Self-cleaning ovens

An automatic cleaning and automatic cleaning technology, applied in the field of ovens, can solve the problems of accumulated oil stains and residues, low production efficiency, poor product quality, etc., and achieve the effect of improving sanitation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

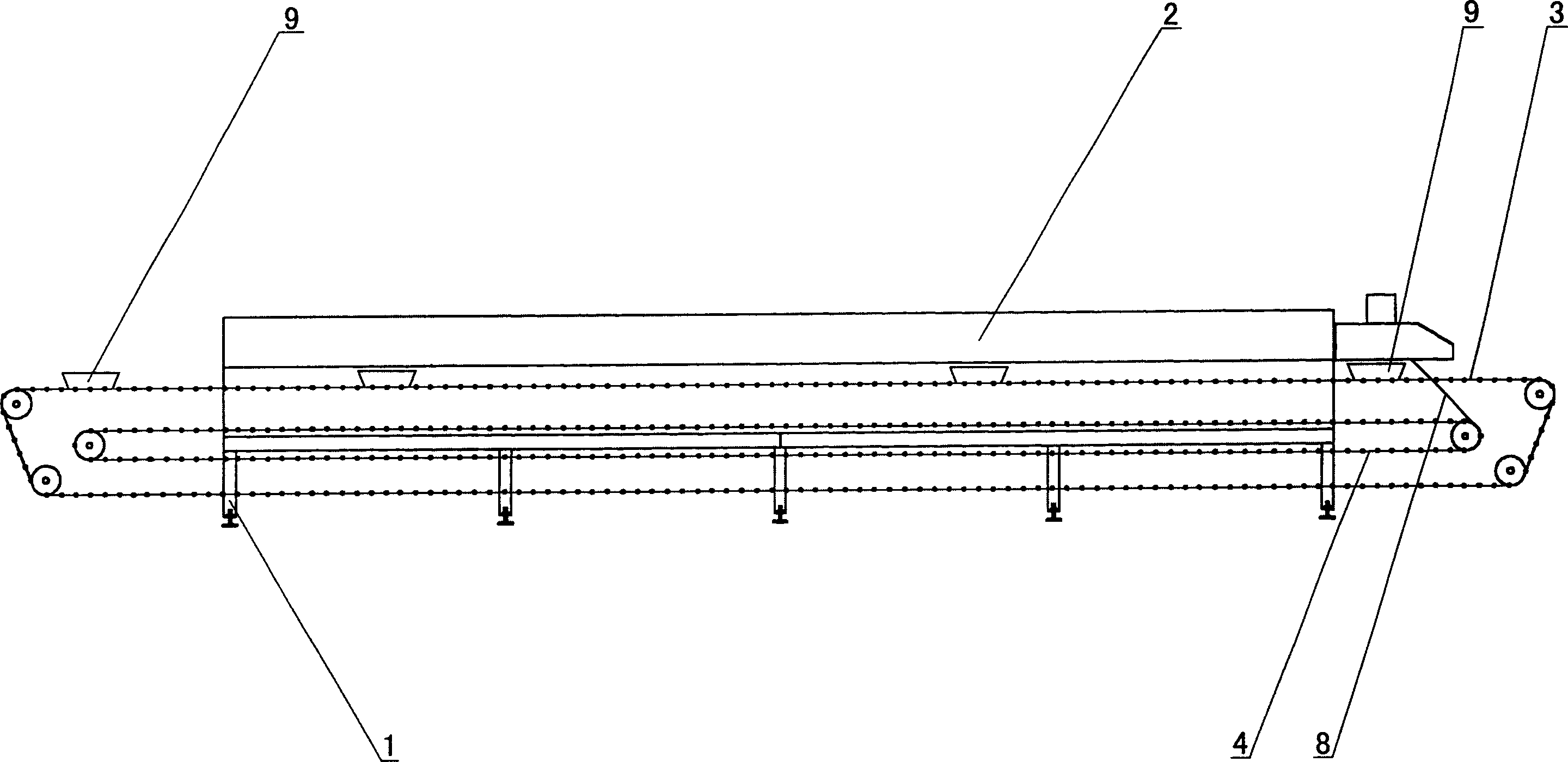

[0016] The automatic cleaning oven in this preferred embodiment comprises a hob 1, a baking device 2 arranged above the hob, a main conveyer 3 below the roaster 2, and a plurality of baking trays (not shown) located on the main conveyer Out), the inner side of the main conveyor belt 3 is provided with an automatic furnace cleaning device, which includes an automatic furnace cleaning conveyor belt 4 and an oil receiving part arranged on the automatic furnace cleaning conveyor belt.

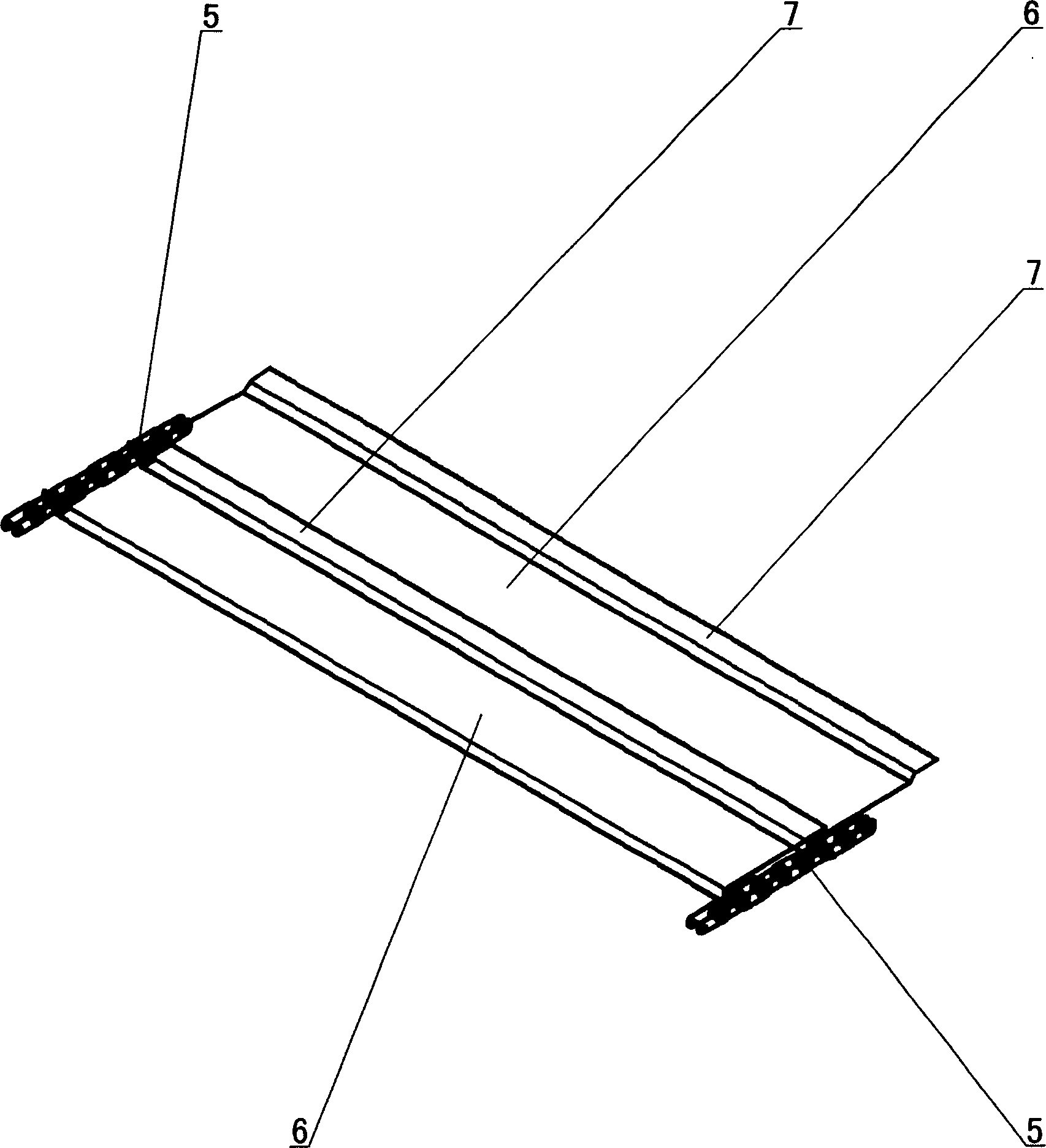

[0017] The oil receiving part is composed of a plurality of identical sheet units 6 connected in sequence.

[0018] The automatic furnace cleaning conveyor belt includes two parallel endless conveyor chains 5, and the two ends of each sheet unit 6 are respectively fixed on the two conveyor chains 5.

[0019] The sheet-like units 6 are sheet-shaped, and each sheet-like unit 6 is provided with a leak-proof edge 7 on the same side, and the leak-proof edge 7 is arranged above the adjacent sheet-like un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com