Full-automatic preparation method for deep-fried dough sticks

A fully automatic, deep-fried dough stick technology, which is applied to the loading/unloading of ovens, dough forming and cutting equipment, dough sheeting machines/rolling machines/rolling sticks, etc. Realize automatic preparation of deep-fried dough sticks and other issues, and achieve the effect of smooth process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A fully automatic preparation method for deep-fried dough sticks,

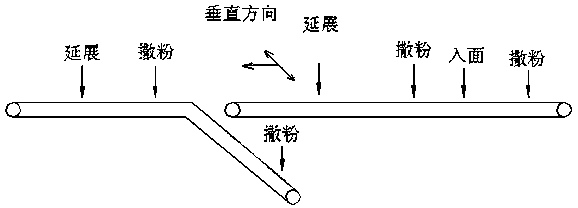

[0022] Firstly, use the dough pre-processing device to pre-treat the raw dough. The pre-processing device should realize the extension of the opposite dough in the vertical direction of the conveying direction, and form a dough piece that is dusted with powder or brushed with oil. During the processing, increase or not increase the number of stretching times for the produced dough sheet. When increasing the number of stretching times, increase the number of stretching and rolling devices according to the number of times, and form a dough sheet that is sprinkled with flour or brushed with oil on the top and bottom;

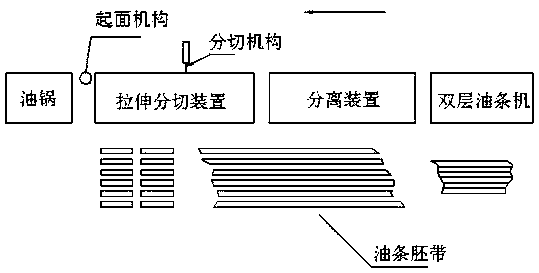

[0023] Then, in the double-layer deep-fried dough stick machine, the dough sheet is cut into multiple noodle strips parallel to the conveying direction, and then superimposed to form a double-layer fried dough stick embryo noodle strip;

[0024] Then, use the noodle belt separation device to...

Embodiment 2

[0028] Such as figure 1 , 2 Shown, as embodiment 1 has design scheme example, described dough embryo pretreatment device comprises frame and is installed on the conveying mechanism on the frame, is installed on the extension rolling device and powdering device or oil brushing device on the conveying mechanism , Upper and lower powdering or upper and lower brushing means that the powdering device or oiling device is installed above the conveyor belt, and one of the powdering device or oiling device is located in front of the feeder, and the powder or oil is sprinkled or brushed on the conveyor belt.

[0029] The extended noodle rolling device includes an extended noodle rolling frame and a noodle rolling roller installed on the frame body, the moving direction of the noodle rolling roller is perpendicular to the conveying direction, and reciprocating motion.

[0030] Described noodle strip separating device comprises separation roller, roller holder and a conveyer belt that ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com