Anti-sticking forming equipment for cake food processing and forming method

A technology for food processing and molding equipment, applied in the field of food processing, can solve problems such as stickiness, stickiness between cake raw materials and molding grooves and pressing plates, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

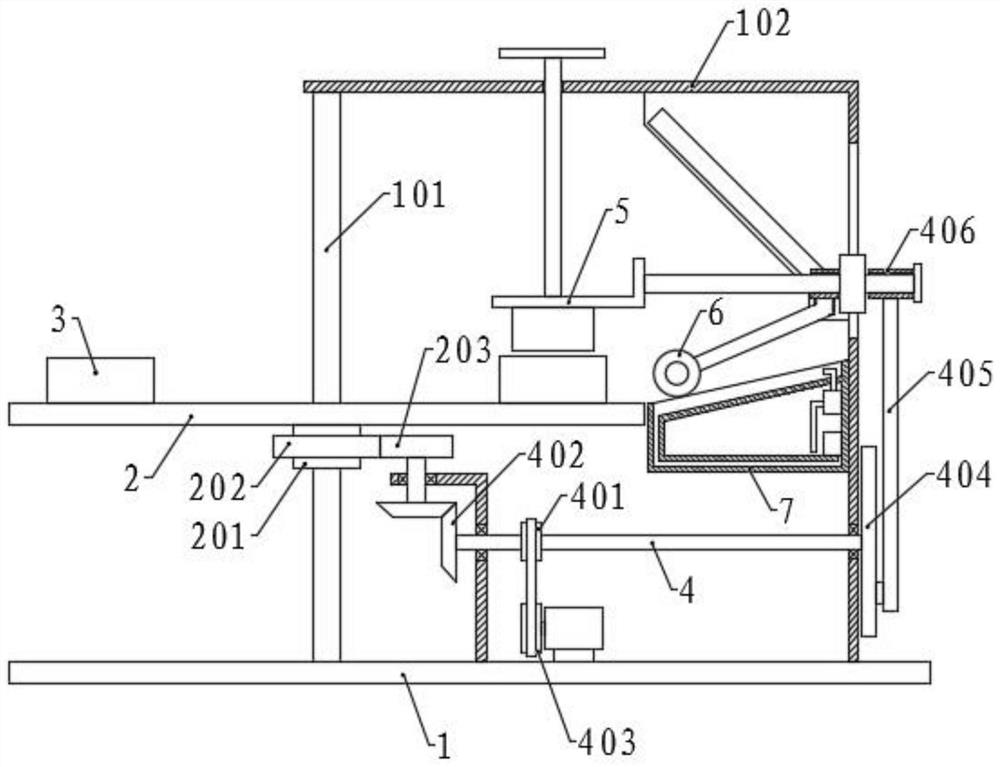

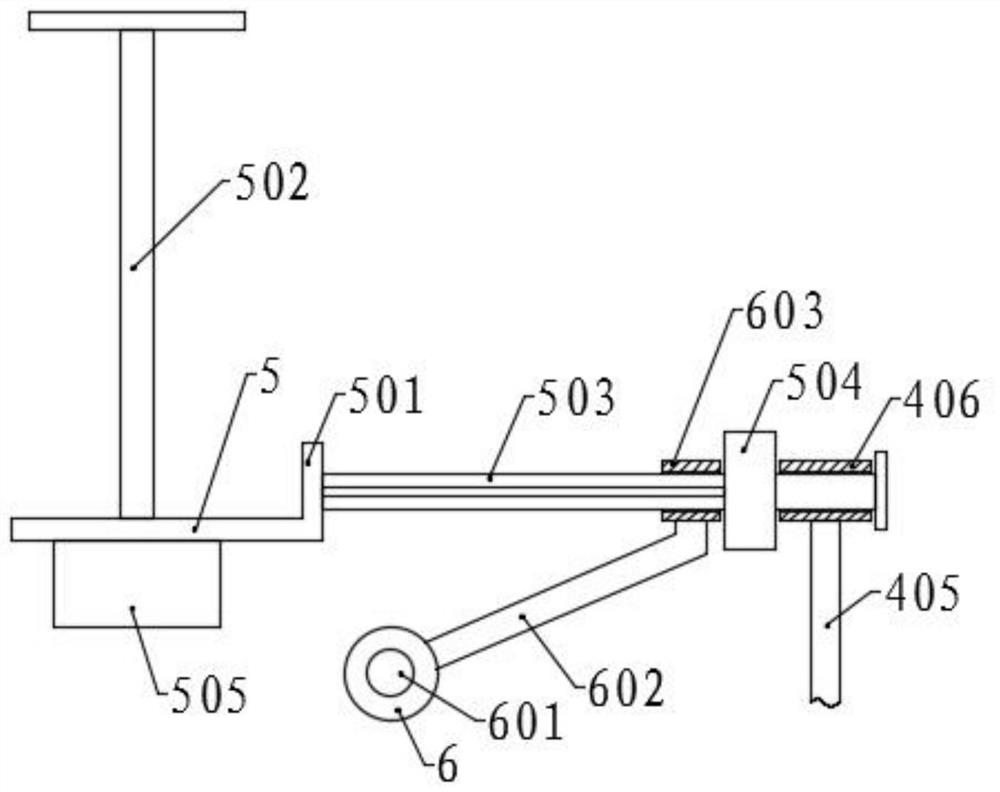

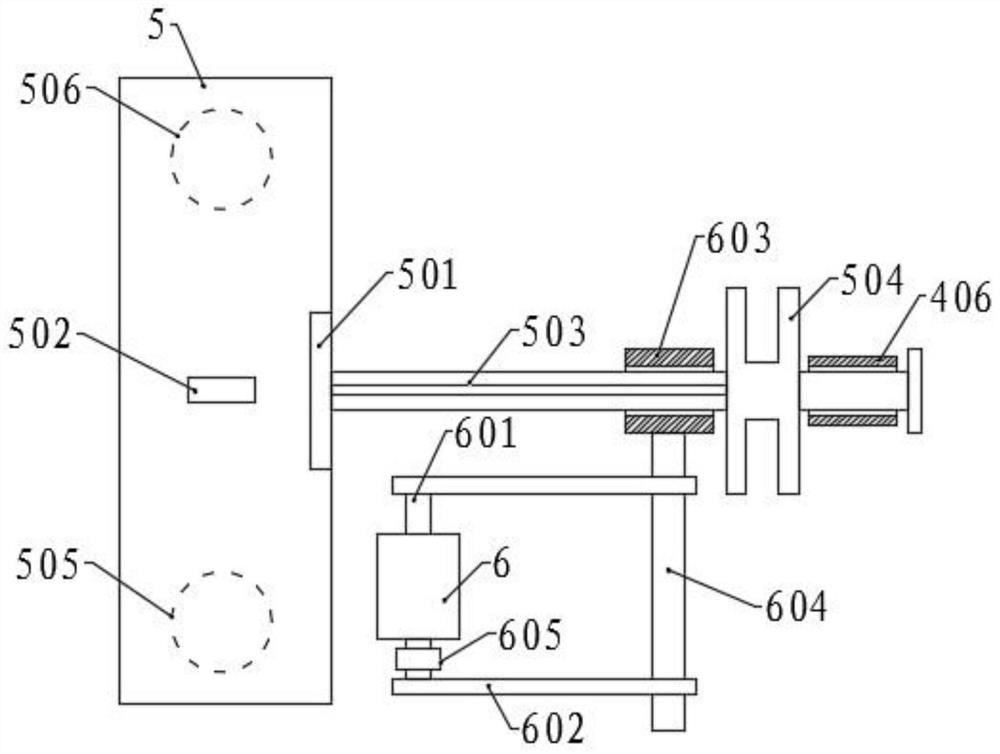

[0048] Please refer to the accompanying drawings, the present invention provides a technical solution: a kind of anti-sticking forming equipment for cake food processing, including a base 1, the top surface of the base 1 is fixed with a vertical fixed shaft 101, and the fixed shaft 101 is rotatably connected There is a turntable 2, the top surface of the turntable 2 is evenly fixed with a plurality of forming die grooves 3 along the circumferential direction, and the bottom of the turntable 2 is provided with a rotating assembly, the top of the fixed shaft 101 is fixed with a horizontal plate 102, and the top of the horizontal plate 102 The outer end is fixed with a vertical vertical plate 103, and the bottom end of the vertical plate 103 is fixedly connected with the base 1, the horizontal plate 102 is provided with a forming assembly, the forming assembly is connected with a smear assembly, the base 1 is provided with a driving assembly, and Both the rotating assembly and the...

Embodiment 2

[0060] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the position corresponding to the smearing assembly on the riser 103 is fixed with an adding tank 7. The adding tank 7 is provided with a liquid storage chamber 703. mold oil, etc., and the top of the liquid storage chamber 703 is provided with an inclined deflector 701, and the liquid storage chamber 703 is provided with a liquid outlet pump 705, and the liquid outlet pump 705 is connected with a suction pipe and a liquid outlet pipe 801, and the outlet The top end of the liquid pipe 801 protrudes from the liquid storage chamber 703 and is located above the deflector 701. The lower end of the deflector 701 is provided with a return channel 702, and the other end of the return channel 702 communicates with the liquid storage chamber 703, and the connection A recovery pump 704 is provided, a motor is fixed on the outside of the adding tank 7, a second friction wheel 706 ...

Embodiment 3

[0067] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a bottom plate 301 is slidably connected in the molding groove 3, a push rod 302 is fixed on the bottom surface of the bottom plate 301, and a spring plate 303 is fixed on the lower section of the push rod 302. And between spring plate 303 and the bottom surface of molding die groove 3, spring is arranged, and the corresponding blanking position on the base 1 is fixedly connected with top plate 304 by fixed rod, and the both sides of top plate 304 are inclined downwards and set, and the top surface of top plate 304 and The bottom ends of the push rods 302 are correspondingly connected.

[0068] When the molding groove 3 drives the formed pastry to move to the blanking position, the bottom end of the ejector rod 302 contacts the top plate 304 and gradually moves up, so that the spring plate 303 compresses the spring, and the bottom plate 301 moves up to move the pastry u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com