Patents

Literature

137results about "Baking surface cleaning/greasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

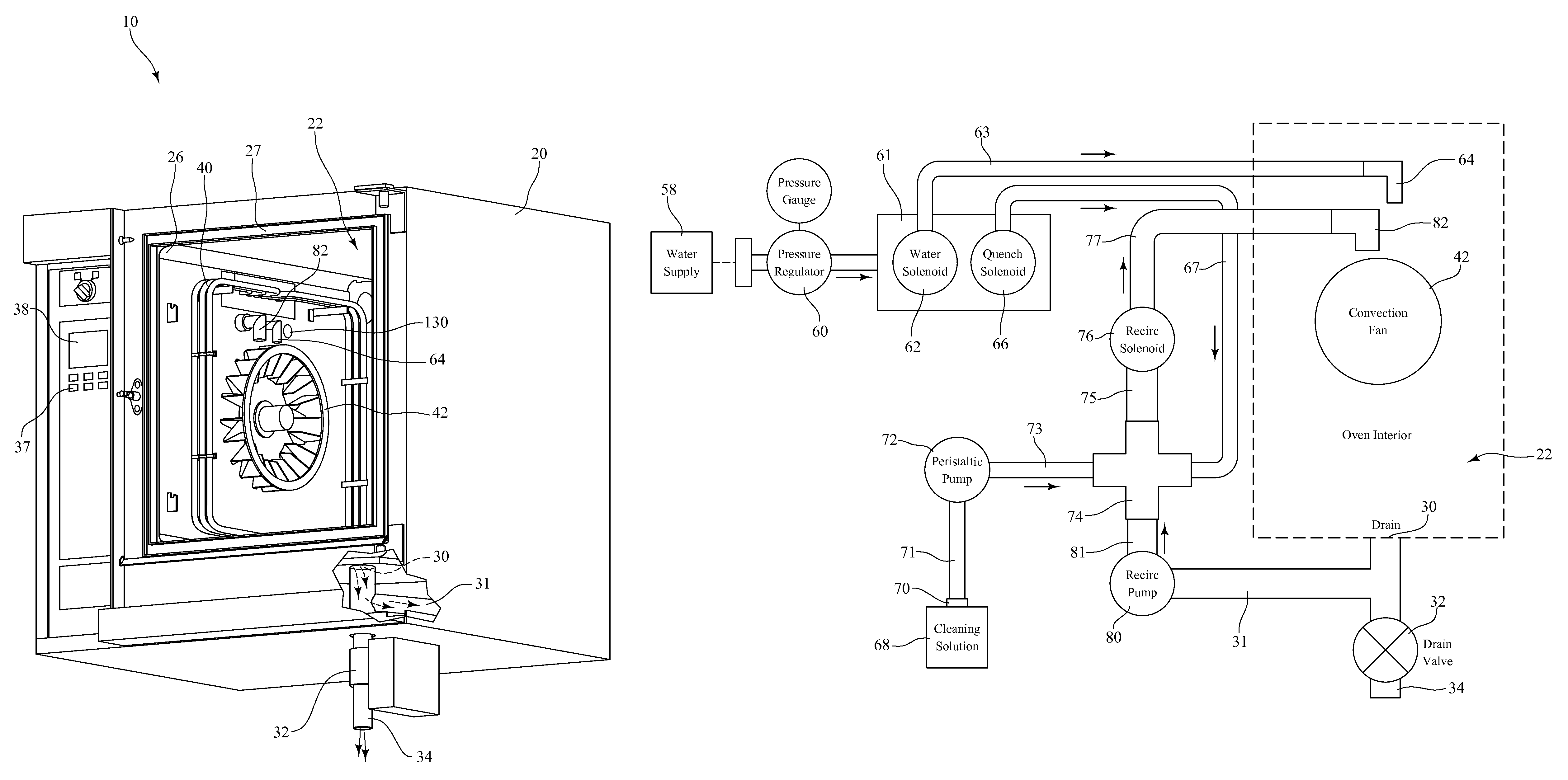

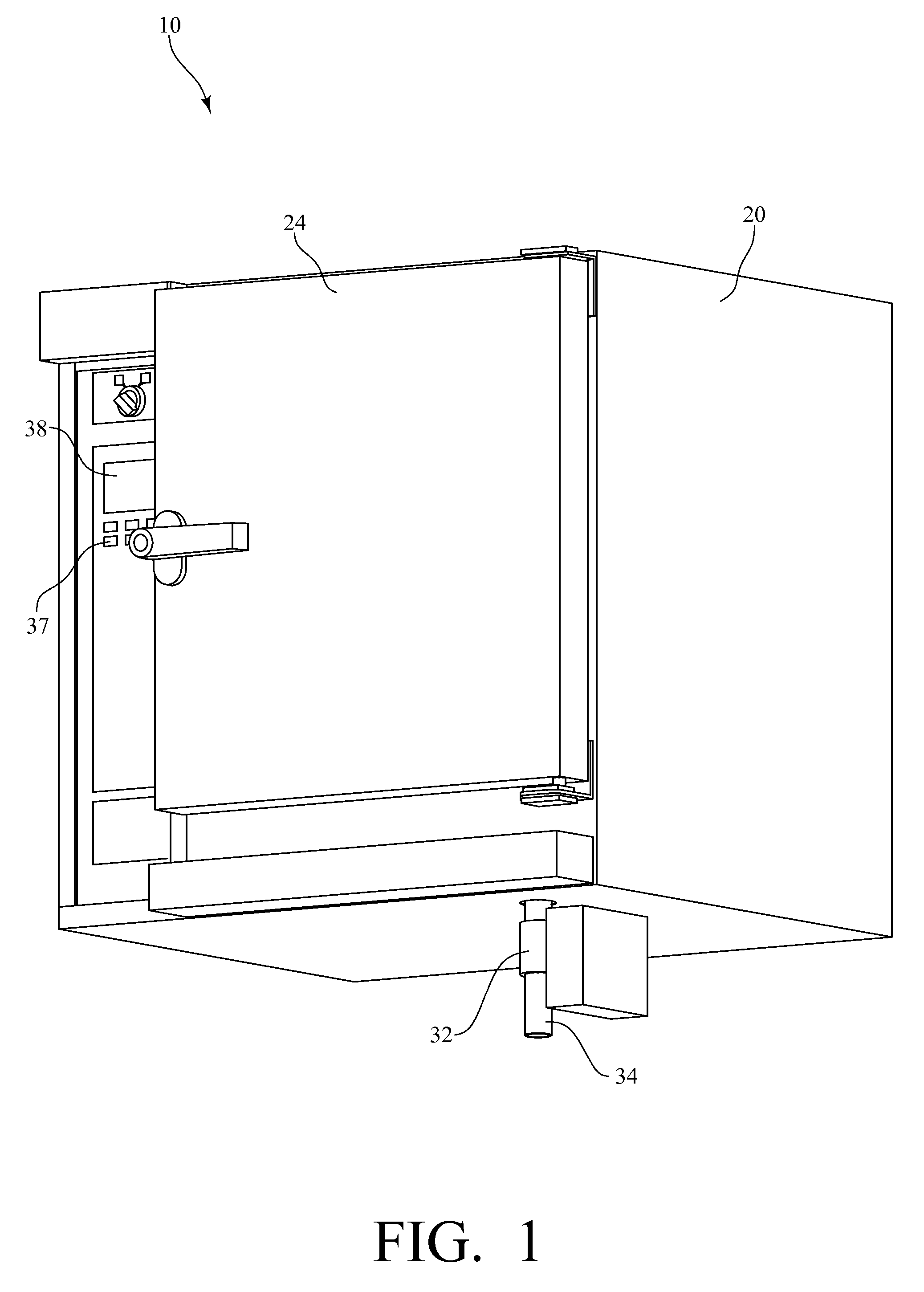

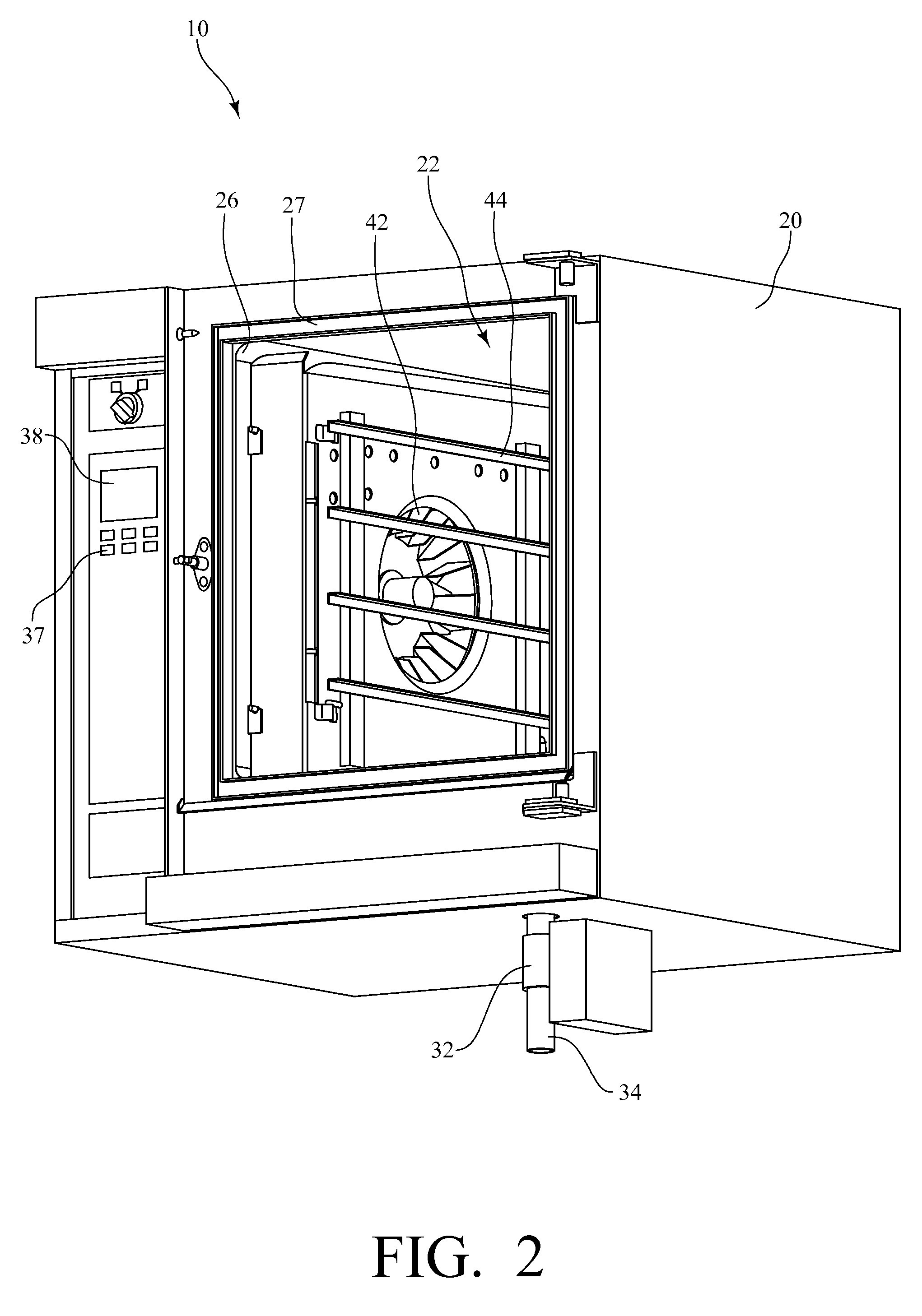

Self-cleaning convection oven

InactiveUS8193470B1Self-cleaning stoves/rangesOven air-treatment devicesEngineeringMechanical engineering

A self-cleaning convection oven includes a cabinet defining an interior cavity for cooking a food product; a door moveable between an open position and a closed position for allowing access to the interior cavity; one or more heating elements positioned in the interior cavity for delivering heat to the interior cavity; a fan positioned within the interior cavity; and a plumbing system operably connected to a water supply for delivering water into the interior cavity of the oven through a first nozzle positioned near the fan. The plumbing system of the self-cleaning convection oven further also delivers a cleaning solution into the interior cavity of the oven.

Owner:KFC CORP

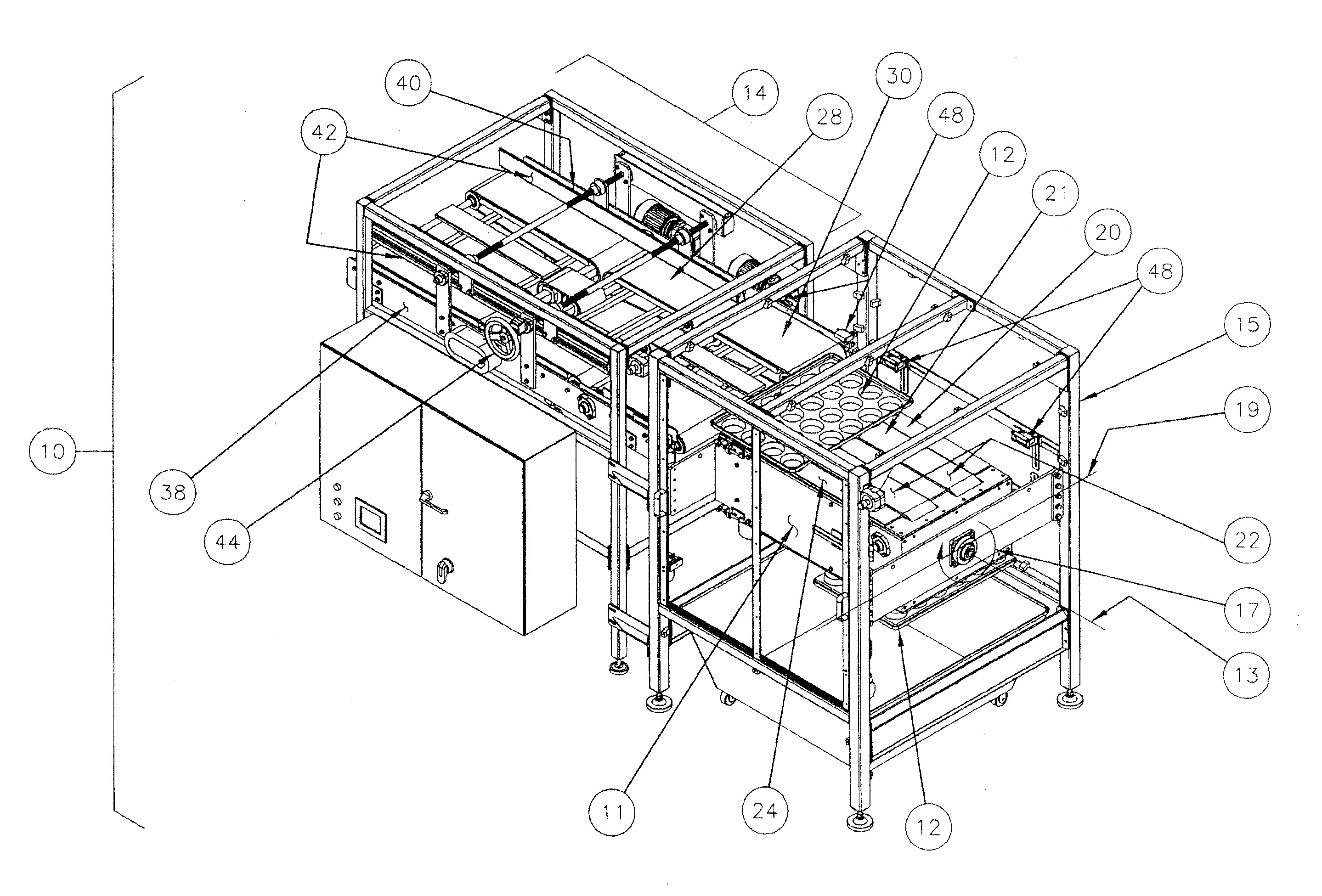

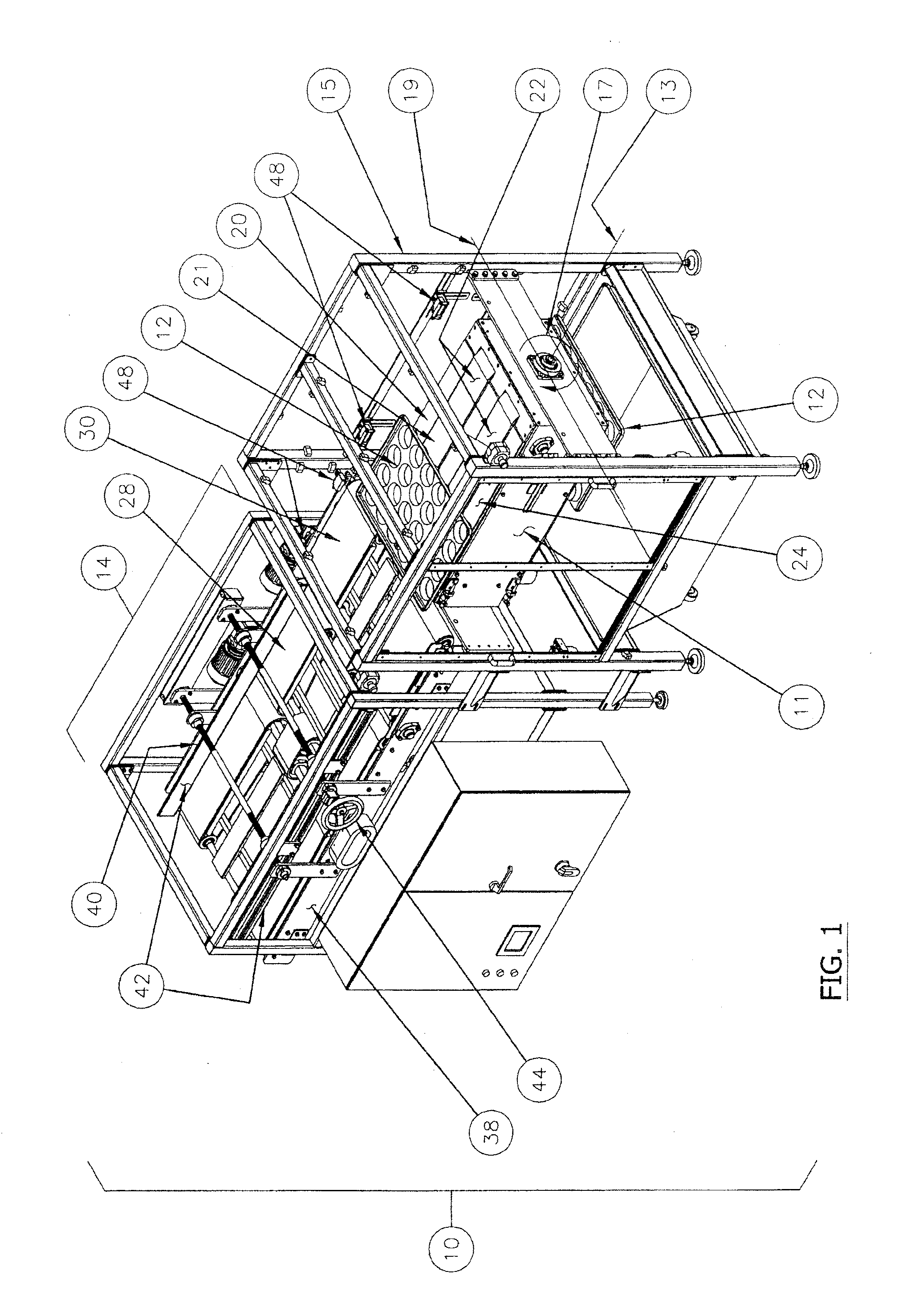

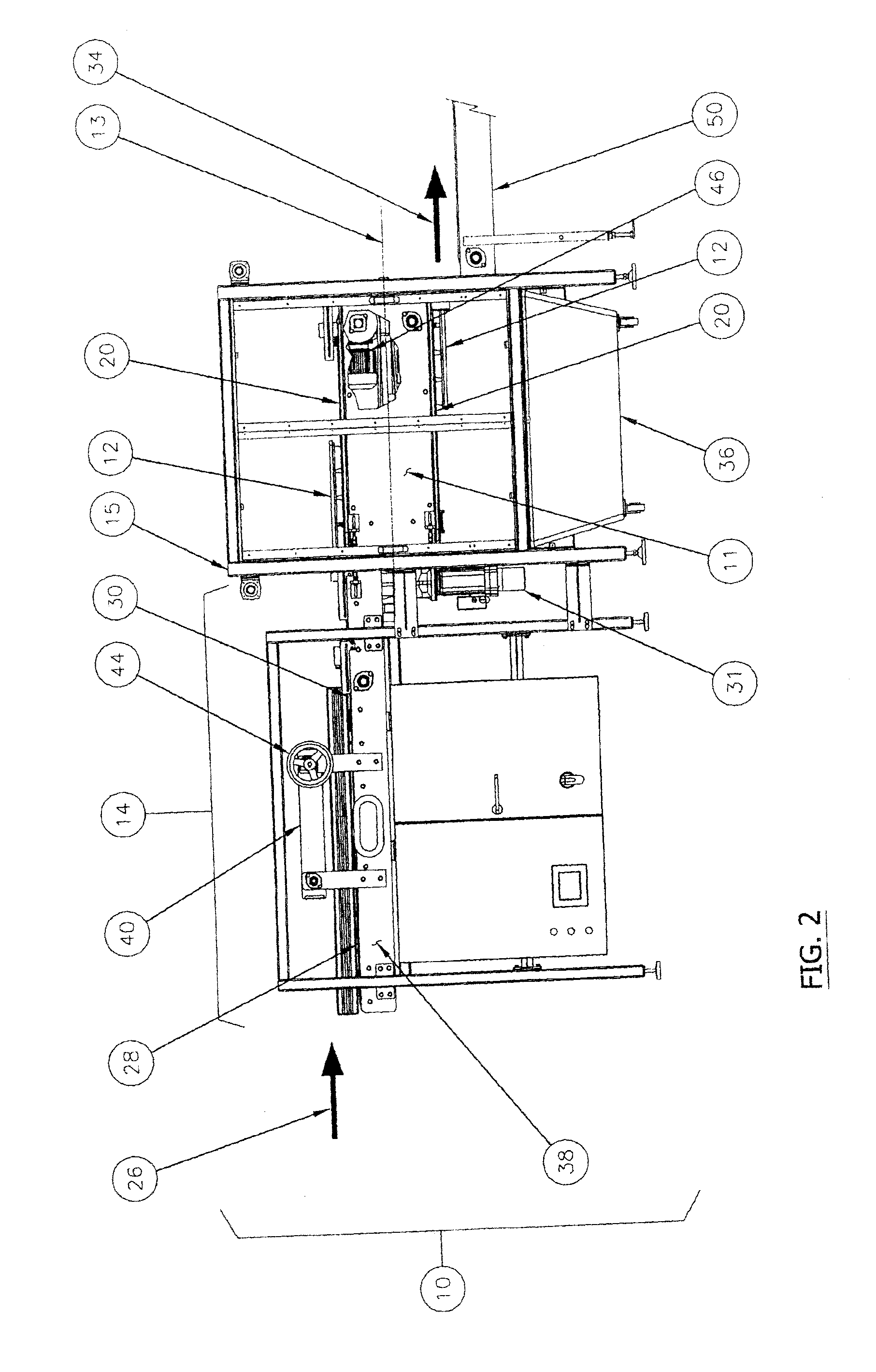

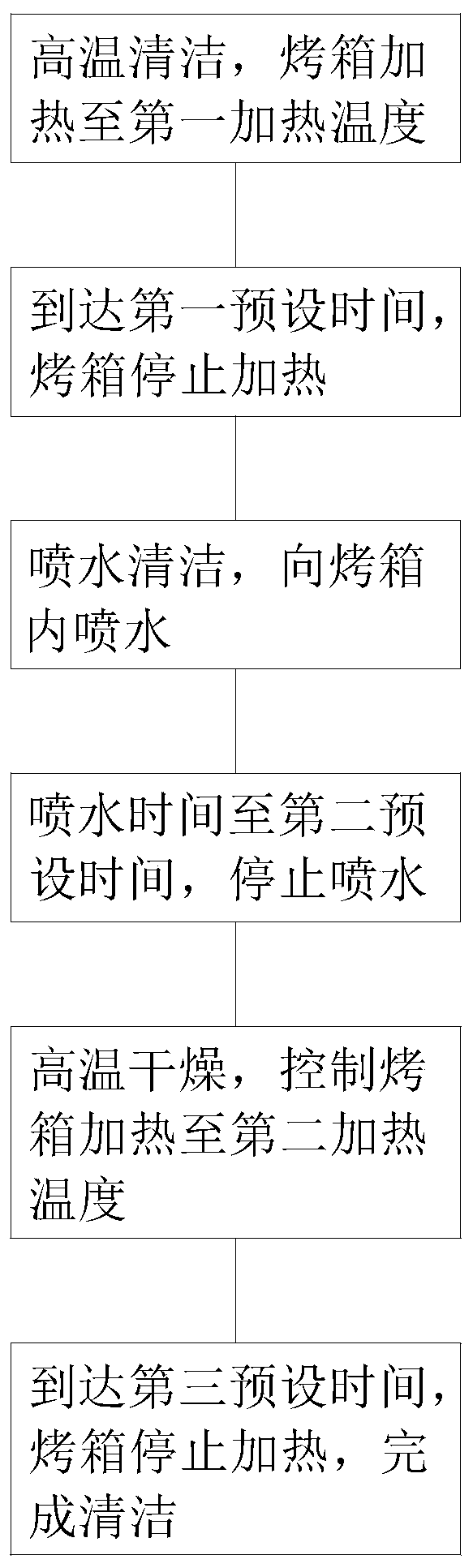

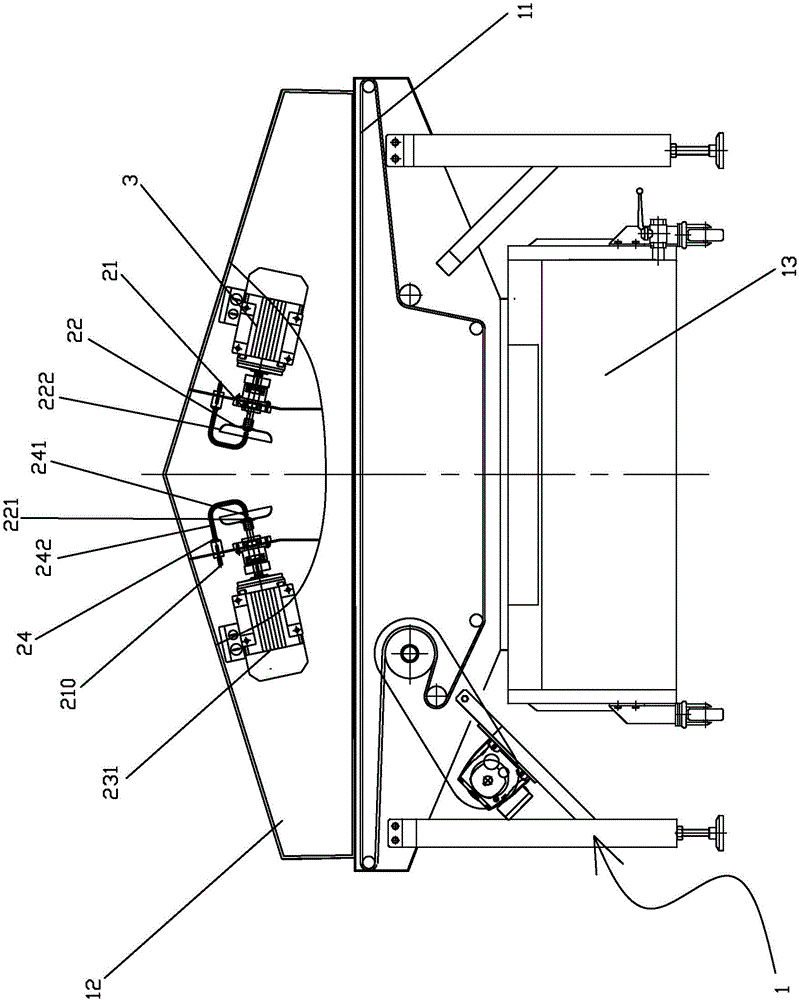

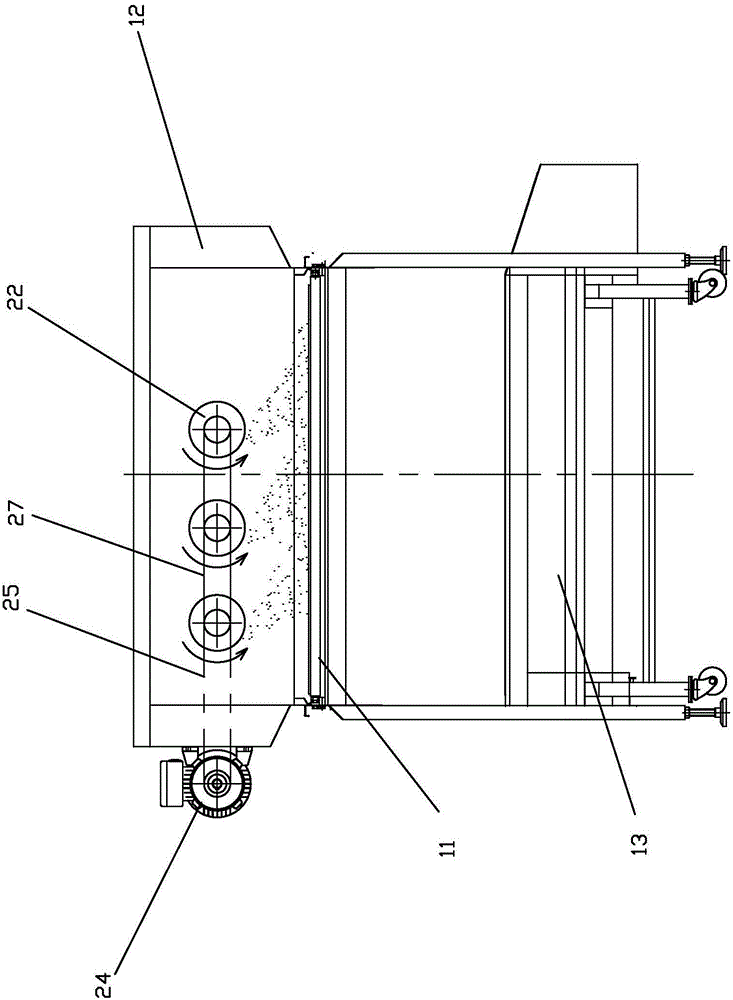

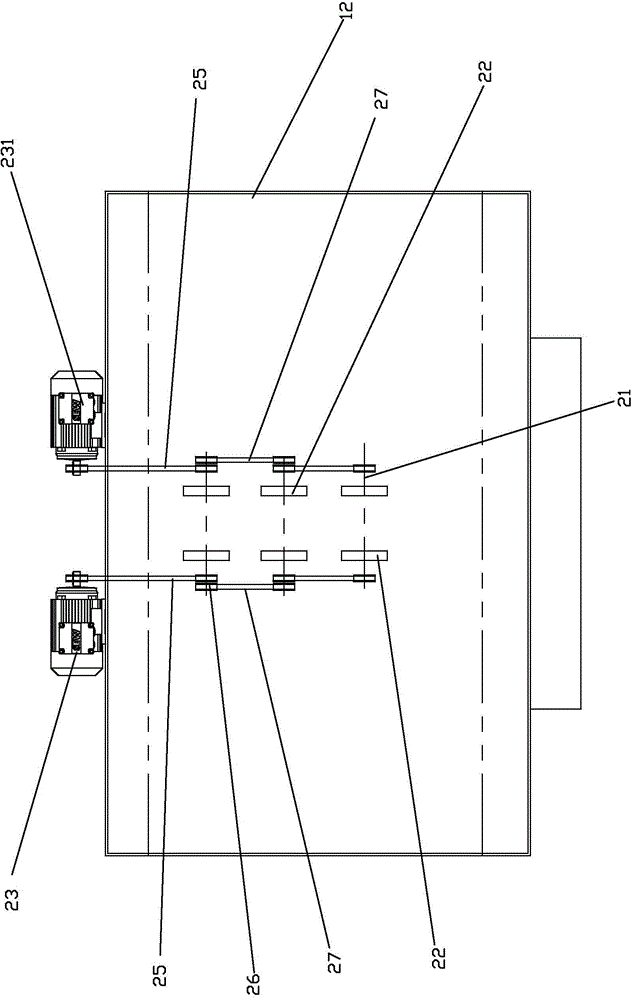

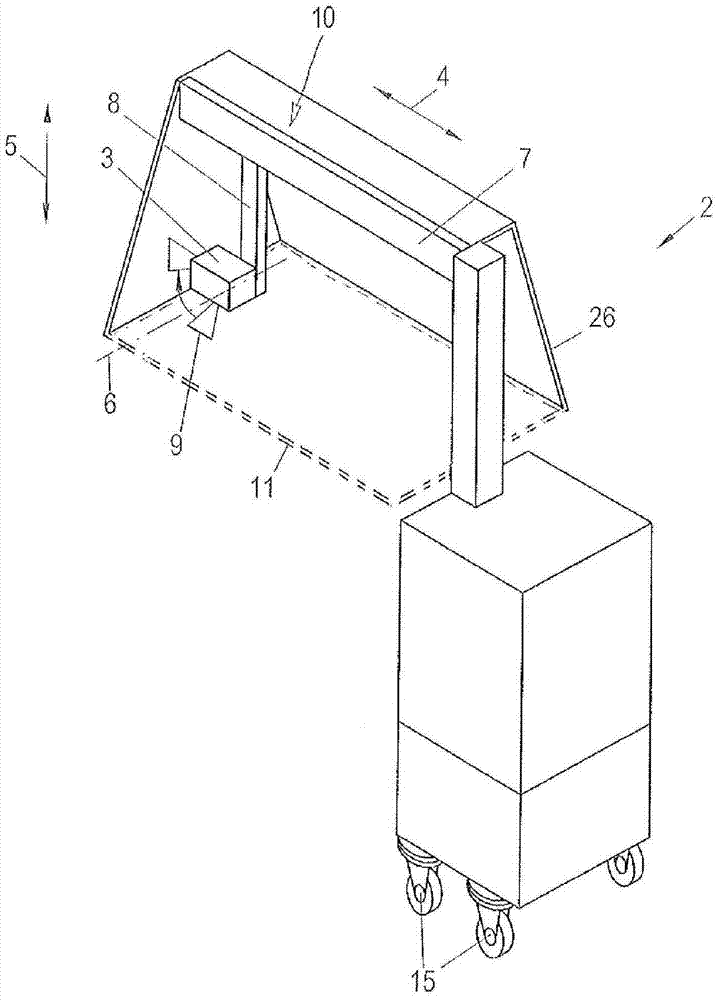

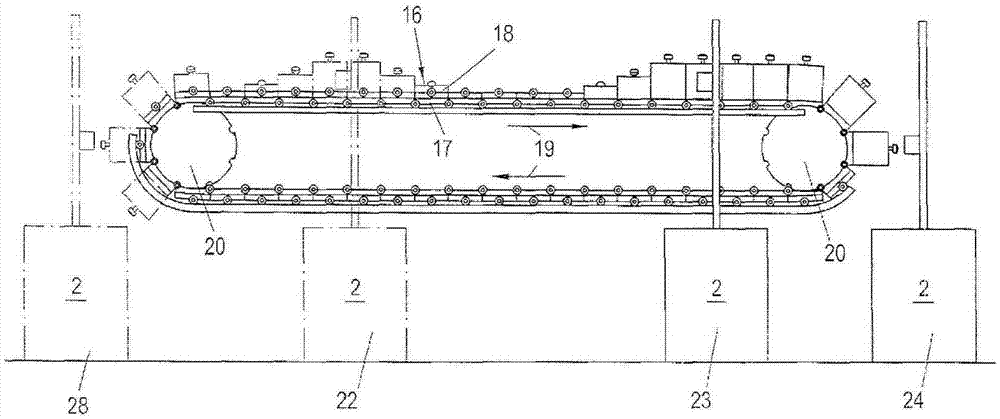

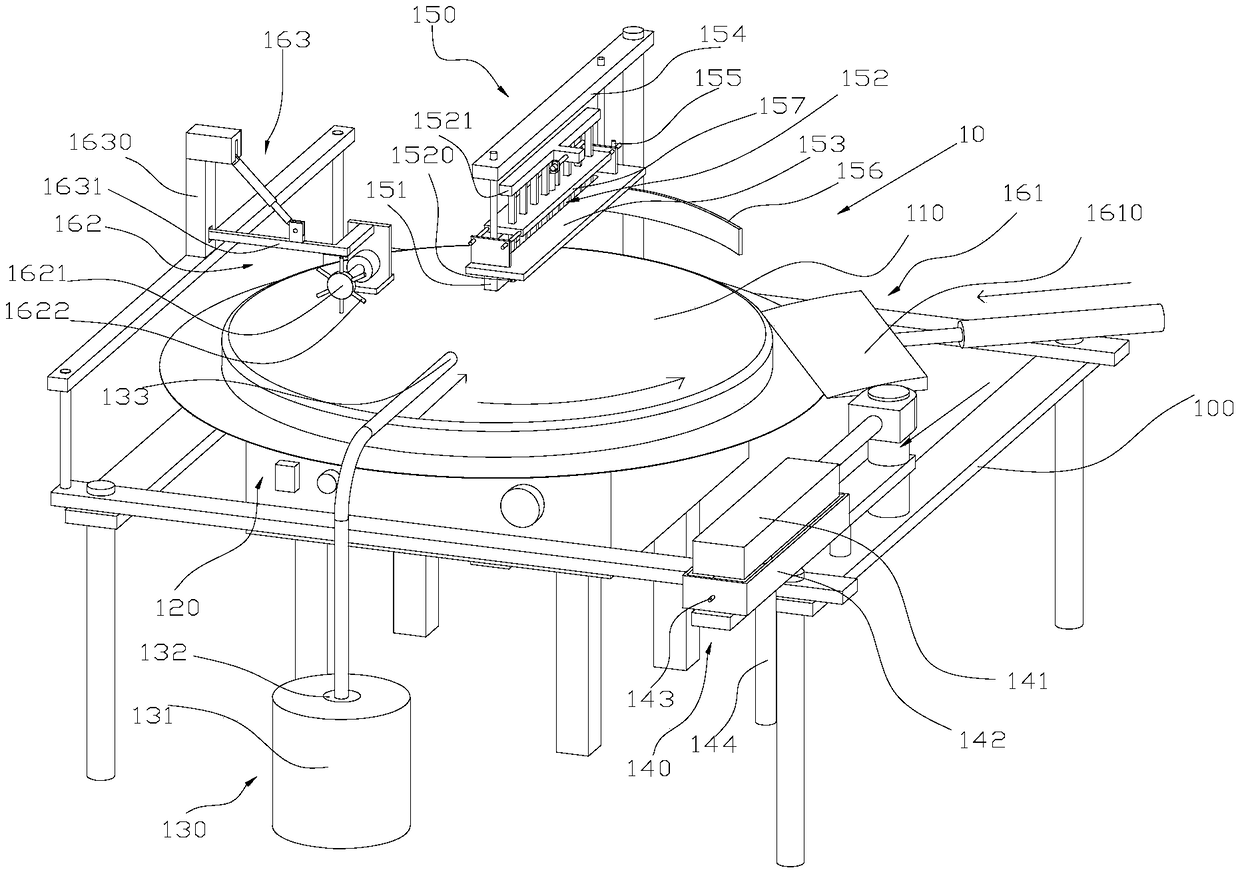

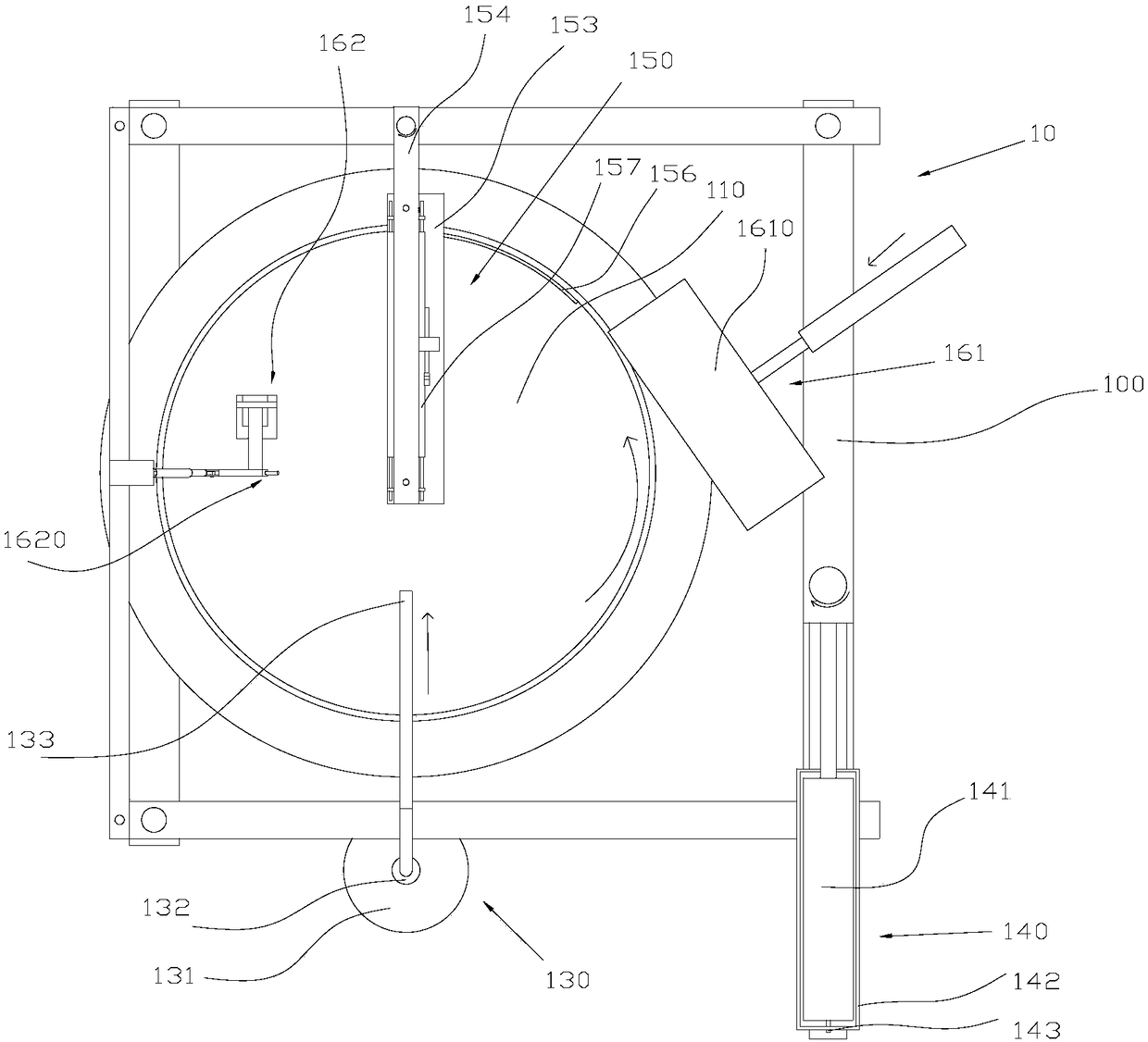

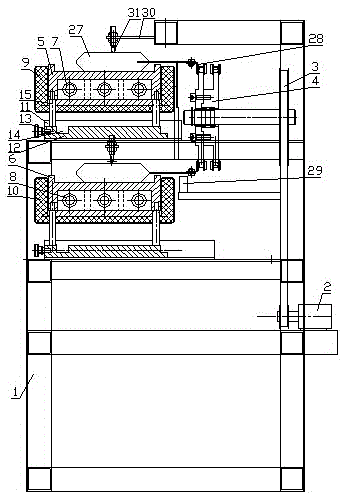

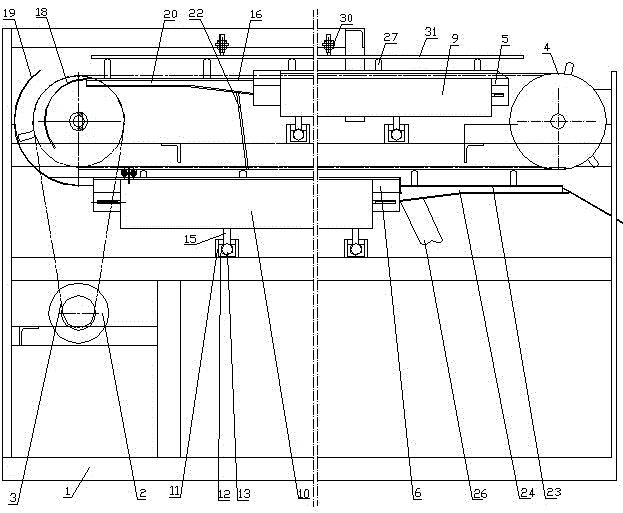

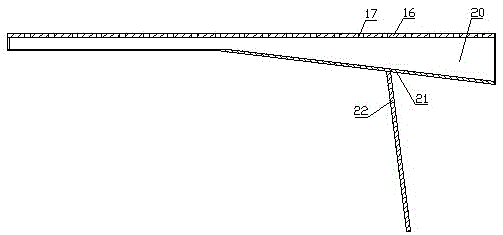

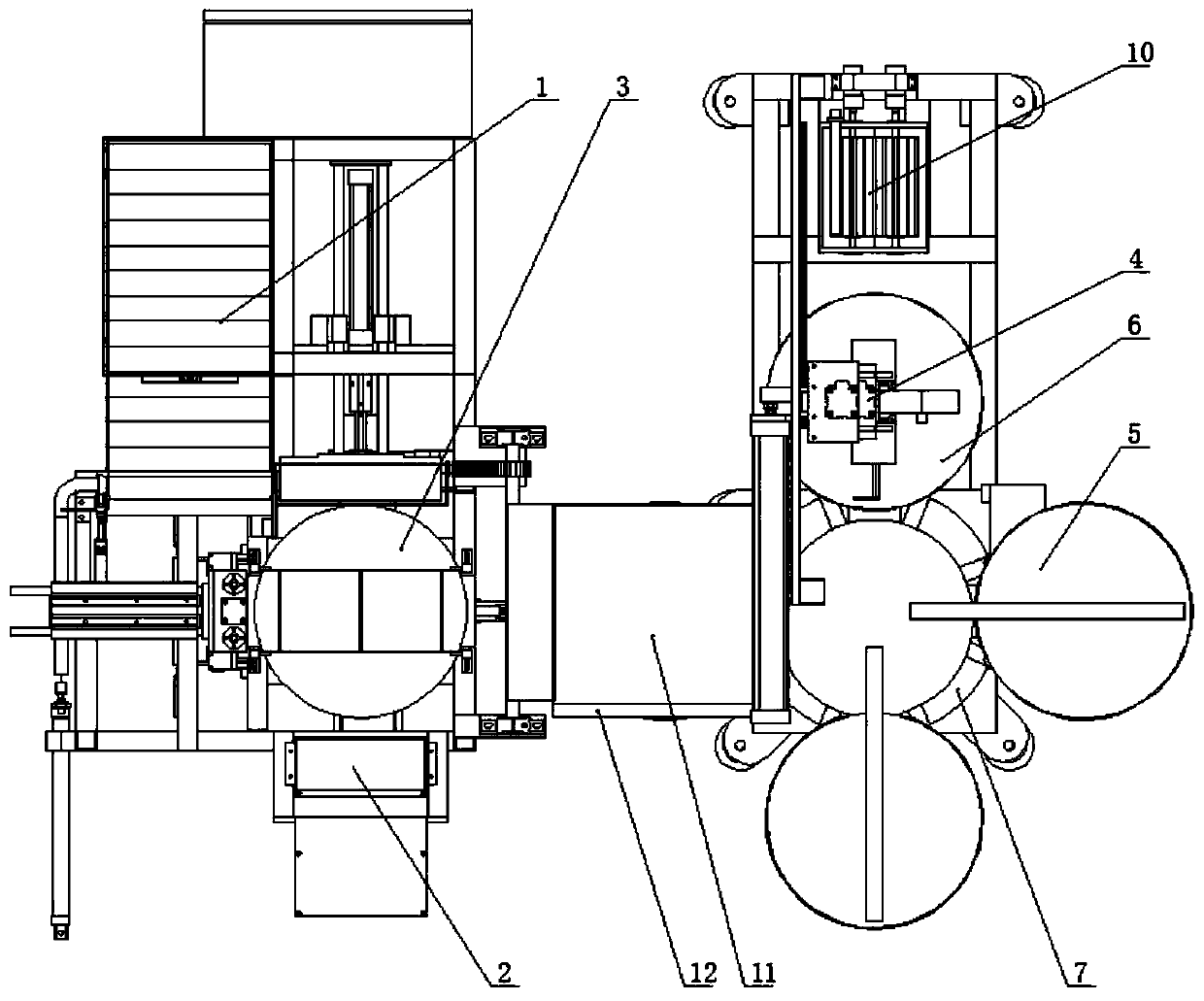

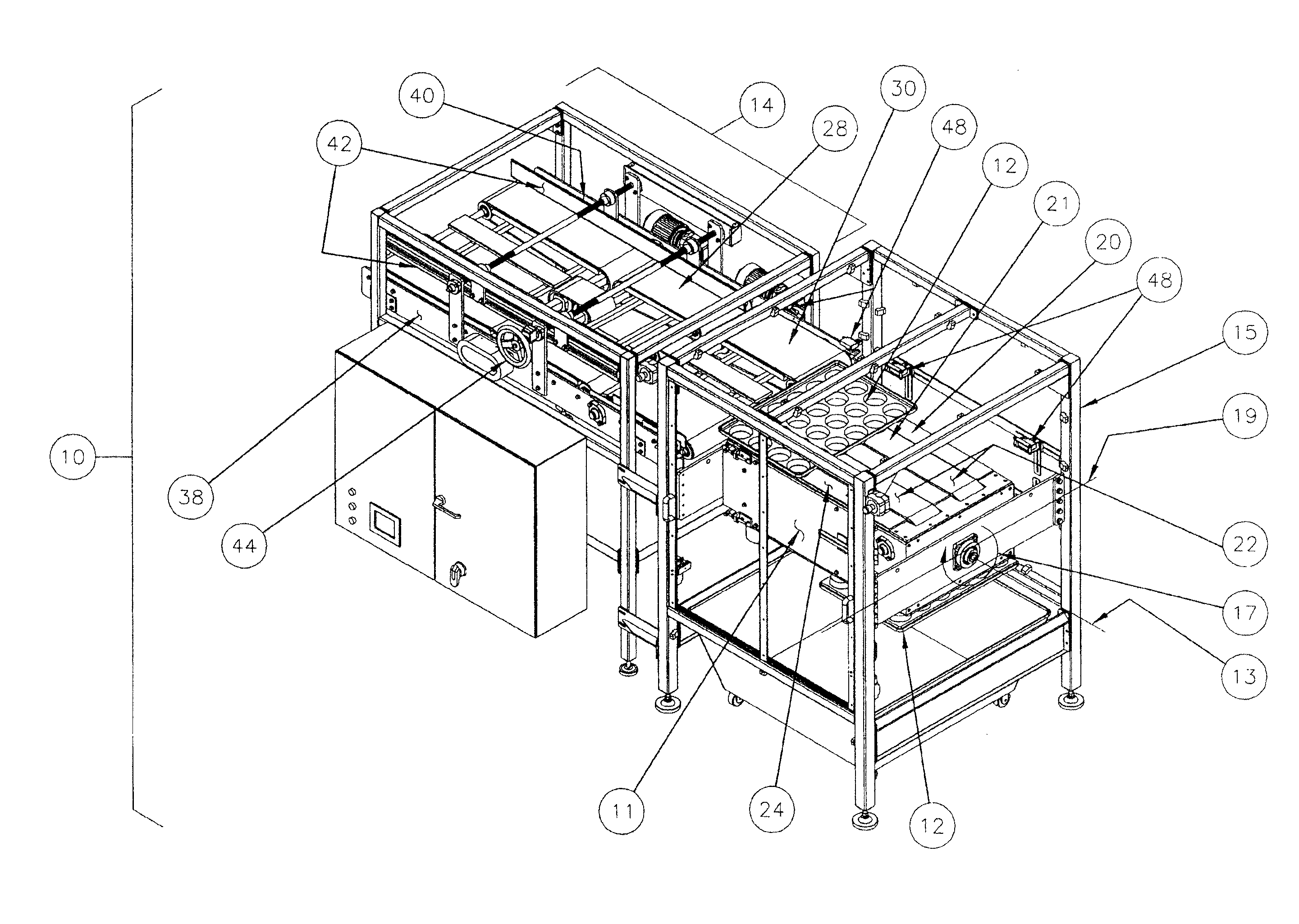

Pan inverting and/or cleaning system

ActiveUS20100094454A1Easy to optimizeDigital data processing detailsHollow article cleaningEngineeringAir knife

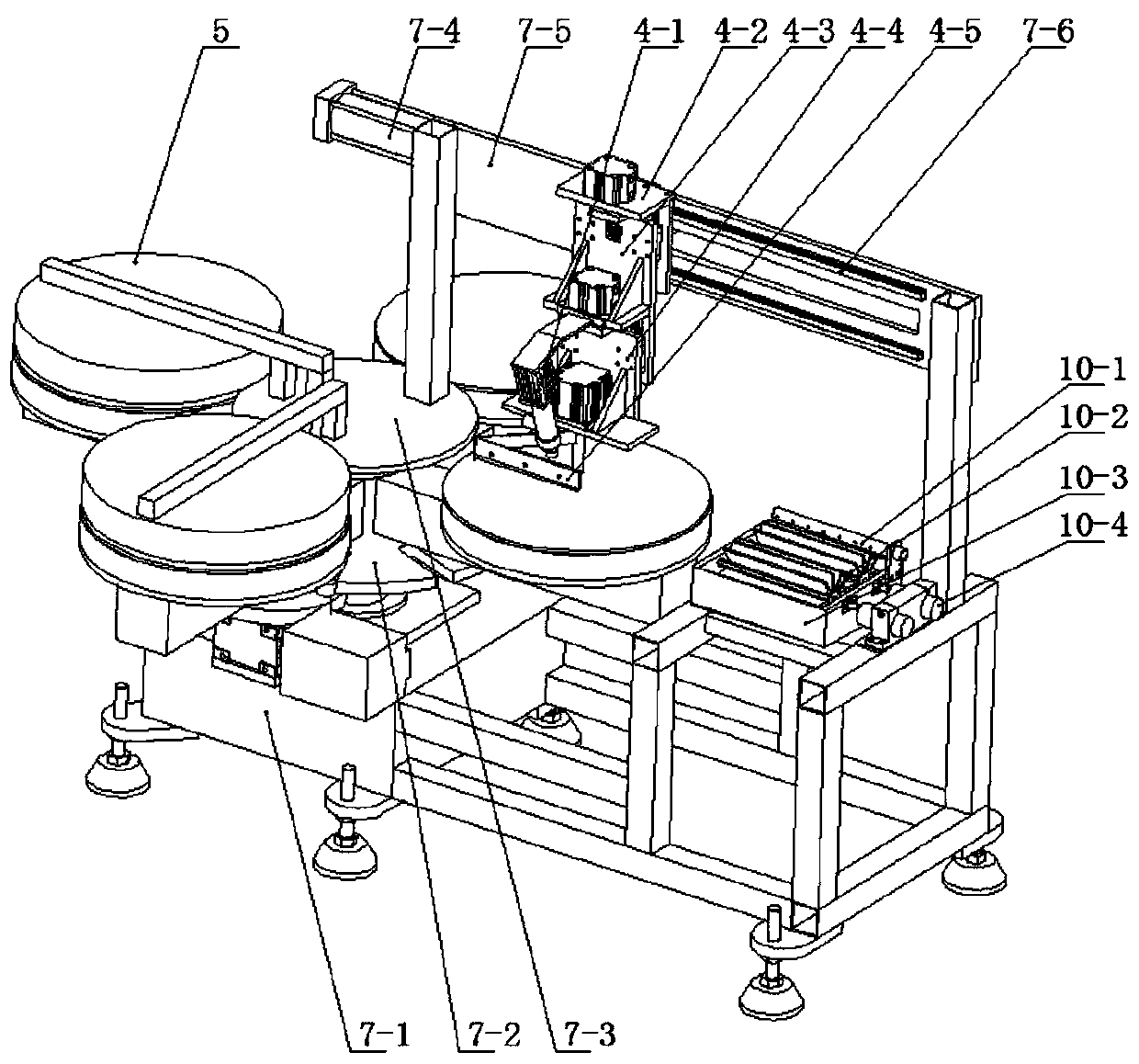

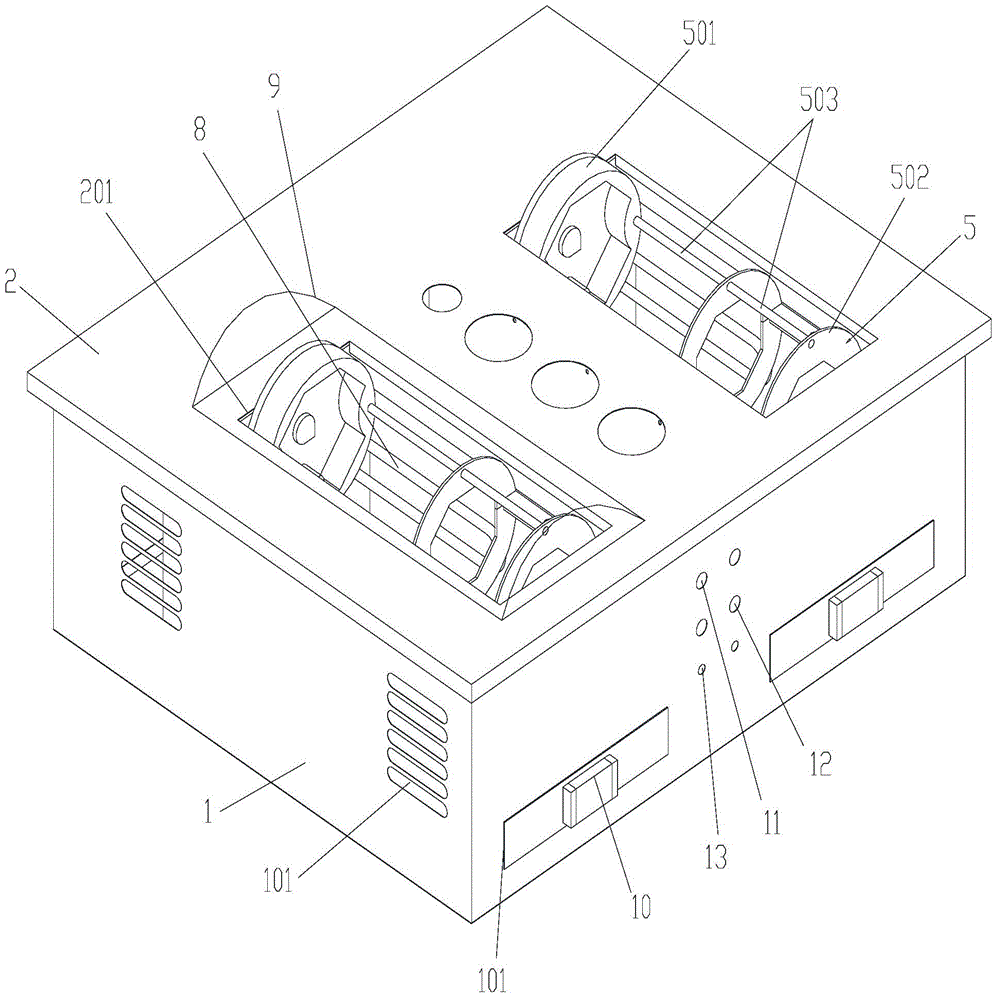

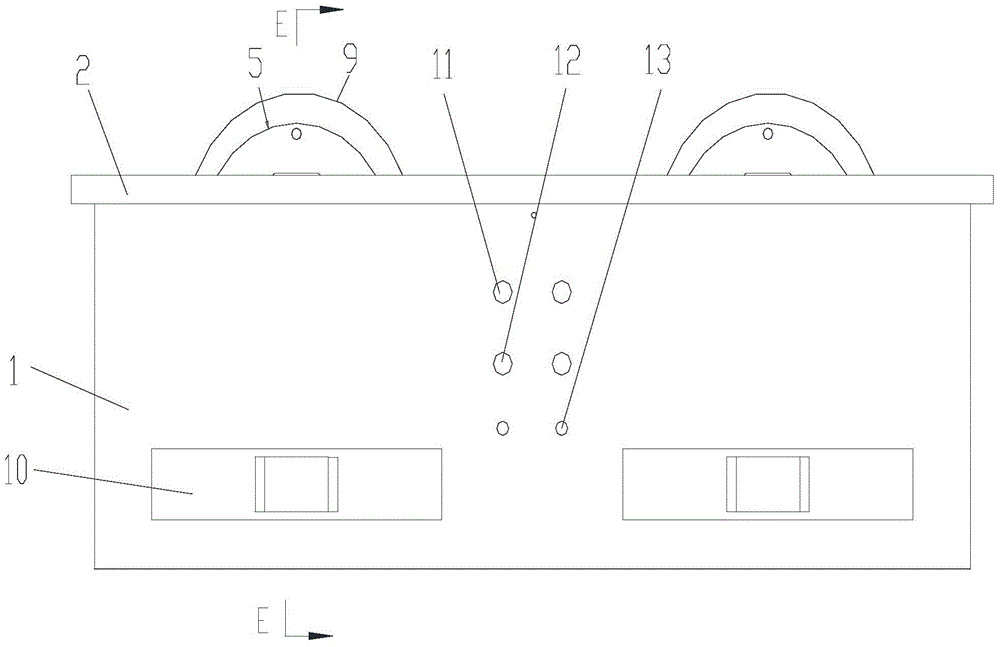

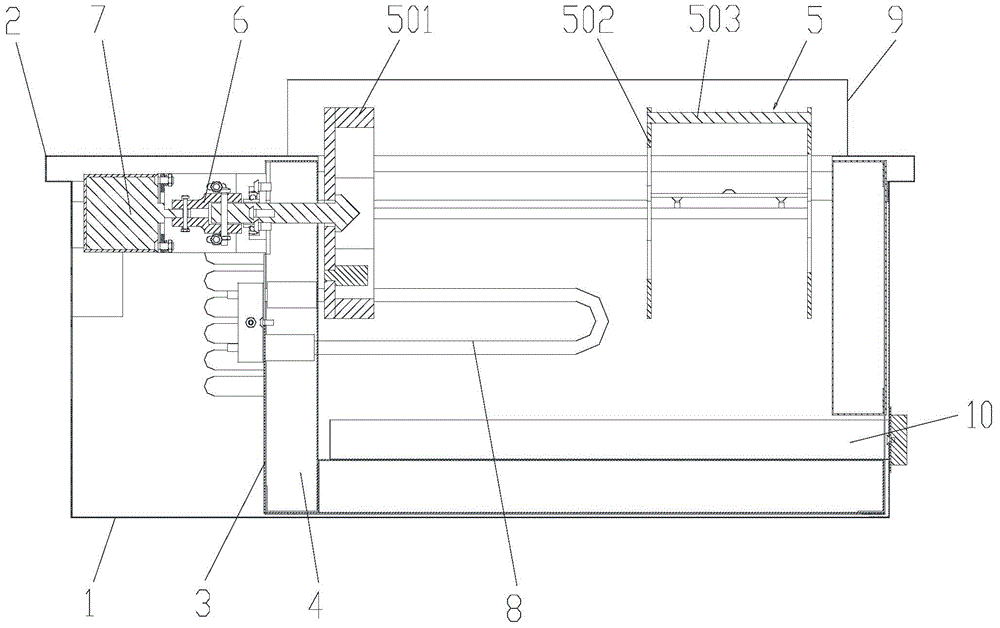

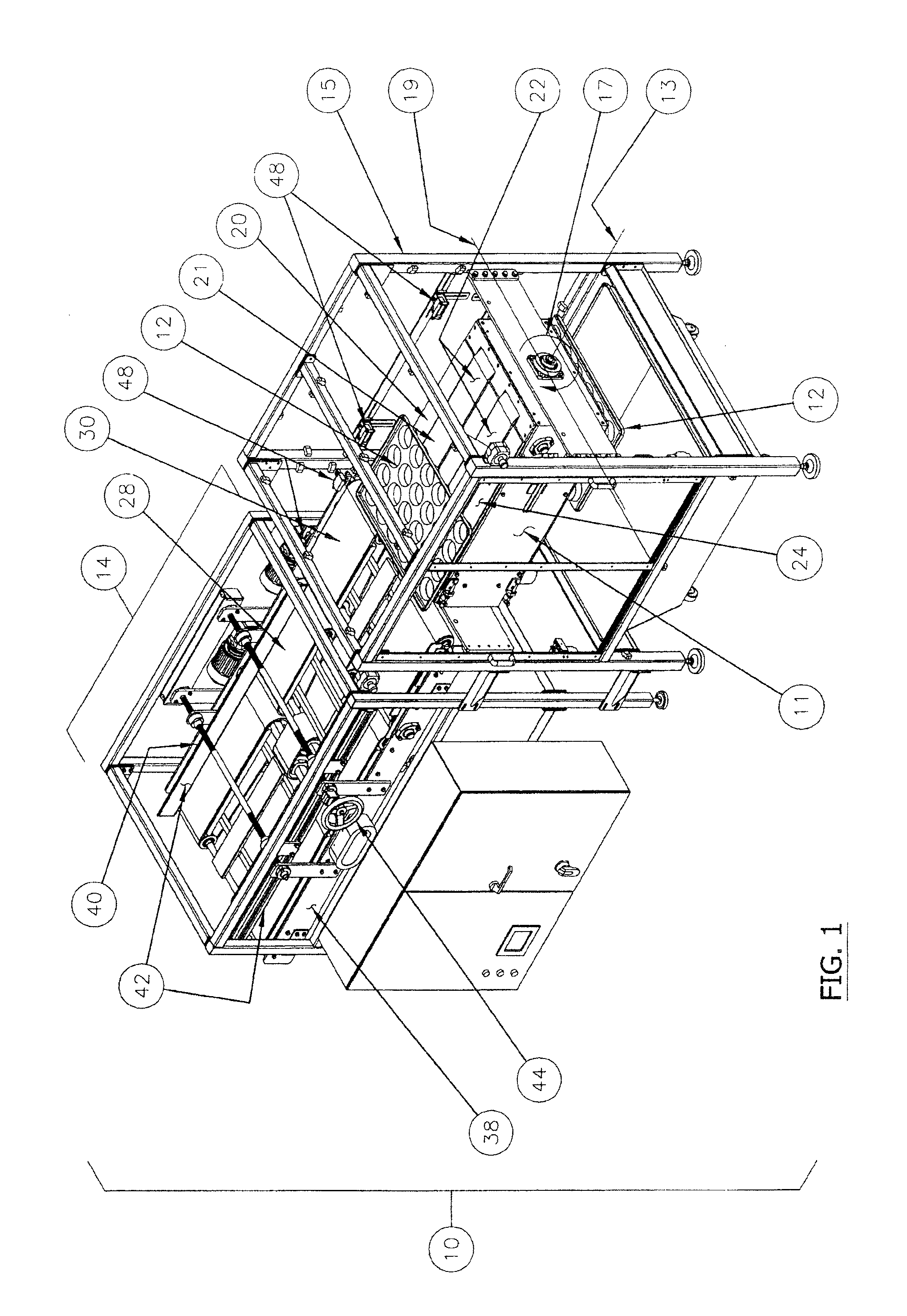

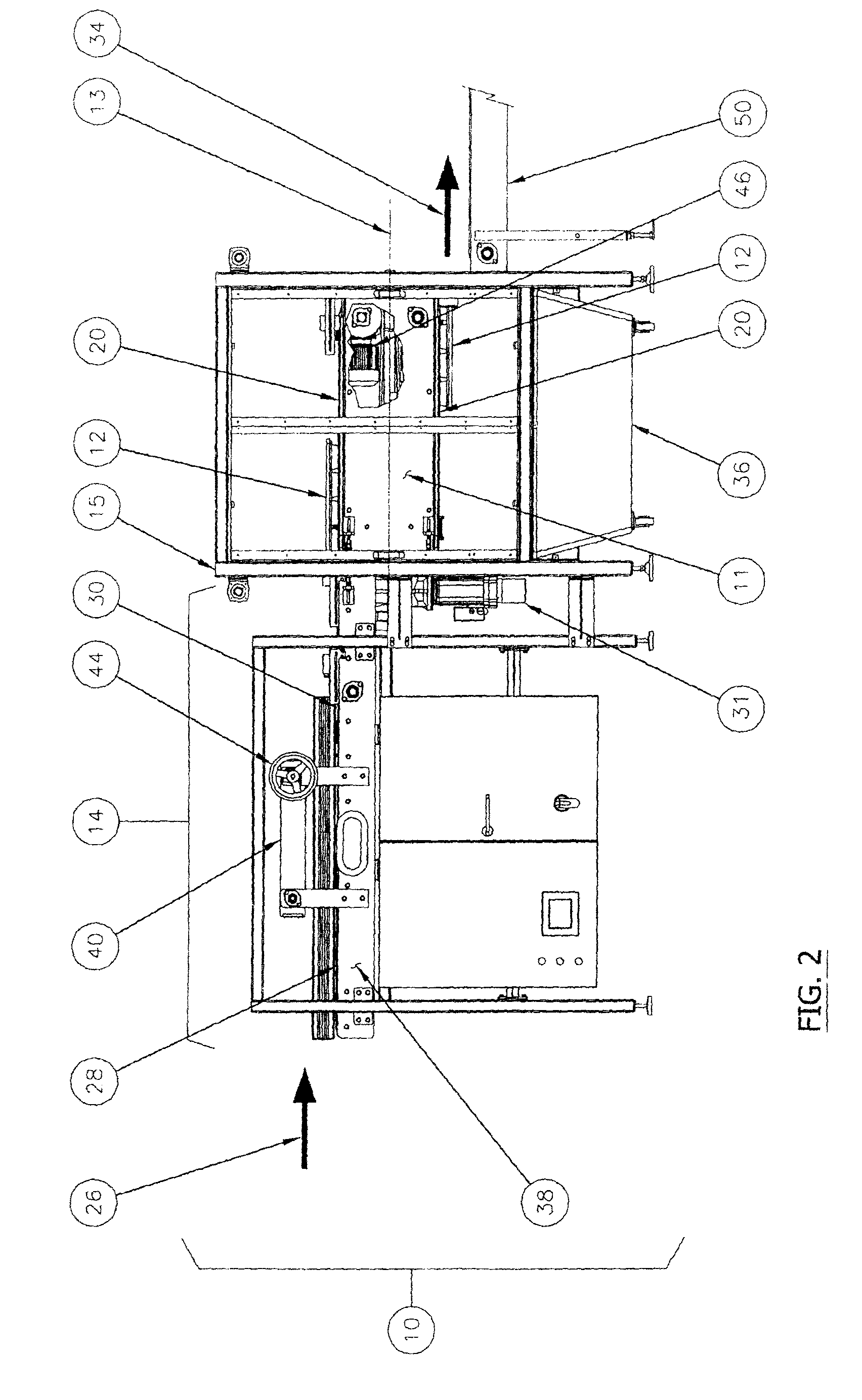

A pan inverting system (10) comprises a rotating table (11) having a central longitudinal axis (13), the table being rotatably mounted within a static frame (15) for rotation about the longitudinal axis (13). Conveyors (21) are disposed on opposed pan-receiving surfaces (20) of the table (11). The conveyors (21) are independently operable to displace a pan (12) along the table (11) in a direction substantially parallel to the longitudinal axis (13). A pan engagement device (24) within the table (11) is operable to releasably fasten the pan (12) to the pan receiving surface (20) of the table (11), such that when the pan (12) is fastened to one of the pan receiving surfaces (20) by the pan engagement mechanism (24), rotation of the table (11) about the longitudinally extending axis (13) will invert the pan (12). The table (11) may also equipped with air headers (507), nozzles and / or air knives (508) to clean the pans (12), for example during the rotating operation, by injecting cleaning air jets onto the surfaces of the pan (12).

Owner:REXFAB

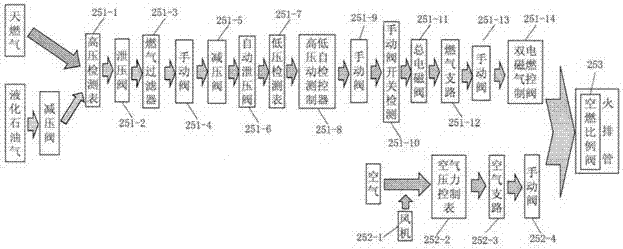

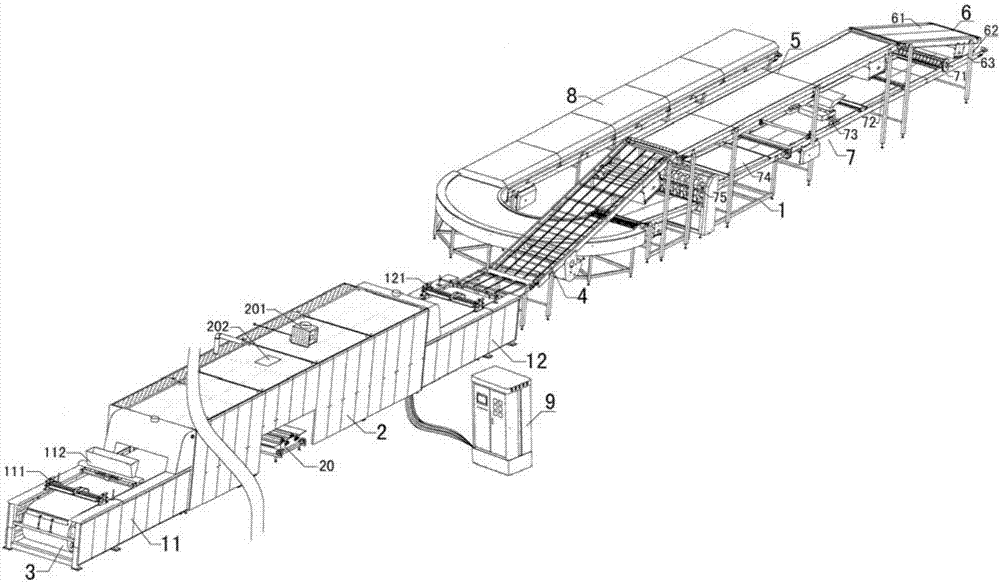

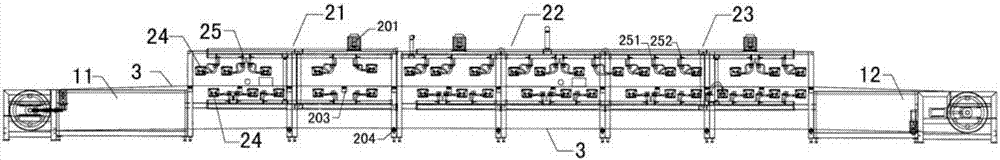

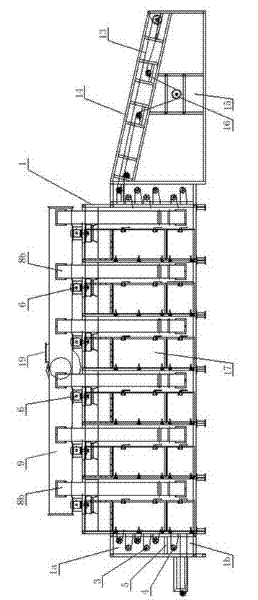

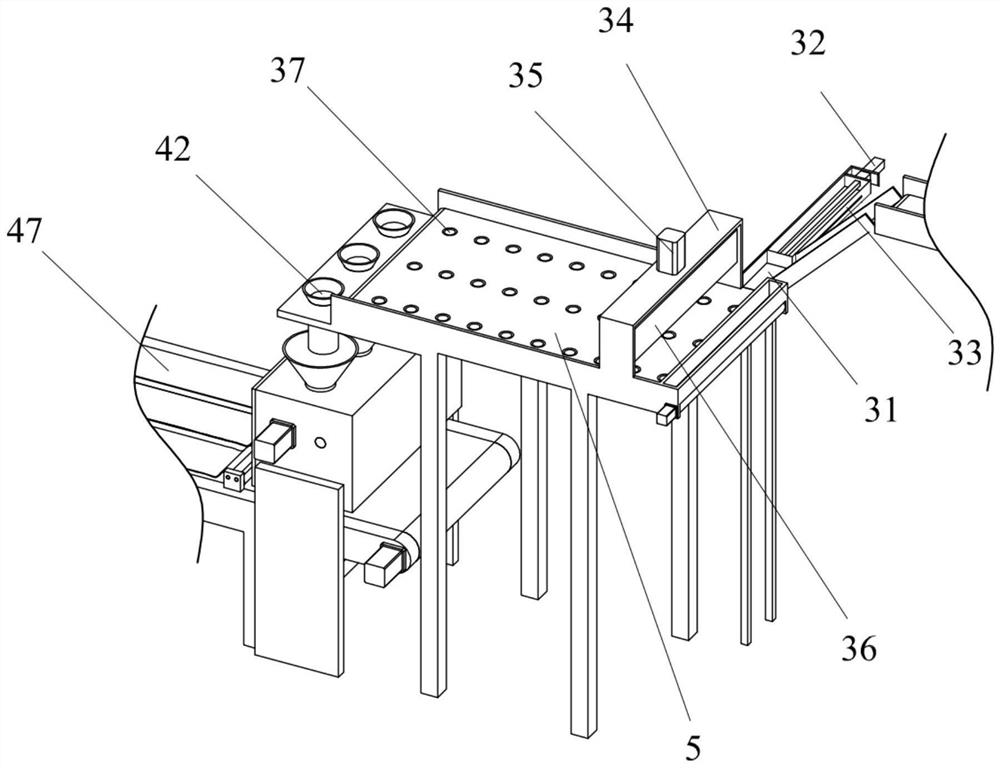

Full-automatic pocket cake baking production line and production processing method

InactiveCN107212037AGood conditionGreat tasteBaked article fillingBaking surface cleaning/greasingProgrammable logic controllerMolding machine

The invention discloses a full-automatic pocket cake baking production line and production processing method. The full-automatic pocket cake baking production line comprises a furnace inlet platform, a furnace outlet platform, a tunnel oven, a steel belt, a net chain conveying belt, a cooling transmission belt, a turning and rolling mechanism, a sandwich forming mechanism, a sterilization mechanism, a frame and a PLC (programmable logic controller) control box, the cooling transmission belt and the sandwich forming mechanism are arranged on the upper layer and the lower layer of the frame, the turning and rolling mechanism is connected with the cooling transmission belt and the sandwich forming mechanism, the tunnel oven is provided with a preheating area, a baking coloring area and a moisture control area, so that baking quality is controlled, a first pneumatic oil spray machine, a grouting machine, a second pneumatic oil spray machine, an automatic steel belt cleaning mechanism, an arc-shaped turning plate, a cutting slitting machine, a turnover mechanism, a paste machine, a laminating mechanism, a continuous forming separation mechanism and the sterilization mechanism are sequentially arranged on the production line, the PLC control box is connected with devices of the production line in a controlled manner, and intelligent control is achieved.

Owner:福建省亿焙机械有限公司

Food folding equipment

ActiveCN108925596AImprove efficiencyImprove folding efficiencyConveyorsBaked articles handlingAssembly lineEngineering

The invention discloses food folding equipment. The food folding equipment comprises a cake transporting unit for transporting cakes and a cake folding unit for folding the cakes. Through adoption ofthe food folding equipment provided by the invention, the automation degree of the processing of the cakes is increased, the product quality is improved, and the processing and making cost of the products is reduced; and the food folding equipment is particularly suitable for assembly lines and large-scale production, and has favorable application prospect.

Owner:泾县集知佳工业设计有限公司

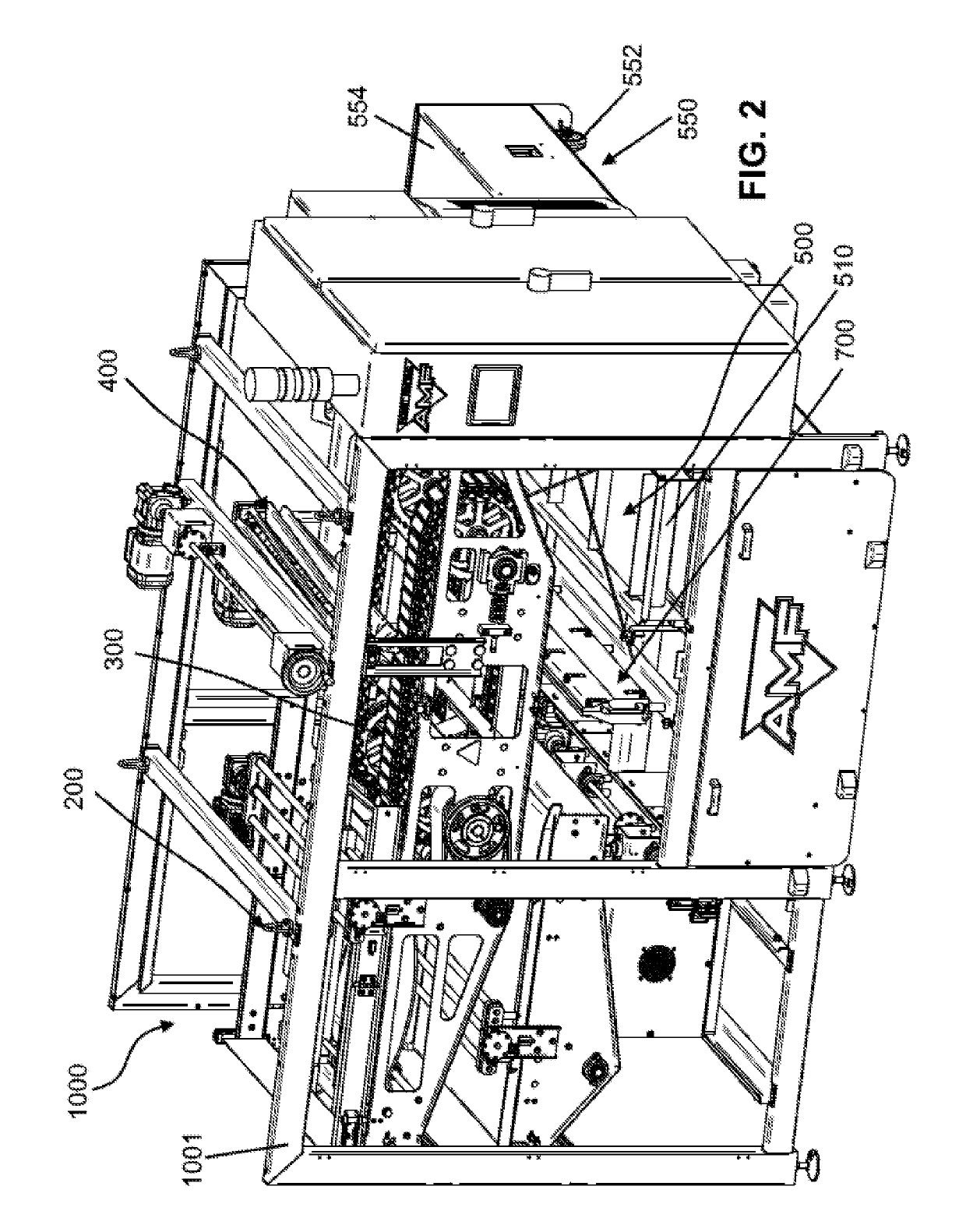

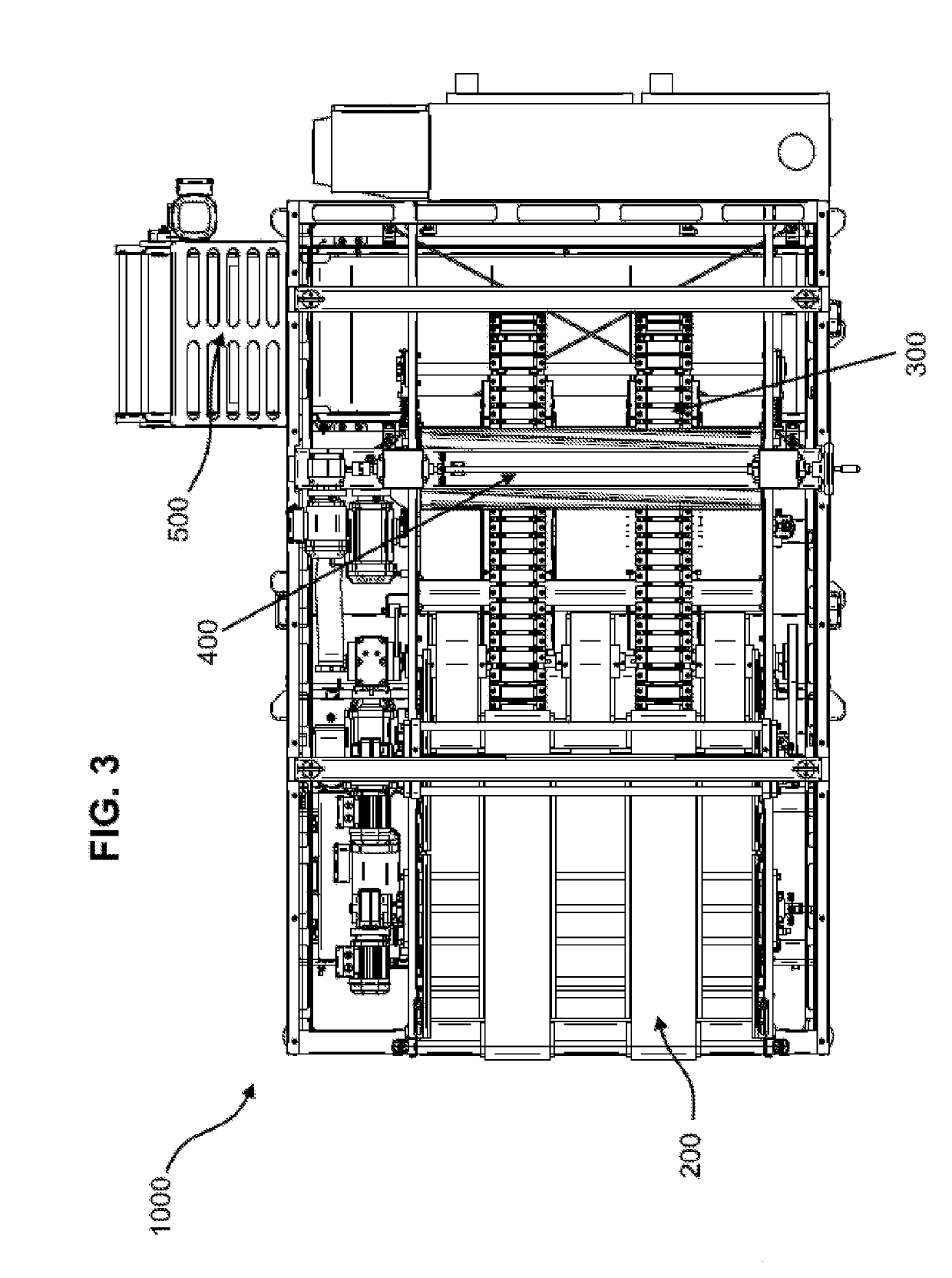

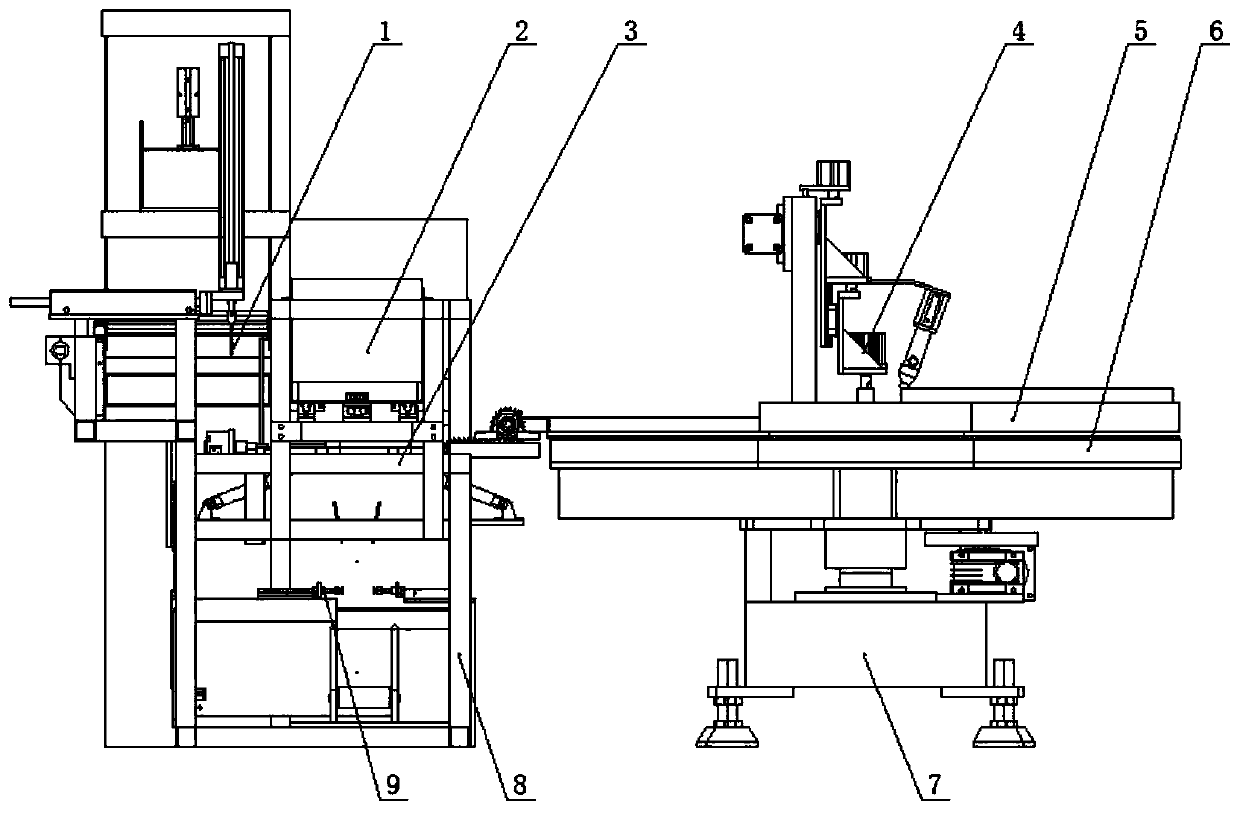

Pan Cleaner System and Method

ActiveUS20190090718A1Less cleaningReduce delaysConveyorsWashing processesWaste managementProcess engineering

The present invention relates to a pan cleaner system. The pan cleaner system comprises a main frame adapted to house a supply system, an inverting system and a cleaning system. The supply system, the inverting system and the cleaning system are configured to form a synchronized continuous functional line beginning by the supply system receiving a pan to be cleaned and ending by the cleaning system releasing a clean pan. The supply system comprises a first conveyor adapted to guide the pans towards the inverting and the cleaning systems. In one embodiment, the inverting system comprises a second conveyor adapted to magnetically hold the pans during the transport and the cleaning process. The pan cleaner system further comprises a releasing system adapted to release the pans from the magnetic conveyor once the cleaning process has been completed.

Owner:AMF AUTOMATION TECH CO OF CANADA

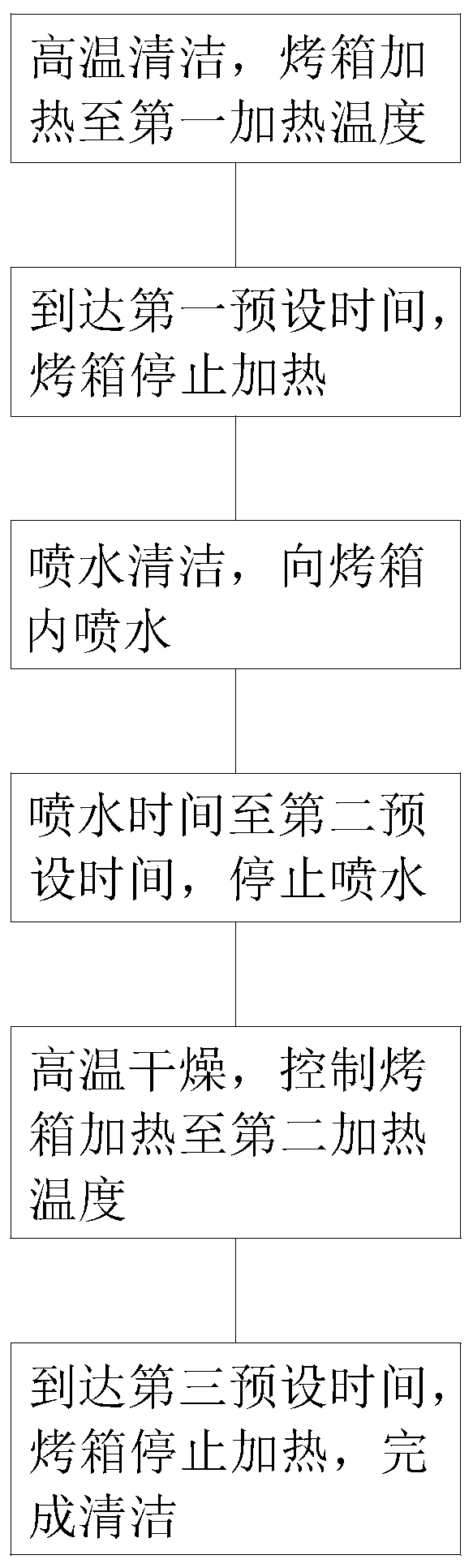

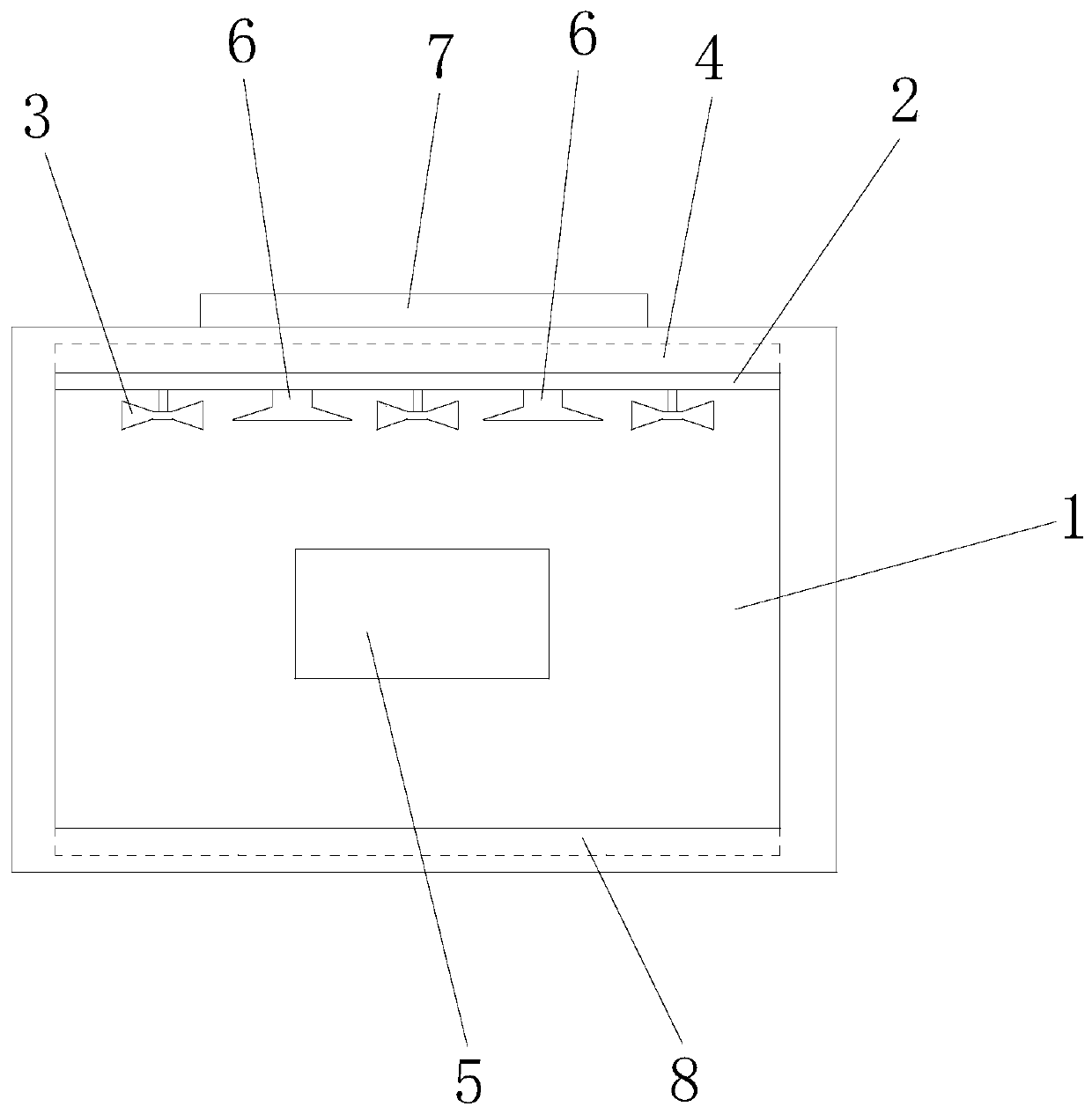

Oven self-cleaning method and oven

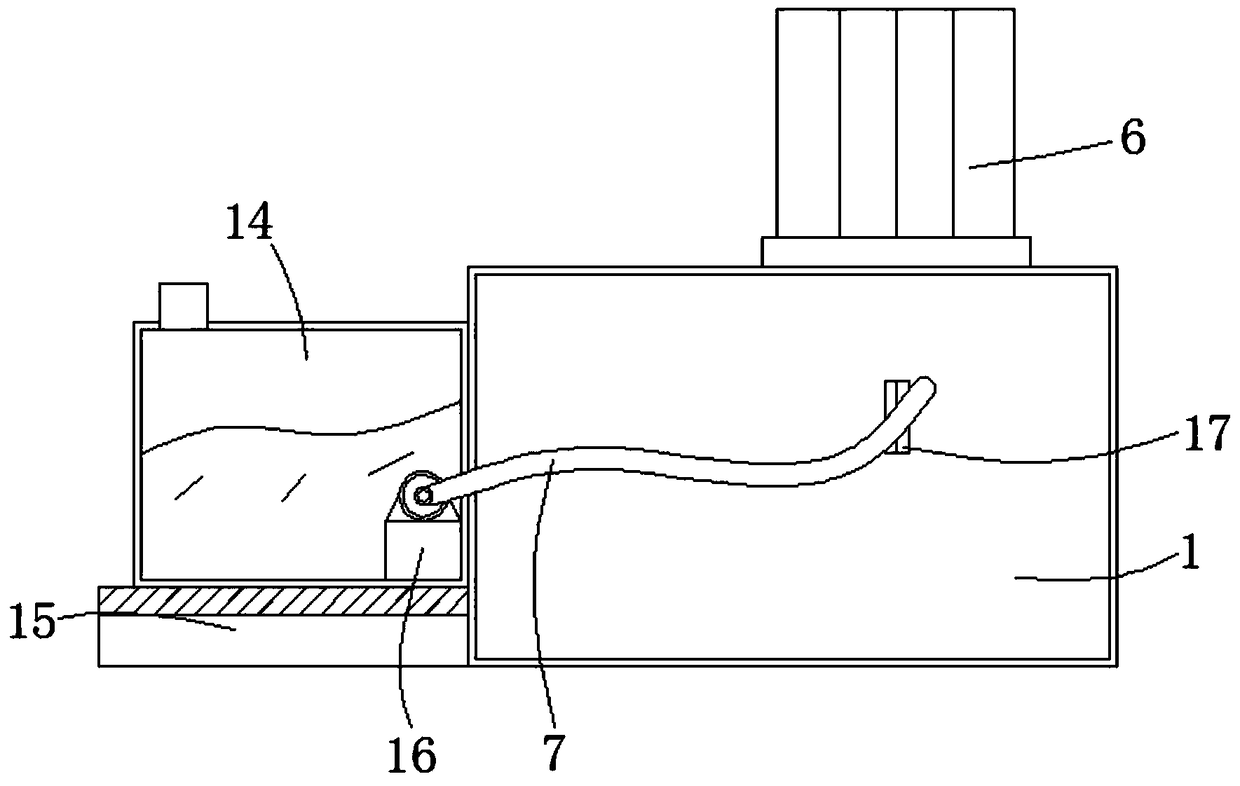

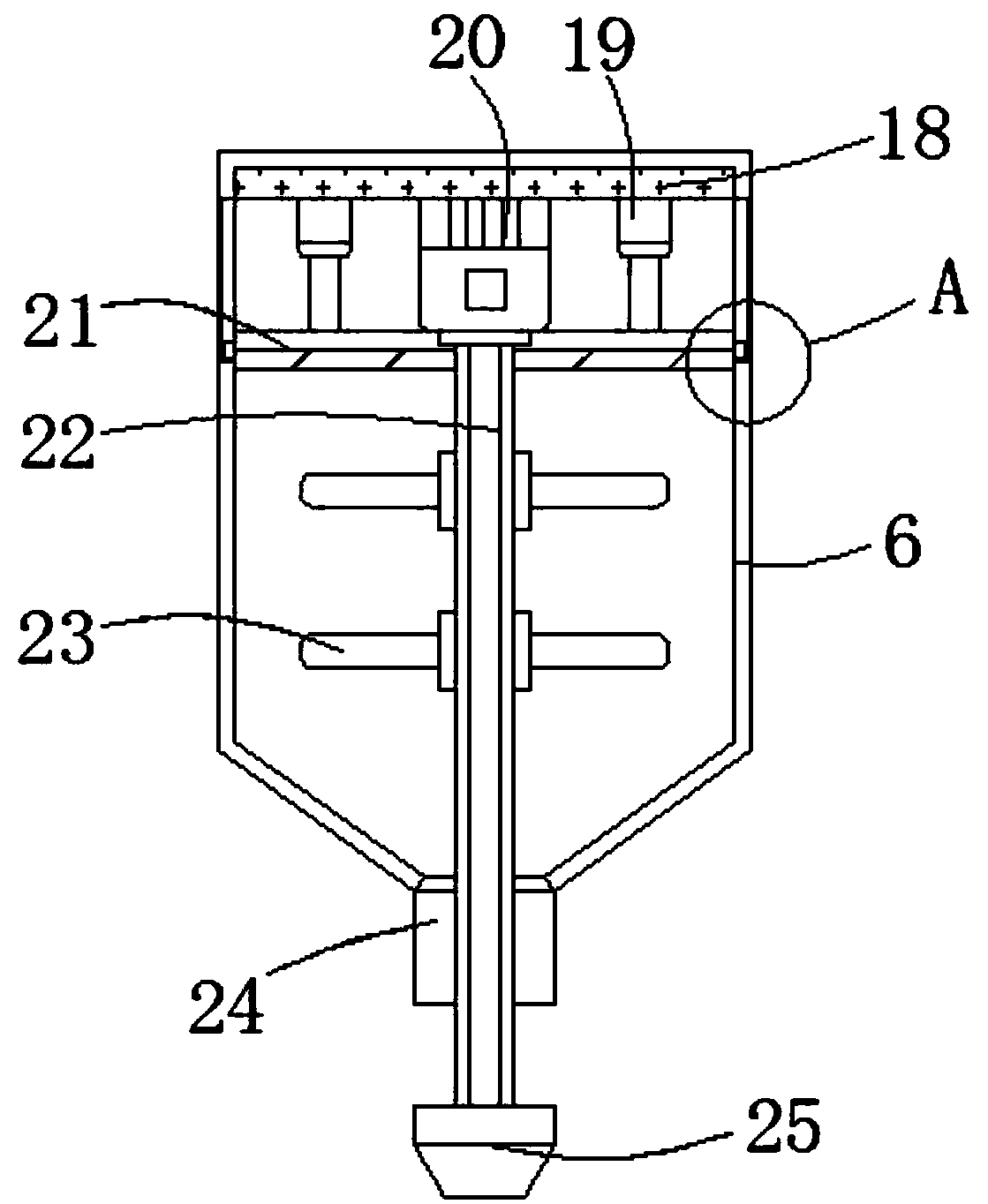

InactiveCN109699694AMaintain food hygiene and safetyImprove product experienceBaking surface cleaning/greasingSewageCleaning methods

The present invention relates to the technical field of oven equipment, in particular to an oven self-cleaning method and an oven. The method comprises: high-temperature cleaning: heating the oven toa first heating temperature, and stopping heating of the oven when reaching a first preset time; water-spray cleaning: spraying water into the oven, and stopping water spraying when the water sprayingtime reaches a second preset time; and high-temperature drying: controlling and heating the oven to a second heating temperature, and stopping heating of the oven when reaching a third preset time soas to complete cleaning. Compared with the prior art, the oven of the present invention is firstly subjected to the high-temperature cleaning so as to carbonize stains attached to the oven into ash,and then is subjected to the water-spray cleaning so as to clean the carbon ash on the inner wall of the oven. After the sewage in the oven is treated, the oven is dried to avoid water stain residuesin the oven and a problem of bacterium breeding due to long-time vacancy, and to maintain the user's food hygiene and safety. Besides, the oven cleaning method of the invention is convenient to operate, saves time and labor, has good cleaning effect, and improves the product experience of the oven user.

Owner:GREE ELECTRIC APPLIANCES INC

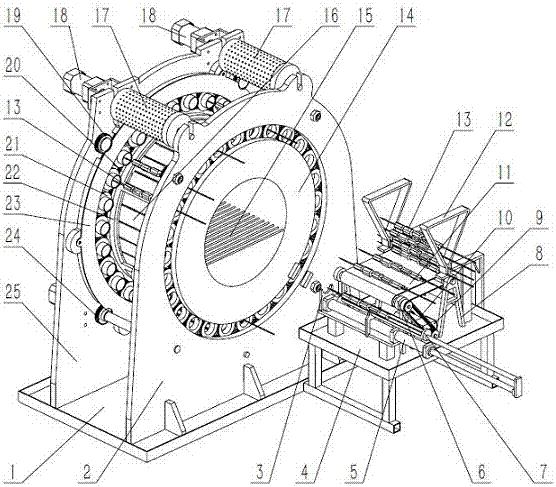

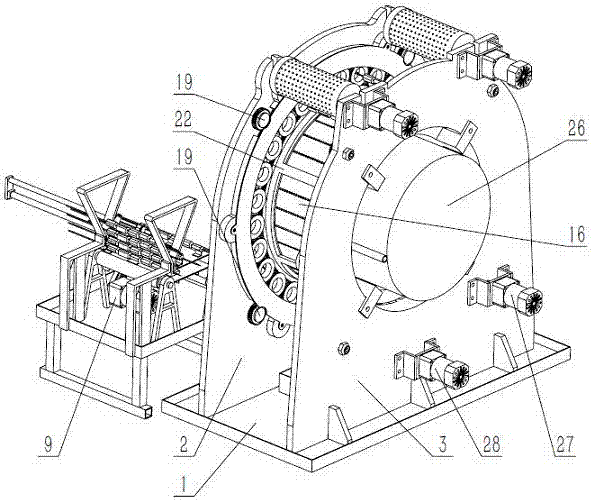

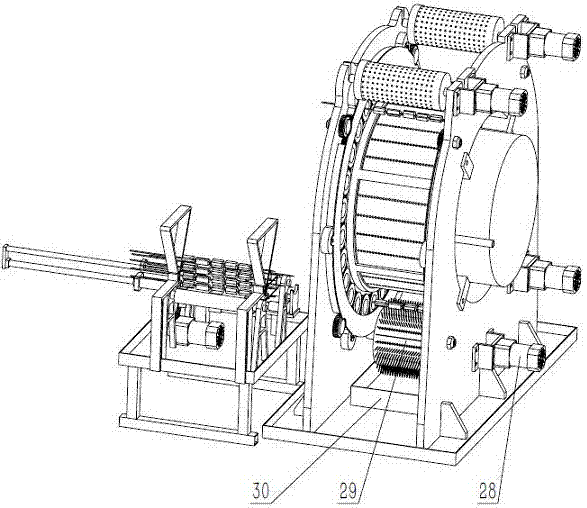

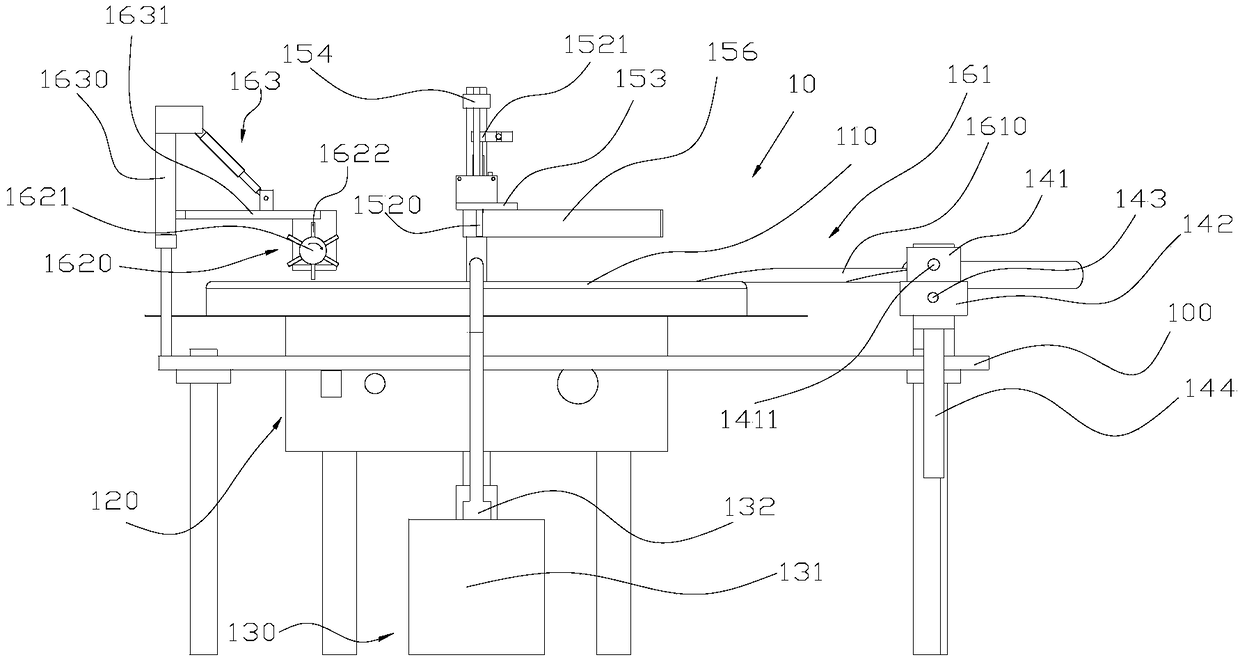

Automated kebab barbecue processing equipment

ActiveCN106879655ARealize automatic revolutionEvenly heatedBaking surface cleaning/greasingCharging/discharging ovensGear wheelAdditive ingredient

The invention discloses automated kebab barbecue processing equipment. The purpose of automatic 360-degree overturning of kebab is finally achieved by arranging a big gear ring, a small gear ring and small gears evenly arranged between the big gear ring and the small gear ring, and by driving the small gears to revolve around the axis of the small gear ring and meanwhile driving the small gears to rotate through the big gear ring so that the kebab can be heated evenly, and the barbecue quality is high; meanwhile the equipment is further provided with a material conveying related mechanism, automatic getting-on-equipment of the kebab can be achieved, manual operation is reduced, and not only can the barbecue processing efficiency of the kebab be improved, but also the problems of uneven barbecue processing caused by a personnel quality problem and the like are avoided to a great extent; besides, the automated kebab barbecue processing equipment is further provided with an automatic ingredient adding structure and an oil brushing device, the manual operation is reduced as well to a great extent, the manpower cost is saved, and the work efficiency is improved.

Owner:台山市冠荣金属制品有限公司

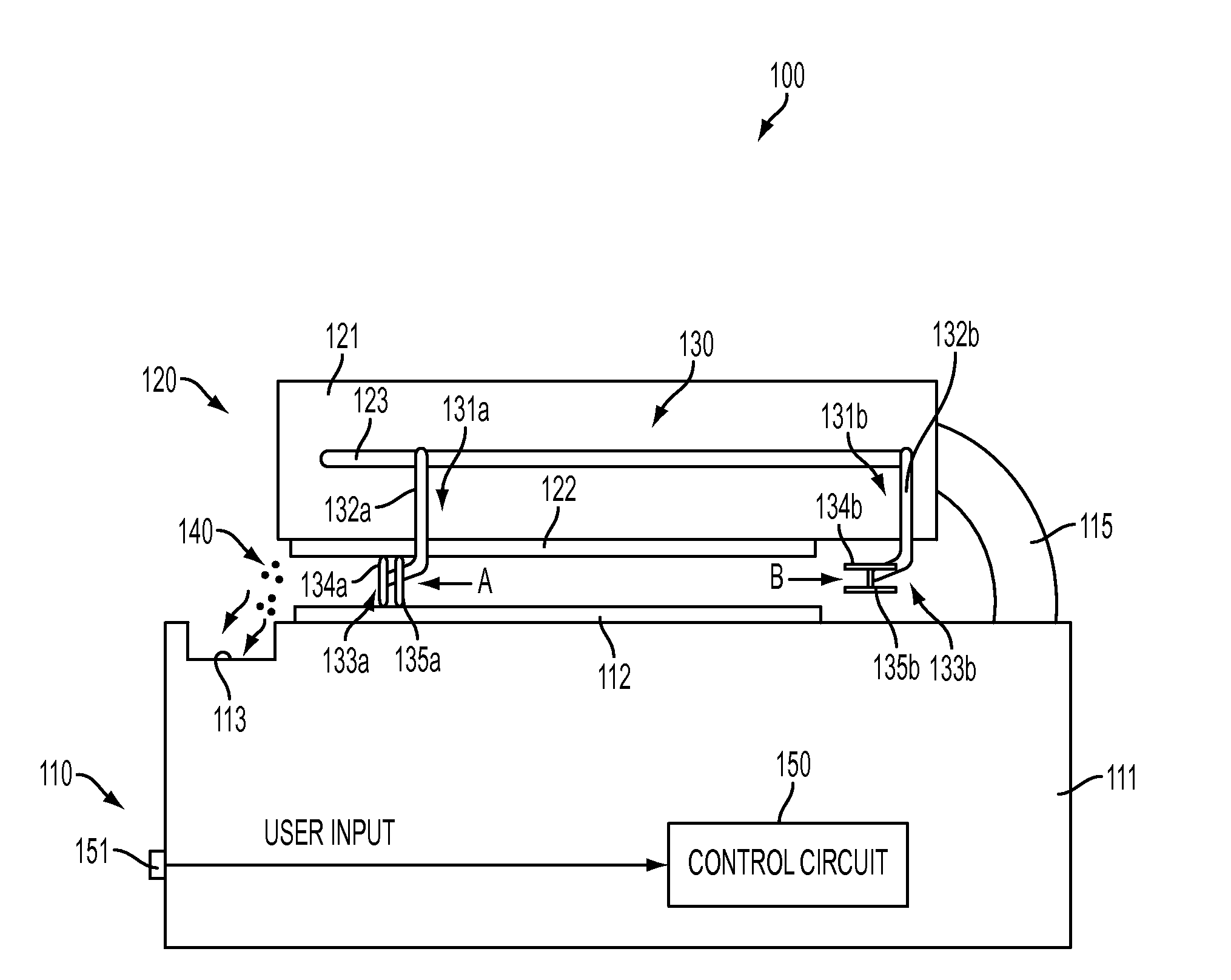

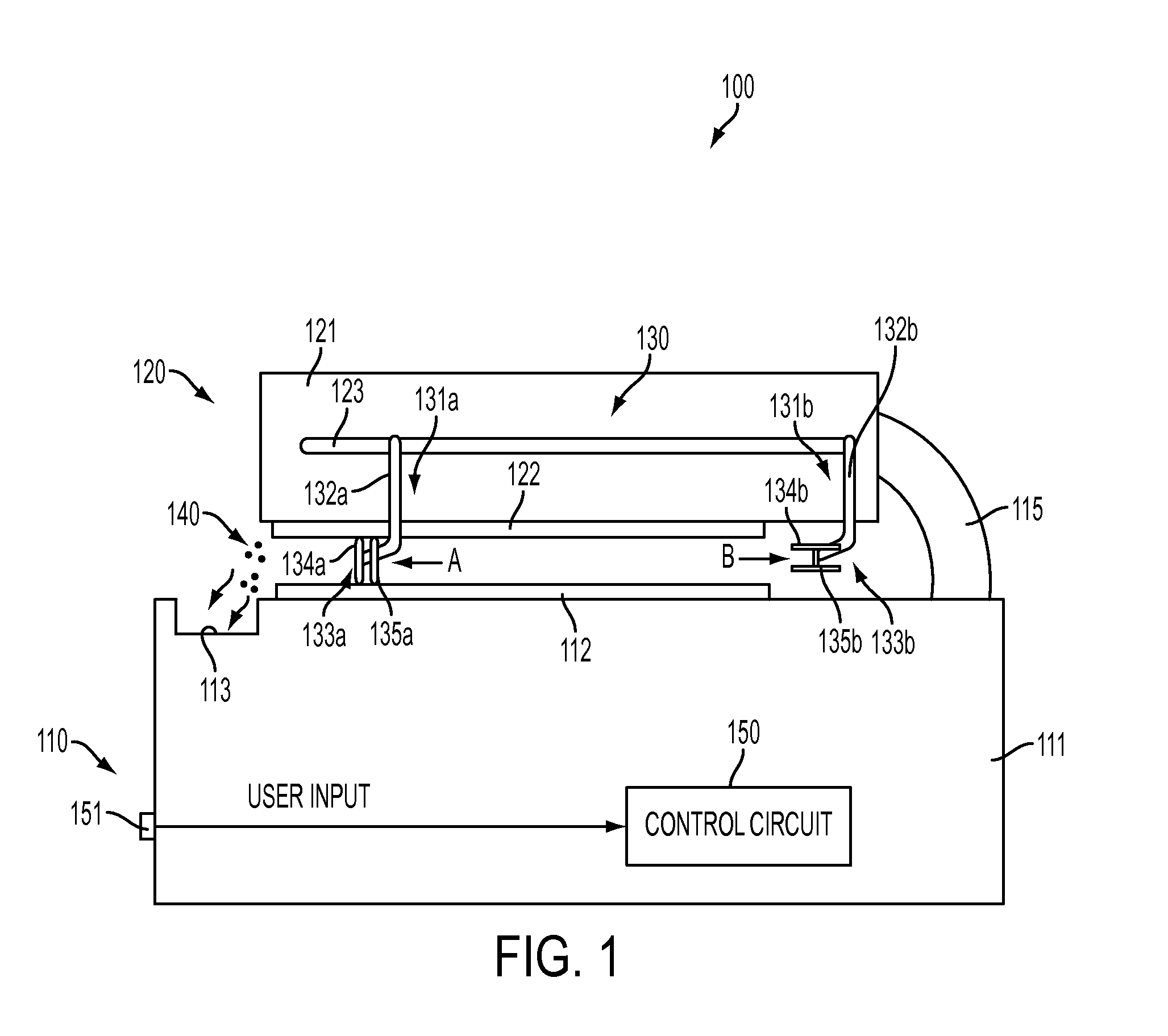

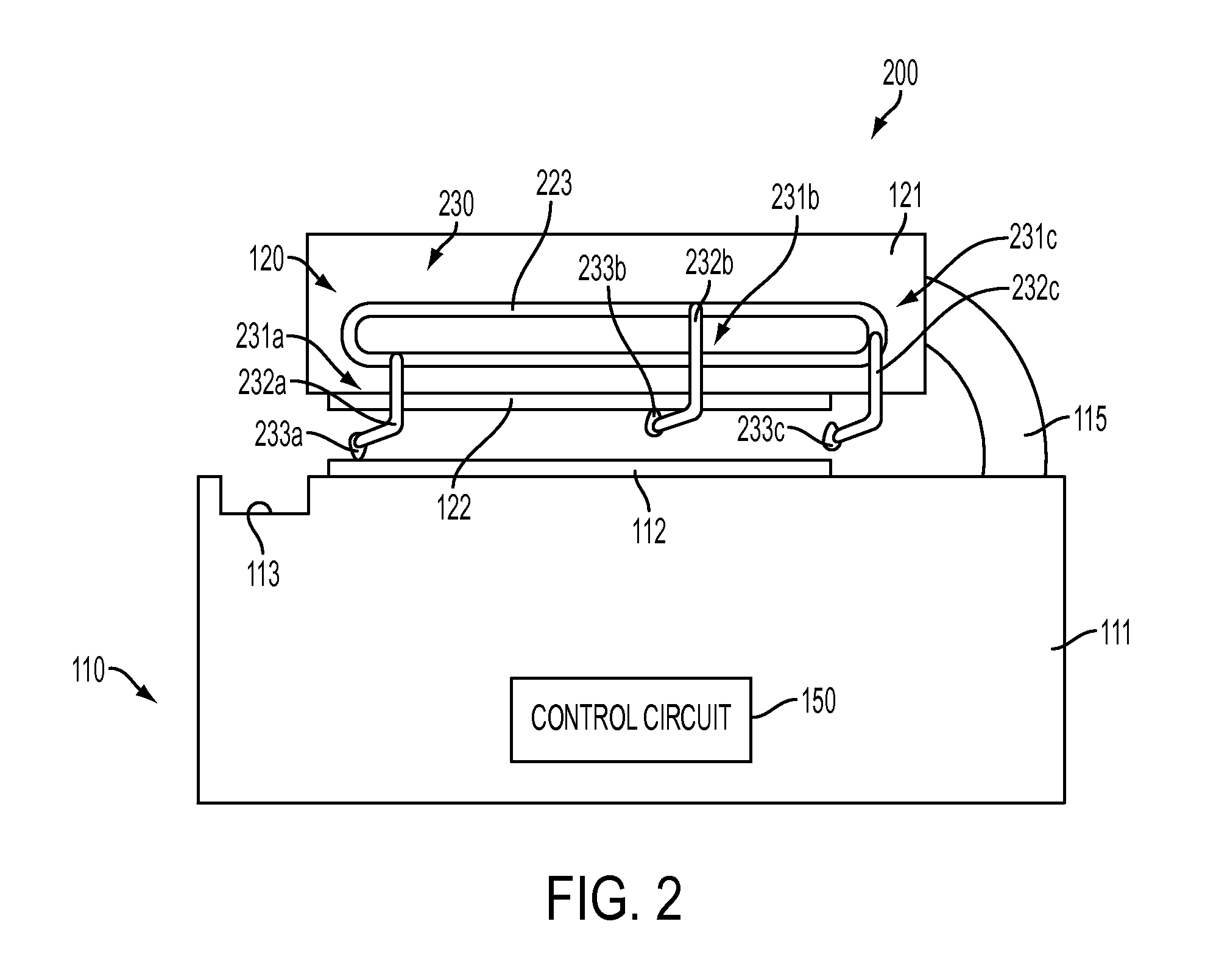

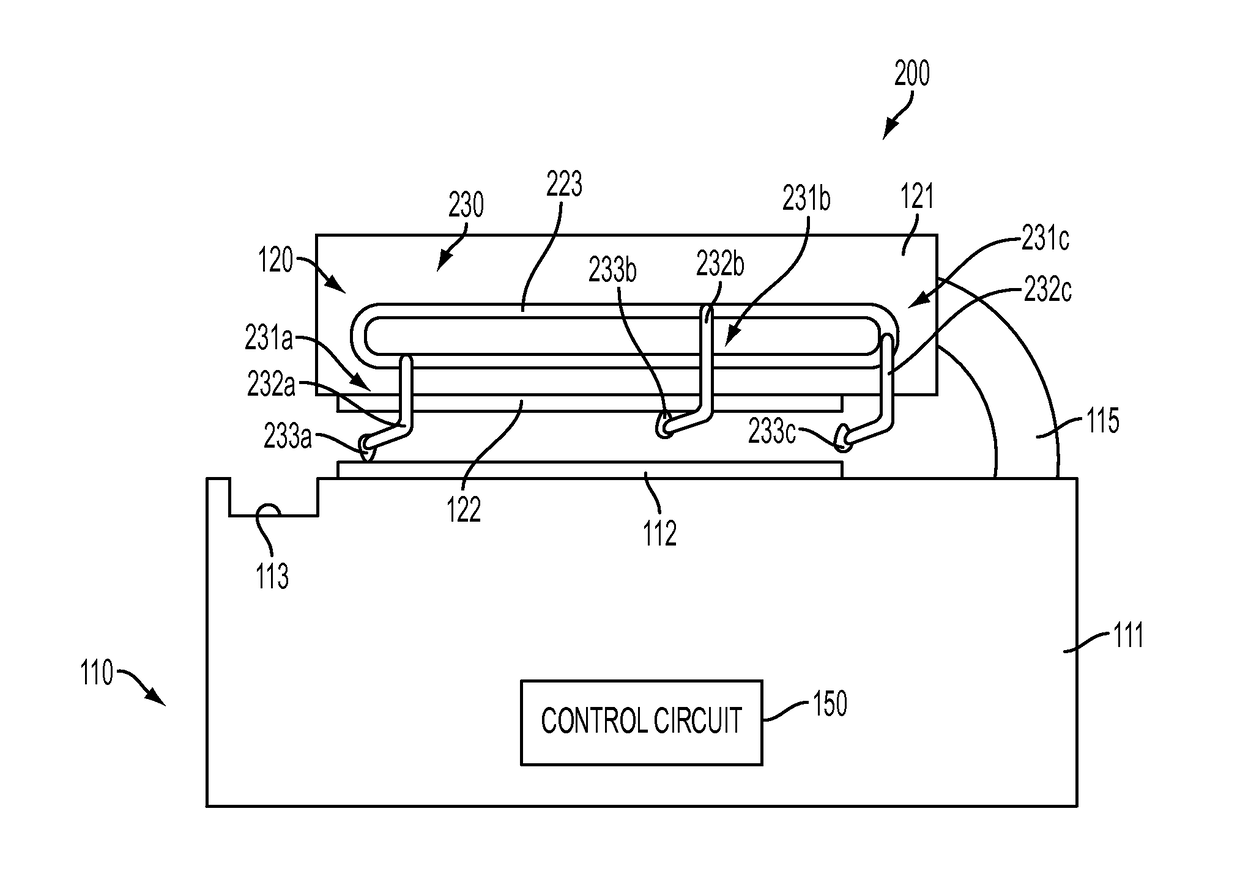

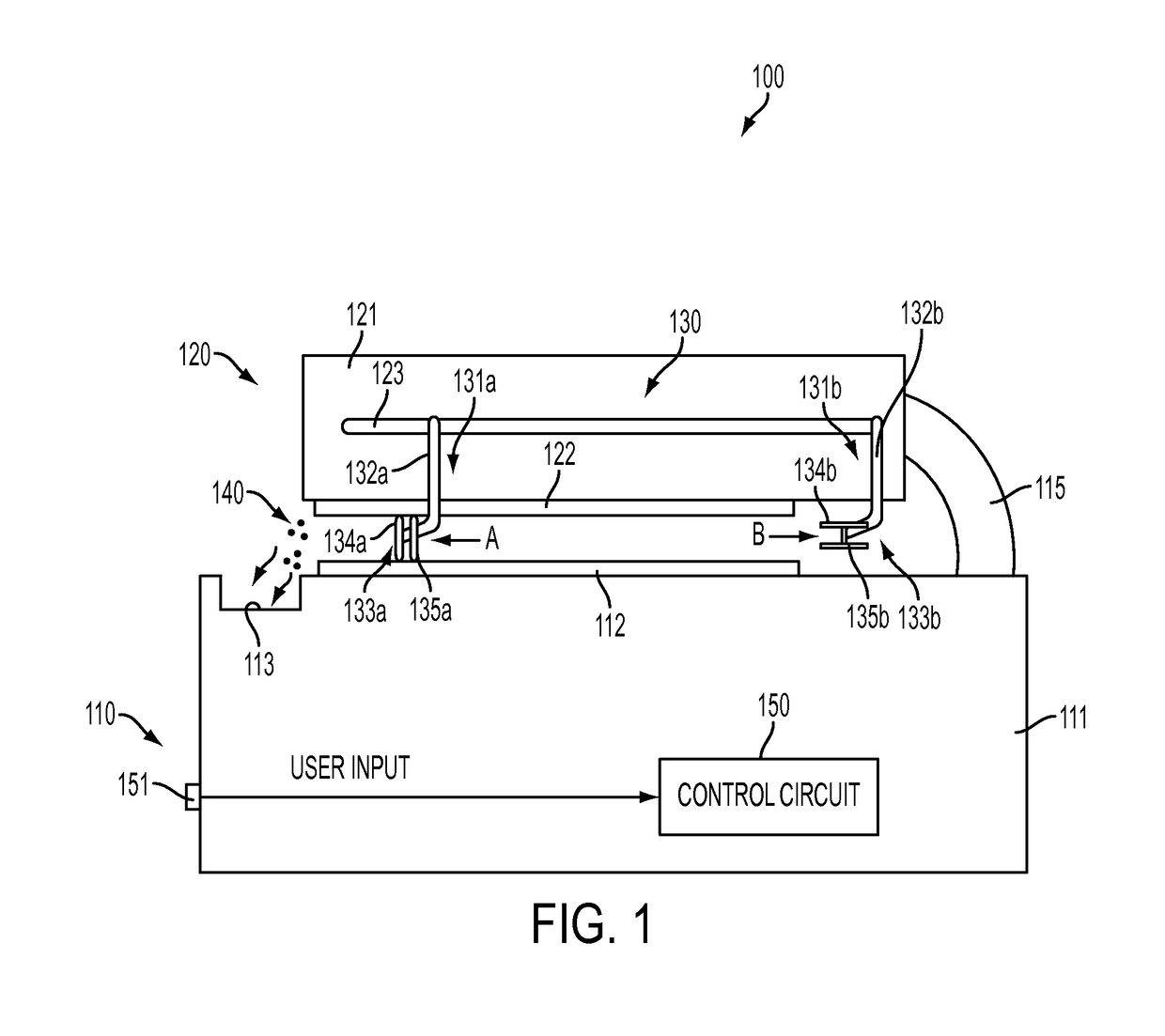

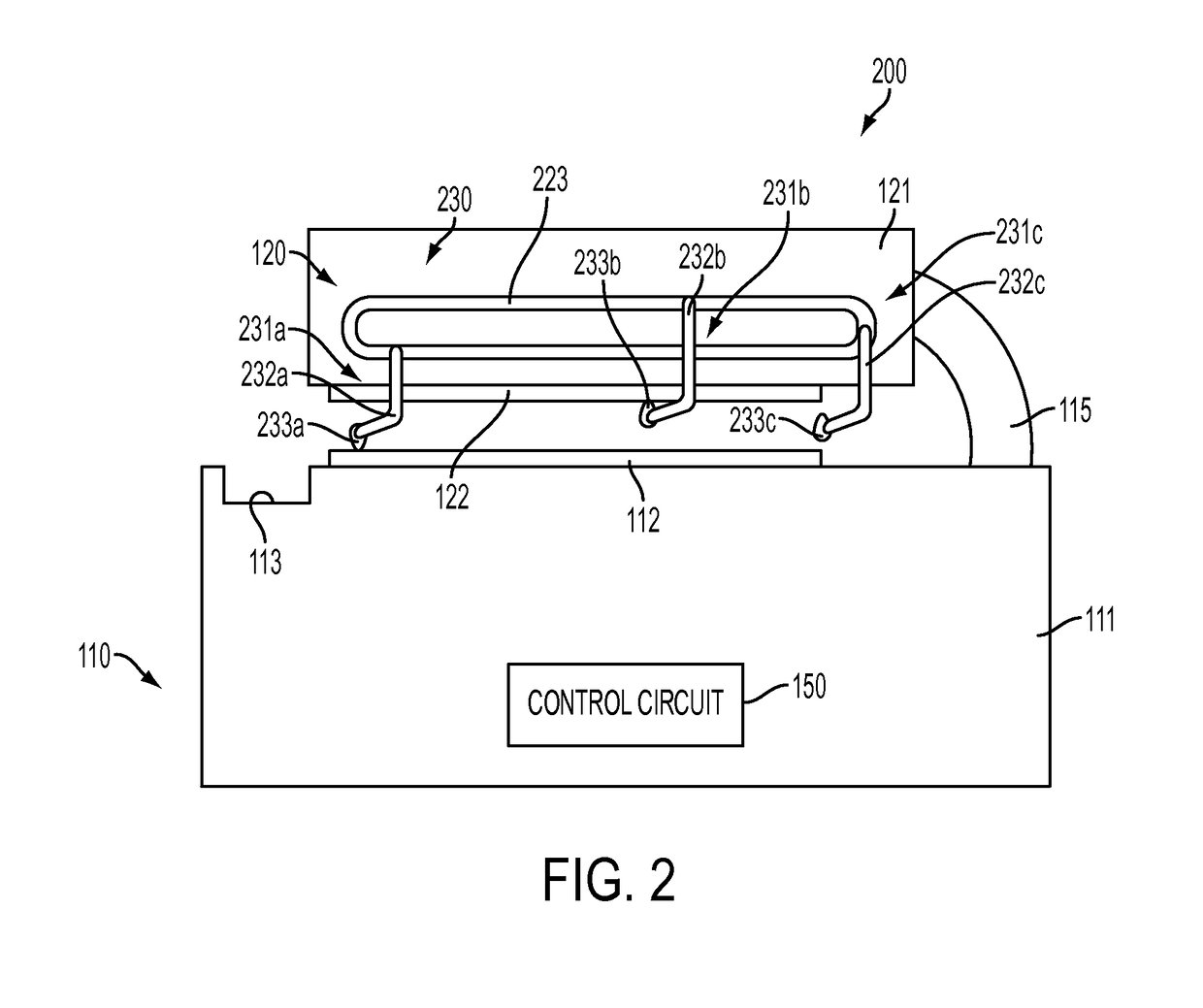

Automated cleaning of cooking apparatus

A cooking apparatus includes a base including a lower heating plate an upper heating unit including an upper heating plate and a cleaning structure configured to move a cleaning blade along at least one of the lower heating plate and the upper heating plate. The apparatus also includes a control circuit configured to control movement of the cleaning blade across the one of the lower heating plate and the upper heating plate.

Owner:TAYLOR COMML FOODSERVICE LLC

Automated cleaning of cooking apparatus

Owner:TAYLOR COMML FOODSERVICE LLC

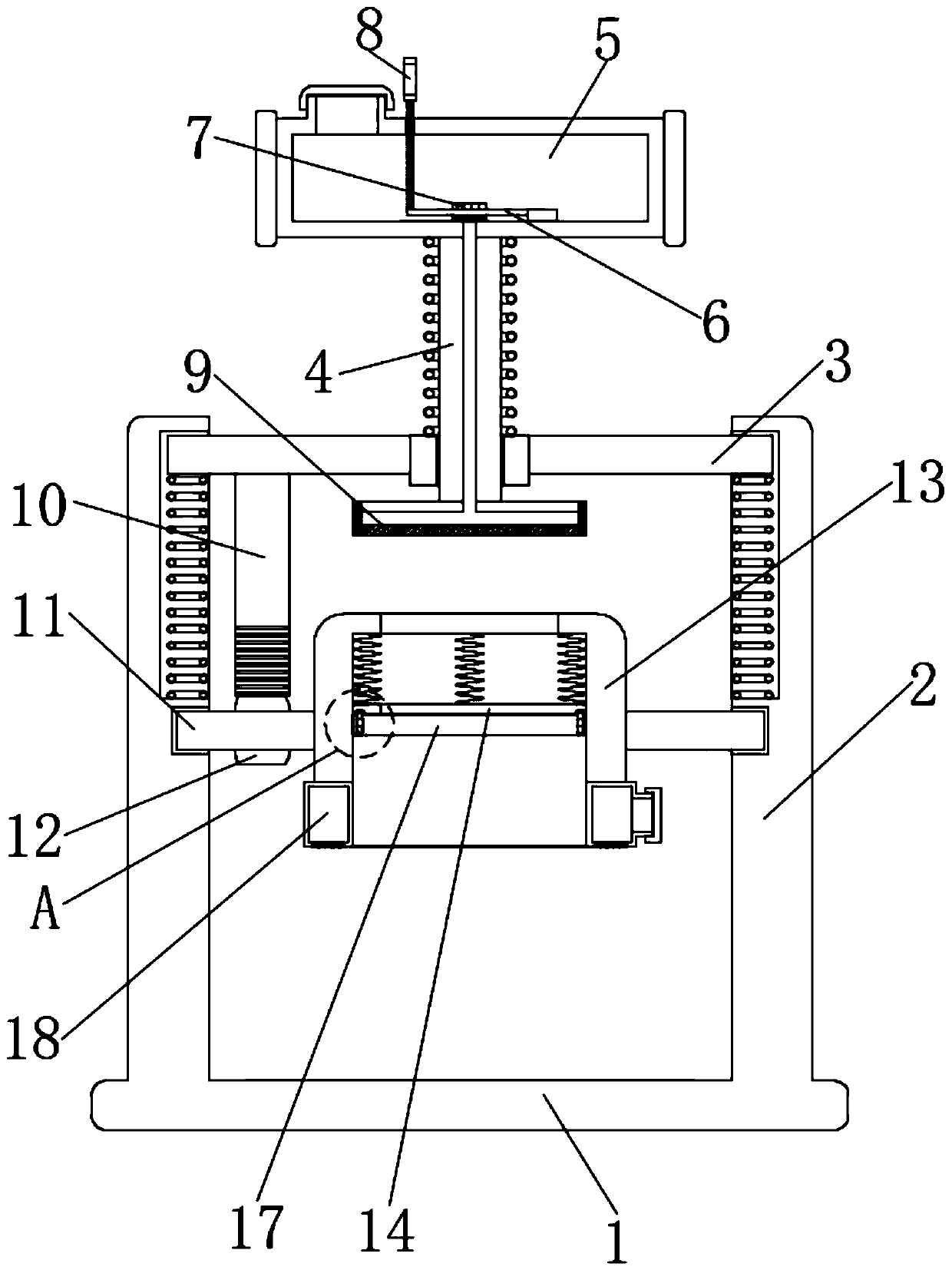

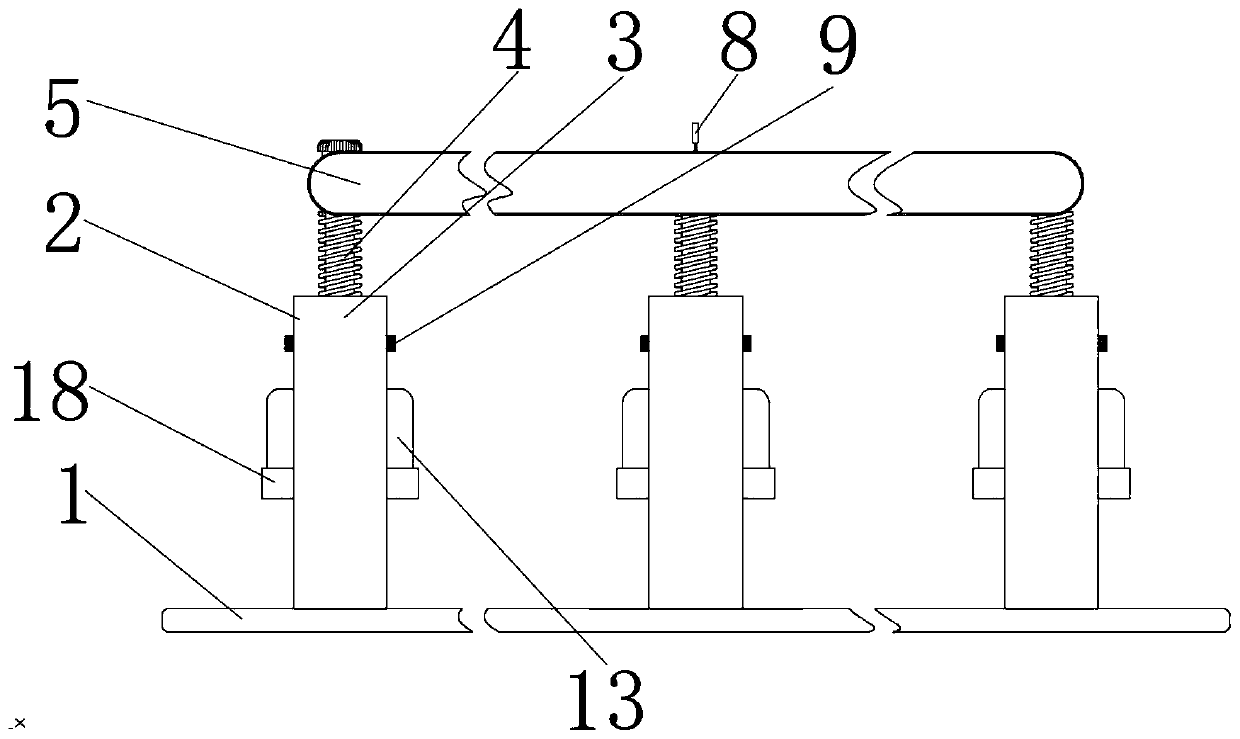

Moon cake preparation machine with replaceable pattern shapes and rapid demoulding

ActiveCN110663721AEasy to replaceIncrease profitBaking surface cleaning/greasingDough embossing machinesTextile printerStructural engineering

The invention provides a moon cake preparation machine with replaceable pattern shapes and rapid demoulding. The machine includes a base seat, supporting columns are respectively welded on the left and right sides of the upper surface of the base seat, a sliding rod is inserted in the inner sides of the upper parts of one set of the supporting columns, a supporting rod is inserted in the middle position of the sliding rod, and an oil storage tank is welded on the top end of the supporting rod; an elastic sheet plate is fixedly installed on the bottom right side of the oil storage tank, and a plugging block is inserted in the middle position of the elastic sheet plate; and a pulling ring is connected to the middle position of the left end of the elastic sheet plate through a pulling rope. The moon cake preparation machine with the replaceable pattern shapes and rapid demoulding integrates operation of powdering, oiling, pressing and demoulding during preparation of moon cakes by adopting spring support and the working mode of tooth meshing to change the direction, the preparation steps are simplified, and the work efficiency is greatly improved; and the machine cooperates with a fast-changeable printing template, so that the produced moon cakes are more diverse, and the quality of the products is greatly improved.

Owner:GUANGDONG ZHANYANG CAKE IND CO LTD

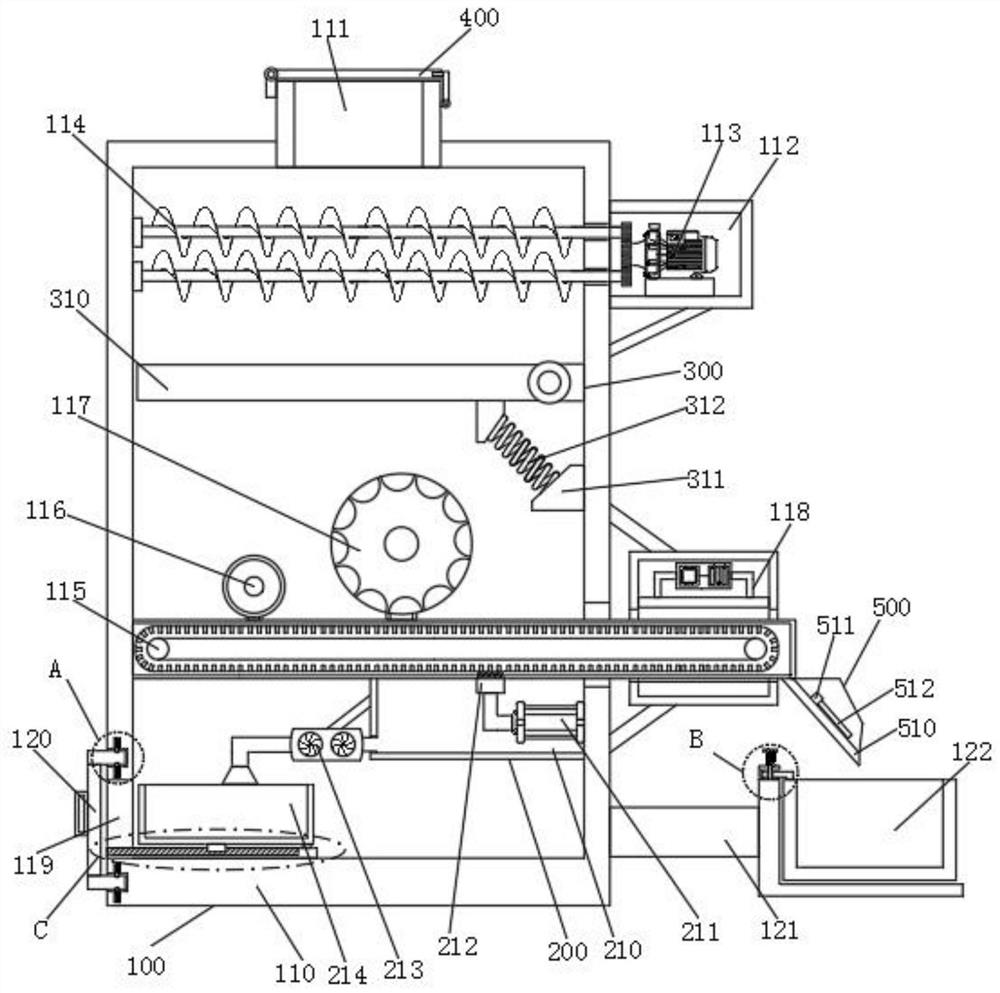

Fully-automatic cleaning system for food baking tray

InactiveCN102669202AReduce labor intensitySimple structureBaking surface cleaning/greasingEngineeringCleansing Agents

The invention discloses a fully-automatic cleaning system for a food baking tray, comprising a cleaning chamber, a washing chamber and an air drying chamber which are arranged in sequence; the cleaning chamber is internally provided with a cleaning roller communicated with a cleaning agent supply device; the washing chamber is internally provided with a water gun; and the air drying chamber is internally provided with an air drying and sterilizing device. The fully-automatic cleaning system is simple in structure, good in washing effect and capable of greatly relieving the labor intensity of workers, increasing the washing efficiency, preventing from causing secondary pollution and reducing the production cost.

Owner:郭宇斌

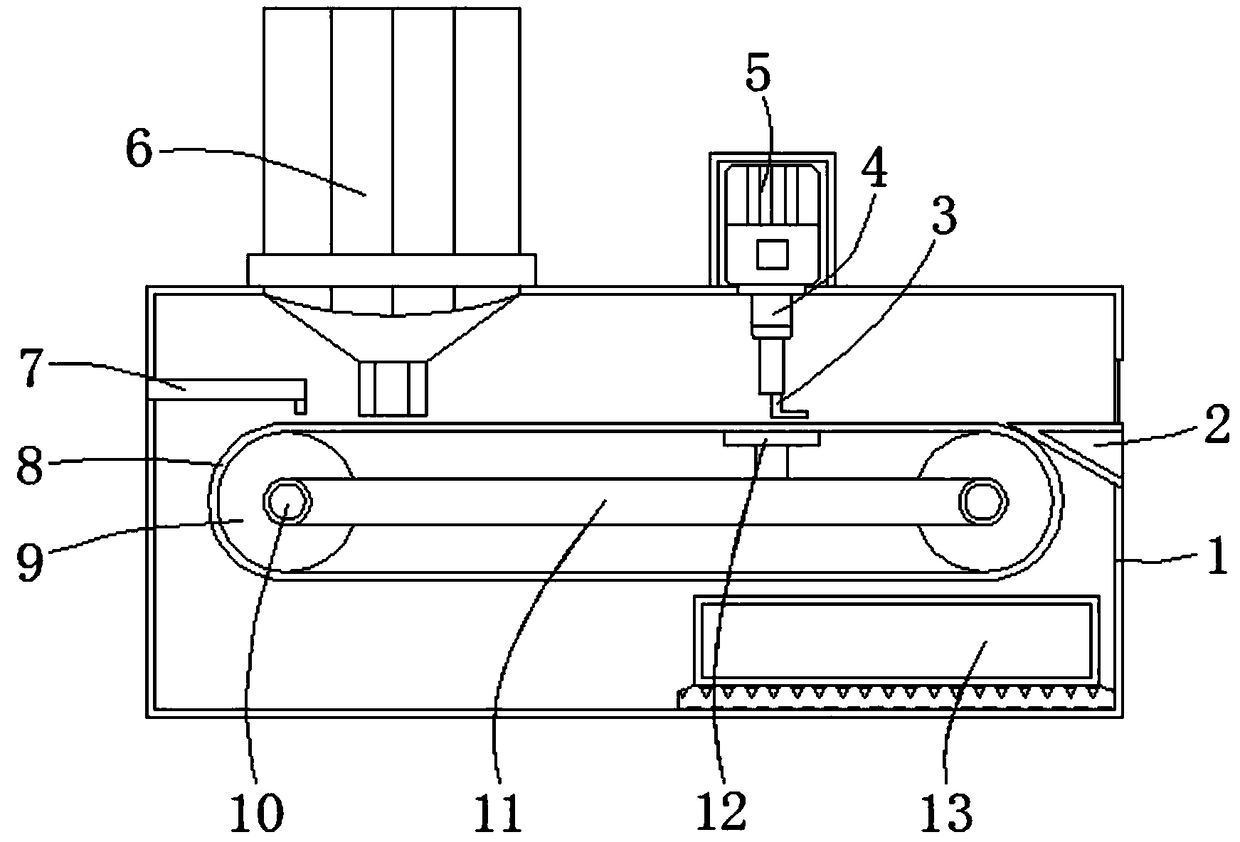

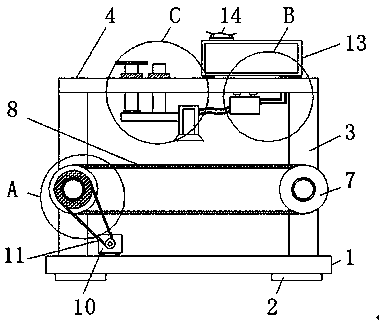

Biscuit surface oil spraying device

ActiveCN104397081AGuaranteed appearanceGuaranteed tasteBaking surface cleaning/greasingHigh pressureEnergy consumption

The invention discloses a biscuit surface oil spraying device. The biscuit surface oil spraying device comprises a machine frame. A conveying device used for conveying biscuits is arranged on the machine frame. According to the technical scheme, the biscuit surface oil spraying device is characterized in that an oil throwing device is arranged on the portion, located above the conveying device, of the machine frame, the oil throwing device comprises a rotating shaft arranged on the upper portion of the machine frame, an oil throwing plate with an inclined and upward opening is arranged at one end of the rotating shaft, the other end of the rotating shaft is connected with a driving device for driving the rotating shaft to rotate, and the machine frame is provided with an oil spraying device for spraying oil on the middle of the oil throwing plate. According to the biscuit surface oil spraying device, oil spraying is achieved in the oil throwing plate oil throwing mode instead of an existing high-pressure pipeline oil spraying mode; meanwhile, oil is evenly sprayed to surfaces of biscuits through the cooperation with the automatic conveyor line work, the appearance color and luster and the taste of biscuits are ensured, the energy consumption is lowered, and the oil leakage is reduced.

Owner:中山市顶盛食品机械有限公司

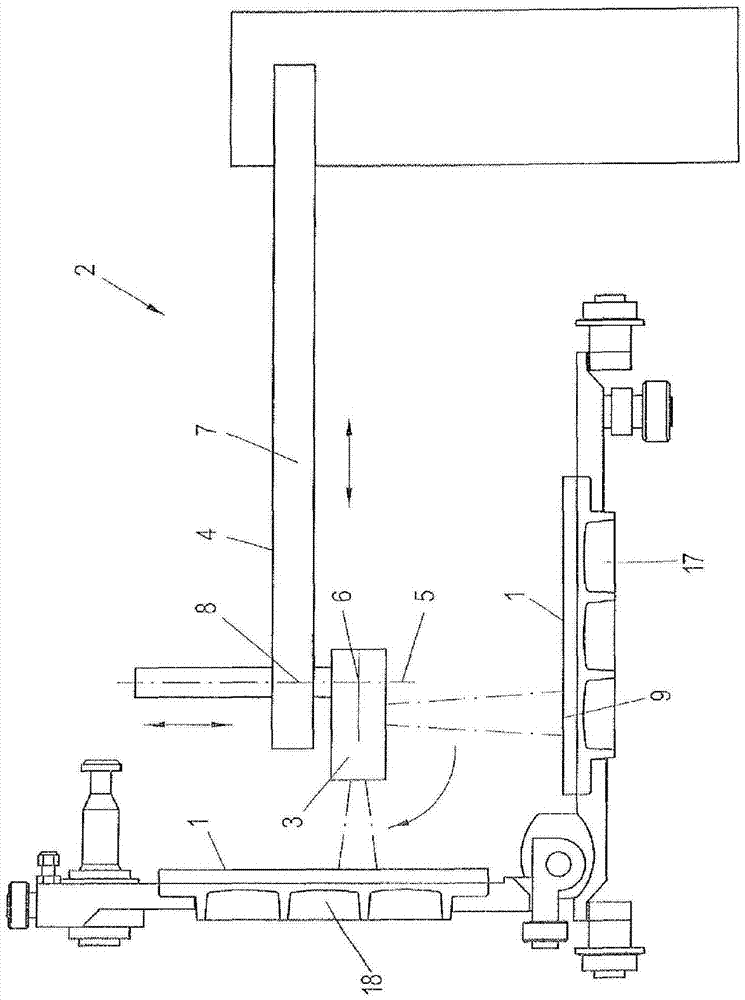

Method and device for cleaning baking surfaces

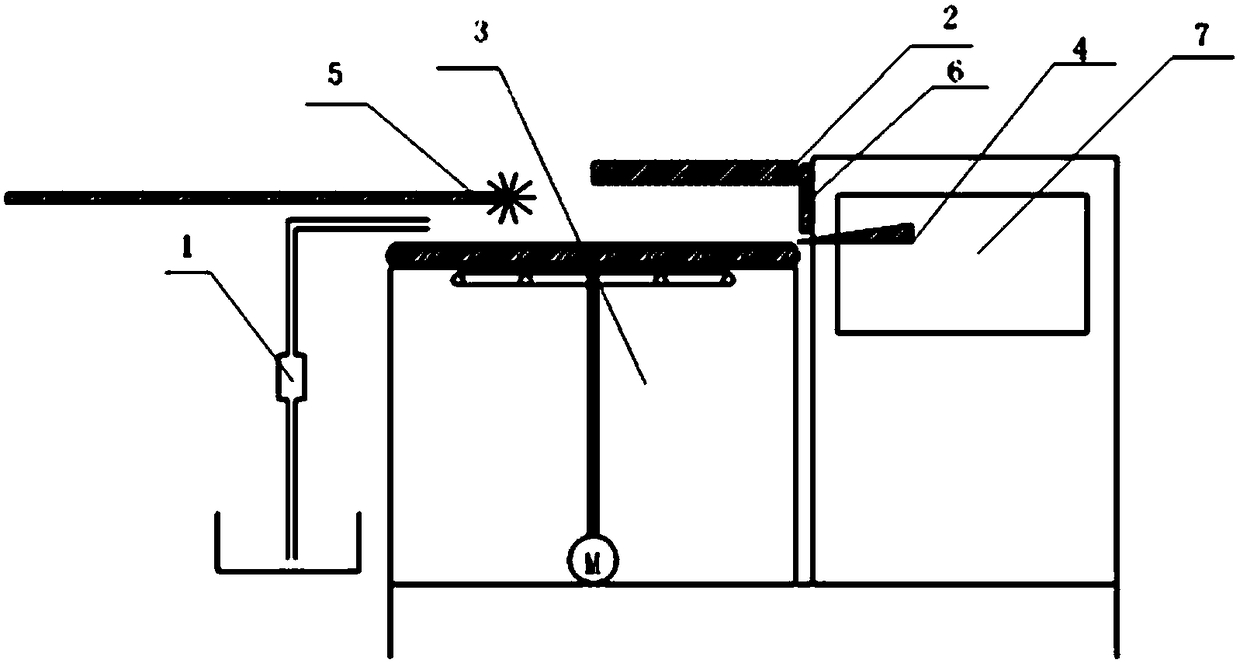

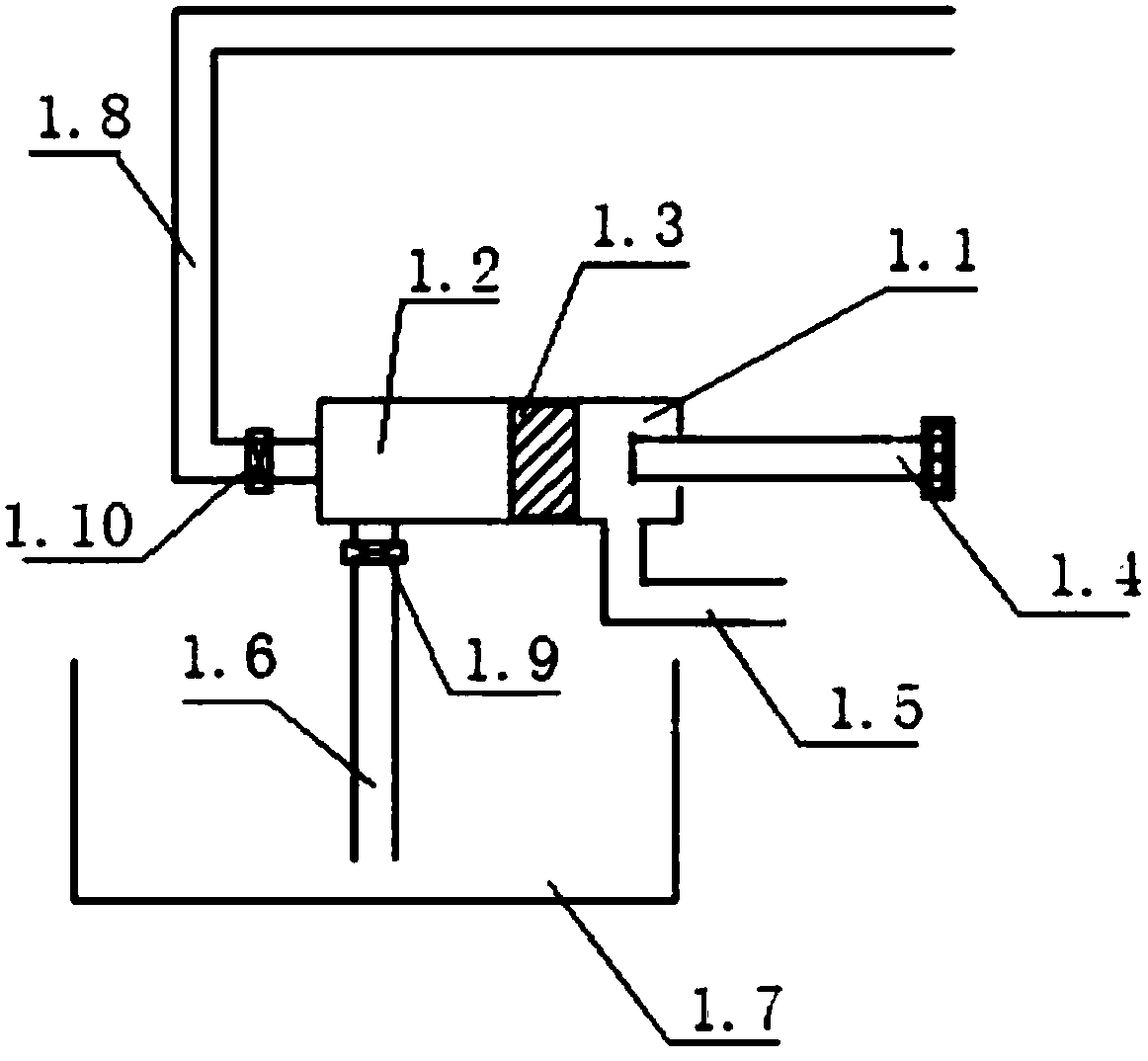

ActiveCN104519744ACleaning using toolsBaking surface cleaning/greasingCooking & bakingRelative motion

The invention relates to a laser assembly (2) for cleaning one or more baking surfaces (1) of a baking machine, comprising a laser head (3), wherein an interface is provided for connecting to the baking machine and the laser assembly is connected to the baking machine mechanically and / or in regard to control, a baking machine having a laser assembly (2) according to the invention, and a method for cleaning baking surfaces, wherein a laser head is arranged in the area of the baking surface of a baking machine, wherein a laser beam is conducted onto the baking surface in order to clean the baking surface, and wherein the processing area of the laser assembly is moved over the baking surface by means of relative motion between the laser head and the baking surface.

Owner:HAAS FOOD EQUIP

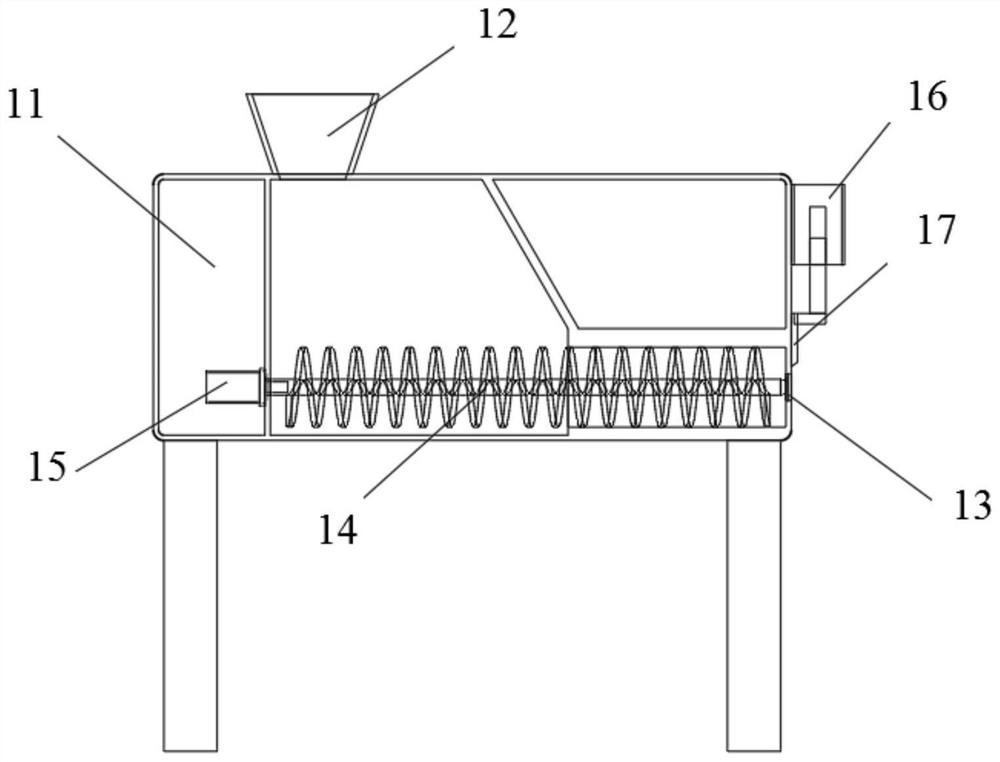

Scrap processing mechanism of biscuit forming machine

InactiveCN111955499AEasy to cleanImprove practicalityDough-sheeters/rolling-machines/rolling-pinsMixing/kneading with horizontally-mounted toolsElectric machineryDried food

The invention relates to the technical field of biscuit food processing, in particular to a scrap processing mechanism of a biscuit forming machine. The mechanism comprises a device body, the device body comprises a box body, a feeding port is formed in the top end of the box body, a mounting box is fixedly mounted at one end of the box body, and a motor is fixedly mounted in the mounting box. Themechanism is provided with a cleaning bin, an electric telescopic rod, a cleaning brush, a fan and a scrap storage box, the cleaning brush is arranged to scrape and clean scraps attached to a conveying belt, the electric telescopic rod drives the cleaning brush to move back and forth to better clean away the scraps, and the scraps falling into the cleaning bin are absorbed through the draught fanand then discharged into the scrap storage box to be collected. The mechanism can automatically clean the scraps on the inner conveying belt, the situation that the use of the mechanism is affected due to the adherent scraps on the surface is avoided, and the practicability of the mechanism is improved.

Owner:湖南嘉士利食品有限公司

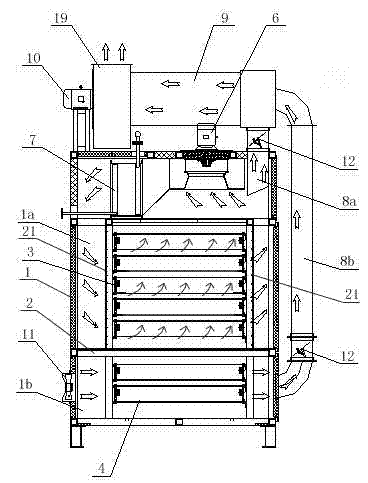

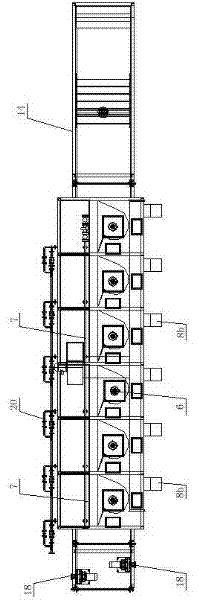

Roasting air cooler

ActiveCN102326594AChange processRealize the function of automatic flippingBaking surface cleaning/greasingEngineeringManufacturing line

The invention discloses a roasting air cooler. The roasting air cooler comprises a box, and the box is internally equipped with an interlayer and is divided into a roasting part and an air-cooling part through the interlayer, wherein, the roasting part is internally equipped with at least one layer of material conveying belt for a roasting section, and the air-cooling part is internally equipped with at least one layer of material conveying belt for an air-cooling section; the discharge end of the material conveying belt for the roasting section is corresponding to the feed end of the material conveying belt for the air-cooling section; the interlayer is correspondingly equipped with a material passing port through which materials enter the feed end of the material conveying belt for the air-cooling section from the discharge end of the material conveying belt for the roasting section; and a roasting mechanism is correspondingly arranged in the roasting part, and an air-cooling mechanism is correspondingly arranged in the air-cooling part. The roasting air cooler has the beneficial effects that by organically combining a roasting process with an air-cooling process, the utilization area of a workshop is increased and meanwhile an automatic production line is realized, thus greatly improving production efficiency and reaching uniform roasting and air-cooling effect; the water content of the roasted materials can be accurately controlled; and the air cooler is simple in operation.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

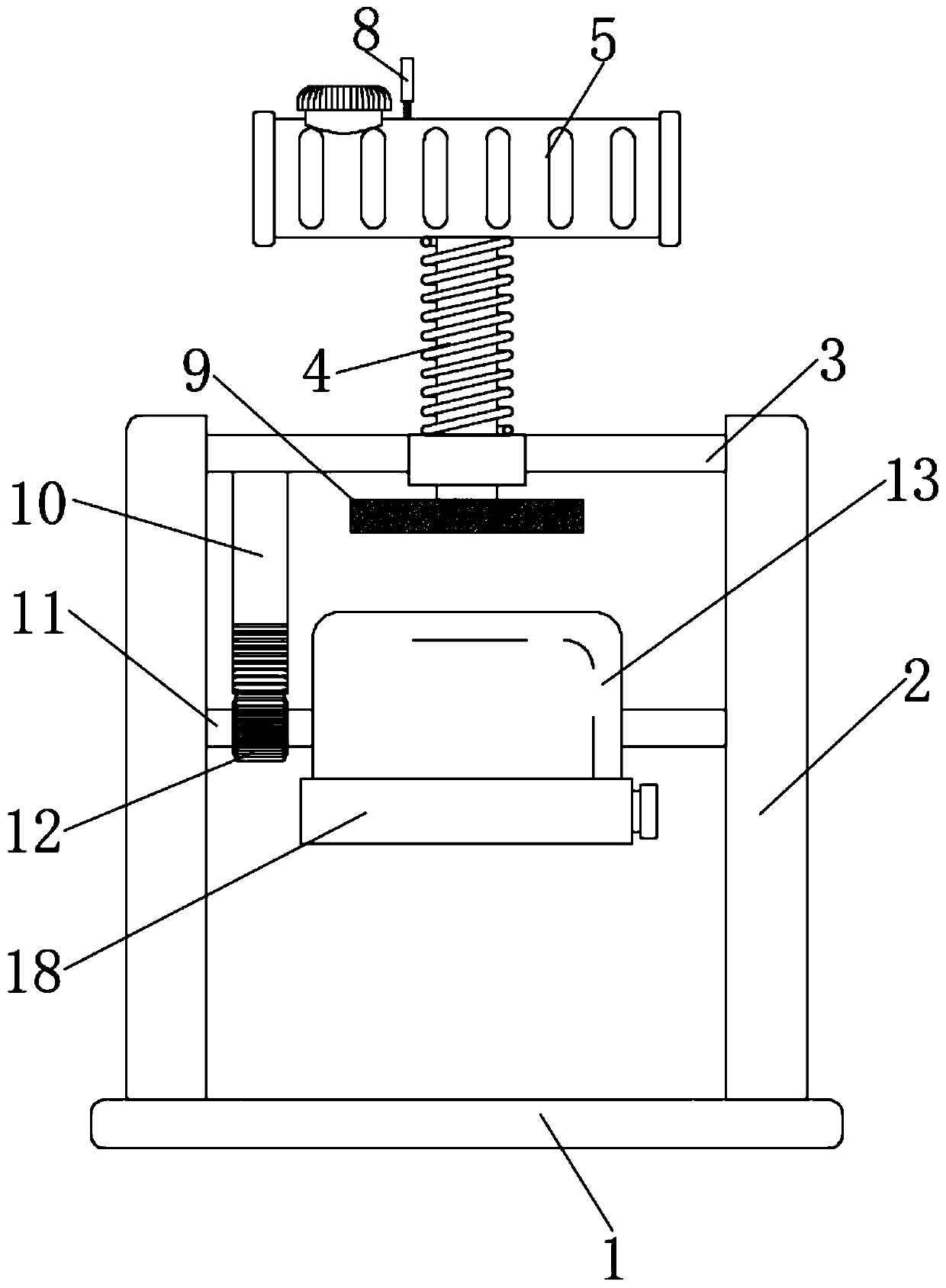

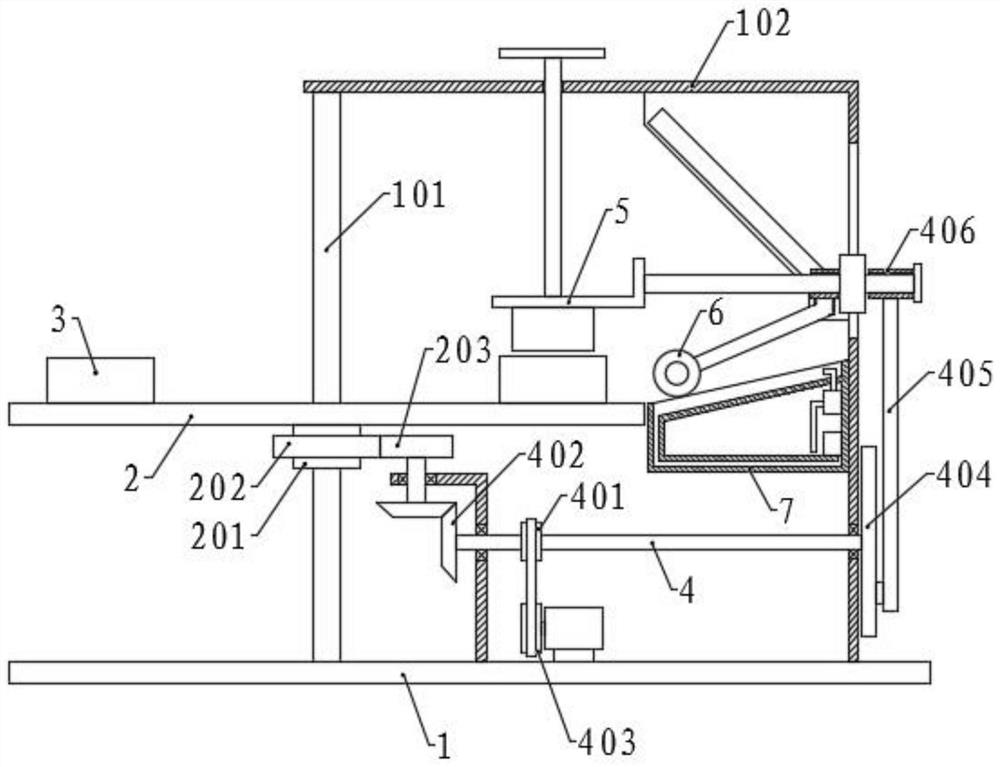

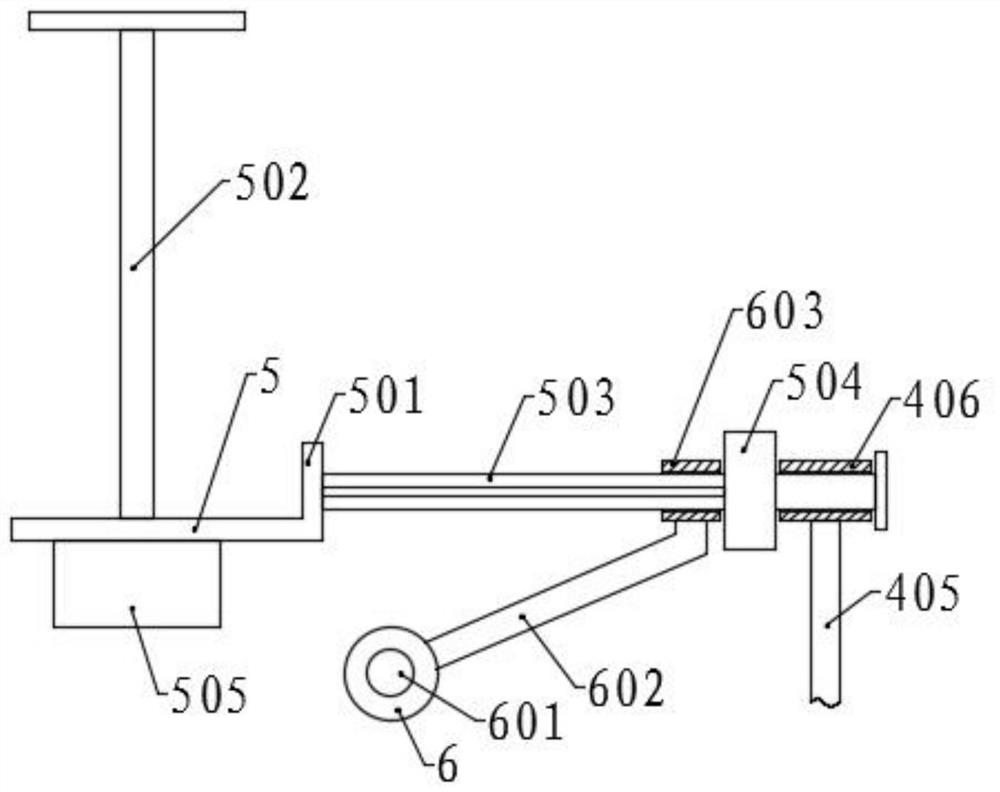

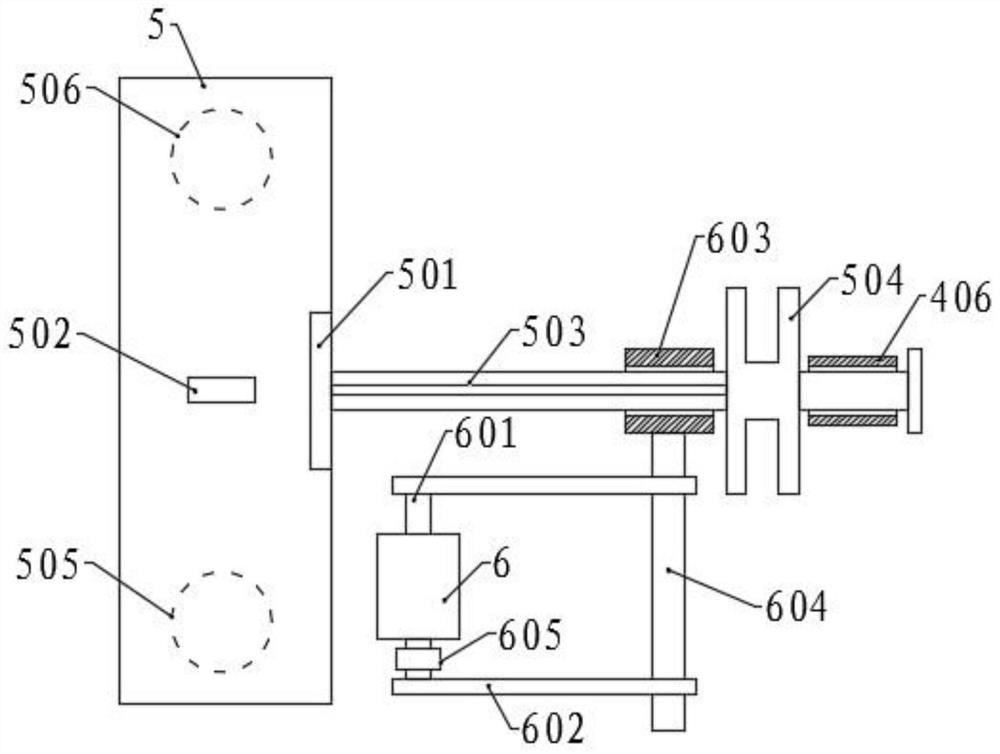

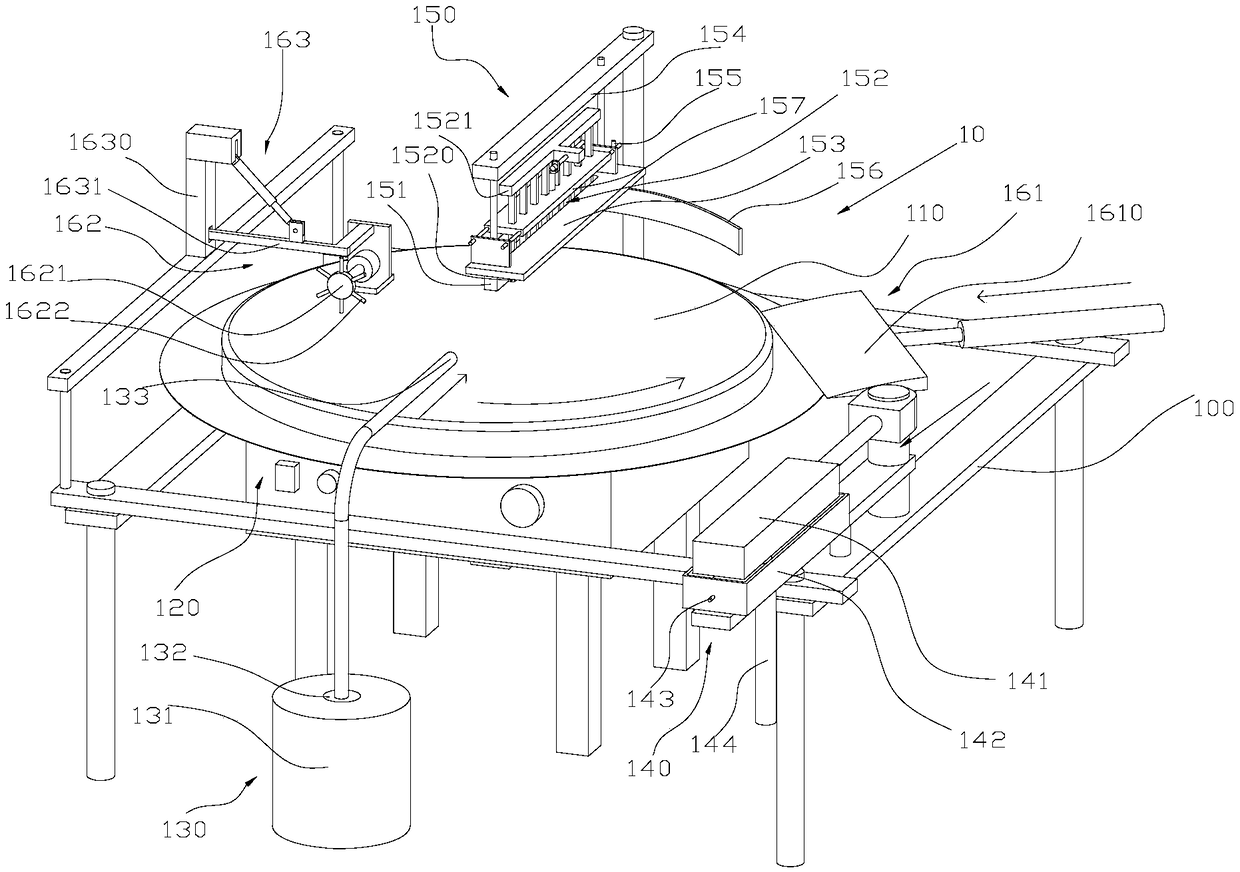

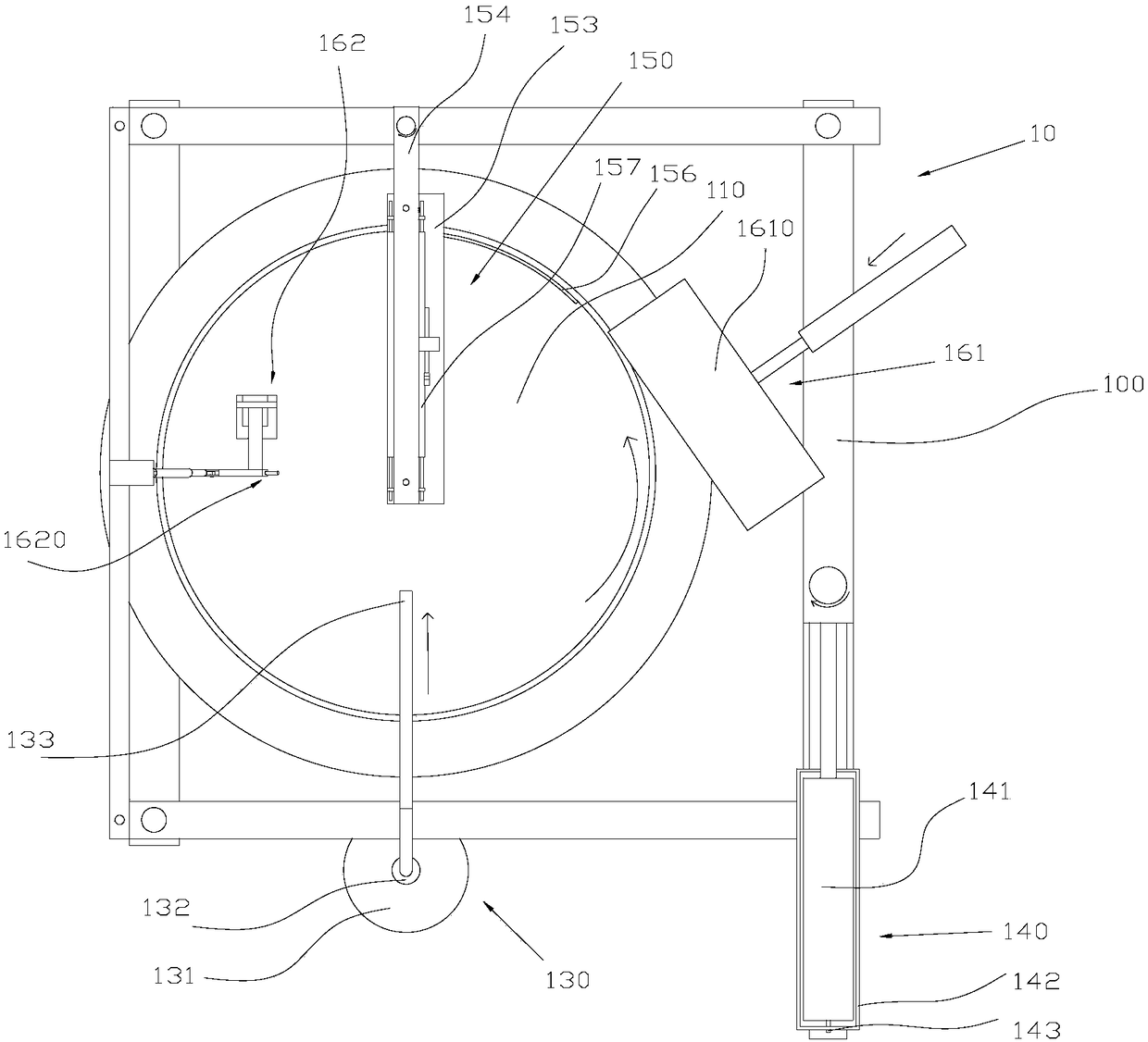

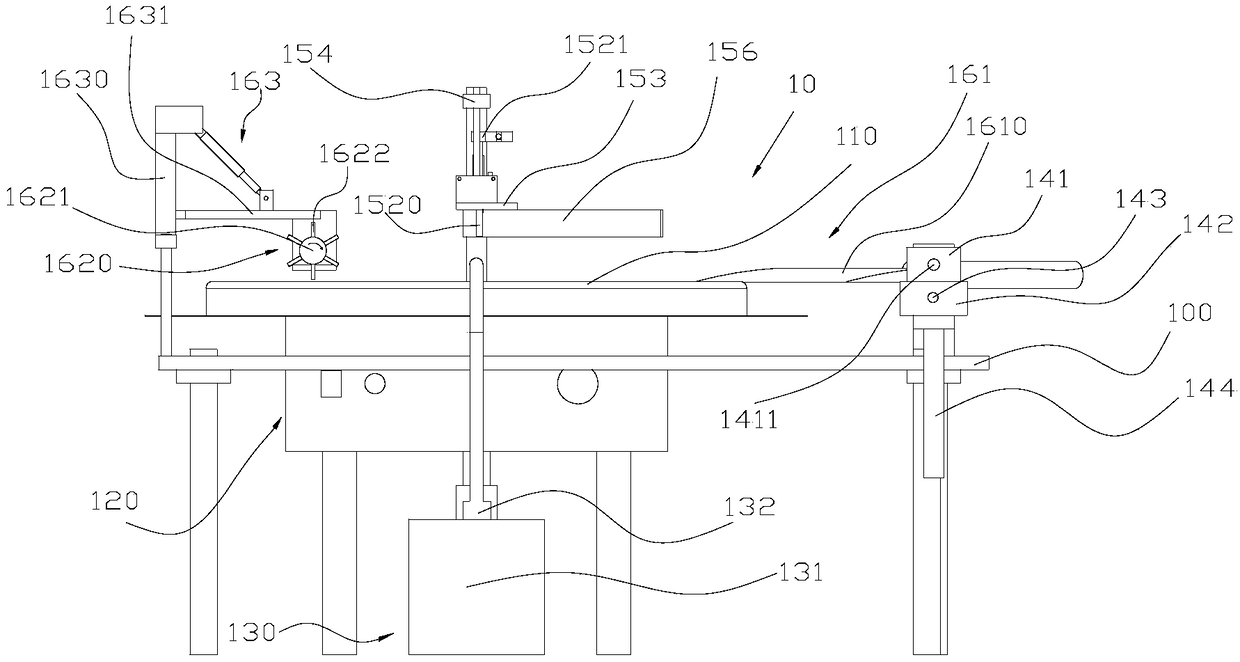

Anti-sticking forming equipment for cake food processing and forming method

InactiveCN111802425AImprove work efficiencyAvoid problems such as stickinessBaking surface cleaning/greasingFood shapingReciprocating motionEngineering

The invention discloses anti-sticking forming equipment for cake food processing and a forming method, and belongs to the technical field of food processing. The equipment comprises a base and a rotating table, a fixed shaft, a transverse plate and a vertical plate are fixed on the base, a forming die groove and a rotating assembly are arranged on the rotating table, a forming assembly is arrangedon the transverse plate, the forming assembly is connected to a smearing assembly, a driving assembly is arranged on the base, and the driving assembly is correspondingly connected to the rotating assembly and the forming assembly. The rotating assembly drives the rotating table and the forming die groove to move intermittently through the driving assembly; a lifting block and a lifting plate aredriven by the driving assembly to reciprocate up and down; the side wall and the bottom surface of the forming die groove are coated with mold release oil through a coating block; the bottom surfaceof a forming pressing block is coated with mold release oil through a coating roller, so that pastries cannot be adhered to the forming die groove and the forming pressing block during forming; and cake materials in the forming die groove are extruded and formed through the downwards-moving forming block, and cake forming is easy and convenient.

Owner:安徽创瑞文化传媒有限公司

Food production line and food processing method

InactiveCN109247354AEasy to adjustAvoid stickingMixing/kneading structural elementsOil/fat bakingProduction lineEngineering

The invention discloses a food production line and a food processing method, and relates to the technical field of food production and processing. The food production line comprises a main body and astorage box, wherein a scraping sheet is mounted on the right side of the inner wall of the main body, the storage box is arranged on the left side of the top end of the main body in a penetrating mode, the storage box and the main body are in threaded connection, a first electric pushing rod is arranged on the right side of the top end of the main body in the penetrating mode, and a scraping plate is arranged at the bottom of the first electric pushing rod. The food production line and the food processing method have the beneficial effects that mold discs, a conveying belt and the scraping plate are arranged, the mold discs are distributed on the inner side of the top end of the conveying belt in a circular shape at equal distances, and thus when materials on the inner side of the storagebox slide down into the mold discs along a discharging outlet, food can be subjected to shaping production operation through the mold discs; and under the effect of threaded connection between the mold discs and the conveying belt, workers can replace the mold discs of different types, and the food production line conveniently conducts adjusting operation on the shape and size of the food.

Owner:FOSHAN UNIVERSITY

Food production system

ActiveCN108925595AImprove efficiencyImprove folding efficiencyConveyorsBaked articles handlingAssembly lineProduct processing

The invention discloses a food production system, and is used for production of cakes. The food production system comprises cake making equipment, folding equipment for folding the cakes, and packaging equipment for packaging the cakes. Through adoption of the production system provided by the invention, the automation degree of the processing of the cakes is increased, the product quality is improved, and the processing and making cost of the products is reduced; and the food production system is particularly suitable for assembly lines and large-scale production, and has favorable application prospect.

Owner:戴静静

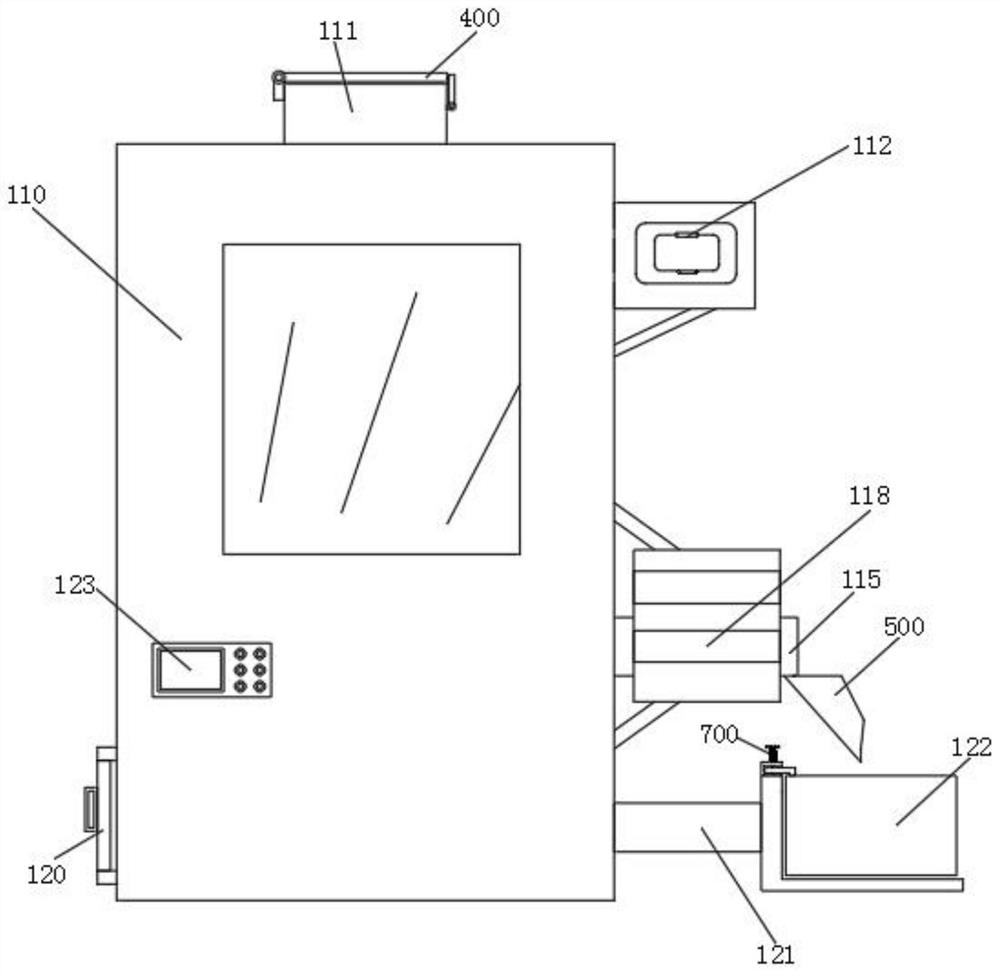

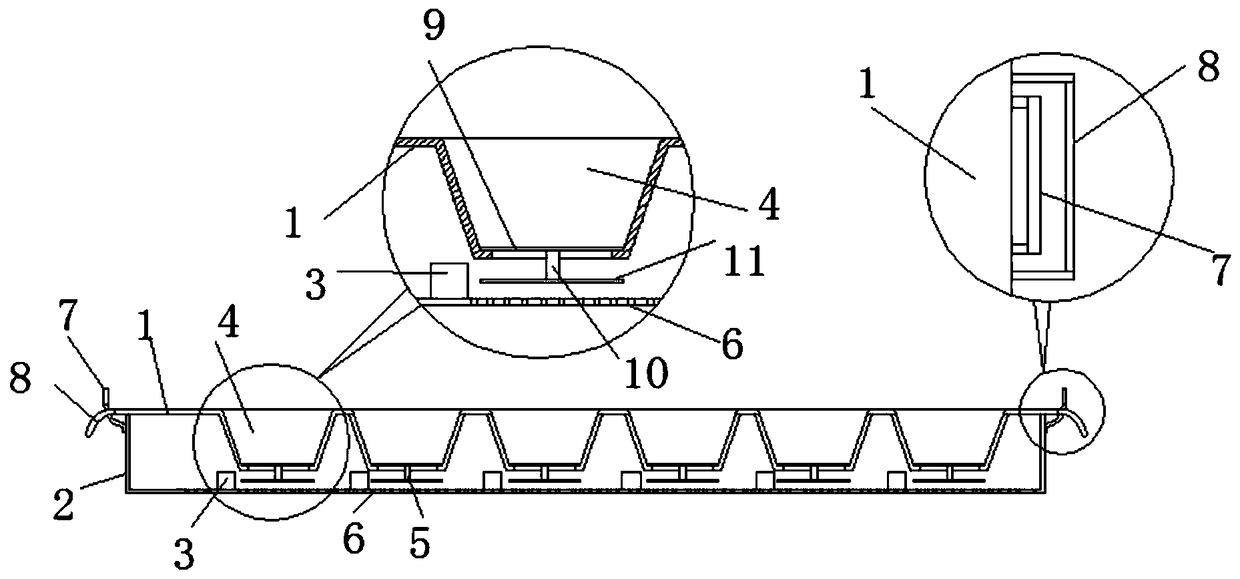

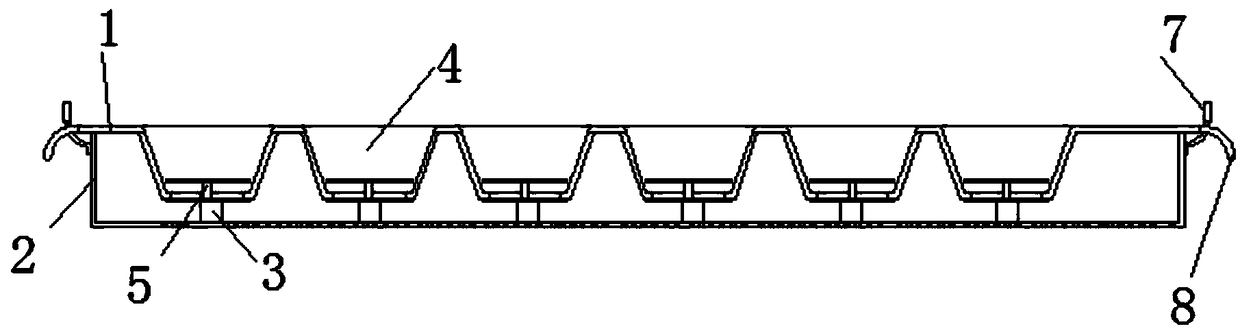

Cake mold and oil brushing device thereof

ActiveCN108991053AEasy to jack upGuaranteed releaseBaking surface cleaning/greasingBaking-tinsBristleEngineering

The invention belongs to the cake and pastry processing equipment field and relates to a cake mold and an oil brushing device thereof. The cake mold comprises an upper mold and a lower mold; a plurality of model cavities distributed in an array are arranged on the upper mold; the bottoms of the model cavities are hollowed out and are provided with I-shaped movable jacking pieces; and when the lower parts of the movable jacking pieces are jacked, the upper parts of the movable jacking pieces jack out cakes from the model cavities. The oil brushing device includes a heat insulation box body, anoil pool, an oil brushing rolling brush, a heating lamp, an electric heater and a conveyor belt mechanism. With the cake mold adopted, the cakes can be conveniently jacked by the movable jacking pieces, and the de-moulding of the cakes in the model cavities can be ensured; when the upper mold is arranged with the left side and right side reversely located, jacking columns can cooperate with the jacking of the movable jacking pieces; and an oil brushing rolling wheel is arranged in the back direction of the upper mold, such that edible oil adhered to bristles can be applied to the surface of the upper mold, and therefore, a process for applying the oil to the surface of the upper mold can be realized.

Owner:涡阳县佳美食品有限公司

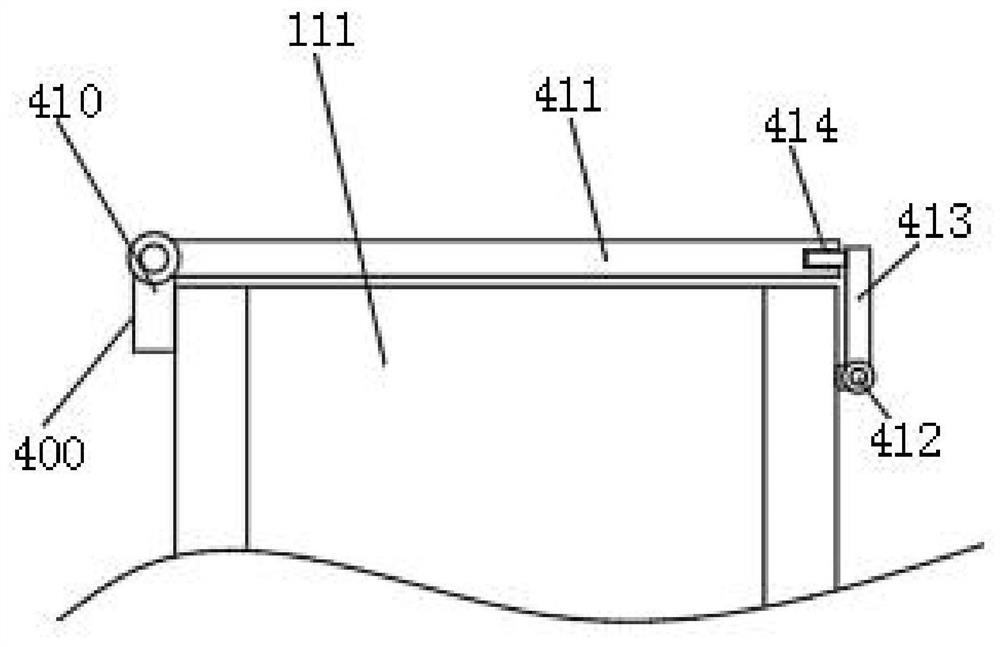

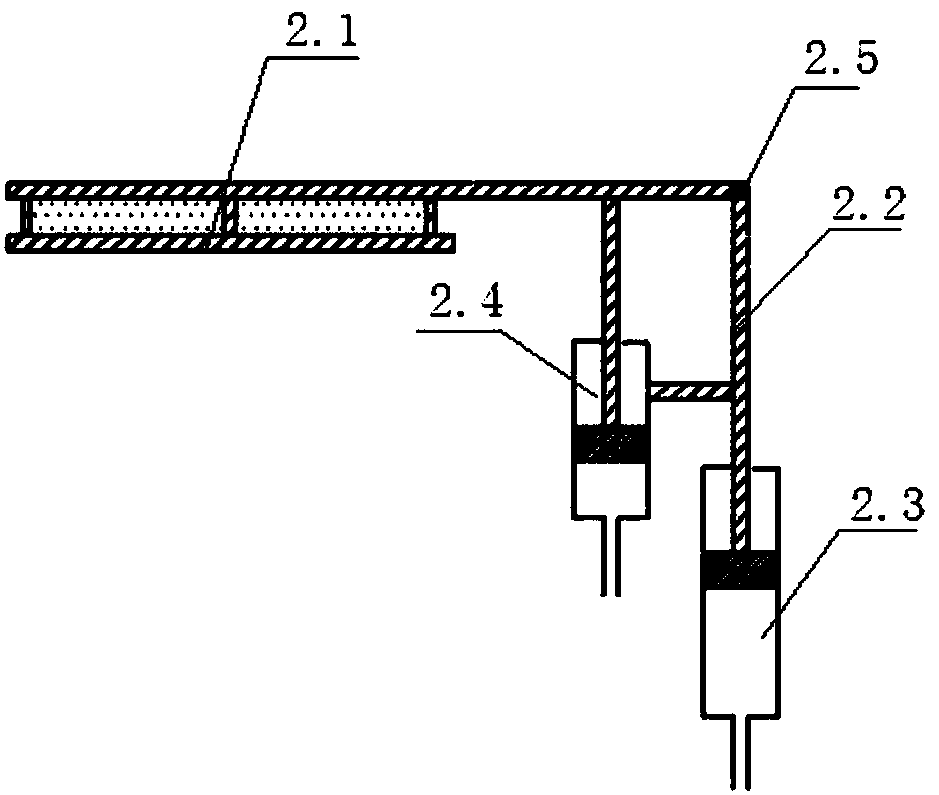

Ash-removing and oil-applying mechanism used for food production

ActiveCN108935557AImprove efficiencyImprove folding efficiencyConveyorsBaked articles handlingAssembly lineEngineering

The present invention discloses an ash-removing and oil-applying mechanism used for food production. The ash-removing and oil-applying mechanism comprises an applying head; the applying head is composed of an erasing sleeve and an internally arranged gas distributing pipe; the outside of the gas distributing pipe is sleeved with the erasing sleeve with a sponge texture; and an oil and gas mixtureis introduced into the gas distributing pipe. The applying head has two states: one state is as follows: the applying head is arranged in an avoiding position located outside a griddle and conductingavoiding of material distributing to manufacture pastry on the griddle; and the other state is as follows: the applying head is arranged in a working position closely attached to a griddle surface toconduct cleaning and oil-applying of the griddle surface. The provided ash-removing and oil-applying mechanism improves automation degree and product quality of pastry processing, reduces manufacturecost of product processing, is particularly suitable for assembly line and large-scale production, and has a good application prospect.

Owner:苏州果汁网信息科技有限公司

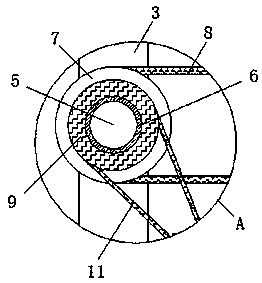

Automatic two-sided pancake machine

ActiveCN105454338AIncrease profitIngenious structureOil/fat bakingBaking surface cleaning/greasingThermal insulationAssembly line

The invention discloses an automatic two-sided pancake machine. The machine comprises a machine frame, a motor, a chain-wheel and chain mechanism, an upper pan body and a lower pan body. The upper pan body and the lower pan body are arranged on the machine frame and each provided with a horizontal groove and an inner cavity under the groove. Electric heating tubes are arranged in each cavity, and a thermal-insulation layer is connected to each of the two sides and the lower portions of the upper pan body and the lower pan body. A filtering plate is connected to the tail end of the upper pan body, multiple filtering holes are formed in the filtering plate, an inner guide plate which is bent is connected to the tail end of the filtering plate, an outer guide plate which is bent is connected to the machine frame, the inner guide plate and the outer guide plate are arranged at a radial gap, and the lower end of the outer guide plate is adjacent to the head end of the groove of the lower pan body. Multiple shifting sheets are connected to a chain, and two layers of shifting sheets on the chain are located above the upper pan body and the lower pan body respectively. The automatic two-sided pancake machine has the advantages of being ingenious in structure and capable of turning over a product automatically and improving two-sided frying conveniently, improving the automatic degree, processing efficiency and product quality and reducing the product cost and being particularly suitable for assembly line and large-scale production.

Owner:盐城市荣意来纺机有限公司

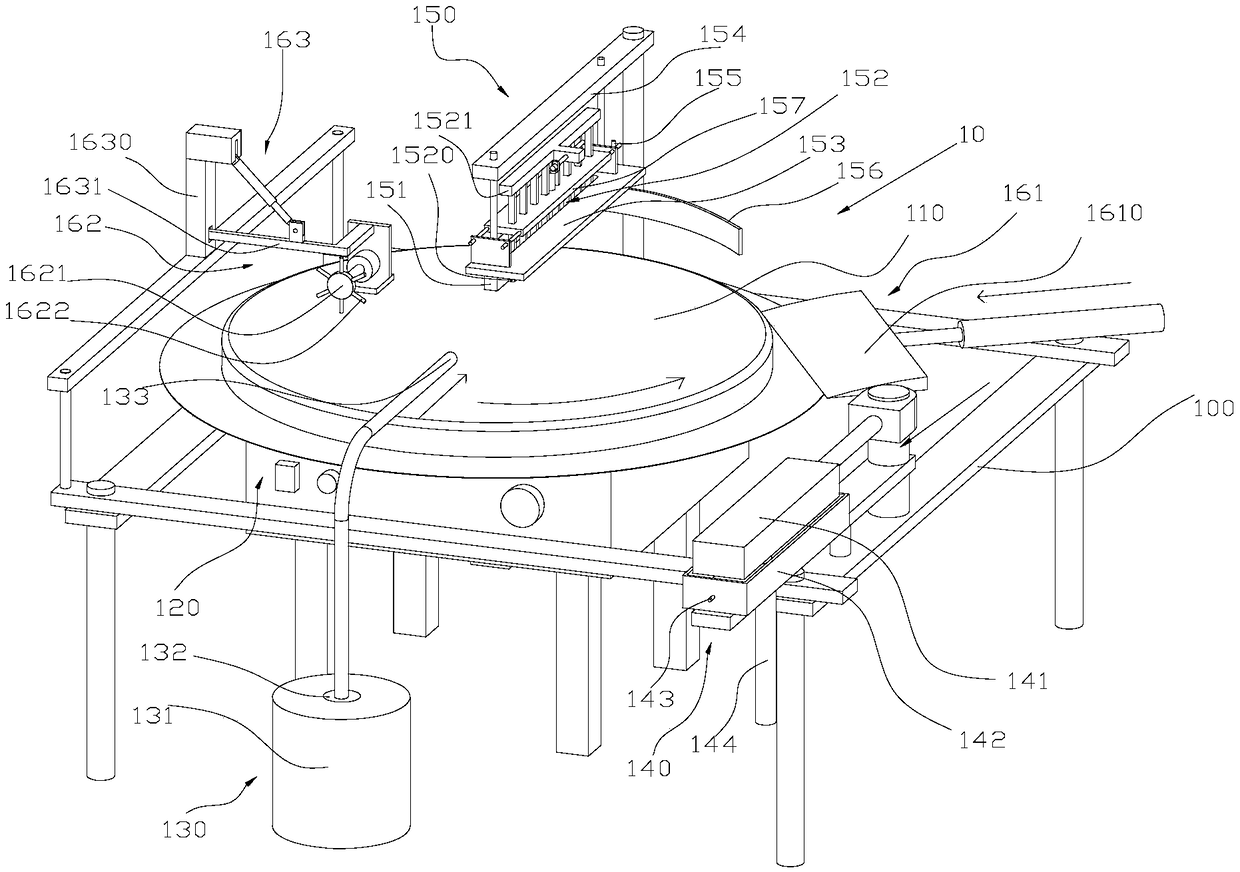

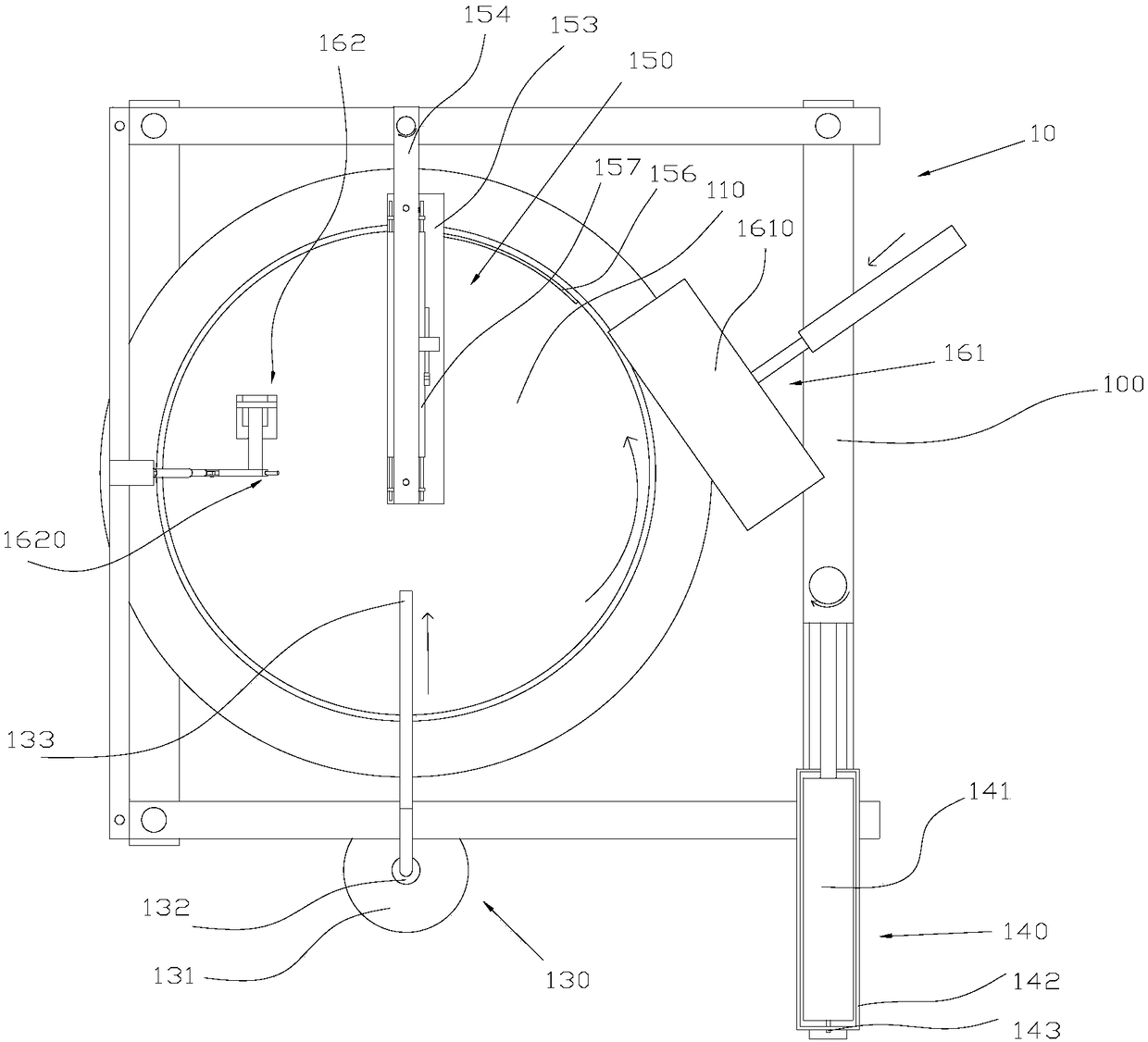

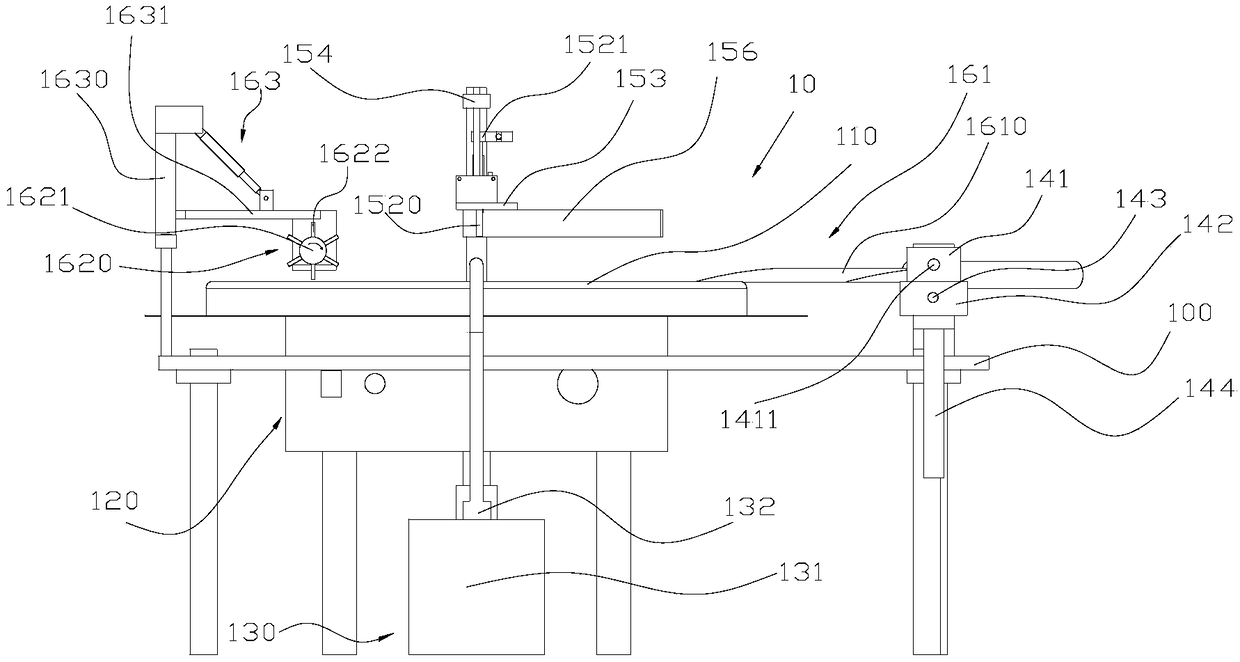

Rotary Chinese hamburger machine

PendingCN109730101AEnsure hygieneEnsure safetyBaking surface cleaning/greasingPackagingMeat burgerEngineering

The invention relates to a rotary Chinese hamburger machine. The rotary Chinese hamburger machine is composed of a rotary pancake making device and a pancake folding device, four pan bodies are uniformly and radially installed on the periphery of the middle of a rotary rack of a rotary device and driven by the rotary rack to rotate, and successively pass through a pancake making station, a heatingstation, a reheating station and a pancake shoveling station in the rotating process, and the four stations are perpendicularly arranged on the four sides of the rotary rack transversely and longitudinally; a pancake making assembly is arranged on the upper portion, located on the horizontal and longitudinal side, of the rotary rack, and a cleaning mechanism is installed on the outer side of thepancake making assembly radially; heating covers capable of covering the pan bodies are respectively installed on the heating station and reheating station of the rotary rack; the pancake shoveling station is connected with the pancake folding device. The four pan bodies circularly rotate among the four stations, pancake making, heating, pancake shoveling and pancake folding are continuously conducted differently, the cooperation degree among the mechanisms is good, the time difference among the manufacturing processes is effectively utilized, and therefore the processing quality is ensured, and the processing efficiency is greatly improved.

Owner:马士通安全设备(天津)有限公司

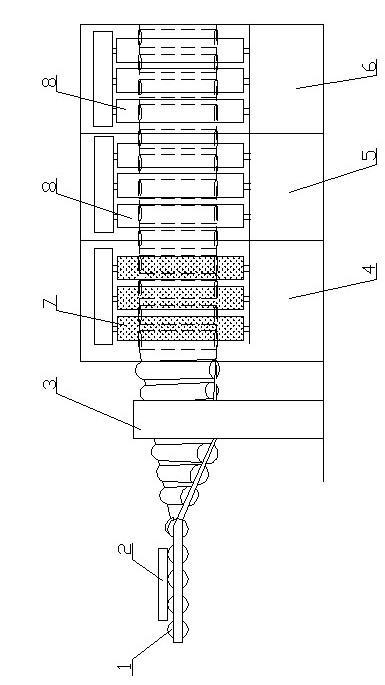

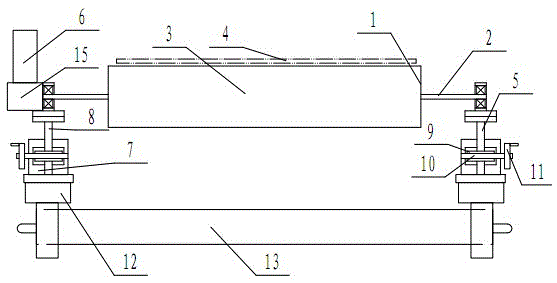

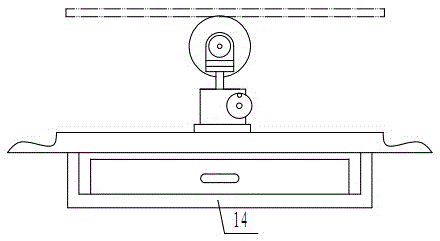

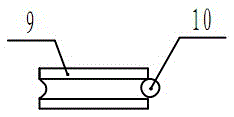

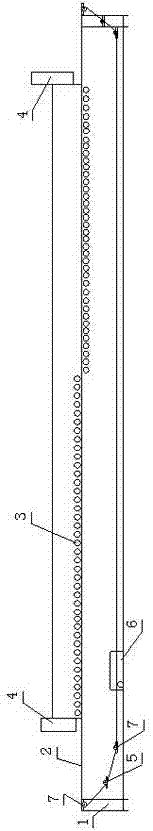

Horizontal automatic skewer baking machine

InactiveCN104921615AClean energyImprove thermal efficiencyBaking surface cleaning/greasingRoasters/grillsCooking & bakingGlass cover

The invention provides a horizontal automatic skewer baking machine which is provided with a housing and a housing cover. Multiple supports are arranged inside the housing in parallel, multiple rectangular holes rightly facing the supports are formed in the housing cover, rollers for skewer arrangement are arranged inside the supports, the upper portions of the rollers are arranged outside the rectangular holes, the rollers are of cylinder cage-shaped structures, a motor for driving the corresponding roller to turn over is arranged outside one end of each support, heating tubes for skewer baking are arranged inside the supports and on two sides of each roller, oil drip plates are arranged under the rollers, tempered glass covers are arranged above the upper end face of the housing cover and the rollers, and the motors drive the rollers to turn over so as to enable skewers to be evenly baked. The horizontal automatic skewer baking machine avoids the problem that oil-water drips drop onto the heating tubes to produce lampblack in baking, is suitable for various skewers, facilitates oil brushing and seasoning scattering in baking, ensures that the skewers are not polluted in the baking process and has the advantages of being high in skewer baking efficiency and safe in operation, reducing the labor intensity of an operator and the like.

Owner:宝鸡市建鑫机械设备有限责任公司

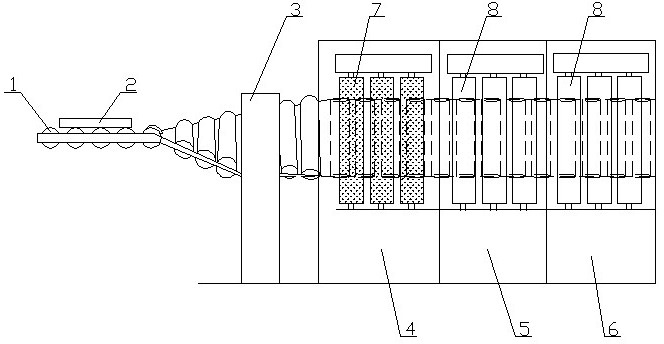

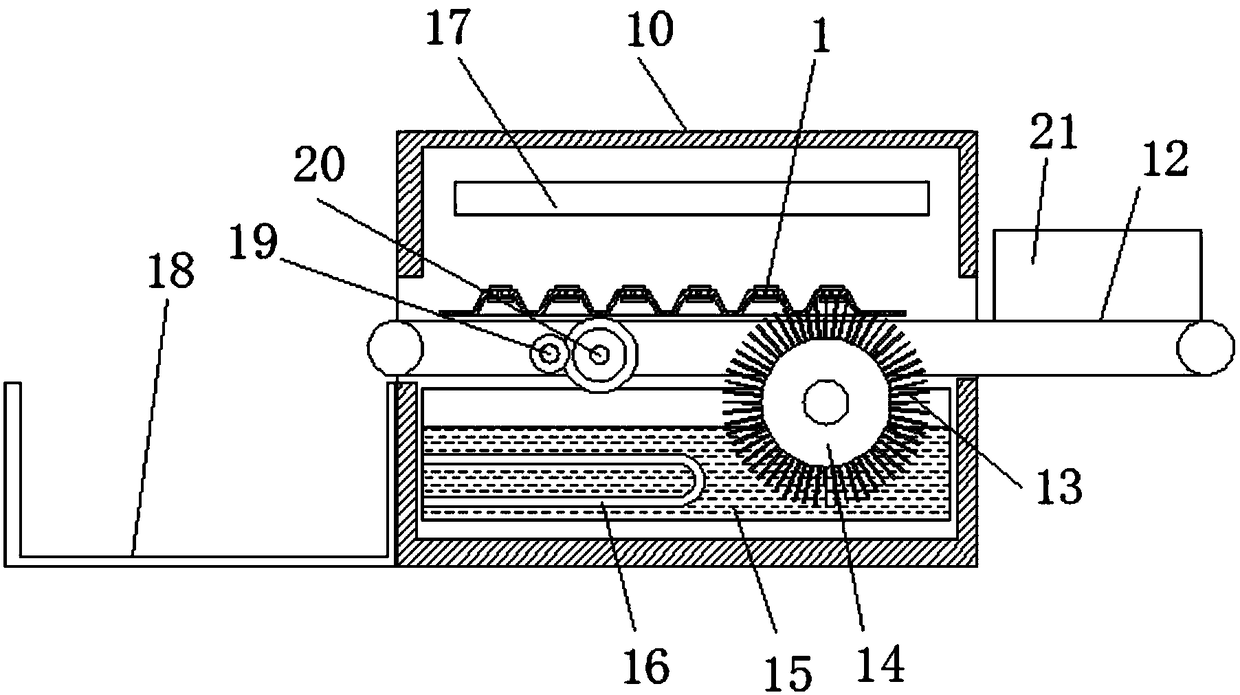

Baking oven conveying net band cleaning device

InactiveCN105454336AEasy to cleanImprove efficiencyBaking surface cleaning/greasingBristleMotor drive

The invention discloses a baking oven conveying net band cleaning device. The baking oven conveying net band cleaning device comprises a cylindrical metal brush, the metal brush is provided with a rotating shaft and brush bristles fixedly installed in the circumferential direction of the rotating shaft, the metal brush is installed under a baking oven conveying net band, the brush bristles can make tight contact with the net band, two ends of the rotating shaft are connected to a supporting seat in a rotatable manner, and one end of the rotating shaft is connected with a motor. The motor drives the metal brush to rotate to clean waste materials on the net band, labour and time are saved, the cleaning effect is good, the efficiency is high, the safety is high, automation can be achieved conveniently, problems existing in the prior art that manual cleaning is time-consuming and labor-consuming, and is poor in effect, low in efficiency and poor in safety are effectively solved, and the baking oven conveying net band cleaning device is advantaged in that the device is simple in structure and low in cost, and can be installed, dismounted, used and operated conveniently and quickly.

Owner:GUIZHOU HUATENG AGRI TECH CO LTD

Pan inverting and/or cleaning system

A pan inverting system (10) comprises a rotating table (11) having a central longitudinal axis (13), the table being rotatably mounted within a static frame (15) for rotation about the longitudinal axis (13). Conveyors (21) are disposed on opposed pan-receiving surfaces (20) of the table (11). The conveyors (21) are independently operable to displace a pan (12) along the table (11) in a direction substantially parallel to the longitudinal axis (13). A pan engagement device (24) within the table (11) is operable to releasably fasten the pan (12) to the pan receiving surface (20) of the table (11), such that when the pan (12) is fastened to one of the pan receiving surfaces (20) by the pan engagement mechanism (24), rotation of the table (11) about the longitudinally extending axis (13) will invert the pan (12). The table (11) may also equipped with air headers (507), nozzles and / or air knives (508) to clean the pans (12), for example during the rotating operation, by injecting cleaning air jets onto the surfaces of the pan (12).

Owner:REXFAB

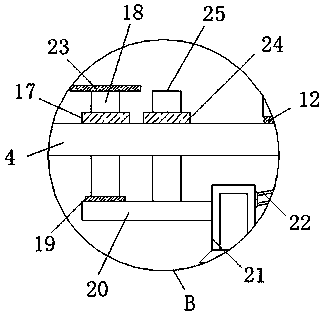

Numerical control machine of imitation handmade pancakes

InactiveCN108244162ARealize fully automatic productionUniform fireOil/fat bakingBaking surface cleaning/greasingNegative feedbackNumerical control

The invention discloses a numerical control machine of imitation handmade pancakes. The numerical control machine of imitation handmade pancakes comprises a heating and baking device, a paste feedingdevice, a paste scraping device, a pancake scraping and taking device, a gripping device, an oil applying device and a control system, wherein the heating and baking device, the paste feeding device,the paste scraping device, the pancake scraping and taking device and the gripping device are all connected with the control system. According to the numerical control machine of imitation handmade pancakes, the control system which uses a PLC and a sensor system as a core is adopted, and various parameters are digitally adjustable, so that the fully-automatic production of the imitation handmadepancakes is truly achieved; closed-loop negative feedback constant temperature control is adopted; and the numerical control machine is energy-saving, environmentally friendly and uniform in durationand degree of heating.

Owner:张同金

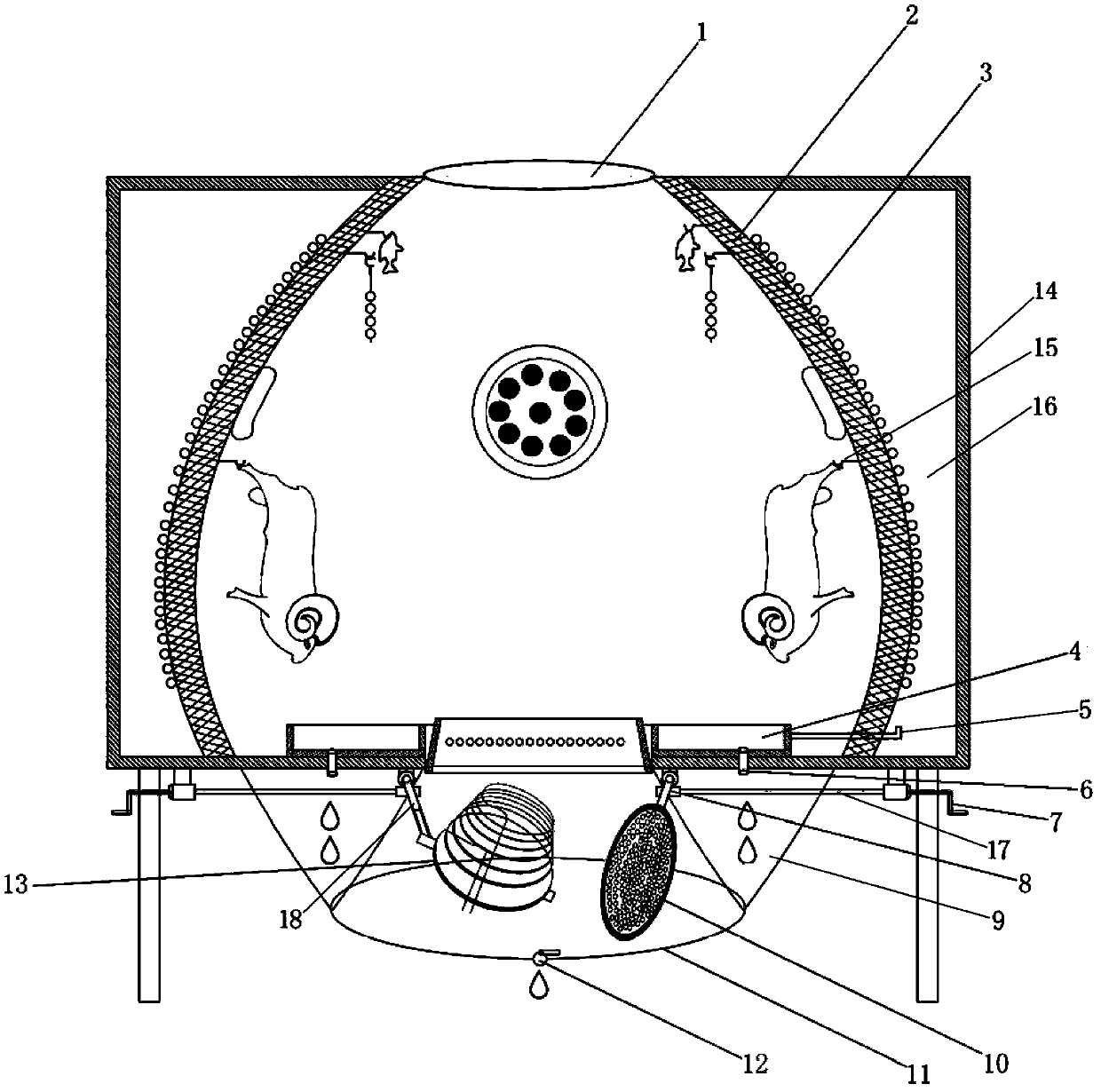

Multifunctional energy-saving and environment-friendly naan pit type oven

ActiveCN103719177AClear in timeAvoid it happening againBaking surface cleaning/greasingHollow article bakingWater pipeWaste management

The invention discloses a multifunctional energy-saving and environment-friendly naan pit type oven. The multifunctional energy-saving and environment-friendly naan pit type oven comprises a protecting shell, an oven shell and an annular tank, wherein a transmission device and a heater transfer device are arranged on the outer wall of the bottom of a shell body of the protecting shell, the heater transfer device is provided with a movable part, and the heater transfer device is driven to work by power through the transmission device so as to drive the movable part of the heater transfer device to transfer a heater to a roasting chamber from the outer portion of the protecting shell through a first through hole or transfer the heater to the outer portion of the protecting shell from the inner portion of the roasting chamber through the first through hole. The multifunctional energy-saving and environment-friendly naan pit type oven further comprises water inlet pipes, a waste liquid containing portion and a waste liquid discharge valve, wherein the water inlet pipes are communicated with a tank cavity formed by the annular tank, the waste liquid discharge valve is arranged on a waste liquid discharge port formed in the bottom of the waste liquid containing portion, and the tank cavity is communicated with a valve cavity of the waste liquid discharge valve through liquid leakage holes and a liquid accumulation cavity, wherein the liquid leakage holes are formed in the bottom of the shell body of the protecting shell, and the liquid accumulation cavity is formed in the waste liquid containing portion. The multifunctional energy-saving and environment-friendly naan pit type oven is reasonable in structure, solid animal fat dripping to the bottom inside a naan pit can be timely cleared out, and the work intensity for clearing out the solid animal fat is greatly lowered.

Owner:艾力·加帕尔

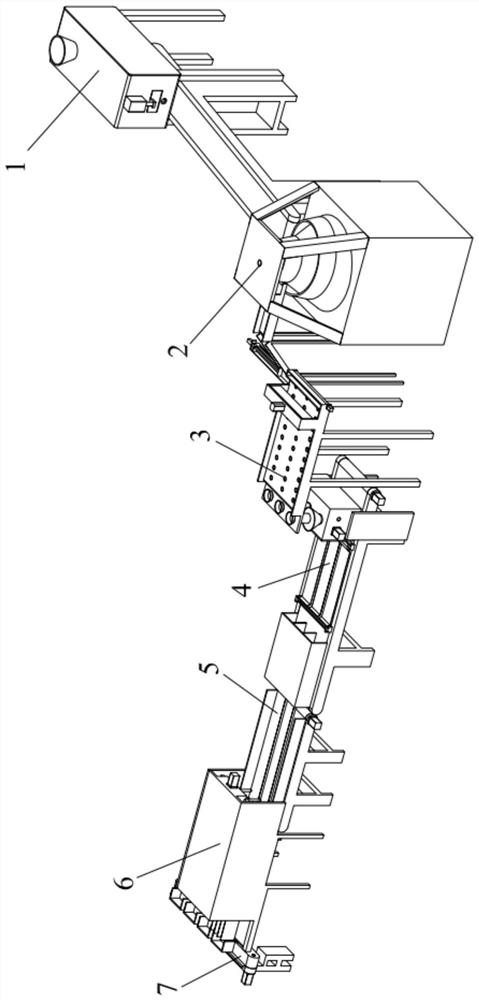

Full-automatic toast production line

PendingCN113243405AIncrease productivityReduce manual involvementConveyorsDough dividingMechanical engineeringIndustrial engineering

The invention discloses a full-automatic toast production line, and belongs to the field of toast preparation. The full-automatic toast production line comprises a toast conveying device and a folding device arranged along the toast conveying device and used for folding strip-shaped dough into a U shape. Compared with the prior art in which toast is produced by adopting a U-shaped shaping making method, the strip-shaped dough needs to be folded into a U shape and then put into a toast box when the toast is put into the box for baking, so that relatively more workers need to manually fold and put into the box, the full-automatic toast production line has the beneficial effects that by means of the folding device, the formed strip-shaped dough is folded through the folding device, so that the strip-shaped dough is changed into a U-shaped folded shape, manual operation is not needed, a plurality of U-shaped folded dough can be formed at a time, and the speed is equivalent to several times of the manual processing speed, so that the production and processing efficiency is well improved, and the labor cost is reduced.

Owner:漳州金钥匙机械有限公司

Oil spraying device for biscuit processing

InactiveCN110623014AIncrease the speed of oilingImprove brushing efficiencyBaking surface cleaning/greasingSpray nozzleThreaded rod

The invention relates to the technical field of biscuit processing equipment and discloses an oil spraying device for biscuit processing. The oil spraying device comprises a fixing plate, the top of the fixing plate is fixedly connected with a box through a fixing block, the top of the box is fixedly connected with an oil inlet pipe, the bottom of the fixing plate is fixedly connected with an oilpump, an oil inlet of the oil pump is fixedly connected with an oil outlet of the box through an oil delivery pipe, an inner cavity of the fixing plate is fixedly connected with a nut, a threaded rodis in threaded connection in the nut, the bottom of the threaded rod is fixedly connected with a movable plate through a bearing block, one end of the movable plate is fixedly connected with a spray nozzle, an oil inlet of the spray nozzle and the oil outlet of the oil pump are fixedly connected through an oil drain pipe. Through cooperation of the box, the oil pump, the oil delivery pipe, the spray nozzle and the oil drain pipe, the oil spraying device for biscuit processing can increase the oil brushing speed for biscuits, reduce demands for labor force, save a large quantity of labor force,improve the oil brushing efficiency of biscuits and increase the production speed of biscuits.

Owner:胡殿芬

Automation fish grilling device

InactiveCN103109882AAvoid stickingGrill evenlyBaking surface cleaning/greasingSpecial goods bakingAgricultural engineeringSprocket

The invention discloses an automation fish grilling device. The automation fish grilling device comprises a strip-shaped machine frame, the machine frame is provided with at least two chain wheel shafts and stainless steel wires, the stainless steel wires are wound on the chain wheel shafts to form an annular shape, and the chain wheel shafts drive the stainless steel wires to rotate. The machine frame is further provided with two rows of fire doors, and the two rows of fire doors directly face two faces of the stainless steel wires. By means of the automation fish grilling device, grilled fish is uniform in dehydration and color and luster and appropriate in strength, energy consumption of per unit output is reduced by 25 %, and grilled fish production efficiency is improved.

Owner:博湖县蓝翔食品水产有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com