Cup shaped baked confectionary and manufacturing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

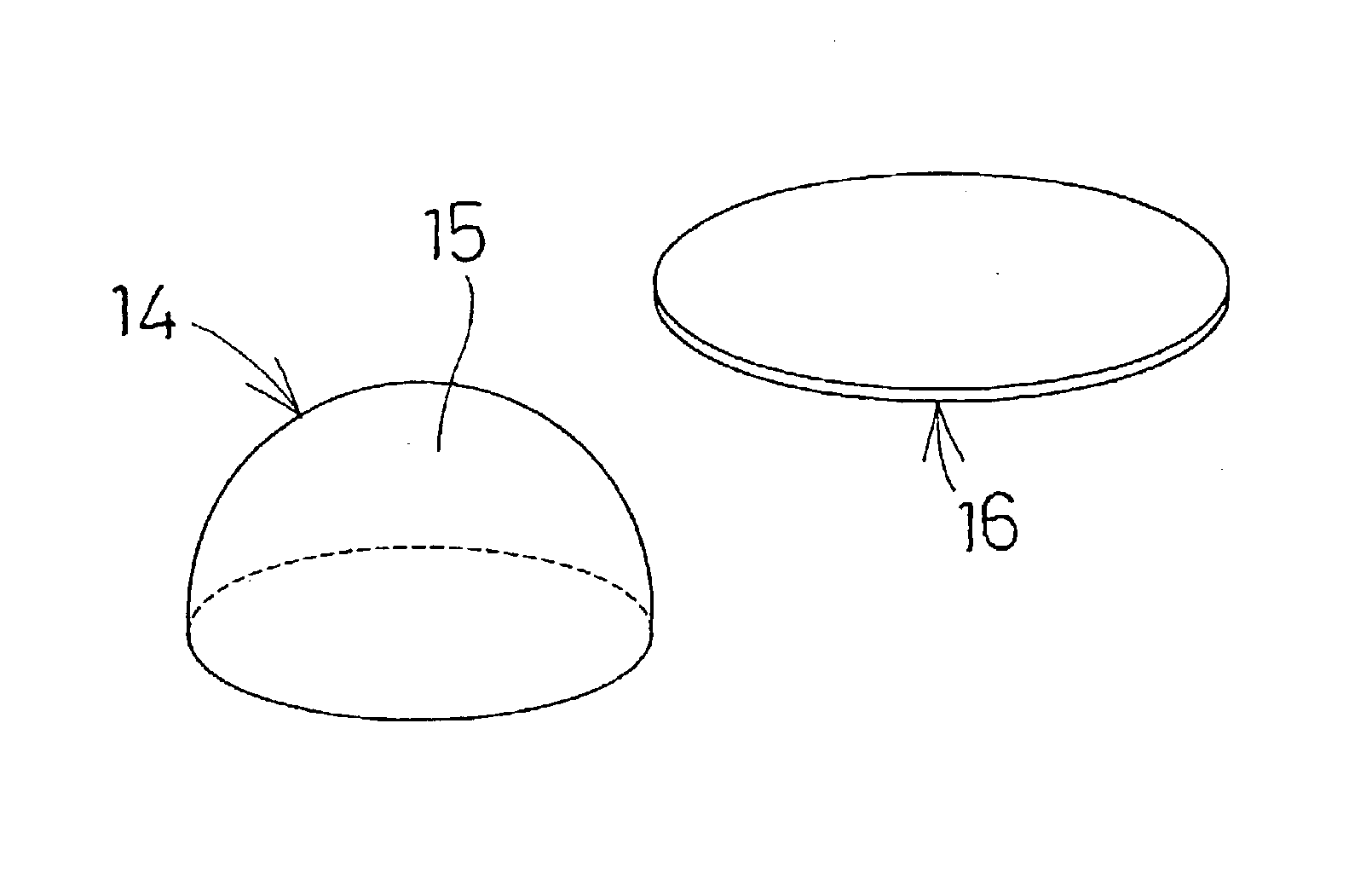

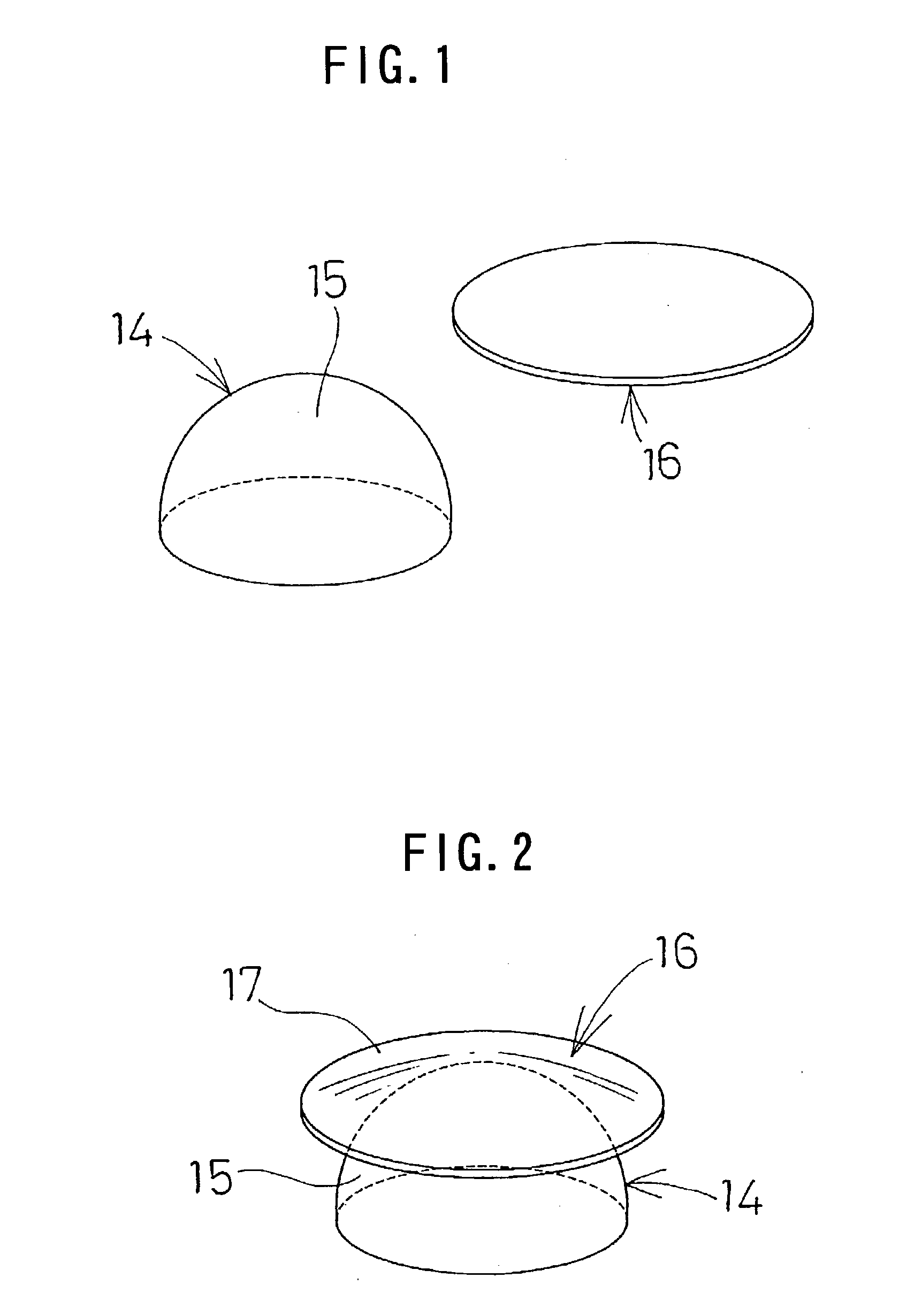

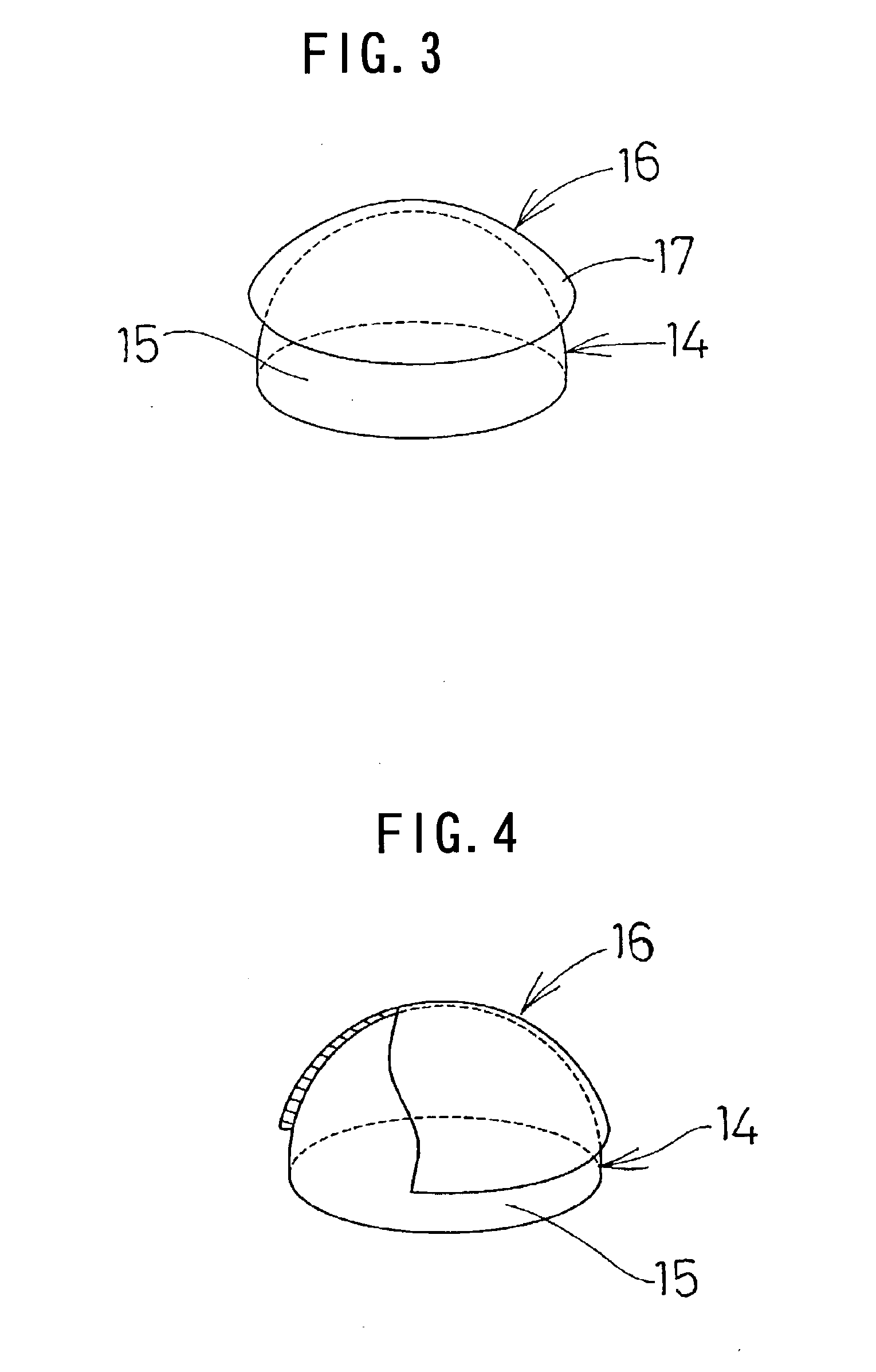

[0054] The sheet dough is punched into circular dough for cup shaped baked confectionary having a diameter of 4 cm, put on the three dimensional baking die 14 used in the embodiment 1 and baked for 20 minutes at 200.degree. C.

[0055] The dough 16 of the cup shaped baked confectionary has large expansion during baking and can slack off the three-dimensional baking die 14, or cavity surrounded by the peripheral wall can be substantially filled to cause difficulty in baking the cup shaped confectionary. It should be noted that the confectionary thus baked contained 7.8 Wt % of protein, 35.7 Wt % of fat, 55.2 Wt % of sugar in solid component.

embodiment 2

[0065] Embodiment 2

[0066] In this embodiment, in place of the hemi-sphere three-dimensional baking die 14 used in the foregoing embodiment 1 and comparative examples 1 to 4, a three-dimensional baking die 24 having substantially hemi-sphere outer periphery as a whole with a flat portion 22 at the top thereof, and having 3 cm of diameter in a bottom surface (FIG. 6) was used.

[0067] At first, raw materials consisted of 100 Wt parts of hard flour, 30 Wt parts of wheat starch, 40 Wt parts of shortening, 40 Wt parts of sugar, 5 Wt parts of liquid sugar, 5 Wt parts of condensed milk, 1.3 Wt parts of salt, 1 Wt part of baking powder, 1 Wt part of ammonium carbonate, 0.5 Wt parts of vanilla flavor agent and 60 Wt parts of water were blended and stirred to prepare a dough mass containing 6.0 Wt % of protein, 20.8 Wt % of fat and 70.5 Wt % of sugar in solid component. By punching the sheet dough formed by rolling the dough mass into a sheet having thickness of about 2 mm, the circular dough 1...

embodiment 3

[0071] Embodiment 3

[0072] Raw materials consisted of 100 Wt parts of medium flour, 10 Wt parts of butter, 20 Wt parts of shortening, 30 Wt parts of sugar, 2 Wt parts of skim milk, 5 Wt parts of whole egg, 1 Wt part of salt, 0.1 Wt parts of baking powder, 0.2 Wt parts of ammonium carbonate, 0.5 Wt parts of vanilla flavor agent and 15 Wt parts of water were blended and stirred to obtain the dough mass containing 6.3 Wt % of protein, 20.3 Wt % of fat and 71.5 Wt % of sugar in sold component was obtained. The dough mass is rolled to obtain a sheet dough in a thickness of 3 mm. Then, the 4 cm diameter circular dough of the cup shaped baked confectionary obtained by punching of the sheet dough was mounted on the hemi-sphere three-dimensional baking die having the bottomsurface of 3 cm diameter similar to that employed in the embodiment 1 and baked for 12 minutes at 180.degree. C.

[0073] The baked cup shaped baked confectionary 19 had uniform thickness of about 5 mm entirely, contained 6.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com