Patents

Literature

311results about "Hollow article baking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

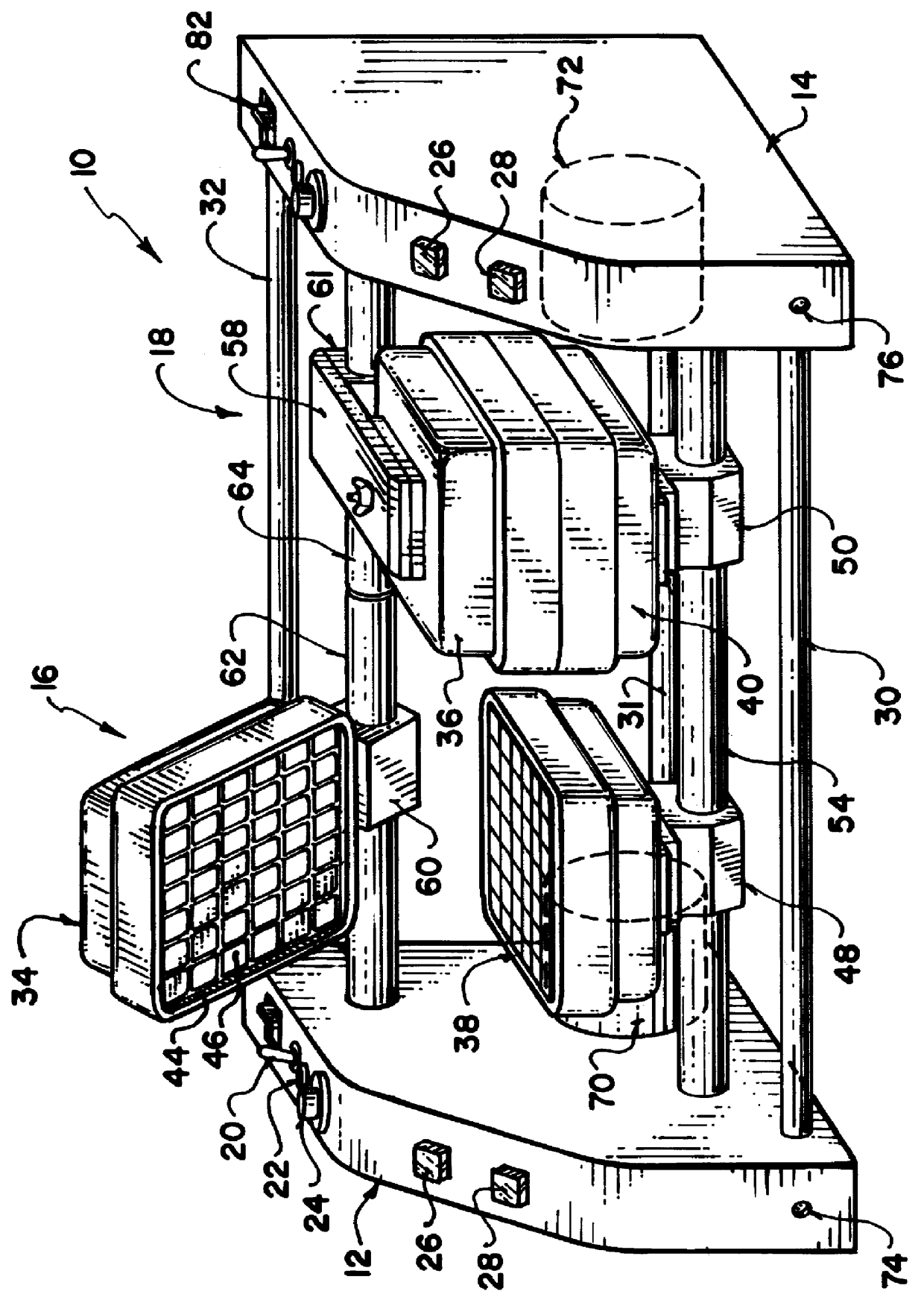

Griddle

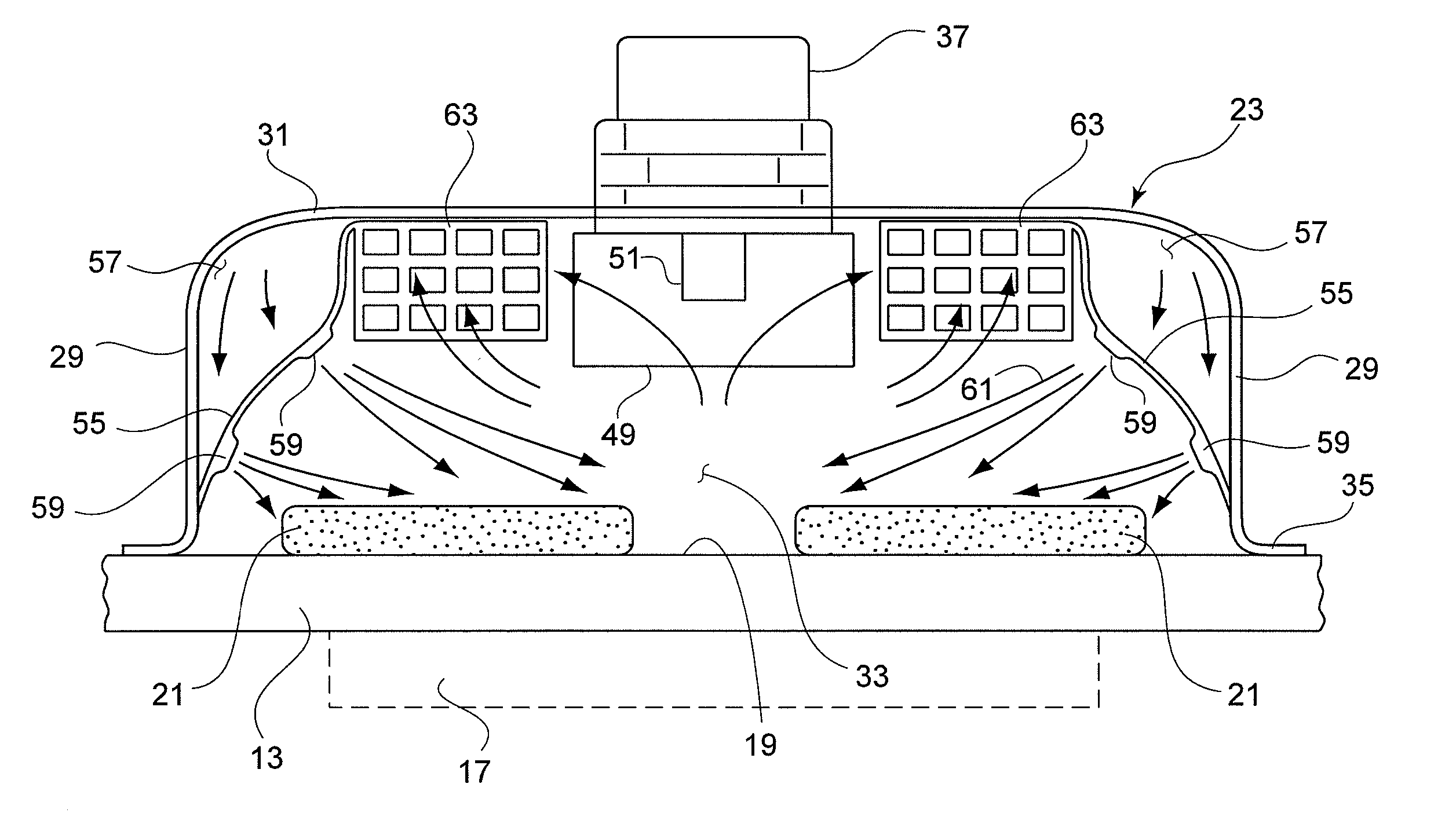

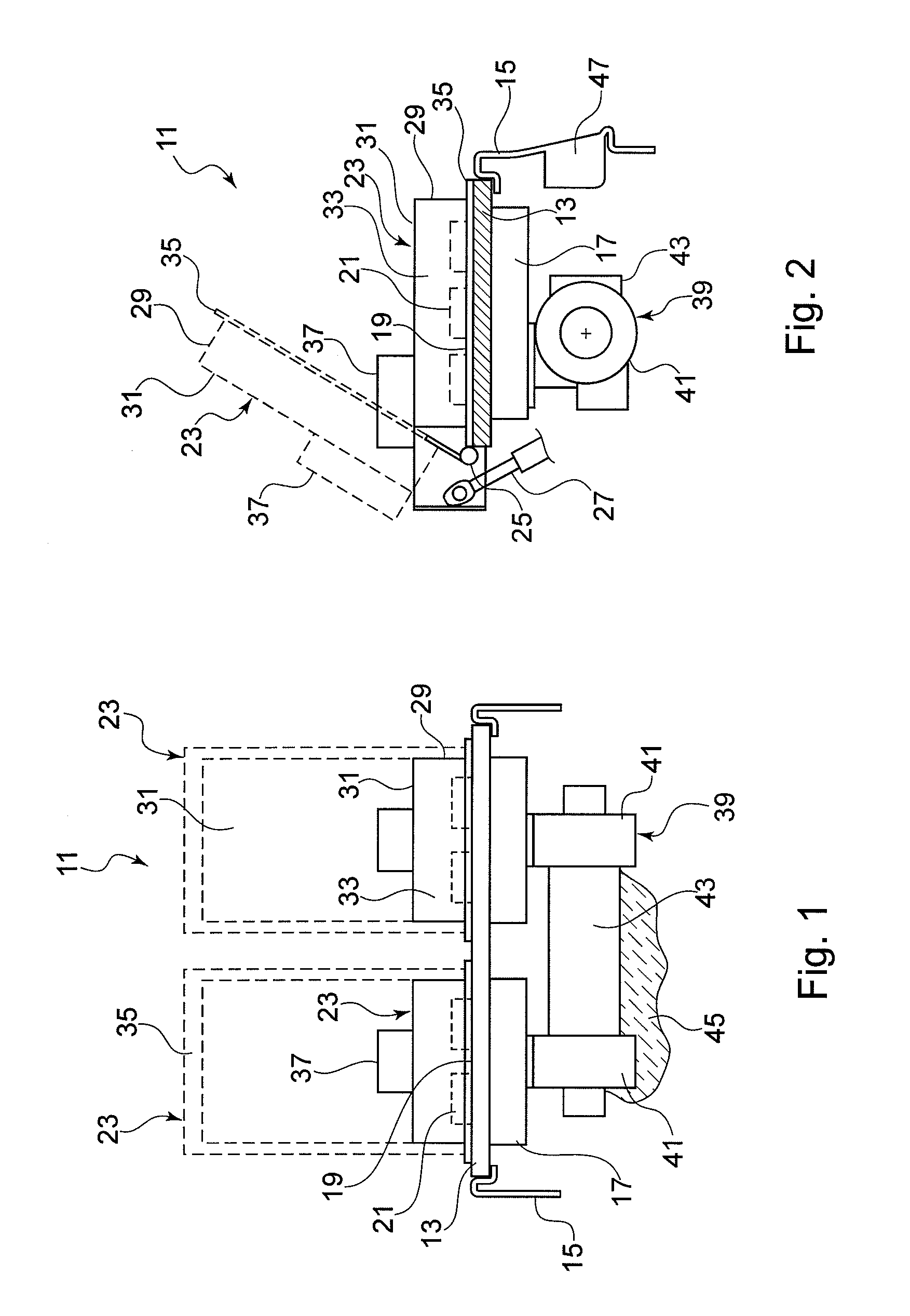

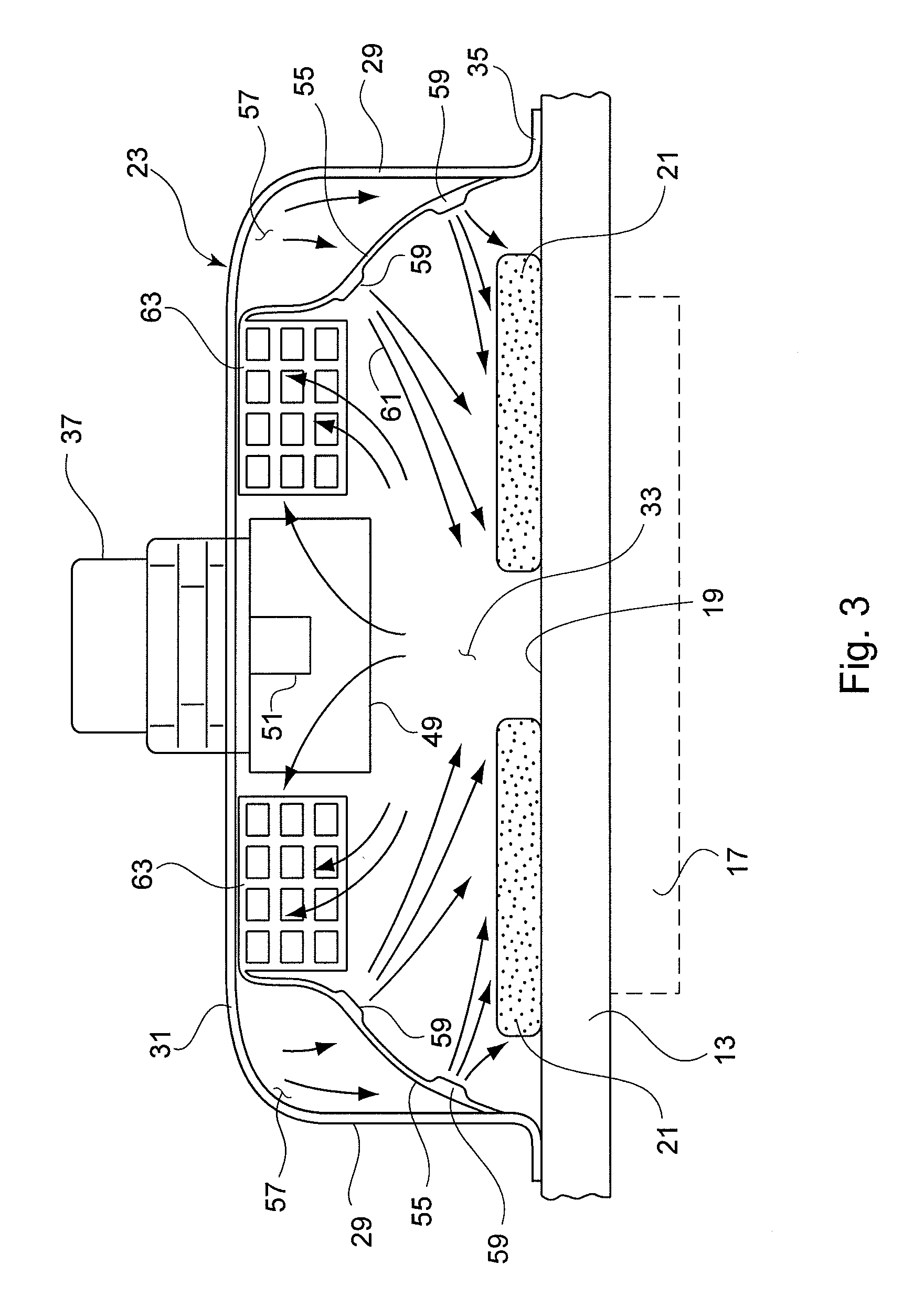

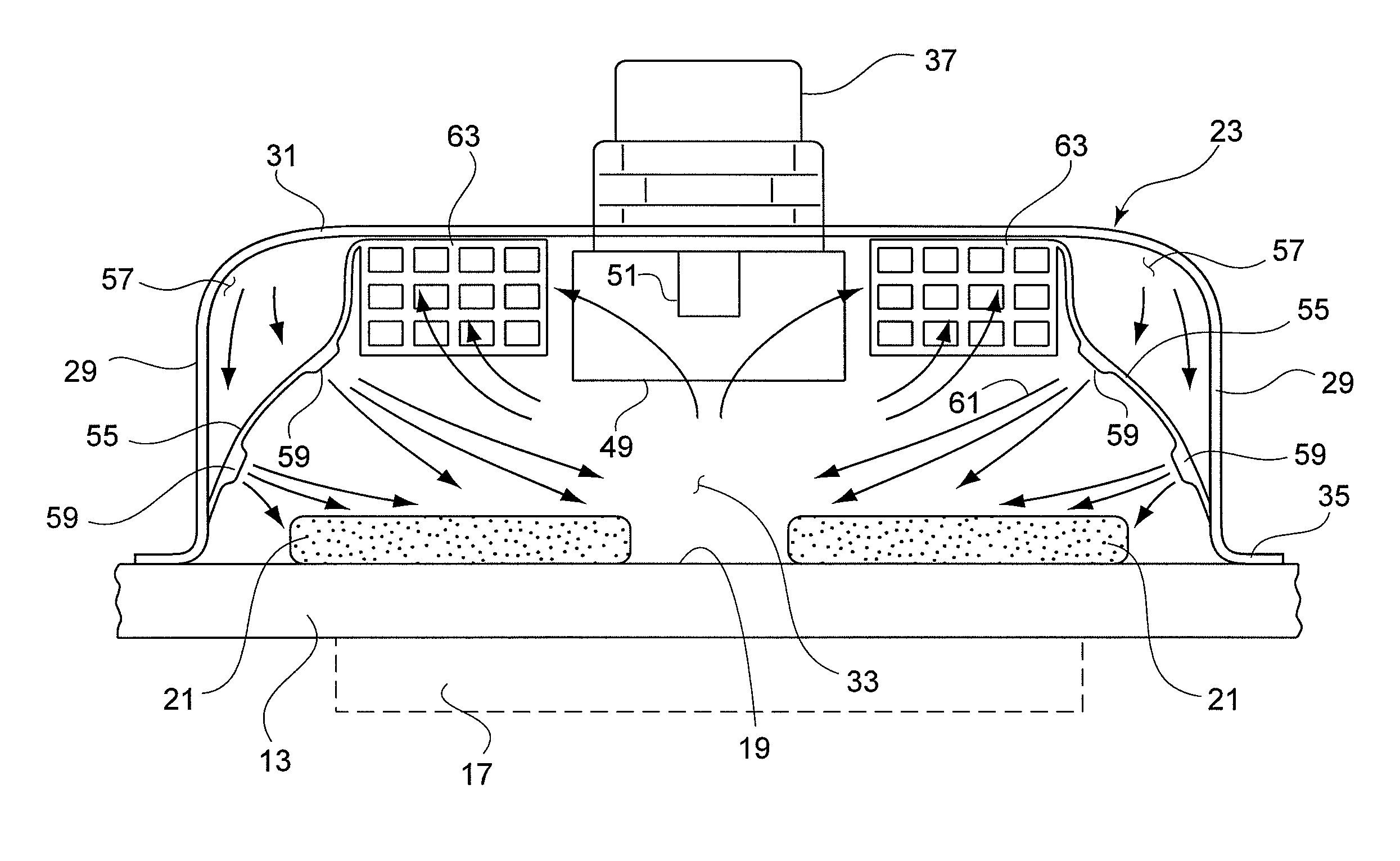

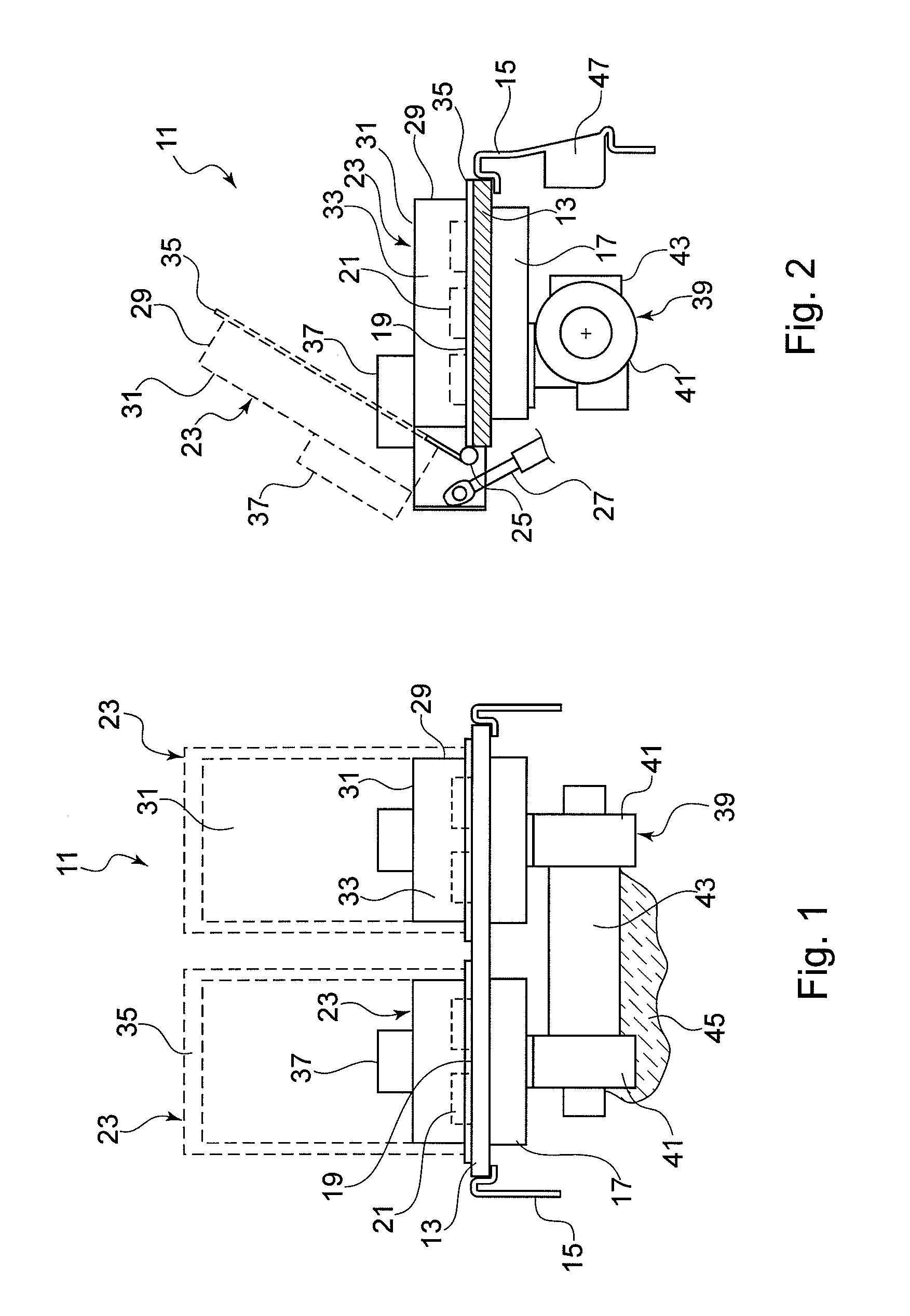

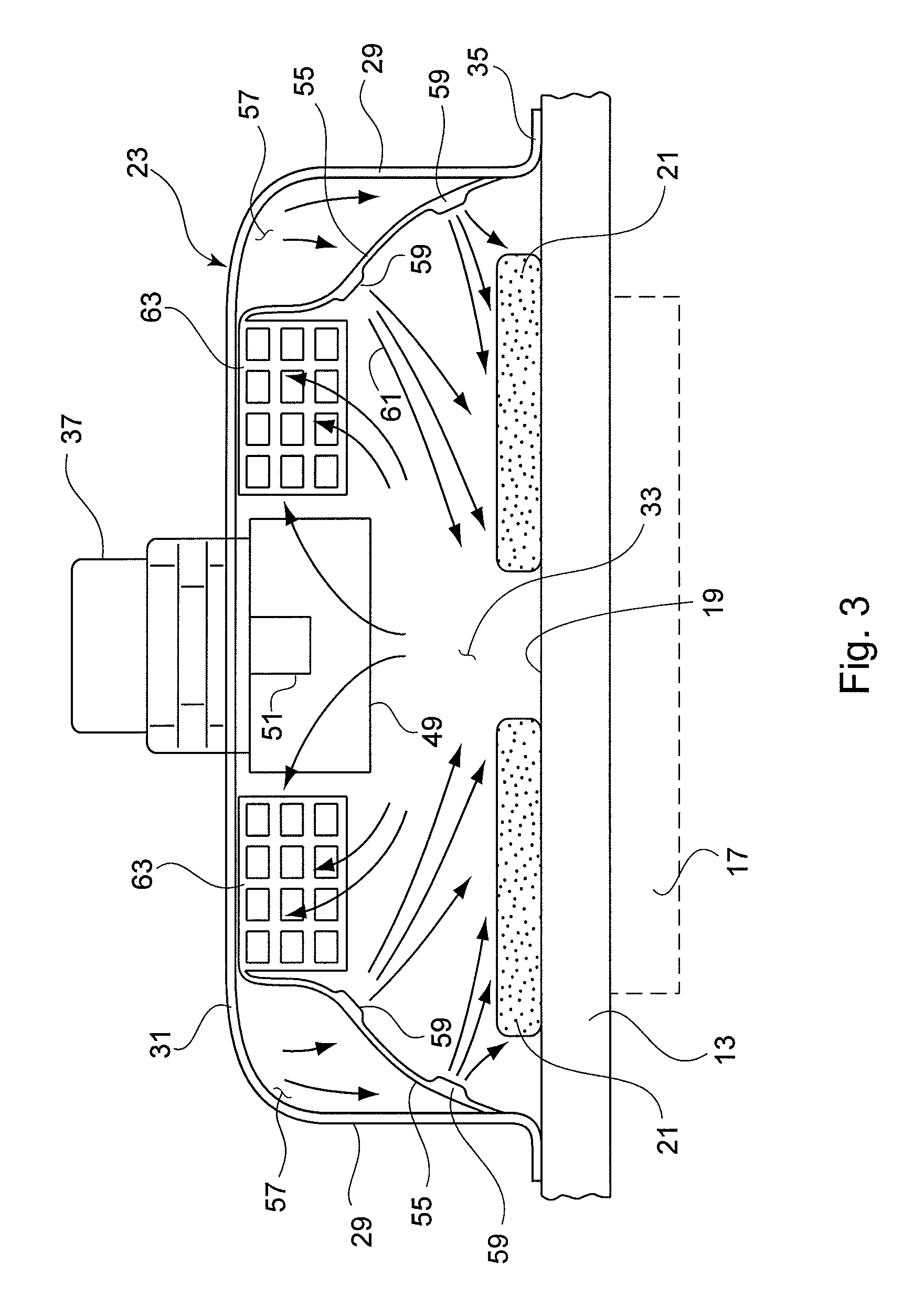

ActiveUS20080105136A1Reduce cooking timeAir-treating devicesMilk preservationProcess engineeringInternal heating

A high-speed griddle for cooking food products has a griddle platen having a cook surface for receiving food products thereon, and heating means are provided for heating the platen. A clamshell cover is configured for sealing contact with the cook surface of the platen, the cook surface and cover cooperating to enclose a cook volume. An electromagnetic energy source is configured for emitting energy into the cook volume, the energy source emitting energy of a frequency selected to cause internal heating of food products within the cook volume. In addition, a convection air system is configured to provide a flow of heated air into the cook volume. The heated platen, electromagnetic energy source, and convection air system cooperate to rapidly cook food products within the cook volume.

Owner:TURBOCHEF TECH INC

Smoke filter system for a cooking appliance

ActiveUS9474412B2Reducing smoke and associated foul odorReducing smoke and associated odorDispersed particle filtrationCooking vesselsParticulatesFilter system

A cooking appliance includes a lower housing having a lower heating surface and an upper housing operatively connected to the lower housing. The upper housing has an upper heating surface and an air inlet at least partially surrounding the upper heating surface. The cooking appliance further includes a filter disposed in the air inlet. The filter is configured to remove particulates from air passing through the air inlet.

Owner:CONAIR CORP

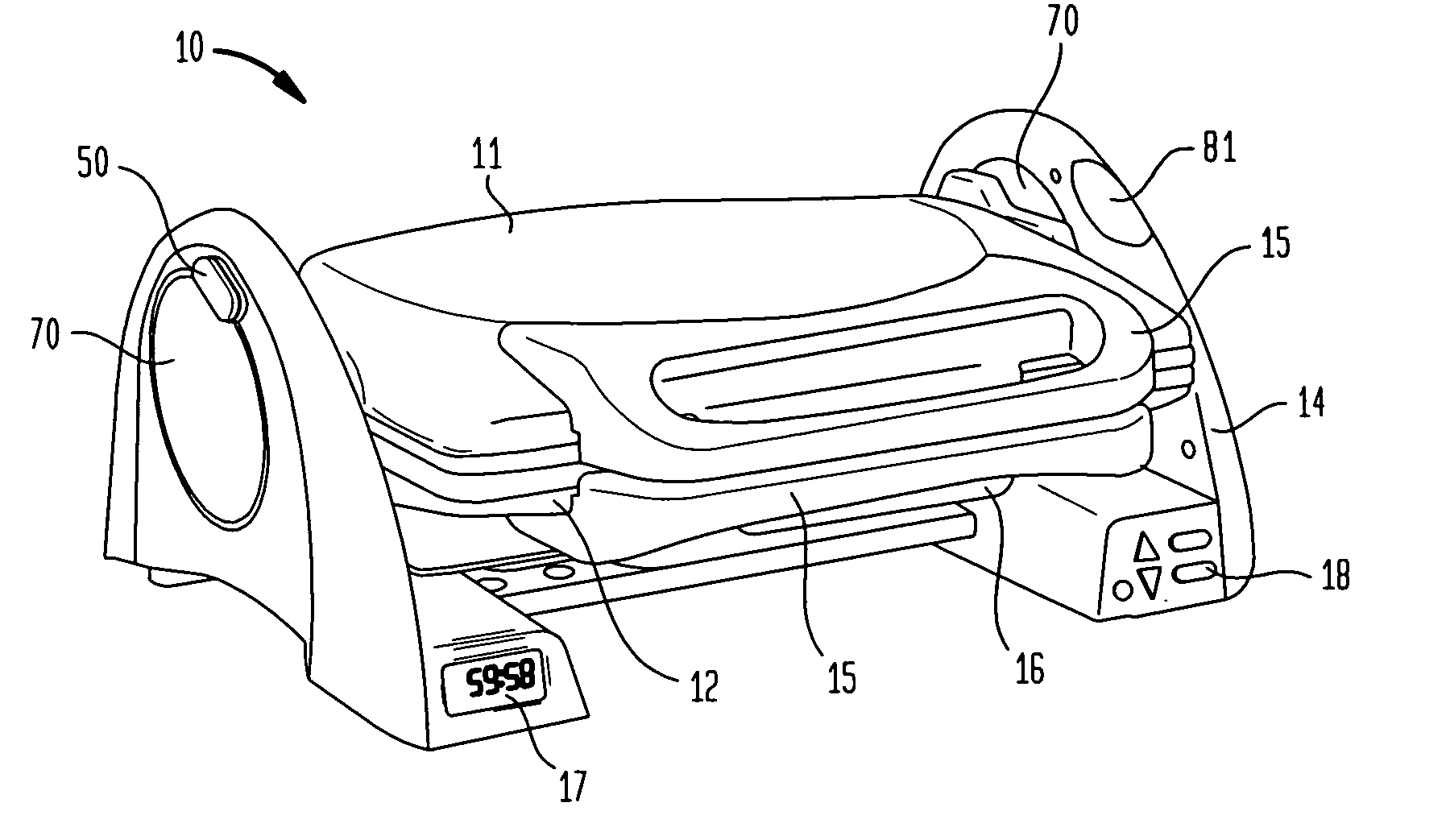

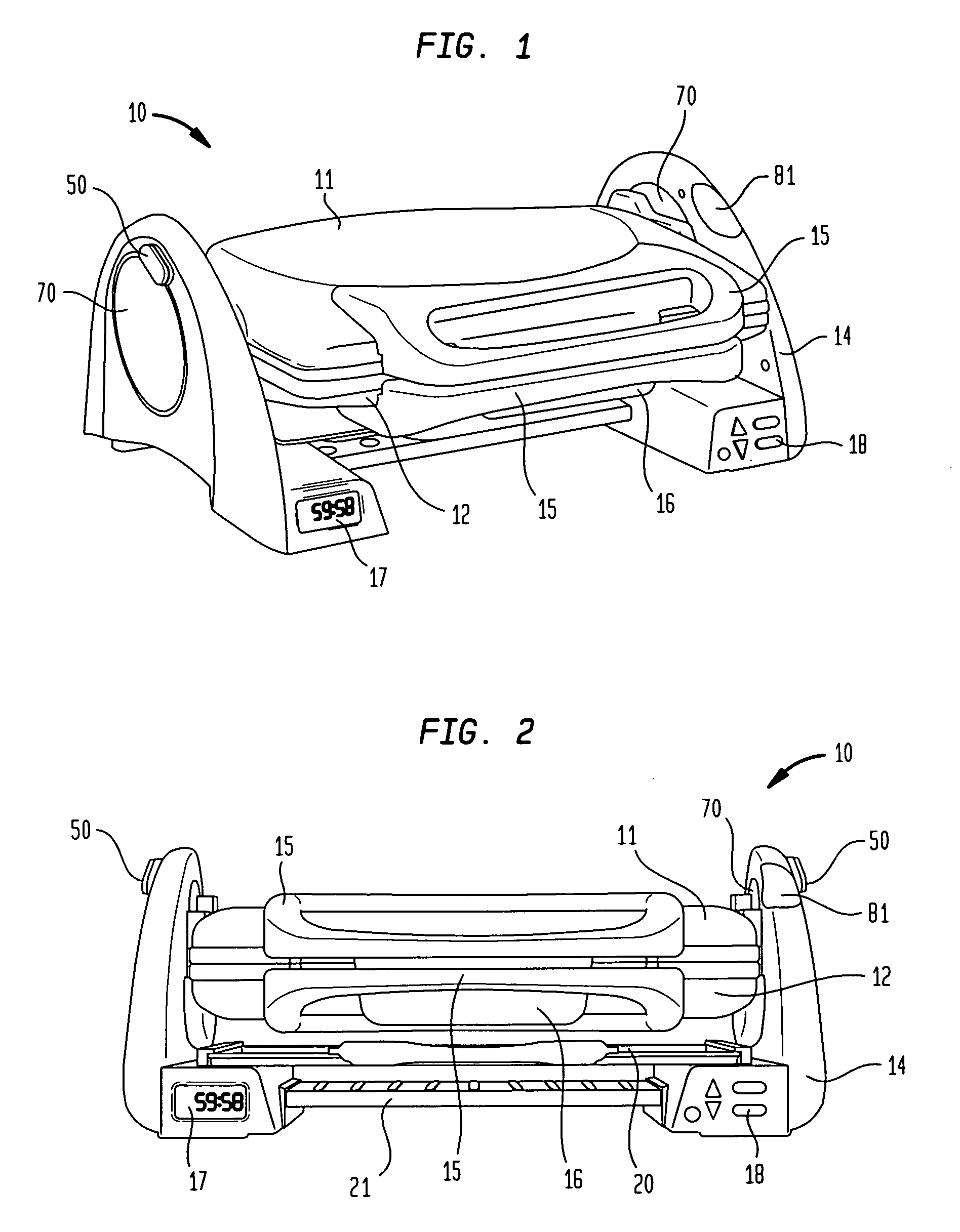

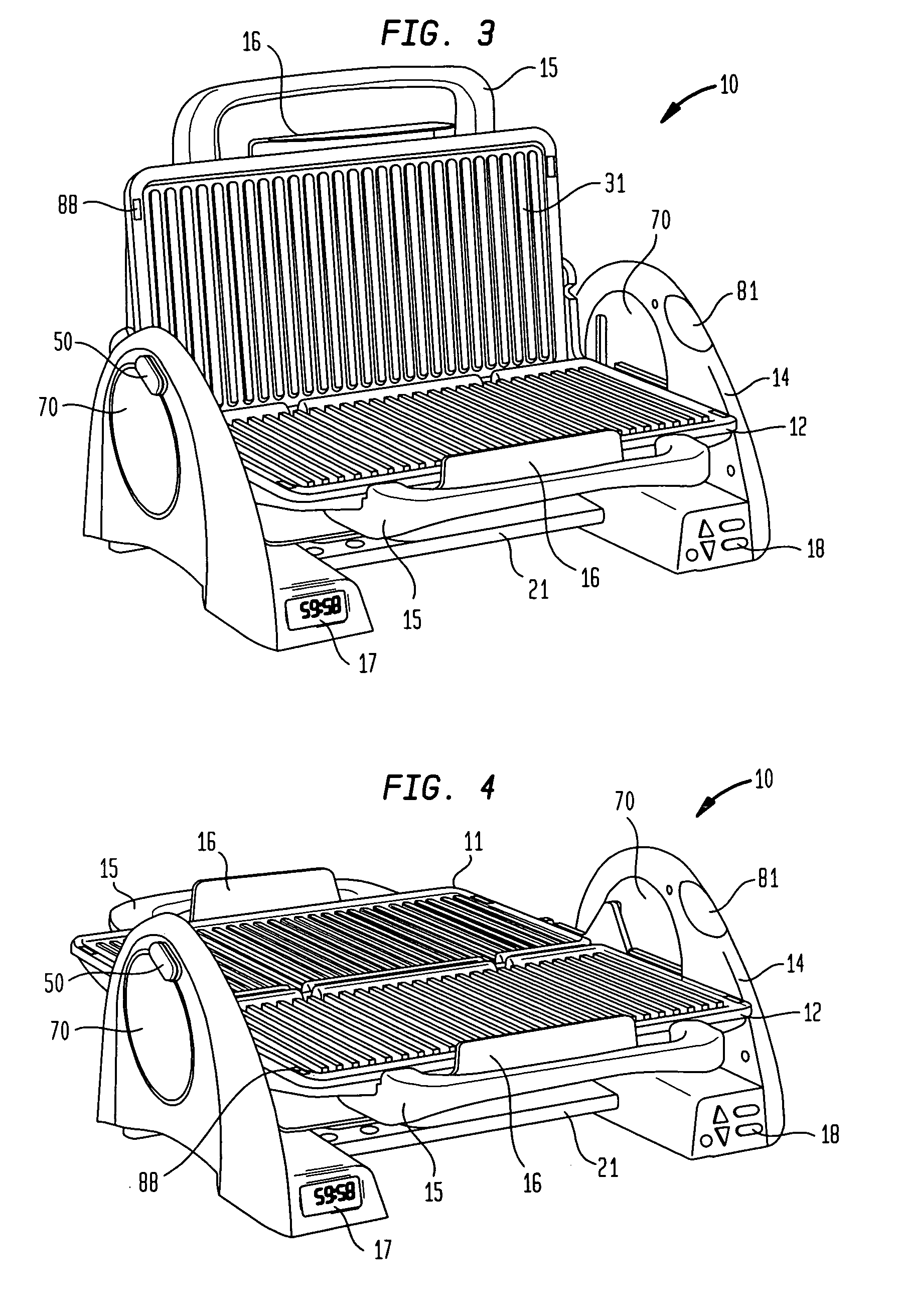

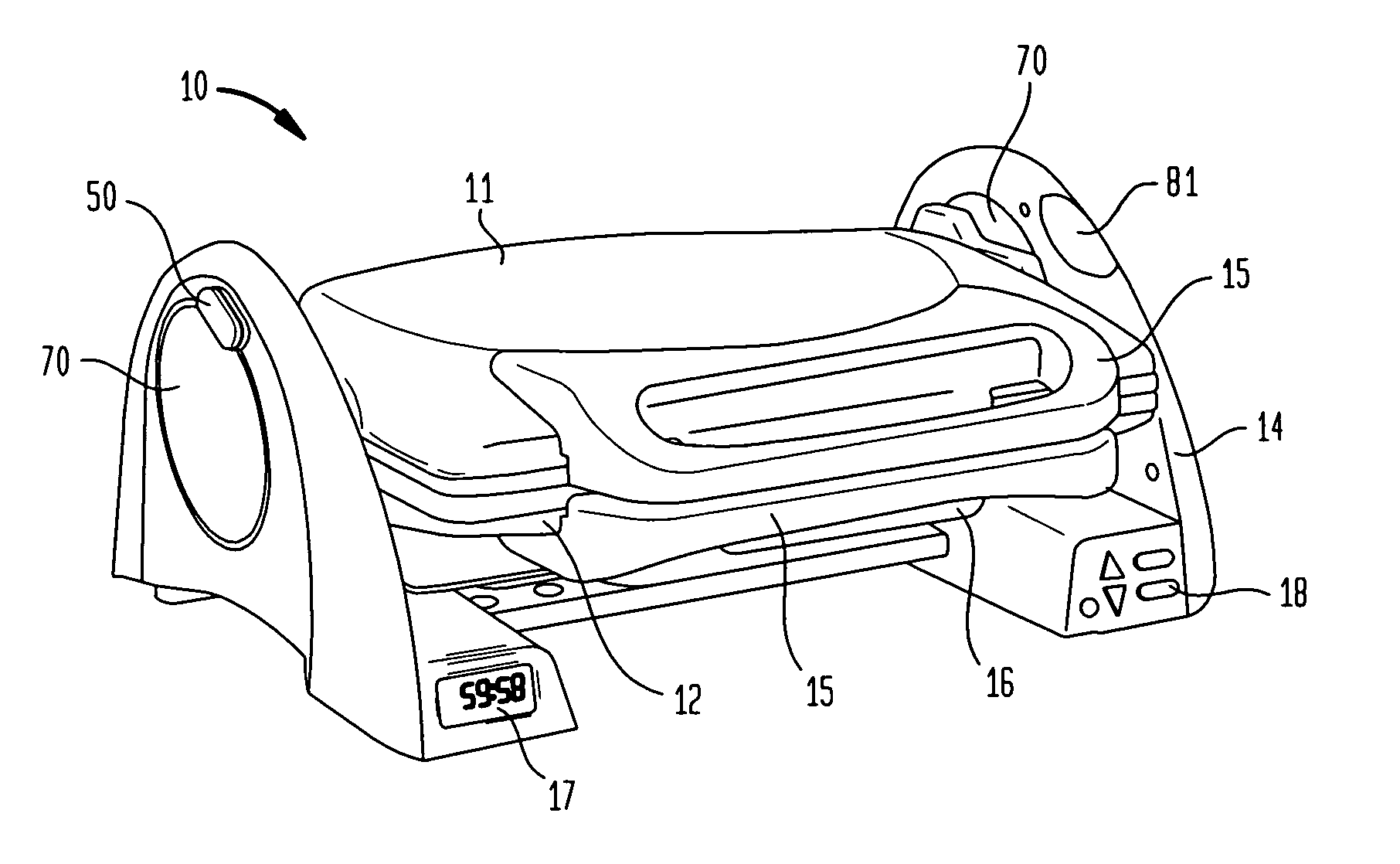

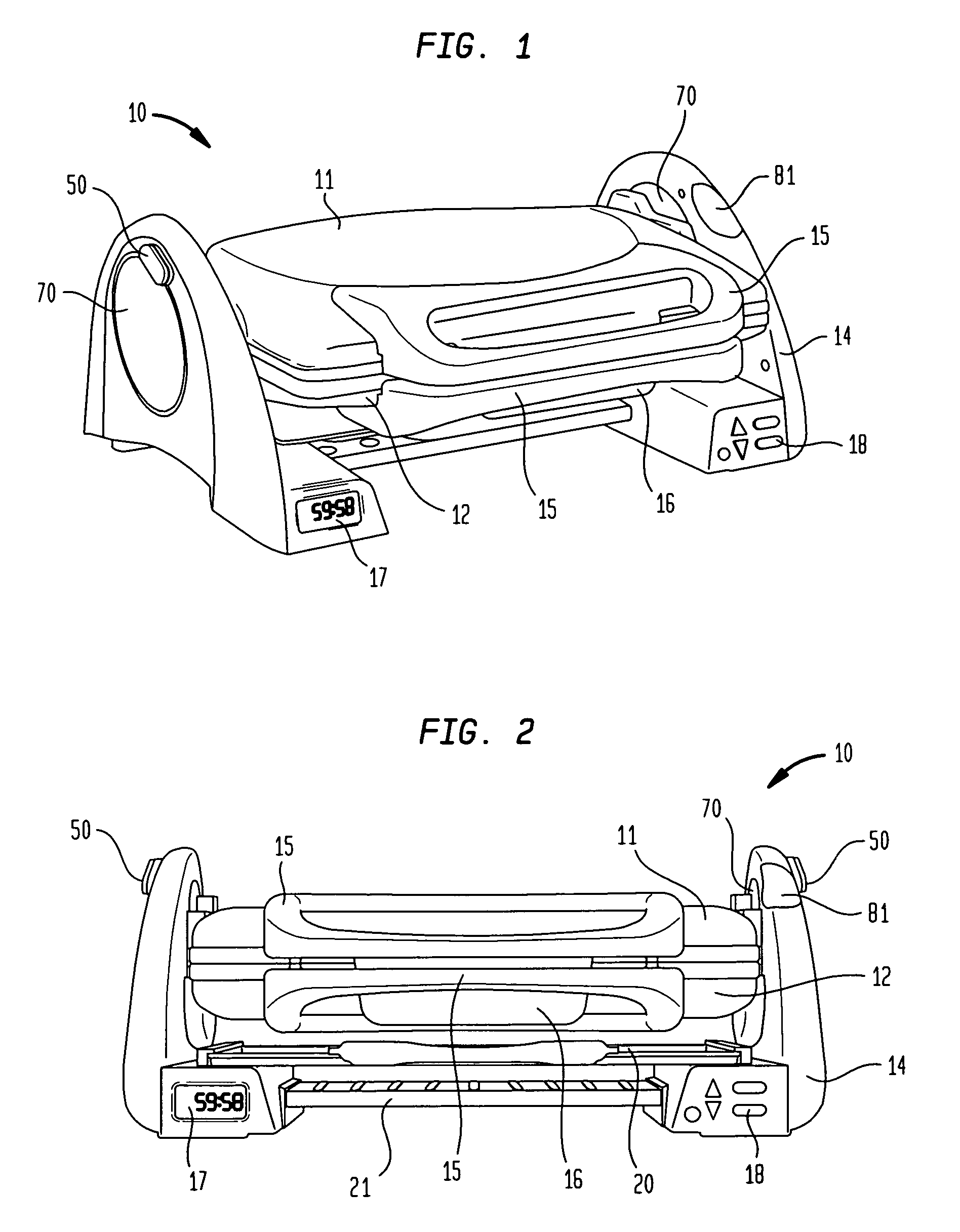

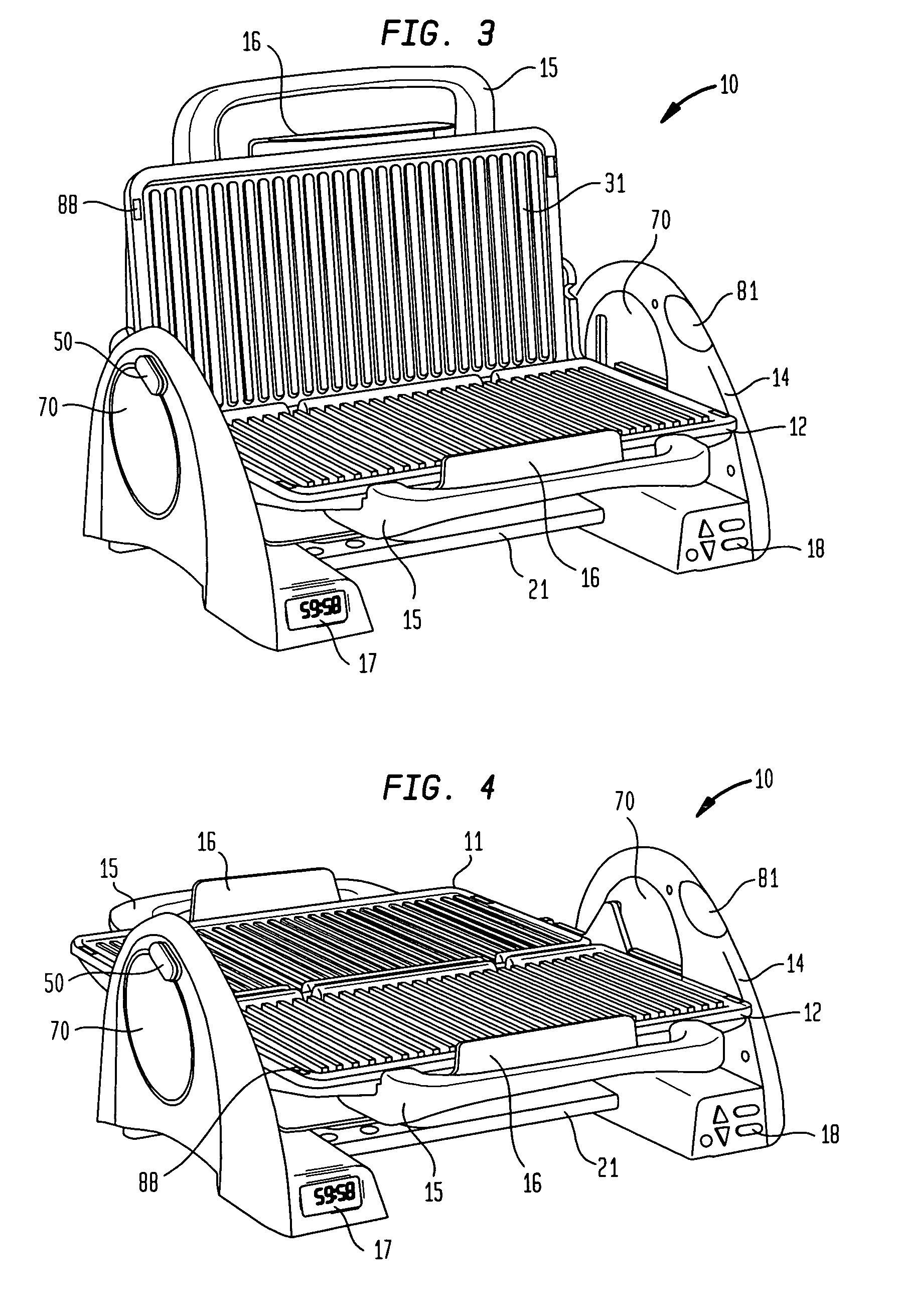

Tiltable pannini grill

InactiveUS20060213373A1Reduce cooking timeEasy to placeDomestic stoves or rangesElectrical heating fuelUser inputDisplay device

An electric grill for use to create healthier meals is disclosed. The electric grill comprises a support structure which holds a top heating section and a bottom heating section connected by a hinge. The hinge allows for a wide range of movement whereby the top heating section may be face to face with the bottom heating section, may be perpendicular, or may be at a 180 degree angle. Moreover, the top and bottom heating sections may be tilted such that excess grease, oils and juices may be separated from the food being cooked. The electric grill disclosed herein also may include a digital read-out display and a user input keypad.

Owner:SOUTH ASIA INT H K +1

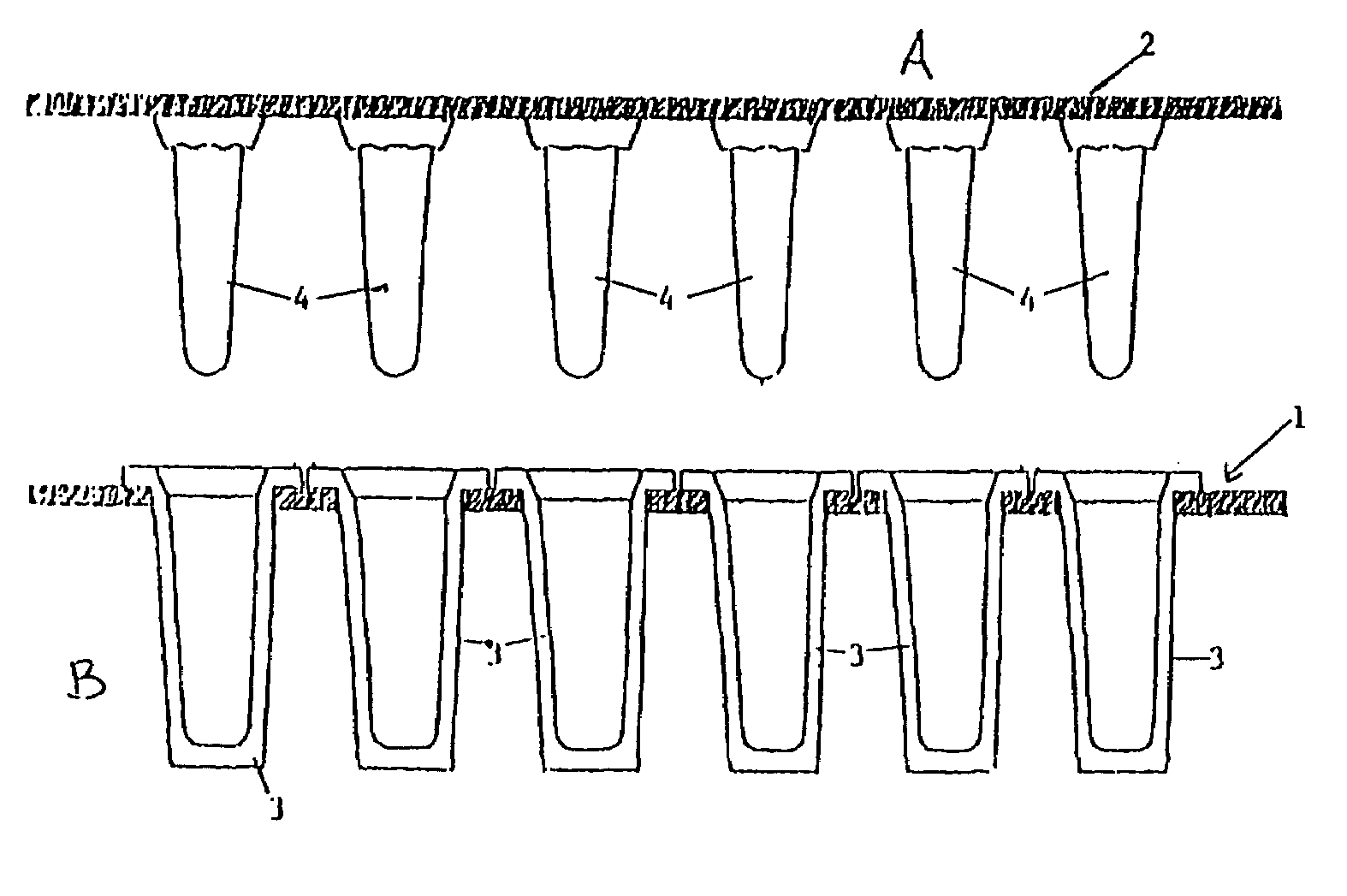

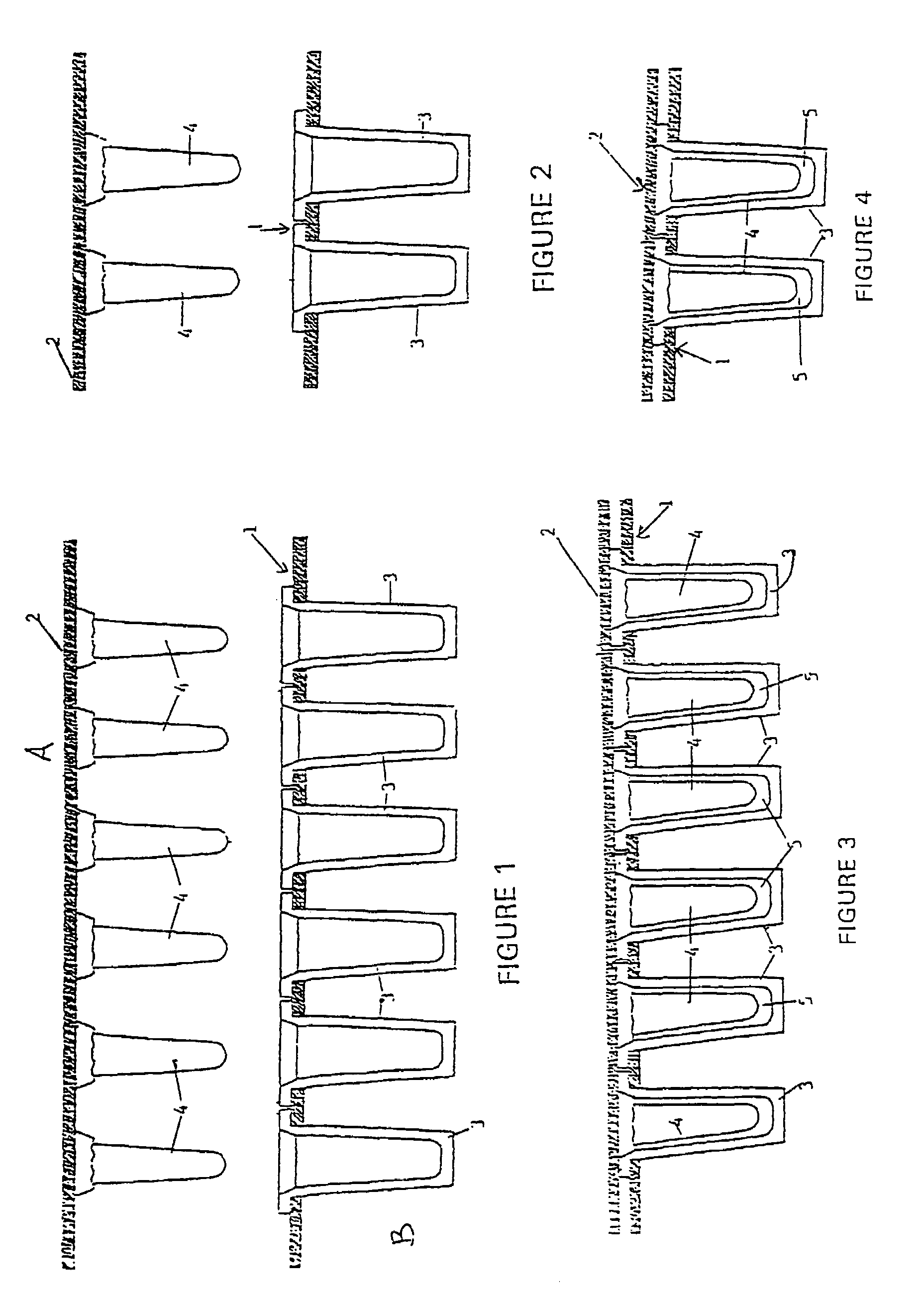

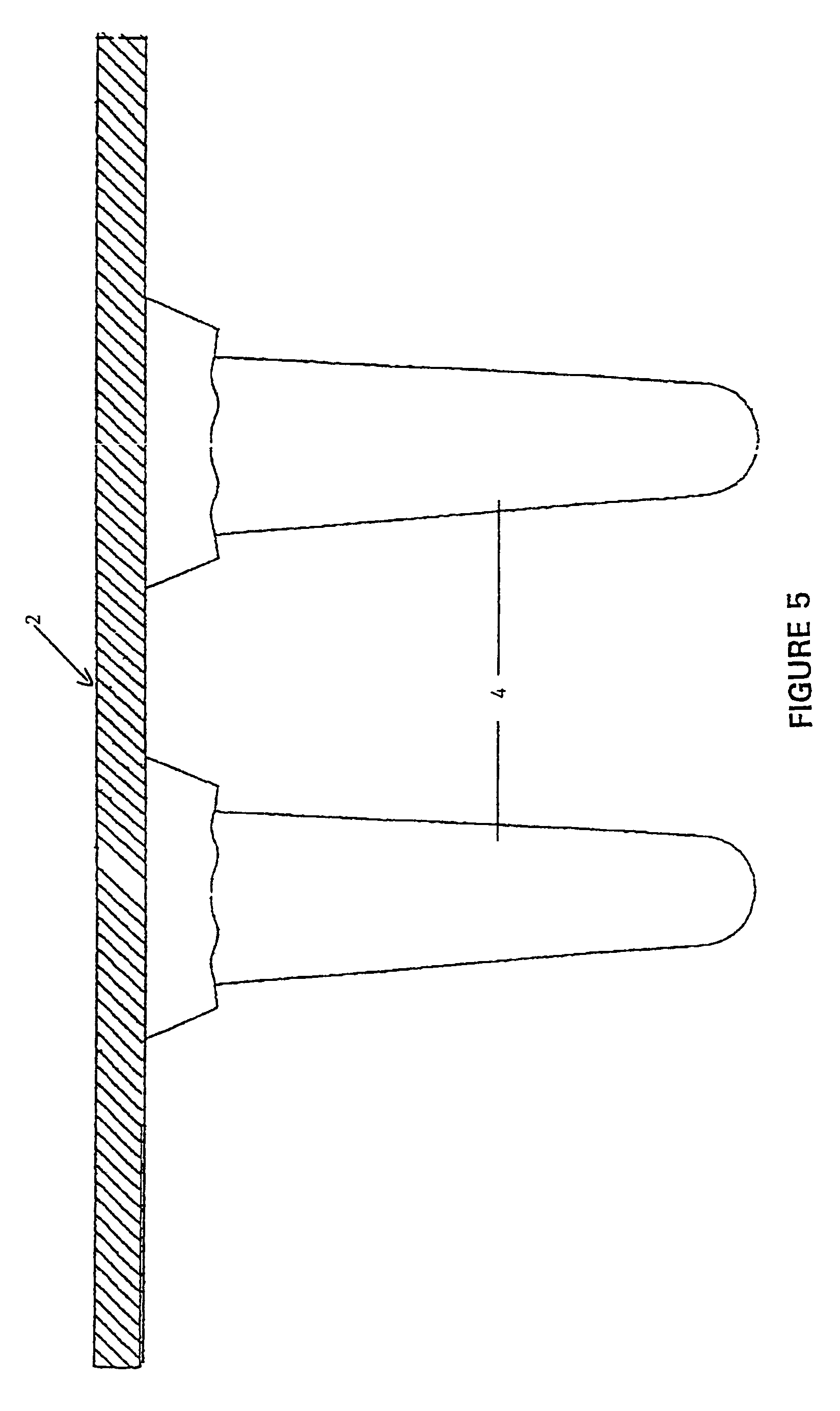

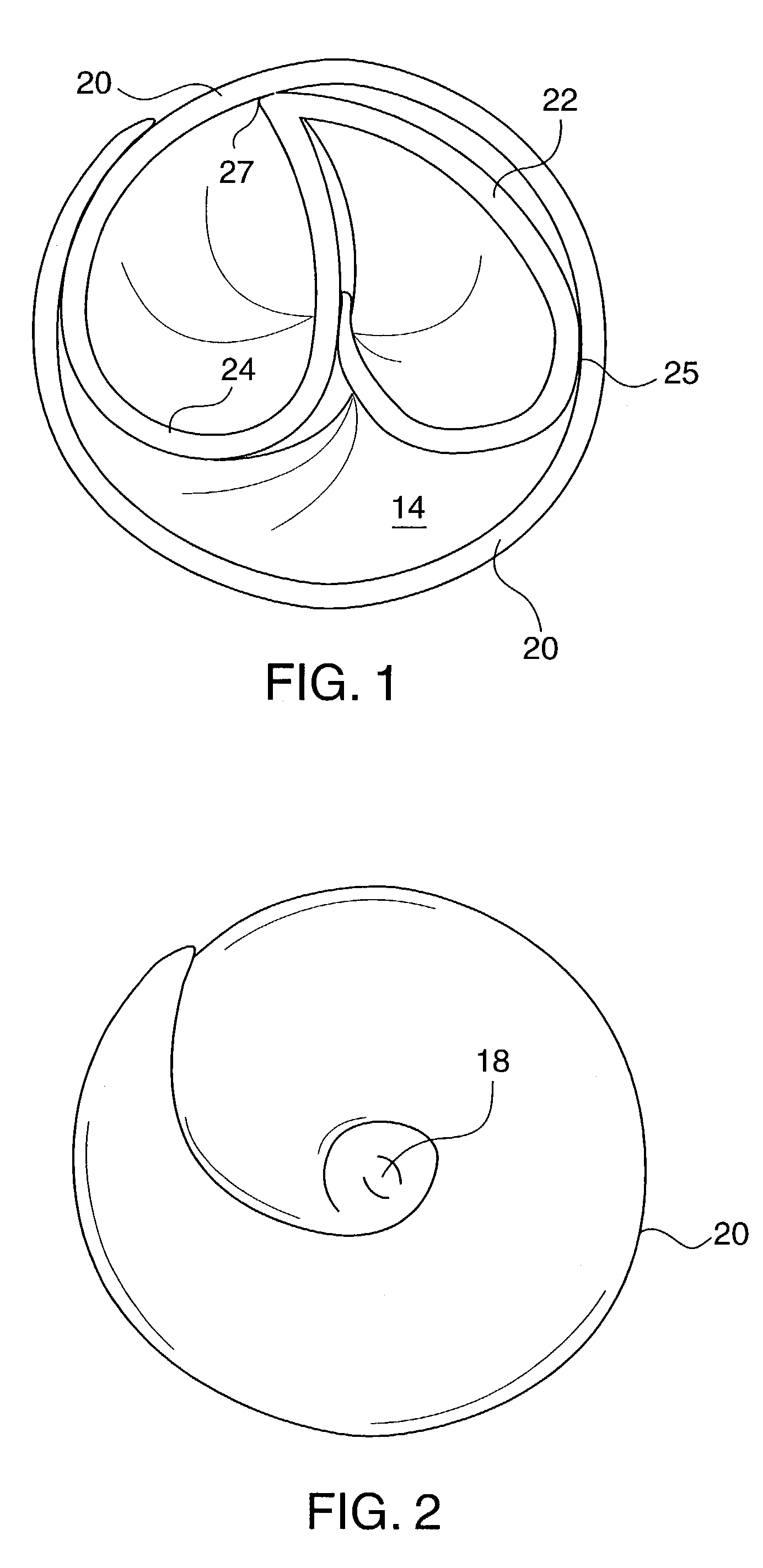

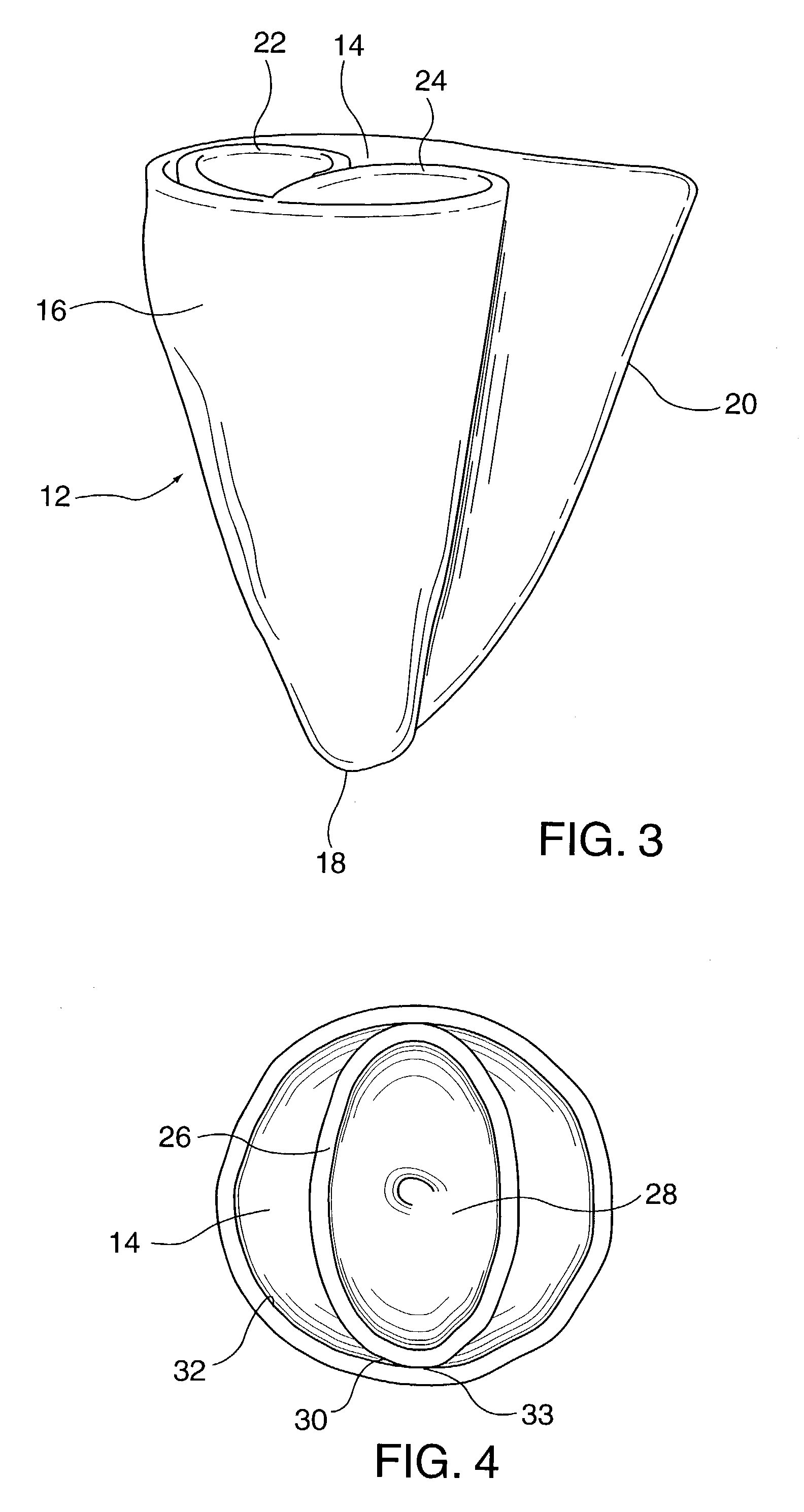

Process for making a baked cup shaped food product

A process for manufacturing a food product, a food product produced thereby and a plant for production of the food product. The food product may have a generally truncated cone shape which allows the product to be stood on its base. The baking mixture is inserted into mould cavities of a tray and fitting a second tray with male formers corresponding to the mould cavities into the first tray prior to baking. The trays may pass through the oven on an endless conveyor as part of a plant which includes a filling station, for filling the baked product with sweet or savoury fillings, and a freezing station. The food product is baked with a high liquid content to allow for the formation of a thin, tough impervious layer of gelatinised starch skin to form on the product surfaces.

Owner:ARTOS INT

Tiltable pannini grill

InactiveUS7514655B2Easy to placeReduce cooking timeDomestic stoves or rangesElectrical heating fuelUser inputDisplay device

Owner:SOUTH ASIA INT H K +1

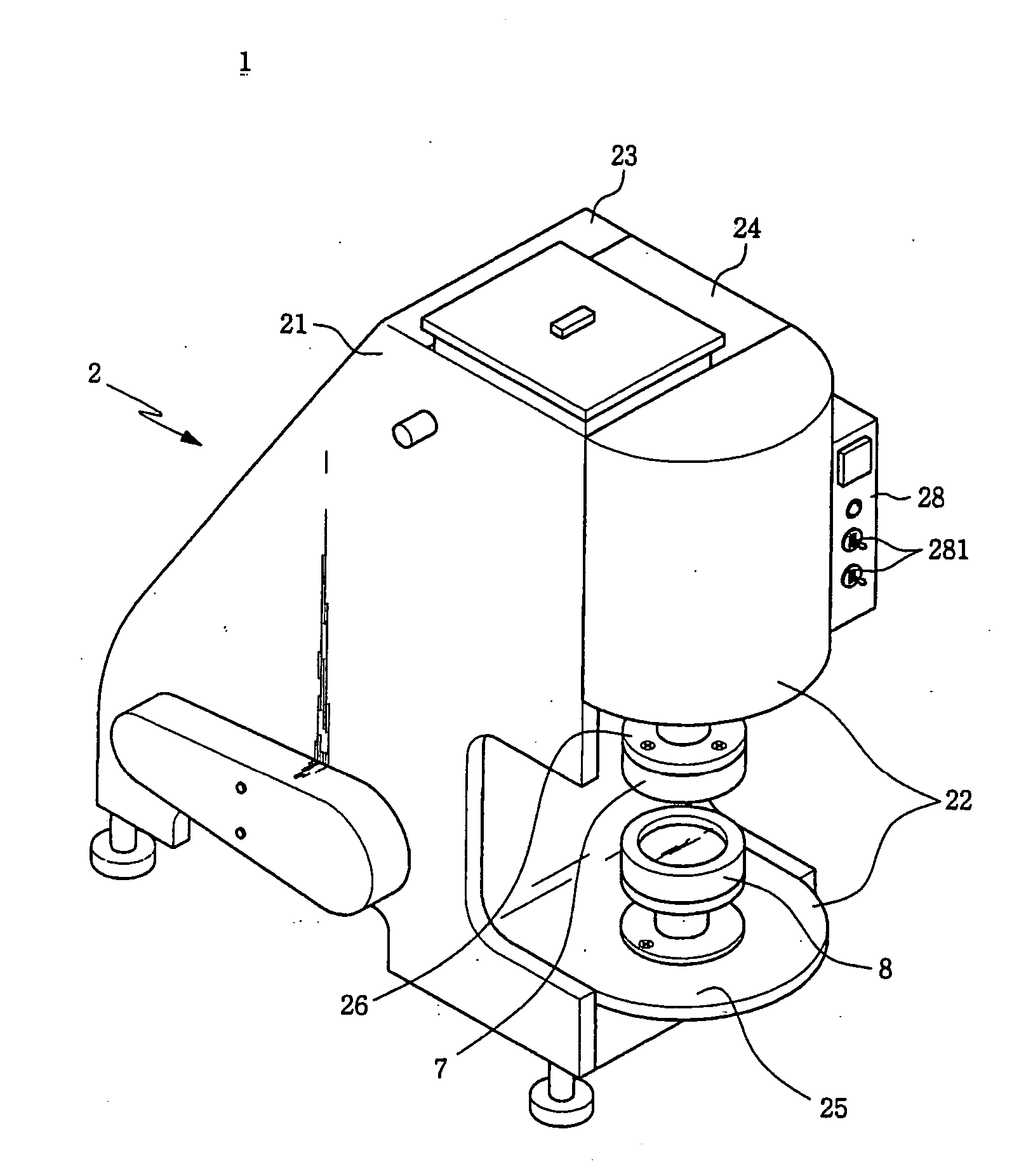

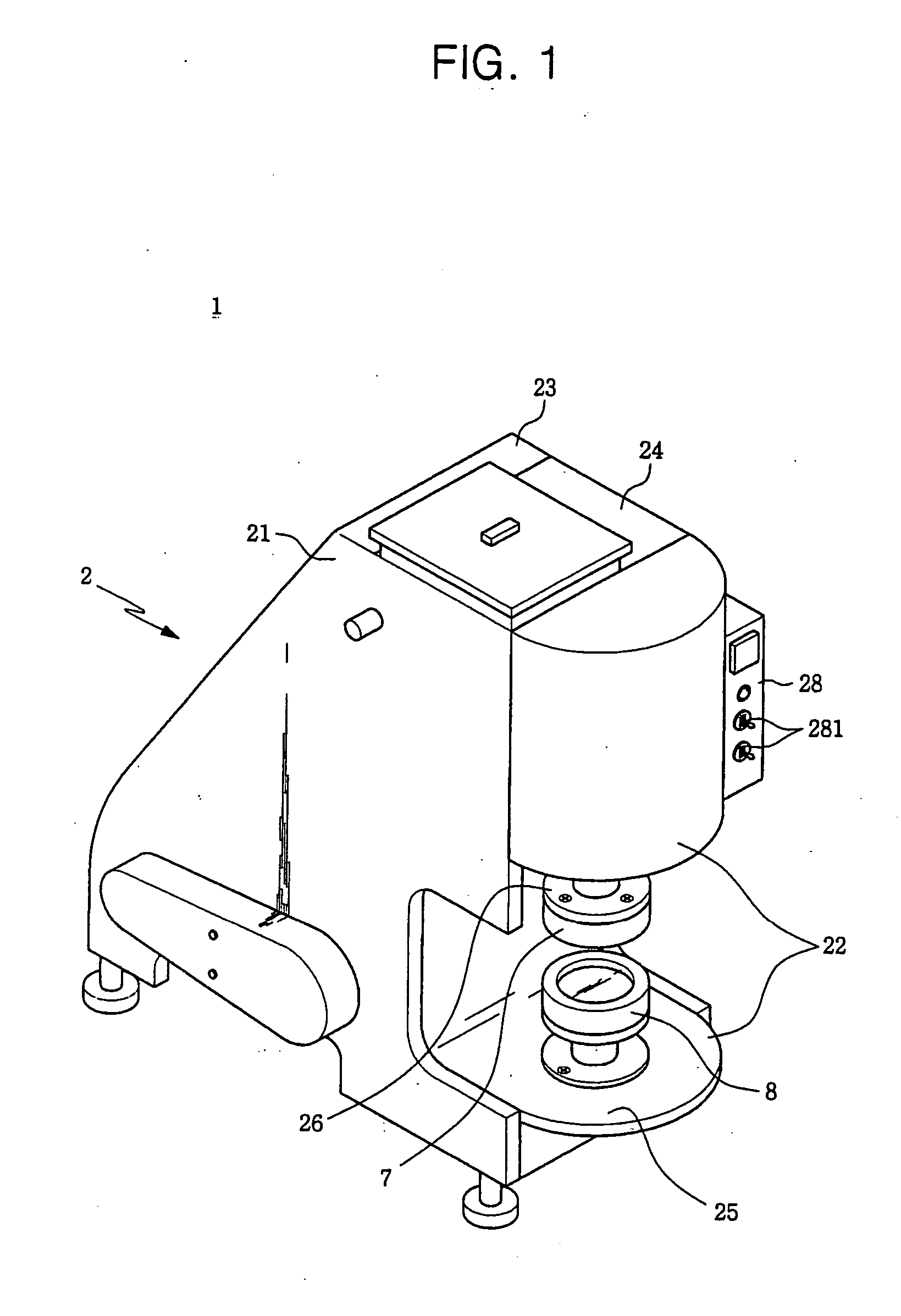

Ice cream cone making machine

Prior ice cream cone baking machines were manually raised and lowered, causing the cone to be sometimes overcooked or burnt. The present invention automatically raises the upper cooking plate after a pre-set cooking time, and maintains the baked cake at a warm temperature until removed from the lower cooking plate.

Owner:MISCEO VINCENZO

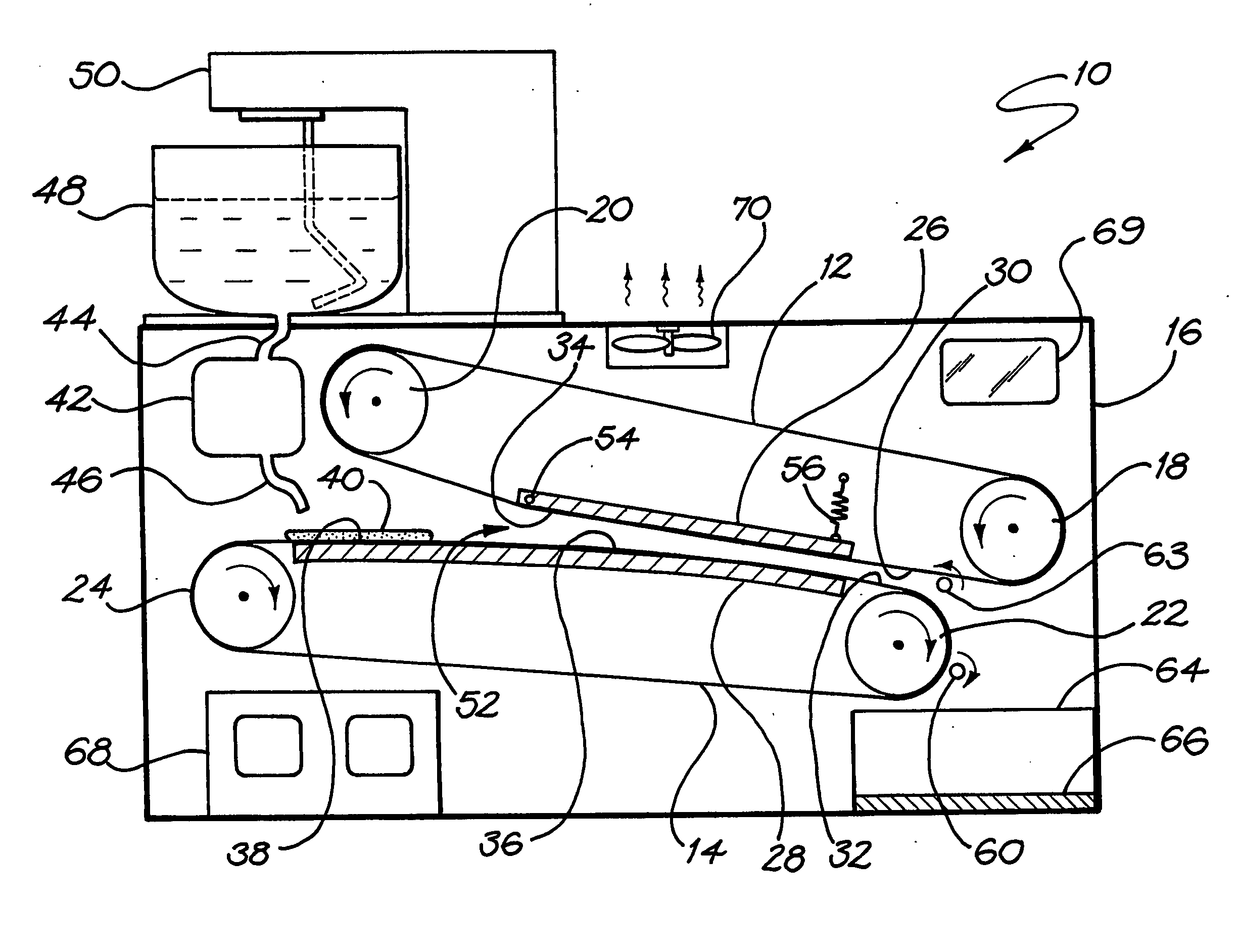

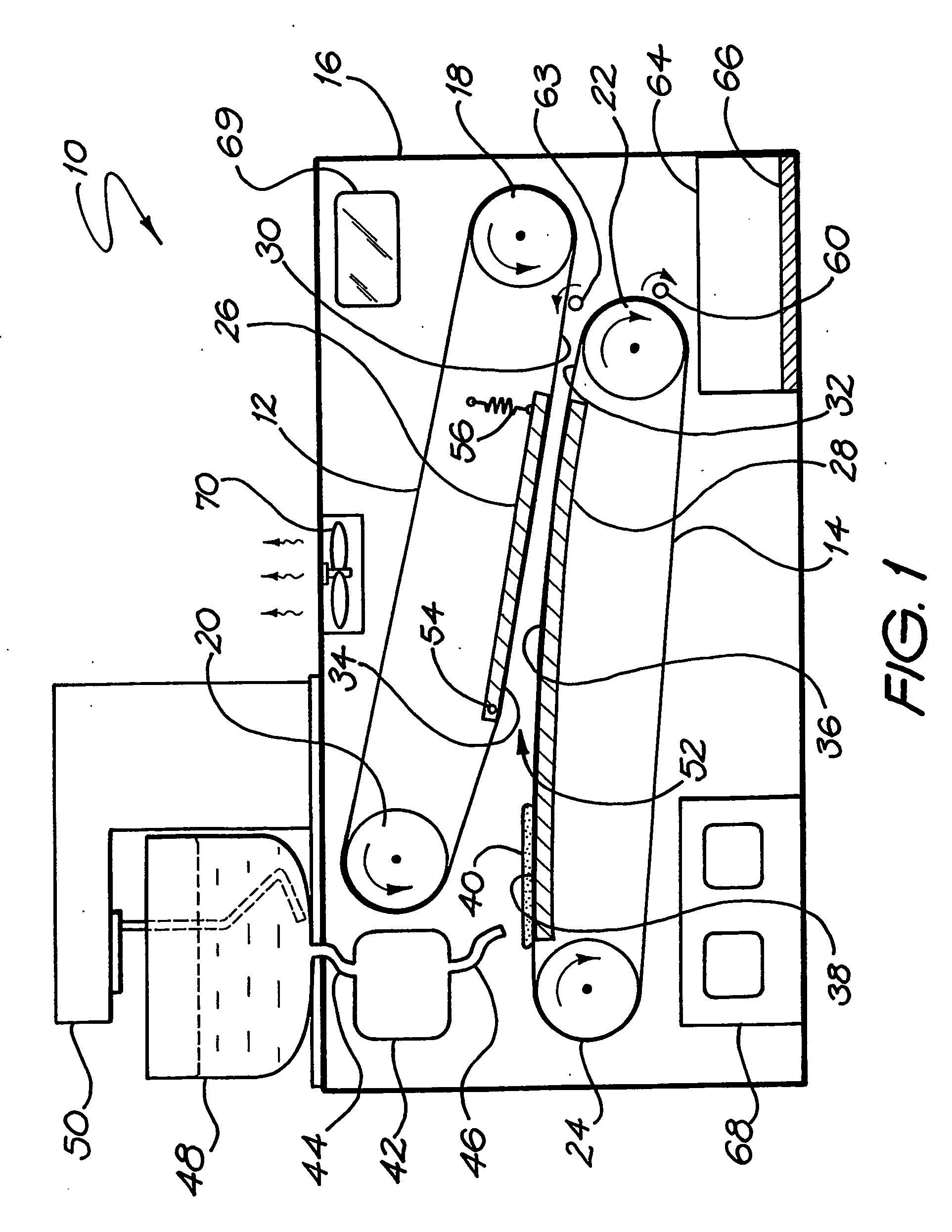

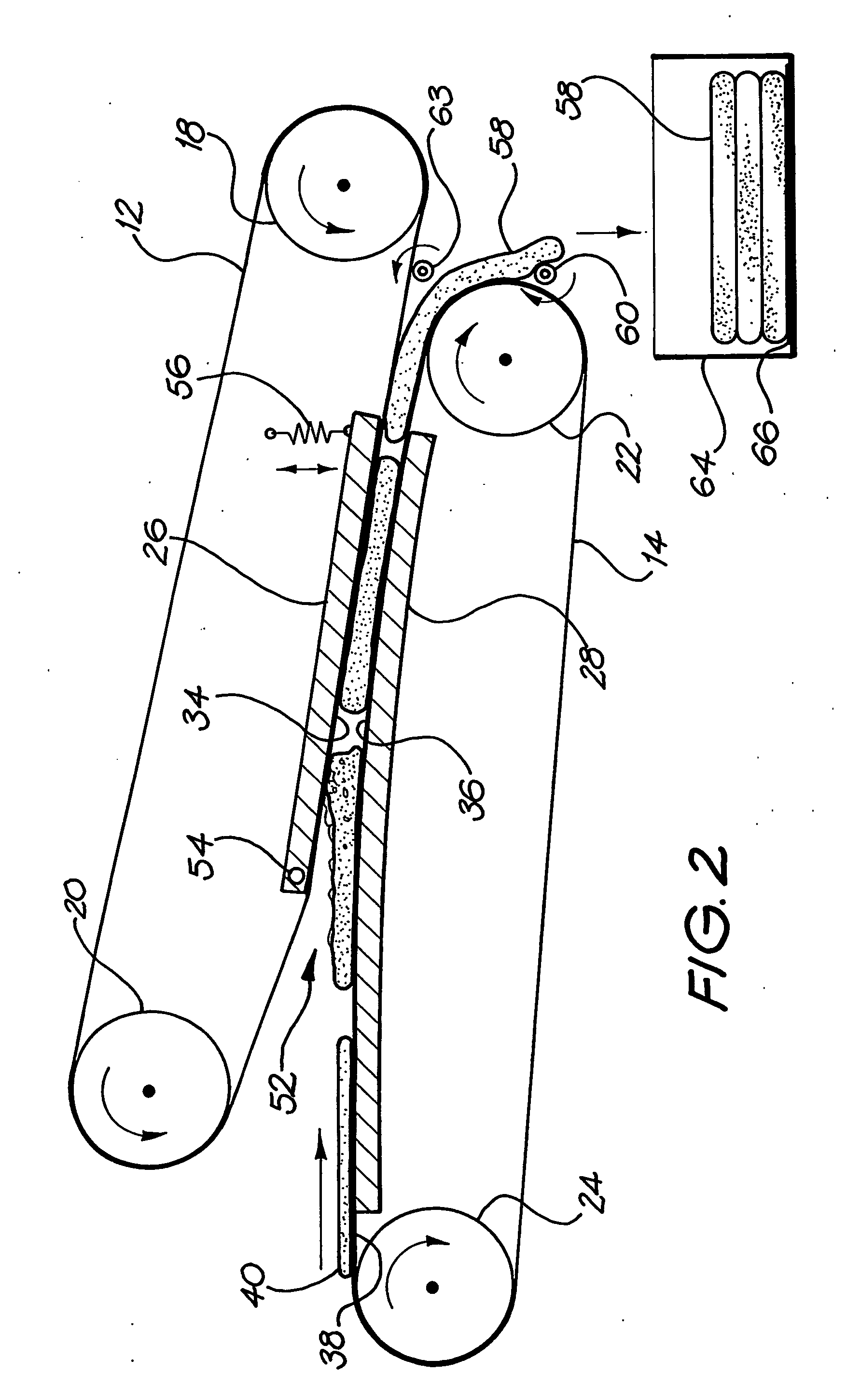

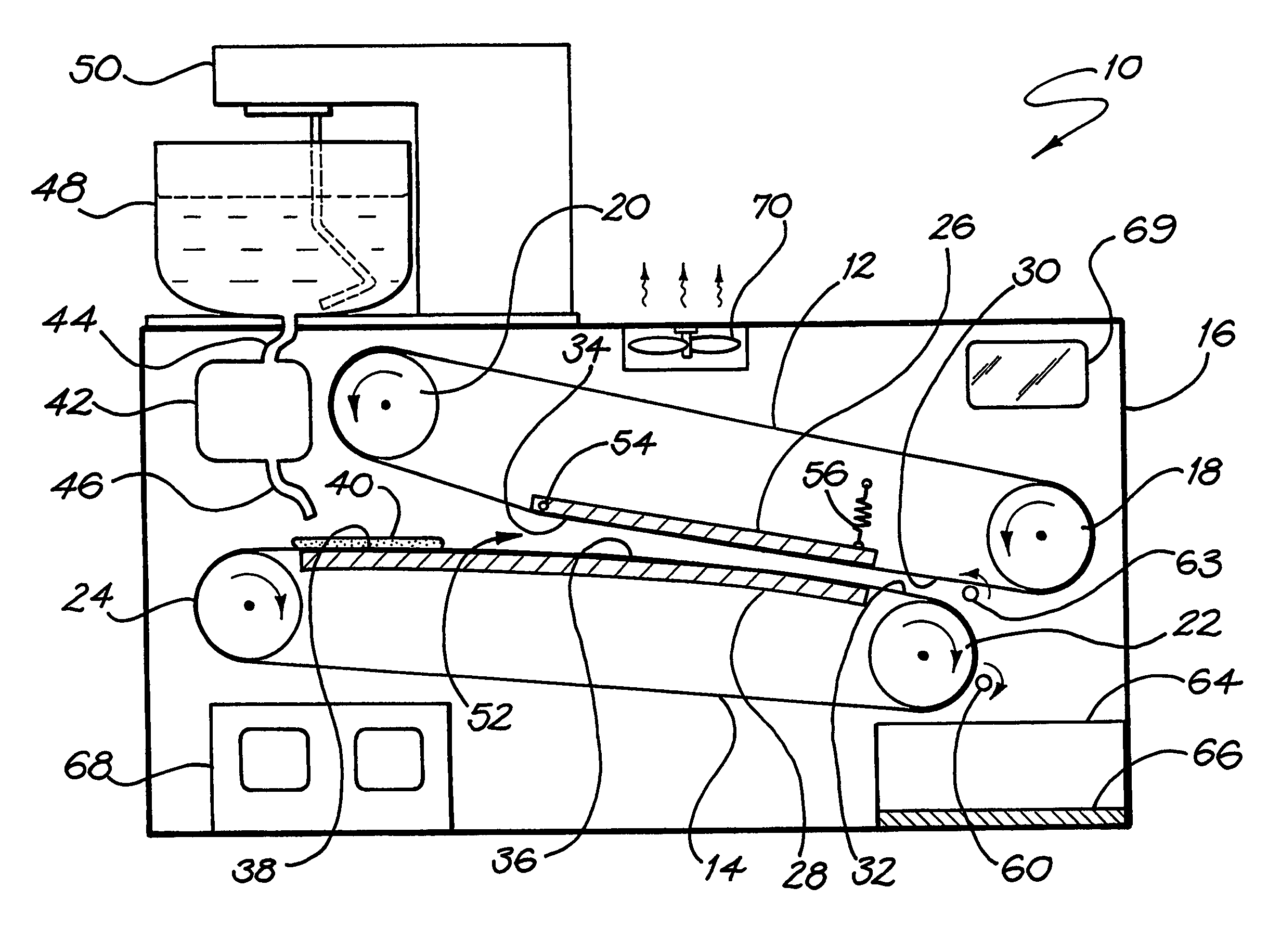

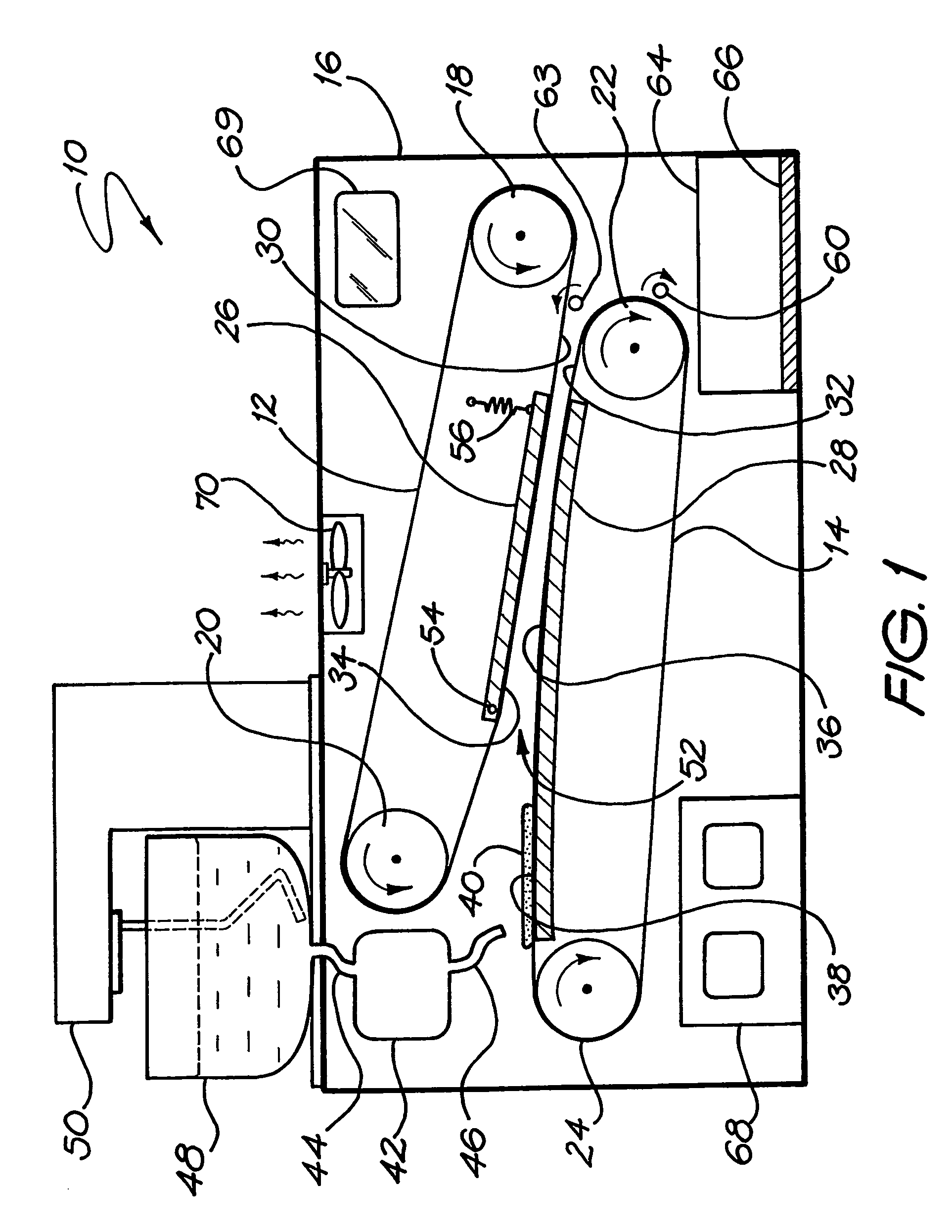

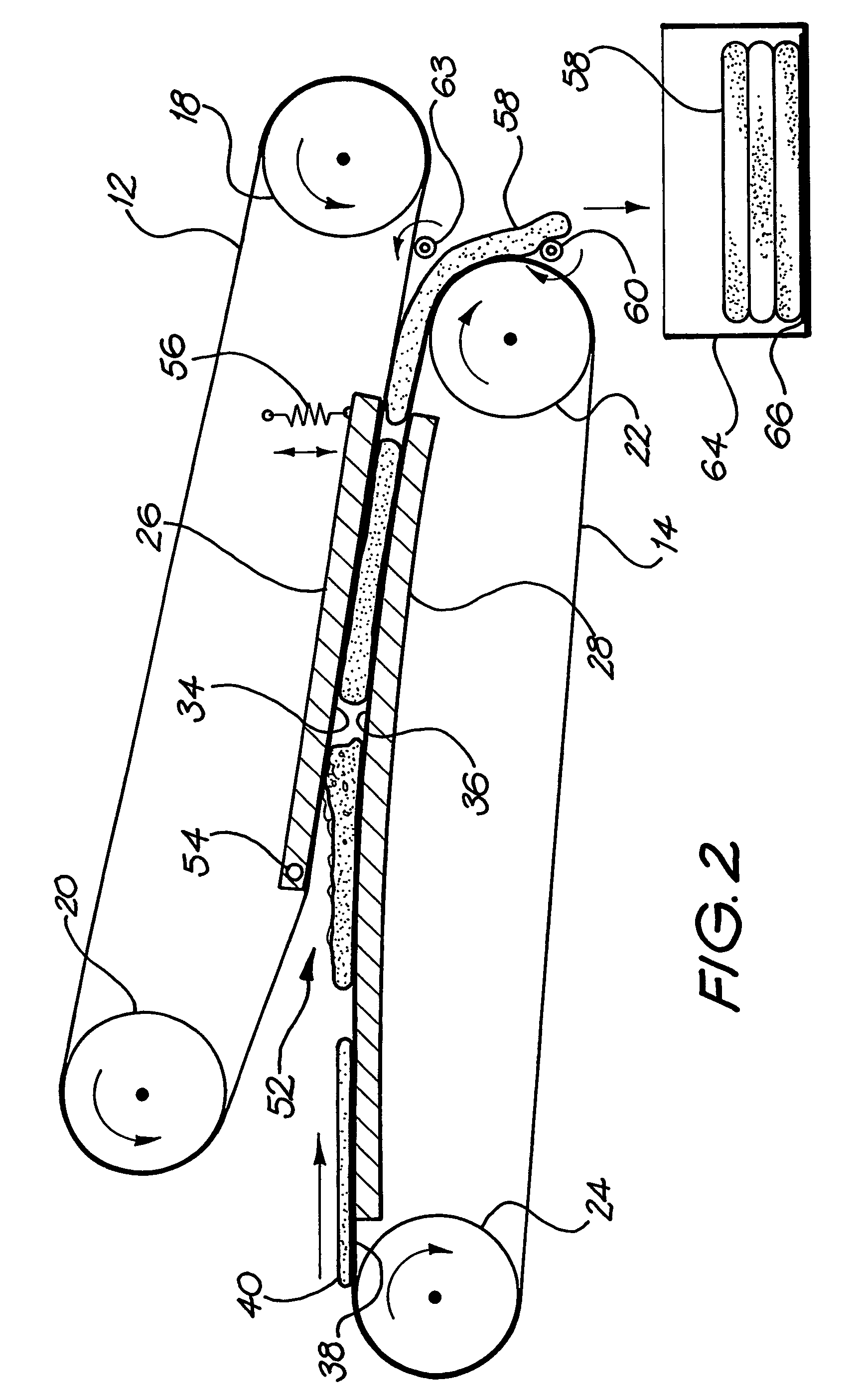

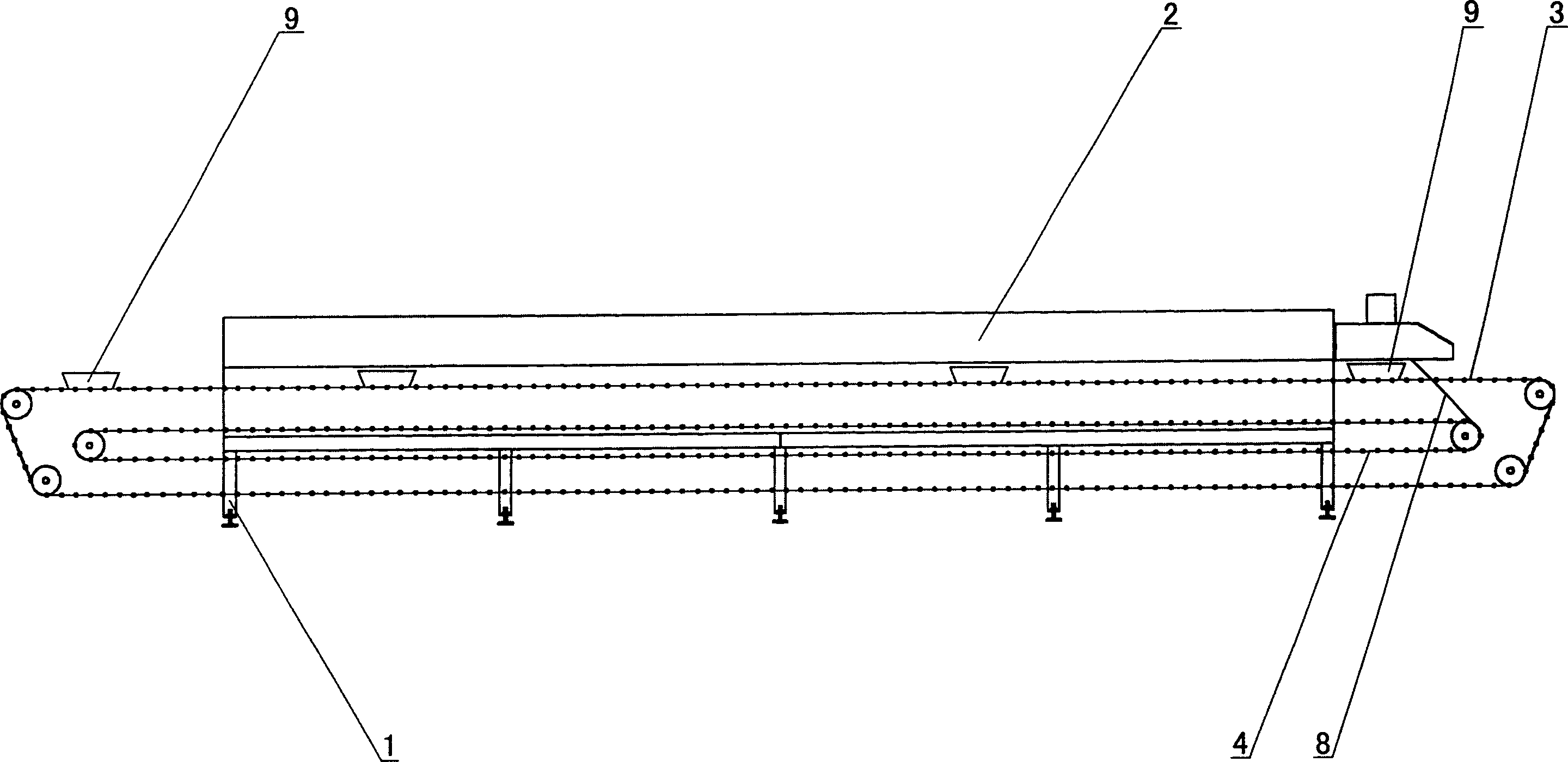

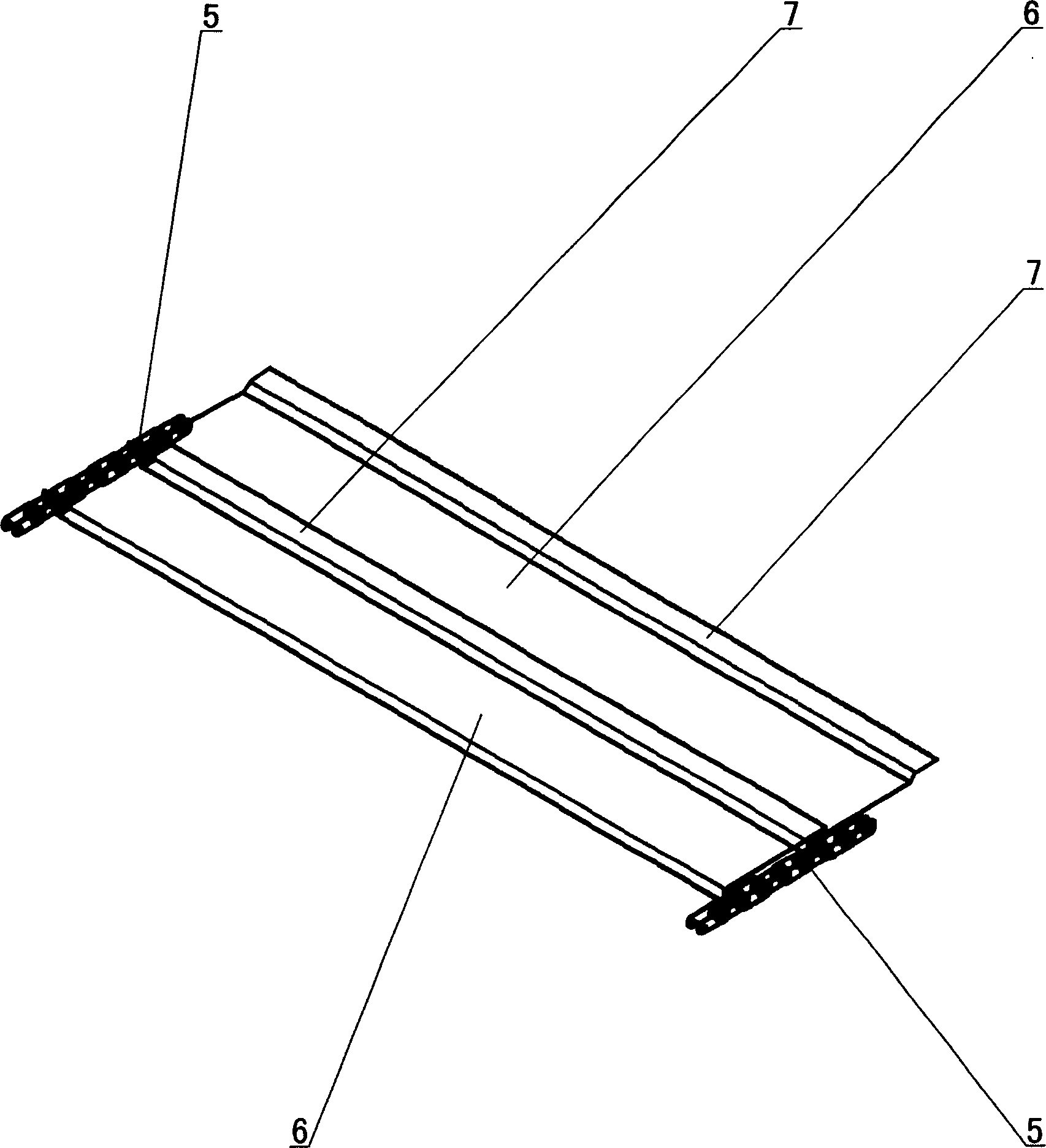

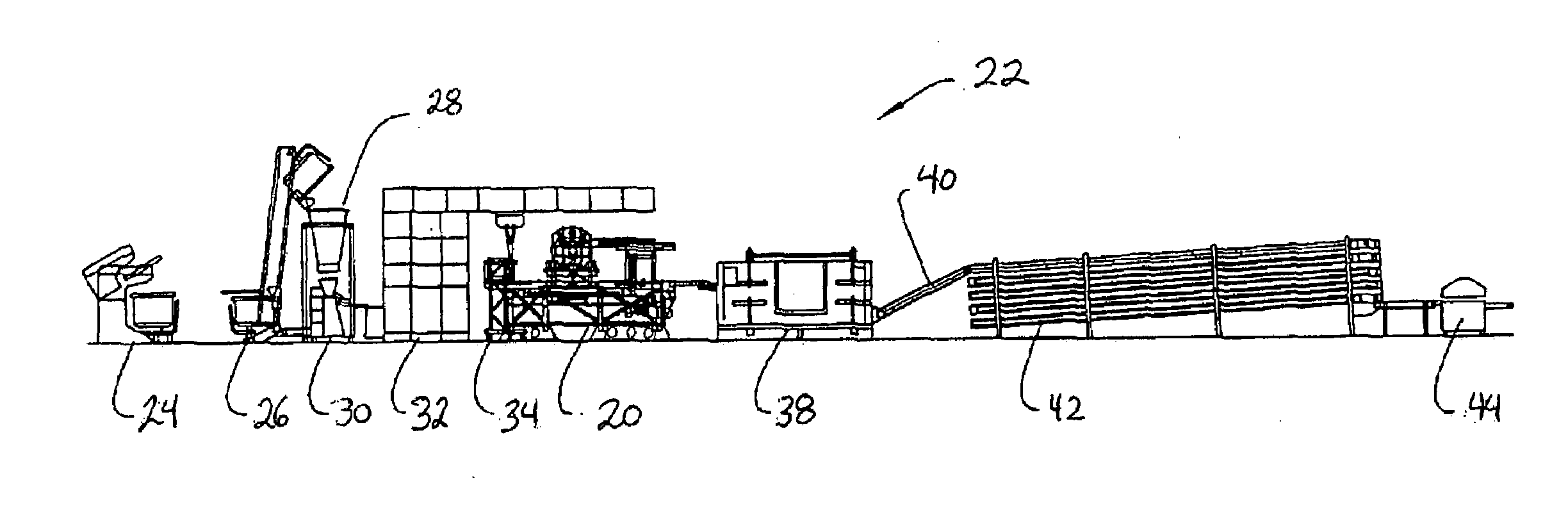

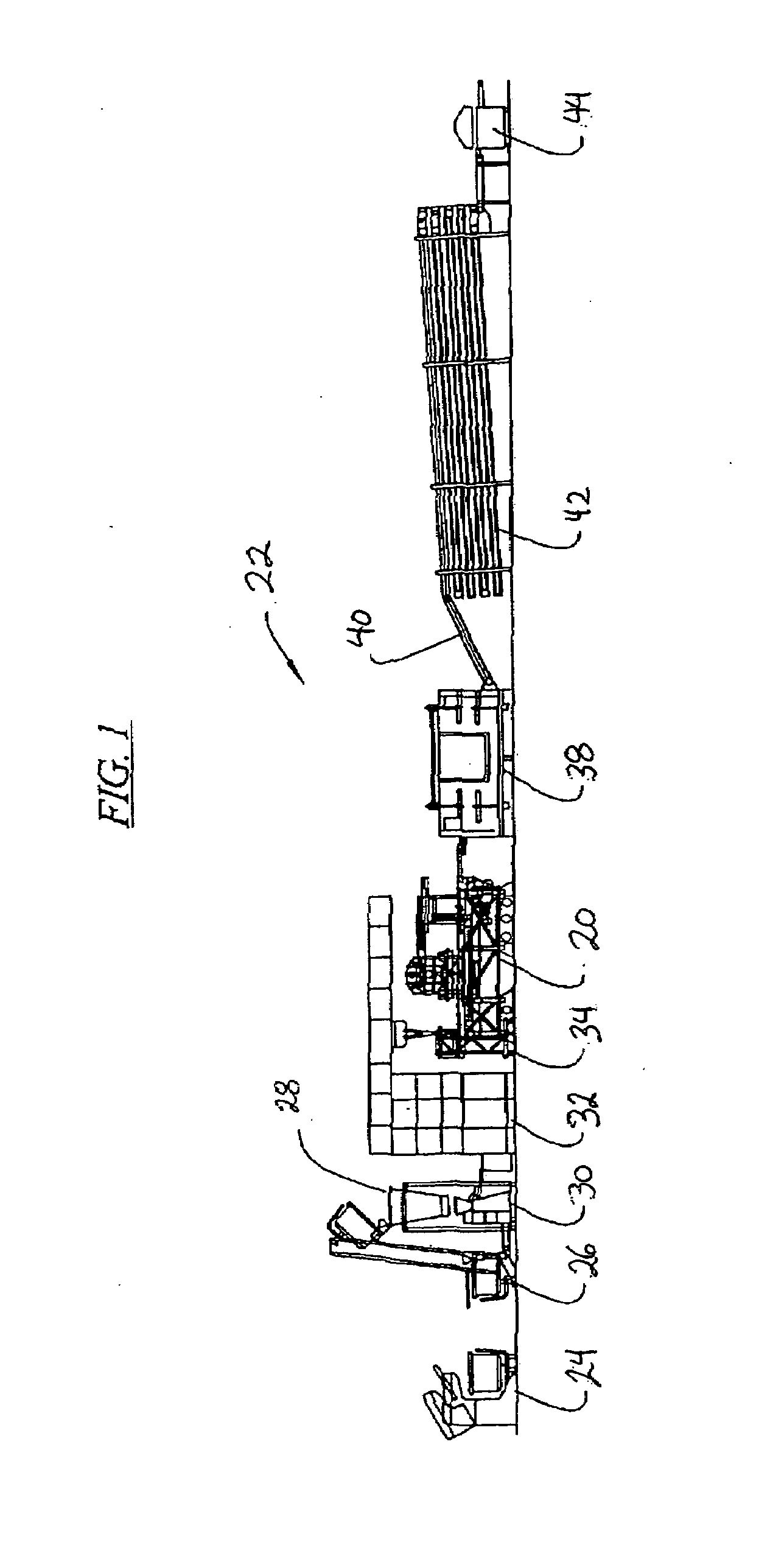

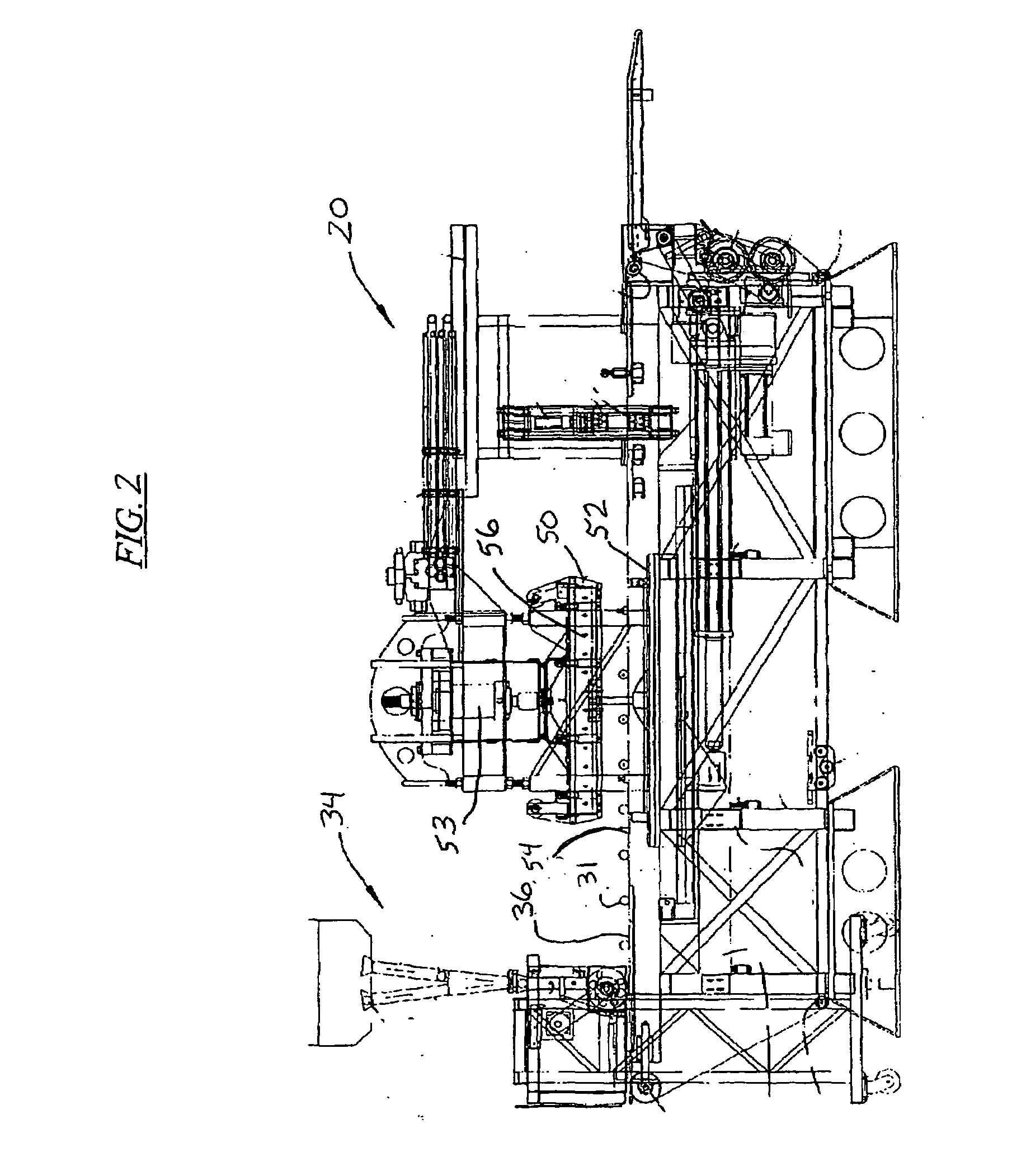

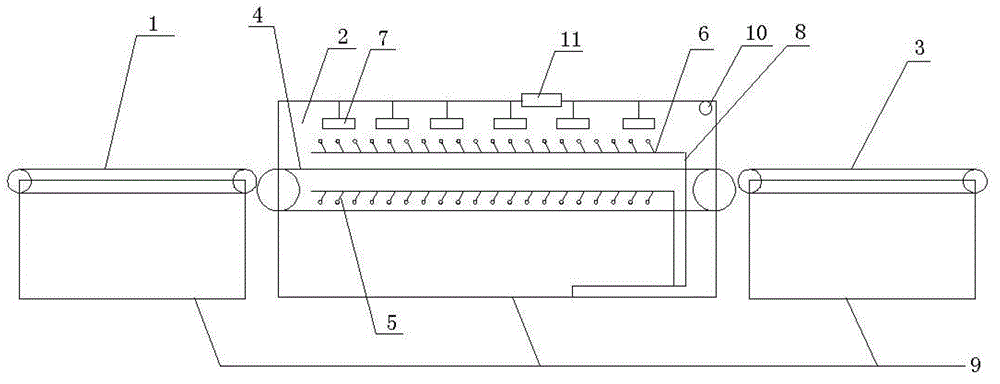

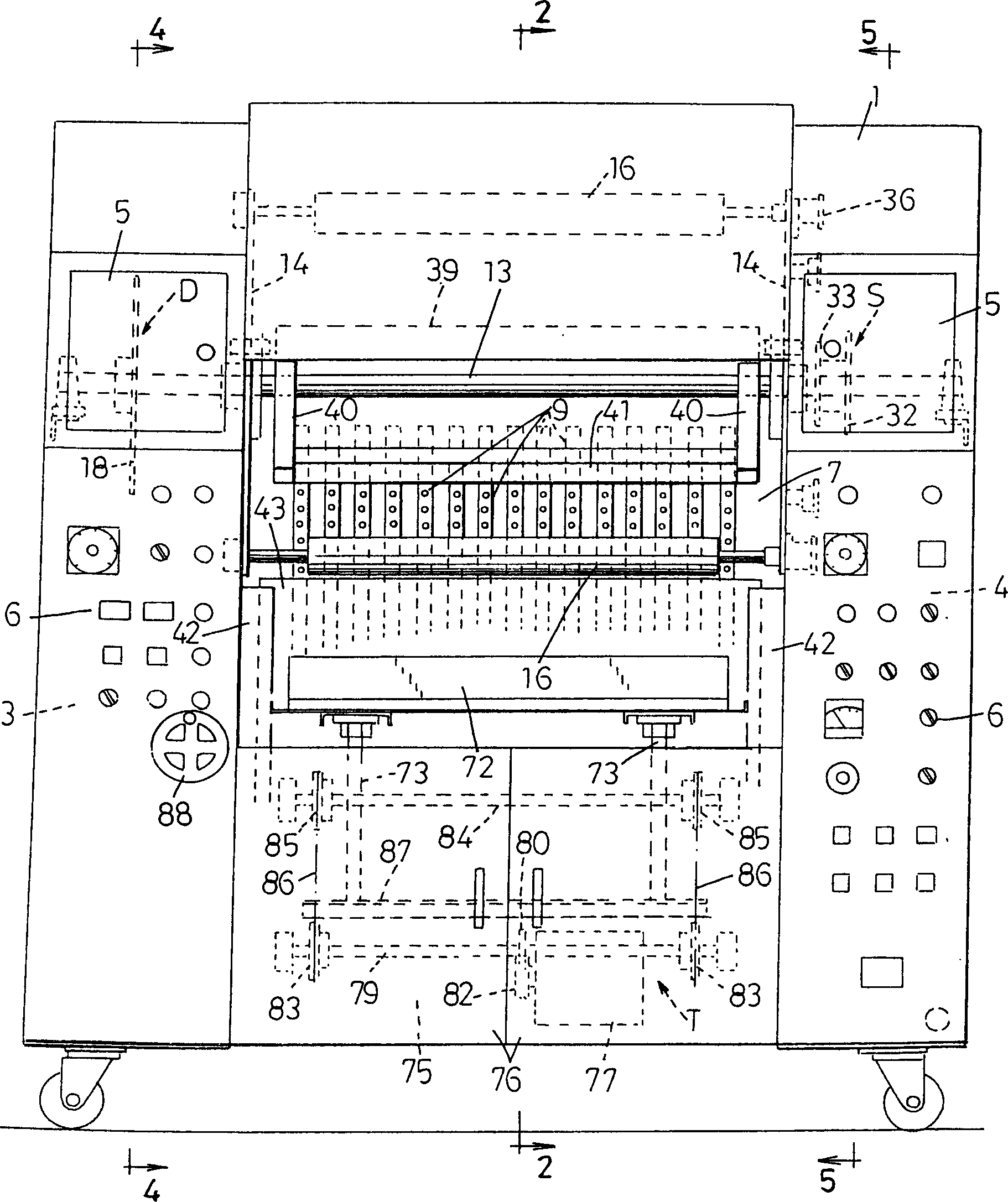

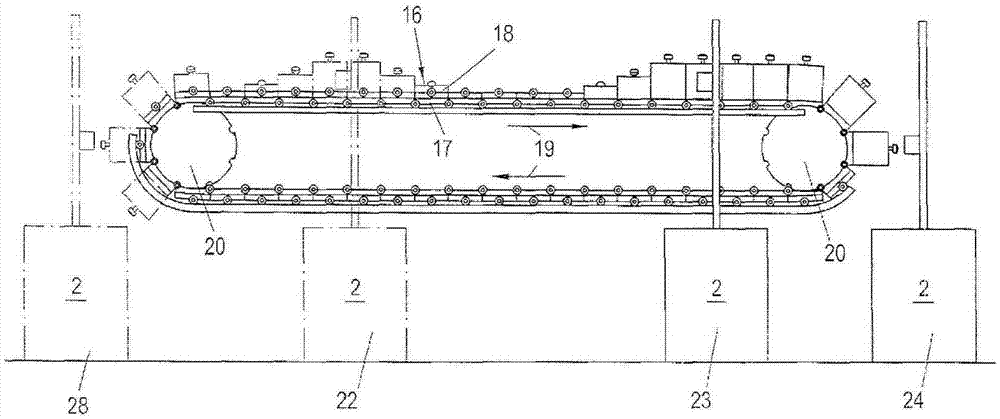

Automated belt cooking machine pancakes or the like

An automated belt cooking machine (10) for pancakes and the like food products has upper and lower overlapping, thermally conductive belts (12, 14), counter-rotatably mounted to a frame (16) so that, in use, a bottom run (30) of the upper belt (12) and a top run (32) of the lower belt (14) co-operate to convey food (40) to be cooked. The lower belt (14) extends a predetermined distance to one side of the upper belt (12) so as to provide a dispensing platform portion (38) for dispensing thereon the food to be cooked (40), so that the food (40) is conveyed towards a mouth (52) formed between the upper belt and lower belts (12, 14) and thereafter is conveyed sandwiched between the bottom and top run (30, 32). Upper and lower heating platens (26,28) are mounted to the frame (16) and are in thermal contact with the bottom and top run (30, 32), wherein the food to be cooked (40) is initially exposed to heat from the lower platen (28) conducted through the dispensing platform portion (38).

Owner:SZYMANSKI MAREK

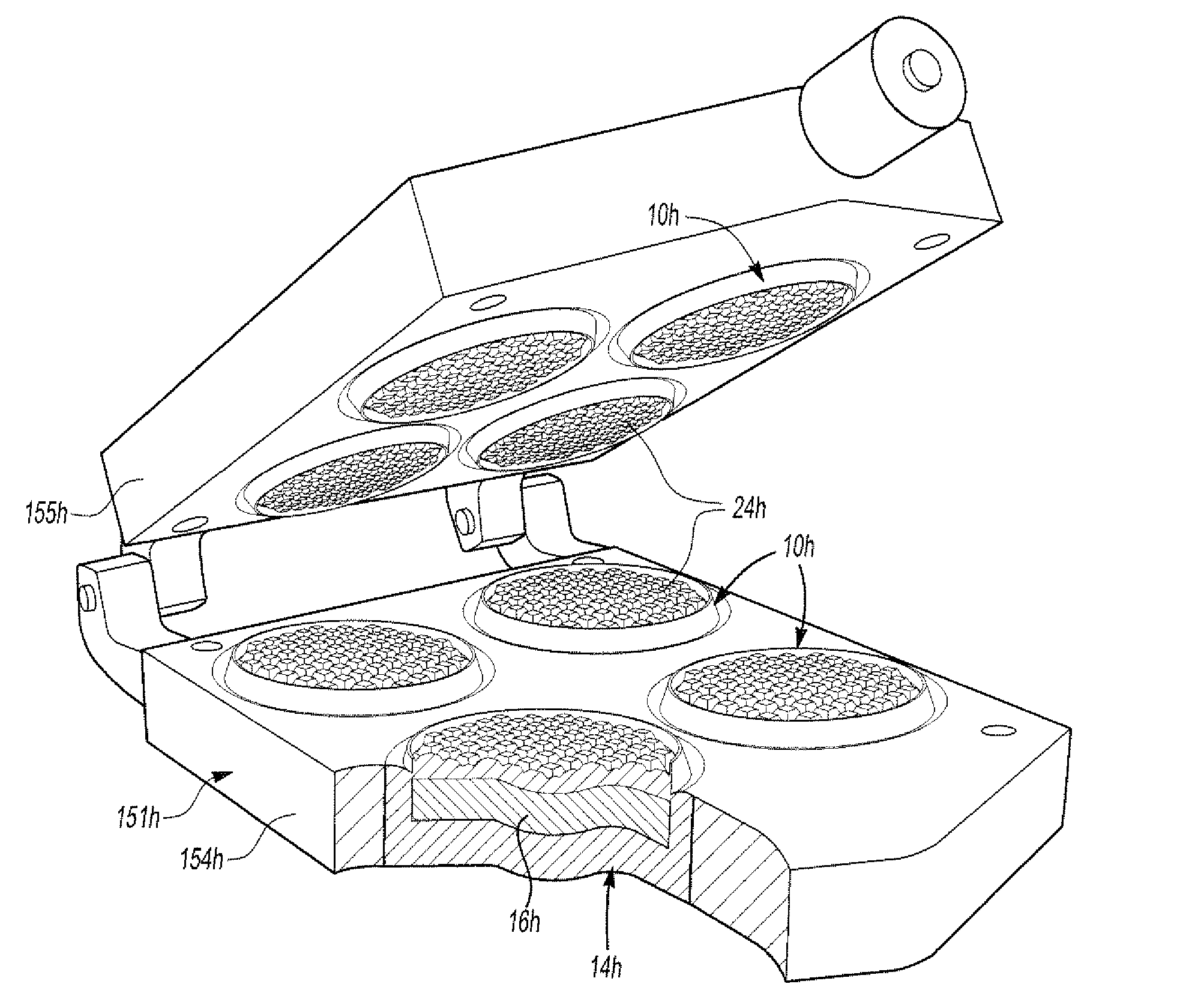

Induction cooking structure and system and method of using the same

In summary, the invention is a method of producing an edible food product. The method includes the step of forming a vessel core with a first material having a first level of susceptibility to heating by induction. The method also includes the step of casting an apron of a second material with a second level of susceptibility to heating by induction lower than said first level around at least a first portion the vessel core in an in situ casting process to form a clad cooking vessel having a cooking surface. An uncooked food product is then disposed on the cooking surface of the clad cooking vessel and heated to produce the edible food product by subjecting the vessel core to a magnetic field.

Owner:KELLOGG CO

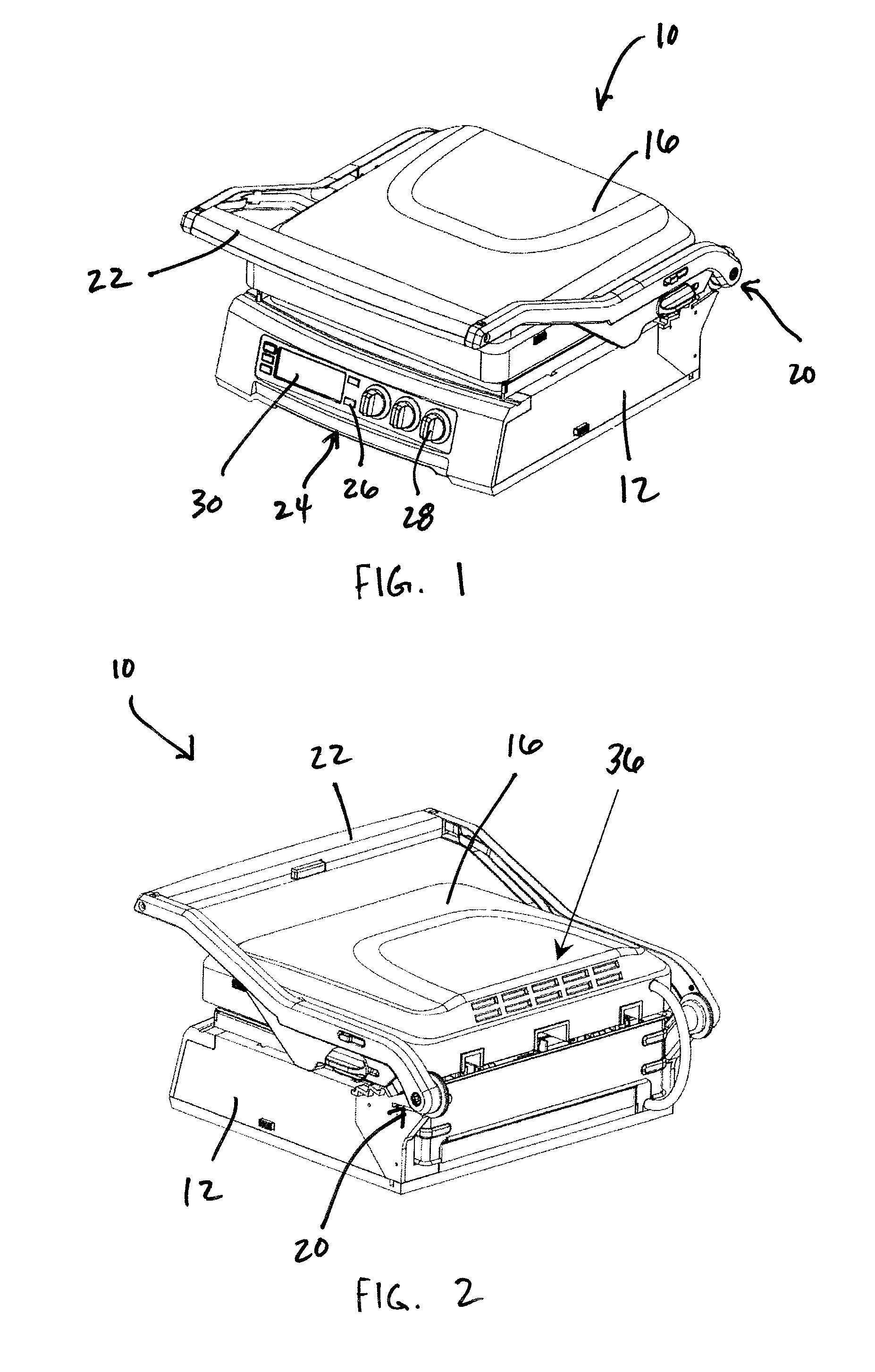

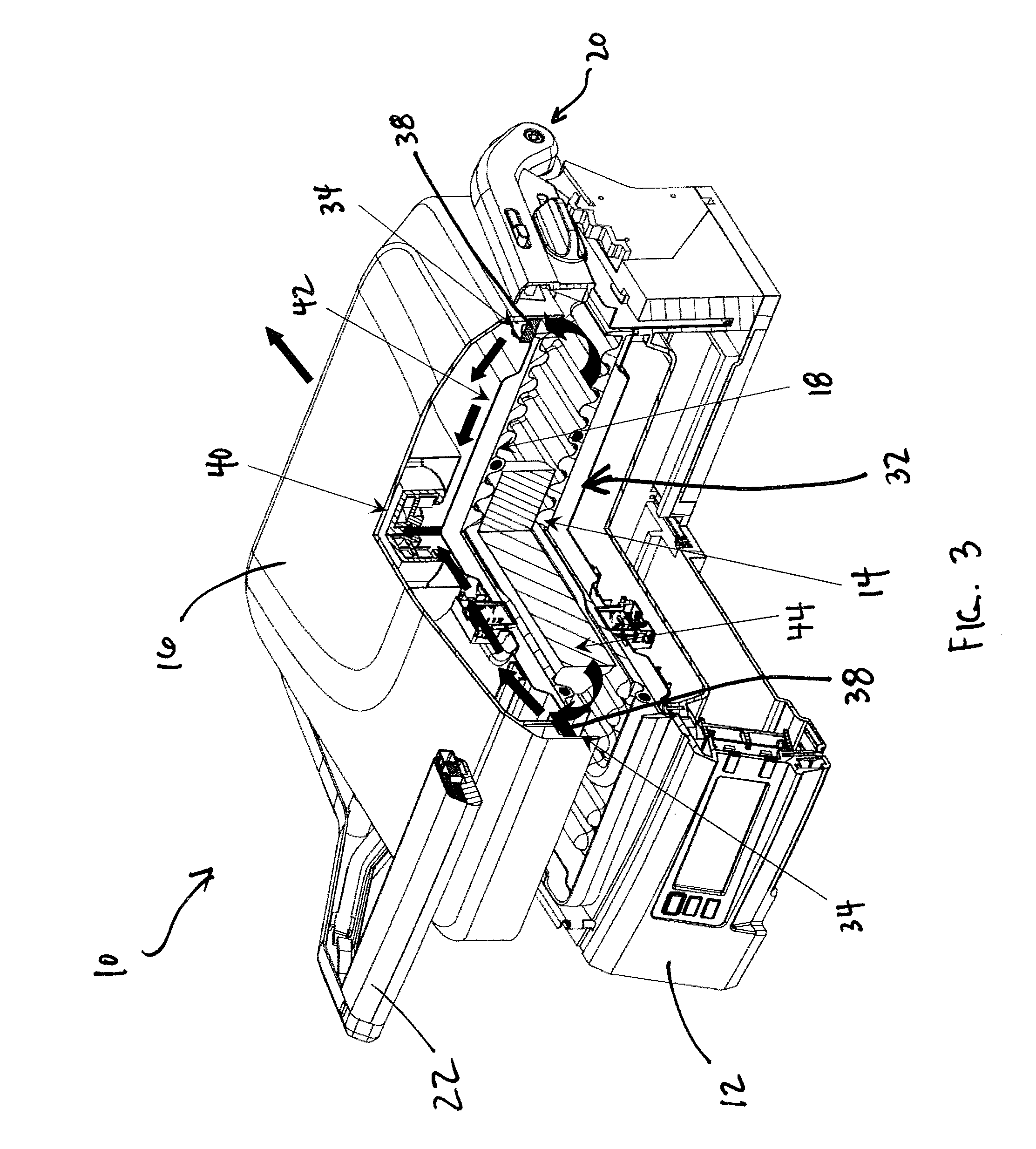

Griddle

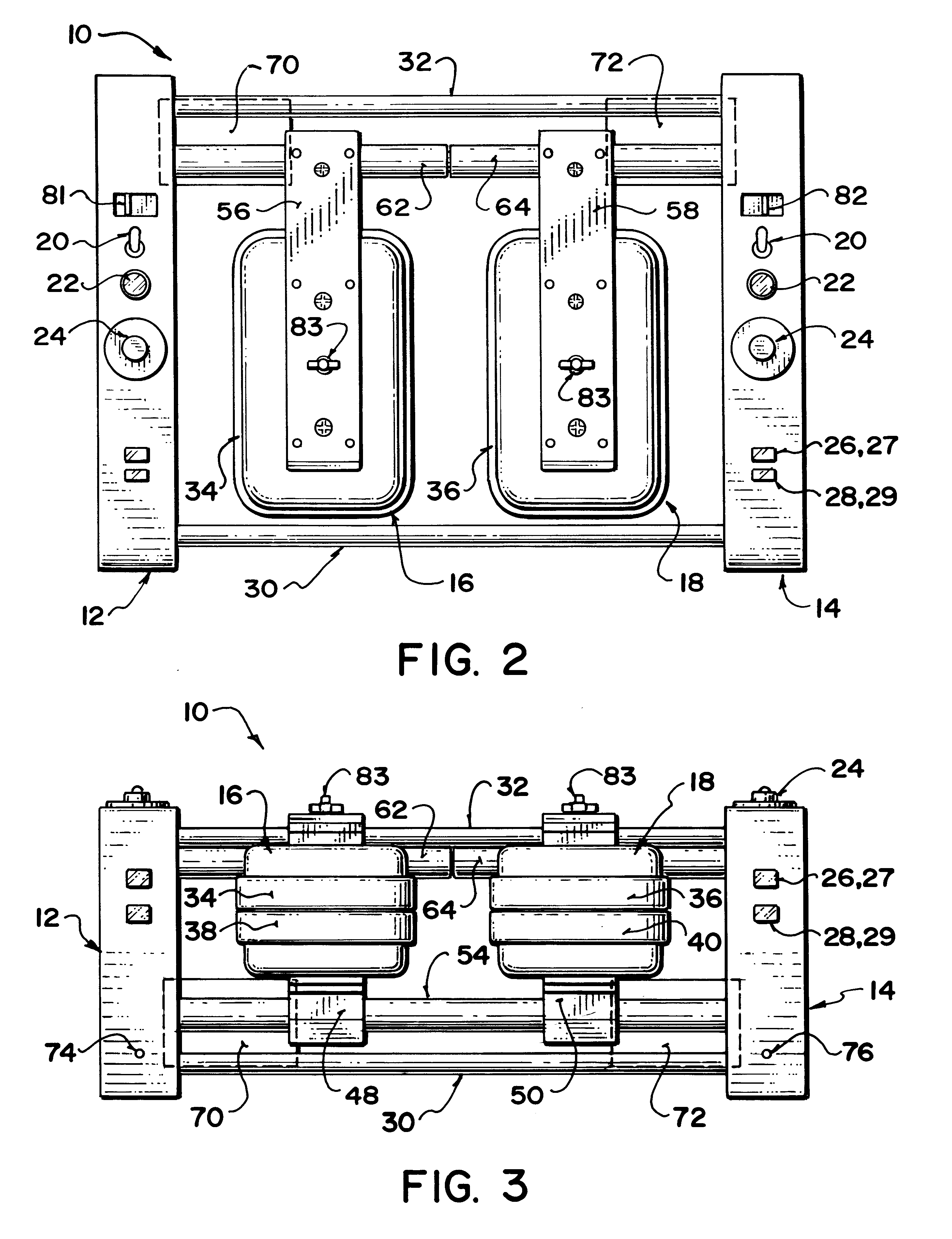

ActiveUS7946224B2Reduce cooking timeAir-treating devicesDomestic stoves or rangesProcess engineeringInternal heating

A high-speed griddle for cooking food products has a griddle platen having a cook surface for receiving food products thereon, and heating means are provided for heating the platen. A clamshell cover is configured for sealing contact with the cook surface of the platen, the cook surface and cover cooperating to enclose a cook volume. An electromagnetic energy source is configured for emitting energy into the cook volume, the energy source emitting energy of a frequency selected to cause internal heating of food products within the cook volume. In addition, a convection air system is configured to provide a flow of heated air into the cook volume. The heated platen, electromagnetic energy source, and convection air system cooperate to rapidly cook food products within the cook volume.

Owner:TURBOCHEF TECH INC

Automated belt cooking machine pancakes or the like

Owner:SZYMANSKI MAREK

Machine for making ice cream cones and other food products such as pannini

Prior ice cream cone baking machines were manually raised and lowered, causing the cone to be sometimes overcooked or burnt. The present invention automatically raises the upper cooking plate after a pre-set cooking time, and maintains the baked cake at a warm temperature until removed from the lower cooking plate.

Owner:MISCEO VINCENZO

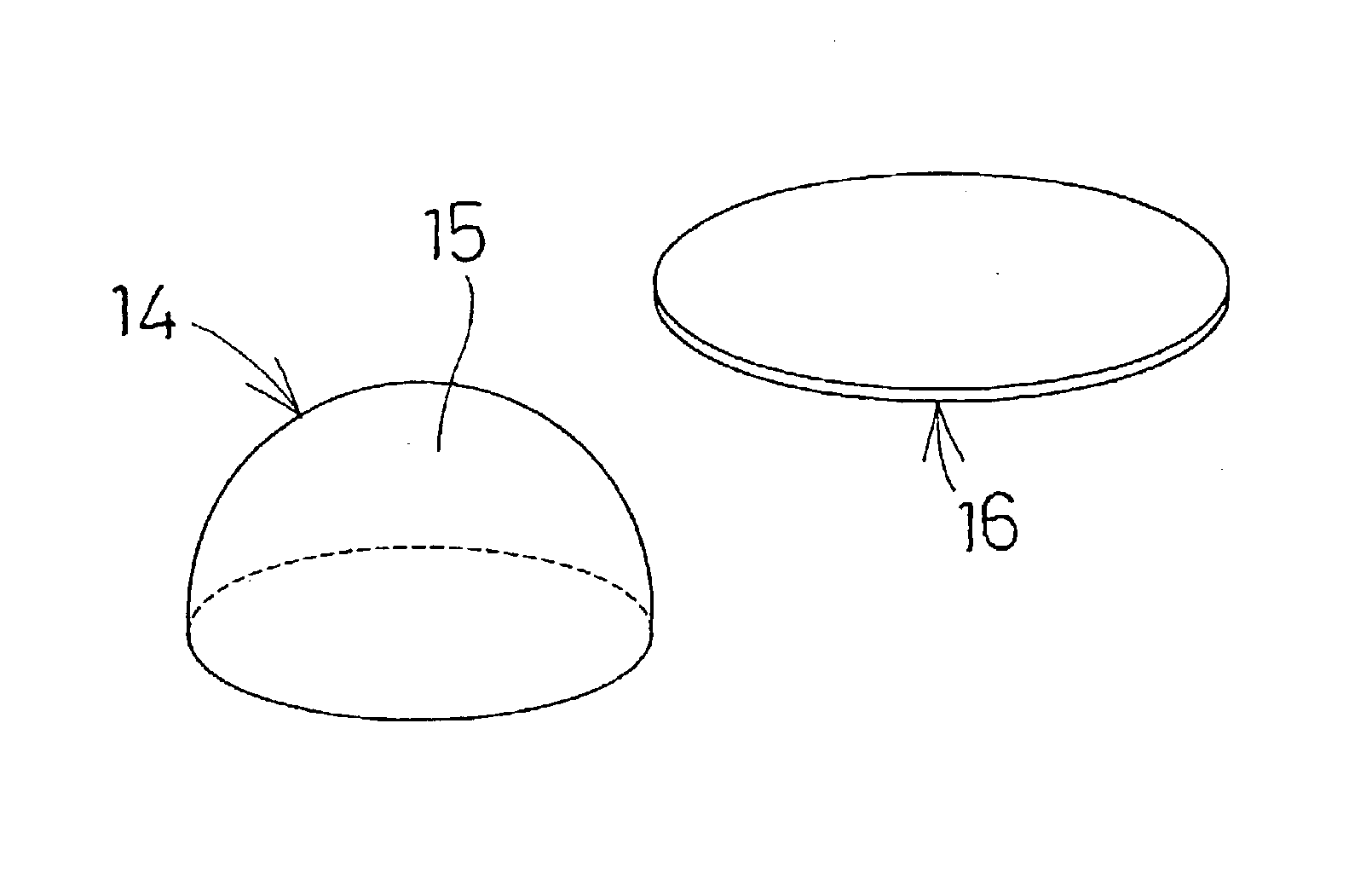

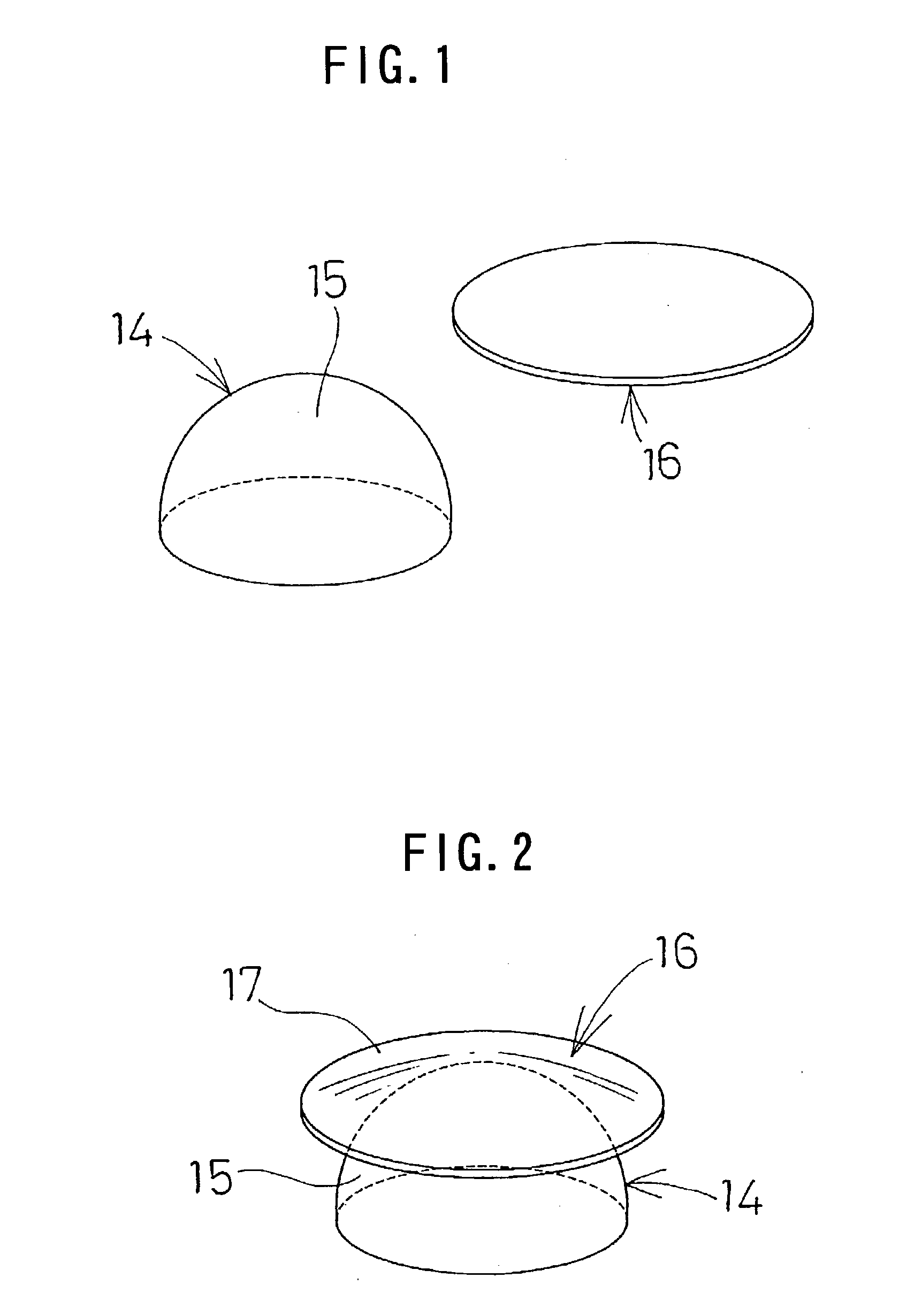

Cup shaped baked confectionary and manufacturing method thereof

InactiveUS20030219527A1Easily causedEasily brokenConfectionerySweetmeatsEngineeringBiomedical engineering

A cup shaped baked confectionary has light texture, uniform thickness and easy to release from the die. The cup shaped baked confectionary may be produced by mounting a dough of a cup shaped baked confectionary having desired contour shape on a top of a metallic three-dimensional baking die having desired shape of outer peripheral surface, in a condition extending horizontally with placing outer periphery thereof outside of the three dimensional baking die and heating the dough for softening the dough of the cup shaped baked confectionary to contact on the outer peripheral surface of the three-dimensional baking die and baking.

Owner:LOTTE CO LTD

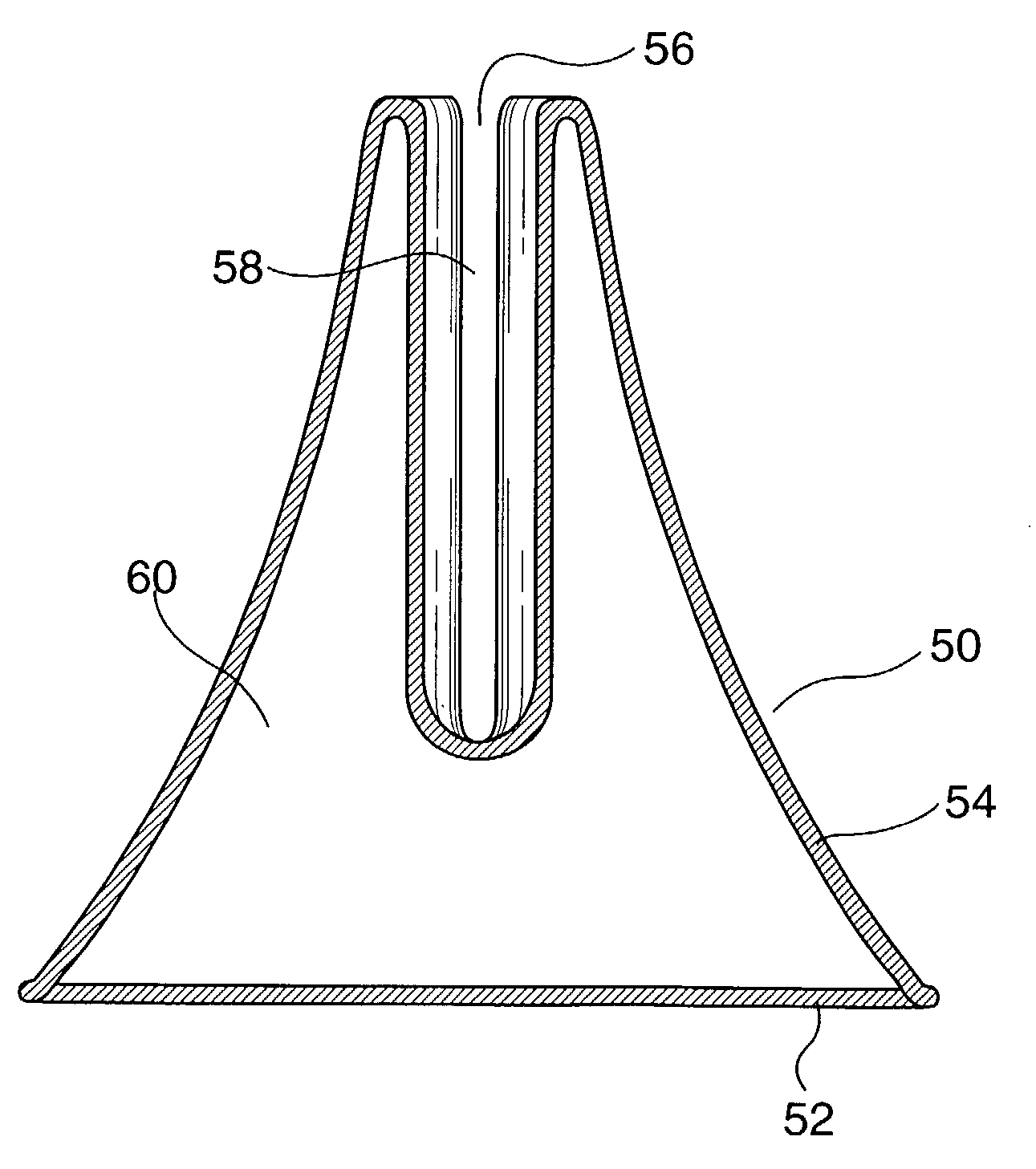

Mold for the making of a hand-holdable edible food product

InactiveUS7131626B2Maintain stabilityMaintain sturdinessConfectioneryMeat processingEngineeringMechanical engineering

A mold having an upper end and a downwardly extending wall terminating in a lower end, and a continuous notch spanning across the wall extending upwardly from the lower end, with both an outside surface of the wall and an inside surface being of a coating which is non-stick to dough wrapped around the outside surface of the mold and to dough which is pushed downwardly through the notch from the upper end of the mold towards its lower end.

Owner:COLE LAWRENCE A

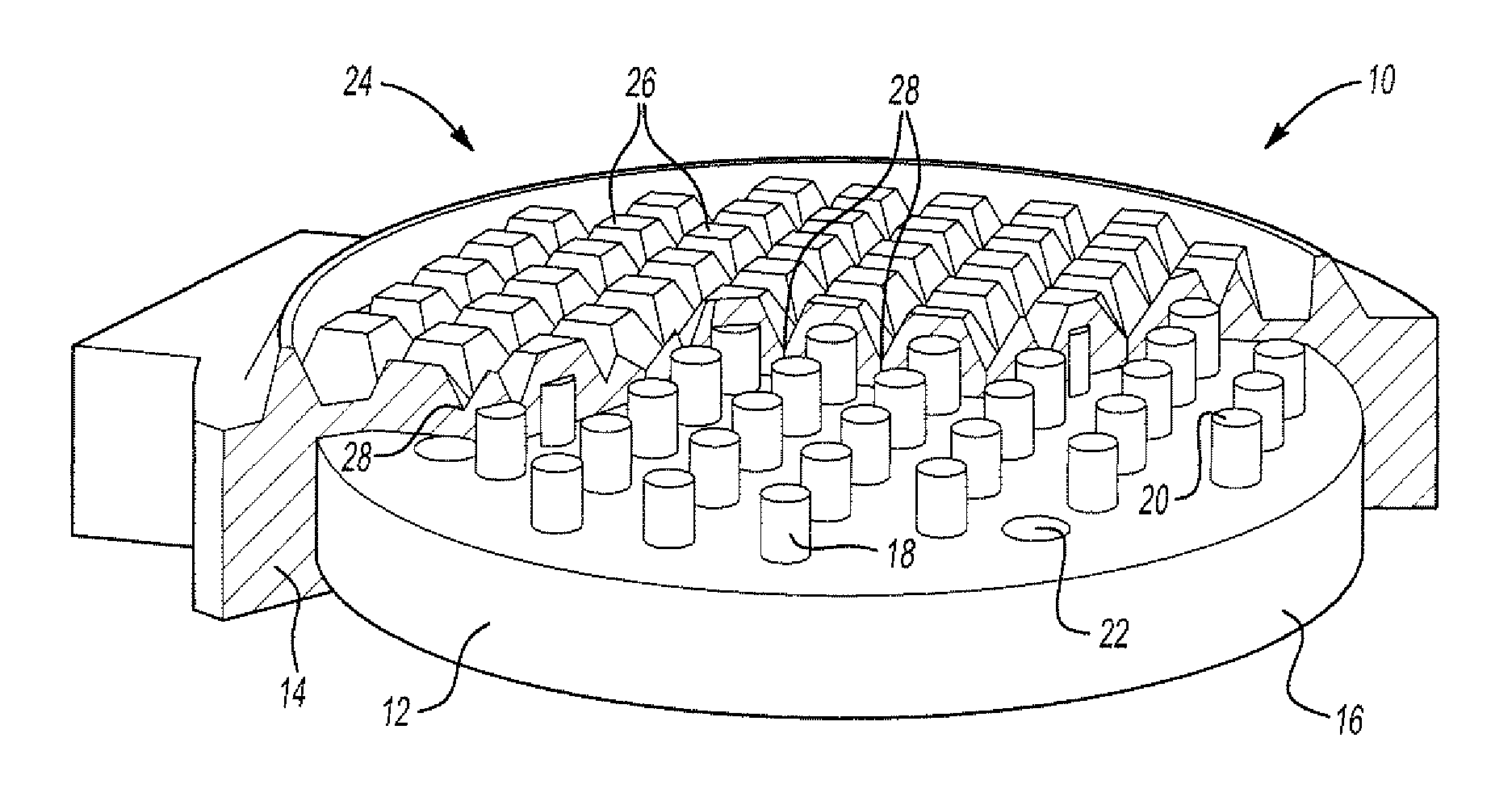

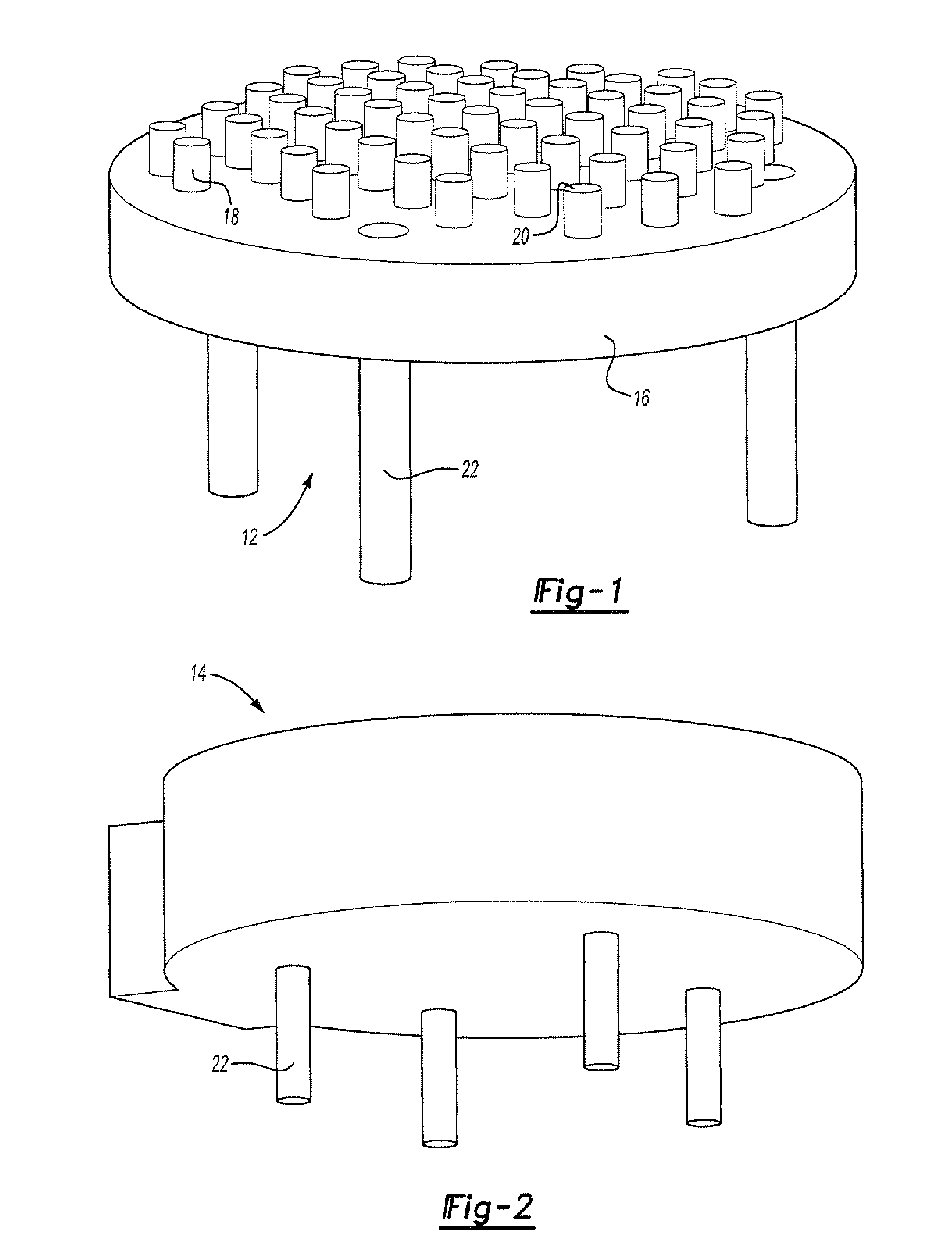

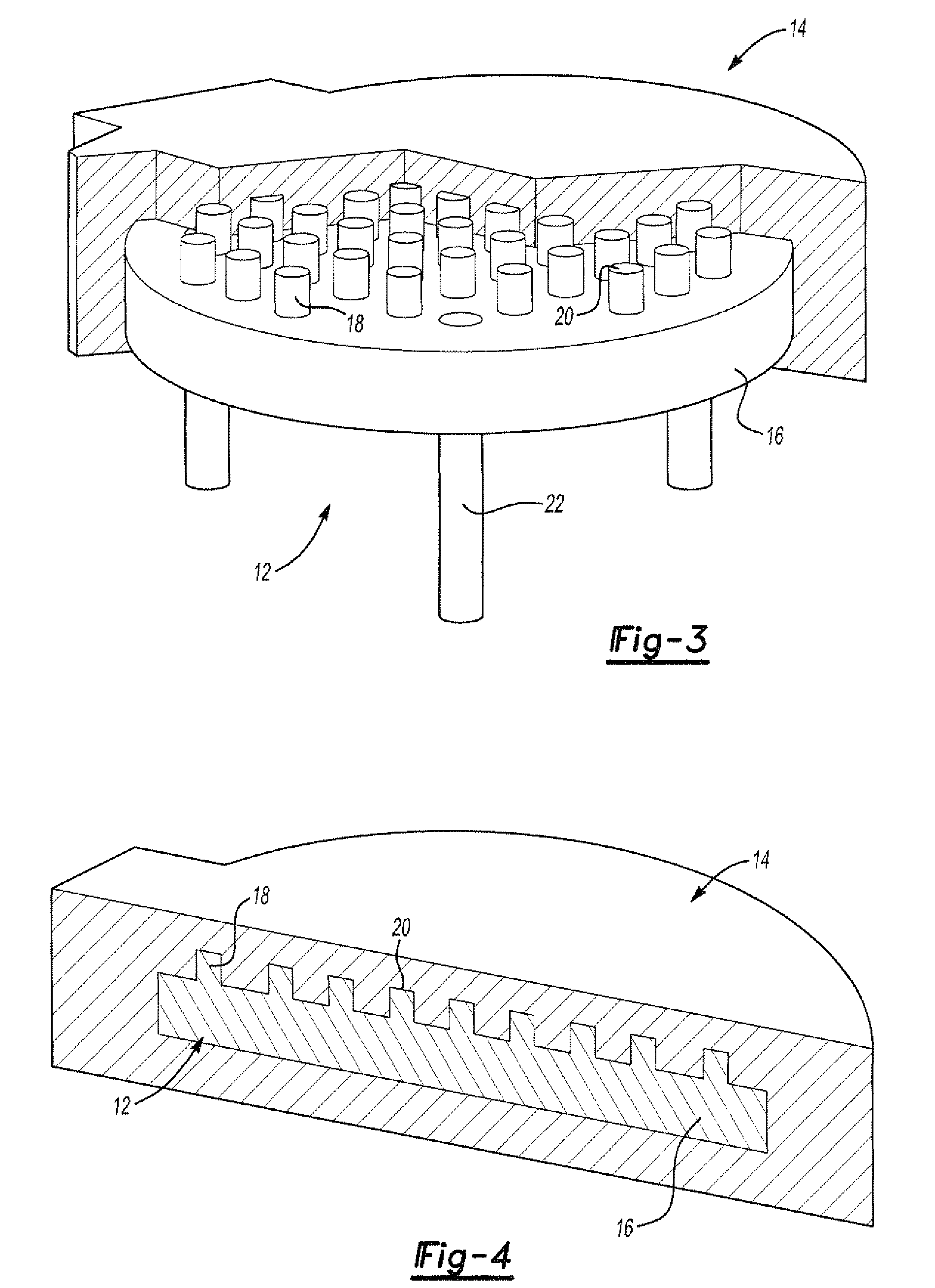

Induction cooking structure and system and method of using the same

In summary, the invention is a method of producing an edible food product. The method includes the step of forming a vessel core with a first material having a first level of susceptibility to heating by induction. The method also includes the step of casting an apron of a second material with a second level of susceptibility to heating by induction lower than said first level around at least a first portion the vessel core in an in situ casting process to form a clad cooking vessel having a cooking surface. An uncooked food product is then disposed on the cooking surface of the clad cooking vessel and heated to produce the edible food product by subjecting the vessel core to a magnetic field.

Owner:KELLOGG CO

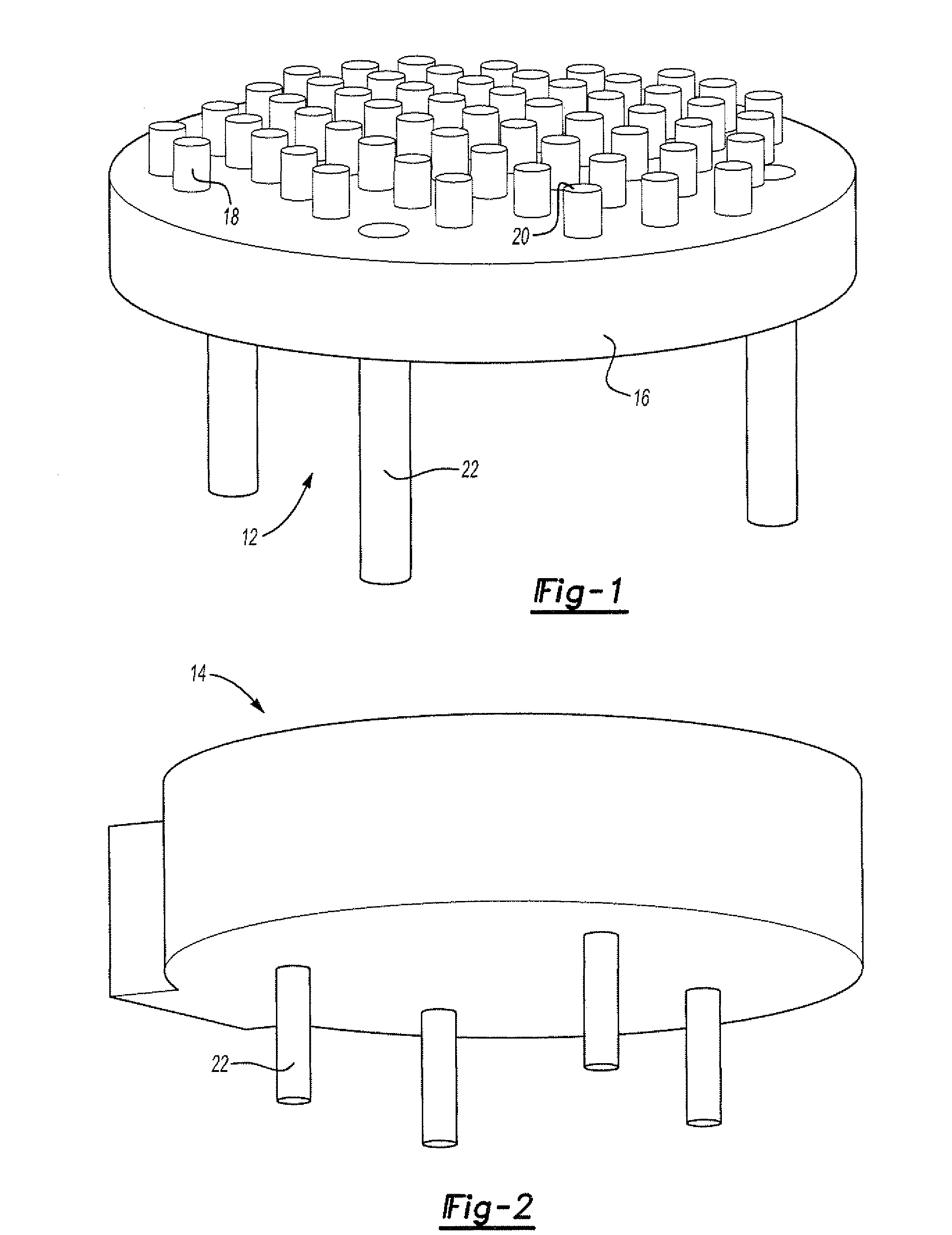

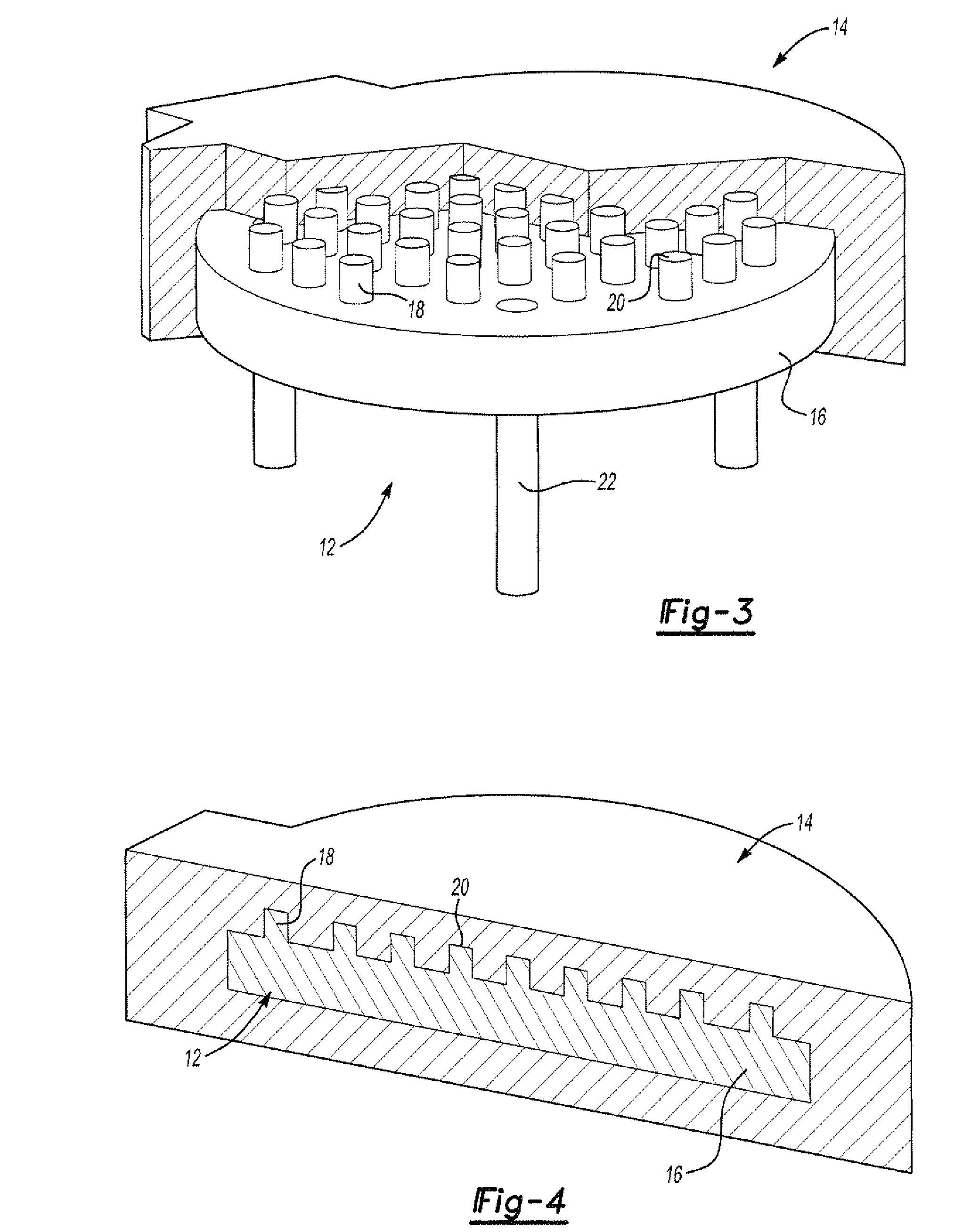

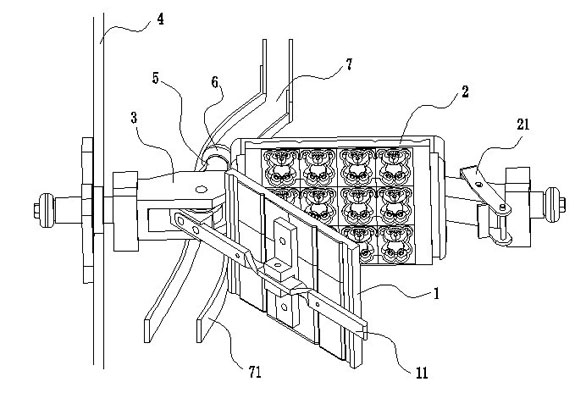

Roasting plant capable of automatically opening and closing mould

ActiveCN101897350AFully automatedImprove work efficiencyBaking ovenHollow article bakingMechanical equipmentEngineering

The invention discloses a roasting plant capable of automatically opening and closing a mould, belonging to the mechanical equipment for food processing. The roasting plant comprises a roasting mould composed of a top die and a lower die, wherein the lower die and an actuating device are fixed by a formwork, and the lower die can move along with the actuating device. The roasting plant is characterized in that one end of the top die is connected with the pin of the lower die, and an idler wheel is fixed on the other end of the joint by a crank; the position of the whole mould, which requires to open and close, is provided with an opening and closing rail by cooperating with the position of the corresponding idler wheel, the idler wheel can enter an opening and closing rail which has contorted configuration, and the idler wheel carries out curvilinear motion to finally drive the top die to open and close. In addition, the invention is provided with a retaining ring, the retaining ring is controlled by a curve guide rail to buckle the top die and the lower die when closing the cover. The plant has simple structure and reliable action, can automatically open and close the top die and the lower die and improve production efficiency.

Owner:无锡嘉鼎机械科技有限公司

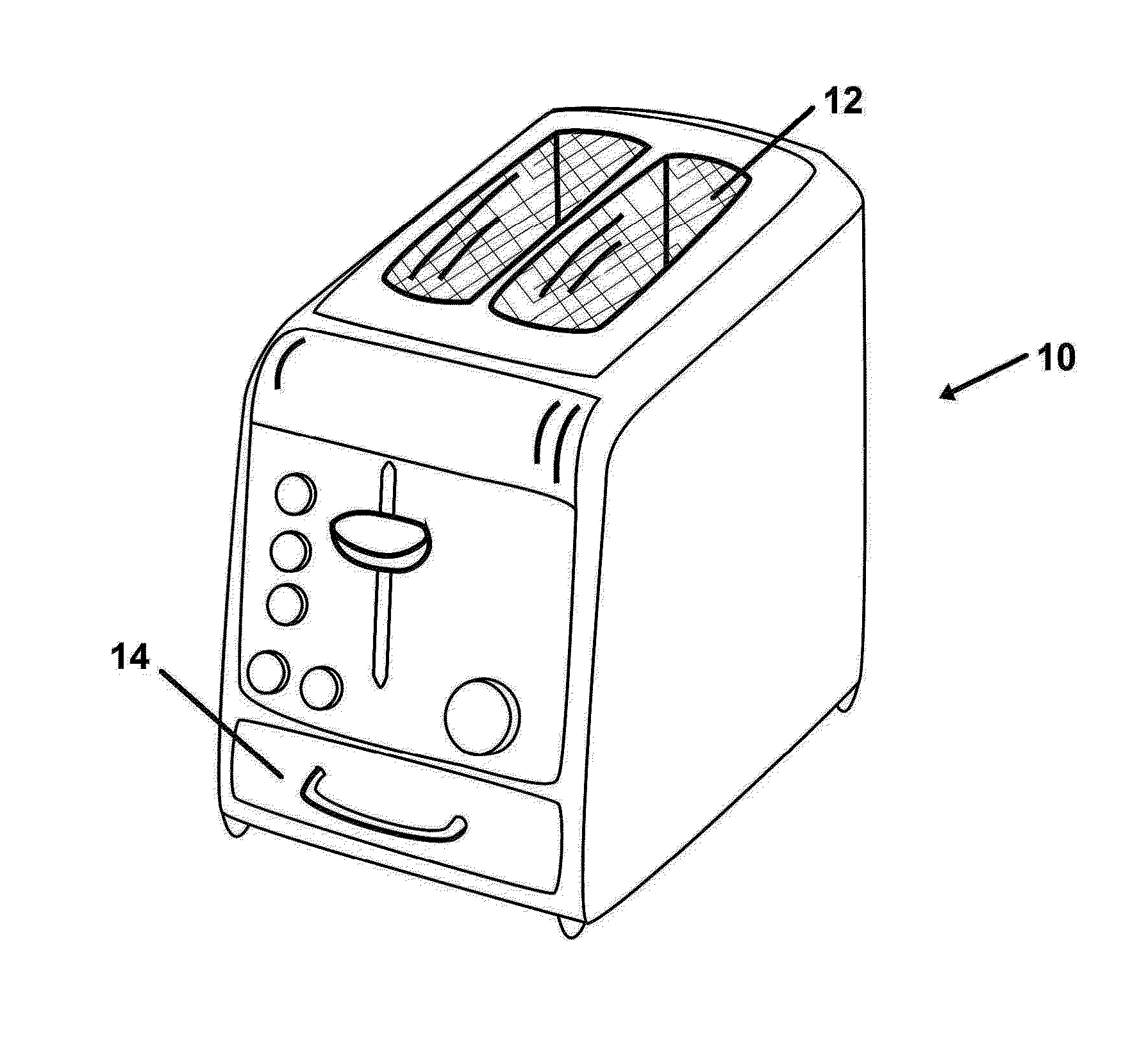

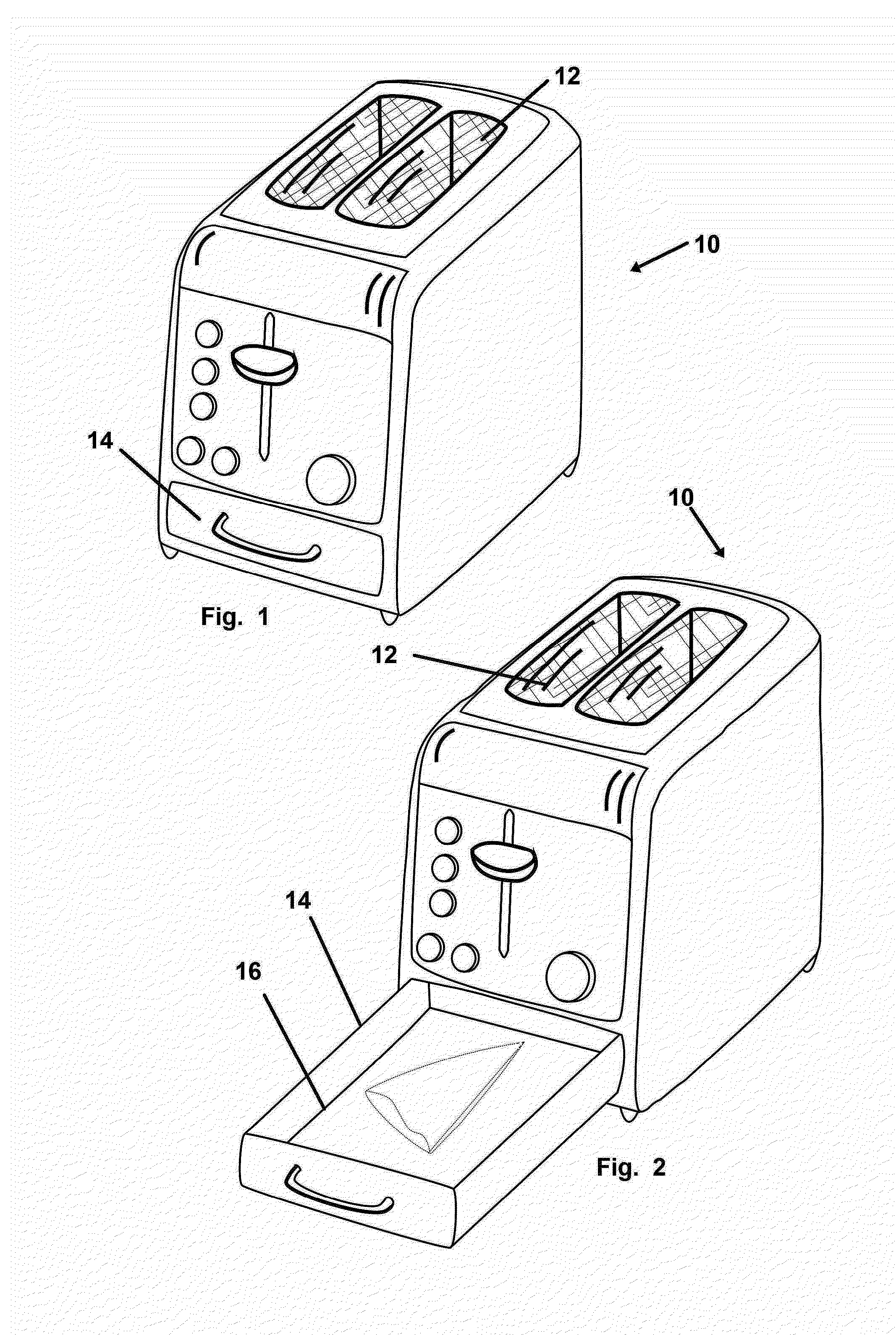

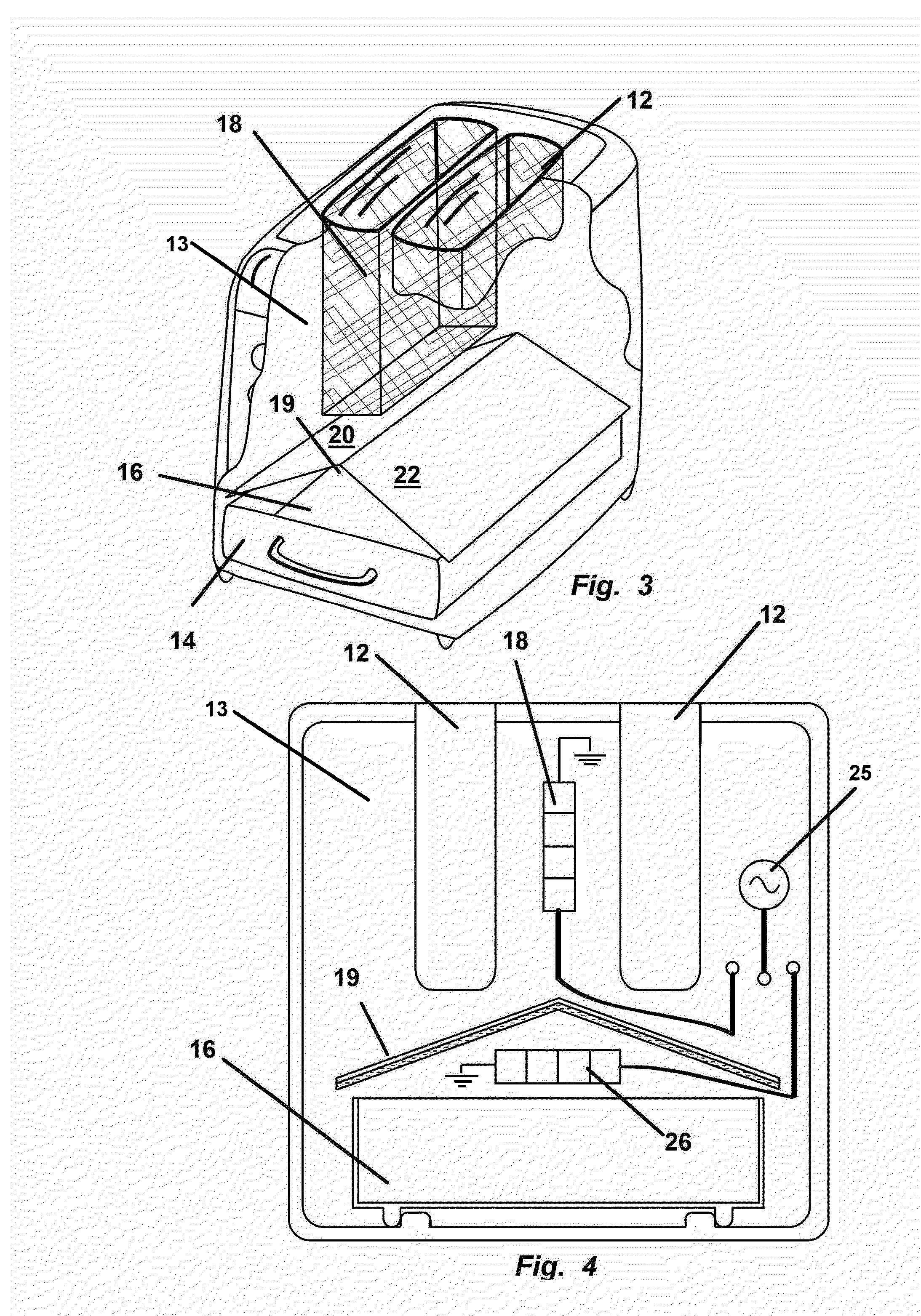

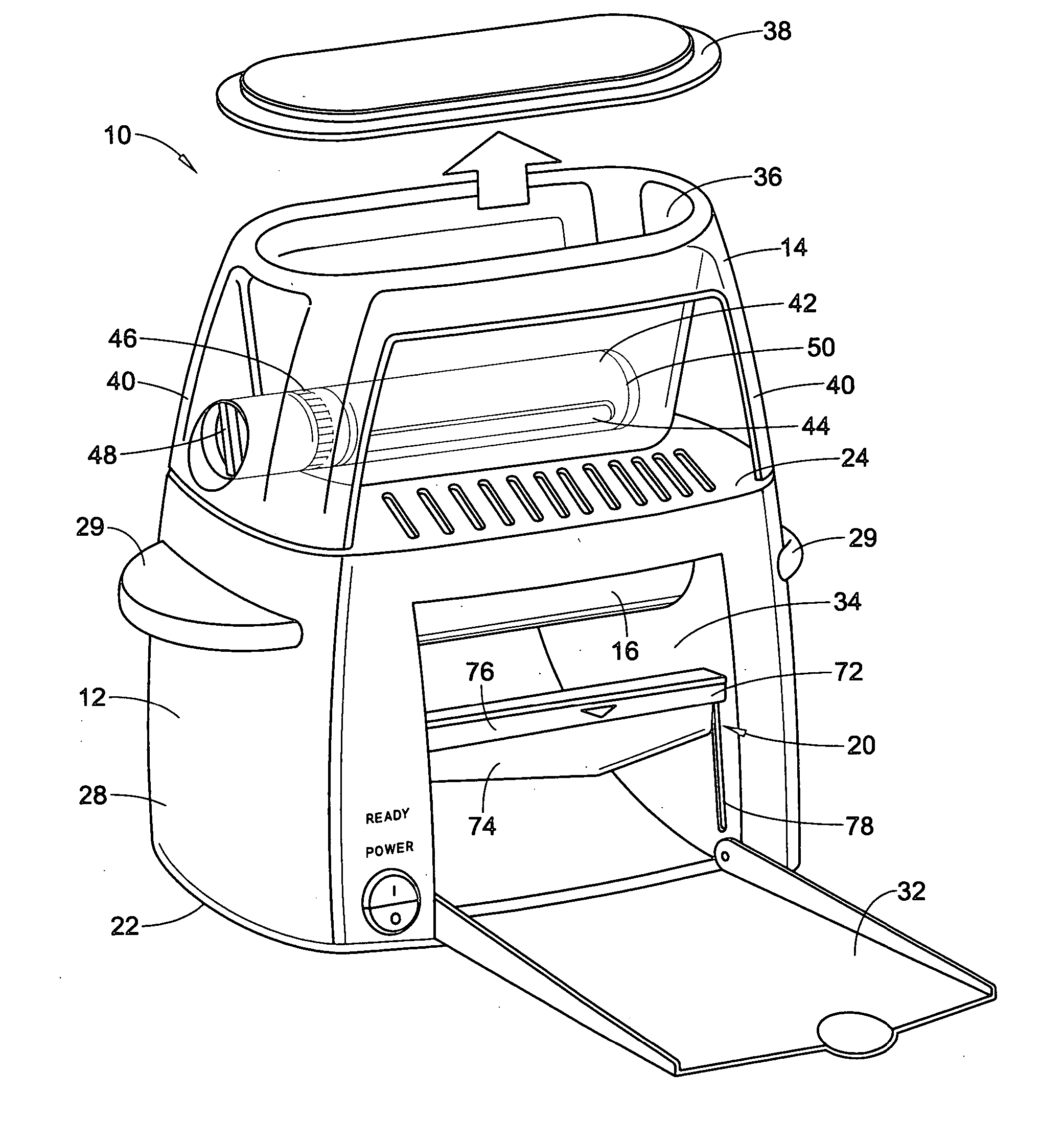

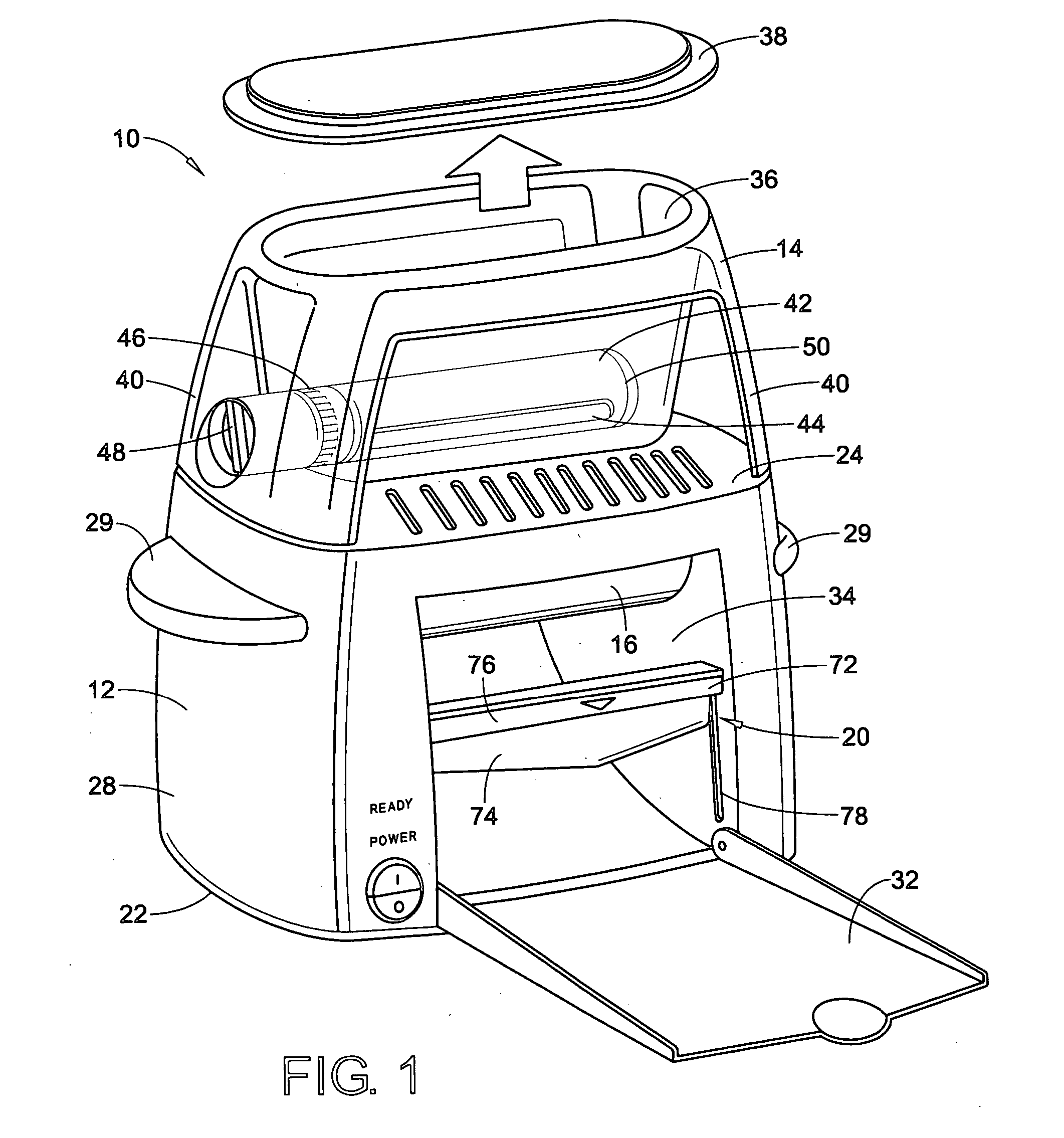

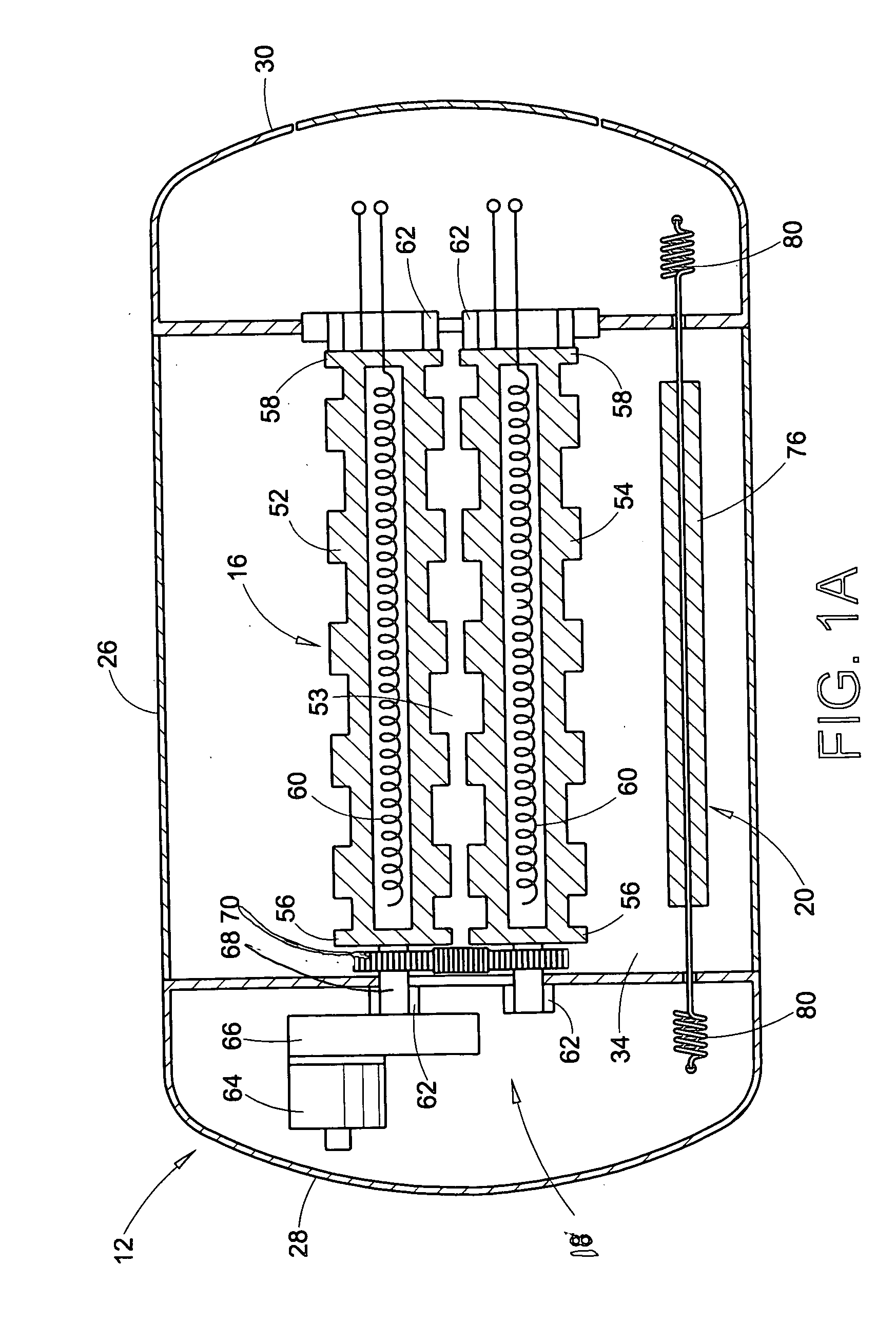

Combination Counter Top Toaster and Food Warmer

InactiveUS20150053093A1Easy to insertEasy to removeRoasting apparatusBread-toastersEngineeringSmall footprint

A toasting appliance is provided having a housing with a small footprint and having a toasting cavity for toasting bread and a horizontally disposed cooking cavity for cooking food. One or more doors in a side of the housing provide access to the cooking cavity and viewing windows to view both cooking food in the cooking cavity or toasting bread in the toasting cavity.

Owner:MIRAMA ENTERPRISES

Self-cleaning ovens

InactiveCN1644058AImprove hygieneIncrease productivityHollow article bakingSelf-cleaning ovenEngineering

An automatically cleaning oven is composed of a supporting frame, a roasting unit, a primary conveying band, multiple roasting trays on said primary conveying band, and an automatic cleaning unit which consists of a conveying band with at least two parallel endless chains for automatic cleaning and at least one oil collecting unit comprising multiple plate units with anti-leakage edge.

Owner:广东顺风行食品有限公司

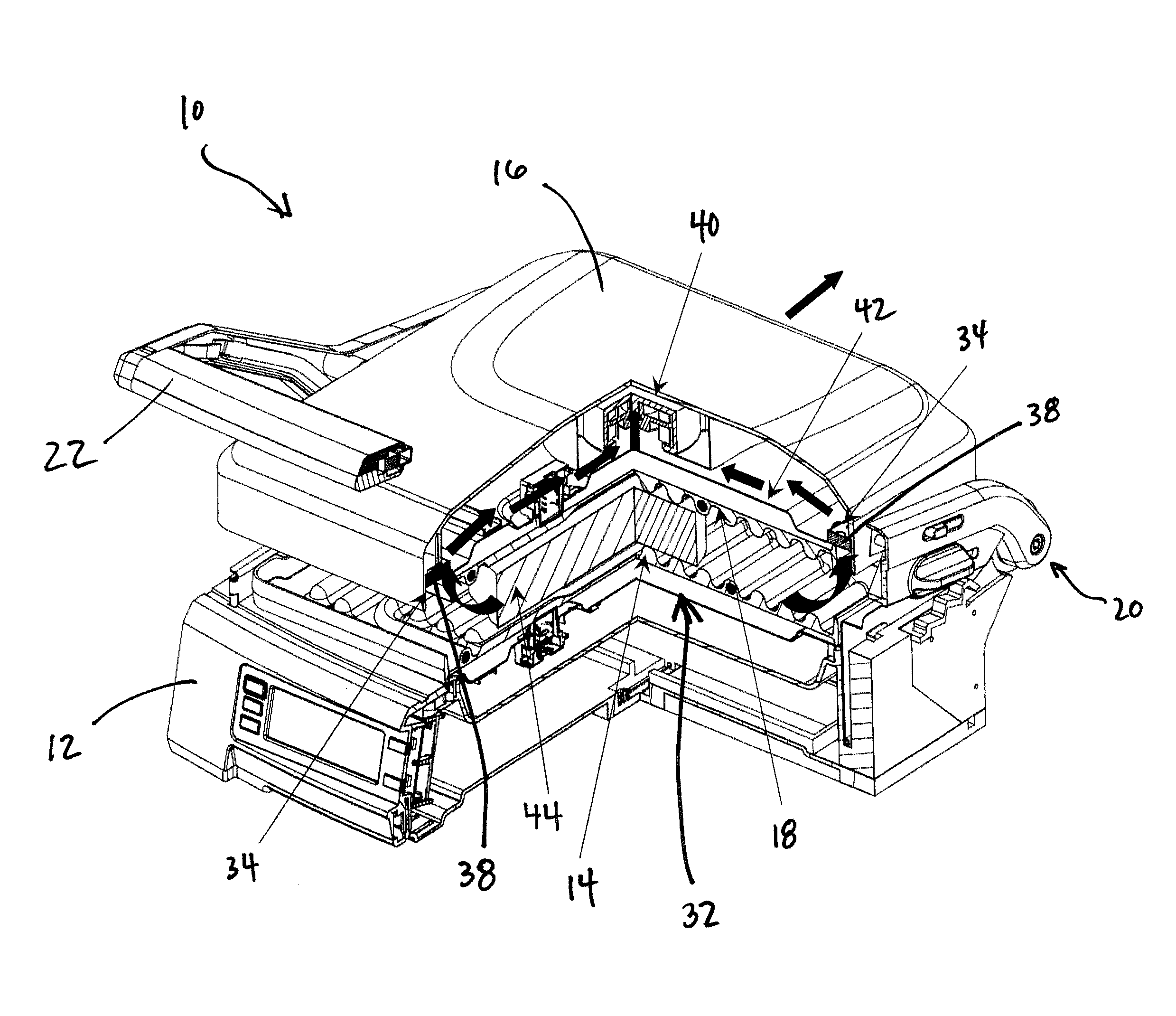

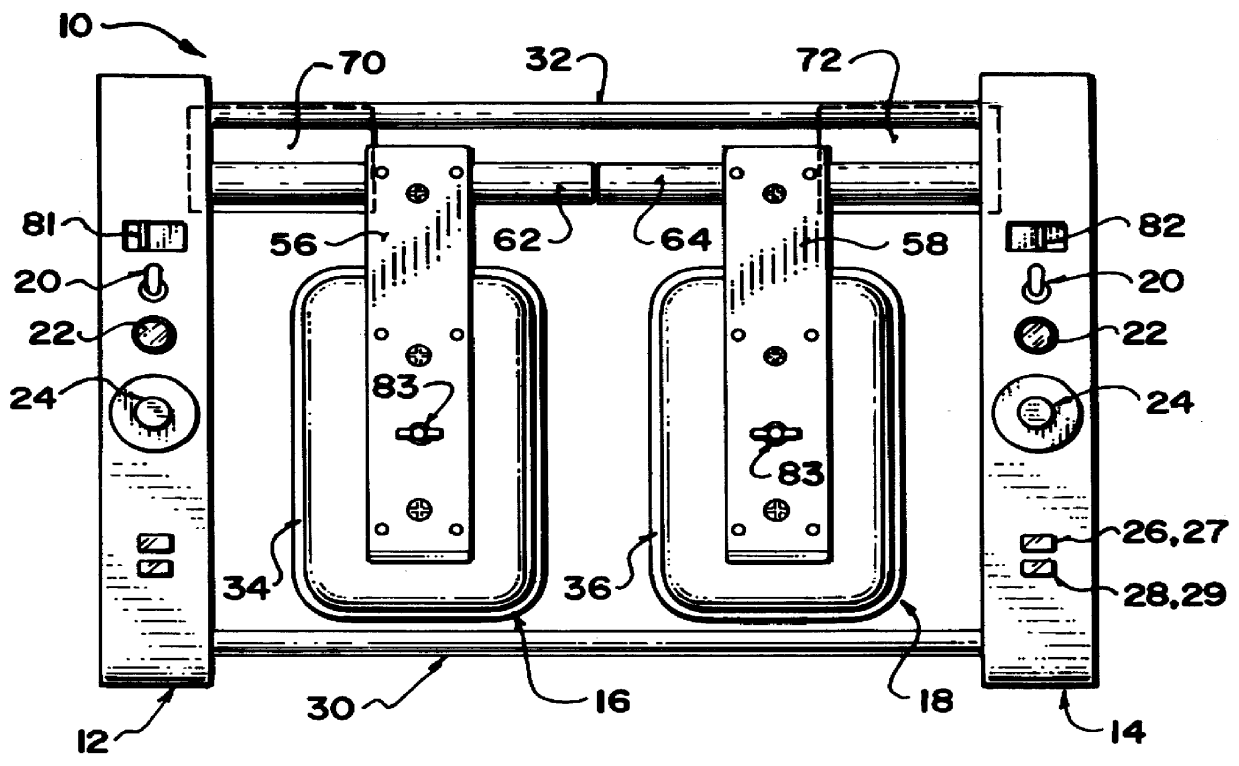

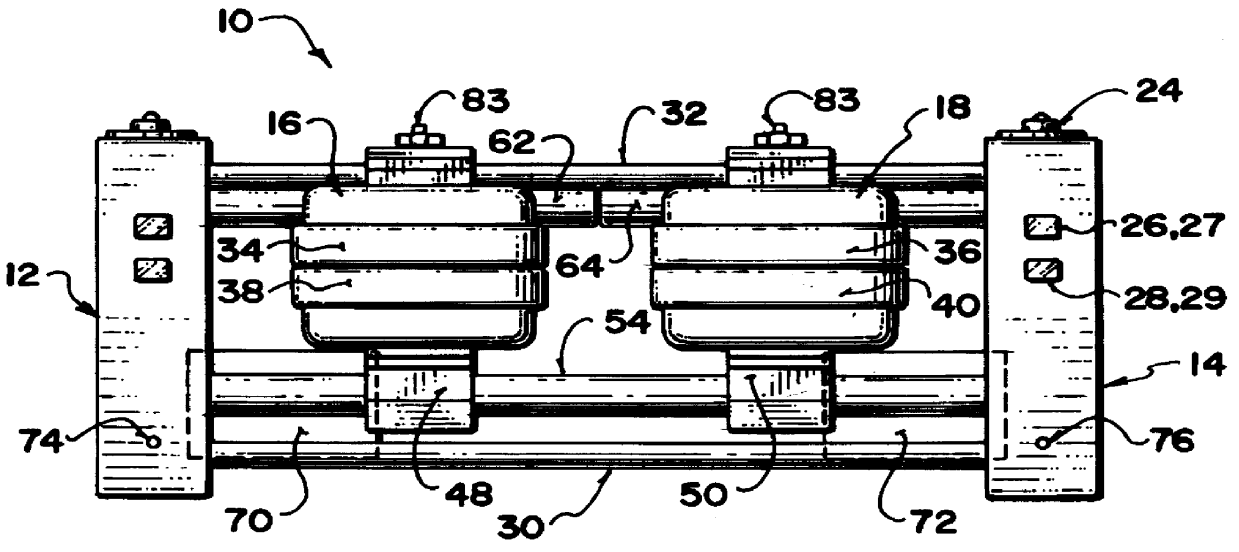

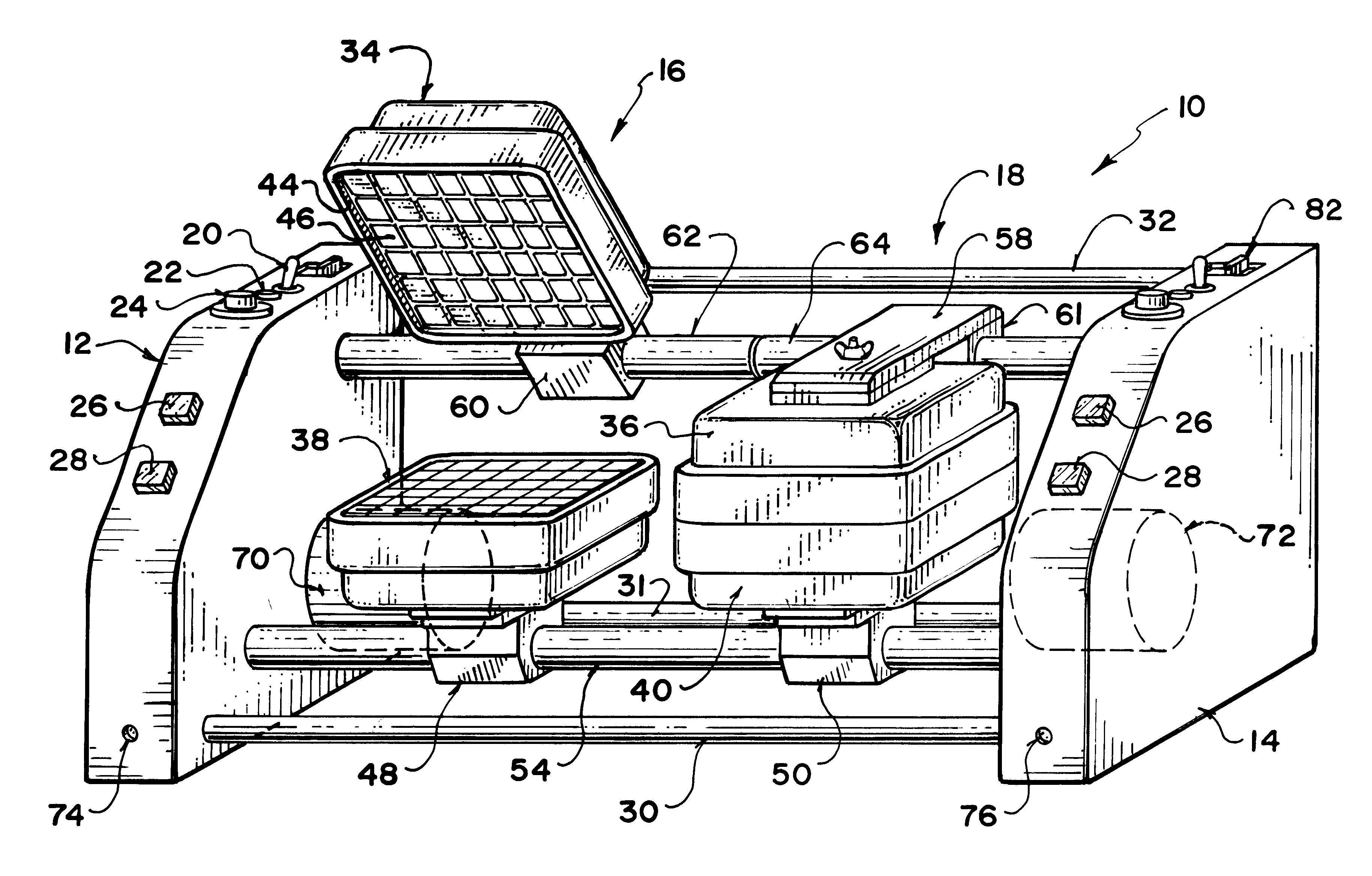

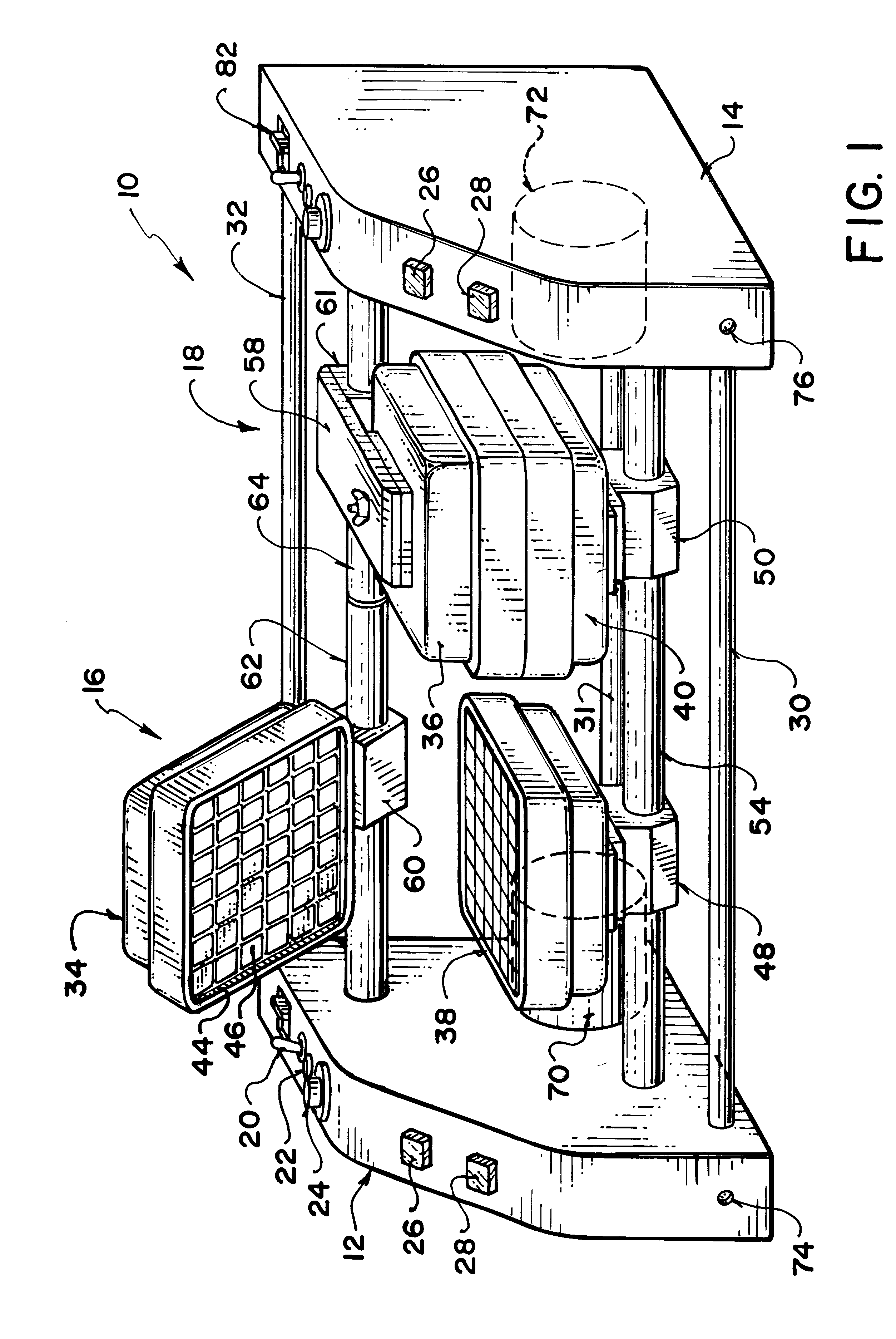

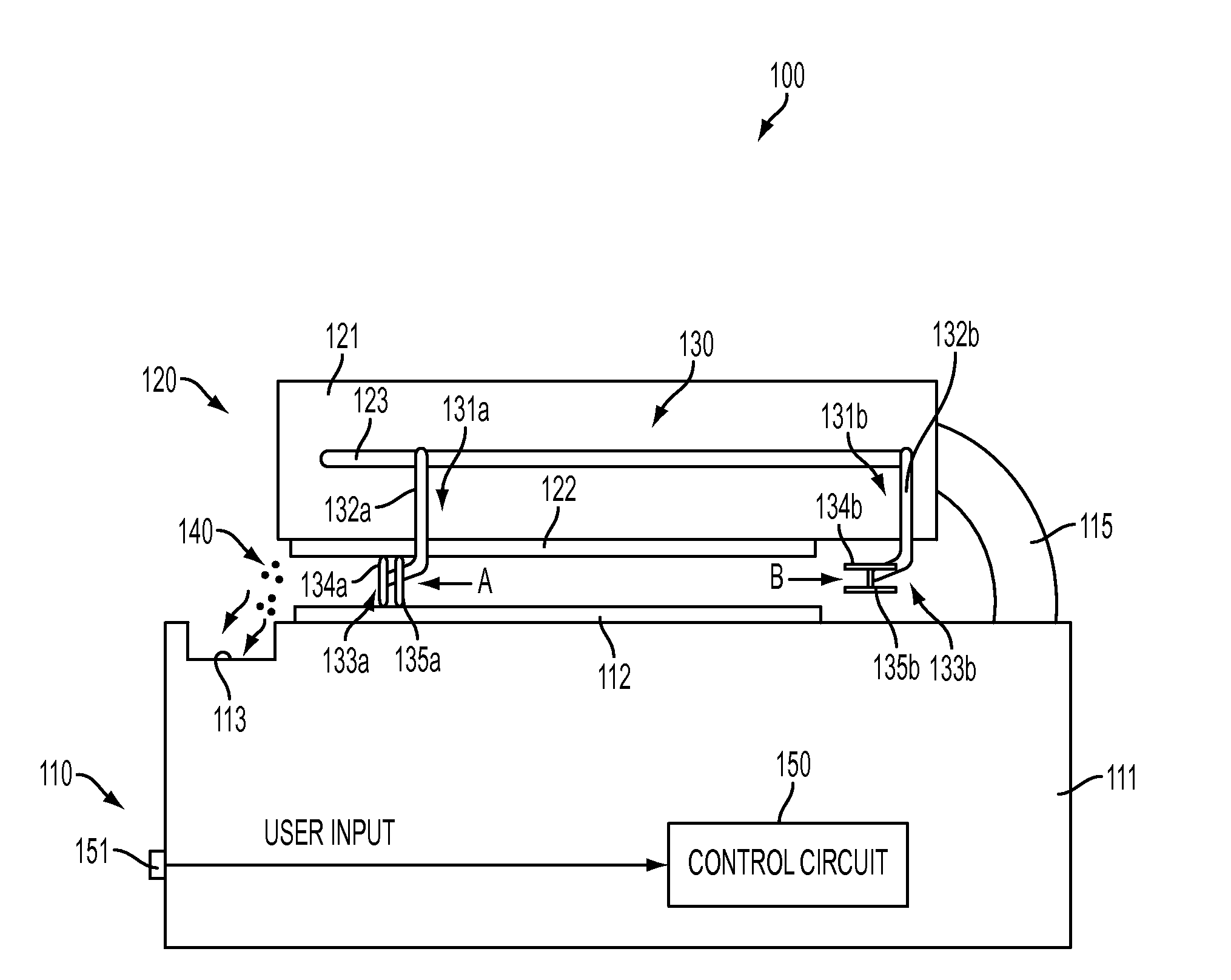

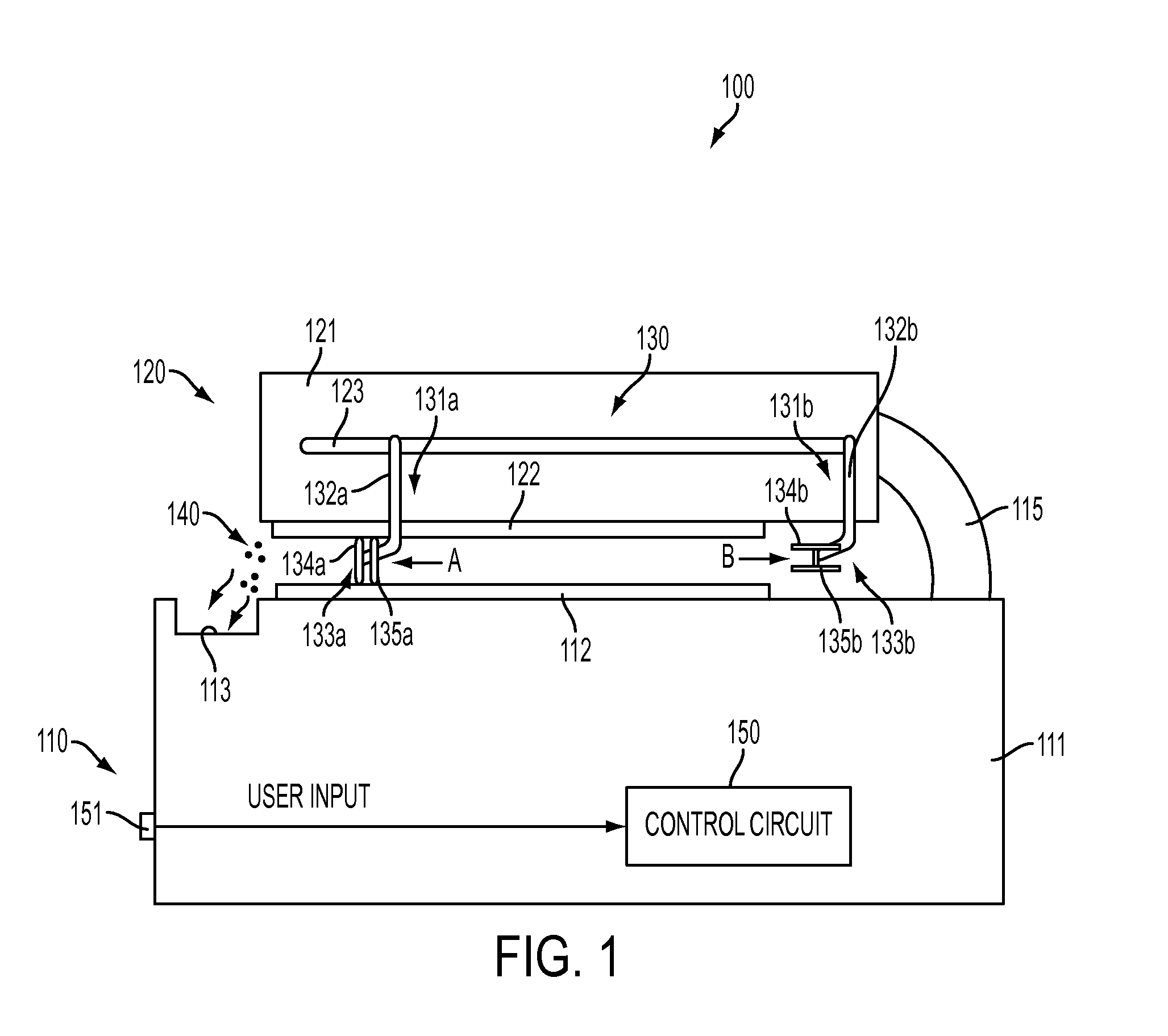

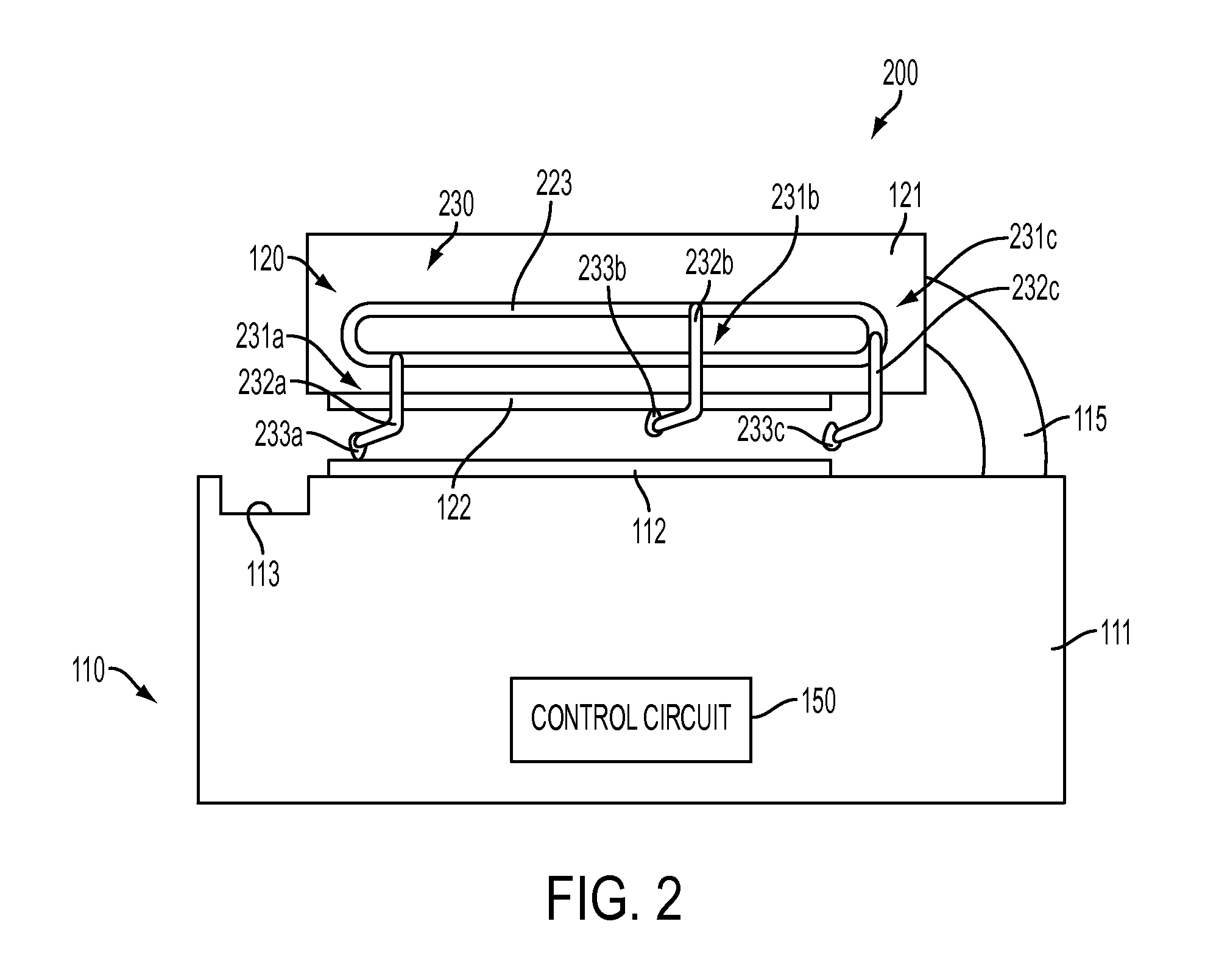

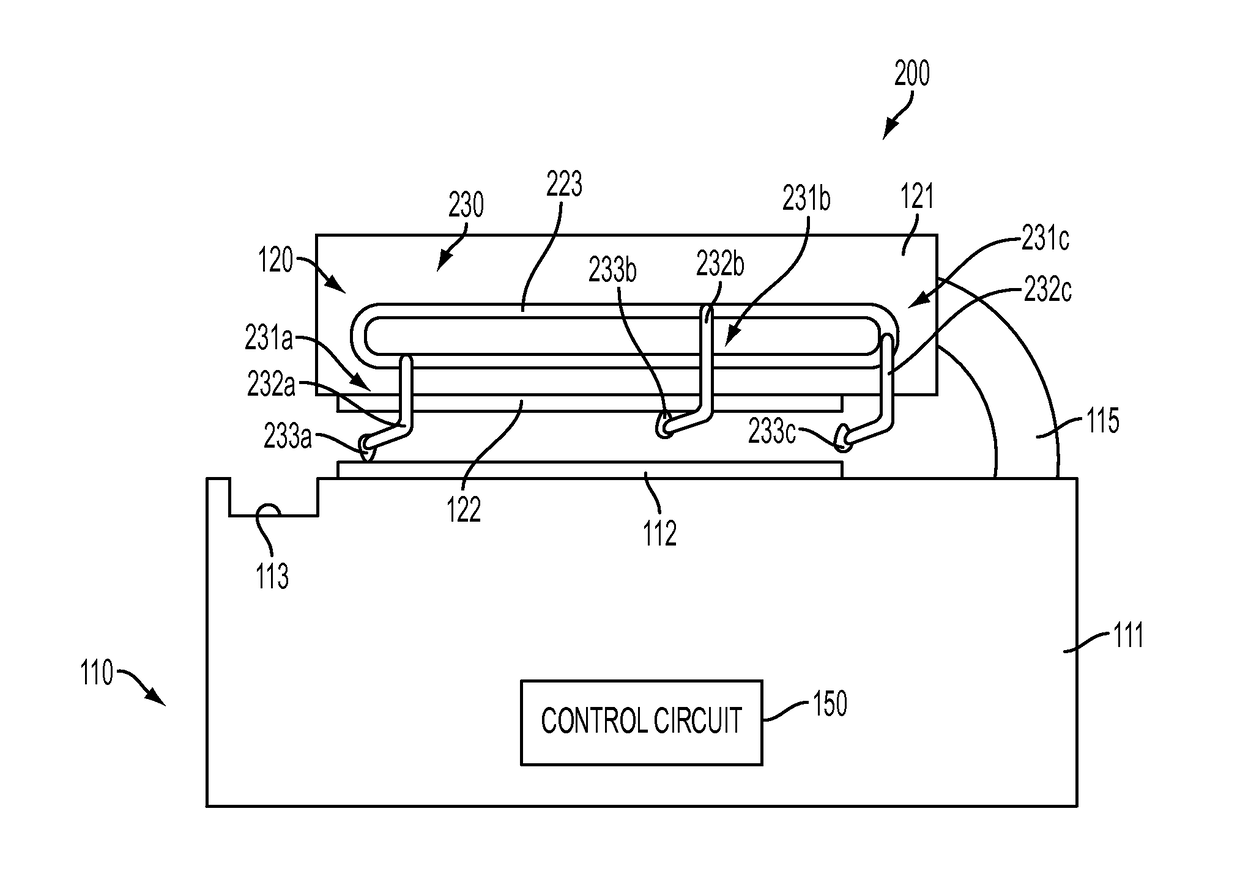

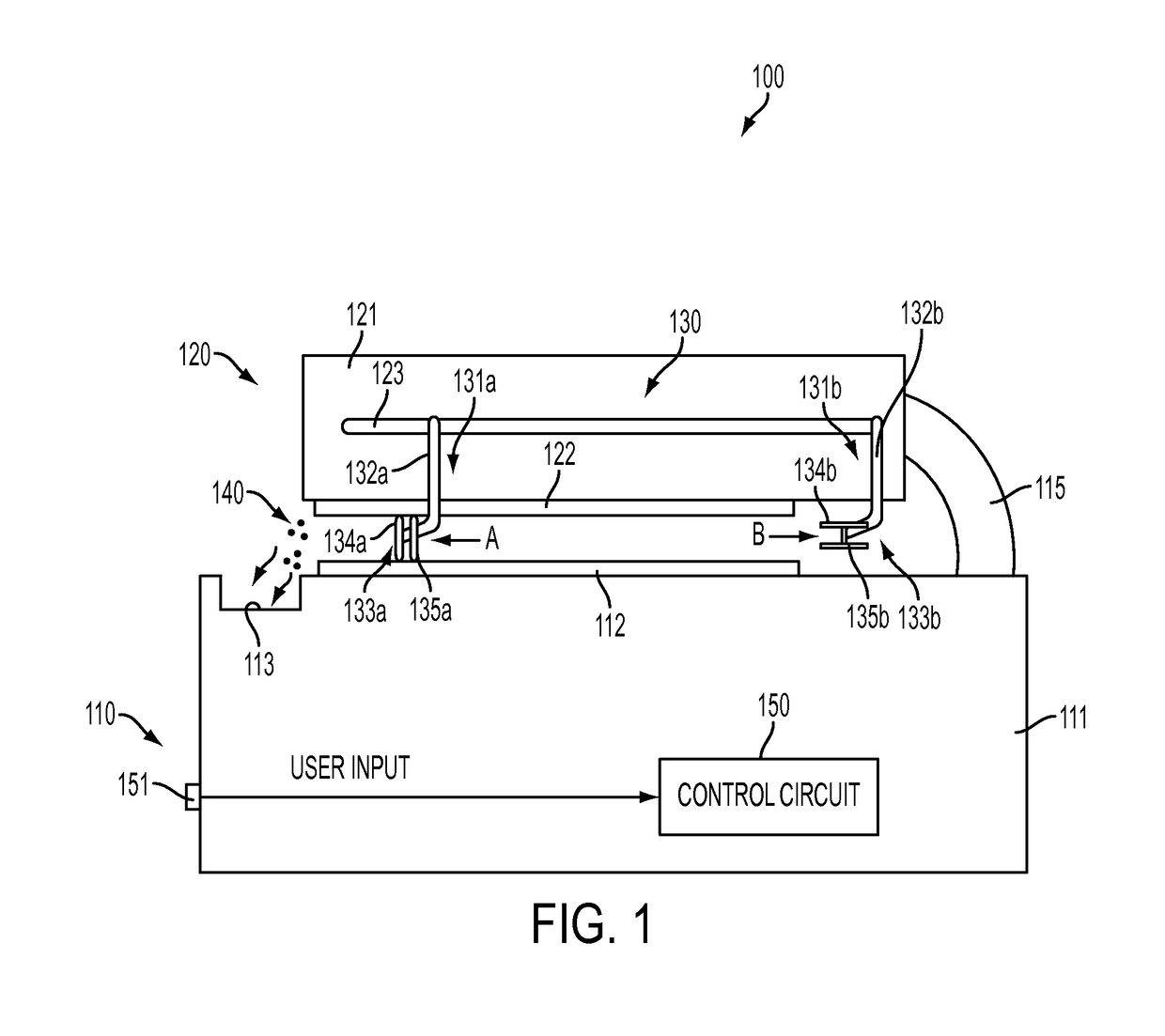

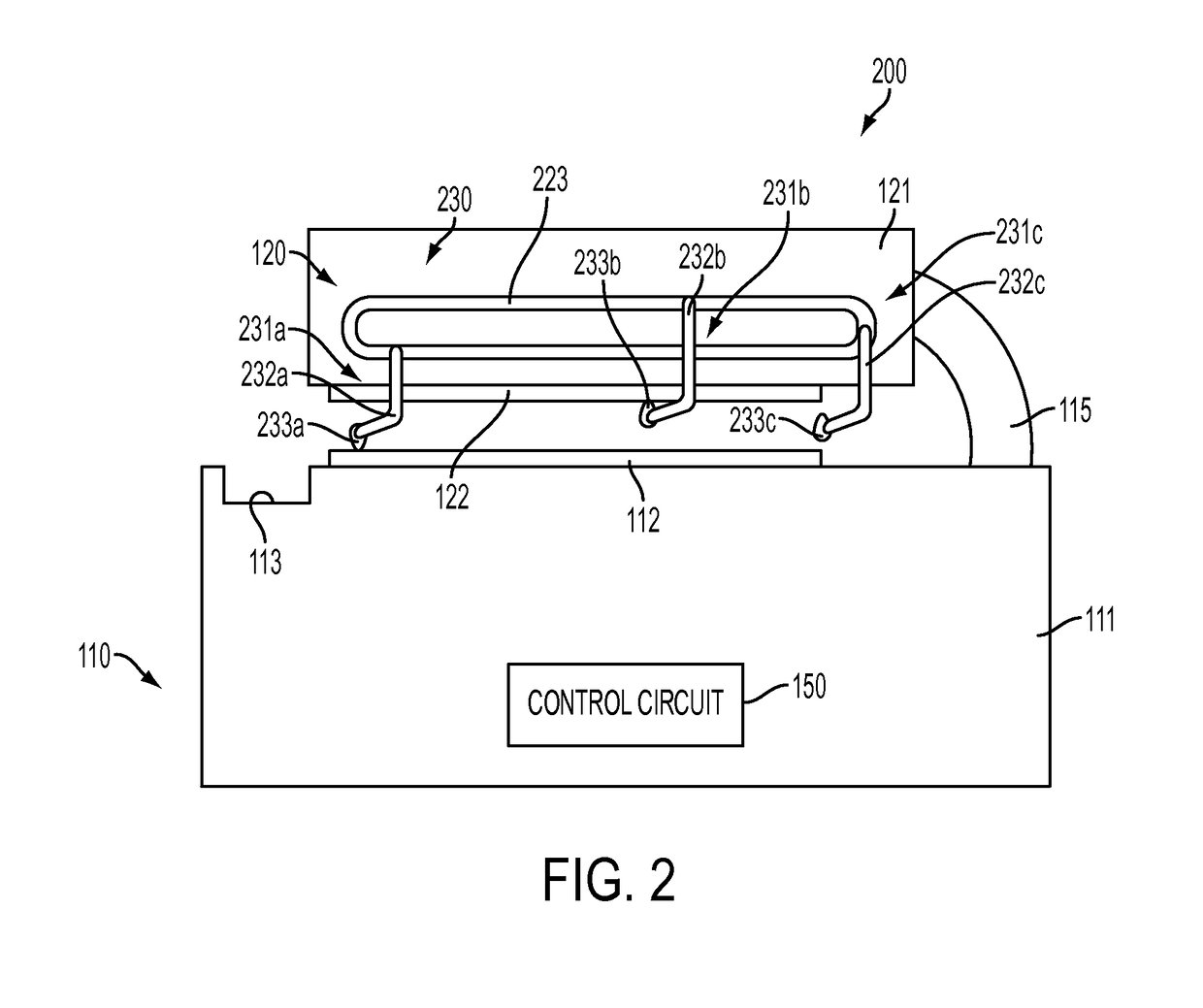

Automated cleaning of cooking apparatus

A cooking apparatus includes a base including a lower heating plate an upper heating unit including an upper heating plate and a cleaning structure configured to move a cleaning blade along at least one of the lower heating plate and the upper heating plate. The apparatus also includes a control circuit configured to control movement of the cleaning blade across the one of the lower heating plate and the upper heating plate.

Owner:TAYLOR COMML FOODSERVICE LLC

Automated cleaning of cooking apparatus

Owner:TAYLOR COMML FOODSERVICE LLC

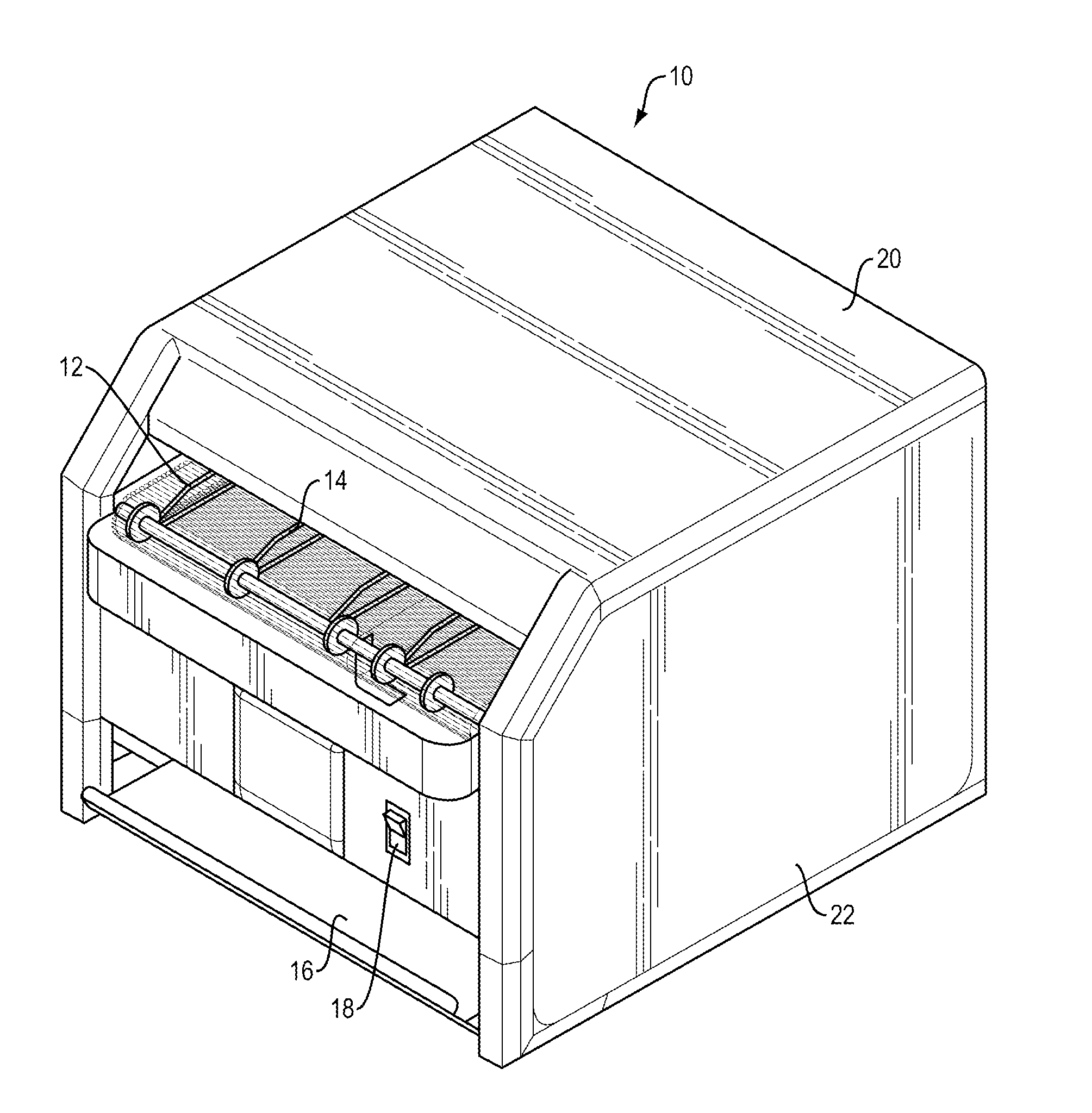

Continuous food cooker

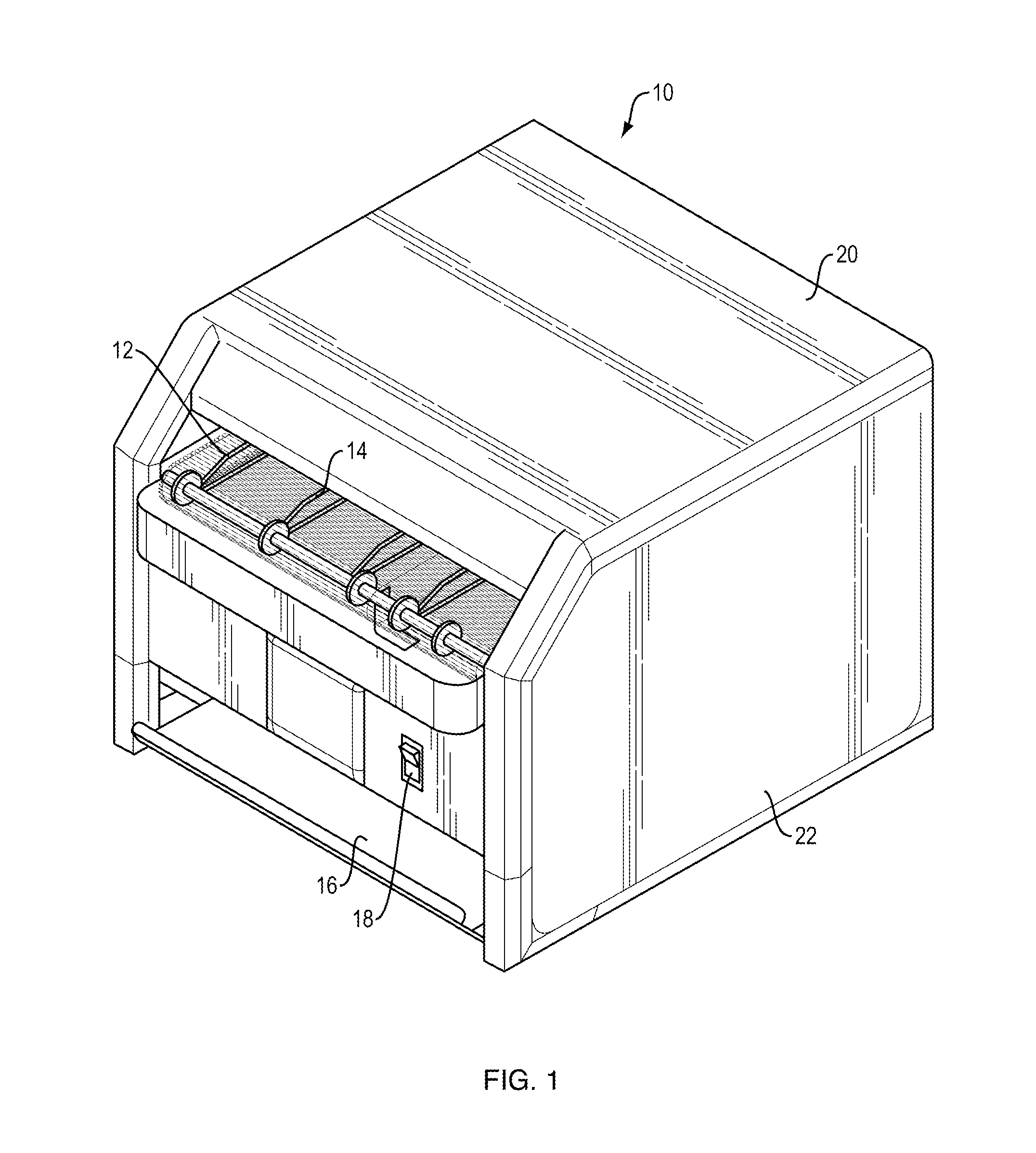

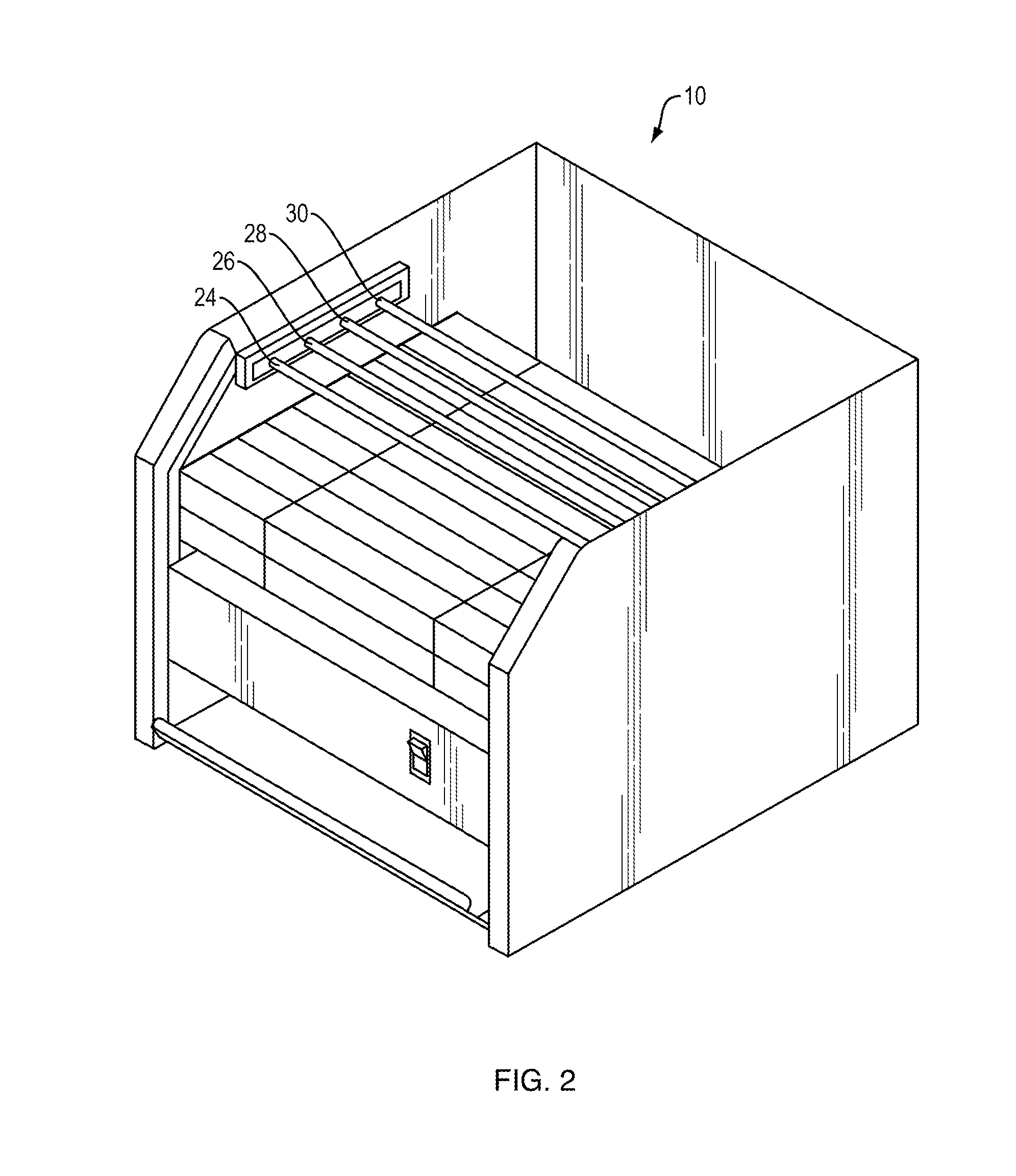

InactiveUS20060236873A1Easy to useConsistencyMeat processingDough embossing machinesEngineeringIngested food

The present invention relates to a portable household food cooker capable of receiving a food mixture and producing food items in a continuous fashion. The continuous food cooker generally includes a housing and a hopper. The hopper is disposed above the housing for receiving the food mixture and for dispensing the food mixture into the cooker. The continuous food cooker also includes a hot roller assembly for forming and cooking the food mixture, a hot roller drive assembly operatively attached to at least one roller, and a cutter for cutting the produced food item at a desired length. The hot roller assembly includes at least one rotatable roller and at least one heating element for heating the at least one roller. The at least one roller and the at least one heating element are disposed internally to the housing.

Owner:NOTTINGHAM SPIRK DESIGN ASSOCS

Quick heating quartz toaster

InactiveUS20140318382A1Save energyHigh voltageBoiling over preventionElectric heatingTemporal changeEnergy requirement

A commercial toaster apparatus having a “quick start” feature that nearly instantly changes from a “stand-by” mode to a “toasting” mode. The “quick start” mode is provided by changing the circuitry of some of the quartz heating elements from a series configuration to a parallel one wherein a higher voltage can be applied for a controlled amount of time to regulate the quartz heaters without adversely affecting the life span of the heating elements. Temperature probes are used to adjust the duty cycle of the apparatus to enable a uniform toast color as the cavity chamber temperature of the toaster changes over time. A sensor is also provided that determines when a last product is placed on the conveyer and the duty cycle has been completed such that the unit will automatically switch to a “stand-by” mode, thus reducing the energy requirements of the toaster.

Owner:STANDEX INT CORP

Moving belt dough press with heated platen

ActiveUS20080141874A1Improve reliabilityReduce replacementPlywood pressesVeneer pressesElectrical resistance and conductanceEngineering

A moving belt conveyor dough press is provided with a pair of vertically opposing platens, at least one of which is movable toward and away from the other. A continuous belt is arranged to pass between the pair of platens, and to carry on an upper surface thereof, a supply of dough masses to be pressed by the platens. At least one of the platens is formed of a cast metal material, and an electrical resistance heating element is cast in place within the at least one platen.

Owner:AM MFG

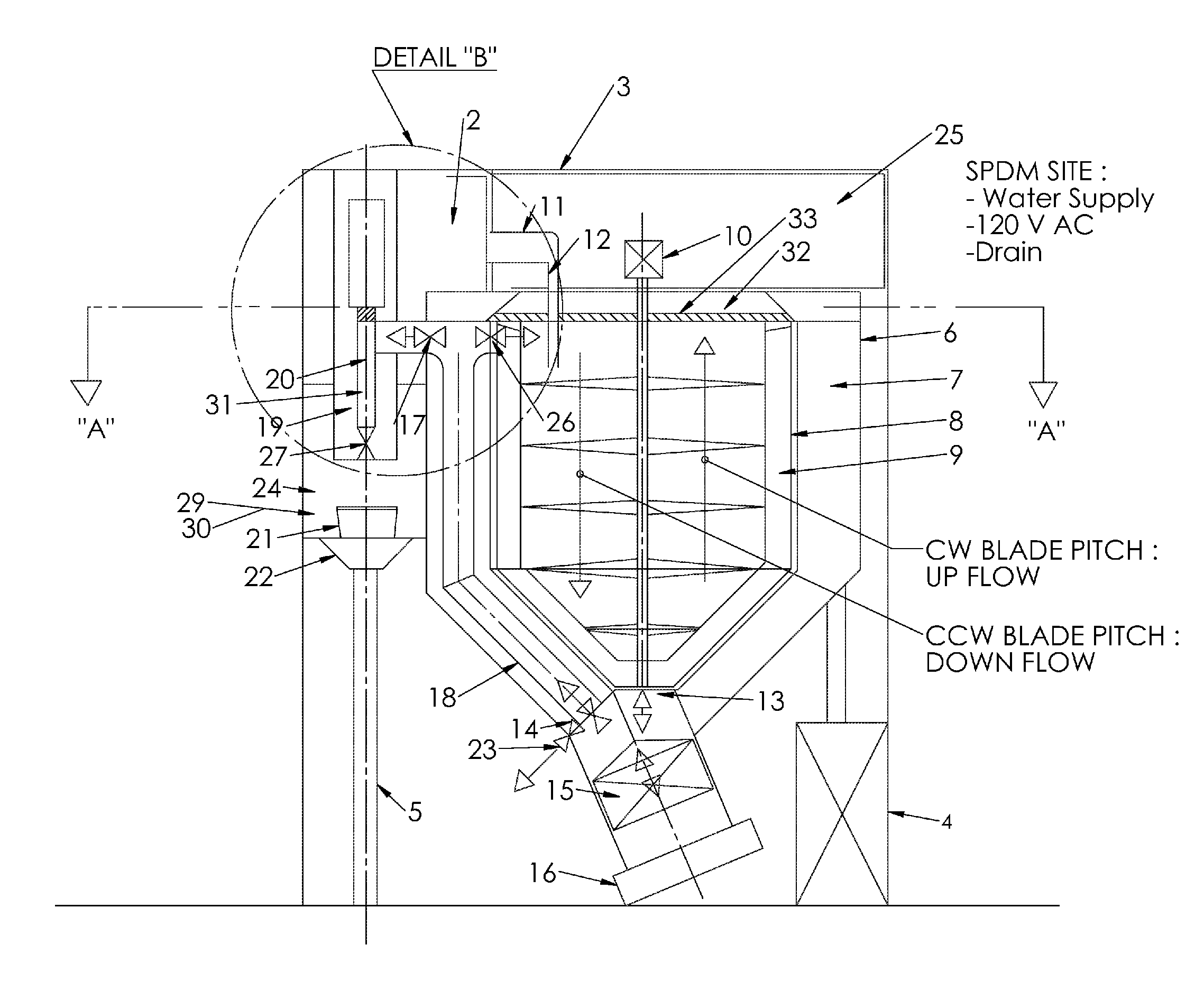

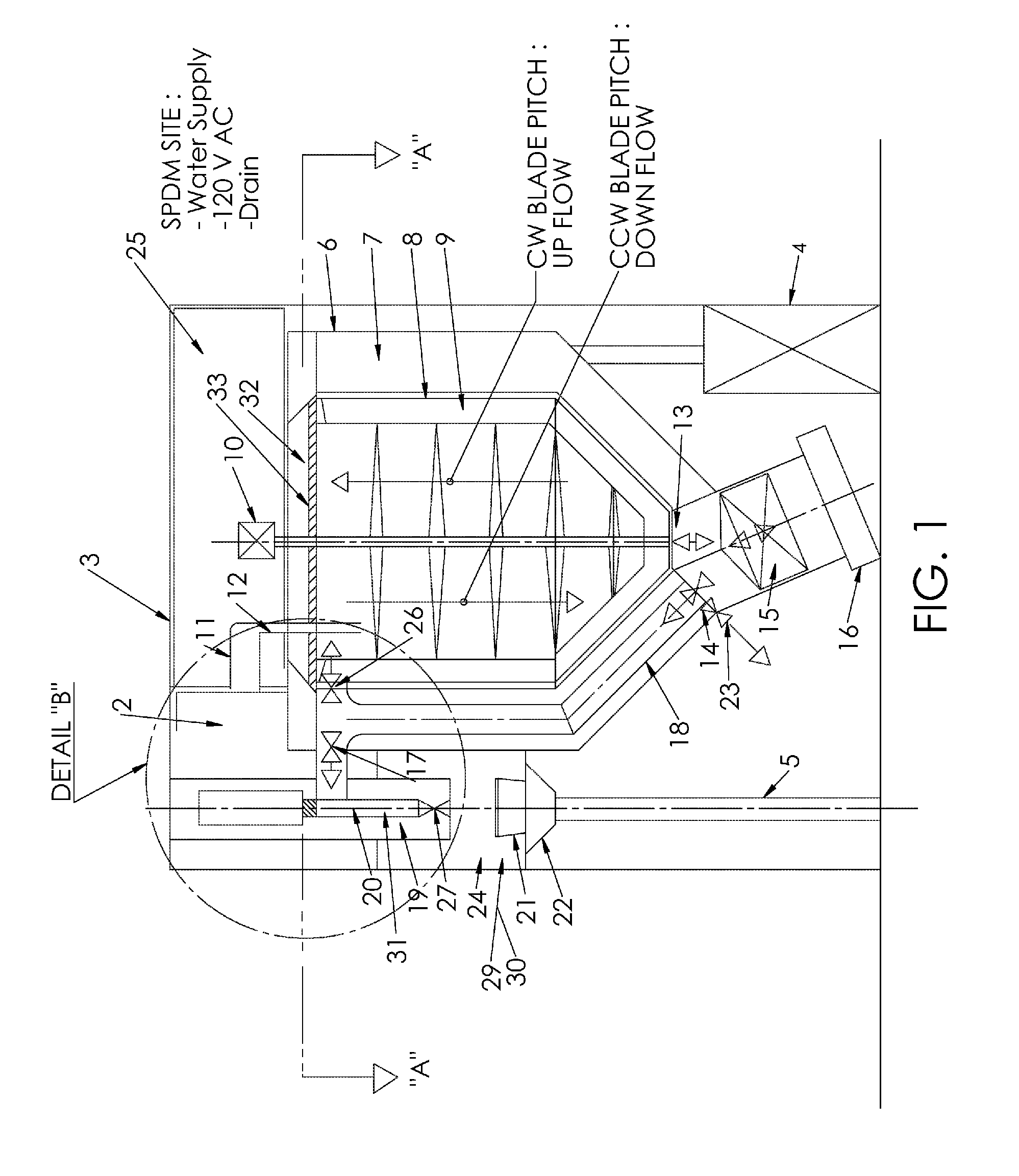

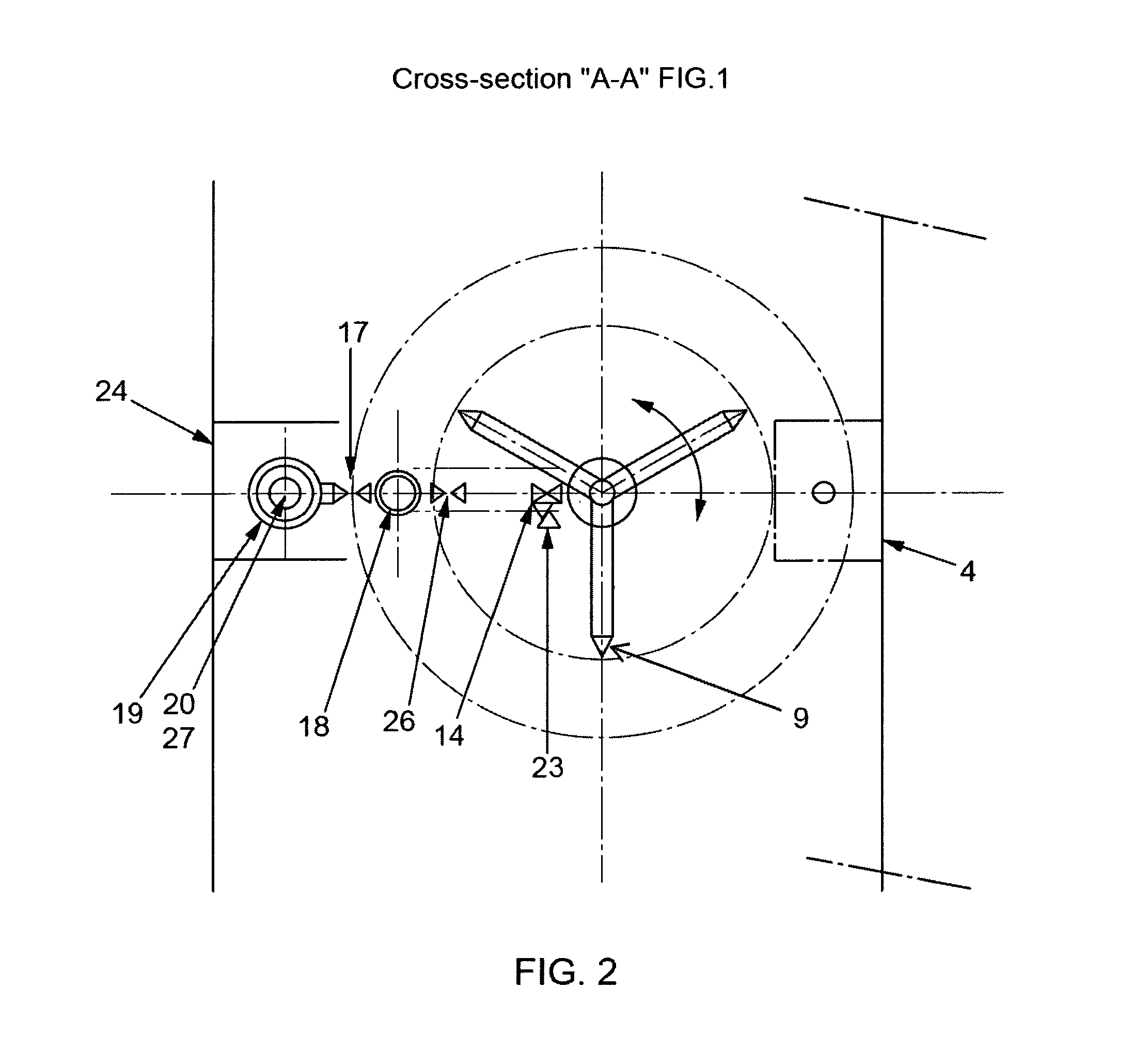

Soup preparing and dispensing machine (SPDM) and method of producing individual servings of hot or cold soup using the same

Hot or Cold soup made fresh from scratch, can or concentrate is prepared in a suitable container and after its preparation is kept cool, blended and re-circulated for long term shelf life until a serving is requested. This serving volume of soup is automatically pumped and heated to serving temperature (hot soup) and served in a suitable container like a cup or a bowl. The entire system where the soup resides is always kept refrigerated. The only portion of the soup that is heated after its preparation is the one dispensed. If it is a soup that is served cold the heating prior to dispensing is by-passed.

Owner:MARTIN BATTURS & ASSOCS

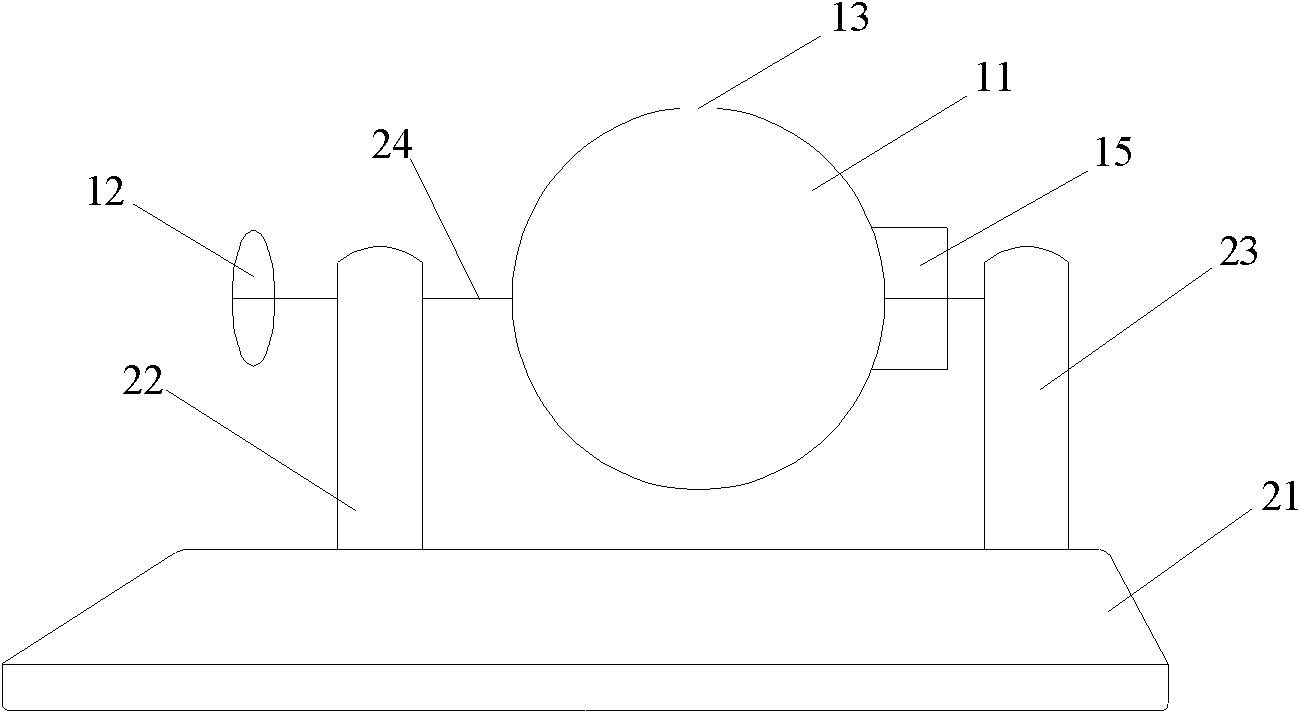

Baking device

ActiveCN102085074APrevent extrusionAvoid getting dirtyRoasters/grillsHollow article bakingCooking & bakingWater vapor

The invention discloses a baking device which comprises a baking mechanism and a fixing mechanism for fixing the baking mechanism, wherein the baking mechanism comprises two baking trays in rotating connection, a baking cavity is surrounded by the two baking trays, one of the baking trays is fixed on the fixing mechanism, an included angles is arranged between the baking tray fixed on the fixing mechanism and the horizontal plane, and a feed port for enabling flour paste to flow into the baking cavity is arranged at the upper end of at least one of the baking trays. As for the baking device in the embodiment of the invention, the included angle is arranged between the two baking trays and the horizontal plane, the two baking trays are arranged obliquely, the feed port is arranged at the upper end of the baking tray, the flour paste is directly poured into the baking cavity from the feed port, and the baking tray does not need to be opened for pouring the flour paste, thereby being convenient to use; simultaneously, when in heating and cake-making, generated water vapor can be discharged from the feed port, thereby avoiding extruding the flour paste which is not cured from a peripheral gap, avoiding smearing a machine and a desktop, saving materials for making a cake, and being convenient and fast to use the device for baking the cake.

Owner:彭韦华

Tunnel kiln

The invention provides a tunnel kiln. The tunnel kiln comprises a charge device, a kiln body and a discharge device, which are disposed in sequence. The kiln body comprises a conveying chain, a lower heating grate, an upper heating grate, a fan and a gas pipe inside. The lower heating grate and the upper heating grate are disposed in parallel inside the kiln body oppositely. The conveying chain is disposed between a lower heating device and an upper heating device. The fan is disposed above the upper heating device or below the lower heating device. The upper heating device and the lower heating device are respectively connected to the gas pipe. The tunnel kiln is simple in structure, low in cost and convenient and safe to use. By the aid of the upper and lower grates inside the tunnel kiln, gas is directly burned in the tunnel kiln to quickly heat up the inside of the kiln. Therefore, production efficiency is improved, productivity is improved, energy resources are saved, and waste gas production is reduced.

Owner:MASHI MANOR NANJING FOOD

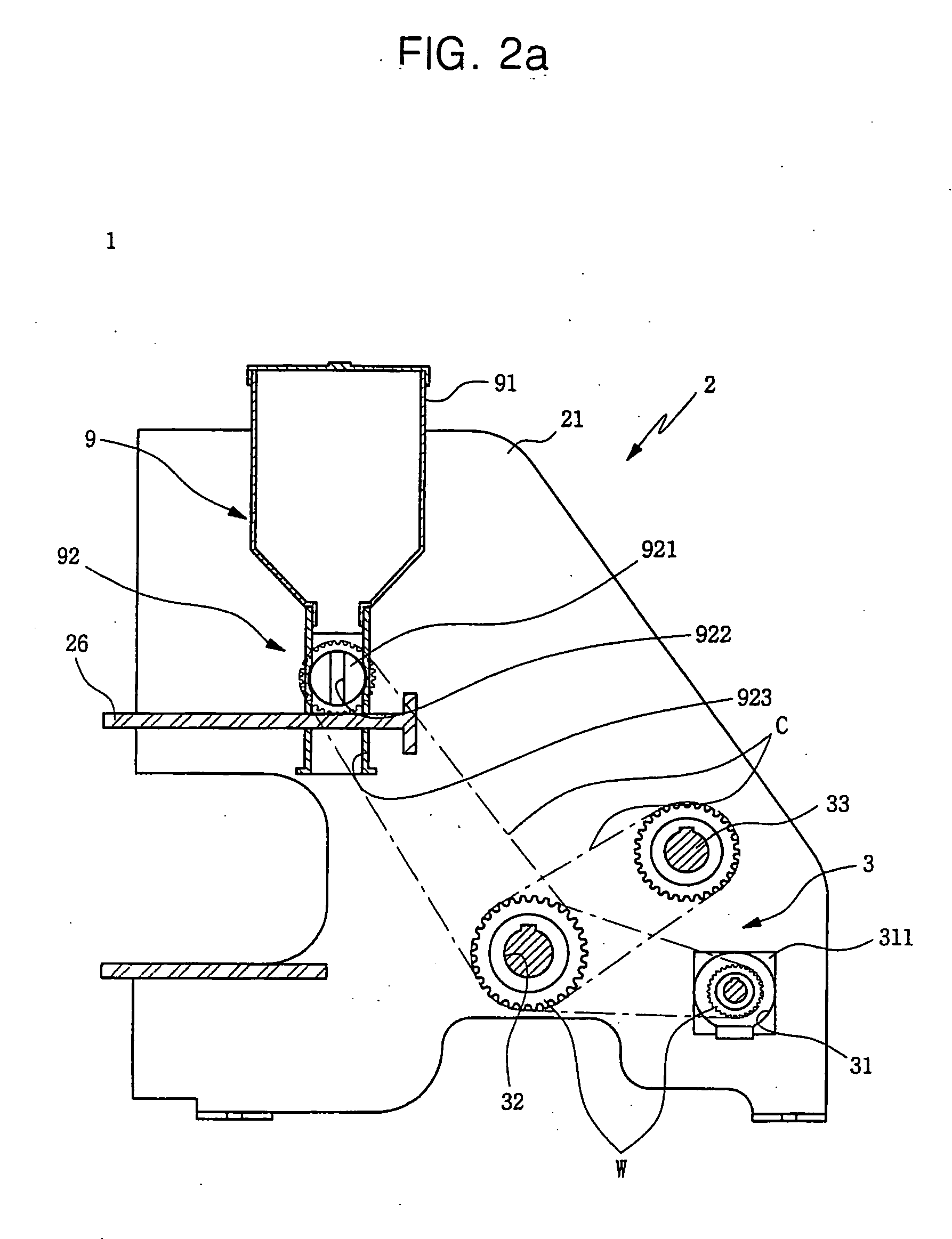

Apparatus for producing crackers

InactiveUS20060249032A1Low production costMinimized volumeRoasters/grillsHollow article bakingDrive shaftReduction drive

An apparatus for producing crackers is provided. The apparatus includes: a main frame; a drive unit installed at the main frame, and having a drive motor provided with a reducer, and first and second drive shafts receiving power from the drive motor; first and second operation cams installed at the first drive shaft; an operation unit pivotally connected to the first operation cam; an upper mold movably connected to the operation unit in a vertical direction and having a heating means; a lower mold installed directly under the upper mold and having a heating means; a grain supply unit connected to the first drive shaft to discharge a predetermined amount of grain; a grain convey unit connected to the second operation cam to convey the grain supplied from the grain supply unit to the lower mold; and a control box installed at the main frame to control the respective components.

Owner:DELICE CO LTD +1

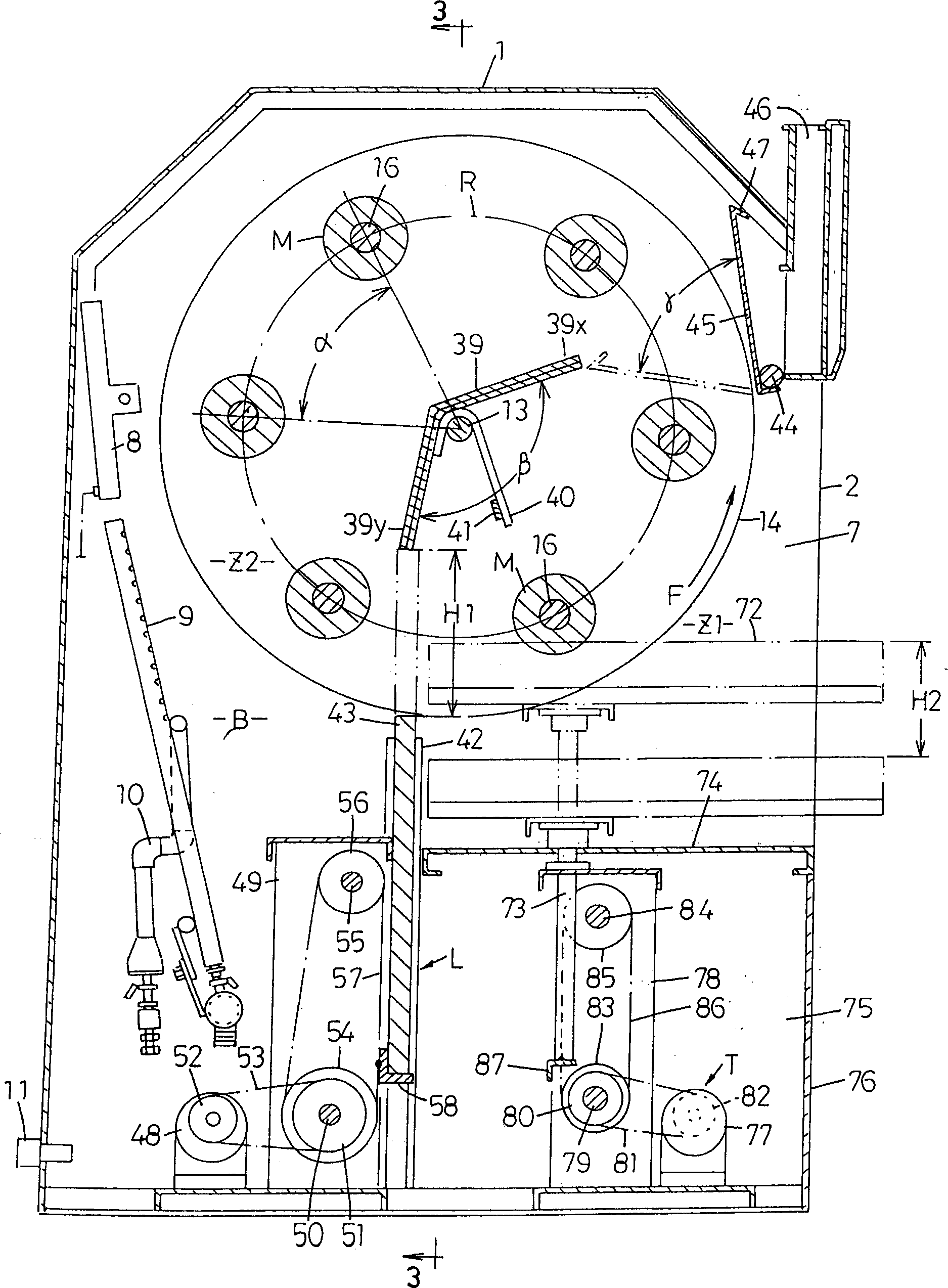

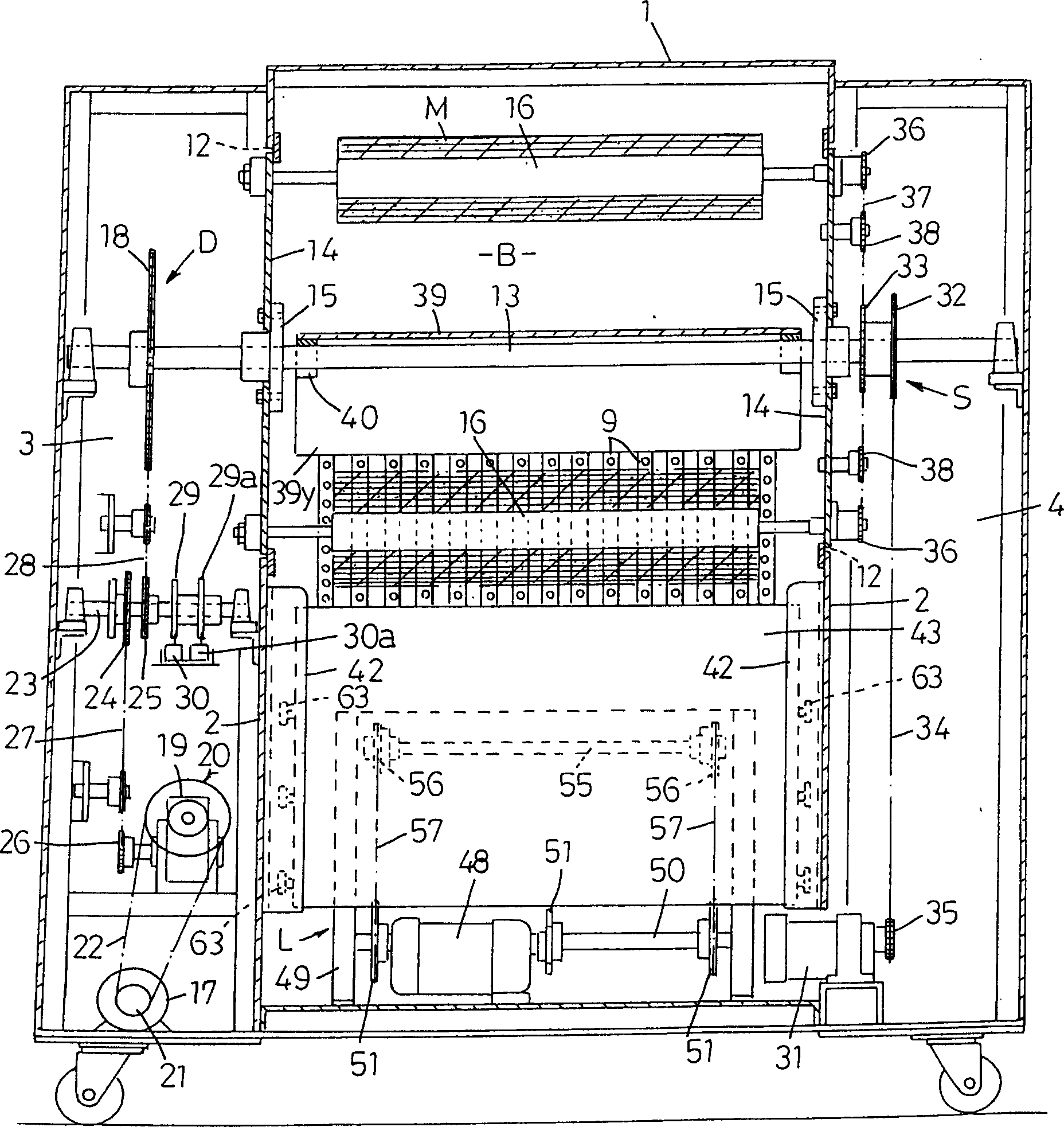

Baumkuchen annual ring cake roast

InactiveCN1768584AExcellent mass productivityImprove qualityCylindrical cake bakingHigh-frequency/infra-red heating bakingEngineeringElectrical and Electronics engineering

PROBLEM TO BE SOLVED: To obtain Baumkuchen having a rich expansion degree and a rich wet touch in a high quality baked state. SOLUTION: This Baumkuchen-baking machine is characterized by disposing the first, second dividing shutters (43), (45) for dividing a baking oven (B) into an entrance side dough-coating zone (Z1) having a dough dish (72) existing therein and an inner deep side dough-baking zone (Z2) having gas burners (8), (9) of heating sources existing therein, moving forward or backward a first and second dividing shutters (43), (45) to shut off the revolution movement locus (R) of rolling pins (16) synchronously with the intermittent rotation driving of a rotation drum (14), closing the dough-baking zone (Z2) to prevent the release of heat from the dough-baking zone during the temporary stop of the rotation drum (14), and opening the dough-baking zone (Z2) in a state communicating with the side dough-coating zone (Z1) during the rotation of the rotation drum (14). COPYRIGHT: (C)2006,JPO&NCIPI

Owner:株式会社 不二商会

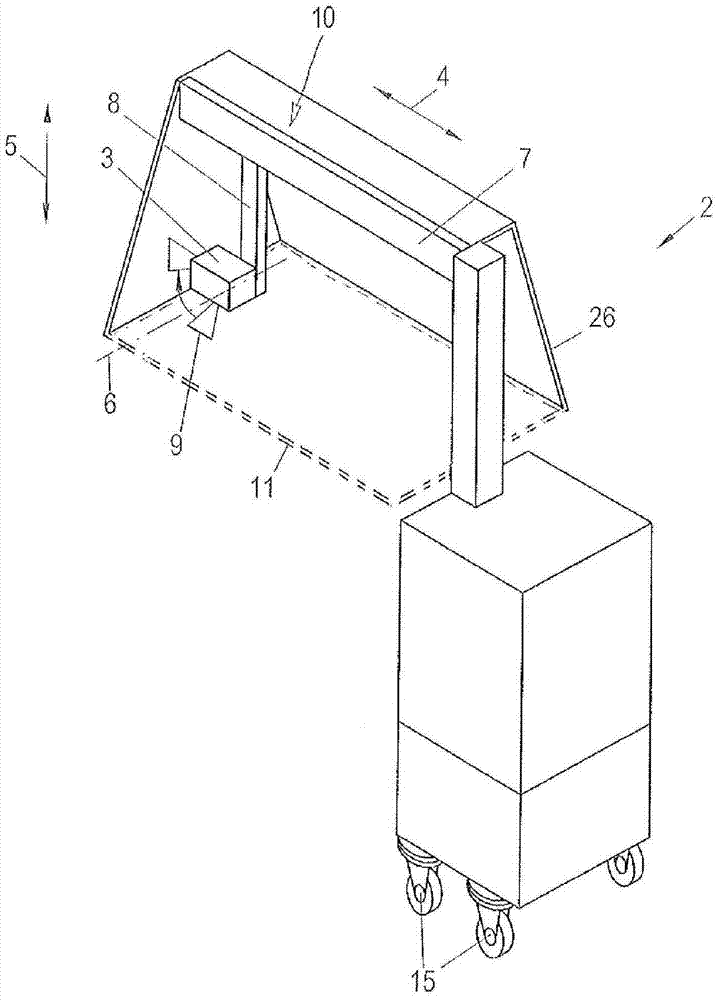

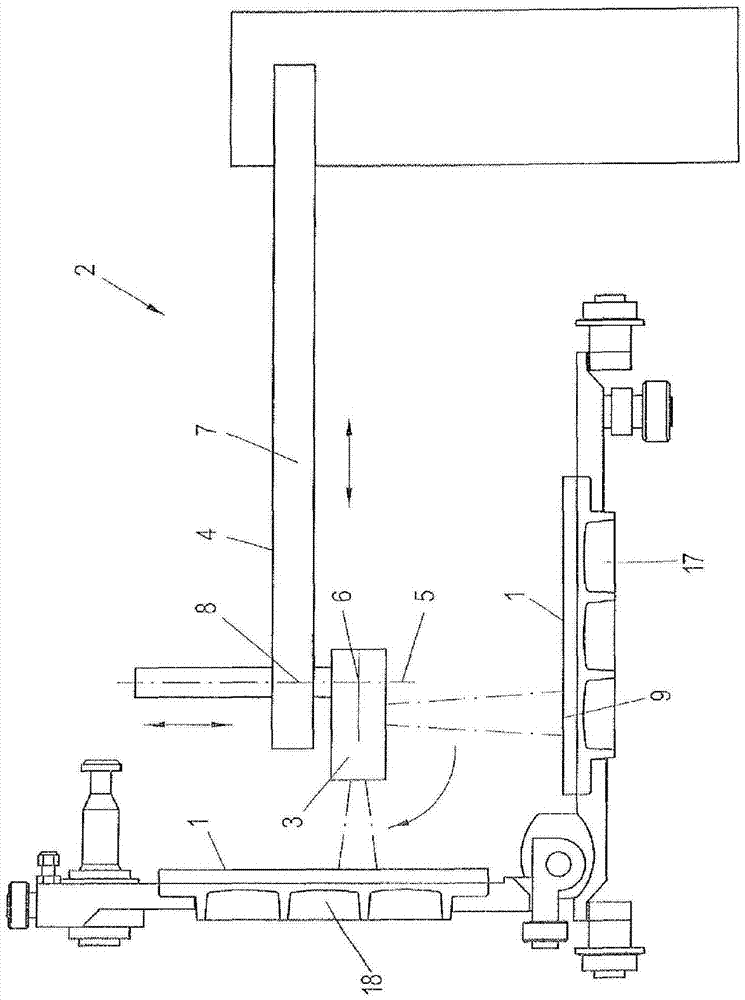

Method and device for cleaning baking surfaces

ActiveCN104519744ACleaning using toolsBaking surface cleaning/greasingCooking & bakingRelative motion

The invention relates to a laser assembly (2) for cleaning one or more baking surfaces (1) of a baking machine, comprising a laser head (3), wherein an interface is provided for connecting to the baking machine and the laser assembly is connected to the baking machine mechanically and / or in regard to control, a baking machine having a laser assembly (2) according to the invention, and a method for cleaning baking surfaces, wherein a laser head is arranged in the area of the baking surface of a baking machine, wherein a laser beam is conducted onto the baking surface in order to clean the baking surface, and wherein the processing area of the laser assembly is moved over the baking surface by means of relative motion between the laser head and the baking surface.

Owner:HAAS FOOD EQUIP

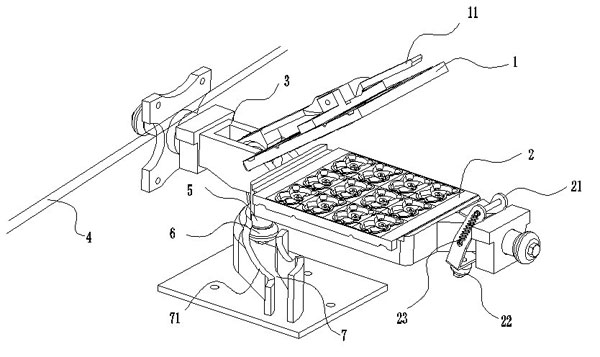

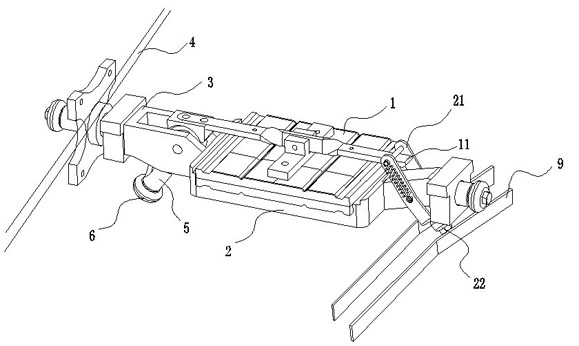

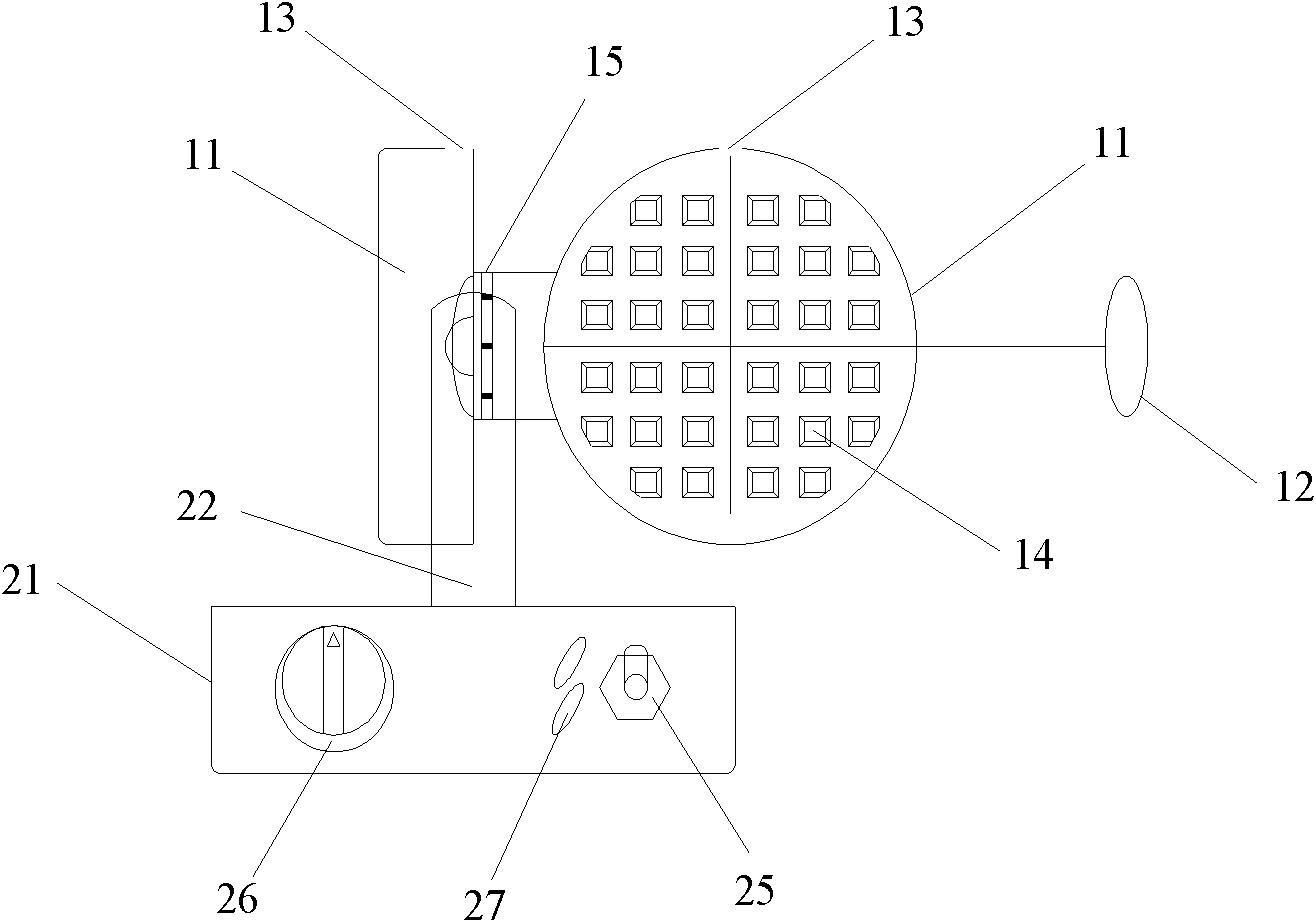

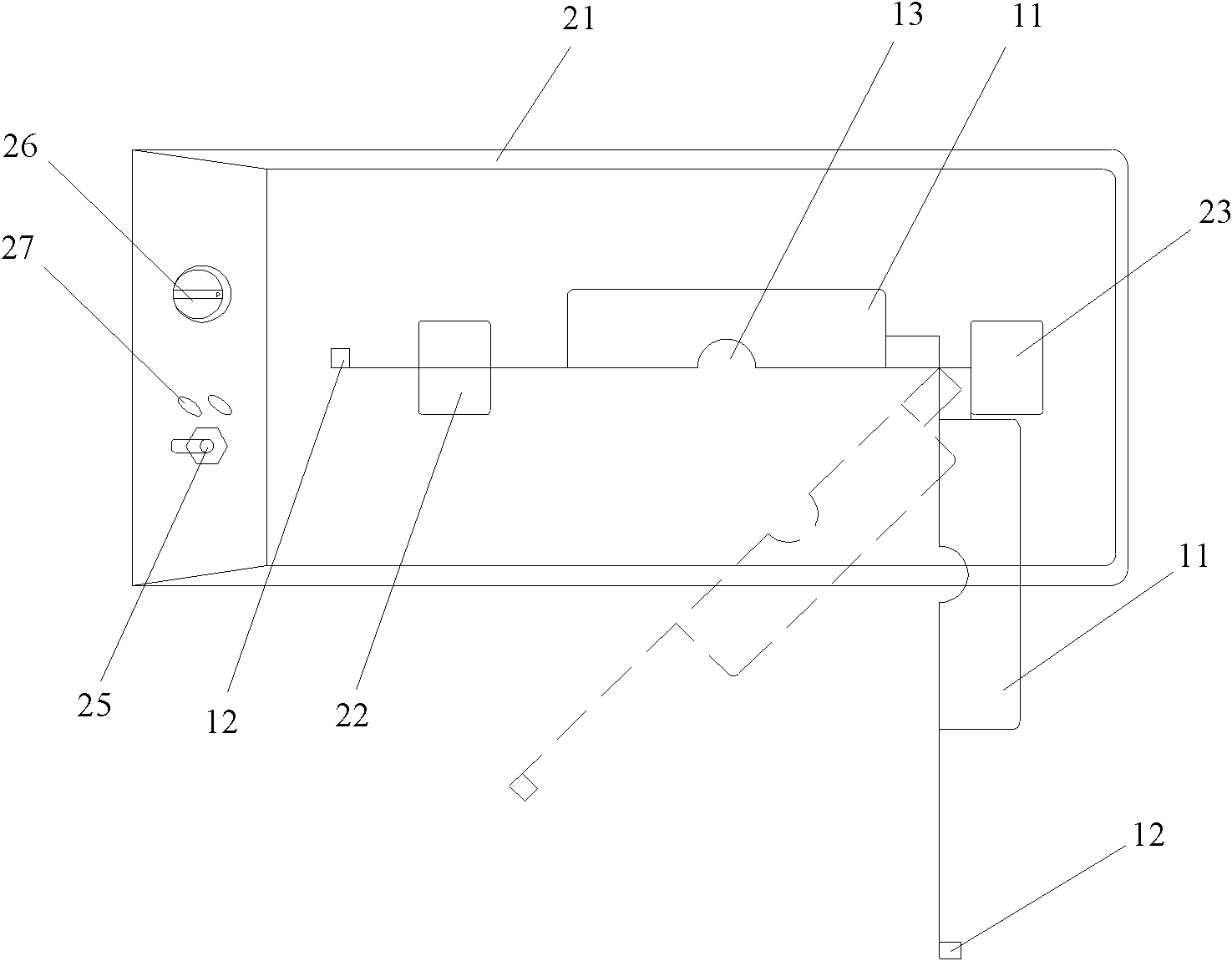

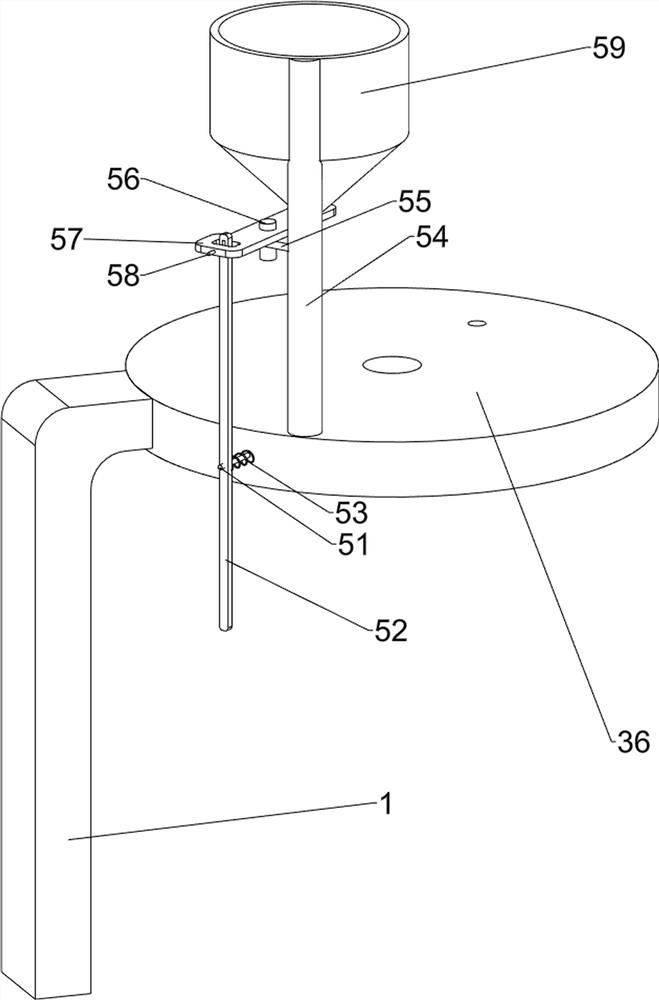

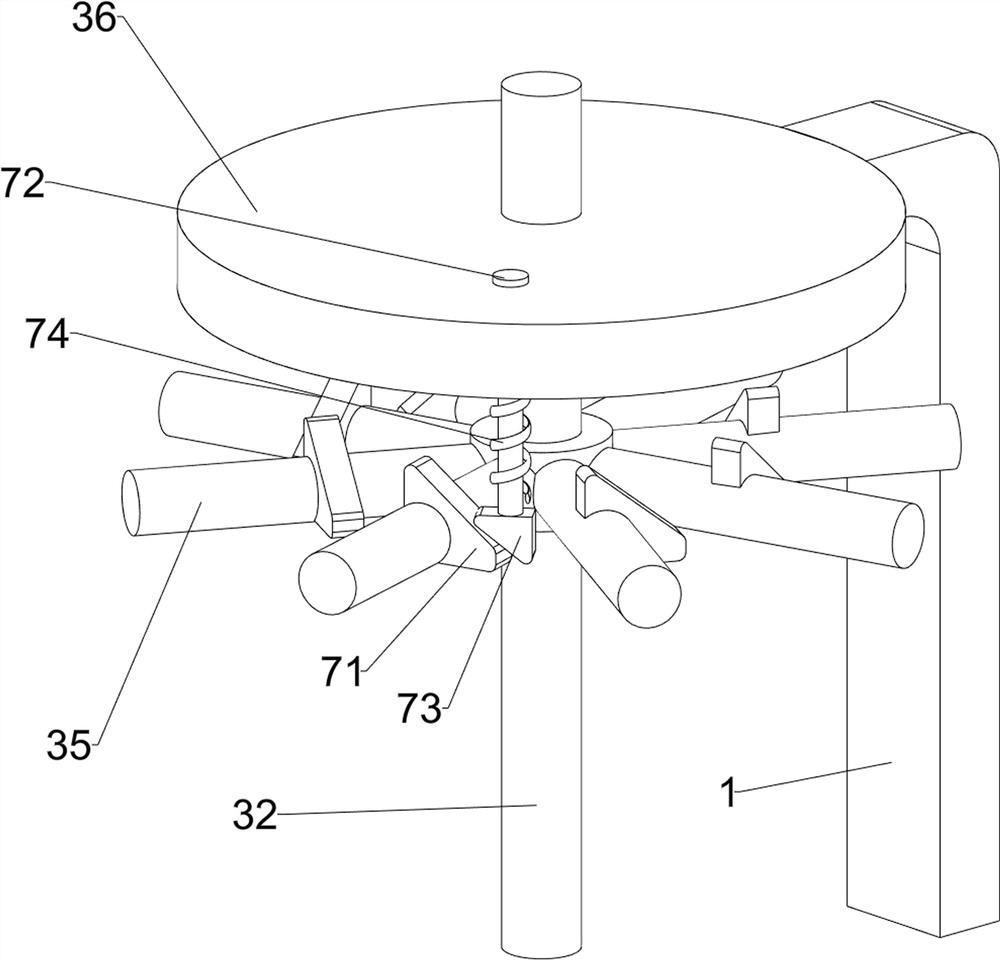

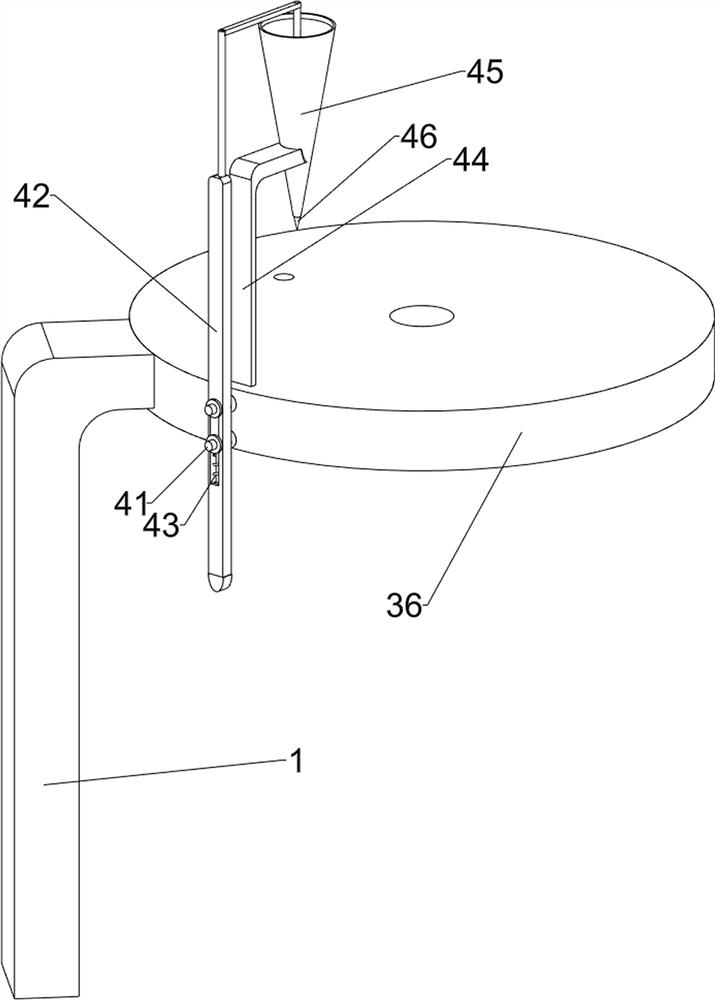

Waffle making and forming equipment for food processing

ActiveCN112293440AConsistent shapeSame sizeBaking ovenHollow article bakingEngineeringMechanical engineering

The invention relates to forming equipment, in particular to waffle making and forming equipment for food processing. According to the waffle making and forming equipment for food processing, wafflescan be automatically blanked, heated and discharged, and the made waffles are consistent in shape and size. The waffle making and forming equipment for food processing comprises a bottom plate, a servo motor, a rotating mechanism, an oil dripping mechanism and a blanking mechanism, wherein the servo motor is arranged on the lower portion of one side of the bottom plate; the rotating mechanism is arranged between the middle of the top of the bottom plate and an output shaft of the servo motor; the oil dripping mechanism is arranged on the rotating mechanism; and the blanking mechanism is arranged on the rotating mechanism. Through the cooperation of the rotating mechanism and the oil dripping mechanism, the functions of automatic blanking, automatic heating and automatic discharging of waffles can be achieved, the working efficiency of people is improved, and the shapes and the sizes of the manufactured waffles are consistent.

Owner:新乡市口口妙食品有限公司

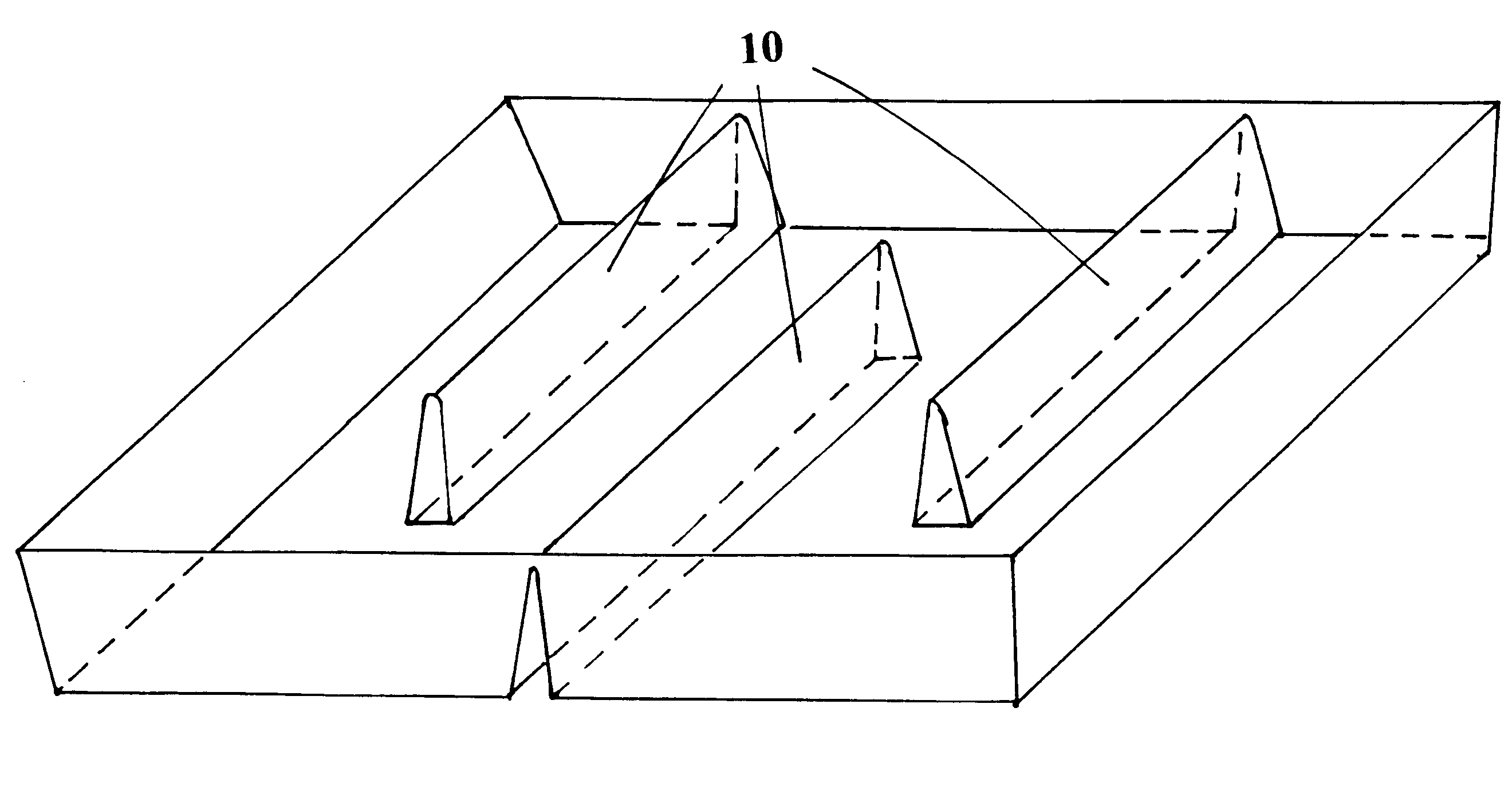

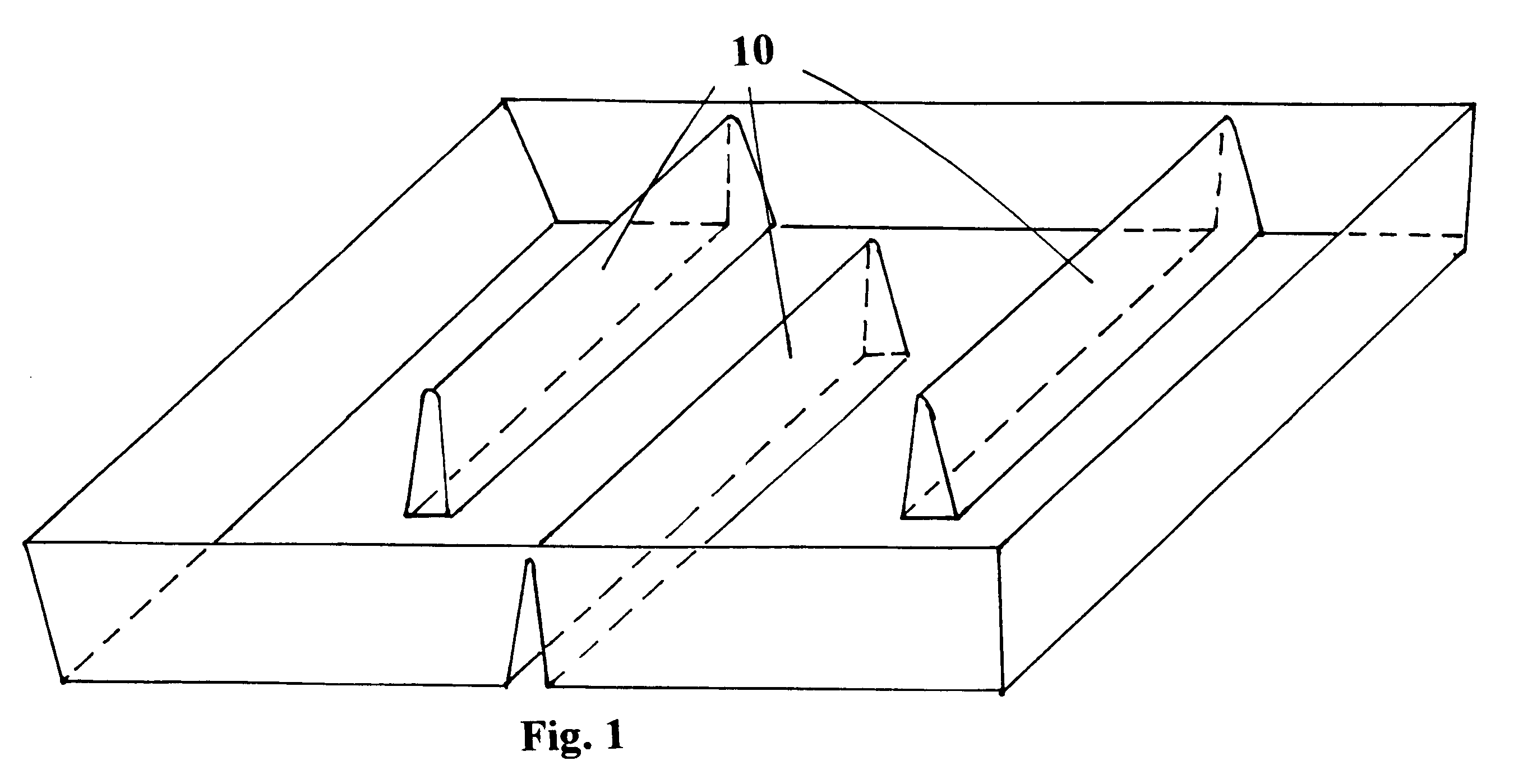

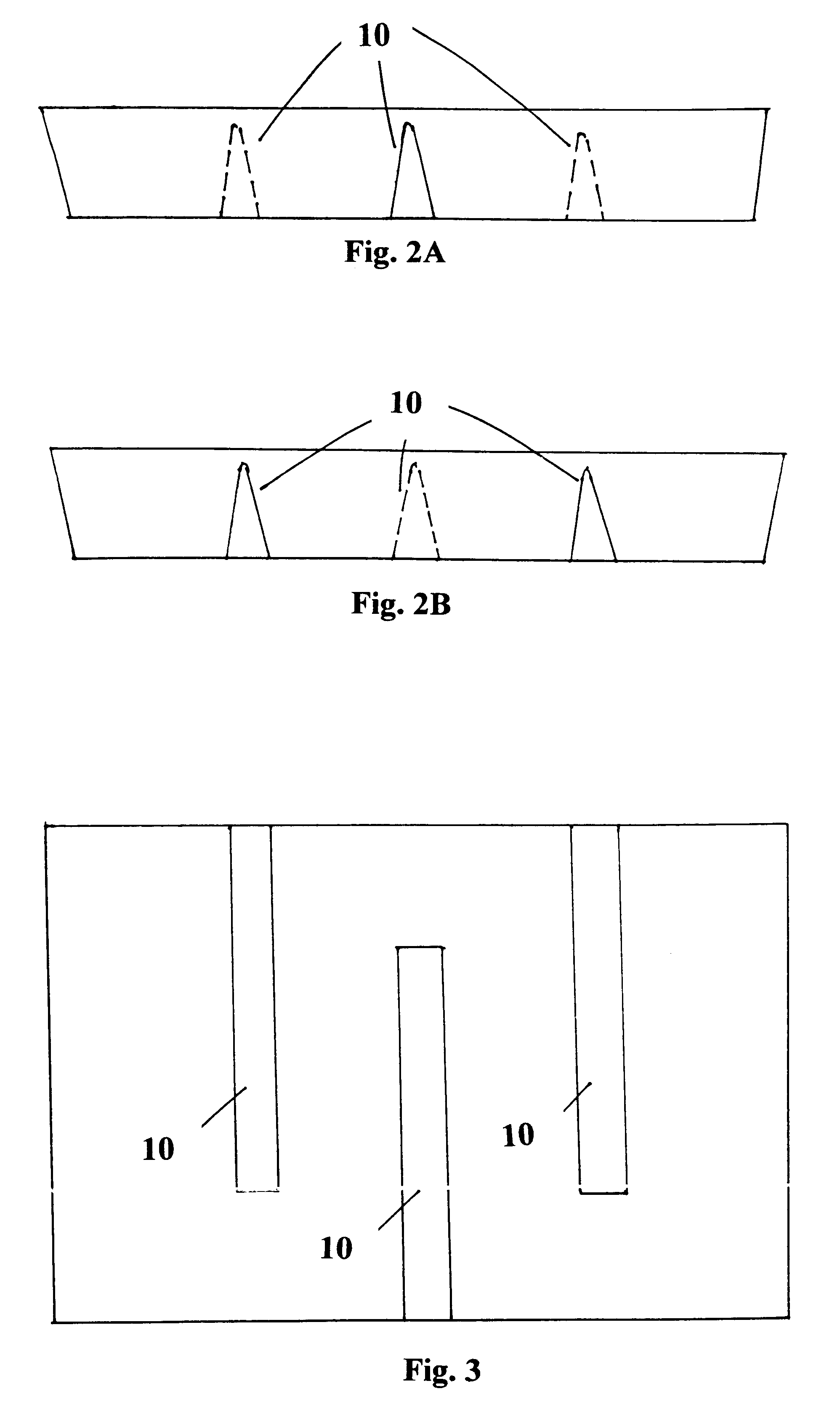

Edge making baking pan

Owner:GRIFFIN MATTHEW L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com