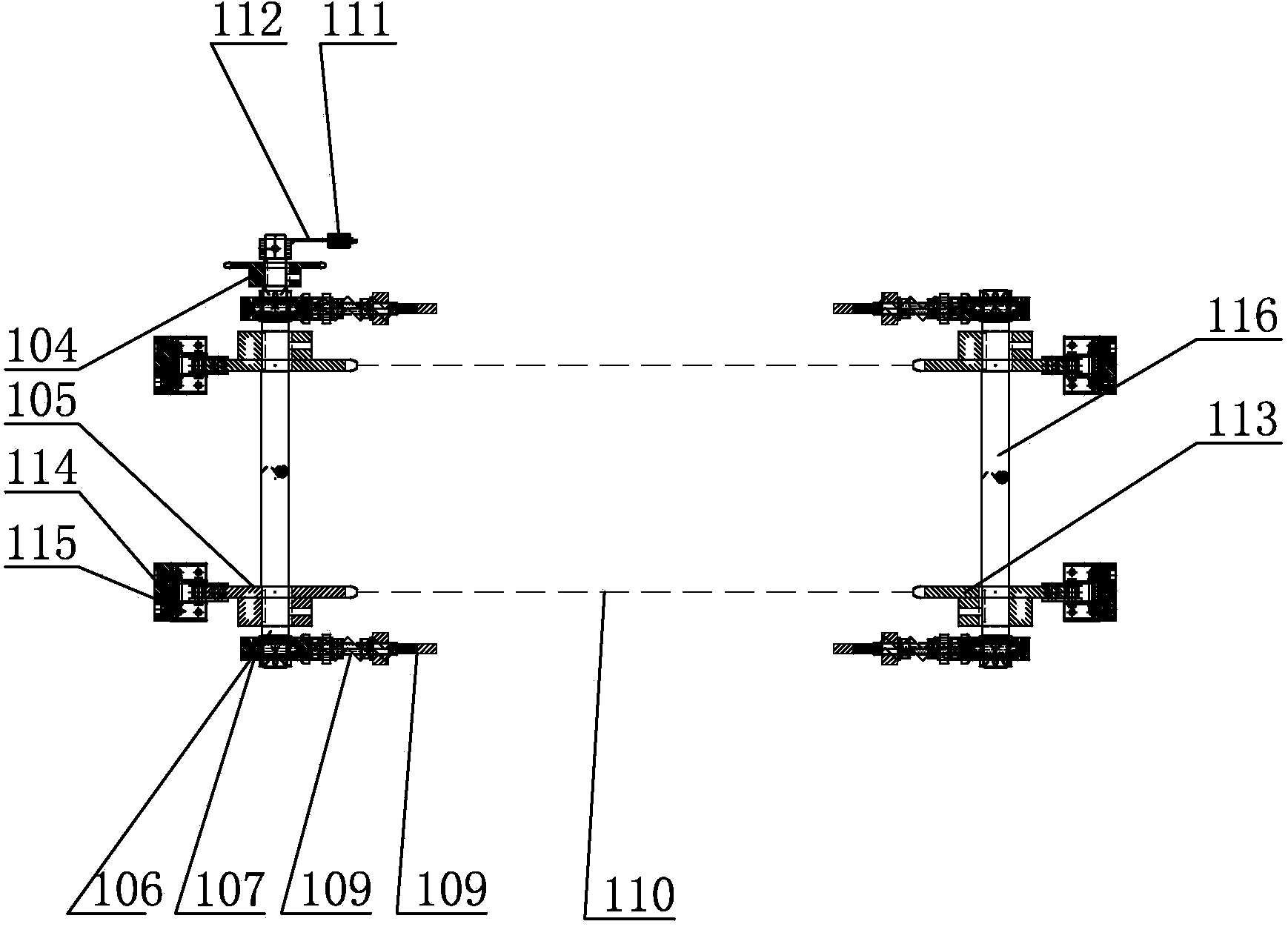

Baking tray moving and recovery device

InactiveCN103651642ARealize displacement conveyingAchieve abutment in placeCharging/discharging ovensComputer moduleMechanical engineering

The invention relates to a baking tray moving and recovery device which comprises a first conveying unit arranged in a first rack and a third conveying unit arranged in a second rack. A second conveying unit is arranged between the first conveying unit and the third conveying unit, and the structure of the first conveying unit, the structure of the second conveying unit and the structure of the third conveying unit are identical. The baking tray moving and recovery device is simple in structure and convenient to operate and use, the first conveying unit, the second conveying unit and the third conveying unit are arranged in a U shape, a chain chuck component and a chuck protection sleeve are fixedly connected to form a power module, the in-place abutting of a baking tray and a tray blocking plate is effectively achieved, the baking tray can move from a position I to a position J, from the position J to a position K and from the position K to a position L at one time, meanwhile, the recovery of empty baking trays is effectively achieved, manpower cost is lowered, and production efficiency is improved.

Owner:YANG JENQ MACHINERY

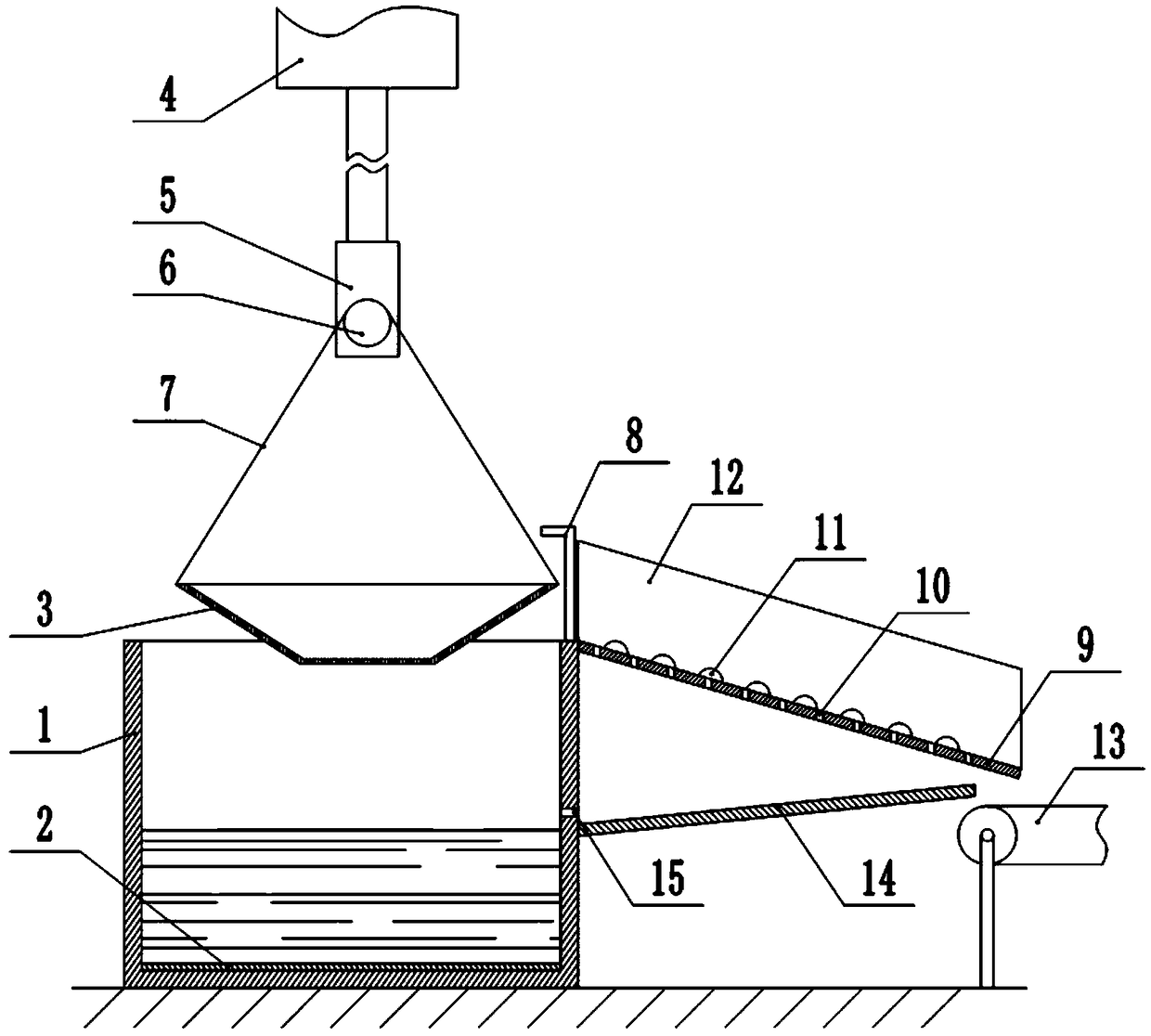

Mechanized apparatus for the preparation of pizzas

InactiveUS20100107899A1Small sizeLess expensivePancakes bakingCharging/discharging ovensEngineeringVertical axis

The apparatus comprises a frame, an oven having two pizza reception areas which are accessible through an inlet opening, and a pizza-holding arm hinged to the frame about a vertical axis and supporting a pizza-holding shover which is movable between a loading position outside the oven and an unloading position inserted in the oven, under control of first motor means. A second motor can rotate the arm at predetermined angular positions, in each of which the path of the shover is directed to a respective pizza reception area. A control unit controls both the first motor with different speeds in the two directions, whereby the shover slowly enters the oven while conveying a pizza and suddenly withdraws from the oven to unload the pizza, and the second motor for successively positioning the pizza-holding arm at such predetermined angular positions.

Owner:CMT COSTR MECCANICHE E TECNOLOGIA PEVERAGNO

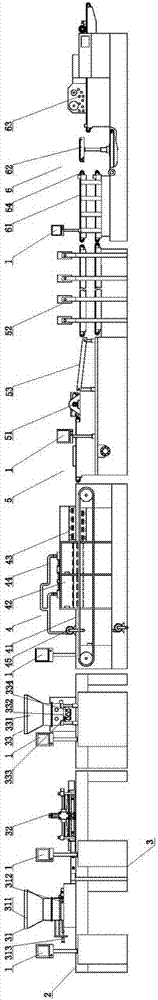

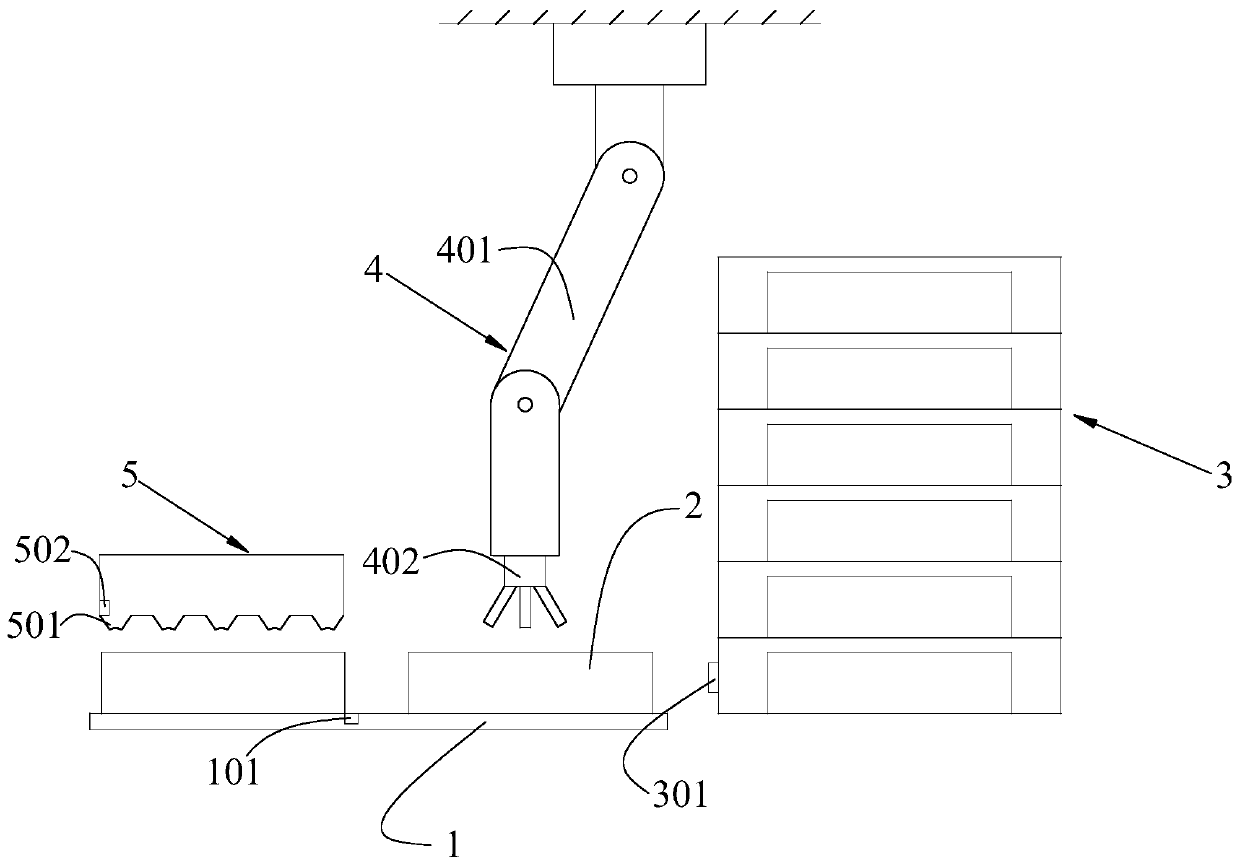

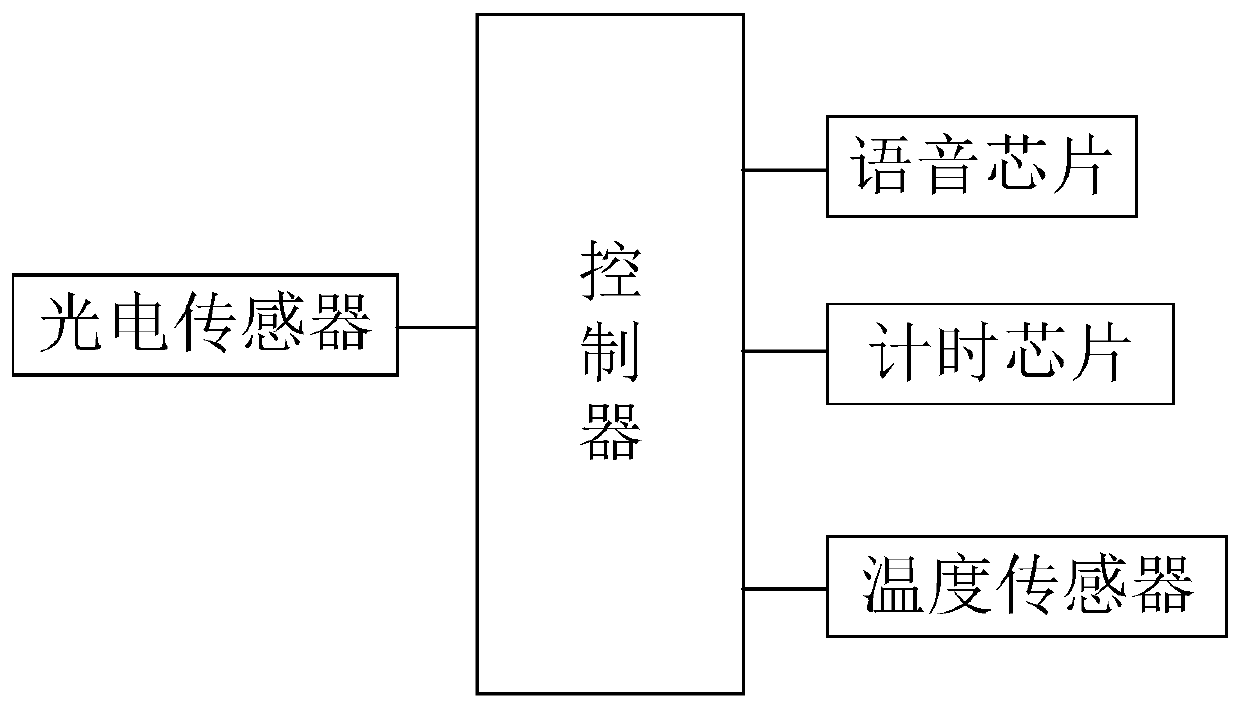

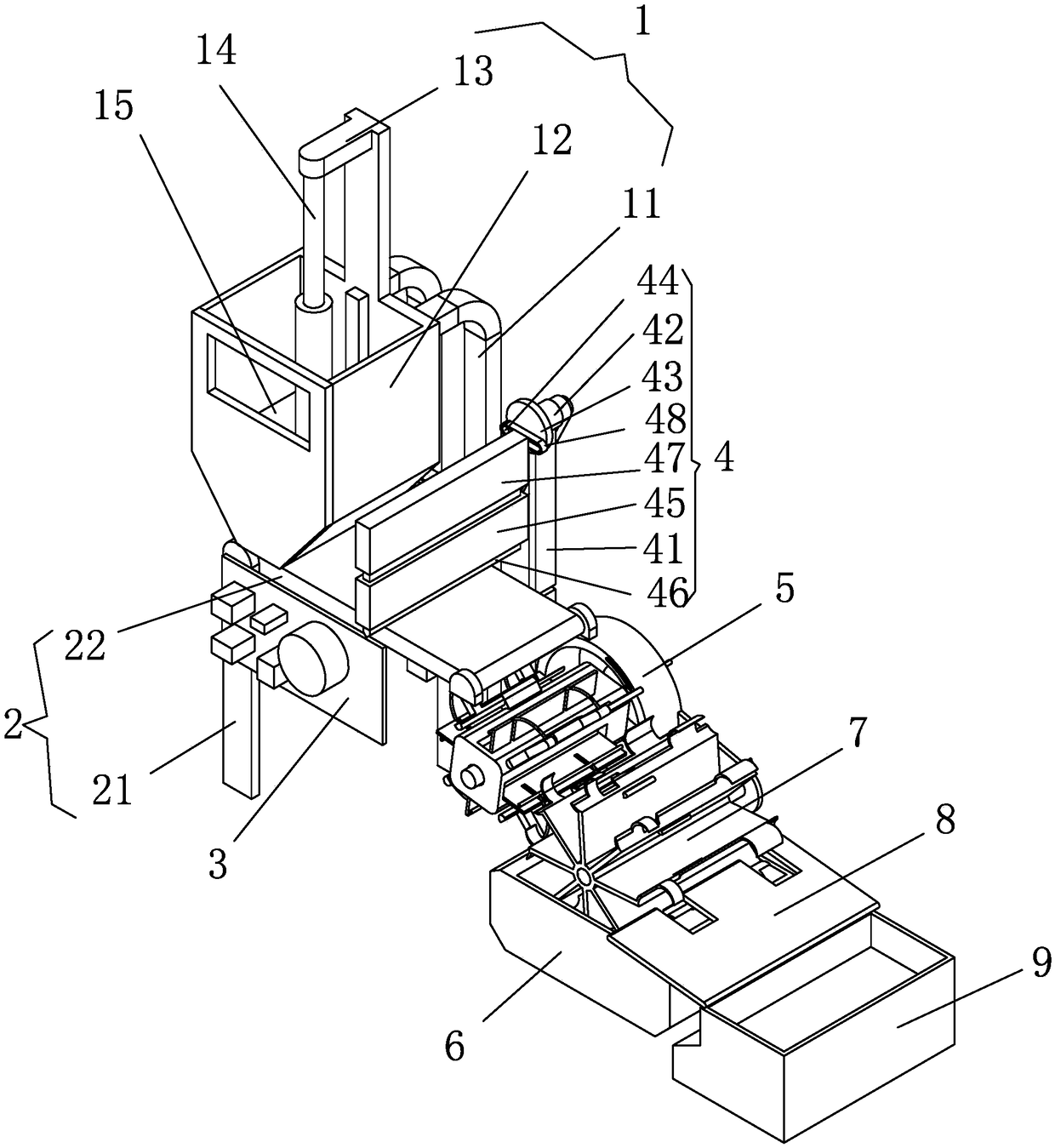

Full-automatic baking line and operating method thereof

InactiveCN109907081AImprove baking efficiencyImprove efficiencyCharging/discharging ovensCooking & bakingProduction line

The invention belongs to the technical field of cake baking and particularly relates to a full-automatic baking line and an operating method thereof. The full-automatic baking line comprises a controller, an oven, a conveyer belt at a feed port of the oven and a manipulator suspended, wherein both the conveyer belt and the manipulator are controlled via the controller; the part of the oven corresponding to the conveyer belt is provided with a first photoelectric sensor electrically connected with the controller; a plurality of cake molds with cake liquid are conveyed in sequence through the conveyer belt; when the cake molds are close to the oven, the first photoelectric sensor is triggered, and the controller controls the conveyer belt to stop conveying and controls the manipulator to grab the cake molds into the oven. The full-automatic baking line can provide automatic cake baking under high one-off baking quantity and has improved cake baking efficiency.

Owner:江苏金世康电器科技有限公司

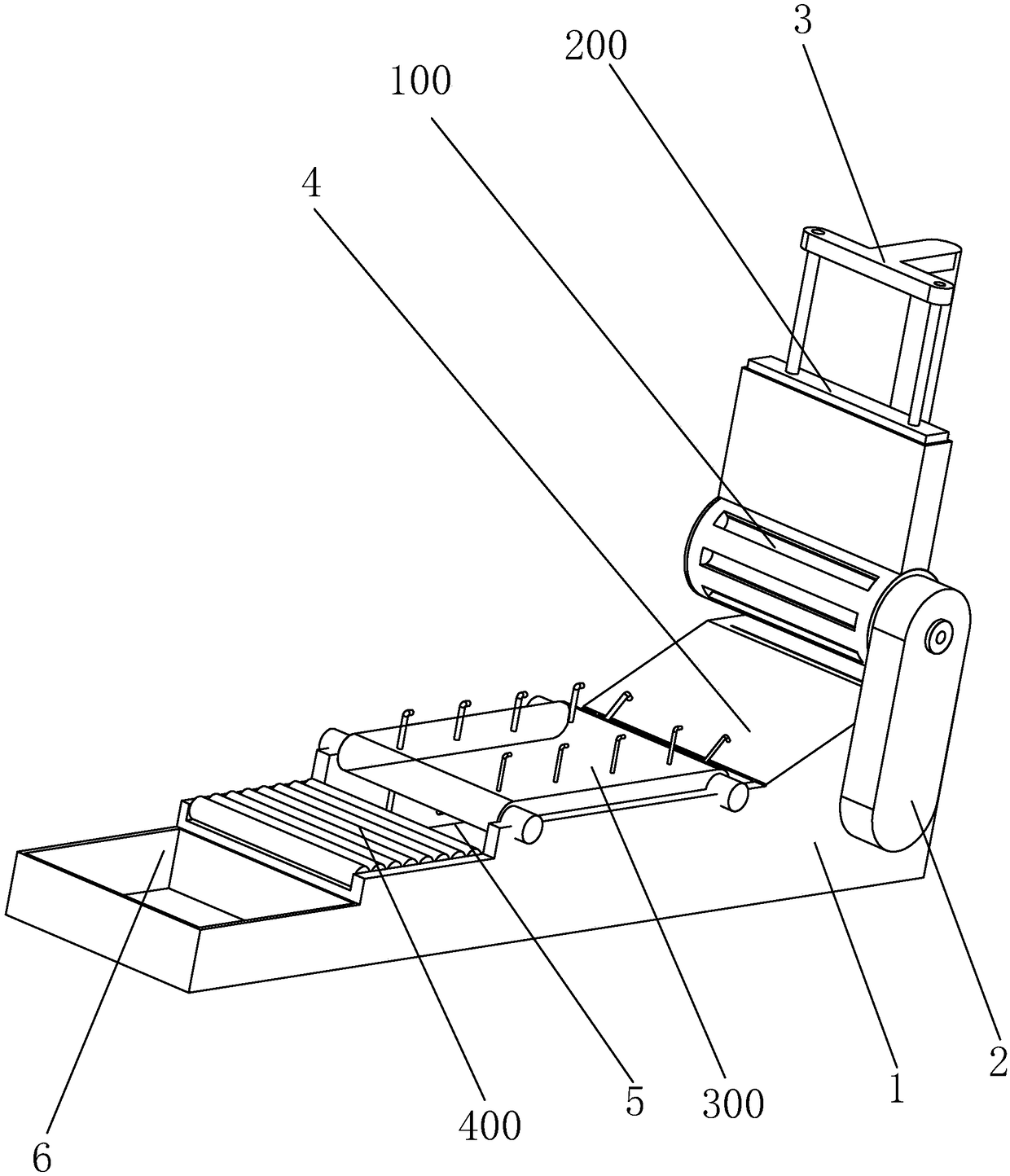

Oil-fried food production apparatus

ActiveCN108244166AFast strip cuttingReduce the difficulty of operationDough embossing machinesDough extruding machinesEngineering

The invention discloses an oil-fried food production apparatus. The oil-fried food production apparatus comprises a transmission base; and a control panel is arranged on the transmission base. The oil-fried food production apparatus is characterized in that a flour extruding device and a dough strip cutting device are arranged on the transmission base; a dough stick indenting device is connected to one side of the transmission base; a circumferential dough stick delivering device is connected to one side of the dough stick indenting device; an oil-frying cavity is arranged under the circumferential dough stick delivering device. The oil-fried food production apparatus further comprises a carrier trolley on which the transmission base, the dough stick indenting device, the oil-frying cavityand the circumferential dough stick delivering device are arranged; and a dust-proofing cover is arranged on the carrier trolley, and covers the transmission base, the dough strip cutting device, thedough stick indenting device, the oil-frying cavity and the circumferential dough stick delivering device. The oil-fried food production apparatus disclosed by the invention is capable of rapidly performing cutting on the dough strips so as to greatly reduce difficulties of manual operation and save time; moreover, the oil-fried food production apparatus is simple in structure, and convenient touse.

Owner:山西名沙食品有限公司

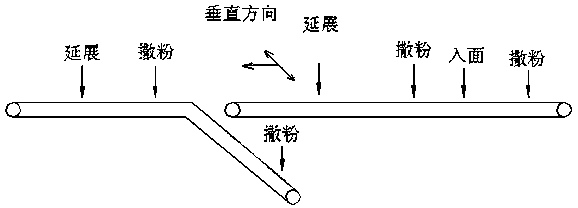

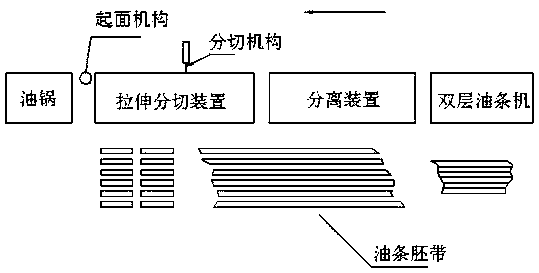

Full-automatic preparation method for deep-fried dough sticks

InactiveCN110235907ARealize fully automatic processingProcess stabilityDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusDeep fryingEngineering

The invention discloses a full-automatic preparation method for deep-fried dough sticks. A dough pretreatment device is utilized for pretreating a dough raw material and vertically extends dough in the forward conveying direction, and a dough sheet with upper and lower surfaces scattered with flour or brushed with oil is formed; then, in a double-layer deep-fried dough stick making machine, the dough sheet is cut into a plurality of dough strips parallel to the conveying direction, and through overlaying, double-layer deep-fried dough stick dough piece strips are formed; then, a dough strip separation device is utilized for separating each double-layer deep-fried dough stick dough piece strip to make a certain gap formed in each double-layer deep-fried dough stick dough piece strip; a deep-fried dough stick dough piece stretching and cutting device is utilized for stretching each separated double-layer deep-fried dough stick dough piece strip and cutting the separated double-layer deep-fried dough stick dough piece strips into double-layer deep-fried dough stick dough pieces; finally, through a dough lifting mechanism, the double-layer deep-fried dough stick dough pieces are quickly separated from a conveying belt of the deep-fried dough stick dough piece cutting device, enter a fryer or are quick-frozen for the next deep frying. According to the full-automatic preparation method, full-automatic processing from the deep-fried dough stick dough to the deep-fried dough sticks can be achieved, the process is smooth, and the efficiency is high; the quality of the deep-fried dough stick dough pieces is similar to that of the deep-fried dough stick dough pieces made by hand, and the taste of the deep-fried dough sticks is similar to that of the deep-fried dough sticks made by hand.

Owner:SUZHOU GUOEN FOOD MACHINERY

Device for making small deep-fried dough sticks

InactiveCN108308215ALabor savingQuick and orderly productionOil/fat bakingDough shapingEngineeringFishing

The invention discloses a device for making small deep-fried dough sticks. The device comprises a box body, and is characterized in that a motor is arranged on one side of the box body, a forming andpushing mechanism is connected with the end of the motor, a support frame is arranged at one end of the box body, an extrusion mechanism capable of extruding raw materials into the forming and pushingmechanism is connected with the end of the support frame, an inclined plate is arranged on one side of the forming and pushing mechanism, a frying box is arranged on one side of the forming and pushing mechanism, the inclined plate is inclined to the frying box, a fishing mechanism for fishing deep-fried dough sticks in the frying box is arranged above the frying box, an oil drying mechanism is arranged on one side of the fishing mechanism, and a collecting box capable of collecting the formed deep-fried dough sticks is arranged on one side of the oil drying mechanism. According to the deviceprovided by the invention, the forming and pushing mechanism, the extrusion mechanism and the oil drying mechanism are provided, so that the production can be carried out quickly and orderly, the production is quick and convenient, the labor force of workers is greatly reduced, and the problems in the prior art can be solved.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com