Patents

Literature

140results about "Baked article filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food injection device

InactiveUS6840161B2Easy to addEasy to operateBaked article fillingInjection based meat processingReady to useSyringe needle

Owner:LAURUS MASTER FUND +1

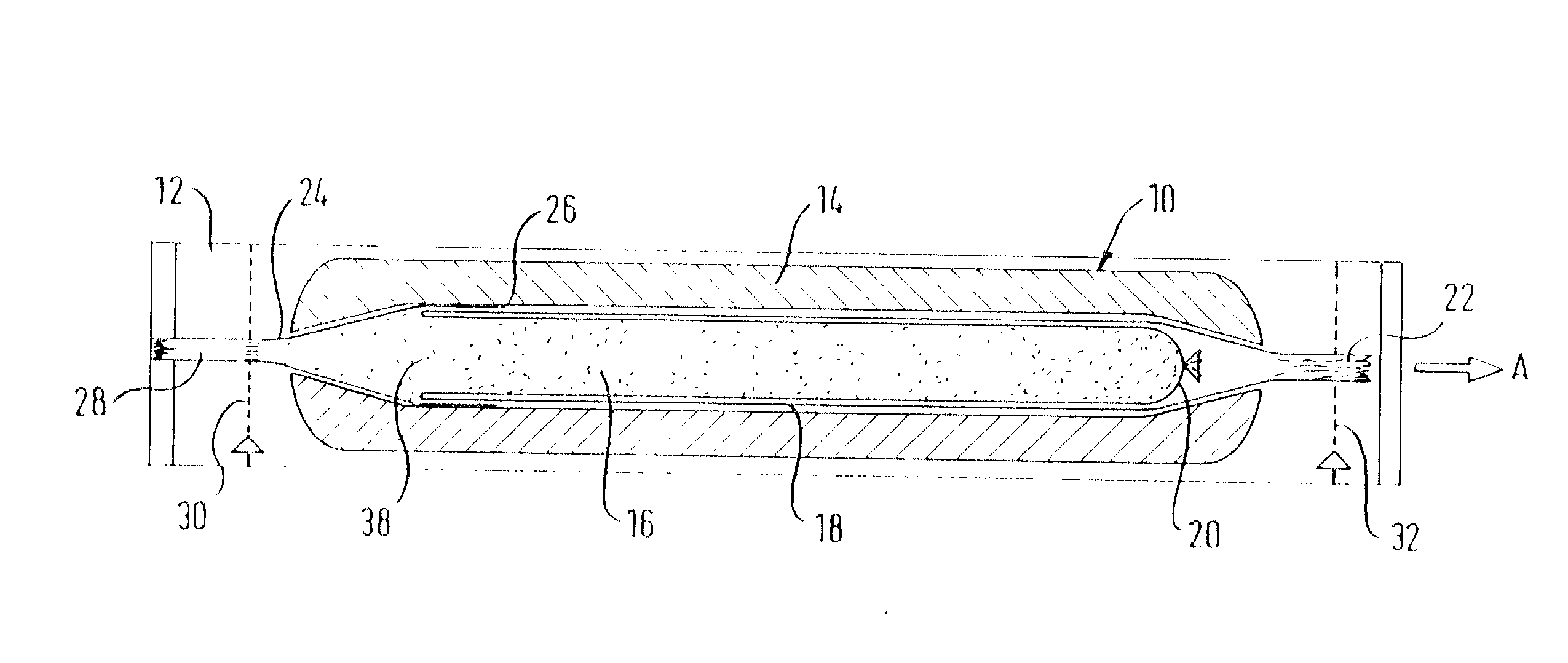

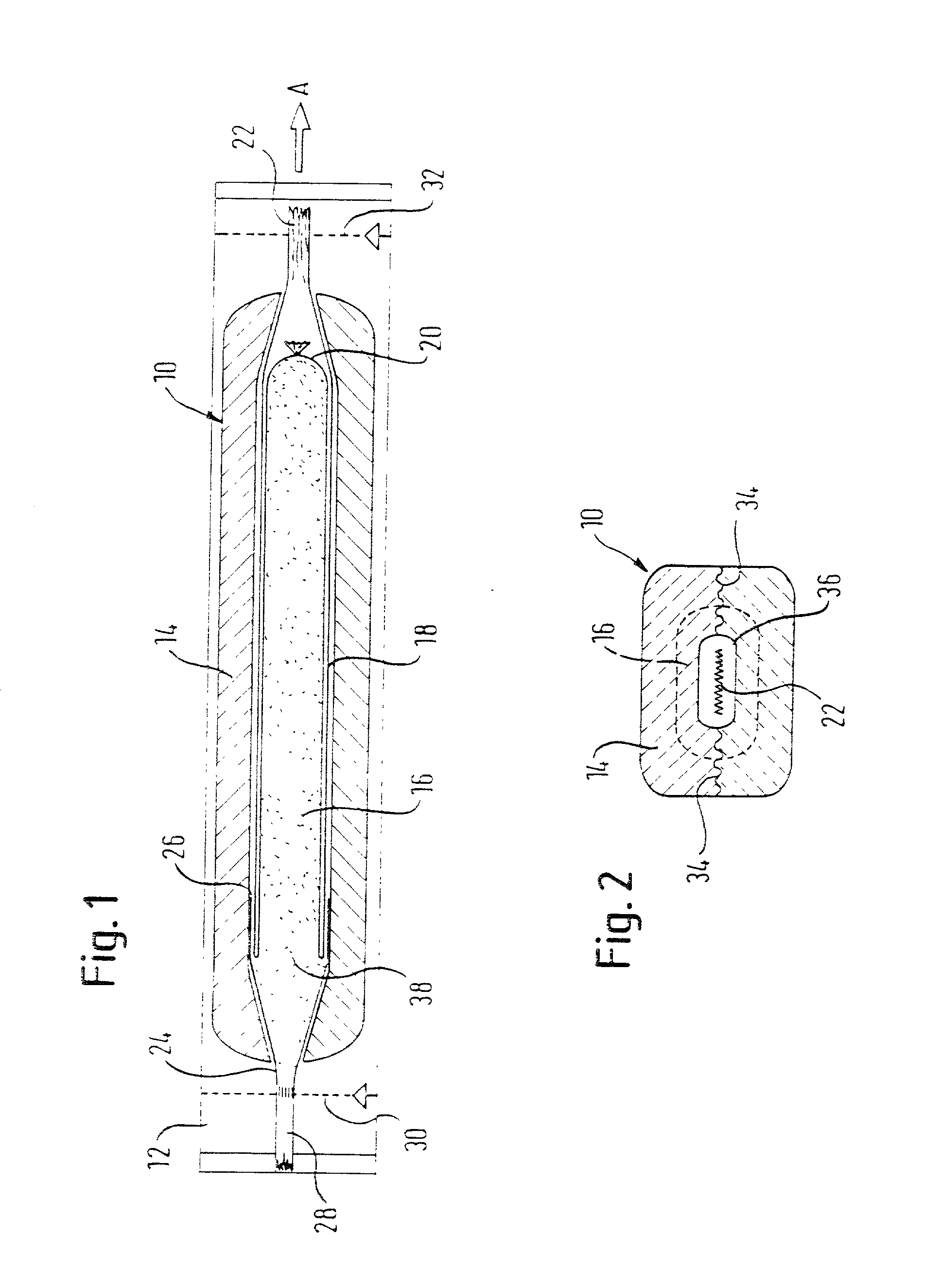

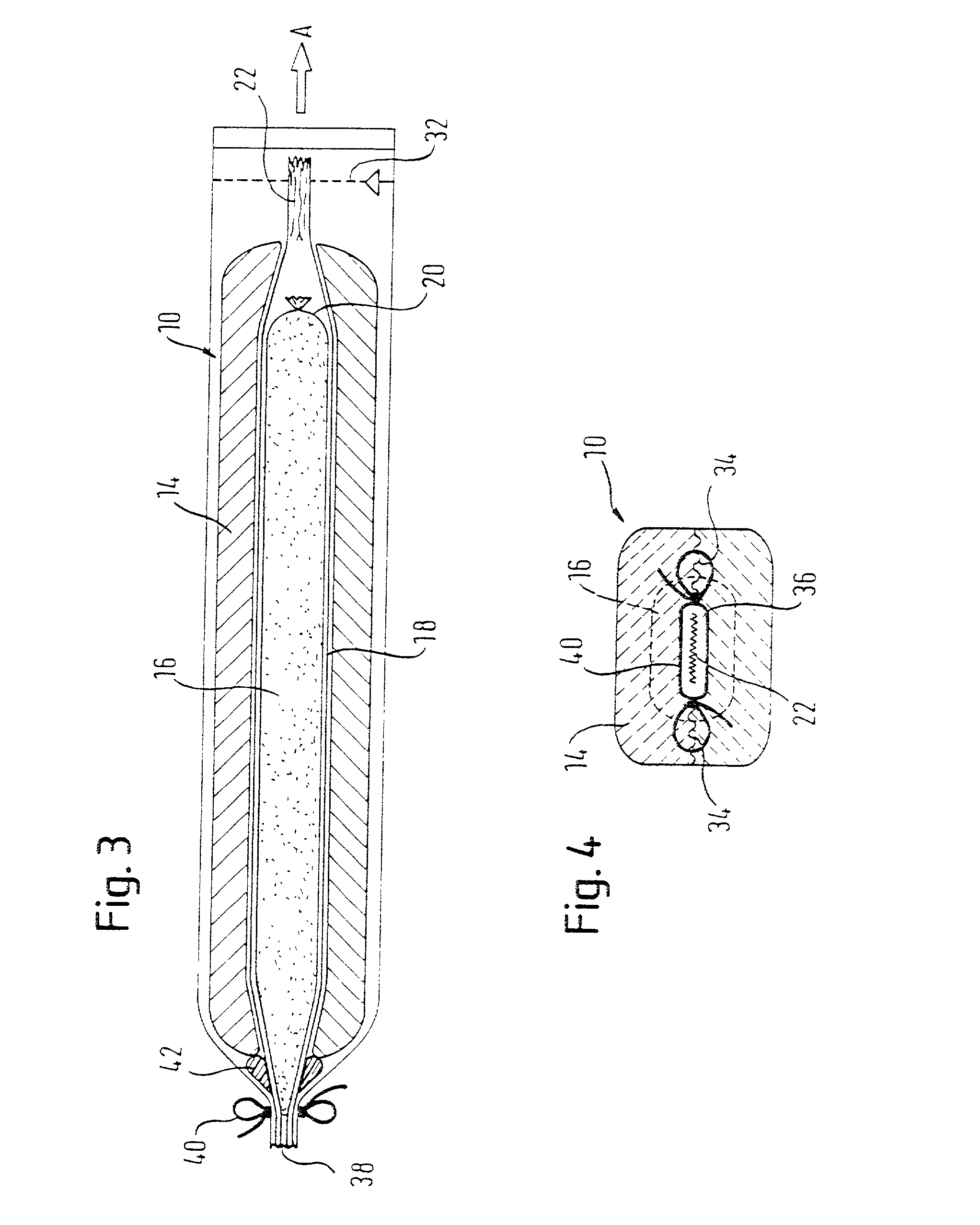

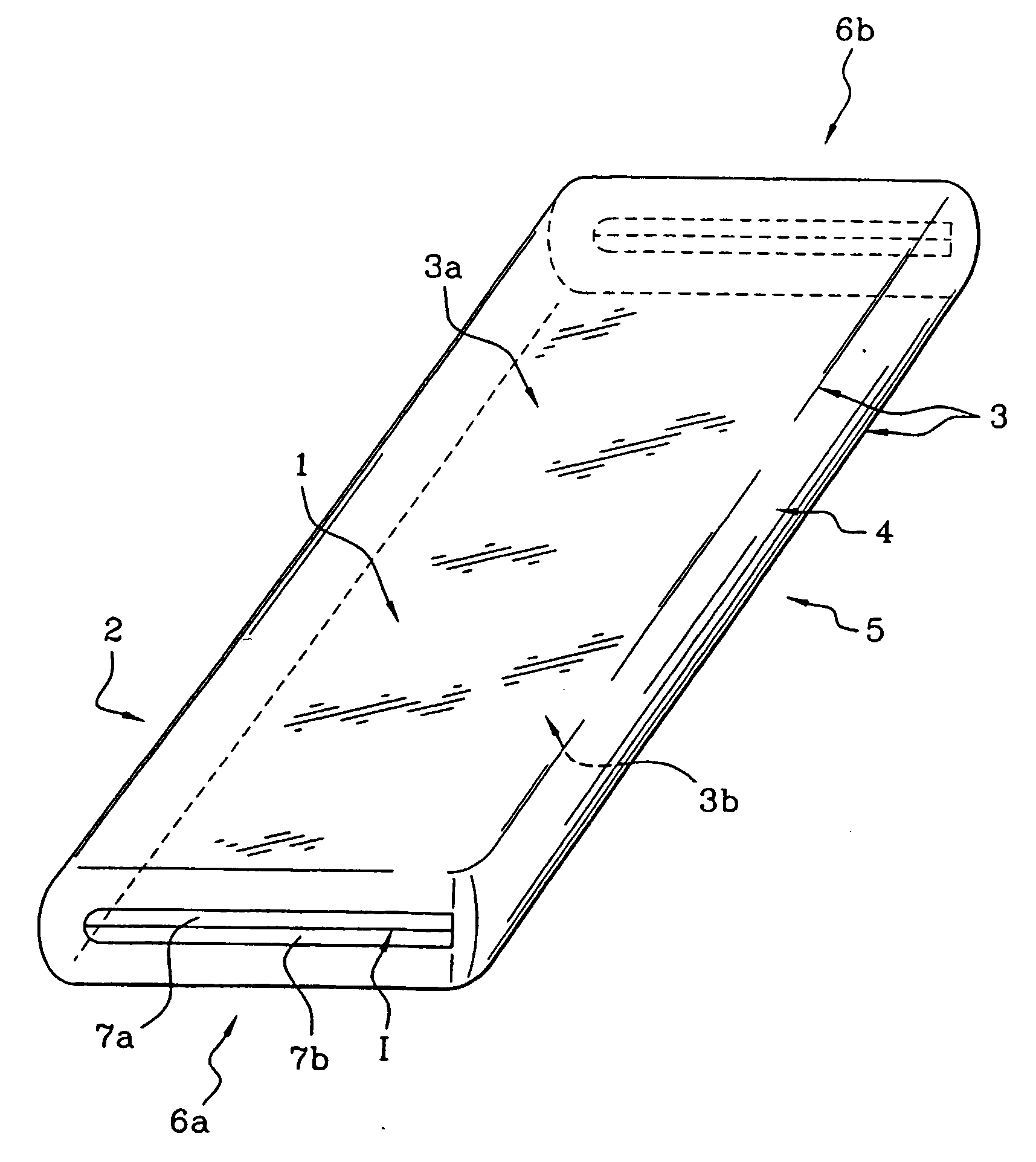

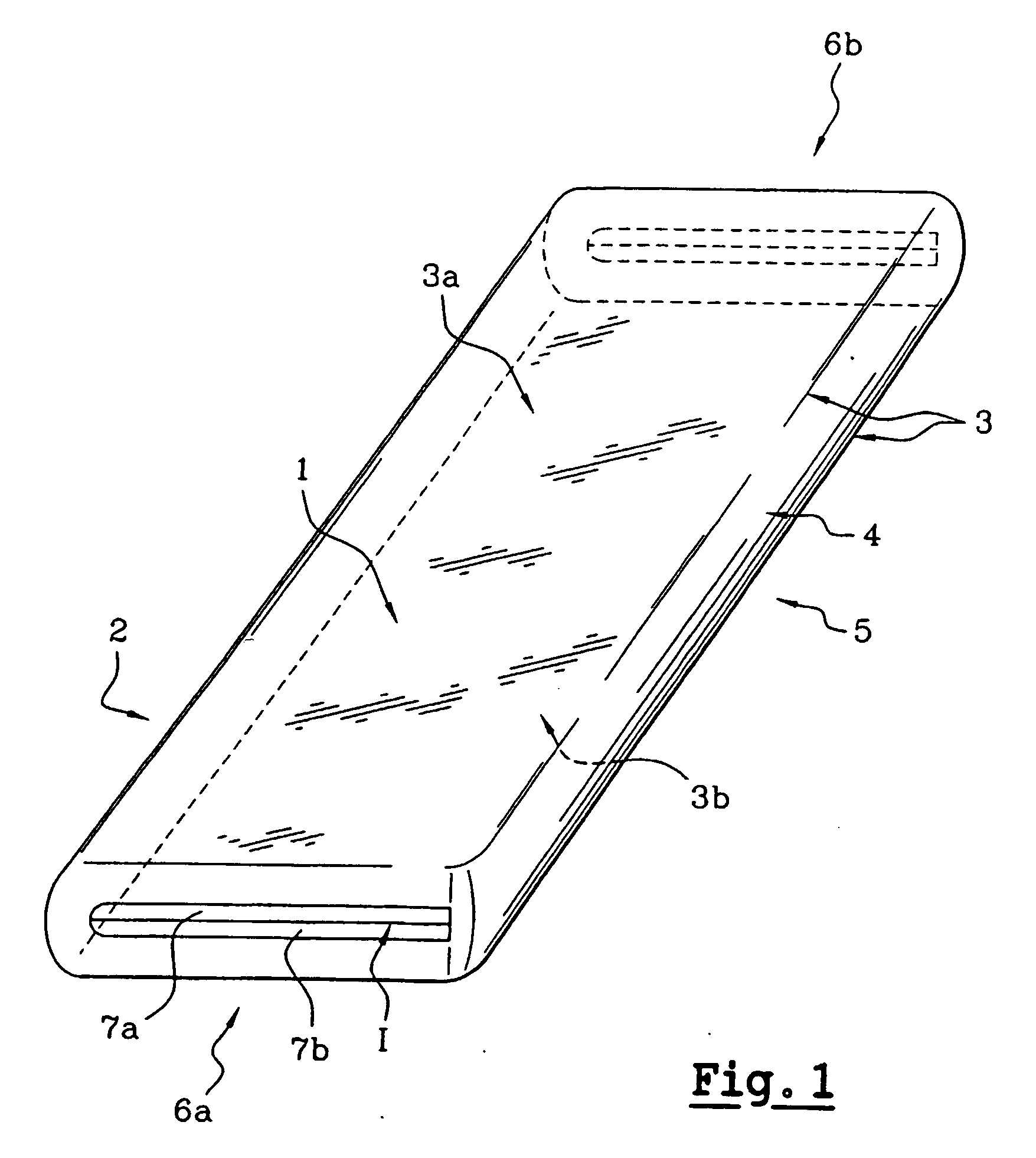

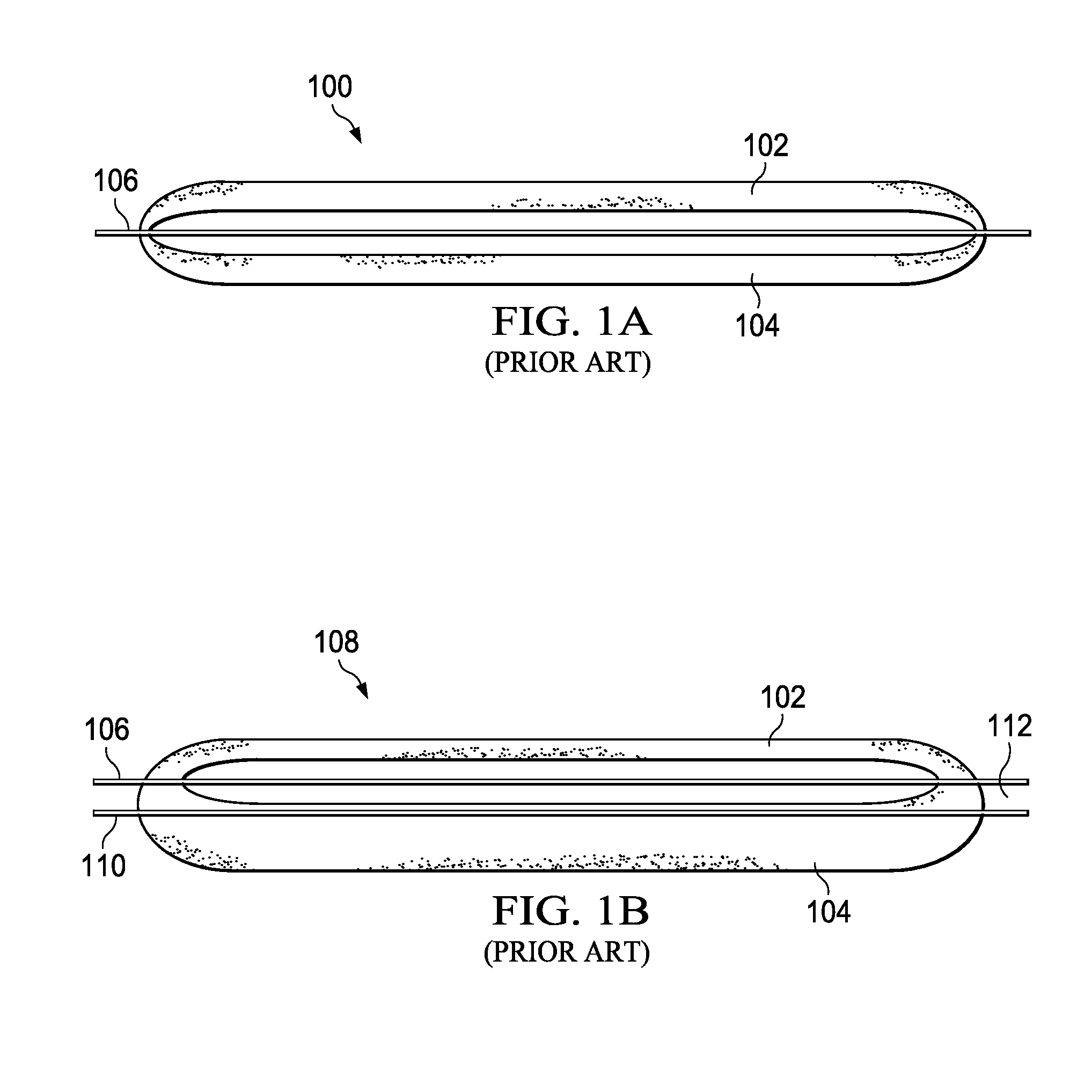

Food product and method of manufacturing a food product

A food product (10) comprises at least two components (14, 16) with different moisture and / or fat contents and at least one pouch (18, 24), at least partially enclosing one of the components (16), preferably a high-moisture component, and is characterized in that the open end (22) of the pouch (18) is turned back so as to form a cuff and so as to be exposed to the outside of the food product (10). In a method of making a food product comprising at least two components with different moisture and / or fat contents and at least one pouch at least partially enclosing one of the components, preferably a high-moisture component, the open end of the pouch is turned back so as to form a cuff, the component is filled into the pouch, and the pouch is enclosed with another component so as to seal the pouch and expose the open end of the pouch to the outside of the food product.

Owner:KRAFT FOODS R & D INC

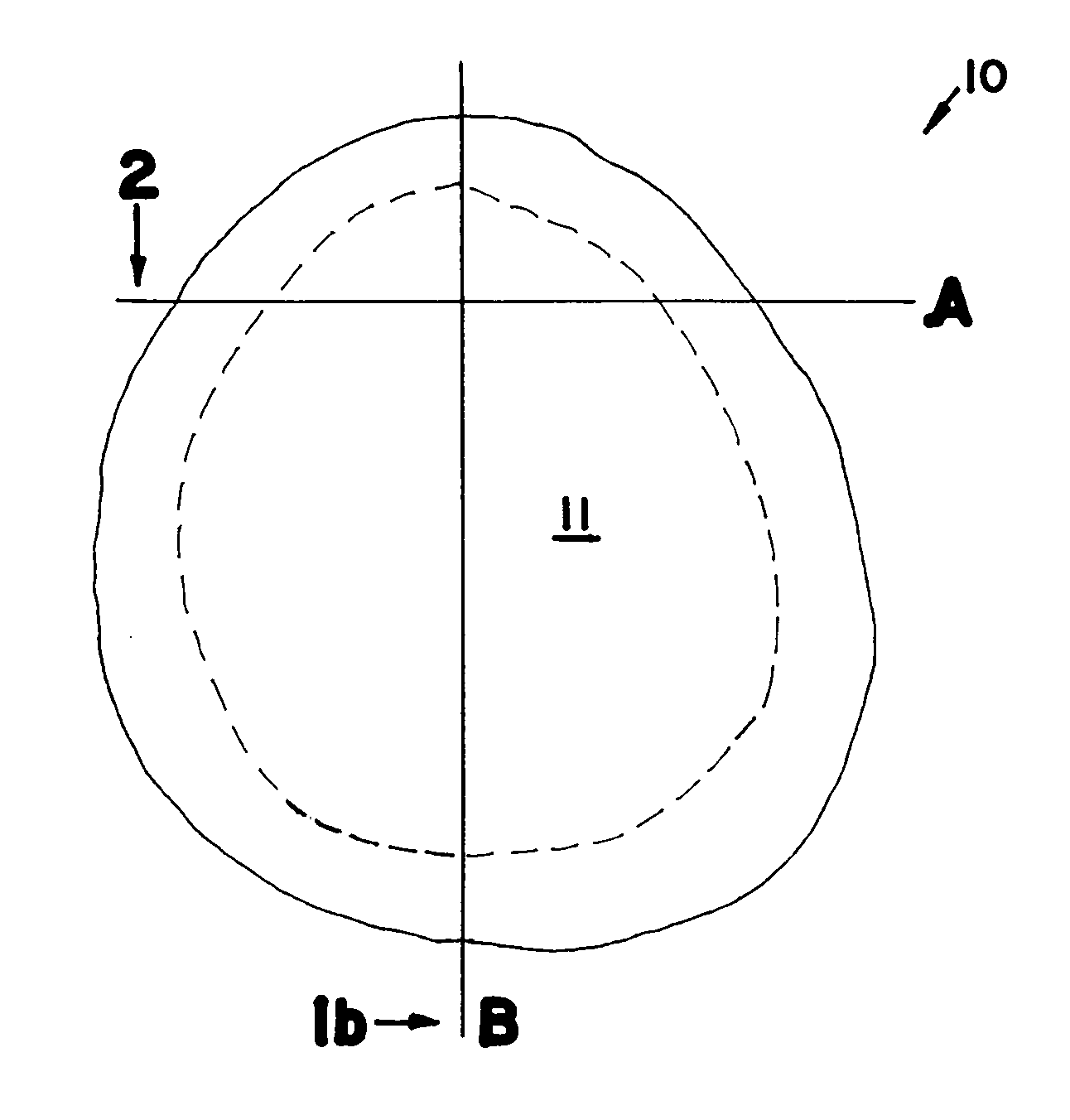

Container comprising edible manifold

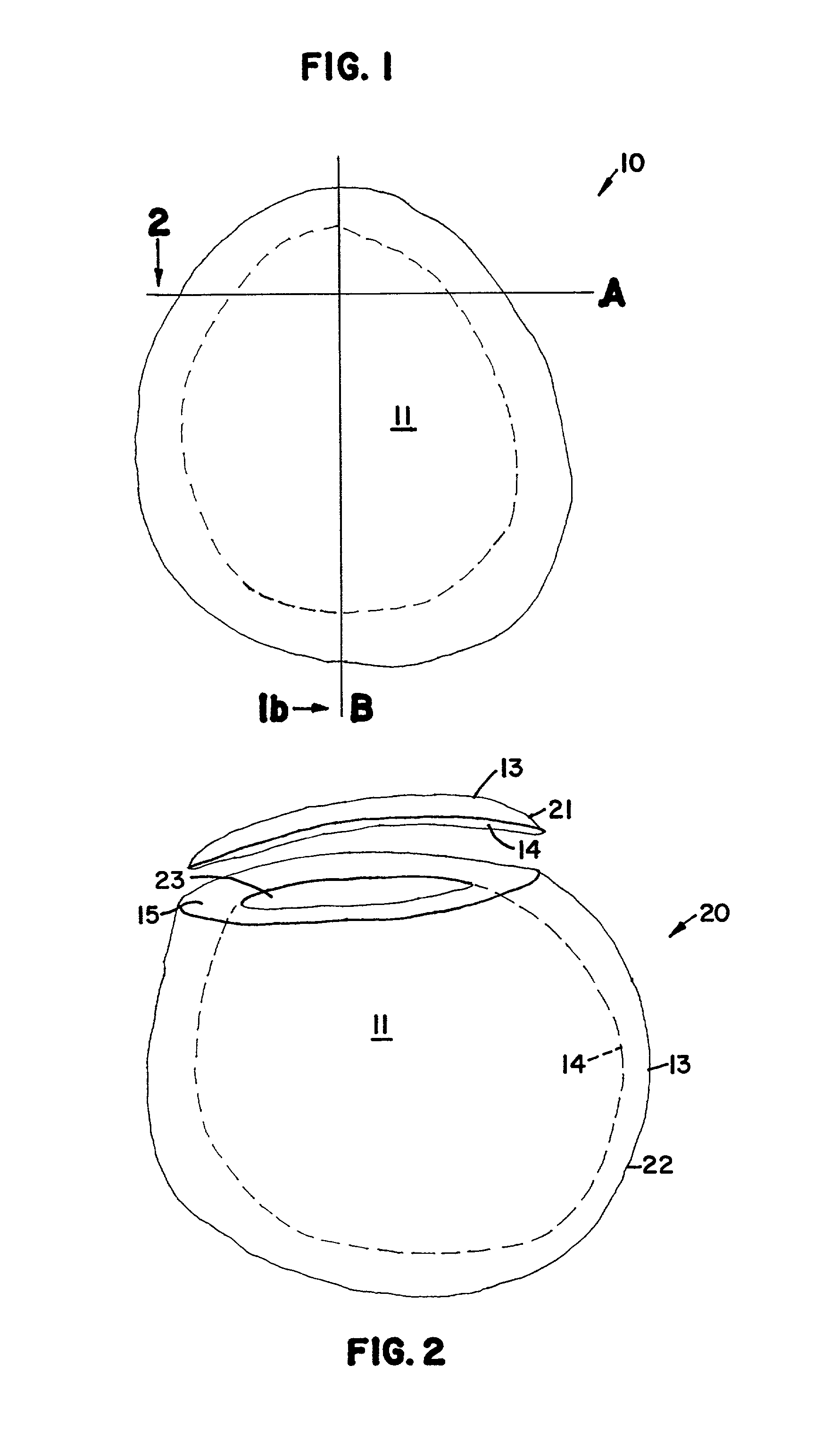

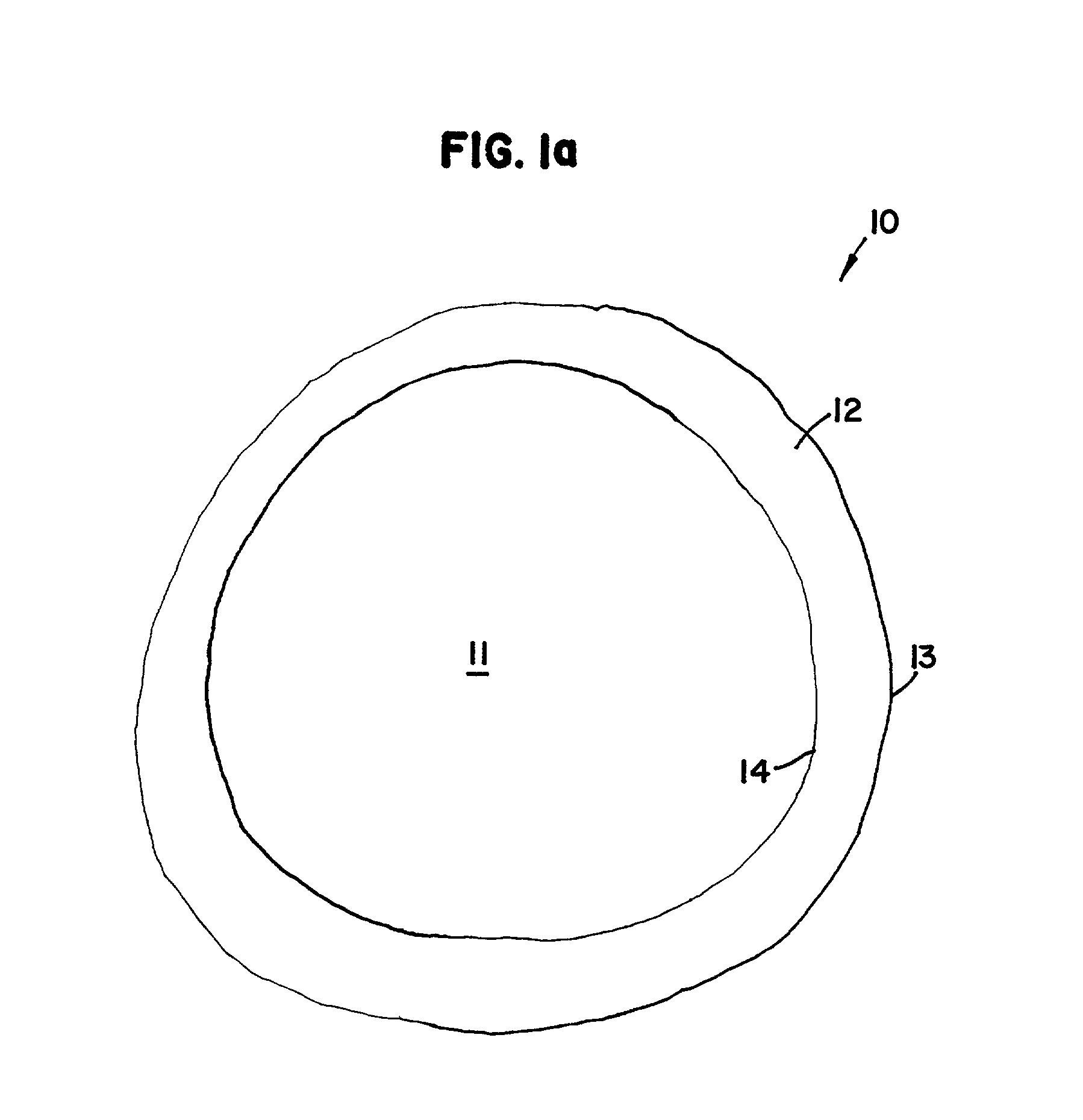

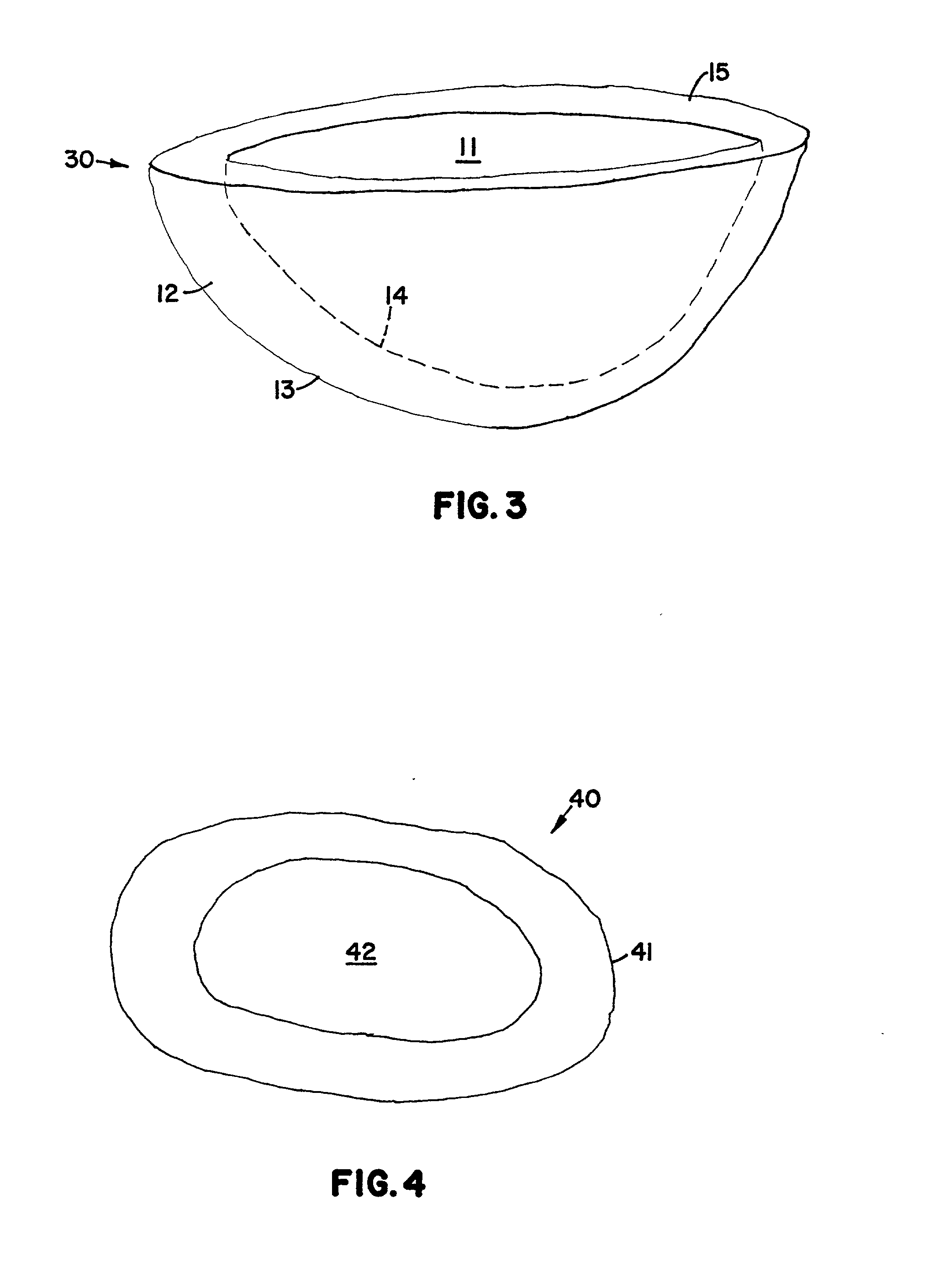

InactiveUS20030044493A1Maintain interior volumeQuick buildBaked article fillingPre-baking dough treatmentFilling materialsServing size

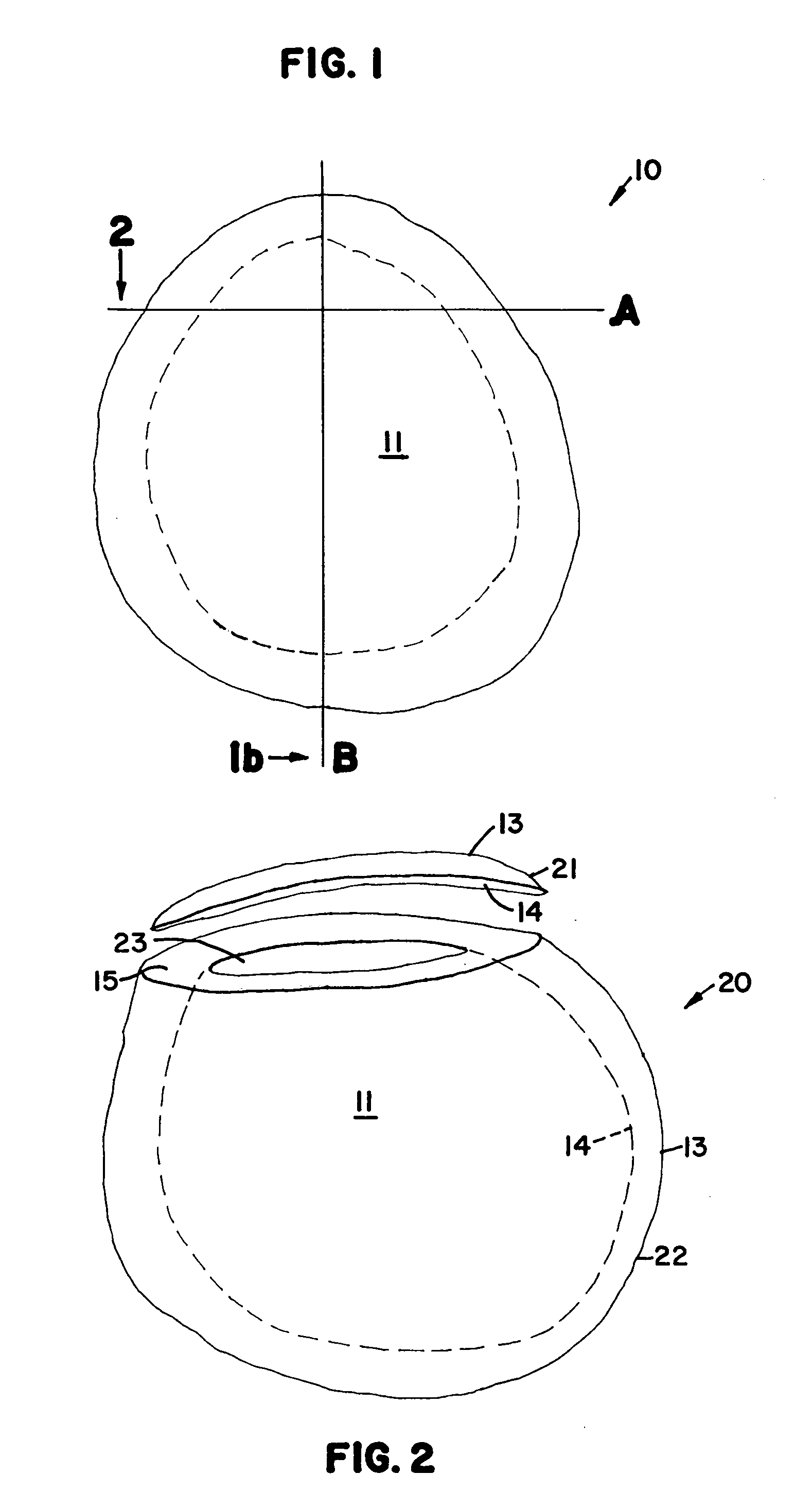

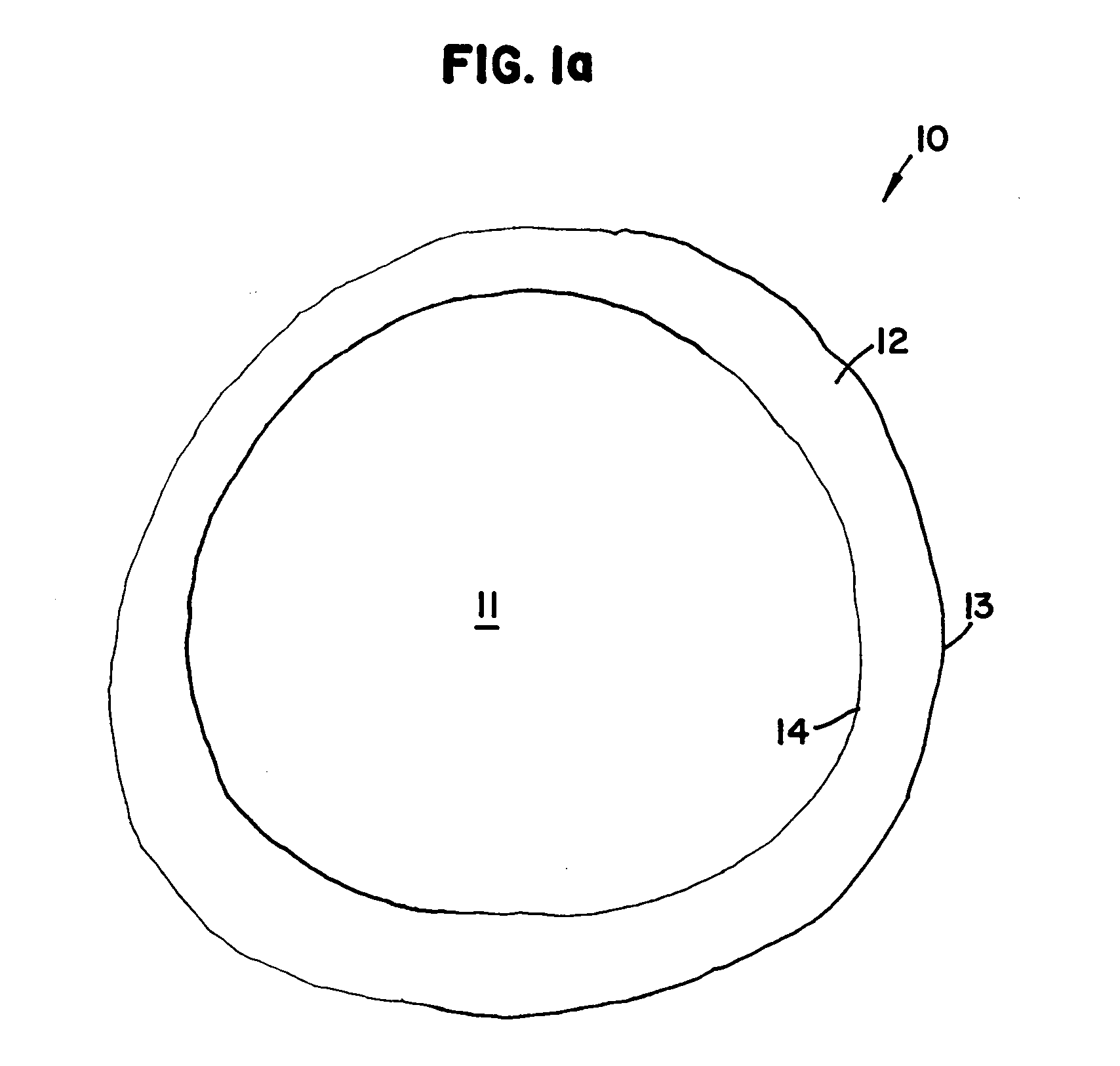

A bread bowl or boule comprises a spherical edible shell. The volume of the shell provides a space, volume, or container of at least one individual serving size portion of a food material. The bowl typically comprises a spherical shell with an opening resulting from a section removed. The bowl can be manufactured by forming a bakable shell surrounding a fugitive space filling composition. Upon baking, the heat of baking results in a change of state such that the fugitive space filling material exits the interior of the bowl leaving a volume suitable for a single serving portion. The structure adapted for baking comprises an exterior dough shell and an interior fugitive section. Extruding the dough with a fugitive composition in the interior and sealing the extruded ends into a substantially rounded or spherical structure can make the production unit. In preparation, the unbaked bowl is baked leaving a spherical hollow structure. A section of the sphere is removed, exposing the interior volume and the consumable food is then introduced into the interior of the bowl.

Owner:SCHWANS GLOBAL SUPPLY CHAIN +1

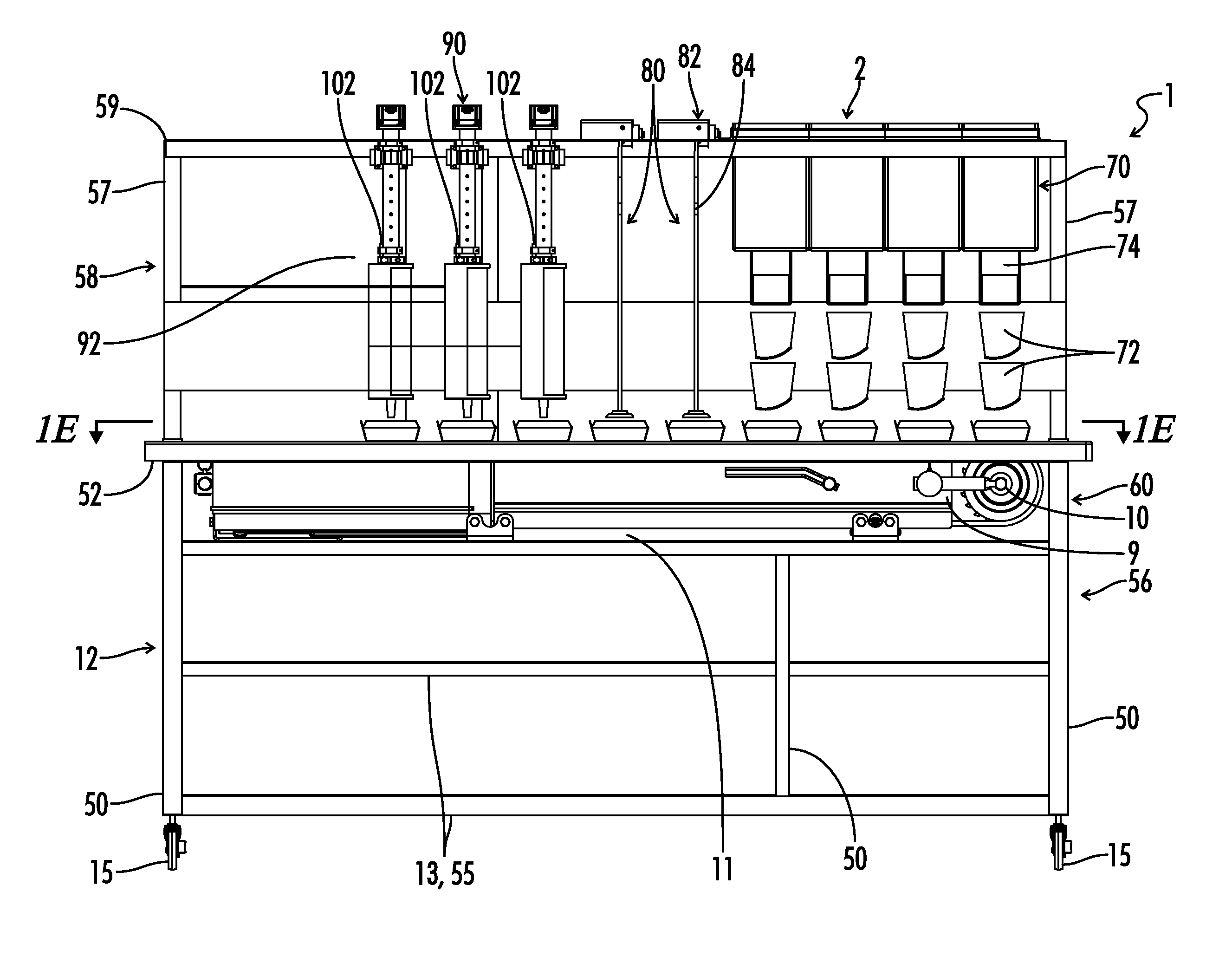

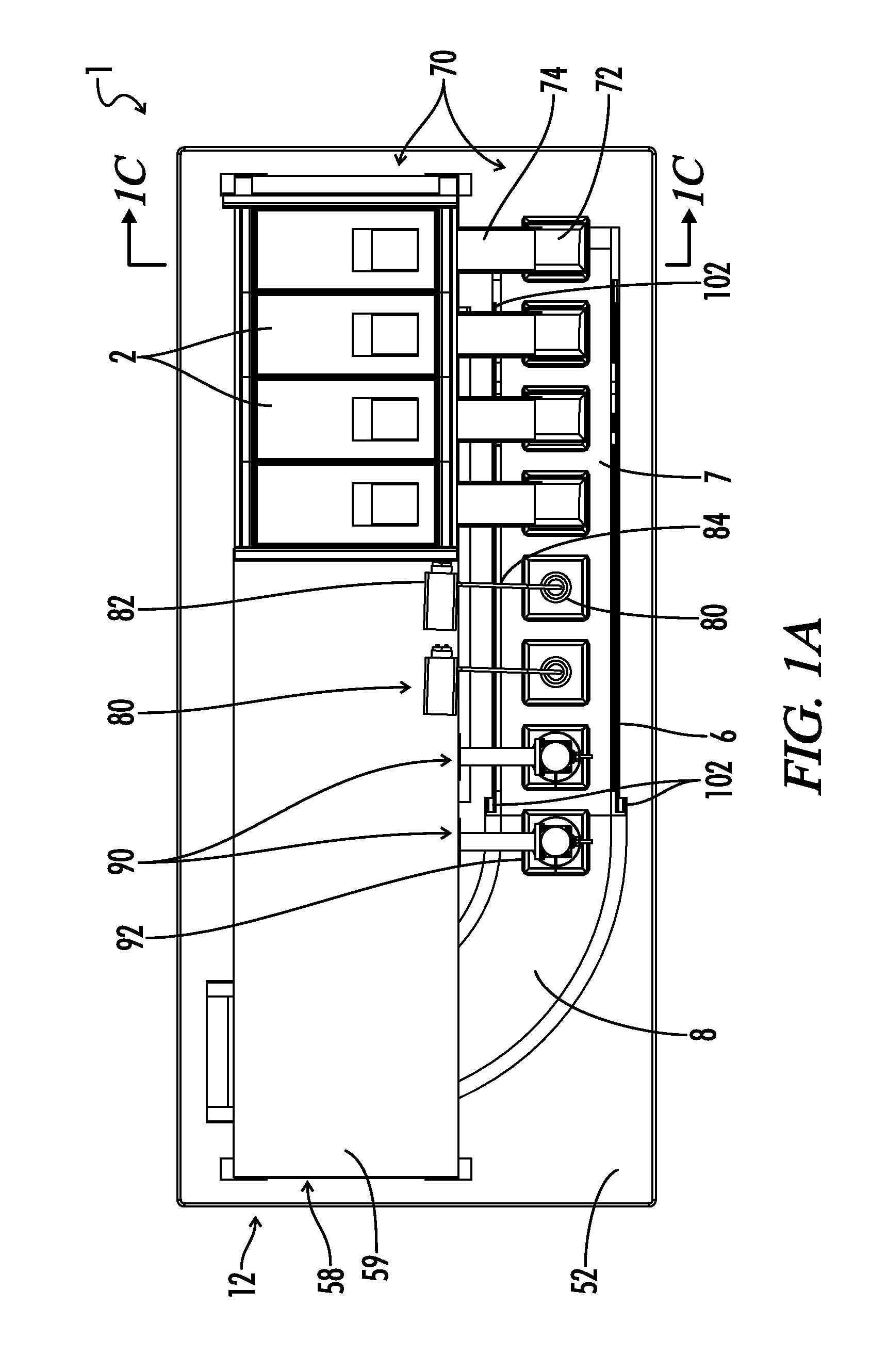

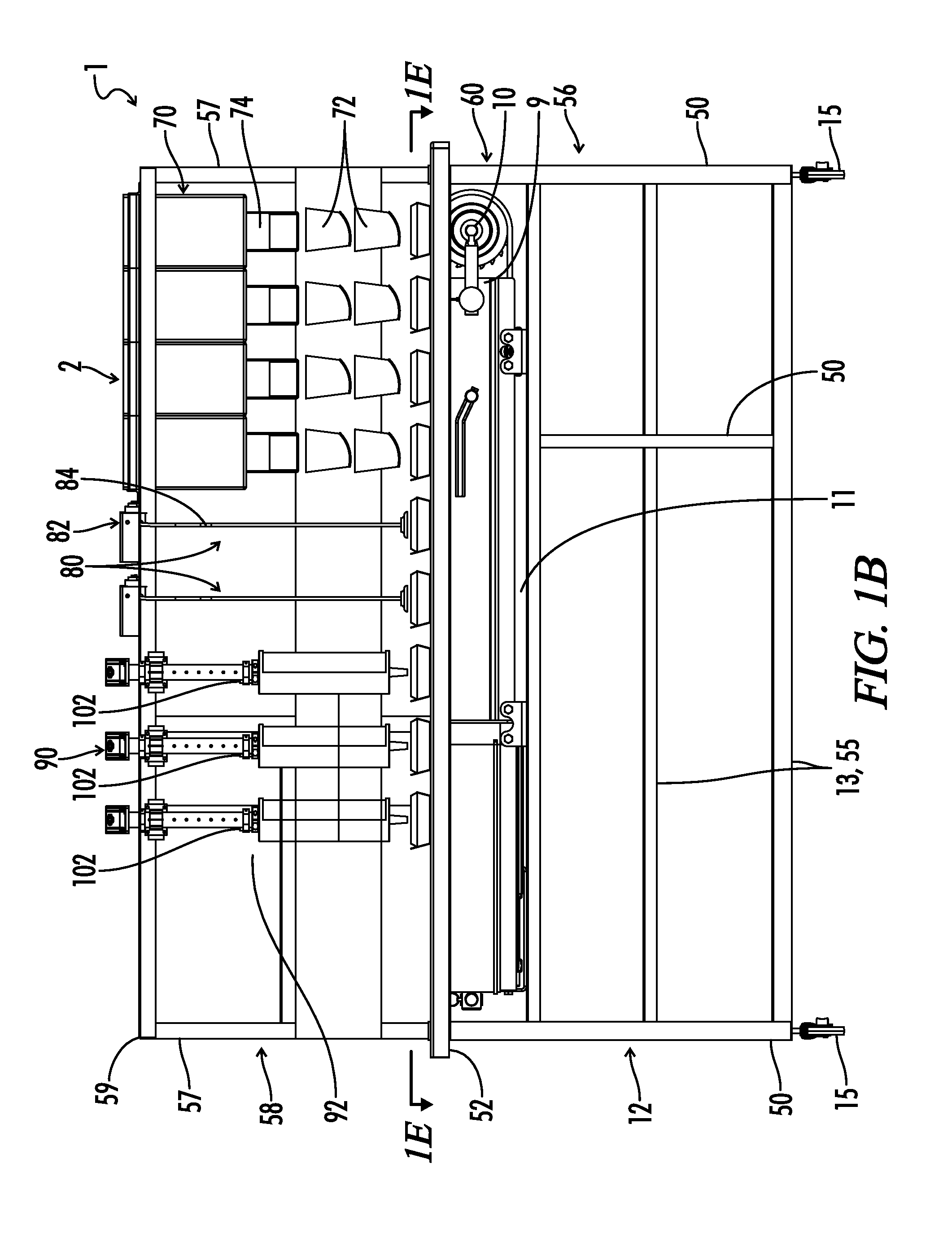

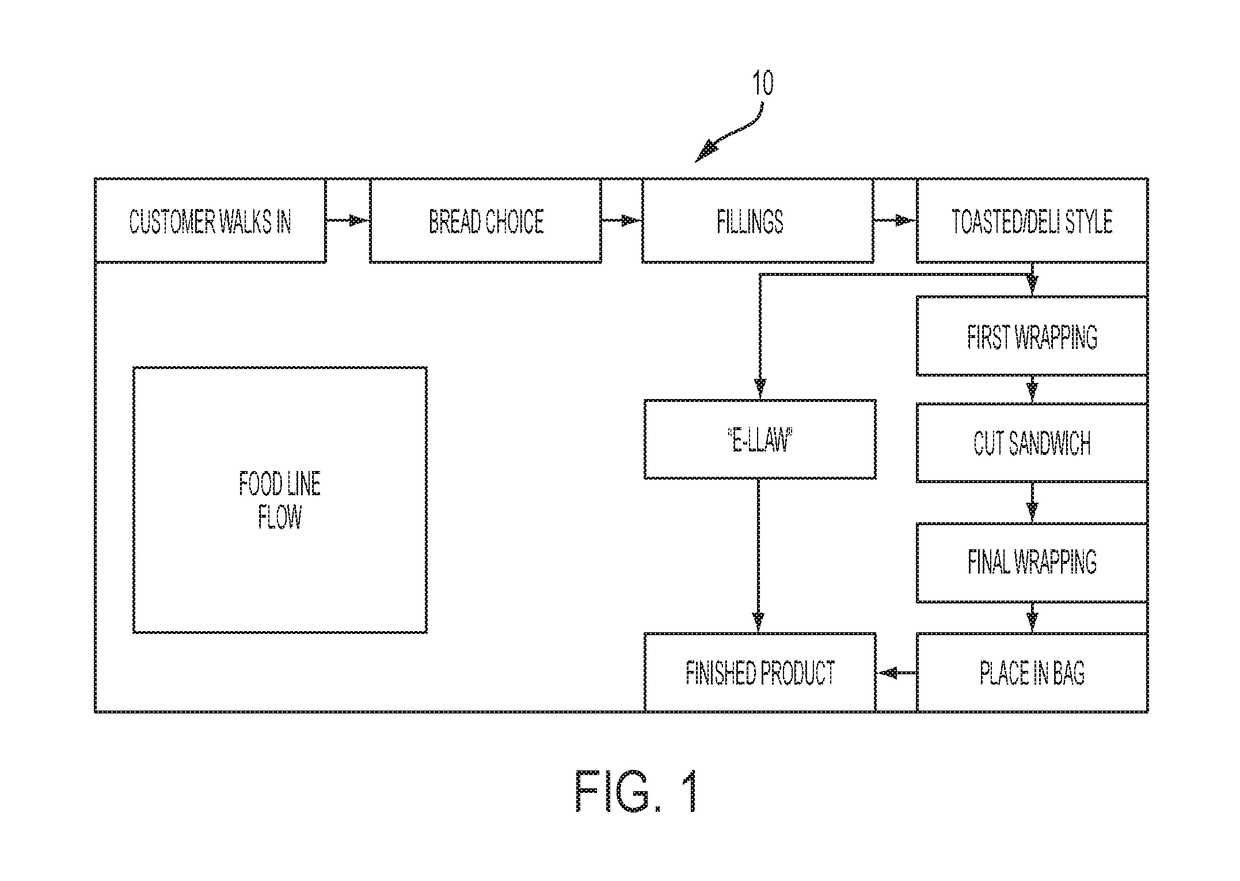

Automated sandwich assembly unit

ActiveUS9532575B1Reduce manpower requirementsEnhanced ingredient controlBaked article fillingCoin-freed apparatus detailsCommunication interfaceAdditive ingredient

An automatic sandwich maker designed to automate the process of preparing sandwiches, including hamburgers, is included. This automated sandwich maker is designed for use in commercial kitchens, including small commercial kitchens, such as fast-food kitchens. The apparatus and method for automatically making sandwiches overcomes the drawbacks and limitations of the prior art. The individual sandwich process can be controlled by communications interface with a point of sales system. The inventive apparatus and method reduces manpower requirements for restaurants, provides enhanced ingredient control, and improves overall product quality.

Owner:DONISI VICTOR +1

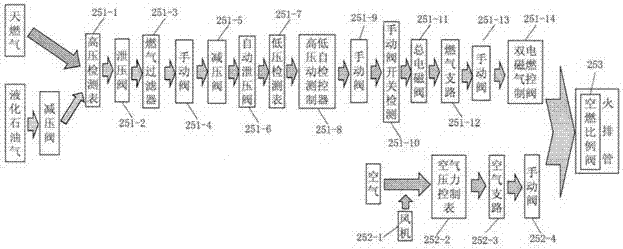

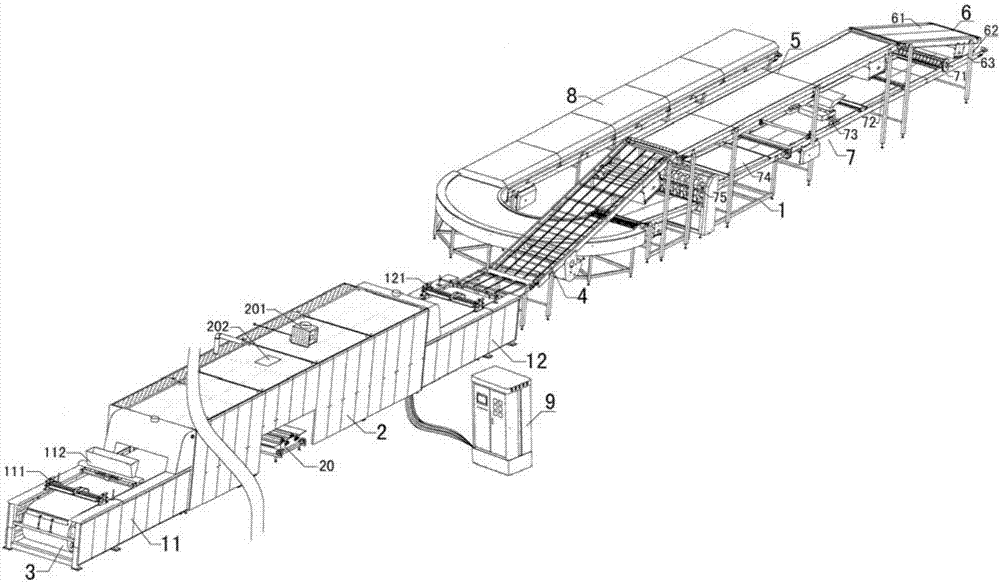

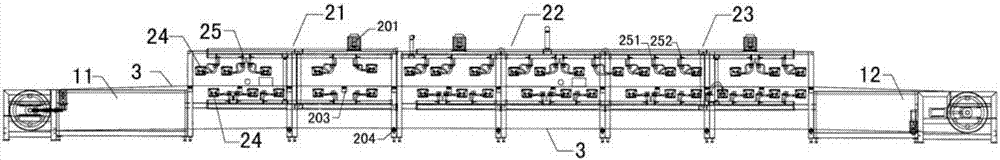

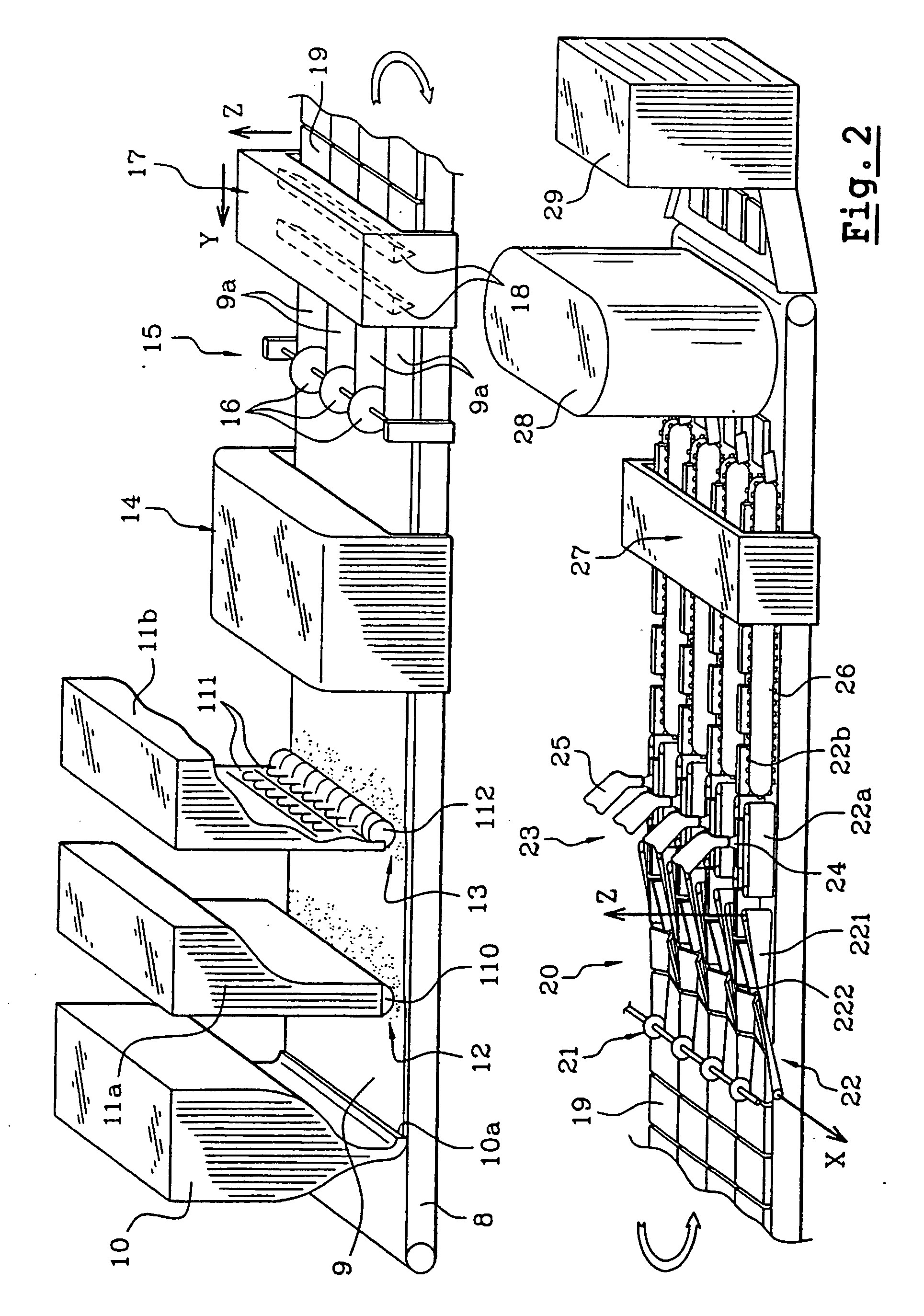

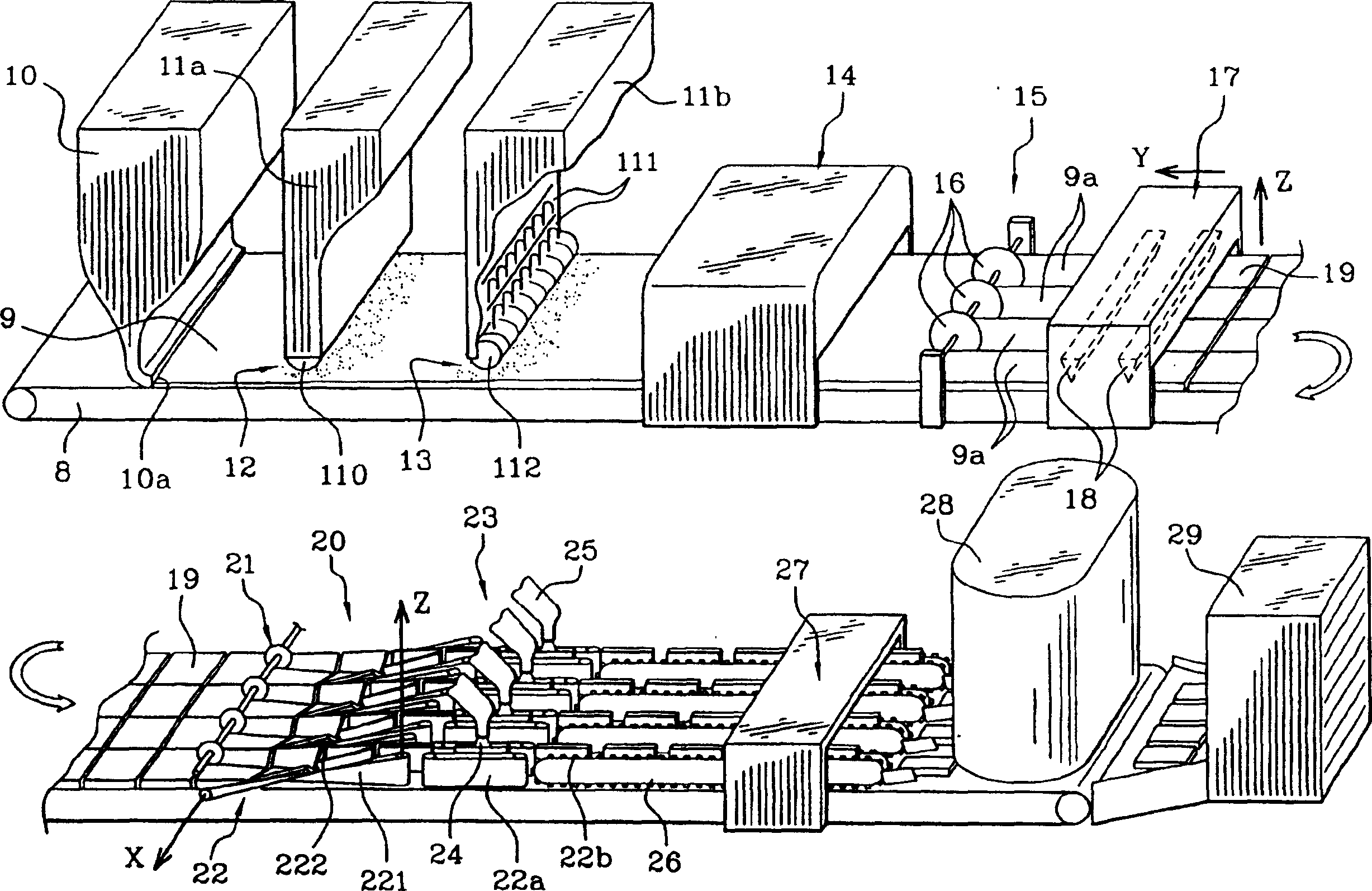

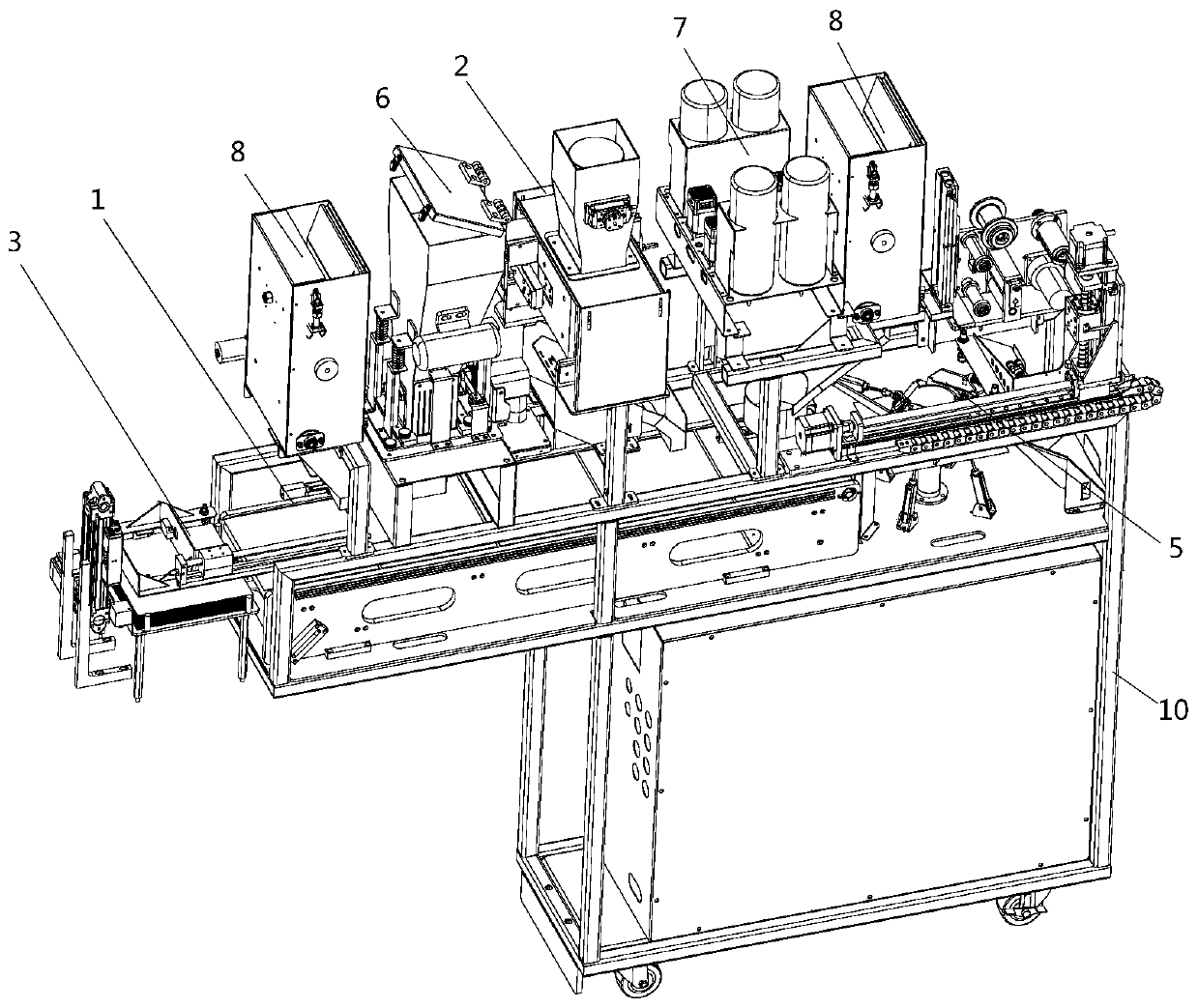

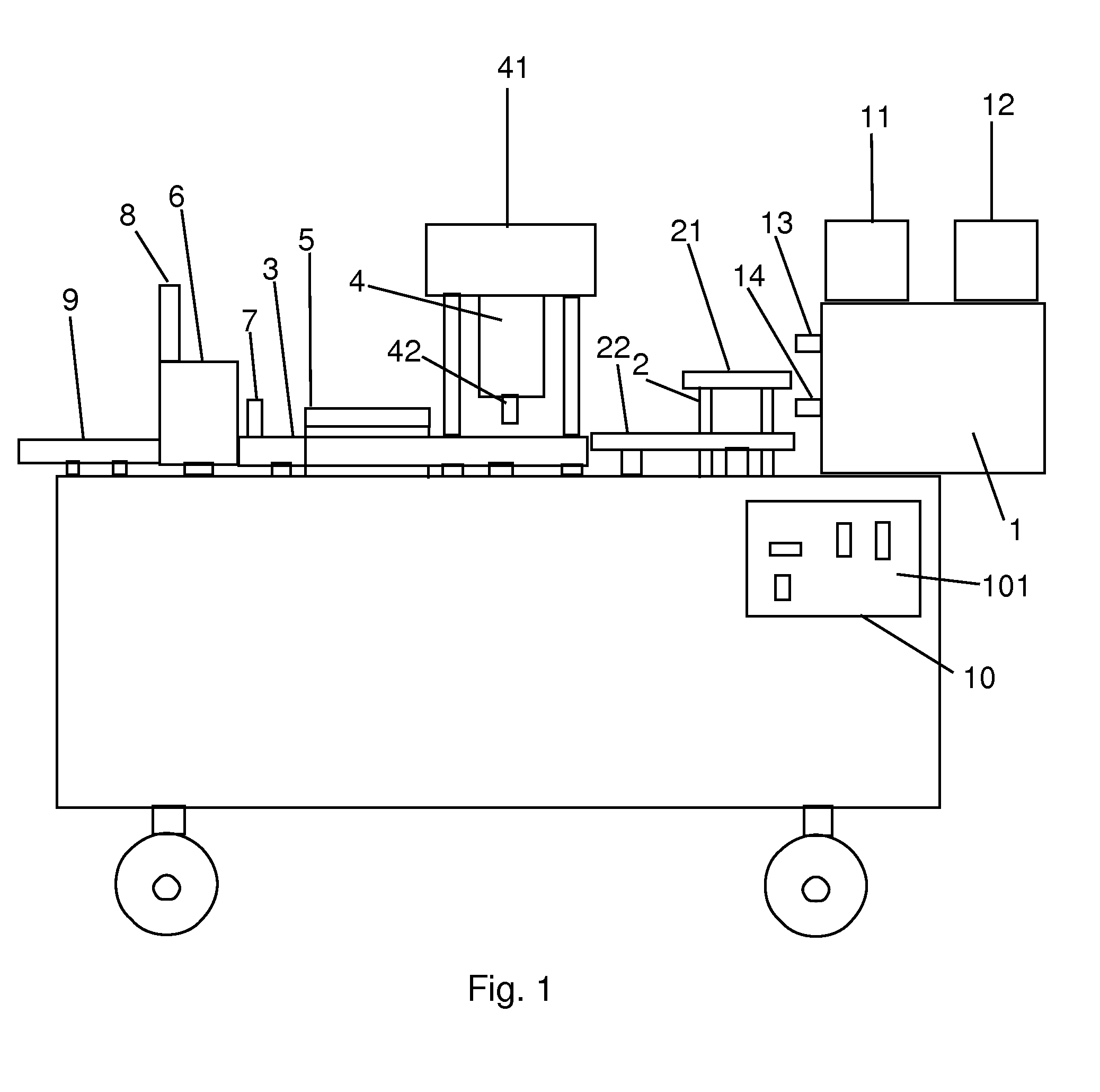

Full-automatic pocket cake baking production line and production processing method

InactiveCN107212037AGood conditionGreat tasteBaked article fillingBaking surface cleaning/greasingProgrammable logic controllerMolding machine

The invention discloses a full-automatic pocket cake baking production line and production processing method. The full-automatic pocket cake baking production line comprises a furnace inlet platform, a furnace outlet platform, a tunnel oven, a steel belt, a net chain conveying belt, a cooling transmission belt, a turning and rolling mechanism, a sandwich forming mechanism, a sterilization mechanism, a frame and a PLC (programmable logic controller) control box, the cooling transmission belt and the sandwich forming mechanism are arranged on the upper layer and the lower layer of the frame, the turning and rolling mechanism is connected with the cooling transmission belt and the sandwich forming mechanism, the tunnel oven is provided with a preheating area, a baking coloring area and a moisture control area, so that baking quality is controlled, a first pneumatic oil spray machine, a grouting machine, a second pneumatic oil spray machine, an automatic steel belt cleaning mechanism, an arc-shaped turning plate, a cutting slitting machine, a turnover mechanism, a paste machine, a laminating mechanism, a continuous forming separation mechanism and the sterilization mechanism are sequentially arranged on the production line, the PLC control box is connected with devices of the production line in a controlled manner, and intelligent control is achieved.

Owner:福建省亿焙机械有限公司

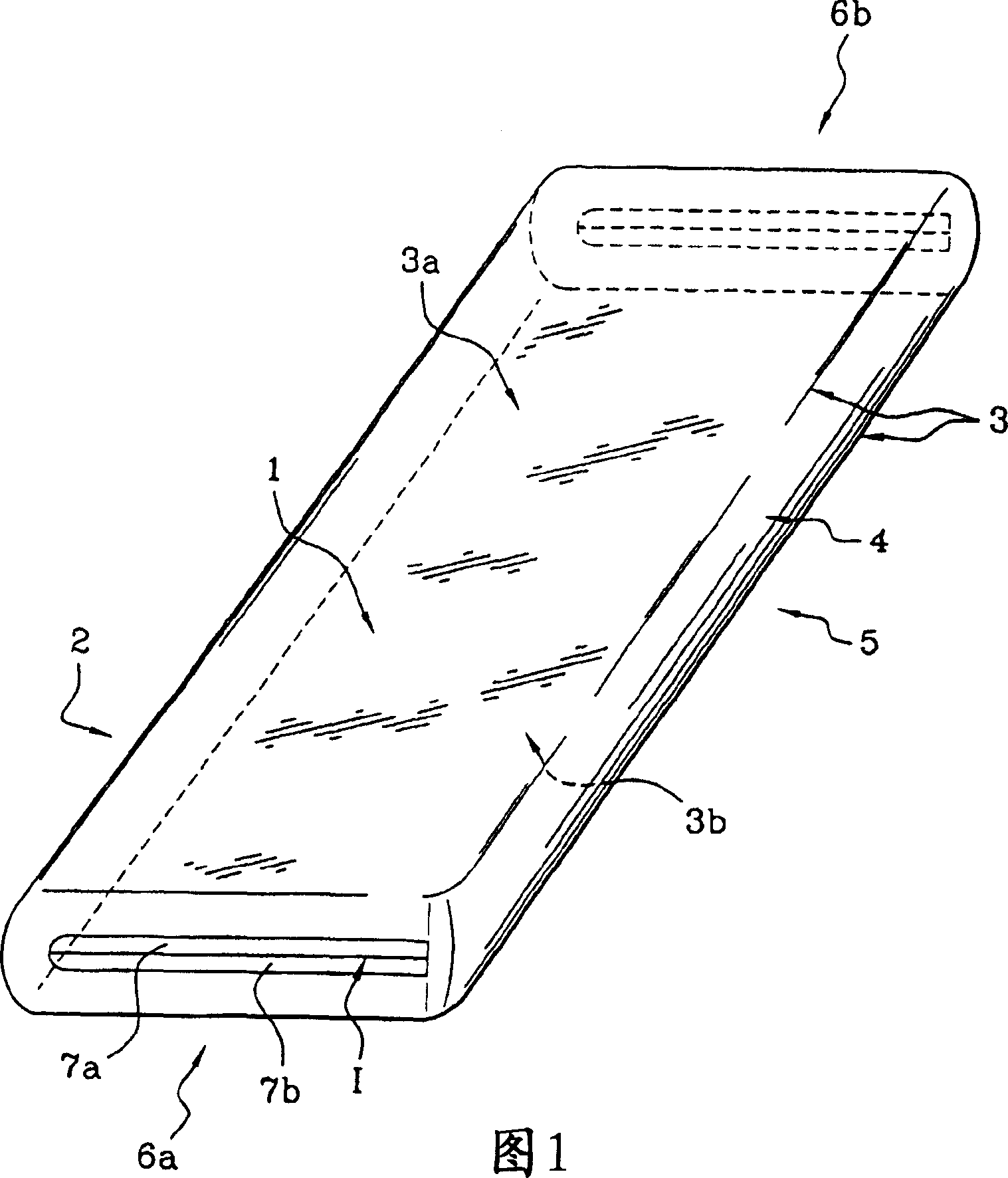

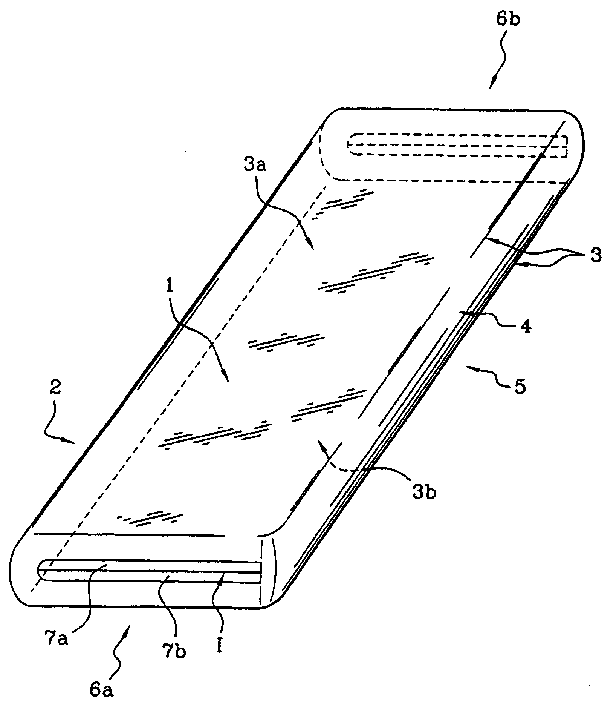

Method of producing a folded-dough food product, industrial chain used for same and product thus obtained

InactiveUS20060115557A1Risk of leakageSufficient retentionBaked article fillingConfectioneryAdditive ingredientEngineering

Owner:GERARD SCHLIENGER INVESTISSEMENTS

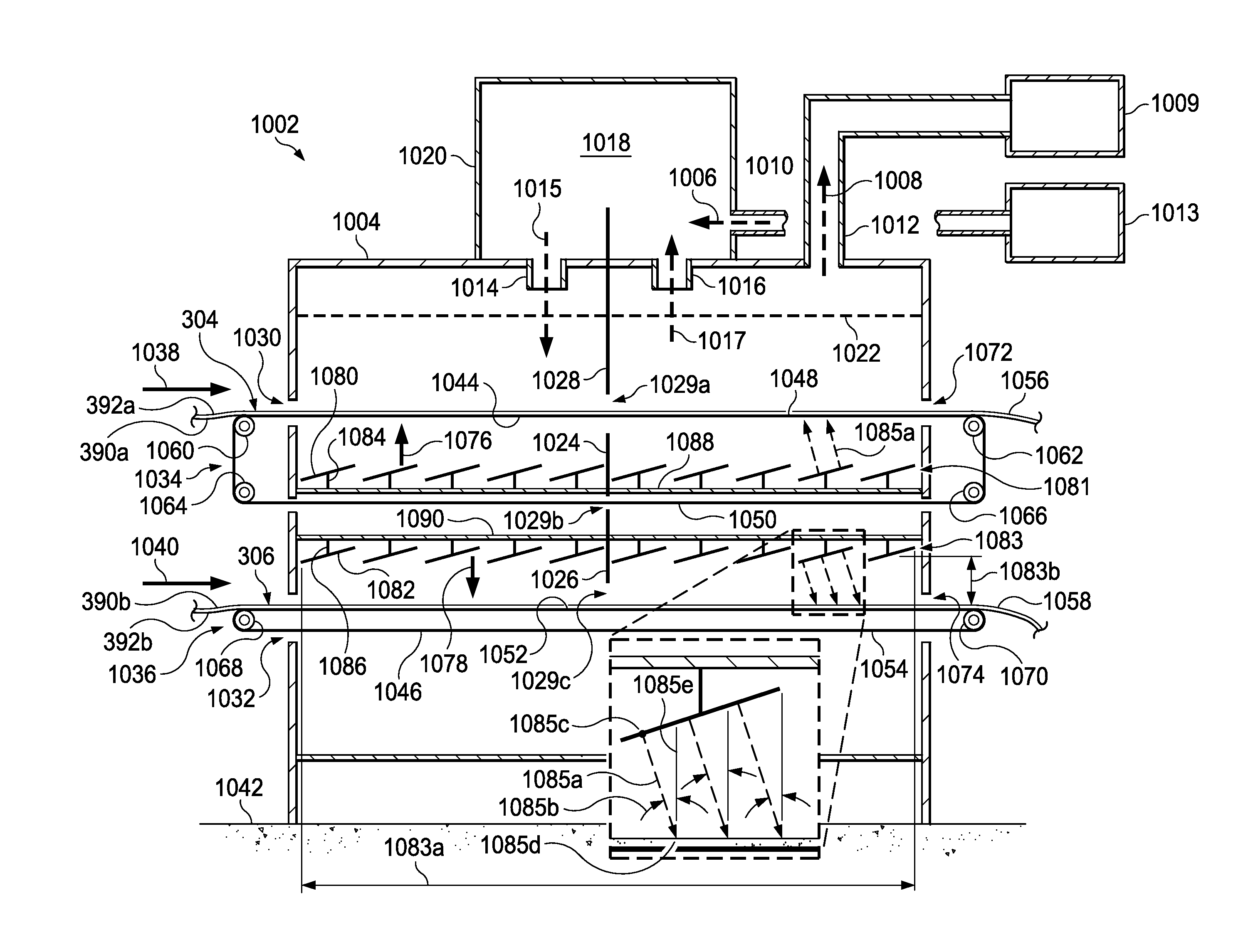

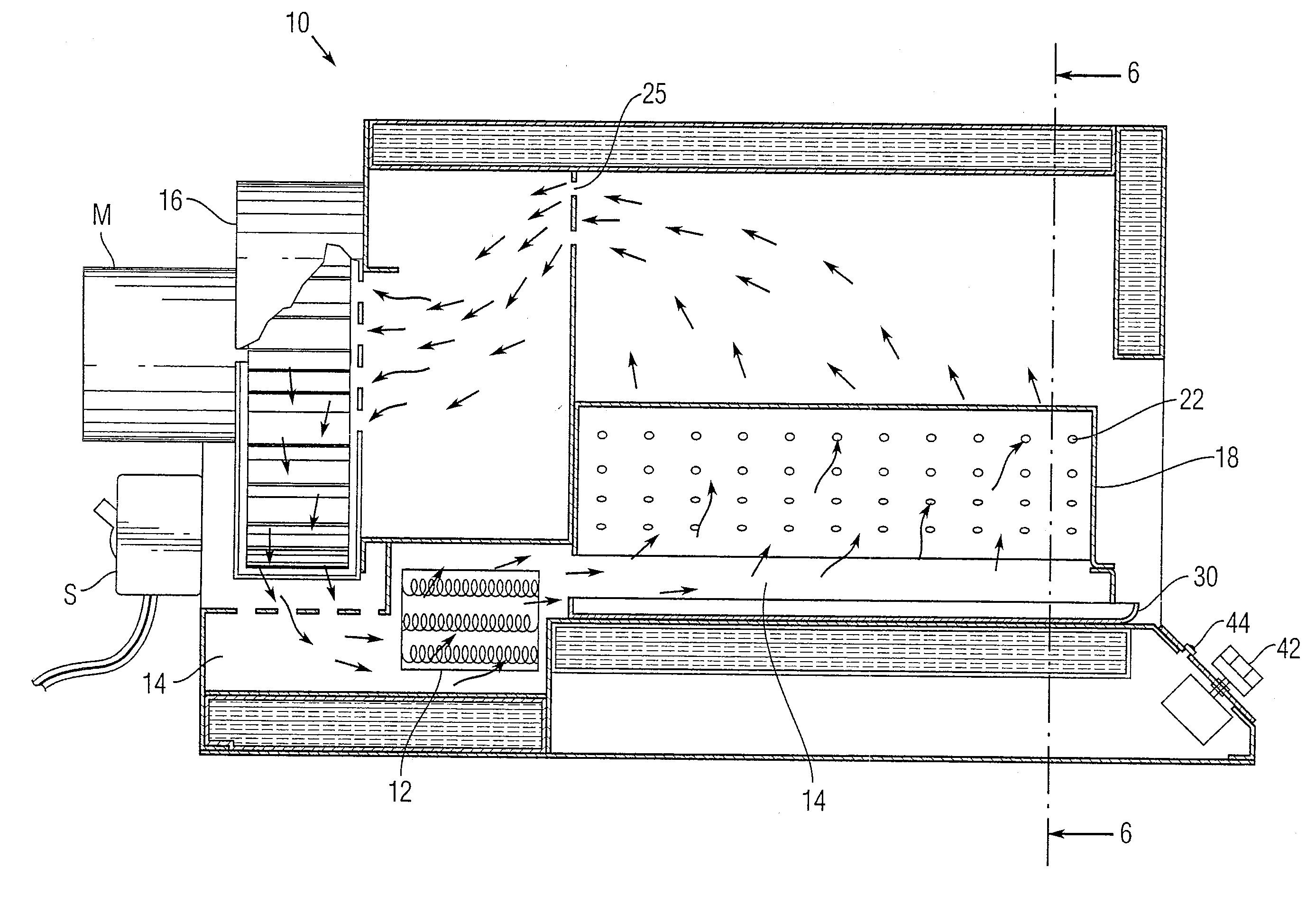

Continuous process and apparatus for making a pita chip

InactiveUS20150150270A1Eliminates and reduces disadvantageDrying solid materials with heatBaked article fillingEngineeringMechanical engineering

A method and apparatus for processing dough, for example, curing dough to make a pita chip. In a first aspect, the method comprises providing a first portion of dough on a first conveyor, conveying the first portion into an oven, directing a heating medium at the first portion using a first discharge array, and conveying the first portion out of the oven. In a second aspect, the apparatus comprises an oven, a first conveyor for conveying a first portion of dough, and a first discharge array. The oven comprises an oven housing, a first entrance of the oven housing for the first portion of dough, and a first exit of the oven housing for the first portion of dough. The first discharge array is positioned and oriented to direct a heating medium at the first portion of dough when the first portion of dough is positioned for conveyance by the first conveyor.

Owner:FRITO LAY NORTH AMERICA INC

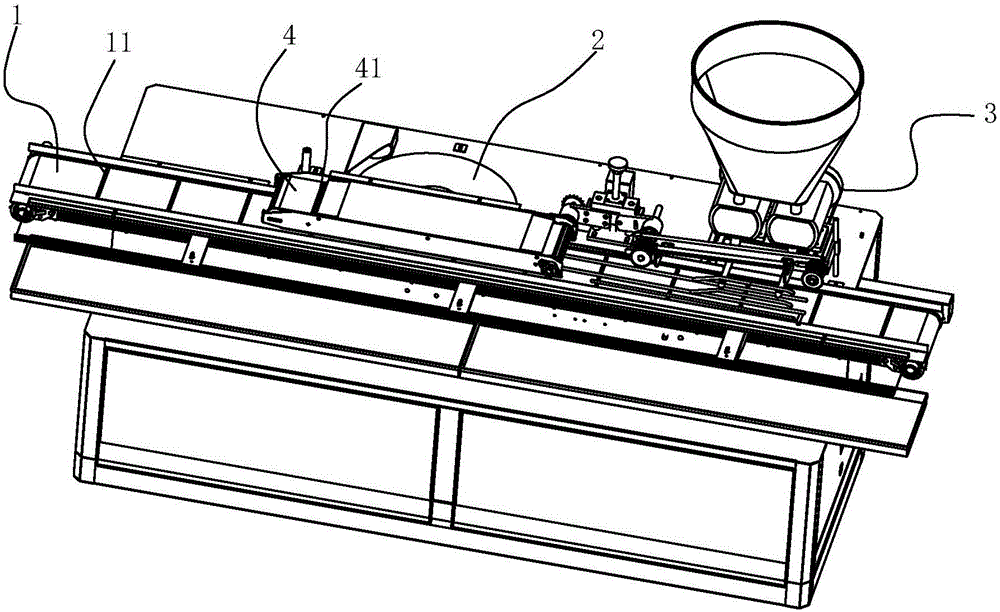

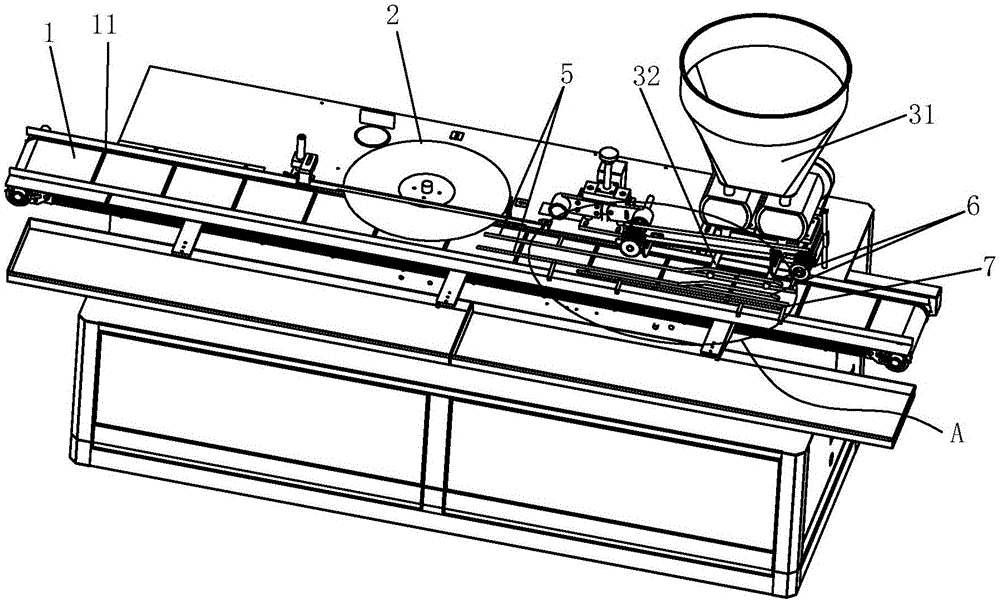

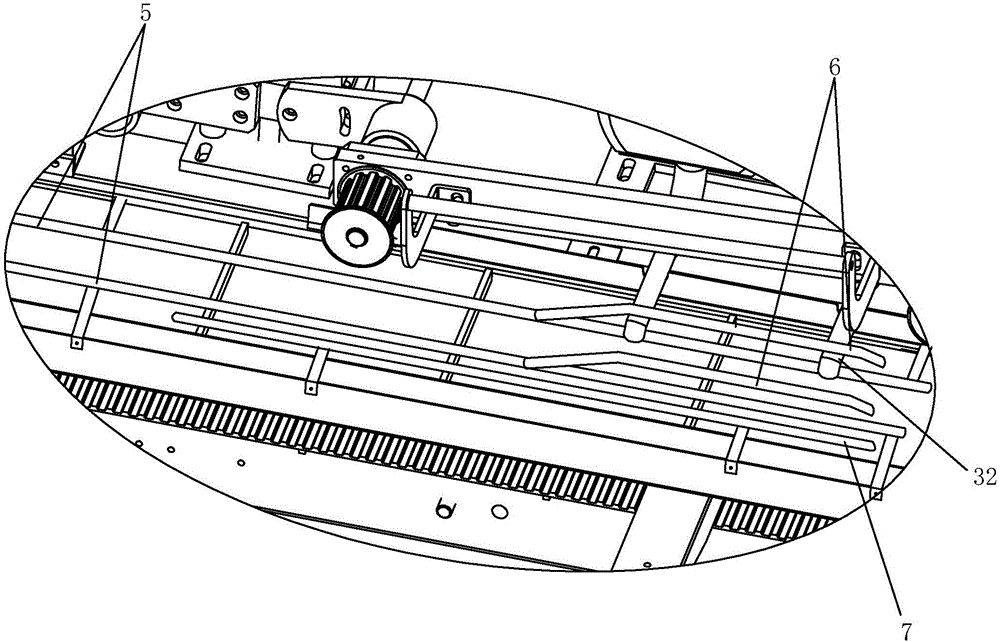

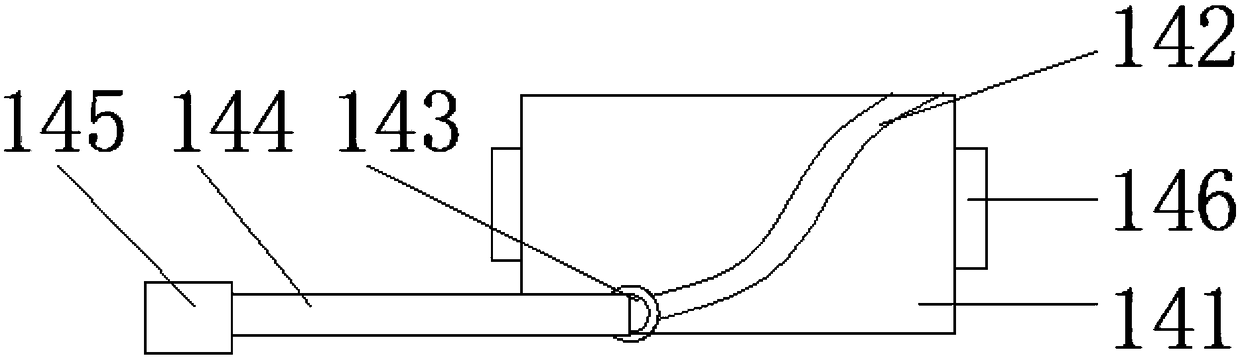

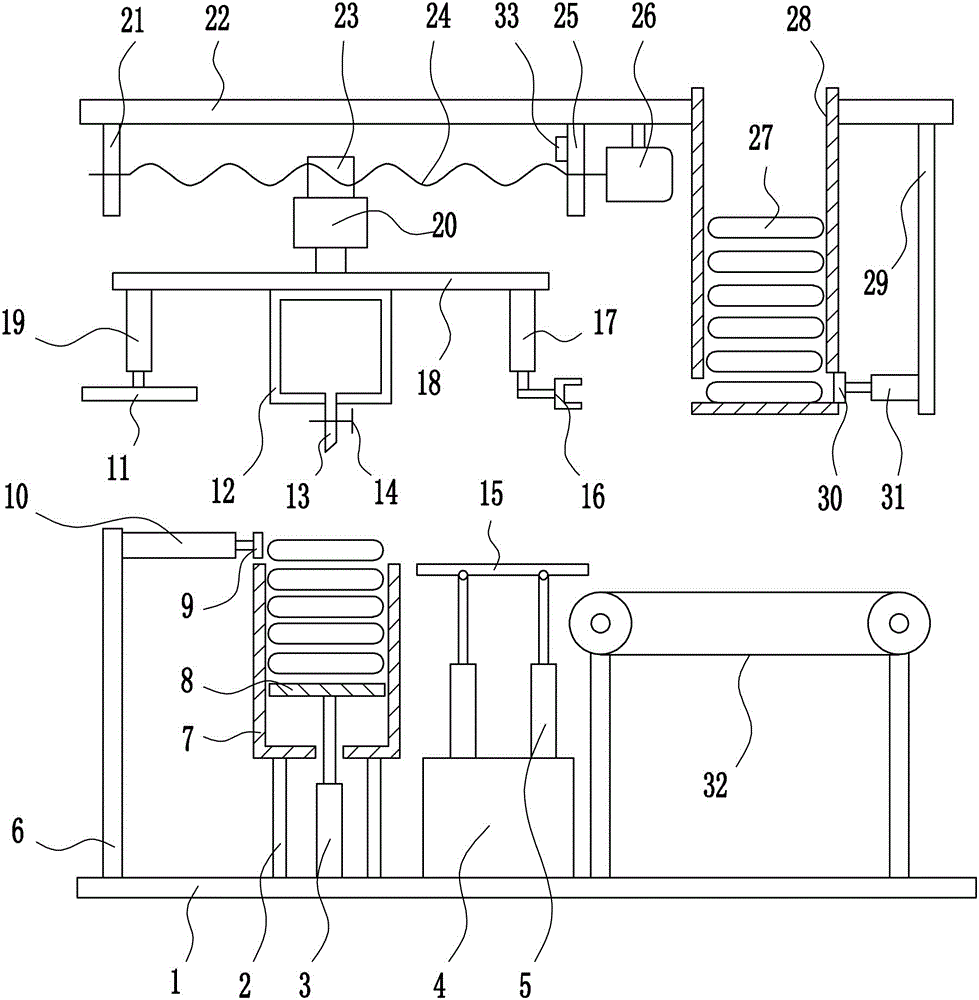

Automatic bread and cake sectioning and filling device

InactiveCN106720016ARealize automatic cuttingRealize stuffingBaked article fillingBaked article cutting/slicingFilling materialsEngineering

The invention discloses an automatic bread and cake sectioning and filling device which comprises a first conveyor belt, a cutter and a filling machine, wherein a to-be-filled material sequentially passes through the cutter and the filling machine along a first transmission direction of the first conveyor belt; and to-be-filled bread or cake is put on the first conveyor belt and sequentially passes through the cutter and the filling machine, so that automatic section and filling are achieved. The to-be-filled material passes through a first compression bar and a top bracing rod through a horizontally sectioned opening; and the first compression bar and the top bracing rod can push the opening in the side surface of the to-be-filled material open, so that a filling pipe of the filling machine can smoothly enter the opening of the to-be-filled material and inject sandwich filling. The automatic bread and cake sectioning and filling device can work reliably and is high in automatic degree and the production efficiency can be effectively improved.

Owner:江门市神川自动化设备有限公司

Method of producing a folded-dough food product, inductrial chain used for same and product thus obtained

InactiveCN1662144APreserve heating qualityBaked article fillingBakery productsAdditive ingredientEngineering

Owner:GERARD SCHLIENGER INVESTISSEMENTS

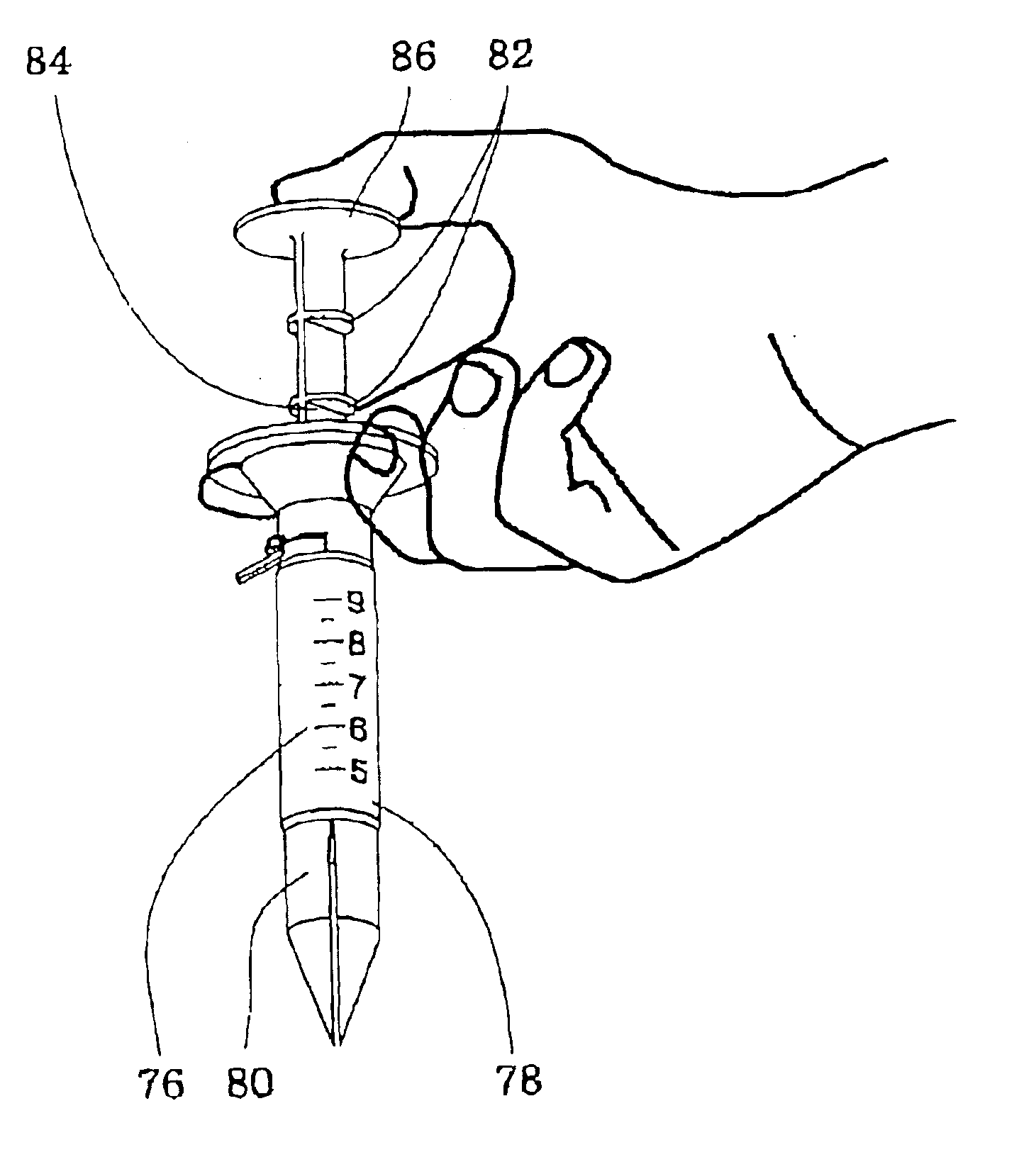

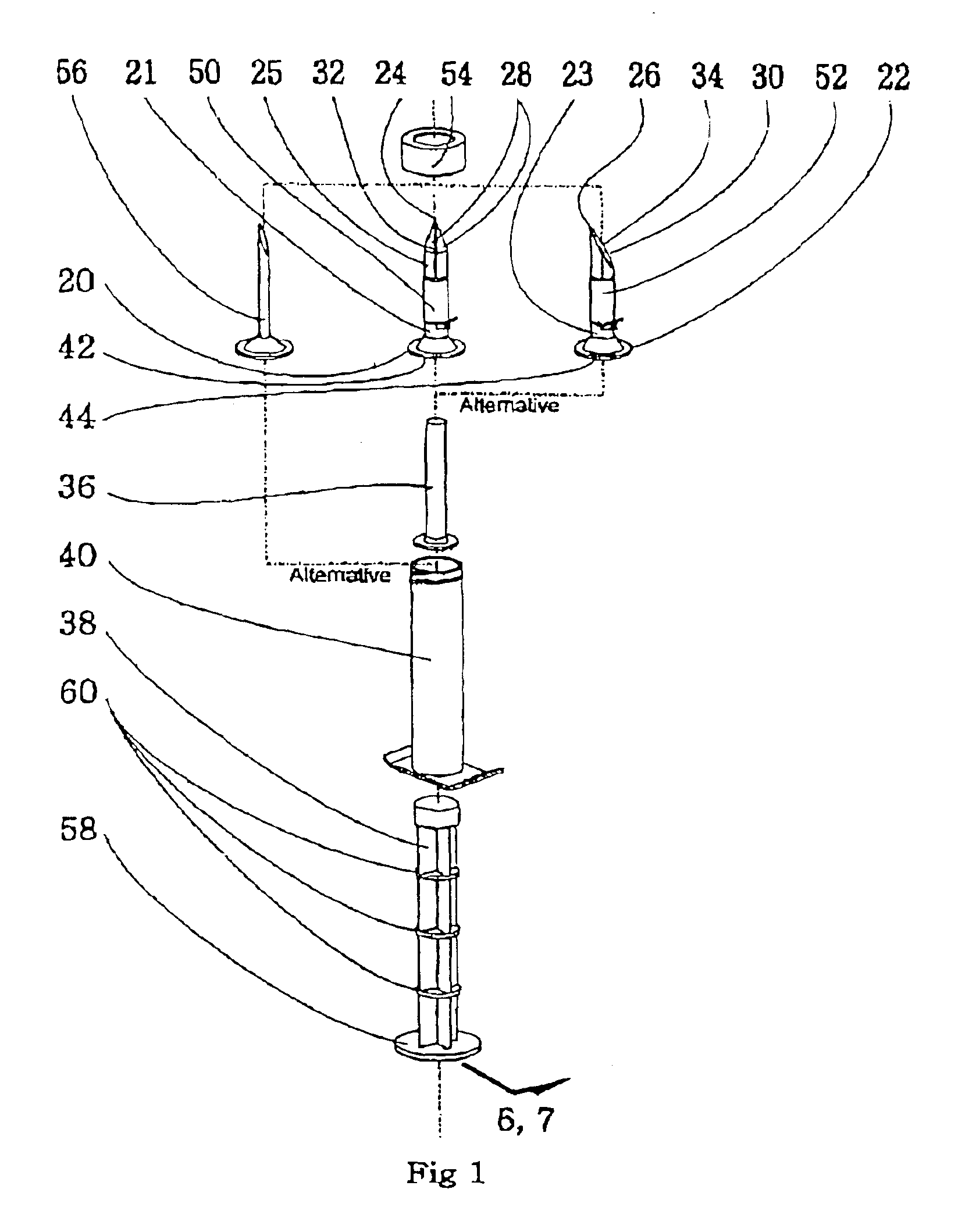

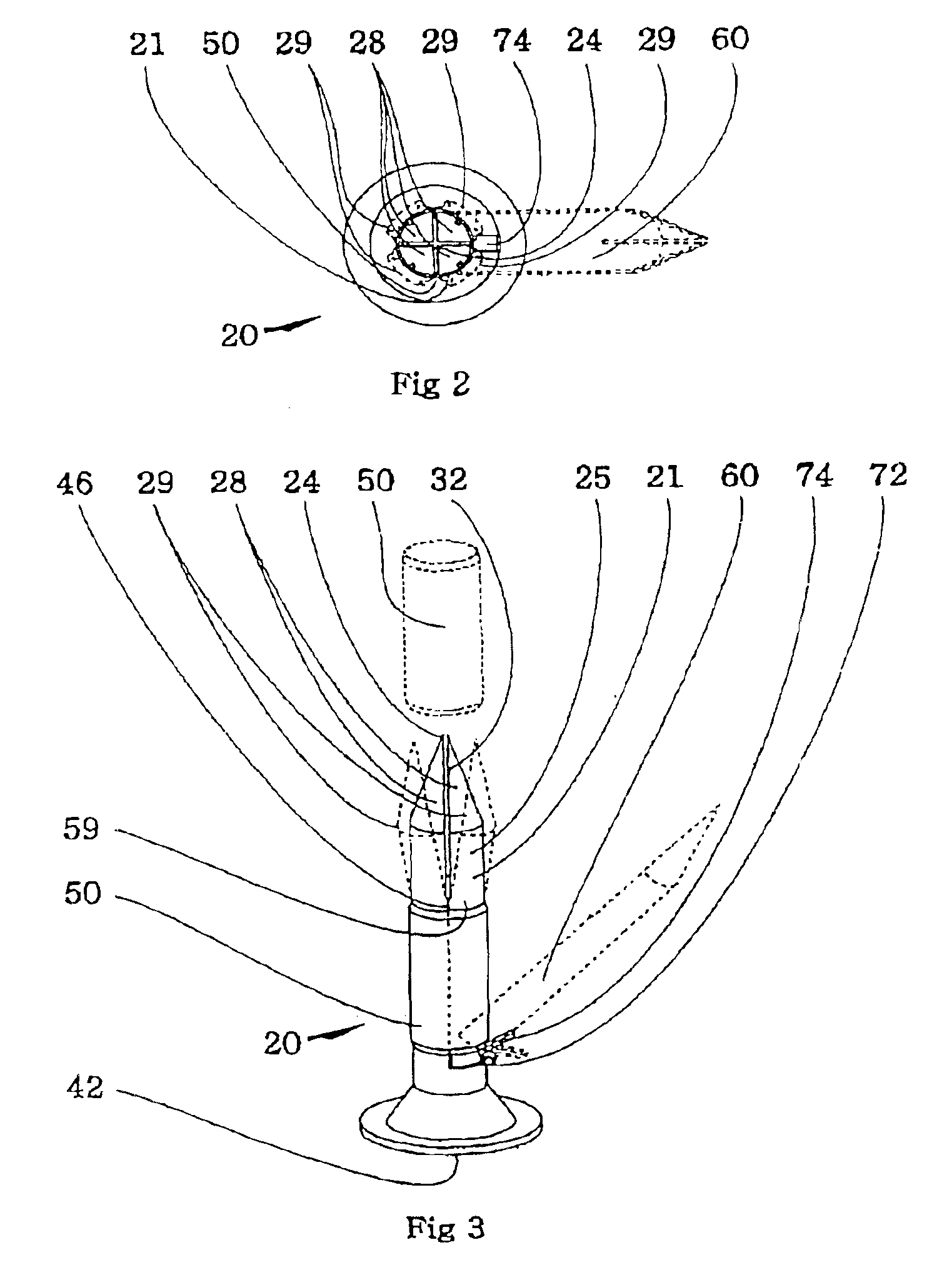

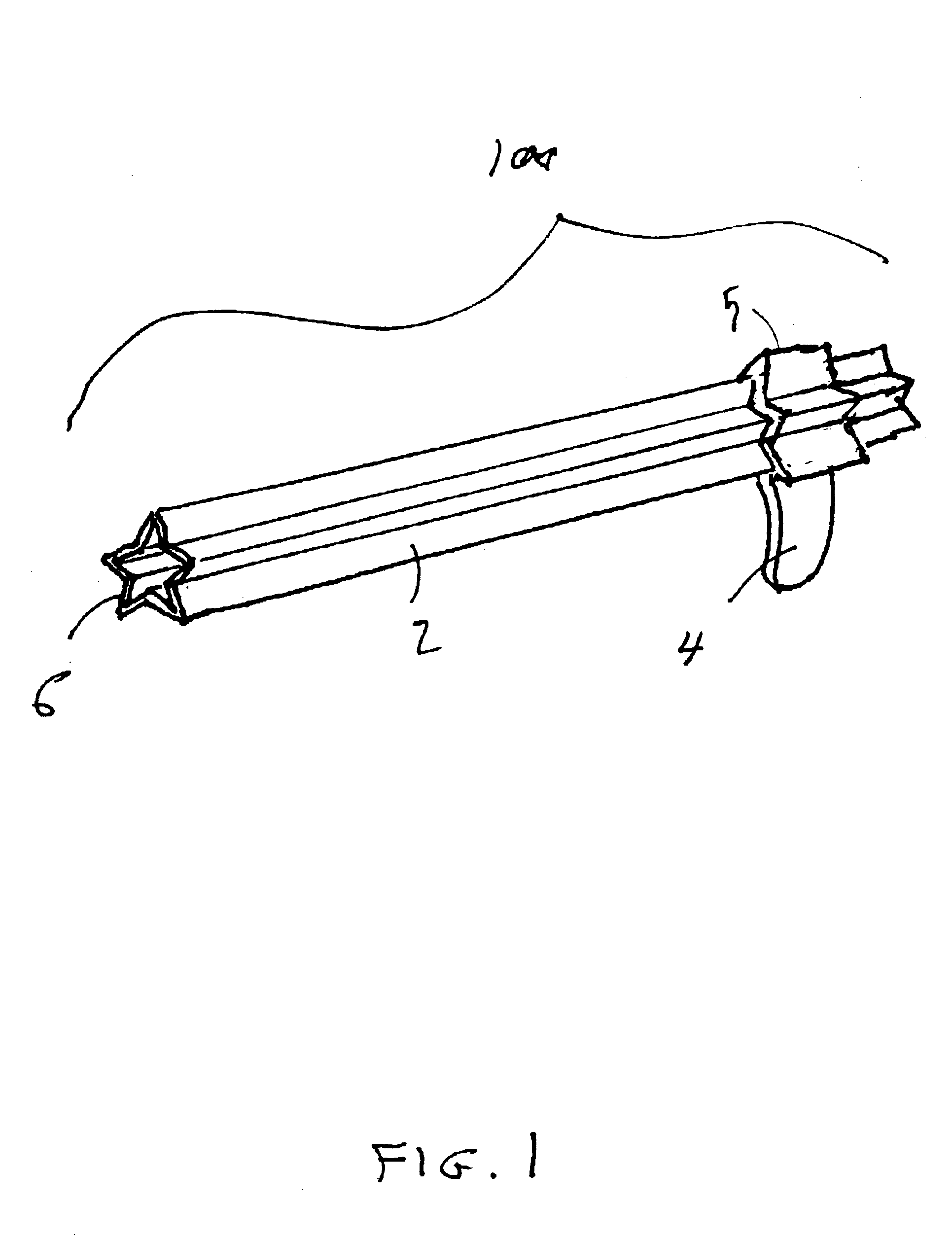

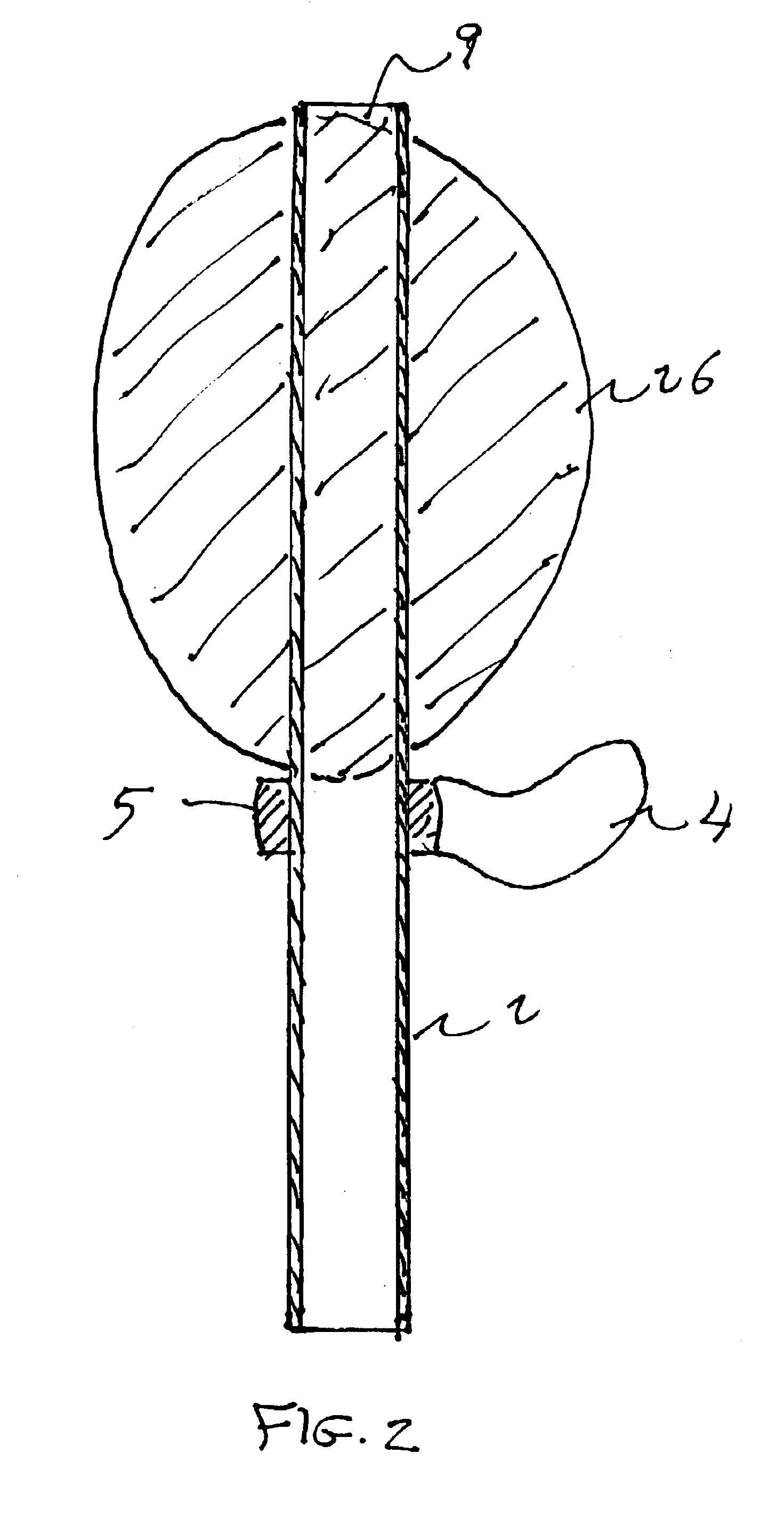

Food injection device

Food Injection Device has an injection tube member and integral handle, and a piston holding stand. The tube member is rigid and has a thin wall structure capable of piercing and penetrating a variety of food items and retaining the food items for future deposit into a second food item. The piston is positioned within the piston holding stand in such a way that the injection tube can fit over the piston and be retained by the piston holding stand so that when the tube handle is pushed down, the tube moves down the stationary piston and the food item within the tube is prevented from moving by the piston and is therefore left within the second food item. A preferred embodiment includes a variety of shaped injection tubes such as heart shaped, star shaped, and circular shaped.

Owner:GABLE DEREK J

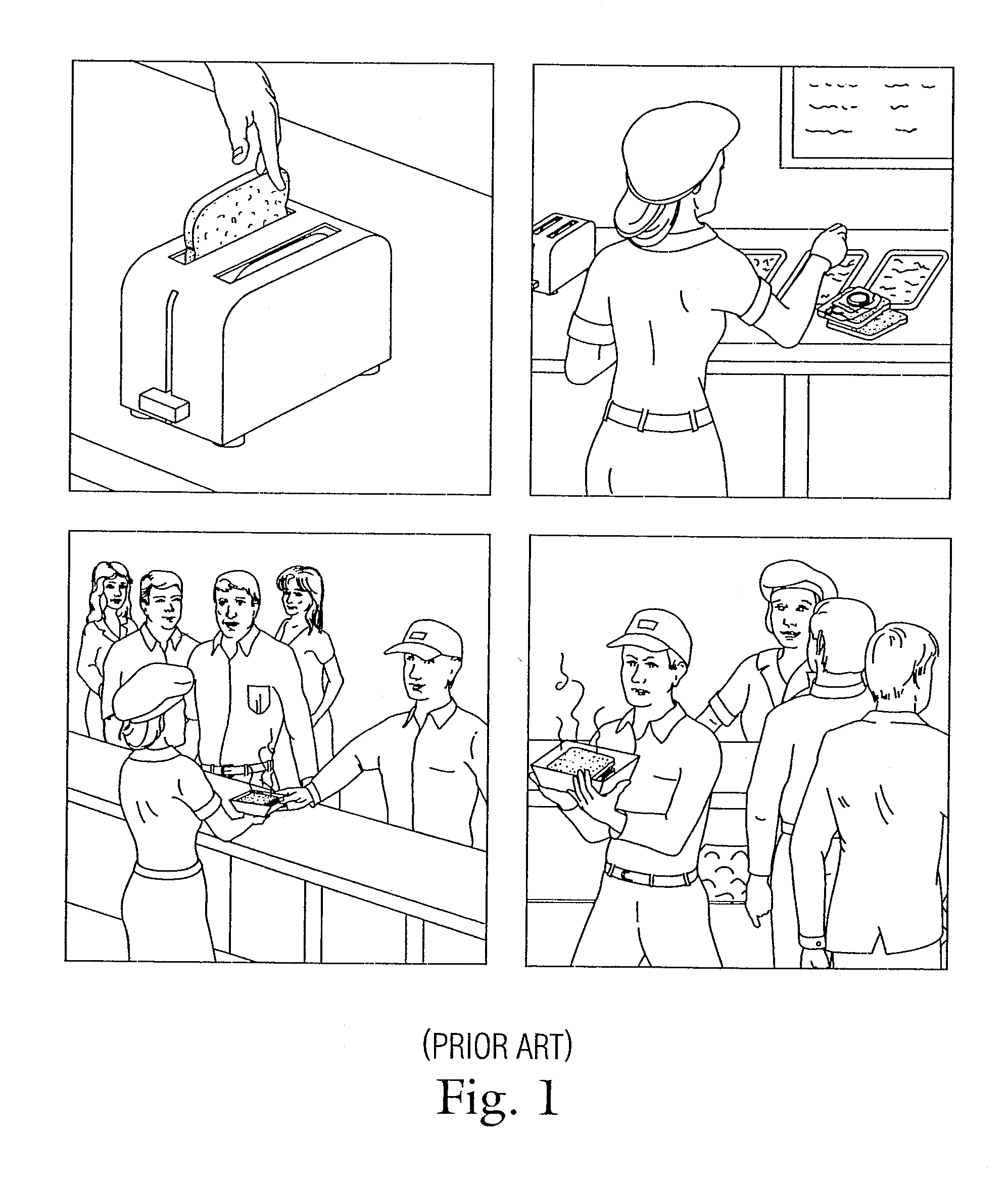

Apparatus and method of toasting sandwiches without heating the sandwich filling

InactiveUS20090324781A1Pleasing appearancePleasing feelDomestic stoves or rangesBaked article fillingMechanical engineeringRefrigerated temperature

Owner:SOUDRY JONATHAN N +2

Food forming and cooking apparatus and associated method

In a method for manufacturing a food product, a closed dough preform is formed having an arcuate portion that is at least partially hollow. The dough preform is cooked to form a comestible item having an internal chamber in the arcuate portion. The preform has an internal space that is closed off from communication with the ambient atmosphere so that the preform has no openings or holes in an external surface that communicate with the internal space or hollow interior of the preform. An apparatus for carrying out the method includes a transport mechanism moving the dough preforms from an assembly line to a heating device.

Owner:WILK PETER J

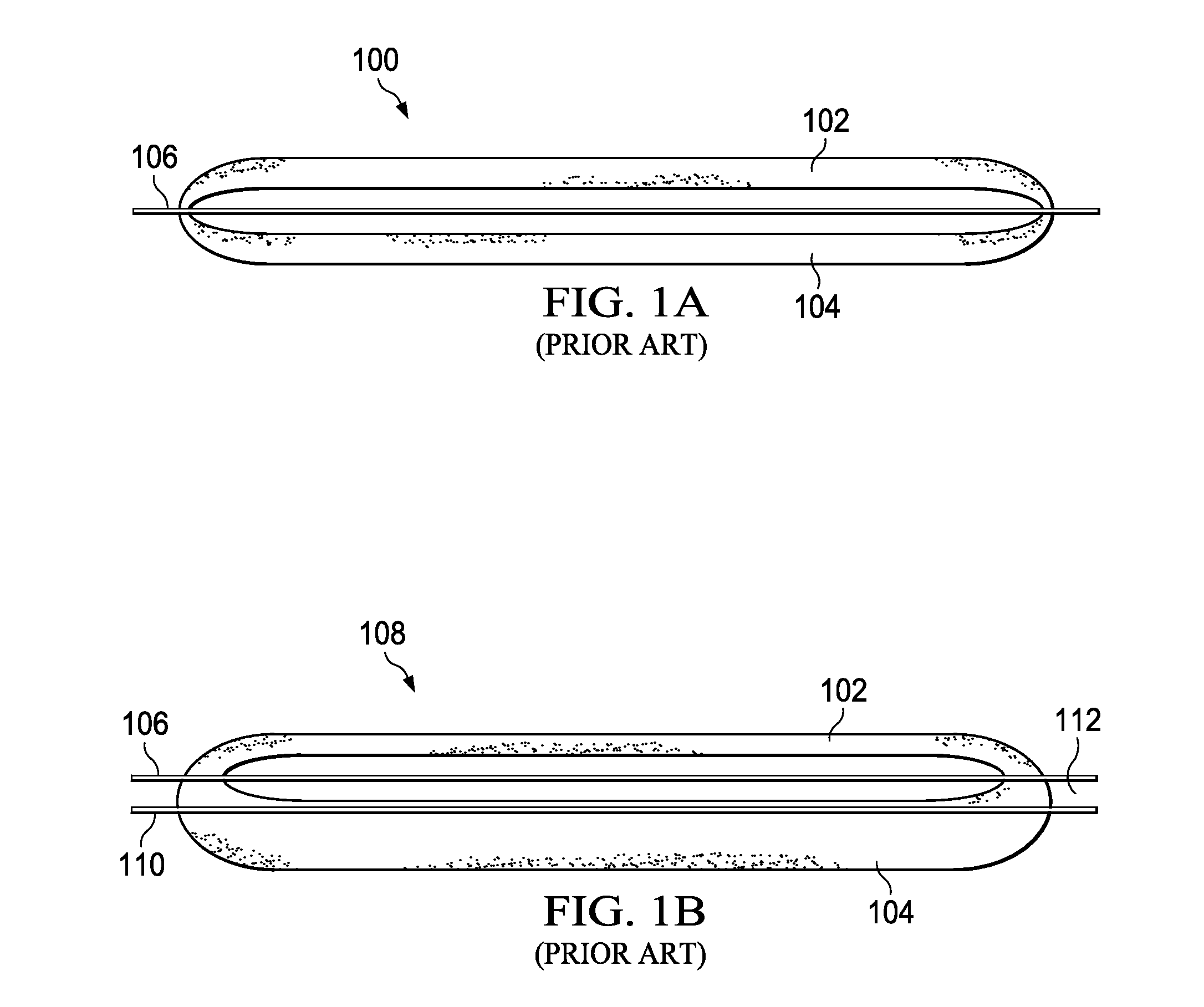

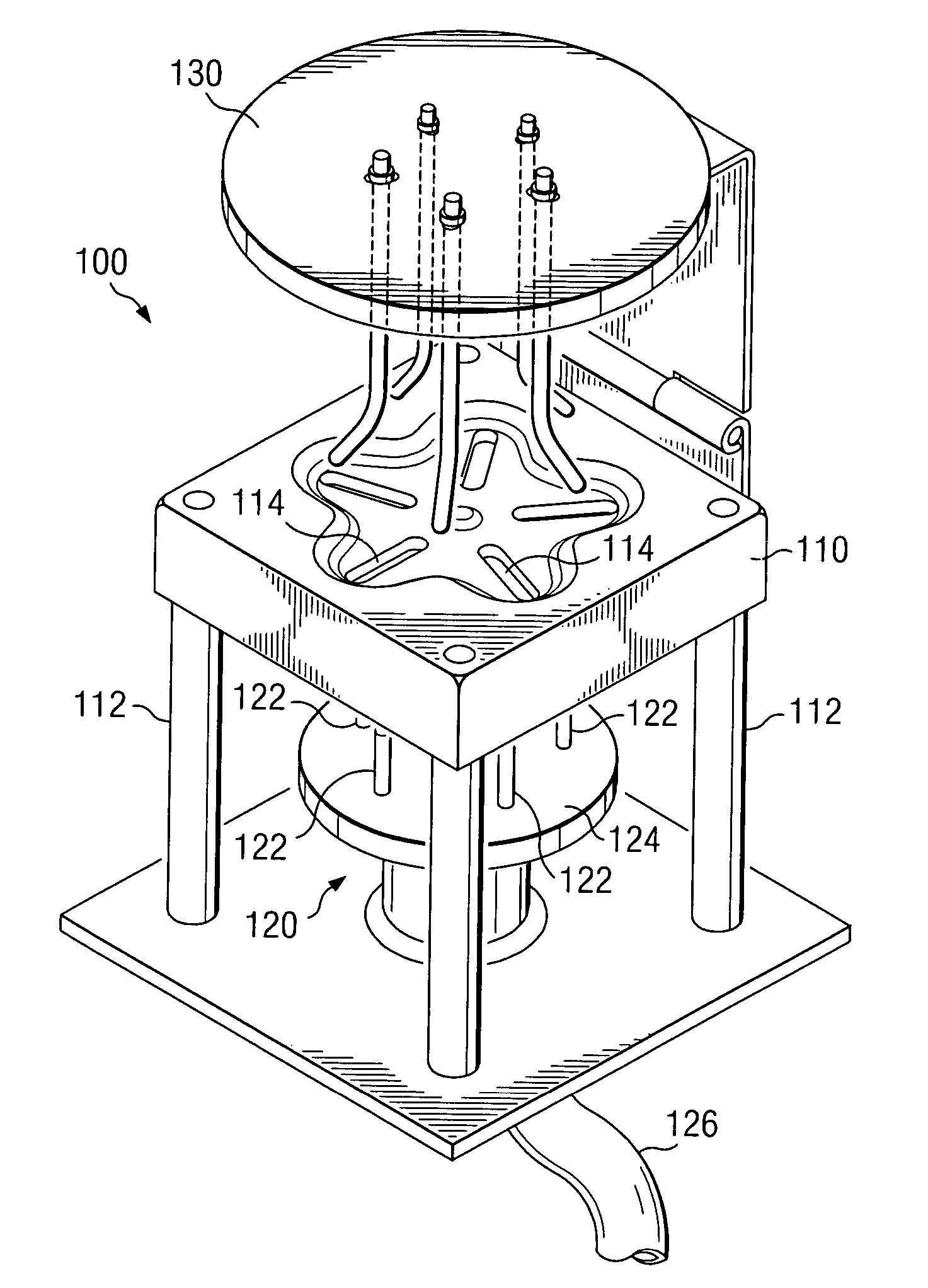

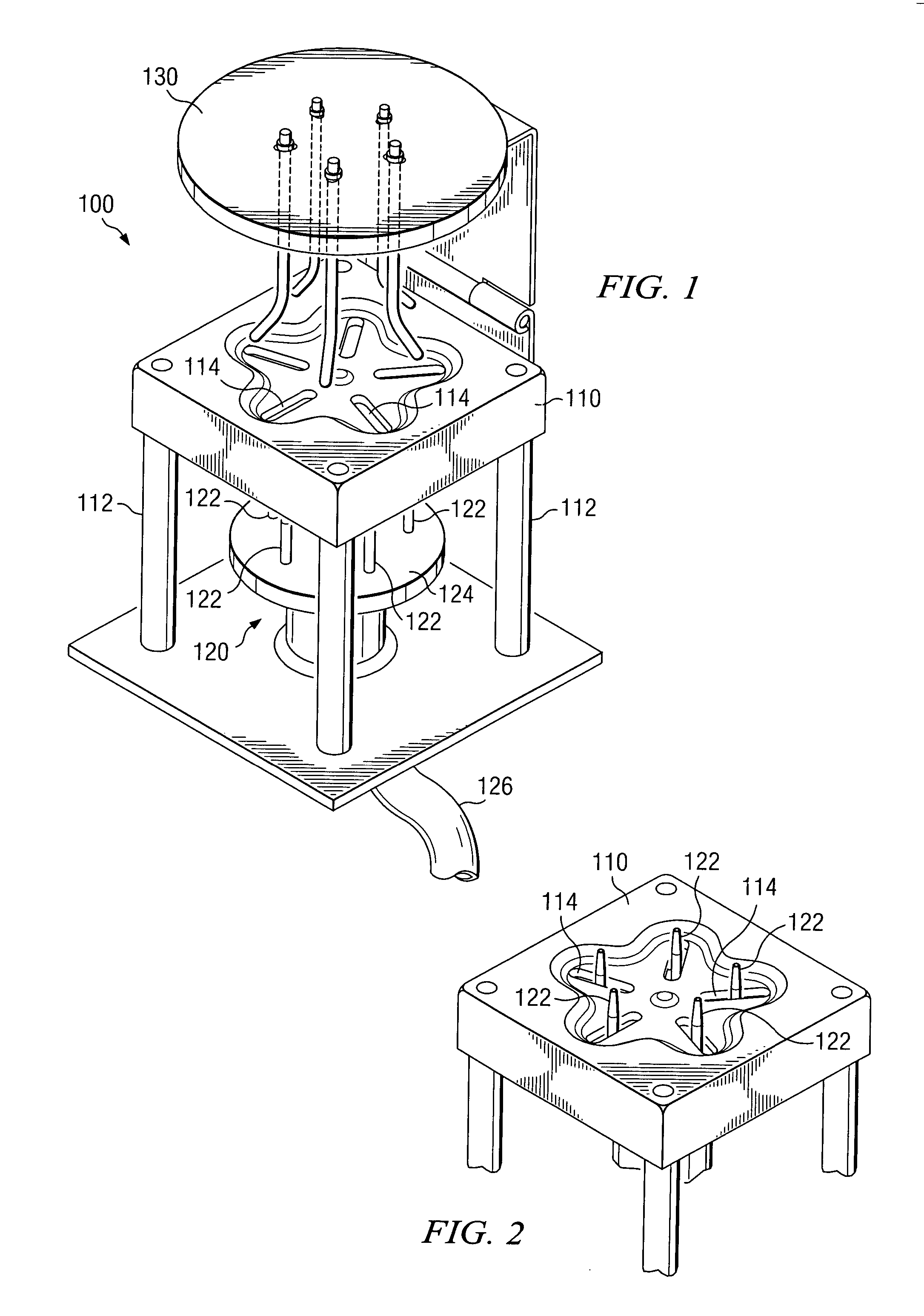

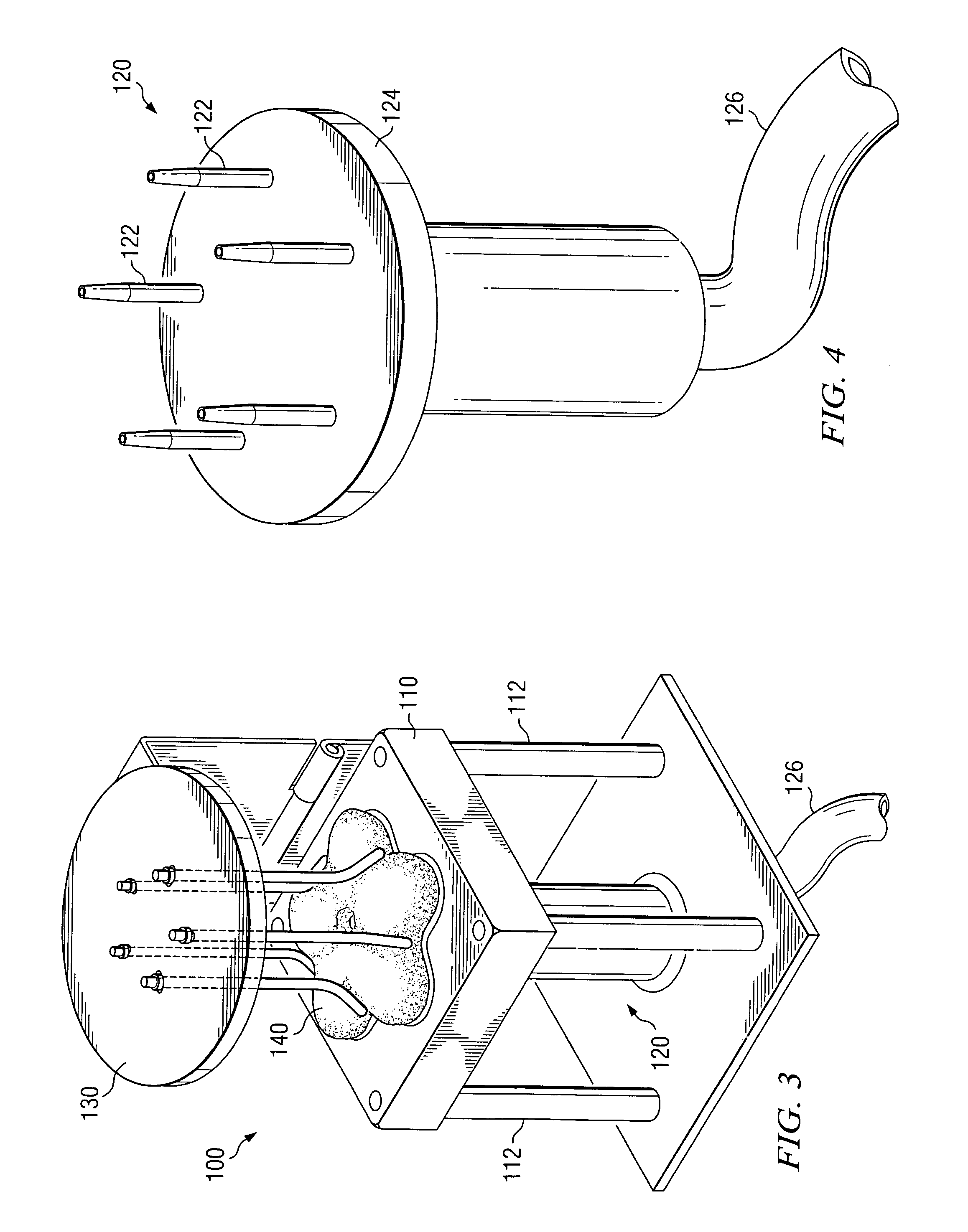

Automatic bottom-filling injection system

InactiveUS20050087079A1Efficient fillingGrain huskingGrain polishingMulti portBiomedical engineering

A multi-port, bottom-filling injection device having a filling head that splits a flow of filling among two or more spouts or needles. In accordance with one embodiment of the present invention, an injection device comprises a filling head having several spouts attached to a spout cap, a platen for holding a chambered food item, and a holding apparatus for securing the food item during filling. The injection device can simultaneously provide a food filling to each chamber of a multi-chambered food item without leaving unsightly fill holes in the top or side surfaces.

Owner:FRITO LAY NORTH AMERICA INC

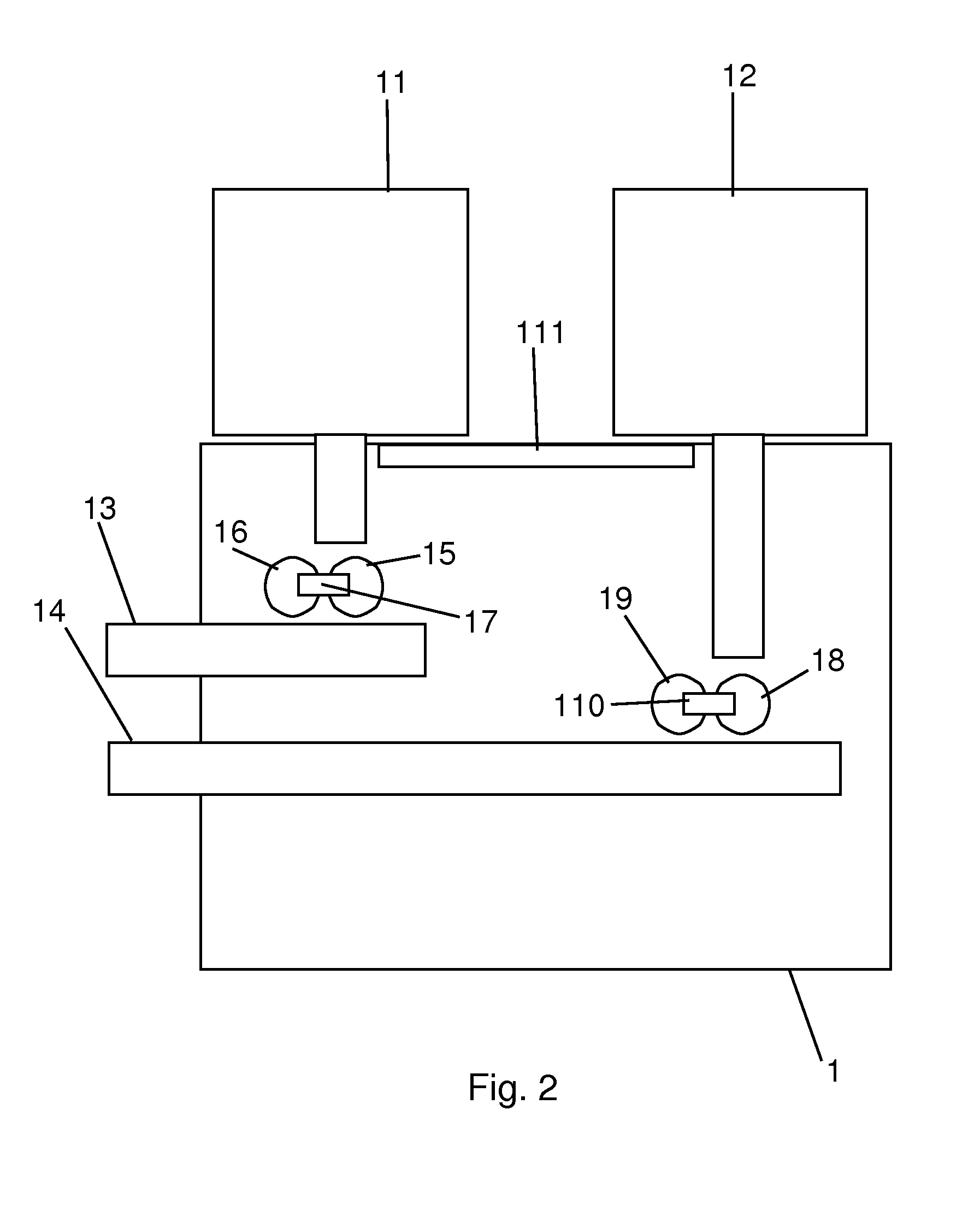

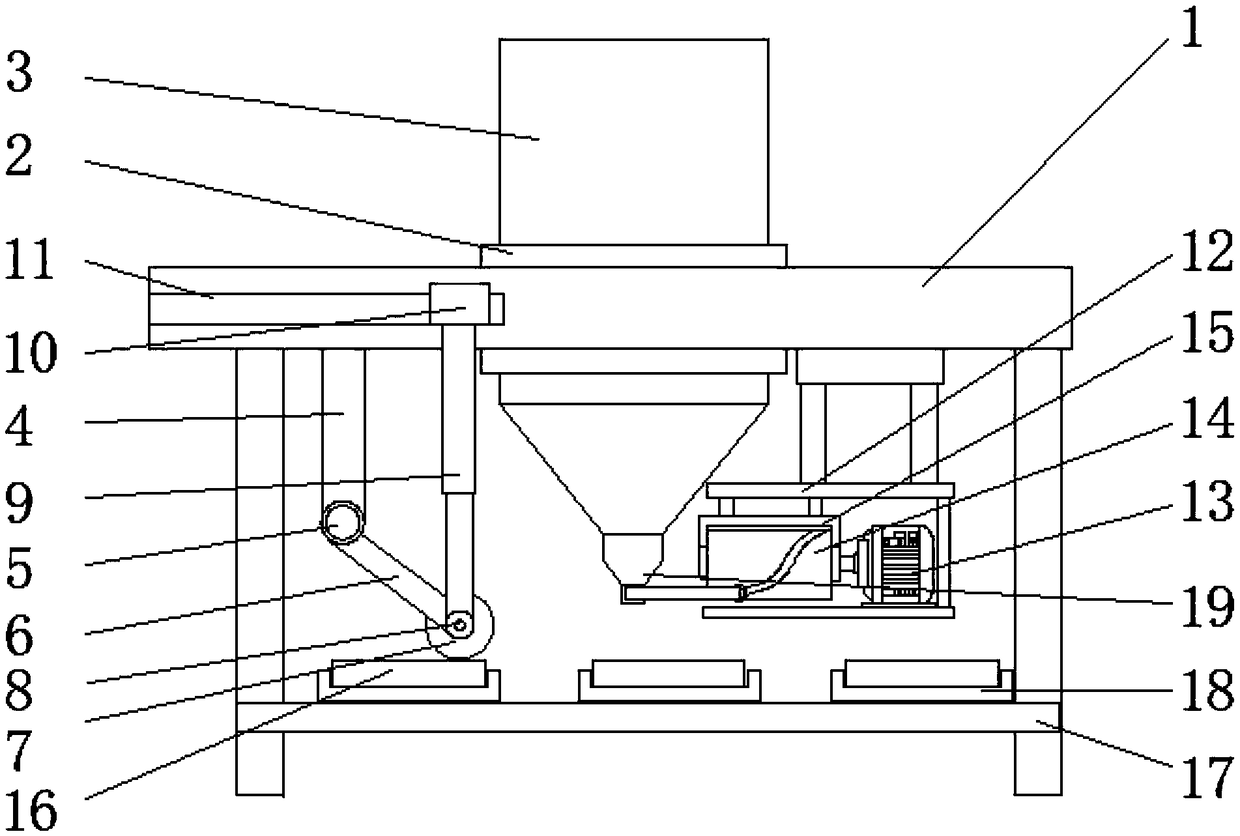

Food material processing equipment

ActiveCN111053091AImprove processing efficiencyRealize the processing effectBaked article fillingBaking ovenManufacturing efficiencyManufacturing engineering

The invention provides food material processing equipment which comprises a food material storage device used for storing a first food material and a second food material, wherein the food material storage device is provided with a first burdening port for discharging the first food material and a second burdening port for discharging the second food material; a baking mechanism with a baking gap,wherein the baking mechanism is at least partially arranged below the food material storage device, and the first batching opening is arranged to be corresponding to the baking gap; a frying and baking mechanism with a heating cavity, wherein the frying and baking mechanism is at least partially arranged below the food material storage device, and the second burdening port is arranged to be corresponding to the frying and baking mechanism; a conveying mechanism, wherein the baking mechanism and the frying and baking mechanism are arranged at intervals in the extending direction of the conveying mechanism, an output port of the baking gap and an output port of the heating cavity are both arranged to be corresponding to a conveying belt of the conveying mechanism, the first food material isloaded and conveyed to the position below the frying and baking mechanism through the conveying belt, so that the second food material is stacked on the first food material to form at least part of afood material to be packaged, and the problem that in the prior art, the hamburger food materials are low in manufacturing efficiency is solved.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

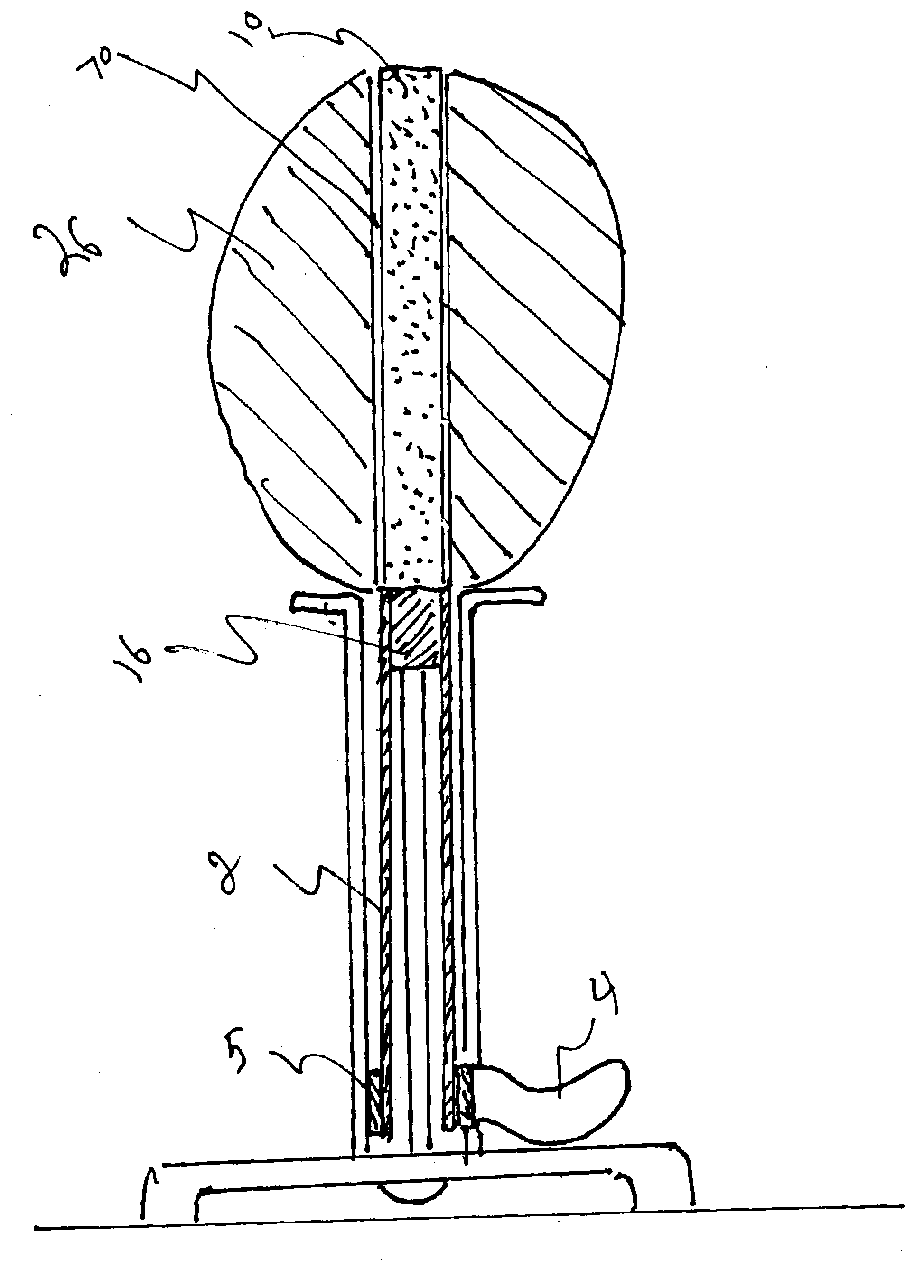

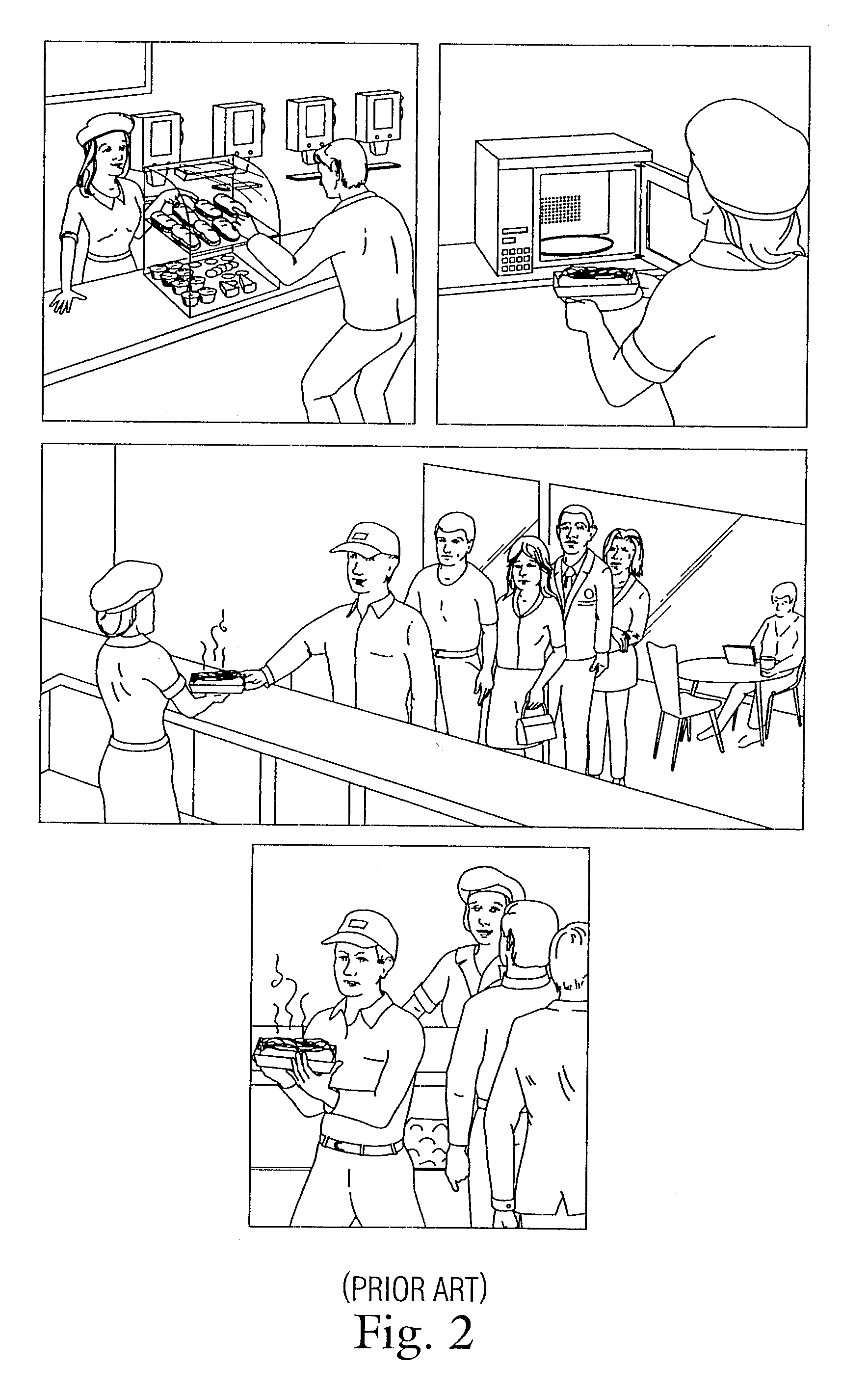

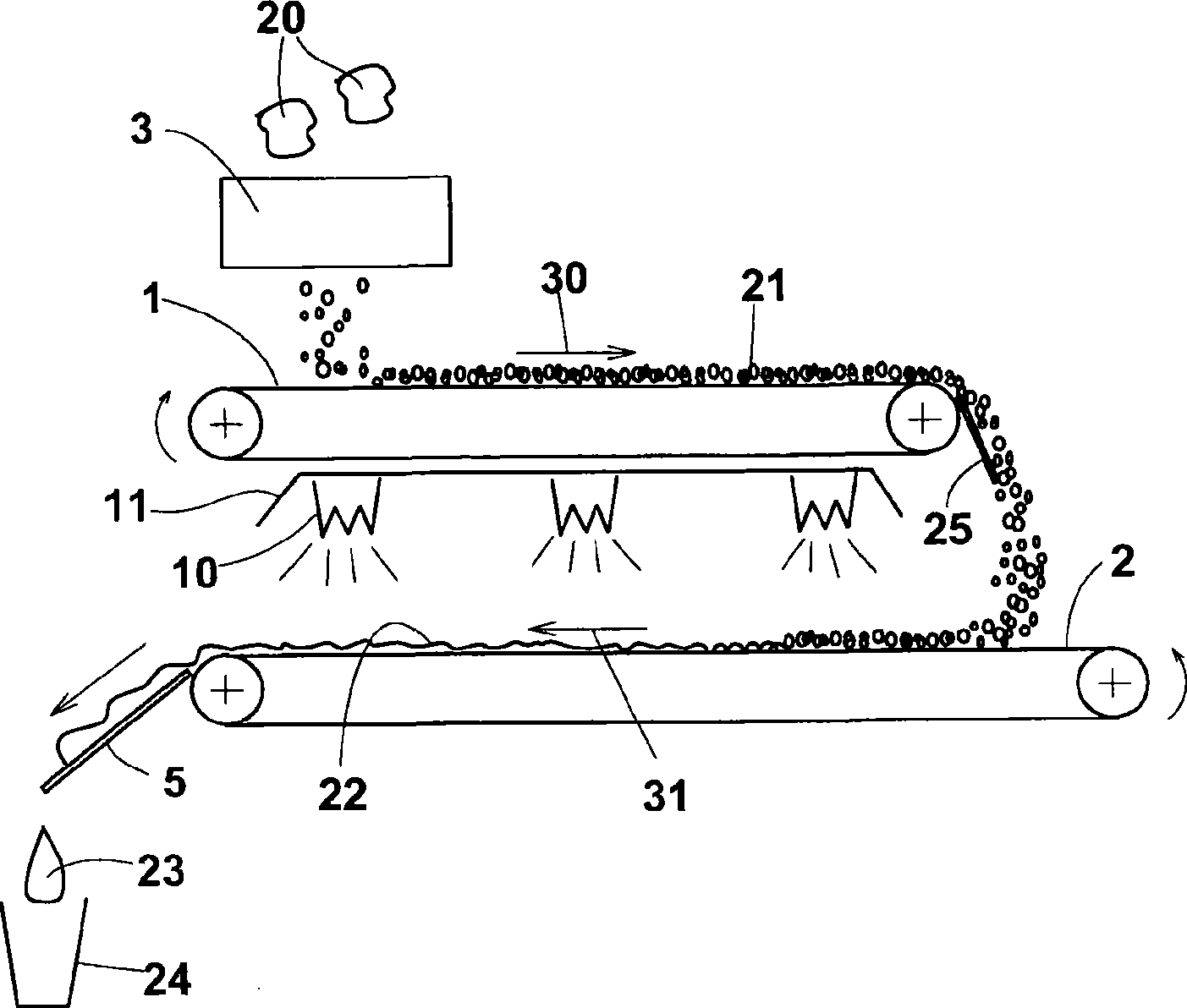

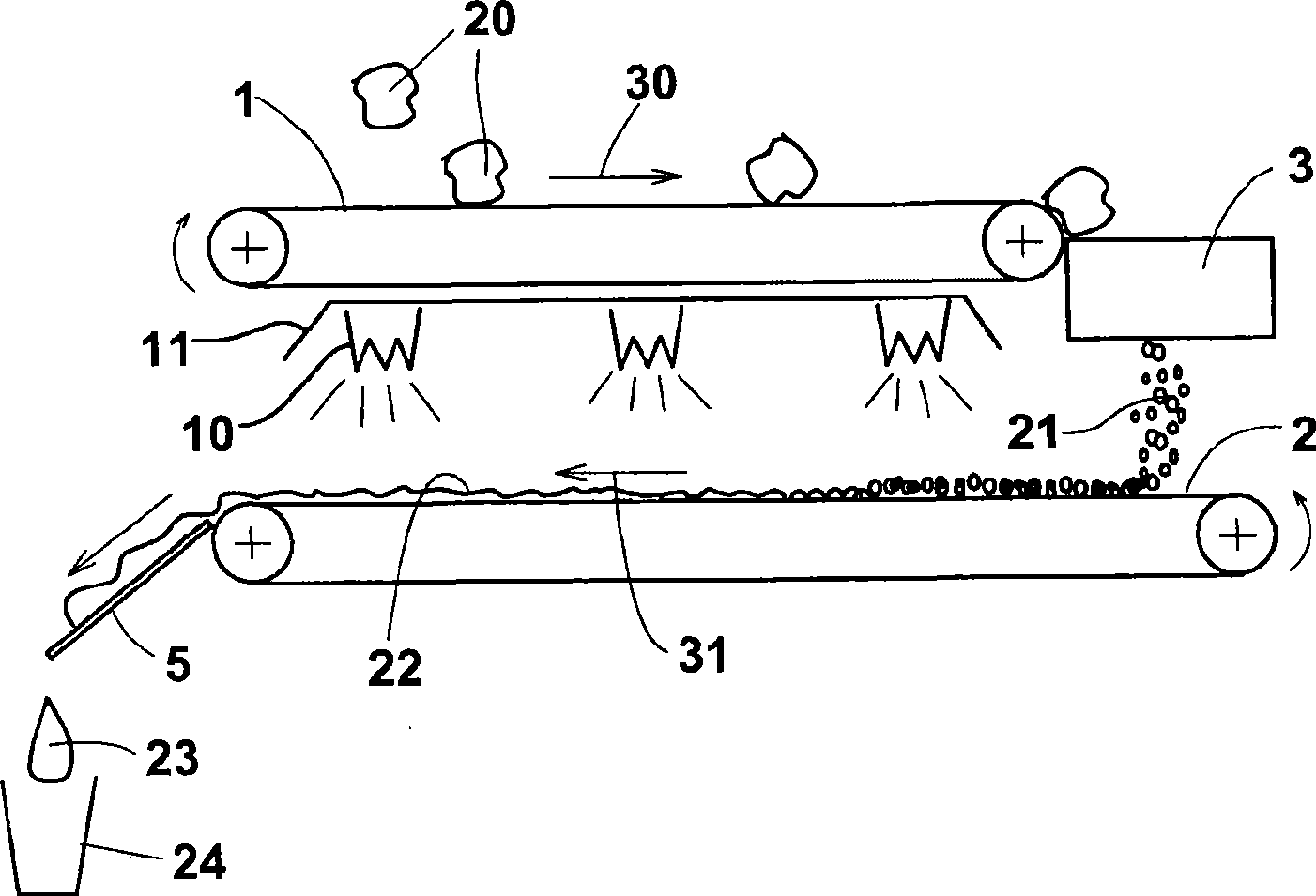

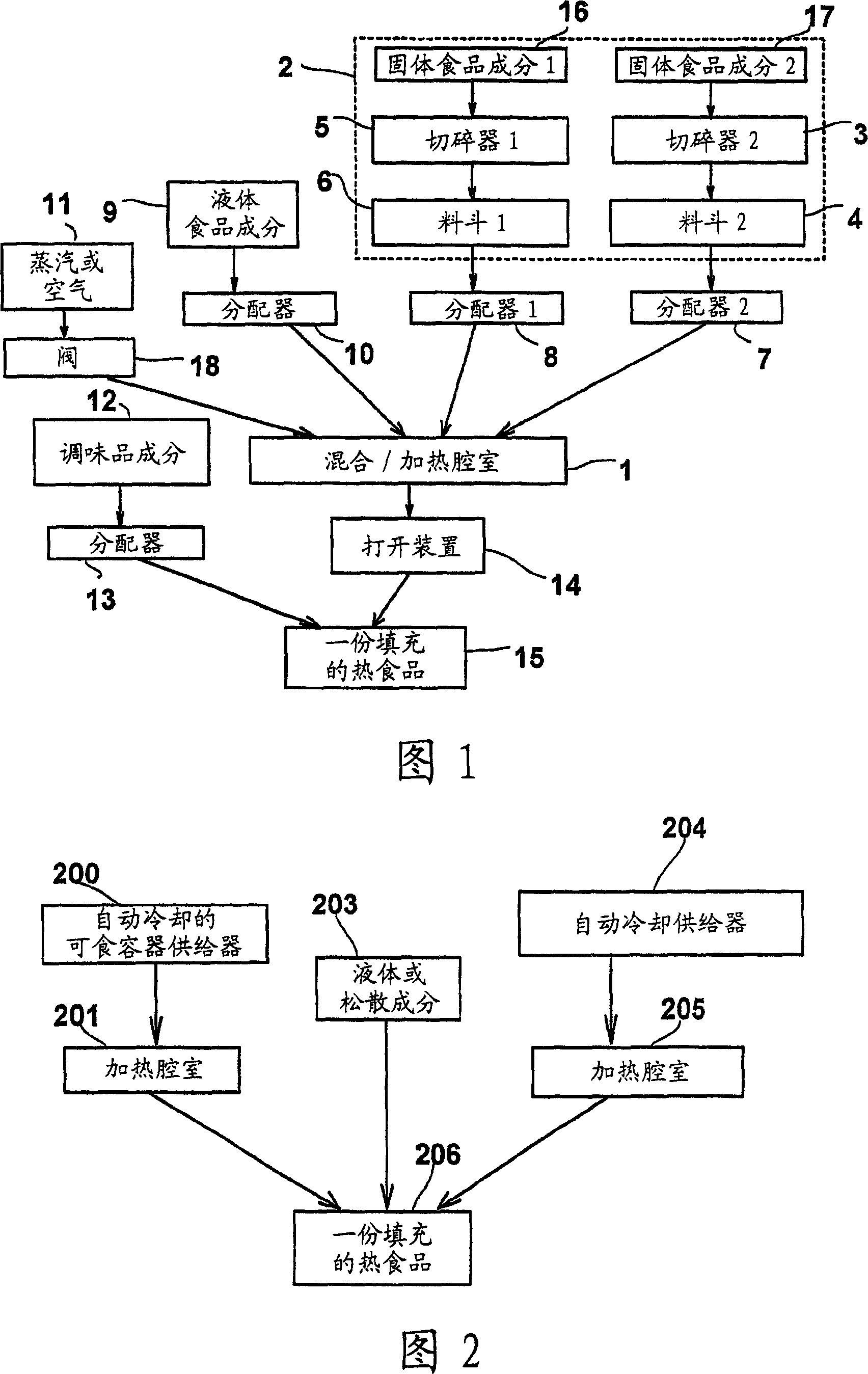

Improved warm food product distributor

An apparatus for supplying a single-dose portable express portion of a warm food product that can be eaten keeping it in hand, this warm food product having a stiff edible container (24) and a stuffing with at least one food component selected from the group comprised of : dressing of a pizza, in particular, comprising cheese. The apparatus comprises a conveyor belt (2) exposed to irradiation by at least one heat source (10), and optionally an auxiliary conveyor belt (1). The heated component (23) comprising cheese, is brought from the conveyor belt (2) towards an outlet where it falls in the edible container (24).

Owner:STARSTATUS TRADING INT LDA

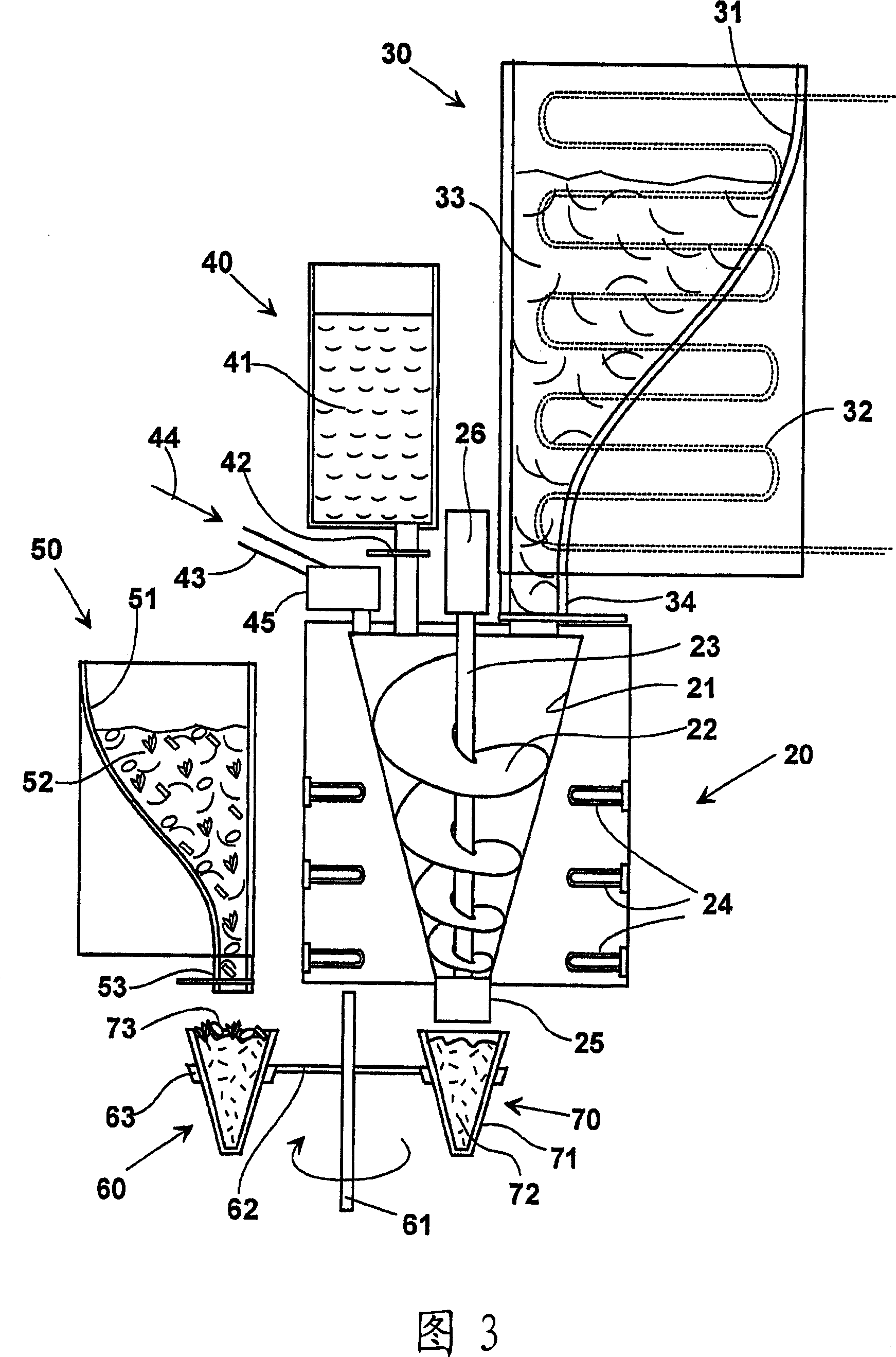

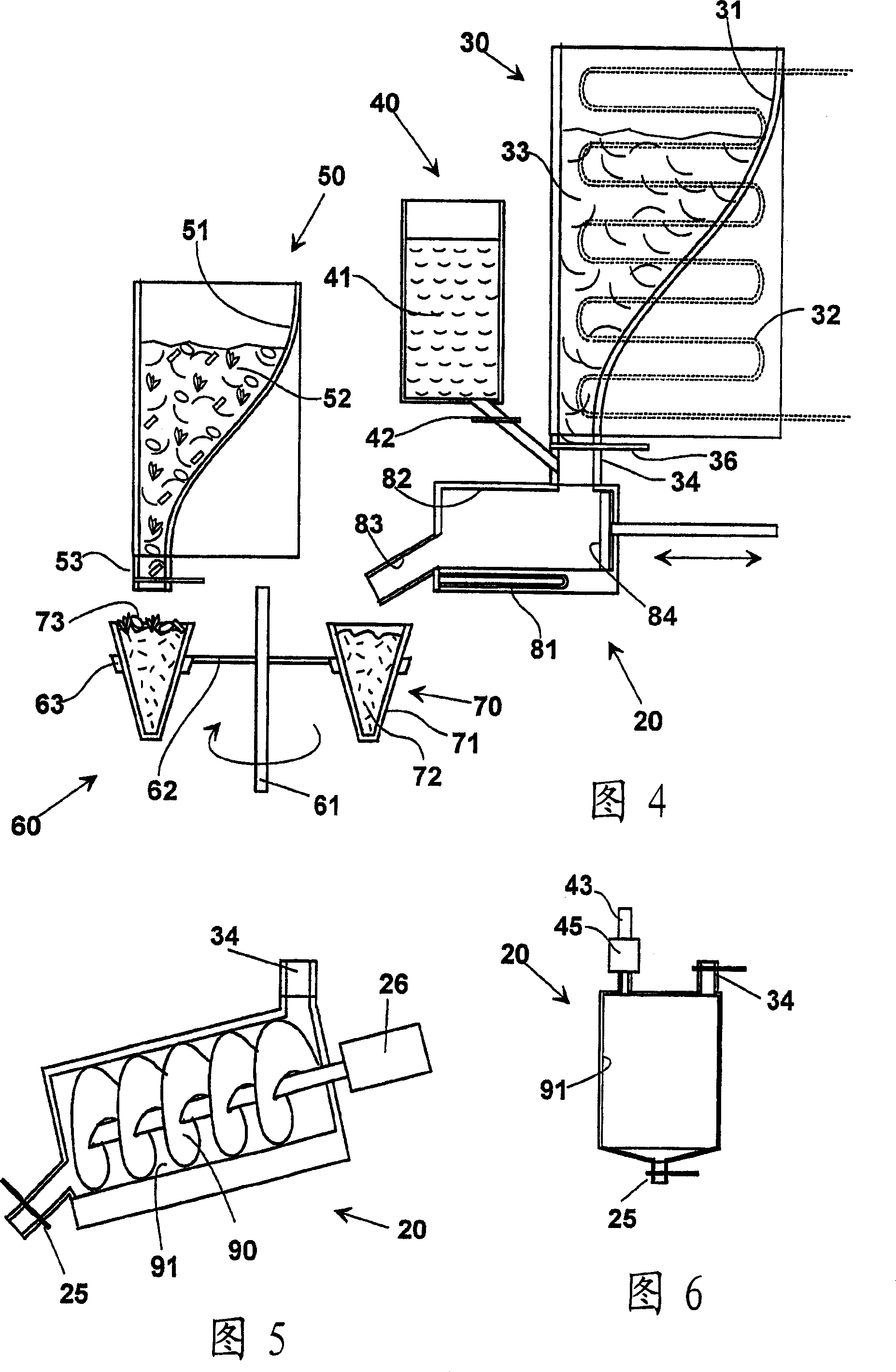

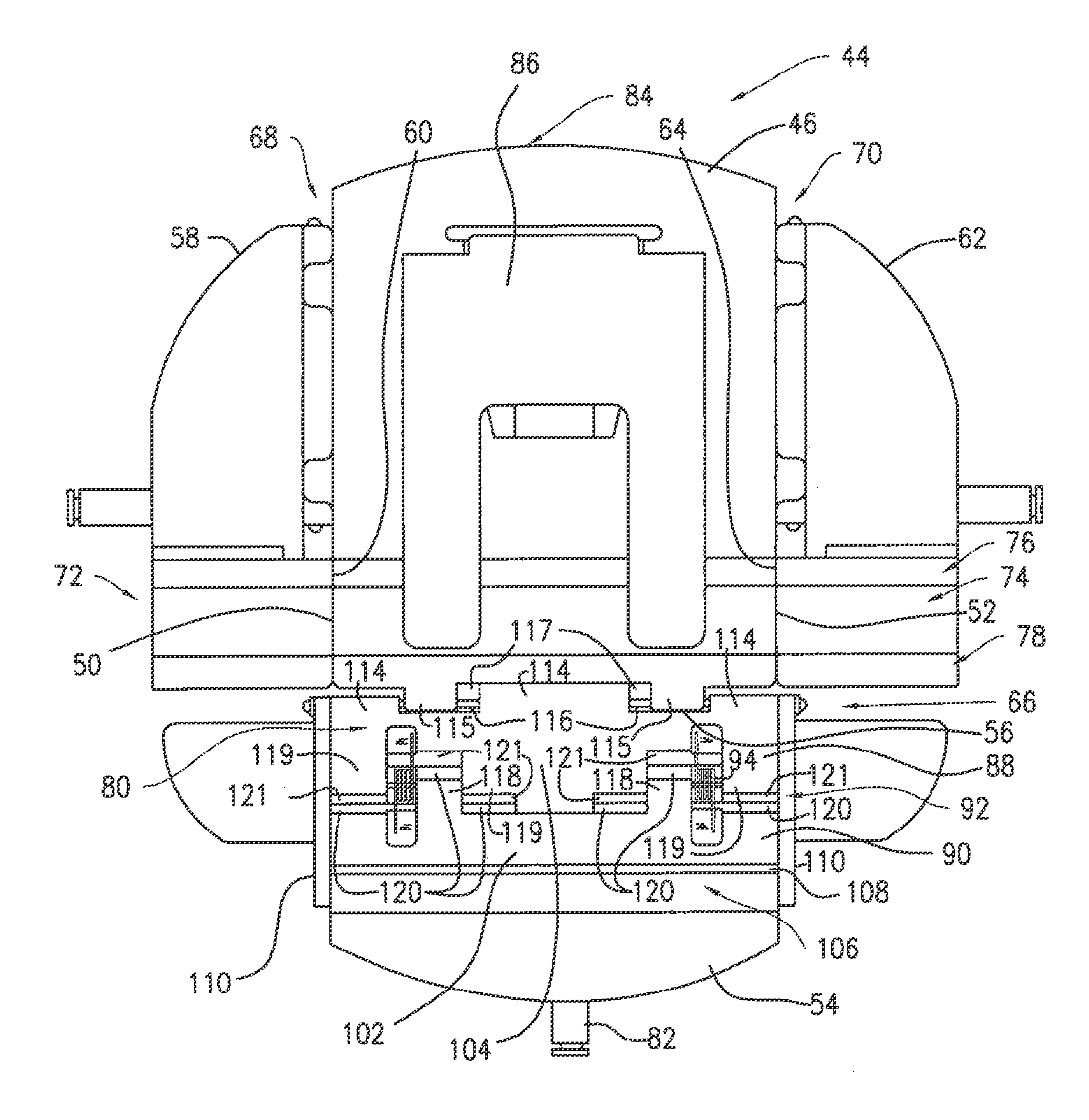

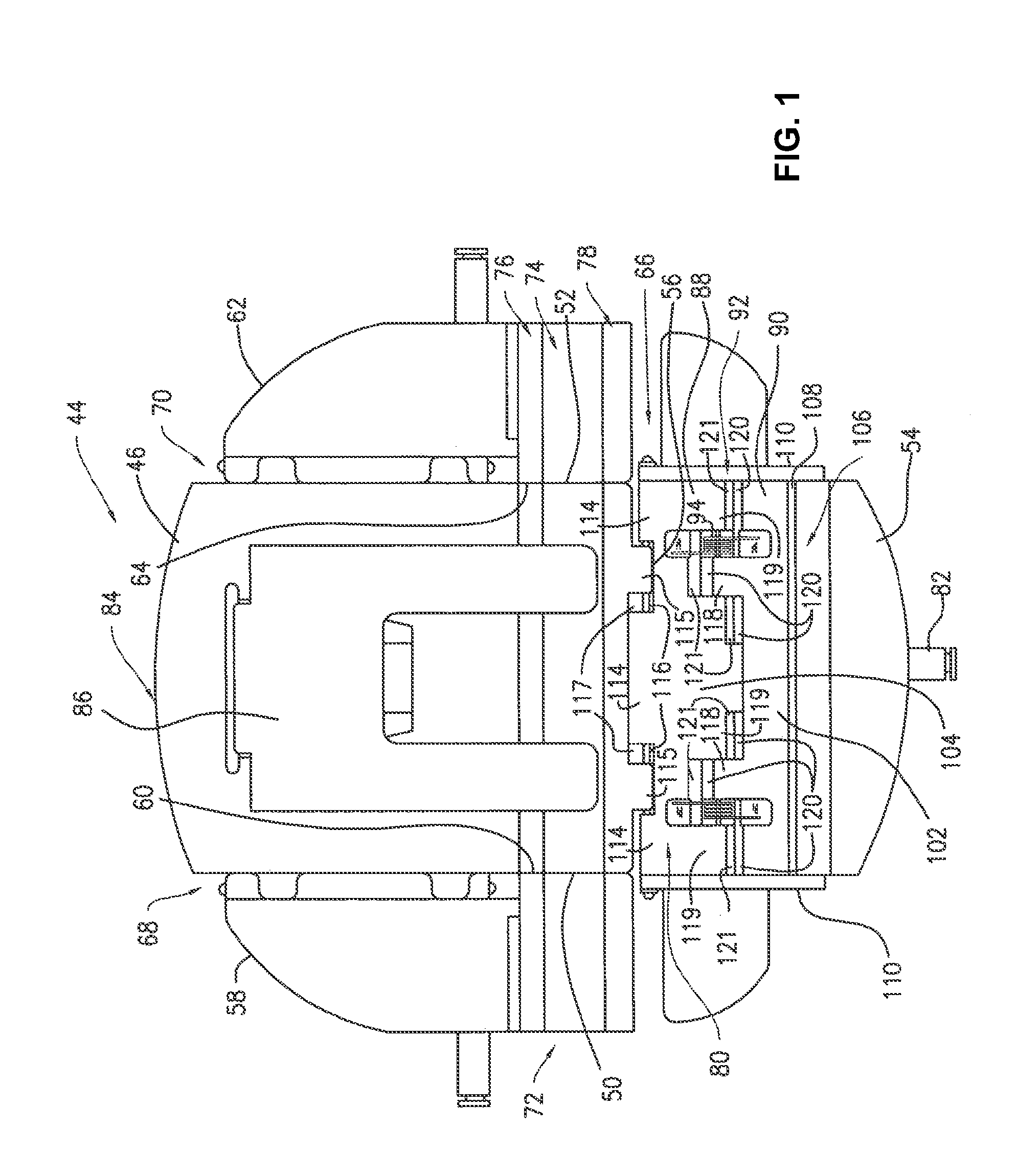

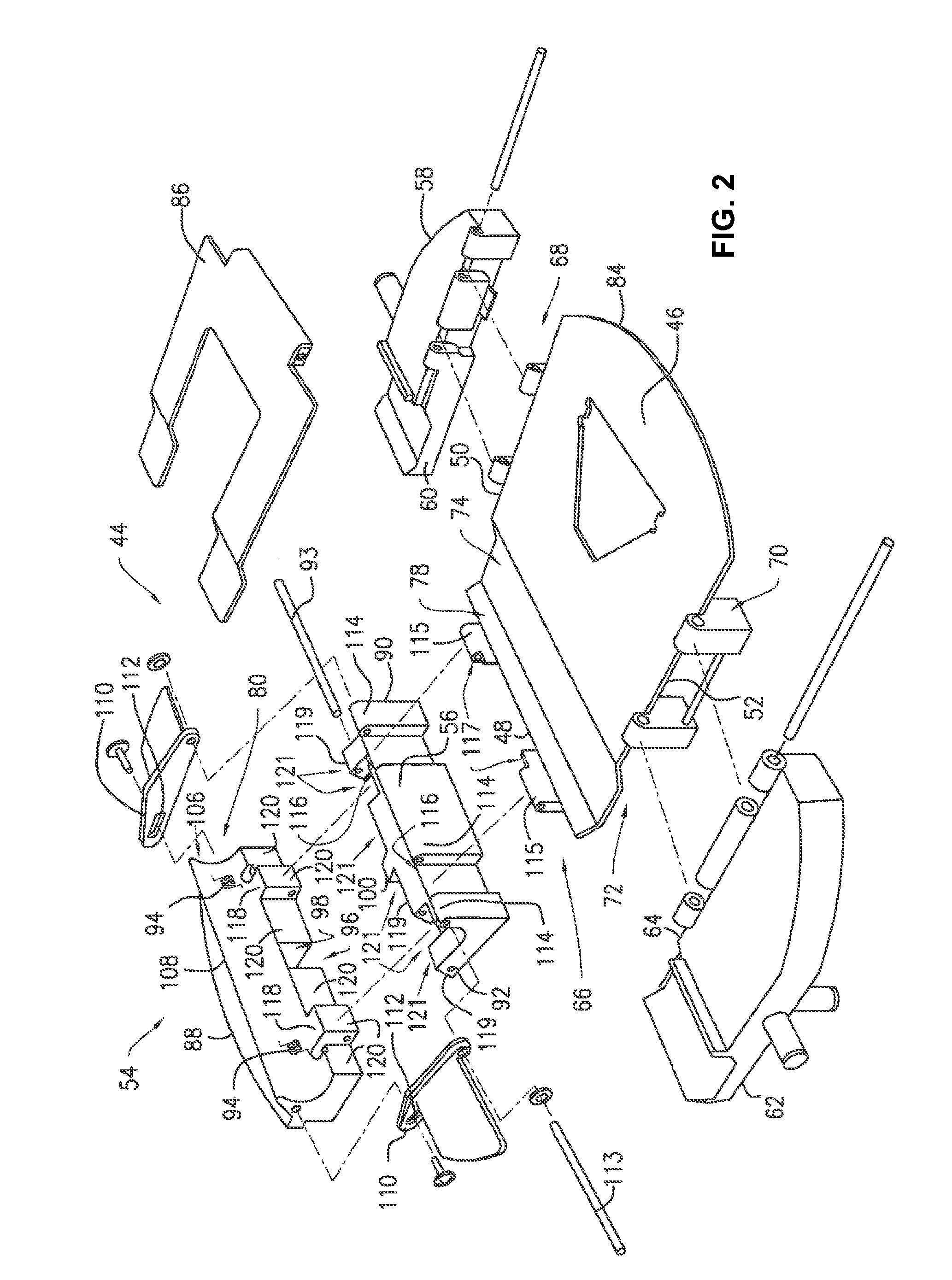

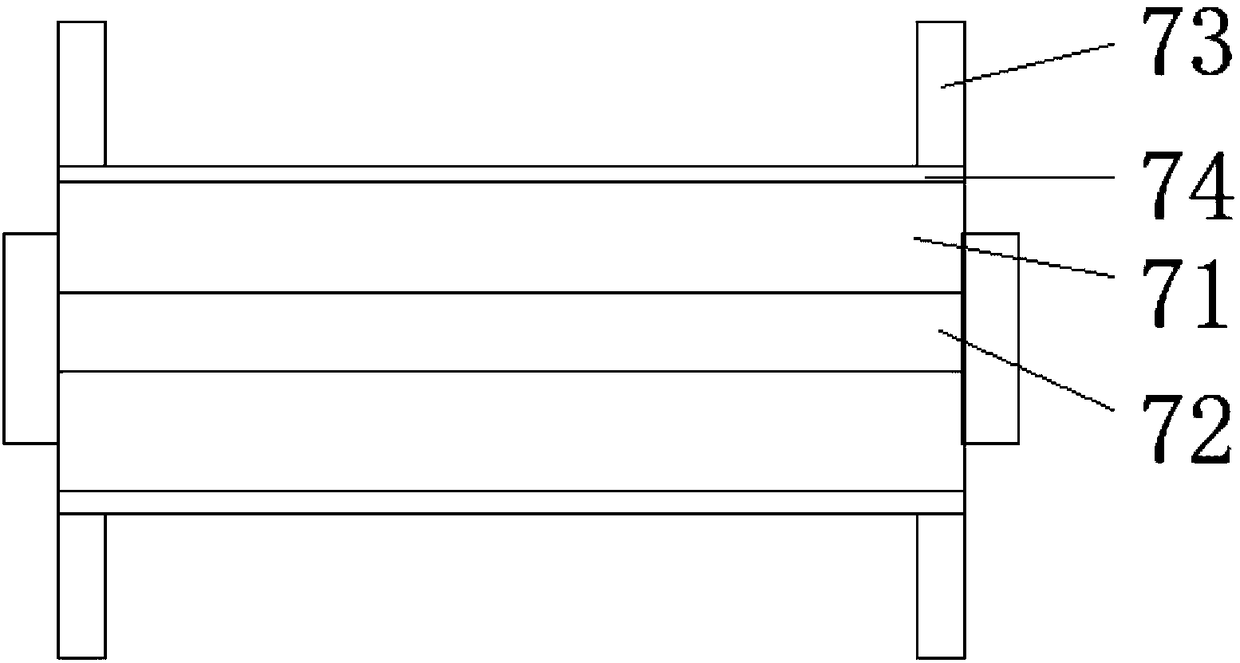

Warm food product distributor

InactiveCN101072507ABaked article fillingLiquid transferring devicesReady to eatElectrical resistance and conductance

The present invention relates to an apparatus capable of supplying a portion of warm food product, consisting at least of one food component, for example selected among typical components of the dressing of a pizza, and used for filling an edible container, for example a wafer, creating a ready-to-eat single-dose warm food product. The apparatus provides a heating chamber (20) comprising a recess having an inner heated surface (82), in which a piston (84) slides sweeping the surface (82) and pushing towards an outlet (83) at least one food component (33) heated in said heating chamber (20) and coming from a magazine (30). The magazine (30) may be refrigerated (32), and a liquid food component (40) may be added. The heating chamber (20) is heated by an electrical resistance (81). The apparatus, furthermore, comprises a system (50) for applying a dressing on the upper surface of the product and a carousel (60) for positioning automatically an edible container (71) in different operative stations.

Owner:STARSTATUS TRADING INT LDA

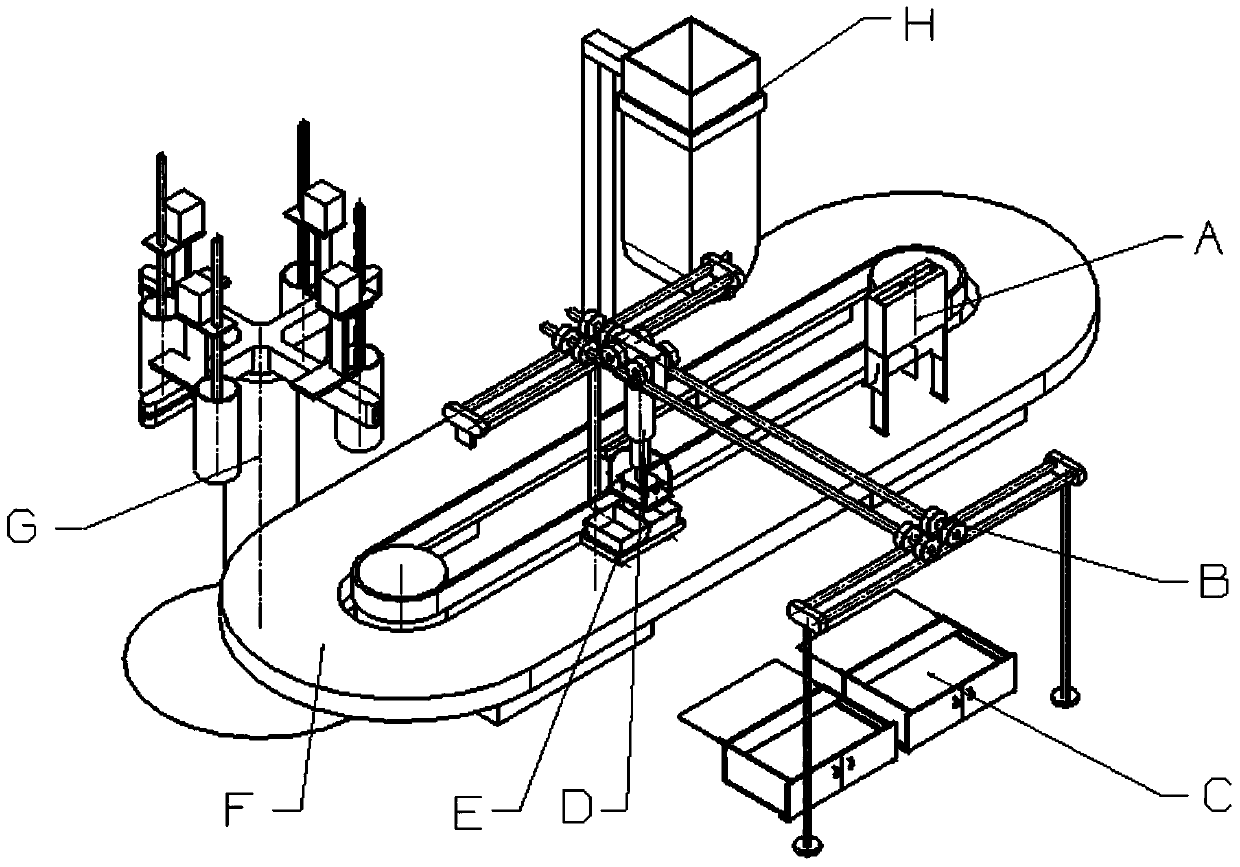

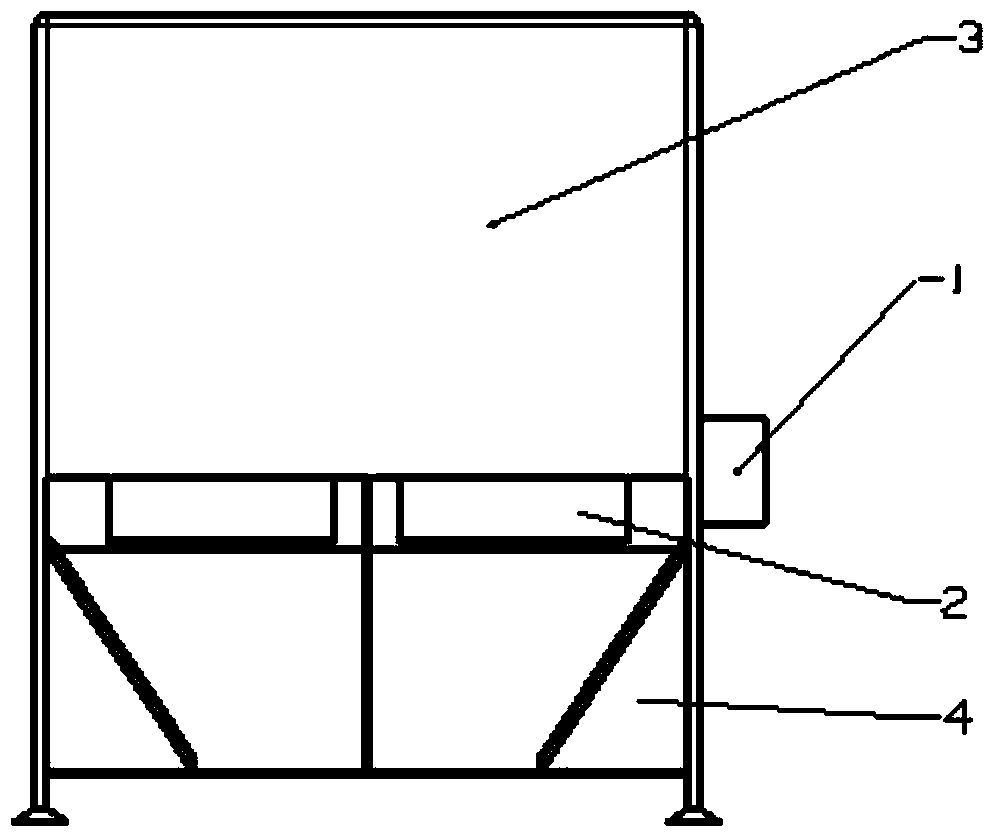

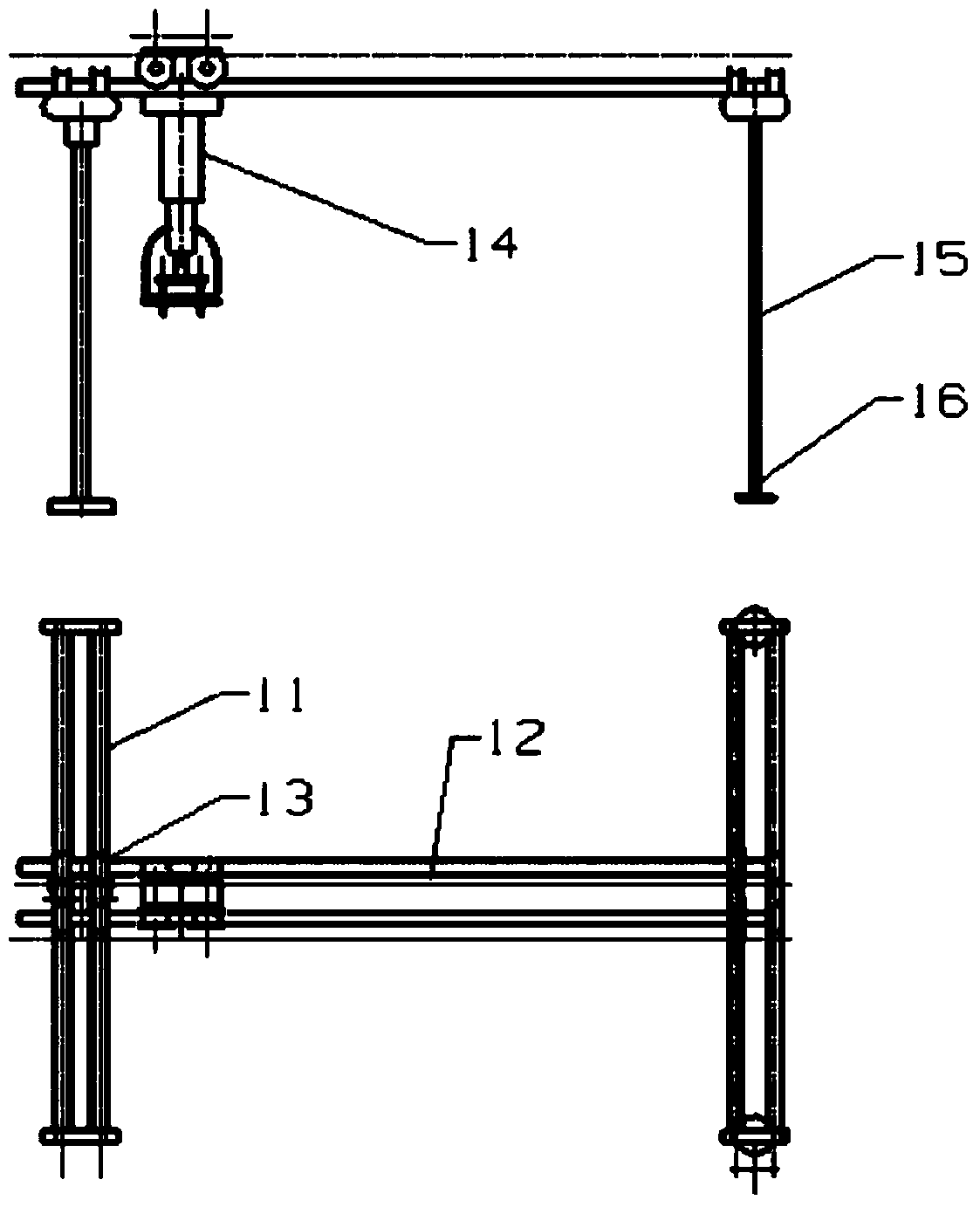

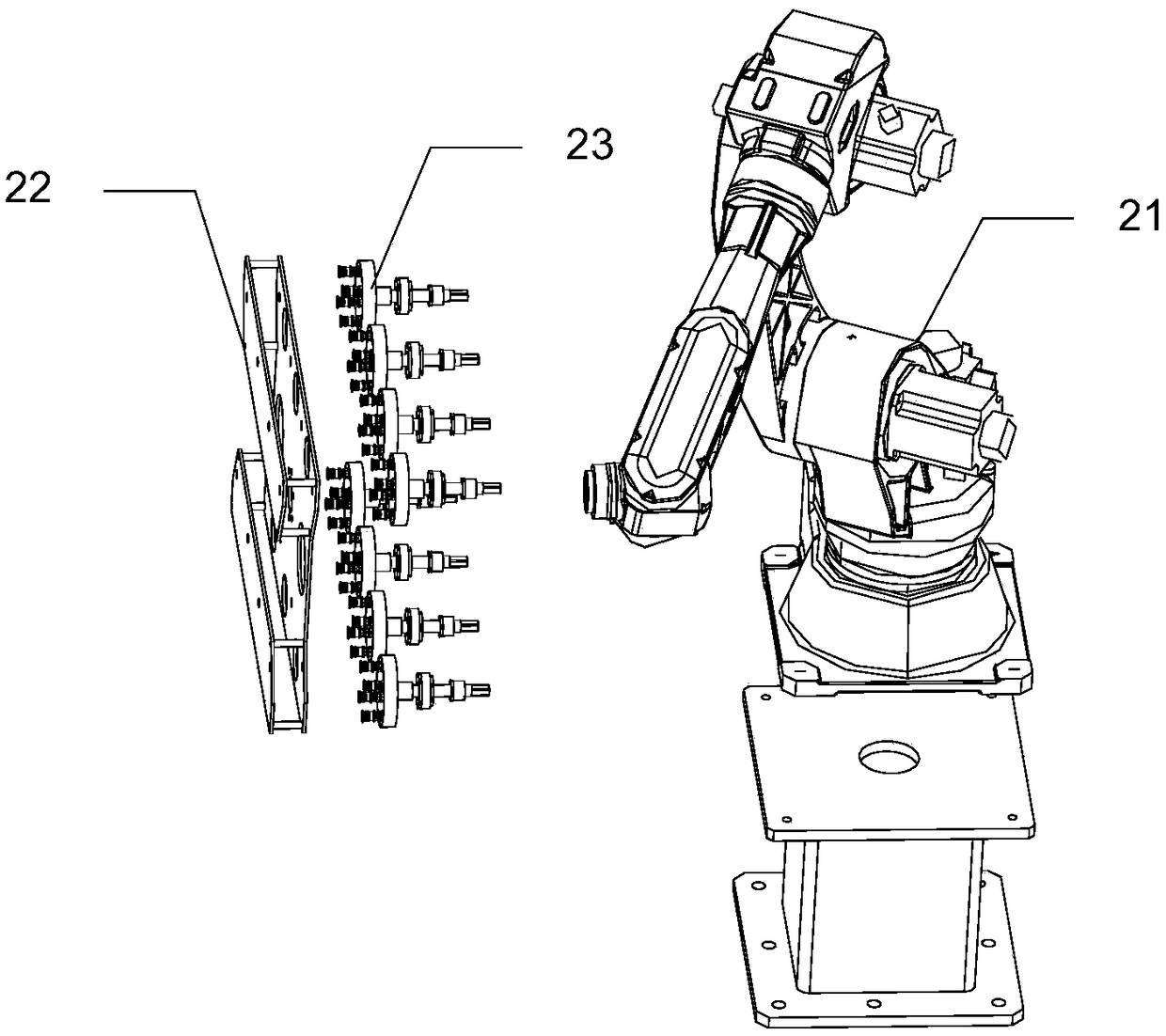

Automatic hamburger making machine

InactiveCN104172203AInsulation in timeConvenient detachable structureBaked article fillingBakery productsMeat burgerTransmission belt

The invention discloses an automatic hamburger making machine which comprises an oven mechanism, an overhead traveling crane system, an object storage cabinet, a manipulator, a tray trolley, a rotary assembly line, a crossed rotary sauce gun mechanism, an automatic vegetable adding mechanism and a control system, wherein the overhead traveling crane system comprises transverse beams and vertical beams which are arranged above the rotary assembly line; the object storage cabinet is placed at the lower parts of the transverse beams on one side of the overhead traveling crane system and is close to the rotary assembly line; the rotary assembly line is provided with a workbench, a main motor, a rotating shaft and a transmission belt; the manipulator moves on the vertical beams of the overhead traveling crane system through rollers; the tray trolley mechanism is connected with the transmission belt of the rotary assembly line through a connection shaft and rotates on the workbench under the driving of the belt; the crossed rotary sauce gun mechanism and the automatic vegetable adding mechanism are arranged on the side surface of the rotary assembly line; the oven mechanism is arranged on the workbench. The automatic hamburger making machine can automatically realize steps of baking bread and adding meat, sauce and lettuce on the rotary assembly line.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Bun machine

InactiveUS20160113291A1Easily brokenKeep longBaked article fillingDough-sheeters/rolling-machines/rolling-pinsEngineeringMechanical engineering

A bun machine includes: a pressing device for forming a first layer and a second layer; an overlaying device for forming a bun crust with the first layer and the second layer; a main transporter, wherein a first end of the main transporter is connected to the overlaying device for transporting the bun crust; a feeding device provided aside the main transporter, comprising: a filling tank for storing and inputting fillings into the feeding device; and a feeding unit feeding the fillings onto the bun crust; a wrapping device provided above the main transporter, wherein the wrapping device wraps the fillings with the bun crust for forming a filled roll; and a separating device connected to a second end of the main transporter, wherein the separating device squeezes the filled roll for separating and sealing the filled roll, so as to produce buns.

Owner:AURNISH ENTERPRISES

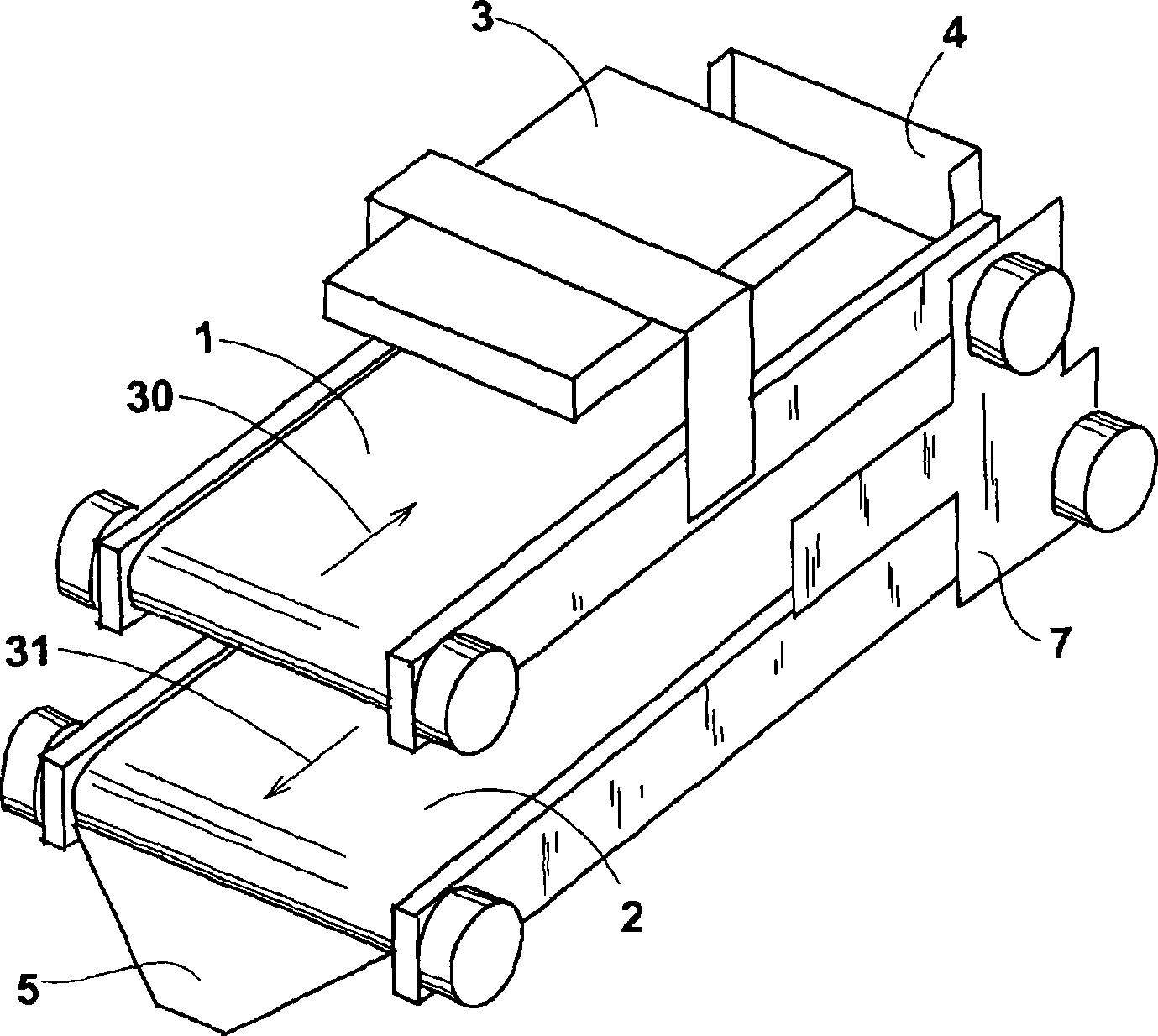

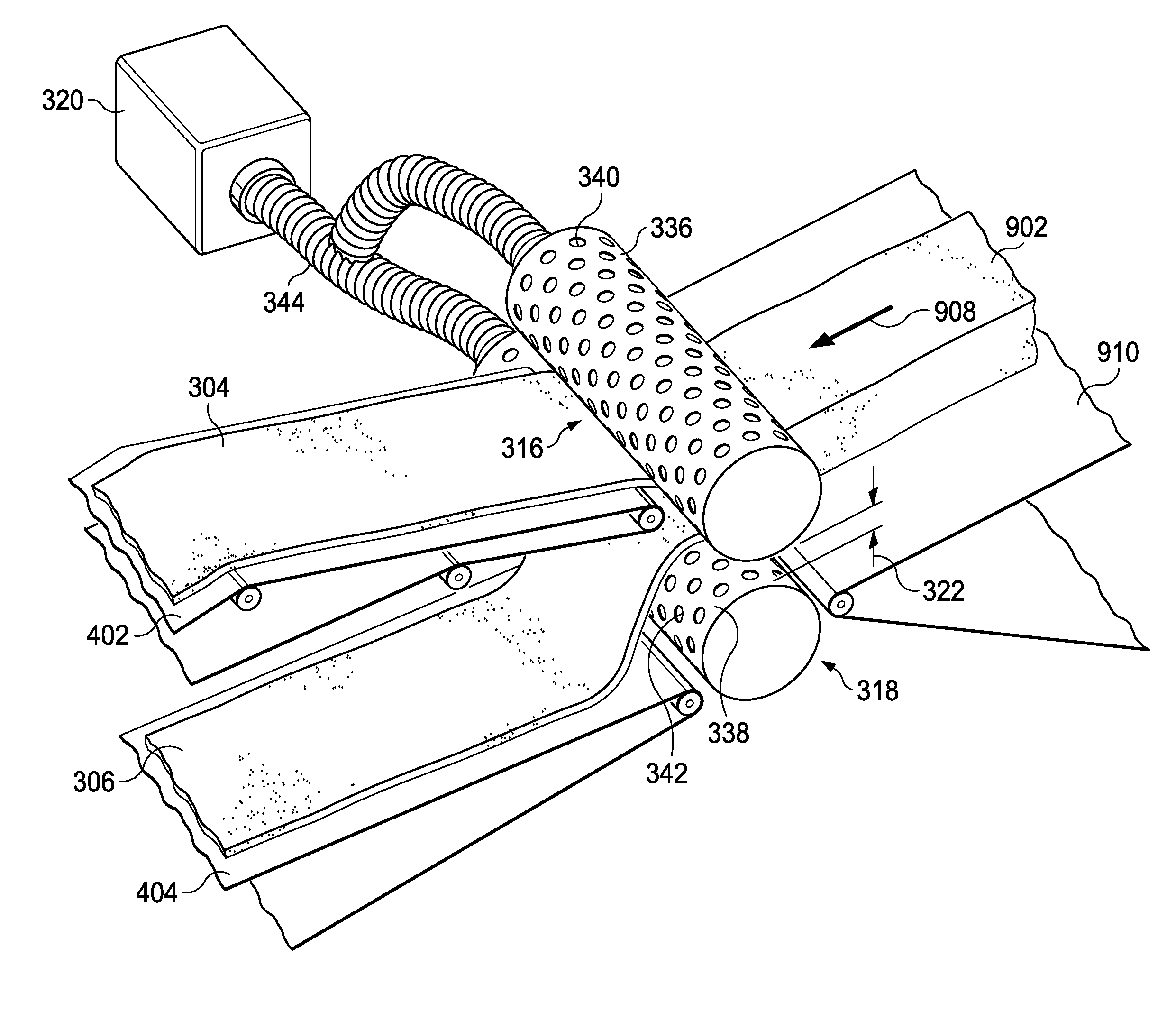

Continuous process and apparatus for making a pita chip

InactiveUS20150150268A1Eliminates and reduces disadvantageDough treatmentBaked article fillingLiquid jetEngineering

A method and apparatus for forming chips, for example, pita chips, from a continuous mass of dough. In a first aspect, the apparatus comprises a first conveyor, a second conveyor, and a first trimmer. The first conveyor and the second conveyor are spaced apart a distance to form a gap. The first trimmer, which can comprise a liquid jet nozzle, is positioned above the gap. In a second aspect, the method comprises using a first conveyor to convey a continuous mass of dough to a first trimmer positioned over a gap between the first conveyor and a second conveyor. The method also comprises using the first trimmer to longitudinally trim a first portion of the continuous mass of dough to form thinner strips of the continuous mass of dough. The thinner strips can be integral with the first portion.

Owner:FRITO LAY NORTH AMERICA INC

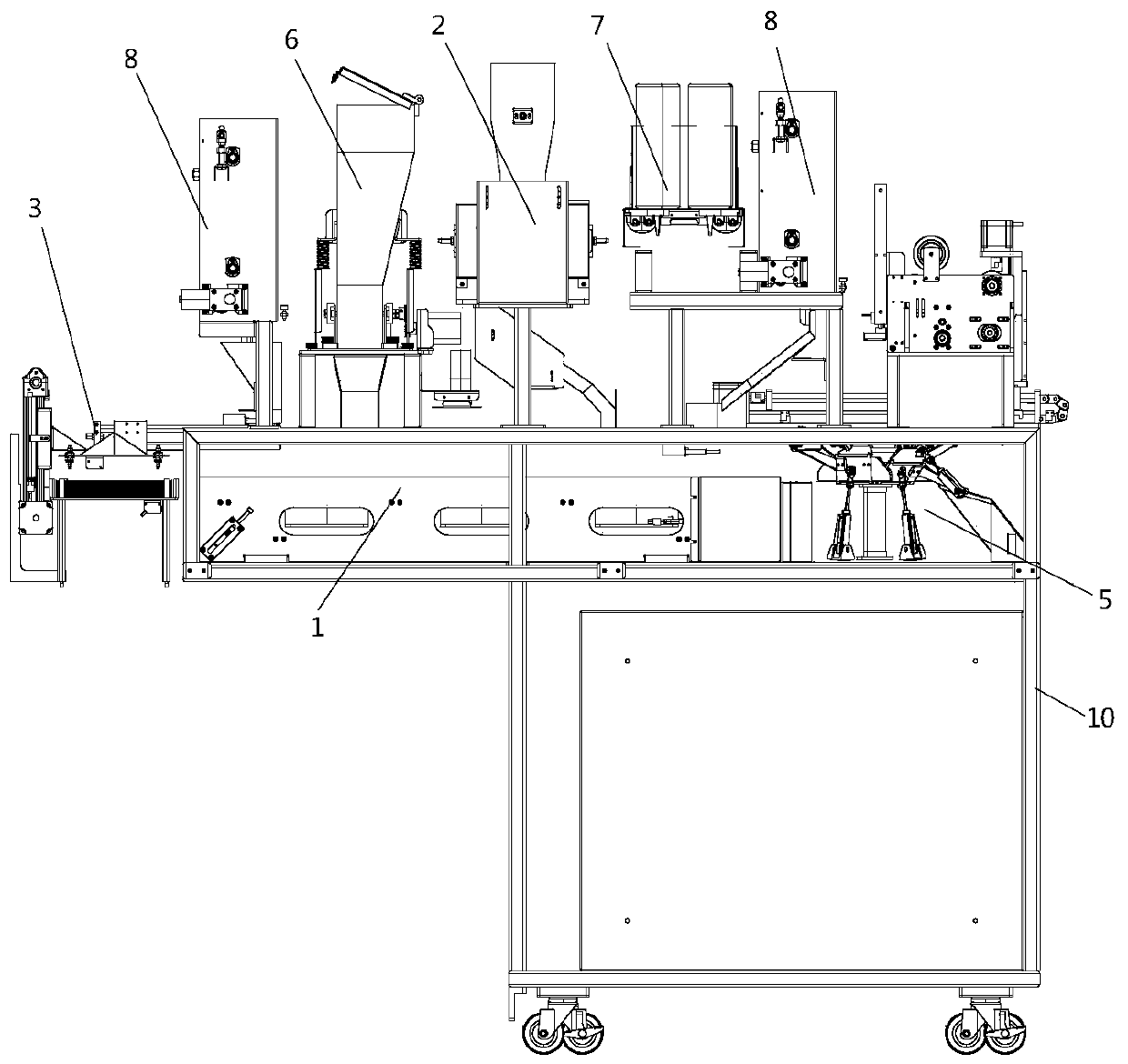

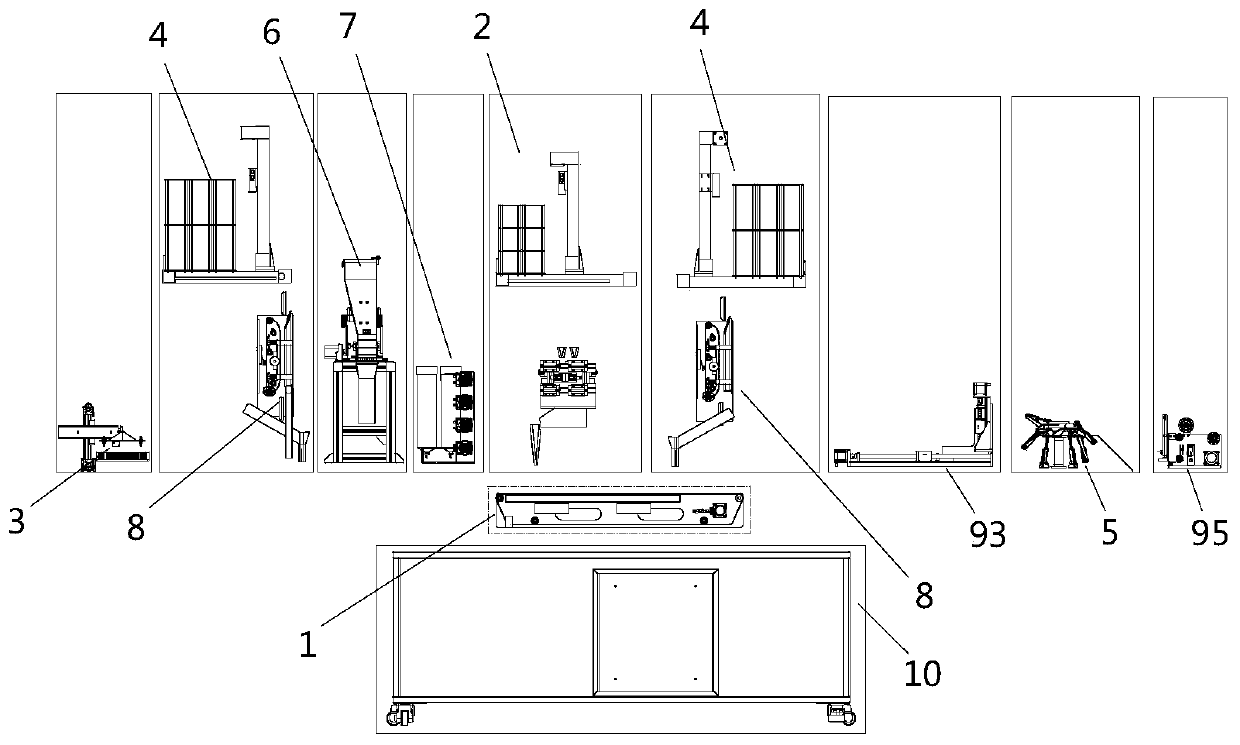

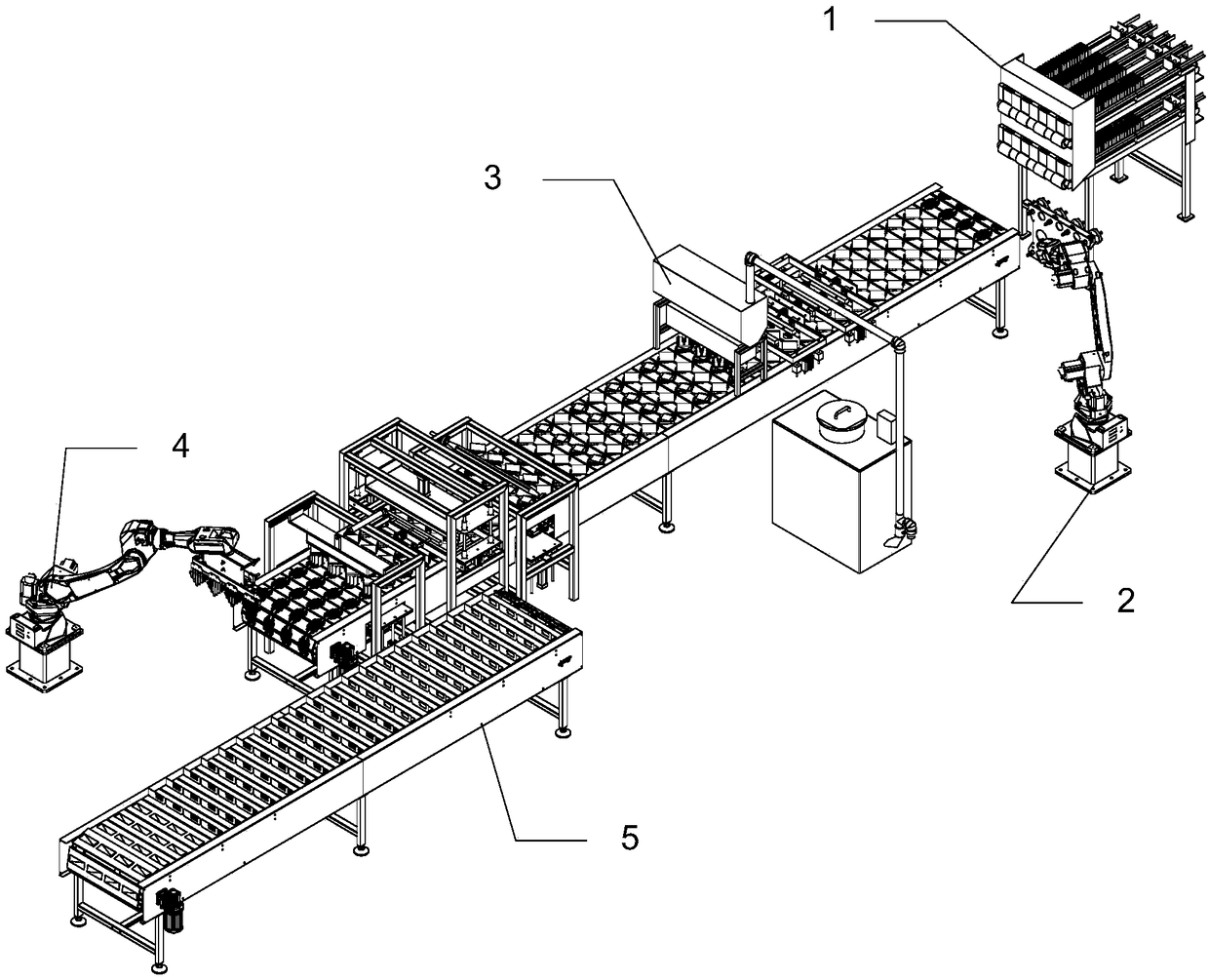

Processing system for sandwich bread

InactiveCN107927052AFully automatedEnsure hygiene and safetyBaked article fillingMetal working apparatusMechanical engineeringFully automated

The present invention discloses a processing system for sandwich bread. The processing system comprises a conveyor belt pushing device at a starting end, a bread cutting conveyor connected with the conveyor belt pushing device, a mechanical carrying hand device arranged at a rear side of the bread cutting conveyor, and a bread feeding machine and a cutting and filling mechanism successively arranged at a rear side of the mechanical carrying hand; and a plurality of paratactic whole-block rectangular bread moves on the conveyor belt pushing device along an own length direction, the bread stopsat a connection place of the bread cutting conveyor and is pushed to the bread cutting conveyor vertically by the conveyor belt pushing device, the bread is initially cut and pushed to the mechanicalcarrying hand device, the bread is conveyed to the subsequent bread feeding machine by all-round movements of the mechanical carrying hand device, then the bread feeing machine conducts material feeding and the cutting and filling mechanism at the rear side conducts cutting and sandwich filling successively, and thus a fully automated process of sandwich processing is realized. The processing system ensures sanitation and safety, and reduces labor input costs.

Owner:江门市神川自动化设备有限公司

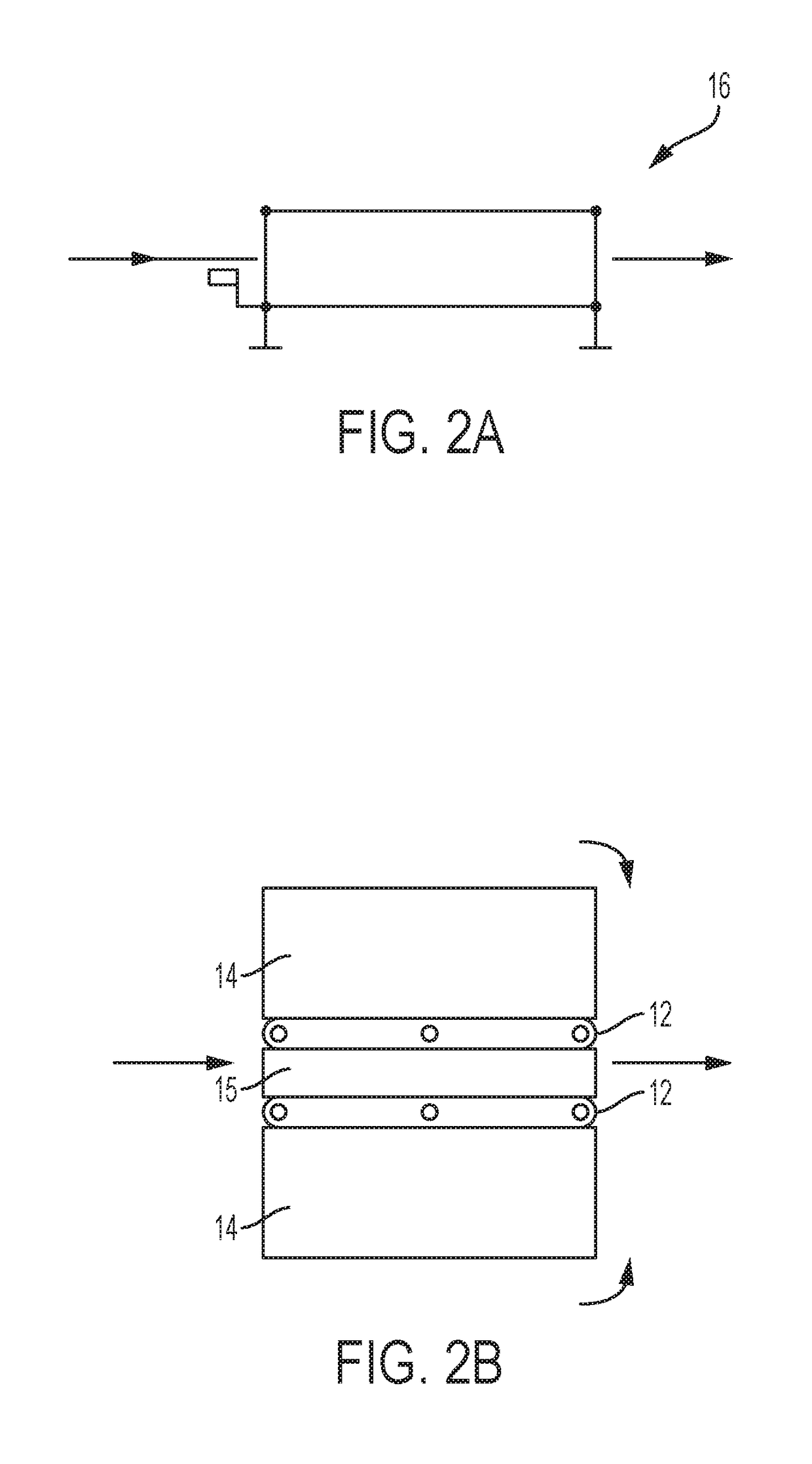

Folding apparatus and partial press for submarine sandwiches

InactiveUS10159258B1Maximize efficiencyQuickly and efficiently prepareBaked article fillingFood coatingAdditive ingredientEngineering

An improved assembly for automatically folding and pressing submarine sandwiches in line production. Once a preparer has assembled the sub with the customer's selection of meats and vegetables, it is placed on the assembly to quickly and efficiently prepare the sub for cutting, wrapping and delivery without uncoordinated or awkward handling by the employee and the loss of ingredients. The assembly includes a conveyor belt for movement of the sandwiches into a curvilinear channel having a converging outlet which provides the dual functions of folding and pressing the sandwich, following which it ready for packaging and / or delivery to a customer. In other embodiments, the assembly includes a plurality of hinged plates, a central press down bar, and options for a hand crank or foot pedal control.

Owner:AUTOMATED SYST & SOLUTIONS INC

Container comprising edible manifold

InactiveUS20060068065A1Increase contactBaked article fillingPre-baking dough treatmentInterior spaceCooking & baking

Owner:SCHWANS GLOBAL SUPPLY CHAIN

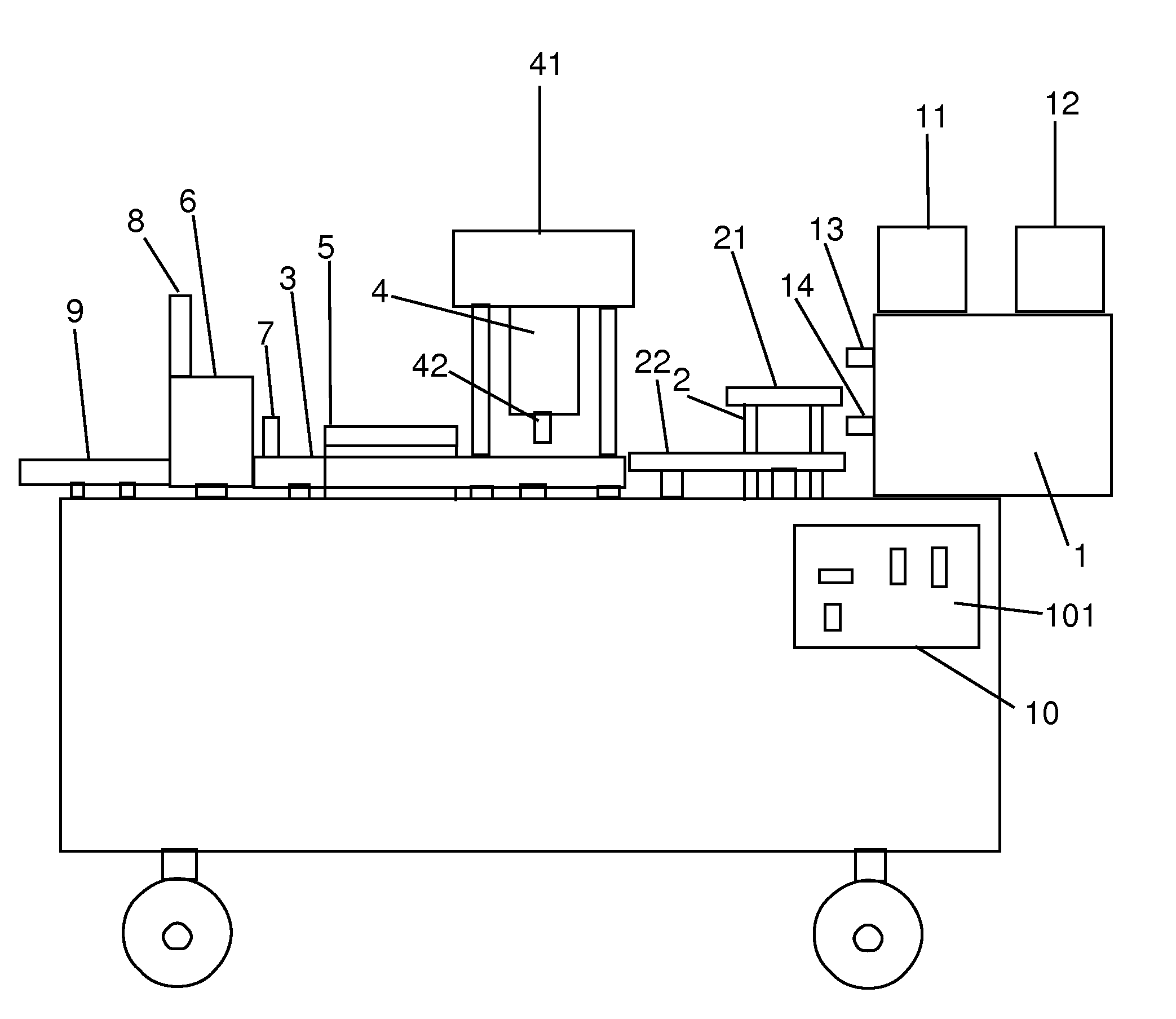

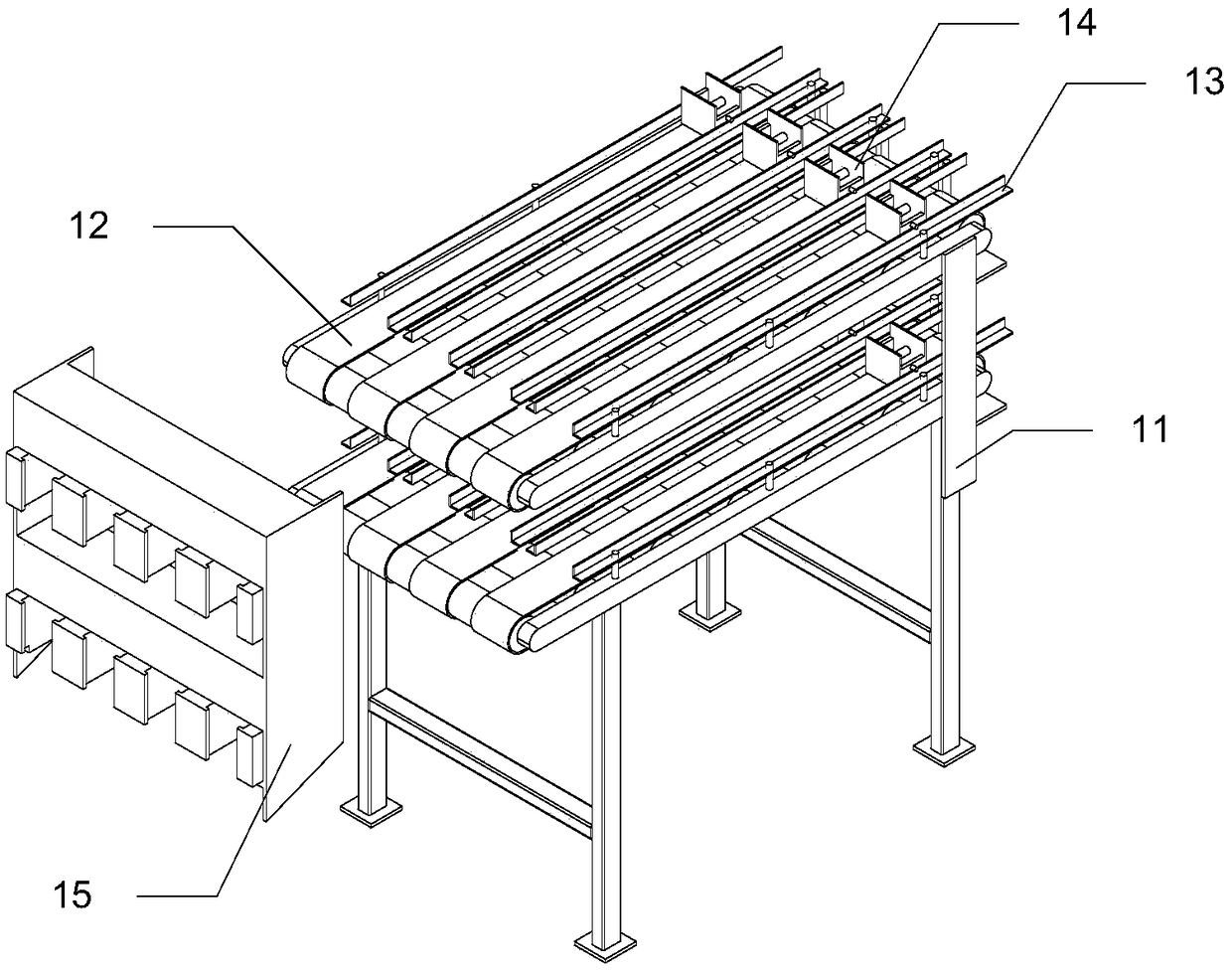

Automatic cake production system with discharge packaging function

InactiveCN108910147AHigh degree of automationEasy to operateBaked article fillingPackaging bakeryManipulatorFood processing

The invention relates to the field of food processing and particularly relates to an automatic cake production system. The automatic cake production system with discharge packaging function comprisesa feeding mechanism, a first manipulator mechanism, a processing mechanism, a second manipulator mechanism and a package transmission mechanism, wherein the feeding mechanism is arranged at the frontend of the system; the processing mechanism is connected with the feeding mechanism; toast slices are taken down from the feeding mechanism by the first manipulator and put on the processing mechanism; the front end of a packaging mechanism is arranged in parallel with the rear end of the processing mechanism; the second manipulator mechanism clamps cake from the processing mechanism and puts on the package transmission mechanism. The system can realize automatic discharge packaging of cake and has the characteristics of high automation degree, simplicity and easiness in operation.

Owner:杨立撒

Food Folding Platform And Components Therefor

A folding platform includes a base, first folding flap, lift arm, and lift arm linkage. The first folding flap is rotatably connected with the base and facilitates the folding of a food item placed on the folding platform. The lift arm linkage is rotatably connected with the base and the lift arm to operatively lift the lift arm and allow the lift arm to rotate in a first rotational direction, and includes a spring that engages the lift arm linkage and the lift arm, and biases the lift arm in a second rotational direction opposite the first rotational direction. The lift arm is capable of rotating a first rotational distance, and rotating a second rotational distance greater than the first rotational distance without bending or breaking when the lift arm contacts an obstruction. The lift arm automatically returns to its normal position due to the bias force of the spring.

Owner:SOLBERN CORP

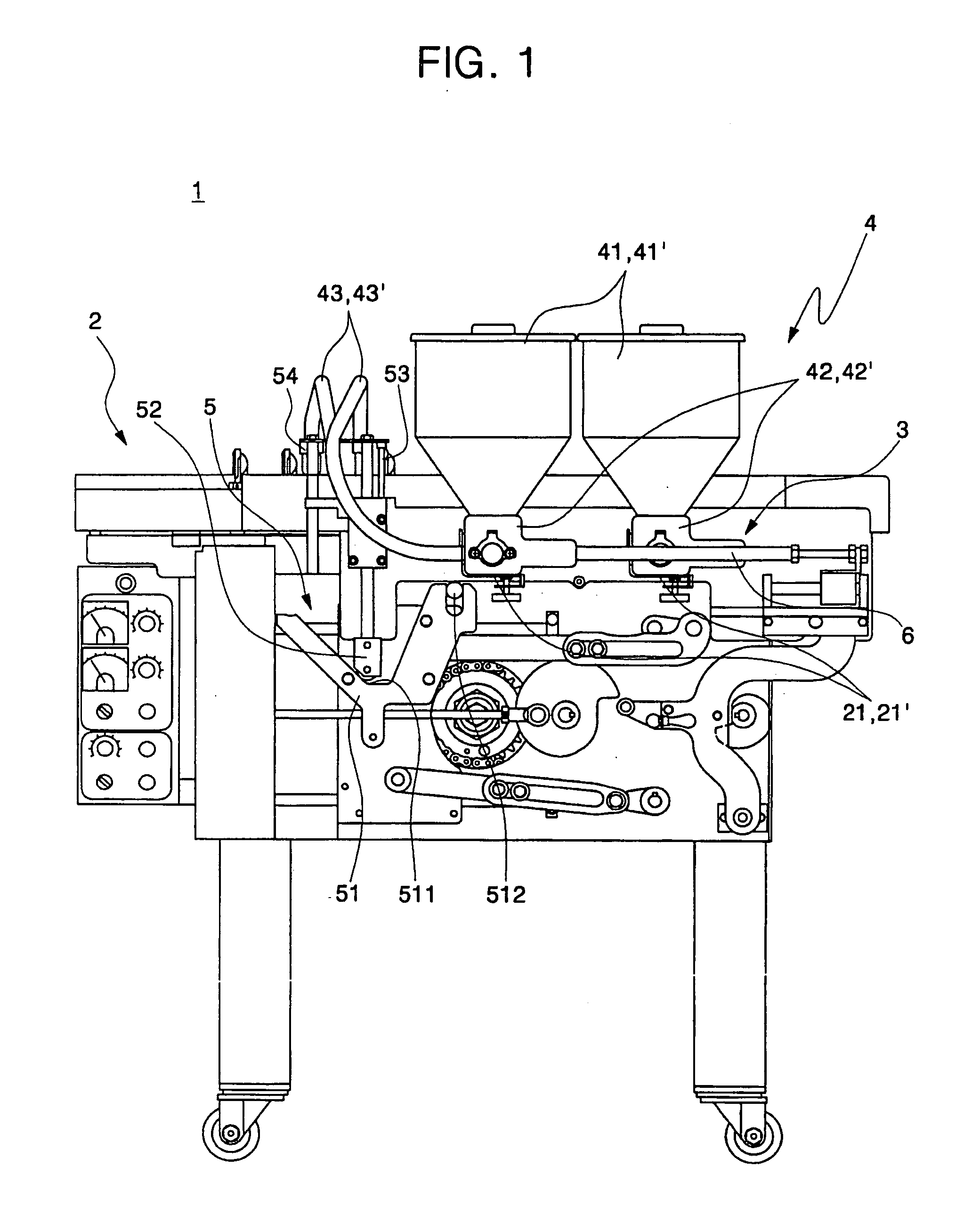

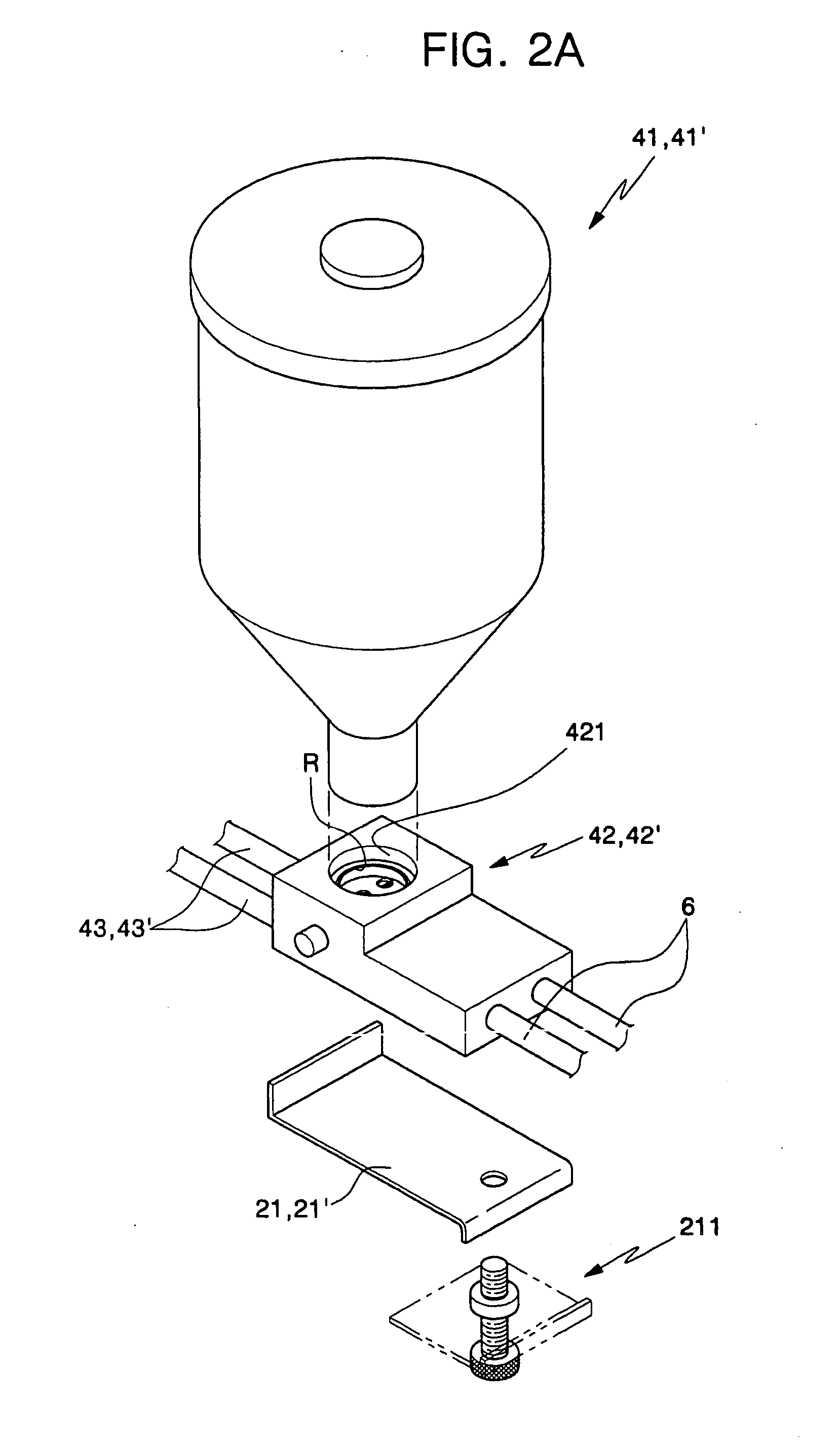

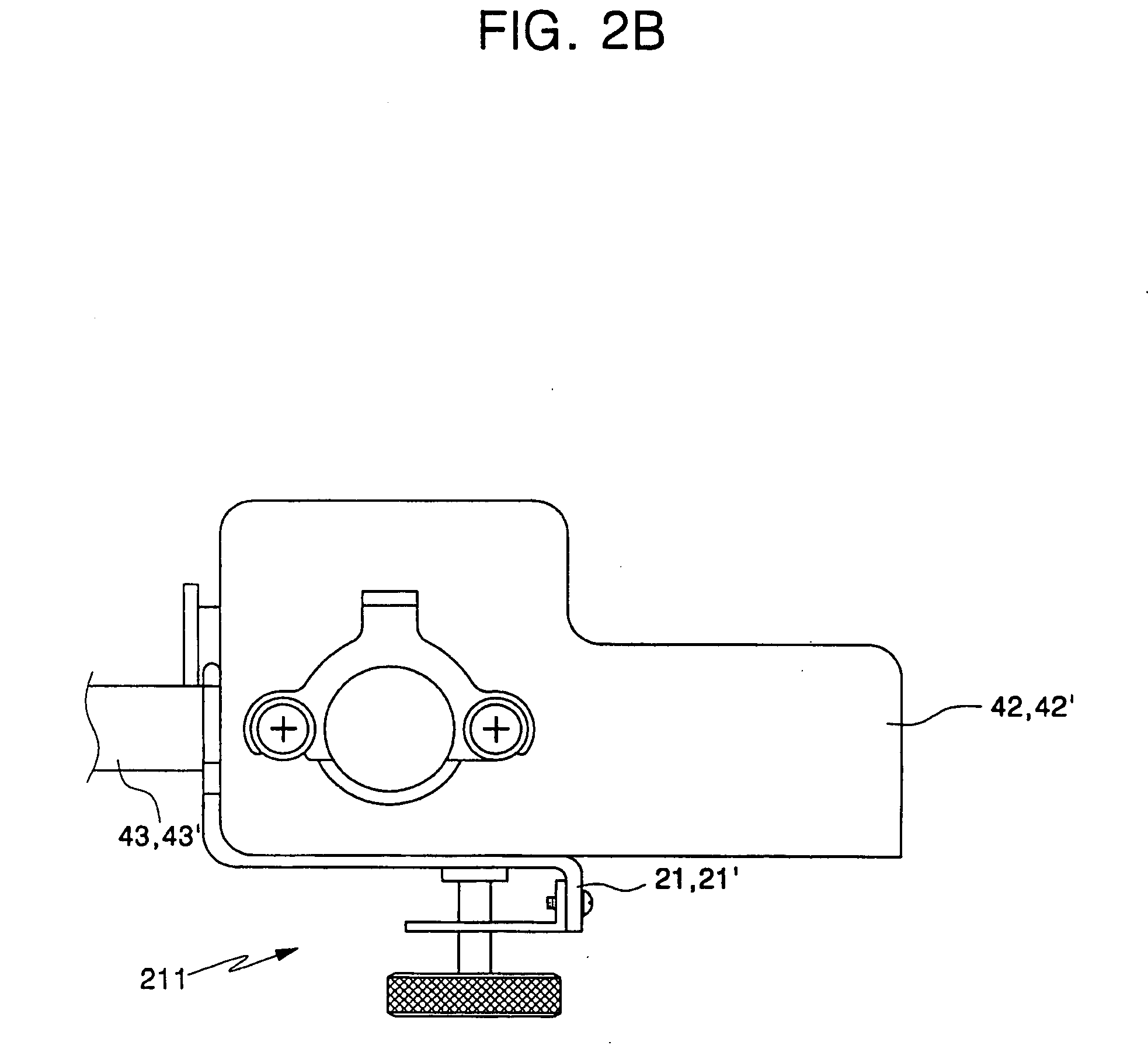

Apparatus for producing confectionery

ActiveUS20050103208A1Easy to disassembleEasy to cleanBaked article fillingConfectioneryEngineeringActuator

Disclosed is an apparatus for producing confectionery. In the apparatus for producing confectionery, a material injection unit for supplying materials into a confectionary mold includes a hopper, an injector, a hose, and a piston actuator, which are detachably connected to a main frame. With this configuration, the foregoing elements are detached and cleaned, thereby keeping the elements sanitary.

Owner:KO DUCKJONG +1

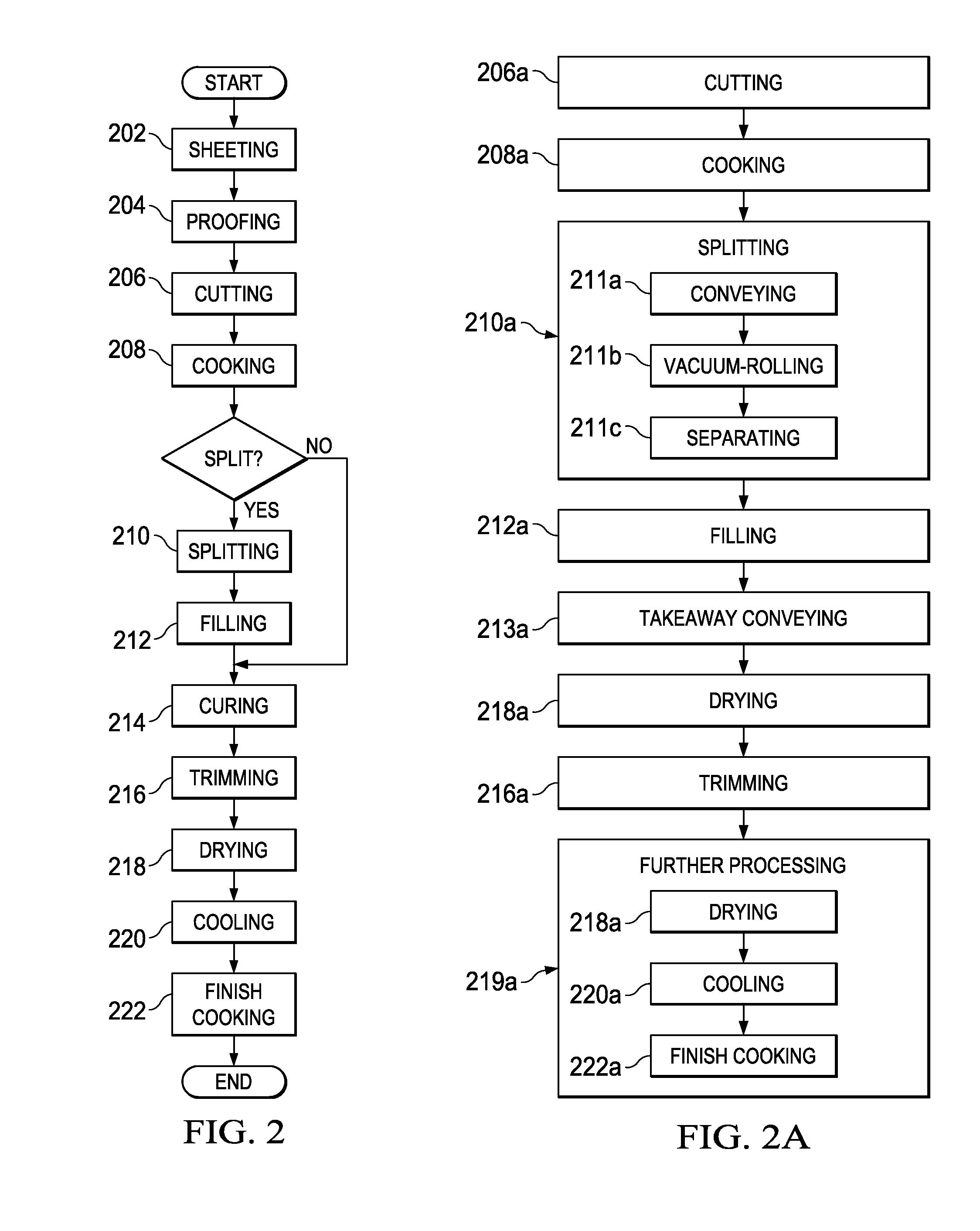

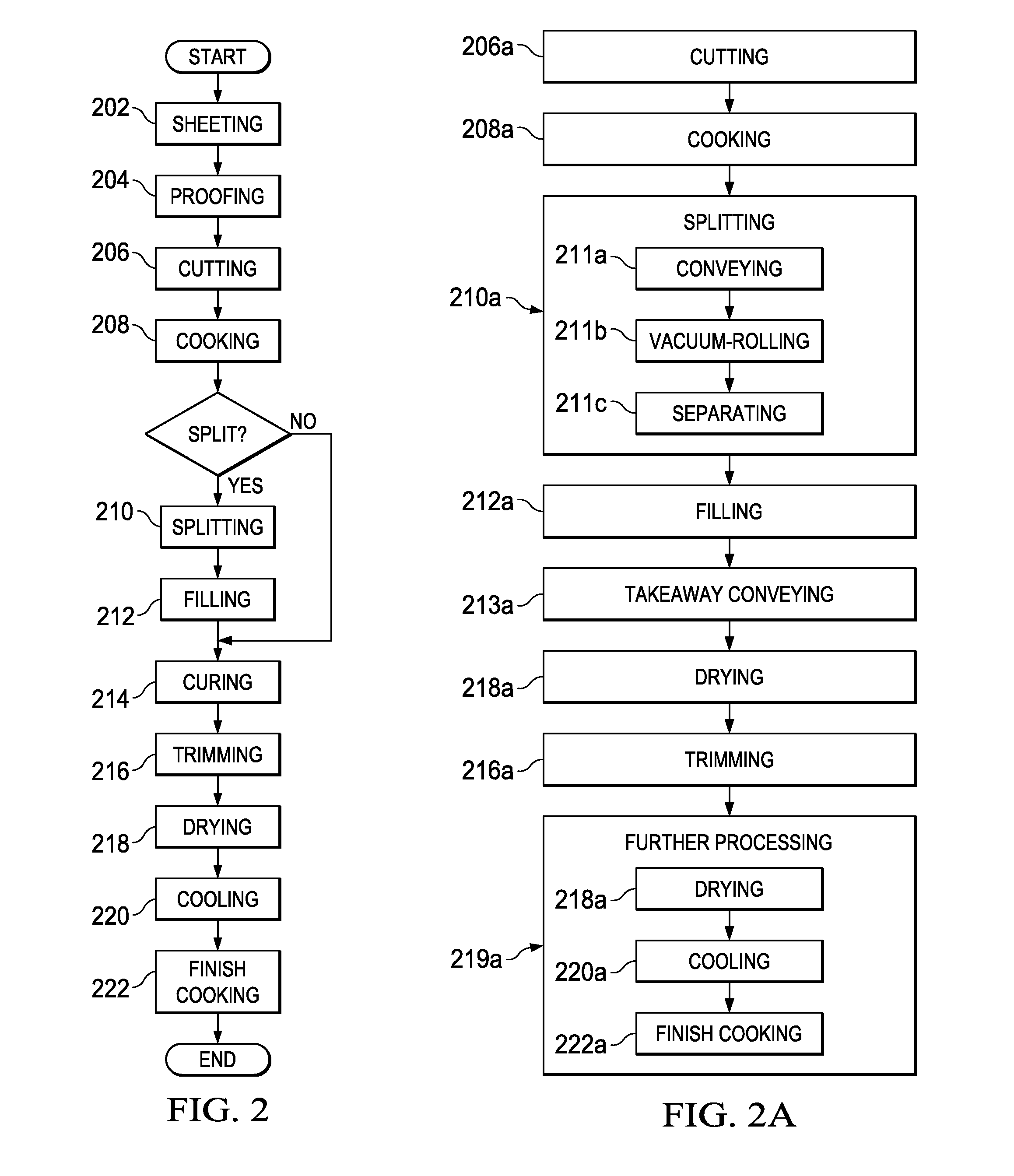

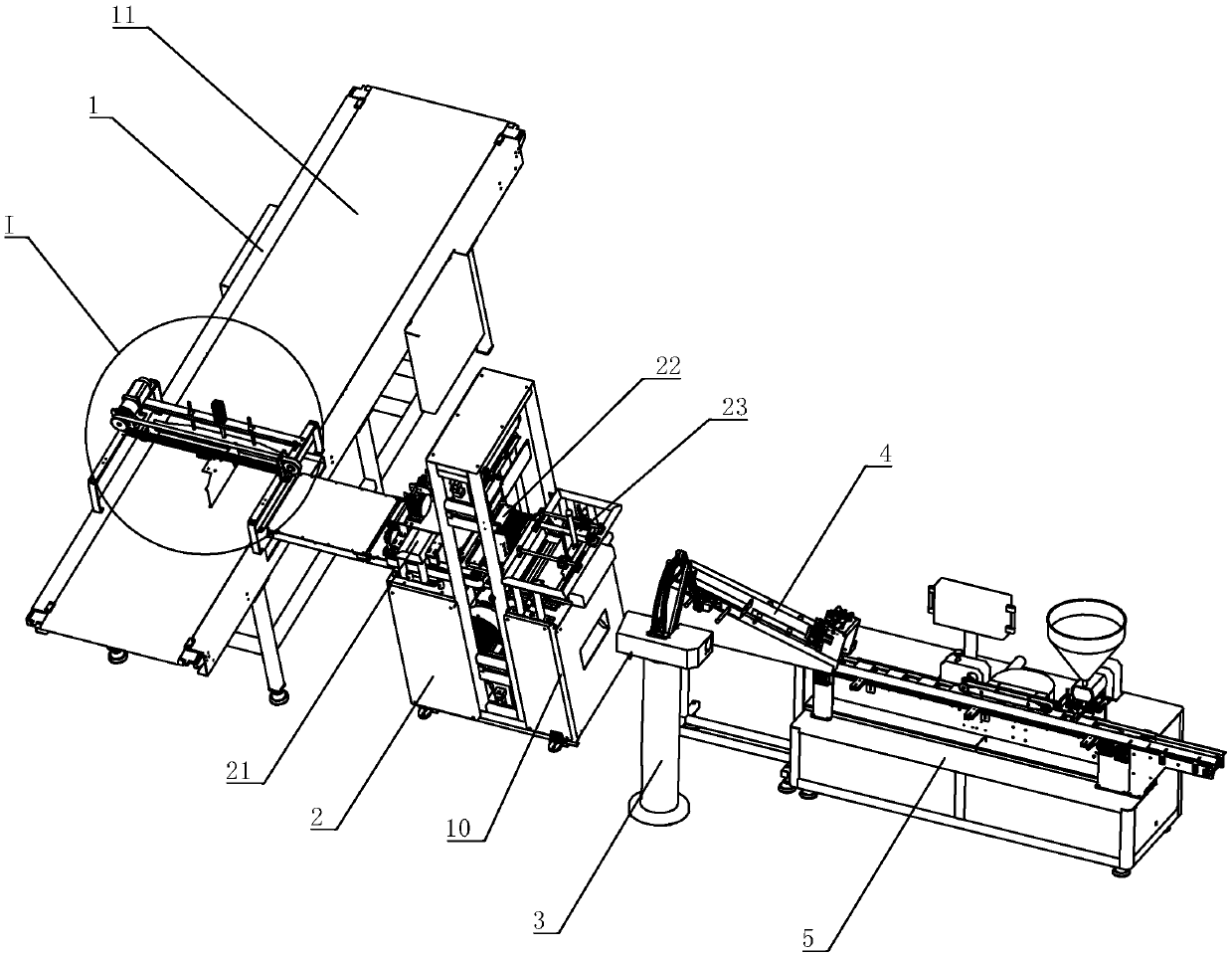

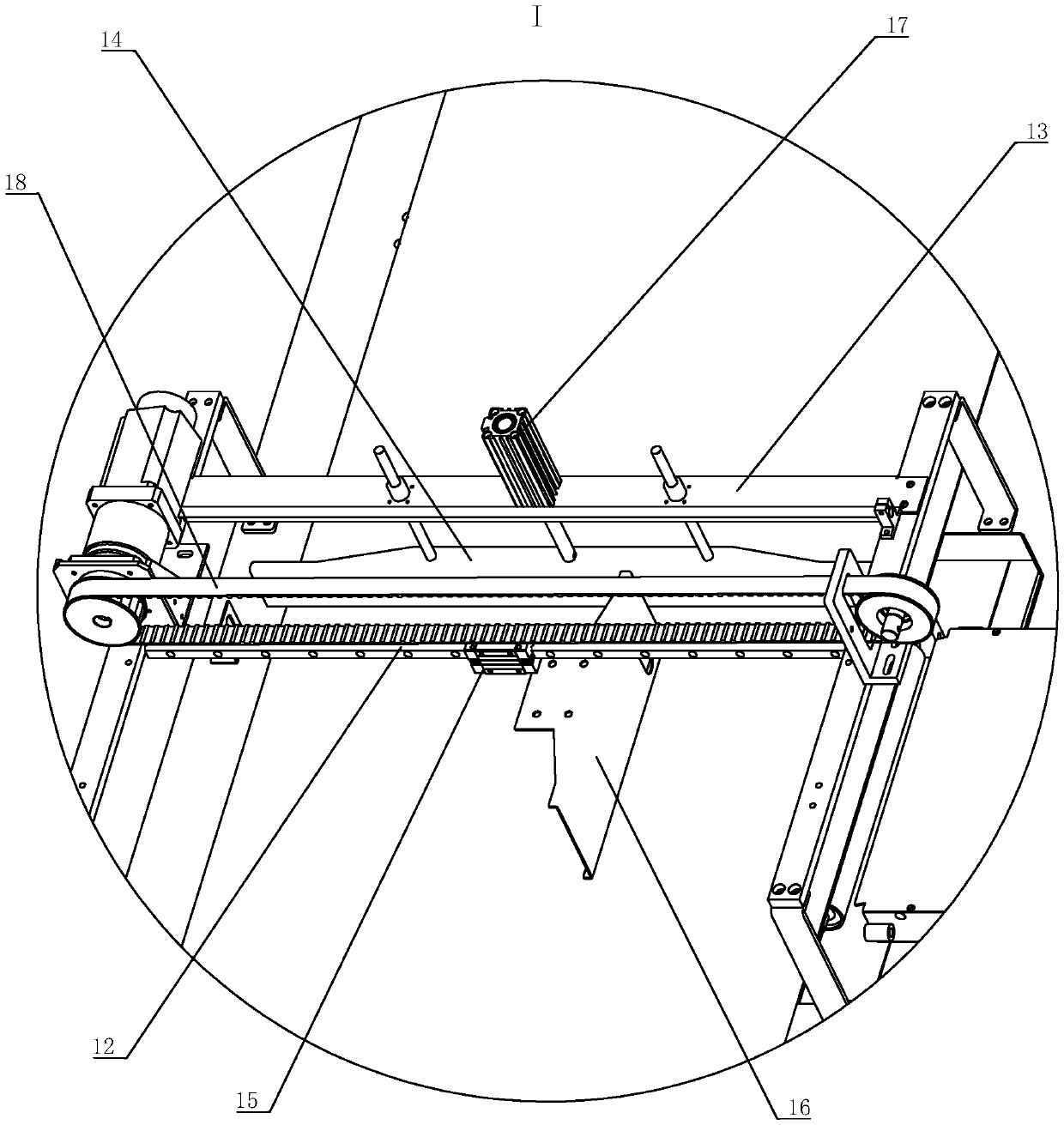

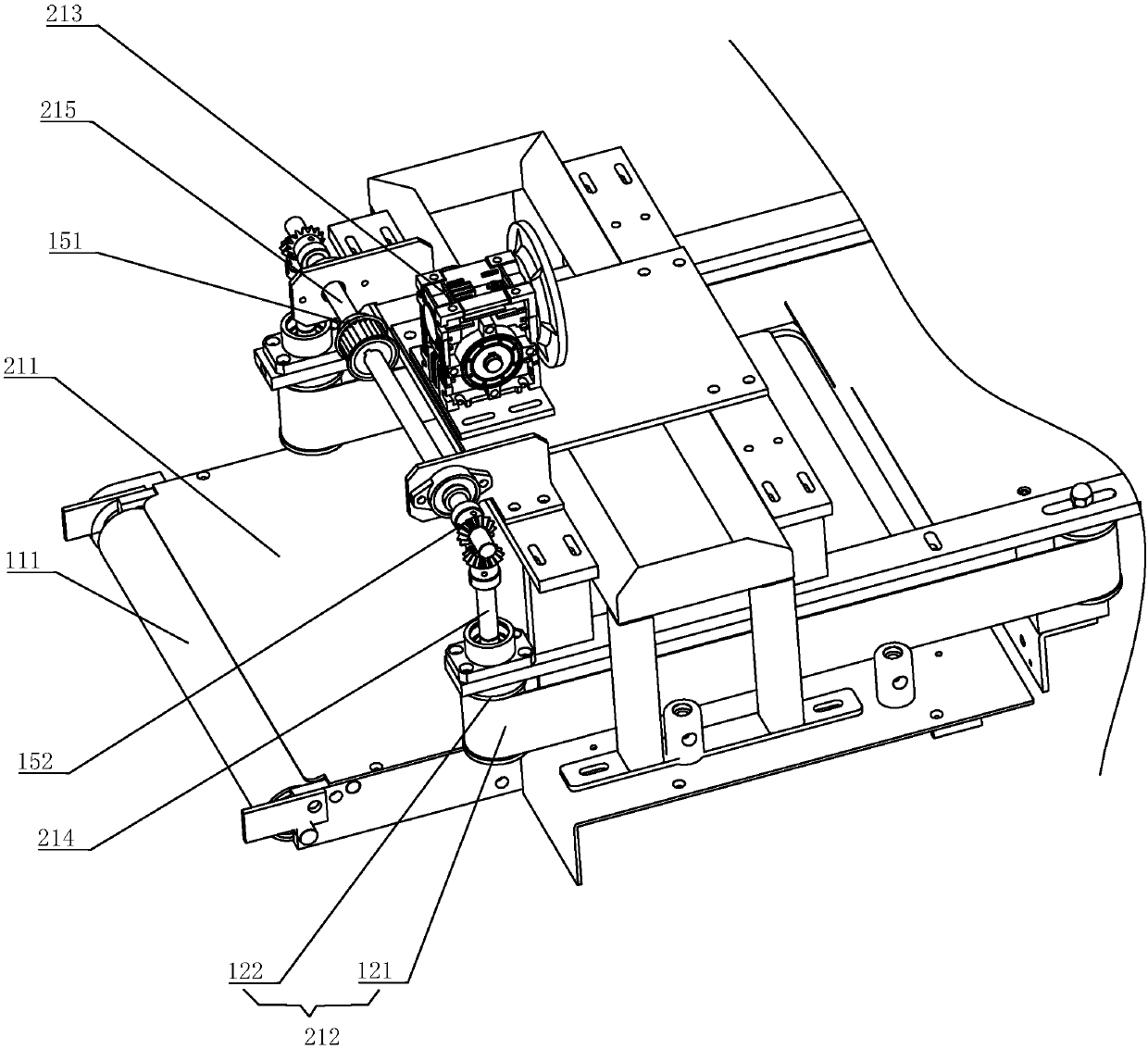

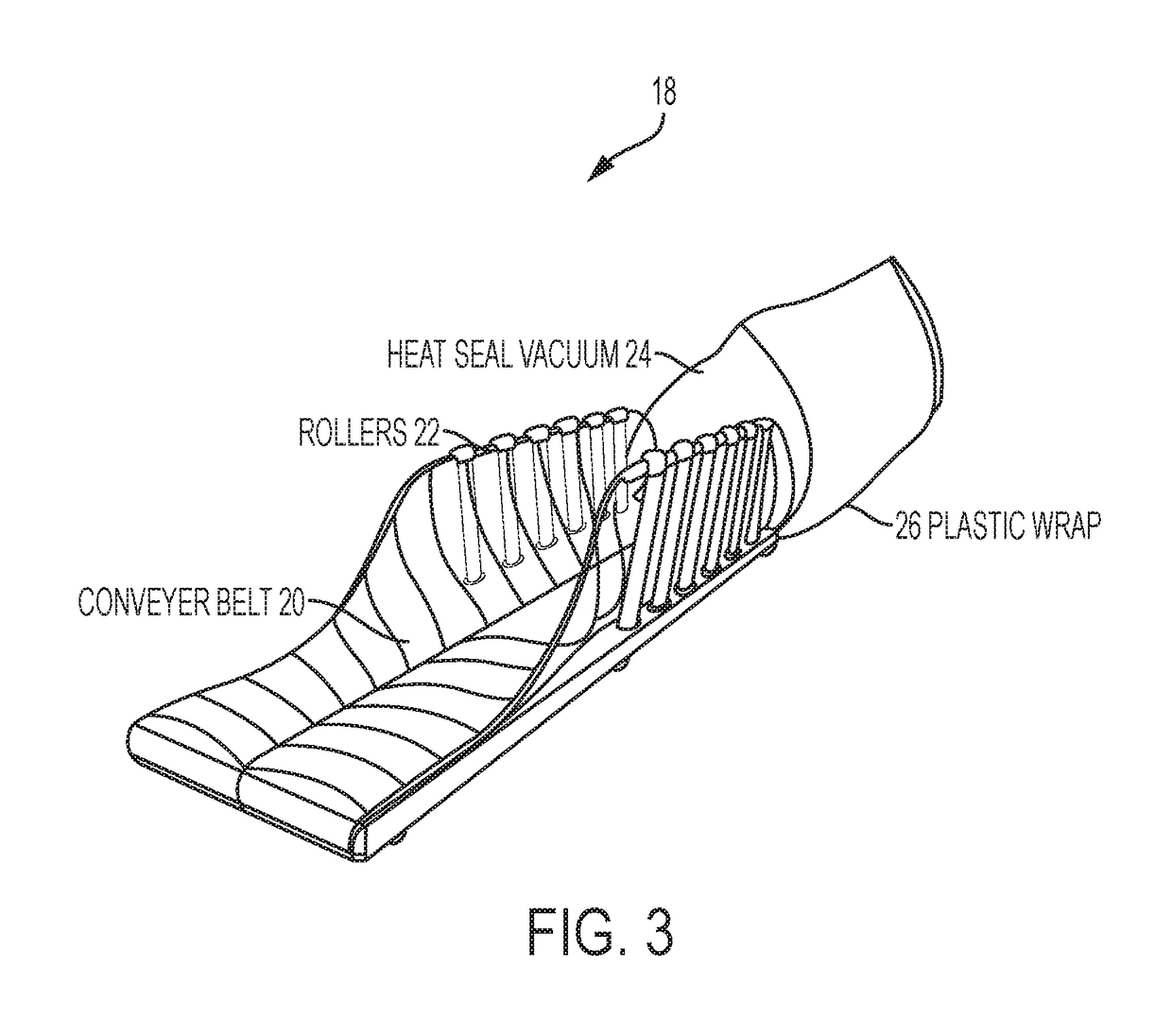

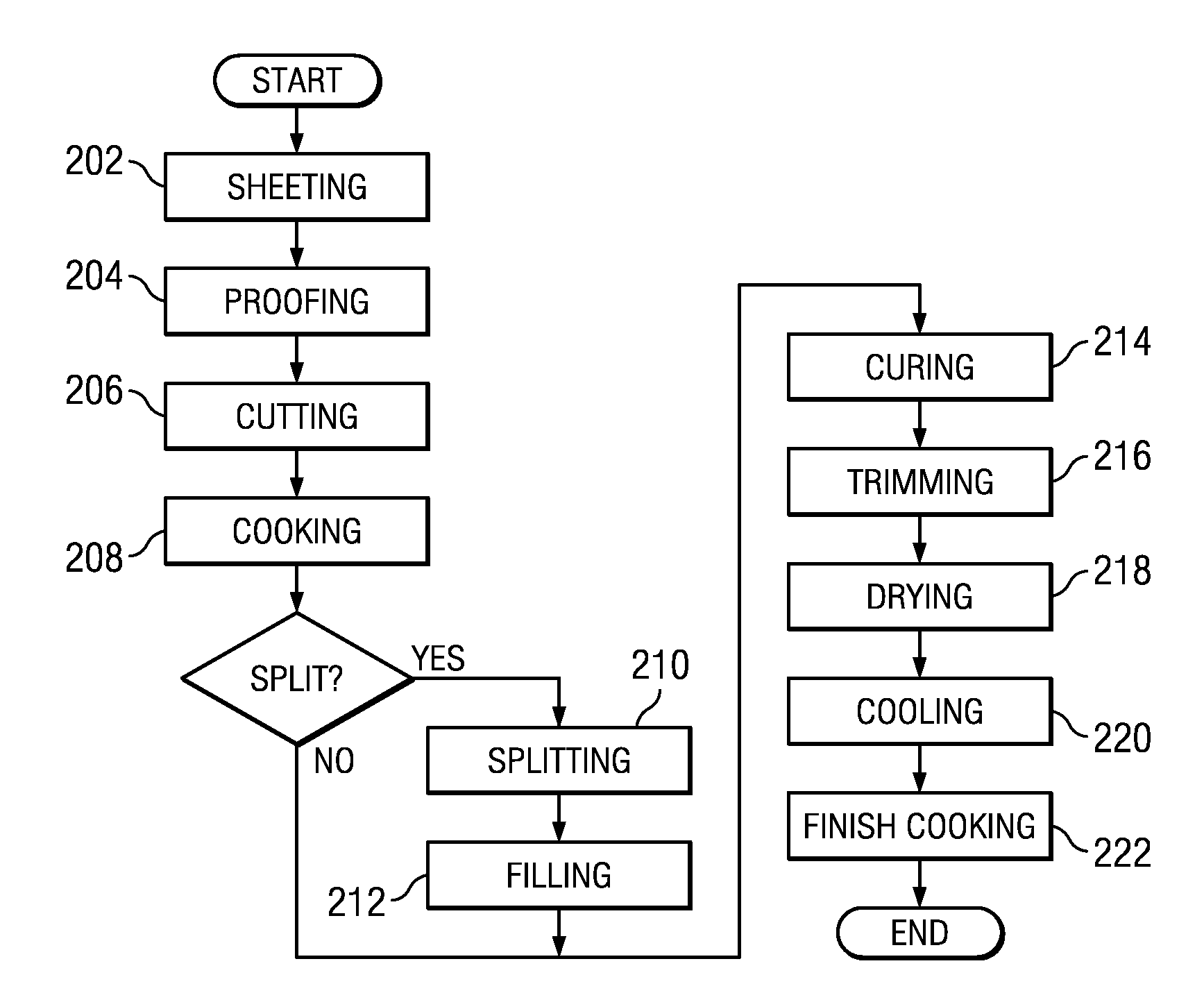

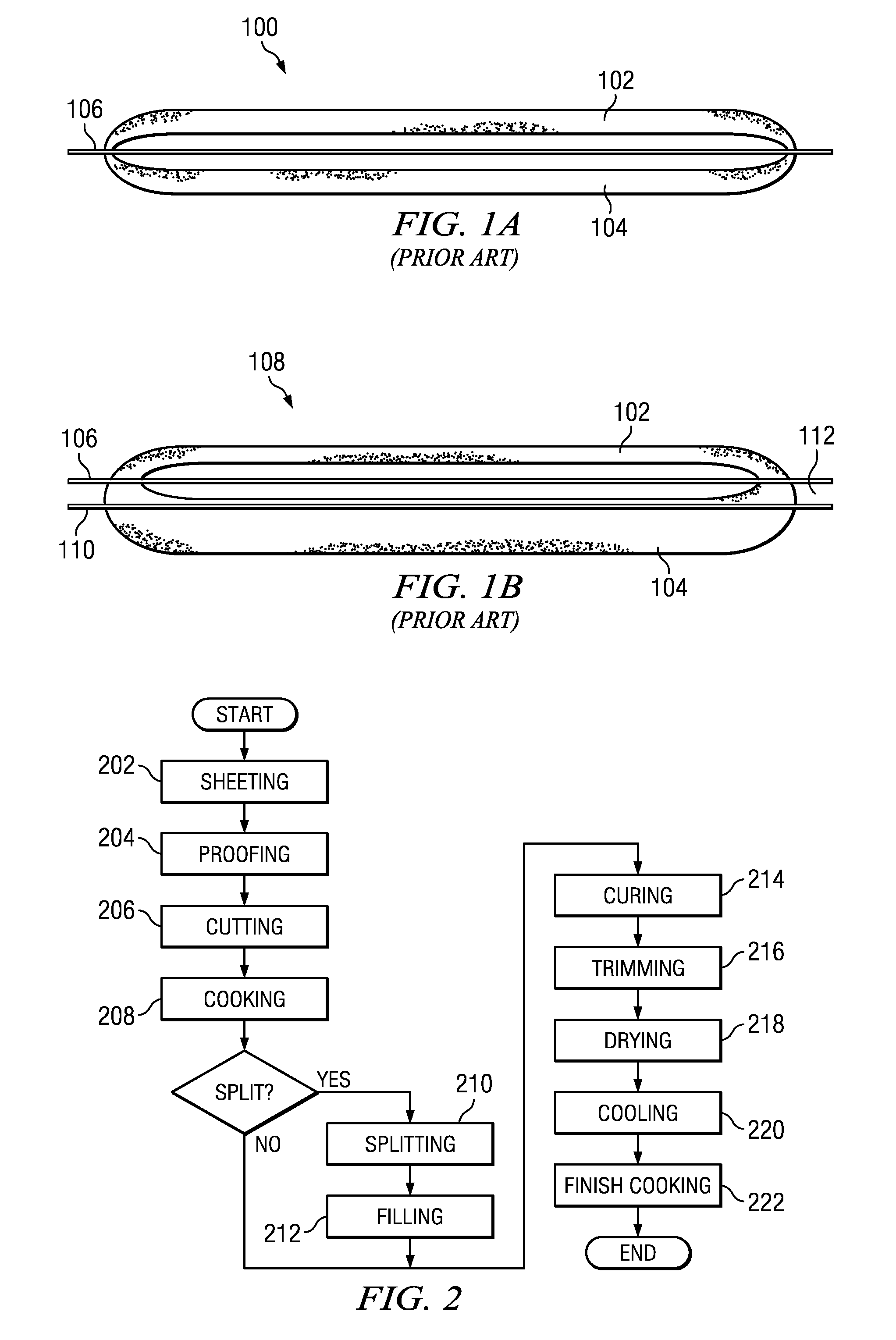

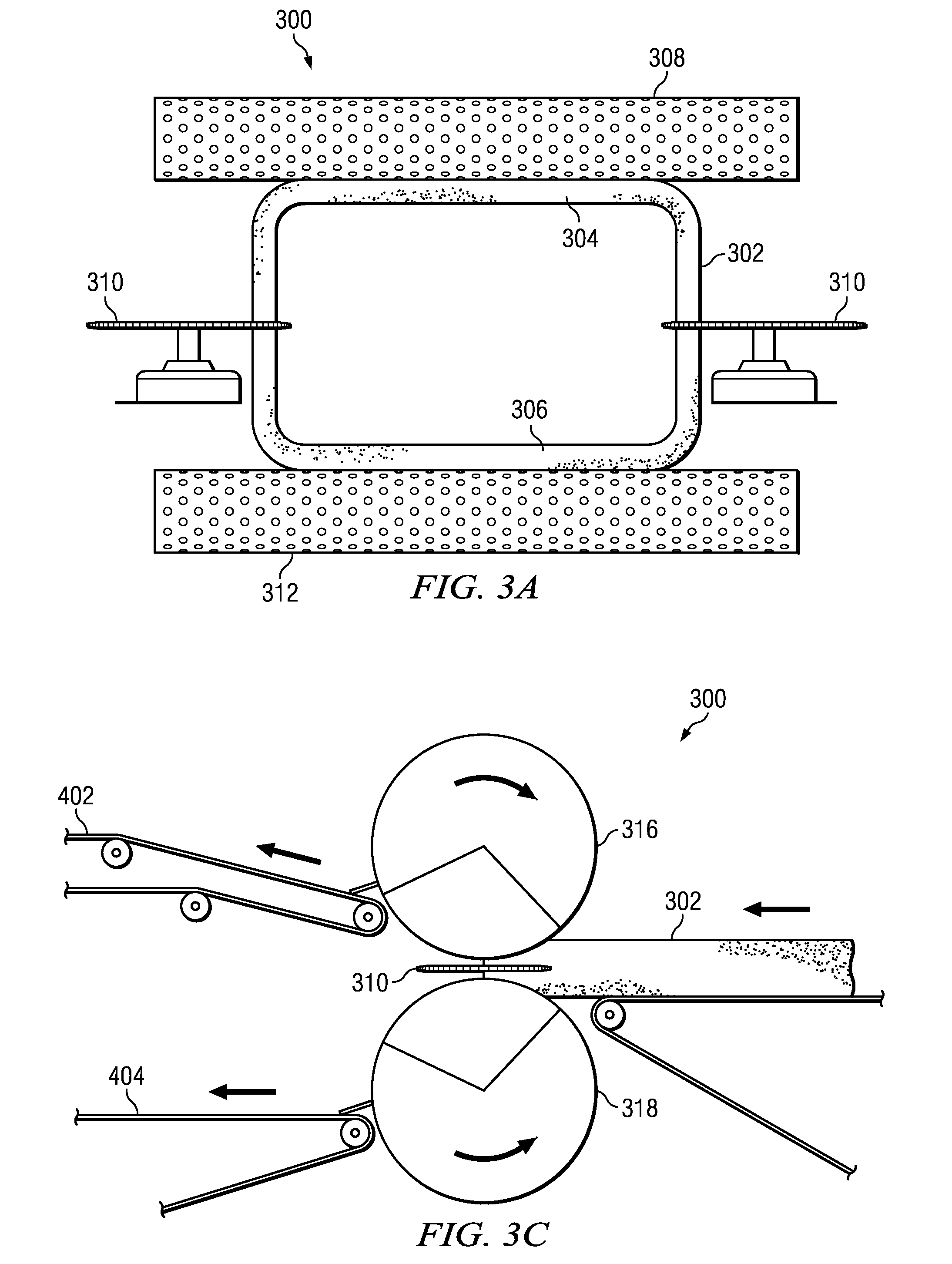

Continuous Process and Apparatus for Making a Pita Chip

InactiveUS20140037789A1Shorter coolingShort curing timeDough treatmentDrying solid materials with heatVacuum assistedMechanical engineering

A continuous process and the accompanying equipment for making a chip product, such as pita chips. The process involves cutting sheeted dough into continuous longitudinal strips, and cooking them to form hollow tubes. In some embodiments, these tubes are split longitudinally. Also disclosed is a vacuum-assisted splitter. These bread tubes or strips are cured in an accelerated process. The bread tube is trimmed into chip-sized pieces. In one embodiment, the pita bread strips are cut into chip-sized pieces using a continuous, low-pressure water jet cutting system. The resulting chip-sized pieces are nearly uniform in size, shape, and texture.

Owner:FRITO LAY NORTH AMERICA INC

Automatic jam applying device for mass production of baked products

The present invention discloses an automatic jam applying device for mass production of baked products. The automatic jam applying device comprises a fixed support frame; the fixed support frame is fixedly connected with a funnel-shaped jam bucket through an annular fixator; the bottom end of the funnel-shaped jam bucket is provided with a material discharge pipe; besides, the material discharge pipe extends through the inner wall of the fixed support frame and extends to the outside of the bottom end of the fixed support frame; the one side bottom end outer wall of the fixed support frame isfixedly connected with a first positioning support rod; the bottom end of the first positioning support rod is rotatably connected with a second positioning support rod through a first rotating connecting shaft; and an even applying device is fixedly connected with one end of the second positioning support rod far away from the first positioning support rod. The present invention relates to the technical field of food machinery related devices. The automatic jam applying device for the mass production of the baked products can automatically perform quantitative jam adding and uniform applying,has a relatively high degree of standardization, and at the same time improves the production efficiency of the packaged bread products.

Owner:灌云现化金属制品有限公司

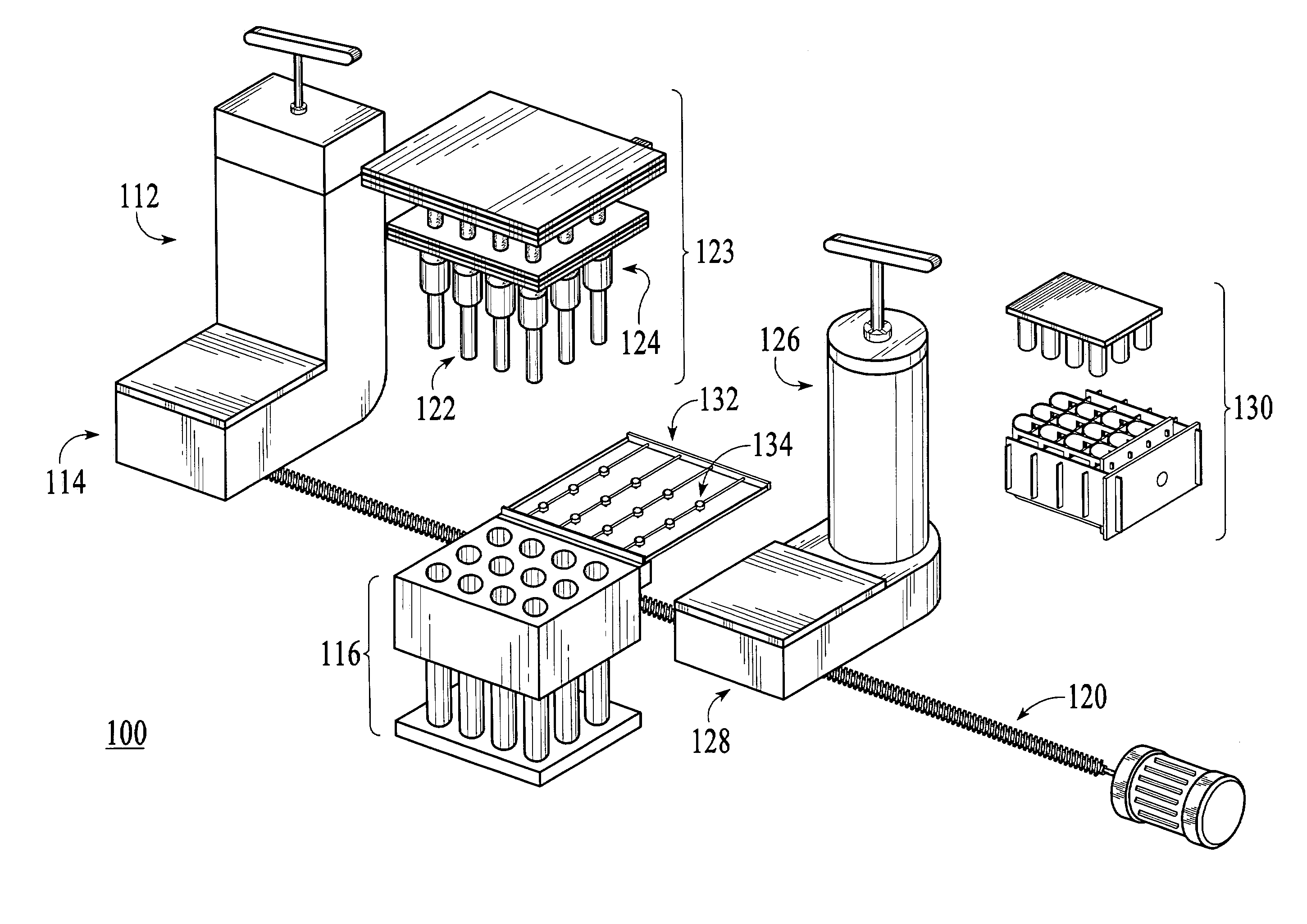

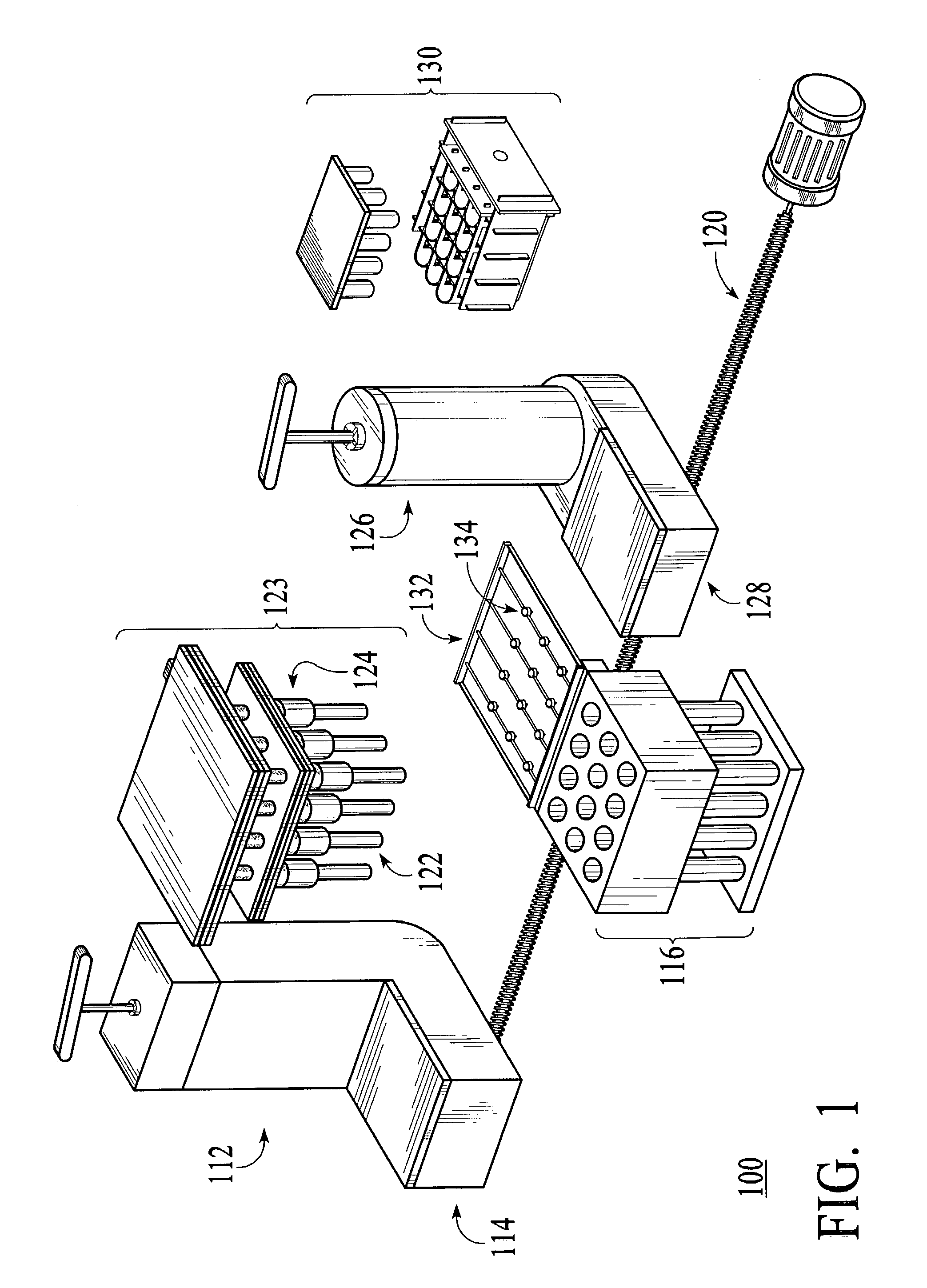

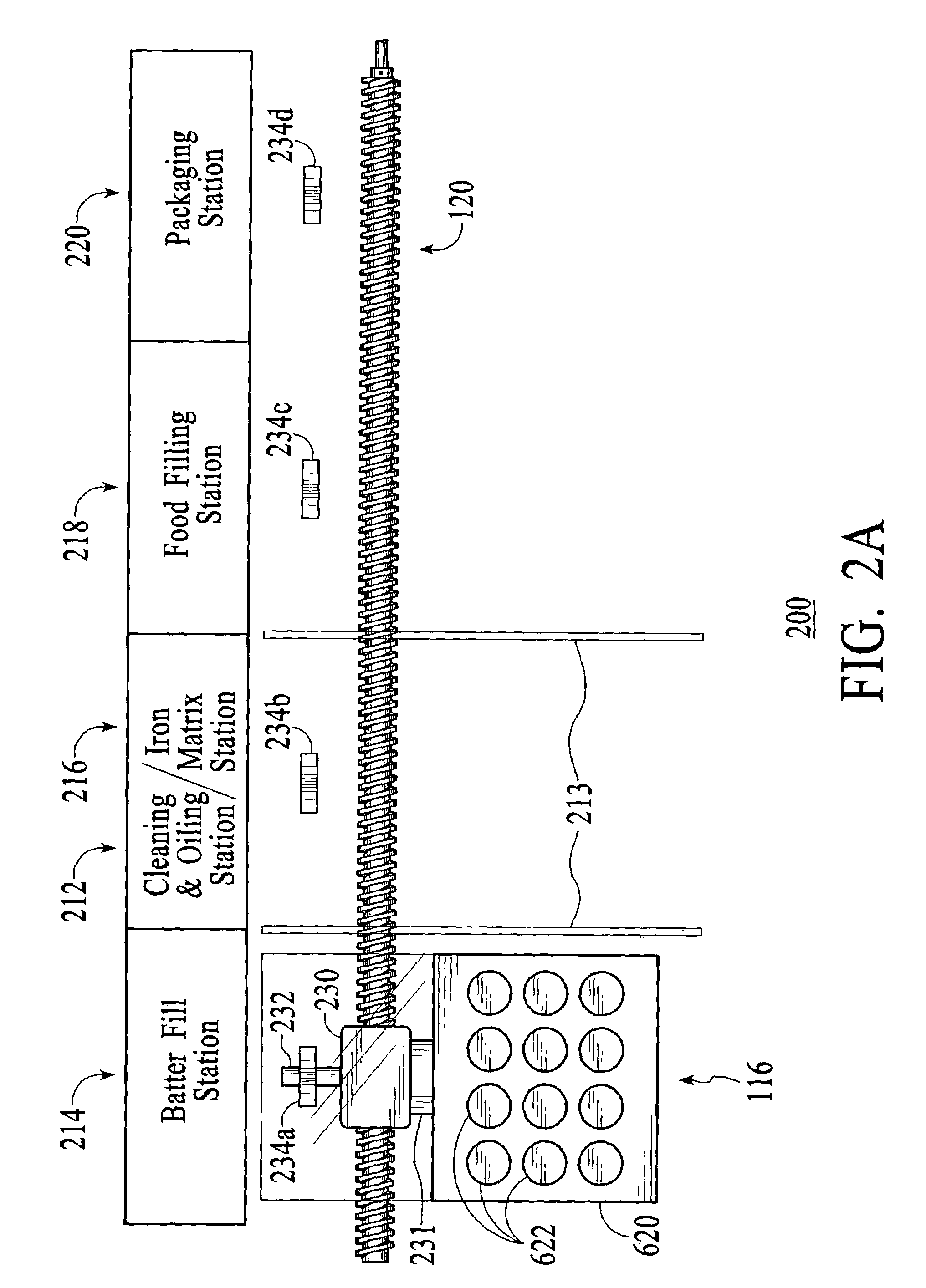

Method and apparatus for making a hand held food product

An automated machine and process to form a food product consisting of a batter shell and a food filling. The process is started with a cooking matrix that includes a plurality of cooking openings to receive the batter. The batter is cooked to form shells. The automated process then inserts the food filling into the shells, and packages the filled shells as end products.

Owner:ADAIR DARRYL

Efficient bread sandwiching device

InactiveCN105961478AReduce volumeSimple structureBaked article fillingClassical mechanicsElectric machinery

The invention relates to a sandwiching device, in particular to an efficient bread sandwiching device, and aims to provide the efficient bread sandwiching device which is small in size, simple in structure, convenient to operate and rapid in sandwiching speed. The efficient bread sandwiching device provided by the invention comprises a bottom plate, a support rod, an electronic push rod I, a boss, electronic push rods II, a left rack, a holding tank I, a push plate, a push block I, an electronic push rod III, a pressing block, a cream tank, a discharge tube, an electronic valve, a holding plate, a thrum cylinder, an electronic push rod IV, a fixing plate, an electronic push rod V, a rotating motor, a left bearing seat, a top plate, screw nuts, a screw rod, a right bearing seat, a servo motor, a holding tank II, a fixing rod, a push block II, an electronic push rod VI and a conveying device. The efficient bread sandwiching device has the effects of being small in size, simple in structure, convenient to operate and rapid in sandwiching speed; bread can be sandwiched uniformly, so that the bread can be delicious and nutrient.

Owner:吴忠市方圆食品科技有限责任公司

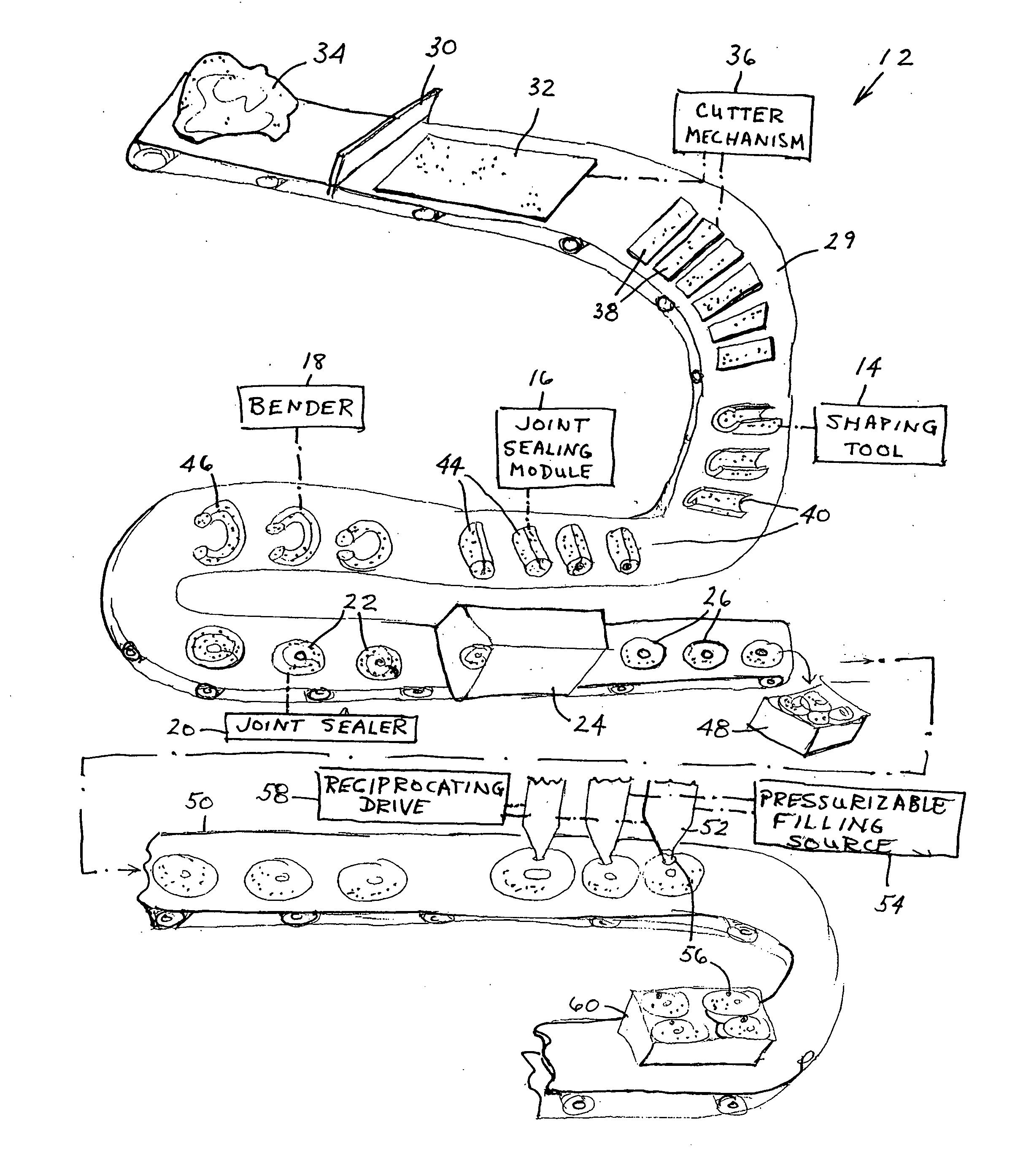

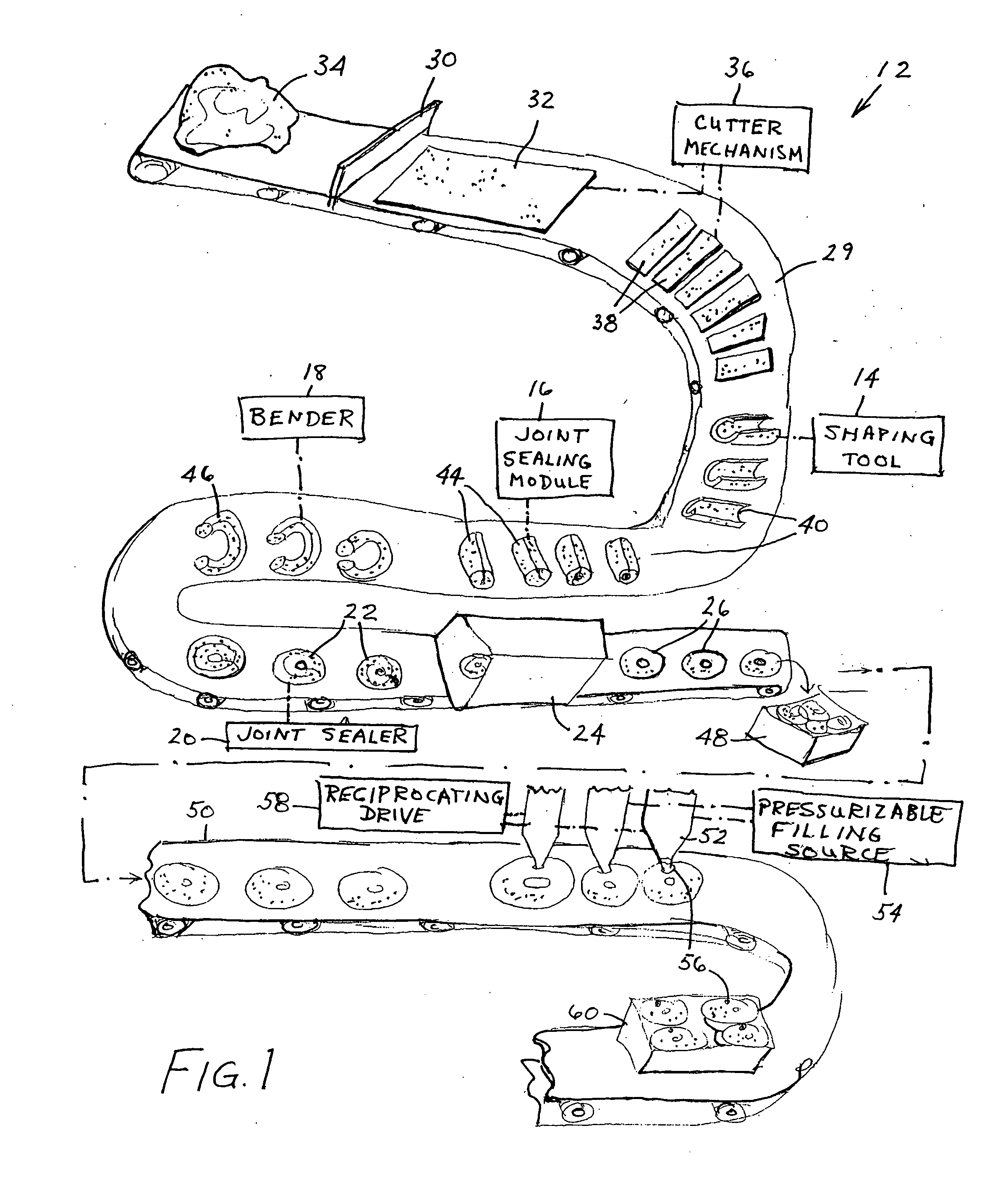

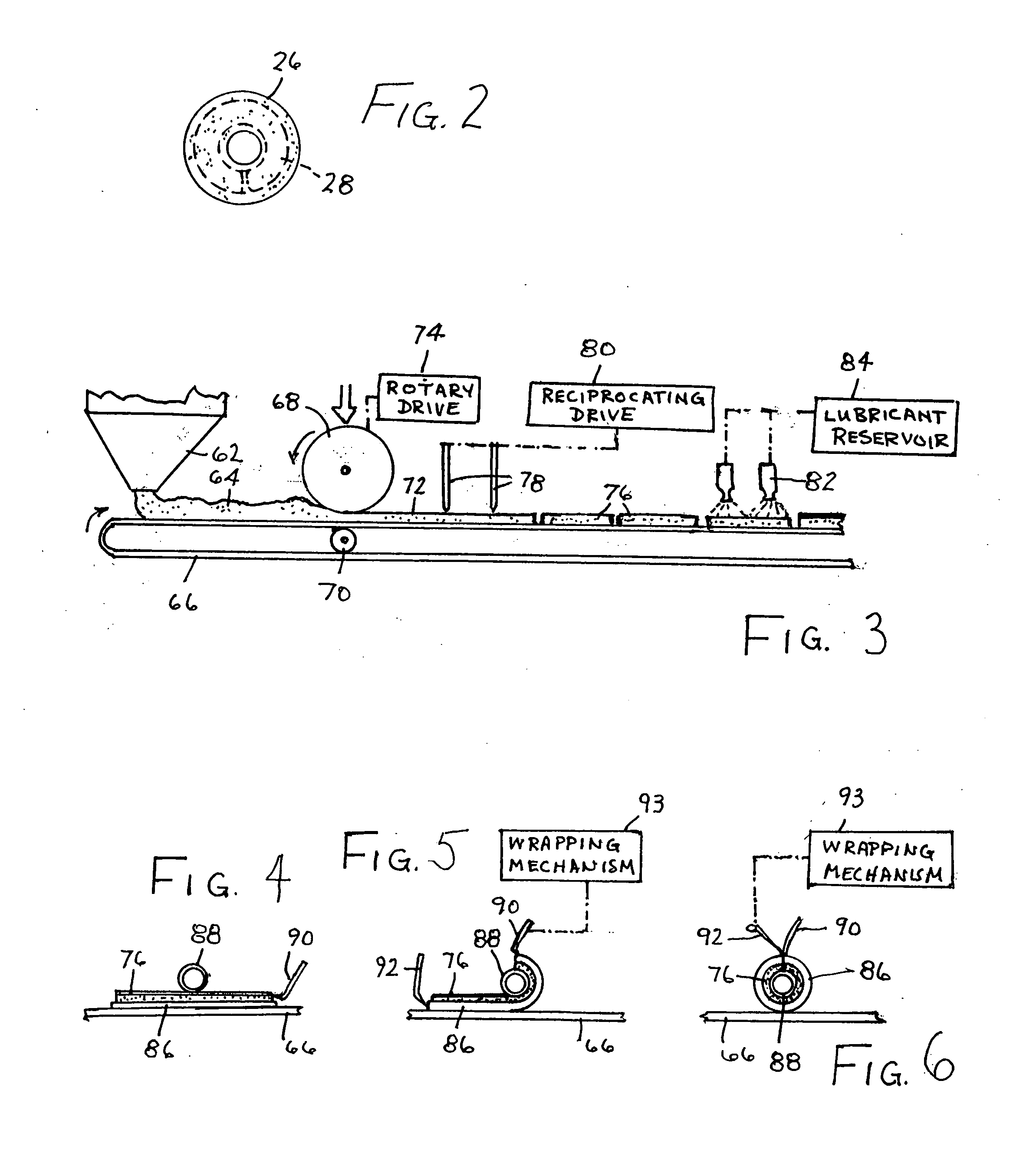

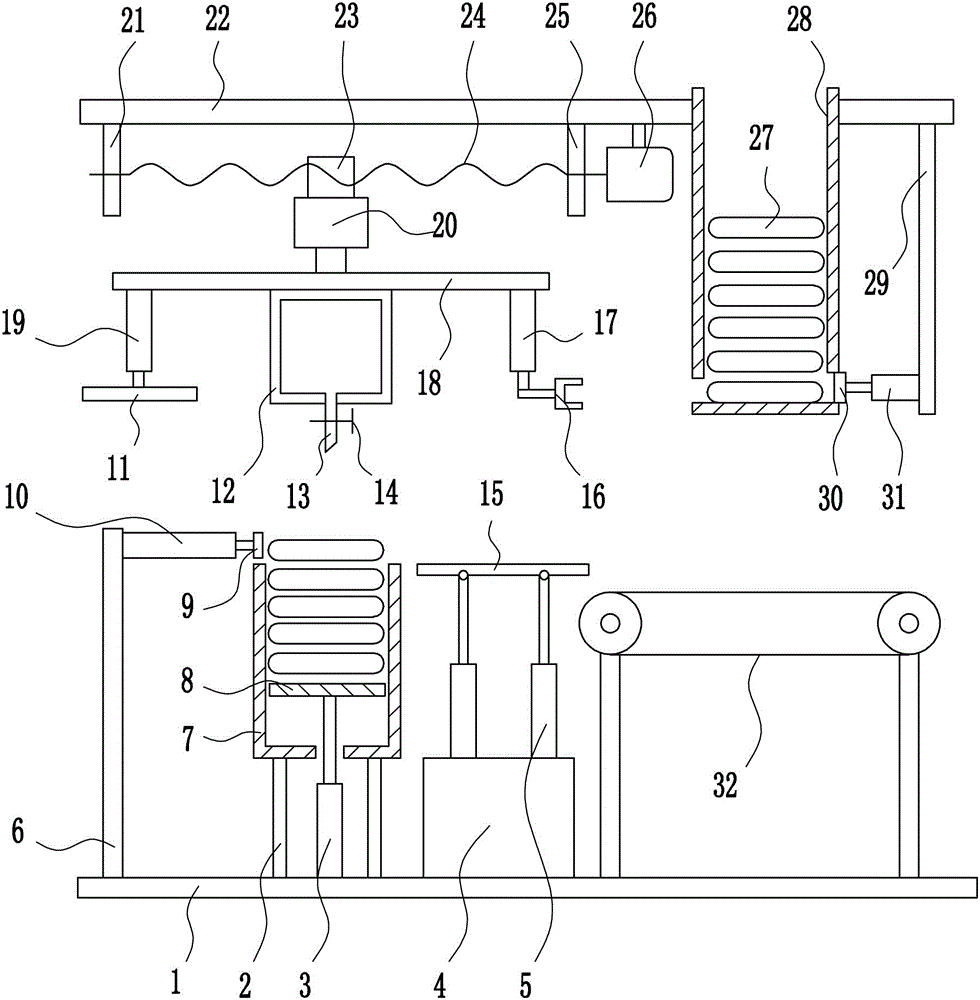

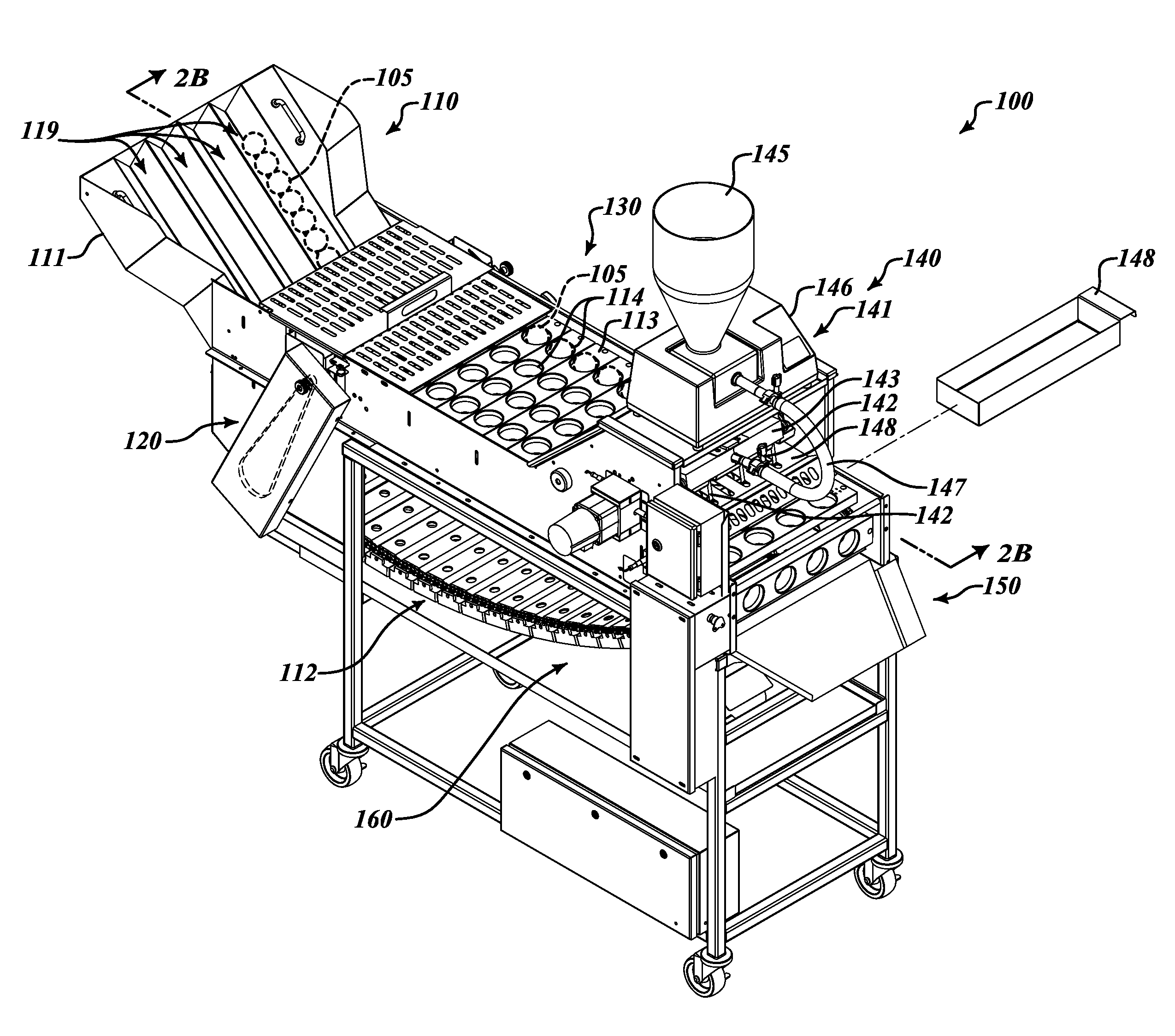

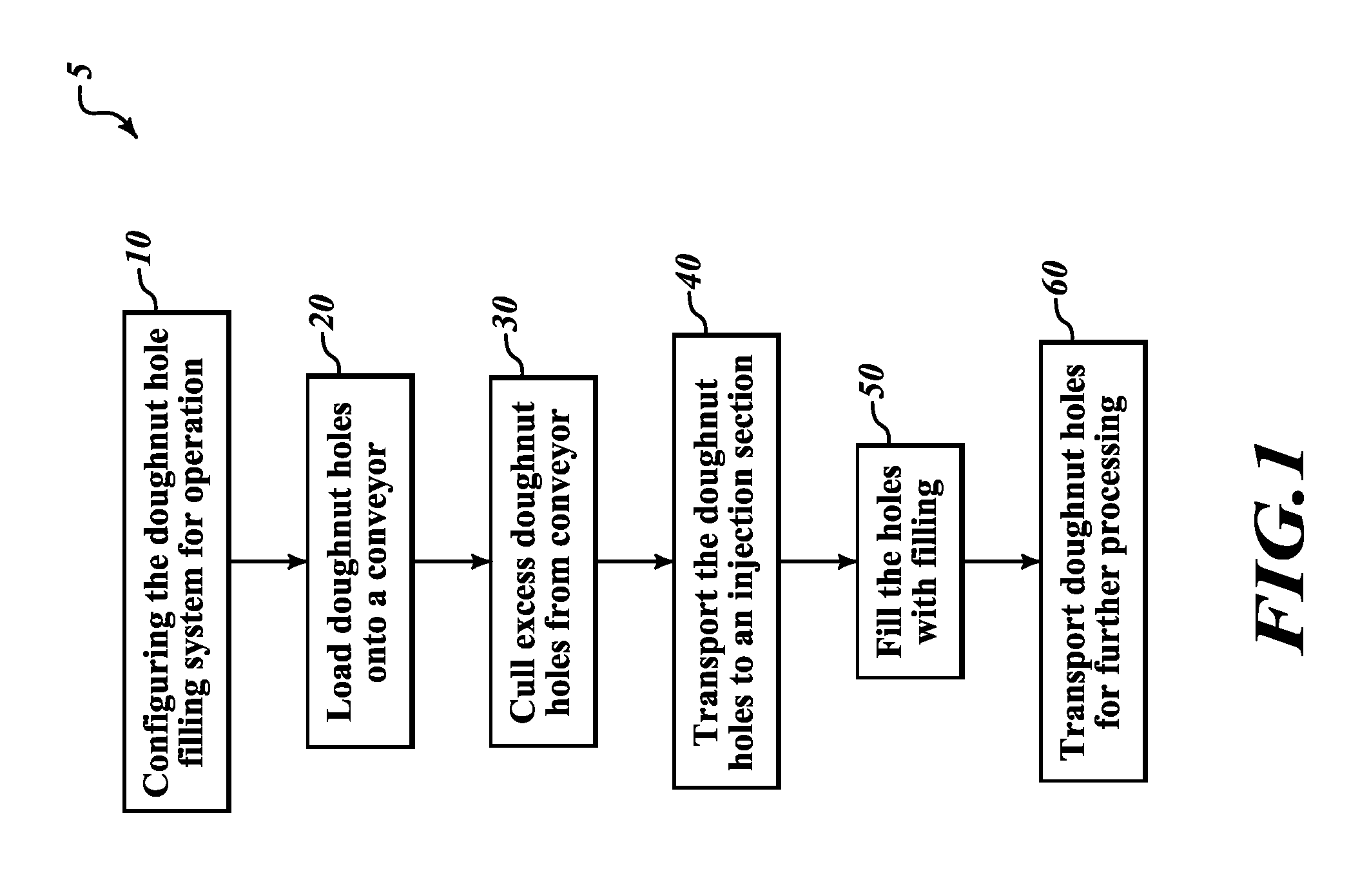

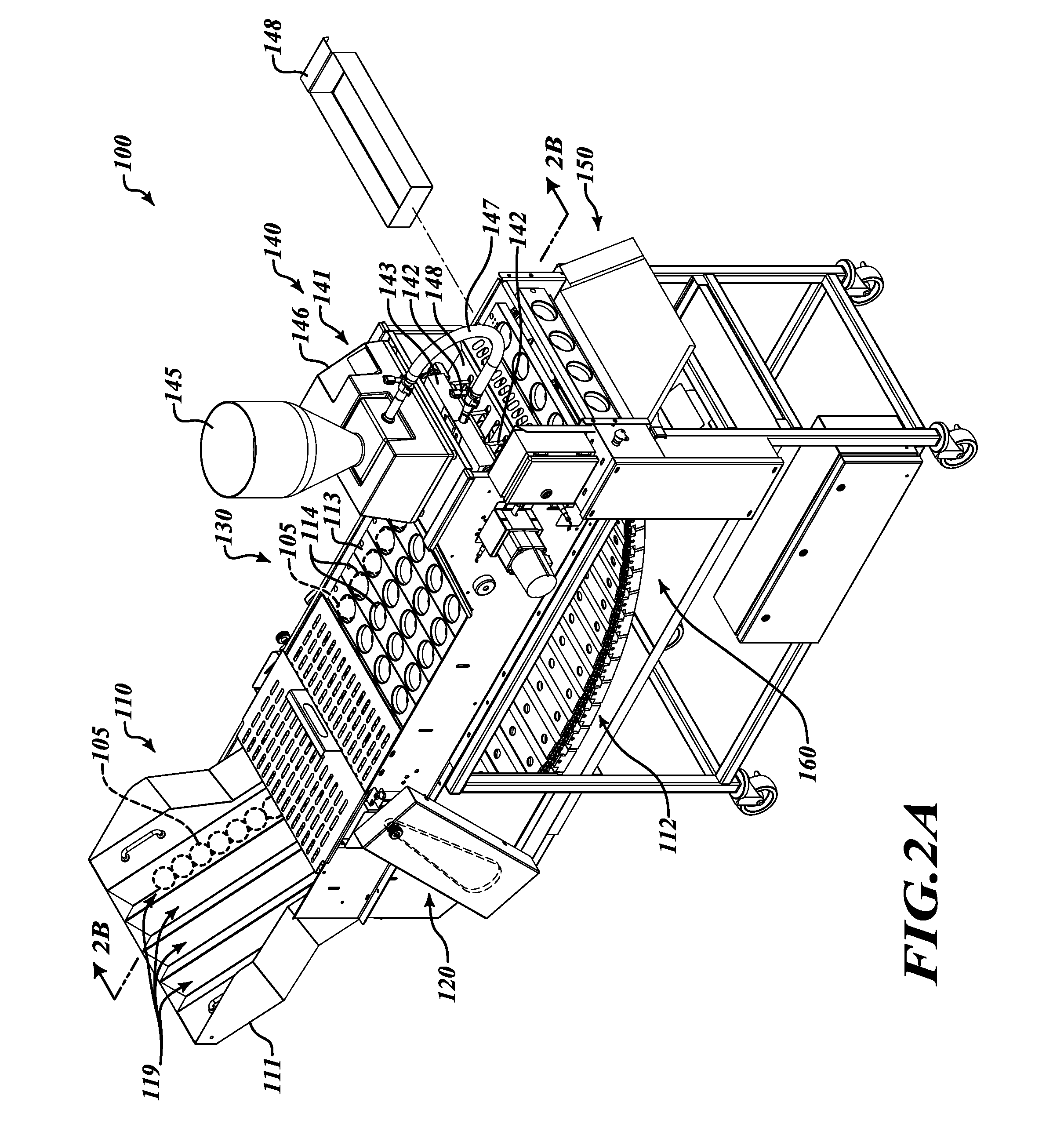

Devices, systems, and methods for filling doughnut holes

The present disclosure is directed towards systems, devices, and methods for filling doughnut holes. The system comprises a conveyor system that transports doughnut holes between at least a loading section, a culling section, and an injection section. The conveyor system includes a plurality of links coupled together to form a belt. The loading section includes a feeding device that feeds doughnut holes onto the conveyor system. The culling section includes a culling bar that culls excess doughnut holes from the conveyor. The injection section includes an injector system that injects feeds doughnut holes with a filling.

Owner:BELSHAW BROS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com