Waffle making and forming equipment for food processing

A molding equipment and food processing technology, applied in food ovens, baked hollow foods, applications, etc., can solve the problems of low working efficiency of waffles, difficulty in consistent size and shape of waffles, etc., to facilitate work and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of waffle making molding equipment for food processing, such as figure 1 with figure 2 As shown, it includes a bottom plate 1, a servo motor 2, a rotating mechanism 3, an oil dripping mechanism 4, and a feeding mechanism 5. The bottom right side of the bottom plate 1 is provided with a servo motor 2, and the middle of the top of the bottom plate 1 and the output shaft of the servo motor 2 are provided. There is a turning mechanism 3, the turning mechanism 3 is provided with an oil dripping mechanism 4, and the turning mechanism 3 is provided with a feeding mechanism 5.

[0068]When people need to make waffles, put the prepared batter into the feeding mechanism 5, put the oil into the oil dripping mechanism 4, put a heating rod in a certain part of the rotating mechanism 3, and then start the servo motor 2. The output shaft of the servo motor 2 drives the rotating mechanism 3 to rotate, and the rotating mechanism 3 drives the oil dripping mechanism 4 and the fee...

Embodiment 2

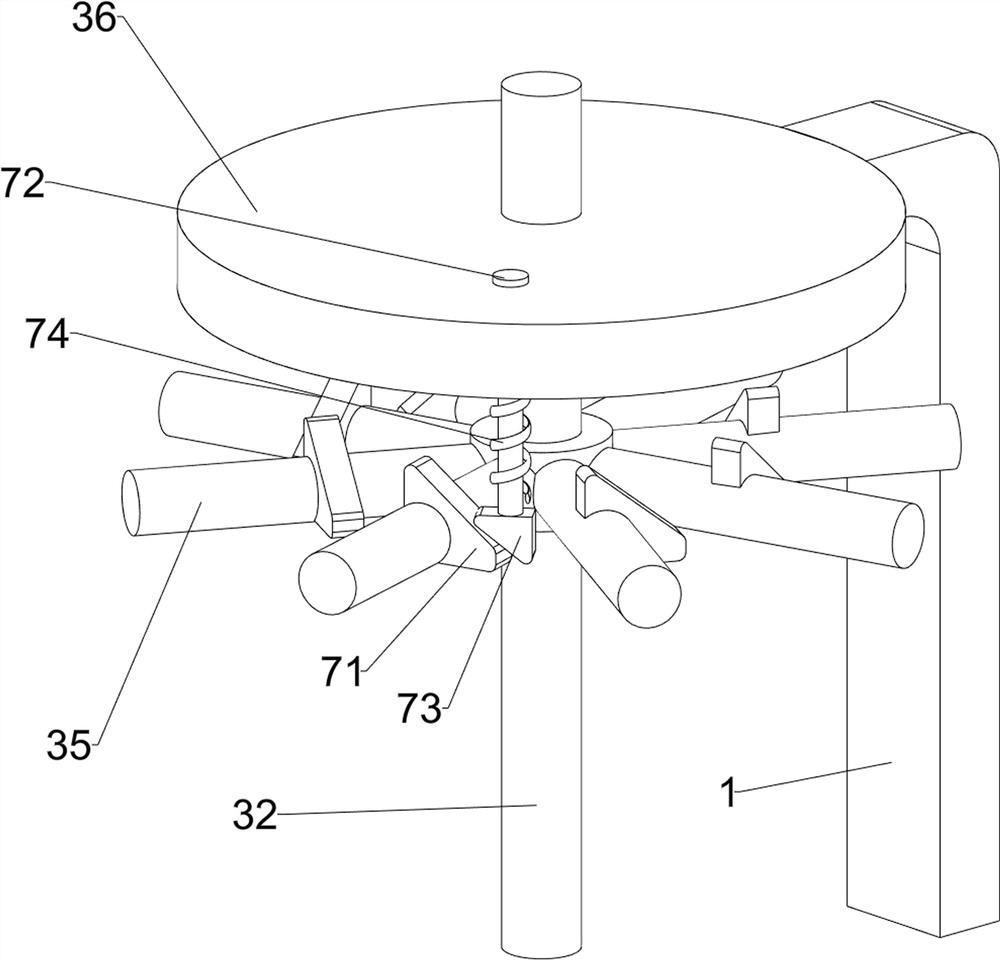

[0070] On the basis of Example 1, such as image 3 with Figure 4 As shown, the rotating mechanism 3 includes a bearing seat 31, a first rotating shaft 32, a spur gear 33, a missing gear 34, a rotating lug 35, a support plate 36, a heating plate 37, a bucket 38 and a fixed pin 39, and the bottom plate 1 right The upper part of the side is provided with a support plate 36, the middle of the top of the bottom plate 1 is provided with a bearing seat 31, the bearing seat 31 is provided with a first rotating shaft 32, the middle part of the first rotating shaft 32 is provided with a spur gear 33, and the output shaft of the servo motor 2 is provided with a missing gear. 34, the missing gear 34 and the spur gear 33 mesh with each other, the upper part of the first rotating shaft 32 is provided with a rotating protrusion 35, the top of the first rotating shaft 32 passes through the middle of the supporting plate 36, and the upper part of the first rotating shaft 32 is provided with a...

Embodiment 3

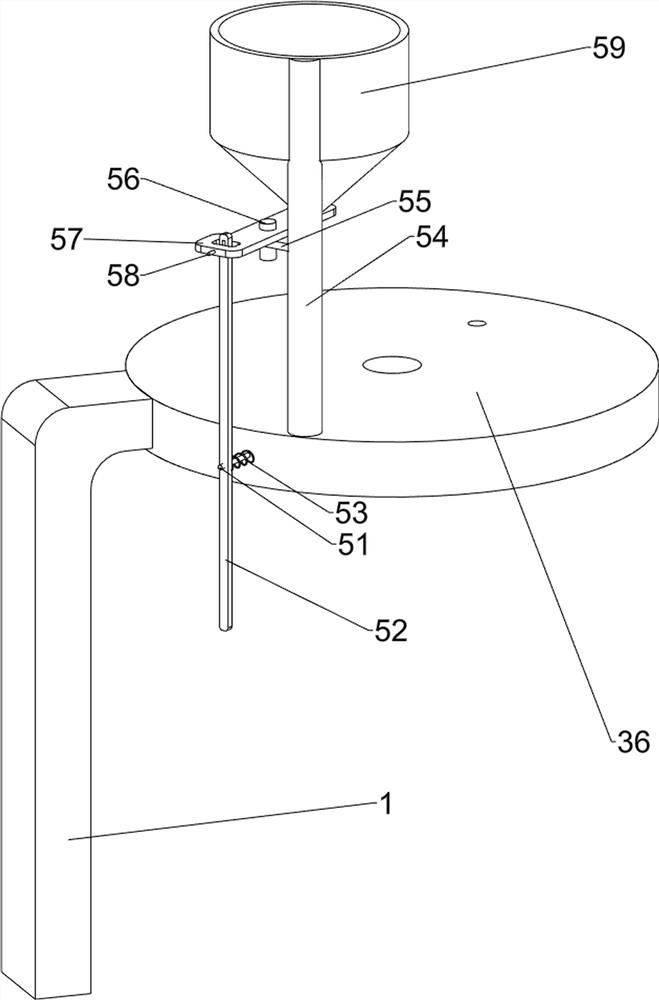

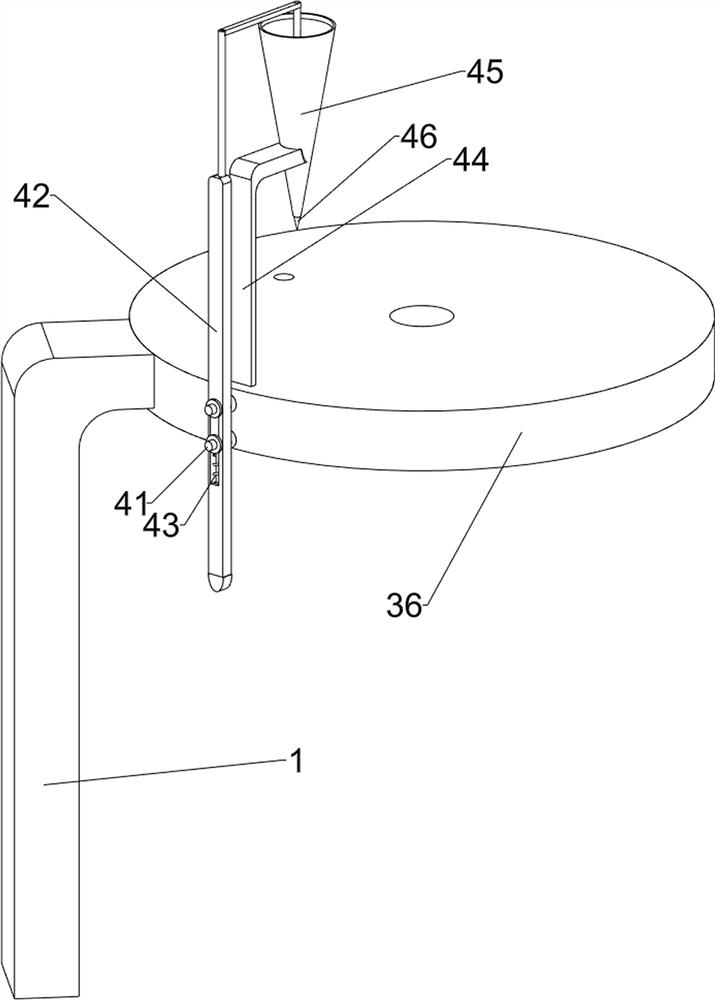

[0075] On the basis of Example 2, such as figure 1 , Figure 5 , Image 6 with Figure 7 As shown, the unloading mechanism 5 includes a second rotating shaft 51, a rotating rod 52, a first spring 53, a second support frame 54, a fixed rod 55, a third rotating shaft 56, a material retaining plate 57, a first positioning pin 58 and a positioning pin 58. Material bucket 59, the rear side of support plate 36 is provided with second rotating shaft 51, and the rear portion of second rotating shaft 51 is rotatably provided with rotating rod 52, and rotating rod 52 cooperates with rotating lug 35, and rotating rod 52 front side and supporting plate 36 rear A first spring 53 is provided between the sides, and the first spring 53 is sleeved on the outside of the second rotating shaft 51. A second support frame 54 is provided on the rear side of the top of the support plate 36, and a fixed rod 55 is provided in the middle of the right side of the second support frame 54. The right par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com